Full-automatic storage battery joint continuous punch forming equipment and production process

A stamping and forming, battery technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost and maintenance cost, multiple labor and machines, etc., to reduce handling steps, speed up production efficiency, production efficiency improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

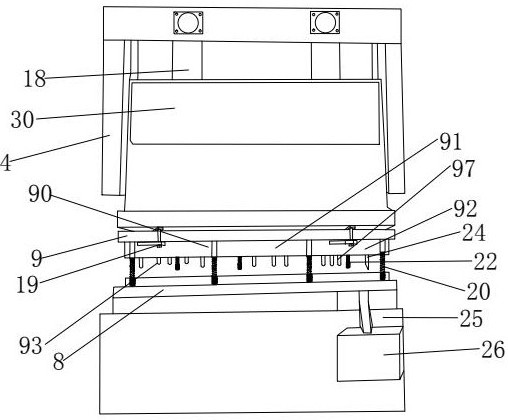

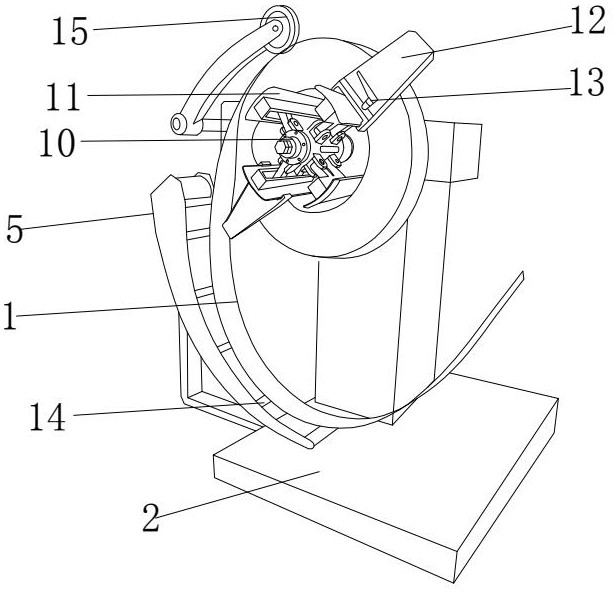

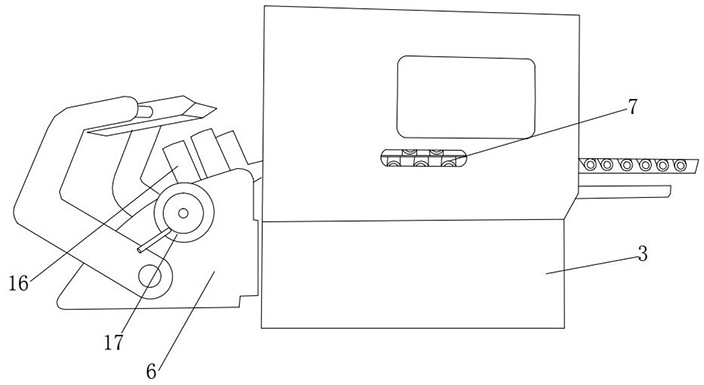

[0034] Such as Figure 1-10 As shown, a fully automatic continuous stamping and forming equipment for battery joints, including a discharge rack 2 for placing copper sheets 1, a shaping machine 3 for shaping copper sheets 1, and a battery joint punching machine 4, is characterized in that the A copper sheet 1 is placed on the discharge rack 2 through a reel 10, and the copper sheet 1 is guided and transported along the guide frame 5 on the lower side of the discharge rack 2, and the copper sheet 1 is transported to the limit frame 6 on the side of the shaping machine 3, and the shaping Inside the machine 3 are provided with several rollers 7 for extruding and conveying the copper sheet 1, the copper sheet 1 is arranged on the lower die 8 of the punching machine 4, and the upper die 9 of the punching machine 4 is arranged above the copper sheet 1, and the discharge rack 2 is used to transport the copper sheet 1 smoothly. The feeding rack 2 transports the copper sheet 1 to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com