Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce transit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

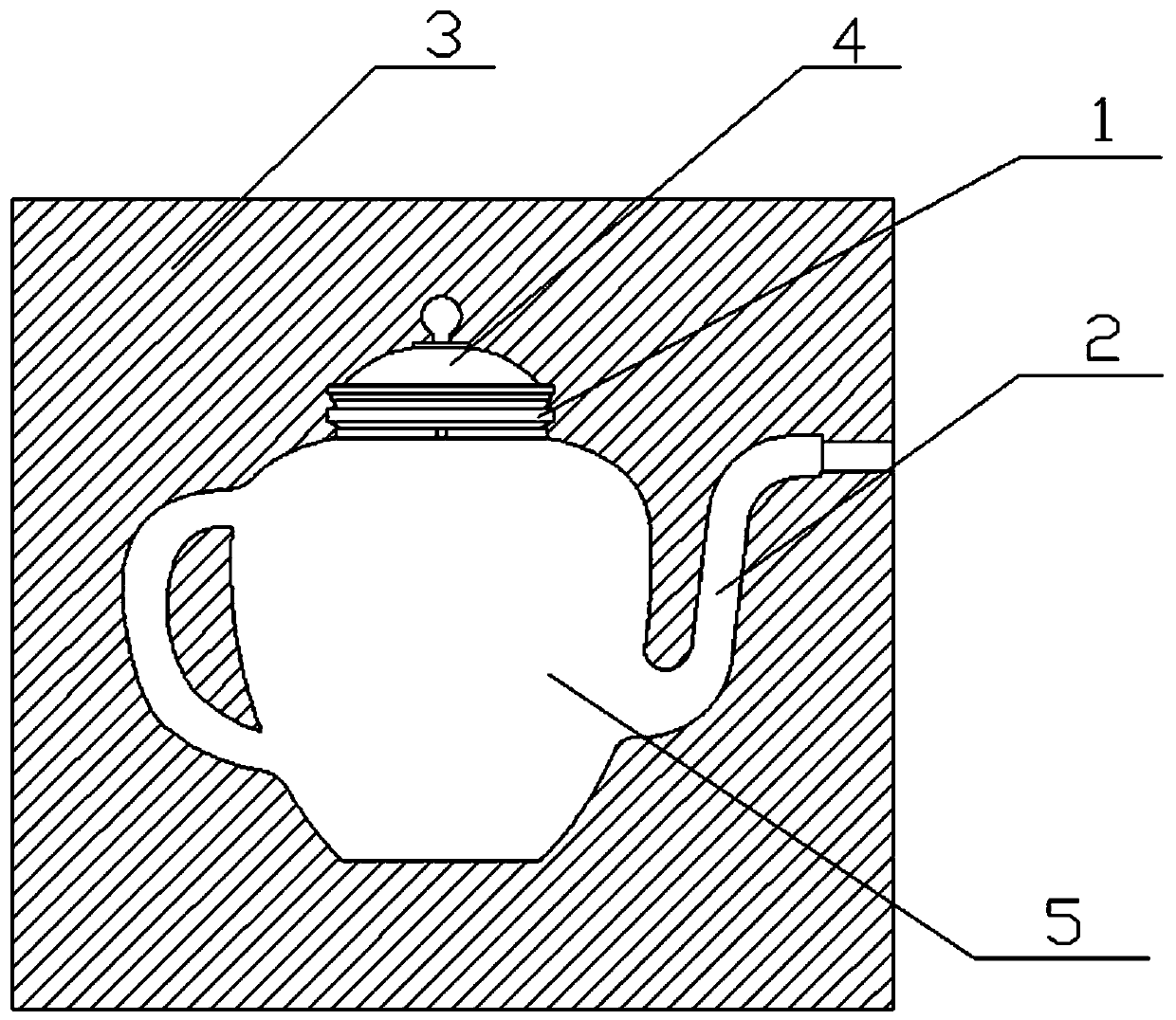

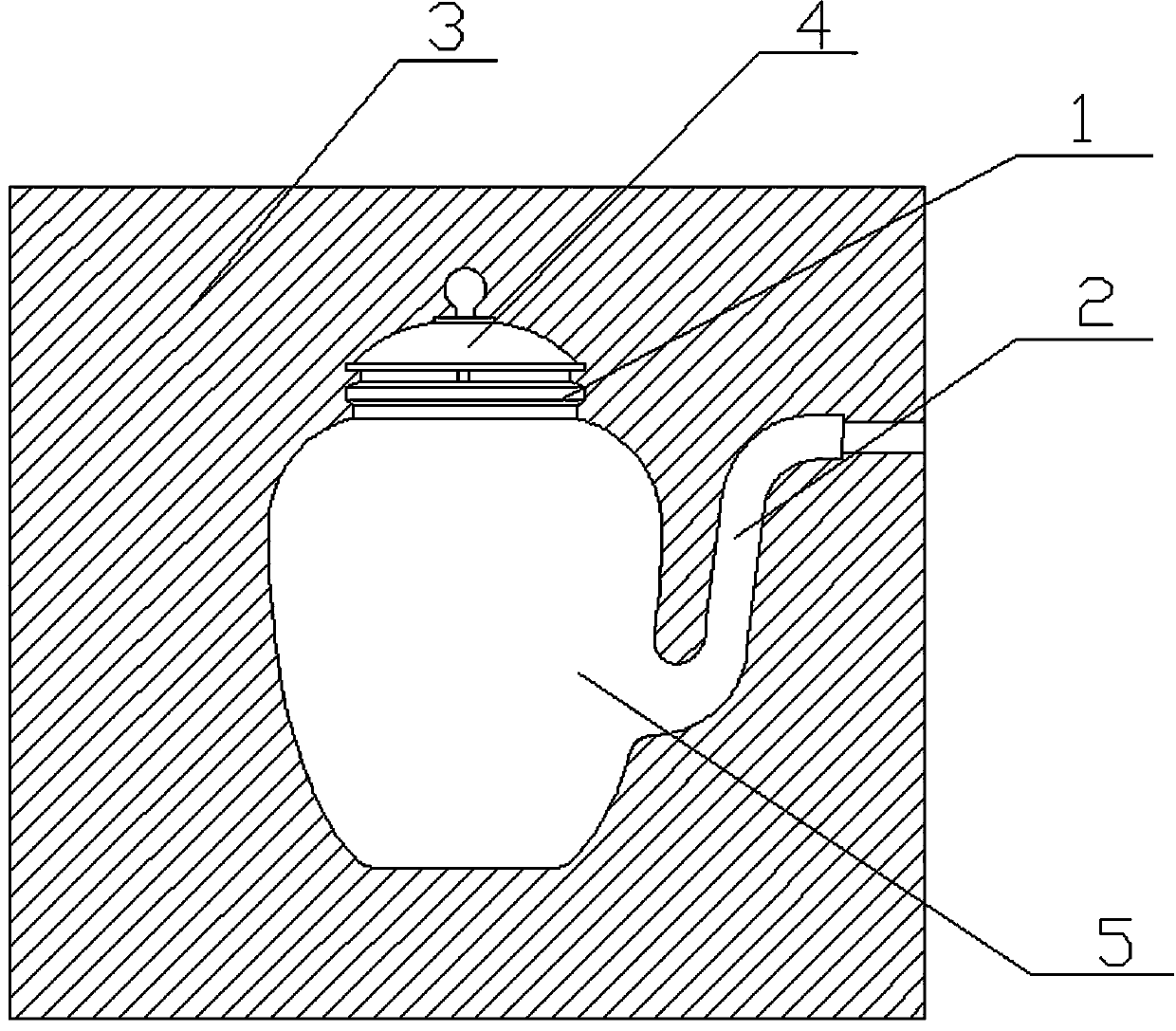

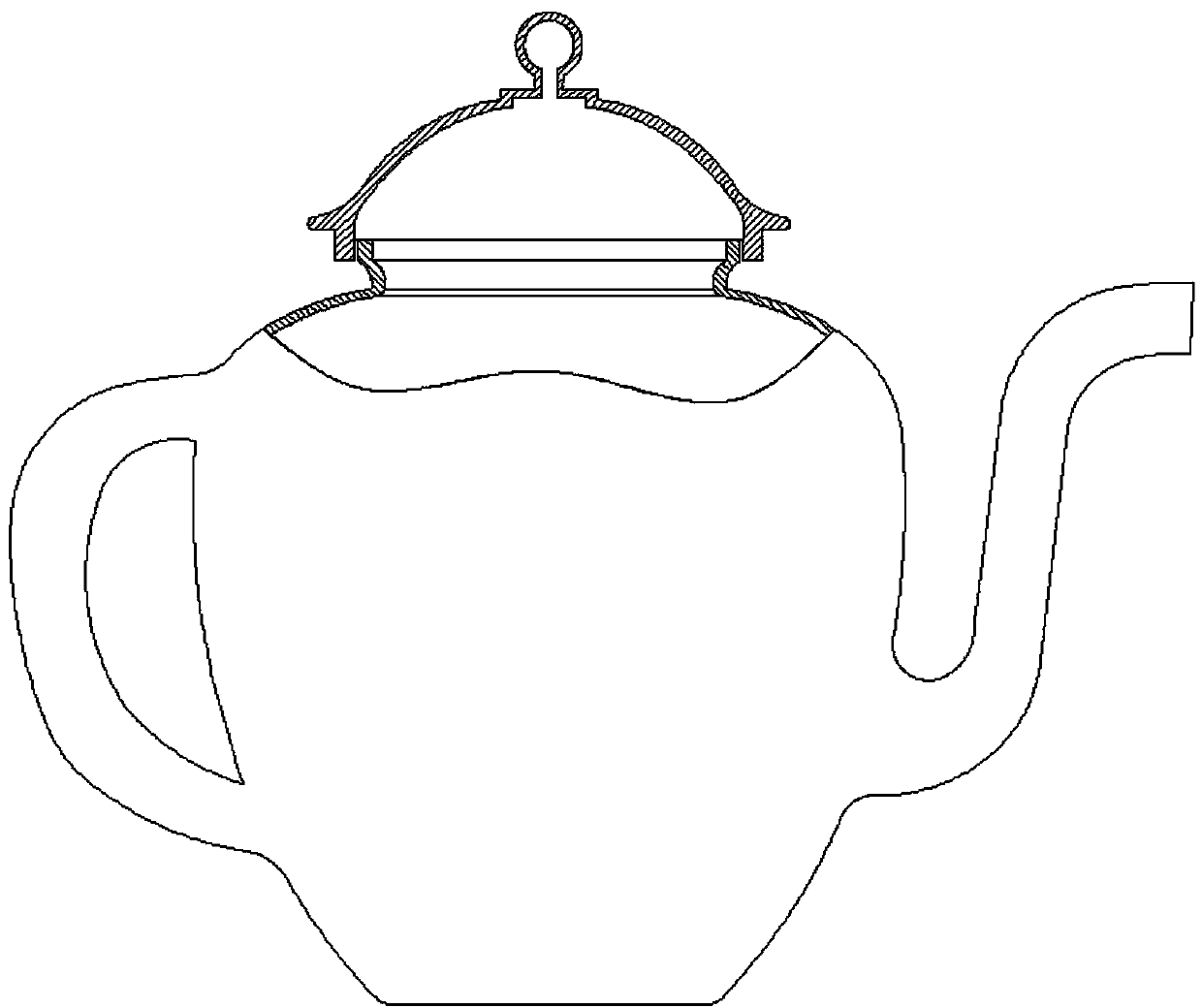

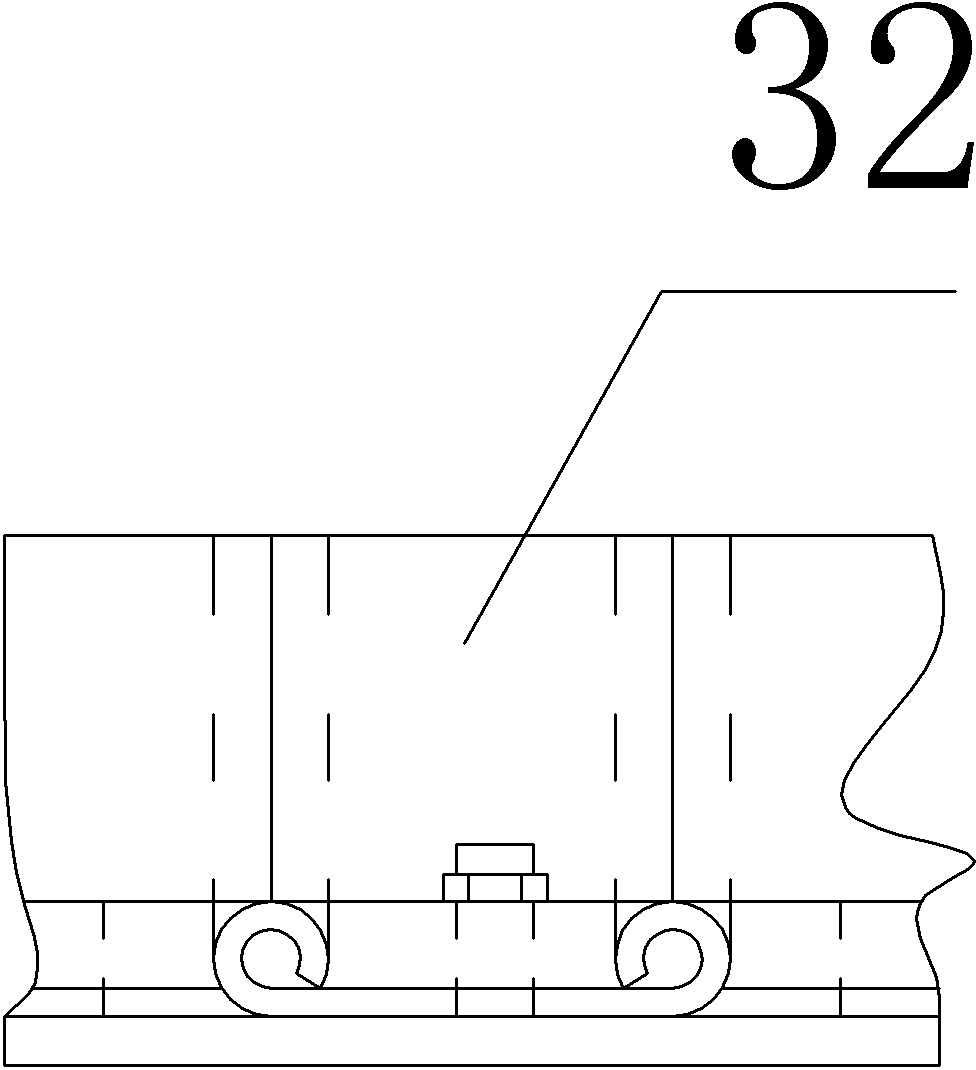

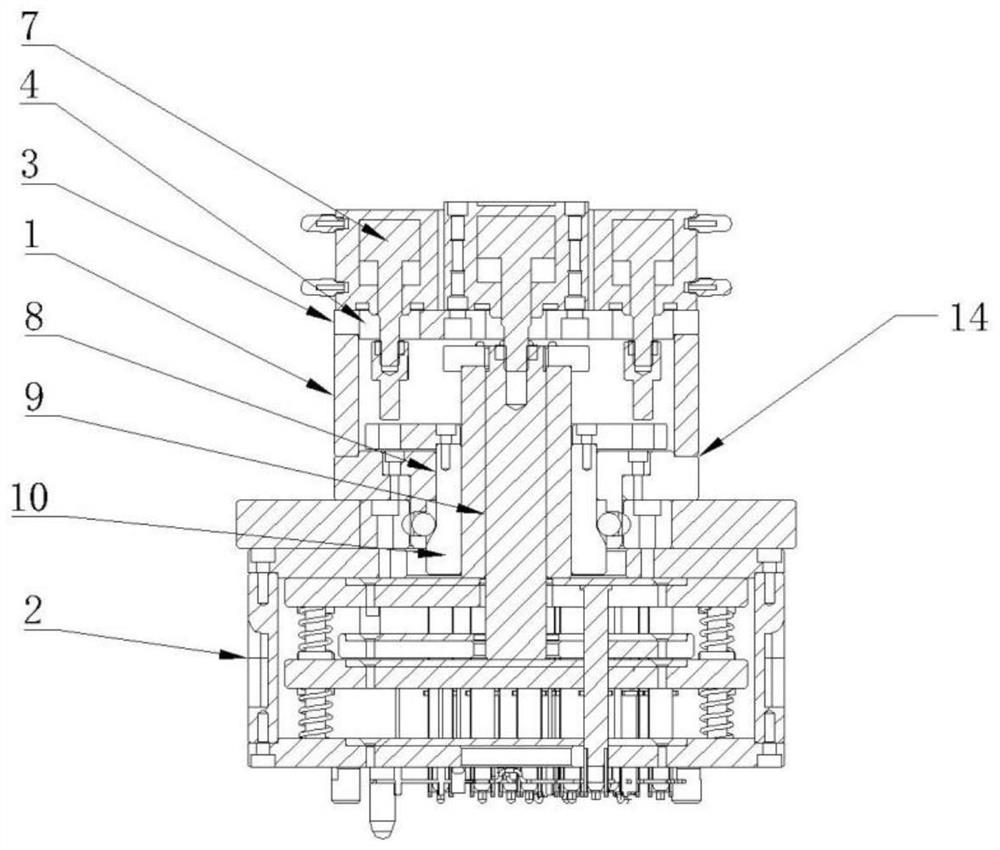

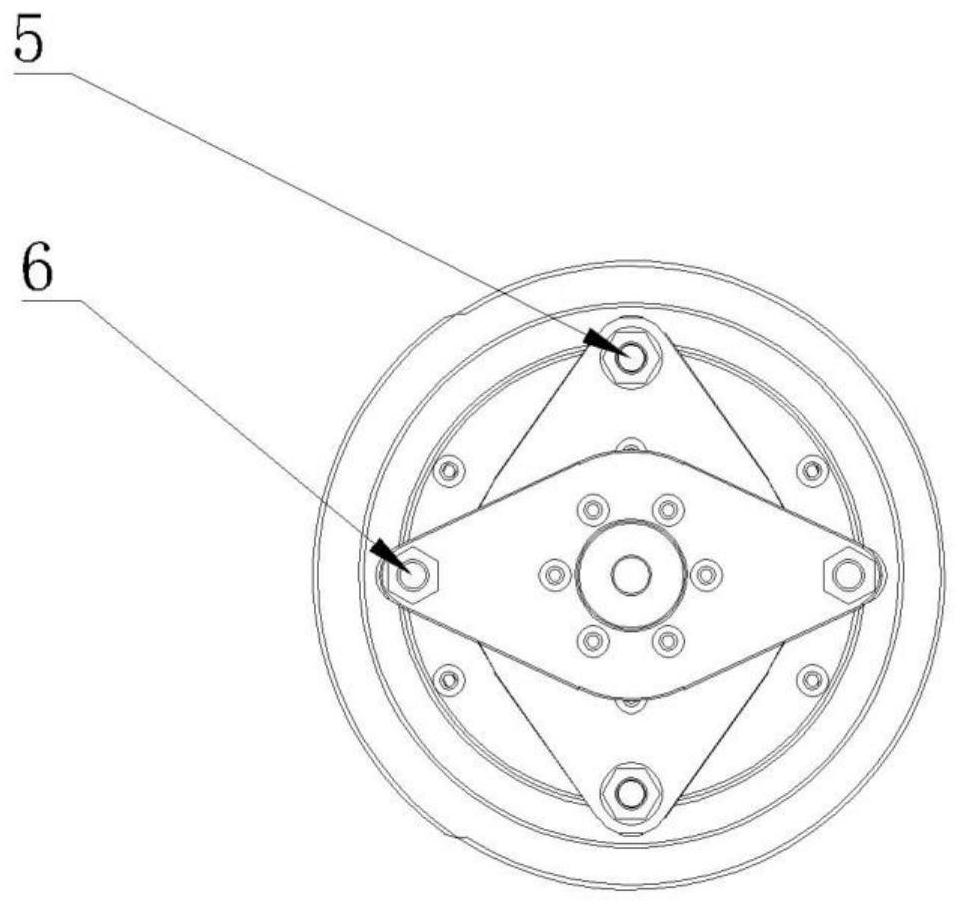

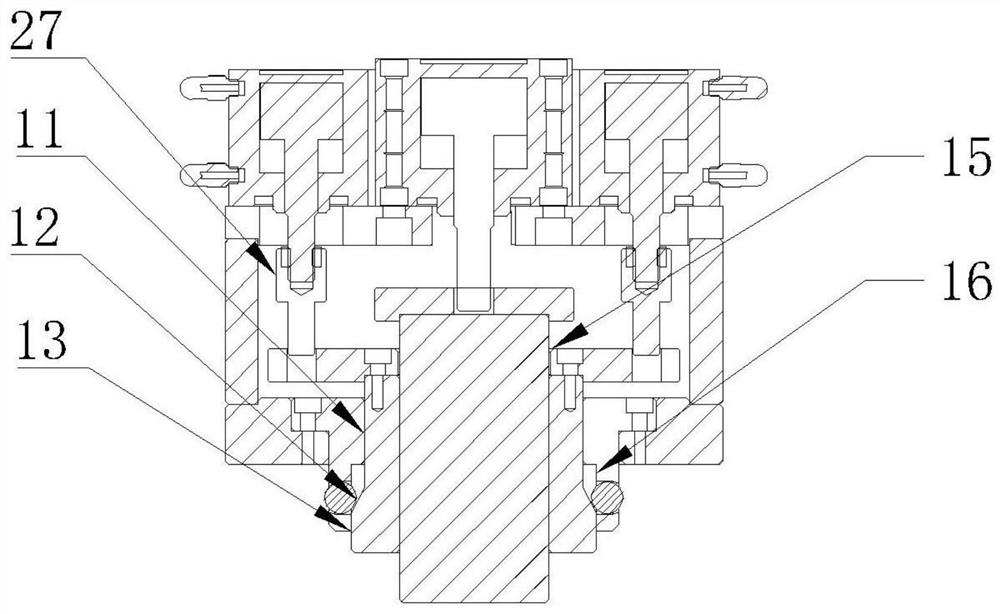

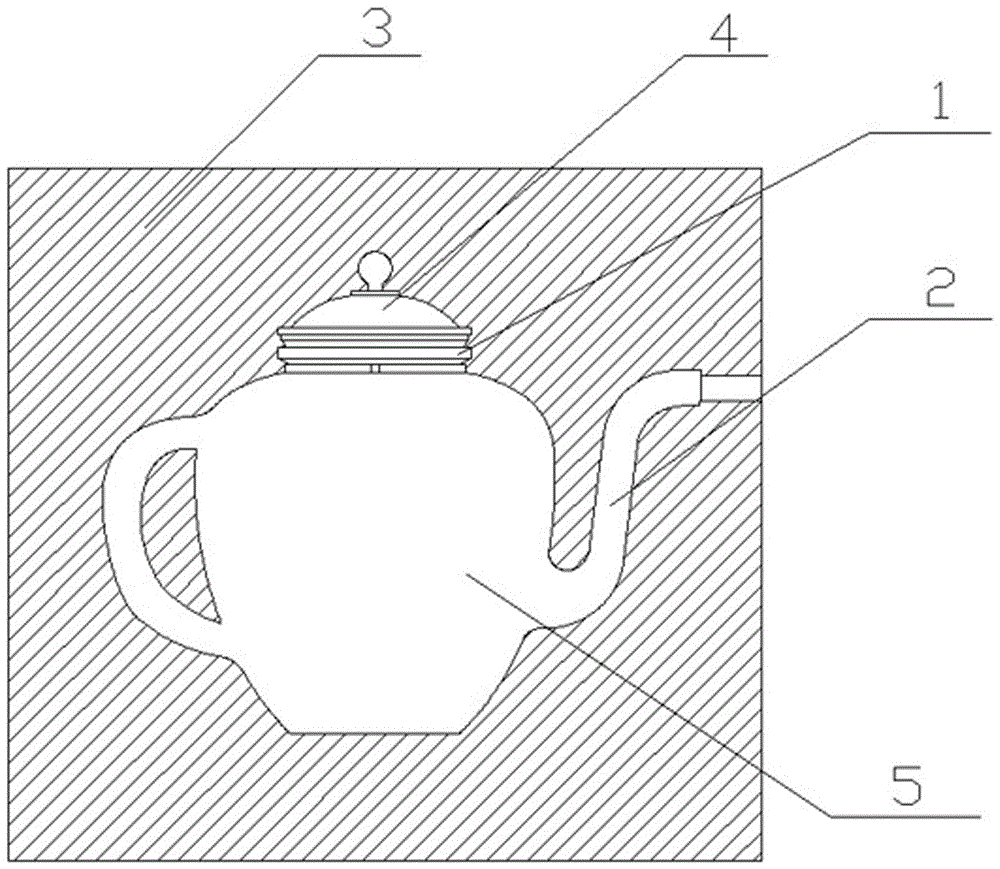

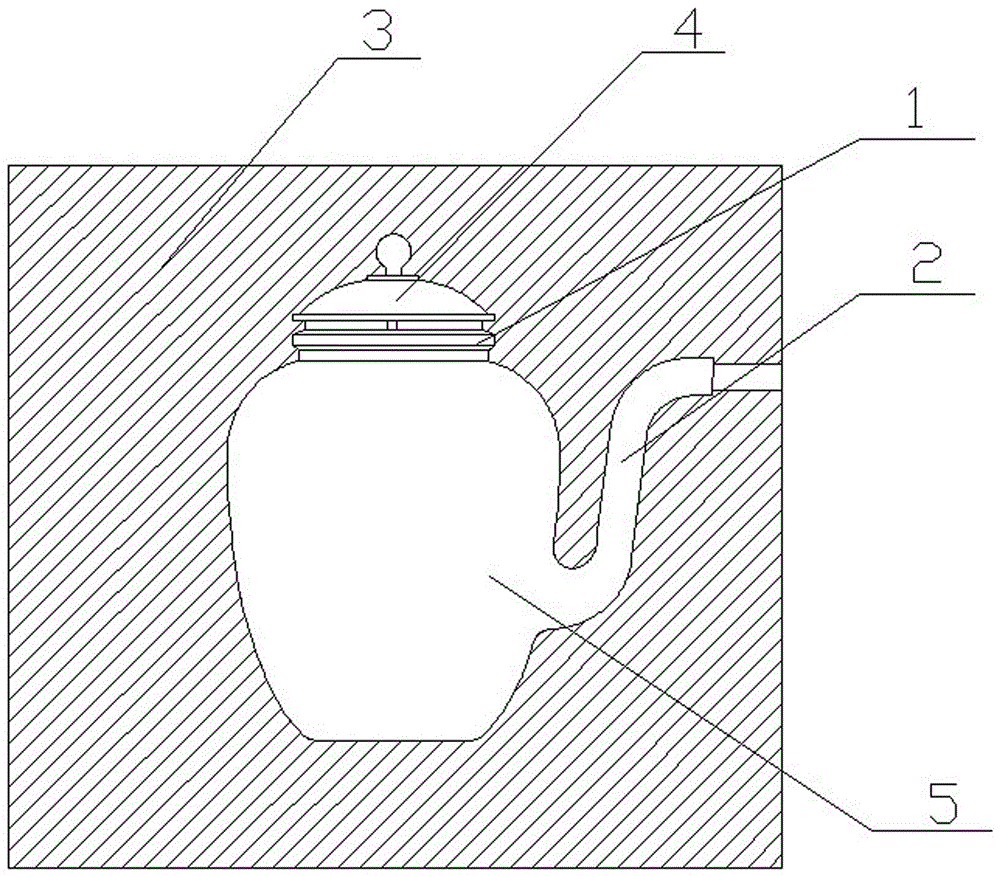

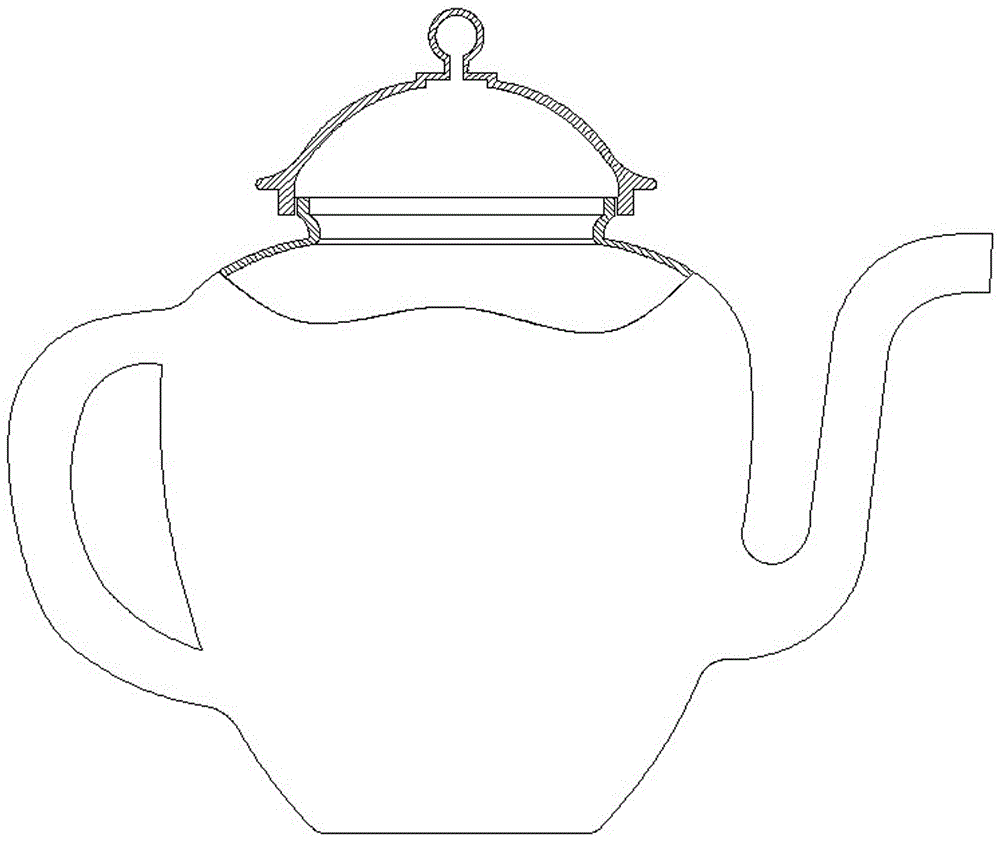

One-step extrusion-blown molding pot forming technology, dedicated mold pressing extrusion molding blow molding die and product

ActiveCN103419355AOvercome the problem of color differencePromote technological progressBlow moldingHollow form

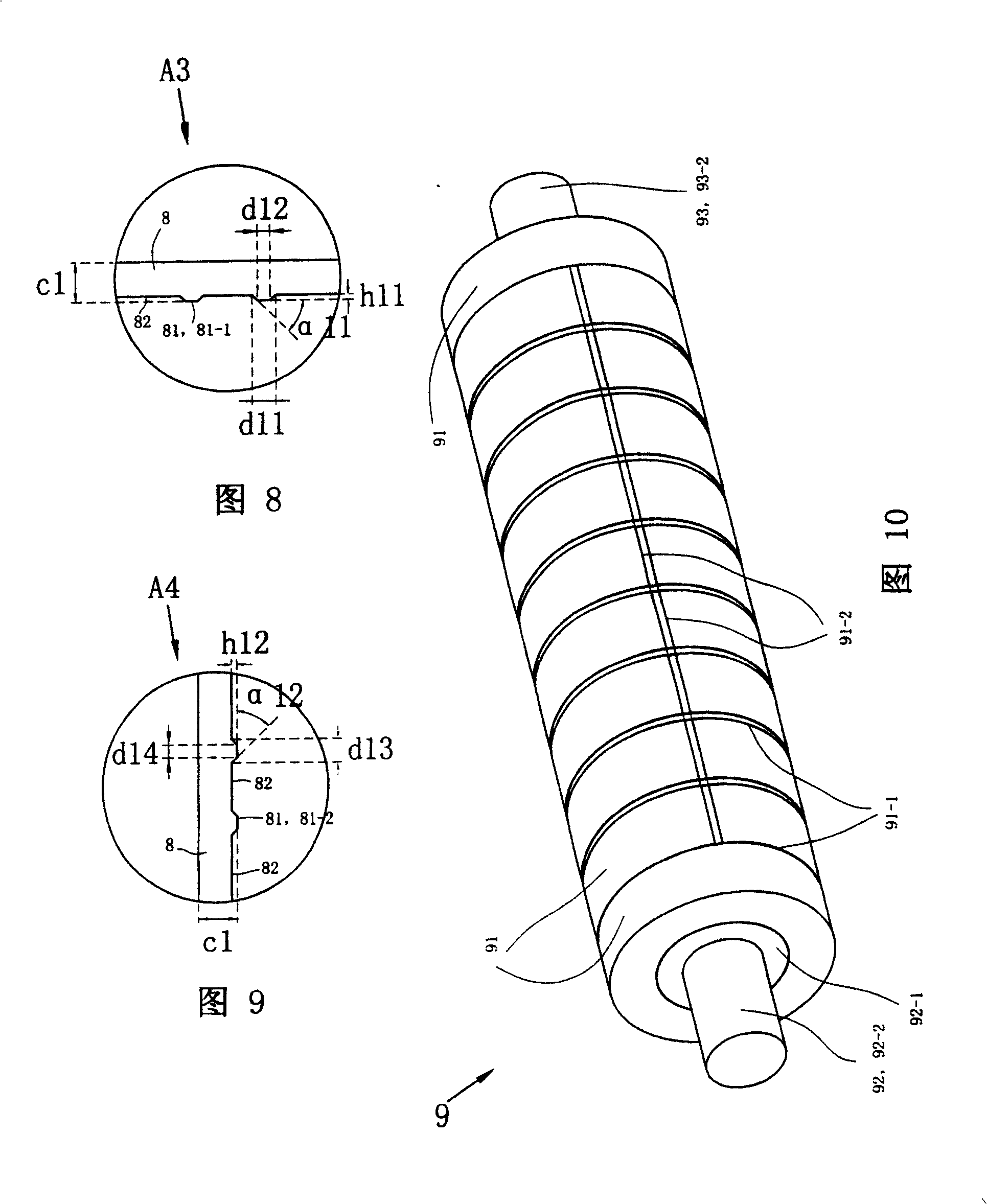

The invention discloses a one-step extrusion-blown molding pot forming technology. According to the one-step extrusion-blown molding pot forming technology, a mold pressing forming technology and an extrusion-blown molding technology are combined into a whole. An air inlet core bar of the extrusion-blown molding technology is also a male mold of the mold pressing forming technology. A pot cover, a spout and a pot body of a formed pot can be formed in an extrusion-blown molding mode with one mold in one step. The technological advance of the hollow forming technology field is promoted, the complex and refine development tendency of current hollow products is met, and more complex products can be developed through the idea.

Owner:临夏市民政福利塑料厂

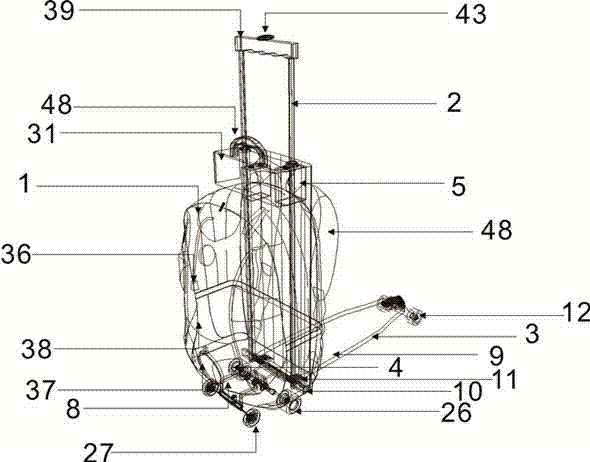

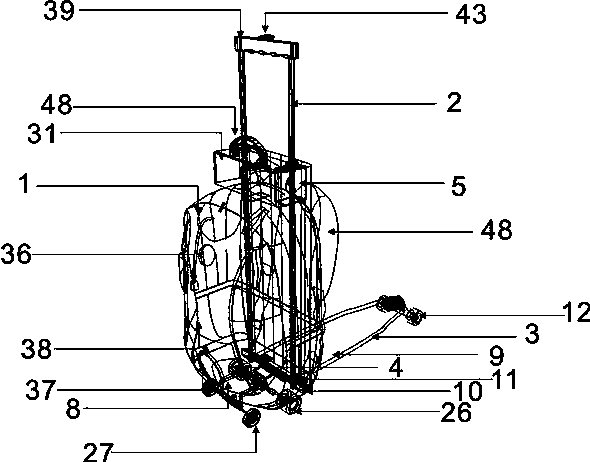

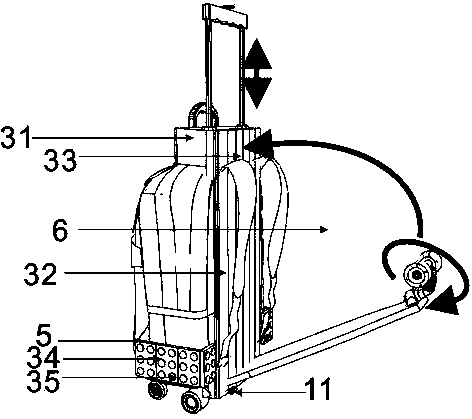

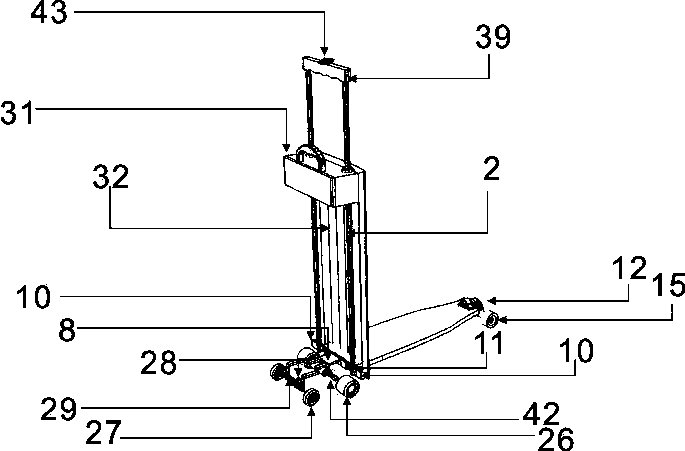

Folding slide plate luggage box

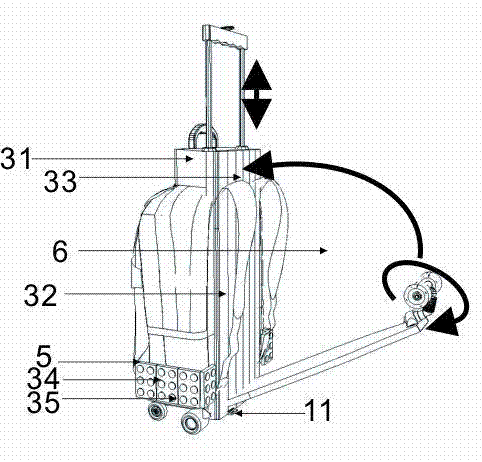

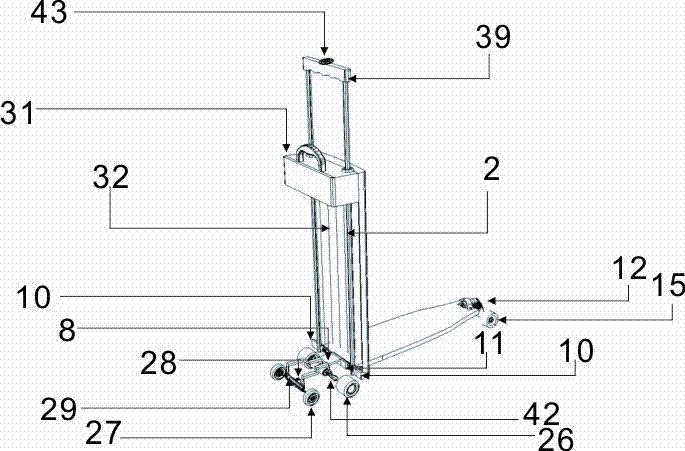

InactiveCN103156364AImprove passabilityFlexible planningLuggageFoldable cyclesRolloverControl system

The invention discloses a folding slide plate luggage box which comprises a luggage box, a pulling rod, a slide plate, a motor, a battery pack, and a control system. The folding slide plate luggage box is characterized in that the slide plate is provided with a spinning wheel rollover folding structure or a spinning plate rollover folding structure, and at least one wheel set of the slide plate can be turned over and folded in a space on the luggage box or in a space in the luggage box. According to the folding slide plate luggage box, a luggage box self which is usually carried when people go out becomes a complementation traffic tool, and commuting requirements among a starting point, bus stations and a terminal point and short-distance commuting requirements of bus transfer are met. People can flexibly plan bus routes, and transfer and waiting time is reduced.

Owner:罗轶

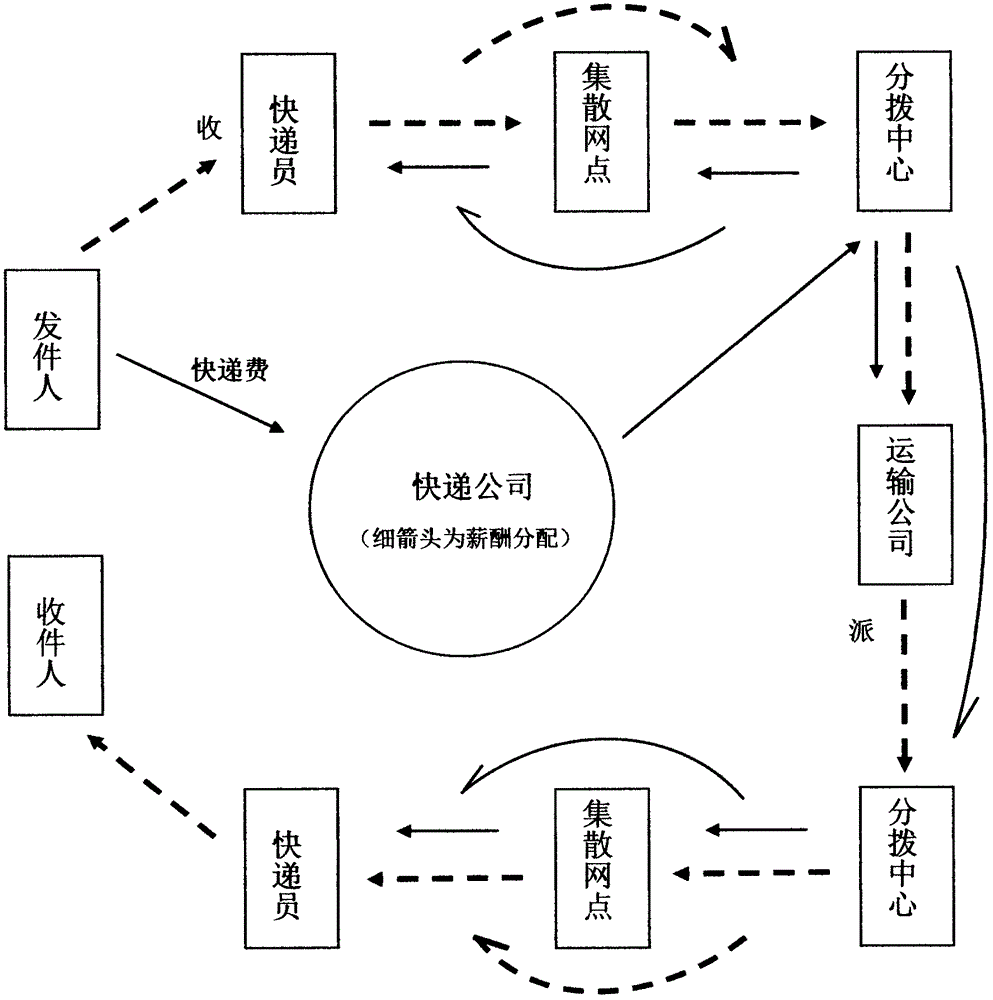

Express integration method

The invention provides an express integration method, wherein a set of express management system is established. All links during the express transportation process are connected together based on the internet and satellite positioning technology. The connection of all links can be freely selected according to geographical locations and salary distribution bid prices. The salary distribution is generated during the hand-over process and then the billing is conducted. Finally, the settlement and the payment are completed by express companies. According to the technical scheme of the invention, on the basis of the express management system, an extra company field is added besides the database of the system. Therefore, a management platform shared by multiple companies is constituted. Based on the above platform, the practitioners of each link can register multiple companies to receive the services of multiple companies. As a result, the purpose of integrating the express industry is realized, so that the efficiency of the express industry is improved.

Owner:钟庆生

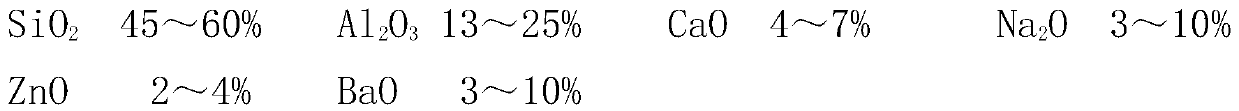

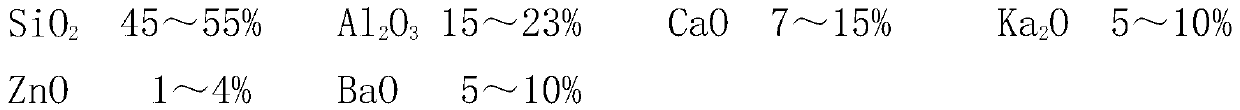

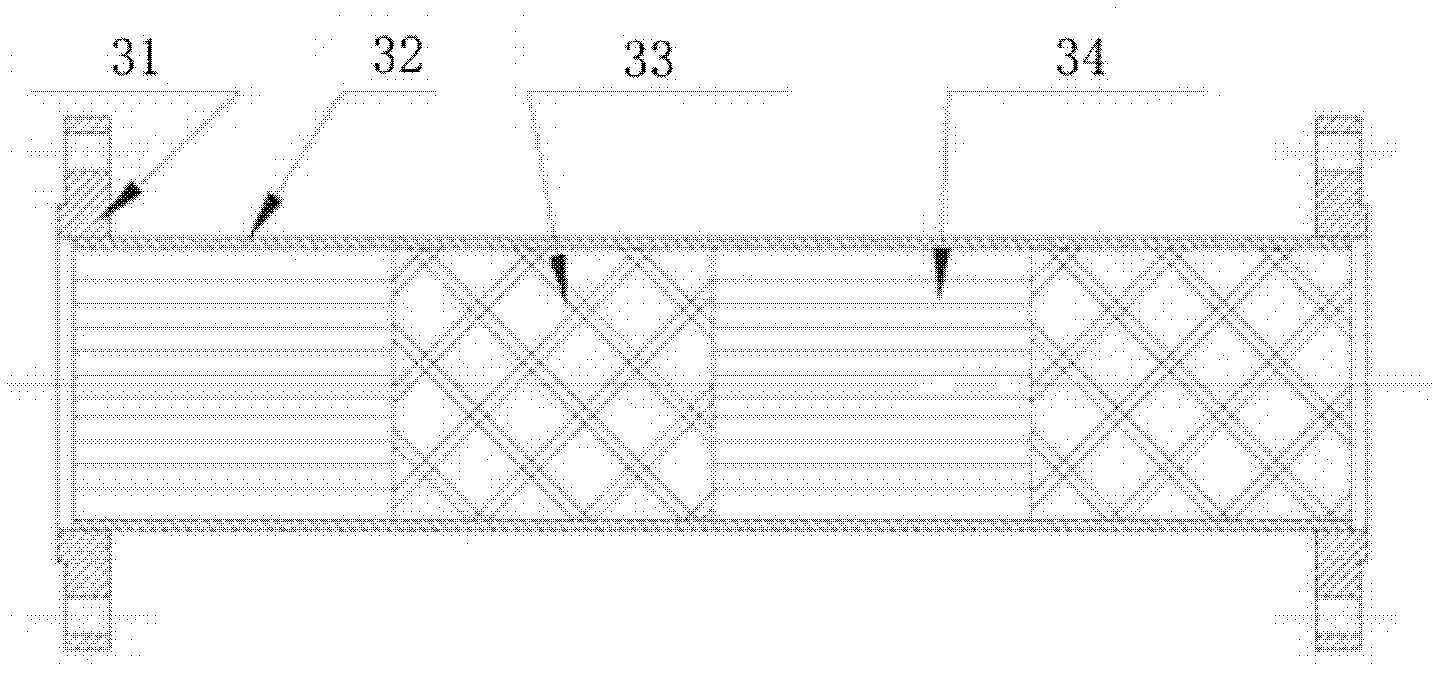

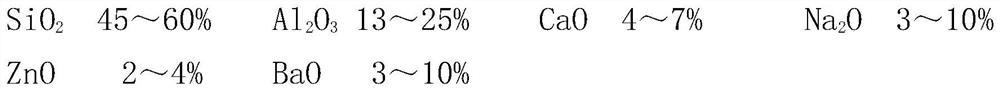

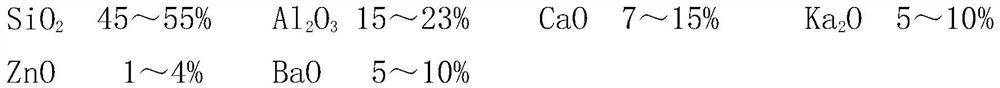

Preparation method for stable brindled brick

ActiveCN109795017AReduces unevennessSpot stabilizationCeramic shaping apparatusCeramic materials productionPrint-throughMaterials science

The invention relates to a preparation method for a stable brindled brick. The preparation method includes the steps that (1) a green body is pressed with 5-10% of the white brindle ratio, 10-20% of the blue brindle ratio and 70-80% of the black brindle ratio; (2) the green body is dried at the temperature of 80-130 DEG C for 40-60 minutes; (3) simulation treatment is conducted, a translucent glaze layer is applied to the surface of the green body, then false ink jet brindle which is approximate to the green body brindle in size and color is printed through ink jetting, and the color and spoteffects of translucent glaze are basically consistent with the color and surface effects of the green body; (4) printing decoration is carried out; (5) protecting glaze is applied, after screen printing or rubber covered roller printing or ink jet printing for color and pattern decoration effects, transparent glaze slip is applied to protect the decoration, the brindle is settled under the glaze layer and achieves highly simulated fusion with the brindle of the green body; and (6) firing is carried out at the temperature of 1150-1250 DEG C for 40-60 minutes.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

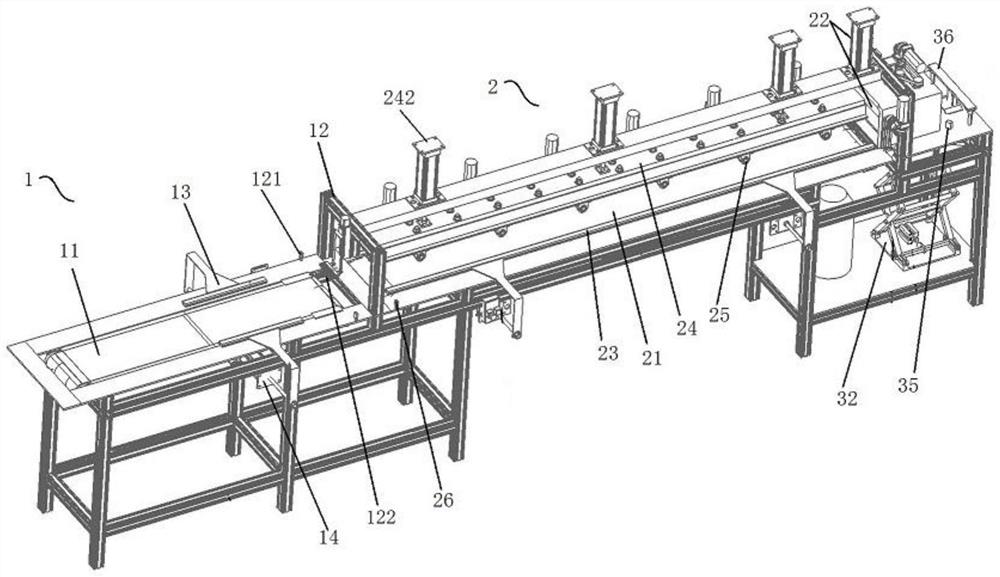

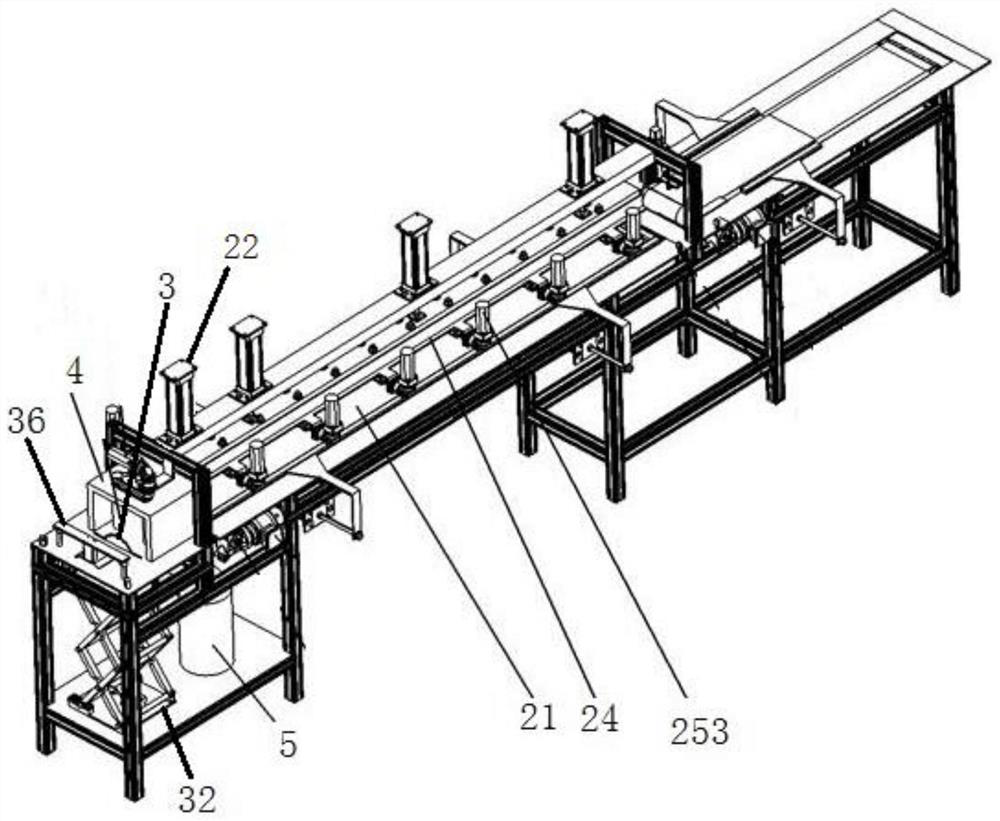

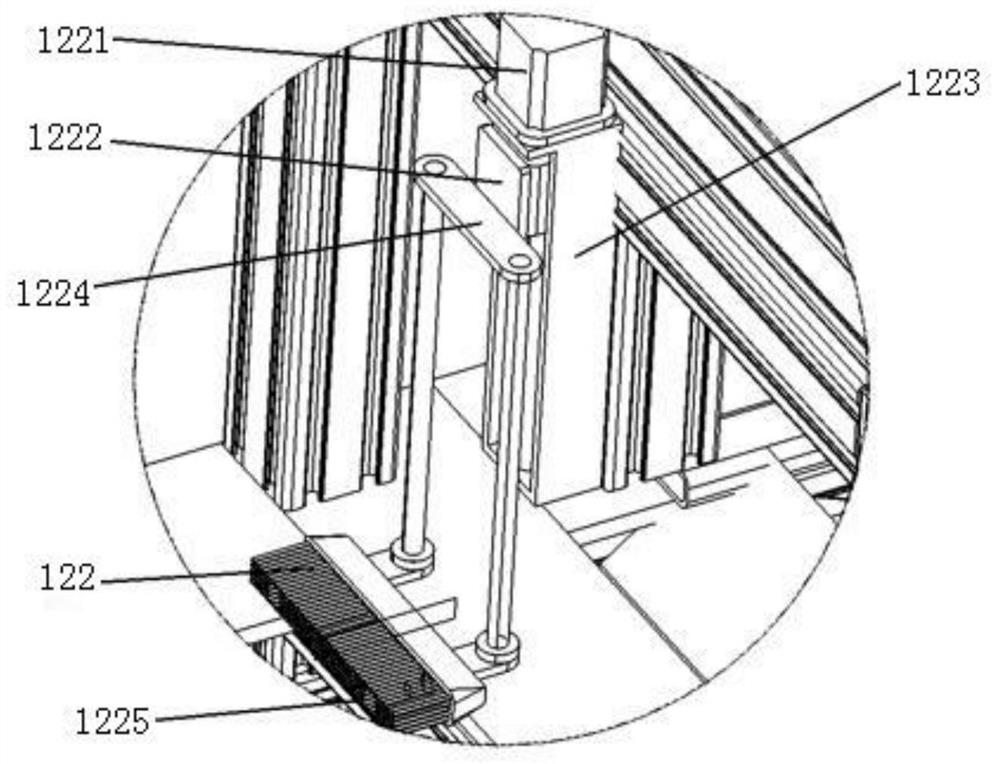

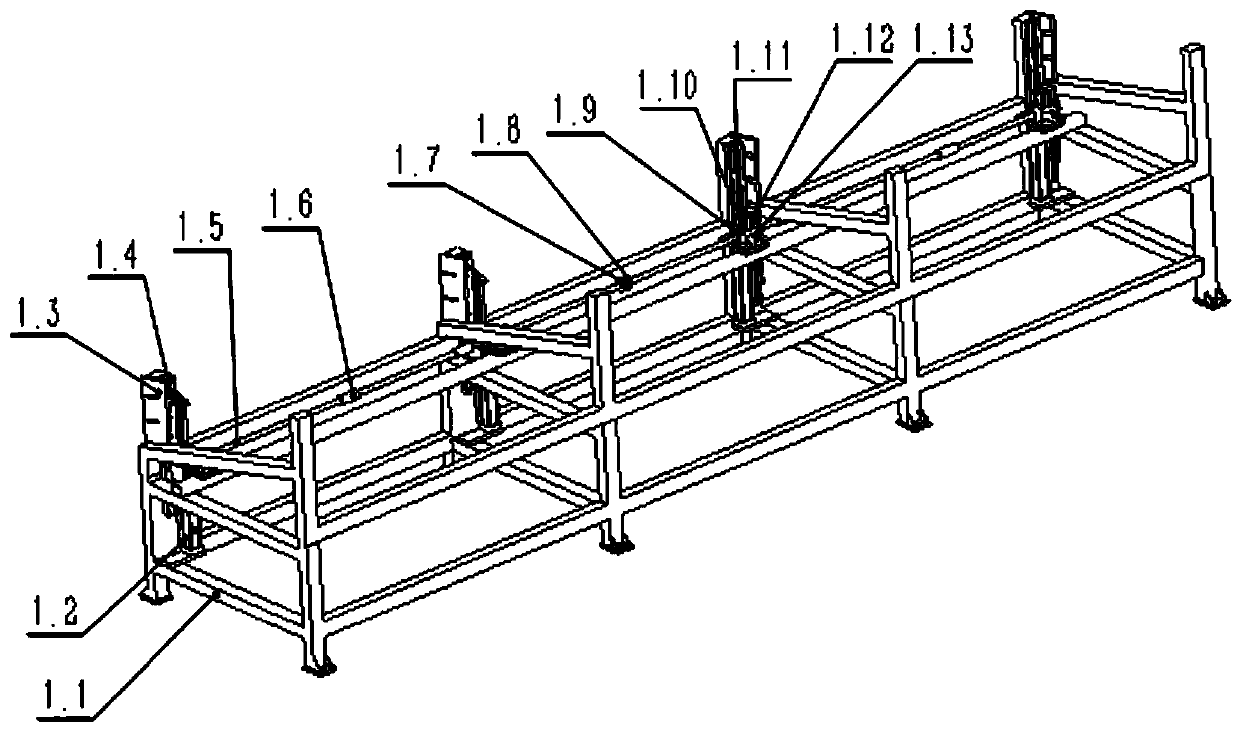

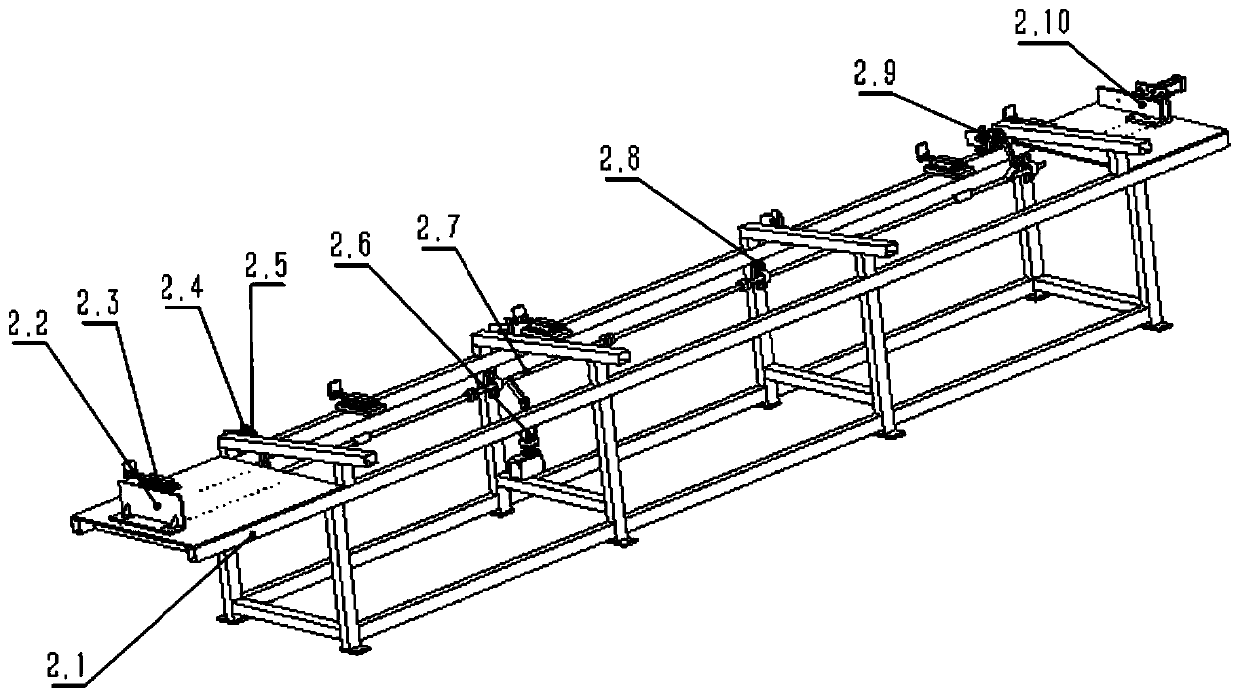

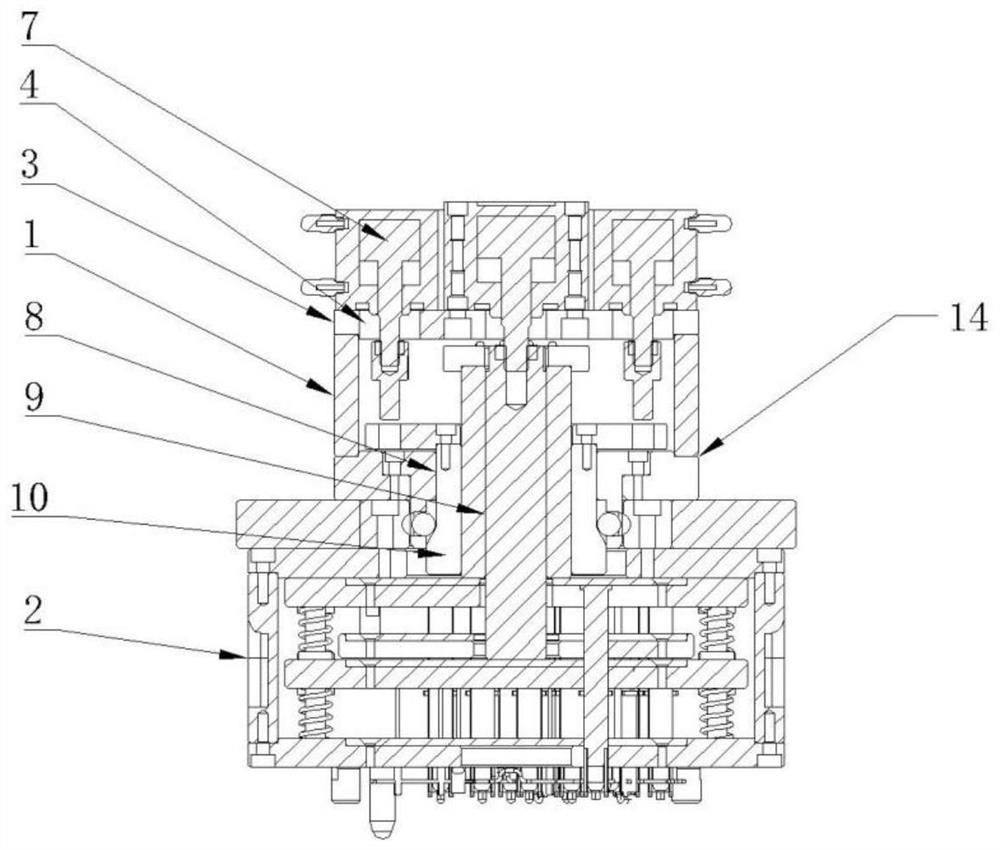

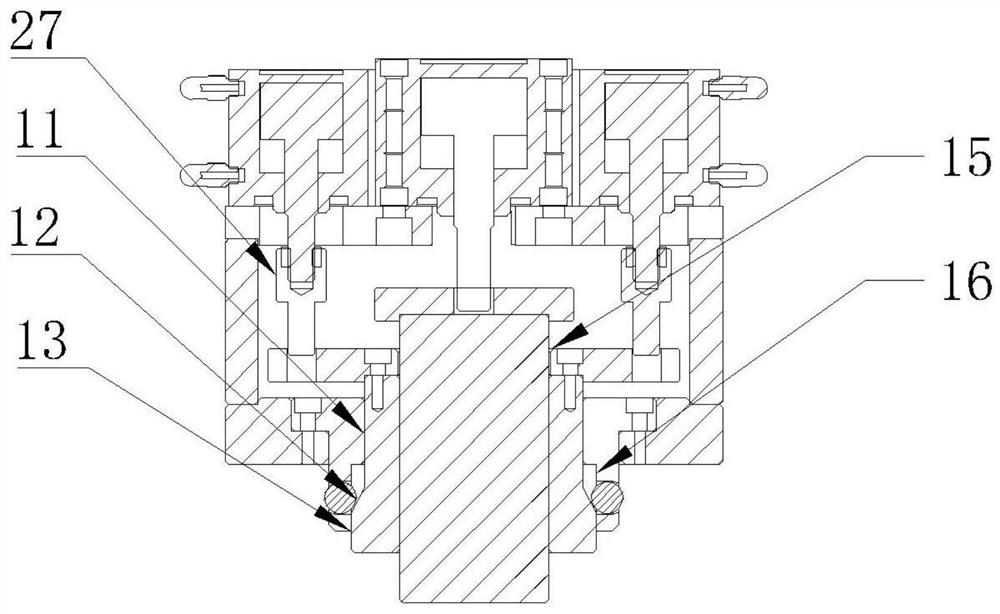

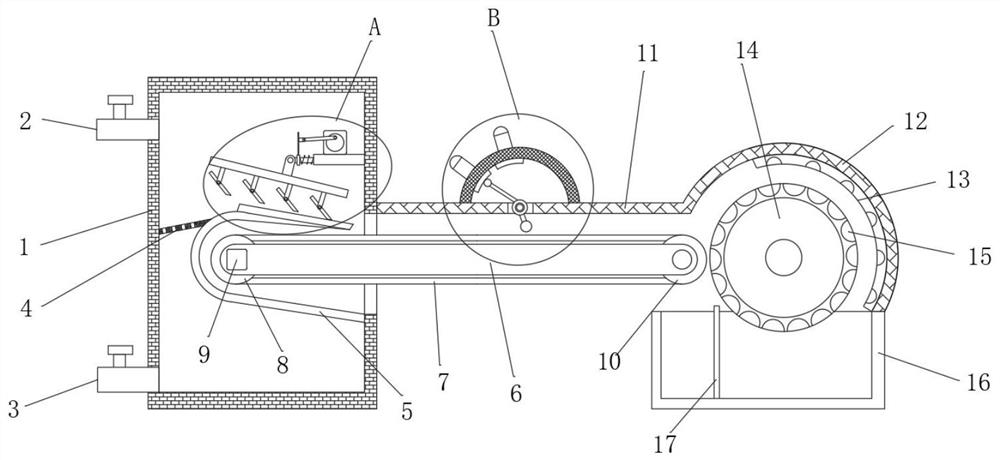

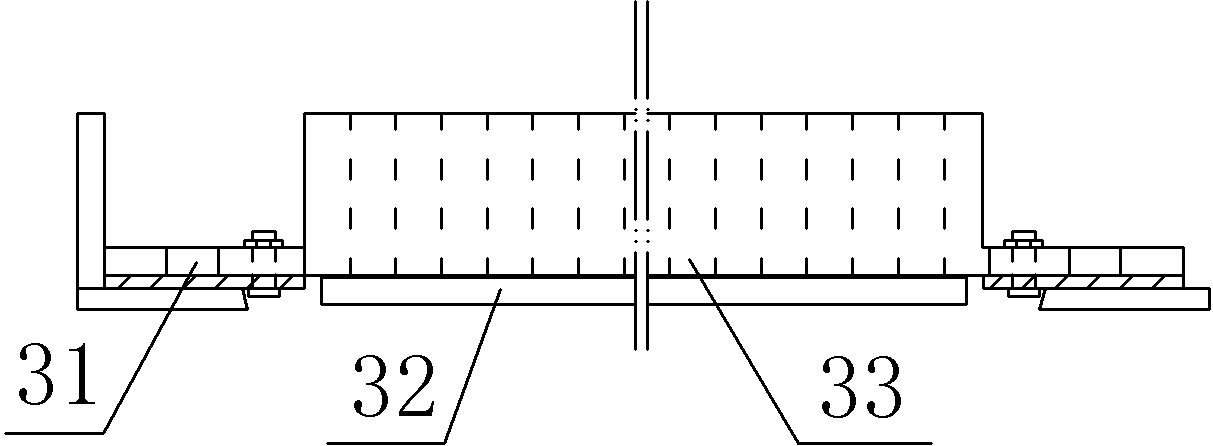

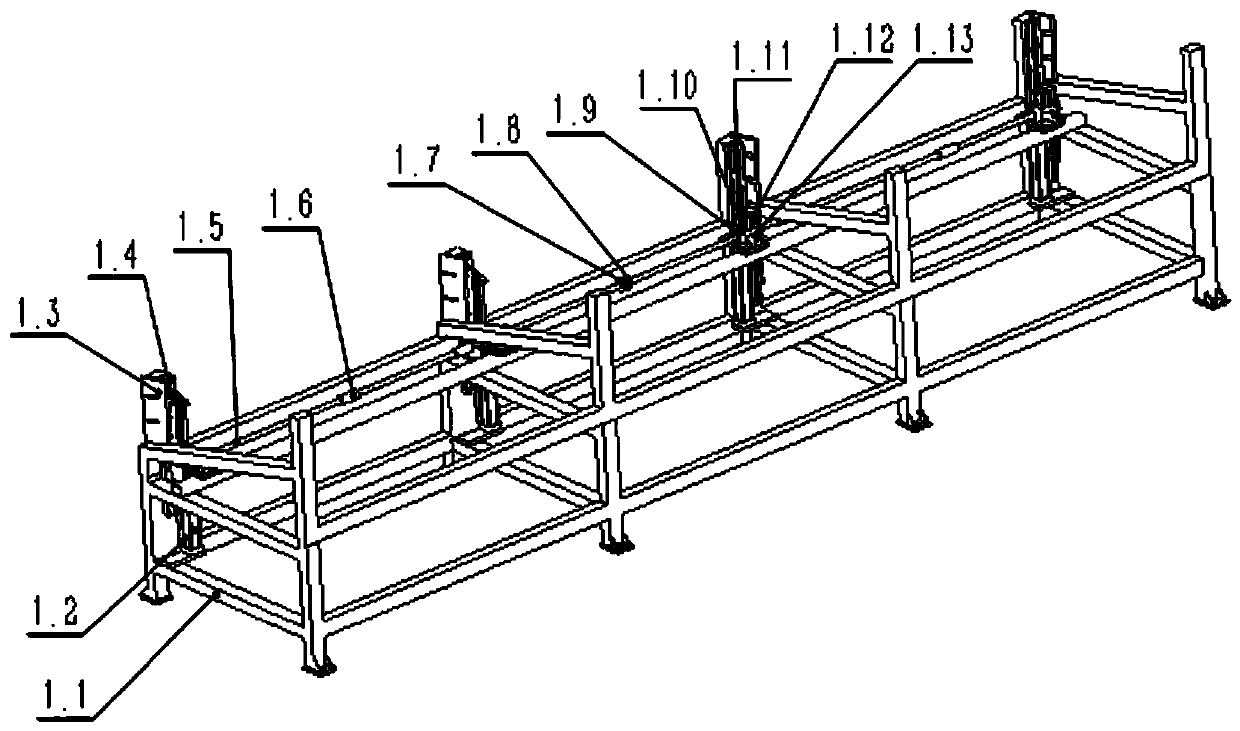

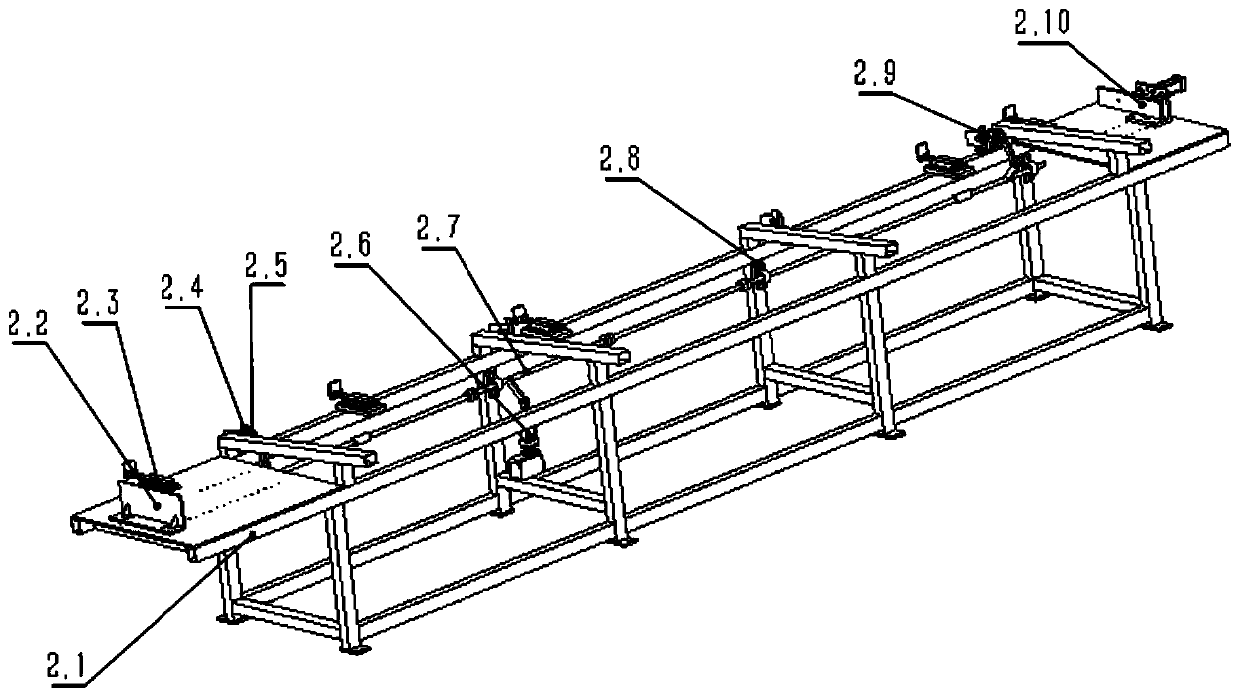

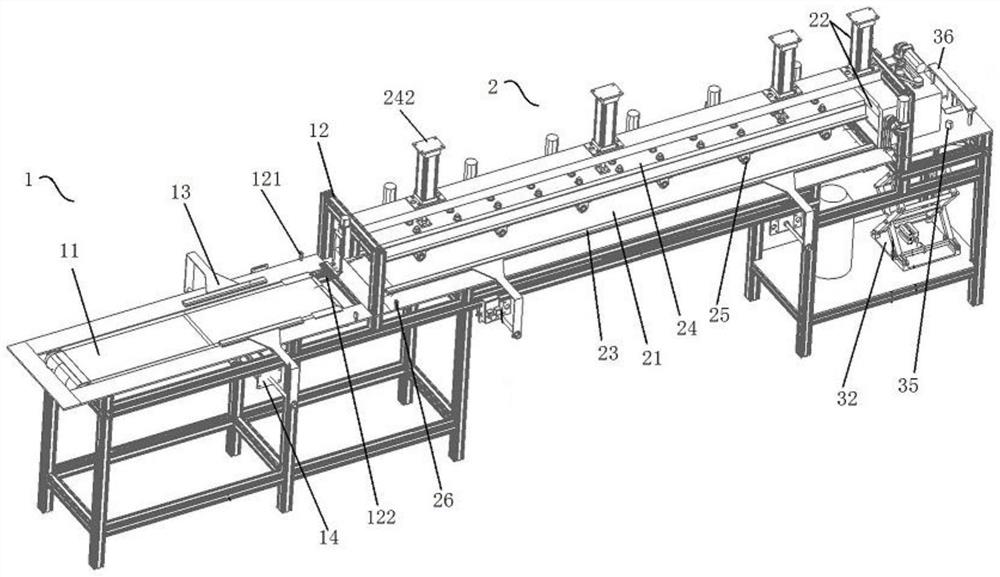

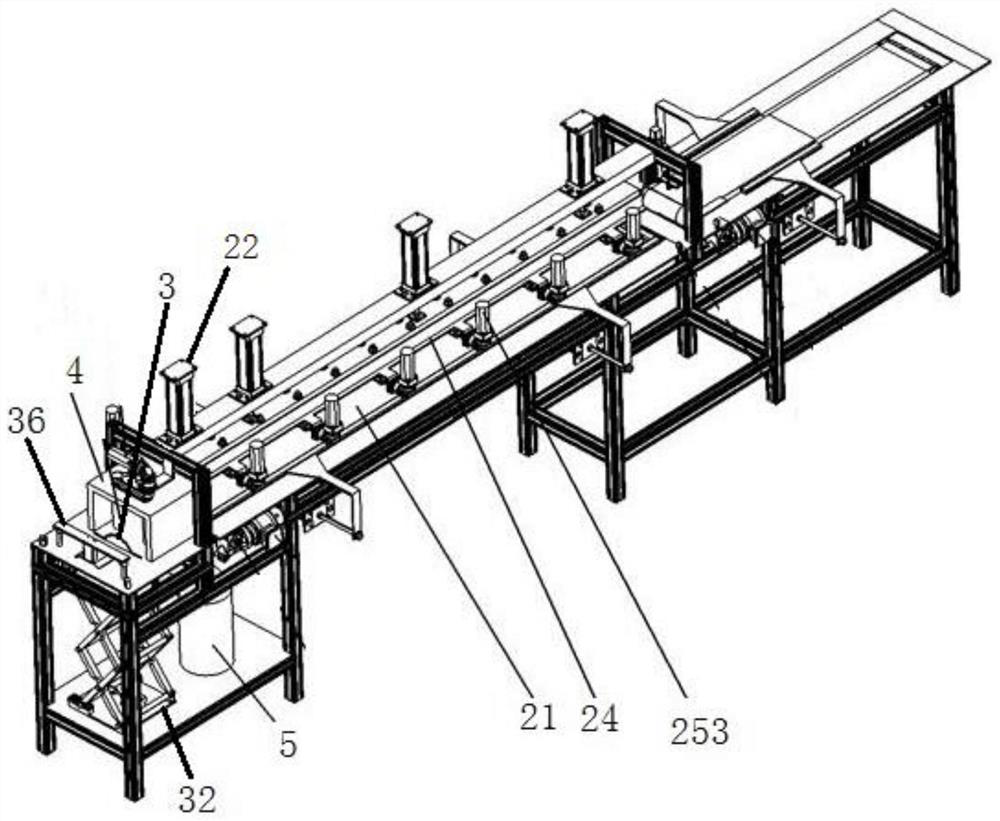

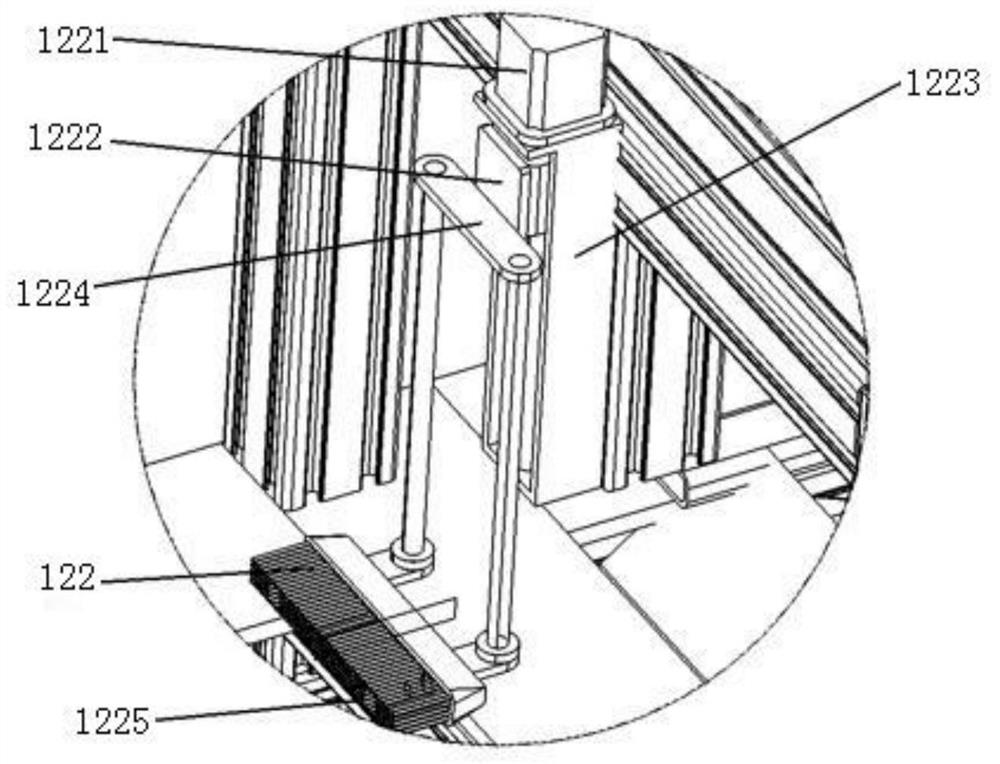

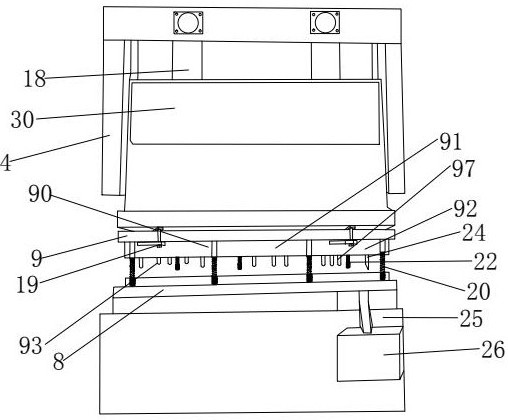

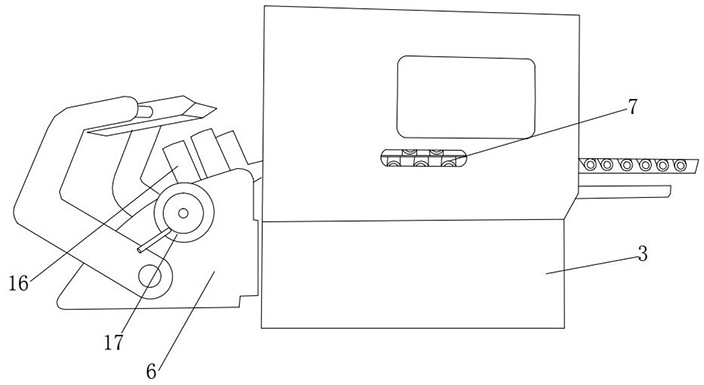

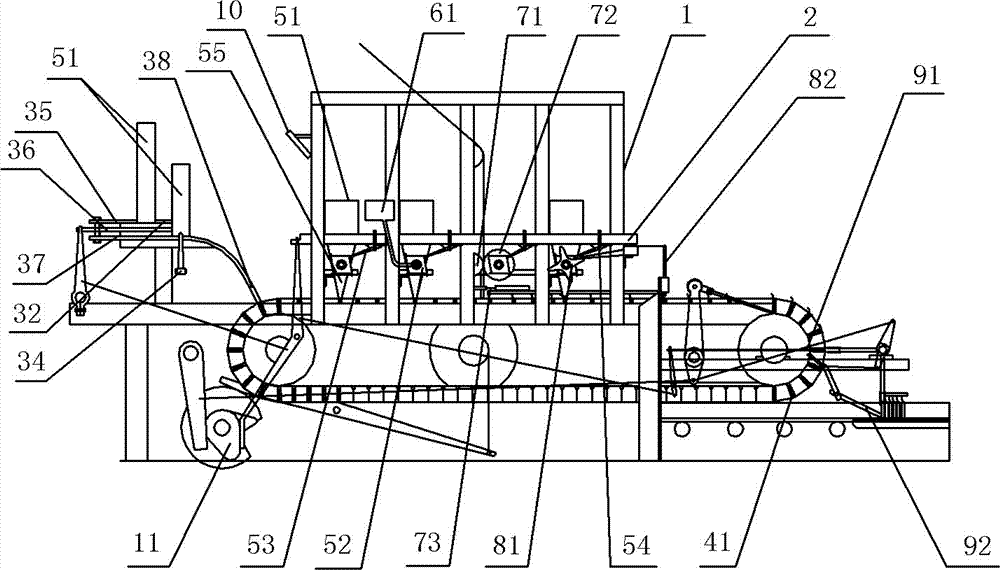

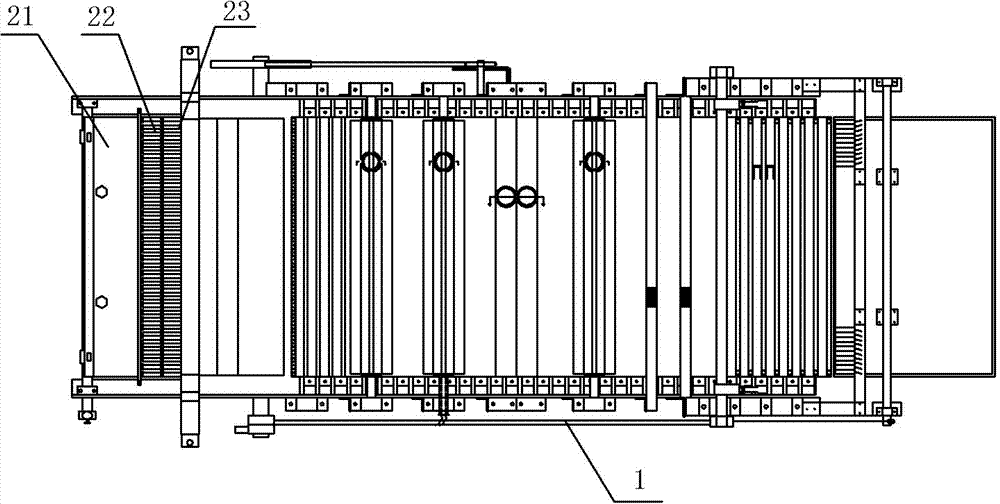

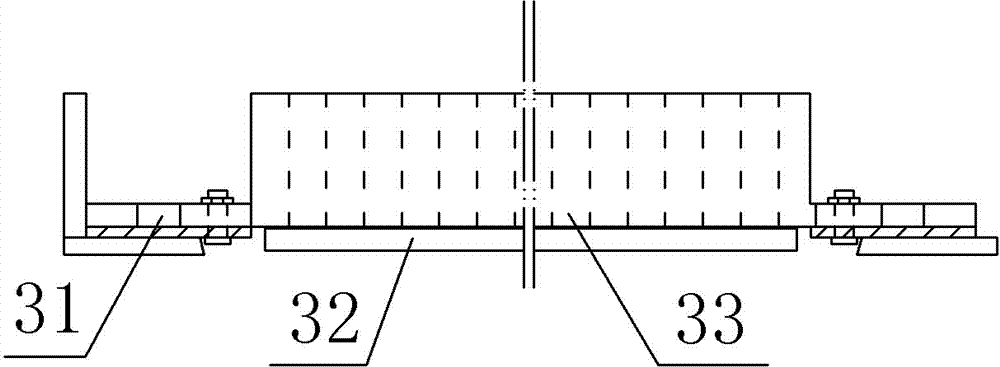

Multi-dimensional automatic sizing and forming wood finger jointing machine

ActiveCN111805645AAdhesivelyQuality improvementGuide fencesGrinding drivesAgricultural engineeringStructural engineering

The invention discloses a multi-dimensional automatic sizing and forming wood finger jointing machine. The multi-dimensional automatic sizing and forming wood finger jointing machine comprises a feeding and gluing device (1). The tail end of the feeding and gluing device (1) is connected with a pressing device (2). The feeding and gluing device (1) comprises a conveying belt I (11). The tail end of the conveying belt I (11) is provided with a gluing mechanism (12). Two sides of the conveying belt I (11) are provided with a pair of positioning and clamping side plates I (13) capable of moving towards each other. The pressing device (2) comprises a conveying belt II (21). The head end of the conveying belt II (21) is connected with the gluing mechanism (12). The tail end is provided with a material blocking mechanism (22). Two sides are provided with a pair of positioning and clamping side plates II (13) capable of moving towards each other. A pressing mechanism (24) capable of moving vertically is arranged above. The bottom of the pressing mechanism (24) is provided with a rolling wheel (25) capable of rotating. The multi-dimensional automatic sizing and forming wood finger jointingmachine has the characteristics of good splicing quality, using flexibility, high production efficiency, low production cost and environmental protection.

Owner:GUIZHOU INST OF TECH

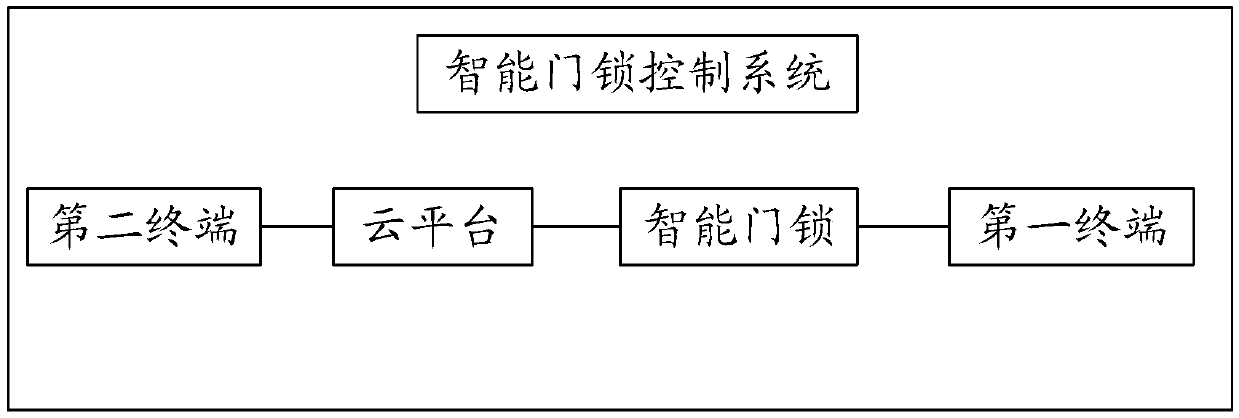

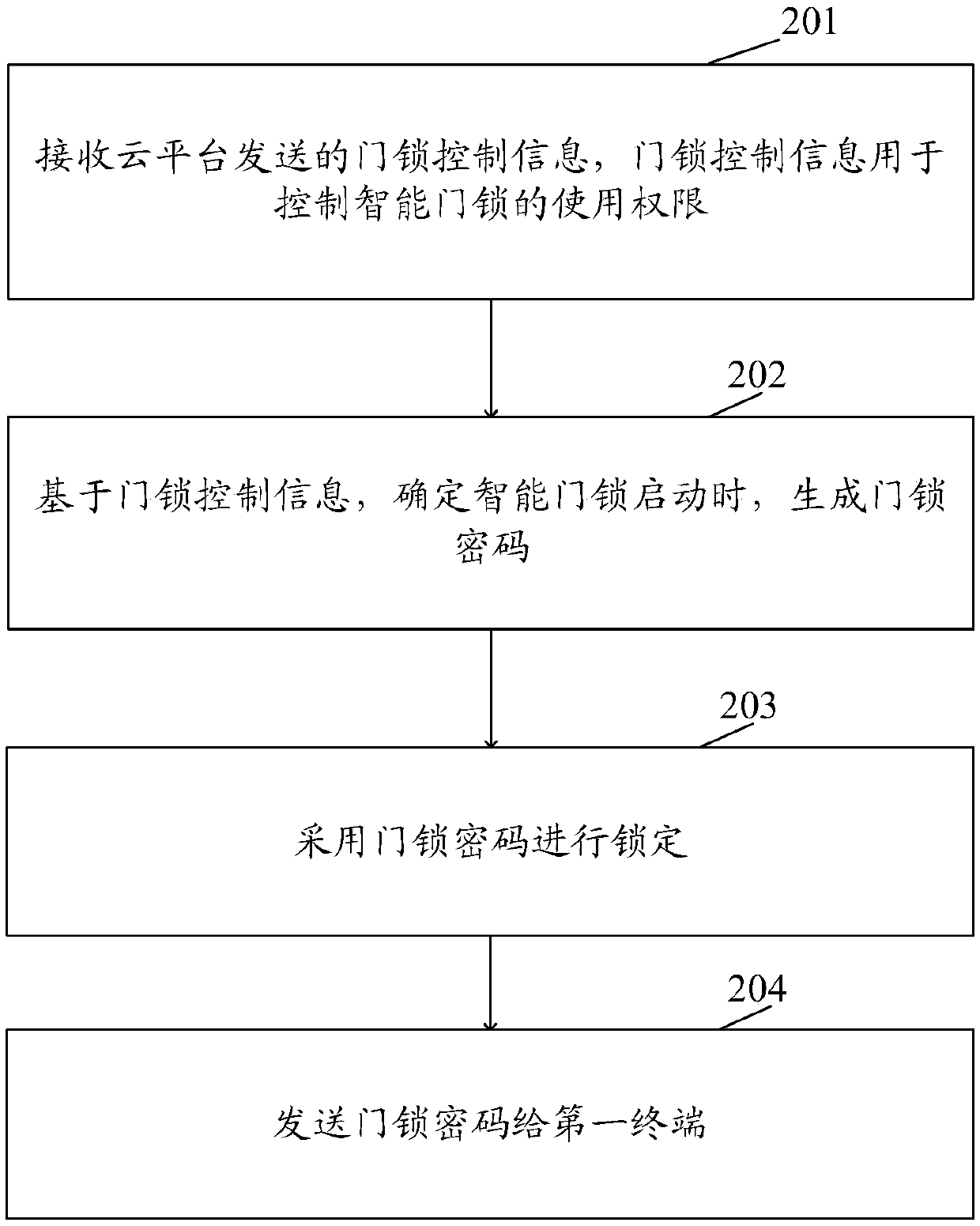

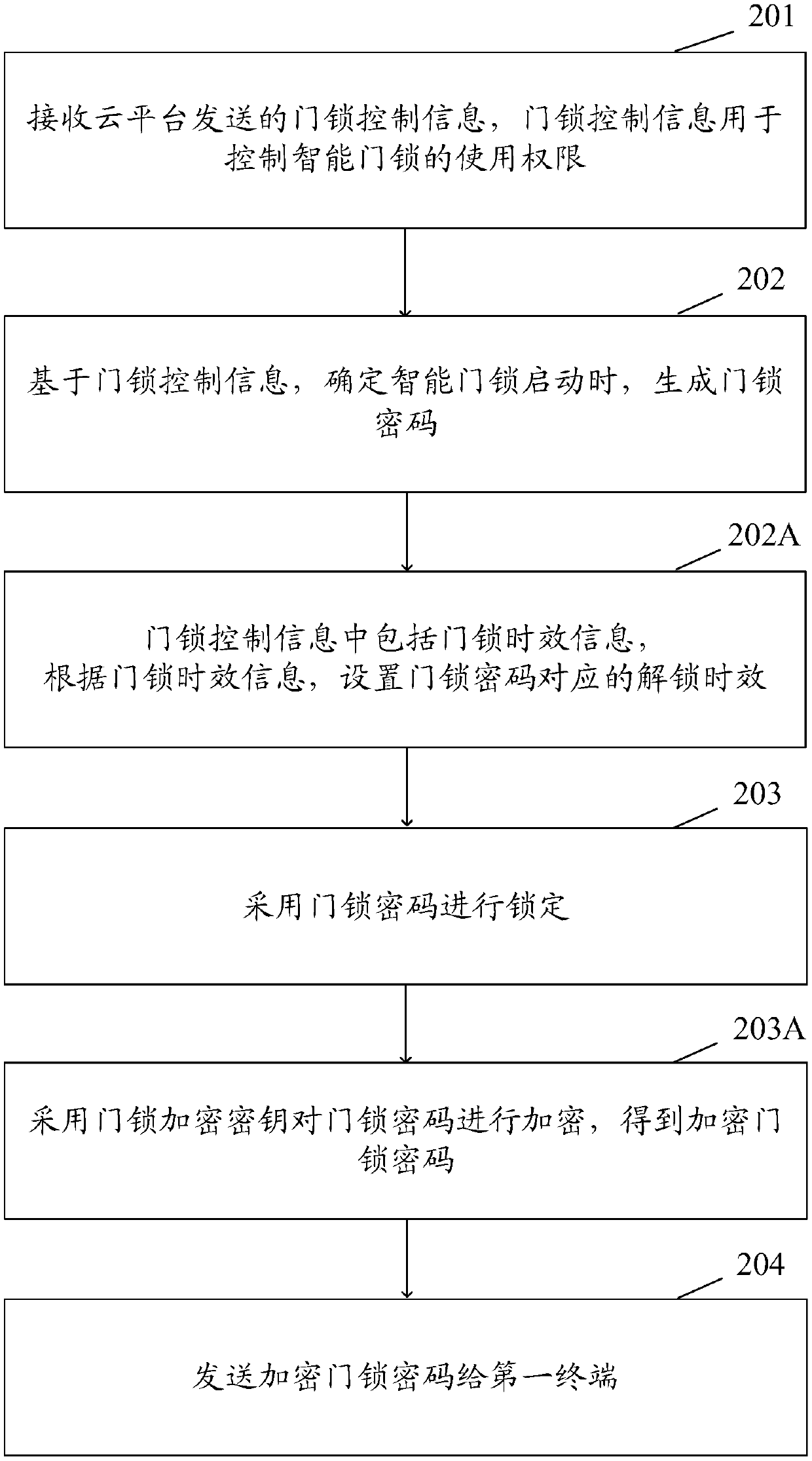

Control method and device of intelligent door lock and storage medium

InactiveCN110866999AImprove securityAvoid complex processIndividual entry/exit registersAlarm locksEmbedded systemOperating system

The embodiment of the invention discloses a control method of an intelligent door lock. The method is applied to the intelligent door lock. The intelligent door lock communicates with a cloud platformand a first terminal. The method includes the steps that door lock control information sent by the cloud platform is received, and the door lock control information is used for controlling the use permission of the intelligent door lock; based on the door lock control information, and when determining that the intelligent door lock is started, a door lock password is generated; the door lock password is used for locking; and the door lock password is sent to the first terminal. The embodiment of the invention further discloses a control device for the intelligent door lock and a storage medium.

Owner:ZTE CORP

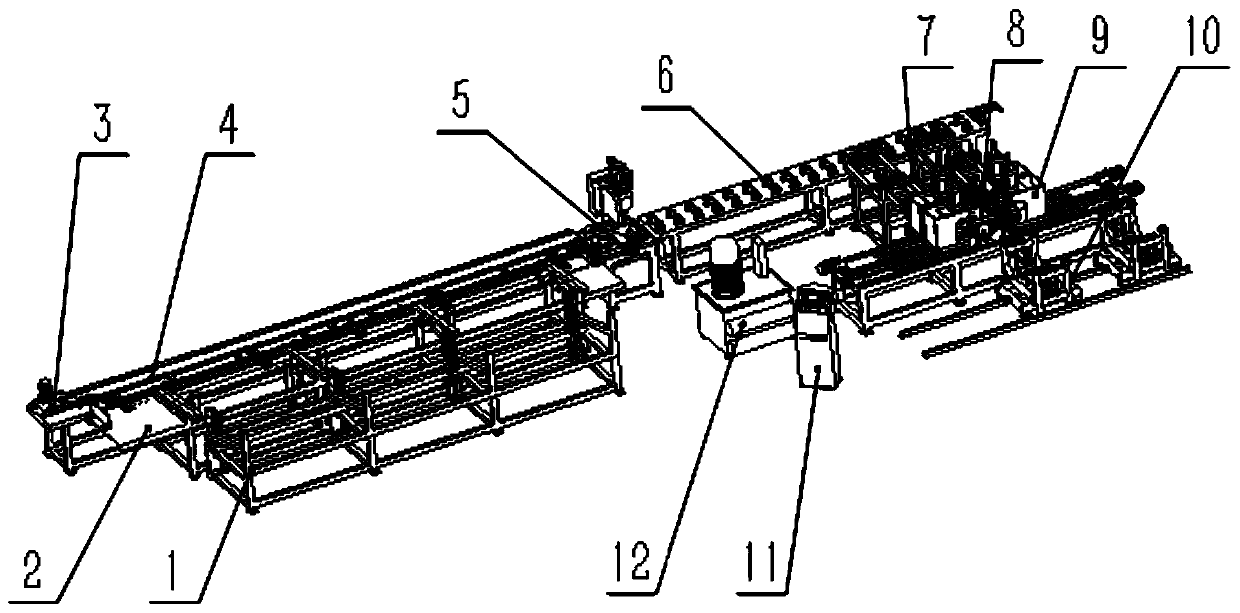

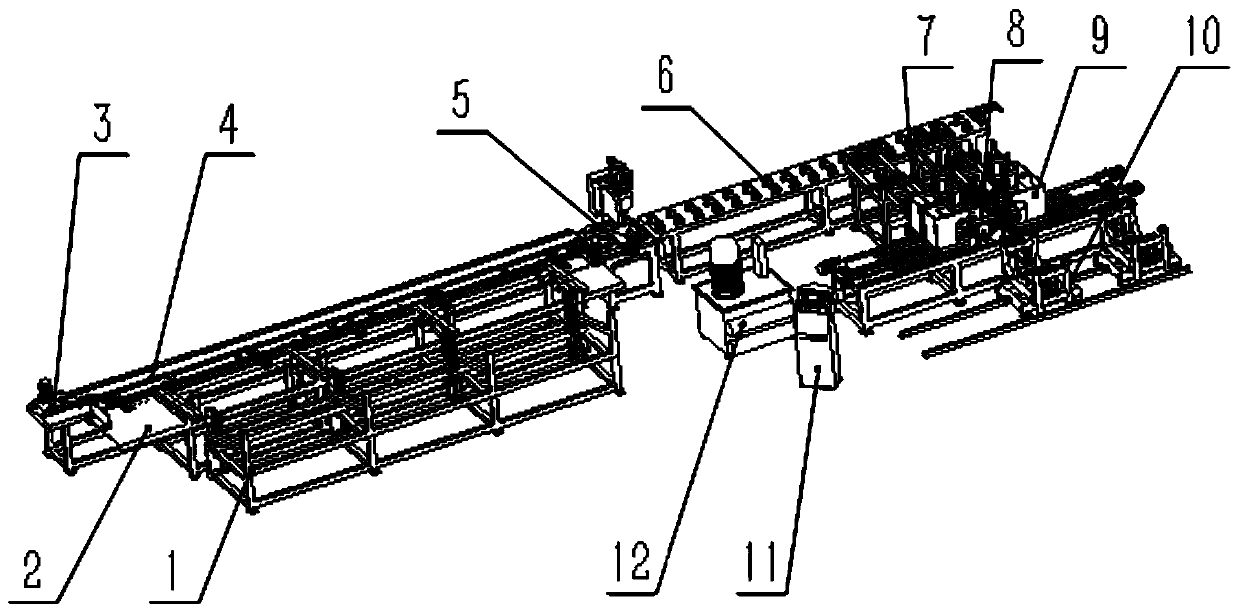

Pipe crescent notch punching combination unit, production line and method

ActiveCN110064938AHigh degree of automationIncrease profitOther manufacturing equipments/toolsProduction linePunching

The invention discloses a pipe crescent notch punching combination unit, production line and method. A cutting mechanism, a power material rolling mechanism and a punching mechanism are included and sequentially arranged. The punching mechanism is further provided with an overturning mechanism and at least provided with two stations. The overturning mechanism is arranged between the two stations.When an ultra-long circular pipe is cut, the cutting mechanism cuts the ultra-long circular pipe. After cutting is finished, the ultra-long circular pipe enters the punching mechanism through the power material rolling mechanism. The executing end of the punching mechanism can punch the ultra-long circular pipe with two stations. Through implementation of the pipe crescent notch punching combination unit, ultra-long circular pipe feeding, tidying, fixed-length feeding, saw cutting and crescent notch punching are effectively integrated, and the equipment automation degree is high.

Owner:山东金博利达精密机械有限公司 +1

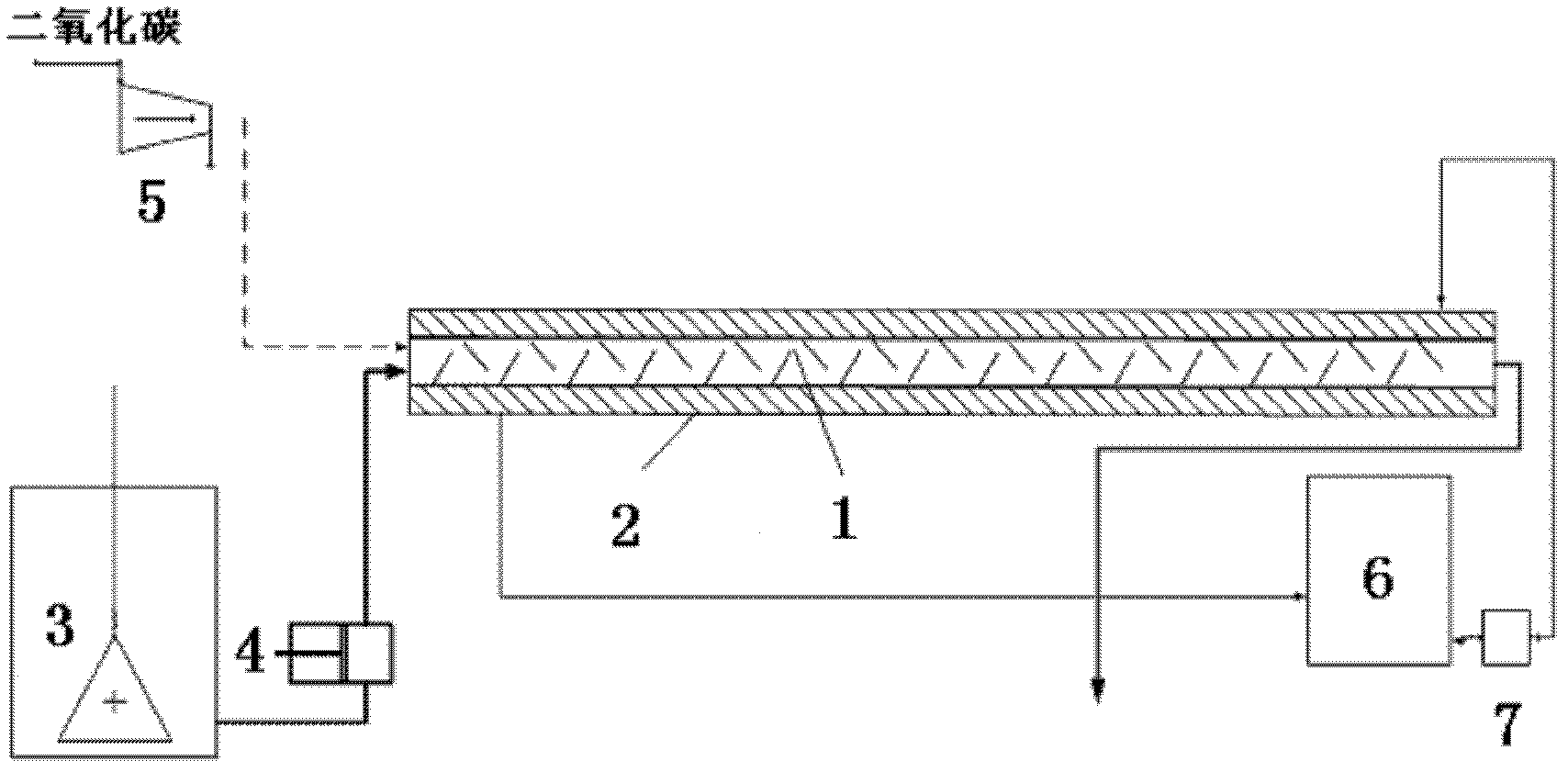

Apparatus and method for pipeline continuous carbonization of calcium and magnesium

ActiveCN103183369BIncrease contact surfaceImprove carbonization efficiencyCalcium/strontium/barium carbonatesMagnesium carbonatesInsulation layerCalcium bicarbonate

The invention relates to an apparatus and a method for pipeline continuous carbonization of calcium and magnesium. The apparatus comprises a tubular reactor. The tubular reactor comprises an inner cavity and a heat-insulation layer; a fold fin or a spiral unit is arranged in the inner cavity of the tubular reactor; a slurry and carbon dioxide inlet is arranged at the front end of the tubular reactor. The method comprises the following steps: stirring and uniformly beating to-be-carbonized slurry containing at least one solid selected from the group consisting of calcium oxide, calcium hydrate, magnesium oxide and magnesium hydroxide, wherein the concentration of the slurry is 2 to 30 g / L in terms of an oxide, pumping the slurry and carbon dioxide into the tubular reactor and allowing the slurry and carbon dioxide to converge and contact; retaining the slurry in a pipeline for 10 to 60 min; and discharging the slurry having undergone carbonization out from a rear end of the tubular reactor and carrying out solid-liquid separation to obtain at least one selected from the group consisting of a magnesium bicarbonate solution, a calcium bicarbonate solution and calcium carbonate. According to the invention, increase of a contact surface between gas and the slurry is realized under the action of local high-speed turbulent flow of fluid in the pipeline, the amount of mixed flows in a whole system is small, and integral carbonization efficiency is high.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Folding slide plate luggage box

InactiveCN103156364BFlexible planningMeet short-distance commuting needsLuggageFoldable cyclesRolloverShortest distance

The invention discloses a folding slide plate luggage box which comprises a luggage box, a pulling rod, a slide plate, a motor, a battery pack, and a control system. The folding slide plate luggage box is characterized in that the slide plate is provided with a spinning wheel rollover folding structure or a spinning plate rollover folding structure, and at least one wheel set of the slide plate can be turned over and folded in a space on the luggage box or in a space in the luggage box. According to the folding slide plate luggage box, a luggage box self which is usually carried when people go out becomes a complementation traffic tool, and commuting requirements among a starting point, bus stations and a terminal point and short-distance commuting requirements of bus transfer are met. People can flexibly plan bus routes, and transfer and waiting time is reduced.

Owner:罗轶

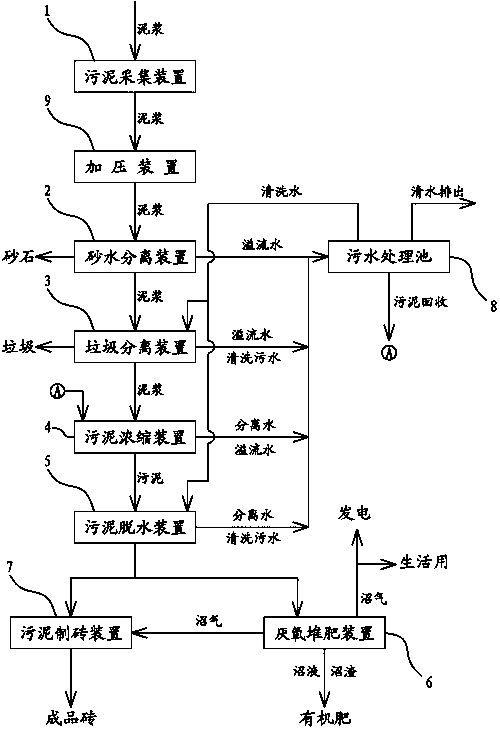

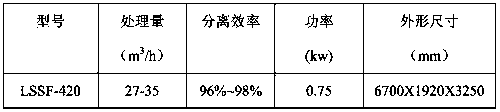

Environment-friendly sludge treatment system

InactiveCN108483833AAvoid recontaminationImprove closureSludge treatmentDewatered sludgeSludge dewatering

The invention discloses an environment-friendly sludge treatment system. The environment-friendly sludge treatment system comprises a sludge collecting device, a sand and water separating device, a garbage separating device, a sludge concentrating device, a sludge dewatering device and a sludge posttreatment device, wherein the sludge collecting device, the sand and water separating device, the garbage separating device, the sludge concentrating device and the sludge dewatering device are sequentially connected. The environment-friendly sludge treatment system completes dredging, conveying, concentrating and dewatering processes at one time; the environment-friendly sludge treatment system is high in sealing performance, good in continuity, less in transfer, short in time, safe and reliable; dewatered sludge is recycled by the sludge posttreatment device, so that waste is turned into treasure, recontamination of the sludge to the environment is avoided and environment-friendly operation of the whole system is achieved.

Owner:SUZHOU BOHAN ENVIRONMENTAL PROTECTION TECH

Reinforced wood floor manufacturing method and reinforced wood floor

InactiveCN100413683CImprove yieldQuick releaseWood veneer joiningWood layered productsFree coolingEngineering

The invention relates to an intensified wooden floors production technique and a kind of intensified wooden floor. In the technique of this invention, the special pallet ageing preserving step is removed after the heat pressing shaped large sheet billets is sawed into small sheet billets, instead, the small billet go on with the fluting and joggling so to transform the original intermittent production techniques into continuum production technique so to enhance the efficiency. Also, the techniques can be that when the large sheets are obtained, move the sheets to the radiating stand natural cooling or wind cooling the sheets, then raw the sheets into small sheets which can increase the rate of finished products. Lock the produced floor along the slots and joggles by both ends then proceed with the following preserving and storing processes which can also improve the rate of finished products. The intensified wooden floors produced with the technique have got edge inclined planes and edge step planes all around which eliminates the ribs in adjacent floors.

Owner:葛跃进

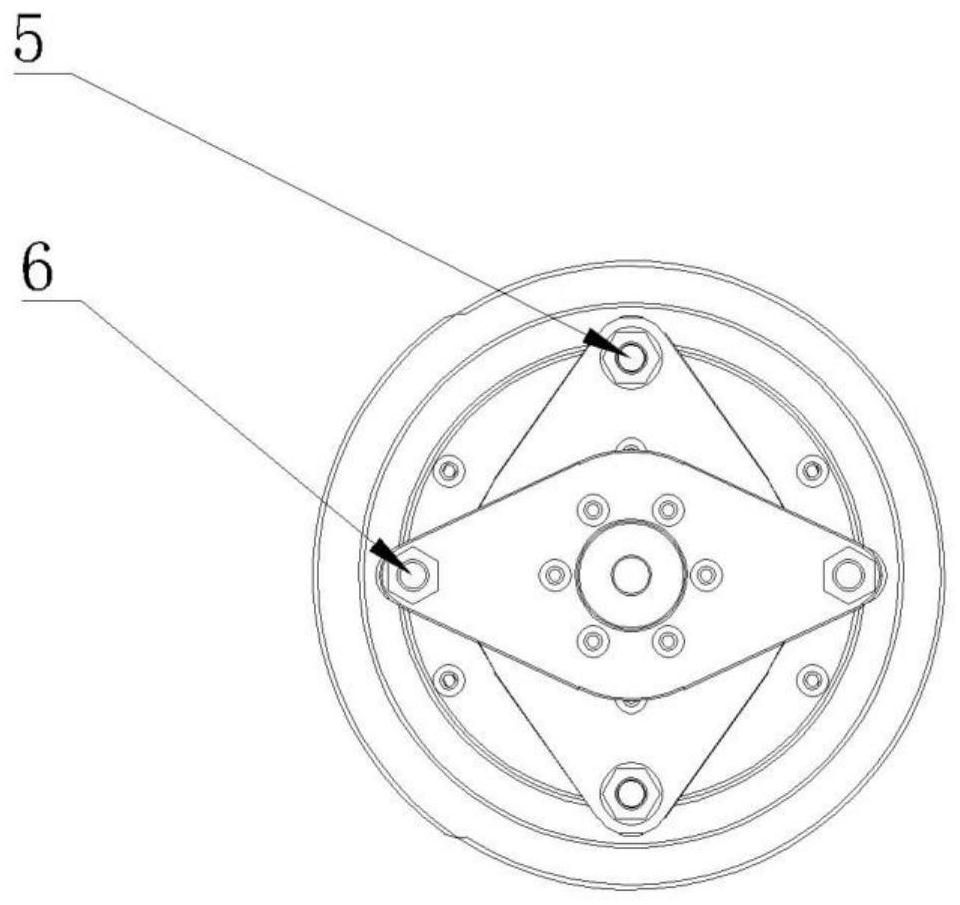

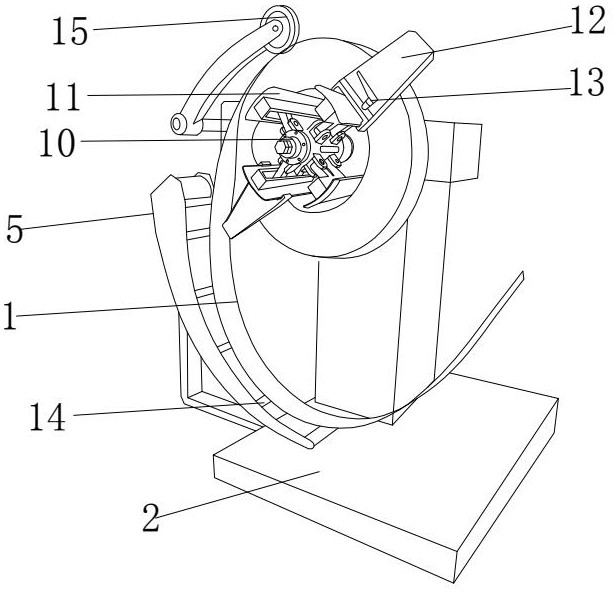

A device for grabbing and loading discs

The invention discloses a device for grabbing a tray, comprising a clamping jaw body and a tray tray body. The clamping jaw body includes a cylinder fixing plate, the cylinder fixing plate is provided with a cylinder hole, a cylinder is arranged above the cylinder hole, and the cylinder piston rod passes through the cylinder The hole is linked to the stroke operation of the cylinder. The cylinder includes a positioning column and a push column. The push column includes a mating surface, an inclined surface and a push surface; the cylinder fixing plate is connected to a support assembly. The step is provided with a spherical counterbore, and a clamping ball is arranged in the spherical counterbore; the carrier body includes a positioning component and an insert carrier, the positioning component is provided with a positioning through hole in the center of the plane, and the wall of the positioning through hole is provided with a spherical groove. The grooves fit with the snap balls. The invention realizes the precise positioning of the carrier plate through the arrangement of the support assembly and the push column, reduces the transfer of the clamping jaws, and reduces the accumulated error; and realizes automatic production for difficult products with complex inserts.

Owner:XUZHOU YUNTAI AUTOMOBILE ELECTRICAL APPLIANCE

Device for preparing bio-organic fertilizer from biogas residue waste liquid based on straw

PendingCN114804946AAchieve finishingAchieve rotationOrganic fertiliser preparationAgricultural engineeringEnvironmental engineering

The invention belongs to the technical field of organic fertilizer preparation, and particularly relates to a device for preparing a bio-organic fertilizer from biogas residue waste liquid based on straw, the device comprises a circulation box, a feeding pipe and a discharging pipe, the upper end and the lower end of the side wall of the circulation box are connected with the feeding pipe and the discharging pipe respectively, and a protective cover is fixed in the circulation box; the multiple scrapers are continuously matched for operation, solid waste is arranged, the smoothness of the solid waste in the conveying process can be improved, meanwhile, later forming operation is facilitated, extrusion forming of the formed waste is achieved after the solid waste is flatly laid and in the rolling process of the roller, integrated machining operation can be achieved, transfer is reduced, and the production efficiency is improved. And meanwhile, the overall processing fluency is improved, the fertilizer processing efficiency is improved, stable forming of solid waste can be ensured when raw materials are insufficient or mechanical faults occur, so that the quality of the bio-organic fertilizer is improved, meanwhile, when the raw materials are insufficient, an alarm can be given in time, shutdown can be conducted in time, energy is saved, and the environment is better protected.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH +1

Loading disc grabbing device

The invention discloses a loading disc grabbing device. The device comprises a clamping jaw body and a loading disc body, the clamping jaw body comprises an air cylinder fixing plate, the air cylinder fixing plate is provided with an air cylinder hole, an air cylinder is arranged above the air cylinder hole, an air cylinder piston rod penetrates through the air cylinder hole to be linked with a cylinder body for stroke operation, the cylinder body comprises a positioning column and a pushing column, and the pushing column comprises a matching face, an inclined face and a pushing face; a supporting assembly is connected below the air cylinder fixing plate, a sliding step in sliding fit with the pushing face is arranged on the lower portion of the supporting assembly, a spherical counter bore is formed in the sliding step, and a clamping ball is arranged in the spherical counter bore. and the loading disc body comprises a positioning assembly and an insert loading disc, a positioning through hole is formed in the center of a plane of the positioning assembly, a spherical groove is formed in the hole wall of the positioning through hole, and the spherical groove is matched with the clamping ball. According to the device, through the arrangement of the supporting assembly and the pushing column, accurate positioning of a loading disc is achieved, transfer of a clamping jaw is reduced, and accumulative errors are reduced; and automatic production is realized for products with high difficulty and complicated inserts.

Owner:XUZHOU YUNTAI AUTOMOBILE ELECTRICAL APPLIANCE

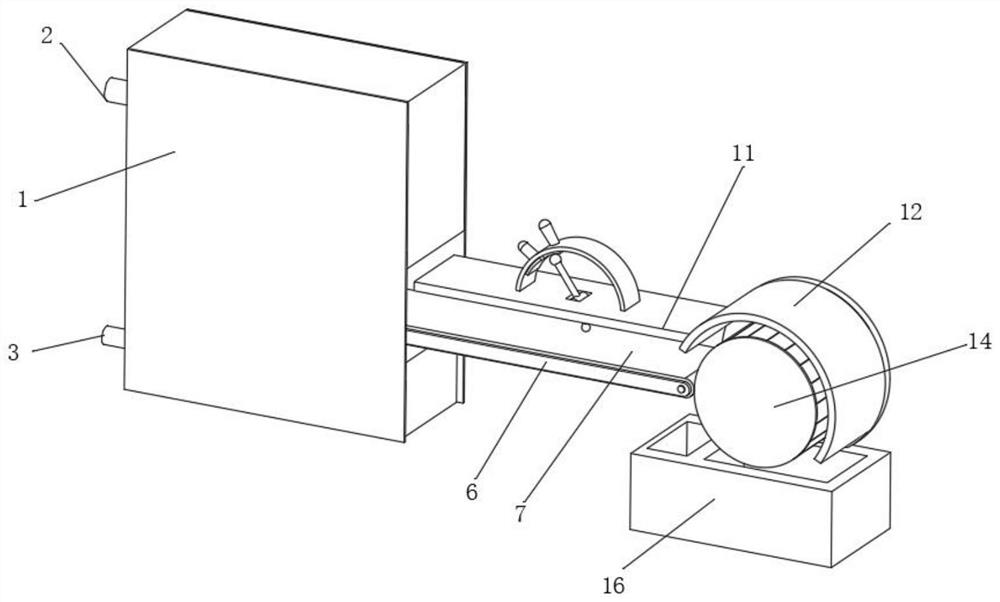

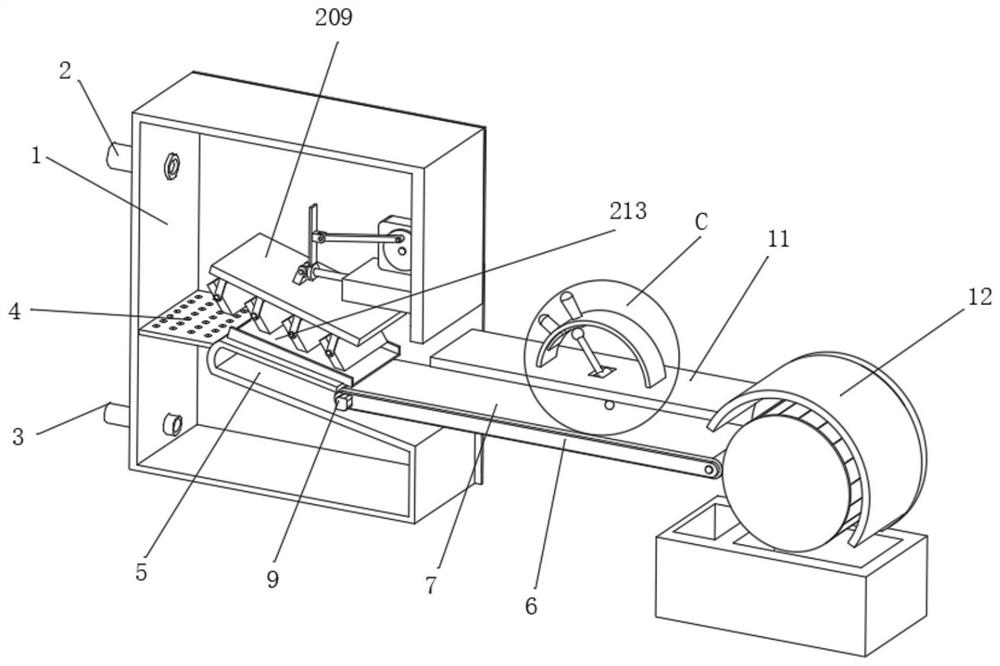

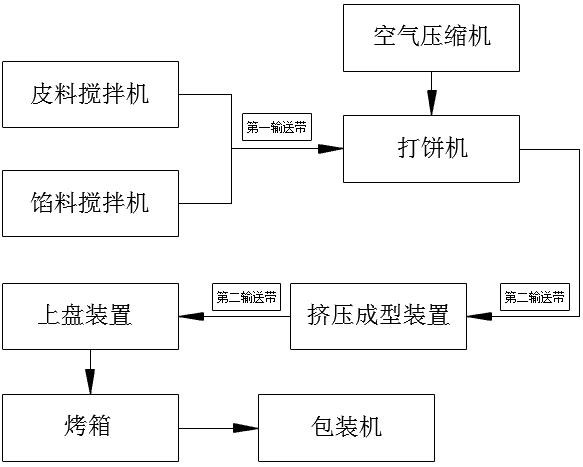

Yak milk residue cake production system

PendingCN113575633AReduce transitImprove fluencyBaked article fillingBaking ovenChemistryProcess engineering

The invention discloses a yak milk residue cake production system. The yak milk residue cake production system is characterized by comprising a wrapper stirring machine, a stuffing stirring machine, first conveying belts, a cake making machine, a second conveying belt, an extrusion forming device, a tray feeding device, an oven and a packaging machine; the two first conveying belts are used for conveying the wrapper of the wrapper stirrer and the stuffing of the stuffing stirrer to the cake making machine respectively; the extrusion forming device is arranged on one side of the second conveying belt between the cake making machine and the tray feeding device and is used for extruding and forming semi-finished yak milk residue cakes; the tray feeding device is used for sequentially placing semi-finished yak milk residue cakes on trays; the oven is used for baking the semi-finished yak milk residue cake on the tray to prepare the yak milk residue cake; the production modules are connected through the conveying belts, transfer of raw materials before forming is reduced, the system continuity is enhanced, the extrusion forming device is arranged on one side of the second conveying belt between the cake making machine and the tray feeding device, extrusion forming is carried out in the natural air drying process of semi-finished products, and the product yield is ensured.

Owner:西藏福帝食品有限公司

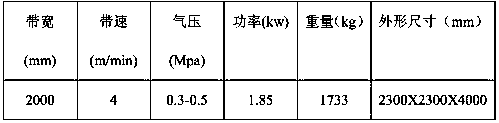

One-step extrusion blow molding pot technology, special molding extrusion blow molding mold and products

ActiveCN103419355BPromote technological progressIn line with the development trend of complexity and refinementBlow moldingEngineering

The invention discloses a one-step extrusion-blown molding pot forming technology. According to the one-step extrusion-blown molding pot forming technology, a mold pressing forming technology and an extrusion-blown molding technology are combined into a whole. An air inlet core bar of the extrusion-blown molding technology is also a male mold of the mold pressing forming technology. A pot cover, a spout and a pot body of a formed pot can be formed in an extrusion-blown molding mode with one mold in one step. The technological advance of the hollow forming technology field is promoted, the complex and refine development tendency of current hollow products is met, and more complex products can be developed through the idea.

Owner:临夏市民政福利塑料厂

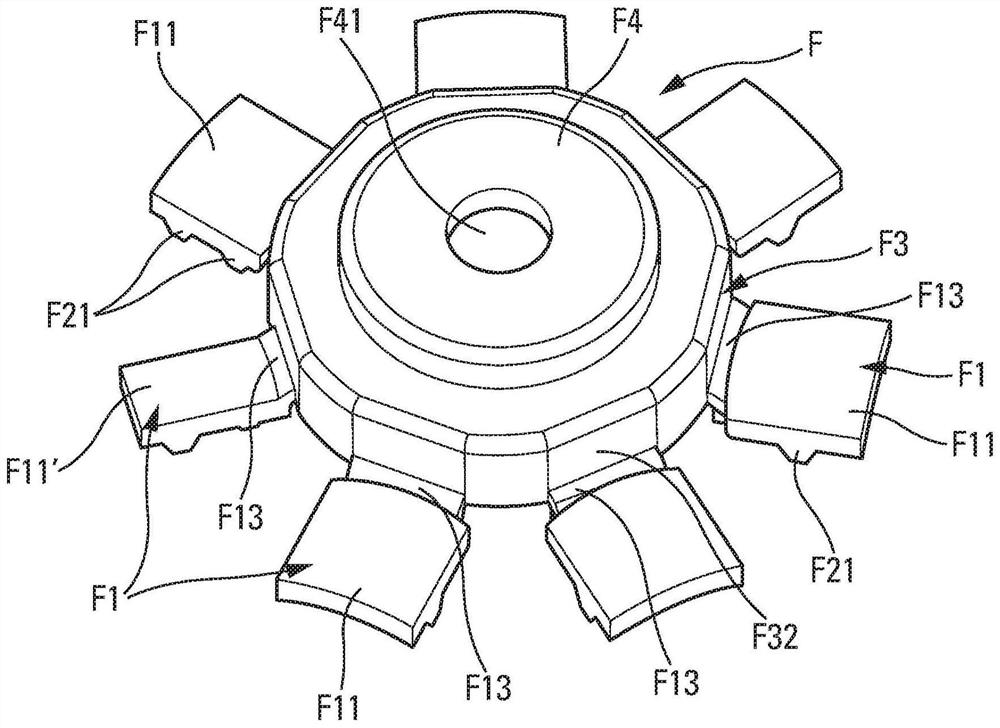

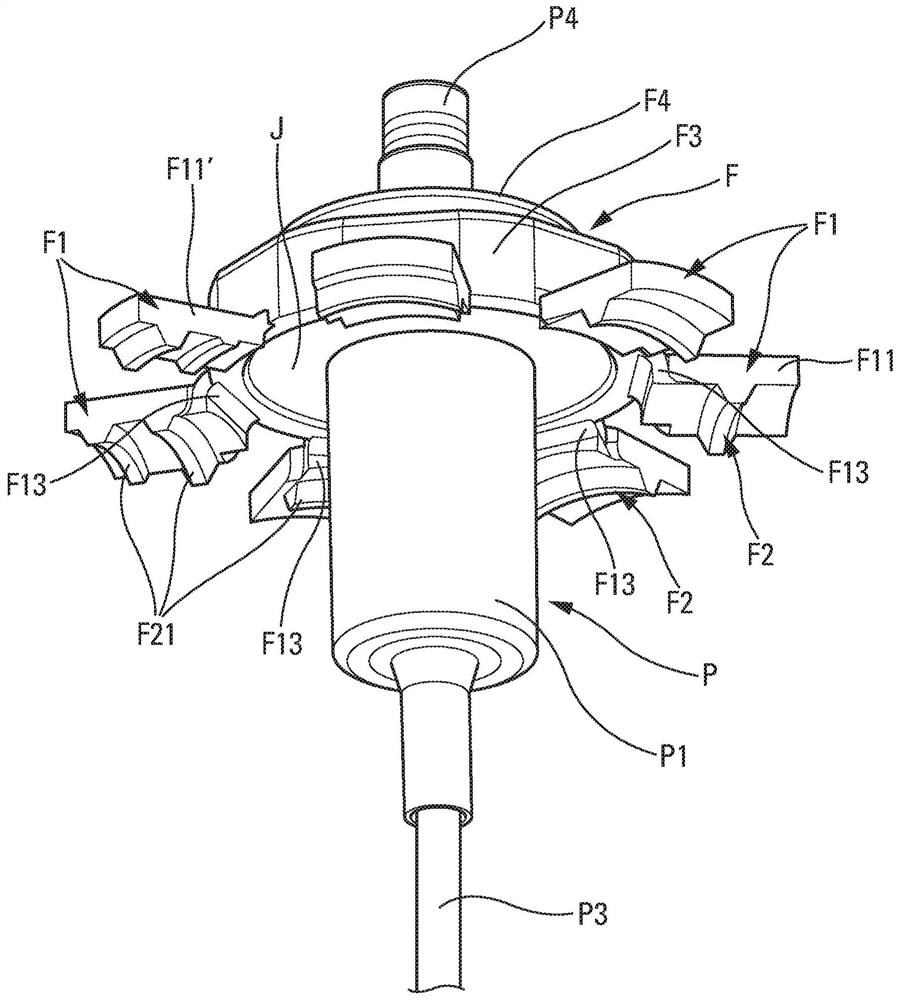

Fluid product dispenser

ActiveCN114072240AQuality improvementImproved unscrewing operationNutsSingle-unit apparatusEngineeringAngular orientation

Fluid product dispenser comprising: - a reservoir (R) provided with a threaded neck (R1) forming at least one external helical thread (R2), - a closure element comprising a threaded skirt (F1) forming at least one internal helical thread (F2), and a band (H) which engages with a clamping action around the threaded skirt (F1), the skirt (F1) comprising a plurality of tabs (F11) each forming a segment (F21) of the internal helical thread (F2), characterized in that: - the fastening member (F) comprises angular indexing means for positioning it with respect to the external helical thread (R2) of the neck (R1) with a predetermined angular orientation, and - the segments (F21) of the internal helical thread (F2) of the threaded skirt (F1) come into corresponding threaded engagement with the external helical thread (R2) of the neck (R1) in the final assembly position.

Owner:资生堂国际法国公司

Combination unit, production line and method for pipe crescent notch punching

ActiveCN110064938BHigh degree of automationIncrease profitOther manufacturing equipments/toolsProduction linePunching

The invention discloses a pipe crescent notch punching combination unit, production line and method. A cutting mechanism, a power material rolling mechanism and a punching mechanism are included and sequentially arranged. The punching mechanism is further provided with an overturning mechanism and at least provided with two stations. The overturning mechanism is arranged between the two stations.When an ultra-long circular pipe is cut, the cutting mechanism cuts the ultra-long circular pipe. After cutting is finished, the ultra-long circular pipe enters the punching mechanism through the power material rolling mechanism. The executing end of the punching mechanism can punch the ultra-long circular pipe with two stations. Through implementation of the pipe crescent notch punching combination unit, ultra-long circular pipe feeding, tidying, fixed-length feeding, saw cutting and crescent notch punching are effectively integrated, and the equipment automation degree is high.

Owner:SHANDONG JINBOLIDA PRECISION MASCH CO LTD +1

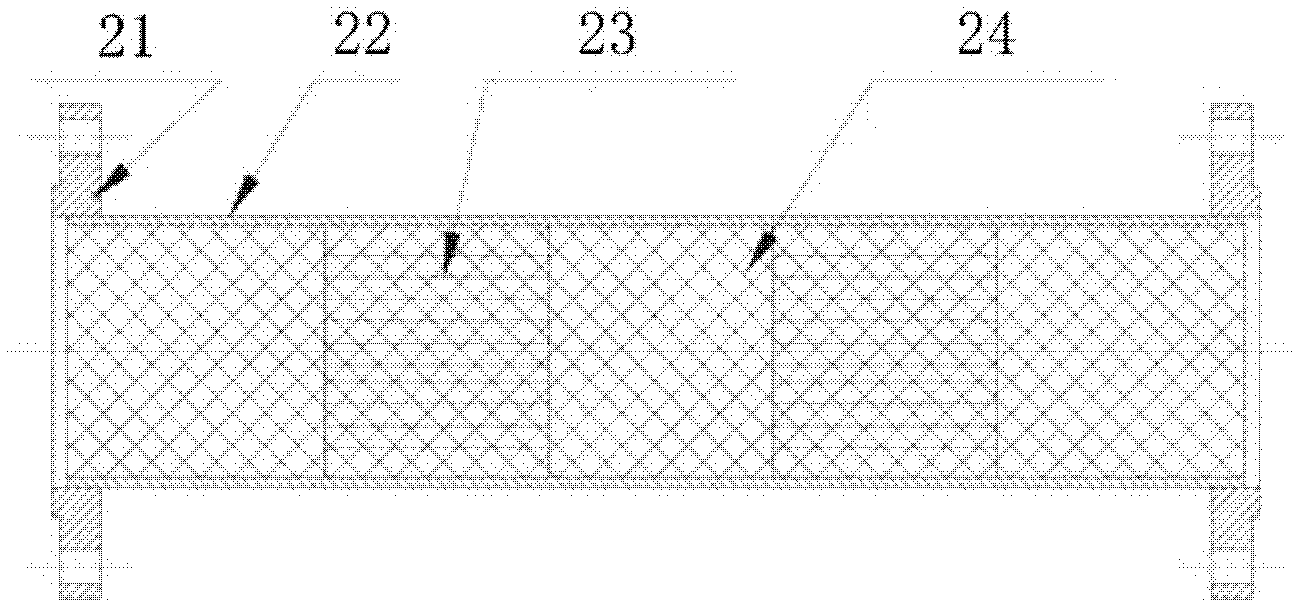

A multi-size automatic fixed-pitch forming wood finger jointing machine

The invention discloses a multi-size automatic fixed-pitch forming wood finger jointing machine. Including a feeding and gluing device (1), the end of the feeding and gluing device (1) is connected with a pressing device (2); the feeding and gluing device (1) includes a conveyor belt I (11), and the end of the conveyor belt I (11) is provided with There is a gluing mechanism (12), and two sides of the conveyor belt I (11) are also provided with a pair of positioning and clamping side plates I (13) that can move toward each other; the pressing device (2) includes the conveyor belt II (21), The head end of the conveyor belt II (21) is connected with the gluing mechanism (12), the end is provided with a material stopper mechanism (22), and two sides are provided with a pair of positioning and clamping side plates II (23) that can move toward each other, and the upper part is provided with a vertical A moving pressing mechanism (24); the bottom of the pressing mechanism (24) is provided with a knurling wheel (25) that can rotate. The invention has the characteristics of good splicing quality, flexible use, high production efficiency, low production cost and environmental protection.

Owner:GUIZHOU INST OF TECH

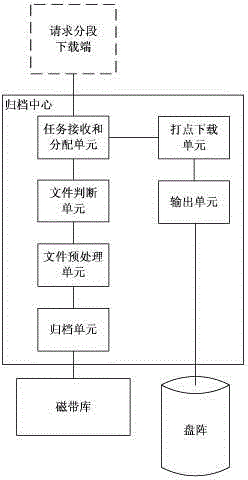

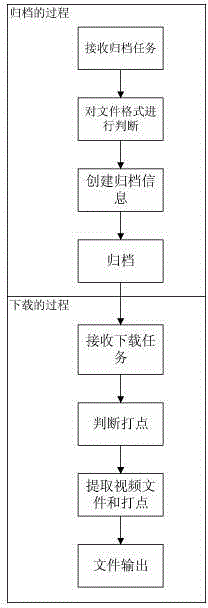

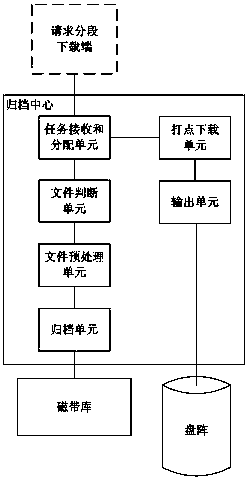

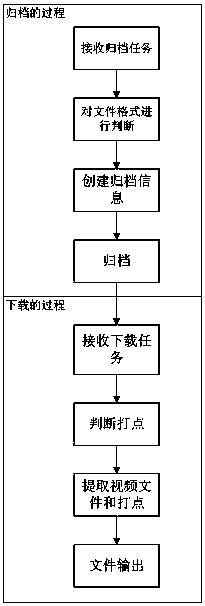

System and method for frame precision tape file callback

The invention relates to a system and method for frame precision tape file callback. The system comprises a filing center connected with a file end requesting segmented downloading. The filing center is connected with a tape library and a memory disk array and comprises a task receiving and assigning unit. The task receiving and assigning unit is connected with a file judging unit, the file judging unit is connected with a file preprocessing unit, the file preprocessing unit is connected with a filling unit, the task receiving and assigning unit is connected with a dotting downloading unit, and the dotting downloading unit is connected with an outputting unit. According to the system and method, different dotting modes are adopted for segmented video files of different formats, each dotting position is accurately calculated, and therefore a user can find required video segments rapidly; for the overall downloading process, the link of transcoding after calling-back can be omitted, the file transferring procedure in the transcoding link is omitted, and therefore the online disk array free space can be saved, and the maintenance cost can be lowered. Because the overall downloading process is shortened, the user can obtain needed resource files more rapidly.

Owner:BEIJING ZHONGKE DAYANG INFORMATION TECH CO LTD

Process for the preparation of stabilized speckled bricks

ActiveCN109795017BBuffer Color EffectsContinuous and stable productionCeramic shaping apparatusCeramic materials productionTextile printerColored white

The present invention relates to a method for preparing stable speckled bricks. The preparation method includes: (1) green body pressing: white spots proportioning 5-10%, blue spots proportioning 10-20%, black spots proportioning 70-80%; (2) green body drying: temperature 80-130°C, time 40 to 60 minutes; ⑶ Simulation processing: apply a translucent glaze layer on the surface of the body, and then use inkjet printing to print inkjet false spots that are close to the size and color of the spots on the body. The color and spot effect of the translucent glaze are consistent with the body. The color and surface effect are basically consistent; ⑷Printing and decoration; ⑸Applying protective glaze: After decorating the color and pattern effects through screen printing, rubber roller printing or inkjet printing, apply transparent glaze slurry to protect the decoration, so that the spots can sink under the glaze layer , achieving highly simulated fusion with the spots on the green body itself; ⑹ Firing: temperature at 1150~1250℃, time 40~60 minutes.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

A system and method for a frame-accurate tape callback file

The invention relates to a system and method for frame precision tape file callback. The system comprises a filing center connected with a file end requesting segmented downloading. The filing center is connected with a tape library and a memory disk array and comprises a task receiving and assigning unit. The task receiving and assigning unit is connected with a file judging unit, the file judging unit is connected with a file preprocessing unit, the file preprocessing unit is connected with a filling unit, the task receiving and assigning unit is connected with a dotting downloading unit, and the dotting downloading unit is connected with an outputting unit. According to the system and method, different dotting modes are adopted for segmented video files of different formats, each dotting position is accurately calculated, and therefore a user can find required video segments rapidly; for the overall downloading process, the link of transcoding after calling-back can be omitted, the file transferring procedure in the transcoding link is omitted, and therefore the online disk array free space can be saved, and the maintenance cost can be lowered. Because the overall downloading process is shortened, the user can obtain needed resource files more rapidly.

Owner:BEIJING ZHONGKE DAYANG INFORMATION TECH CO LTD

Full-automatic storage battery joint continuous punch forming equipment and production process

PendingCN113770276AReduce in quantityReduce handling stepsShaping toolsPunchingIndustrial engineering

The invention discloses full-automatic storage battery joint continuous punch forming equipment and a production process. The full-automatic storage battery joint continuous punch forming equipment comprises a material placing frame for placing a copper sheet, a shaping machine for shaping the copper sheet and a storage battery joint punching machine, and is characterized in that the copper sheet is placed on the material placing frame through a reel, and the copper sheet is guided and conveyed along a guide frame on the lower side of the material placing frame; the copper sheet is conveyed to a limiting frame on one side of the shaping machine, a plurality of rollers used for extruding and conveying the copper sheet are arranged in the shaping machine, the copper sheet is arranged on a lower die of the punching machine, and an upper die of the punching machine is arranged above the copper sheet. The copper sheets are conveyed step by step through full-automatic production equipment, the copper sheets are gradually and continuously machined into the storage battery joints through the punching machine, the number of machines is reduced, meanwhile, the carrying step among a plurality of working procedures is reduced, only one operator is needed to carry out copper sheet discharging and machine nursing, and the cost is effectively reduced.

Owner:WENZHOU FENGDI CONNECTOR

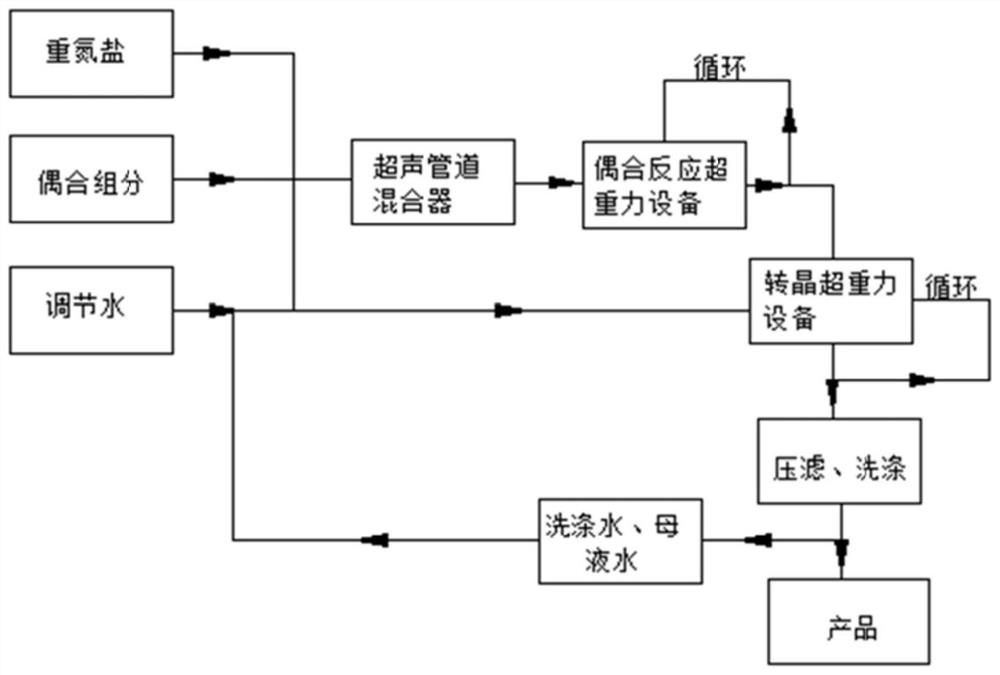

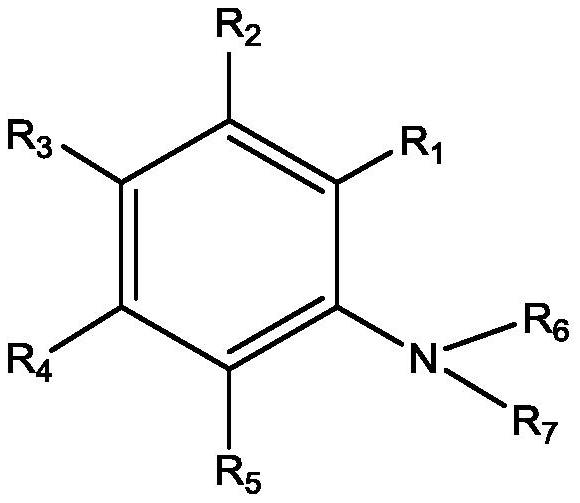

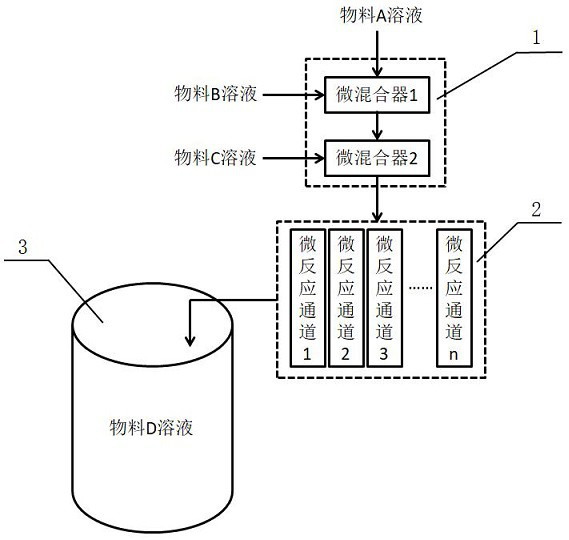

A continuous production process of azo disperse dyes with ester groups

The invention discloses a continuous production process of an azo disperse dye with an ester group. Through the combination of an ultrasonic mixer, a supergravity machine enhanced reaction and a supergravity machine enhanced crystal transformation, the beating process of traditional process materials is reduced, and the post-treatment kettle is reduced. In the crystal conversion process, the entire process from the early stage of the reaction to the post-processing of the finished product is continuous. Through the strengthening of the equipment, the reaction efficiency is improved and the reaction residence time is greatly shortened. Therefore, the volume of the equipment is greatly reduced, and the material in the kettle equipment The transfer process in the process reduces the amount of kettle equipment, greatly reduces the cost of production equipment and site use, reduces the volume of equipment in each link, increases the safety and controllability of the reaction, and has obvious advantages in product purity and yield.

Owner:ZHEJIANG DIBANG CHEM +1

Chain plate slot box stepping firecracker production machine

The invention discloses a chain plate slot box stepping firecracker production machine. The chain plate slot box stepping firecracker production machine comprises a machine frame, a feeding device, a transmission device and a charging device, wherein the feeding device and the charging device are positioned above the transmission device; the transmission device has a chain plate slot box structure; a chain plate strip is mainly formed by connecting a plurality of chain plates end to end; a firecracker tube positioning device is arranged between every two chain plates; each firecracker tube positioning device is formed by connecting a plurality of slot plates end to end; arc-shaped grooves which are matched with firecracker tubes are formed in the back edge walls of the slot plates; the arc-shaped grooves of a horizontal slot plate are clamped with a front slot plate and a back slot plate to form a slot box for clamping the firecracker tubes; and a supporting plate is arranged below the horizontal slot plate. By the chain plate slot box stepping firecracker production machine, a single firecracker tube is positioned and filled; compared with the positioning and the filling of a hexagonal cake tube, the chain plate slot box stepping firecracker production machine is positioned more easily and accurately; neglected loading does not happen easily; the firecracker tubes can be positioned well; and the chain plate slot box stepping firecracker production machine has high fault-tolerance performance.

Owner:王世楷

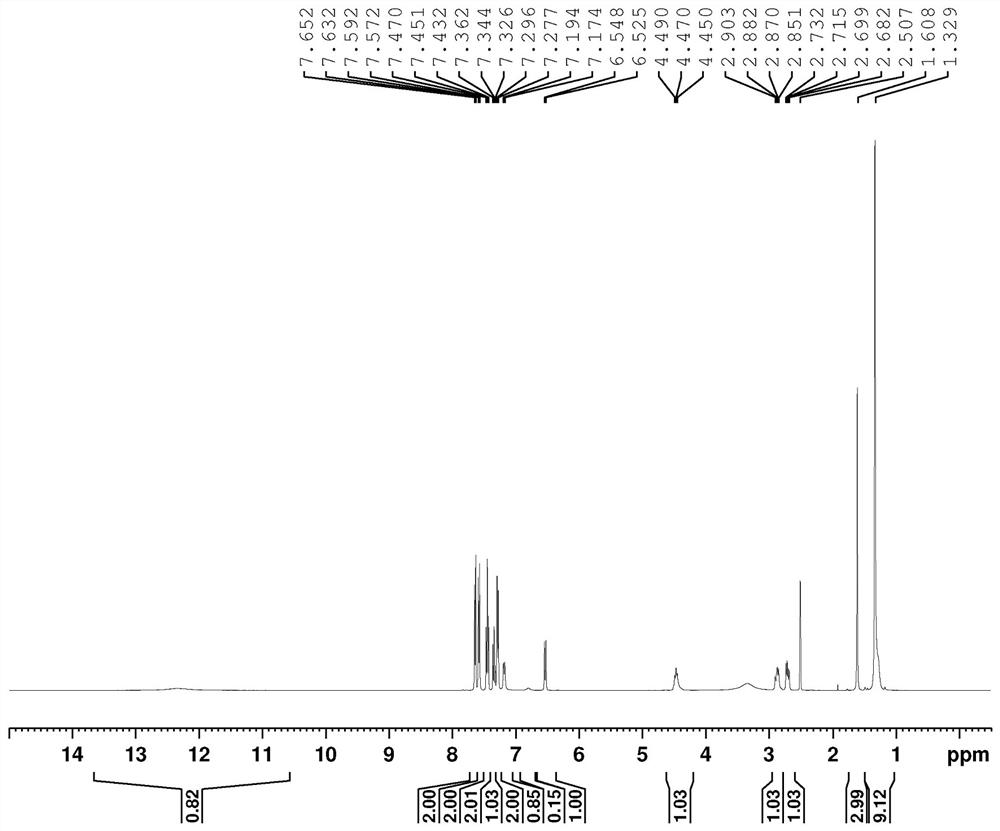

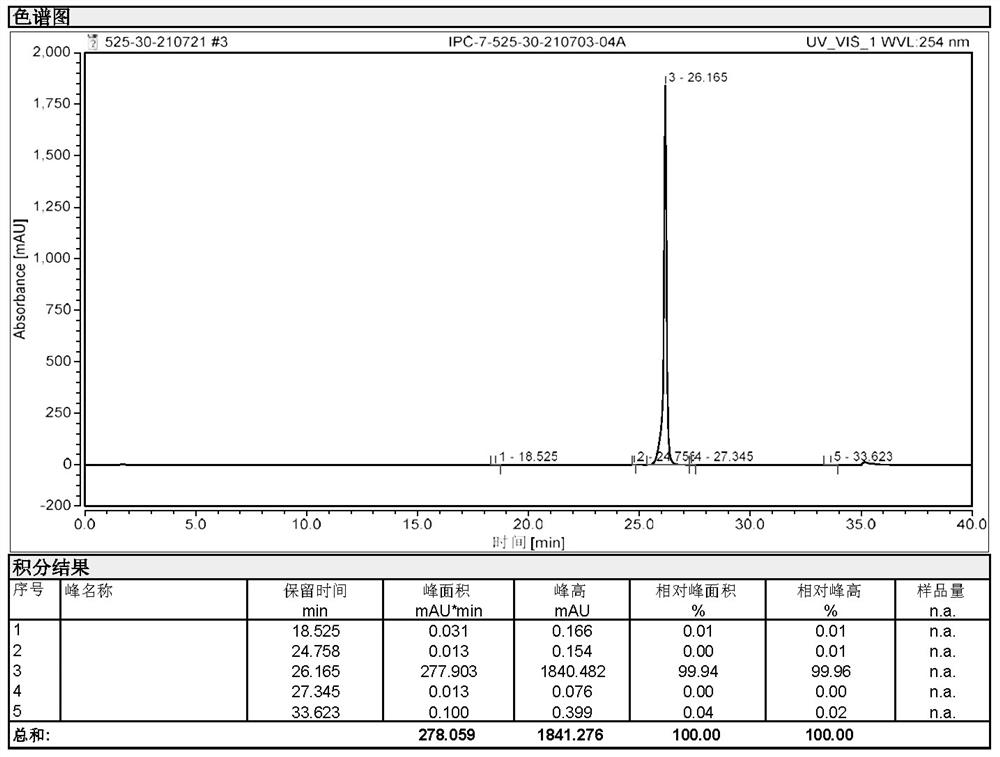

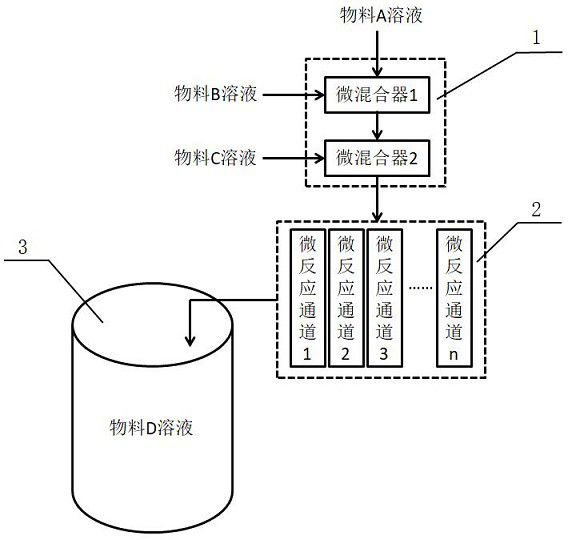

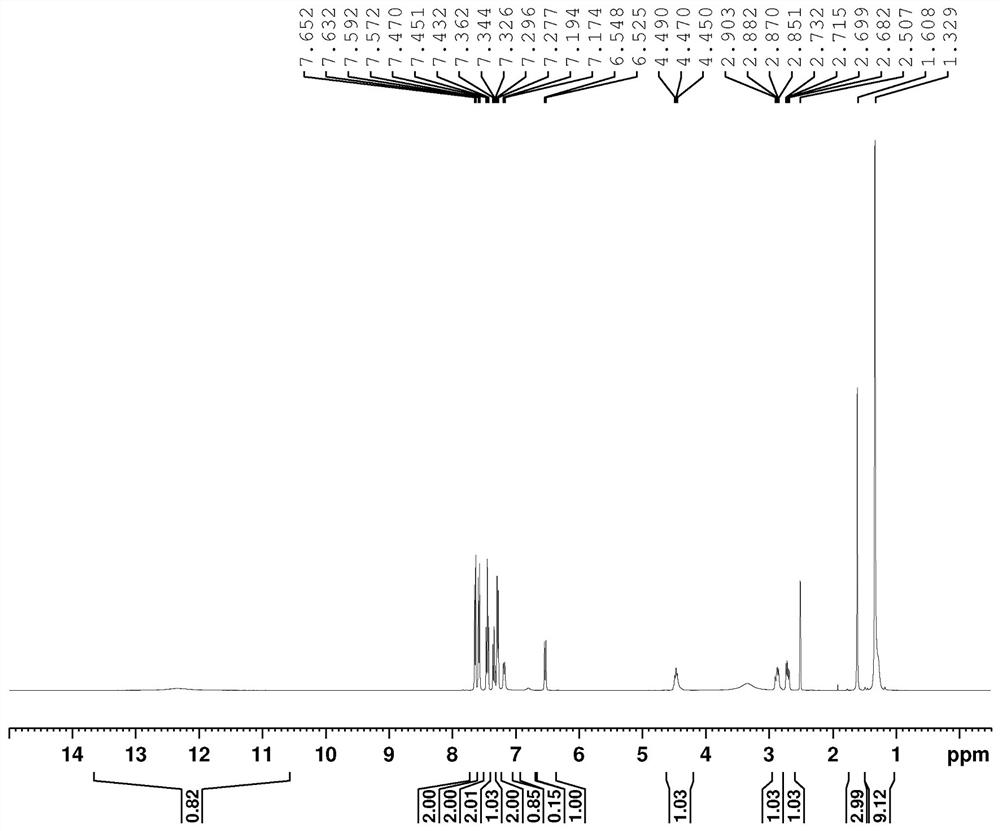

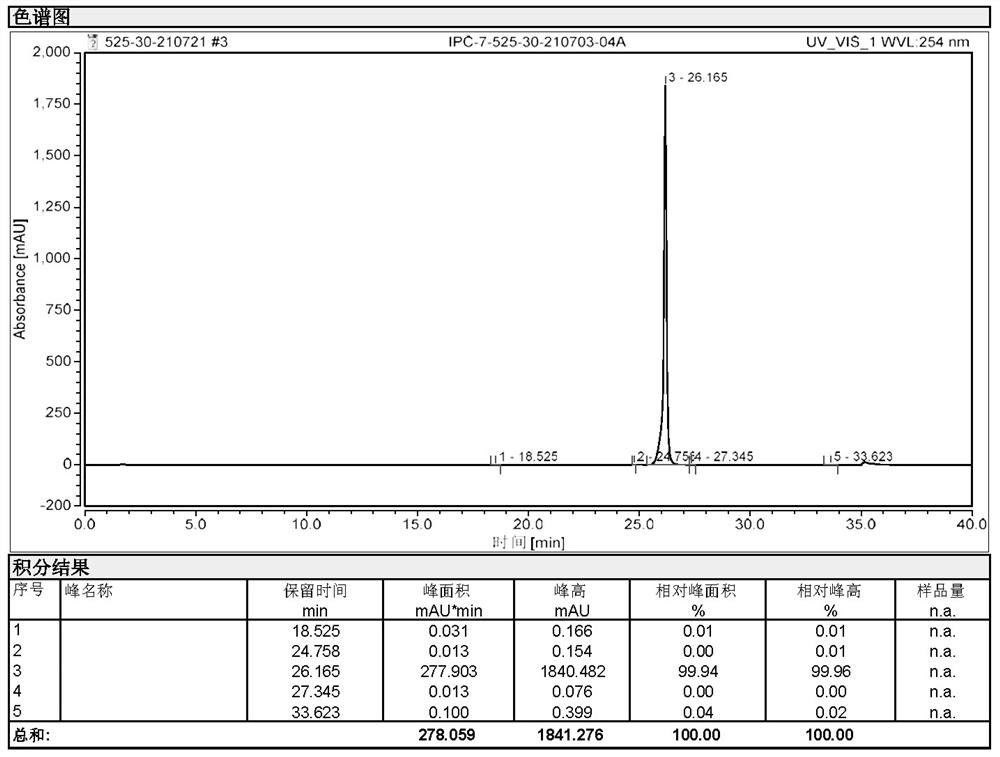

Method for preparing sacubitril intermediate in continuous flow microreactor

ActiveCN113754565AImprove mass transfer efficiencyGood choiceCarbamic acid derivatives preparationOrganic compound preparationSacubitrilSodium thiosulfate

The invention relates to a preparation method of a sacubitril intermediate, in particular to a method for preparing the sacubitril intermediate in a continuous flow microreactor, and belongs to the technical field of medicinal chemistry. According to the method disclosed by the invention, a compound III is prepared by carrying out TEMPO oxidation on a compound II in the continuous flow microreactor, so that the mass transfer efficiency is greatly improved, and the reaction selectivity is better; and the reaction liquid of the compound III directly flows into a reaction kettle containing ethoxyformyl ethylene triphenylphosphine and sodium thiosulfate, sodium hypochlorite is quenched during reaction, the production efficiency is high, the yield is high, the purity is high, and the method is suitable for industrial large-scale production.

Owner:NANJING VCARE PHARMATECH CO LTD

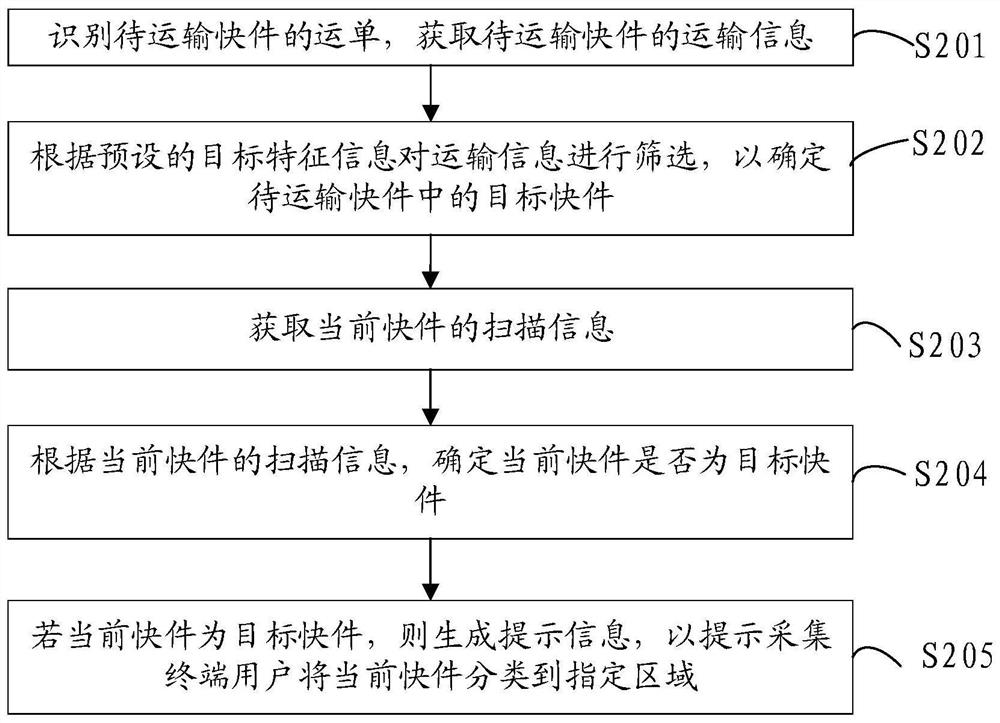

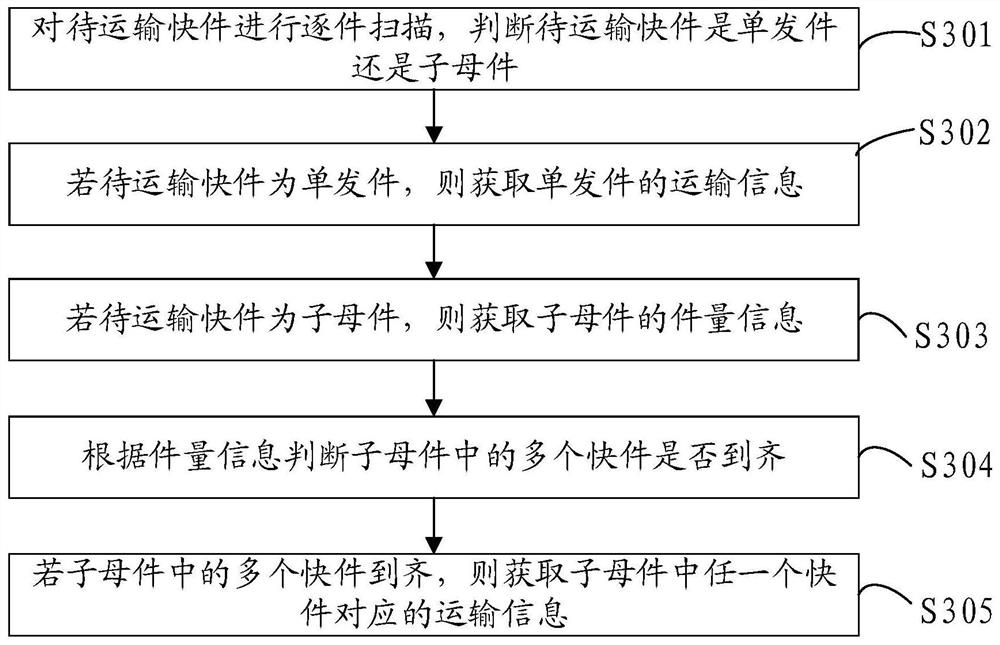

Express identification method and device, express delivery method and device, server and storage medium

PendingCN114118654AImprove timelinessReduce transitResourcesLogisticsLogistics managementEmbedded system

The invention provides an express item identification method and device, an express item delivery method and device, a server and a storage medium. According to the express item identification method, the target express item needing to be directly delivered is screened and determined before the express item is transported, the direct delivery task is generated according to the receiving position information of the target express item, and the direct delivery task is directly allocated to the delivery personnel of the logistics terminal, so that the delivery personnel can directly deliver the target express item, and the delivery efficiency is improved. Transfer of the target express is reduced, the delivery chain is shortened, and the express delivery timeliness is improved.

Owner:SF TECH

A method for preparing sacubitril intermediate in a continuous flow microreactor

ActiveCN113754565BImprove mass transfer efficiencyGood choiceCarbamic acid derivatives preparationOrganic compound preparationMicroreactorAcyl group

The invention relates to a method for preparing a sacubitril intermediate, in particular to a method for preparing a sacubitril intermediate in a continuous flow microreactor, and belongs to the technical field of medicinal chemistry. The method of the present invention prepares compound III by TEMPO oxidation of compound II in a continuous flow microreactor, which greatly improves the mass transfer efficiency and makes the selectivity of the reaction better; and directly flows the reaction solution of compound III into In the reaction kettle of acyl ethylene triphenylphosphine and sodium thiosulfate, the sodium hypochlorite is quenched during the reaction, the production efficiency is high, the yield is high, the purity is high, and it is suitable for industrial scale-up production.

Owner:NANJING VCARE PHARMATECH CO LTD

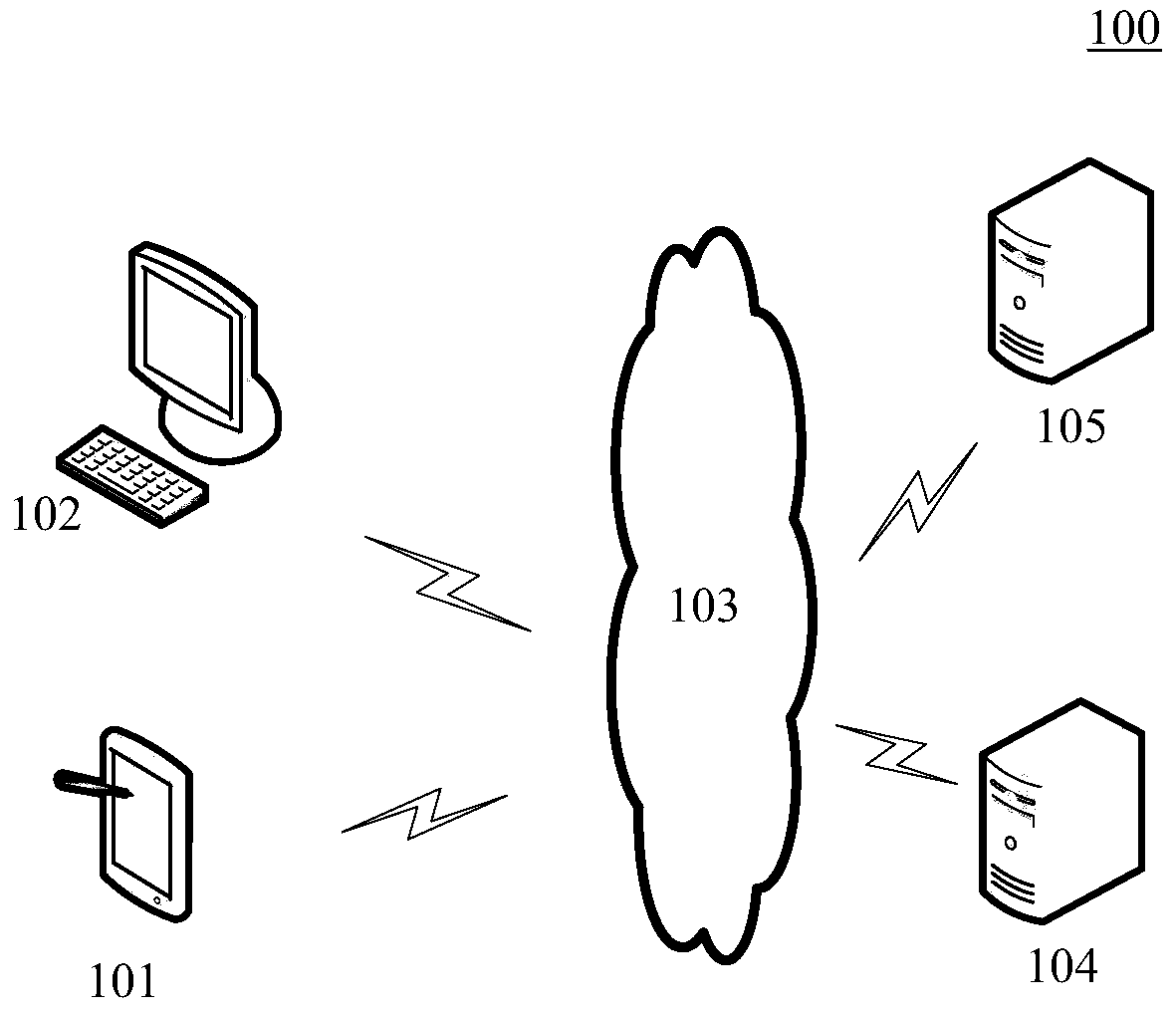

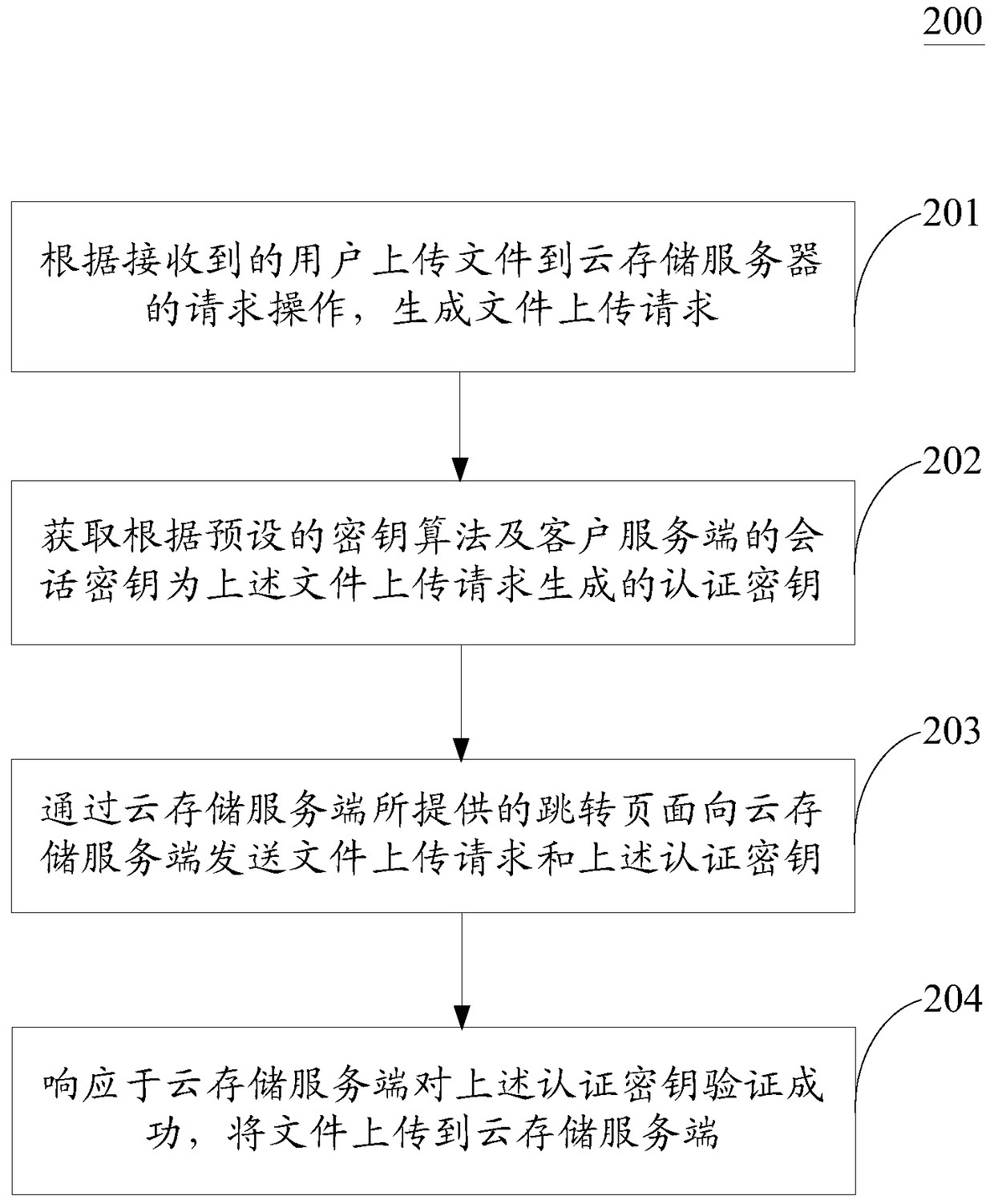

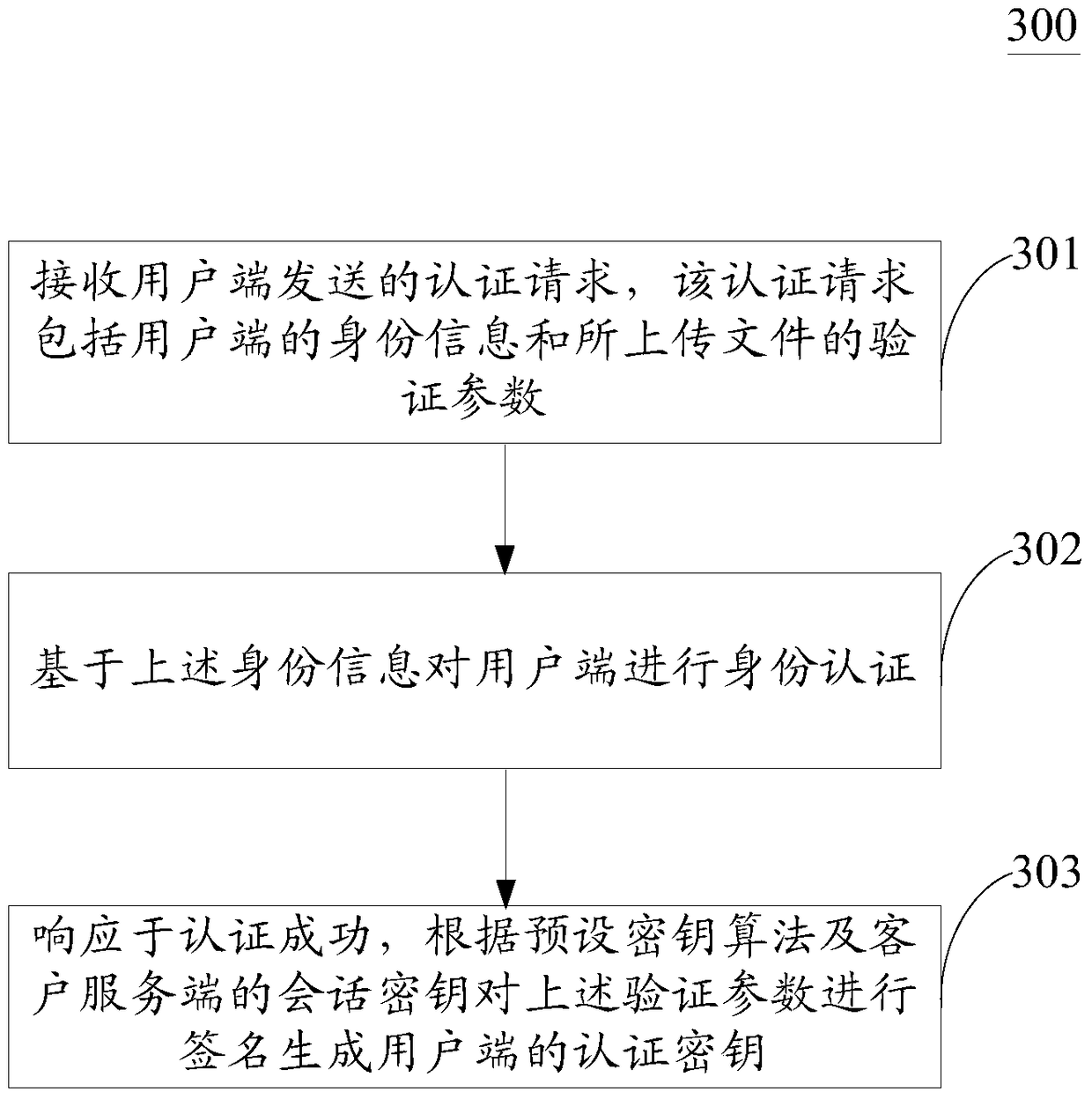

Method, device and system for uploading files

The application discloses a file upload method, a file upload apparatus and a system. In one embodiment, the file upload method concretely comprises the steps of generating a file upload request according to a received request operation for a user to upload a file to a cloud storage server through a user side, and generating an authentication secret key for the file upload request according to a preset secret key algorithm and a session secret key for a client server through the client server or the user side; sending the file upload request and the authentication secret key to the cloud storage server by the user side through a jump page provided by the cloud storage server so that the cloud storage server can generate a verification secret key for the file upload request according to the preset secret key algorithm and the session secret key of the cloud storage server so as to verify the authentication secret key; and uploading the file to the cloud storage server in response to a case that the cloud storage server successfully verifies the verification secret key. The file upload method can reduce the transfer process that the client uploads the file to the cloud storage server through the user server so that the effectiveness for uploading files is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com