Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

601results about "Gripping devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

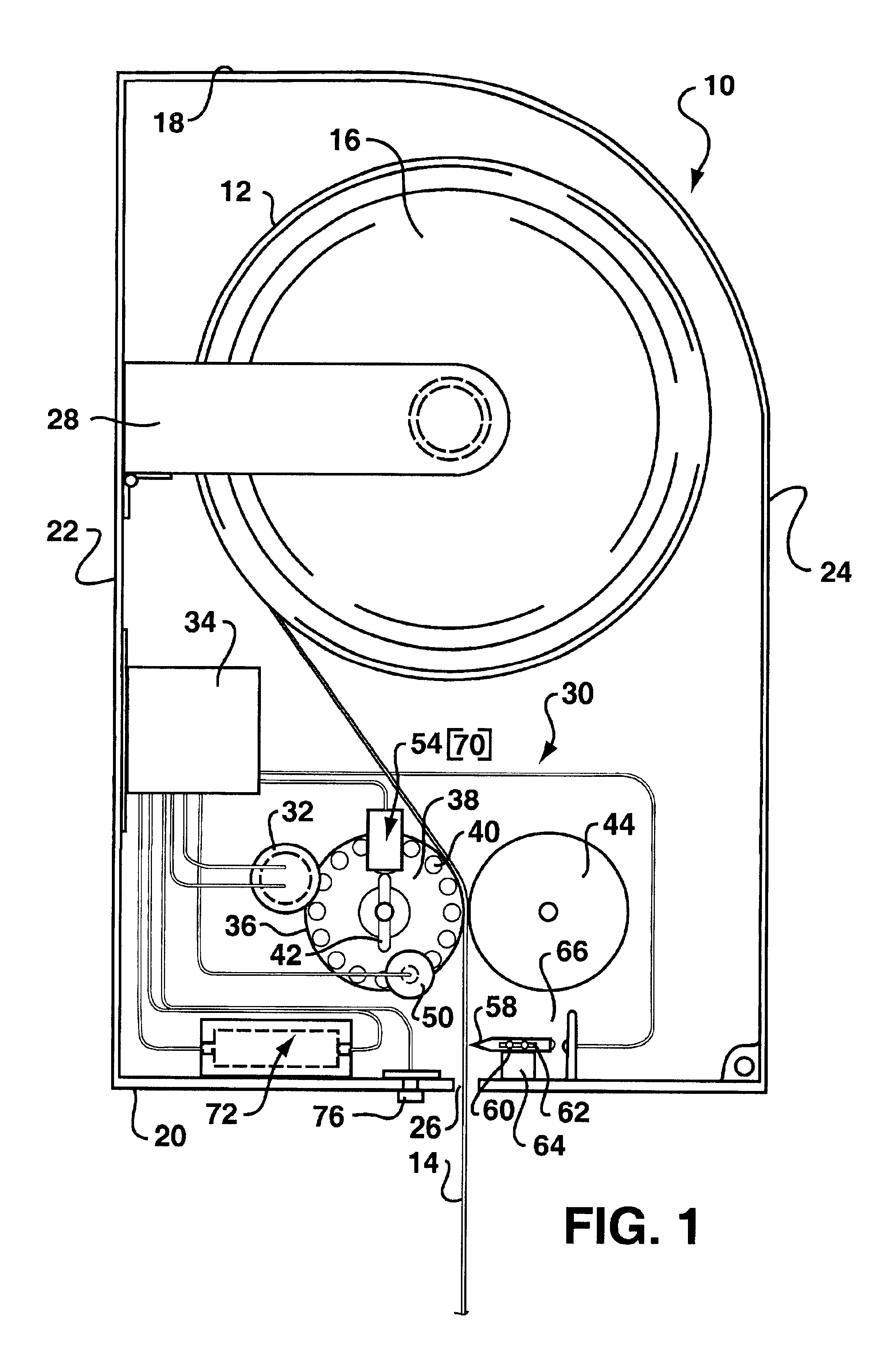

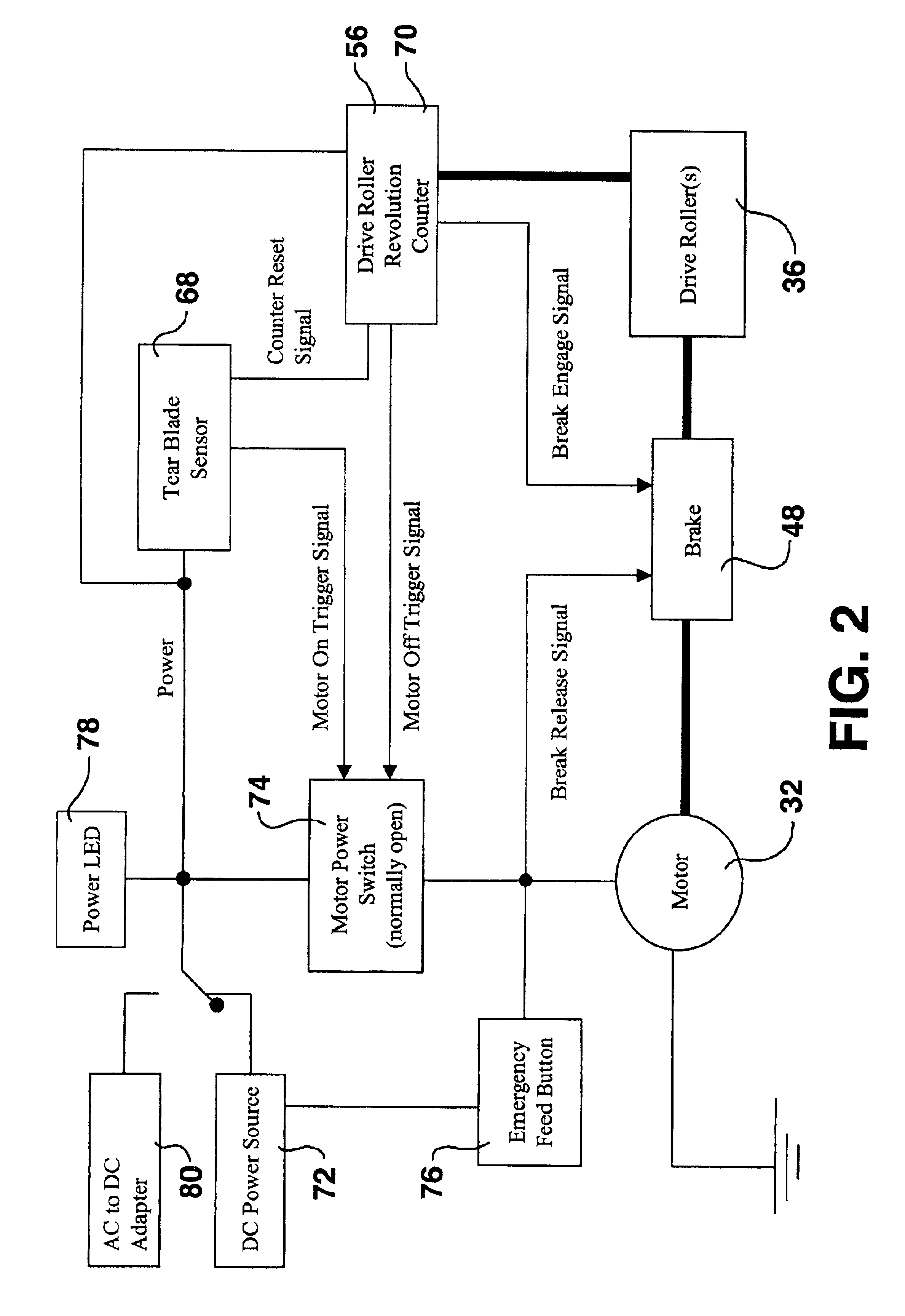

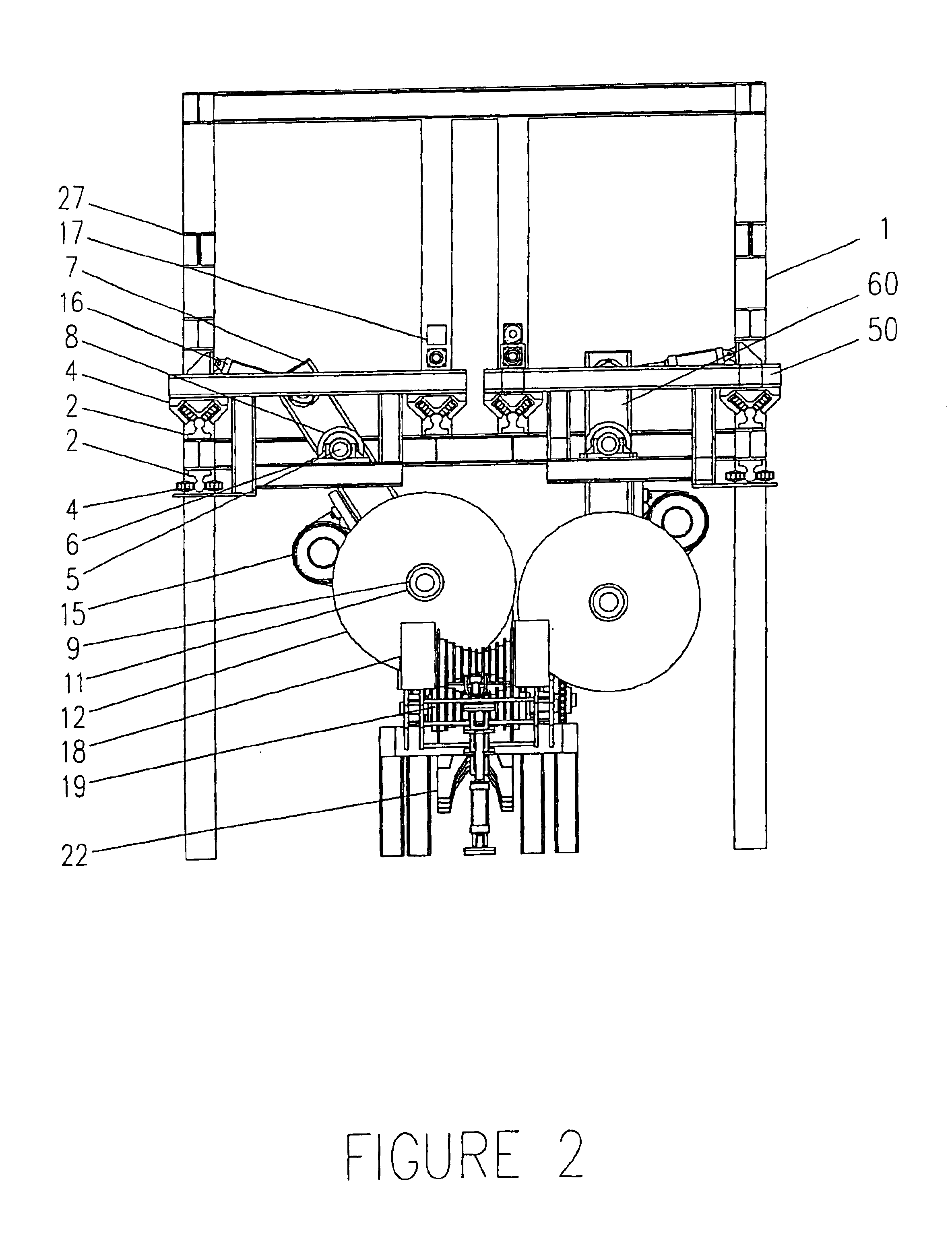

Electro-mechanical roll product dispenser

InactiveUS6892620B2Prevent further rotationFilament handlingGripping devicesFacial tissuePaper sheet

An electro-mechanical roll towel dispenser includes a housing with a roll carrier disposed therein to rotationally support a roll of towel material. An electro-mechanical feed mechanism is disposed in the housing to dispense measured sheets of the towel material. The feed mechanism operates in a first mechanical operational mode wherein the towel sheets are dispensed by a user grasping and pulling on a tail of the towel material extending from the housing, and a second electrical operational mode wherein a measured length of a next sheet is automatically and electrically fed out of the housing to define the tail for the next user.

Owner:KIMBERLY-CLARK WORLDWIDE INC

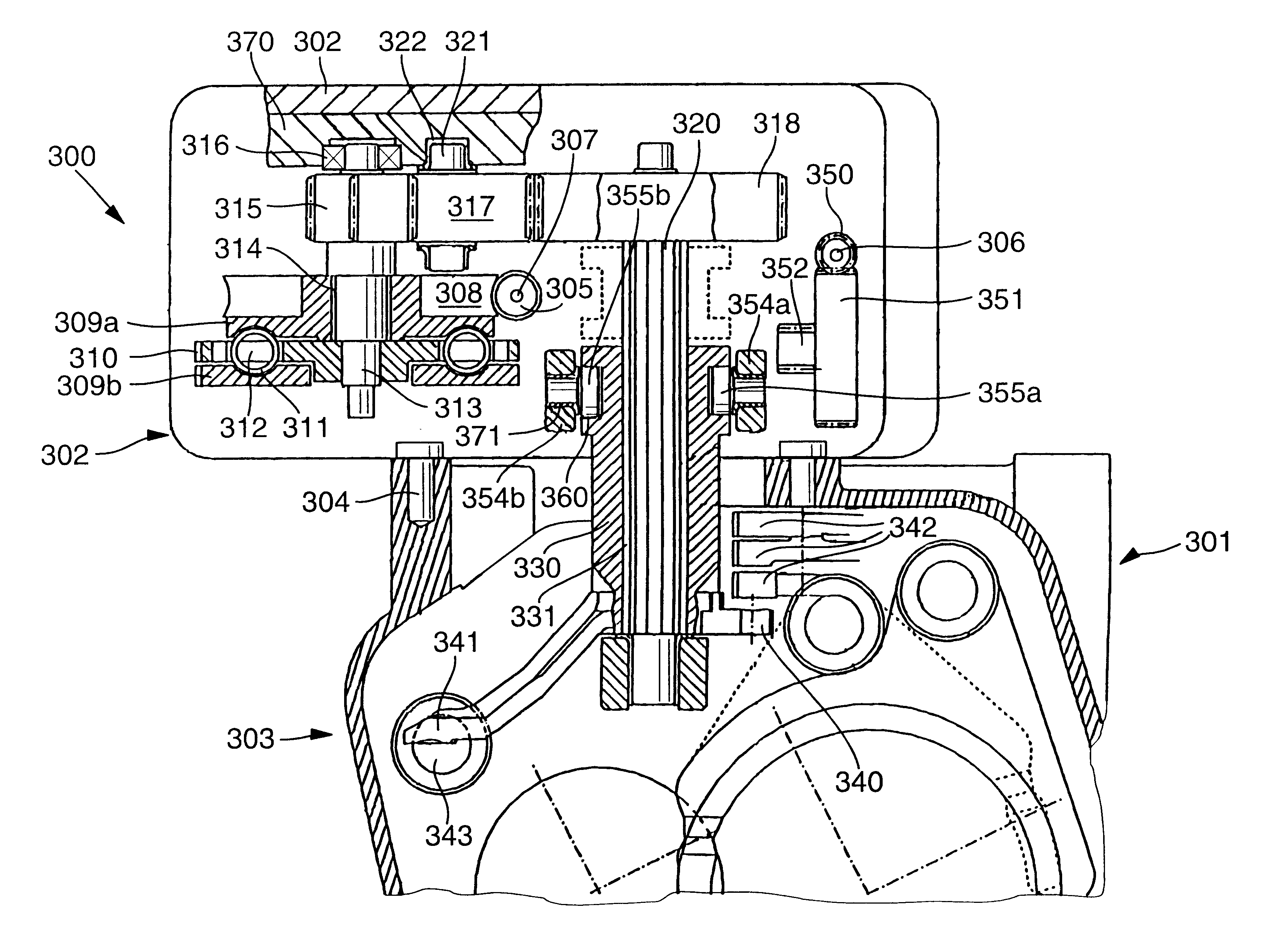

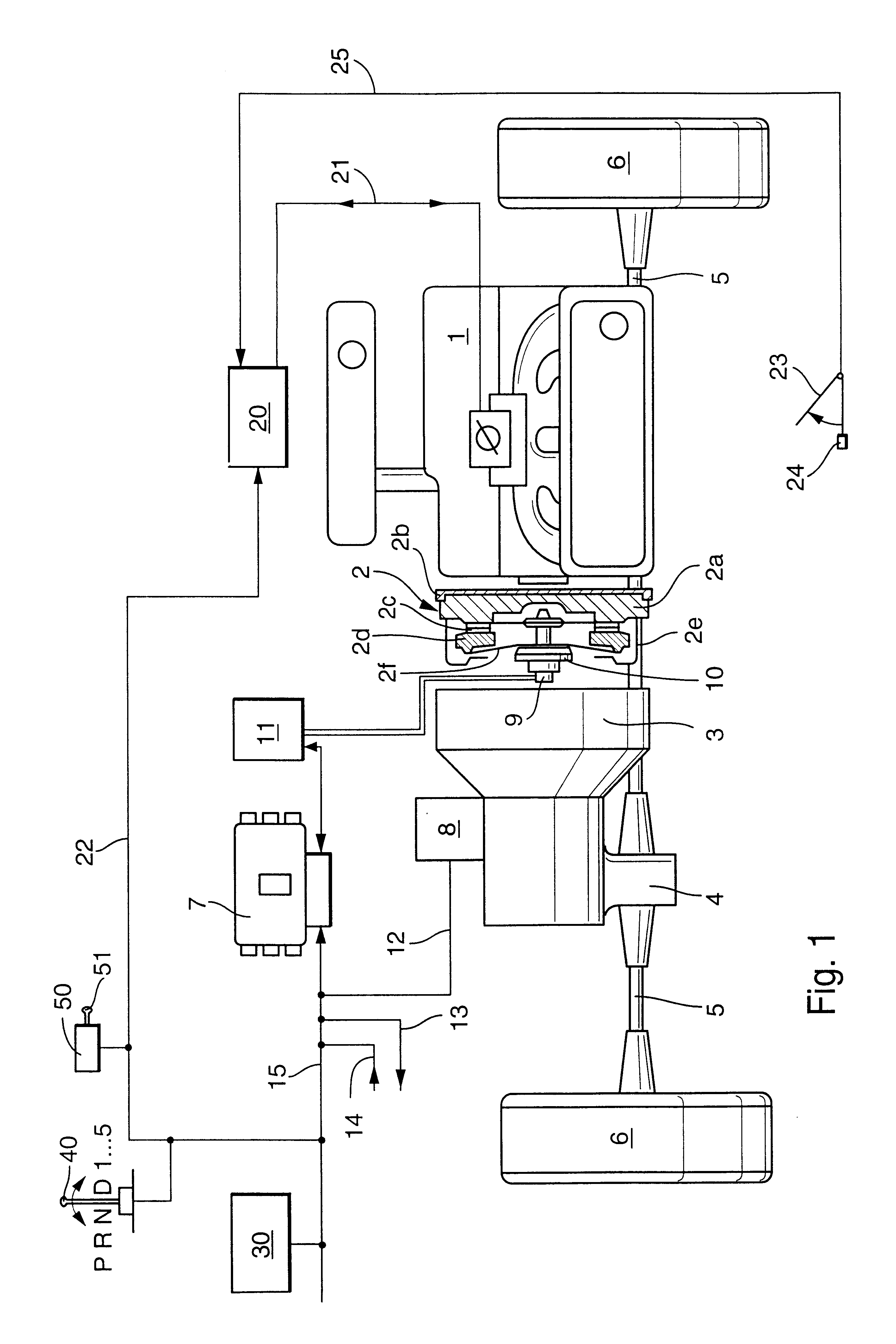

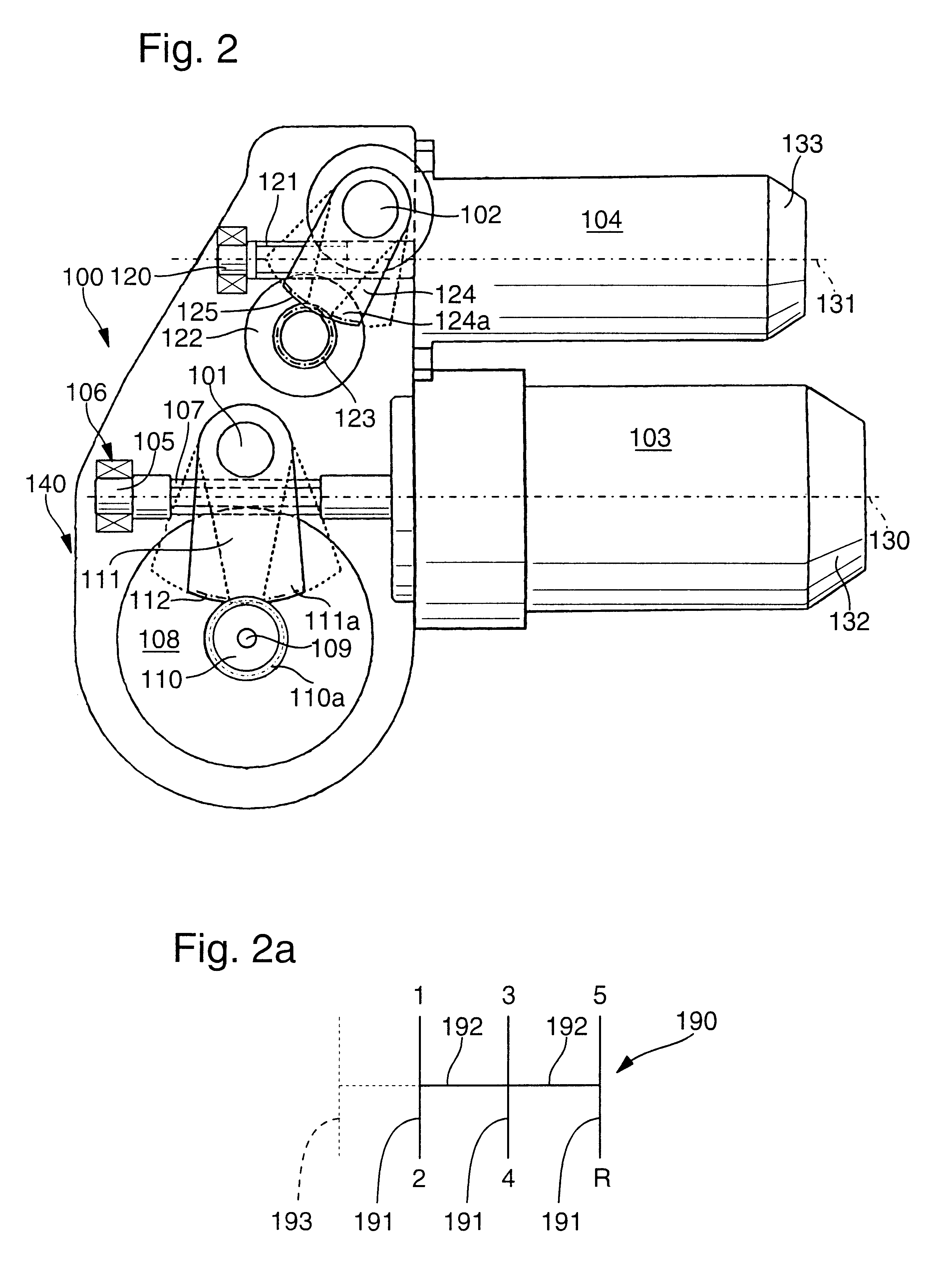

Actuating apparatus for automated constituents of power trains in motor vehicles

InactiveUS6327927B1Simple taskContributes comfort and safetyGripping devicesGearingMobile vehicleCombustion

A power train for us in a motor vehicle has a prime mover (such as a combustion engine), an automated gearbox which transmits torque to the wheels of the vehicle, a friction clutch between the prime mover and the gearbox, a computerized control unit which receives signals from several sensors, and one or more actuators which operate the clutch and / or the gearbox in response to signals from the control unit. The actuator for selecting the gear ratio of the gearbox and for shifting the gearbox into and from selected gears employs two transmissions each of which has a worm gearing receiving torque from a discrete electric motor of the actuator and a spur gearing which transmits motion from the respective worm gearing to a mobile component of the gearbox. The connection between the worm and spur gearings in at least one of the transmissions can comprise a damper cooperating with one or more sensors serving to transmit signals to the control unit.

Owner:LUK GETRIEBE SYST

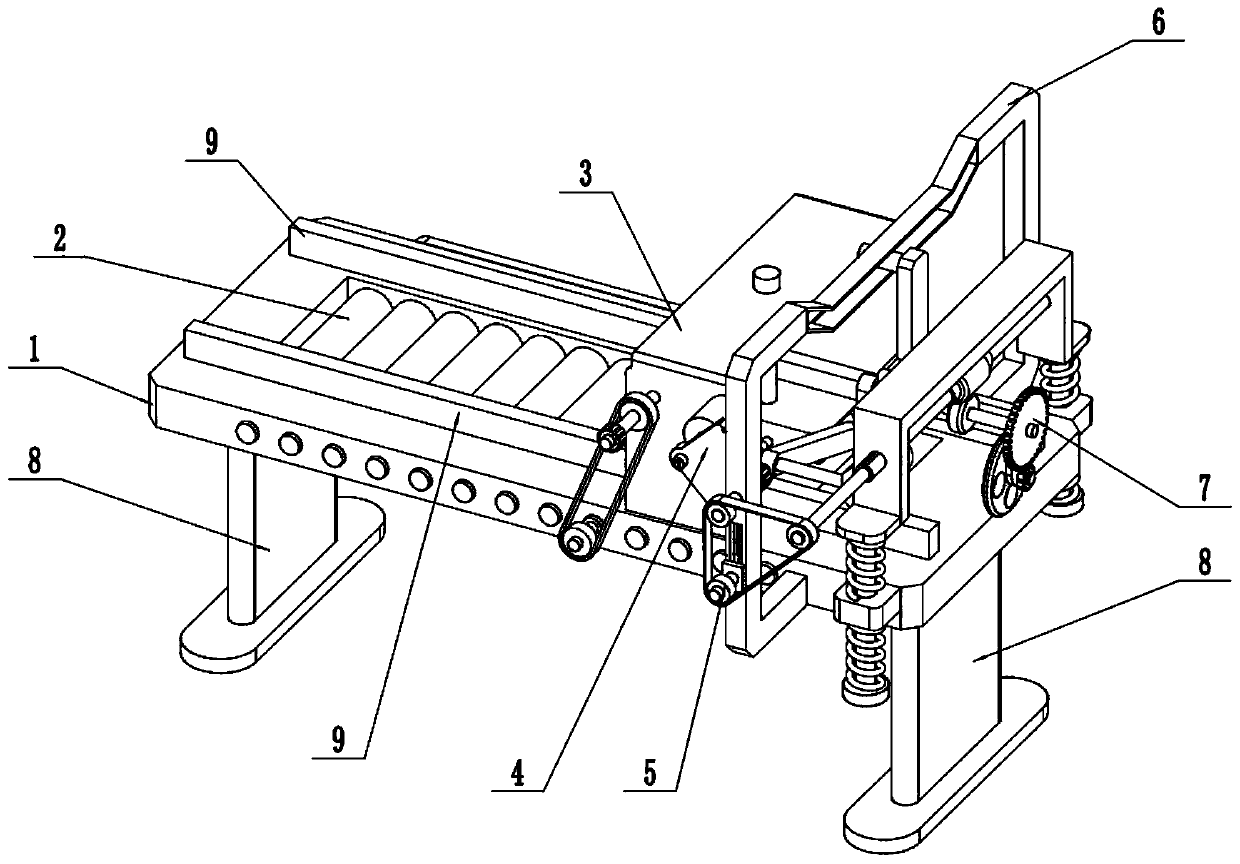

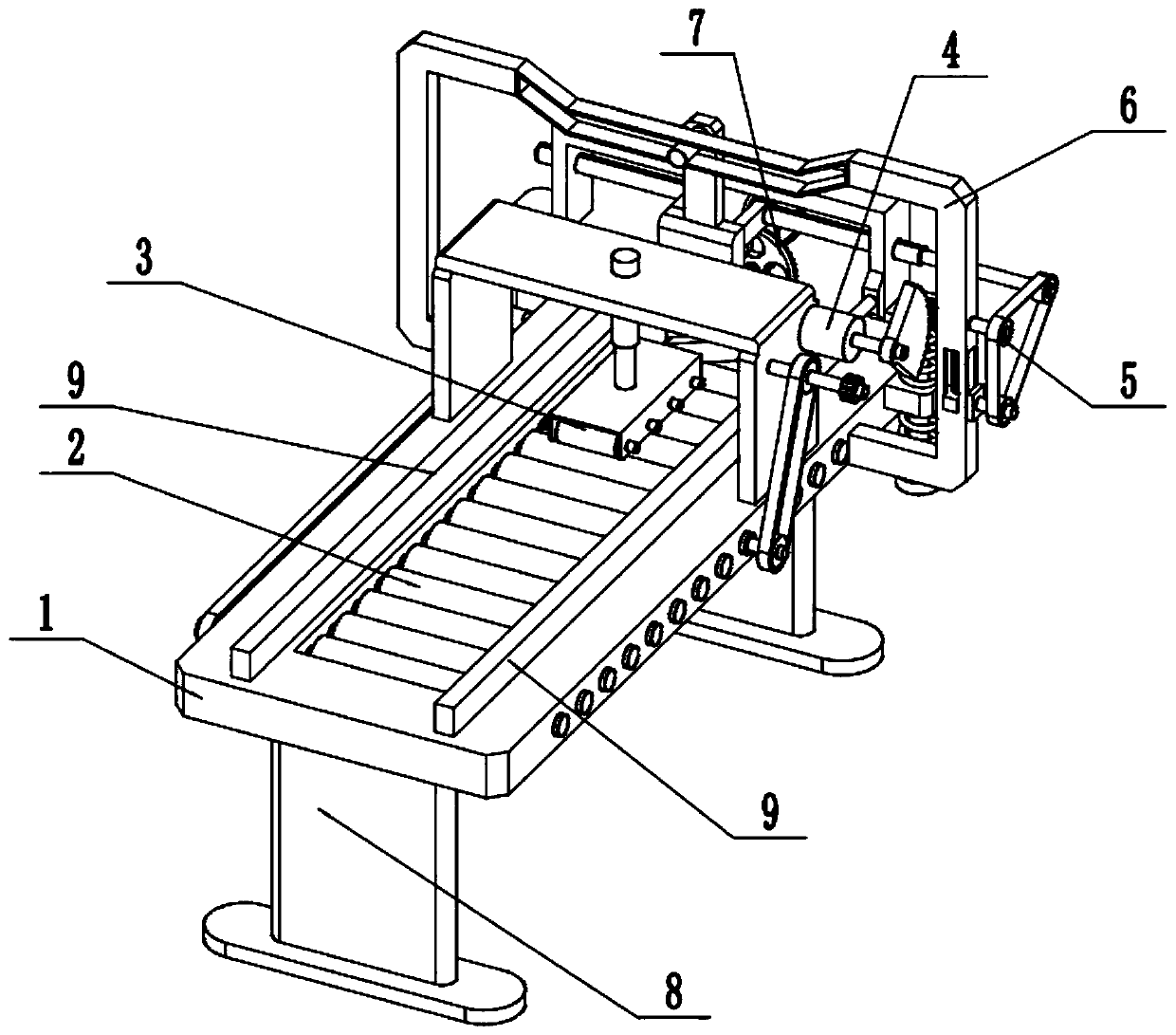

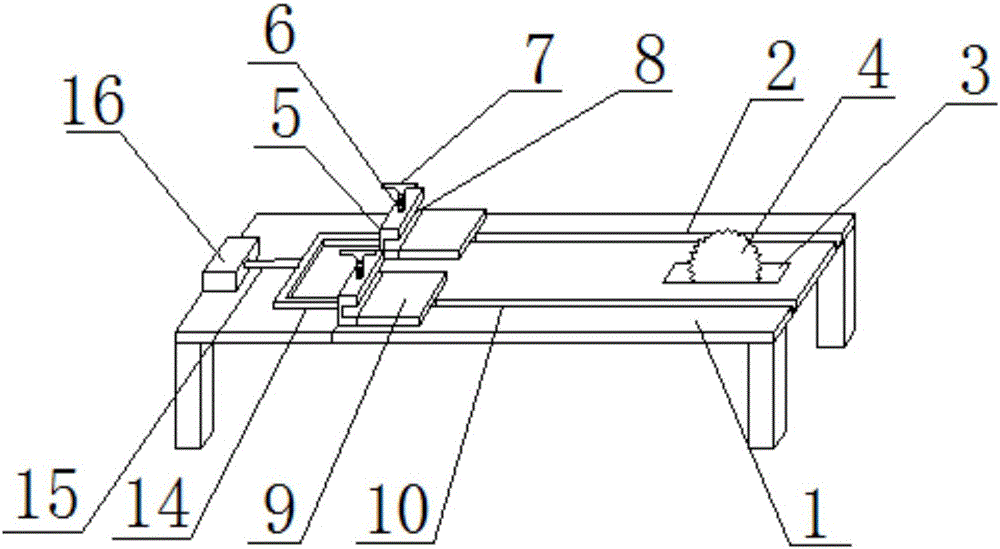

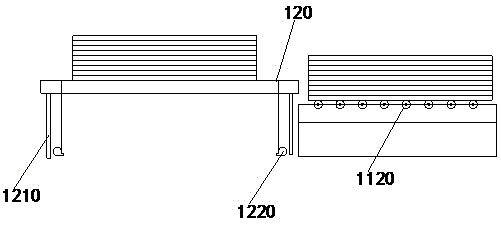

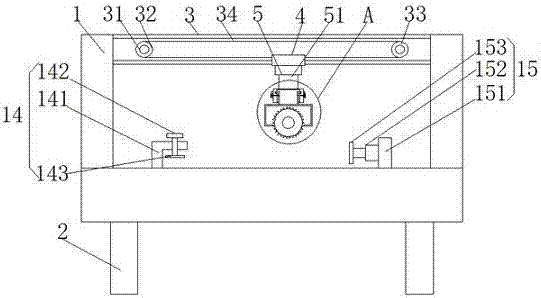

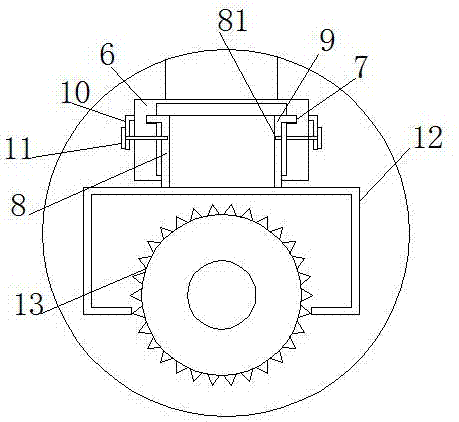

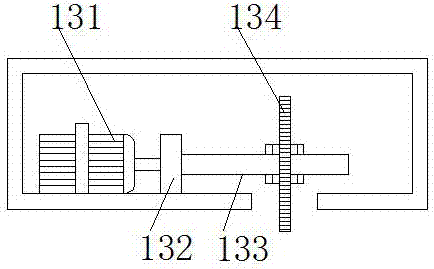

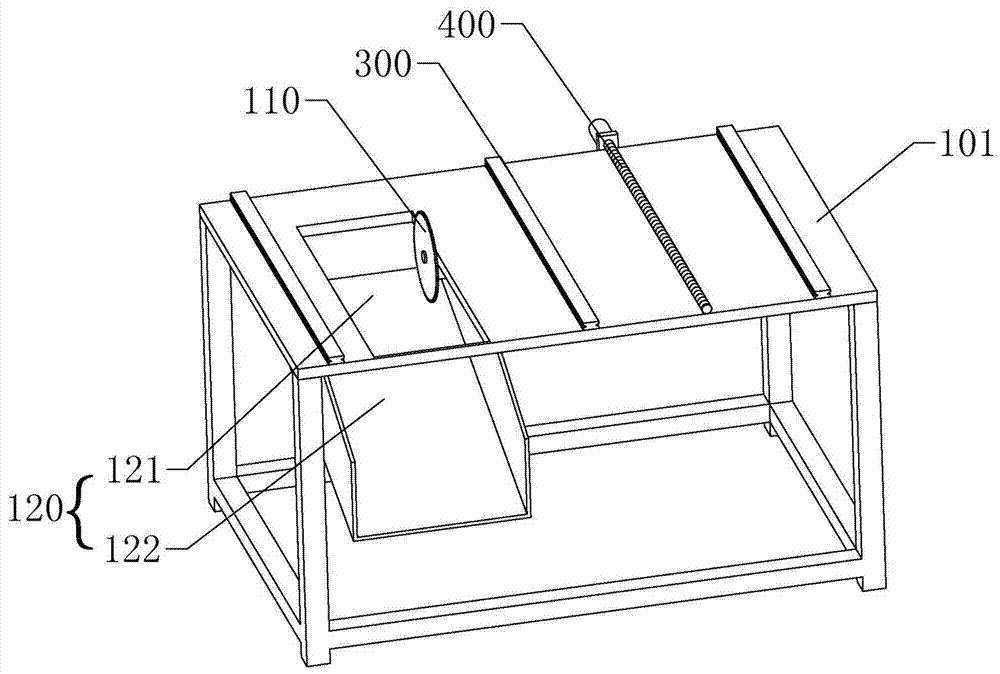

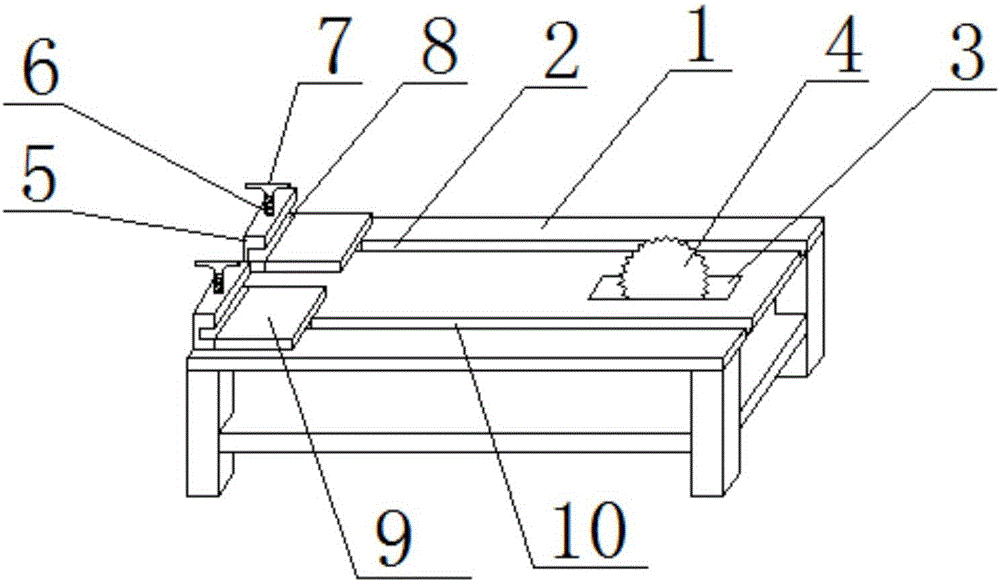

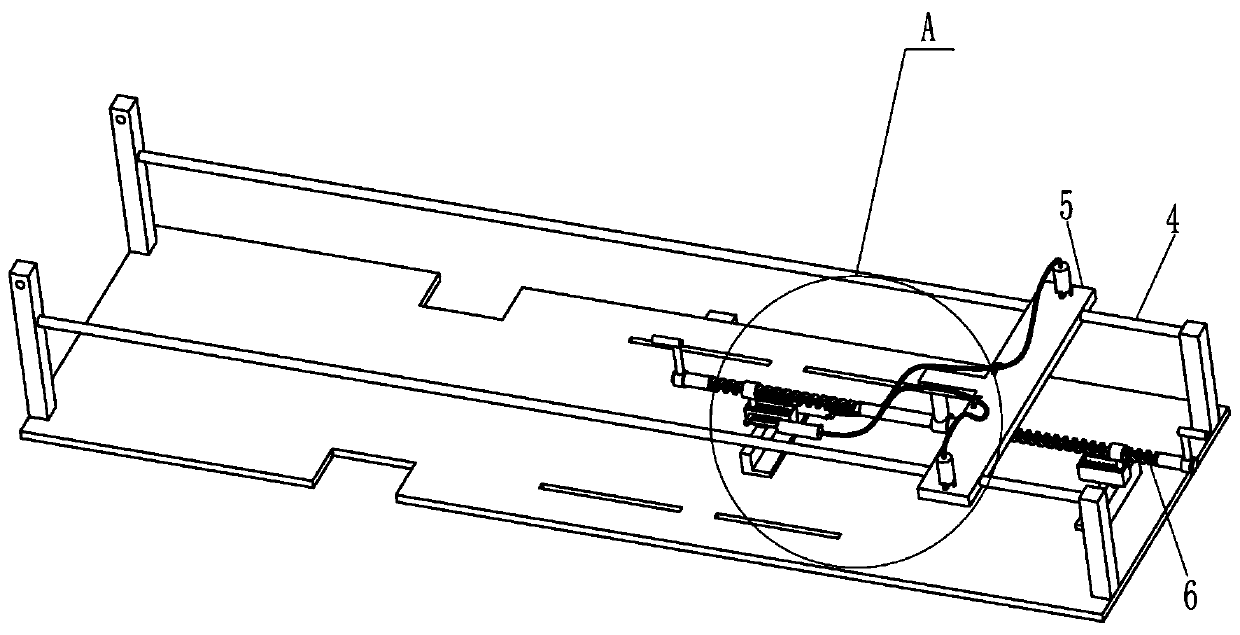

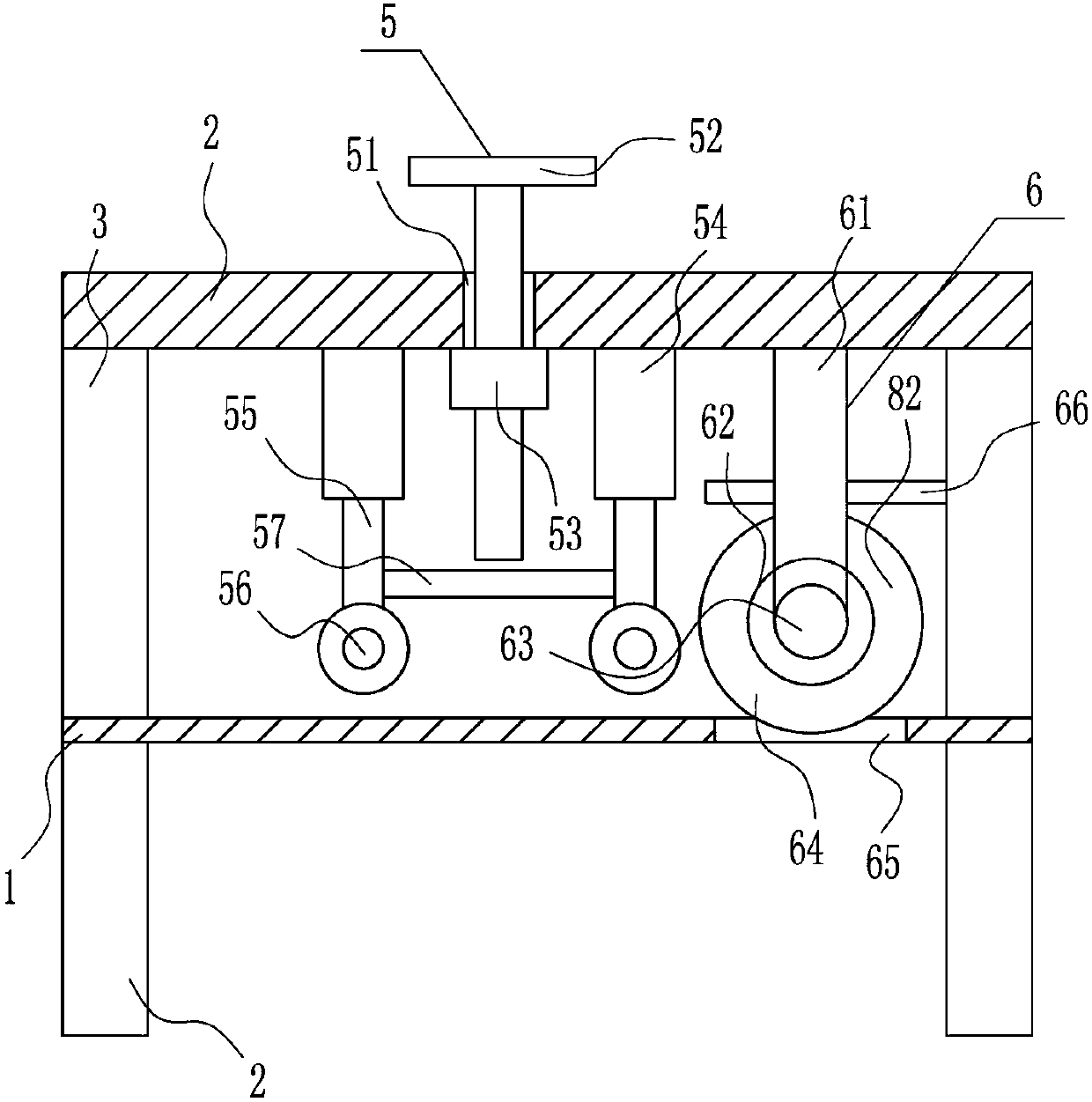

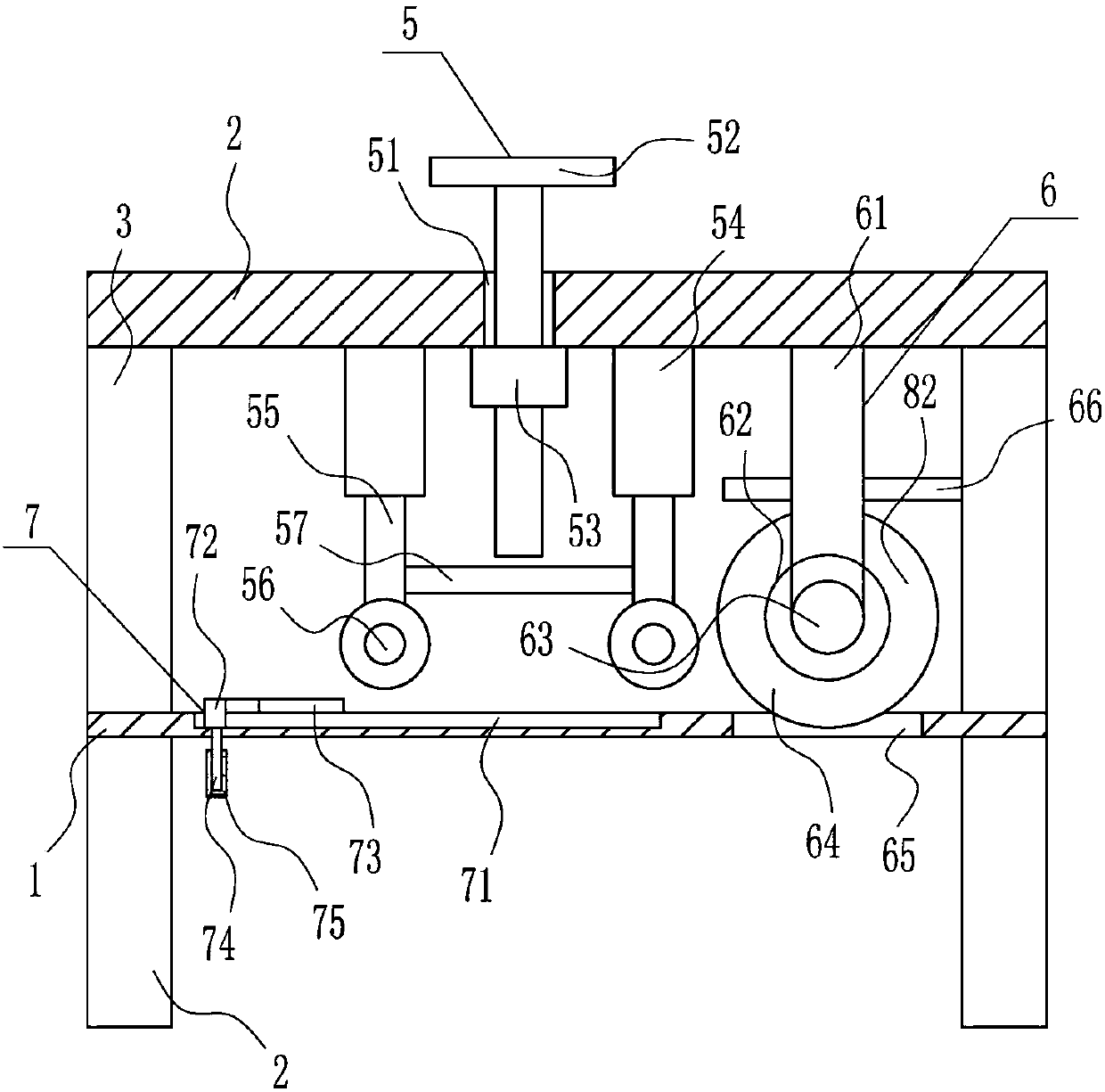

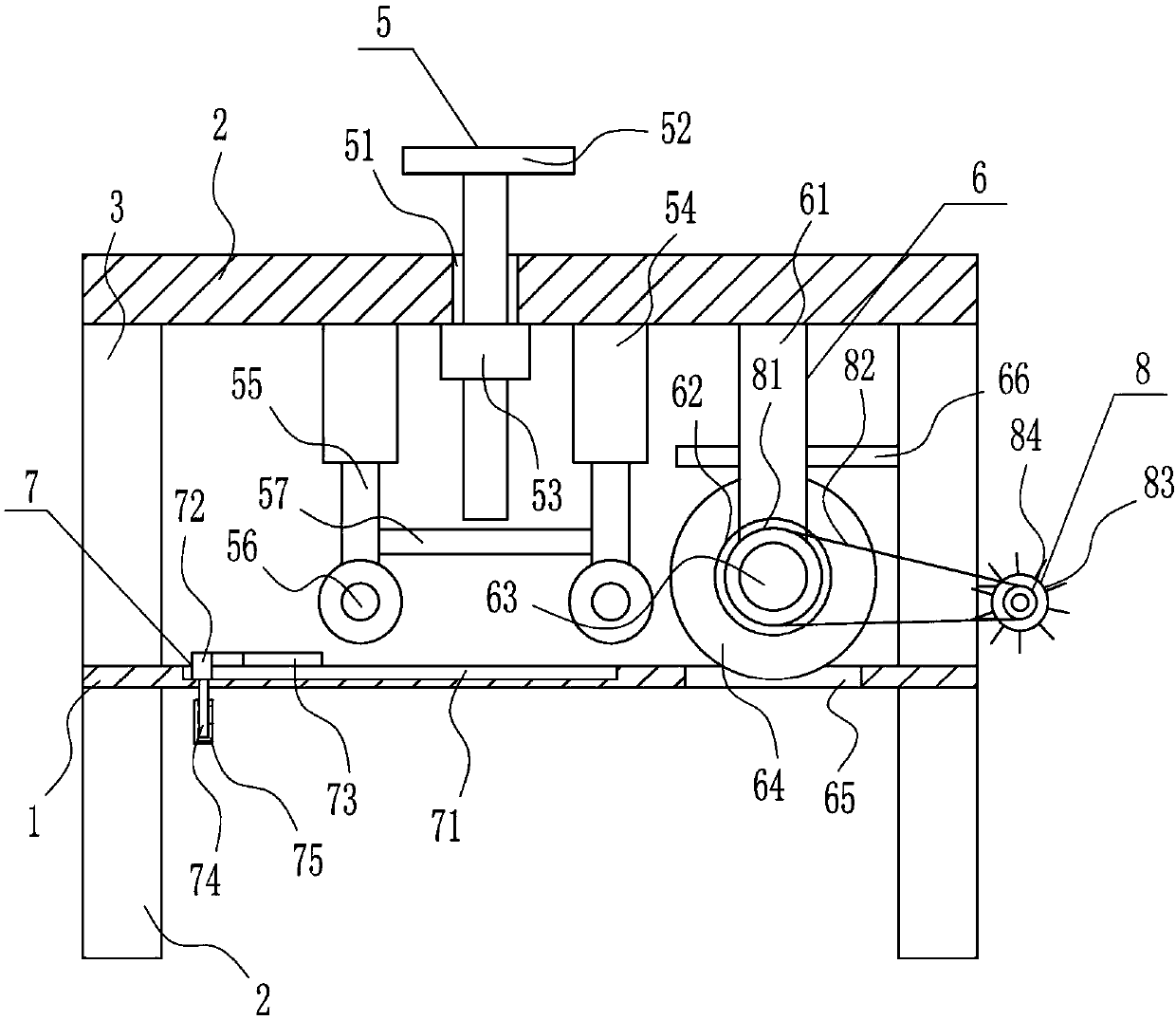

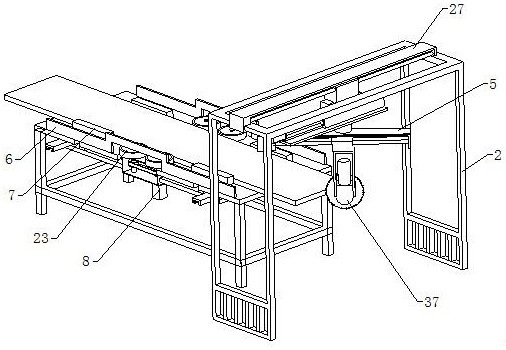

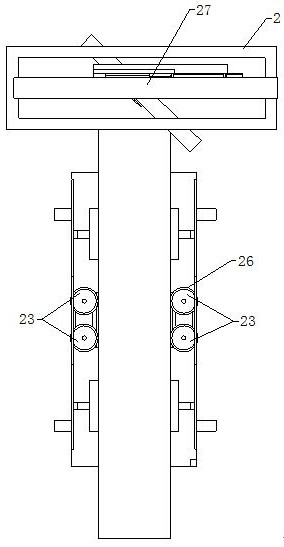

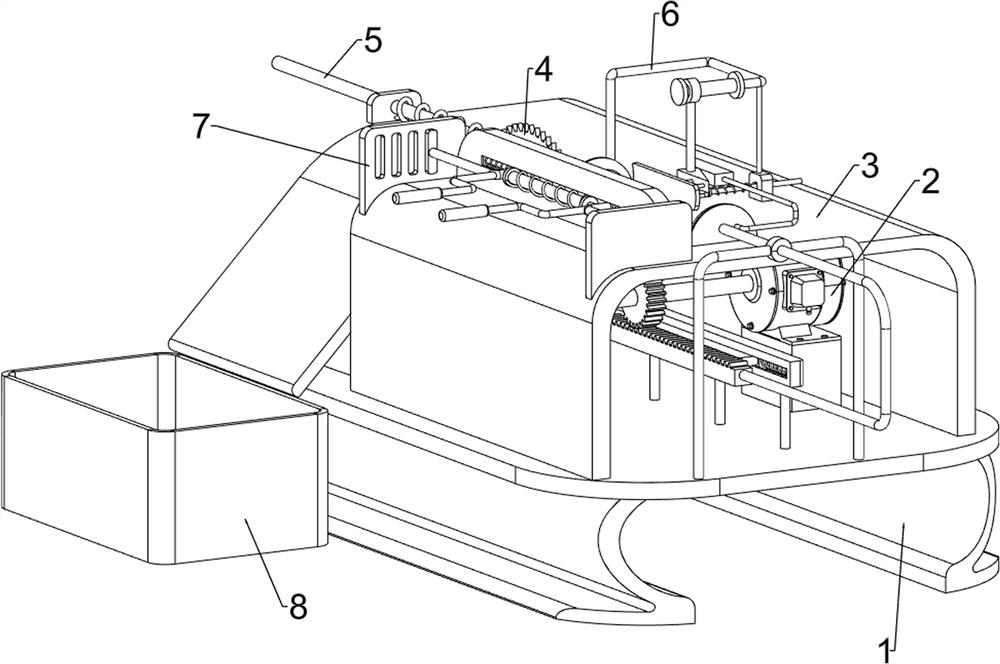

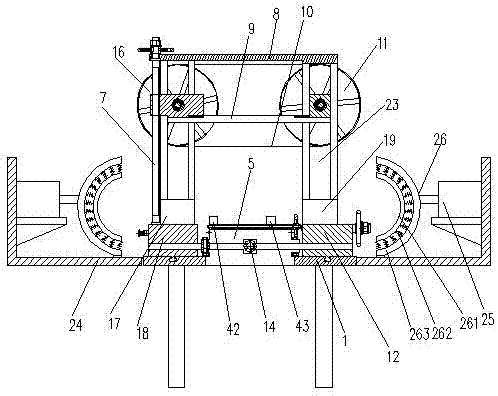

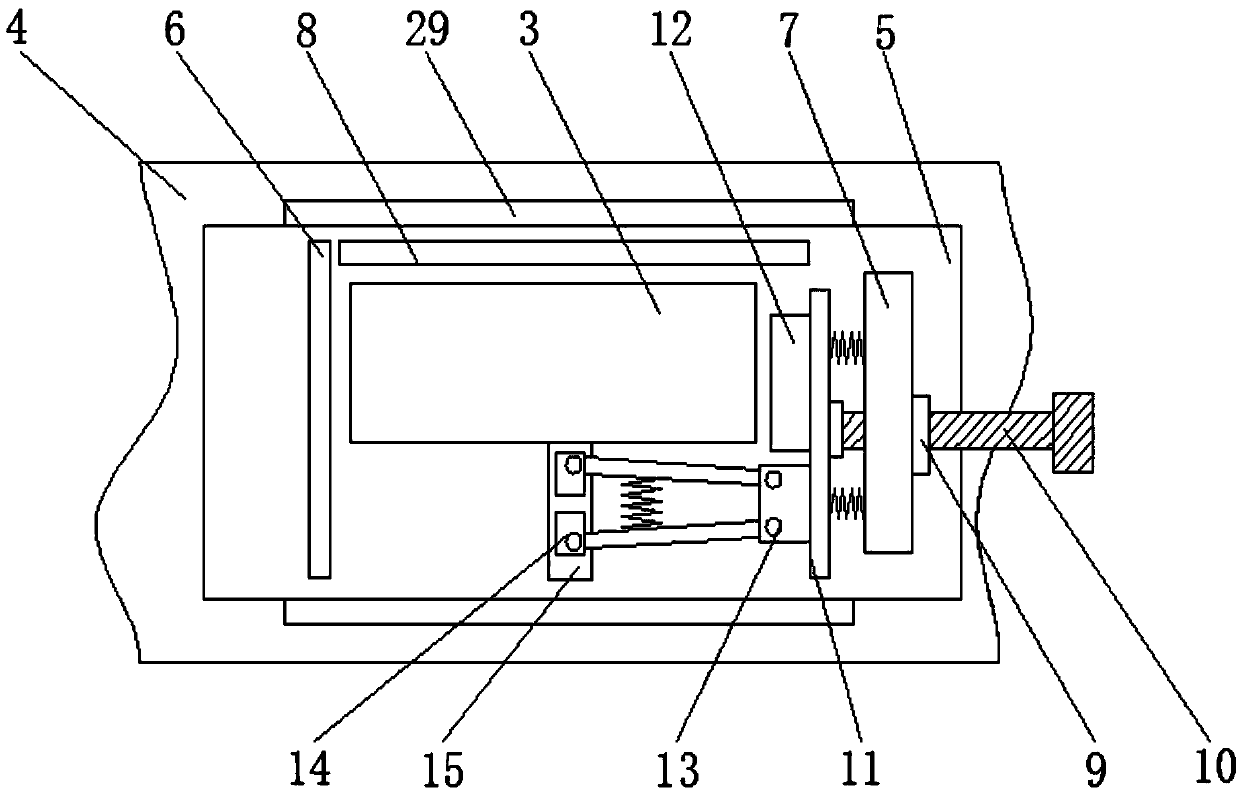

Wood board fixed-length cutting device

InactiveCN110238914AImprove cutting efficiencyImprove stabilityFeeding devicesGripping devicesEngineeringFixed length

The invention relates to the field of wood processing, in particular to a wood board fixed-length cutting device. The wood board fixed-length cutting device comprises a rack, a board conveying roller assembly, a pressure roller, a driving mechanism, a tensioning linkage wheel, a guide frame, a cutting mechanism, supporting legs and side baffles; the supporting legs are fixed at the front end and the rear end of the bottom face of the rack separately; the side baffles are fixed at the left end and the right end of the top face of the rack separately; the board conveying roller assembly is connected in an installation groove in the top face of the rack; the board conveying roller assembly is located between the two side baffles; the pressure roller is arranged at the front end of the top face of the rack; and the board conveying roller assembly is connected to the side end of the pressure roller. According to the wood board fixed-length cutting device, continuous fixed-length cutting is carried out on a wood board by adopting an automatic feeding and fixed length cutting mode, the cutting efficiency is high, and the labor force is low.

Owner:李锋

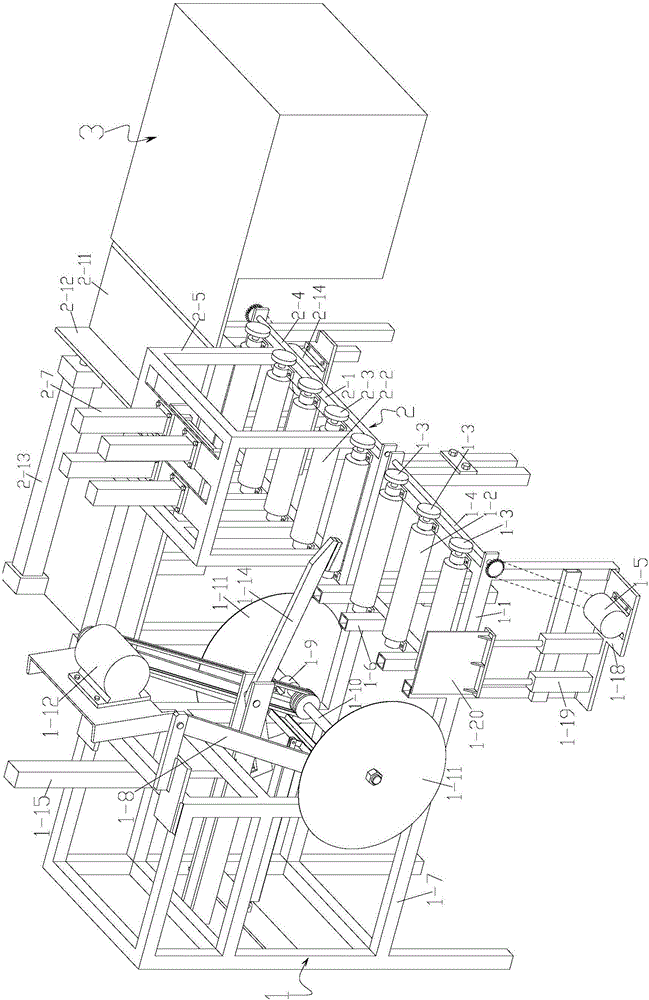

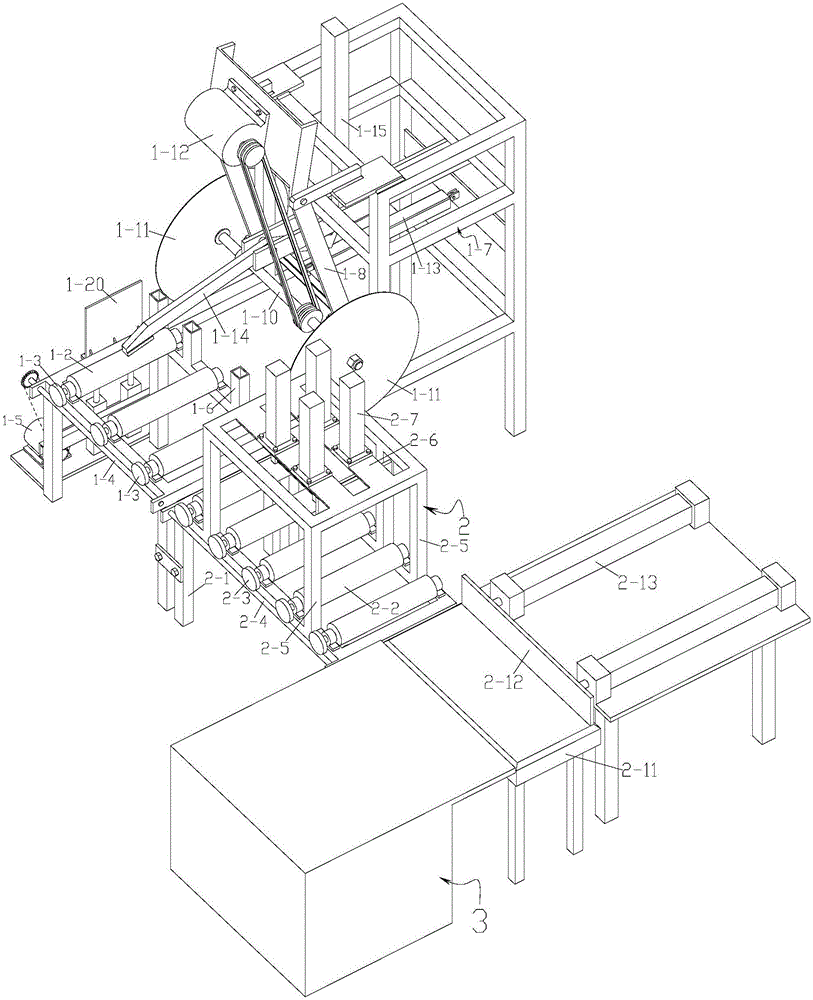

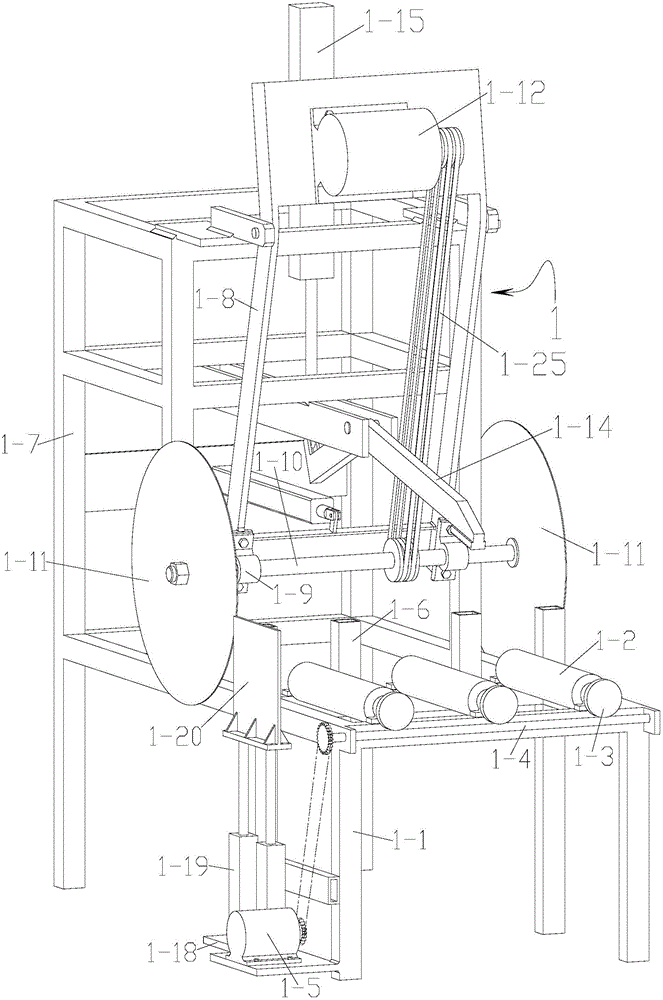

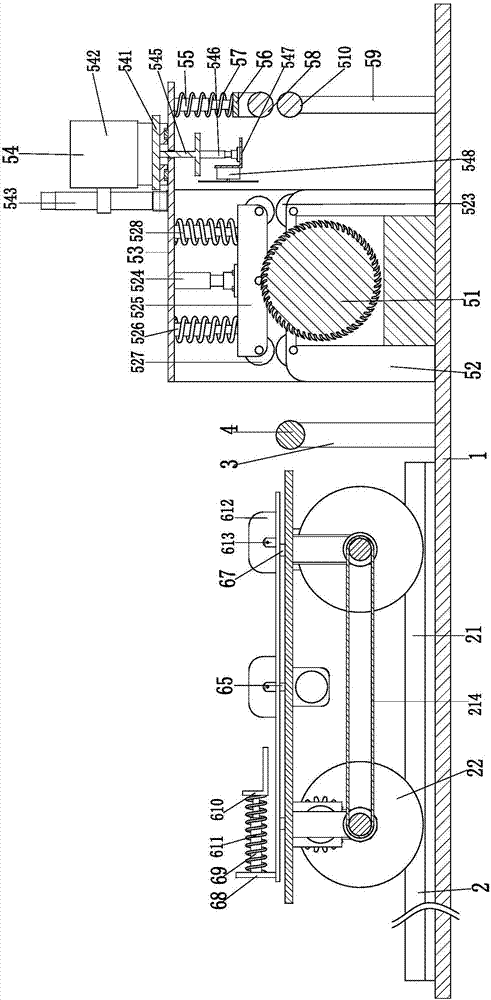

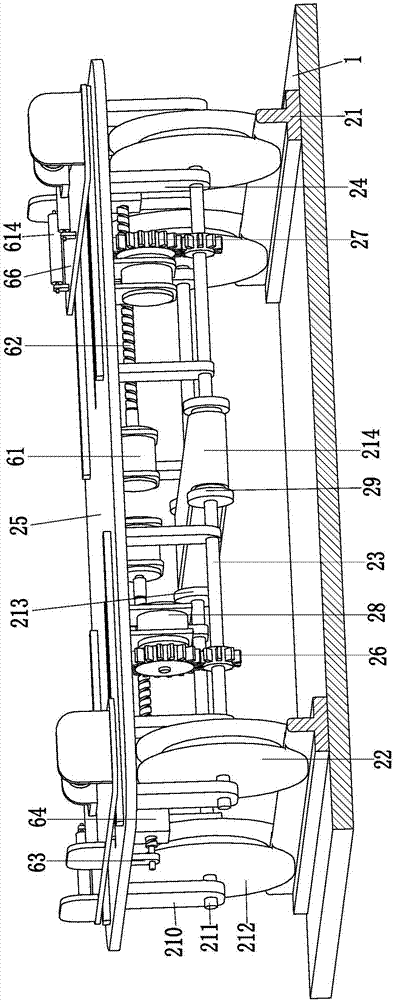

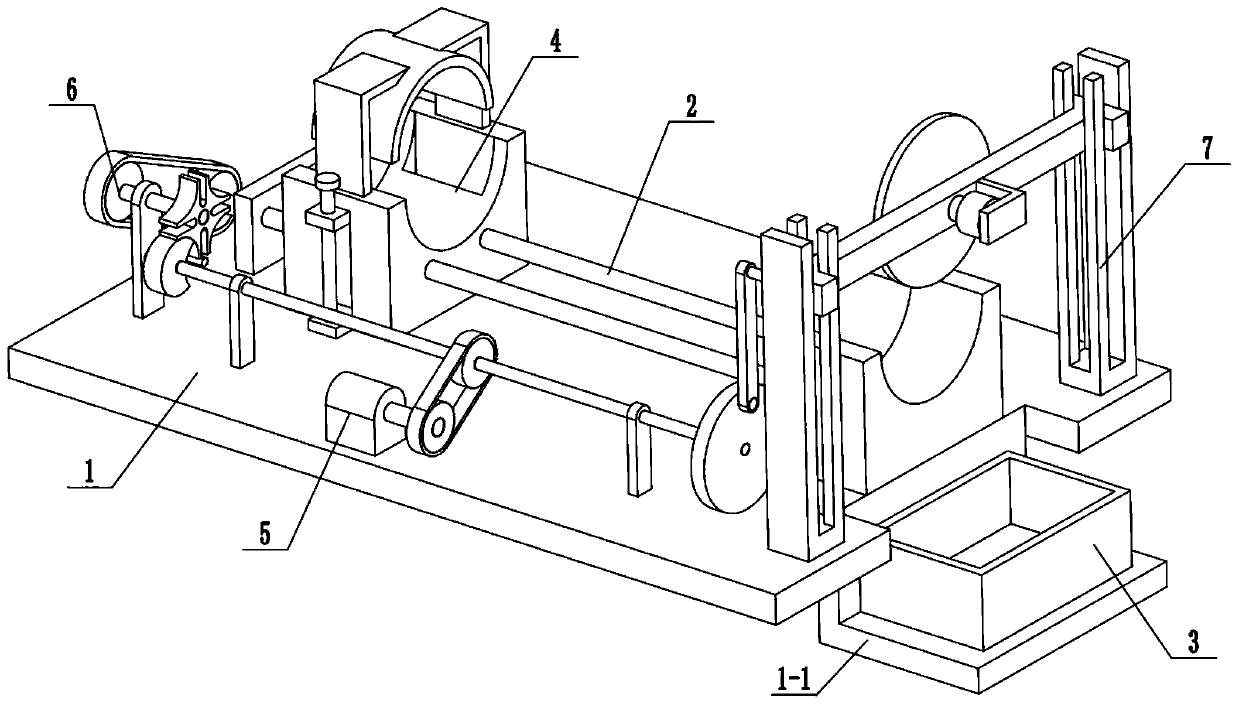

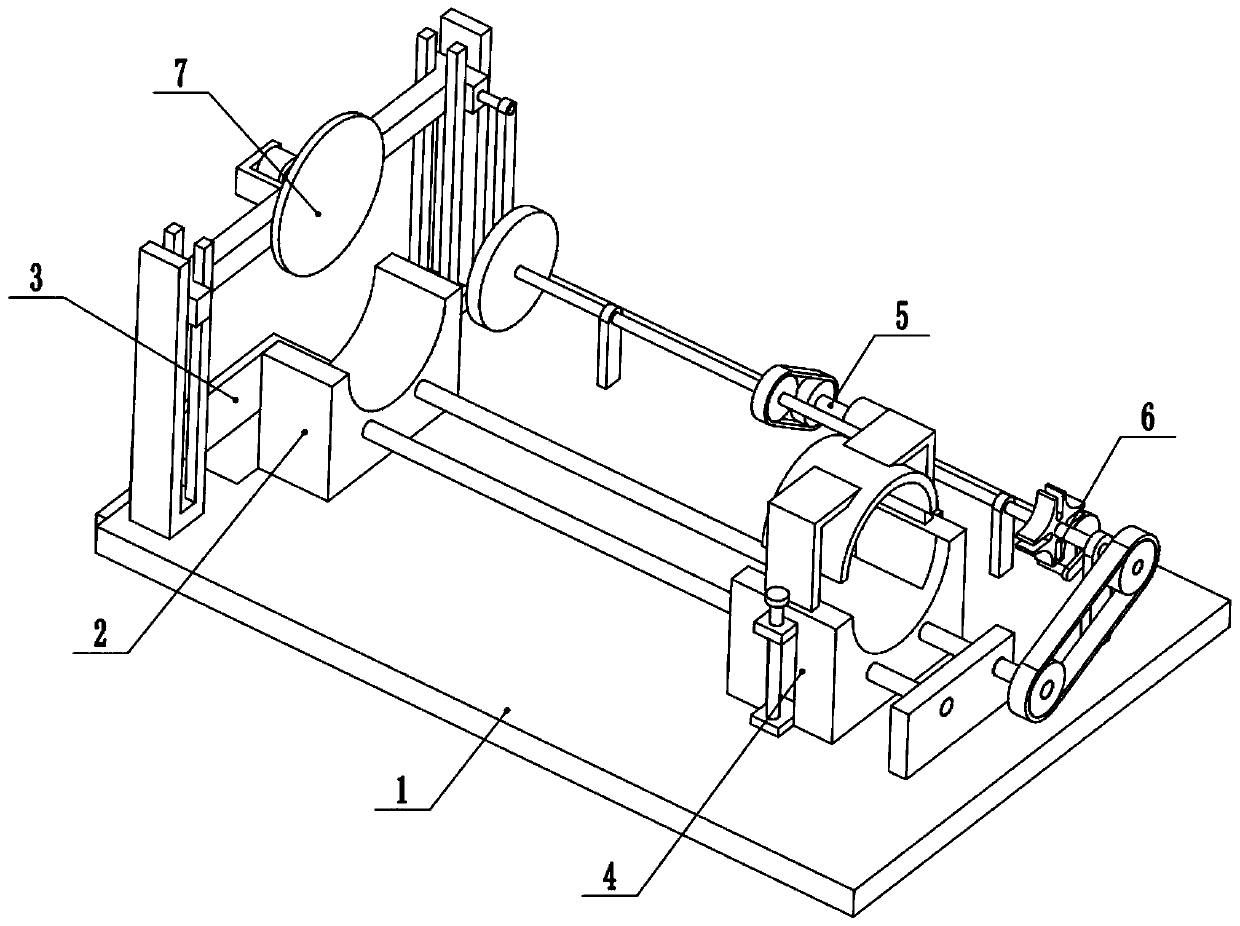

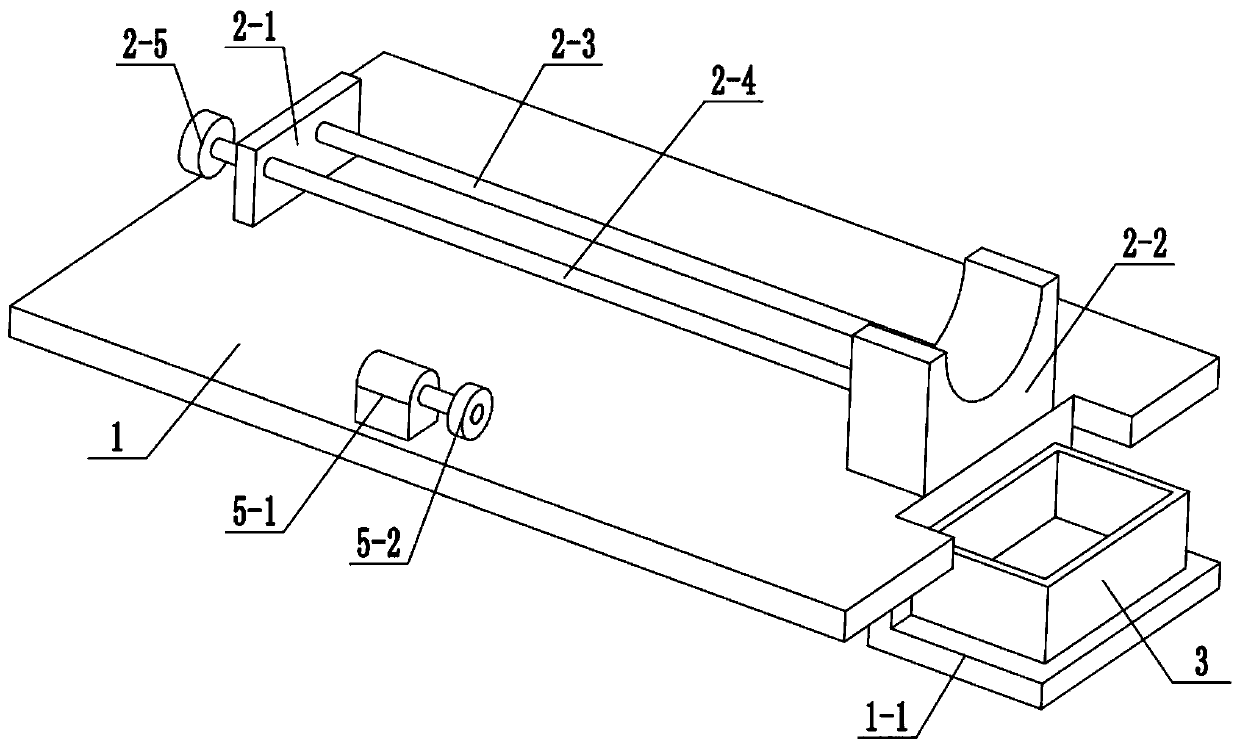

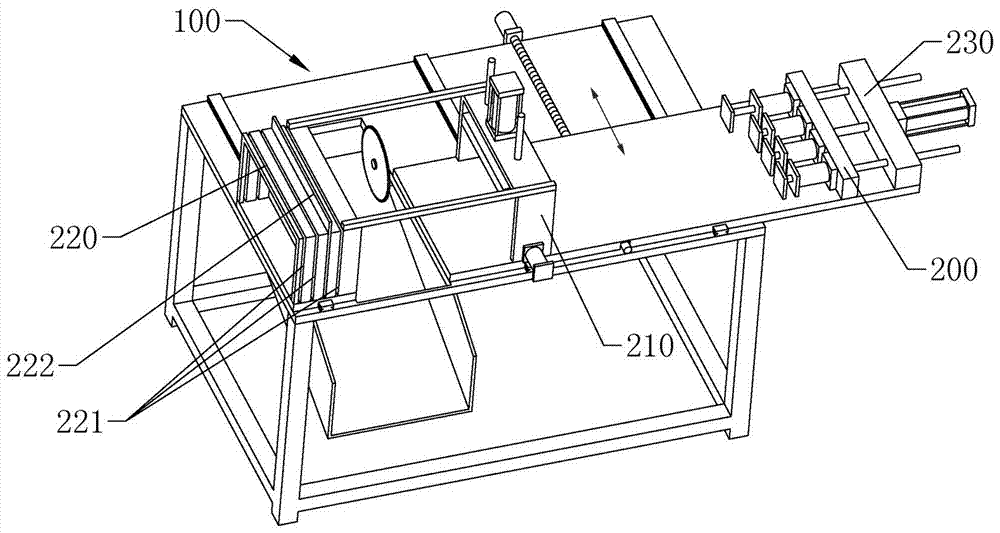

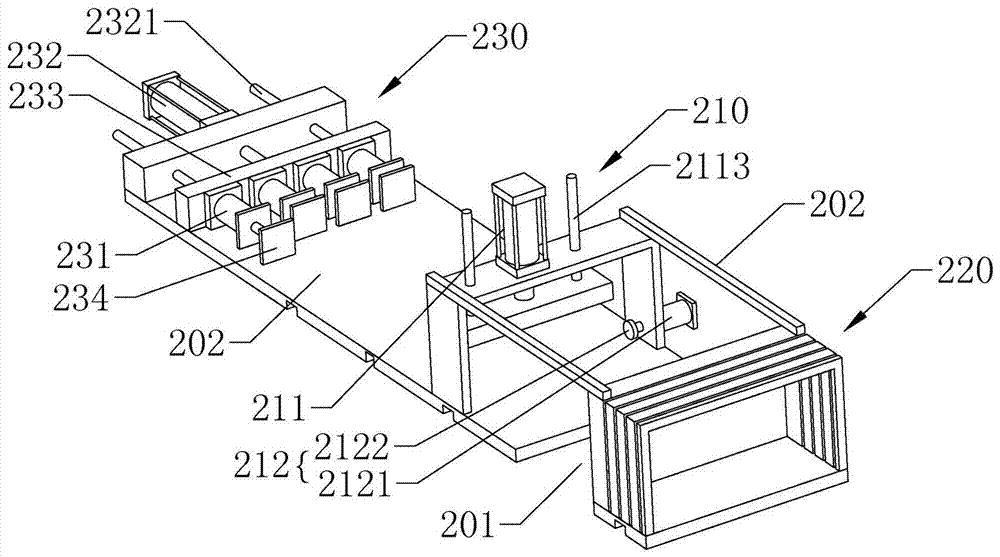

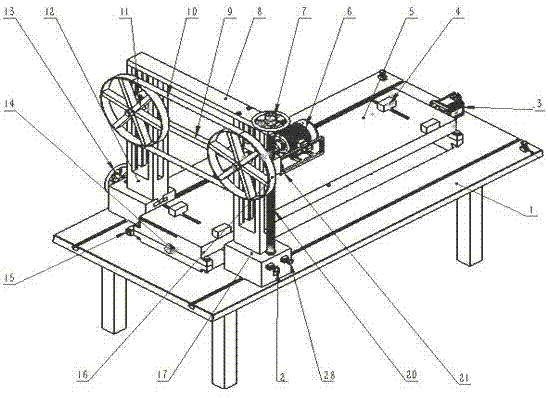

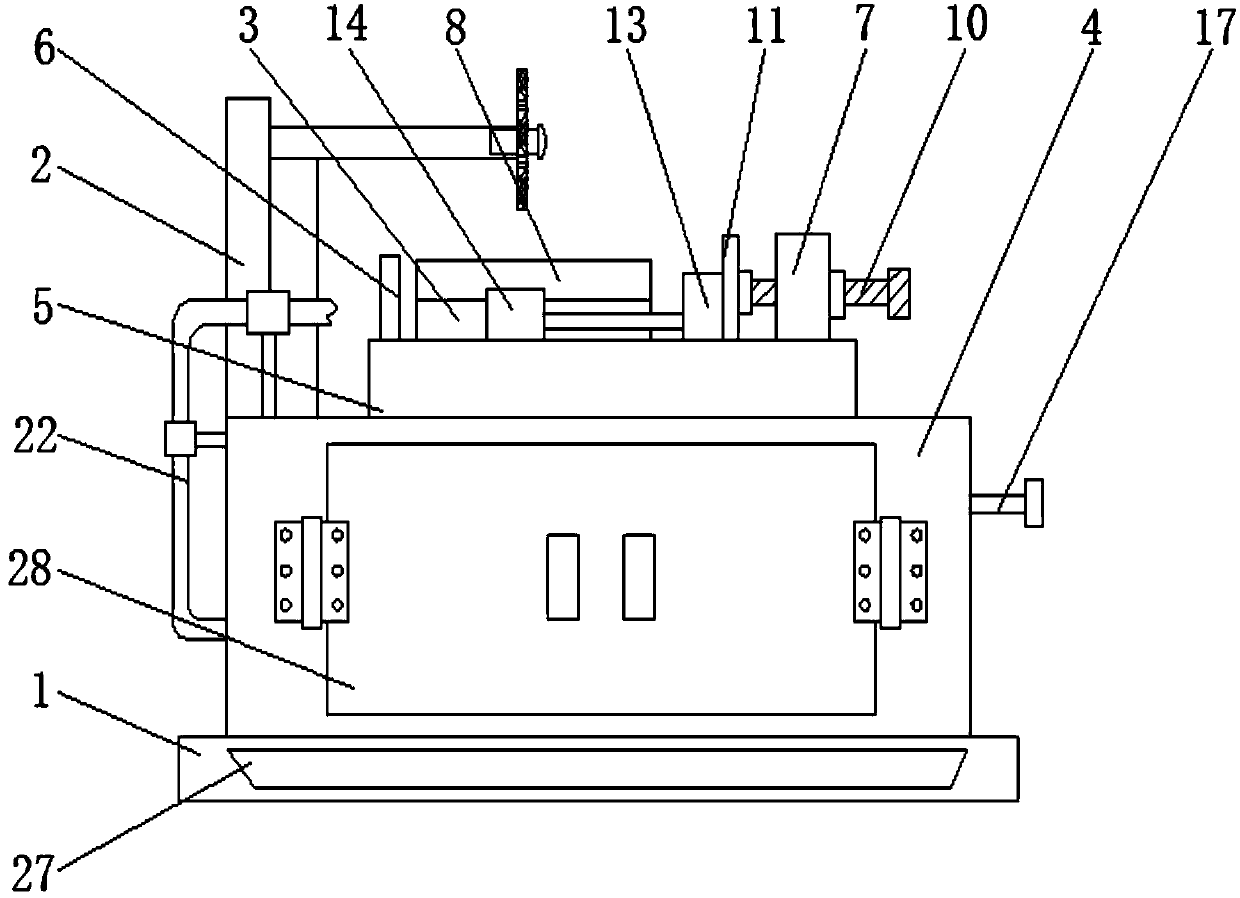

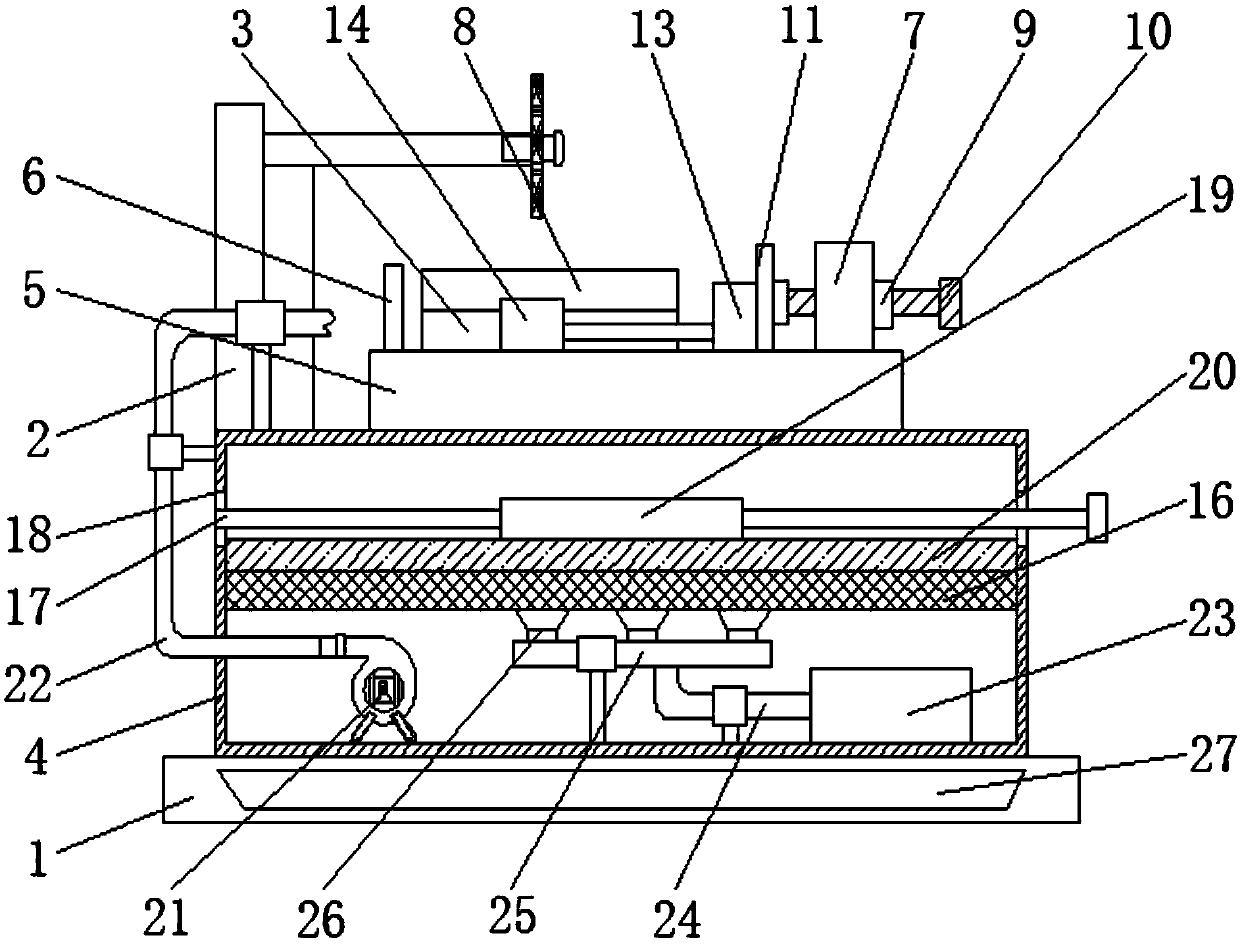

Wood thin-board machining process and wood thin-board automatic machining equipment

ActiveCN105818216AEasy to pushEasy to processFeeding devicesGripping devicesMachining processEngineering

A wood thin-board machining process comprises the following steps: A) clamping a log; B) cutting both ends of the log; C) conveying the cut log; D) machining the cut log. Wood thin-board automatic machining equipment comprises a log clamping and cutting device, a log conveying device and a wood thin-board machining device; a base I disposed on the log clamping and cutting device and a base II disposed on the log conveying device are matched with each other by position, and linked together; a material receiving platform disposed on the log conveying device and a base III disposed on the wood thin-board machining device are matched with each other by position, and linked together. The equipment disclosed by the invention achieves an ingenious and reasonable structure design. The process and equipment disclosed by the invention can greatly improve the efficiency of machining logs into wood thin-board, and are worth popularizing and applying.

Owner:ZHEJIANG DOLO IND

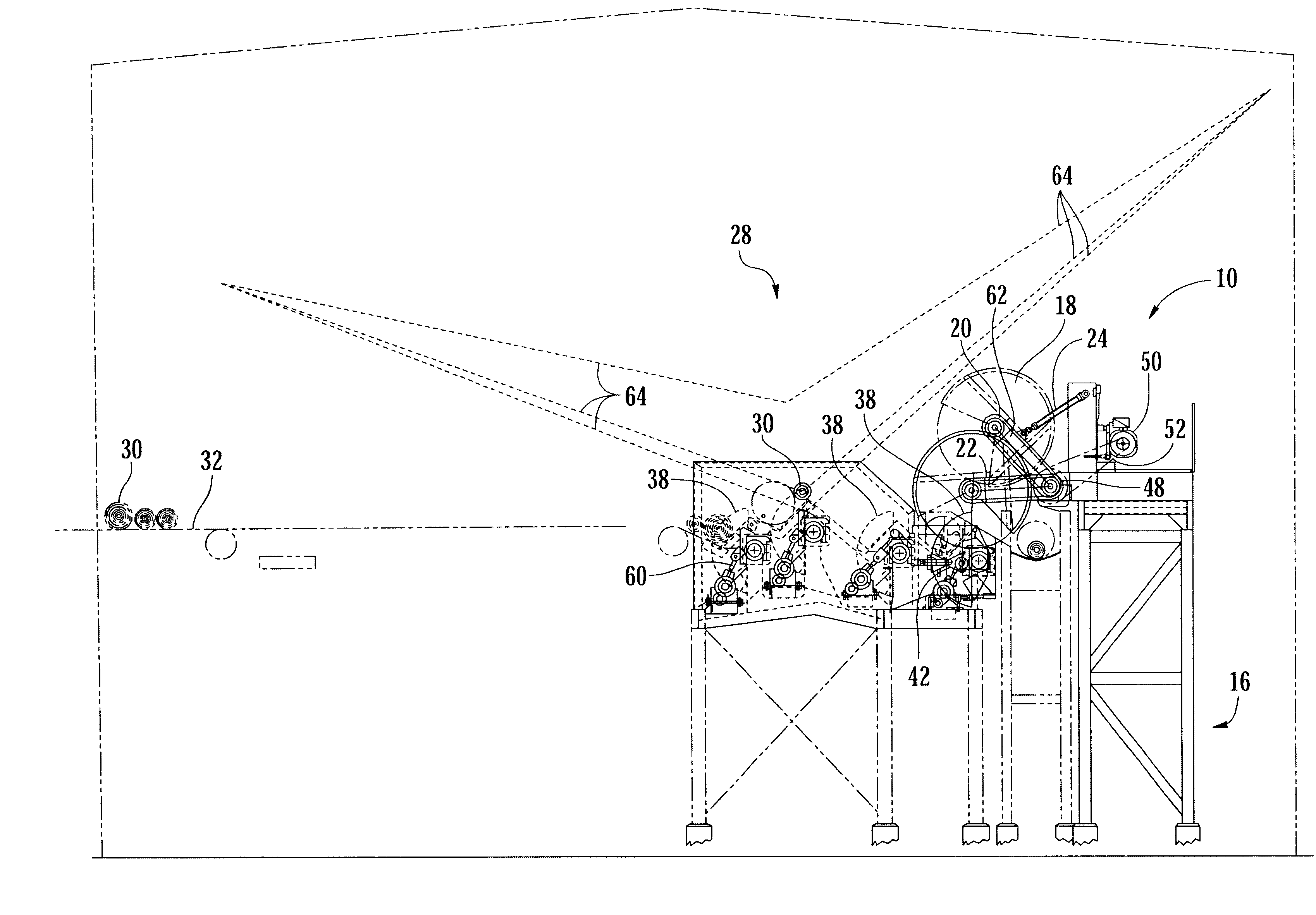

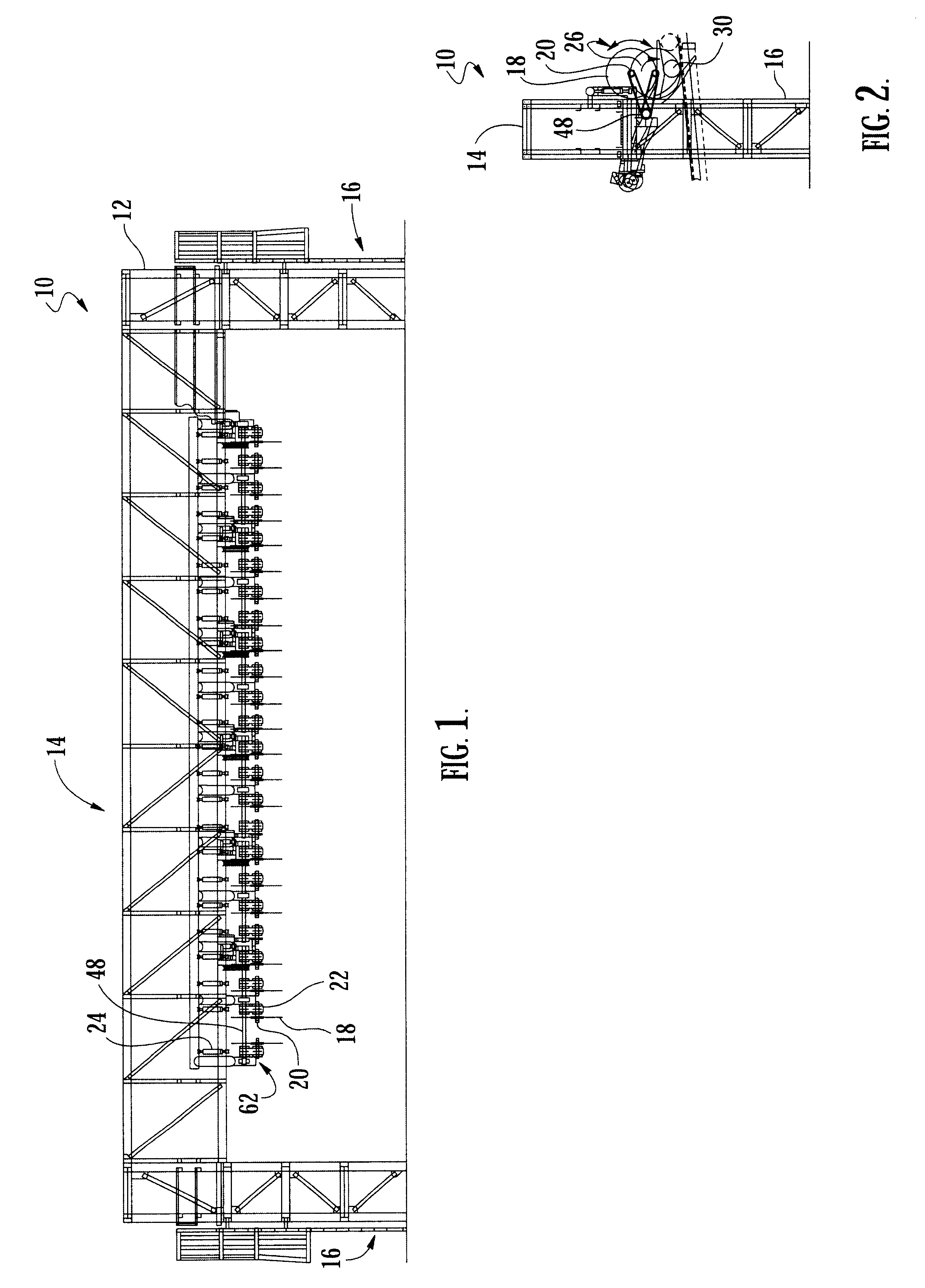

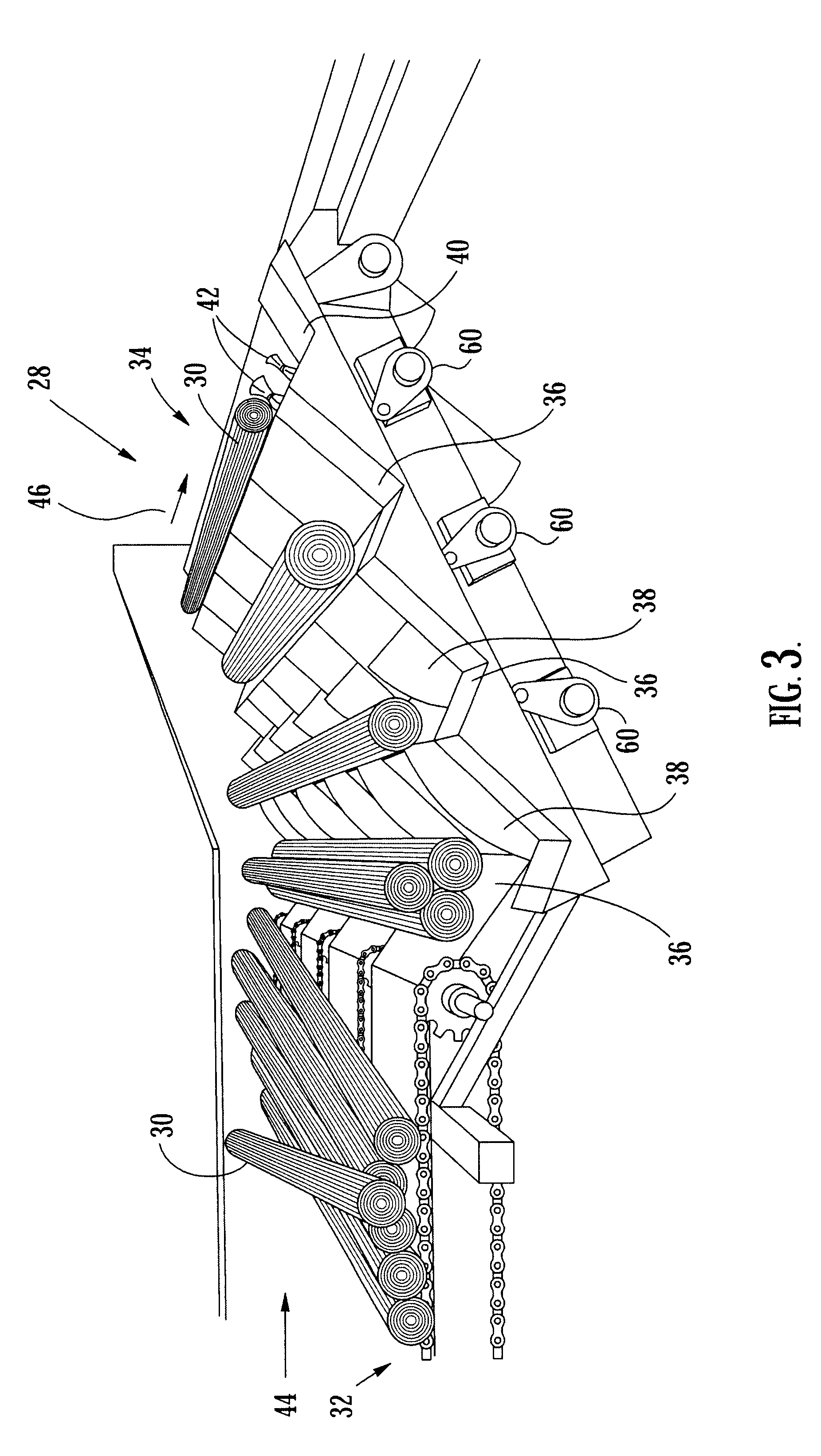

Log cutting system

The present invention discloses a log sawing system comprising multiple cutting blades. The multiple cutting blades are positioned to cut laterally or perpendicular to the centerline of the log which is to be cut. The logs are transported into cutting position using some type of log positioner. The multiple cutting blades are rotatably mounted on an arm which is pivotally mounted on a shaft in groups, being driven by an electrical or like motor, all of which are mounted onto a platform positioned adjacent to the log to be cut. Hydraulic lifters are used to partially rotate the saw blades into the cutting position adjacent the log. Means utilizing a computer and lasers are provided to develop a log cutting solution to best utilize the logs.

Owner:PSI SALES

Cutting machine

InactiveCN105922361ARealize automatic controlEfficient cuttingFeeding devicesGripping devicesHydraulic pumpEngineering

The invention discloses a cutting machine. The machine comprises a working platform, a cutter, clamping plates, threaded rods, a driving mechanism, a hydraulic pump, a connecting rod and a telescoping rod, wherein the upper surface of the working platform is downwards sunken to form a first chute and a second chute which are parallel to each other; the clamping plates are arranged on the first chute and the second chute; a cutter groove is arranged through the working platform, and the cutter is arranged in the cutter groove; clamping grooves are formed in the clamping plate; the threaded rods are arranged on the clamping plates; the hydraulic pump is arranged on the upper surface of the working platform; one end of the connecting rod is connected with one clamping plate while the other end of the connecting rod is connected with another clamping plate; one end of the telescoping rod is connected with the hydraulic pump while the other end of the telescoping rod is connected with the connecting rod. With the adoption of the cutting machine, the problems in the prior art that the deviation of a board in cutting leads to the failure of processing, and hard quality and easy-shaking property of the board influence the board cutting accuracy, and manual operation is low in working efficiency, can be solved.

Owner:ANHUI EMINENT BUILDING MATERIALS TECH

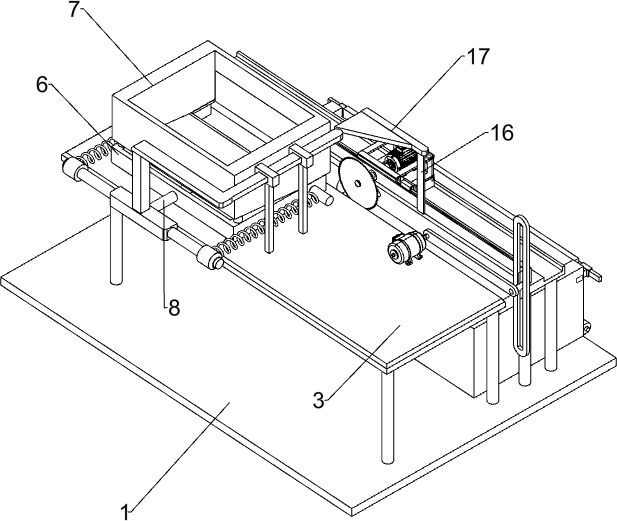

Automatic cutting machine for artificial wood fiber board

InactiveCN107127827ARealize the function of automatic cuttingReduce labor intensityGuide fencesGripping devicesFiberEngineering

The invention relates to an automatic cutting machine for an artificial wood fiber board. The automatic cutting machine for the artificial wood fiber board comprises a base board, a movable pushing device is mounted at the rear end of the base board, two supporting boards are symmetrically mounted in the middle of the base board, a first supporting roller is mounted between the inner walls of the upper ends of the two supporting boards through a bearing, a cutting device is mounted at the front end of the base board, and the movable pushing device and the cutting device cooperate with each other to complete the automatic processing technology of boards. The automatic cutting machine can solve the problems that workers need to use clamps to push the boards and use a disk saw to cut the boards when using a traditional cutting method to conduct cutting processing in small-sized board processing factories, the cutting precision is low, clamps need to be replaced manually according to needs of different board widths, the labor intensity is high, the traditional board cutting method can only conduct cutting in one direction, the boards need to be processed for a second time, and the working efficiency is low; and the automatic cutting machine can achieve the function that the boards are cut automatically.

Owner:广西鹿寨通用人造板有限公司

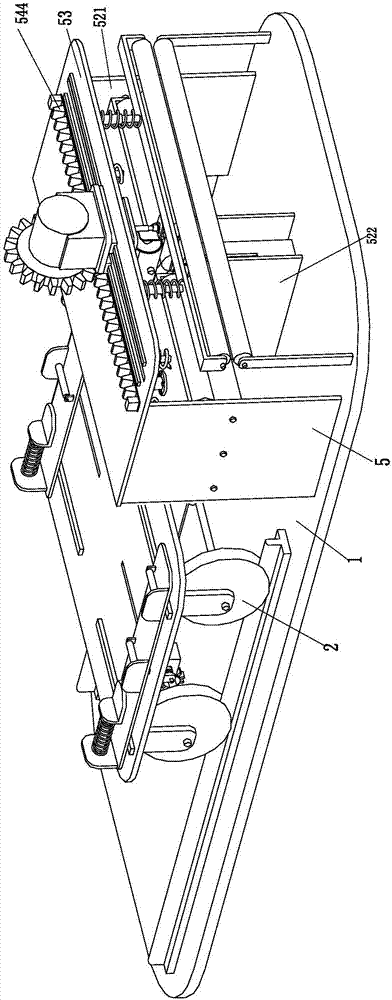

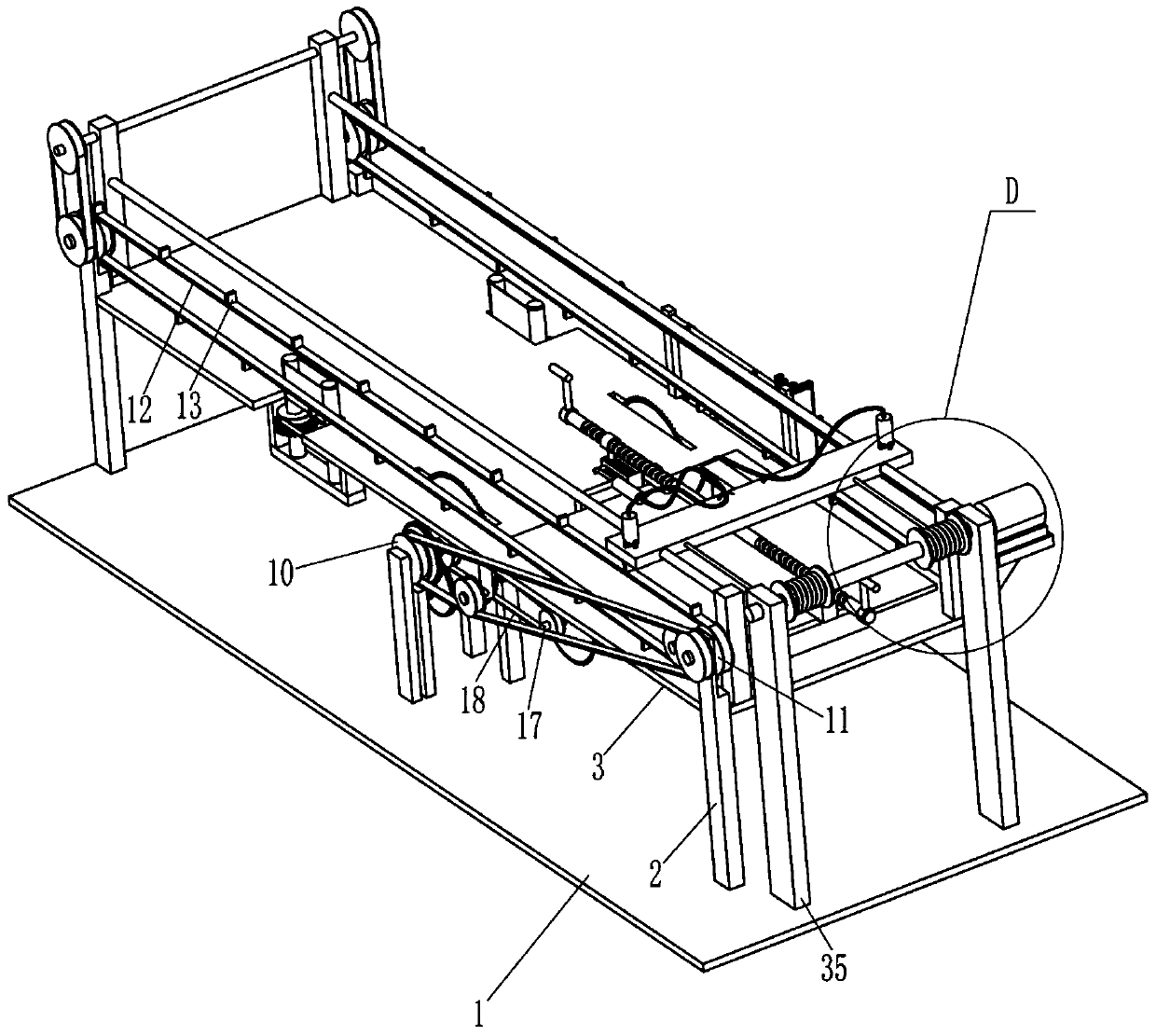

Automatic feeding and cutting process for artificial board

ActiveCN105583911ARealize pushStable recyclingFeeding devicesGripping devicesEngineeringMechanical engineering

The invention provides an automatic feeding and cutting process for an artificial board, comprising a feeding device, a pushing device and a cutting device, wherein the pushing device is arranged between the cutting device and the feeding device and comprises support rods arranged transversely and feeding mechanical arms arranged between adjacent support rods, a transverse moving rack is arranged above the support rods, the feeding mechanical arms are hinged to a fixed seat fixed on the transverse moving rack, a pulling arm cylinder is hinged to the fixed seat, and a telescopic rod of the pulling arm cylinder is hinged to the middle of the mechanical arm. The automatic feeding and cutting process is simple in structure, and the mechanical arms for pushing boards are provided, so that integrated conveying of the cut boards can be realized, and efficiency and safety are greatly improved. Pushing of boards can be well achieved by utilizing the structure of the feeding mechanical arms. Meanwhile, a clamping mechanism is designed to ensure stability in recovery and cutting of the board, and due to the arrangement of a feeding mechanism, working efficiency is greatly improved and manpower needed for conveying is greatly reduced.

Owner:FUTIAN FUZHOU ARTS & CRAFTS

Wood cutting device for forestry engineering

ActiveCN109732707ASmooth cutNot easy to shiftFeeding devicesGripping devicesEngineeringMaterials processing

The invention relates to the field of building material processing equipment, in particular to a wood cutting device for forestry engineering. A rectangular through slot is formed in the middle end ofthe right end of a base; an L-shaped seat plate is fixedly connected into the rectangular through slot; a wood collecting box is placed onto the L-shaped seat plate; a feeding slide base is fixedly connected onto the base; the wood collecting box is positioned below the right end of the feeding slide base; a wood fixed slide base is connected on the feeding slide base; a power device is fixedly connected to the front end of the base; the power device is in transmission connection to a cutting assembly through a belt; and the cutting assembly is fixedly connected to the right end of the base.The wood cutting device can fix wood, and the fixed wood is not liable to deviate, so that wood cutting is more smooth, wood scrap is avoided, and waste of wood resources is avoided; and an intermittent feeding mechanism can automatically feed the fixed wood to cut, so that a constructor is prevented from risk during operation.

Owner:陈芬芬

Cutting device for solid wood panel

InactiveCN107186814AAdjustable angleLow efficiencyGripping devicesClamping devicesSolid woodArchitectural engineering

The invention discloses a cutting device for solid wood panel. The cutting device for the solid wood panel comprises a machine body. The bottom of the machine body is fixedly connected with a support rod. An inner cavity of the top of the machine body is provided with a transverse driving device. The transverse driving device is fixedly connected with a connecting block. The bottom of the connecting block is slidably connected with the interior of a sliding groove of the top of the machine body. The bottom surface of the connecting block is fixedly connected with an air cylinder. The bottom of the air cylinder is connected with a telescopic rod. The terminal end of the telescopic rod is fixedly connected with a sleeve. The top of the inner cavity wall of the sleeve is provided with a round groove. According to the cutting device for the solid wood panel, by the mutual coordination of the sleeve, a rotating shaft, a locking bolt, a positioning hole, a round groove and clamping ring, angles of a cutter can be effectively adjusted, the problems that an existing cutter can not cut the panel at multi-angle and the efficiency is low are solved, through the mutual matching of a fixed clamping device and a movable clamping mechanism, double positioning for the panel needed to be machined can be achieved, positioning machining for the panel can be effectively achieved, and the problem that clamping is not stable during existing panel machining is solved.

Owner:李赵和

Automatic wood cutting machine

InactiveCN107053344AImprove securityImprove clamping effectFeeding devicesGripping devicesFixed frameSlide plate

The invention relates to the field of furniture manufacturing, in particular to an automatic wood cutting machine. The automatic wood cutting machine comprises a fixed frame and a movable frame. The movable frame is arranged above the fixed frame. A guide rail and a lead screw are arranged between the fixed frame and the movable frame. The fixed frame comprises a top plate, a cutting mechanism and a discharging mechanism. The discharging mechanism comprises a discharging outlet formed in the top plate and a discharging slide. The cutting mechanism is a cutting machine body fixed to the lower portion of the top plate. The top of a cutting blade of the cutting machine body is higher than the top of the top plate. The movable frame comprises a cutting area located above the discharging outlet, a clamping mechanism, a length positioning mechanism and a pushing mechanism. The clamping mechanism, the length positioning mechanism and the pushing mechanism are sequentially arranged. The cutting area is arranged between the clamping mechanism and the length positioning mechanism. The clamping mechanism is connected with the top of the length positioning mechanism through a connecting rod. The clamping mechanism is connected with the bottom of the pushing mechanism through a sliding plate.

Owner:ZOY HOME FURNISHING CORP

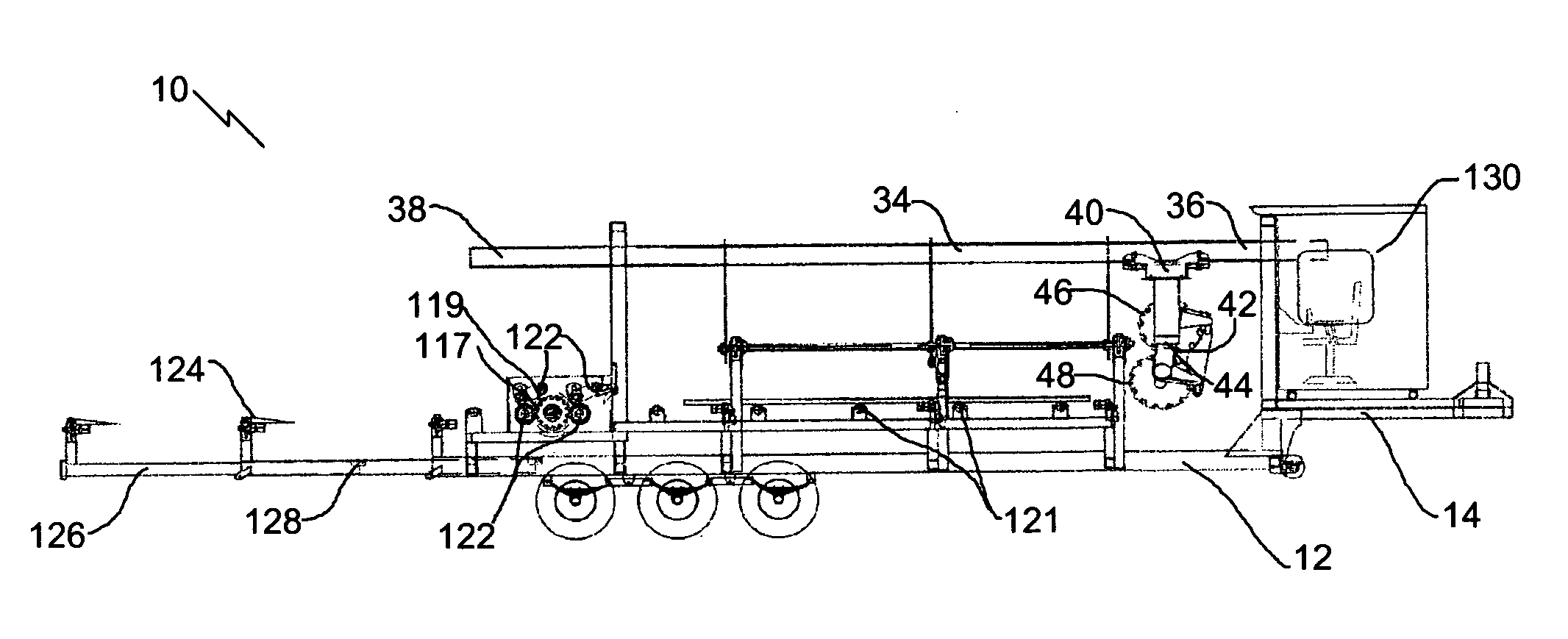

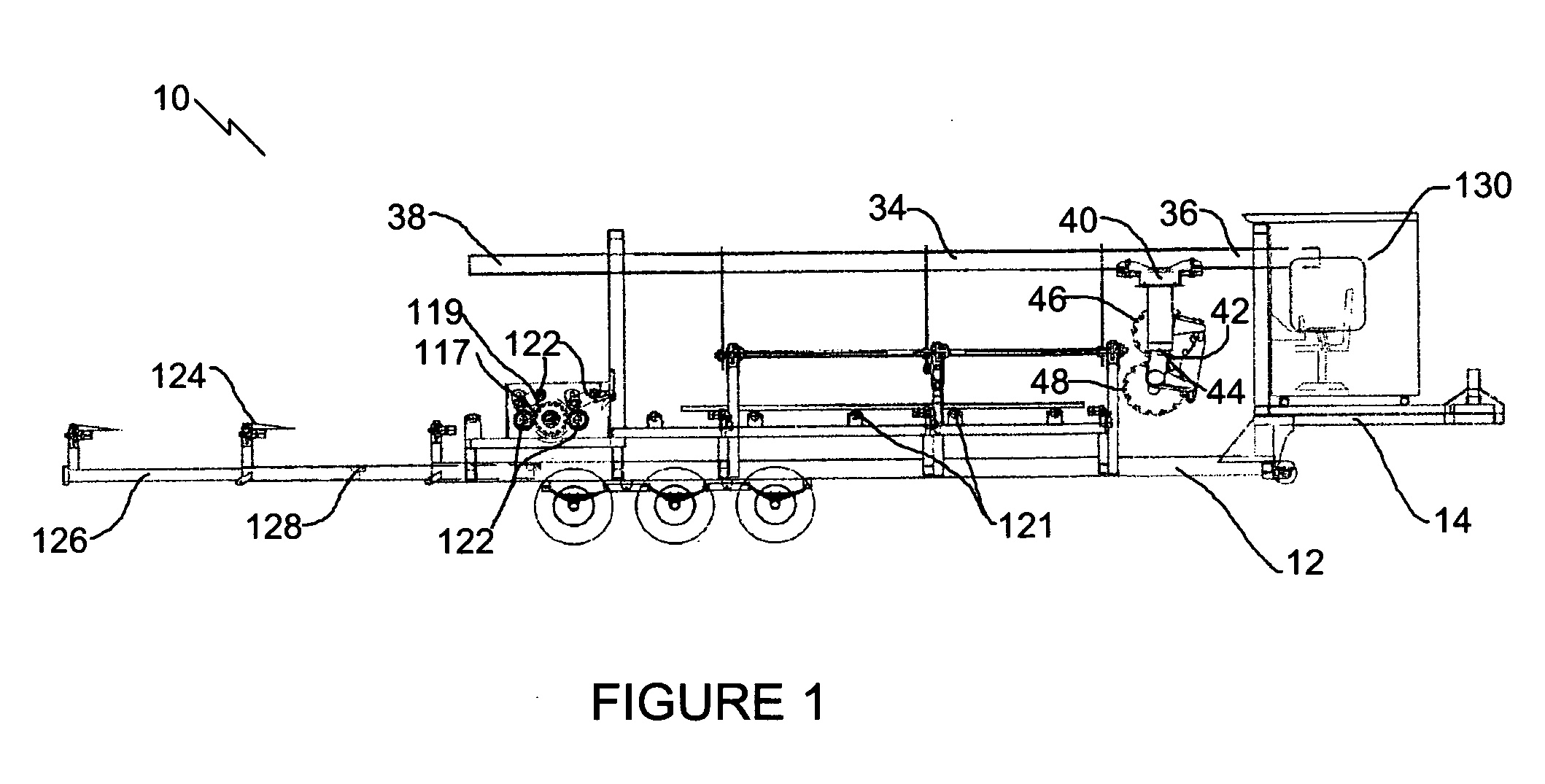

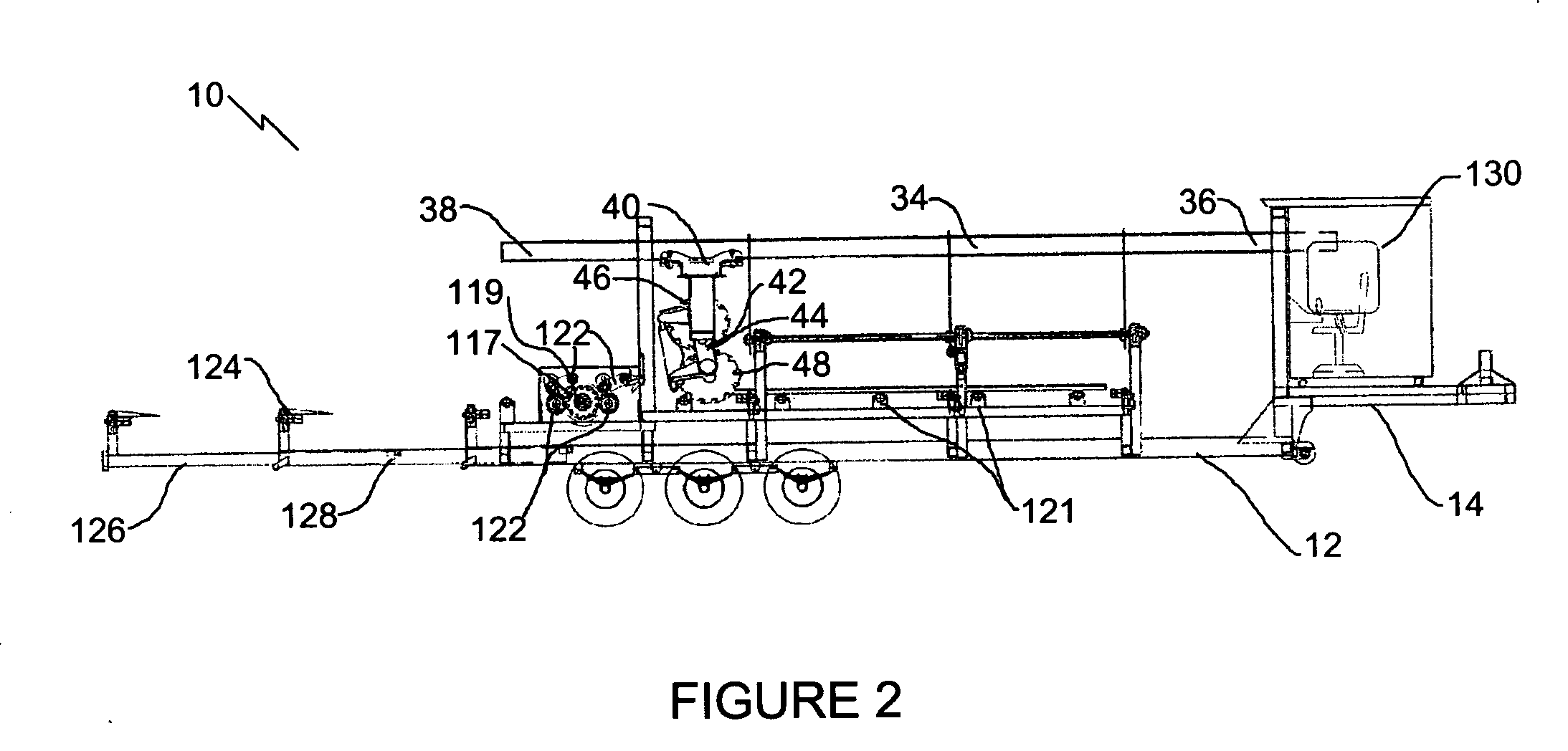

Continuous log bucking saw system and method

InactiveUS6923101B2Improved and efficient cuttingYield maximizationMetal sawing devicesGuide fencesEngineeringMechanical design

A high-throughput, high-end-product-recovery, lineal log bucking device featuring continuous stem travel during the cutting process by using a simple and efficient machinery design for economy of equipment and monies. The apparatus includes: (1) a saw for cutting stem into logs; and (2) apparatus for accelerating the carrier up to the speed of the stem conveyor(s), maintaining the speed during the cut, decelerating the carrier, and then returning the carrier to its starting point.

Owner:MID SOUTH ENG COMPANY

Board cutting machine

The invention discloses a board cutting machine. The machine comprises a working platform, a cutter, clamping boards, threaded rods and a driving mechanism, wherein the upper surface of the working platform is downwards sunken to form a first chute and a second chute which are parallel to each other; the clamping boards are correspondingly arranged on the first chute and the second chute; a cutter groove is arranged through the working platform, and the cutter is arranged in the cutter groove; the plane where the cutter is located is parallel to the length direction of the first chute; the cutter extends out of the upper surface of the working platform; the cutter is connected with the driving mechanism; clamping grooves are formed in the clamping board; a board to be cut is positioned between the clamping grooves and the cutter; the threaded rods are arranged on the clamping boards and can be vertically screwed into the clamping boards by means of threads; the lower ends of the threaded rods are arranged into the corresponding clamping grooves. With the adoption of the board cutting machine, the problems that the deviation of the board in cutting leads to the failure of processing is caused, and the hard quality and easy-shaking property of the board influence the board cutting accuracy can be solved.

Owner:ANHUI EMINENT BUILDING MATERIALS TECH

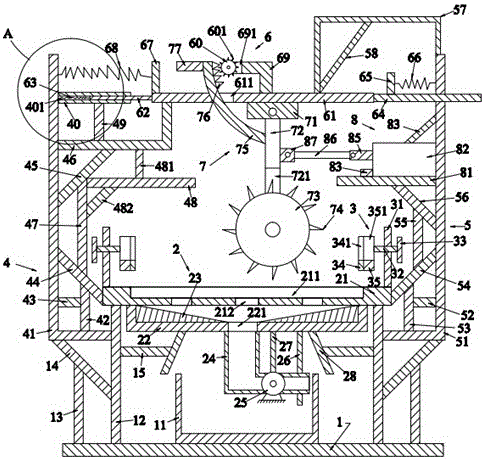

Cutting and polishing equipment for plastic-wood plate

ActiveCN110877370AAvoid shakingFlat cutting surfaceGripping devicesBelt grinding machinesPolishingElectric machinery

The invention relates to cutting and polishing equipment, and in particular relates to the cutting and polishing equipment for a plastic-wood plate. The invention provides the cutting and polishing equipment capable of preventing the plastic-wood plate from shaking and making the cutting surface of the plastic-wood plate more smooth for the plastic-wood plate. The cutting and polishing equipment for the plastic-wood plate includes a base plate, first supports, a placing plate, first sliding rods and the like; and the first supports are fixedly connected to two sides of the top of the base plate, the placing plate and the first sliding rods are fixedly connected between the first supports on two sides, and the placing plate is placed below the first sliding rods. According to the equipment,the plastic-wood plate can be fixed by a clamping component to prevent the plastic-wood plate from shaking, the plastic-wood plate can be polished by the polishing component, so that the cutting surface of the plastic-wood plate is smoother, a clutch component can replace manual operation, so that the equipment can be more automated; and a sliding plate can be pulled back by a small motor, so that the sliding plate can be pulled back quickly, and the time can be saved.

Owner:江西新森岱塑木科技有限公司

Plank cutting device

The invention particularly relates to a plank cutting device. The plank cutting device can save time and labor, is high in cutting speed, can collect wood bits generated in the cutting process, and does not affect the surrounding environment. To achieve the above technical purposes, the plank cutting device comprises a placement board and the like; supporting legs are installed on the left side and the right side of the bottom of the placement board symmetrically; supporting rods are installed on the left side and the right side of the top of the placement board symmetrically; a top board is installed between the top ends of the supporting rods on the left side and the right side; a compressing device is arranged on the left side of the top board; a compressing component of the compressingdevice is located above the placement board; and a cutting device body is arranged on the right side of the bottom of the top board. Through a pushing device, the situation that a person makes contact with a plank and pushes the plank with hands is not needed, the person is not likely to be cut by a saw web, and a collection device can collect the wood bits generated in the cutting process, so that the effects of saving time and labor and being high in cutting speed are achieved.

Owner:钟清

Dissecting device and method for cell and tissue

A dissection device for organisms includes a table bearing an organism and at least one blade lifted or lowered to approach the table. The blade includes a connecting portion, a cutting portion having a curved edge, and a neck portion connecting the connecting portion and the cutting portion. When the blade is lowered to contact the table, the cutting portion is rotated with respect to the neck portion to have rolling contact with the table from a first point to a second point of the edge.

Owner:IND TECH RES INST

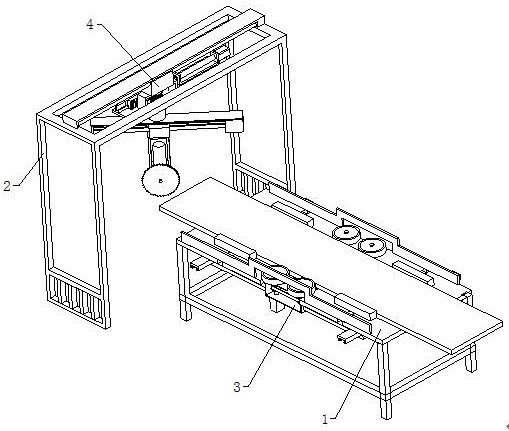

Construction wood-cutting machine with adjustable angle

InactiveCN112140241AReduce labor costsImprove cutting efficiencyFeeding devicesGripping devicesAgricultural engineeringWood machining

The invention relates to the technical field of construction wood cutting, in particular to a construction wood-cutting machine with an adjustable angle. The construction wood-cutting machine with theadjustable angle comprises a conveying table, a portal frame vertically erected at one end of the conveying table, a conveying and positioning mechanism which is arranged on the conveying table and used for transferring wood to a processing portion of the portal frame and conducting positioning, and a rotary adjusting and cutting mechanism which is arranged on the portal frame and used for conducting angle cutting on processing ends of the wood conveyed by the conveying and positioning mechanism, and the construction wood-cutting machine with the adjustable angle is characterized in that therotary adjusting and cutting mechanism comprises a horizontal overturning board which is horizontally arranged at the upper end of the interior of the portal frame and can horizontally rotate. By means of the construction wood-cutting machine with the adjustable angle, the wood can be automatically conveyed and positioned, and cutting is conducted with the angle of a cutting machine body automatically adjusted according to angles needed for wood cutting, so that the labor cost is reduced, and the cutting efficiency is improved.

Owner:潘长艳

Automatic wood slicing device for building materials

ActiveCN112092099AAvoid unevennessSuit one's needsGuide fencesFeeding devicesAgricultural engineeringElectric machinery

The invention relates to a slicing device, in particular to an automatic wood slicing device for building materials. According to the automatic wood slicing device for the building materials, the efficiency can be improved, the thickness of cut wood blocks can be adjusted, and convenience is achieved. The automatic wood slicing device for building materials comprises a first working table, a second working table, an electric saw, a pushing mechanism and a pressing mechanism. A motor is arranged on the side wall of the upper part of the first working table; the second working table is arrangedon the first working table; the electric saw is rotatably arranged on the second working table; the pushing mechanism is arranged on the first working table; and the pressing mechanism is arranged onthe second working table. The pressing mechanism can stabilize the wood block and prevent the wood block from being unevenly cut due to instability during cutting. After the wood blocks are sliced bythe electric saw, the wood chips can be collected by a collecting box and are convenient to arrange; and a distance adjusting mechanism enables the wood block to be cut thick or thin according to needs, the needs of people can be met, and convenience is achieved.

Owner:蓝山县奔嘉木业有限公司

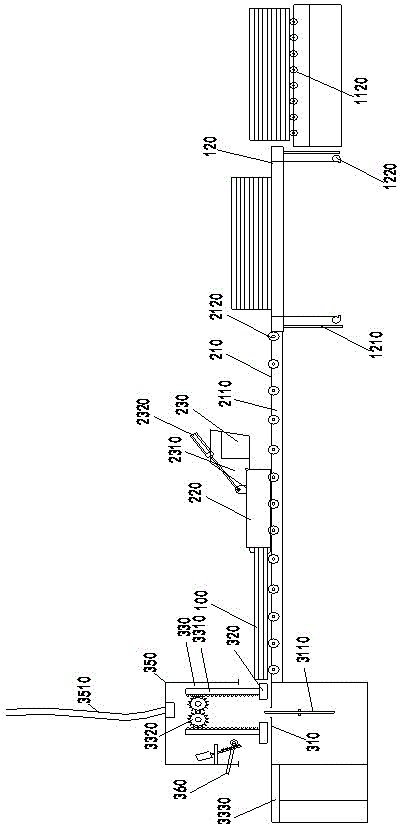

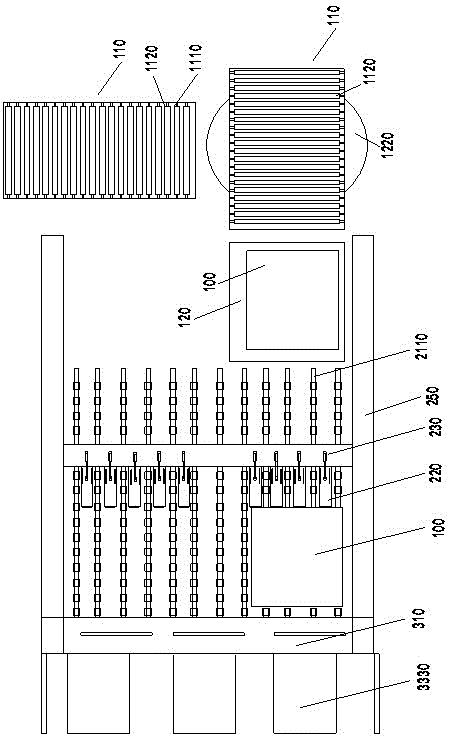

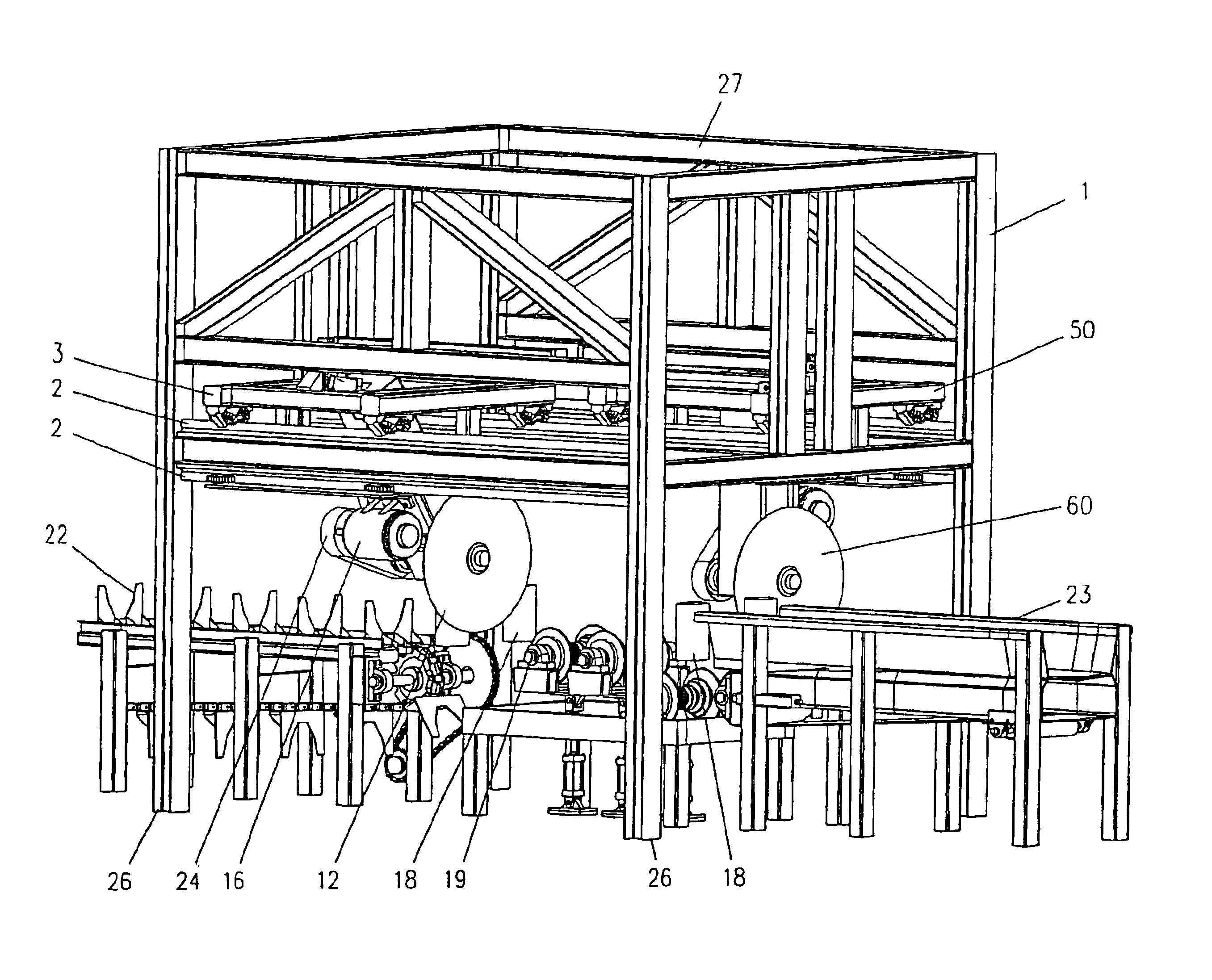

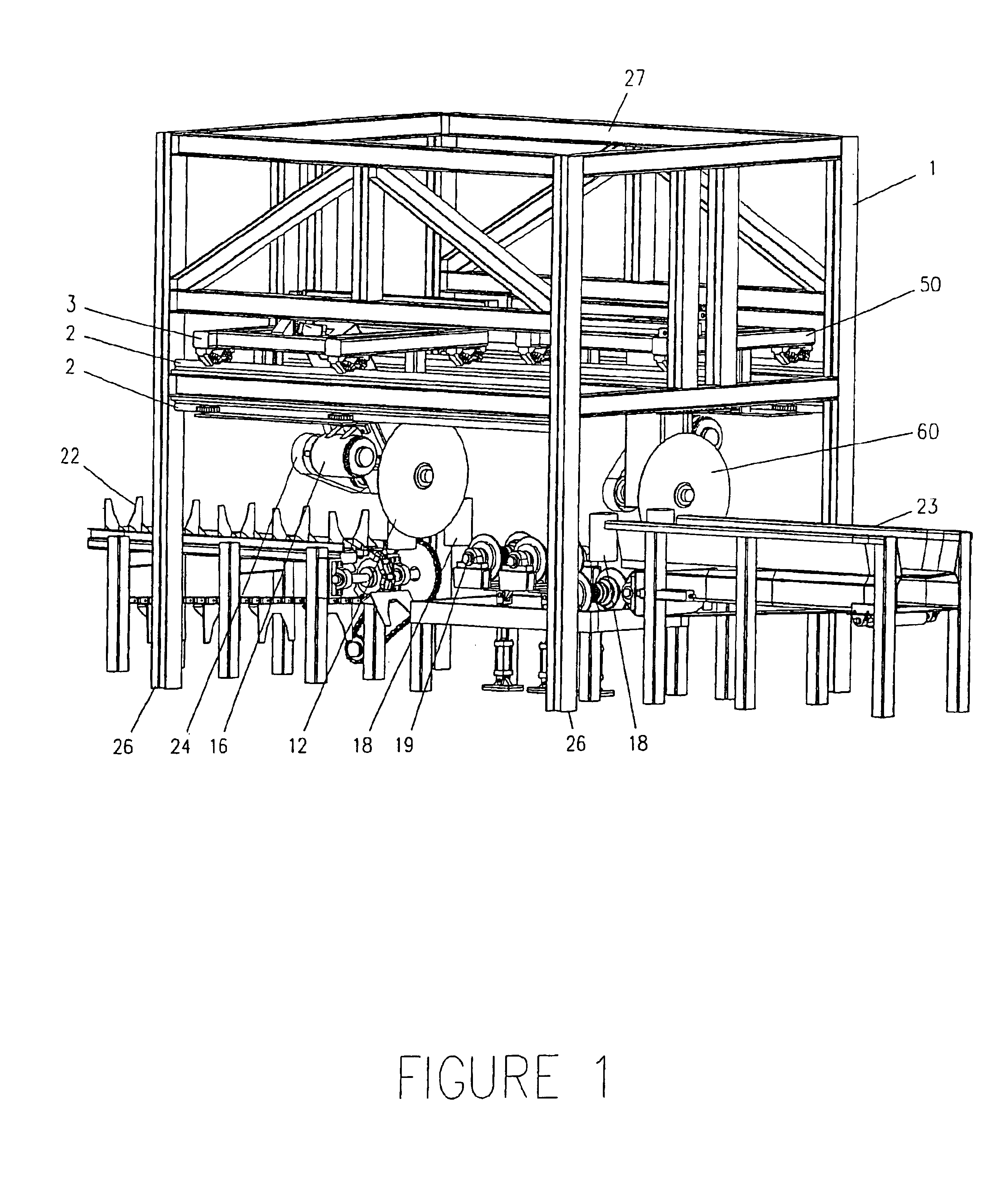

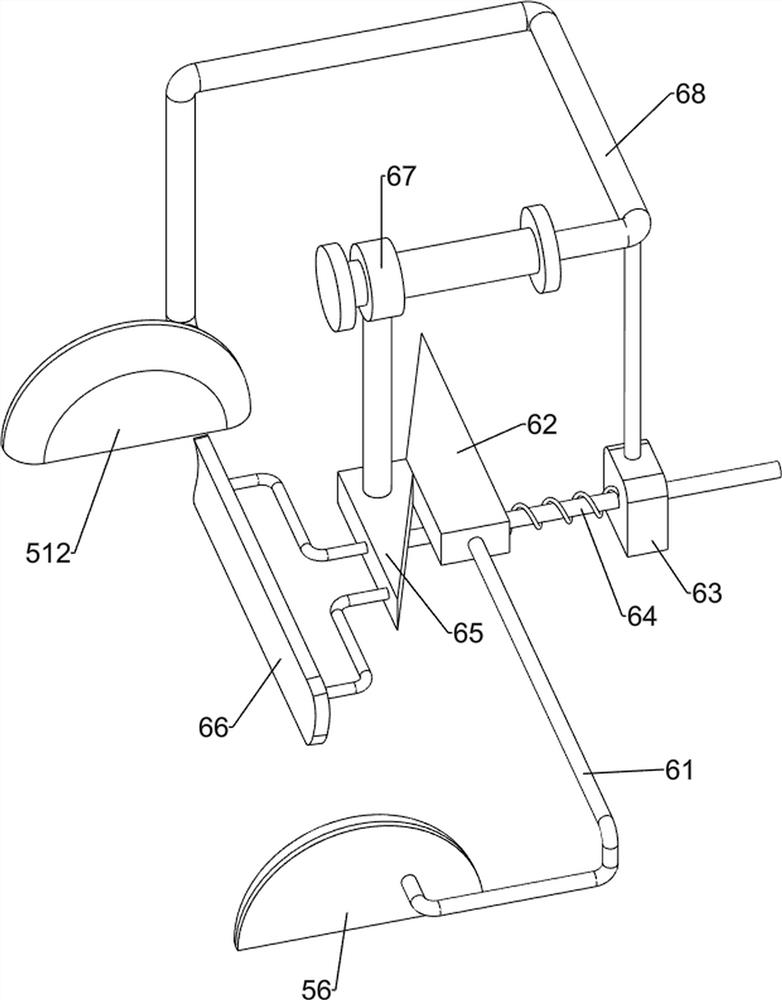

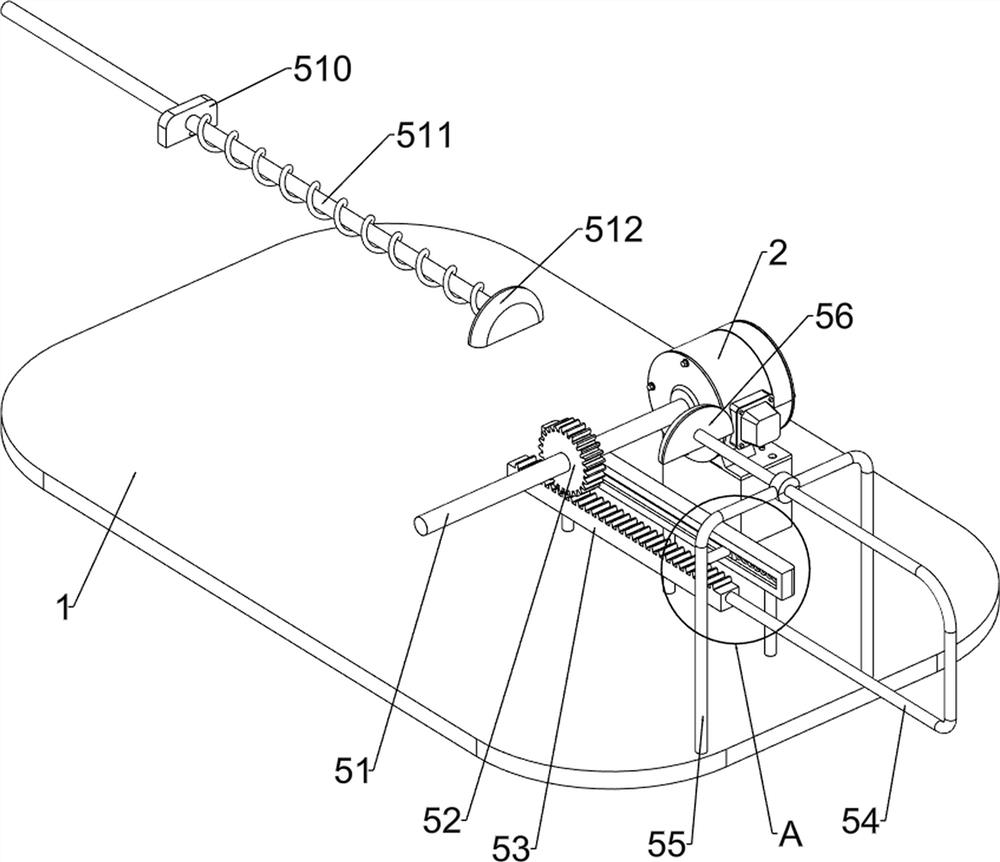

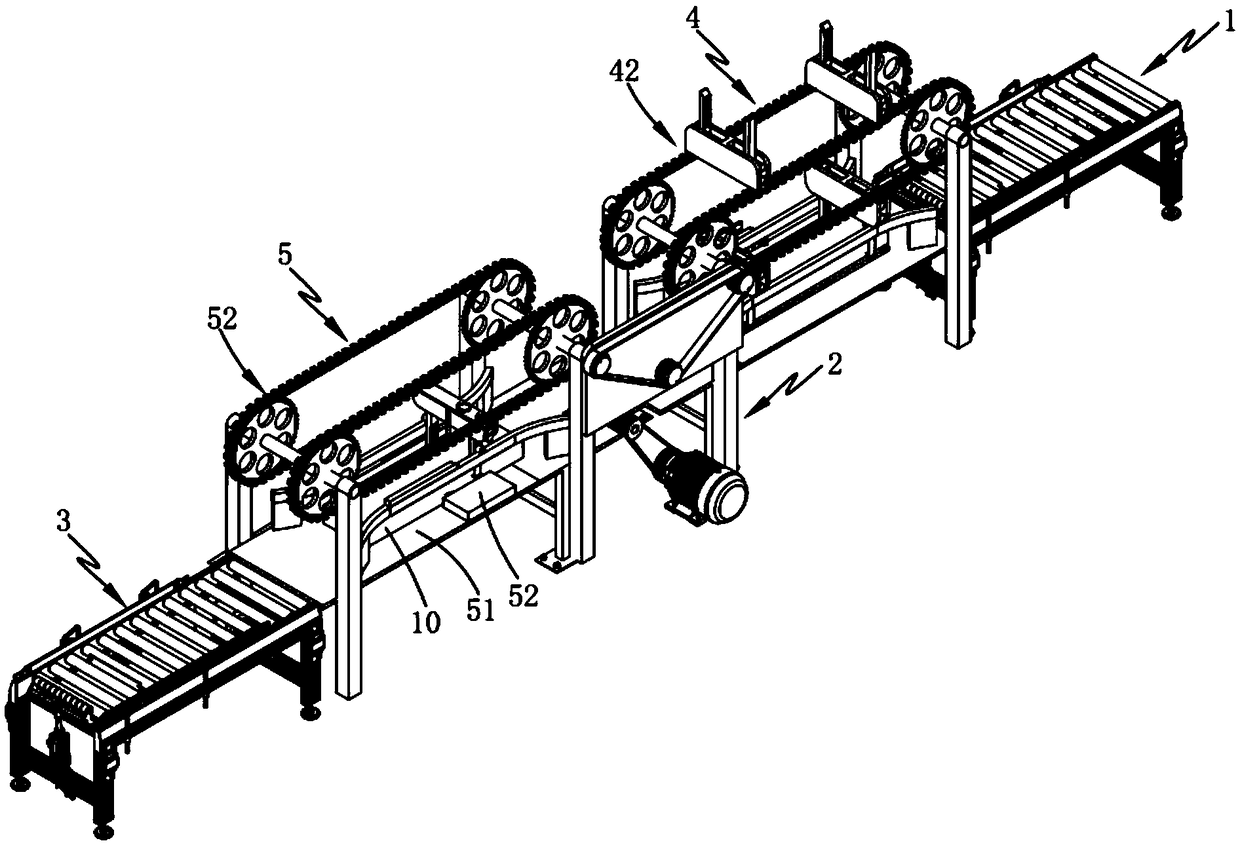

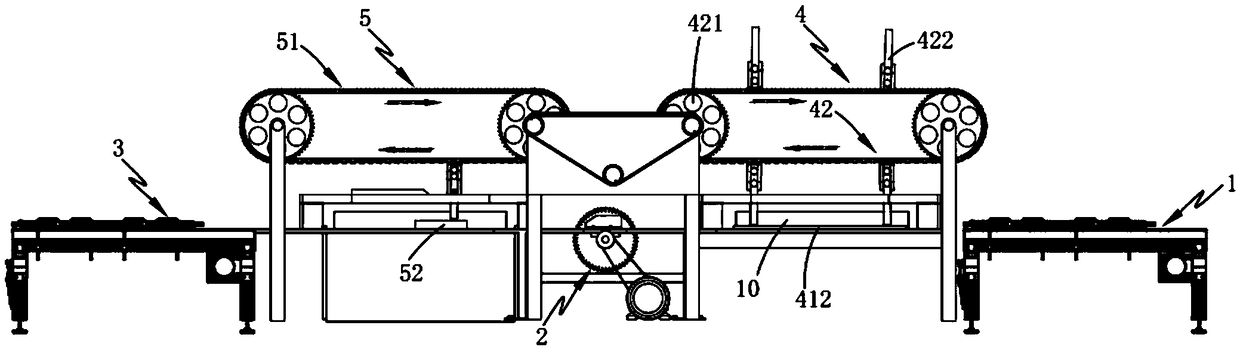

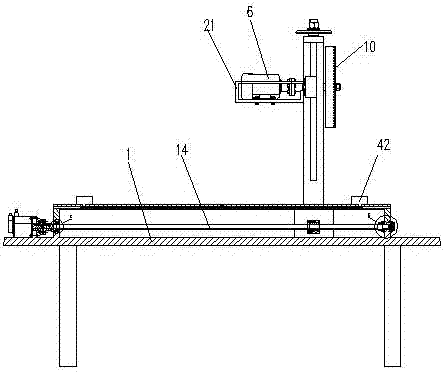

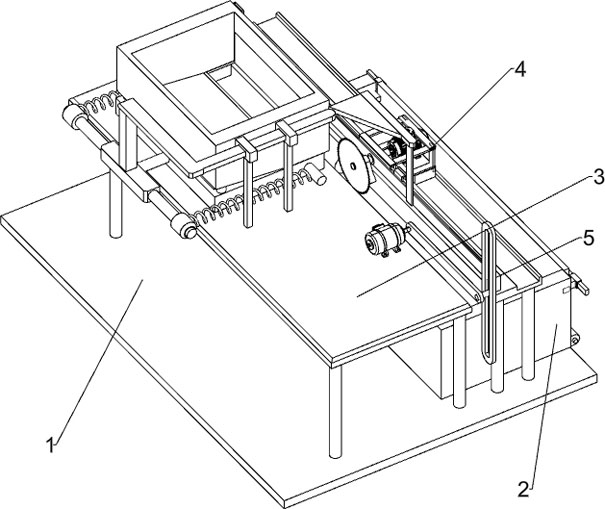

Continuous automatic processing production line for wood of furniture manufacturing

ActiveCN109291140ARealize fully automatic cuttingAchieve separationFeeding devicesGripping devicesProduction lineReciprocating motion

The invention provides a continuous automatic processing production line for wood of furniture manufacturing. The production line comprises a feeding device, a cutting device, an output device, a clamping and feeding device and a waste separating device, wherein the clamping and feeding device is arranged between the feeding device and the cutting device, and comprises a wooden block positioning mechanism and a clamping and transporting mechanism; and the waste separating device is arranged between the cutting device and the output device, and comprises a separating workbench, a clamping staggering mechanism and a separating mechanism. After the clamping and feeding device clamps wooden blocks in a mode of reciprocating motion, the stepwise feeding and cutting are carried out in the cutting device; after the cutting of the wooden blocks is completed, the clamping and feeding device is fitted with the waste separating device to carry out the staggering separation of finished products and waste, so that the full-automatic cutting and the waste separating of the wooden blocks are realized; and in this way, an original manual wooden block feeding and cutting method is replaced, so thatthe problem that the leftward and rightward swaying of the wood results in irregular wood cutting surfaces and the imprecise cutting in the prior art is solved.

Owner:佛山市顺德区博领家具有限公司

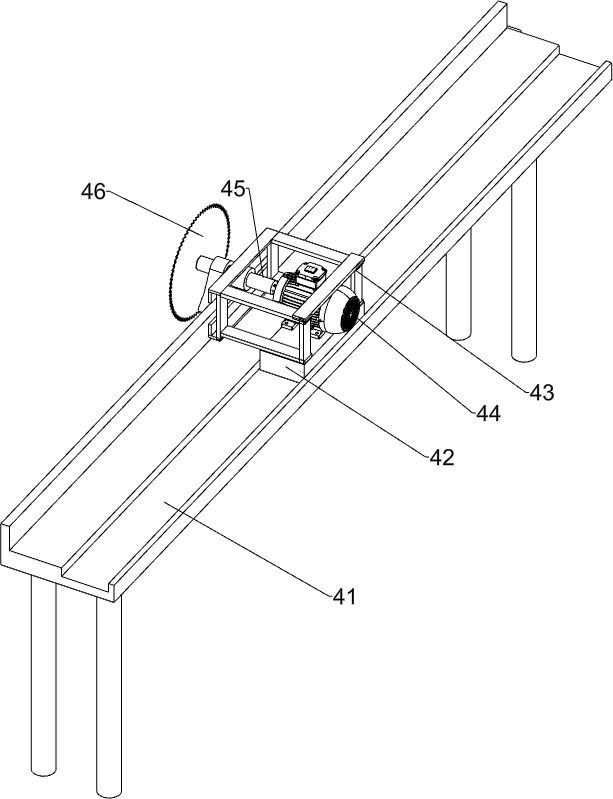

Improved log sawing machine

PendingCN107336286AOptimize the installation structureHigh precisionGripping devicesClamping devicesReciprocating motionSmall footprint

The invention discloses an improved log sawing machine, which comprises an operating desk, a saw bench and a saw blade device. The saw bench is arranged on the operating desk. The saw blade device is connected with the operating desk in a sliding mode. The saw blade device is arranged on the saw bench. The saw bench is provided with at least one clamping device of magnetic type. The operating desk is provided with at least two adjustable clamping devices. The log sawing machine has the advantages of being compact in structure, small in occupied area, achievable in adopting an ordinary feed screw nut pair for driving the reciprocating motion of the saw blade device, achievable in adopting a travel switch for simple control, high in cutting efficiency, low in labor intensity and convenient to operate. Furthermore, the improved log sawing machine is a practical woodworking machinery product of mechanical and electrical integration, and has a certain promotion value; the clamping device has a good improved effect, thereby being suitable for clamping logs of different sizes.

Owner:TAIZHOU POLYTECHNIC COLLEGE

Novel efficient board cutting device

InactiveCN105729578AEfficient cuttingAvoid pollutionGripping devicesClamping devicesEngineeringAutomation

The invention discloses a novel efficient board cutting device which comprises a base, a supporting device, a fixing device, a first bracket device, a second bracket device, a moving device, a cutting device and a cylinder device, wherein a collection box, first supporting rods, second supporting rods, first inclined rods and first cross rods are arranged on the base; the supporting device comprises a first supporting plate, a first frame, first concentration blocks, a first pipeline, a first fan, a first connecting rod, a second connecting rod and second inclined rods; the fixing device comprises a third supporting rod, a first rotating shaft, a first rotating part, a propping block and a friction block; the first bracket device comprises a first bracket, a first vertical rod, a second cross rod, a third inclined rod, a fourth inclined rod, a second bracket, a second vertical rod, a third cross rod, a third vertical rod and a first locating pillar; and the second bracket device comprises a third bracket, a fourth cross rod, a fifth vertical rod, a sixth inclined rod and a sixth vertical rod. According to the novel efficient board cutting device, boards can be cut quickly and efficiently, the automation degree is high, and the labor participation is reduced.

Owner:宁夏丰通新材料科技有限公司

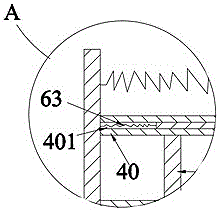

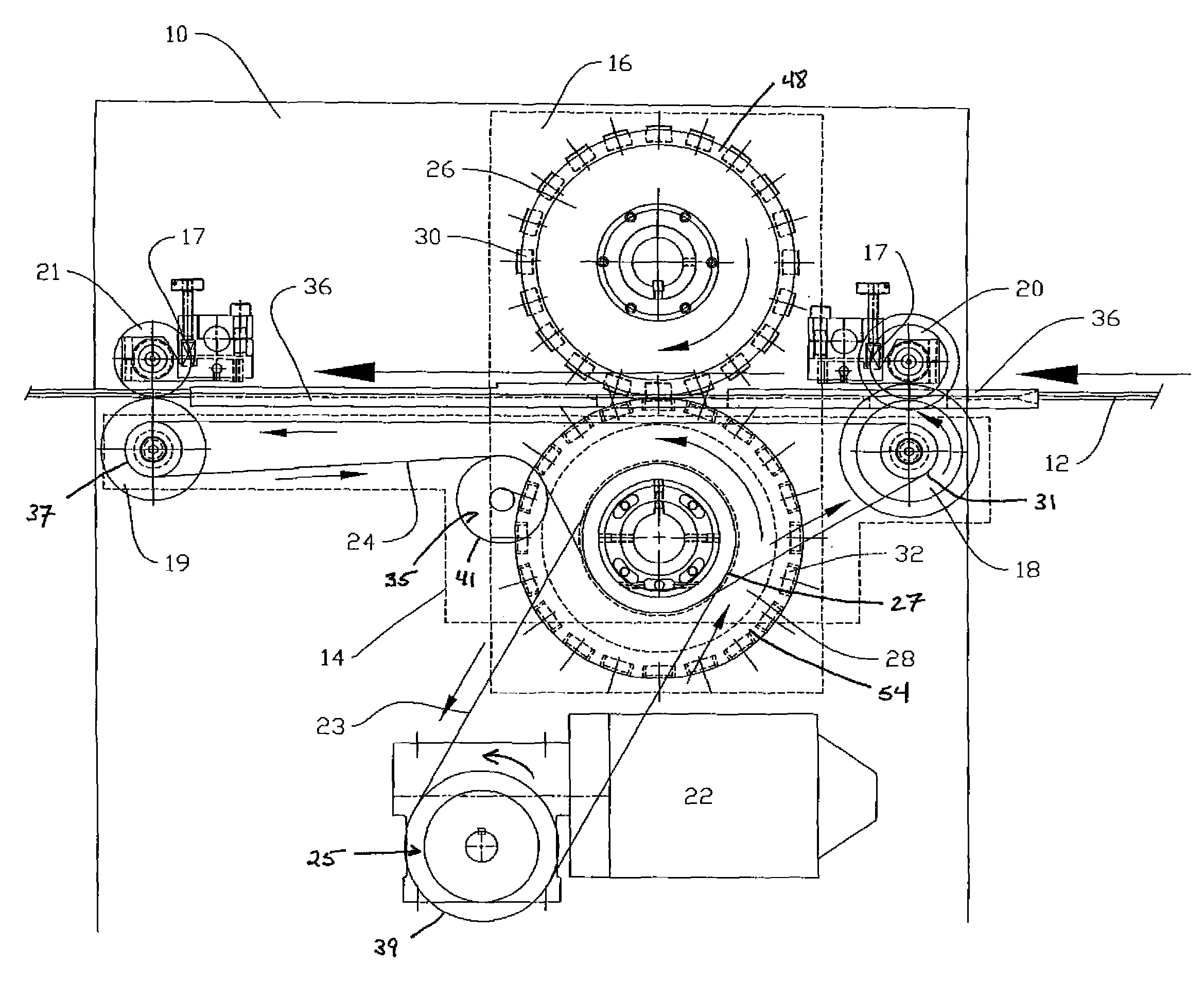

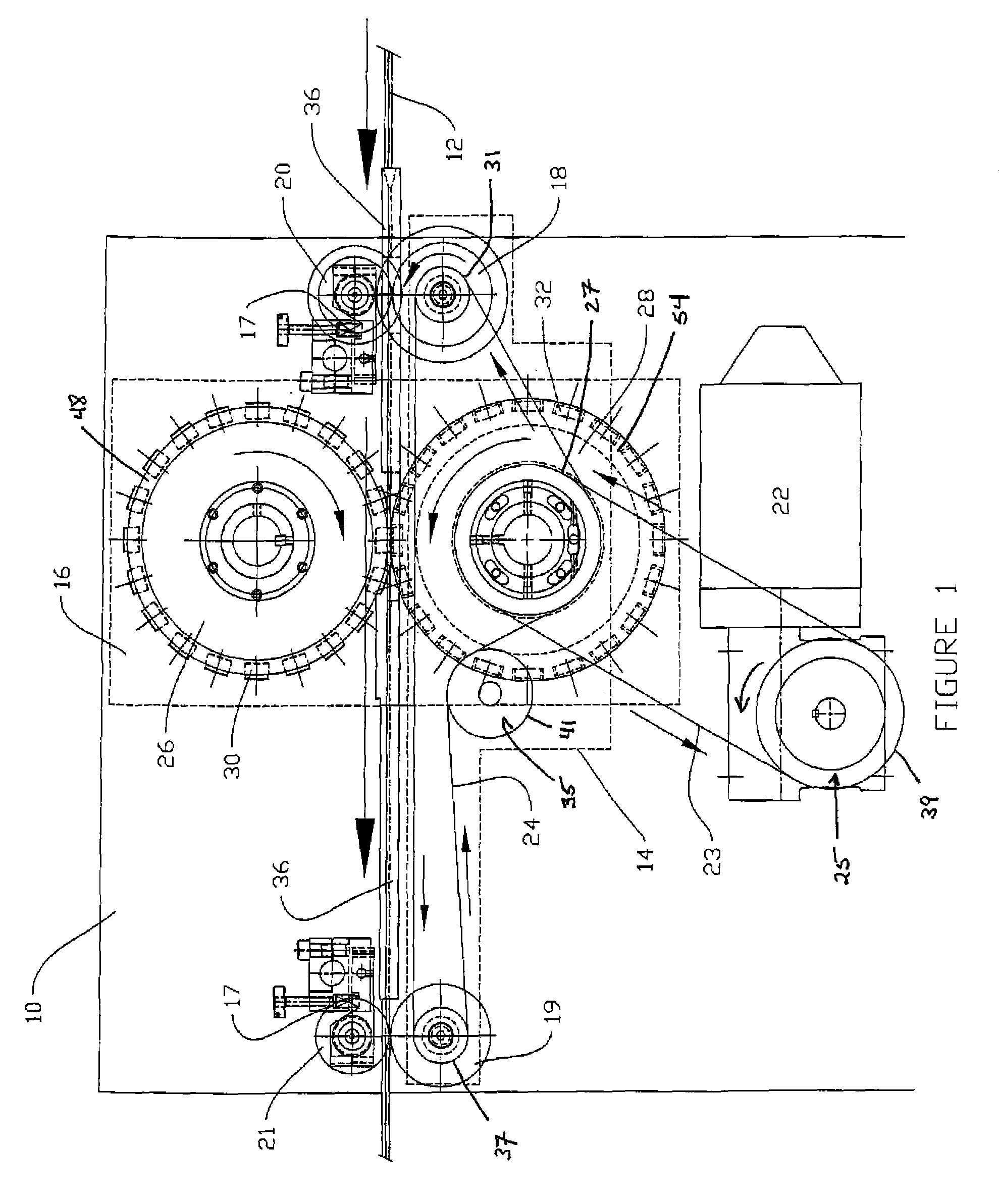

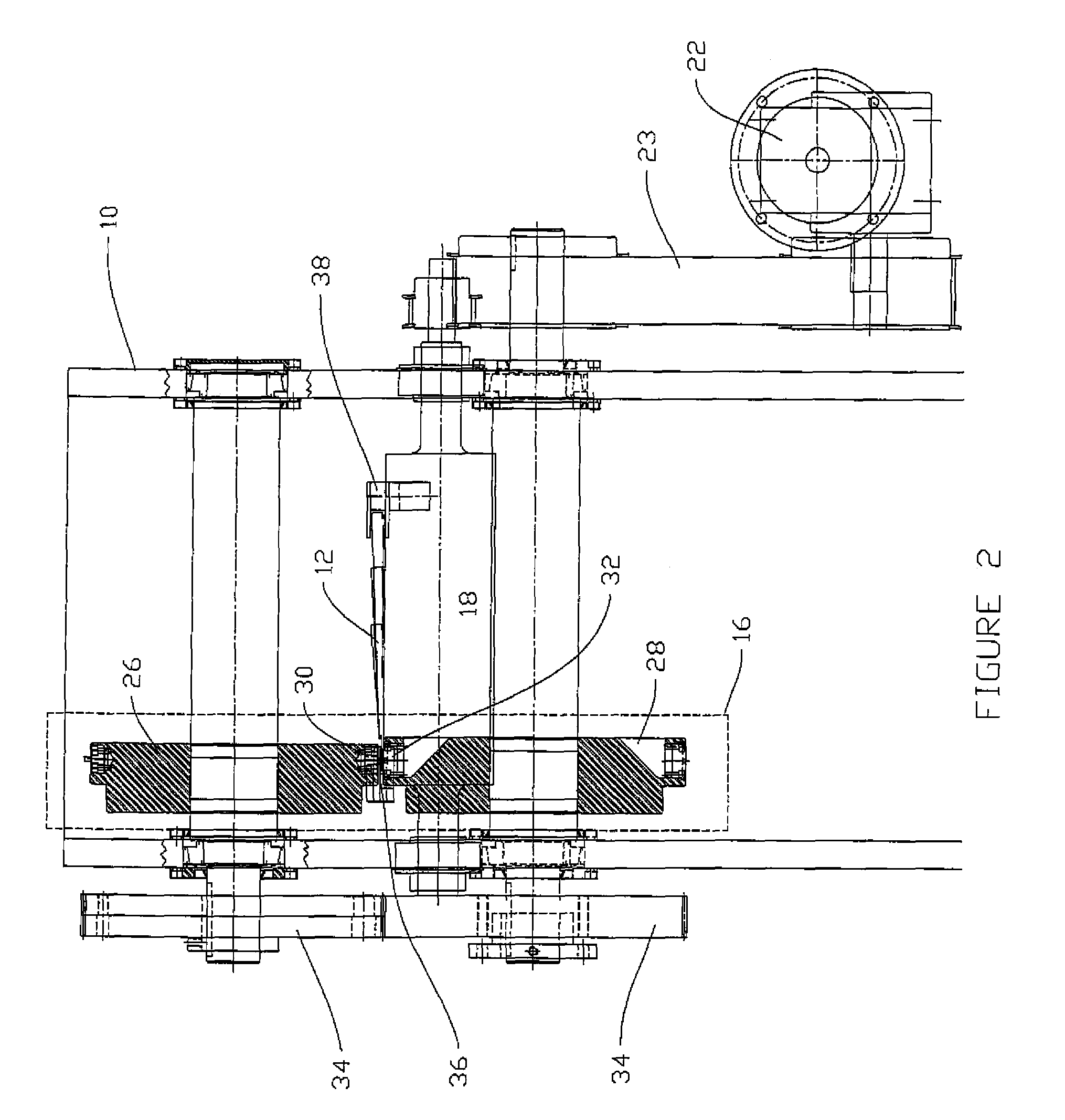

Punching apparatus

A punching apparatus for forming a series of slots in a board, comprising: an upper wheel and a lower wheel, wherein the upper wheel is opposed to the lower wheel, and further wherein: the upper wheel comprises a series of punches disposed on a frame of the upper wheel, wherein each punch comprises a shearing portion that extends from the frame, and which is configured in the shape of a slot; and the lower wheel comprises a series of mating dies, wherein each mating die of the series of mating dies comprises a cavity, wherein the shearing portion of a particular punch is gradually disposed within the cavity of a particular mating die of the series of mating dies as the upper wheel and the lower wheel move in relation to each other.

Owner:JAIN AMERICA HLDG INC

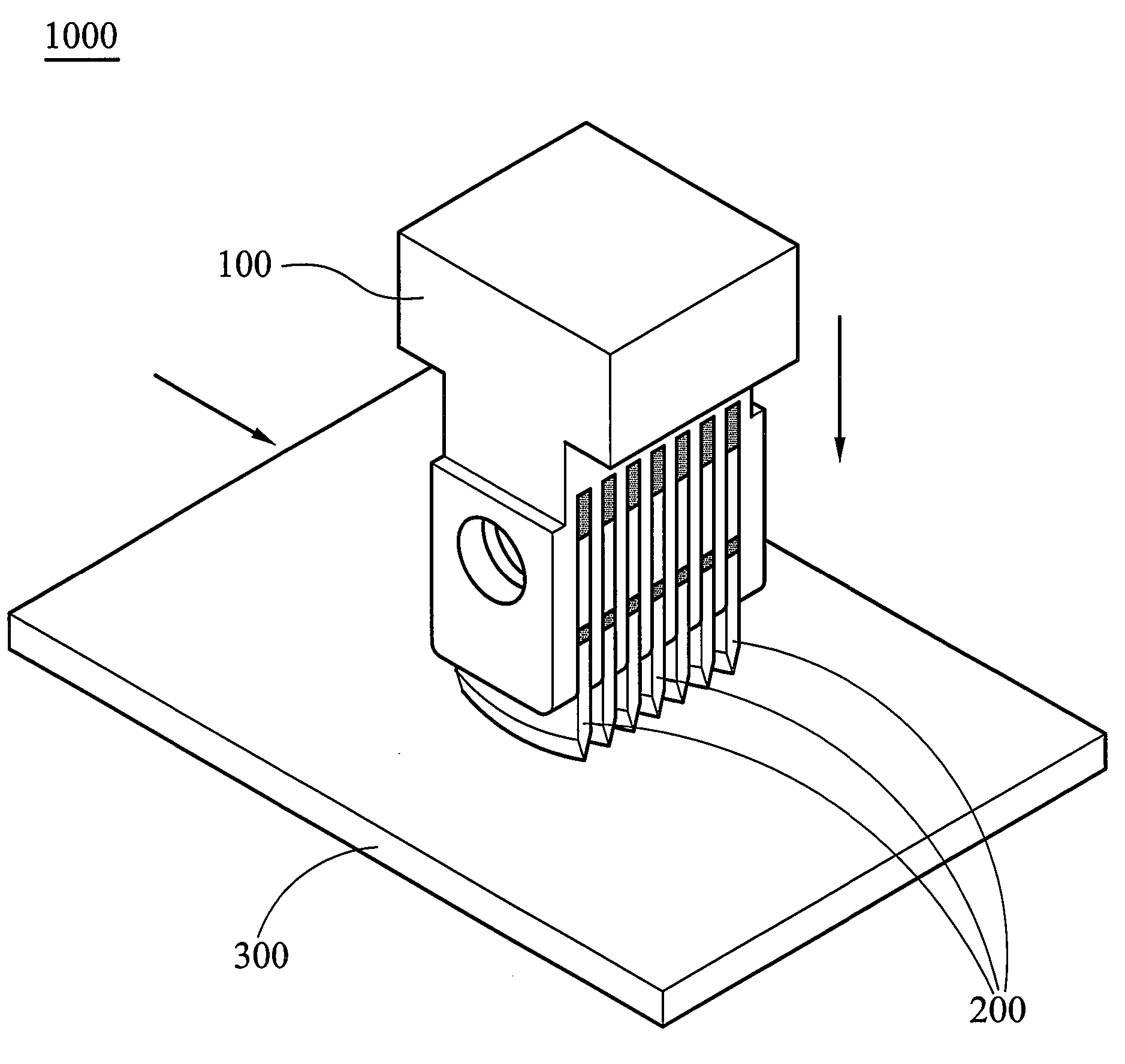

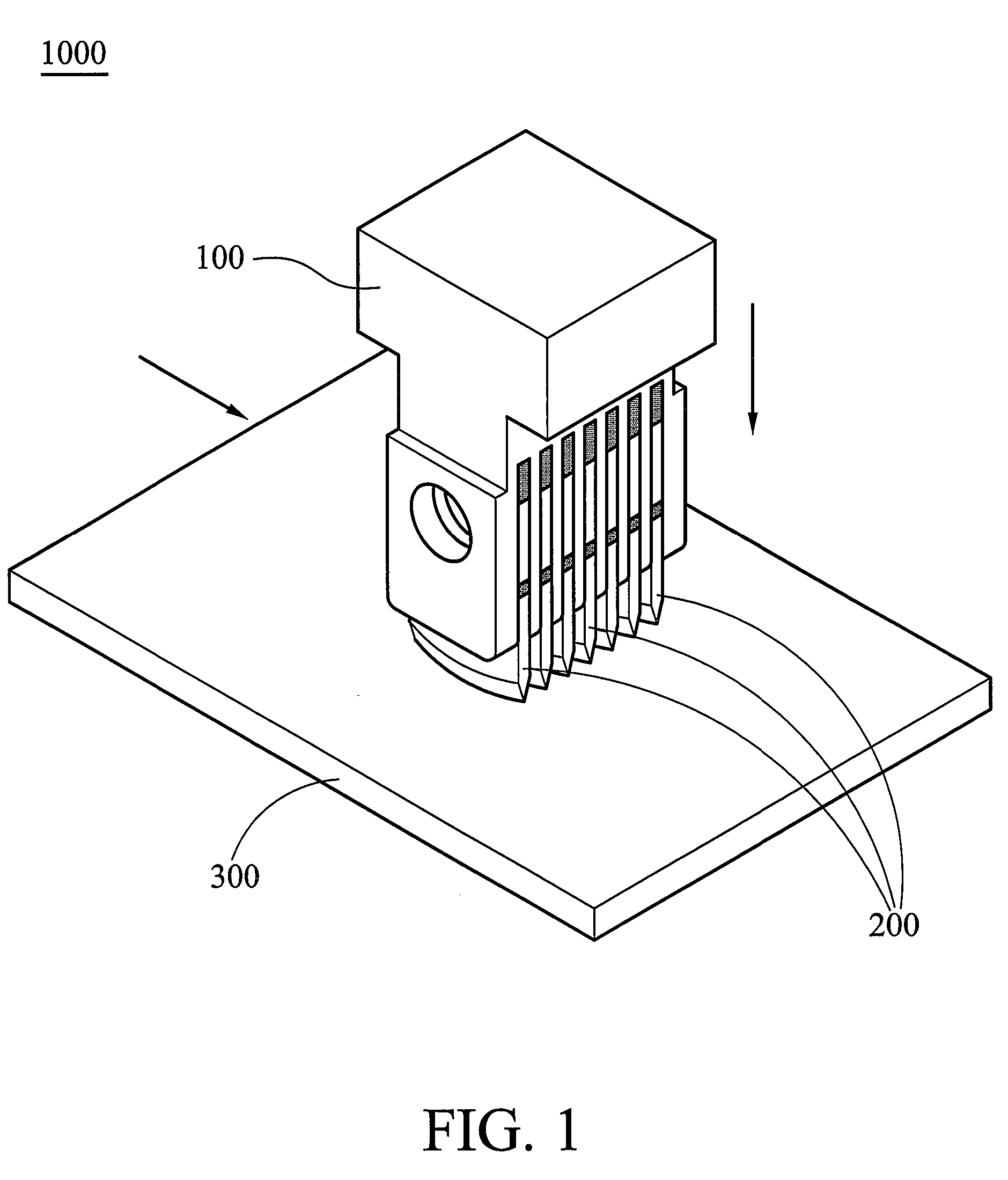

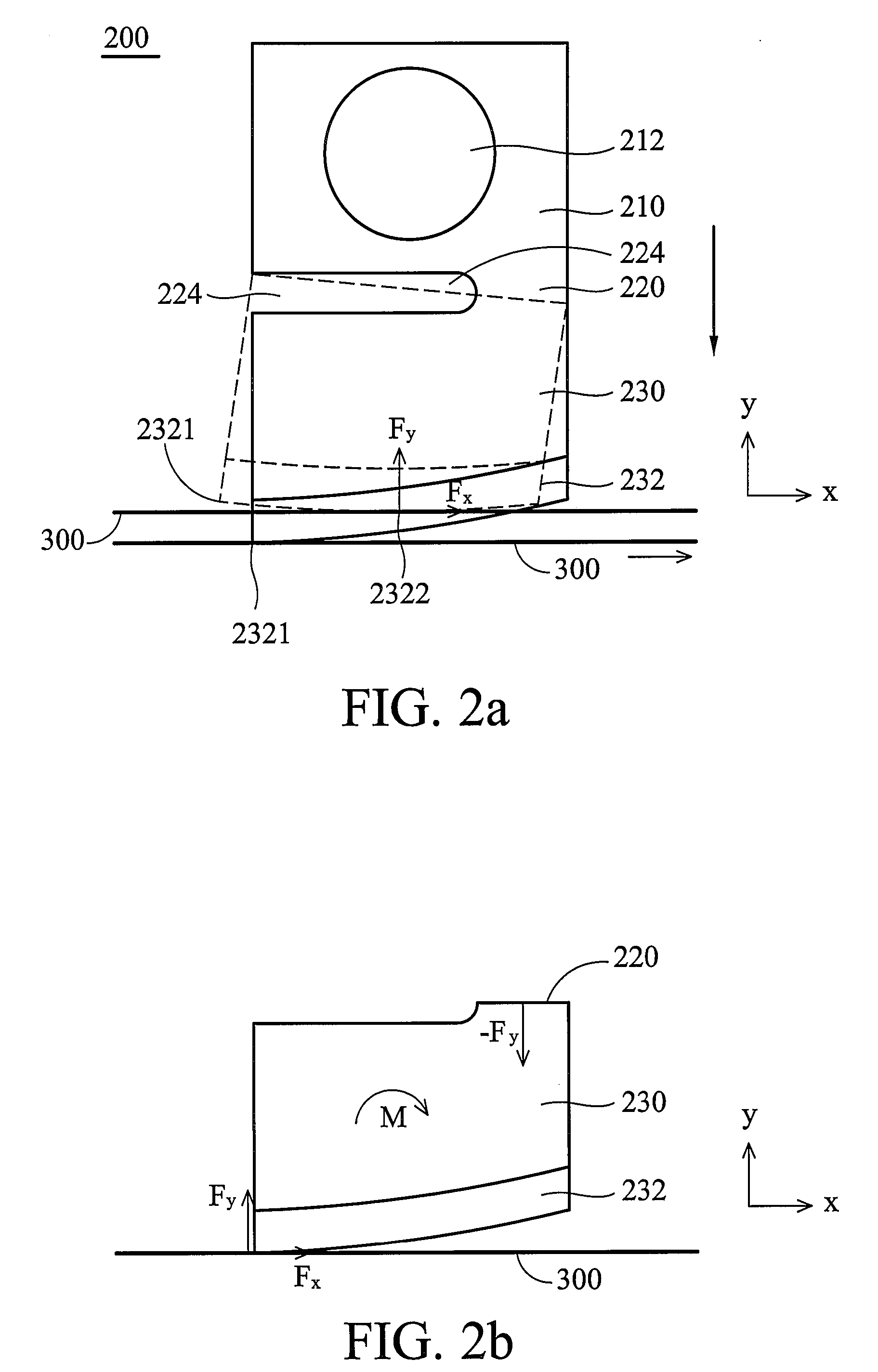

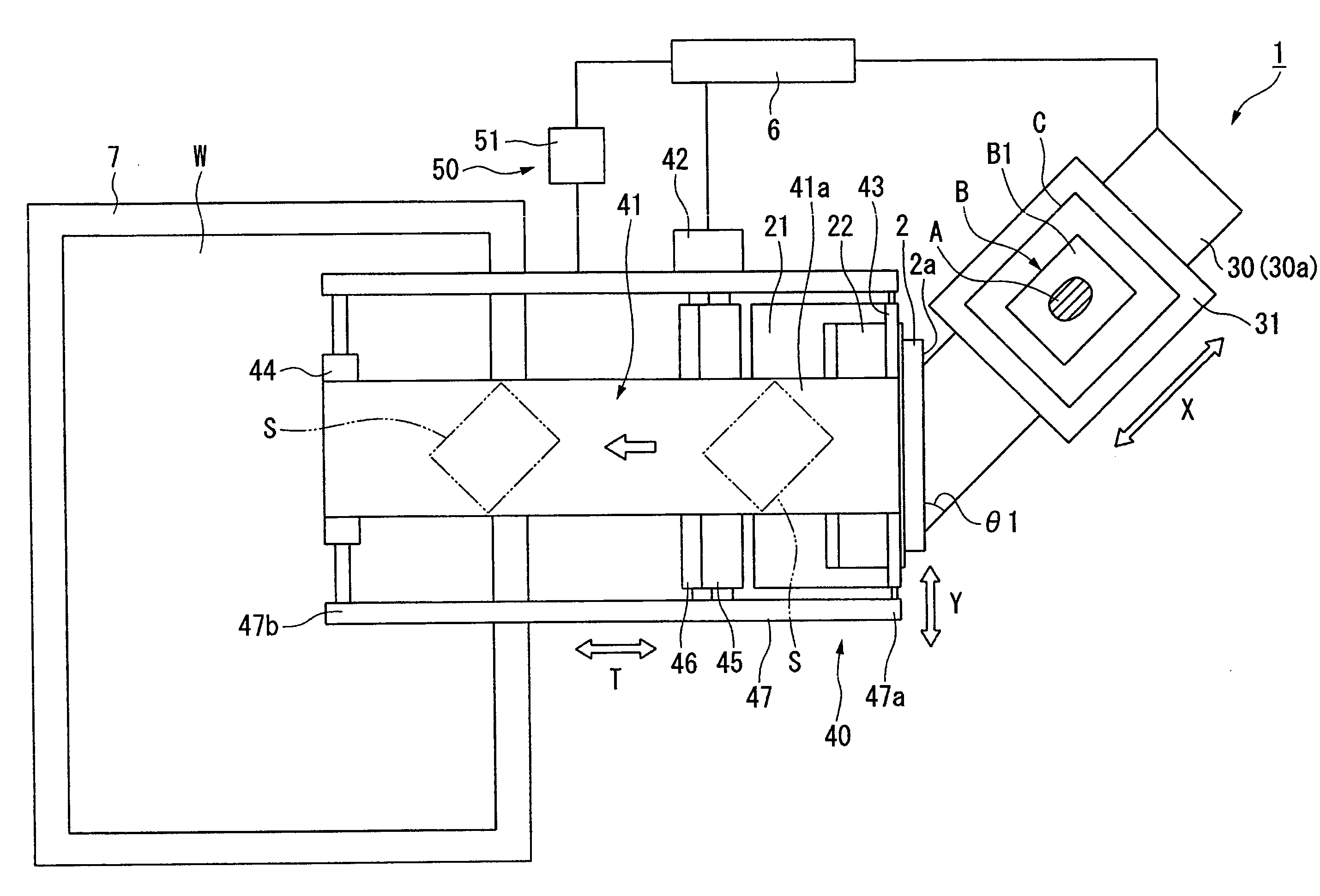

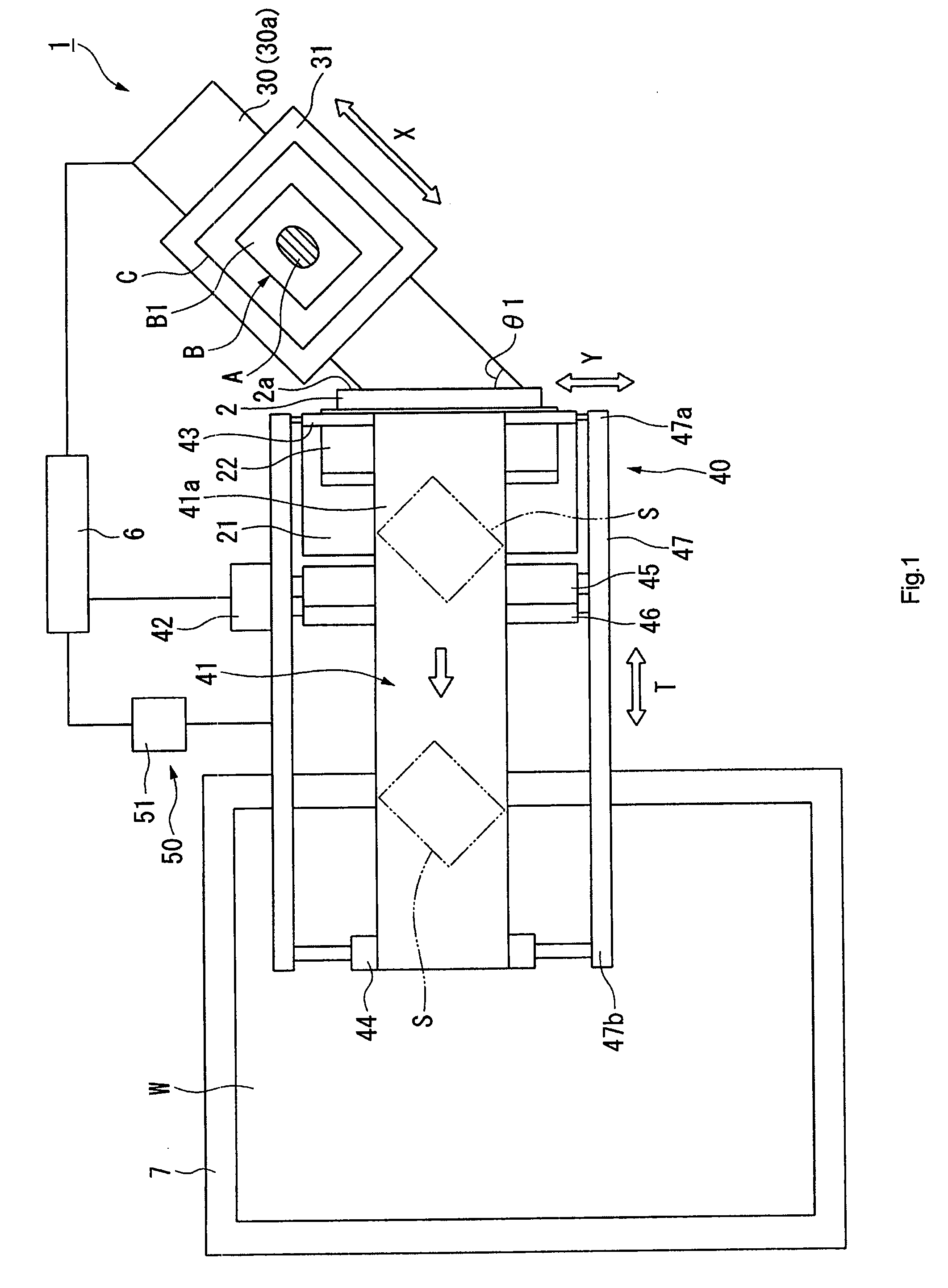

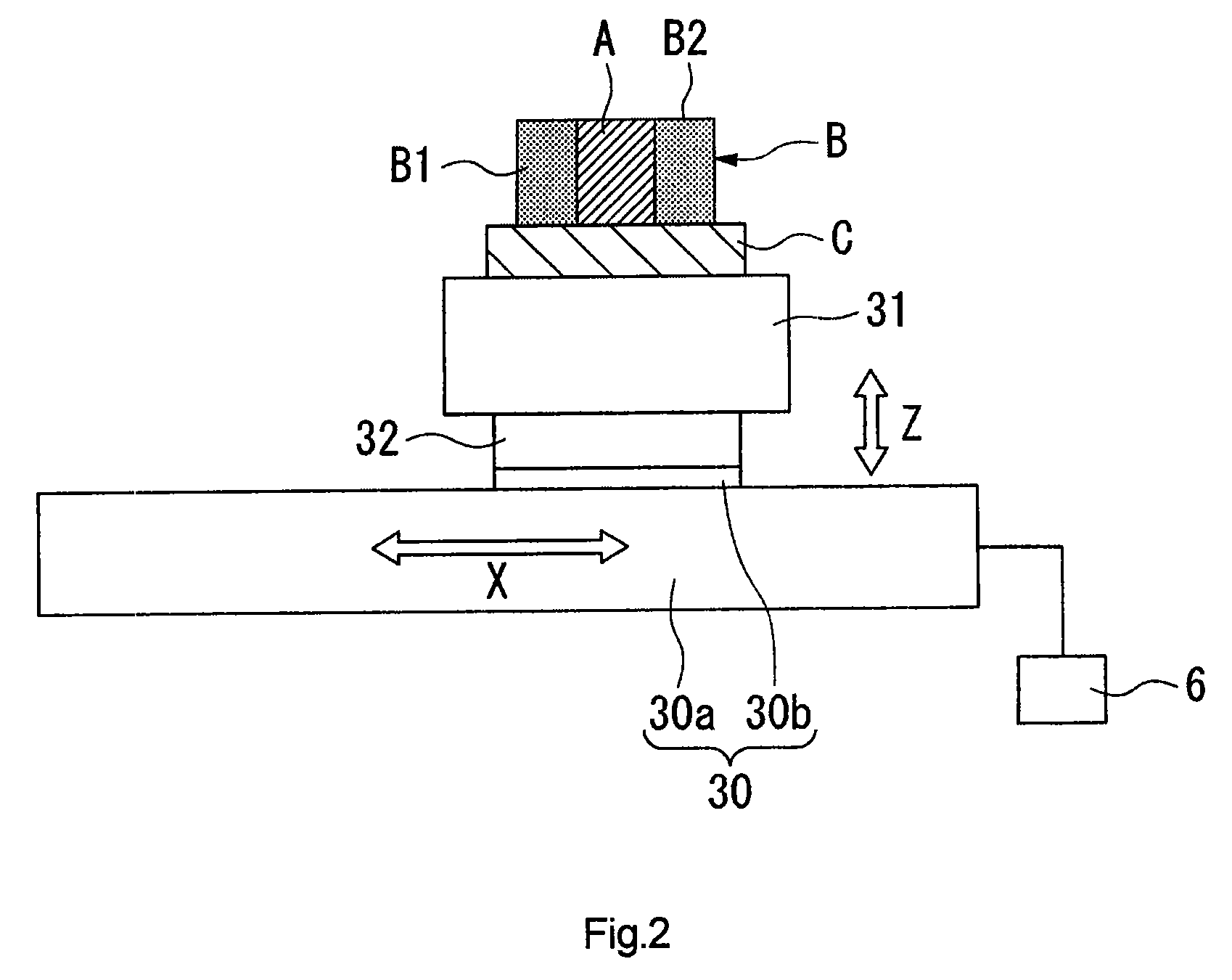

Thin section preparing apparatus and thin section preparing method

ActiveUS20090133556A1Easy to handleEasy to optimizeWithdrawing sample devicesGripping devicesEngineeringVelocity vector

A thin section preparing apparatus is provided, which prepares a thin section from an embedded block having a biological sample embedded and carries it, including: a cutter that slices the block at a pull angle; an approaching and separating mechanism that relatively moves the block and the cutter along an approaching and separating direction; a carrying mechanism having a carrying body arranged as one end side is near a nose, and a moving unit that moves the body along a transport direction; a sliding mechanism that relatively moves the block and the body along a nose direction; and a control unit that controls a combined velocity vector that combines a transport velocity vector of the body along the transport direction with a travel velocity vector of the body along the nose direction to be nearly equal to a block velocity vector of the embedded block along the approaching and separating direction.

Owner:SAKURA FINETEK JAPAN

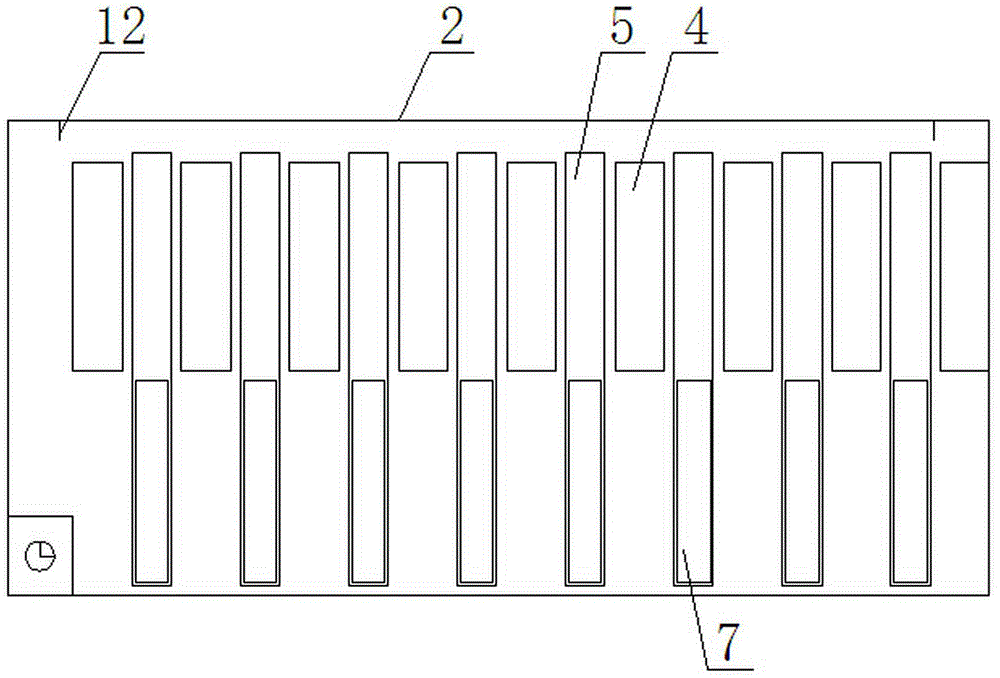

Strip cutting machine suitable for regular plate

ActiveCN104441065AImprove cutting accuracyImprove cutting efficiencyGripping devicesClamping devicesEngineeringMechanical engineering

The invention discloses a strip cutting machine suitable for a regular plate. The strip cutting machine comprises a bracket, a worktable, a cutting mechanism, a receiving box and a conveying belt, wherein a plurality of material-falling holes are formed in one side of the worktable; a cutting groove is formed between the any two adjacent material-falling holes; the width of each material-falling hole is greater than the distance between the material-falling hole and the cutting groove; the length of the cutting groove is greater than that of the material-falling hole; positioning parts are arranged at the two ends of the worktable; a positioning baffle is arranged above the material-falling holes close to the end part of the worktable; the distance between the positioning baffle and the worktable is greater than the thickness of a wood plate to be cut; the distance between the positioning baffle and a cutter close to the positioning baffle is equal to the width of a cut wood strip; the cutting mechanism comprises a plurality of cutters arranged in the cutting grooves; the conveying belt is arranged below the material-falling holes; the receiving box is arranged below the discharging end of the conveying belt. According to the strip cutting machine, one wood plate can be regularly cut into a plurality of wood strips in one time and the cut wood strips can be quickly collected.

Owner:广西北港不锈钢有限公司

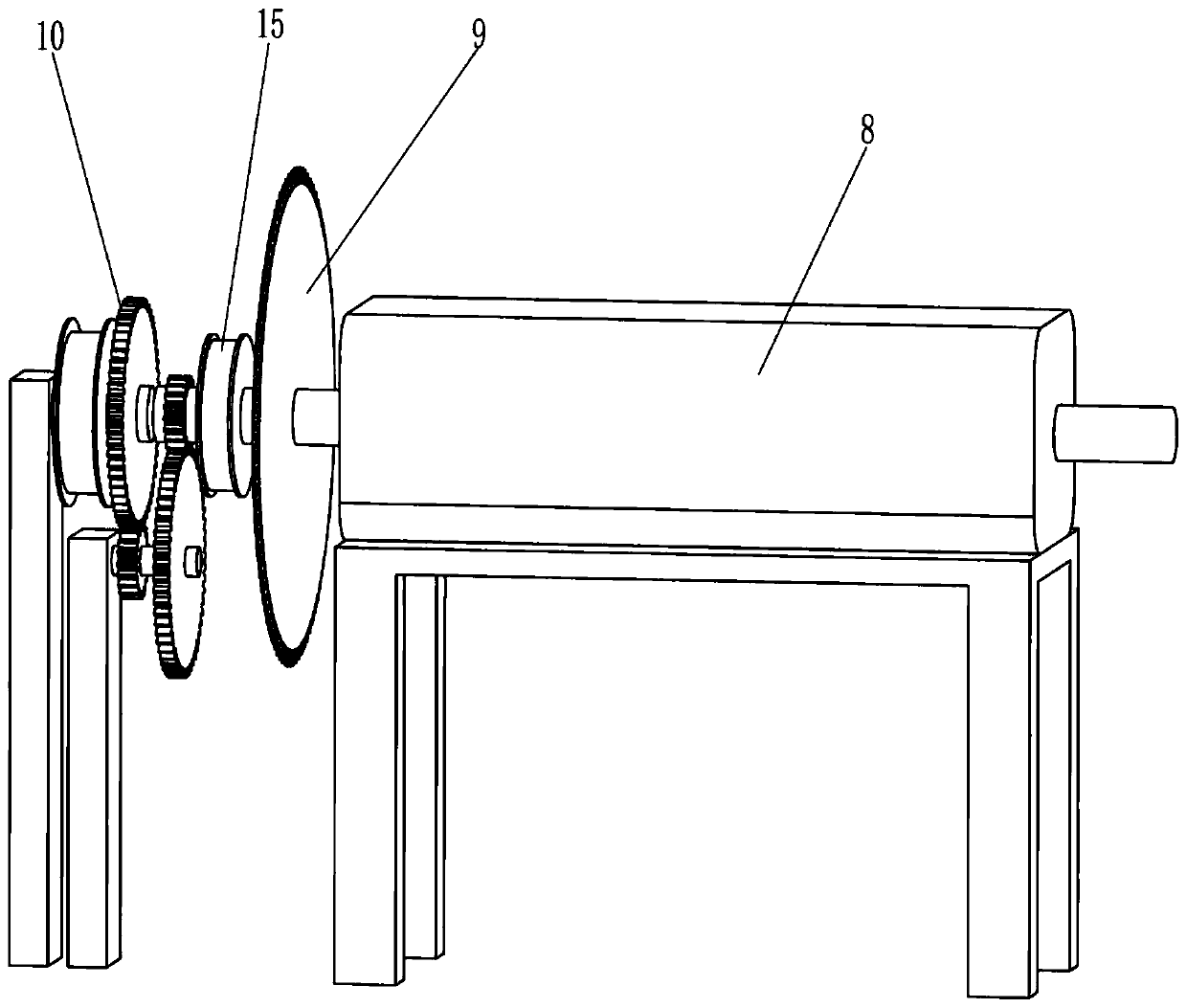

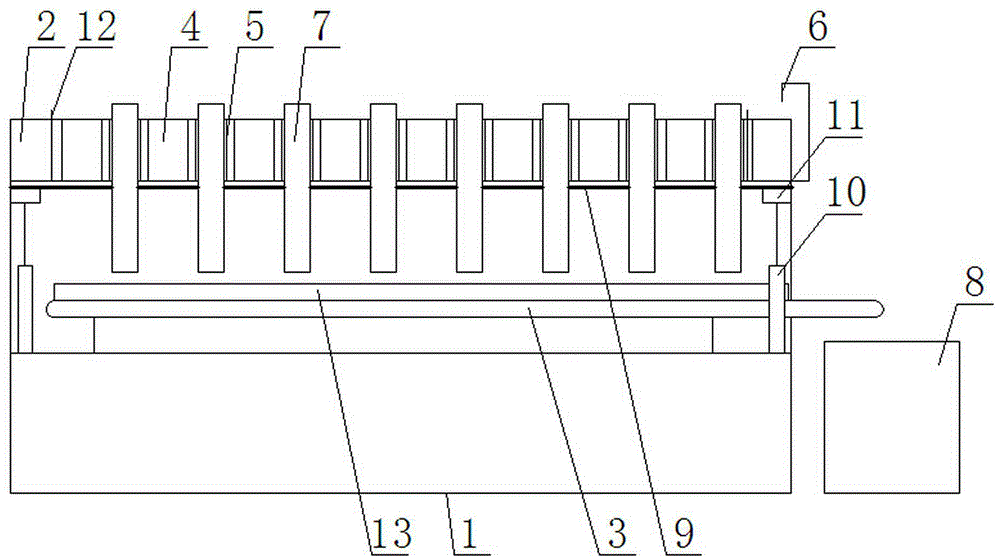

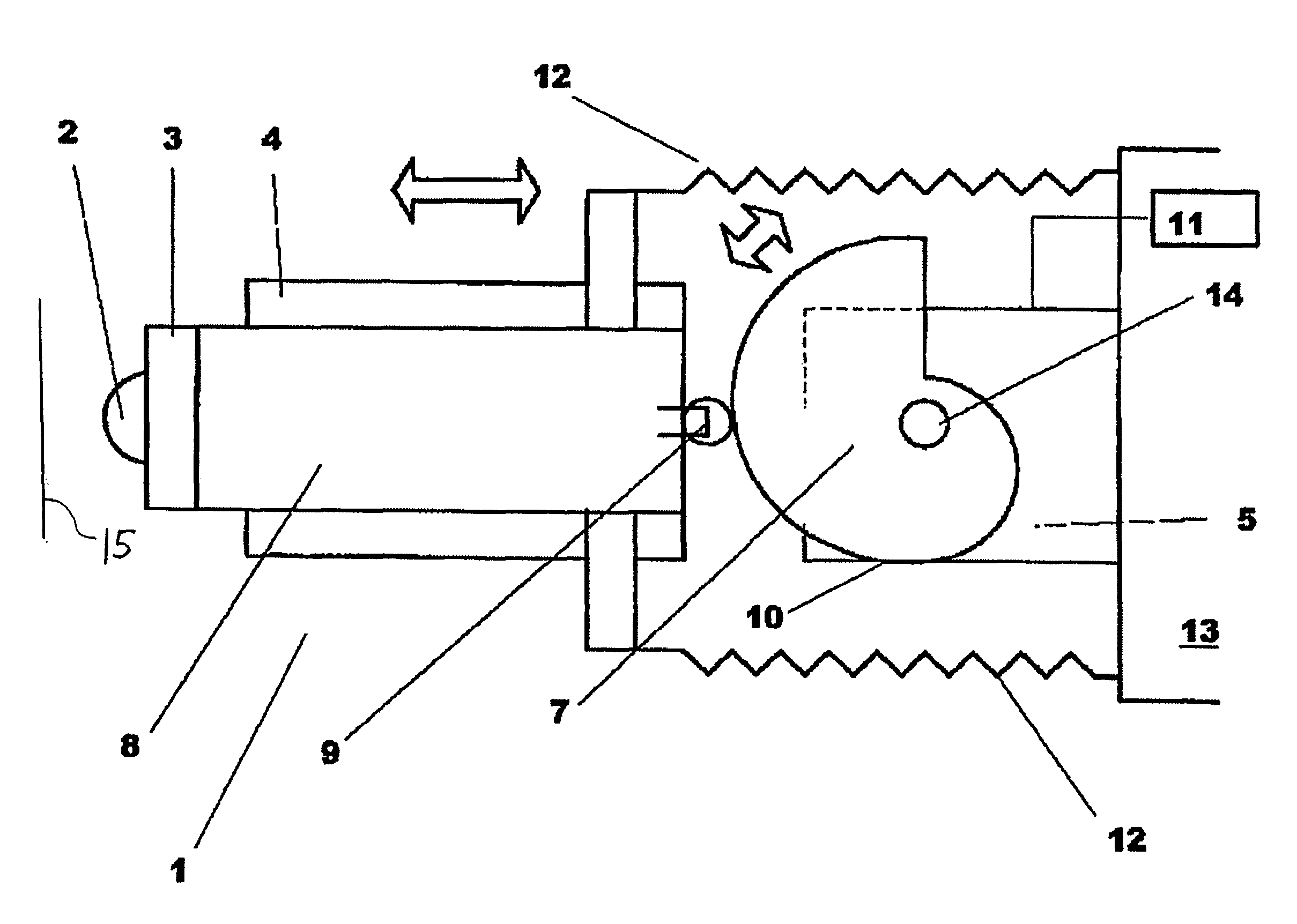

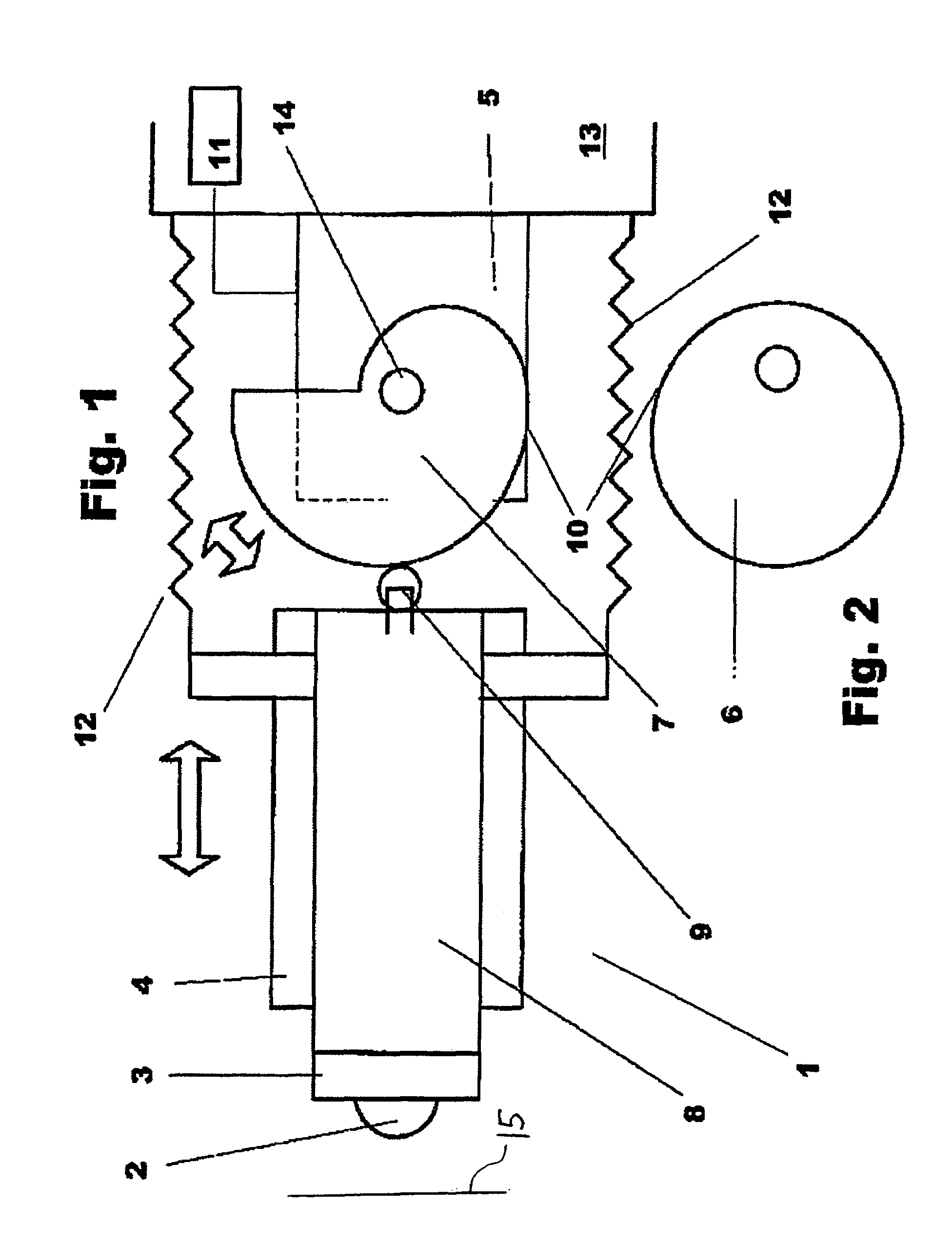

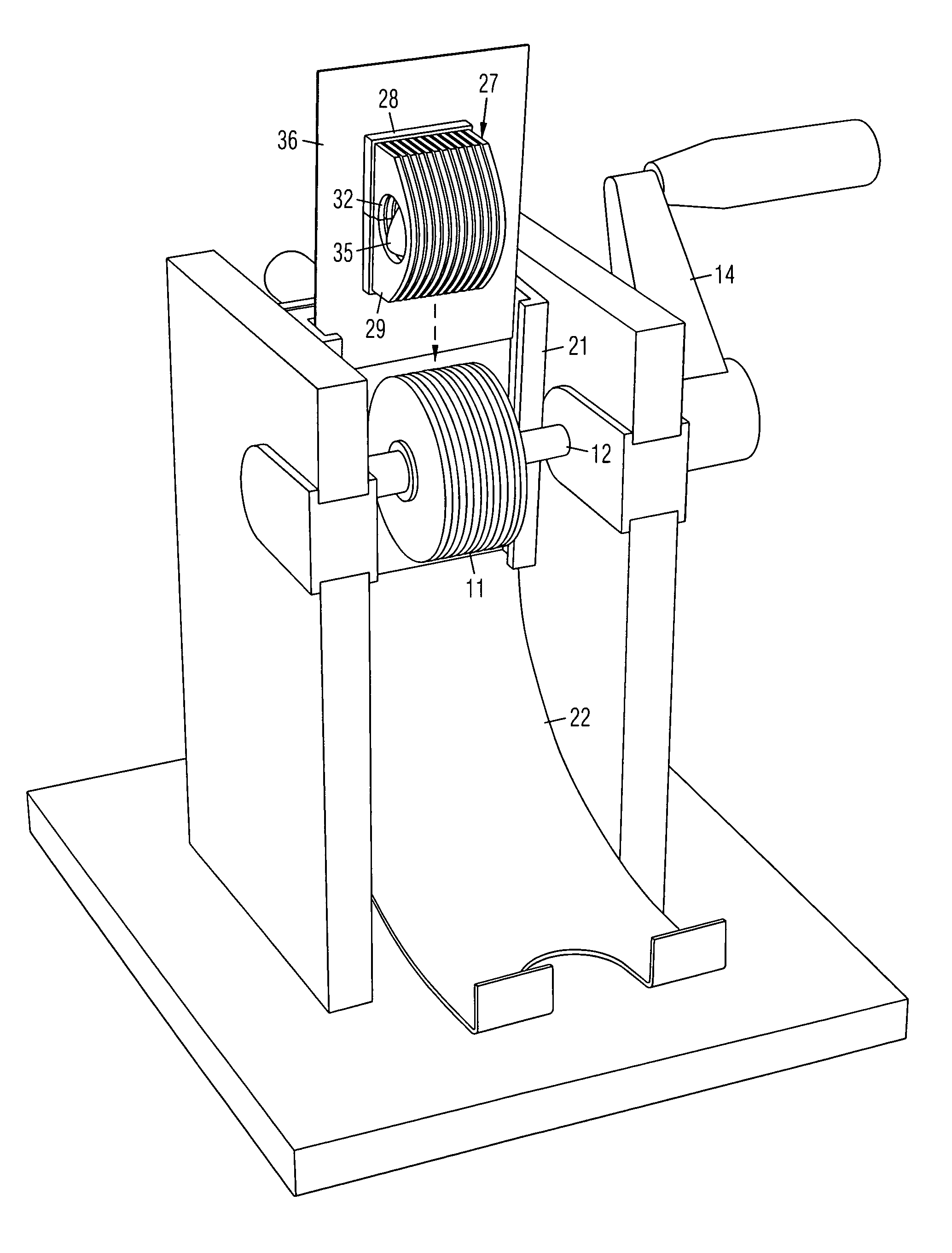

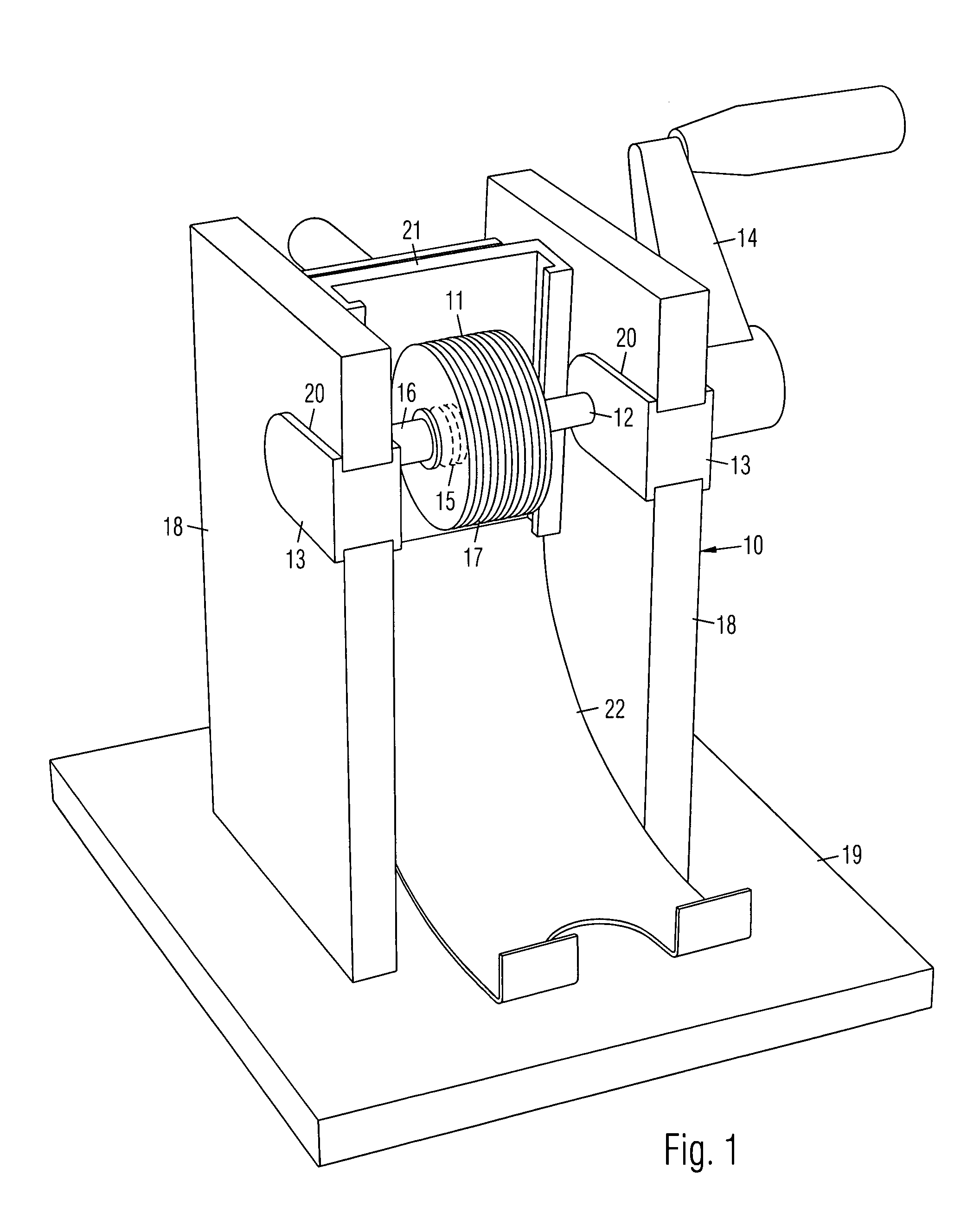

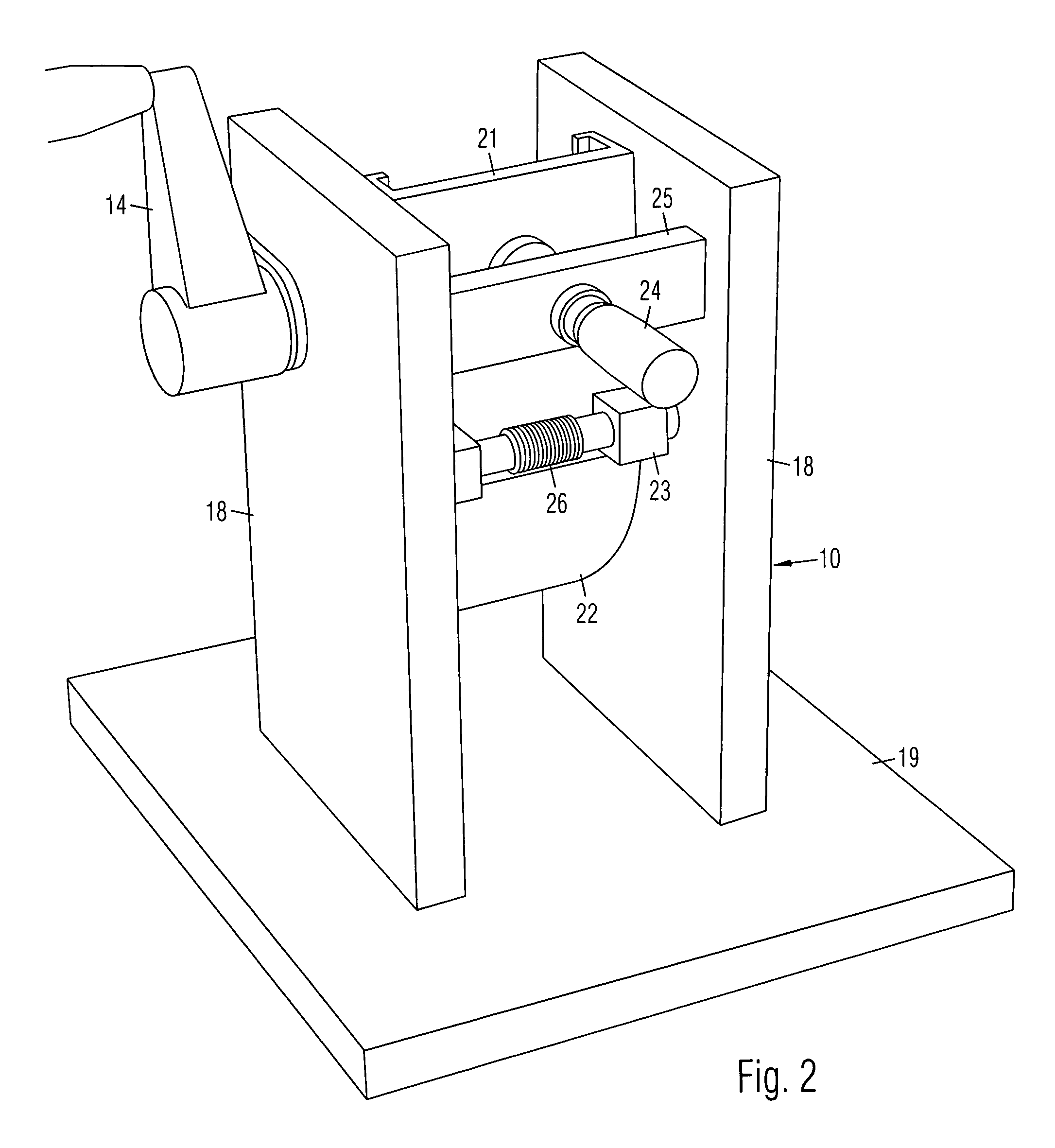

Feeding mechanism for a microtome

InactiveUS7313993B2Avoid unnecessary distractionsWithdrawing sample devicesPreparing sample for investigationCryostat microtomeDrive motor

A feed device (1) for a microtome, in particular for a cryostat microtome, for setting the cut thickness of the specimen (2) to be sectioned, is described. In order to set the cut thickness, either the cutting knife or the specimen holder (3) is mounted on a slide (8) in a slide guide (4) and is connected non-positively to a drive motor (5). The drive motor (5) is connected either to an eccentric cam (6) or to a helical cam (7), and the nonpositive connection between the motor (5) and the slide is accomplished via the eccentric cam (6) or the helical cam (7).

Owner:LEICA BIOSYST NUSSLOCH

Portable sawmill with bi-directional cutting circular saws

Owner:FENTON DAVID S +1

Wood cutting device with sawdust removing function

InactiveCN107718197AEase of workShorten the timeGripping devicesClamping devicesBiochemical engineeringWood cutting

A wood cutting device with a sawdust removing function mainly comprises a bottom plate, a cutter body and a wood body. The top of the bottom plate is fixedly connected with a box body, the top of thebox body is fixedly connected with a workbench, one side of the top of the workbench is fixedly connected with a first limiting plate, the other side of the top of the workbench is fixedly connected with a fixing plate, the top of the workbench is fixedly connected with a second limiting plate located between the first limiting plate and the fixing plate, and one side of the fixing plate is fixedly connected with a thread sleeve. By means of the wood cutting device with the sawdust removing function, easy and rapid fixation can be achieved in the wood cutting process, meanwhile, the fixing effect is good, in this way, the working difficulty is lowered for workers, time is saved, the working efficiency is improved, damage caused during wood cutting is also avoided, and the situations that resources are wasted and the manufacturing cost of furniture is increased are avoided.

Owner:刘毓玉

Forestry log auxiliary cutting device

ActiveCN111791309AAchieve automatic feedingEasy to cutFeeding devicesClimate change adaptationForest industryAgricultural engineering

The invention relates to a cutting device, in particular to a forestry log auxiliary cutting device. The forestry log auxiliary cutting device achieves the technical purposes of automatic dischargingand convenient cutting. According to the technical scheme, the forestry log auxiliary cutting device comprises a base the top side edge of which is provided with a collecting box; a workbench which isarranged in the middle of the top of the base; a cutting device which is arranged at the position, close to the workbench, of the top of the base, and is located over the collecting box; and a movingdevice which is used for driving the cutting device to reciprocate and is arranged on the workbench. The cutting device achieves the effects of automatic discharging and convenient cutting.

Owner:湖南森海碳汇开发有限责任公司

Tissue slicing device

InactiveUS7673545B1Reliable ejectionWithdrawing sample devicesGripping devicesRotational axisParallel plate

Owner:GIBERSON RICHARD T +1

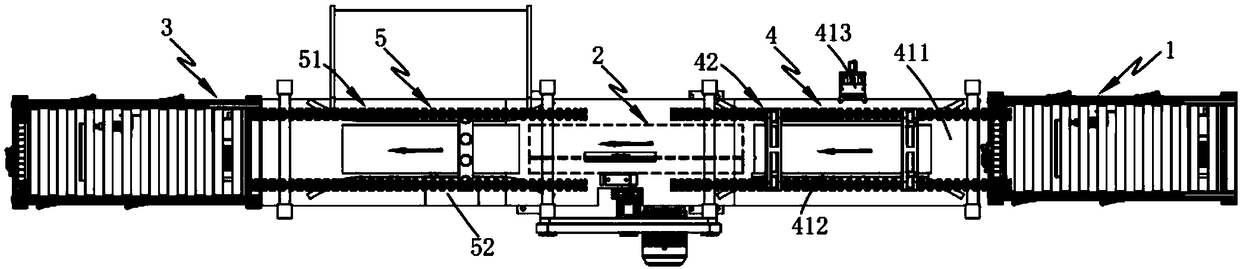

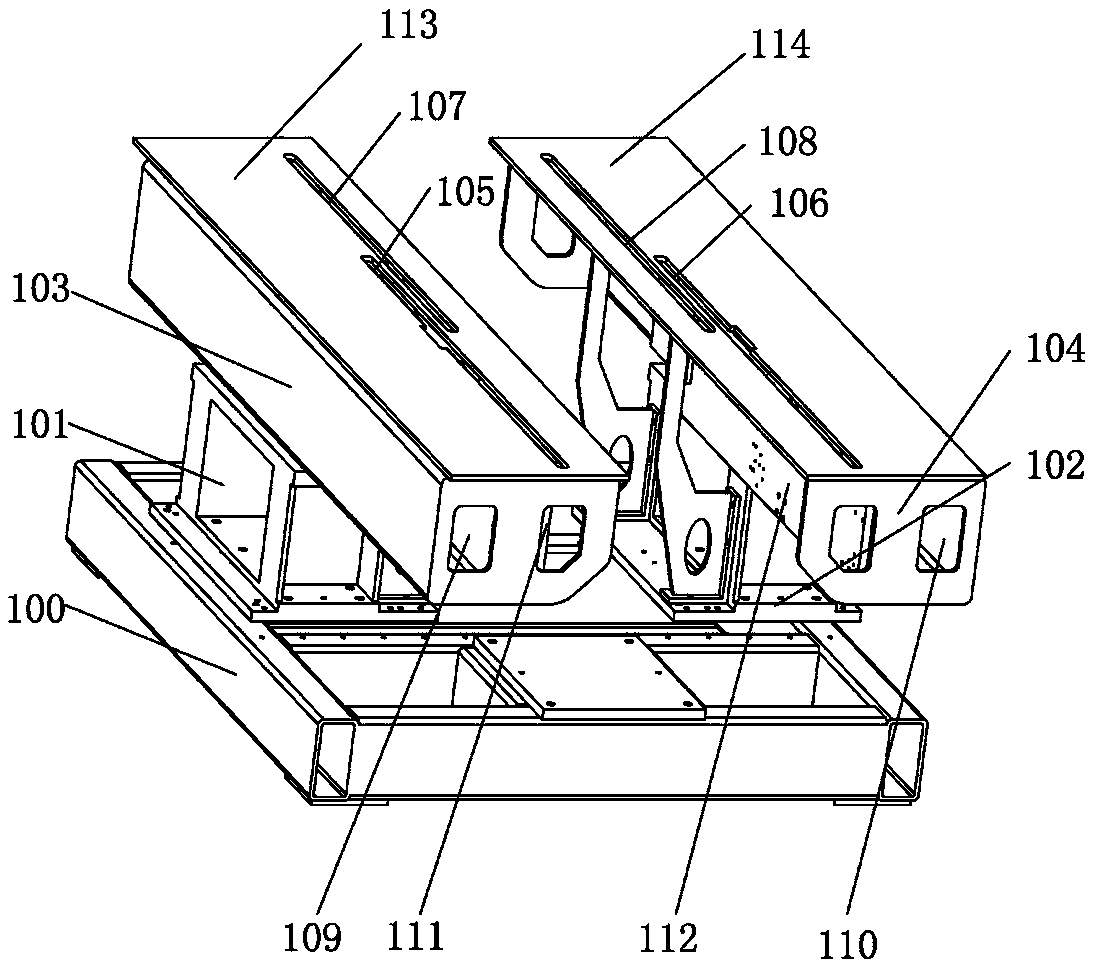

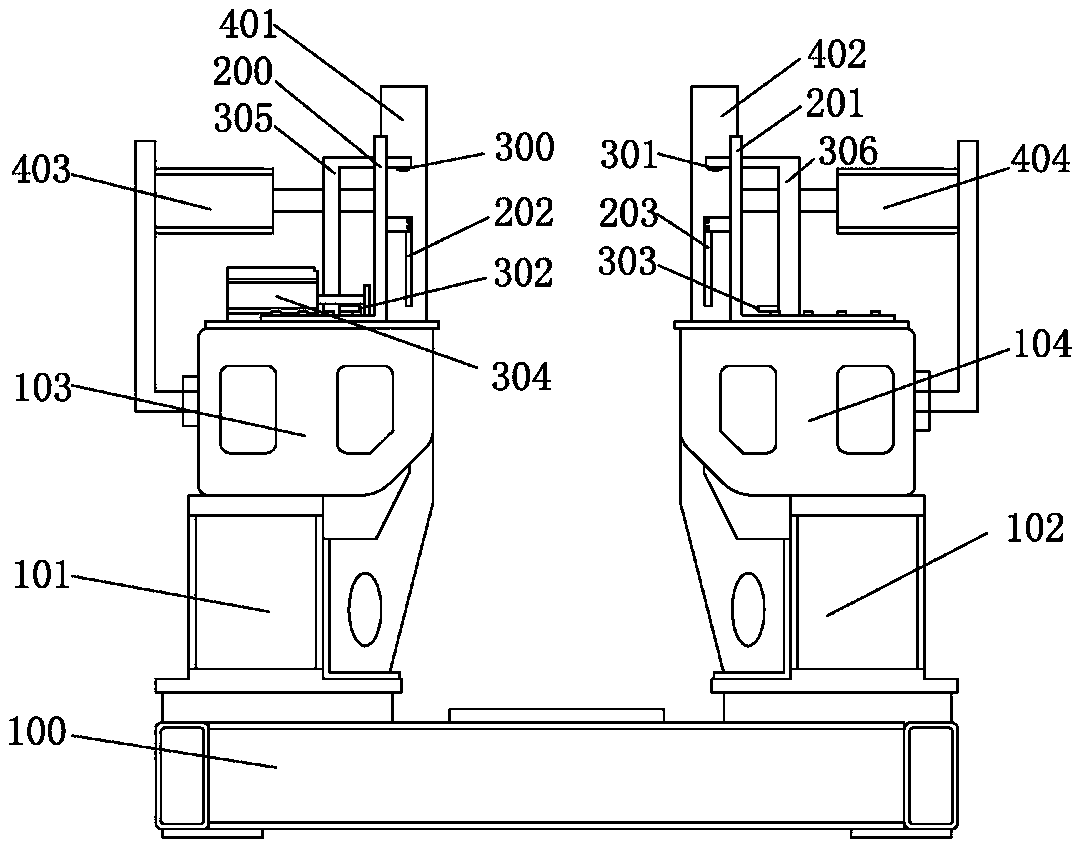

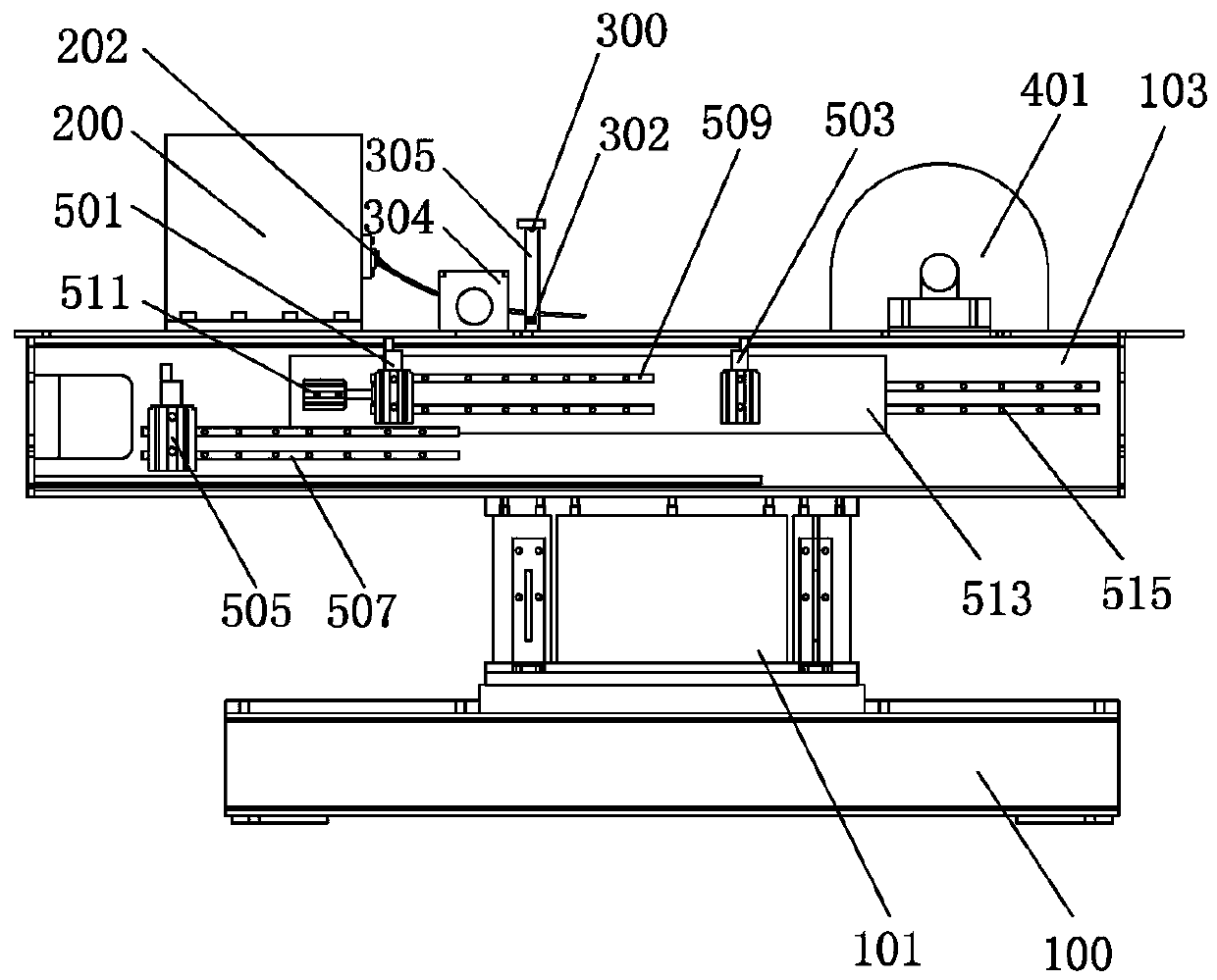

Automatic double-end sawing machine for processing chopping board

PendingCN109822677AReduce irregularitiesIncrease productivityFeeding devicesGripping devicesEngineeringMechanical engineering

An automatic double-end sawing machine for processing a chopping board comprises a frame, a conveying mechanism, a chopping-board horizontal-position adjustment system, a sawing device and a clampingconveying system, wherein the conveying mechanism is arranged on the frame and used for conveying the chopping board to a chopping-board horizontal-position adjustment station; the chopping-board horizontal-position adjustment system is used for adjusting the horizontal position of the chopping board so that two ends of each of an upper board layer and a lower board layer of the chopping board canbe cut; the sawing device is arranged at a sawing station and used for sawing the ends of the chopping board passing through; and the clamping conveying system is used for clamping the chopping boardof which the horizontal position is adjusted and for conveying the chopping board through the sawing station. The automatic double-end sawing machine for the chopping board is achieved; the choppingboard produced is more in line with the requirements; the problem of irregularity of the chopping board in manual sawing is solved; the risk during the processing is reduced; and more importantly, theautomatic double-end sawing machine can cooperate with other processing machines for the chopping board to realize full-automatic flow-line operation for processing the chopping board, thereby improving the production efficiencies of enterprises.

Owner:浙江千束家居用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com