Method for preparing sacubitril intermediate in continuous flow microreactor

A micro-reactor, sacubitril technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, organic chemical methods, etc., can solve the problems of low efficiency, low yield, low purity, etc. The effect of good selectivity, high reaction yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

[0051] (1) Preparation of material a solution: Compound II (100 kg, 305.42 mol, 1.0 Eq.) And TEMPO (9.54 kg, 61.06 mol, 0.20 Eq.) Were dissolved in dichloromethane (680 kg);

[0052] (2) Preparation of Material B Solution: Sodium bicarbonate (38.48 kg, 458.12 mol, 1.5 Eq.) And sodium bromide (1.88 kg, 18.27 mol, 0.06 Eq.) Were dissolved in water (600 kg);

[0053] (3) Material C solution: aqueous solution of sodium hypochlorite, the measurement content is: 9.6%;

[0054] (4) Preparation of the material D solution: Water (200 kg), dichloromethane (132.5 kg), and etched by Ethoxyethyl triphenylphosphine (110 kg, 305.42 mol, 1.0 Eq) were added. ) And sodium thiosulfate (15.16 kg, 61.08 mol, 0.2 Eq.), Stirring and cooling to 0 to 5 ° C;

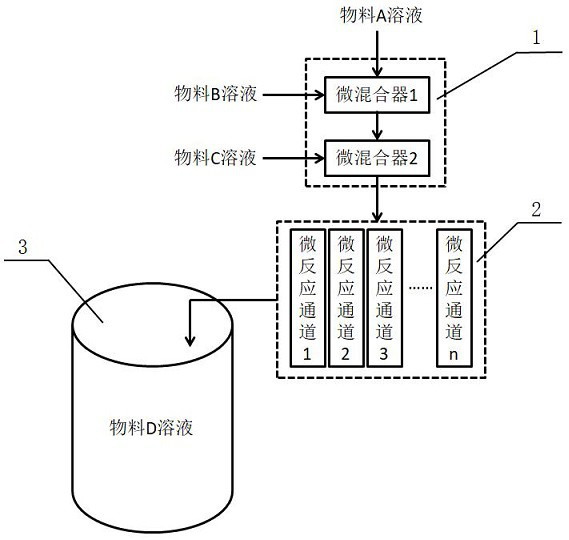

[0055] (5) First mix the material A solution and the material B in the microcomputer 1, and the residence time is 4 to 6 s, and then mixed with the material C solution in the micro-mixer 2, the residence time is 3 ~ 5 s, then Entering the ...

Embodiment 2

[0060]

[0061] (1) Preparation of material a solution: Compound II (100 kg, 305.42 mol, 1.0 Eq.) And TEMPO (2.39 kg, 15.27 mol, 0.05 Eq.) Were dissolved in dichloromethane (680 kg);

[0062] (2) Preparation of material B solution: sodium carbonate (32.36 kg, 305.37 mol, 1.0 Eq.) And sodium bromide (1.57 kg, 15.225 mol, 0.05 eq.) Were dissolved in water (600 kg);

[0063] (3) Material C solution: aqueous solution of sodium hypochlorite, the measurement content is: 8.3%;

[0064] (4) Preparation of material D solution: Water (200 kg), dichloromethane (132.5 kg), and etched by Ethoxyethyl triphenylphosphine (94 kg, 259.61 mol, 0.85 Eq) were added. ) And sodium thiosulfate (15.16 kg, 61.08 mol, 0.2 Eq.), Stirring and cooling to 0 to 5 ° C;

[0065] (5) The material A solution and the material B solution are mixed in the micromixer 1, and the residence time is 3 to 5 s, and then mix with the material C solution in the microcomputer 2, the residence time is 2 to 6 s, then Entering th...

Embodiment 3

[0070]

[0071] (1) Preparation of Material a solution: Compound II (100 kg, 305.42 mol, 1.0 Eq.) And TEMPO (23.85 kg, 152.65 mol, 0.5 Eq.) Were dissolved in isopropyl acetate (700 kg);

[0072] (2) Preparation of material B solution: sodium bicarbonate (30.79 kg, 366.50 mol, 1.2 Eq), sodium carbonate (9.71 kg, 91.61 mol, 0.3 Eq.) And sodium bromide (15.67 kg, 152.27 mol, 0.5) EQ.) dissolved in water (800 kg);

[0073] (3) Material C solution: aqueous sodium hypochlorite, 8.3% measurement content;

[0074] (4) Preparation of the material D solution: water (300 kg), isopropyl acetate (135 kg), ankyl acetyl group (121 kg, 610.83 mol, 2.0 Eq) And sodium thiosulfate (15.16 kg, 61.08 mol, 0.2 Eq.), Stirring is lowered to 0 to 5 ° C;

[0075] (5) The material A solution and the material B solution are mixed in the micromixer 1, and the residence time is 1 to 5 s, and then mixed with the material C solution in the microcomputer 2, the residence time is 1 ~ 5 s, then Entering the micror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com