One-step extrusion-blown molding pot forming technology, dedicated mold pressing extrusion molding blow molding die and product

A technology of extrusion blow molding and extrusion molding, which is applied in the field of molding extrusion blow molding, can solve the problems of color difference of the pot body, etc., and achieve the effect of reducing water consumption, reducing molds and equipment, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

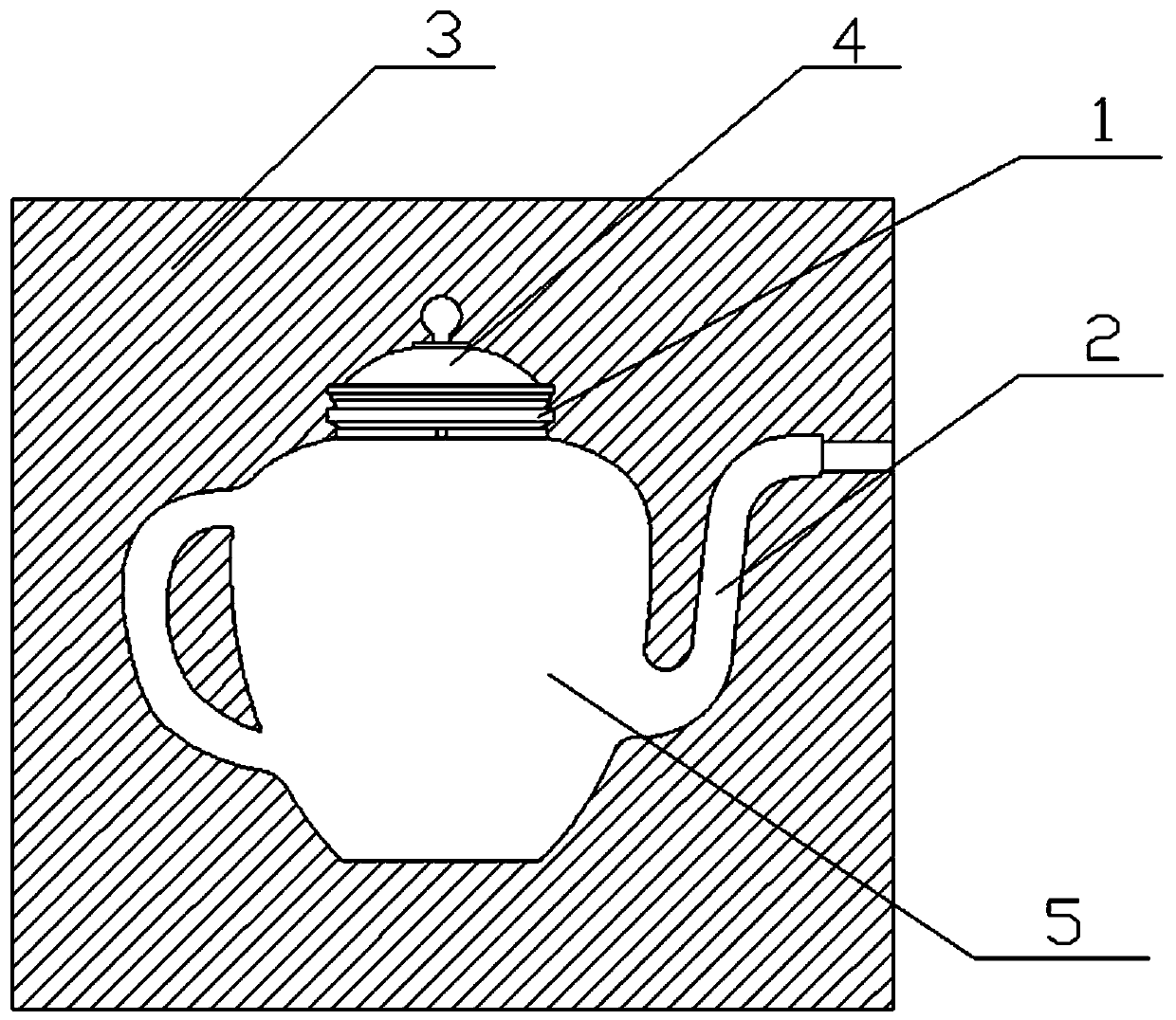

[0040] Embodiment 1, with reference to figure 1 , a one-step extrusion blow molding pot process special molding extrusion molding blow mold, including a two-part mold mold 3 and a forming pot body cavity 5 on it, and the mouth of the forming pot body cavity 5 passes through a connecting ring Die cavity 1 communicates with pot lid die cavity 4. The cavity 5 of the forming pot body communicates with the cavity of the handle.

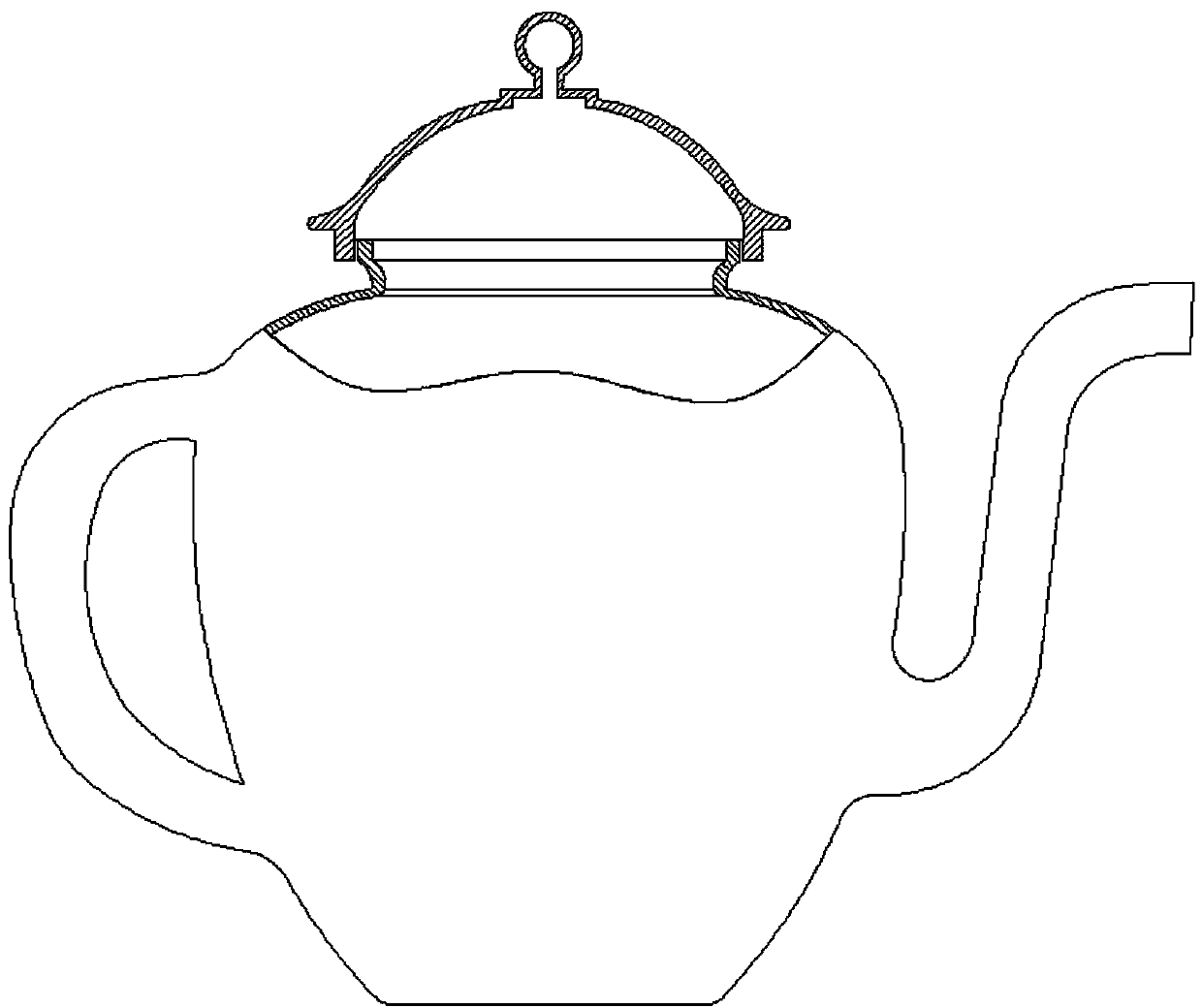

[0041] The connecting ring cavity 1 communicates with the pot lid cavity 4 and the kettle body cavity 5 through the pot lid notch cavity and the pot mouth notch cavity. In order to make a qualified product of the pot lid and the pot body at the same time, a double incision with a vertical angle of less than 40 degrees is designed between the pot lid and the spout. Finally, cut off the connecting ring in the middle along the incision, and the lid can be properly fastened on the spout, thus ensuring the integrity of the two products. And the pot lid and t...

Embodiment 2

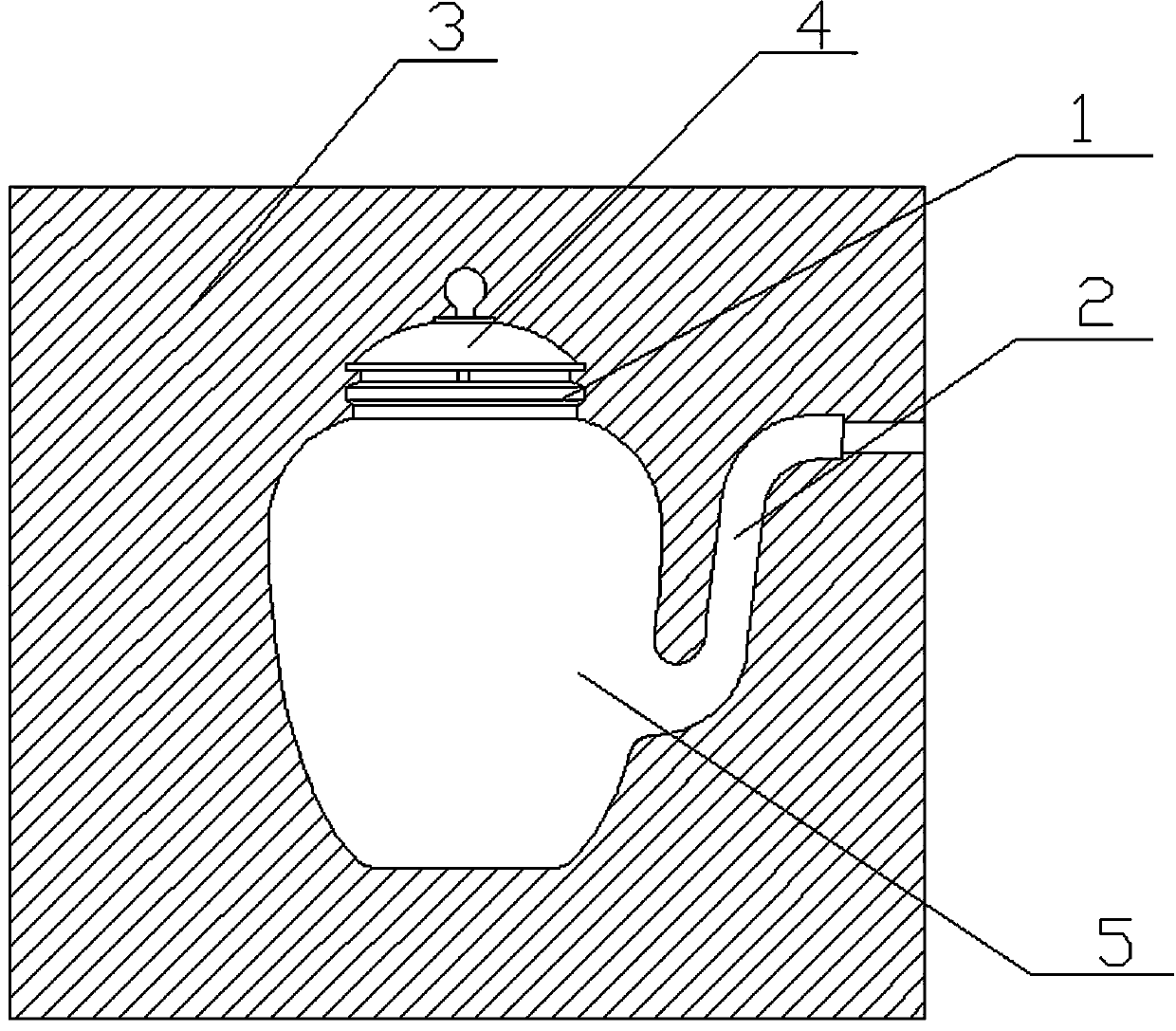

[0043] Embodiment 2, with reference to figure 2 , a one-step extrusion blow molding pot process special molding extrusion molding blow mold, including a two-part mold mold 3 and a forming pot body cavity 5 on it, and the mouth of the forming pot body cavity 5 passes through a connecting ring Die cavity 1 communicates with pot lid die cavity 4. There is no handle cavity on the cavity of the forming pot body. The rest are the same as embodiment 1.

Embodiment 3

[0044] Embodiment 3, a kind of one-step extruding and blowing into the product that pot technology produces, comprises forming kettle blank, cleans and shapes the flash overflow, burr etc. of this molding kettle blank parting surface place, cuts off this molding kettle blank simultaneously The connecting ring connecting the pot lid and the pot body makes the pot lid and the mouth of the pot body snap together to form the plastic pot product with no color difference in each part of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com