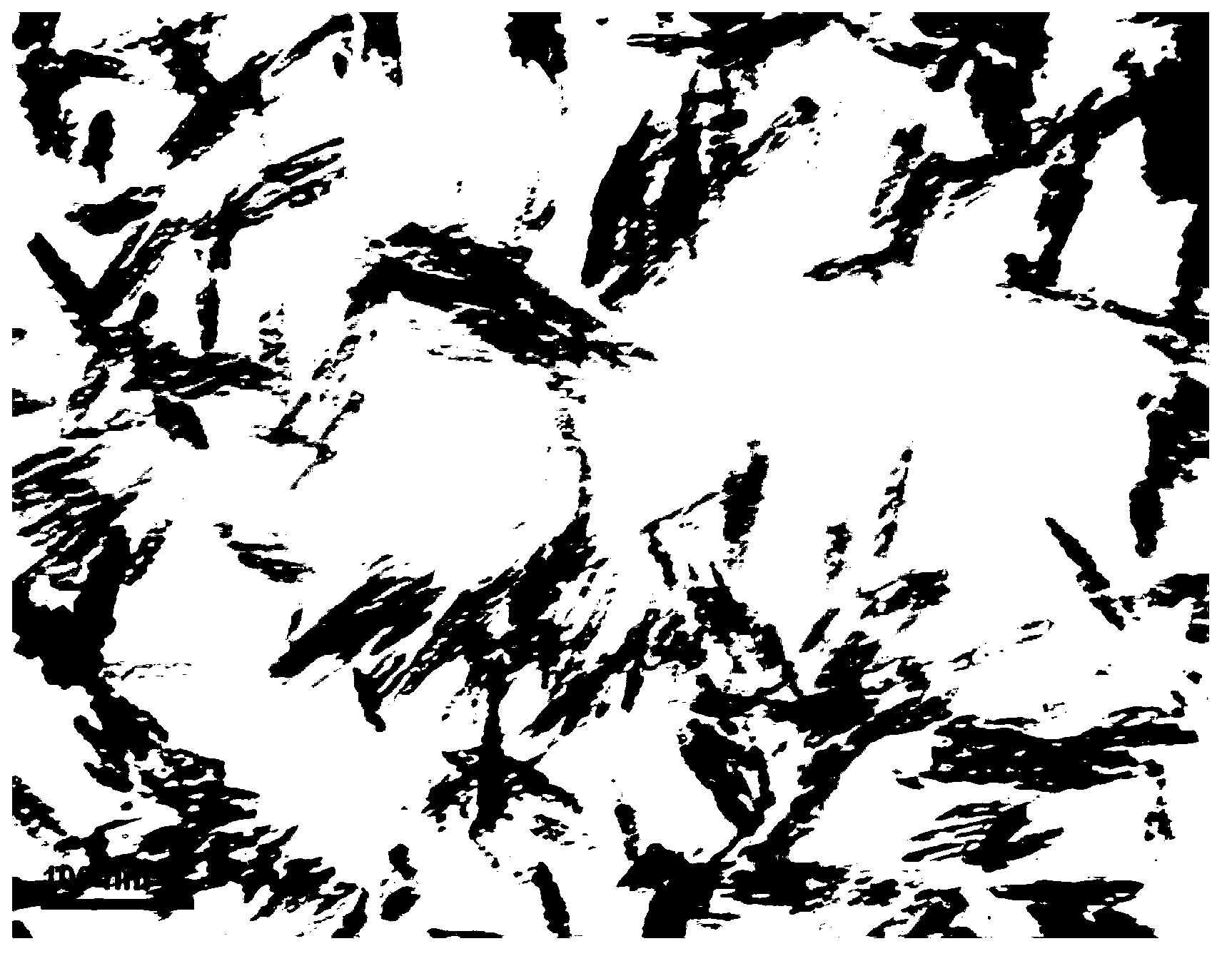

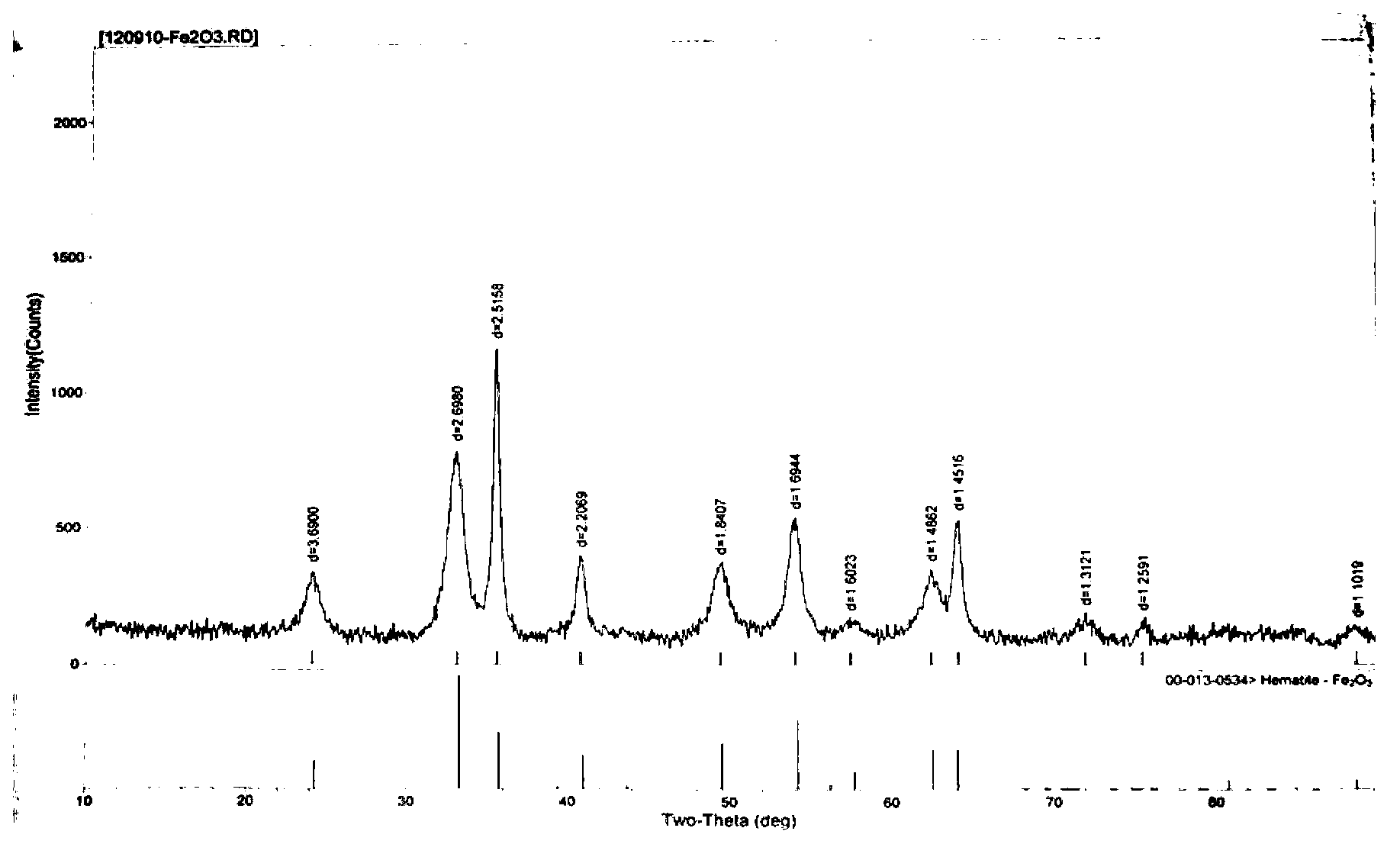

Method for preparing nanometer alpha-Fe2O3 material

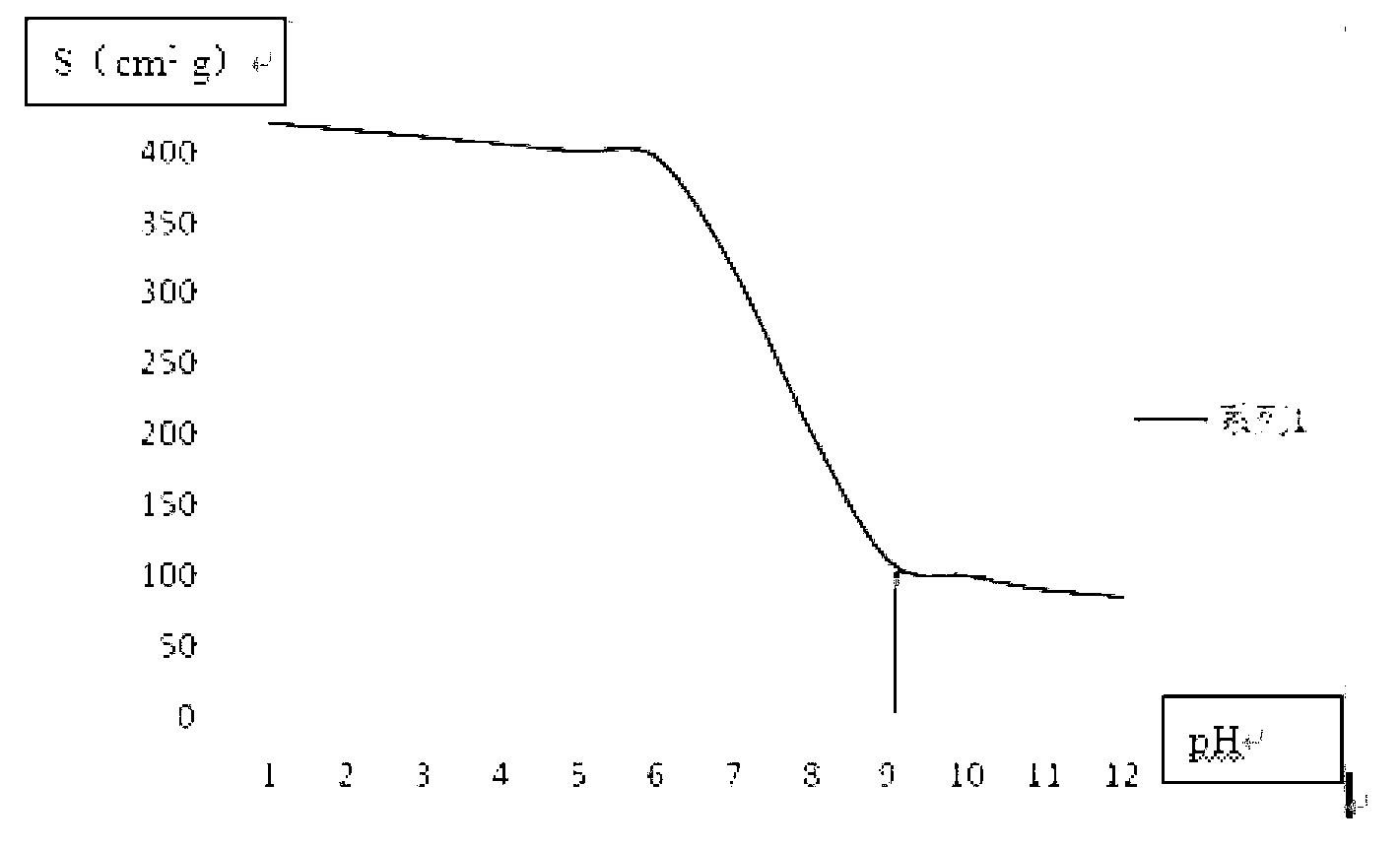

A nanotechnology, seed crystal technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of never involving drying process, high technical requirements for equipment, large capital investment, etc. Solve the effect of not easy to disperse, ensure dispersibility, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take refined and purified vitriol (FeSO 4 ·7H 2 O), configured with deionized water to a concentration of 75g / l (converted into FeSO 4 ·7H 2 O) containing Fe 2+ Solution, under 60 ℃, 150r / min stirring speed, add a certain amount of 98% industrial sulfuric acid (the added quality of 98% industrial sulfuric acid is that contains Fe 2+ Solution Fe 2+ 0.015% of the mass), and then add a certain amount (for Fe-containing 2+ Fe in solution 2+ 7.0% by mass) of NaClO 3 reaction, so that Fe 2+ (FeSO 4 ·7H 2 O) completely turned into Fe 3+ (Fe 2 (SO 4 ) 3 ), the Fe 2 (SO 4 ) 3 Add H 2 O is diluted to a solution with a concentration of 35g / l (converted into FeSO4 7H2O), and the mixture of PVP, sodium dodecylbenzenesulfonate, sodium oleate and sodium naphthalenesulfonate is added at 200 rpm and 50°C. Activation, the amount of PVP added is Fe-containing 2+ Fe in solution 2+ 0.1% of the mass, the amount of sodium dodecylbenzenesulfonate added is Fe 2+ Fe in solut...

Embodiment 2

[0056] Take refined and purified vitriol (FeSO 4 ·7H 2 O), configured with deionized water to a concentration of 100g / l (converted into FeSO 4 ·7H 2 O) containing Fe 2+ Solution, under 65 ℃, 150r / min stirring speed, add a certain amount of 98% industrial sulfuric acid (the added quality of 98% industrial sulfuric acid is to contain Fe 2+ Fe in solution 2+ 0.015% of the mass), and then add a certain amount (for Fe-containing 2+ Fe in solution 2+ 7.0% of mass) NaClO 3 Reaction 8 makes Fe 2+ (FeSO 4 ·7H 2 O) completely turned into Fe 3+ (Fe 2 (SO 4 ) 3 ), the Fe 2 (SO 4 ) 3 Add H 2 O is diluted to a solution with a concentration of 50g / l (converted to FeSO4 7H2O), and the mixture of PVP, sodium dodecylbenzenesulfonate, sodium oleate and sodium naphthalenesulfonate is added at 200 rpm and 60°C. Activation, the amount of PVP added is Fe-containing 2+ Fe in solution 2+ 0.3% of the mass, the addition of sodium dodecylbenzenesulfonate is Fe-containing 2+ Fe in sol...

Embodiment 3

[0062] Take refined and purified vitriol (FeSO 4 ·7H 2 O), configured with deionized water to a concentration of 30g / l (converted into FeSO 4 ·7H 2 O) containing Fe 2+ Solution, 55 ℃, 150r / min stirring speed, add a certain amount (for containing Fe 2+ Fe in solution 2+ Quality 0.015%) 98% industrial sulfuric acid, then add a certain amount (for containing Fe 2+ Fe in solution 2+ mass 7.0%) of NaClO 3 reaction, so that Fe 2+ (FeSO 4 ·7H 2 O) completely turned into Fe 3+ (Fe 2 (SO 4 ) 3 ), the Fe 2 (SO 4 ) 3 Add H 2 O is diluted to a solution with a concentration of 50g / l (converted to FeSO4 7H2O), and a mixture of PVP, sodium dodecylbenzenesulfonate, sodium oleate and sodium naphthalenesulfonate is added at 200 rpm and 50°C. Activation, the amount of PVP added is Fe-containing 2+ Fe in solution 2+ 0.2% of the mass, the amount of sodium dodecylbenzenesulfonate added is Fe 2+ Fe in solution 2+ 2% of the mass, the addition of sodium naphthalenesulfonate is Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com