Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

709results about How to "Complete shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

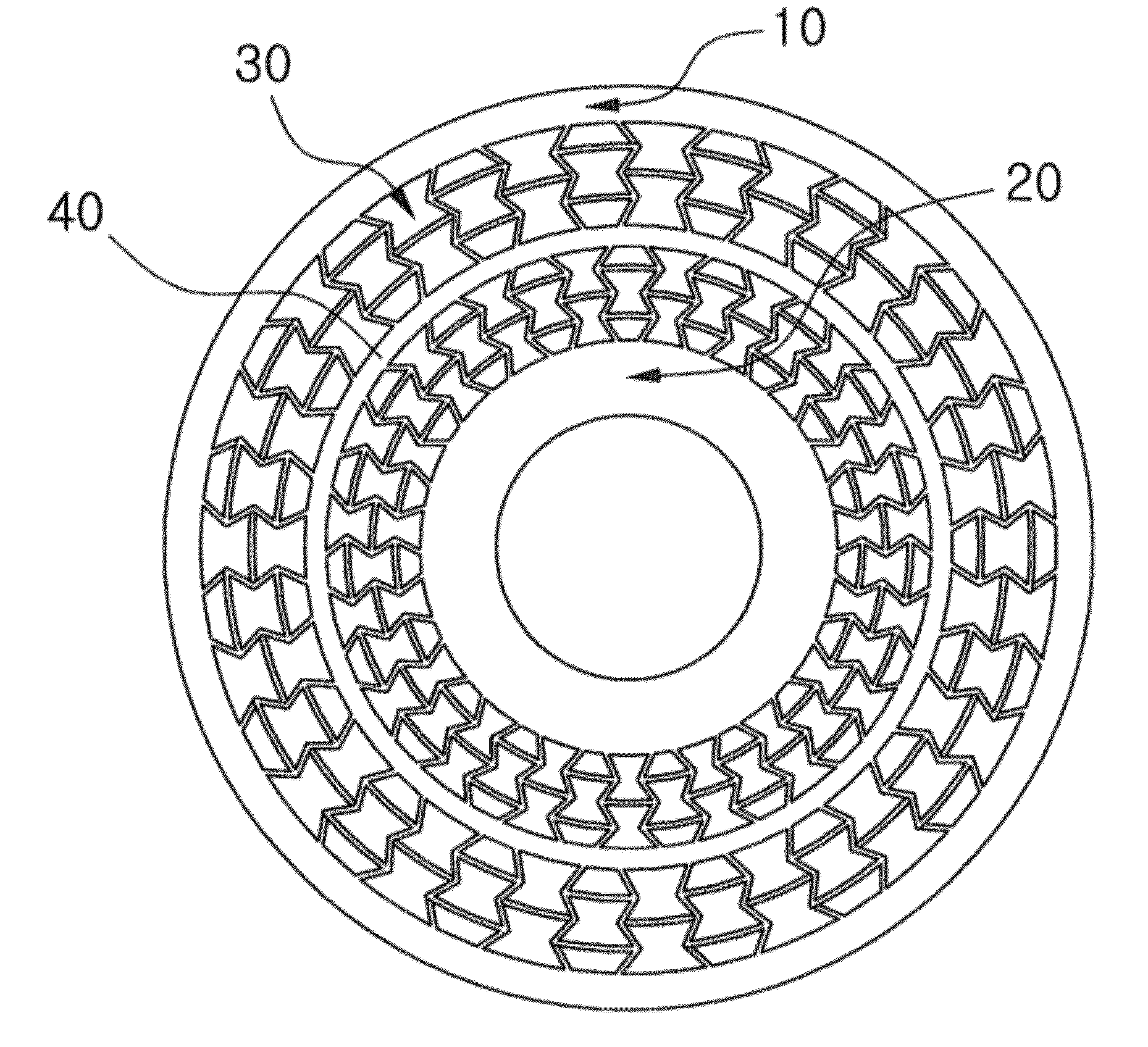

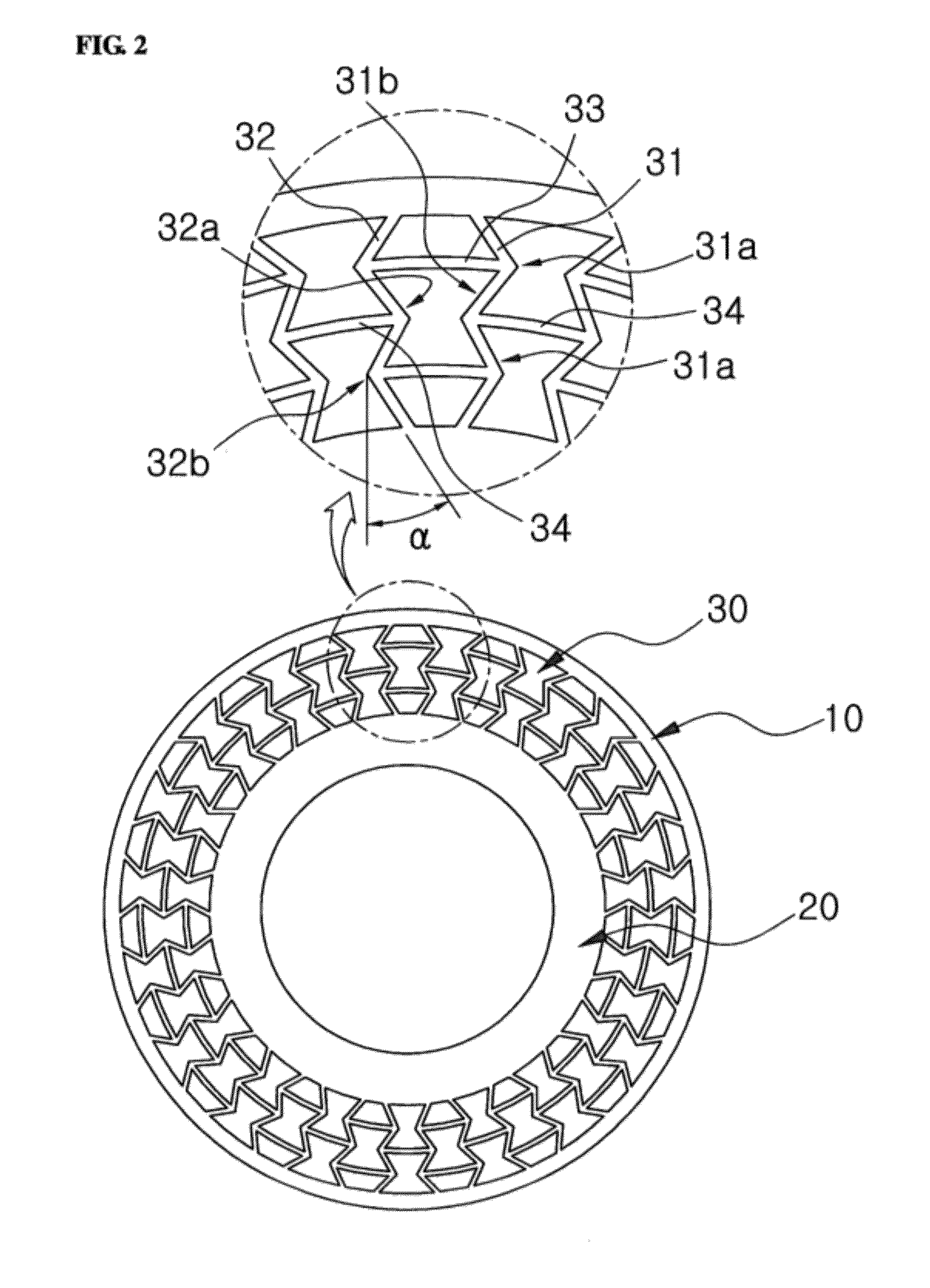

Airless tire

Disclosed herein is an airless are which absorbs shock and holds pressure applied to the tire through an auxetic spoke buffer without using air pressure. The airless tire includes a cylindrical tread being in contact with the ground, an axle fixing section having a smaller circumference than the tread and disposed inside the tread, and an auxetic spoke buffer connecting the tread and the axle fixing section and providing a buffering function. Accordingly, the airless tire is transformed only to an extent to properly function as a fire when the spoke buffer is transformed by pressure or impact and fully returns to an original shape when pressure or impact is removed.

Owner:HANKOOK TIRE WORLDWIDE

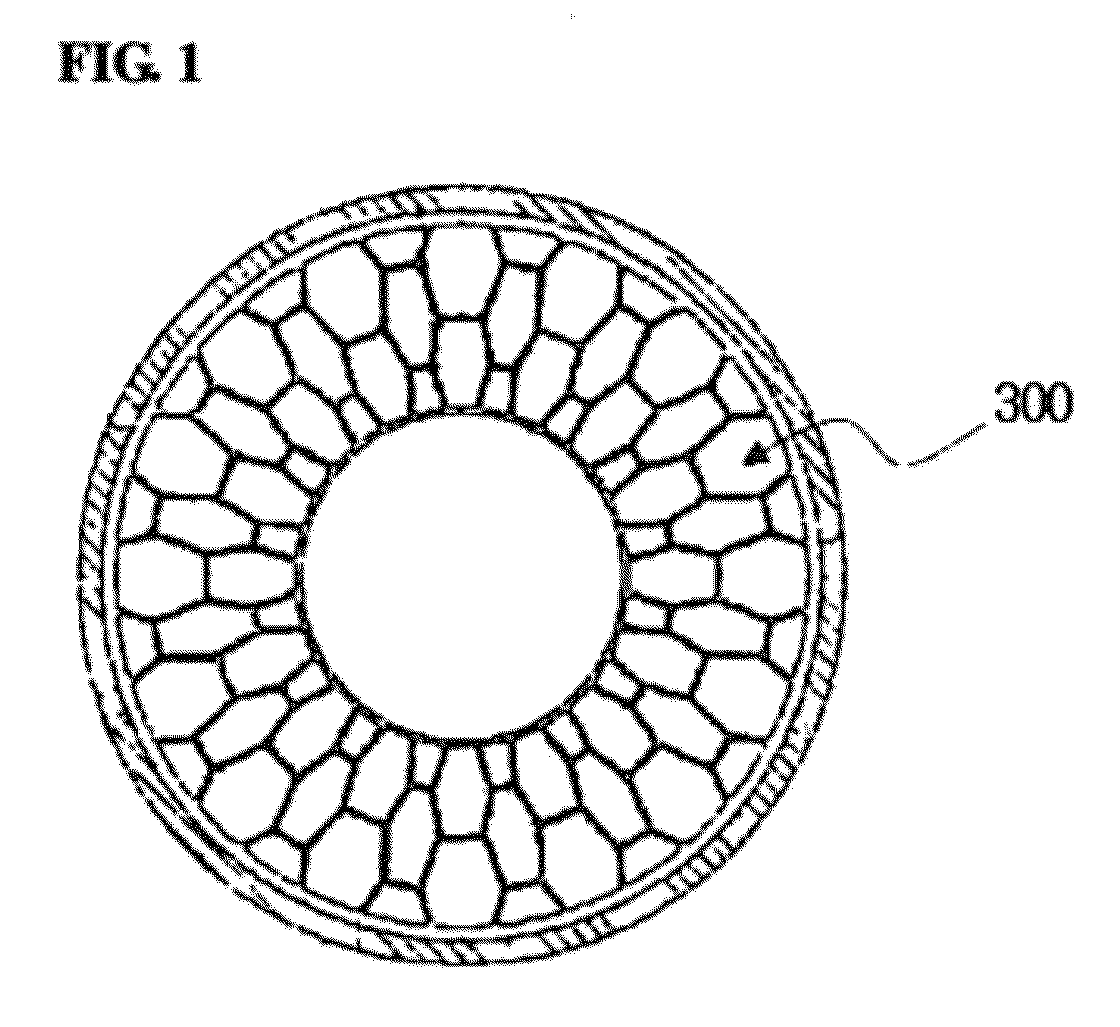

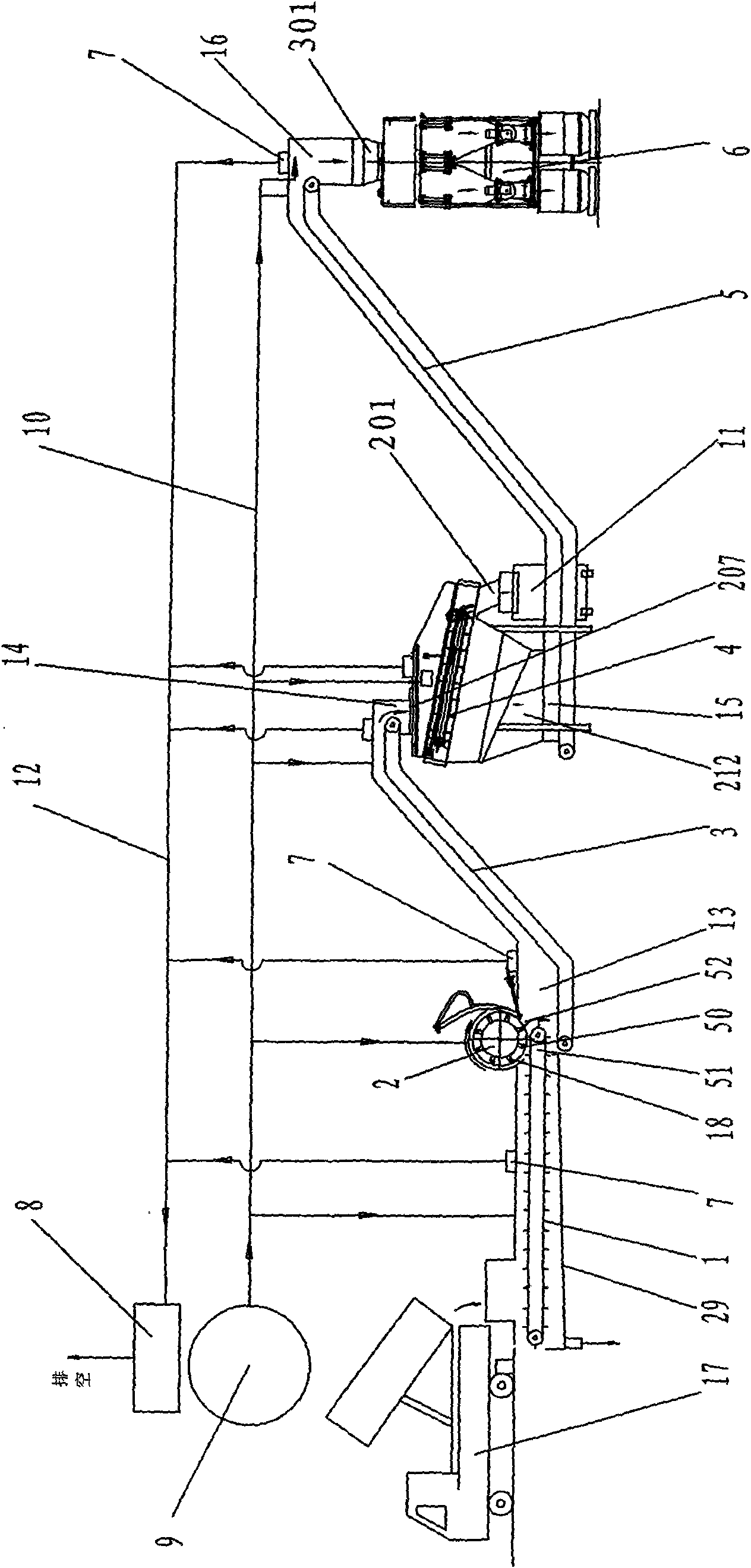

Kitchen waste preprocessing technology

ActiveCN101632996ASatisfy the follow-up resource processingImprove resource conversion rateSolid waste disposalLitterPre treatment

The invention relates to a preprocessing technology for processing kitchen waste with high oil, high viscosity and high water content, comprising the following steps: (1) pouring mixed waste which mainly comprises kitchen waste into a kitchen waste receiver to realize initial solid-liquid separation in a transporting process; (2) when separated solid waste enters a bag-breaking and distributing machine, tearing and breaking bagged waste and waste in other bags; (3) transporting the bag-broken kitchen waste into a grid machine to sort, separating inorganic waste or solid and organic waste with larger grain diameters in waste, and transporting the organic waste into a full-automatic distribution bin; (4) continuously carrying out the solid-liquid separation of the waste in the full-automatic distribution bin, and completing a processing process by entering the solid waste into a lower container. The kitchen waste preprocessing technology further sorts the organic waste with even grain diameters in the kitchen waste, satisfies the following resource processing requirement of the kitchen waste and increases the resource conversion rate of the kitchen waste.

Owner:BEIJING GOLDENWAY BIO TECH

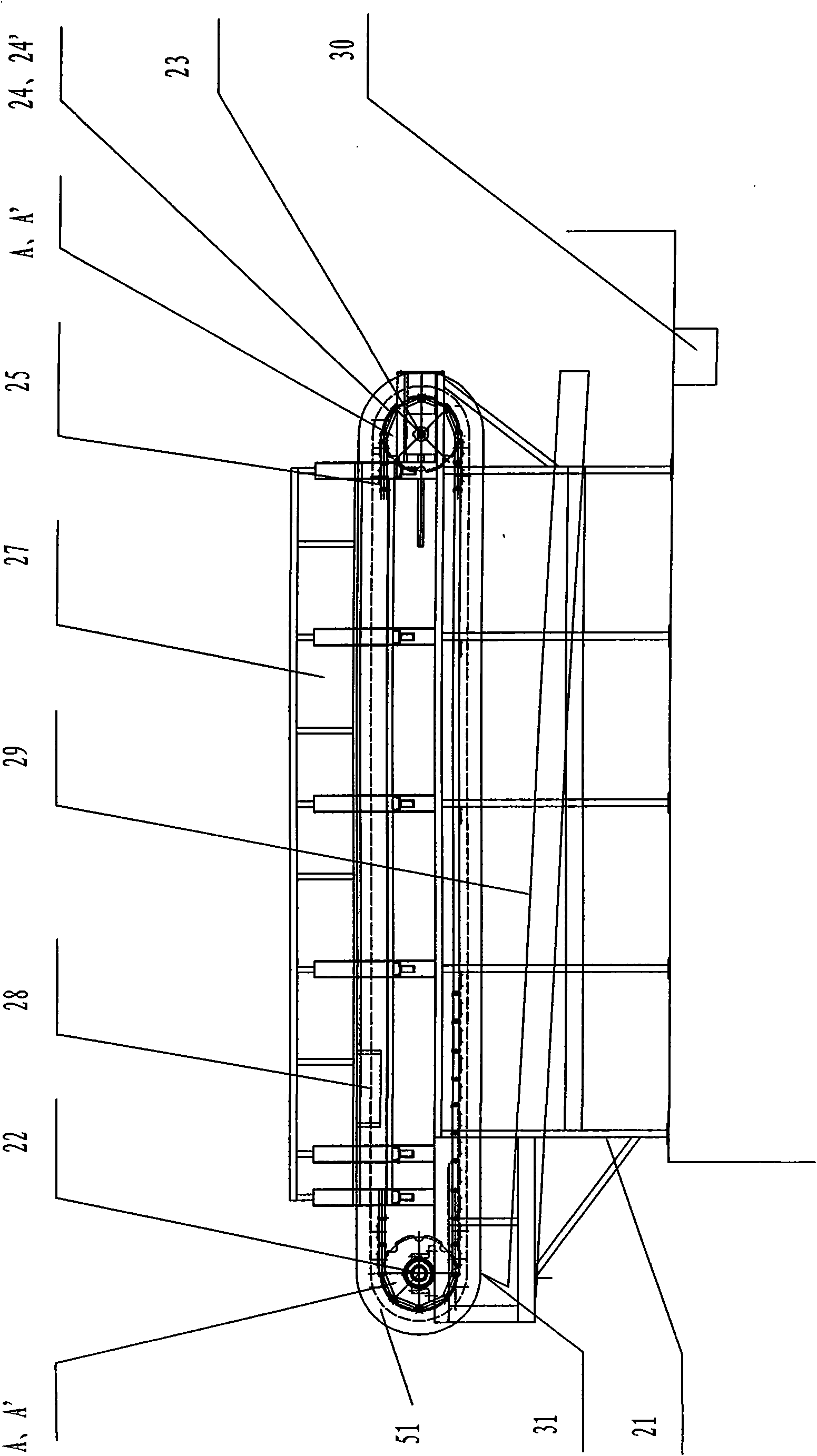

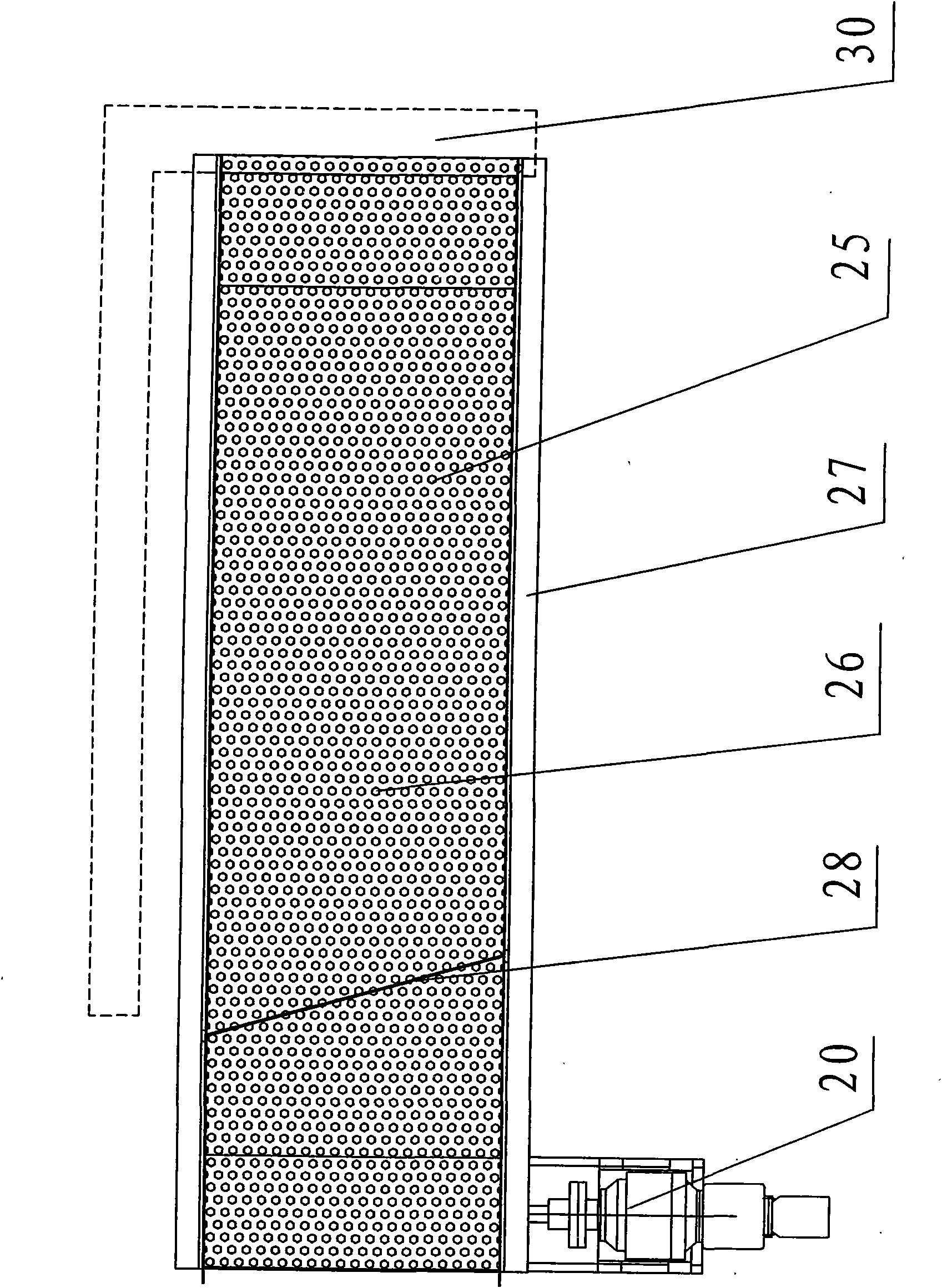

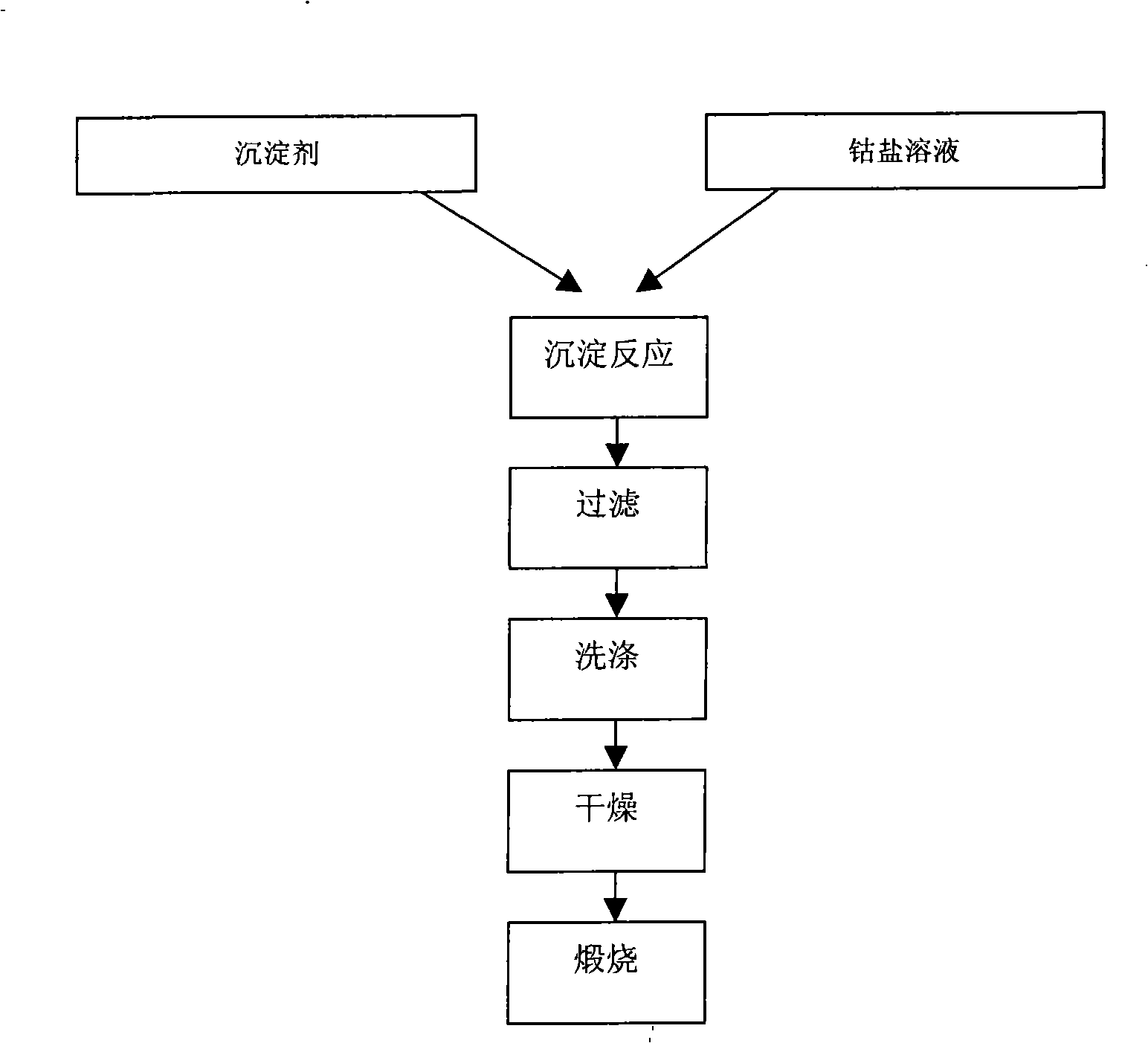

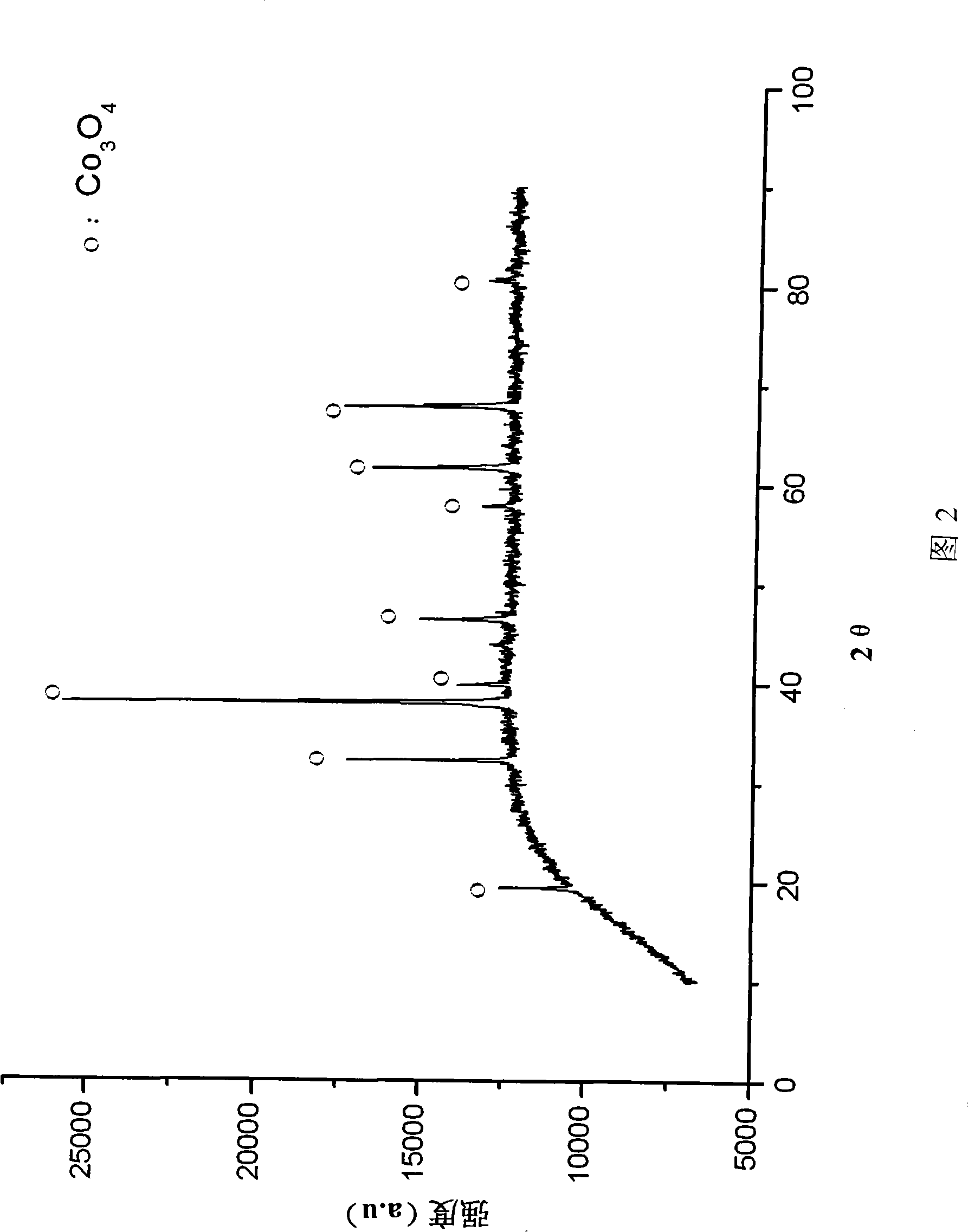

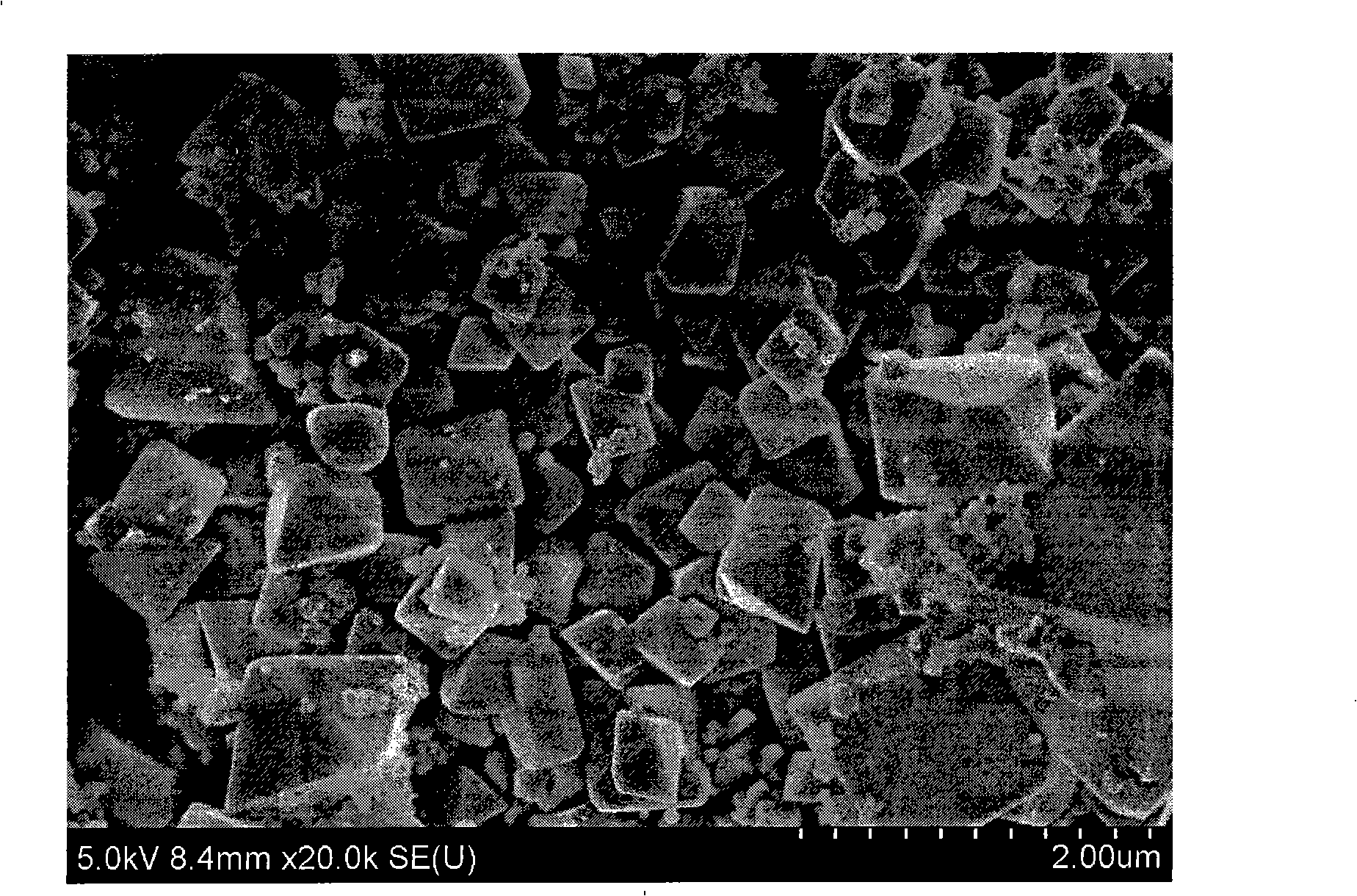

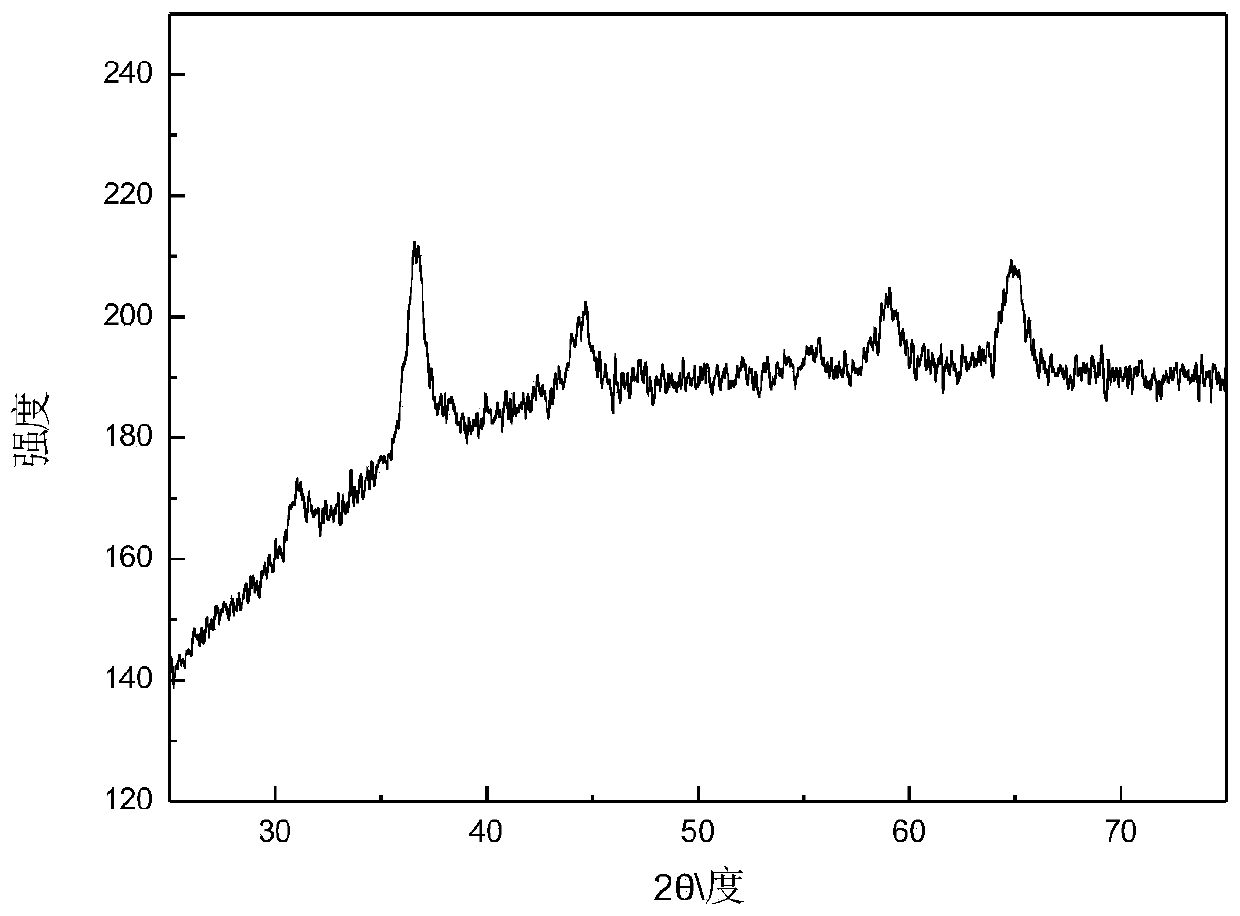

Method for preparing cobaltic-cobaltous oxide powder with octahedron shape

ActiveCN101293677ACrystallization intactMeet the requirements of lithium cobalt oxide for high-performance lithium-ion batteriesCobalt oxides/hydroxidesApparent densityOctahedron

The invention provides a preparation method of an electronic grade cobaltosic oxide powder which is shaped like an octahedron.The cobaltosic oxide powder has the complete appearance of the octahedron, the middle diameter (D50) of the powder is 0.5 to 5 Mum (the value can be adjusted by changing process parameters), the apparent density is more than 0.7g / cm<3>, and the tap density is more than 2.0g / cm<3>. The technological process is characterized in that the soluble cobalt salt solution, such as cobalt chloride and cobalt acetate, and ammonium bicarbonate solution are strongly stirred when being added to a reactor in the form of cocurrent flow at a definite speed, and the reaction temperature and PH value are strictly controlled, so the crystallization process is controlled. The obtained cobalt carbonate sediment is dried at a certain temperature after washing and filtration, and finally calcined at a certain temperature to get the ultimate cobaltosic oxide powder in the shape of an octahedron. The preparation method has the advantages that the cobaltosic oxide powder with the complete crystal form and in the form of the octahedron is prepared at atmospheric pressure, the specific surface area is high and the activity is high, etc., and besides the technique is simple, reliable and easy to industrialize.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Canned abalones and production method thereof

The invention relates to canned abalones and a production method thereof. The canned abalones comprise 50 to 60 percent of abalone meat and 40 to 50 percent of flavoring soup blend. The manufacturing method comprises the following steps: removing mantles, horny jaw plates and melanin on peripheries of feet from the fresh and live abalones and washing the abalones; placing the abalones into 80 to 90 DEG C hot water and cooking the abalones for 3 to 8 minutes, taking meat, removing organs and rims and washing the meat; placing the meat in 0.1 to 0.5 percent solution of citric acid and performing color retention treatment at 75 to 85 DEG C for 20 to 30 minutes; soaking the meat in water for 2 to 2.5 hours; weighing pettitoes, lean pork, mutilated meat of old hens, pork large tripe, ginger, green onion, cooking wine and water to stew stock; mixing the stock, minor ingredients and pure water and heating the mixture to prepare the flavoring soup blend, wherein according to a standard of the weight of the pure water, the weight of the stock is 1 to 3 percent of that of the pure water and the minor ingredients comprise 0.6 to 1 percent of edible salt, 0.2 to 0.6 percent of sugar, 0.1 to 0.3 percent of abalone essence, 0.03 to 0.05 percent of iso-vitamin C sodium, 0.01 to 0.02 percent of citric acid, 0.03 to 0.06 percent of composite phosphate and 0.01 to 0.015 percent of nisin; and canning the abalone meat and the flavoring soup blend, exhausting air, and sealing and sterilizing the abalone meat and the flavoring soup blend. The canned abalones have rich nutrients, complete individuals, a yellow and bright color and a long shelf life. The manufacturing method of the canned abalones is reasonable in process and feasible in operation.

Owner:TAIXIANG GRP TECH DEV

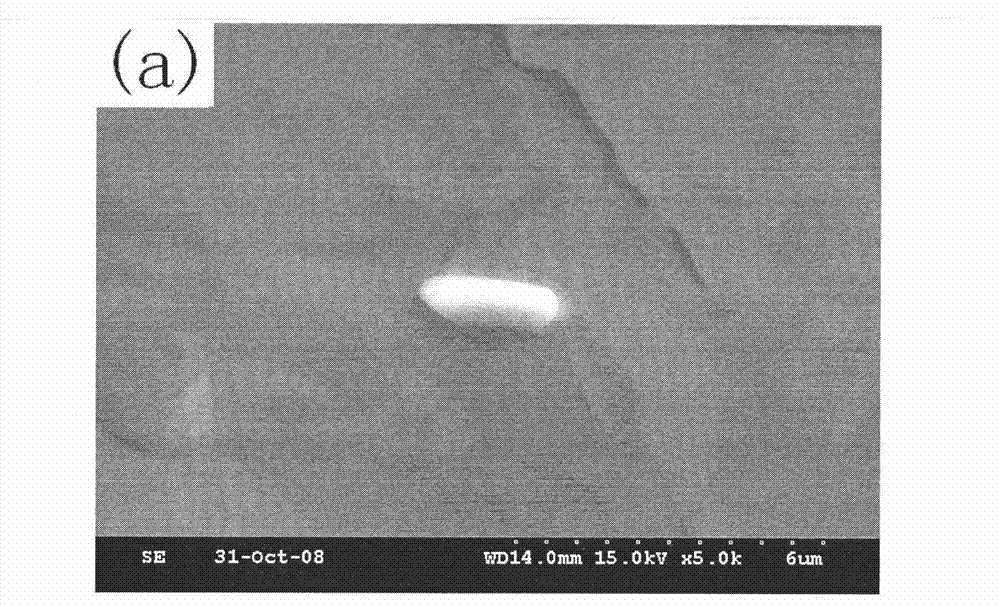

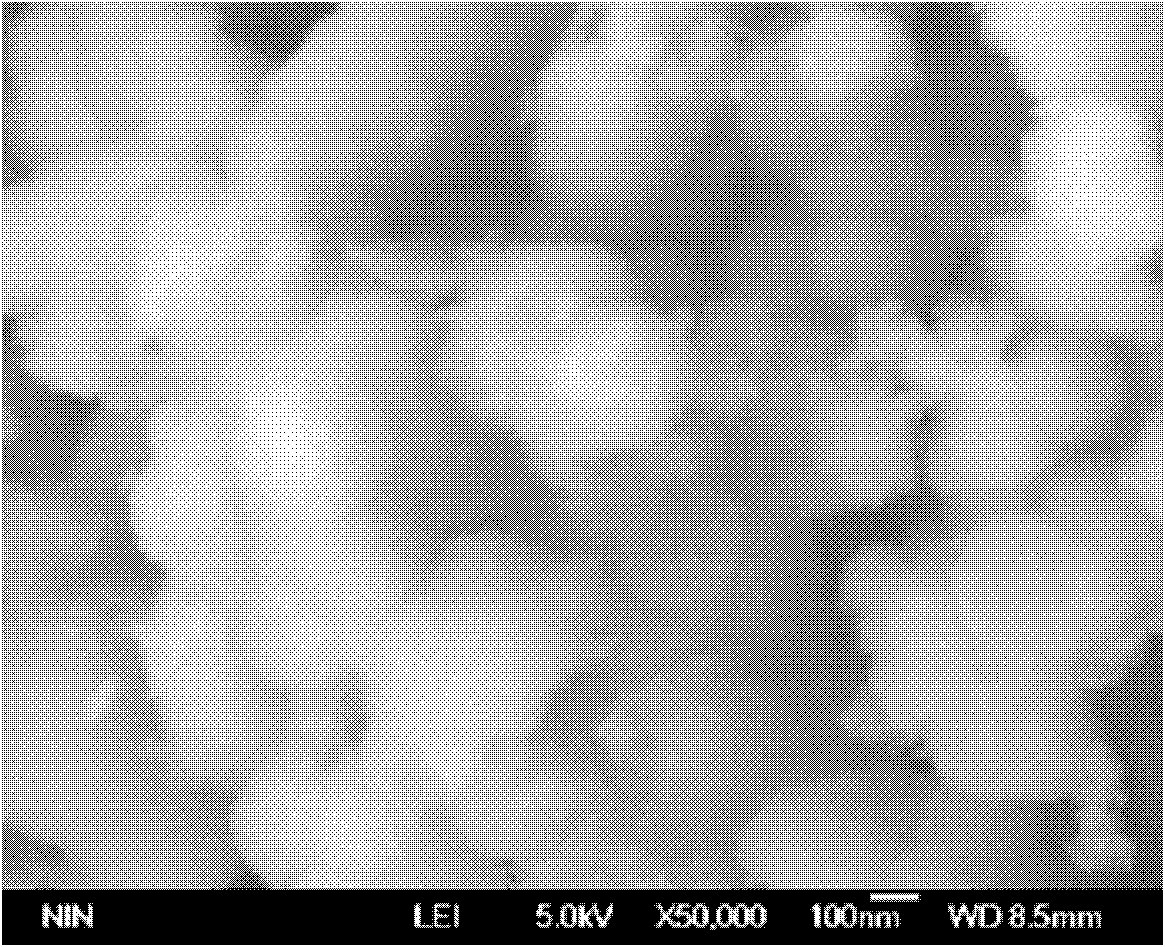

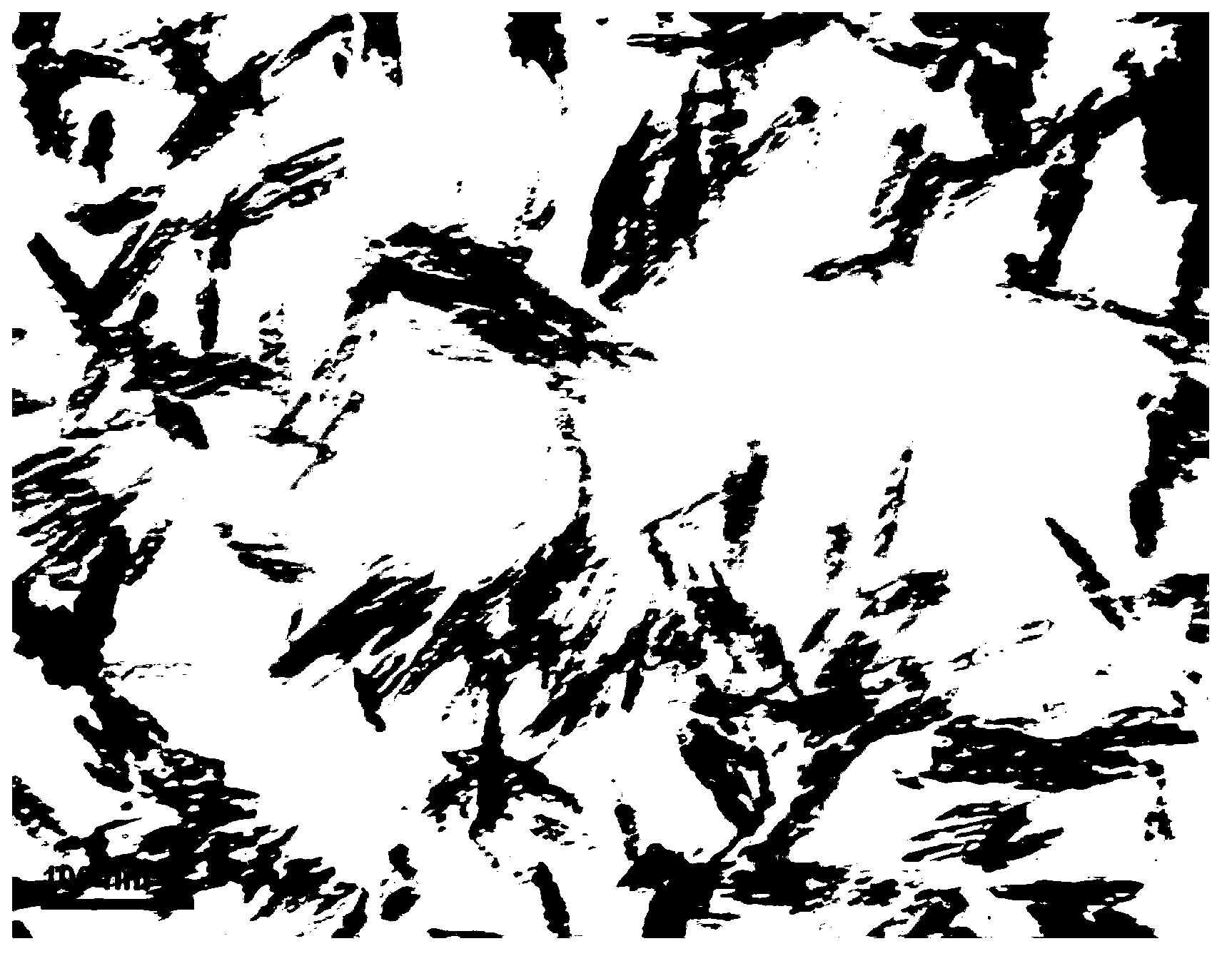

Method for observing in-situ morphologies of nonmetallic inclusions in steel

InactiveCN102879412ATrue form completeThe real shape is fully presentedPreparing sample for investigationMaterial analysis by measuring secondary emissionSpectroscopyGlycerol

The invention relates to a method for observing the in-situ morphologies of the nonmetallic inclusions in steel. The method is characterized by comprising the following steps: a metallographic specimen is prepared and a surface to be observed is polished to be a plane; the superficial electrolytic corrosion is performed on an electrochemical polishing apparatus, an electrolyte is as follows: 5% (v / v) HCl (hydrogen chloride)+5%(v / v) glycerol+1% (v / v) citric acid methanol solution, and the setup parameters of the electrochemical polishing apparatus are as follows: the current density is 0.02A to 0.10A / cm<2>, the electrolytic temperature is from below 15 DEG C to below 5 DEG C, and the electrolytic time is 20 to 40s; a rubber rod is utilized for slightly wiping off the corrosive products on an electrochemical polishing surface of a test sample after the electrochemical polishing, the surface of the test sample is dried by a blow drier, and the nonmetallic inclusions are highlighted on an electrolytic etched surface of the test sample, so that the true morphologies of the nonmetallic inclusions with the different dimensions are completely displayed; and the morphologies of the nonmetallic inclusions are observed by a scanning electron microscope and an energy disperse spectroscopy. The method for observing in-situ morphologies of nonmetallic inclusions in steel provided by the invention has the advantages that the sample is prepared simply, the period is short, the analysis speed is fast, and the constituents and the varieties of the nonmetallic inclusions can be determined accurately by observing the three-dimensional morphologies and dimensions of the nonmetallic inclusions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

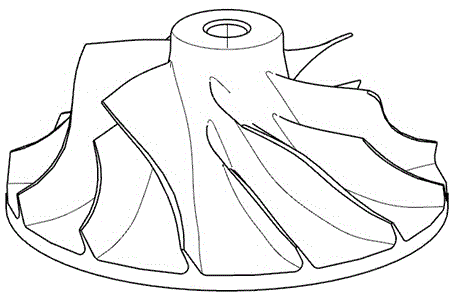

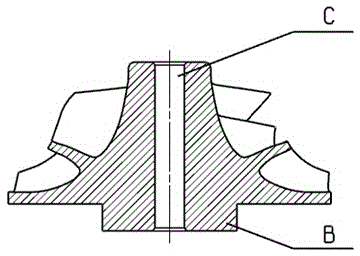

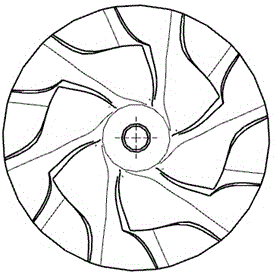

Process method for improving manufacturing accuracy of aluminum-alloy open-type integral impeller

The invention relates to a process method for improving the manufacturing accuracy of an aluminum-alloy open-type integral impeller. The method comprises the concrete steps of preparing materials, carrying out rough-turning on impeller blank shape, carrying out rough-turning on a process gripping head, carrying out heat treatment, carrying out artificial aging, carrying out semi-fine-turning on the process gripping head, carrying out semi-fine-turning on impeller shape, carrying out low-temperature treatment, carrying out five-axis-linkage-machining rough-milling, carrying out natural aging, carrying out five-axis-linkage-machining fine-milling, gripping, carrying out fine-turning on an axle hole, carrying out fine-turning on an impeller, gripping and carrying out dynamic balance. The impeller manufactured by adopting the process method provided by the invention has the characteristics that the shape is complete, the curved face is smooth and unhindered, blade curved faces and flow passage curved faces are low in deformation, and shown by the results of a fluorescent flaw detection, blade surfaces and front edges of the blades are flawless; during the dynamic balance of the integral impeller, mass reduction is relatively low, the qualified rate is high, and the qualified rate of excess-revolution tests of the integral impeller is greatly increased; the improvement of process for the series of integral impeller parts is realized, and good product quality, performance and design requirements are guaranteed; meanwhile, the stability of production quality is improved, and the reliability of products is improved.

Owner:SHANGHAI INST OF TECH

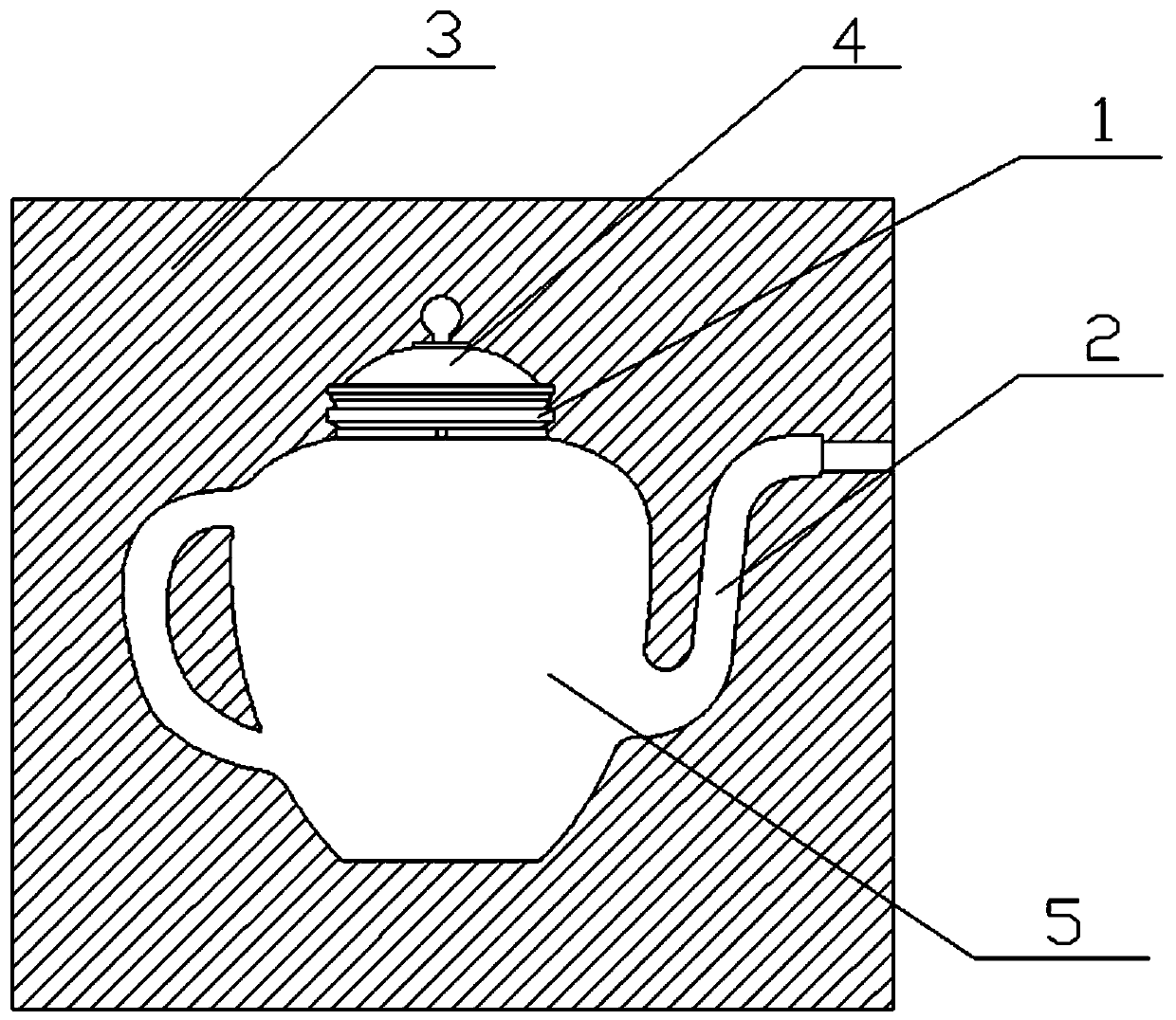

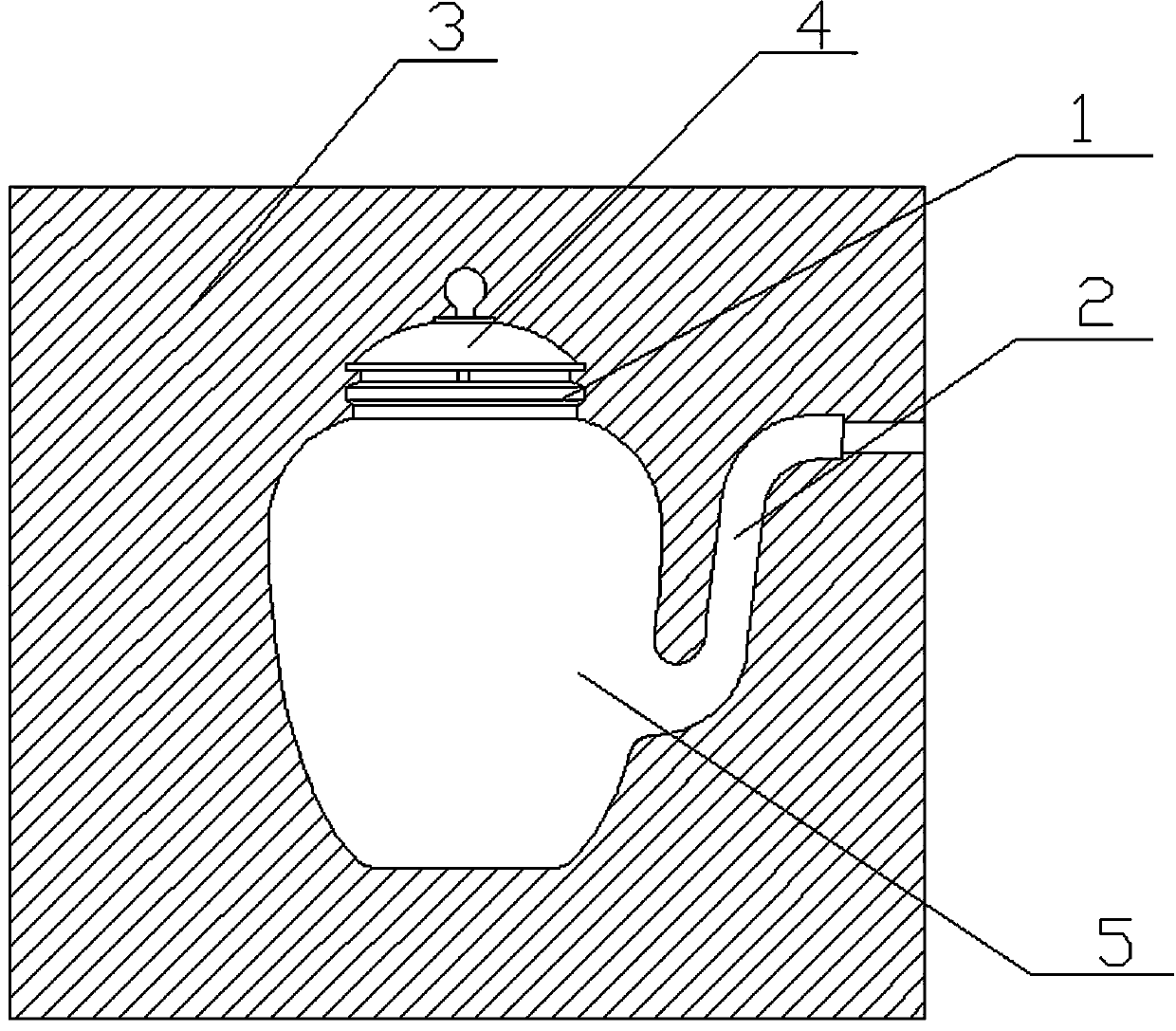

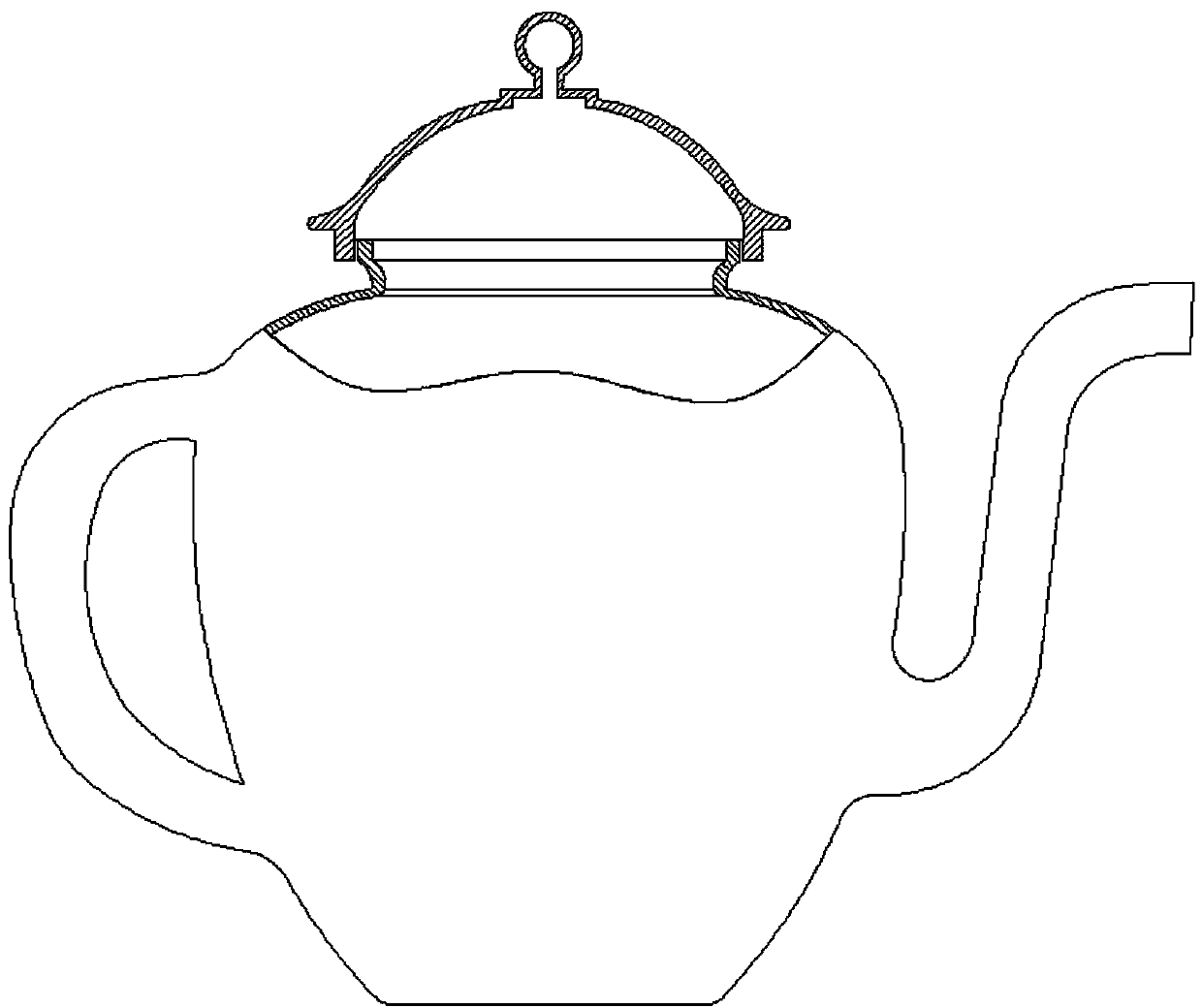

One-step extrusion-blown molding pot forming technology, dedicated mold pressing extrusion molding blow molding die and product

ActiveCN103419355AOvercome the problem of color differencePromote technological progressBlow moldingHollow form

The invention discloses a one-step extrusion-blown molding pot forming technology. According to the one-step extrusion-blown molding pot forming technology, a mold pressing forming technology and an extrusion-blown molding technology are combined into a whole. An air inlet core bar of the extrusion-blown molding technology is also a male mold of the mold pressing forming technology. A pot cover, a spout and a pot body of a formed pot can be formed in an extrusion-blown molding mode with one mold in one step. The technological advance of the hollow forming technology field is promoted, the complex and refine development tendency of current hollow products is met, and more complex products can be developed through the idea.

Owner:临夏市民政福利塑料厂

Tea processing and producing method

InactiveCN101301012AFresh tasteImprove cultural connotationPre-extraction tea treatmentFreeze-dryingAdditive ingredient

The present invention provides a tea processing and production method combining traditional process and vacuum freeze drying technique, which comprises the steps of selecting materials, deactivating enzymes, sorting, stacking, freezing, vacuum freeze-drying, shaping, classifying and packaging. The present applies freezing, vacuum freeze-drying in the tea processing technique, which not only preserves the original nutrition ingredients in the tea furthest, but also endows the products with fresh color, whole shape, good water reabsorbing capacity and fresh taste, effectively enhances the cultural connotation and commercial value of the tea and has wide prospect.

Owner:吕坤秋

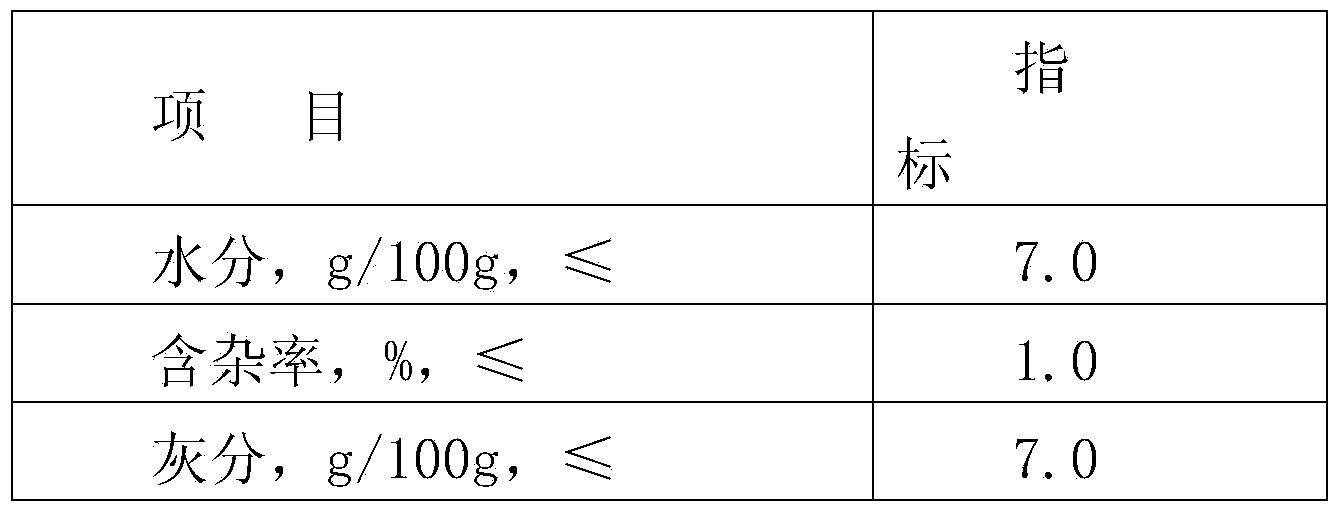

Industrial process for preparing nm-class active calcium carbonate

InactiveCN101108741AComplete shapeGood dispersionCalcium/strontium/barium carbonatesNanostructure manufactureChemistryCarbon dioxide

The invention provides the industrial preparation method of the nano activated calcium carbonate. The crystal control agent is added in the suspending liquid of the calcium hydroxide and is carbonized by the kiln gas containing the carbon dioxide. Through controlling the temperature and concentration of the calcium hydroxide, the concentration of the carbon dioxide and the addition and variety of the crystal control agent, the initial nucleation rate and nucleation quantity of the crystal and the growth rate of each crystal face of the crystal during carbonization are adjusted to realize the shape control of the crystal, and then surfactant is added to conduct activating treatment. The nano activated calcium carbonate is gained after filtering and drying, which has a shape of cube and is regulable when the grain size is between 20nm to 100nm. The product gained by the method has excellent performance and can work as the functional filler, which can be widely used in such industries as top-grade coating, rubber, plastic and adhesive.

Owner:BEIJING CHEM & IND CONSTRUCT MATERIAL FACTORY

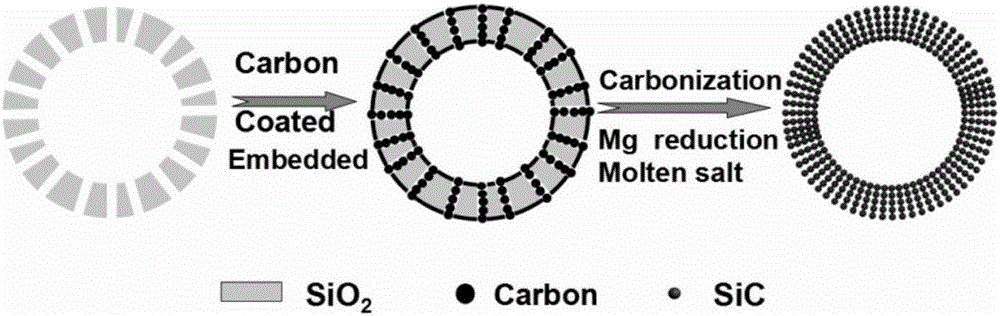

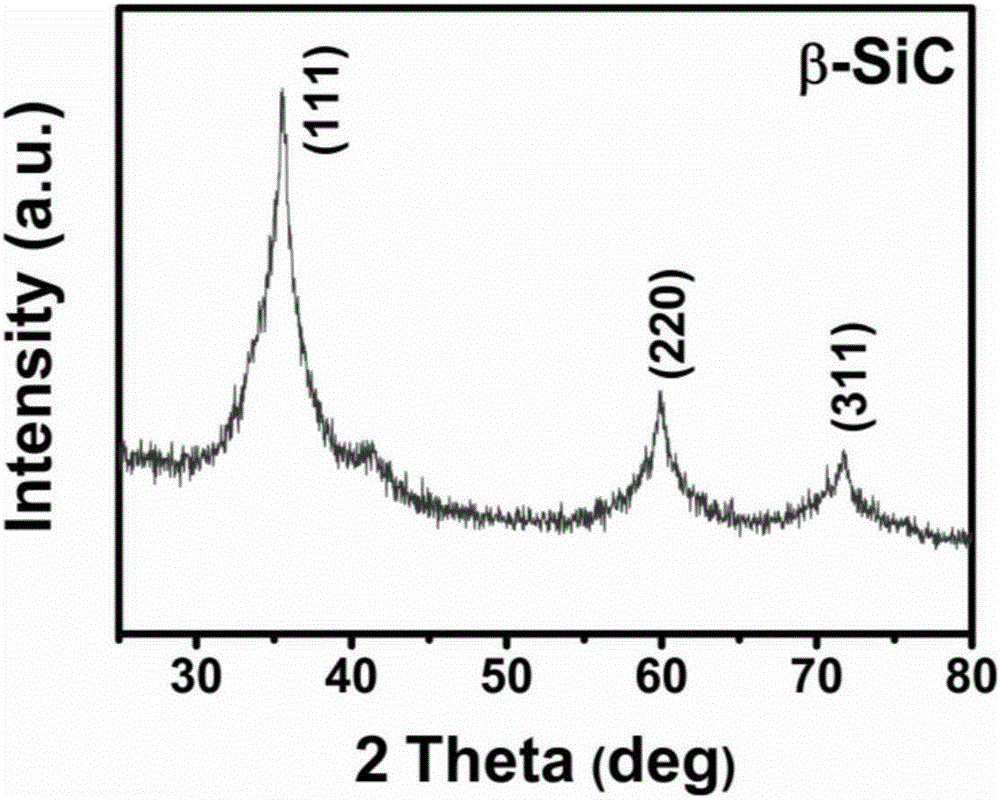

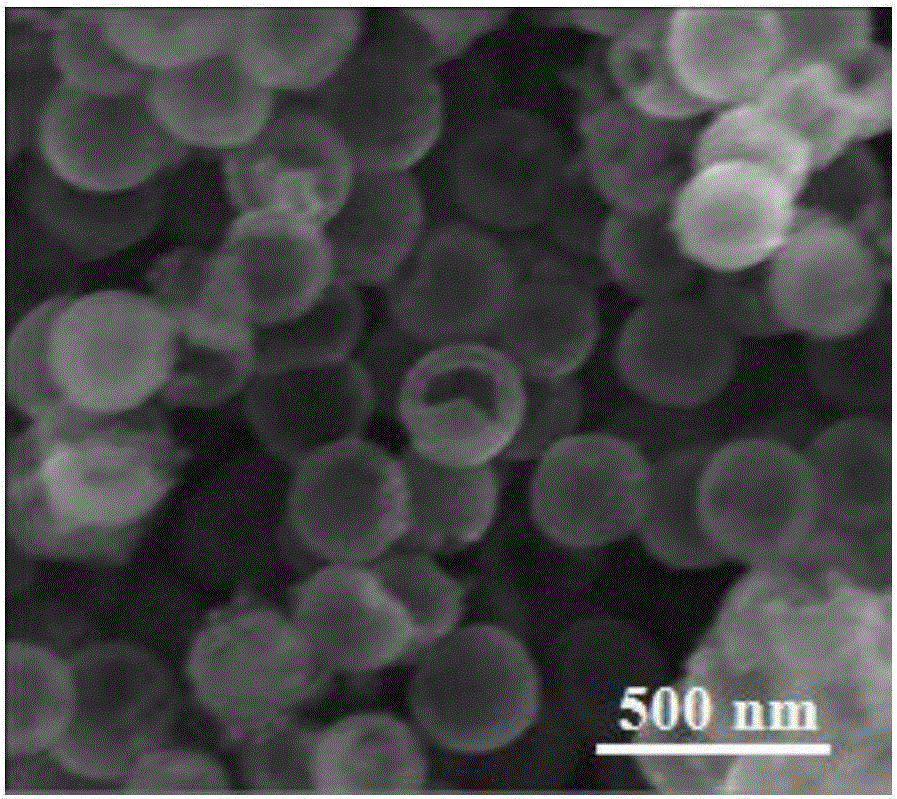

High-specific surface area nanometer mesoporous silicon carbide hollow ball and preparation method thereof

InactiveCN105236411ALarge specific surface areaUniform structureMaterial nanotechnologyThermal insulationReaction temperature

The invention relates to a high-specific surface area nanometer mesoporous silicon carbide hollow ball and a preparation method thereof. The preparation method comprises dropwisely adding different amounts of silica precursor tetraethoxysilane into water-anhydrous ethanol mixed solutions with different ratios so that the silica precursor tetraethoxysilane is hydrolyzed into silica solid nanospheres with different diameters, dispersing the silica solid nanospheres in distilled water with different volumes, carrying out thermal insulation for a certain time to obtain nanometer mesoporous silicon carbide hollow balls with different diameters are obtained, coating the inner and outer shells of the nanometer mesoporous silicon carbide hollow ball with an organic matter layer so that the organic matter is insert into the shell walls, carrying out carbonization, mixing the reaction product, magnesium powder and a metal salt to obtain a uniform mixture, and carrying out thermal insulation in an inert atmosphere for some hours to obtain nanometer mesoporous silicon carbide hollow balls with uniform structures and adjustable sizes. The preparation method has a low reaction temperature and a low cost. The obtained hollow silicon carbide has the advantages of uniform structure, adjustable sizes, superhigh specific surface area of 648m<2> / g and excellent mesoporous structure.

Owner:湖北朗驰新型材料有限公司

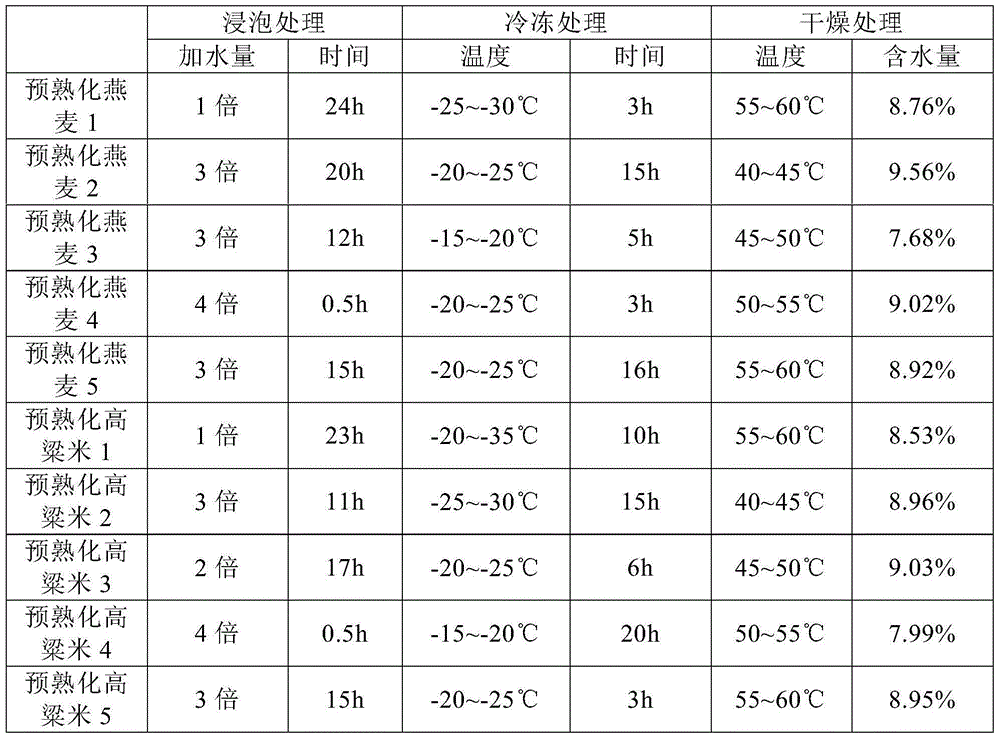

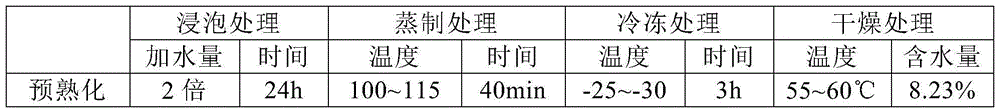

Coarse cereal food and preparation method thereof

The present invention discloses a formula coarse cereal food. The formula coarse cereal food mainly comprises the following coarse cereals in parts by weight: 30 to 45 parts of oat, highland barley and / or barley, 20 to 40 parts of green bean and / or red bean, 1 to 10 parts of black beans, chickpea, garden pea, cowpea, rice bean and / or soybean; 15 to 20 parts of black rice; 5 to 15 parts of sorghum rice, red rice, brown rice and / or pearl barley; 10 to 20 parts of buckwheat, millet, and / or sticky millet. And the mixed beans cereal, the oat and the sorghum rice are subject to a pre-aging treatment, and then mixed with the rest of cereal in a proportion to obtain the formula coarse cereal food. According to the present invention, the formula coarse cereal food has more complete shape retention and has better market prospects as commodity for sale. The formula cereal food has a short aging time when cooking with rice; the cooked cereal porridge has characteristics of rich flavor, soft mouthfeel, good viscosity and uniform dispersion. The formula cereal food can provide a human body with necessary dietary fiber, vitamins and minerals.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Production method for high-quality instant lentinus edodes crisp chips

InactiveCN103652833AComplete shapeFlat surfaceFood freezingFood coatingAdditive ingredientAdditional values

The invention relates to a production method for high-quality instant lentinus edodes crisp chips and belongs to the technical field of deep processing of agricultural products. A main process for producing the instant lentinus edodes crisp chips comprises the following steps: harvesting fresh lentinus edodes with good quality; removing pedicles; washing; immersing; freezing; freezing and drying in vacuum; and seasoning and carrying out nitrogen-filled packing. The production method adopts a novel vacuum freezing and drying process to produce the lentinus edodes crisp chips. Compared with the prior art, the process adopts a low-temperature dehydration manner of freezing and drying in vacuum to keep the nutrition and the flavor components of the lentinus edodes to the greatest extent; the sensory quality of the product is improved and the defects of traditional oil fried crisp chips that the oil content is high, the color and luster are poor, the mouth feel is hard and the like are avoided. The product obtained by the process has the characteristics of rich flavor, crispy mouth feel, low oil content, high additional value, good sensory quality and the like; the invention provides a feasible new way for deeply processing the lentinus edodes.

Owner:NANJING AGRICULTURAL UNIVERSITY

Full-nutritive equilibrium stuffing and dumpling made by the same

InactiveCN101133885AWith health functionFull of nutritionFood preparationMonosodium glutamateEdible mushroom

The present invention relates to a full-nutrients balanced stuffing and dumplings made of said full-nutrients balanced stuffing. Said full-nutrients balanced stuffing is made up by using pork fillet, chicken breast, shrimp meat and egg-white as main raw material and adding water, edible mushroom, algae, nutmeat, fruit, vegetable, salad oil, ginger, salt, sesame oil, granulated chicken bouillon and monosodium glutamate as auxiliary raw material through a certain preparation process.

Owner:孙志刚

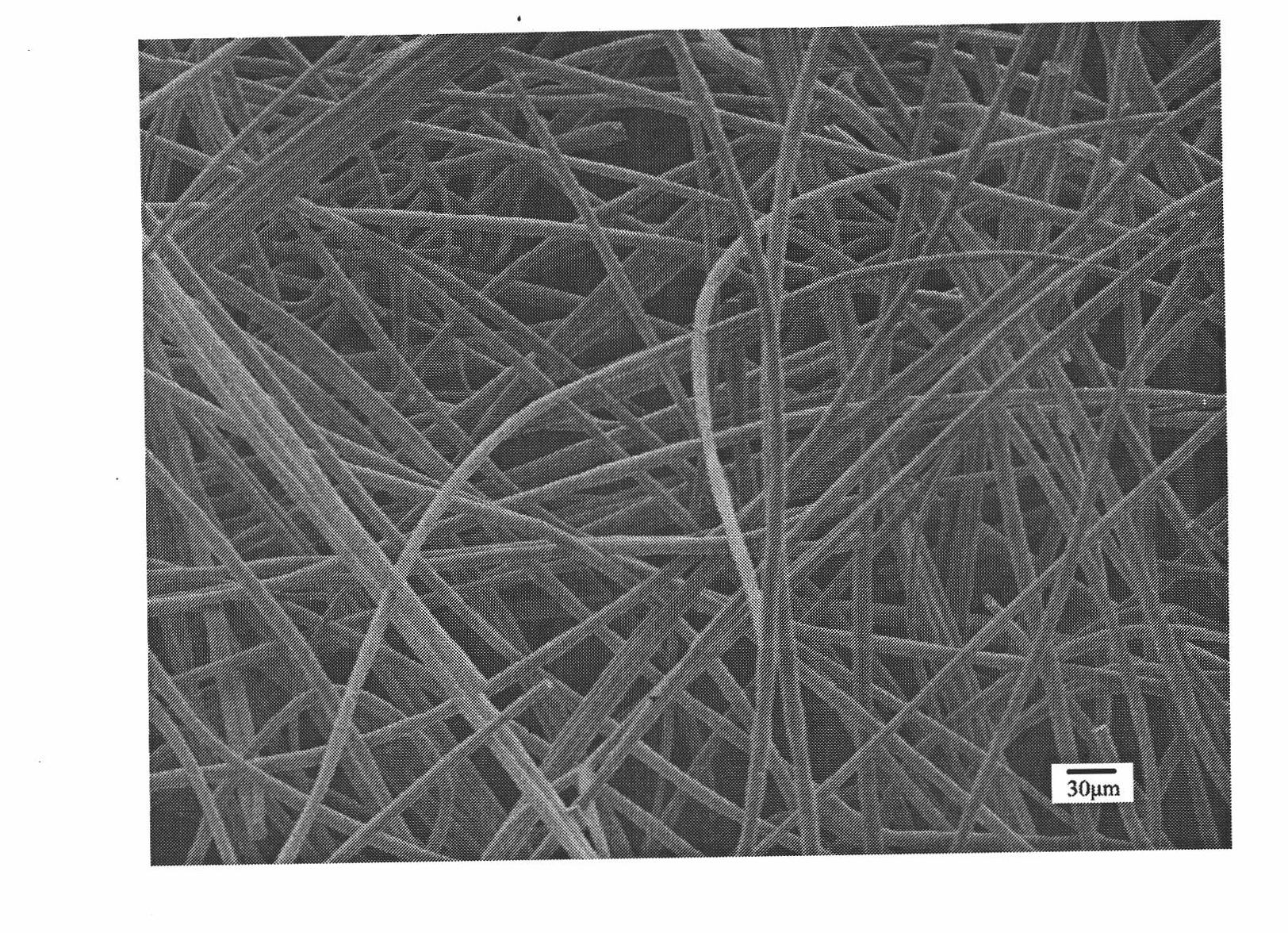

Zirconia mesoporous fiber and preparation method thereof

ActiveCN101781817AComplete shapeHas a worm-like pore structureInorganic material artificial filamentsFilament/thread formingFiberEvaporation

The invention relates to zirconia mesoporous fiber and a preparation method thereof. The diameter of the zirconia mesoporous fiber is between 5 and 10 mum, the length is between 1 and 10 cm, the mesoporous hole diameter is between 4 and 9 nm, the specific surface area is between 80 and 200 m<2>g<-1>, and the pore volume is between 0.1 and 0.35 cm<2>g<-1>. The mesoporous fiber uses segmented copolymers as template agents, adopts a sol-gal process to be combined with an evaporation inducement self assembly mode, and simultaneously utilizes special additives for controlling the hydrolytic polycondensation balance in the precursor sol synthesis process. Solvents are evaporated to obtain the sol with the certain viscosity, and the precursor fiber is obtained through centrifugal thread throwing. Irconia mesoporous fiber which has the complete shape and appearance, the length as long as centimeter grade, vermicular pore passage structures and higher specific surface and stability can be obtained through further heat treatment. The method is mature and reliable, and the obtained fiber has good uniformity, and has the importance application value in the fields of catalysis, separation, absorption and the like.

Owner:山东德艾普节能材料有限公司

Method for preparing multi-shape controllable nano nikel-cobalt spinel oxide

The invention relates to a method for preparing multi-shape controllable nano nikel-cobalt spinel oxide. The method includes the steps that nickel nitrate and cobalt nitrate are dissolved in anhydrous ethanol according to the cobalt-nickel atom ratio to form a solution A; oleylamine is dispersed in an ethanol solution to form a solution B, and the solution B and the solution A are mixed to obtain a mixed solution; the mixed solution is fully and evenly stirred and moved into a dynamic reaction kettle, H2 is replaced in a sealed mode, pressure intensity of H2 is adjusted to 6-15 bar after replacement, and a steel cylinder air outlet valve is closed; the stirring speed of the dynamic reaction kettle is adjusted to 400 r / min, temperature is set to be 150 DEG C, and reaction is carried out for 10 h; a product is cleaned through ethanol and other nonpolar solvents respectively, centrifugal separation is carried out, and a sediment precursor is obtained through drying at the temperature of 60 DEG C; the temperature of the obtained sediment precursor rises in an air atmosphere at the speed of 10 DEG C / min, and the sediment precursor is heated to 200-400 DEG C and kept warm. According to the method, procedures are few, materials are easy to get and low in price, the procedures are safe, nikel-cobalt spinel oxide of different shapes can be obtained by changing a small condition in the procedures, and accordingly preparing of the controllable nano nikel-cobalt spinel oxide is achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

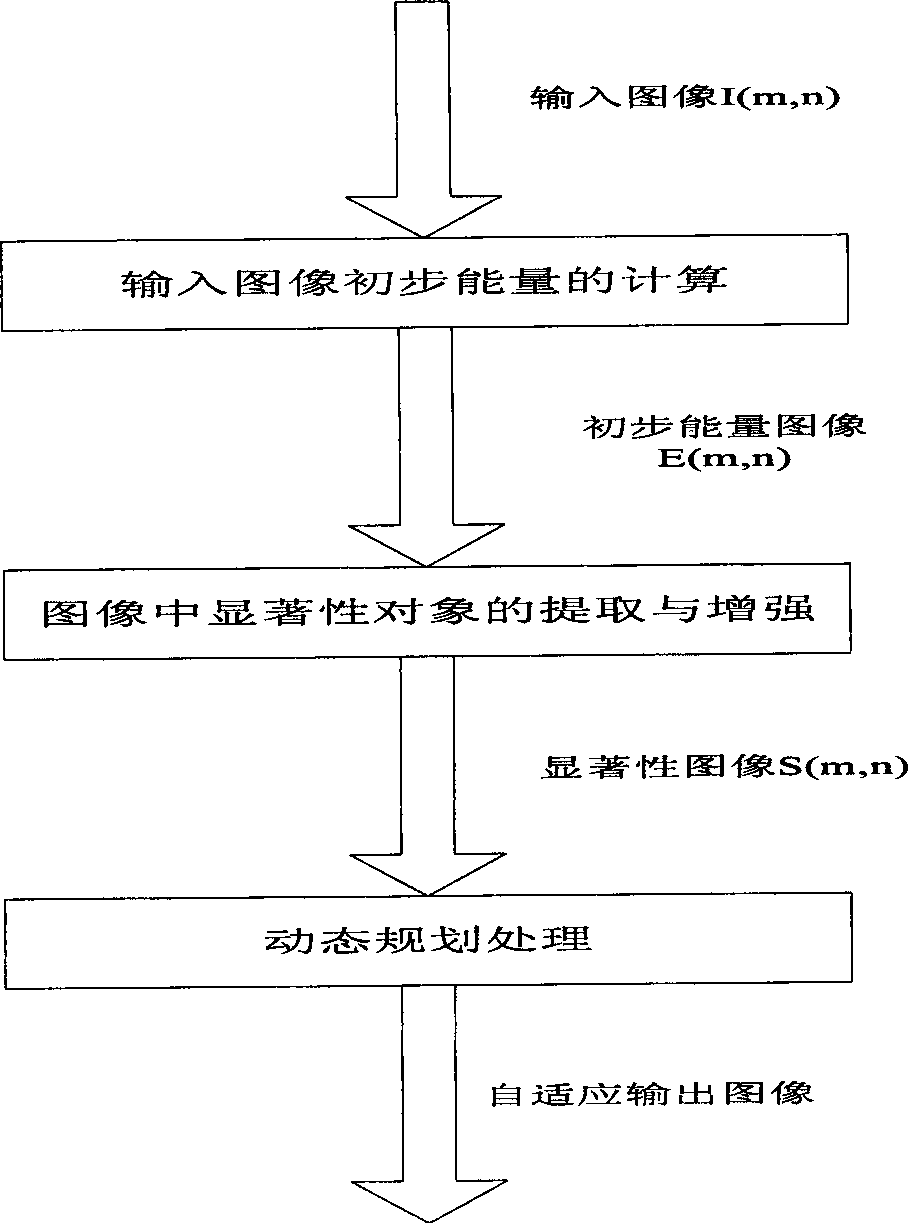

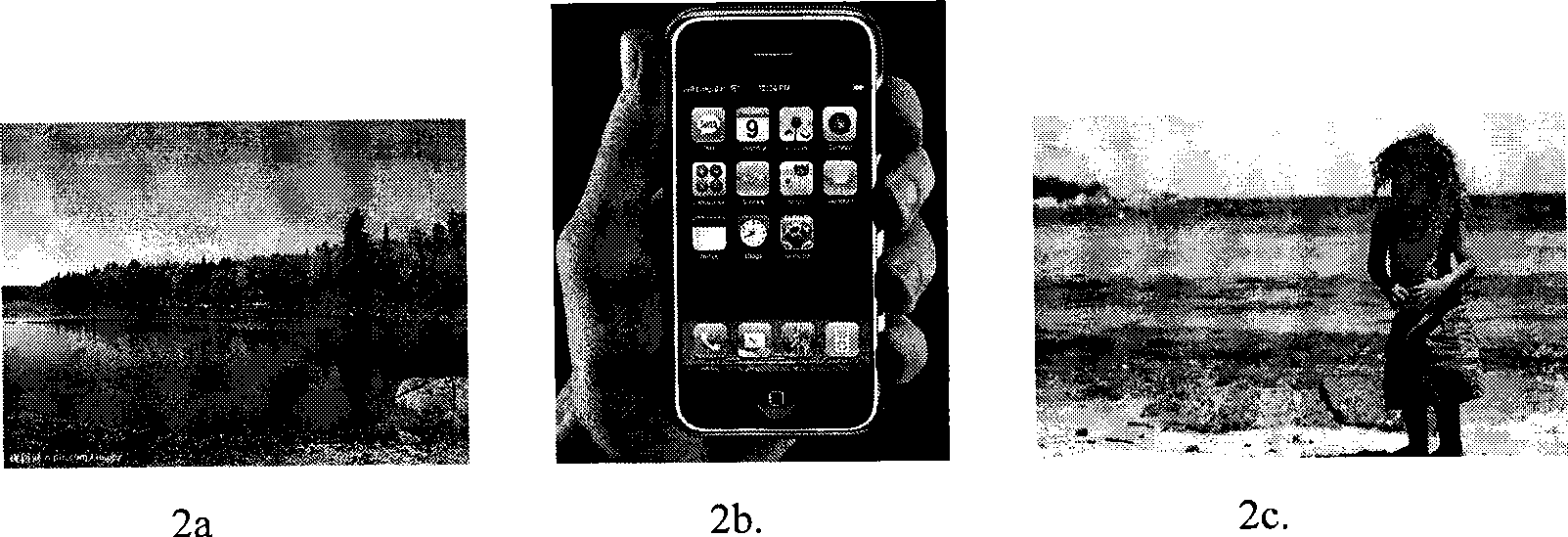

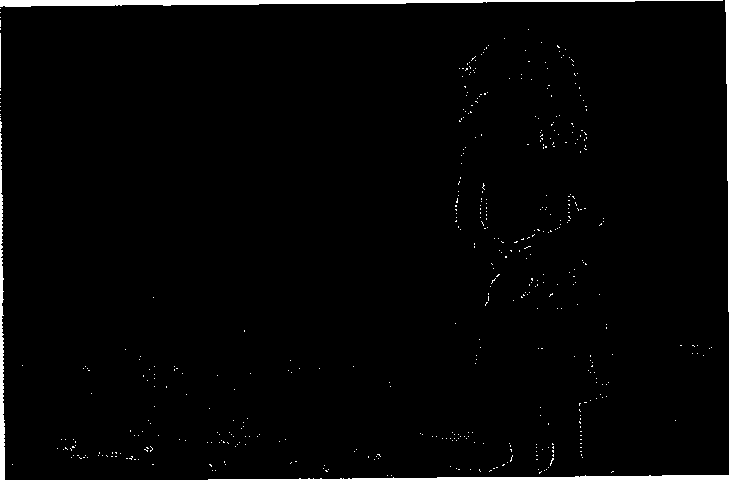

Image self-adapting method based on vision significance

ActiveCN101510299AReduce energy lossLow visual distortionImage enhancementCathode-ray tube indicatorsRelative energyImage resolution

The invention discloses an image self-adaptive method based on visual saliency, comprising the steps as follows: firstly, the energy of an original image is calculated; secondly, a saliency object in the original image are extracted and the relative energy of the saliency object is strengthened; and thirdly, by utilizing a dynamic programming technique, the gaps with the lowest energy on the vertical and horizontal directions in the image are found out and eliminated so as to realize the image self-adaption. As the method eliminates the gaps with the lowest energy in the image, the whole energy loss of the image is the smallest; and as the relative energy of the saliency object is higher, the eliminated gaps can not pass through the saliency object, the saliency object can keep complete after the image self-adaption. Therefore, the method can minimize the image visual effect distortion in intelligent mobile equipment with low resolution and small screen and maintain the completeness of the saliency object, thereby providing a visual effect which is the same as that of display equipment with high resolution.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

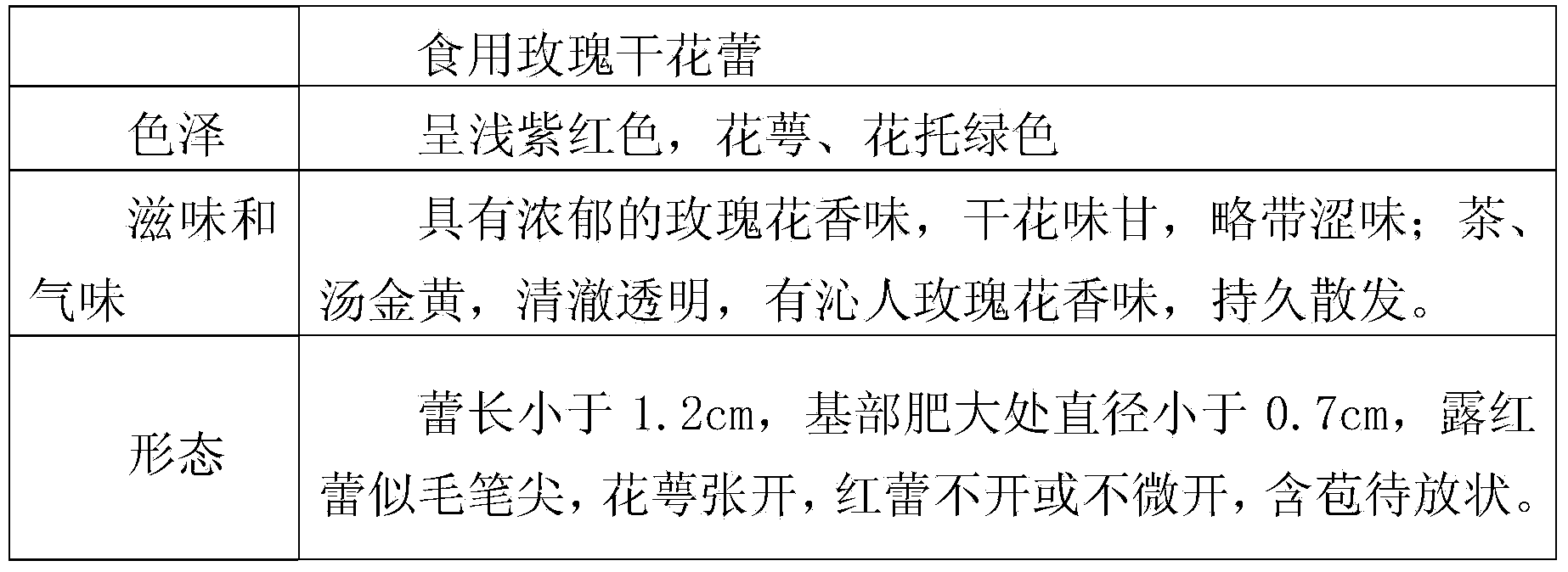

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

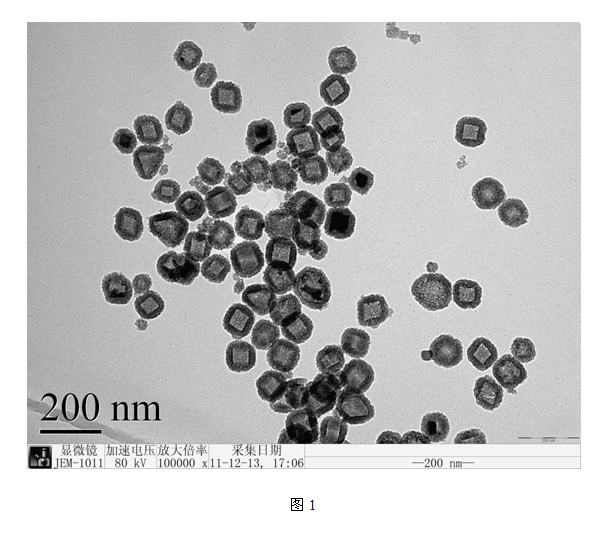

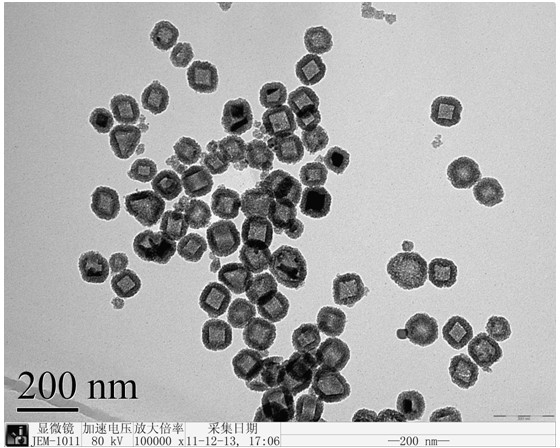

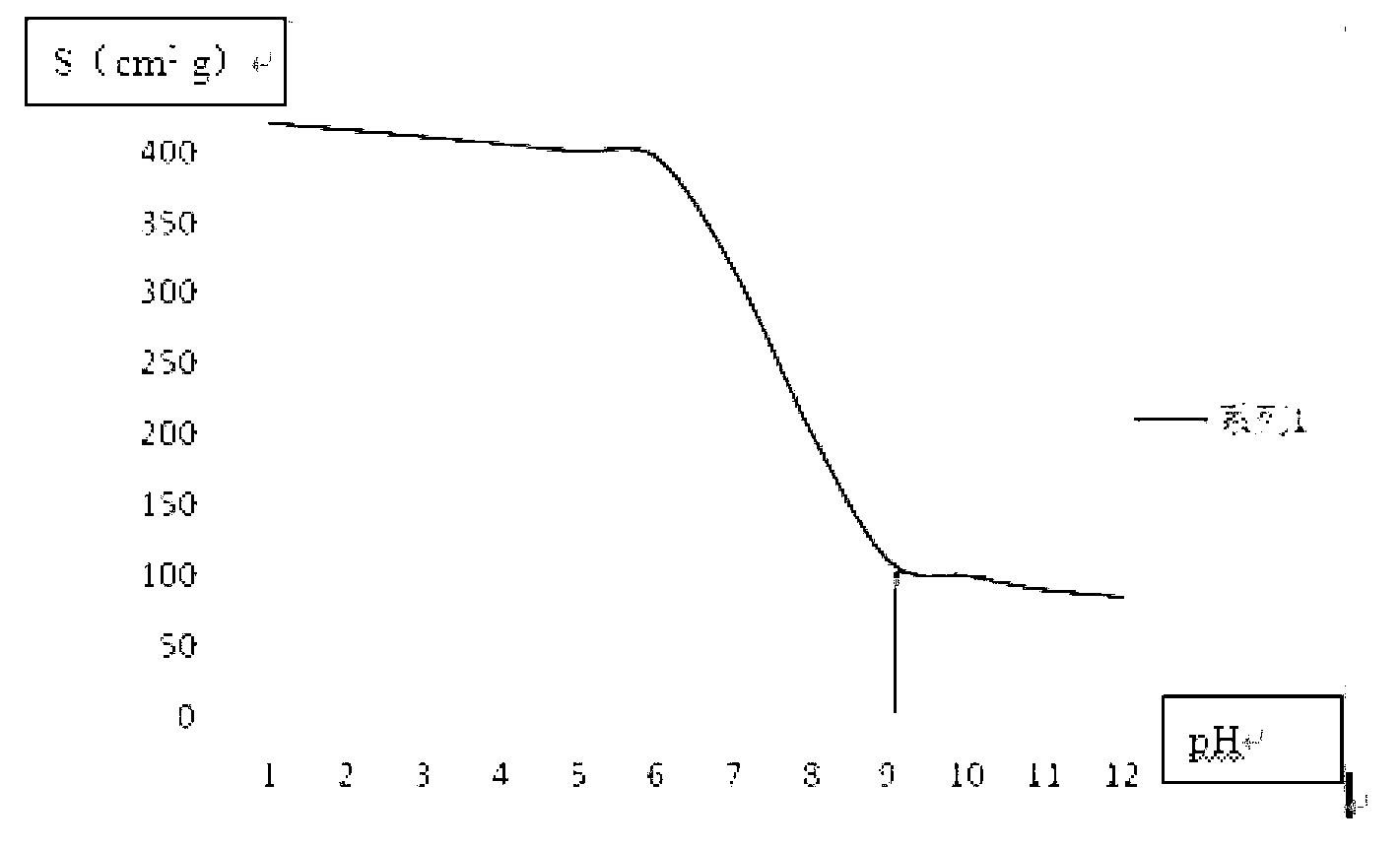

Preparation method for controllable hollow mesoporous silicon dioxide nanospheres

The invention provides a preparation method for controllable hollow mesoporous silicon dioxide nanospheres. The method comprises the following steps of: dissolving iron salt, acetic acid and polyvinylpyrrolidone in ethanol, and uniformly stirring and mixing, then transferring the solution into a polytetrafluoroethylene reaction kettle, and reacting while heating to obtain an iron oxide nanoparticle suspension; adding ethanol, deionized water and cetyl trimethyl ammonium bromide into the iron oxide nanoparticle suspension, adding alkali to adjust the pH value to be 7-12, slowly adding tetraethoxysilane in a stirring condition so as to for 12-72 hours, filtering, drying, and roasting at 400-600 DEG C, thus obtaining a mesoporous silicon dioxide-coated iron oxide nanomaterial with a core-shell structure; and completely soaking the obtained mesoporous silicon dioxide-coated iron oxide nanomaterial with the core-shell structure in a prepared acidic etching solution, dissolving an iron oxide used as a hard template, and washing with the deionized water and the ethanol, filtering and drying, thus obtaining the hollow mesoporous silicon dioxide nanospheres. The preparation method for the controllable hollow mesoporous silicon dioxide nanospheres disclosed by the invention has the advantages of being simple in synthesis process, moderate in operation condition, cheap in raw material and easy in acquisition of raw materials, and easy in enlargement and synthesis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

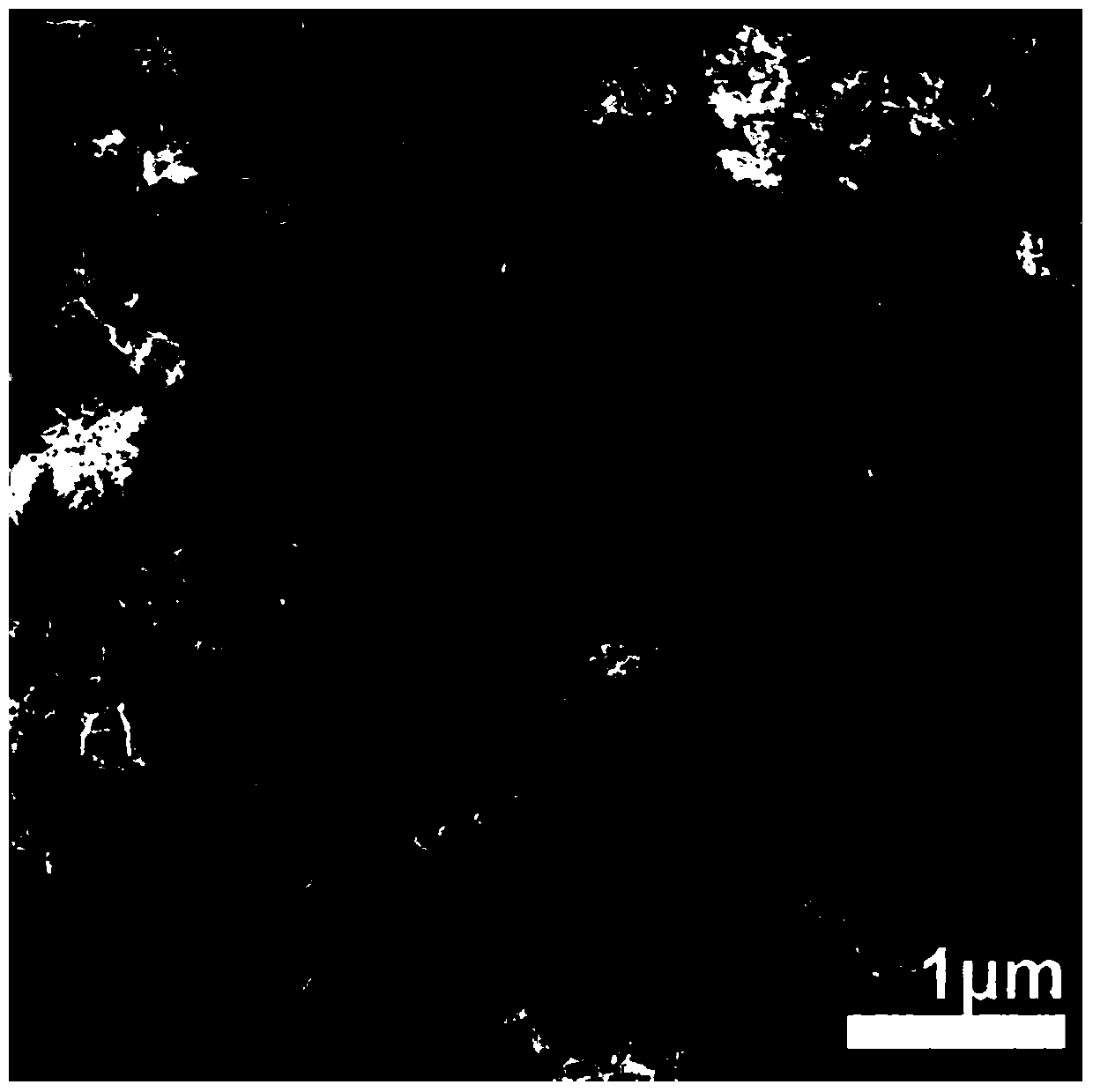

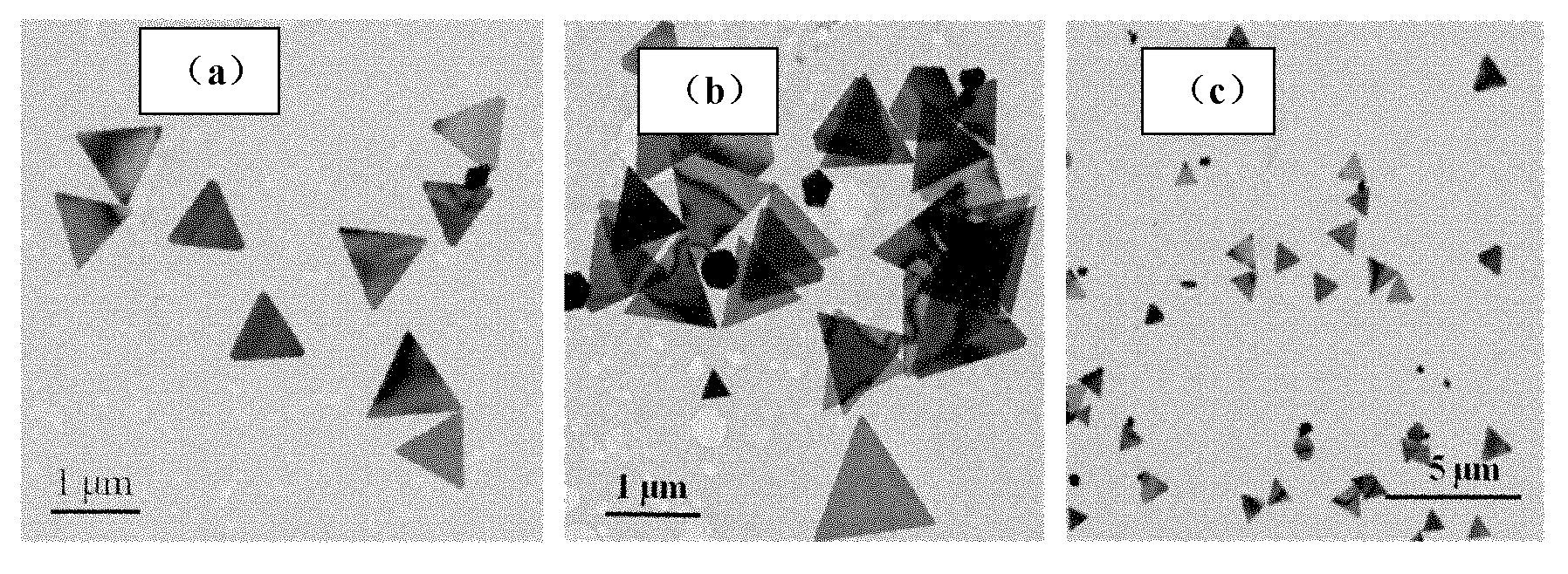

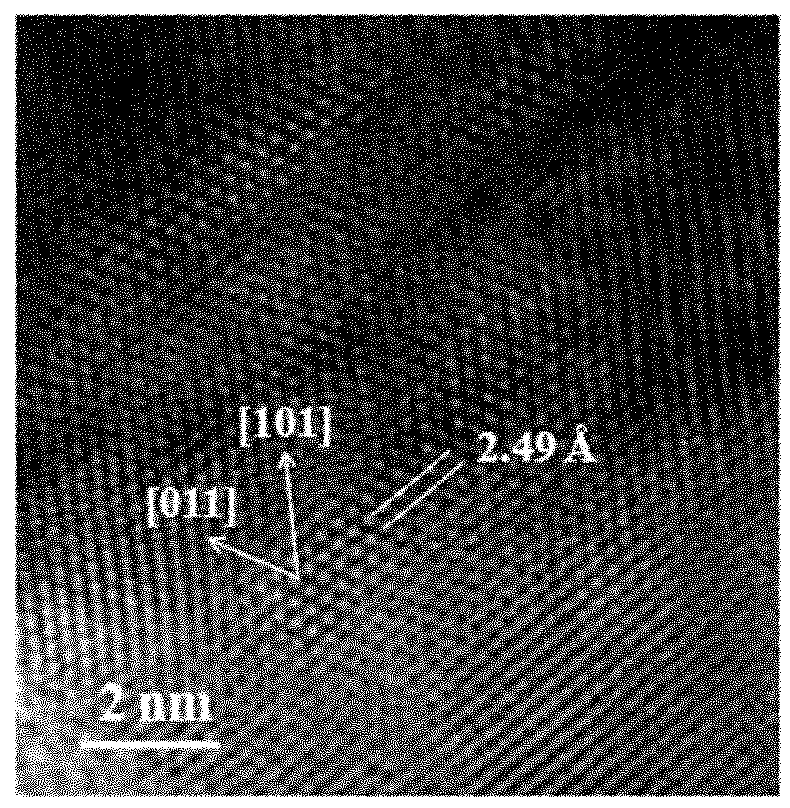

Preparation method of environment-friendly micron-size triangular silver sheet

The invention discloses a preparation method of an environmentally-friendly micron-size triangular silver sheet. The method comprises the following steps of: preparing a silver nitrate oxidation liquid and a reduction liquid containing polyvinyl pyrrolidone (PVP) and D(+)-dextrose, stirring at room temperature and dropwise adding the silver nitrate oxidation liquid into the reduction liquid to obtain a uniform yellow solution; placing the obtained mixed liquor into a drying oven, preserving heat at the temperature between 75 DEG C and 95 DEG C for 48-72 hours to obtain a silver-gray fulmarginsolution; cooling and standing the fulmargin solution, centrifuging and separating; washing nano silver powder obtained by centrifuging with acetone and cold ethanol respectively; and re-dispersing the washed nano silver powder into the ethanol for later use. The prepared micron-size triangular silver sheet has the advantages of high yield, regular shape, difficulty in aggregating, high stability, simple synthesizing process, environmentfriendliness and preparation on a large scale.

Owner:SOUTH CHINA UNIV OF TECH

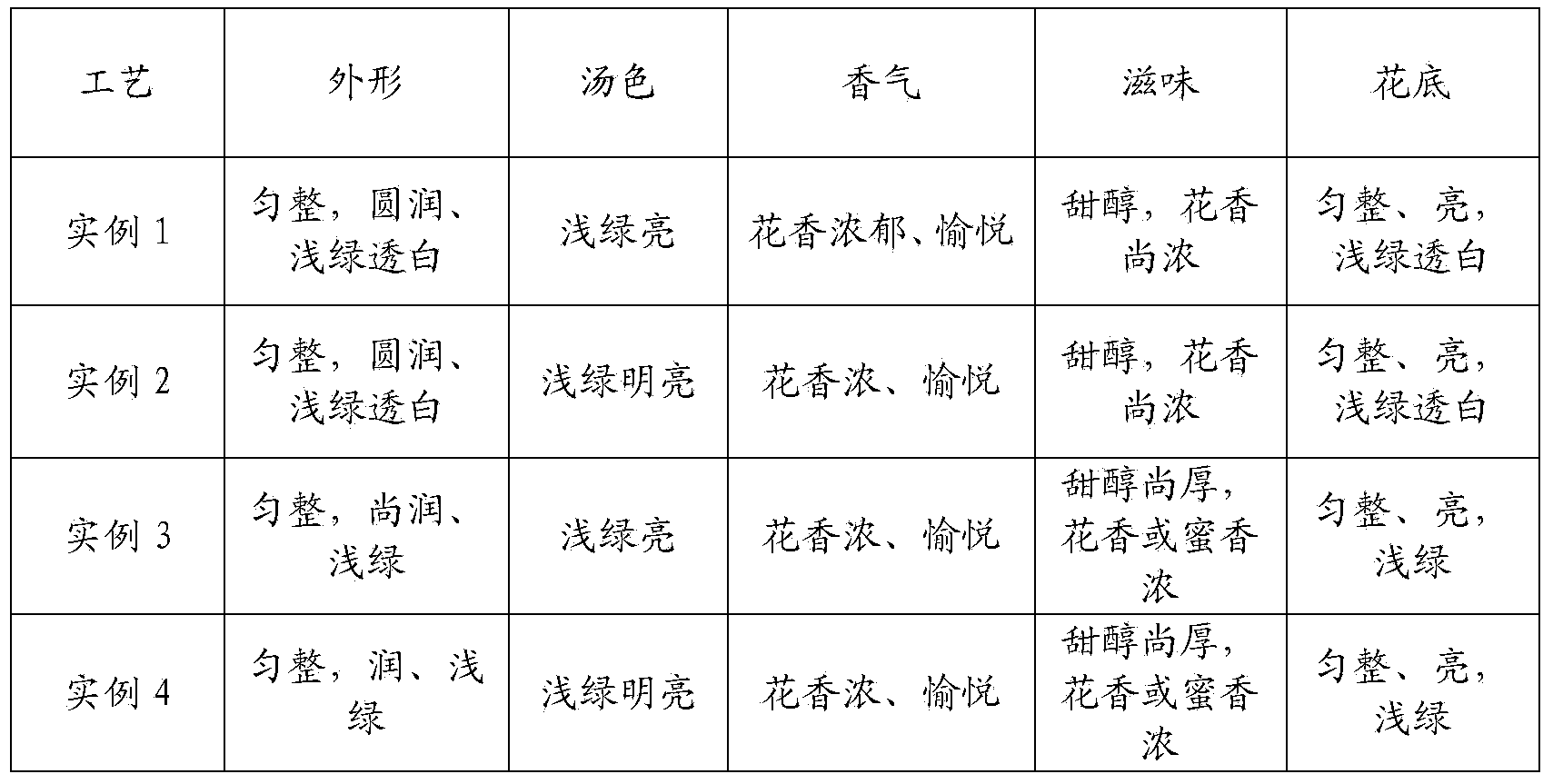

Processing method for tea flowers

The invention relates to a processing method for tea flowers. The processing method comprises the following steps: picking the tea flowers, withering, carrying out fixation, drying and packaging. According to the method, a microwave water removing machine is utilized for rapidly finish fixation in short time; meanwhile, in a fixation process, a lot of water molecules are escaped and evaporated from the tea flowers so as to realize the primary drying aim; the color, the flavor, the shape and the taste of the fresh tea flowers can keep unchanged to the greatest extent and effective substances are kept to the greatest extent; the high-aroma and the high-quality tea flowers are prepared.

Owner:GUANGXI GUILIN TEA RES INST

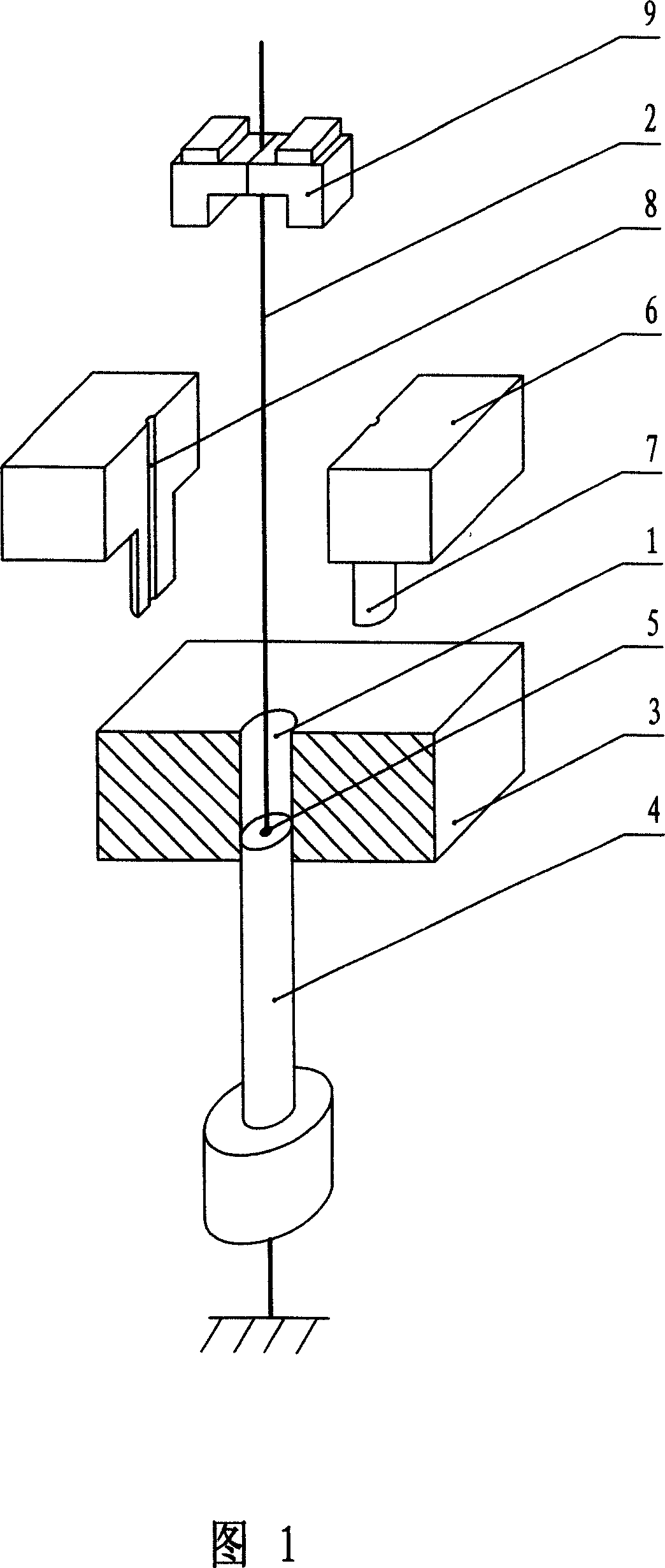

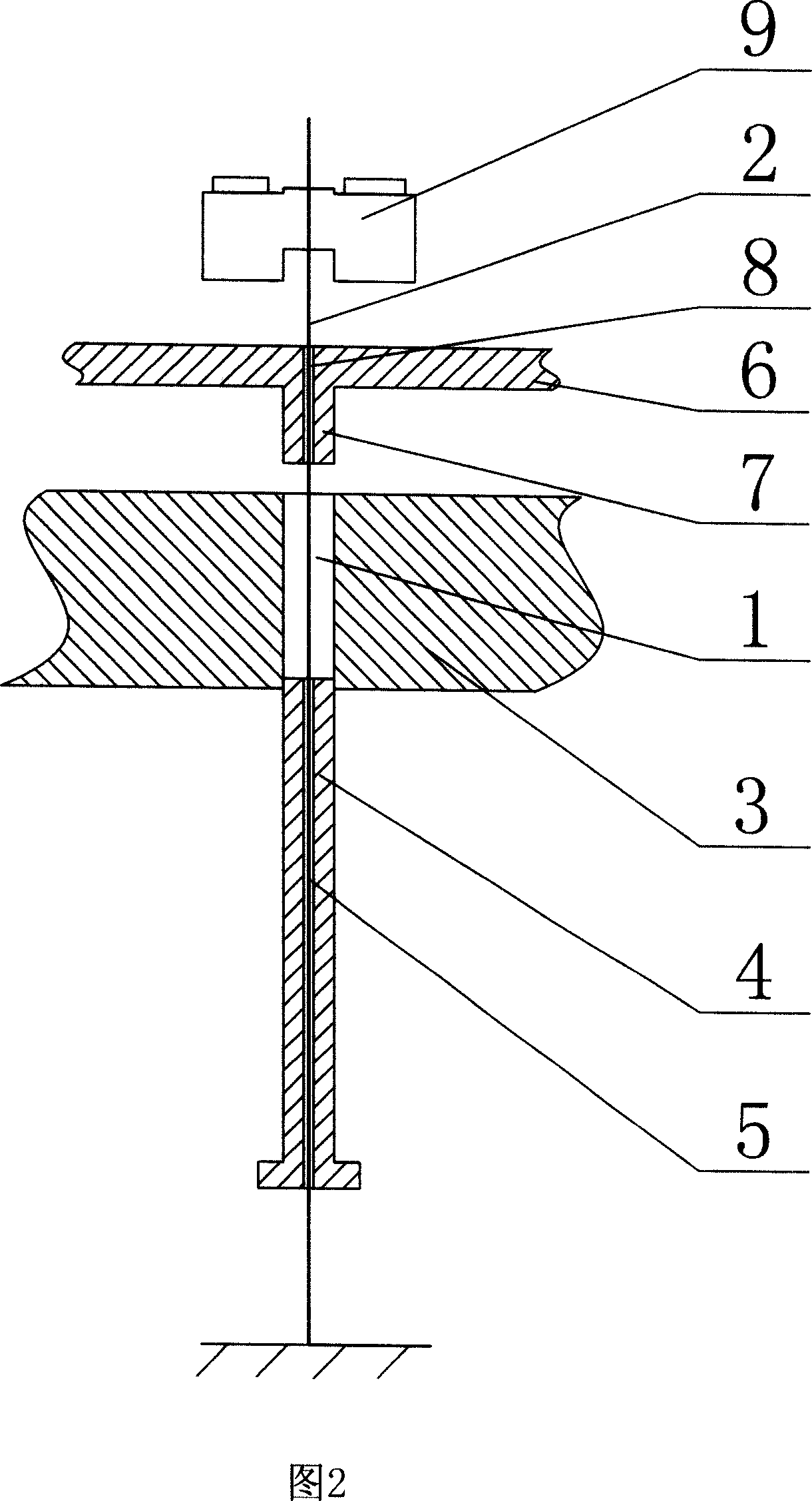

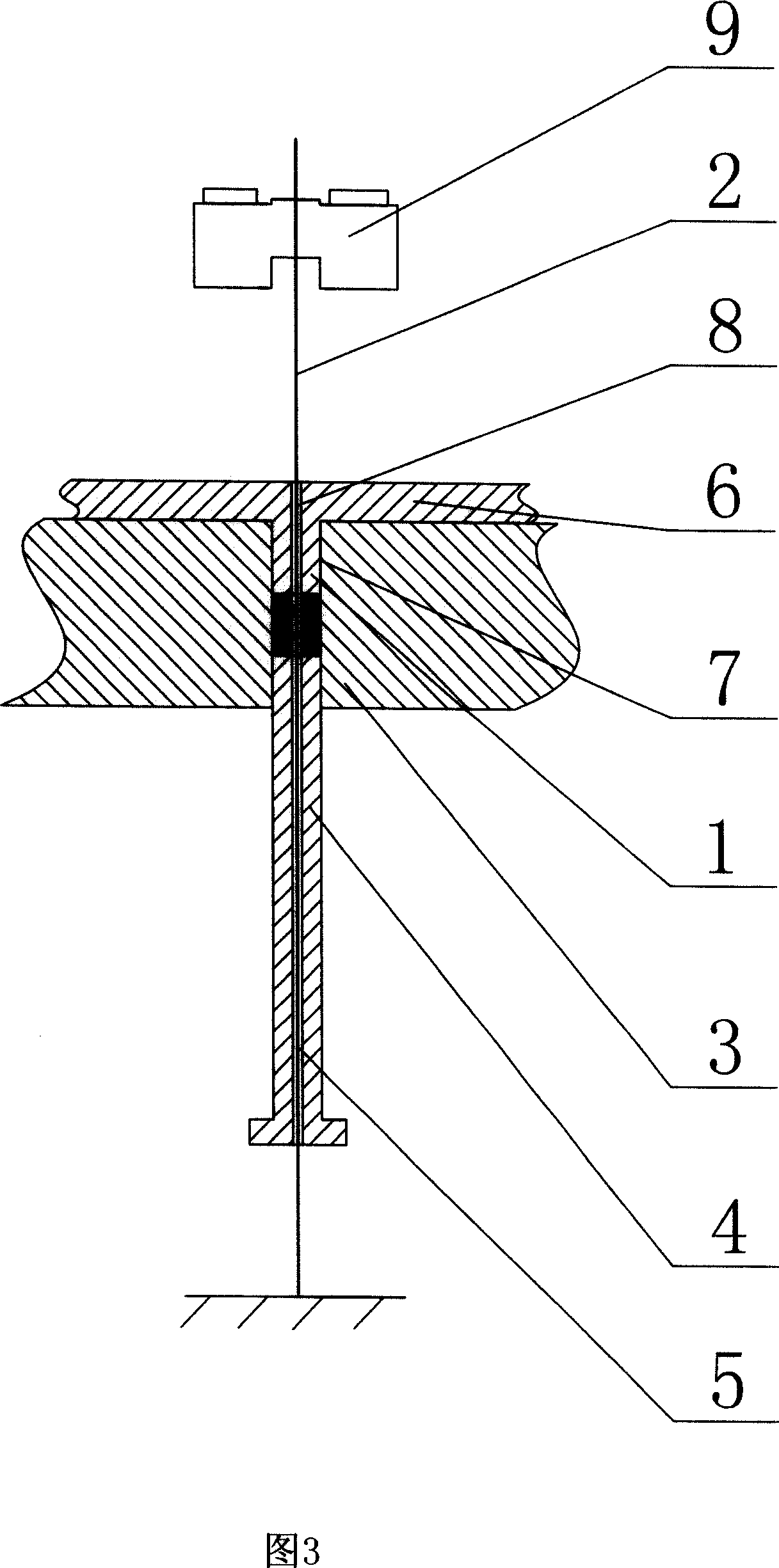

Forming device of blank of cored ceramics and its forming method

InactiveCN101007425AAvoid deformationIncrease profitCeramic extrusion diesShaping press ramPunchingEngineering

The invention discloses equipment and method of ceramic insert core blank, the die cavity of blank molding is equipped with shaping wires, the lower mouth of the die cavity is equipped with thimble die, and the thimble die is equipped with axle hole which passes through the shaping hole, the upper of the die cavity is equipped with two punching semi-dies and semi-dies press ram, the side of semi-dies press ram is equipped with slot for containing shaping wires, one end of shaping wires is fixed under the thimble die and another end is clamped by thread griping device; because he invention uses bidirectional positioning for the shaping wires in the die cavity, it can realize the dry press shaping of blanks, so the ceramic insert core blank produced through the equipment and method is different to distortion and accesses to product, the use of raw materials are not wasted, the inner hole of blank are not blocked and deformed, the yield rate is greatly enhanced, the follow-up fine finishing steps of sintered products is less, production speed is significantly increased; production costs are reduced significantly.

Owner:刘顺峰

Preparation method of sausages

The invention provides a preparation method of sausages. The preparation method of sausages comprises the following steps of stirring materials, filling and baking. The preparation method of sausages is characterized in that the baking comprises low, height and low baking stages. The prepared sausages have red and date red lean meat and milk white fat, the surface is glossy, the flavor is pure and strong, the intrinsic flavor of the sausages is unadulterated and rich, the taste is fresh, the salinity is moderate, appearances are complete and uniform, the surface is dry and comfortable, and the sausages have natural winkles after contraction; and the water content is 20-25%, the storage period is long, and the sausages can still keep the unique color, mouthfeel and nutrition within 3-5 years.

Owner:CHONGQING CHENGKOU COUNTY ZHAO XIAOCHUN WILD FOODDEV

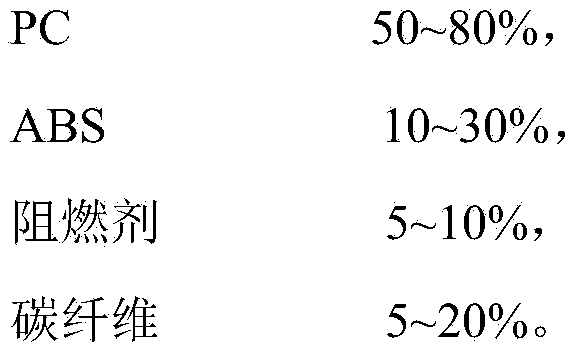

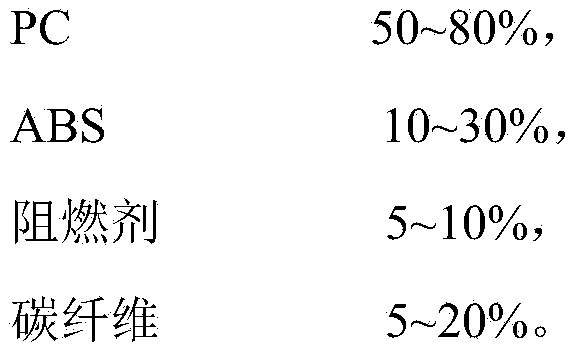

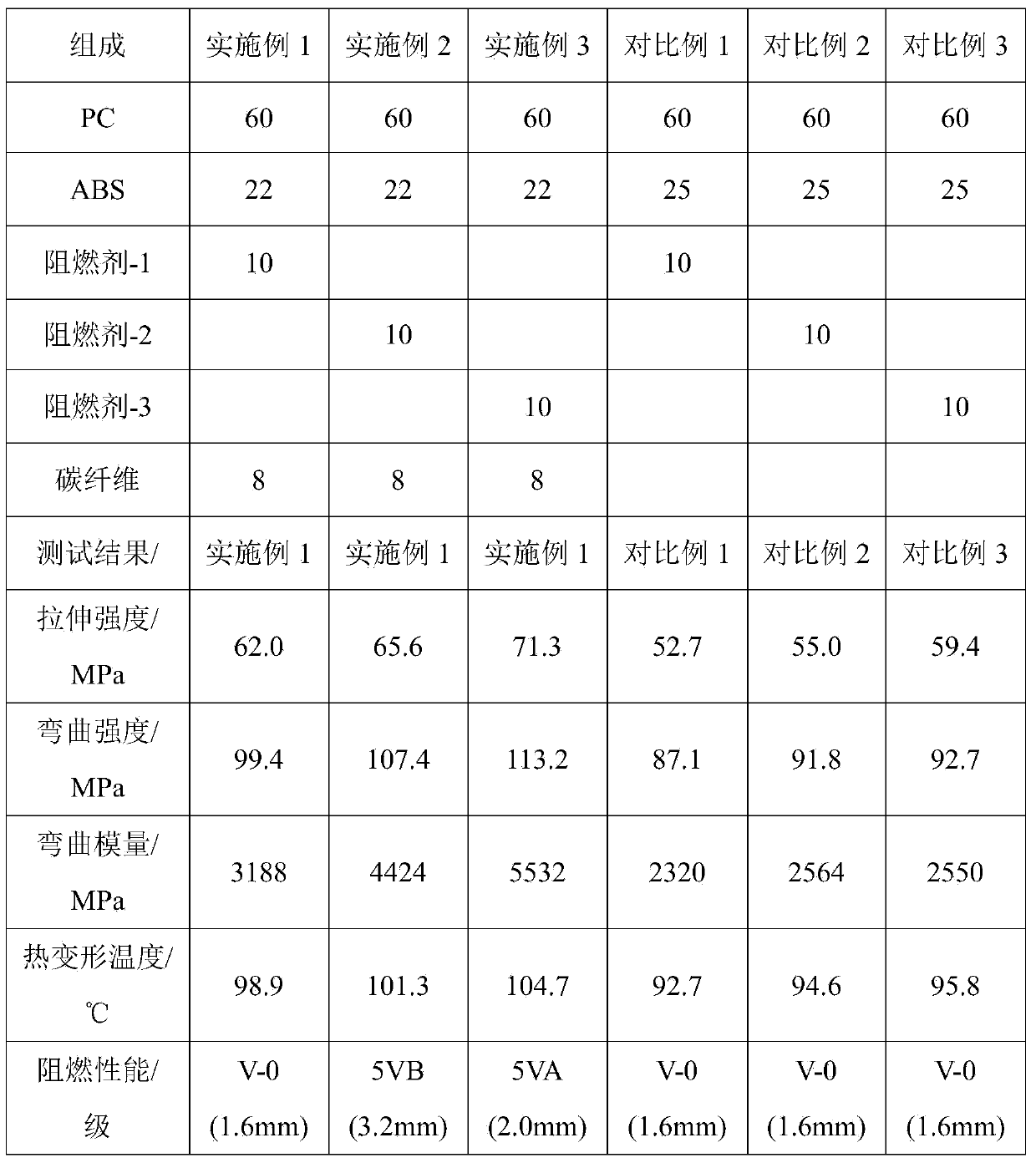

UL94-5VA-grade high-performance flame-retardant reinforced PC (polycarbonate)/ABS (acrylonitrile butadiene styrene) blend and preparation method thereof

The invention discloses a UL94-5VA-grade high-performance flame-retardant reinforced PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) blend and a preparation method thereof. The UL94-5VA-grade high-performance flame-retardant reinforced PC / ABS blend comprises the following raw materials in percentage by weight: 50-80% of PC, 10-30% of ABS, 5-10% of flame retardant and 5-20% of carbon fiber. The blend has multiple properties of high strength, high heat resistance, high flame retardance, low combustion smoking amount and the like. The obtained flame-retardant reinforced PC / ABS blend can not only meet the basic UL94V-0 requirements, but also achieve various indexes of UL94-5VA under the relatively low thickness of 2.0mm of a sample piece, the sample piece has no distortion and no perforation under multiple actions of flame and keeps the relatively complete appearance and shape, and the property has an important role for preventing fire and reducing loss against key electronic parts of automobiles, engineering machines and household electrical products.

Owner:CHONGQNG PRET NEW MATERIAL +2

Method for producing Tibetan medicinal herb incense with foot

The invention relates to a preparation method of incense, in particular to a 'production method of tibetan drug kusaka with incense sticks', pertaining to the field of preparation of incense. The production method of the invention comprises that raw materials are smashed to be 100-mesh to 200-mesh; the proportion of adhesive is also increased; bamboo sticks are used as the incense sticks and a modern machine is used for preparing the tibetan drug kusaka with the incense sticks. The production method of the invention perfectly combines a traditional technology and formula and modern machining and not only keeps various original active ingredients of the tibetan drug kusaka to the maximum extent, but also ensures that the tibetan drug kusaka with the incense drug has a neat shape, good flaming in an upright way (which changes the defects that the traditional tibetan drug kusaka is easy to break and can not be burnt anywhere and fully) and fresh and unique smell. The produced tibetan drug kusaka of the invention not only improves the cultural connotation and economic values of the tibetan drug kusaka, but also has a broad market prospect, thus being another blossoming flower in national brands in Tibetan.

Owner:吕坤秋

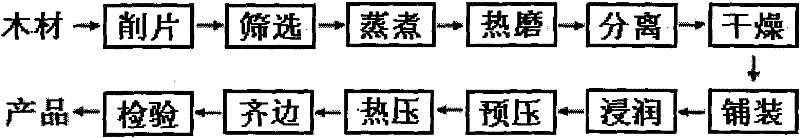

Surface infiltrated wood fiber board and production method thereof

InactiveCN102172948AReduce moisture contentReduce lossFlat articlesDomestic articlesSocial benefitsFiber

The invention discloses a surface infiltrated wood fiber board and a production method thereof. Composite design is performed by adopting the advantages of dry and wet production processes of the wood fiber board; and the method has the following flows of: chipping, screening, digestion, hot grinding, separation, drying, air spreading, surface infiltration, pre-pressing, hot pressing molding, edging, inspection and formation of a finished product. In the digestion, the pressure of steam is 0.55 to 0.68MPa, and the time is 3 to 5 minutes; in the drying, the temperature of airflow is 180 to 280 DEG C, and the time is 5 to 10 seconds; and in the hot pressing molding, the temperature is 190 to 230 DEG C, the pressure is 3.5 to 6.5MPa, and the time is 30 to 50s / mm. The method produces the waterproof, flame-retardant and common hard fiber board; in the production process, the energy consumption is low, and no waste water is discharged; the wood fiber board has high strength and good uniformity; the quality of the wood fiber board reaches the standards of GB12626.1-12626.9-90 Hard Fiber Board; a brand-new method is provided for the production of the wood fiber board; and the method has good economic benefit and social benefit.

Owner:GUANGXI UNIV

Preparation method of nano ferric oxide

The invention relates to a method for producing nanoironoxide, especially method for producing nanoironoxide using electron irradiation, which comprises the following steps: dissolving FeCl3.6H2O into deionized water, titrating by ammonial solution with 25%-28% ammonia. Adding polyvinyl alcohol (PVA) as a surfactant to control the diameter of particles, adding alcohol isopropylicum as a free radical scavenging agent. Irradiating the different PH solution with different arrangement by dissimilar dosage electron beam, separating the production using magnetic separation process, then washing several times by deionized water, vacuum drying 12 h on in the temperature of 60 DEG C, grinding the production to powder to get the nanoironoxide.

Owner:SHANGHAI UNIV

Method for preparing SiO2/TiO2 composite powder

The invention discloses a method for preparing SiO2 / TiO2 composite powder, which comprises the following steps of: dissolving tetraethoxysilane and ammonia water in absolute ethyl alcohol respectively, mixing the tetraethoxysilane and the ammonia water at one time under the ultrasonic condition, continuously performing ultrasonic separation and precipitation to obtain SiO2 submicron spheres with uniform particles and complete appearance; adding the SiO2 submicron spheres into tetrabutyl titanate sol C taking the ammonia water as a solvent, citric acid as a complexing agent and polyethylene glycol as a dispersing agent, performing sufficient ultrasonic dispersion, and stirring and heating to obtain wet gel; and further drying and foaming to compound SiO2 and TiO2 constantly, and calcining to obtain the SiO2 / TiO2 composite powder. The method disclosed by the invention has short preparation period; and the prepared SiO2 / TiO2 composite powder is complete spheres of which the particle size is 200 to 600nm and has high purity and yield.

Owner:SHAANXI UNIV OF SCI & TECH

Forging technology of aviation engine blade based on nickel base superalloy

ActiveCN107598068AReduce depletionReduce chilling effectEngine componentsHeating/cooling devicesAviationMechanical property

The invention discloses a forging technology of an aviation engine blade based on nickel base superalloy and belongs to the technical field of aviation forging. The forging technology comprises the following steps:feeding, coating a bar with a lubricating agent, upsetting and heating, upsetting, cleaning a forging stock, coating the forging stock with the lubricating agent, carrying out finish forging and heating, carrying out finish forging, carrying out side cutting, correcting heating, correcting, cleaning a forge piece, and carrying out thermal treatment and final inspection. The aviationengine blade forged through the forging technology disclosed by the invention is fine and uniform in crystalline grain, and the grain size is grade 9-10; the phenomena that nickel base superalloy is likely to have coarse grain and / or mixed crystal during the forging process are overcome, and the tensile strength can reach 200KSI or above; the forge piece of the blade is complete in outline and isfree of defects including crack, fold and the like, and the machining allowance, mechanical property and the metallographic structure meet the design requirements.A novel selection approach is provided for producing the nickel base superalloy based engine blade with fine and uniform crystalline grain and high tensile strength; and the blade forge piece product can meet the using requirements of the shape and the size of the aviation engine blade.

Owner:AECC AERO SCI & TECH CO LTD

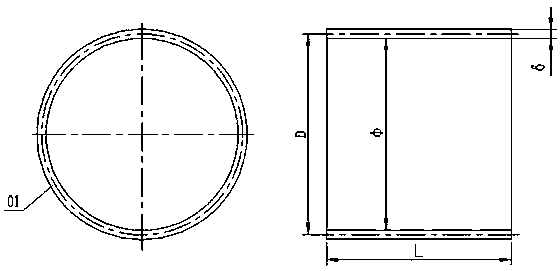

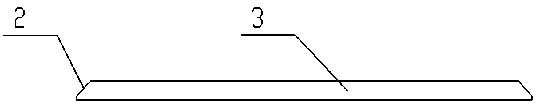

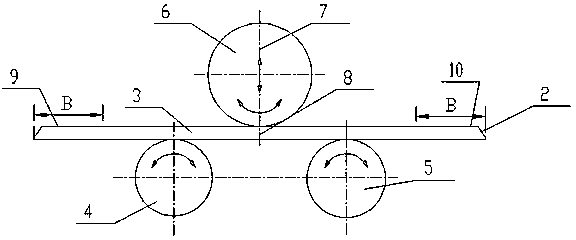

Multi-curvature forming method for stainless steel cylinder

The invention discloses a multi-curvature forming method for a stainless steel cylinder. The method is characterized by comprising the following steps: performing scribing and blanking according to the developed length of the medium diameter of a cylinder to be wound; machining peripheral welding grooves of a plate; rolling-forming a first-curvature circular arc, namely reserving a straight section, not to be wound for the formation of a circular arc, with a width B of 200 to 600 mm at each of the two ends of the cylindrical plate, and bending and winding the middle part of the cylindrical plate into a large circular arc with a curvature radius R of more than or equal to 0.5 Phi to form the first-curvature circular arc of the cylinder; rolling-forming second-curvature circular arcs, namely rolling the parts between the roots of the straight sections with the widths B of 200 to 600 mm and the large circular arc into circular arcs with curvature radiuses r of 0.2 to 0.5 Phi to form second-curvature circular arcs; rolling transition parts between the second-curvature circular arcs and the first-curvature circular arc into smooth transition; performing rolling until the grooves 2 in the two ends of the straight sections get close to each other; performing longitudinal seam assembly and welding on the cylinder, placing the cylindrical body at a horizontal position, and welding longitudinal seams; performing roundness correction on the cylinder after welding.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

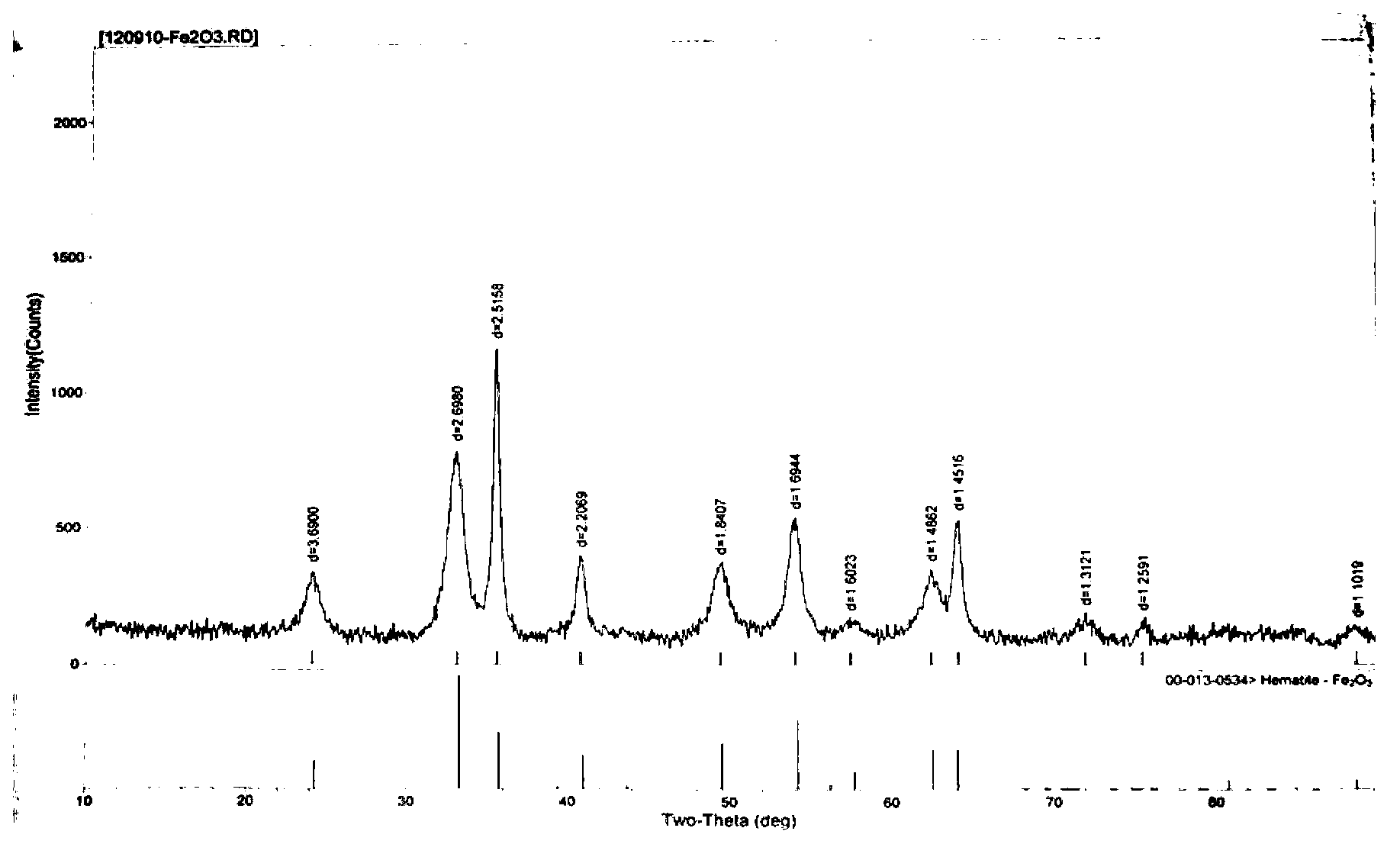

Method for preparing nanometer alpha-Fe2O3 material

ActiveCN102838172AStable controlEasy to controlMaterial nanotechnologyFerric oxidesAlpha-FeOOHColloid

The invention discloses a method for preparing a nanometer alpha-Fe2O3 material. The method comprises the steps of: (1) adding a strong oxidant in a Fe<2+> solution to oxidize Fe<2+> to Fe<3+>, and adding a strong alkali solution after activation of the Fe<3+> until the pH value is 6.0-11.0 so as to generate a Fe(OH)3 seed crystal colloid; (2) heating the Fe(OH)3 seed crystal colloid to be at 80-90 DEG C, adding the Fe<2+>, the Fe<3+> and Fe<0> in sequence, and reacting at a temperature of 80-90 DEG C for 8-12h to enable the Fe(OH)3 seed crystal colloid to grow to form nanometer alpha-FeOOH, wherein the destination pH value of the reaction is 3.5-6.0; and (3) filtering and washing the nanometer alpha-FeOOH to obtain an alpha-FeOOH filter cake, drying and crushing the alpha-FeOOH filter cake, and then calcining at a temperature of 300-400 DEG C to obtain the nanometer alpha-Fe2O3 powder material. The alpha-Fe2O3 prepared by using the method is small in particle size, good in dispersion, and narrow and even in distribution.

Owner:绍兴奥唯特纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com