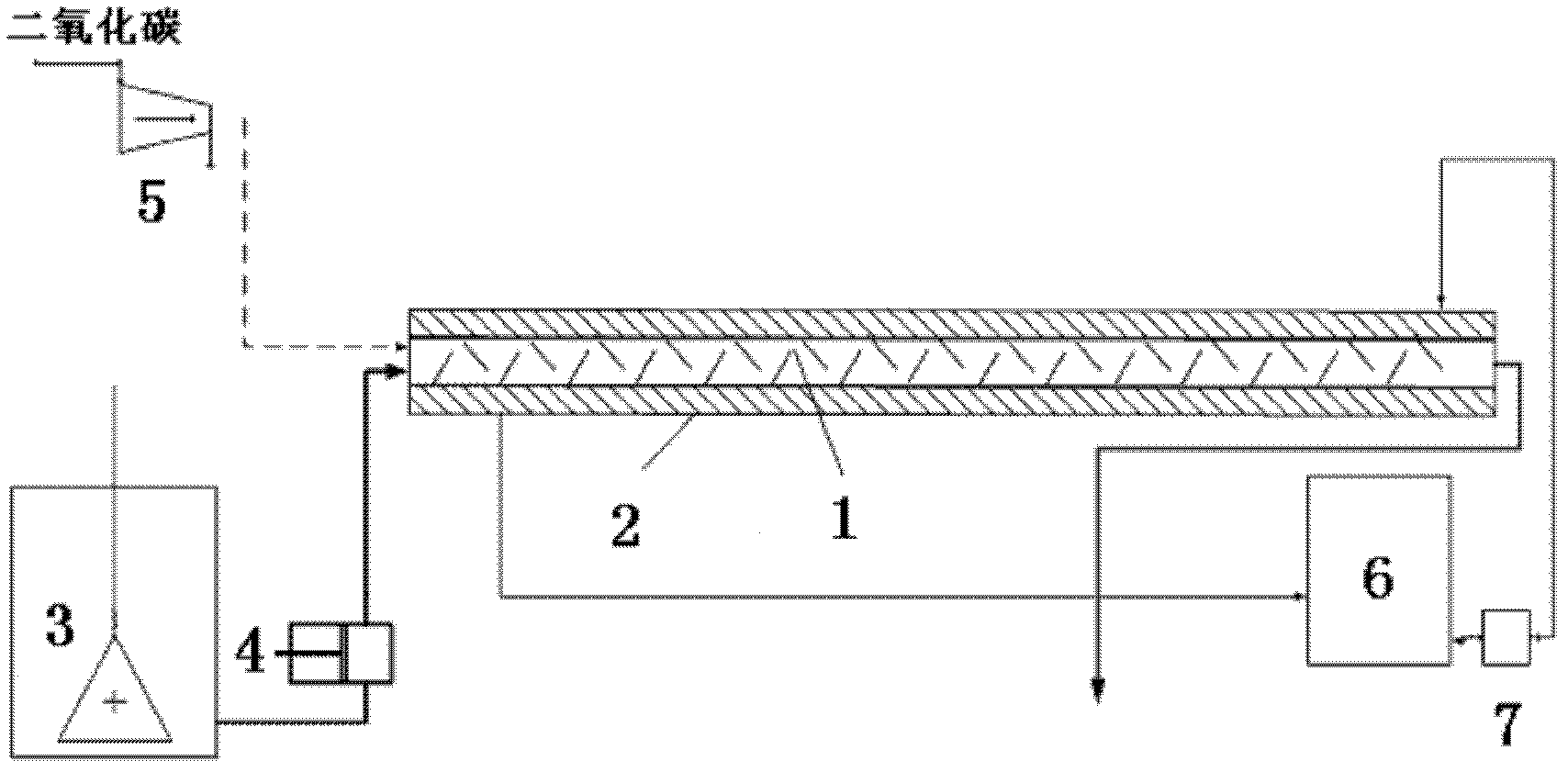

Apparatus and method for pipeline continuous carbonization of calcium and magnesium

A technology of calcium magnesium carbide and tubular reaction device, which is applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of low mechanical efficiency, limited improvement of carbonization efficiency, and high energy consumption, and achieve high carbonization efficiency and contact surface Enhanced, less mixed flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

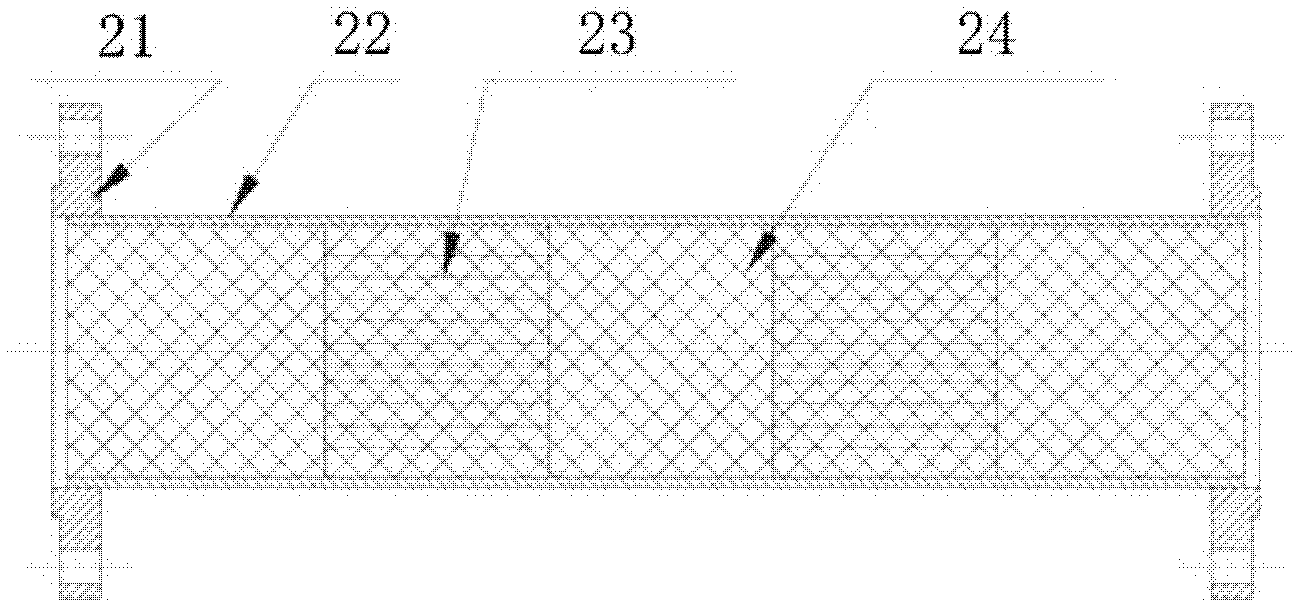

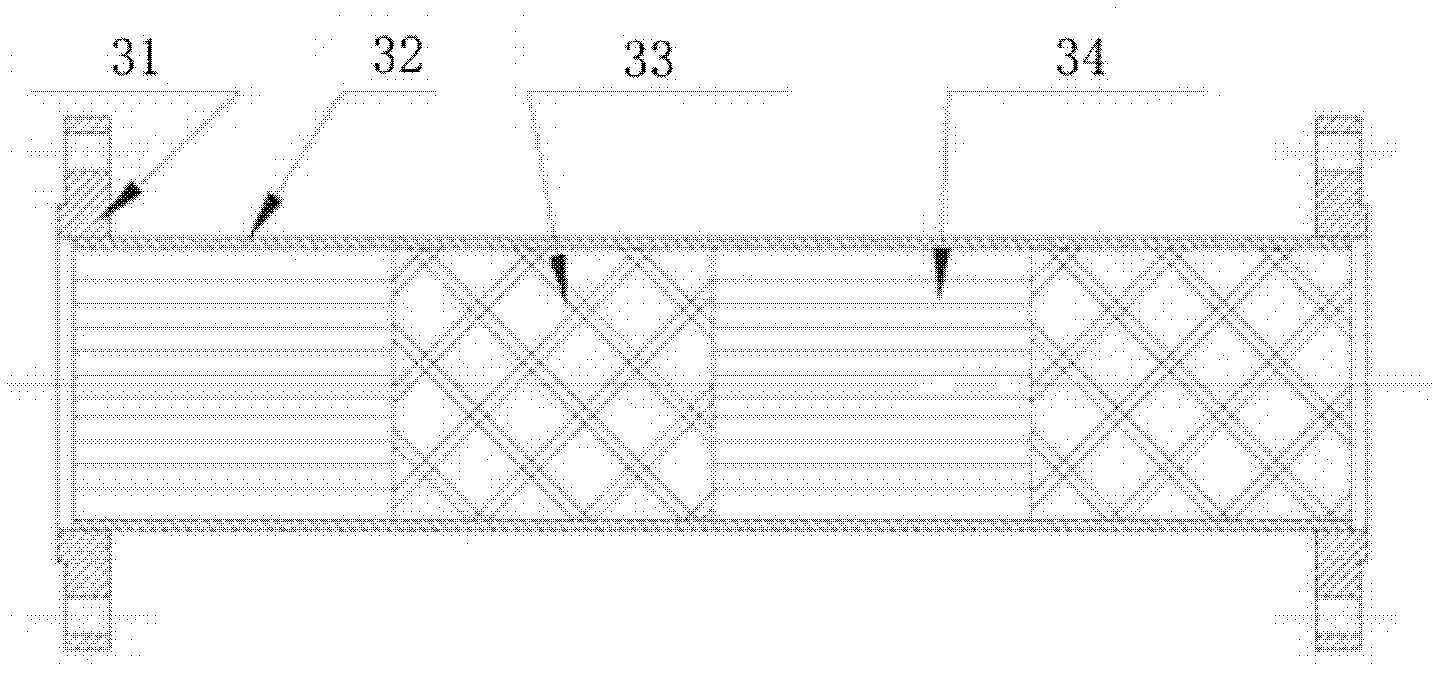

Method used

Image

Examples

Embodiment 1

[0060] Adopt pipeline continuous carbonization device of the present invention to carry out the carbonization of calcium hydroxide, the calcium hydroxide concentration of slurry is 2g / L (calculated as oxide), adopt diaphragm pump to transport slurry, slurry flow rate is 20L / min; Carbon dioxide concentration is 99% , the carbon dioxide flow rate is 0.67L / min, the carbonization temperature is 10°C, the carbonization time is 15 minutes, and the carbonization process pressure is 40 kg. The utilization rate of carbon dioxide in the carbonization process is 99.00%, and the conversion rate of calcium in the slurry into soluble calcium bicarbonate is 98%.

Embodiment 2

[0062] The carbonization of magnesium hydroxide and calcium hydroxide slurry is carried out by pipeline continuous carbonization device, and the mixture slurry of calcium hydroxide and magnesium hydroxide obtained by digesting dolomite is used as raw material, and the concentration of magnesium hydroxide obtained is 12g / L (calculated as oxide) , the concentration of calcium hydroxide is 2g / L (calculated as oxide), the slurry is transported by a diaphragm pump, the flow rate of the slurry is 20L / min, the concentration of carbon dioxide is 99%, the flow rate of carbon dioxide is 36.83L / min, and the carbonization temperature is 15°C. The time is 15 minutes, and the carbonization process pressure is 8 kg. The utilization rate of carbon dioxide in the carbonization process is 97.00%, and the conversion rate of magnesium / calcium in the slurry into soluble bicarbonate is 98%.

Embodiment 3

[0064] The magnesium hydroxide and calcium hydroxide slurry carbonization is carried out using a pipeline continuous carbonization device. The concentration of magnesium hydroxide in the slurry is 12g / L (calculated as oxides), and the concentration of calcium hydroxide is 2g / L (calculated as oxides). The pump transports the slurry, the slurry flow rate is 20L / min, the carbon dioxide concentration is 99%, the carbon dioxide flow rate is 40.39L / min, the carbonization temperature is 20°C, the carbonization time is 45 minutes, and the carbonization process pressure is 8 kg. The utilization rate of carbon dioxide in the carbonization process is 90.00%, and the conversion rate of magnesium / calcium into soluble bicarbonate in the slurry is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com