Three-dimensional (3D) printer

A 3D printer and print head technology, applied in the field of 3D printers, can solve the problems of restricting the market and scale of consumer use, high purchase and maintenance costs, and uncompact structure, and achieve simple structure, low production cost, and reduced labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

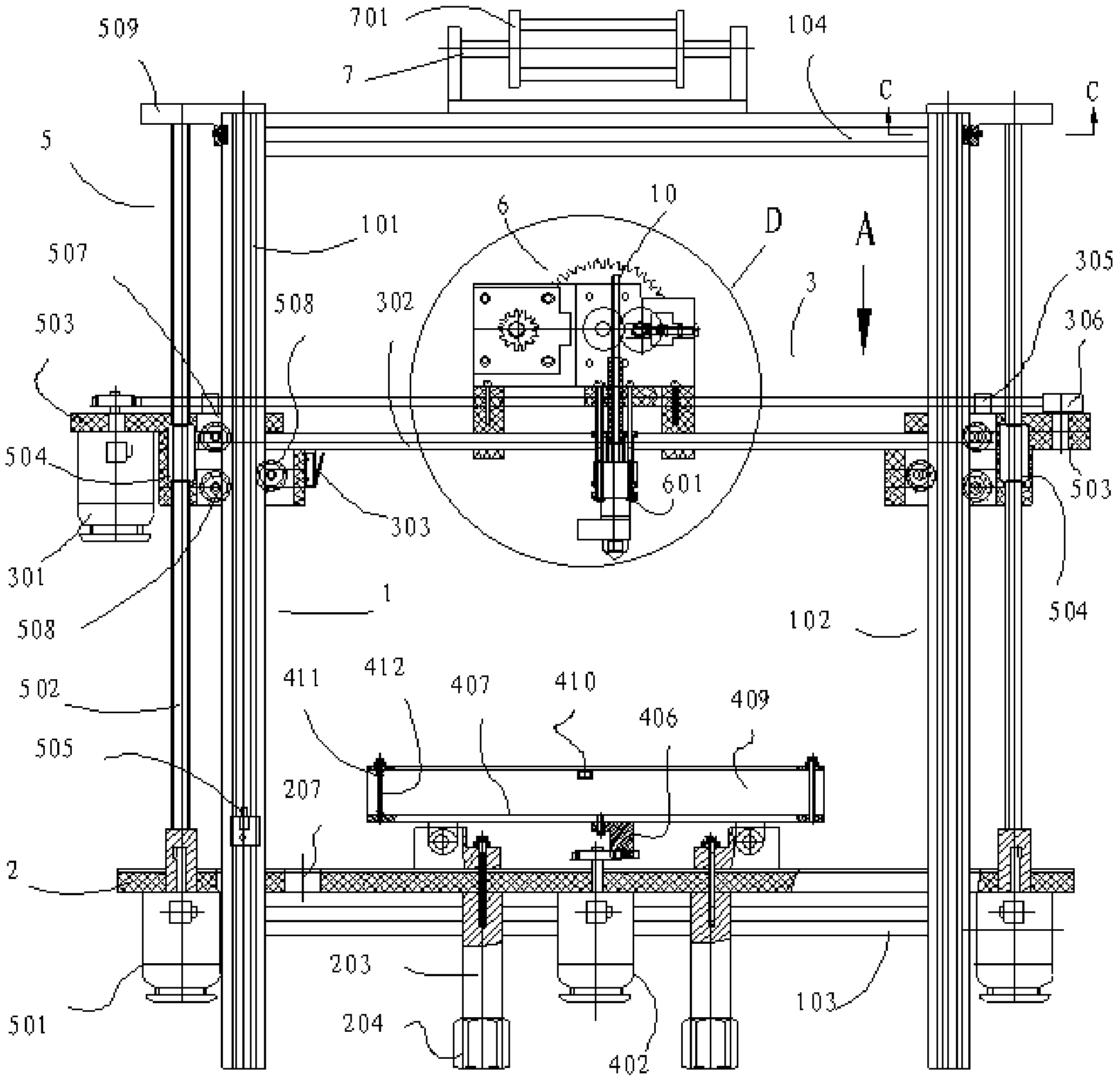

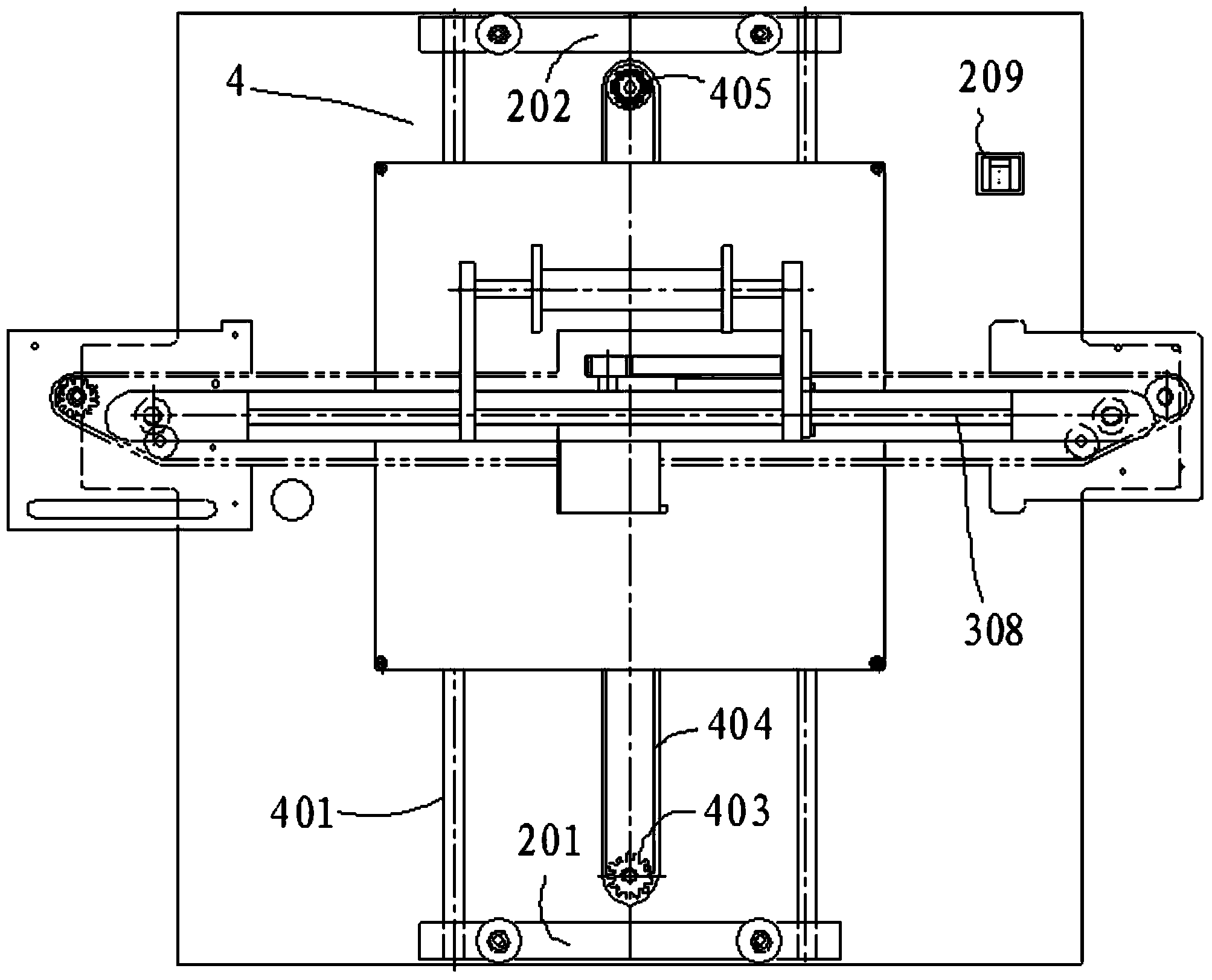

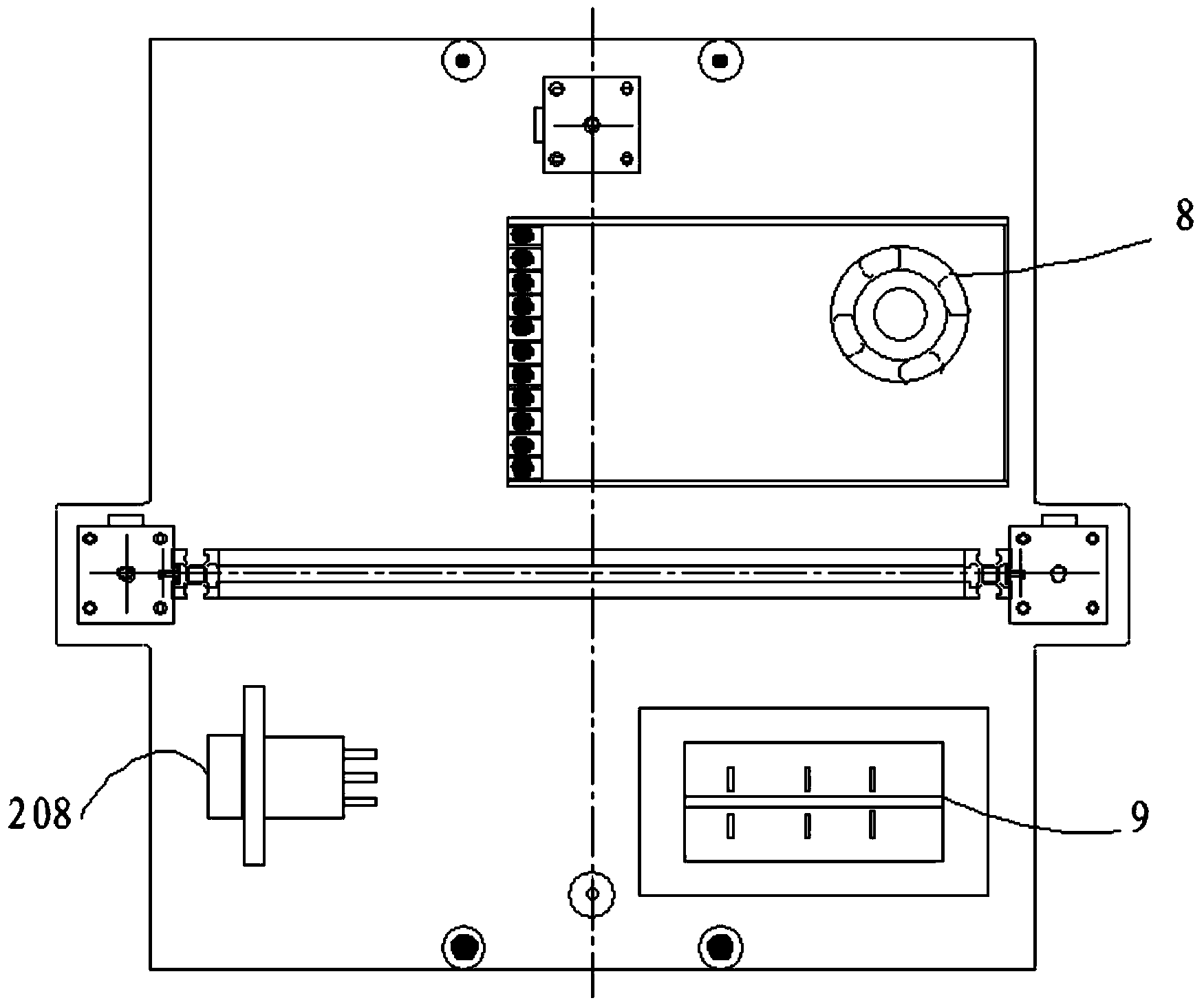

[0039] Such as Figure 1 to 12 As shown, a 3D printer includes a frame 1, a base 2, an X-axis movement system 3, a Y-axis movement system 4, a Z-axis movement system 5, and a printing device 6. The frame 1 includes left uprights on the left and right sides. 101, the right column 102 and the lower connecting plate 103, the upper connecting plate 104, the lower connecting plate 103 and the upper connecting plate 104 are respectively connected to the left column 101 and the right column 102, the base 2 is connected to the lower connecting plate 103, and the upper connecting plate 104 is connected to the printing consumables connection frame 7, and the printing consumables connection frame 7 is provided with a printing consumables fixed plate 701, the printing device 6 is connected to the X-axis moving sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com