Process method for improving manufacturing accuracy of aluminum-alloy open-type integral impeller

A technology of integral impeller and manufacturing precision, applied in the field of open integral impeller processing technology, to achieve the effect of improving stability, good product quality and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

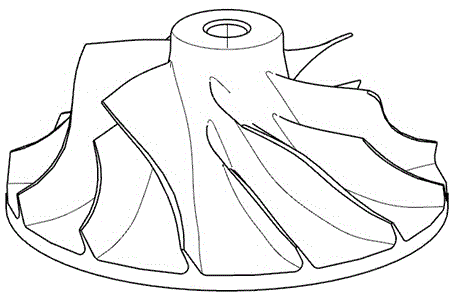

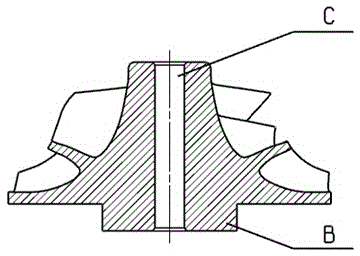

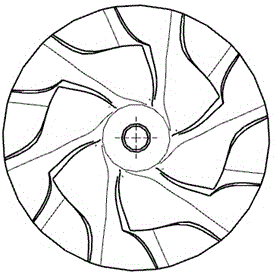

[0053] This example is manufactured as attached Figure 1 to Figure 3 For a high-performance integral impeller shown, the part height of the integral impeller is H=68mm, and the outlet diameter is D 出 =Φ120mm, impeller inlet diameter is D 进 =Φ82mm, blade height H at the inlet end 出 =27.1mm, blade height H at the outlet end 进 =9.58mm, the thinnest blade thickness δ min =0.9mm, the minimum distance l between adjacent blades min =6.3mm, the number of blades distributed on the blade circumference is Z=12, and the material is 2A50 aluminum alloy. The overall impeller working condition must meet high speed, large thrust-to-weight ratio, high performance, and its curved surface error is small, high precision, and good dynamic balance performance.

[0054] The technical method for improving the manufacturing precision of the aluminum alloy open integral impeller, the specific steps are as follows:

[0055] Step 1: Prepare materials:

[0056] Prepare Φ130mm 75mm 2A50 aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com