A multi-size automatic fixed-pitch forming wood finger jointing machine

A multi-size, finger-joining machine technology, applied in the field of wood processing, can solve the problems that the joints cannot be evenly distributed, the size of the finger-joining machine is large, and the space occupied is large, so as to improve the quality of splicing, the equipment structure is compact, and the space is occupied. The effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

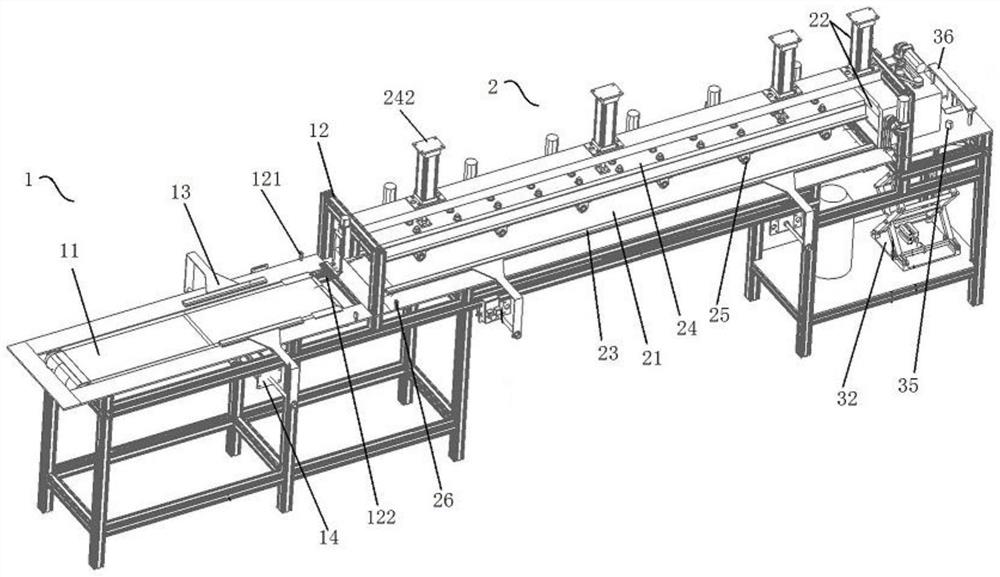

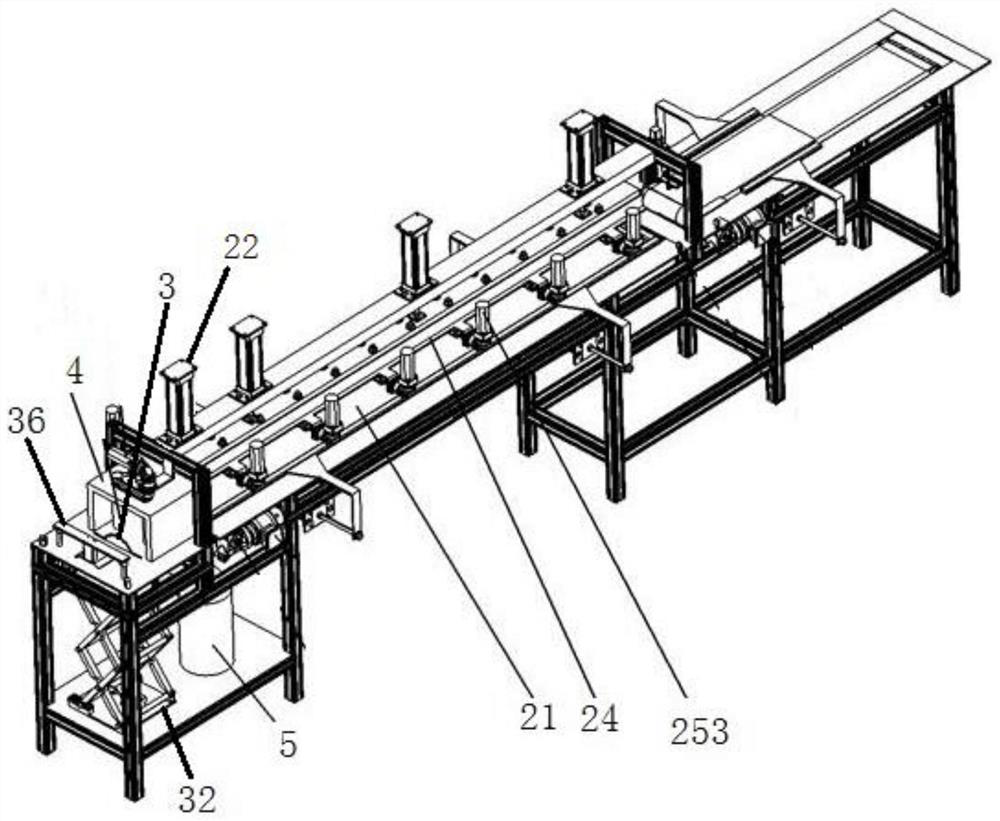

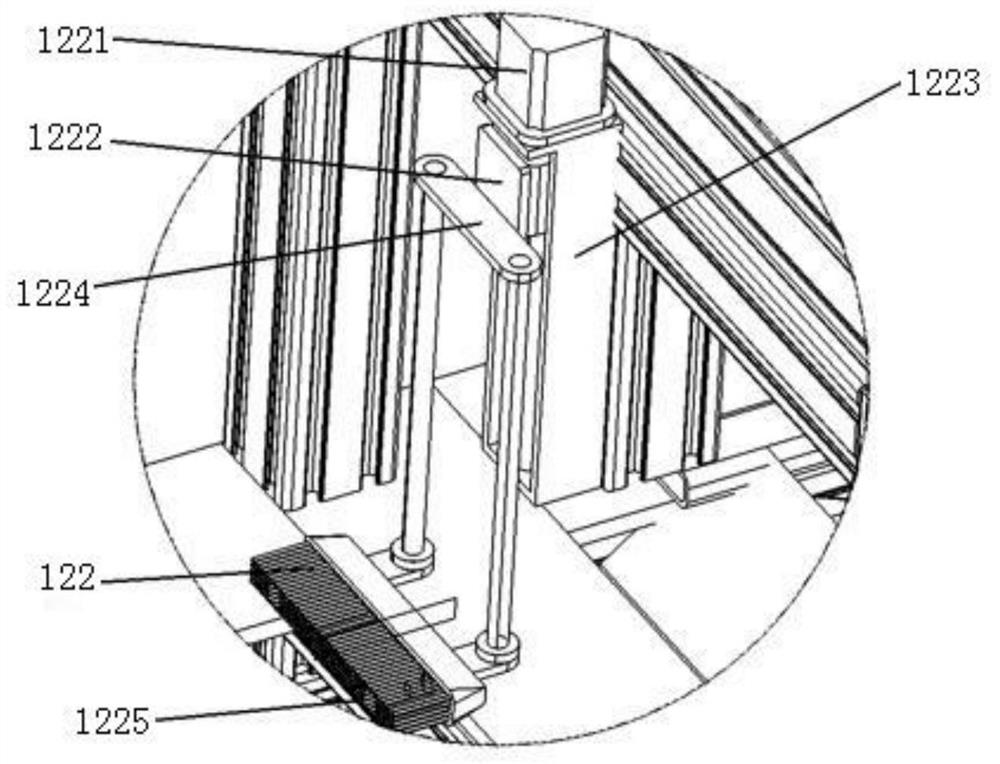

[0036] Example. A multi-size automatic fixed-pitch forming wood finger jointing machine, which is composed of Figure 1-Figure 9 As shown in the figure, it includes a feeding and gluing device 1, and the end of the feeding and gluing device 1 is connected with a pressing device 2; the feeding and gluing device 1 includes a conveyor belt I11, and the end of the conveyor belt I11 is provided with a gluing mechanism 12. Both sides of the conveyor belt I11 There is also a pair of positioning and clamping side plates I13 that can move relative to each other; the pressing device 2 includes a conveyor belt II21, the head end of the conveyor belt II21 is connected with the gluing mechanism 12, the end is provided with a material stopper mechanism 22, and two sides are provided with a pair of The positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com