Combination unit, production line and method for pipe crescent notch punching

A production line and pipe technology, which is applied in the field of pipe crescent notches punching combined units, can solve the problems of uneven gap between pipes and intersecting lines, high labor intensity, early positioning, and low sizing efficiency, etc., to improve processing efficiency and High quality, high degree of equipment automation, and the effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

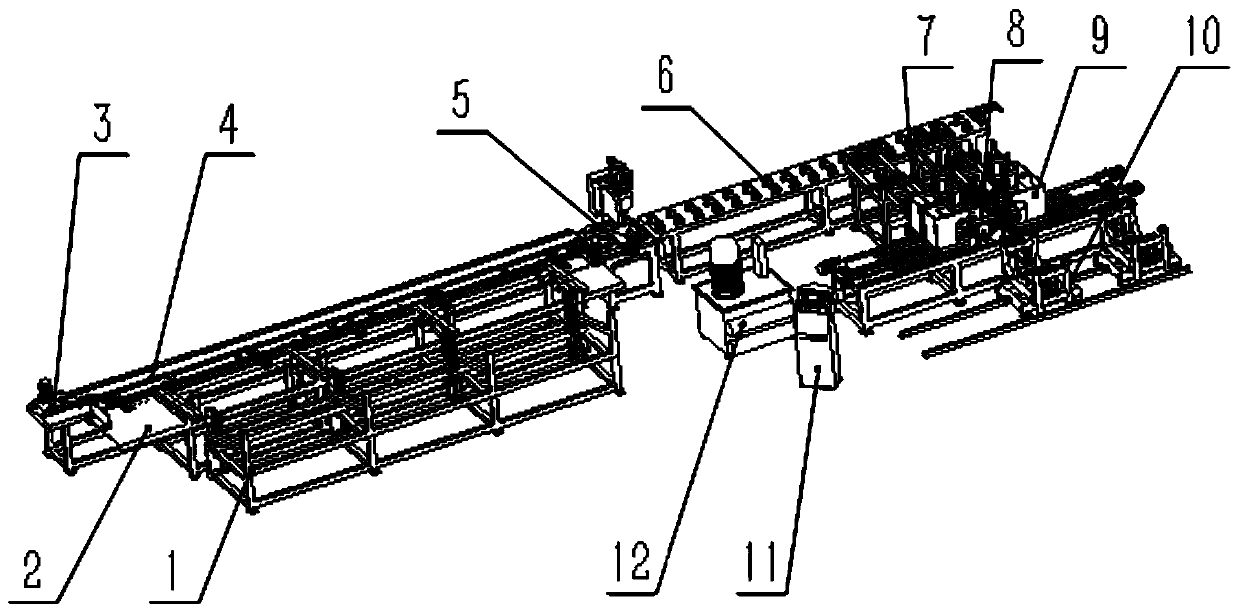

[0037] The pipe material crescent notch punching combination unit is used in this embodiment for super-long round pipes, and the super-long round pipes generally refer to round pipes with a length of more than six meters, including a cutting mechanism, a power rolling mechanism and a punching mechanism arranged in sequence , the punching mechanism is also provided with a turning mechanism, the punching mechanism has at least 2 stations, the turning mechanism is arranged between the 2 stations, when cutting the super long round tube, the cutting mechanism The super-long round tube is cut; after cutting, the super-long round tube enters the punching mechanism through the power rolling mechanism, and the execution end of the punching mechanism can divide the super-long round tube into two stations for punching.

[0038] Further, the turning mechanism includes a power part and an execution part, the power part is connected to and drives the execution part, the execution part includ...

Embodiment 2

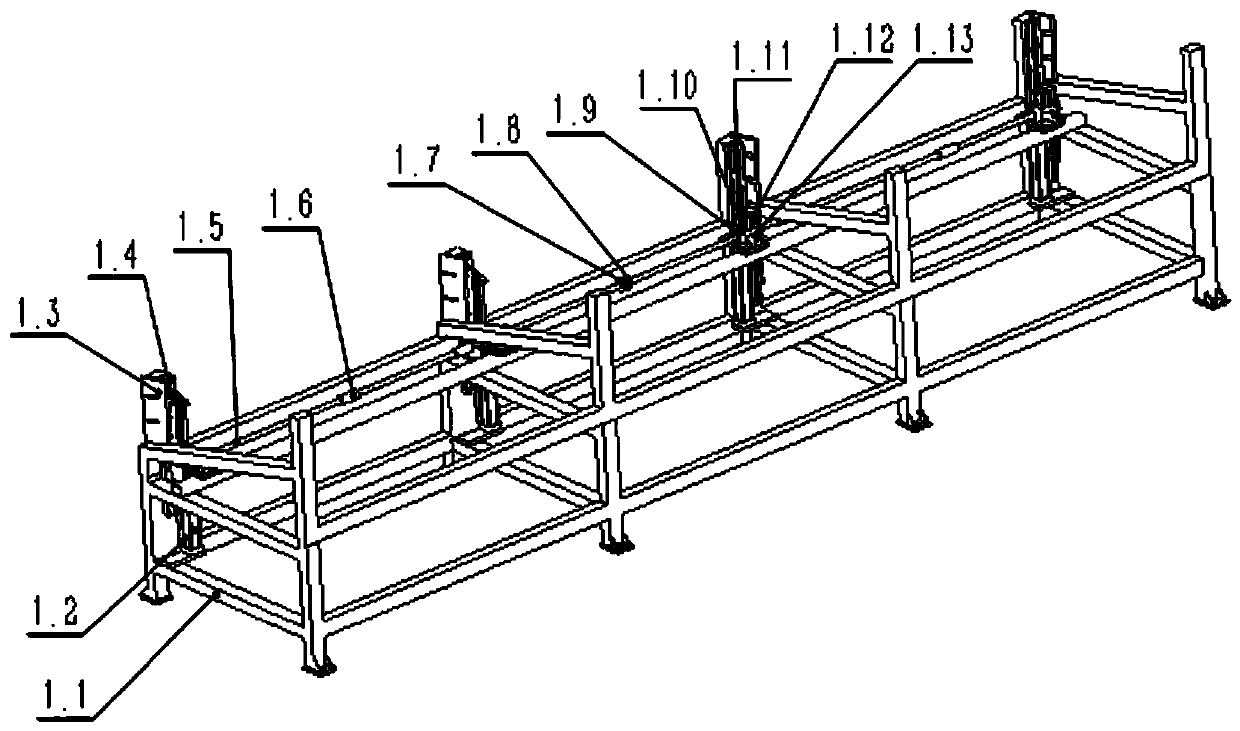

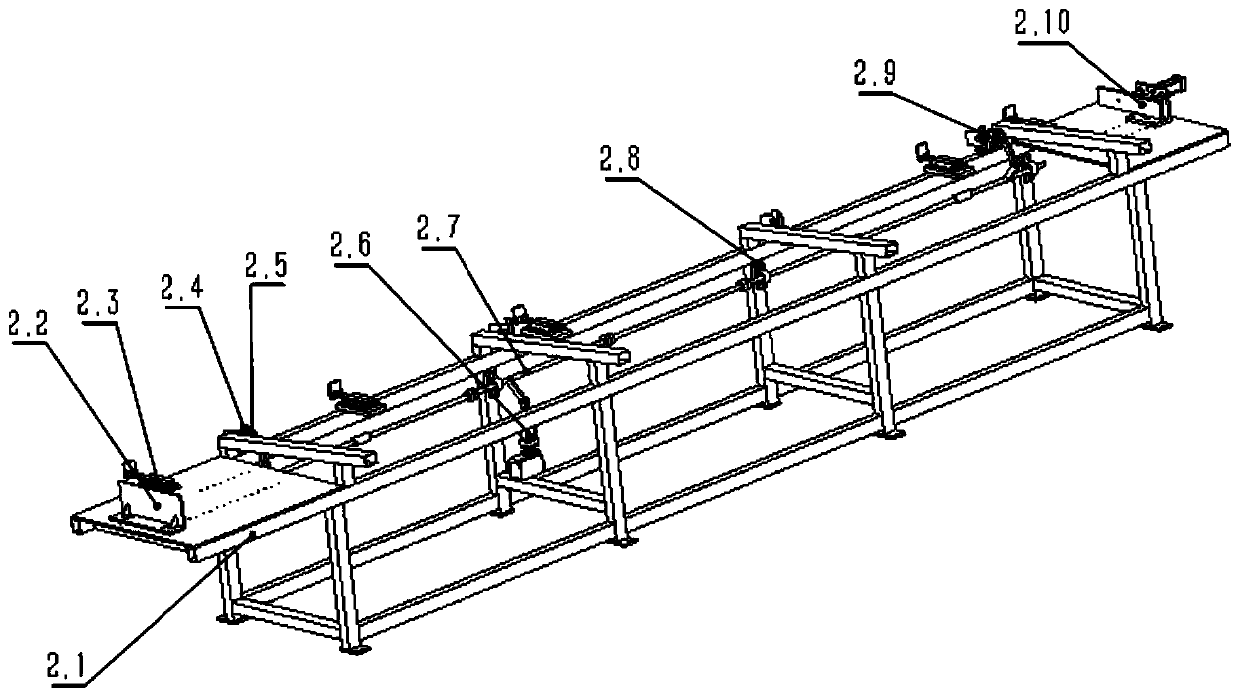

[0044] Embodiment 2 discloses an ultra-long circular pipe crescent notch punching combination production line, including the pipe material crescent notch punching combination unit as described in embodiment 1, and also includes a feeding mechanism, a material sorting mechanism, a feeding mechanism, a clamping mechanism, a positioning Mechanism and controller, the feeding mechanism, material sorting mechanism, and feeding mechanism are arranged in sequence, the clamping mechanism and positioning mechanism are arranged on both sides of the feeding mechanism, and the controller is connected to the feeding mechanism , Material handling mechanism, feeding mechanism, clamping mechanism and positioning mechanism, the round tube can roll along the feeding mechanism in rows to the feeding mechanism.

[0045] The feeding mechanism is a flexible feeding mechanism. The feeding assembly includes a feeding frame and a guide rail arranged on the frame. The sports car is installed on the guide...

Embodiment 3

[0057] Embodiment 3 discloses a super-long circular tube crescent notch blanking method based on Embodiment 2, comprising the following steps:

[0058] 1) The feeding mechanism is started, and the pipe is automatically loaded;

[0059] 2) A plurality of pipes enter the material handling frame, and the feeder moves the plurality of pipes to the feeding mechanism at the same time, and the plurality of pipes enter the feeding mechanism, and the clamping mechanism clamps the pipes;

[0060] 3) The cutting mechanism cuts the pipe;

[0061] 4) The cut round tube falls into the power rolling mechanism, driven by the power rolling mechanism to continue to move to the silo, the first station of the punching mechanism performs punching, and the round tube passes through the turning mechanism Flip over, the second station of the punching mechanism punches out;

[0062] 5) After the pipe processing is completed, the material is dropped to the finished product silo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com