Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

319results about How to "Reduce irregularities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

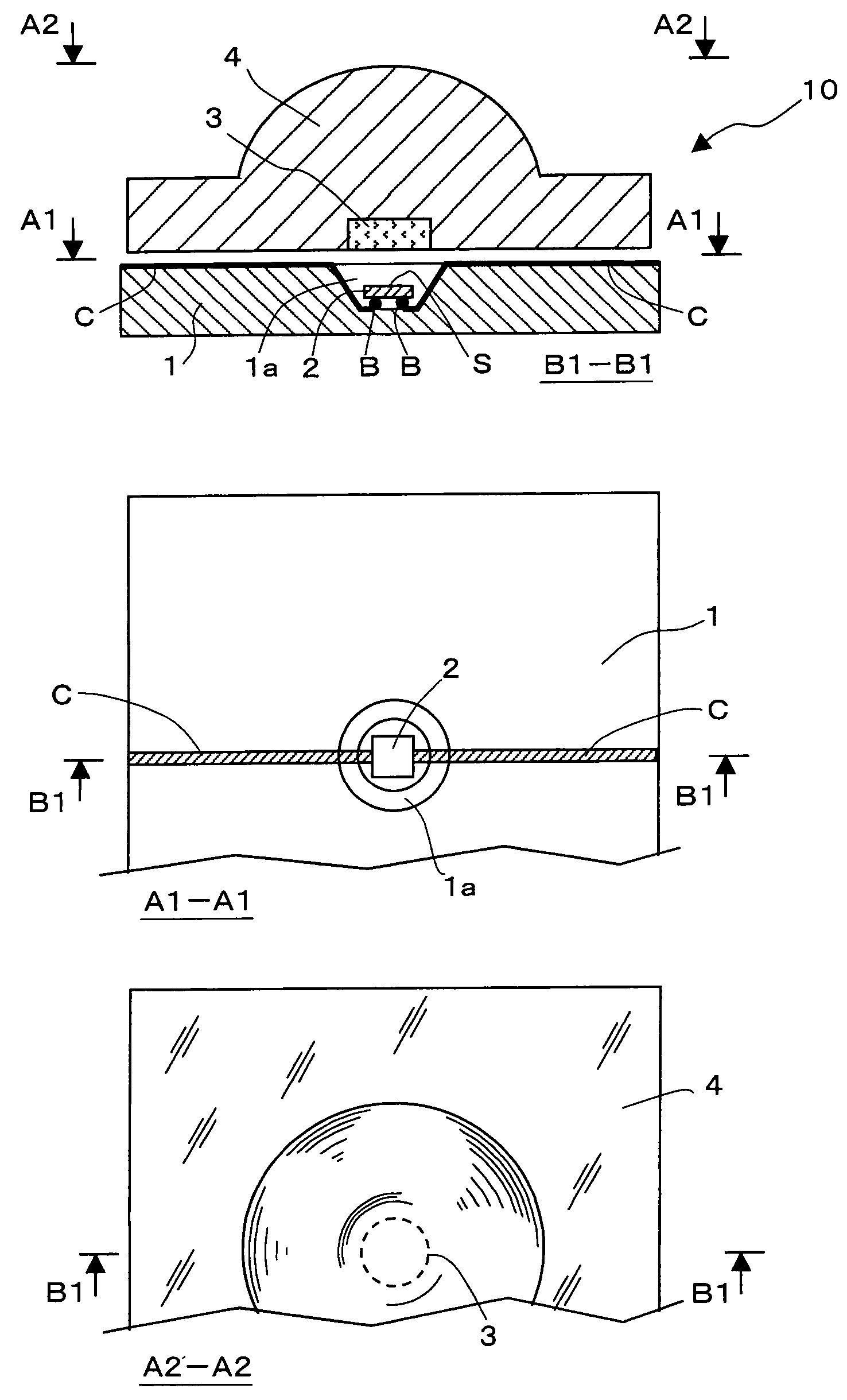

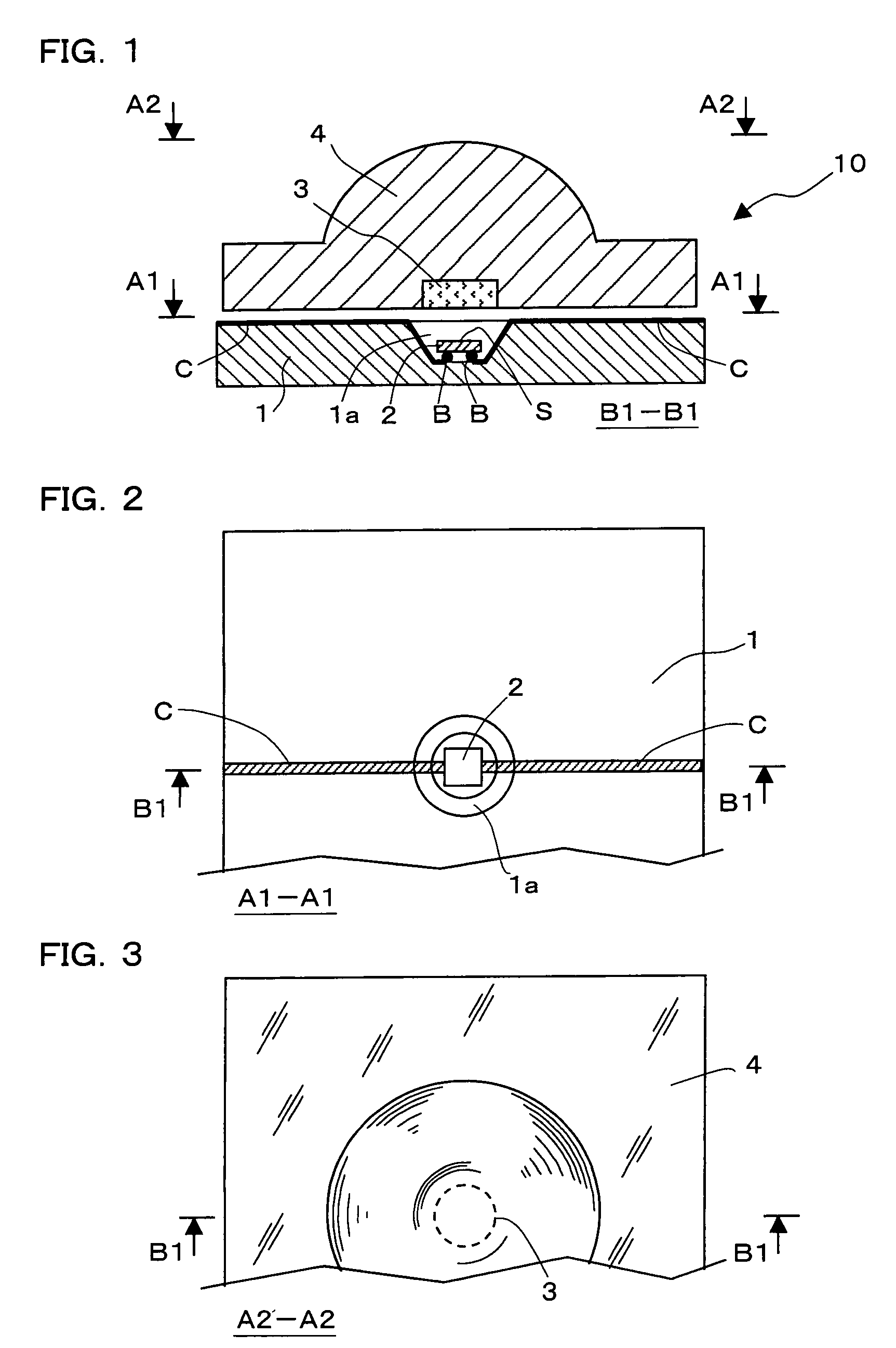

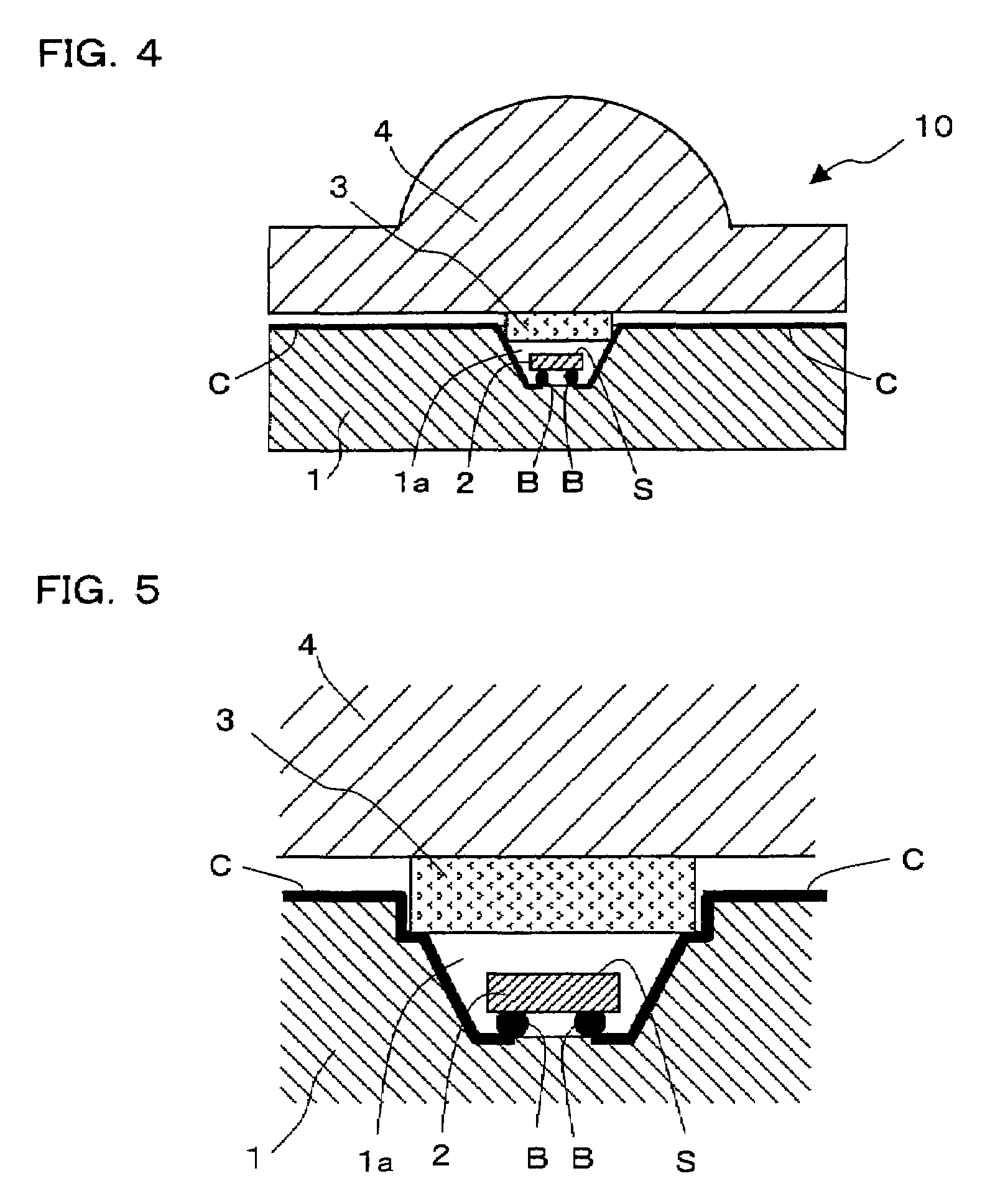

Light emitting device using led

InactiveUS20040190304A1Extended service lifeEffective coolingDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

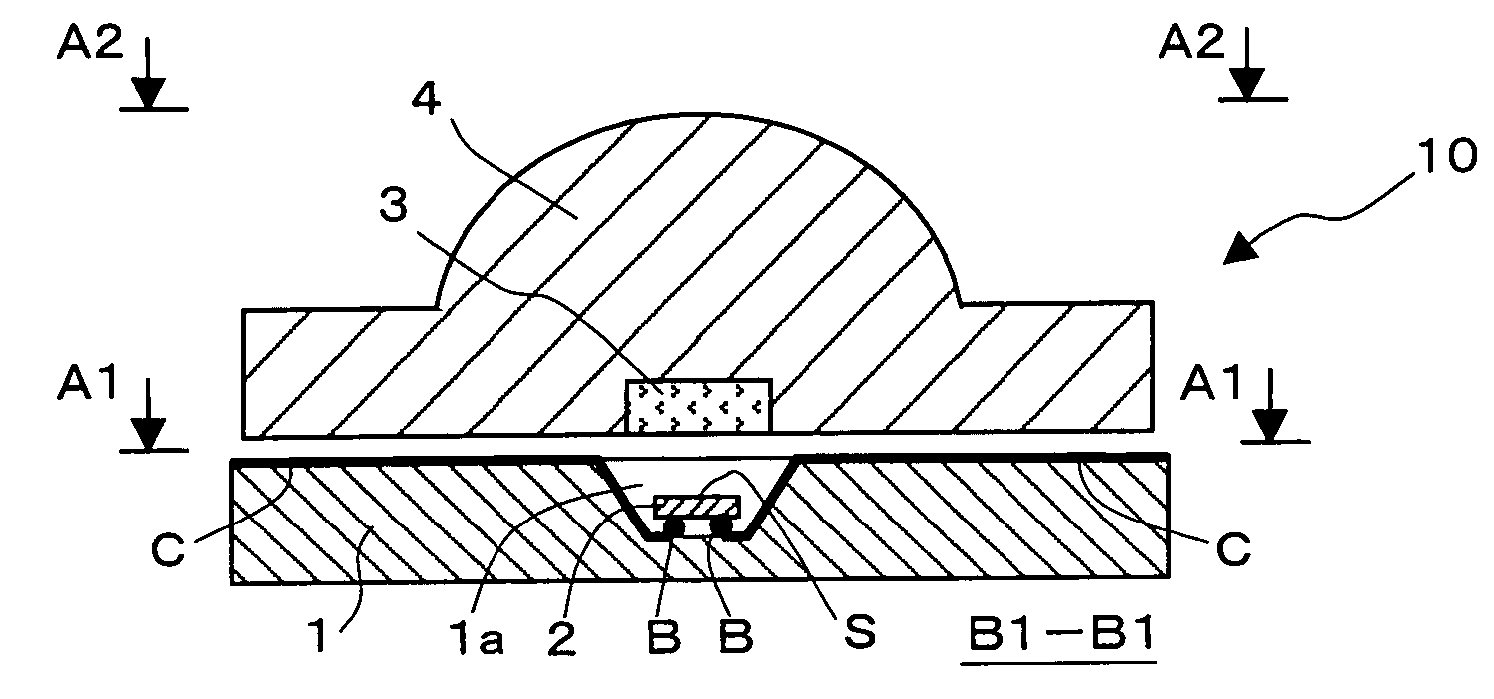

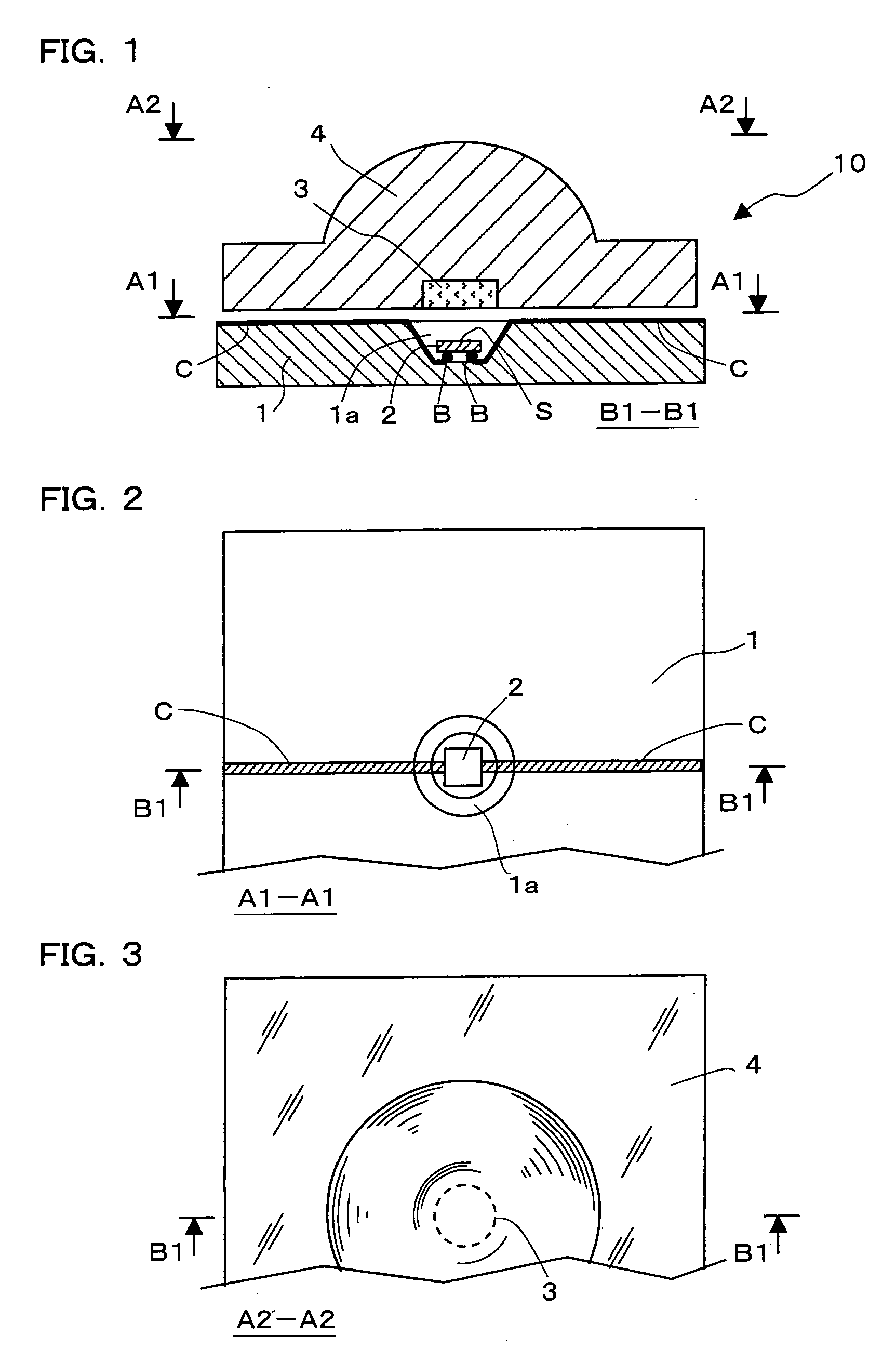

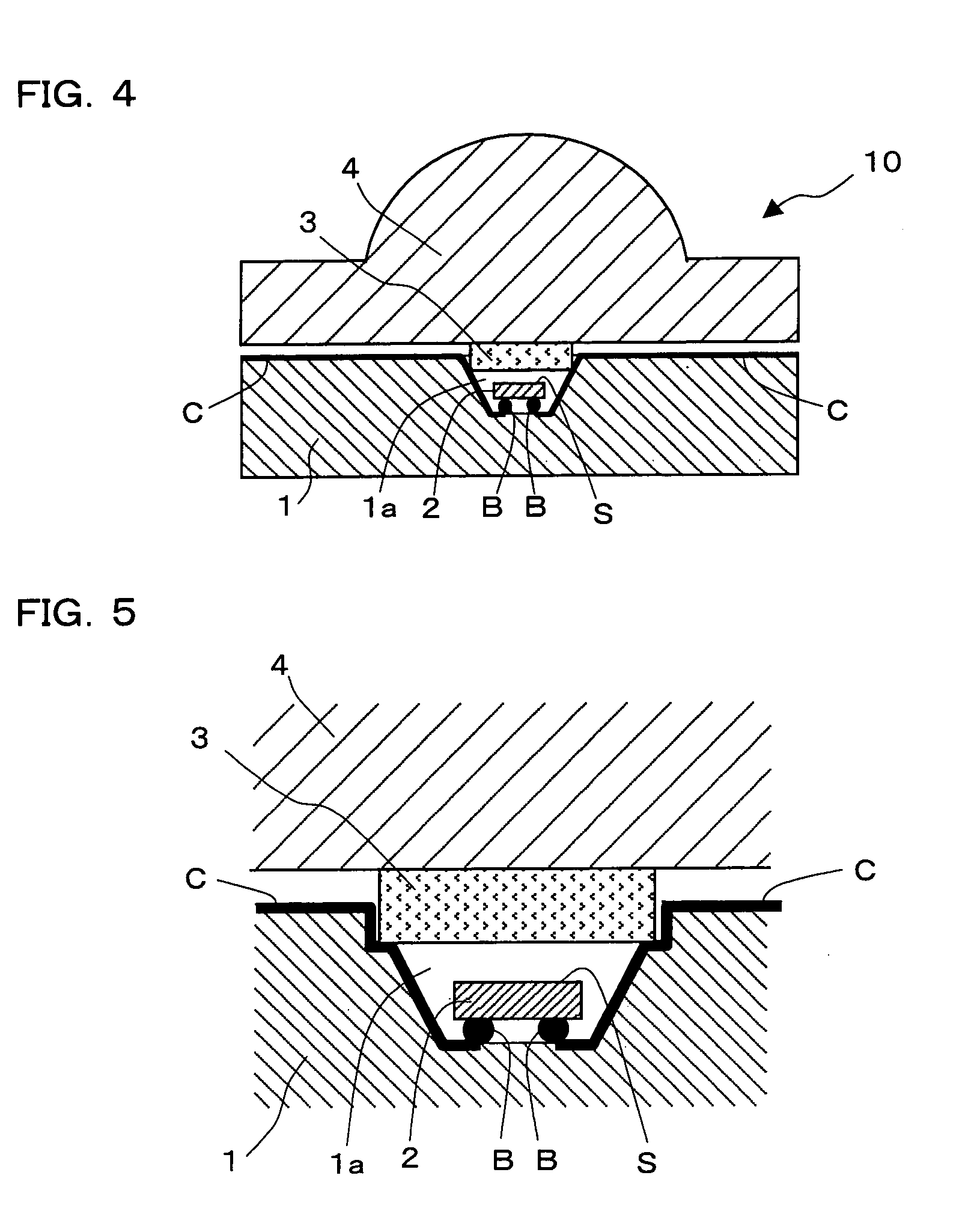

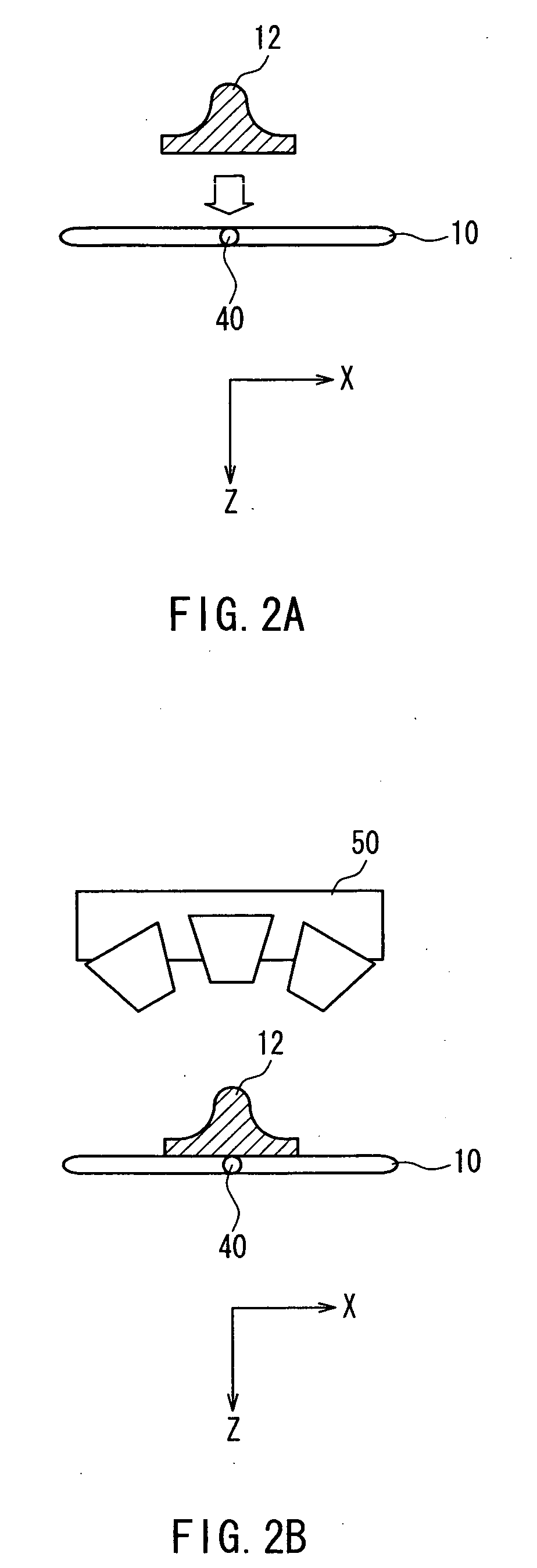

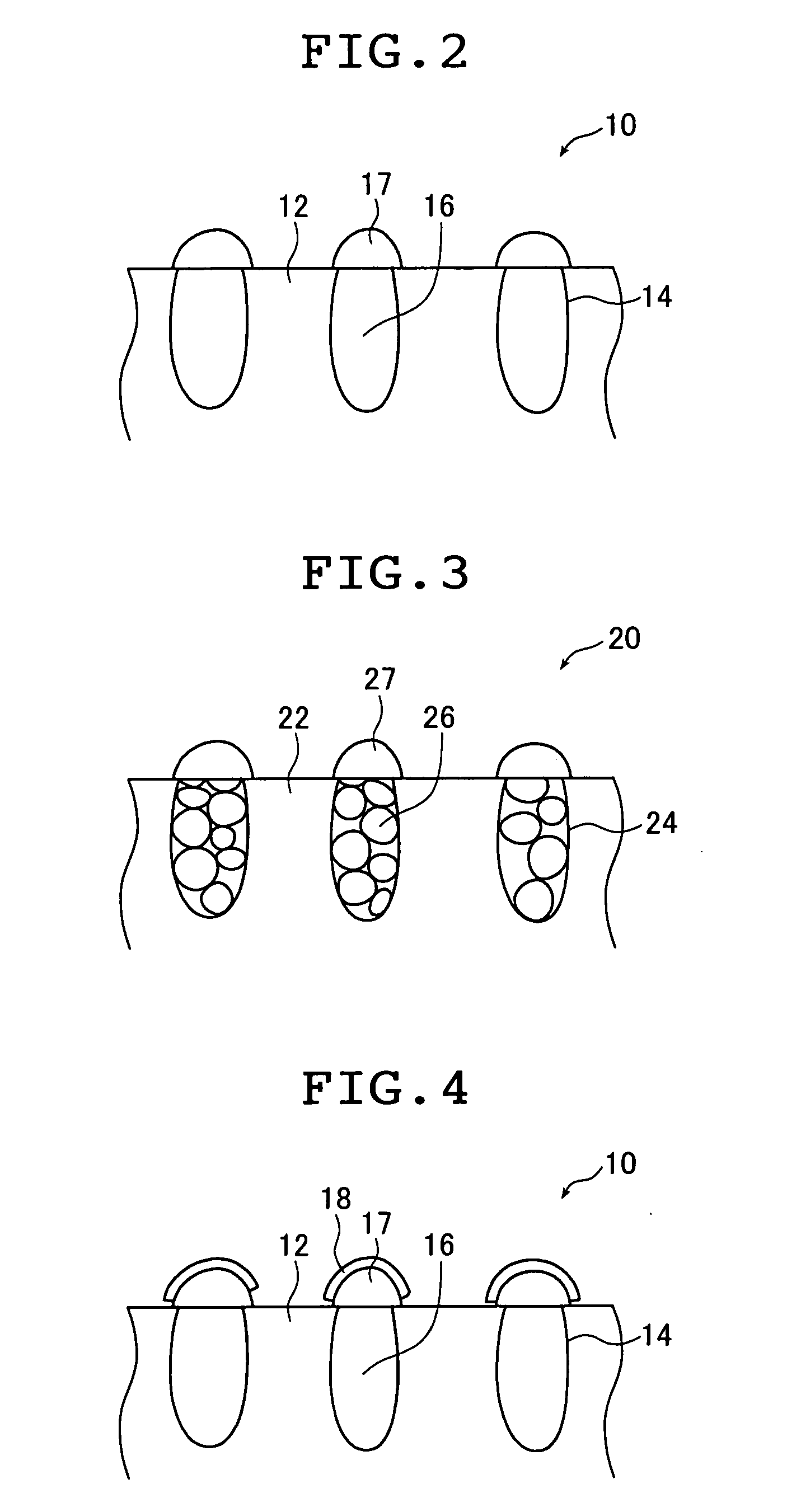

A light-emitting device (10) using an LED is proposed. This light-emitting device (10) is provided with a packaging substrate (1), a light-emitting element (2) which is mounted on this packaging substrate (1) with its face down, a fluorescent member (3) that is arranged face to face with a light-extracting surface (S) of the light-emitting element (2) without contacting the light-emitting element (2) and an optical member (4) which receives light that has been emitted from the light-emitting element (2) and made incident thereon through the fluorescent member (3), and aligns the incident light toward the outside of the device. Light, emitted from the light-emitting element (2), is made incident on the fluorescent member (3) to excite the fluorescent material so that the fluorescent material re-emits light having a wavelength different from that of the incident light. Those light rays, emitted from the light-emitting element (2), which have not been absorbed by the fluorescent member (3) and have passed through the fluorescent member (3) and those light rays that have been emitted from the fluorescent material are made incident on the optical member (4) and are aligned. Because the fluorescent member (3) is not made in contact with the light-emitting element (2), it does not receive the heat from the light-emitting element (2) through heat conduction, and consequently becomes less susceptible to degradation due to heat. Moreover, with the face-down mounting structure, the fluorescent member (3) and the optical member (4) can be placed closer to the light-emitting element (2) as long as they dose not contact the light-emitting element (2). Consequently, the service life of the fluorescent material or the fluorescent-material-mixed resin that tends to deteriorate can be lengthened, lights can be extracted more efficiently, and light rays can be properly aligned in a predetermined direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

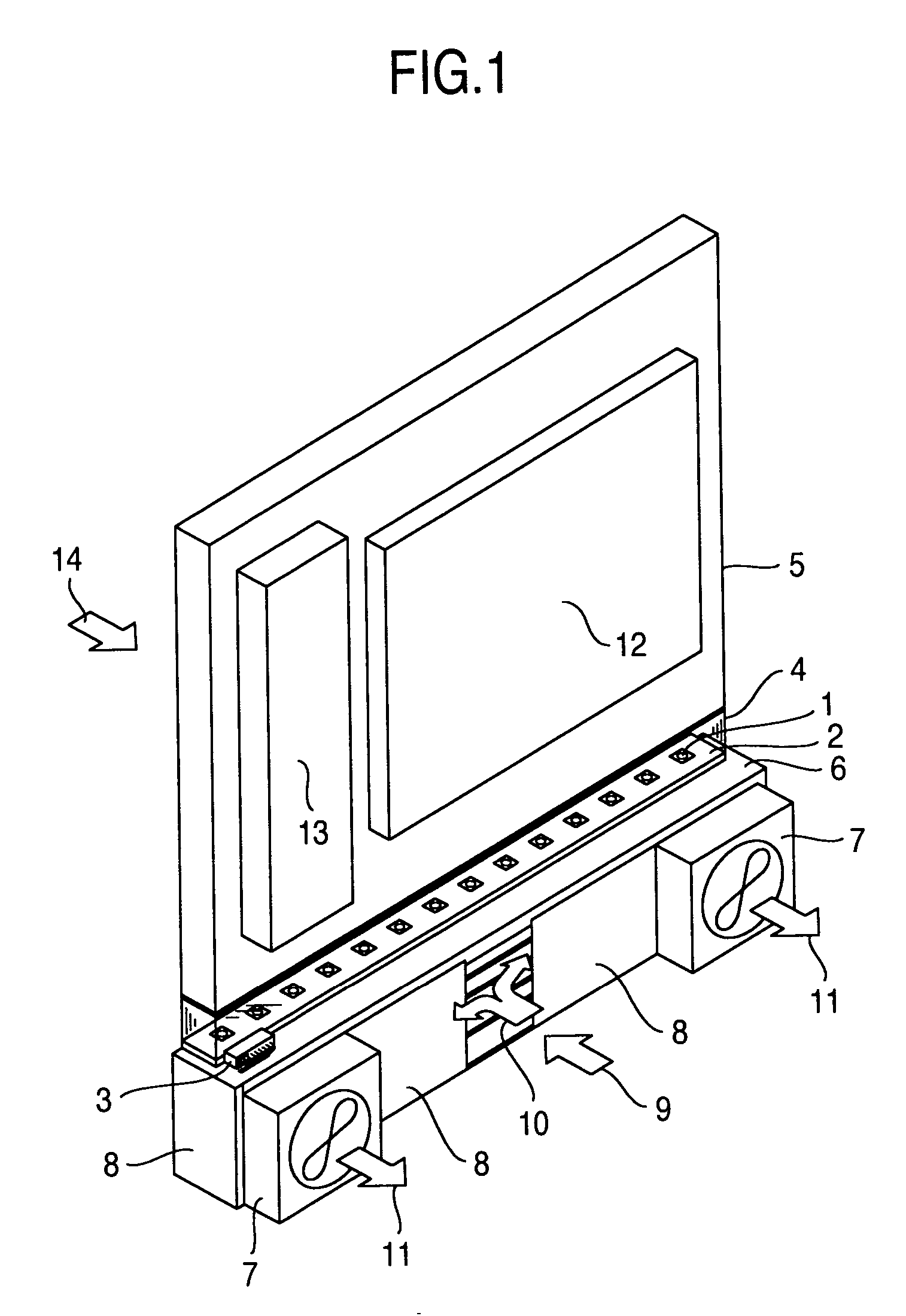

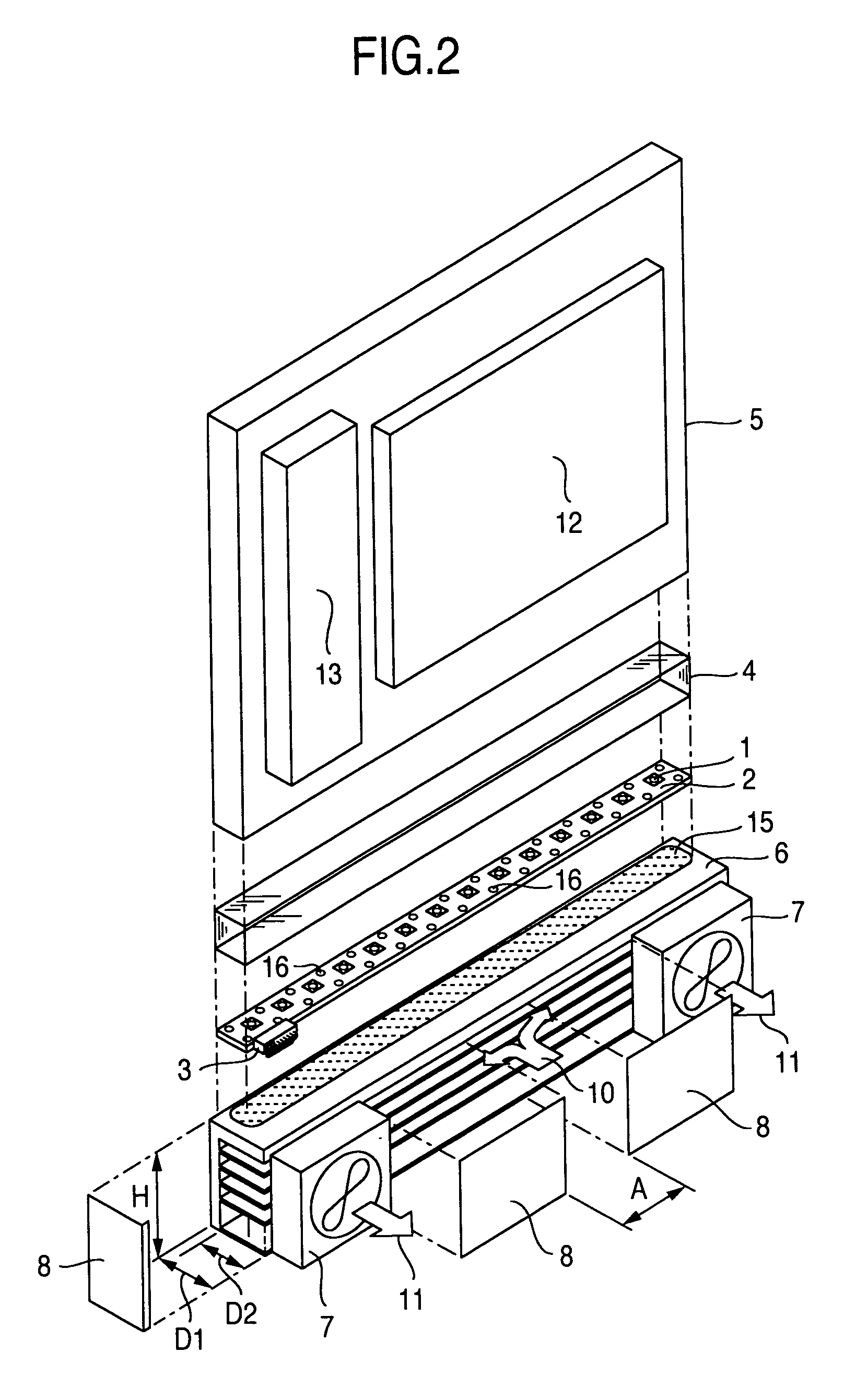

Display unit

InactiveUS20070076431A1Effective coolingReduced brightness irregularityLighting heating/cooling arrangementsOptical signallingDisplay deviceEngineering

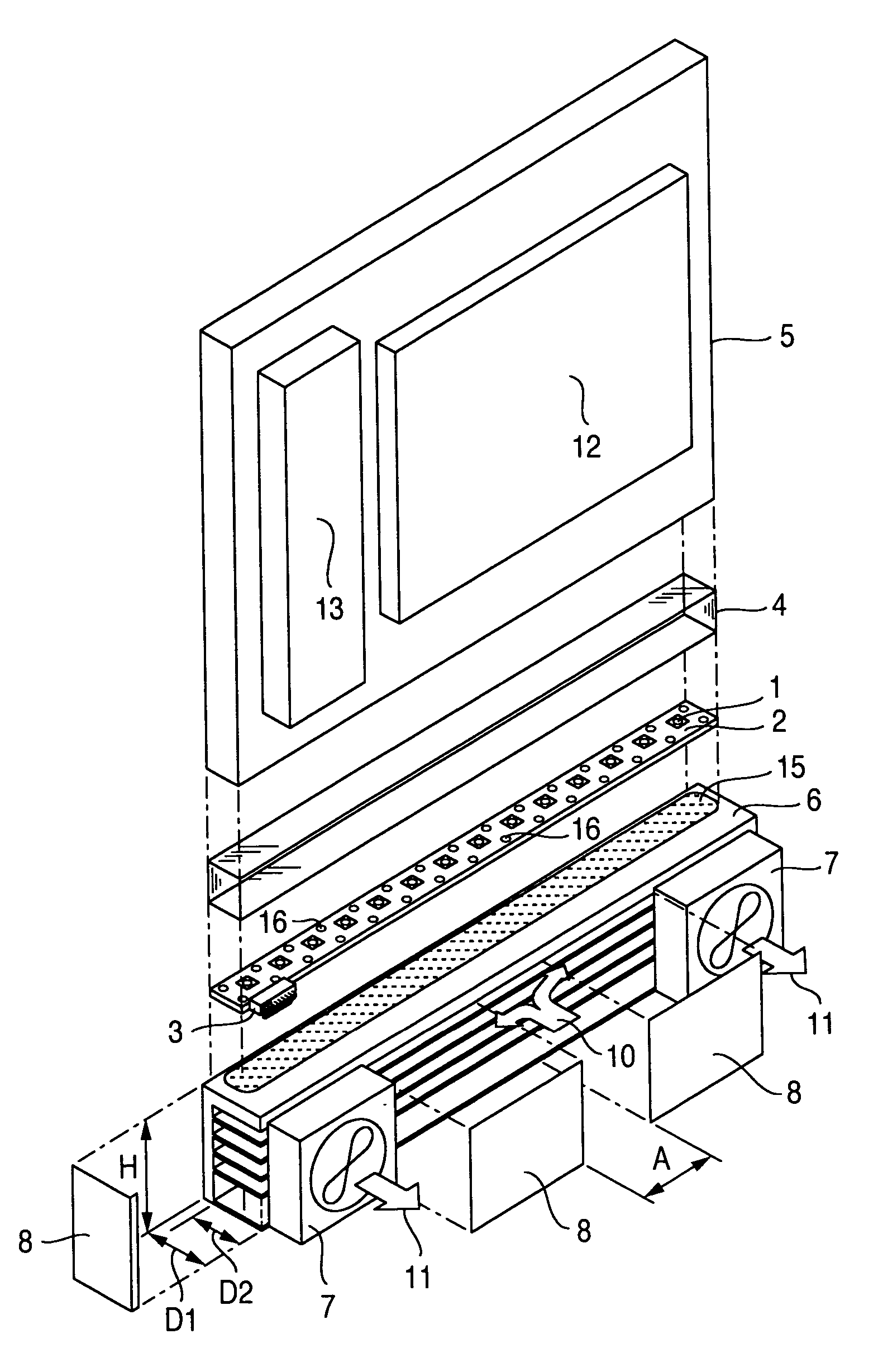

In the case that the LED is used as a light source for a backlight such as a display unit or the like, if a lot of current is circulated for securing a brightness, a lot of heat is generated in view of a characteristic of the LED, so that the LED comes to a high temperature, and there is a problem that the characteristic of the LED itself is deteriorated such as a light output is lowered, a long-term service life can not secured, or the like. Further, in the case that a temperature difference exists between a plurality of LEDs, there is a problem that it appears as a brightness irregularity of a screen of the display unit. The display unit is provided with a heat sink attached so as to be thermally contacted with an opposite side to an LED mounting surface of a substrate on which the LEDs are mounted, and one or a plurality of fans, a base portion of the heat sink has a substrate mounting surface and a fin constituting surface, the fin constituting surface is approximately perpendicular to the substrate mounting surface, and the fin constituting surface of the base portion and an air supply and exhaust surface of a cooling air are formed in an opposite side to a screen display side of the display.

Owner:HITACHI LTD

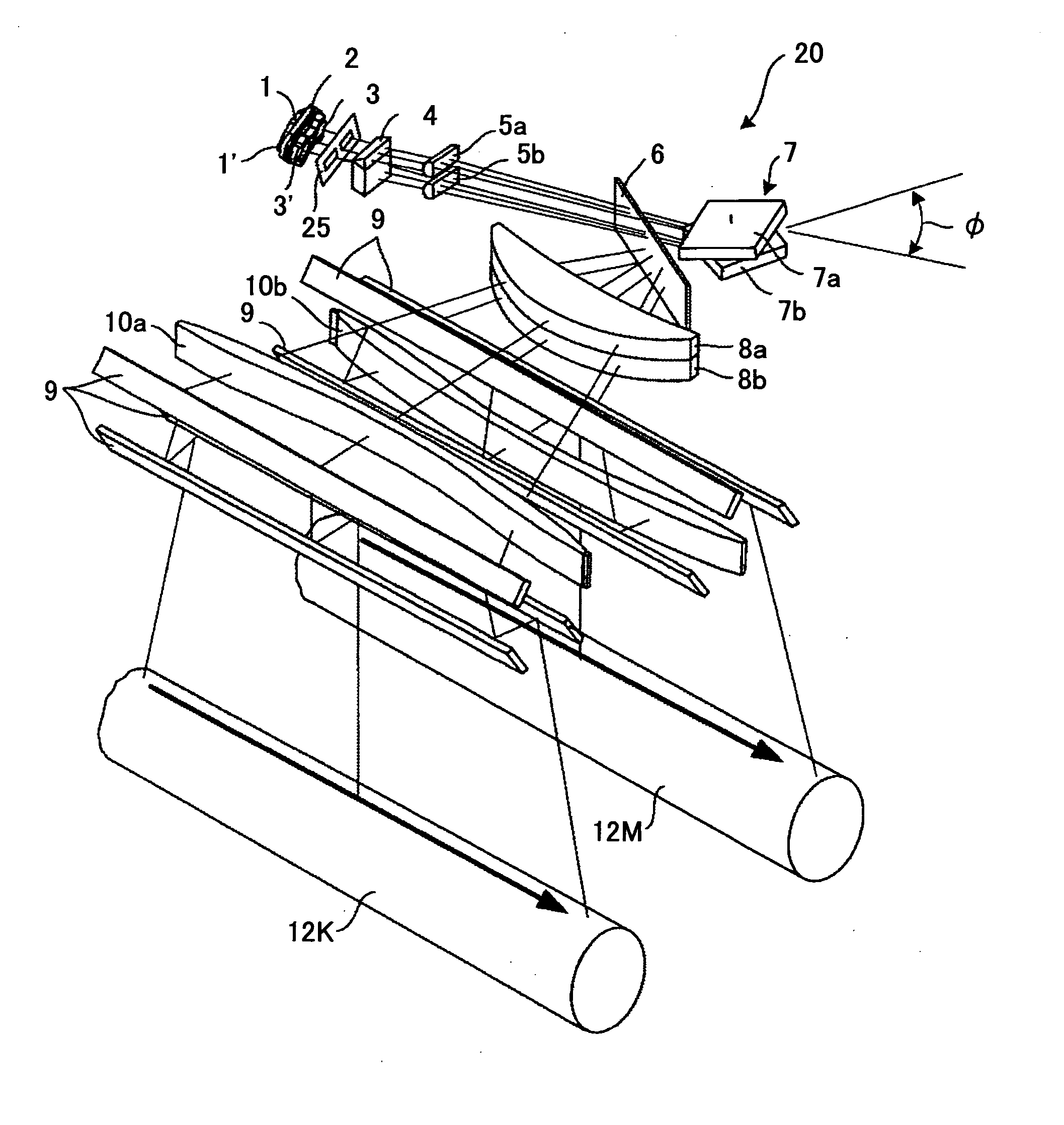

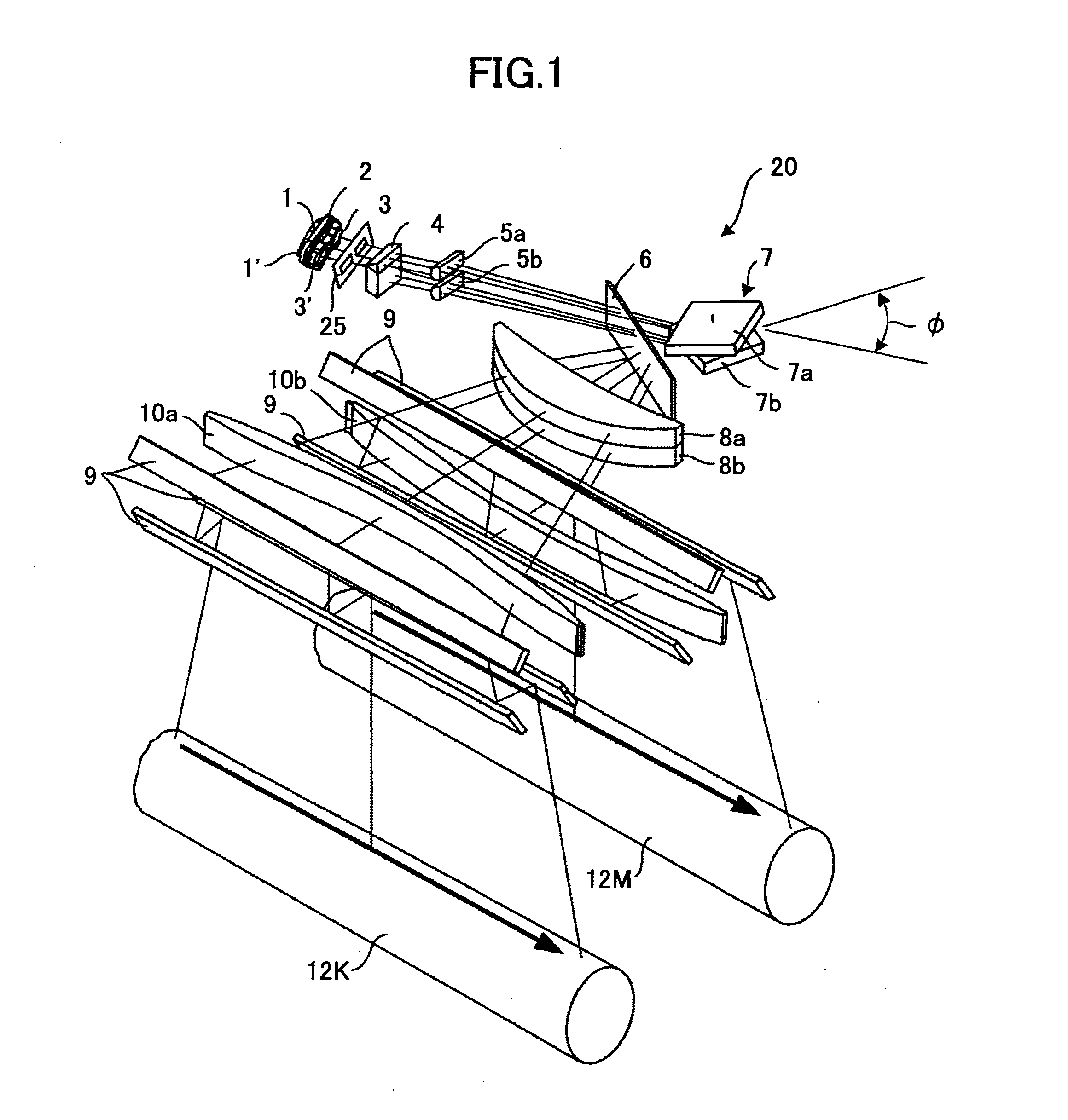

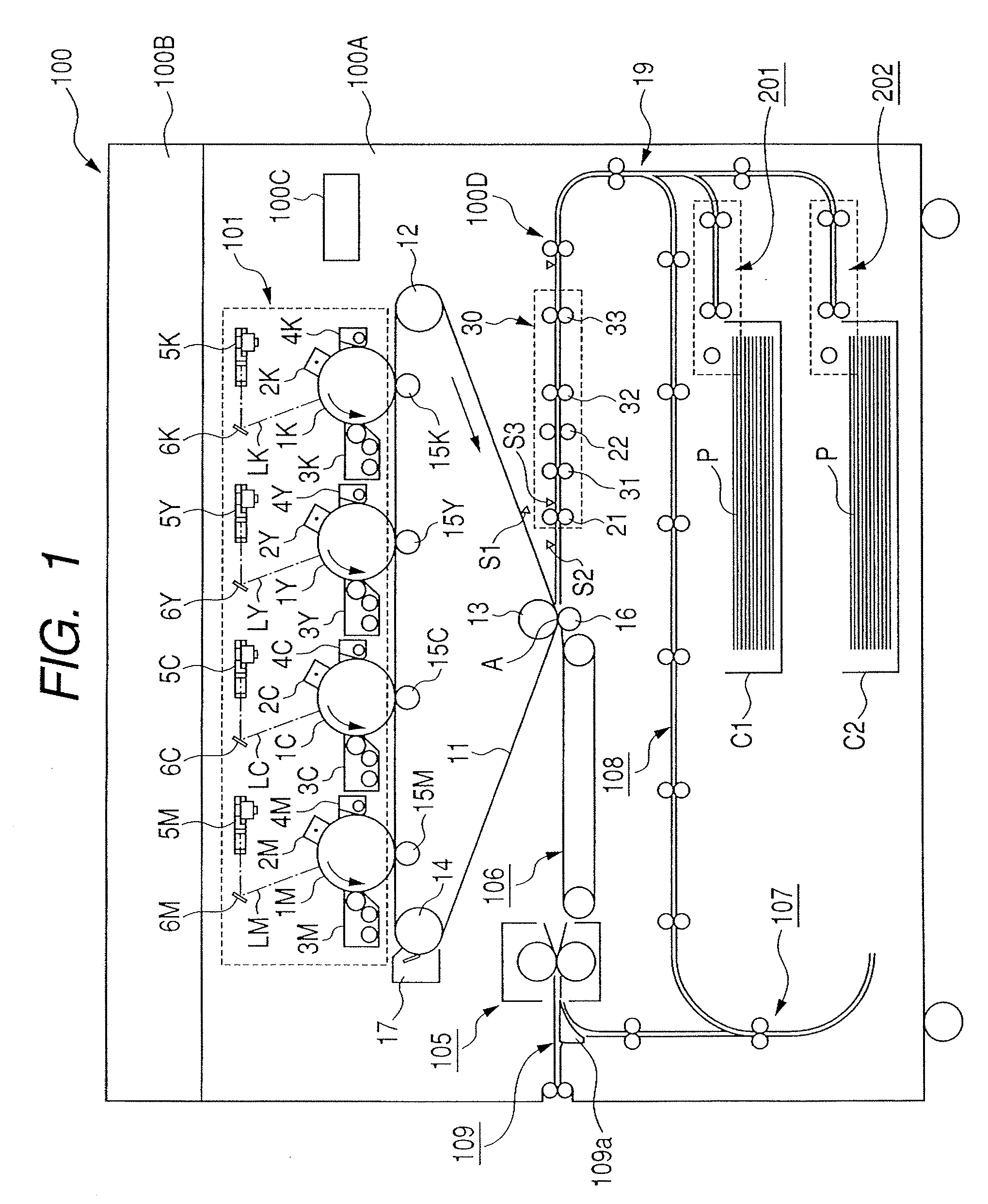

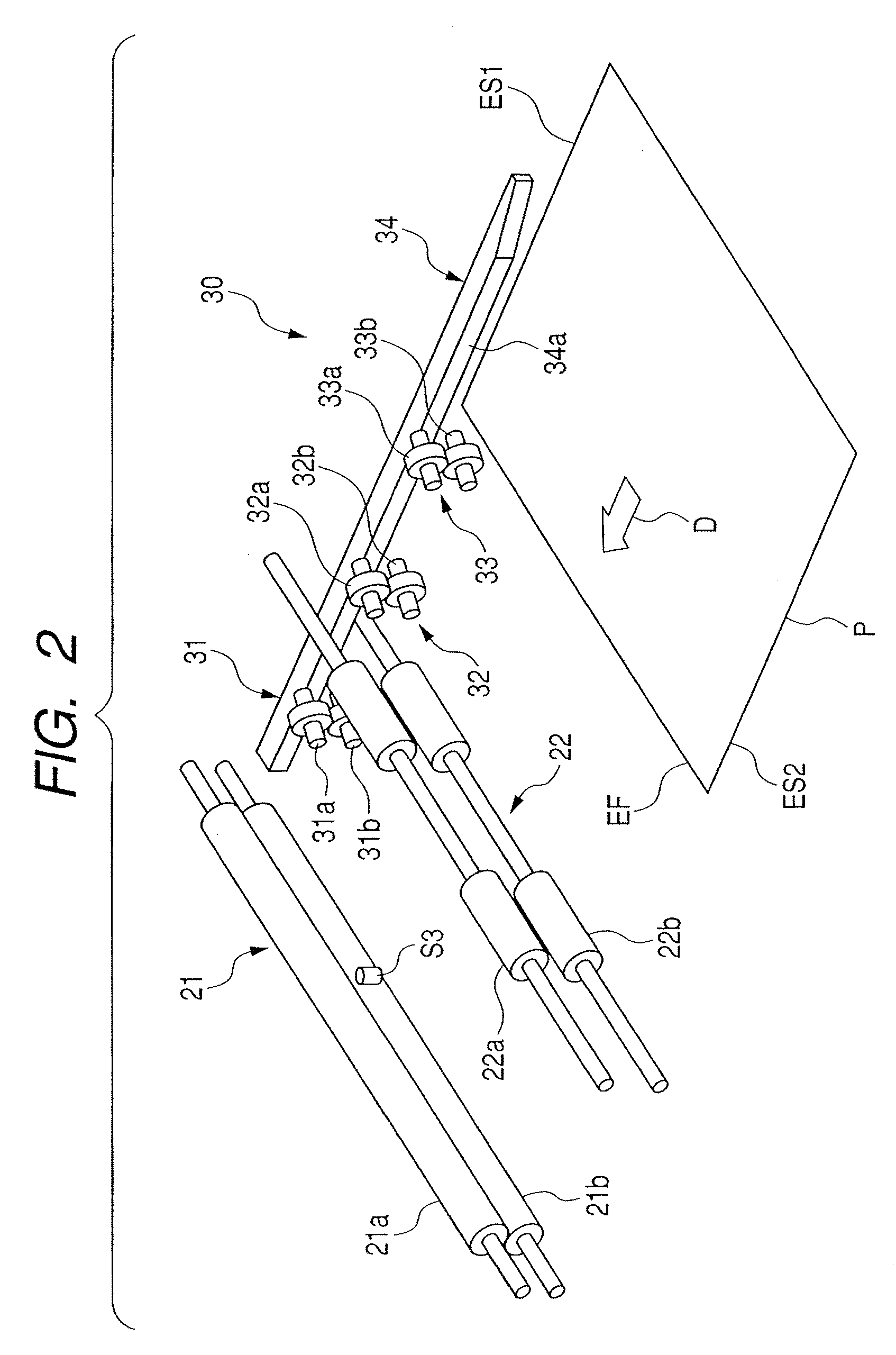

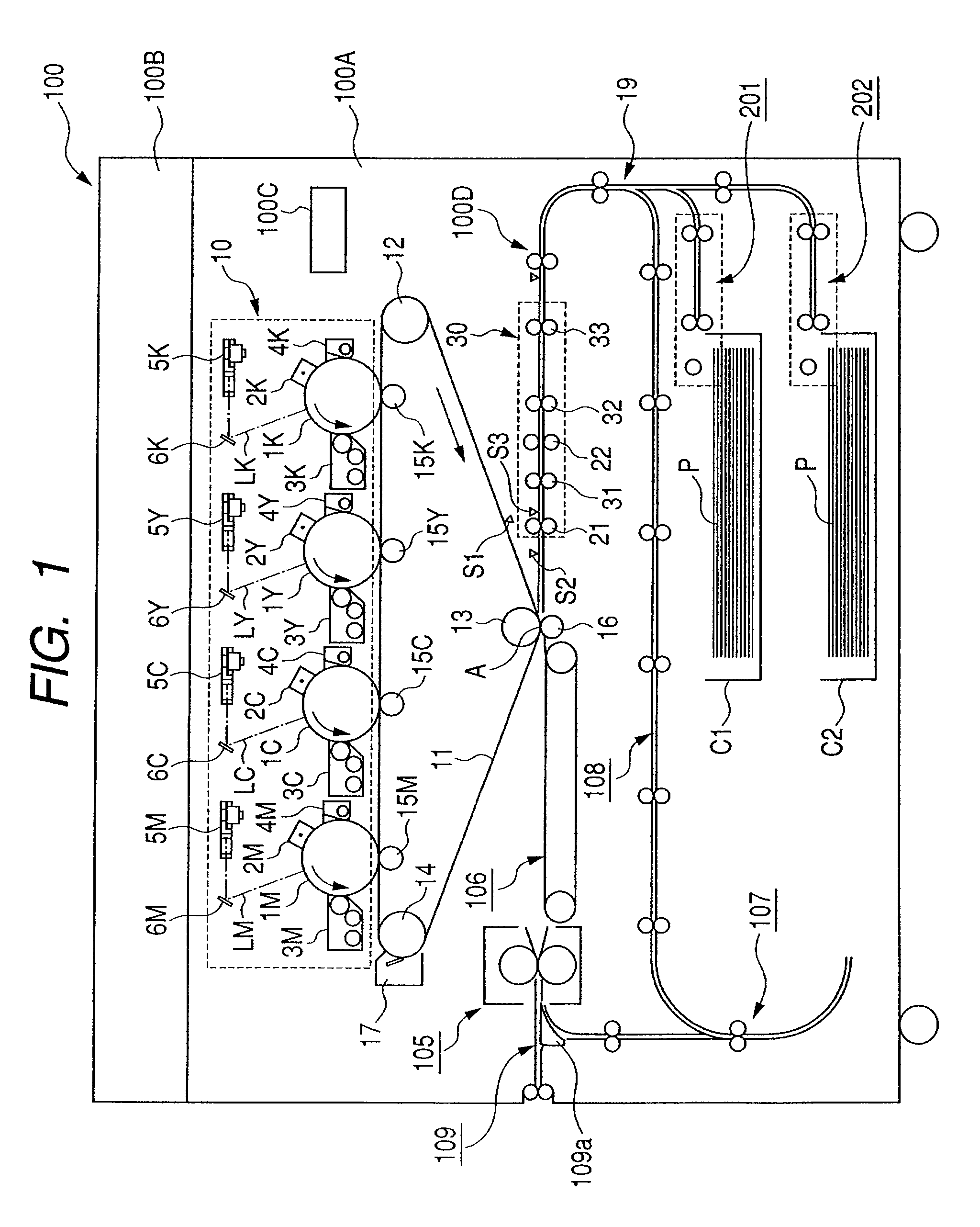

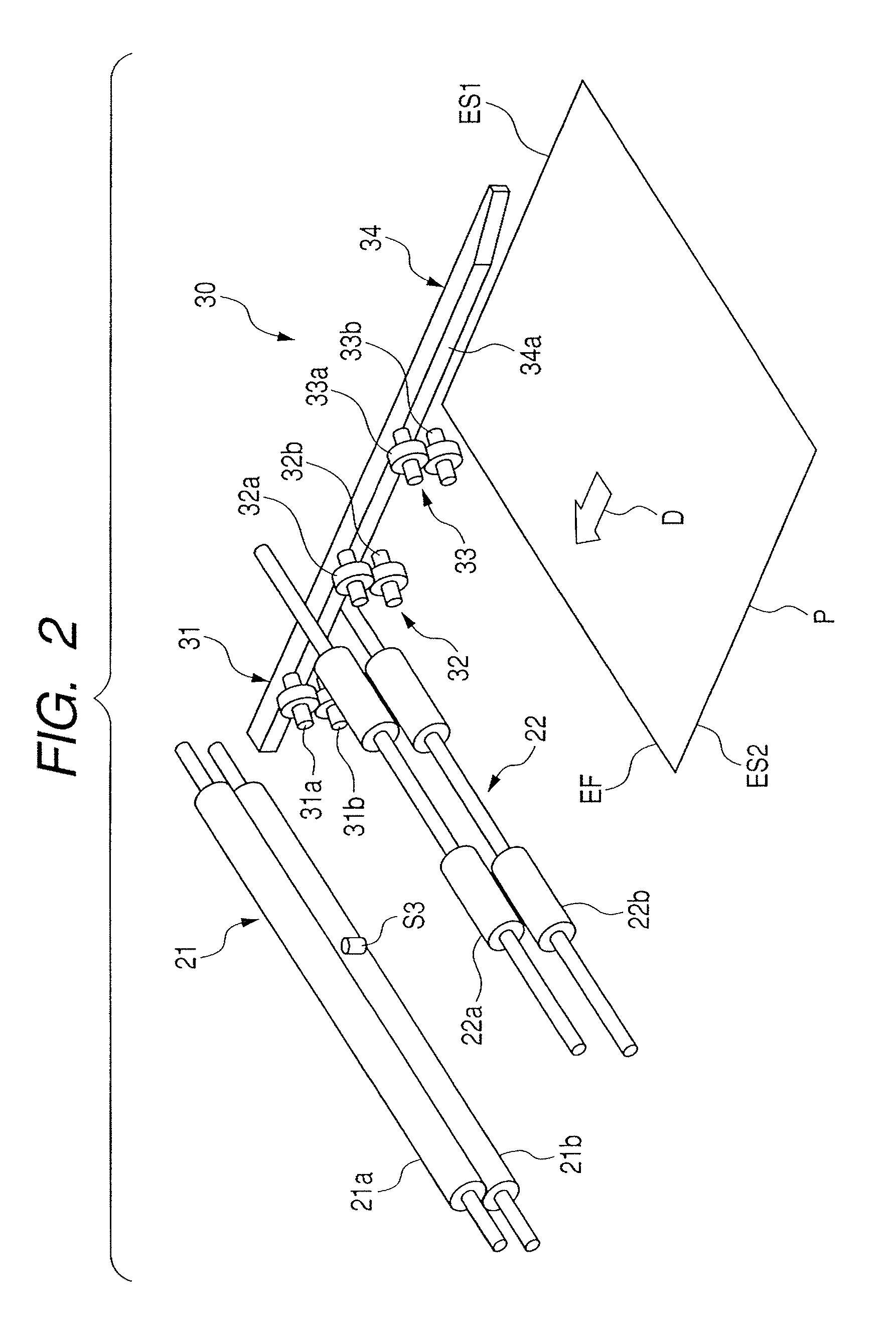

Optical scanner and image forming apparatus

InactiveUS20070058255A1Easy to useHigh quality imagingDiffraction gratingsOptical scannersLight beam

An optical scanner includes a light source; a deflecting unit that deflects and scans a light beam emitted from the light source; a scanning optical system that focuses the light beam deflected and scanned onto different surfaces to be scanned; and a light quantity correcting unit that corrects a light quantity of the light beam. The light quantity correcting unit changes light quantity correction data used for correcting the light quantity of the light beam for each of the surfaces. The light quantity correction data is dependent on positions in a main scanning direction.

Owner:RICOH KK

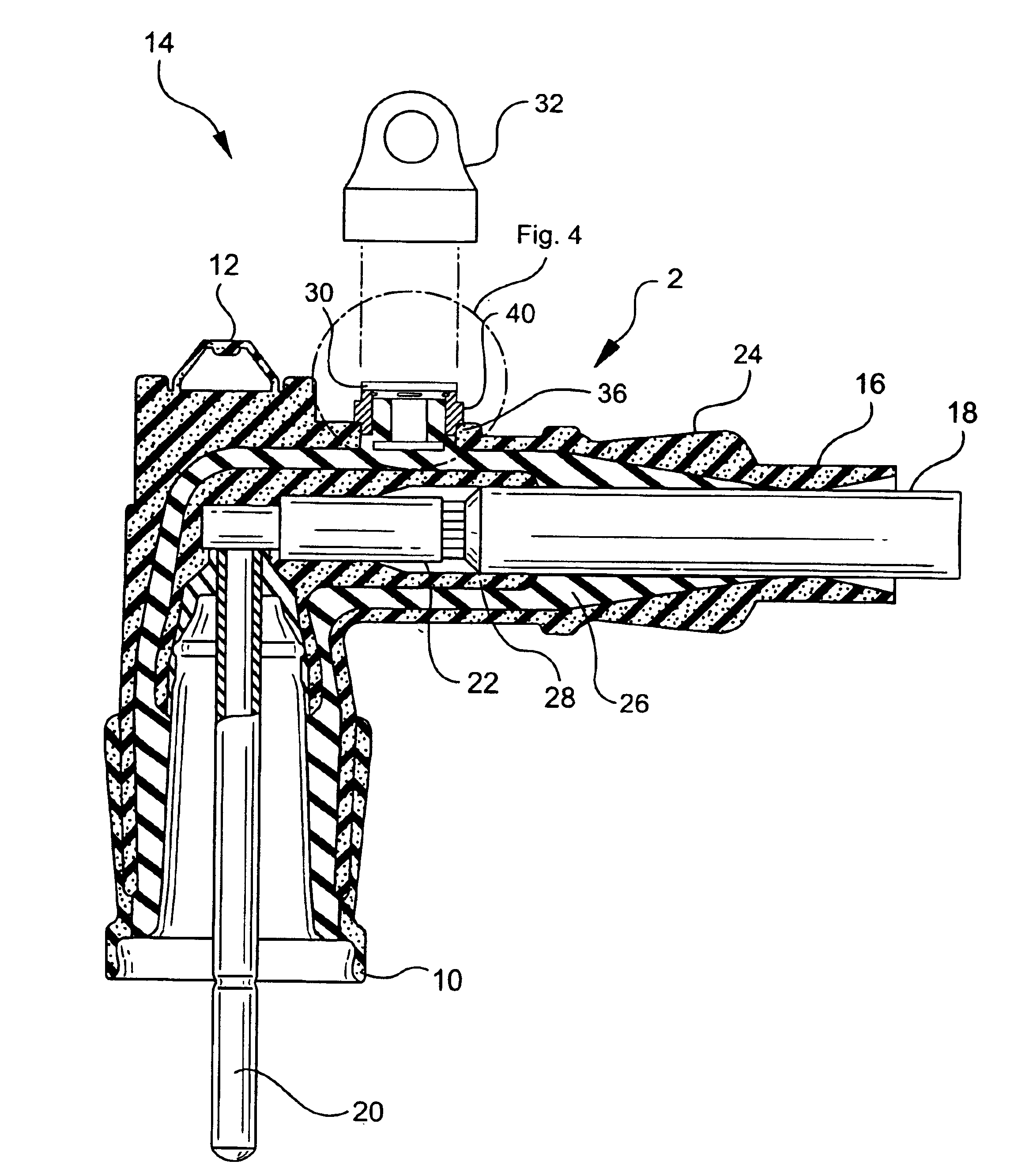

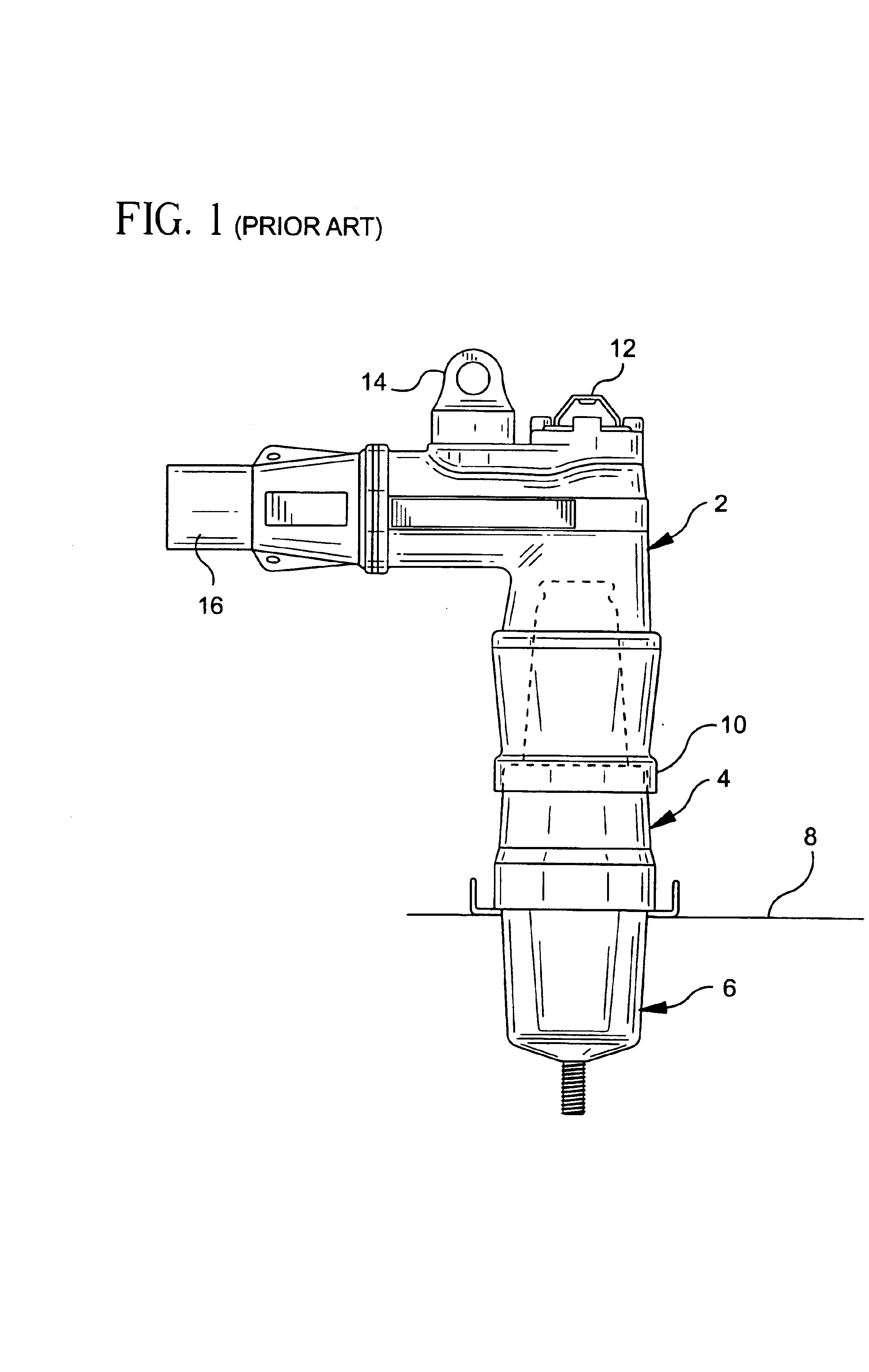

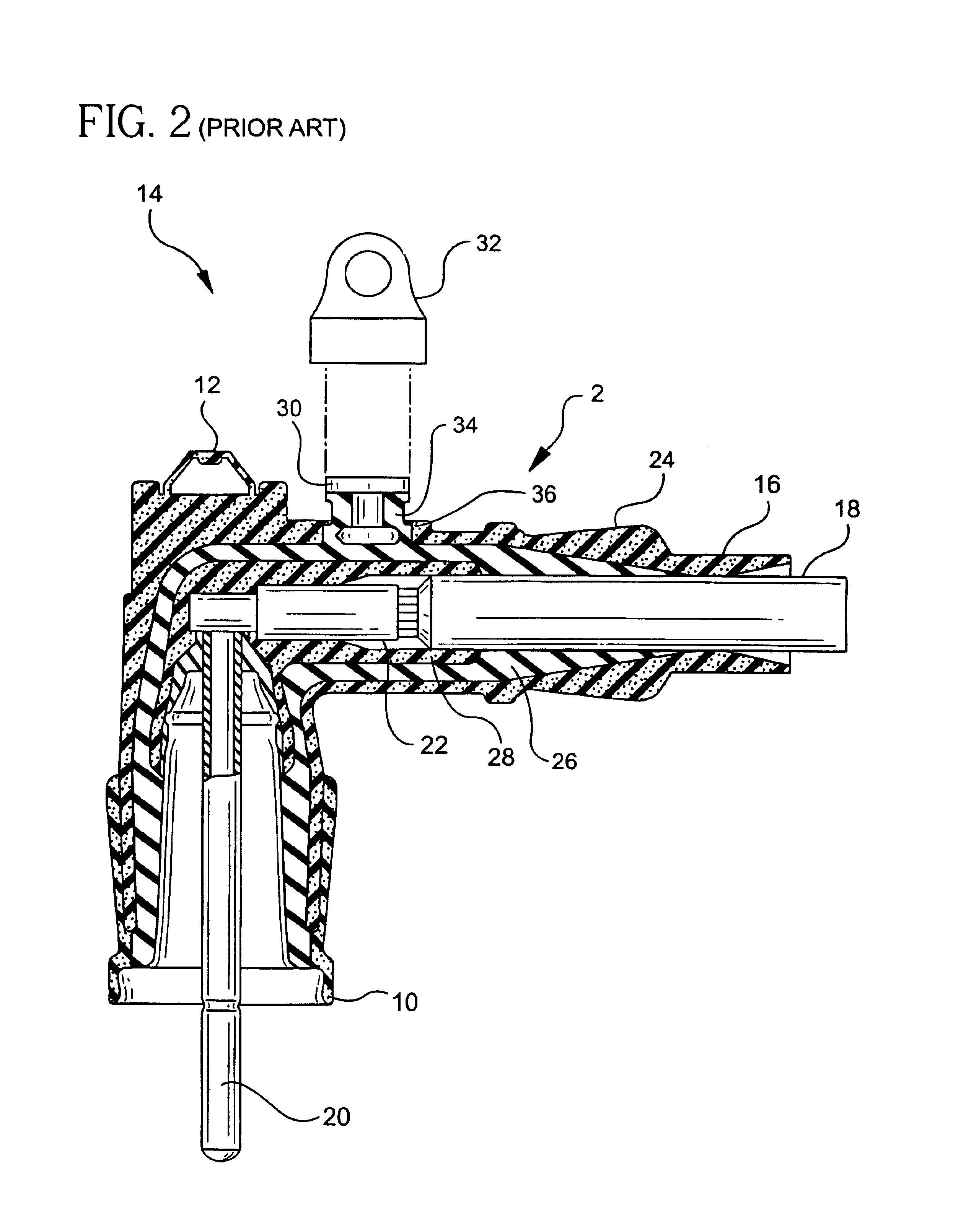

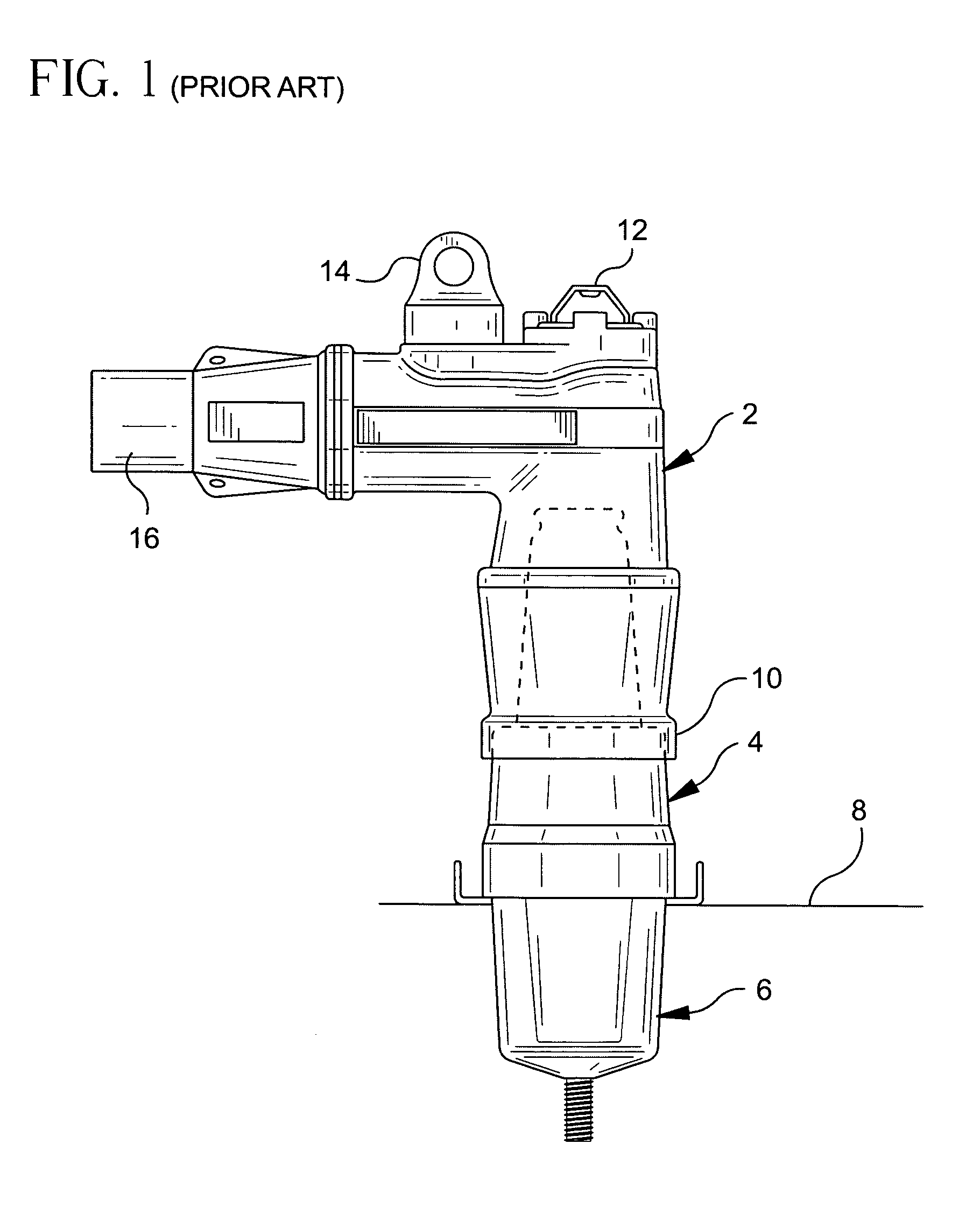

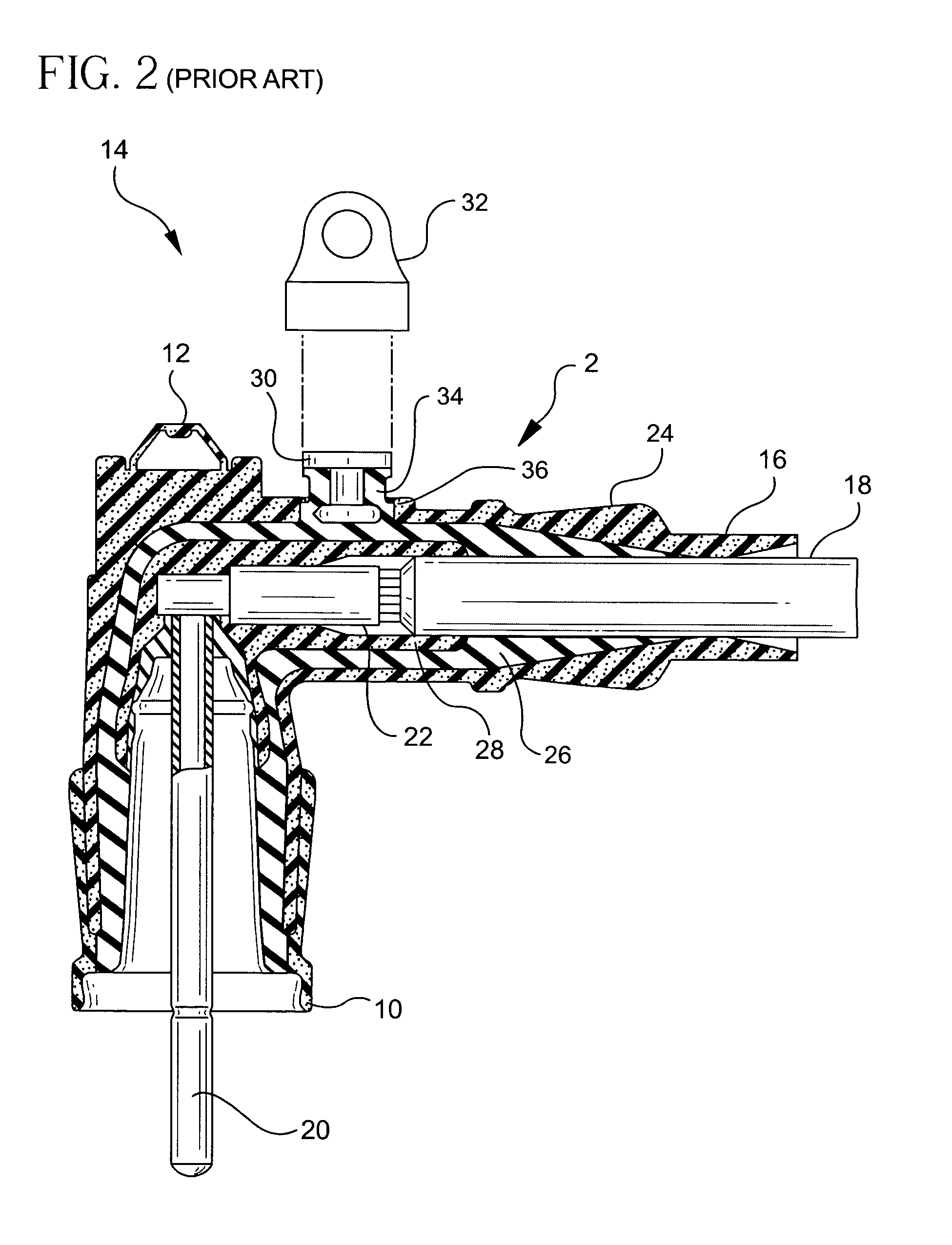

Electrical connector with voltage detection point insulation shield

ActiveUS6843685B1Reduce frictionReduces wear and cleanRelieving strain on wire connectionCouplings bases/casesCapacitive couplingThermoplastic

Owner:THOMAS & BETTS INT INC

Light emitting device using LED

InactiveUS7084435B2Extended service lifeInhibit deteriorationDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

A light-emitting device which uses and LED having a light-emitting element being placed on a package substrate. The light-emitting element has a light-extracting surface. A fluorescent element which is formed by dispersing a fluorescent material in a transparent substance and is placed face to face with the light-extracting surface of the light emitting element and comprises a clearance gap in between. The light-emitting element generates light of a certain wavelength that emanates through the light-extracting surface into the fluorescent element where the wavelength is changed. The device further comprises an optical element which receives light from the light-emitting element through the fluorescent element and directs the light to the outside of the device.

Owner:MATSUSHITA ELECTRIC WORKS LTD

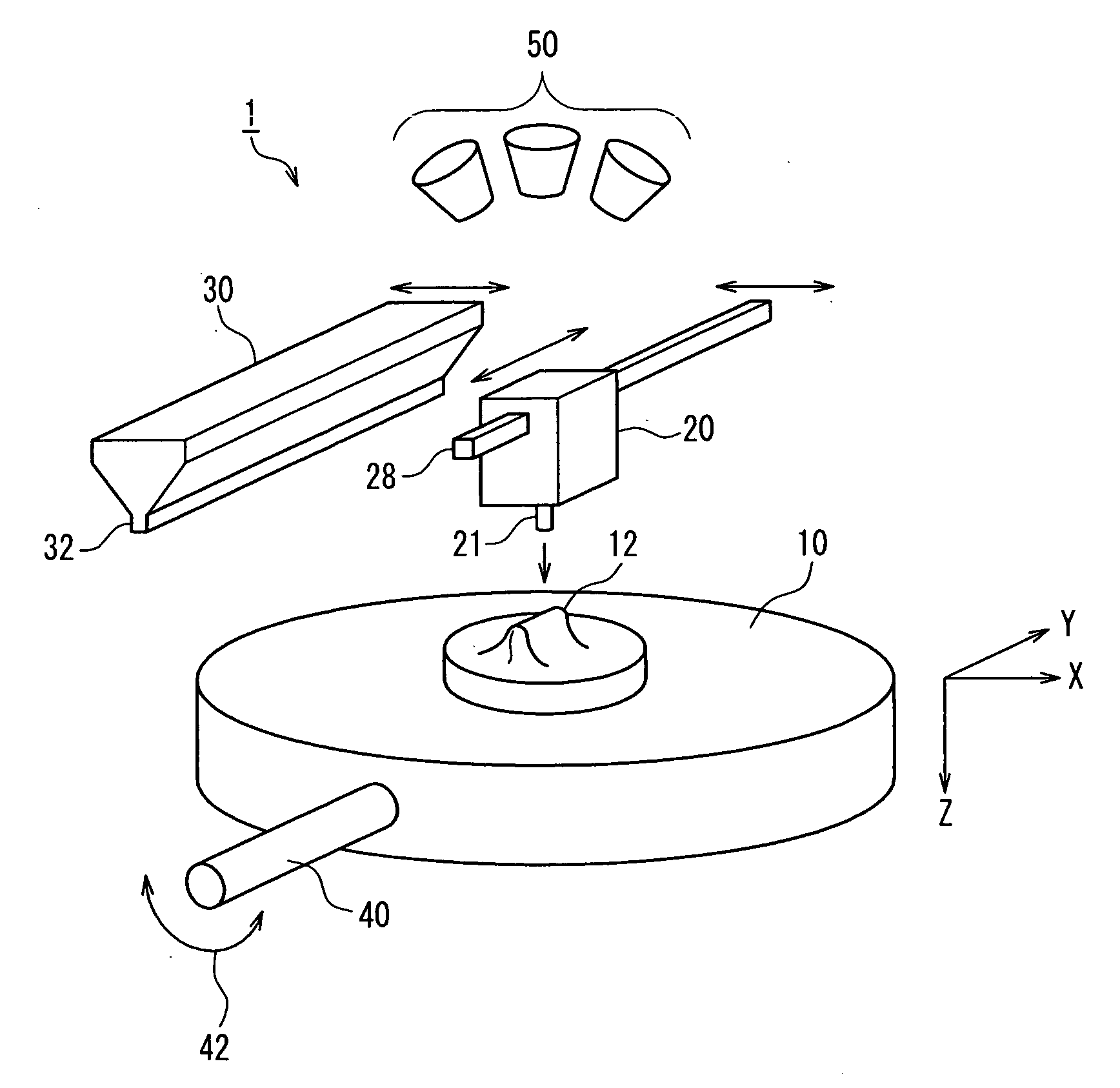

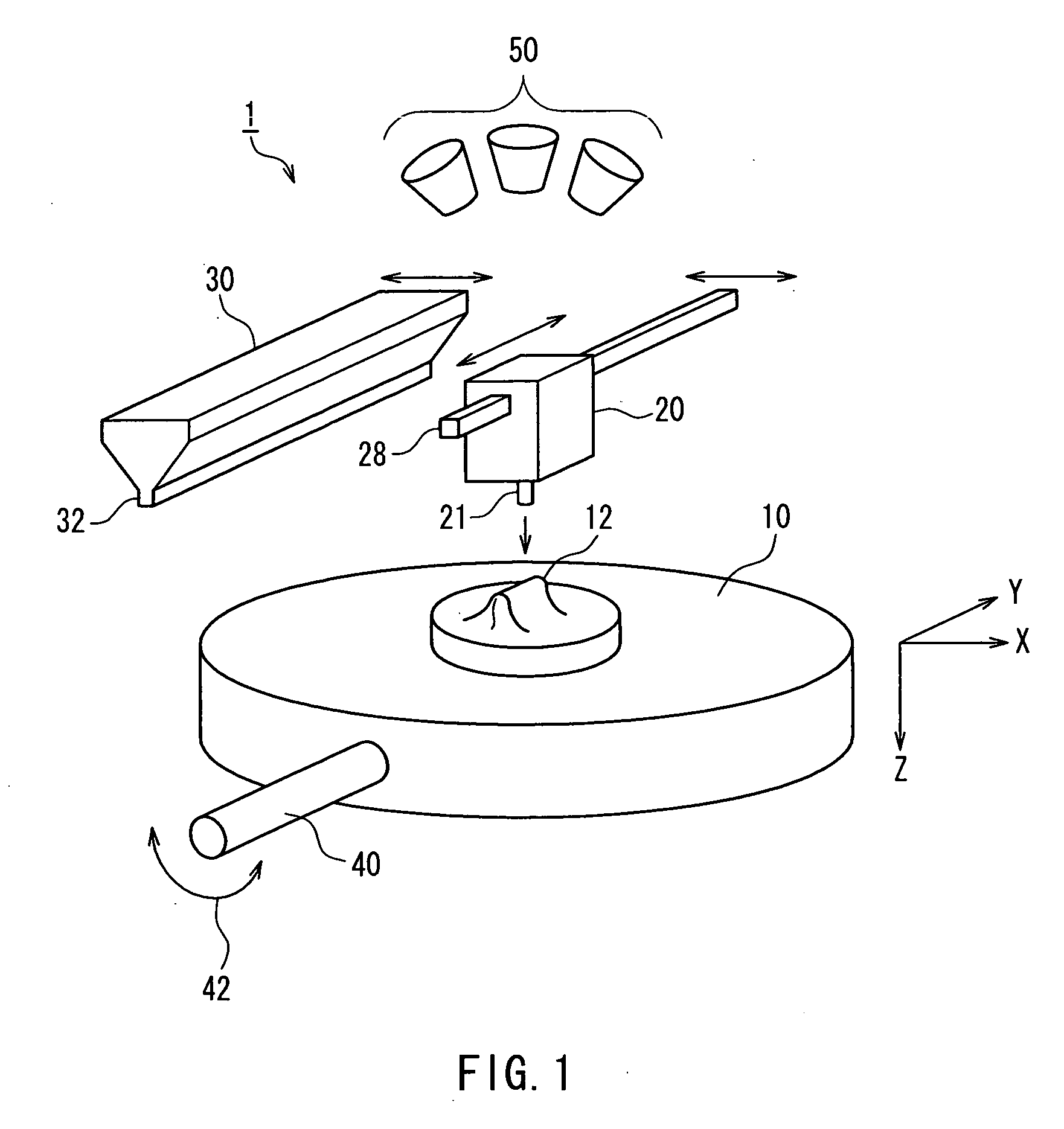

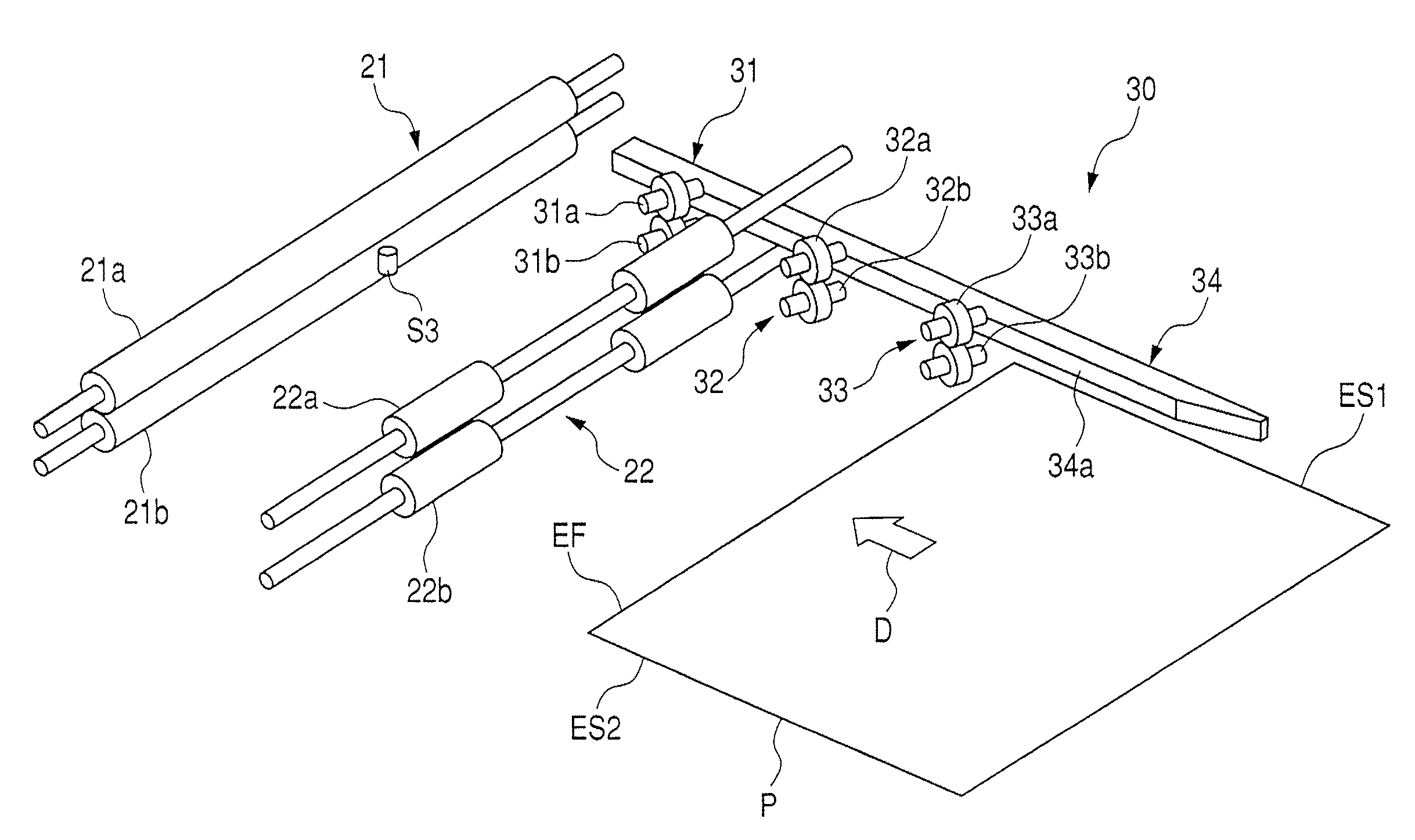

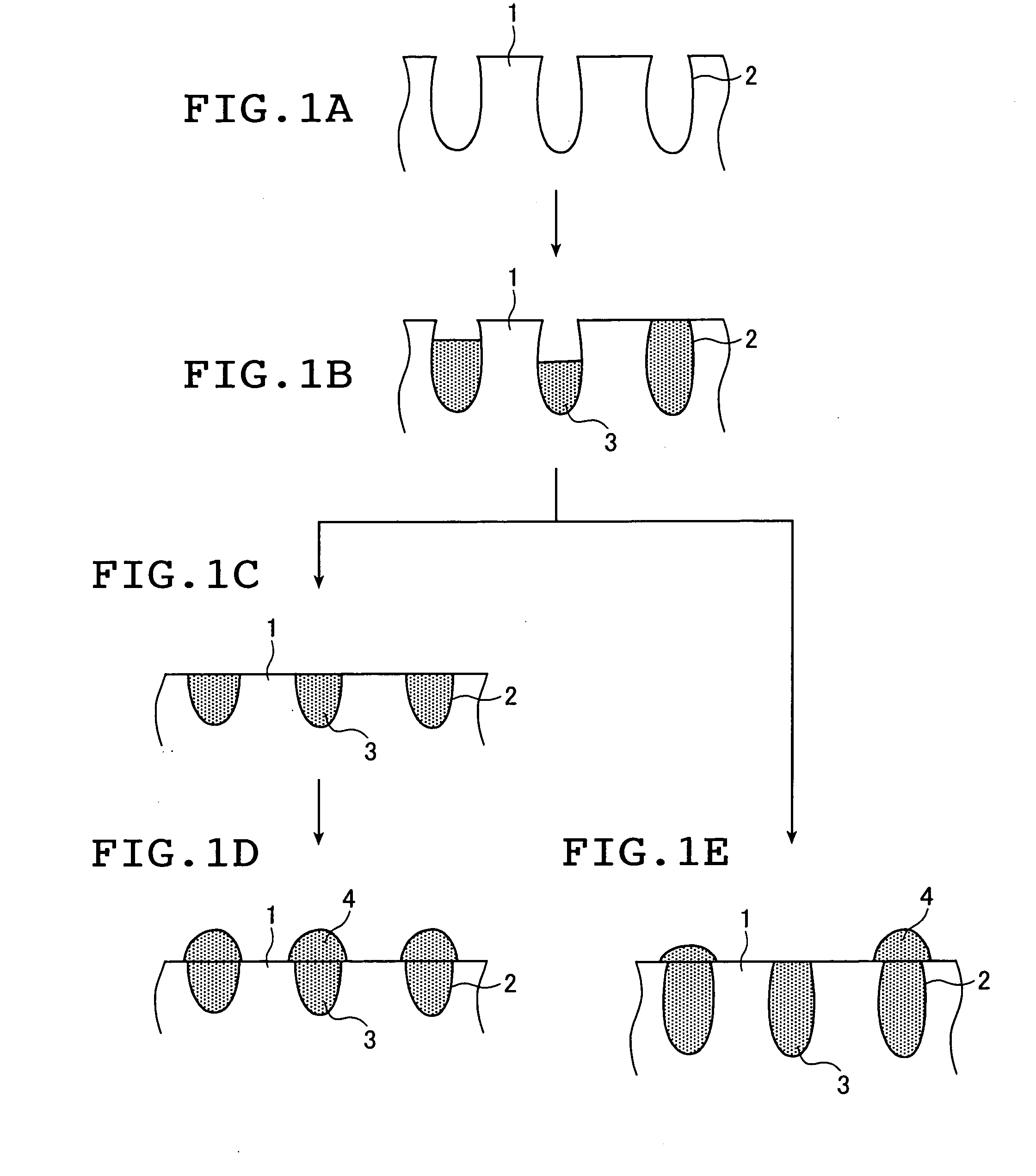

Apparatus for Forming Layered Object

InactiveUS20090025638A1Reduce irregularitiesReduce stepsLiquid surface applicatorsConfectioneryBiomedical engineeringSmooth surface

A layered-object forming apparatus (1) includes a holding mechanism (10) that holds a base (12), a liquid applying device (20) that applies a liquid to a predetermined position from above the base, a powder applying device (30) that allows a powder to fall from above the base, and a powder removing device that removes an unconsolidated powder on the base. Then, a process of applying the liquid by the liquid applying device, subsequently applying the powder by the powder applying device, subsequently consolidating the liquid and the powder applied onto the liquid and then removing the powder that has not been consolidated with the liquid by the powder removing device is repeated, thereby forming a three-dimensional structure on the base. Thus, it is possible to produce a three-dimensional structure that at least partially has a smooth surface, thus allowing omission or simplification of a surface smoothing treatment.

Owner:SHOFU INC

High-k metal gate electrode structures formed at different process stages of a semiconductor device

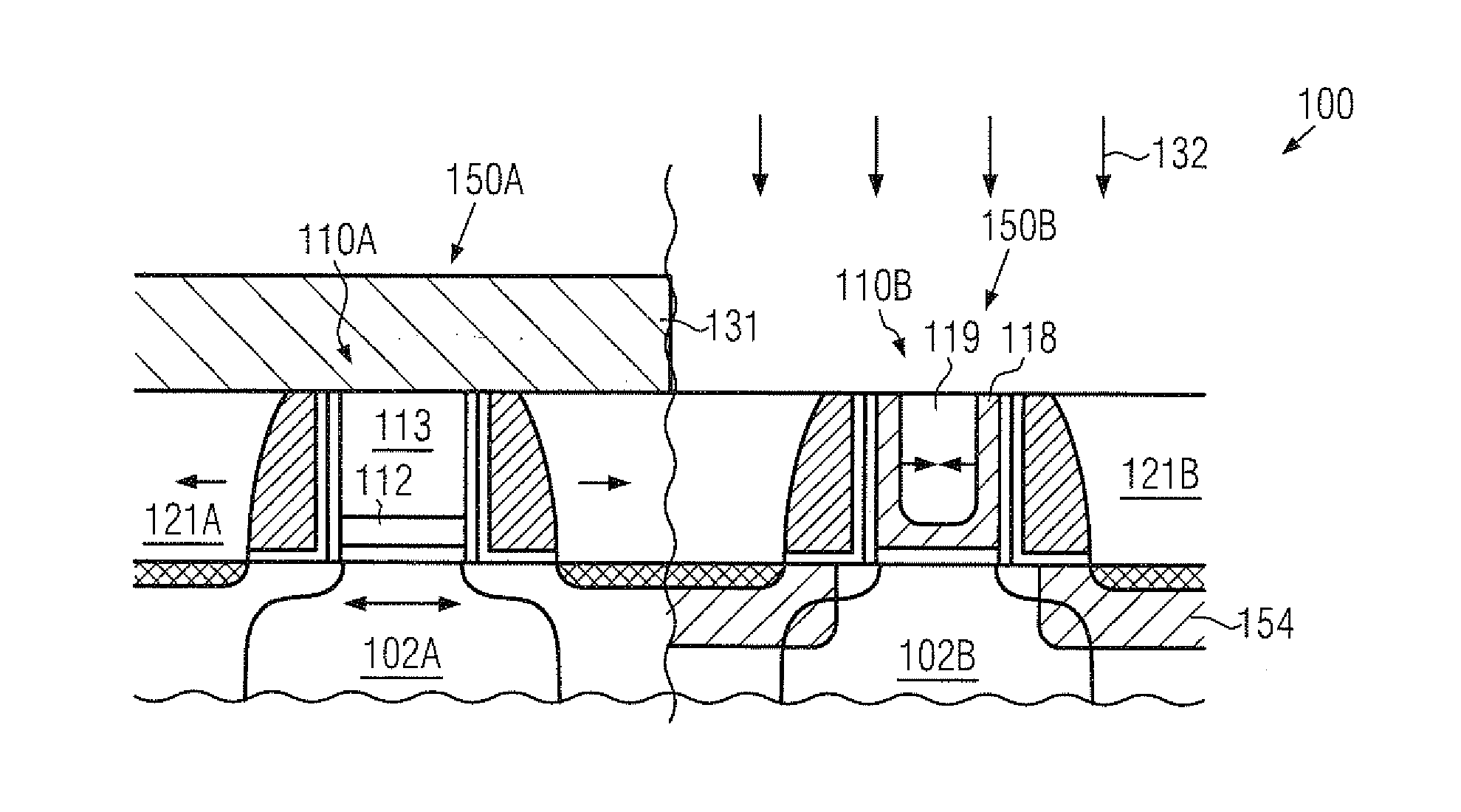

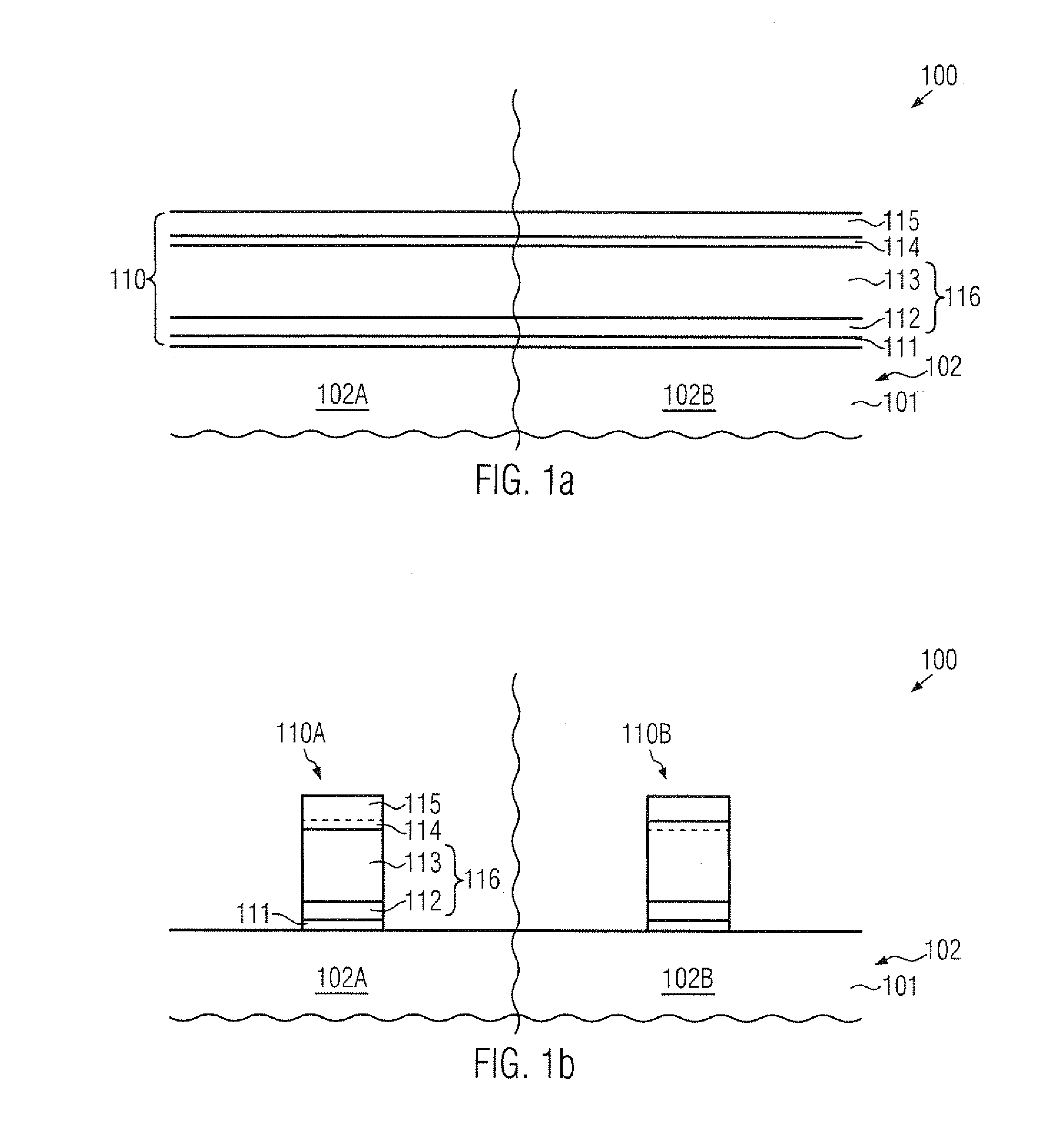

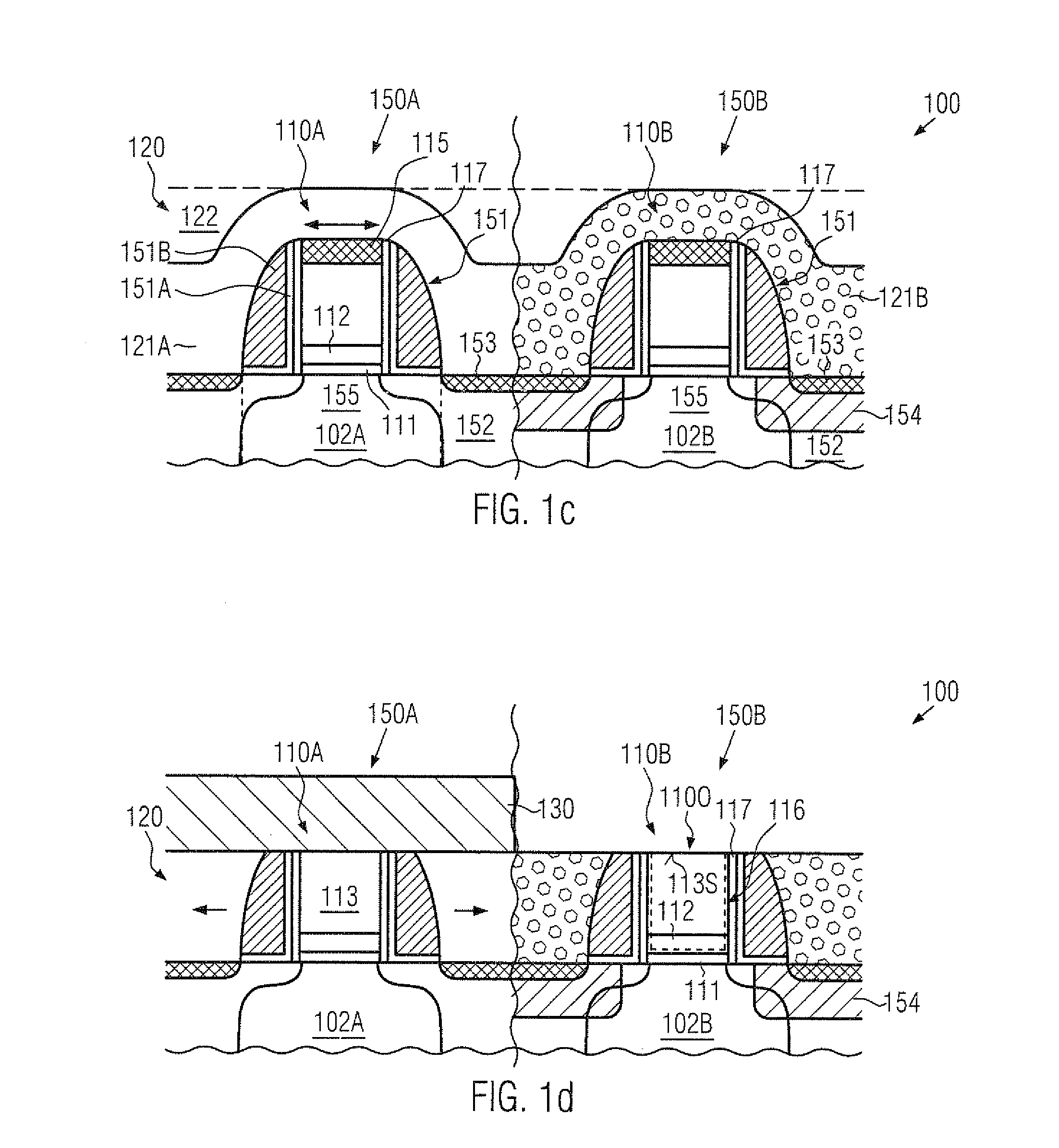

ActiveUS20110156154A1Improve device performanceEffective regulationTransistorSemiconductor/solid-state device manufacturingWork functionGate stack

Sophisticated high-k metal gate electrode structures are provided on the basis of a hybrid process strategy in which the work function of certain gate electrode structures is adjusted in an early manufacturing stage, while, in other gate electrode structures, the initial gate stack is used as a dummy material and is replaced in a very advanced manufacturing stage. In this manner, superior overall process robustness in combination with enhanced device performance may be achieved.

Owner:GLOBALFOUNDRIES US INC

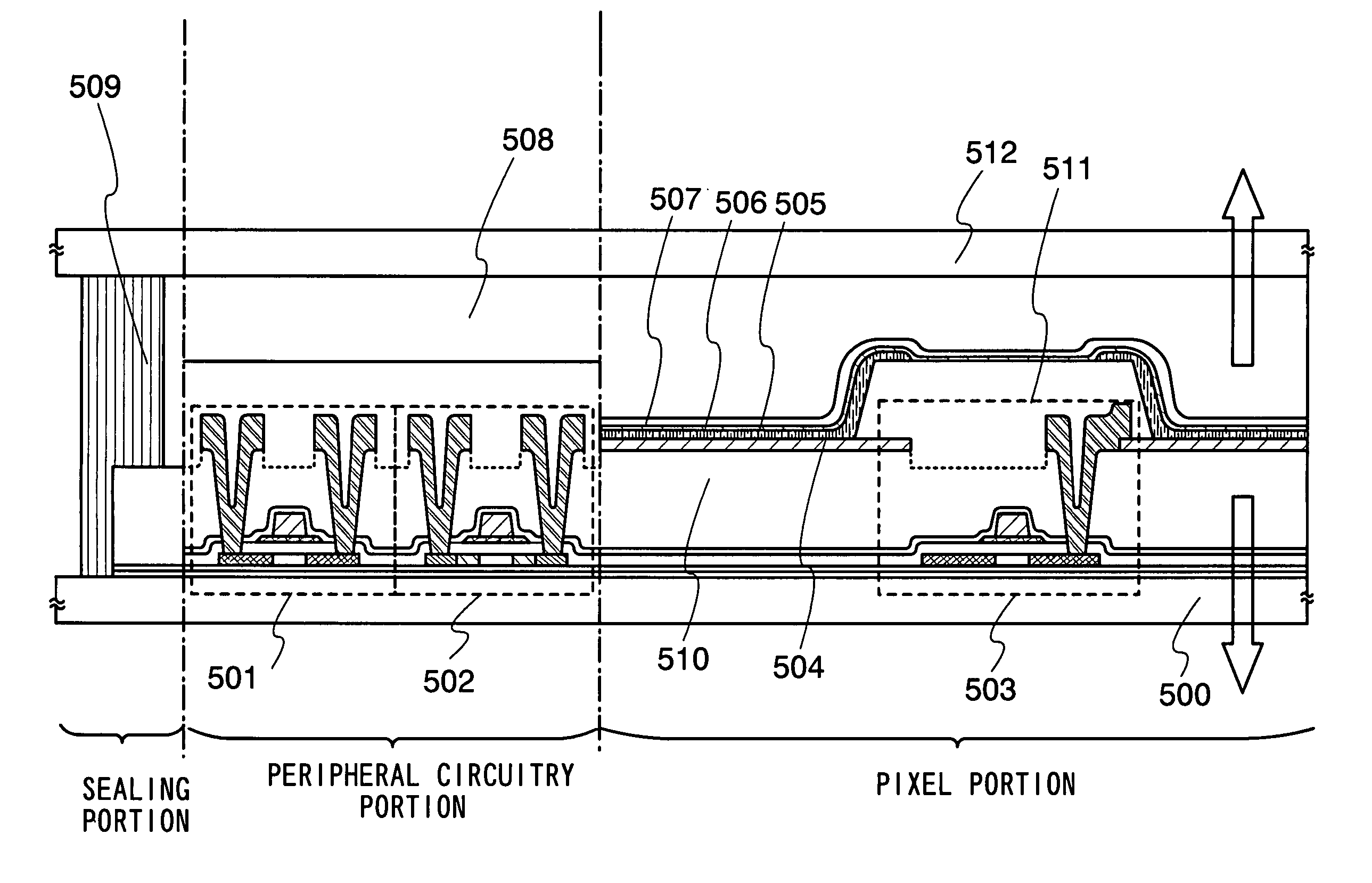

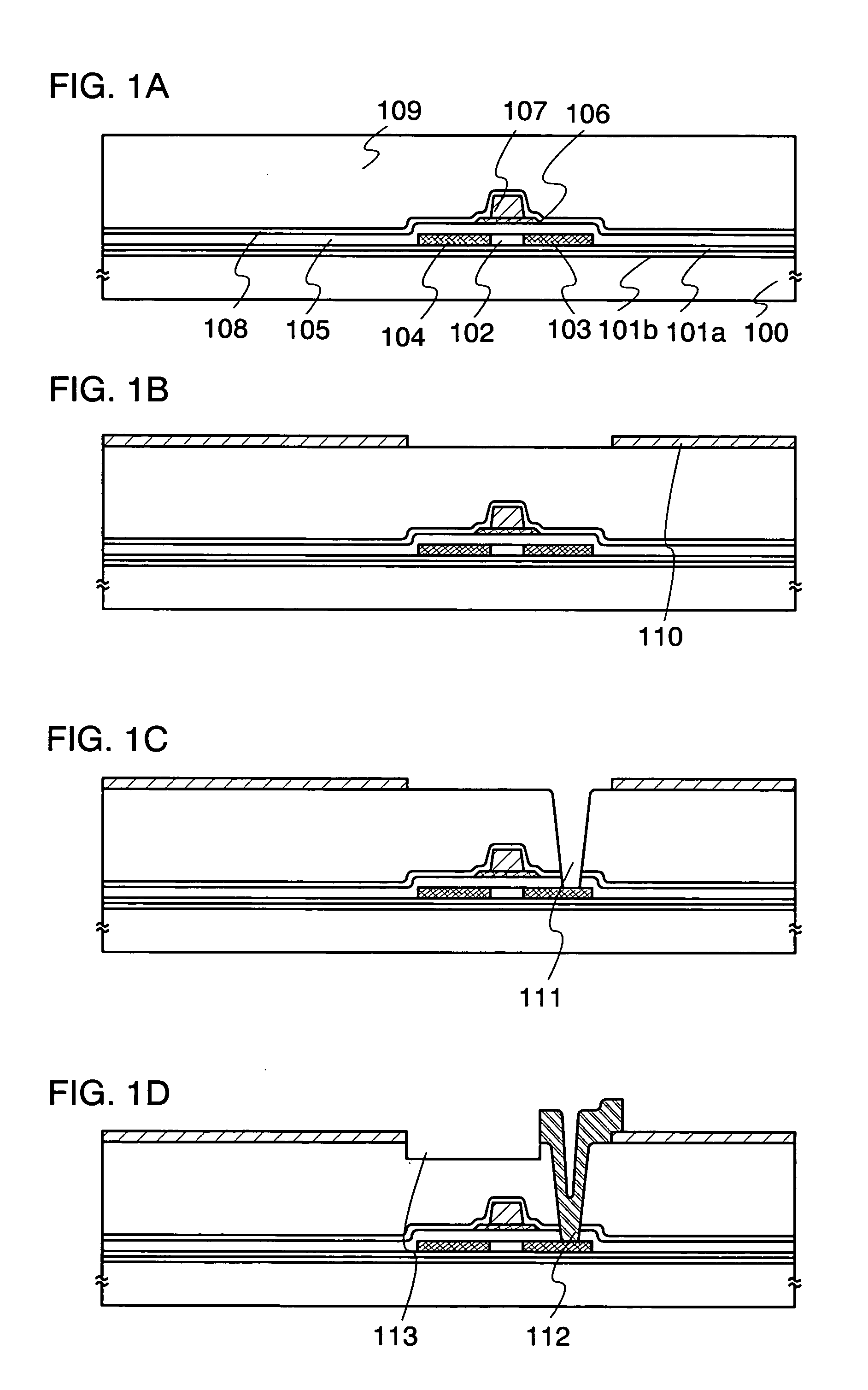

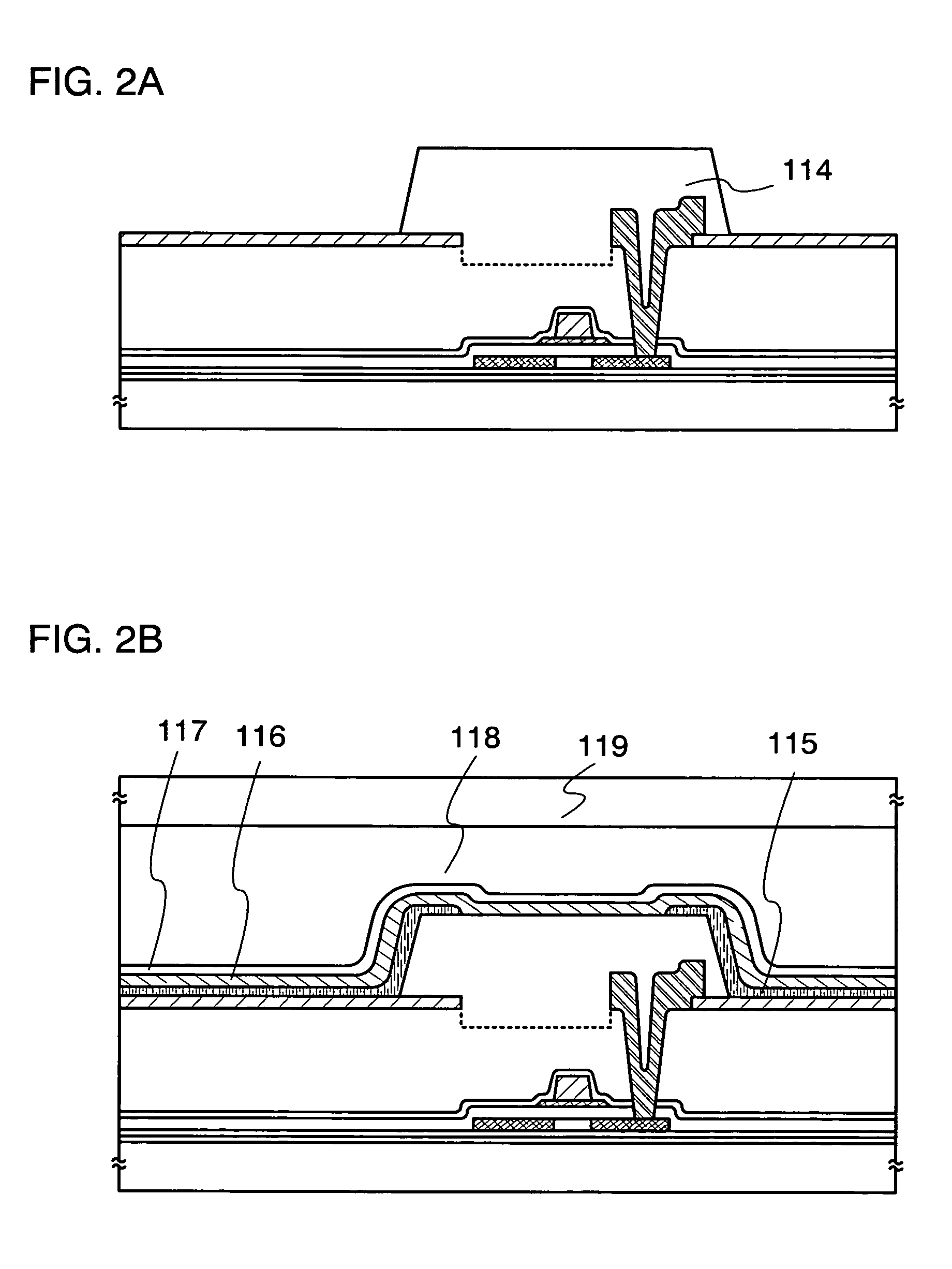

Display device and manufacturing method of display device

InactiveUS20050062409A1High light transmittancePreferable display propertyDischarge tube luminescnet screensElectroluminescent light sourcesSimple Organic CompoundsCompound (substance)

It is an object of the present invention to provide a reliable display device and a method for manufacturing the display device reducing the number of manufacturing steps, and with higher yield. A display device according to the invention includes a plurality of display elements each having a first electrode, a layer containing an organic compound, and a second electrode. The display device further includes a heat-resistant planarizing film over a substrate having an insulating surface, a first electrode over the heat-resistant planarizing film, a wiring covering an end portion of the first electrode, a partition wall covering the end portion of first electrode and the wiring, a layer containing an organic compound, and a second electrode over the layer containing an organic compound.

Owner:SEMICON ENERGY LAB CO LTD

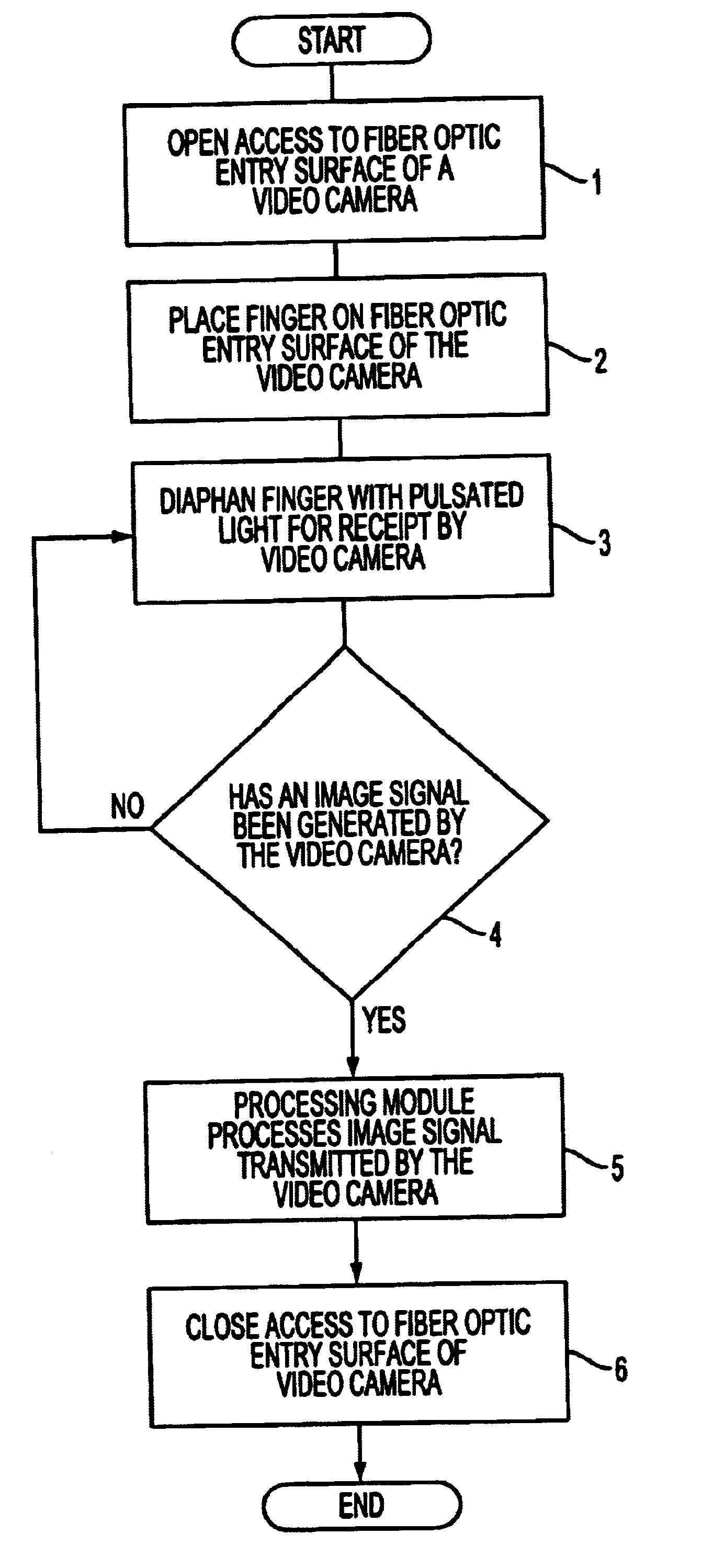

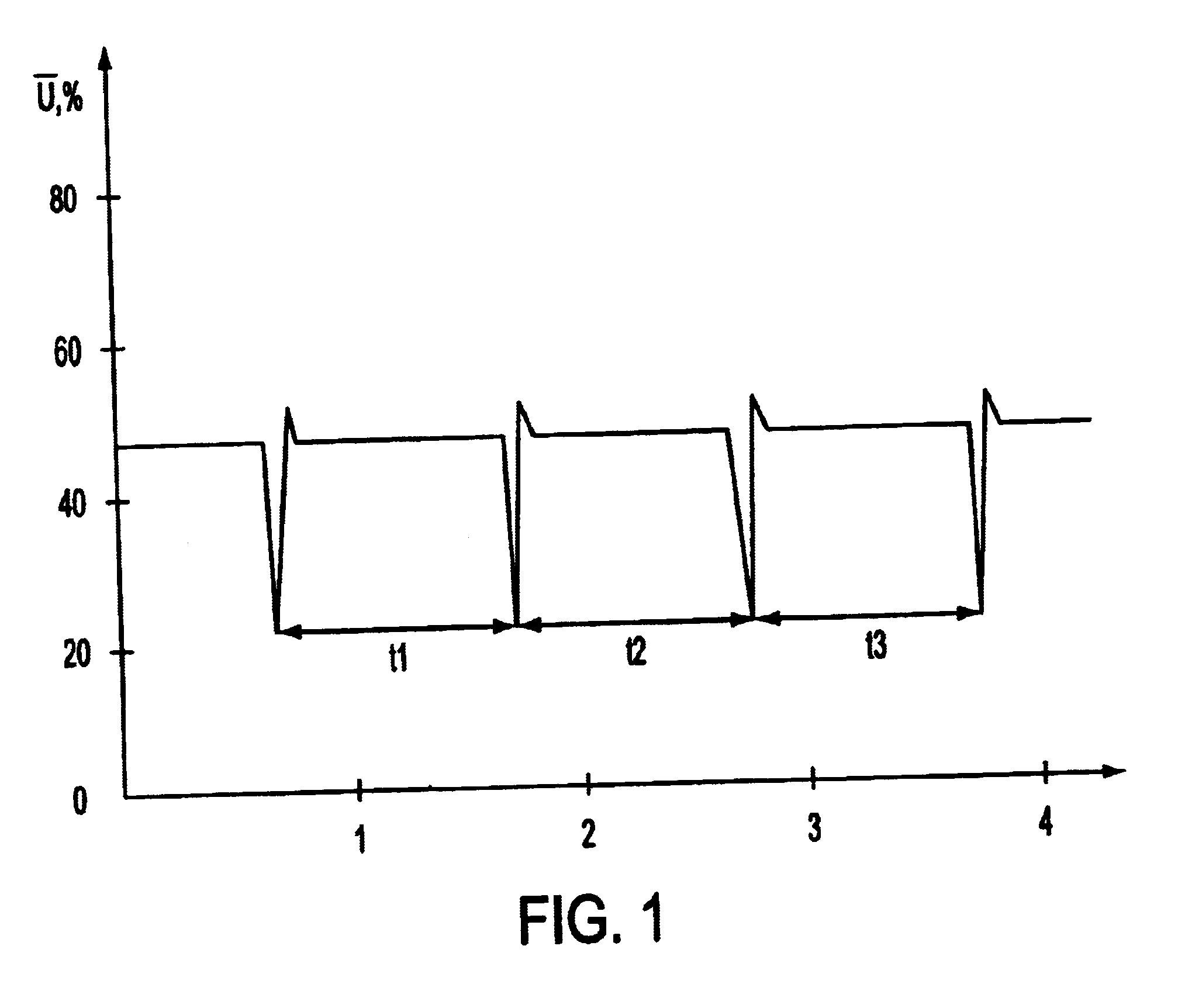

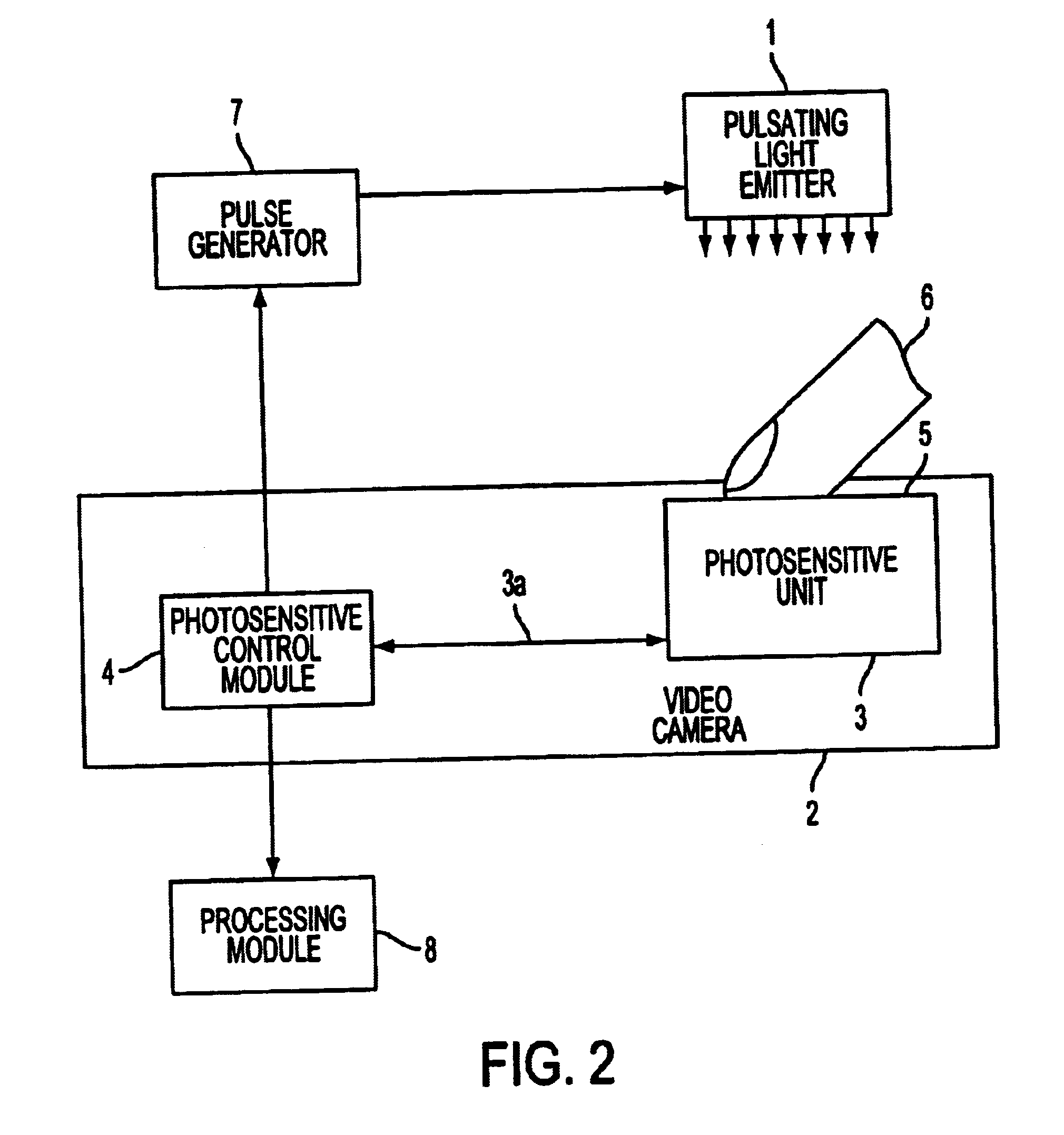

Method and apparatus for user identification using pulsating light source

InactiveUS6668071B1Reduce probabilityReduce instabilityPrint image acquisitionDetecting live finger characterShort durationLight source

Pulsating light is used to penetrate a user's finger placed an input surface (which can be a fiber optic surface) of a video camera to avoid the effects of bloodflow from a normal human pulse on the quality of the image which would otherwise change the contrast of the image. The use of pulsating light of shorter durations than a typical human pulse provides an accurate image of a portion of a finger for identification. A retractable cover blocks the fiber optic input surface during a non-working mode, and allows access for identification during a working mode. A light source having a plurality of light emitting diodes provides light that diaphans a portion of the finger. Several successive frames of image signals allow for biometric detection and verification of a human pulse to ensure the finger is not a counterfeit.

Owner:MINKIN VIKTOR ALBERTOVICH +4

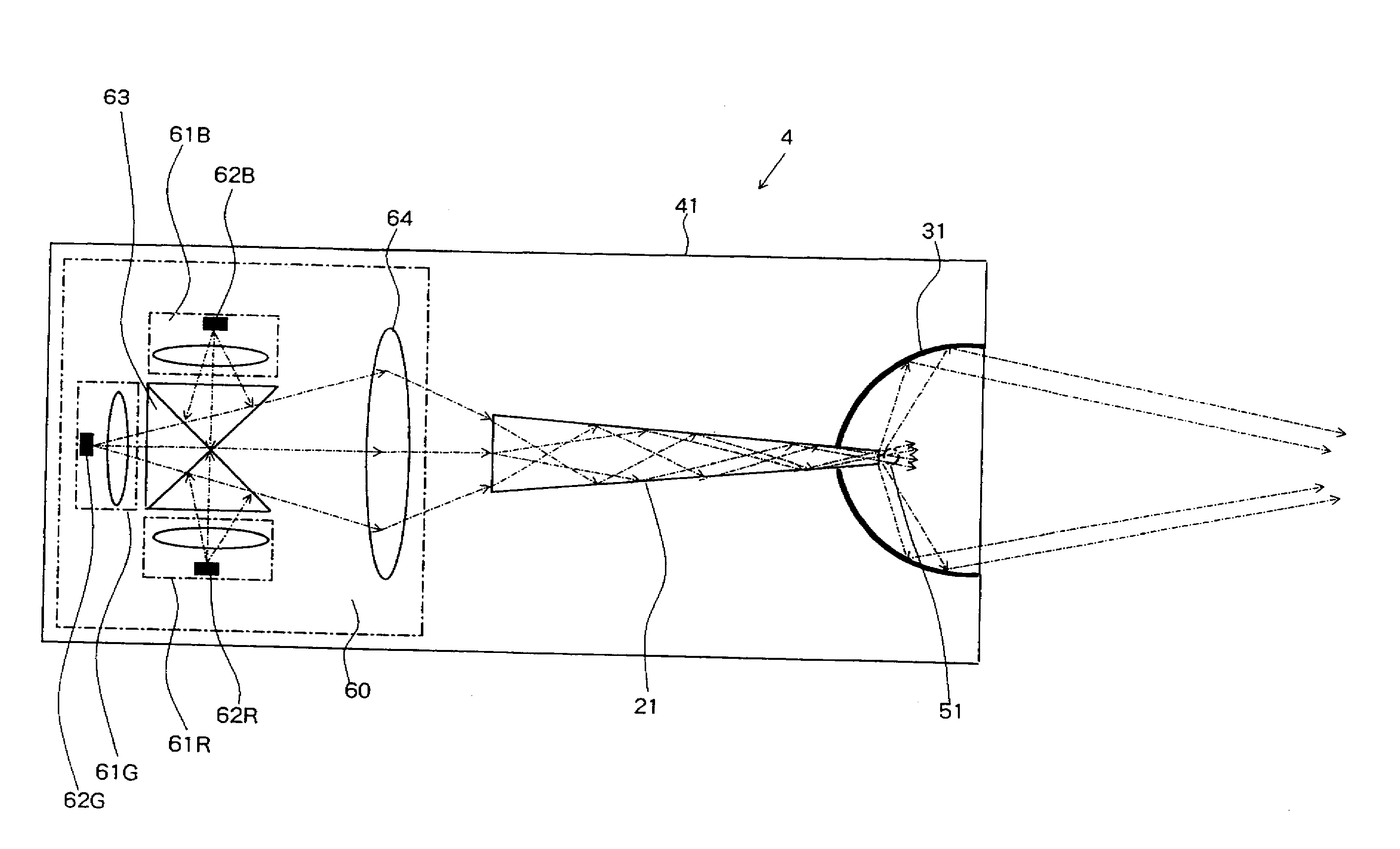

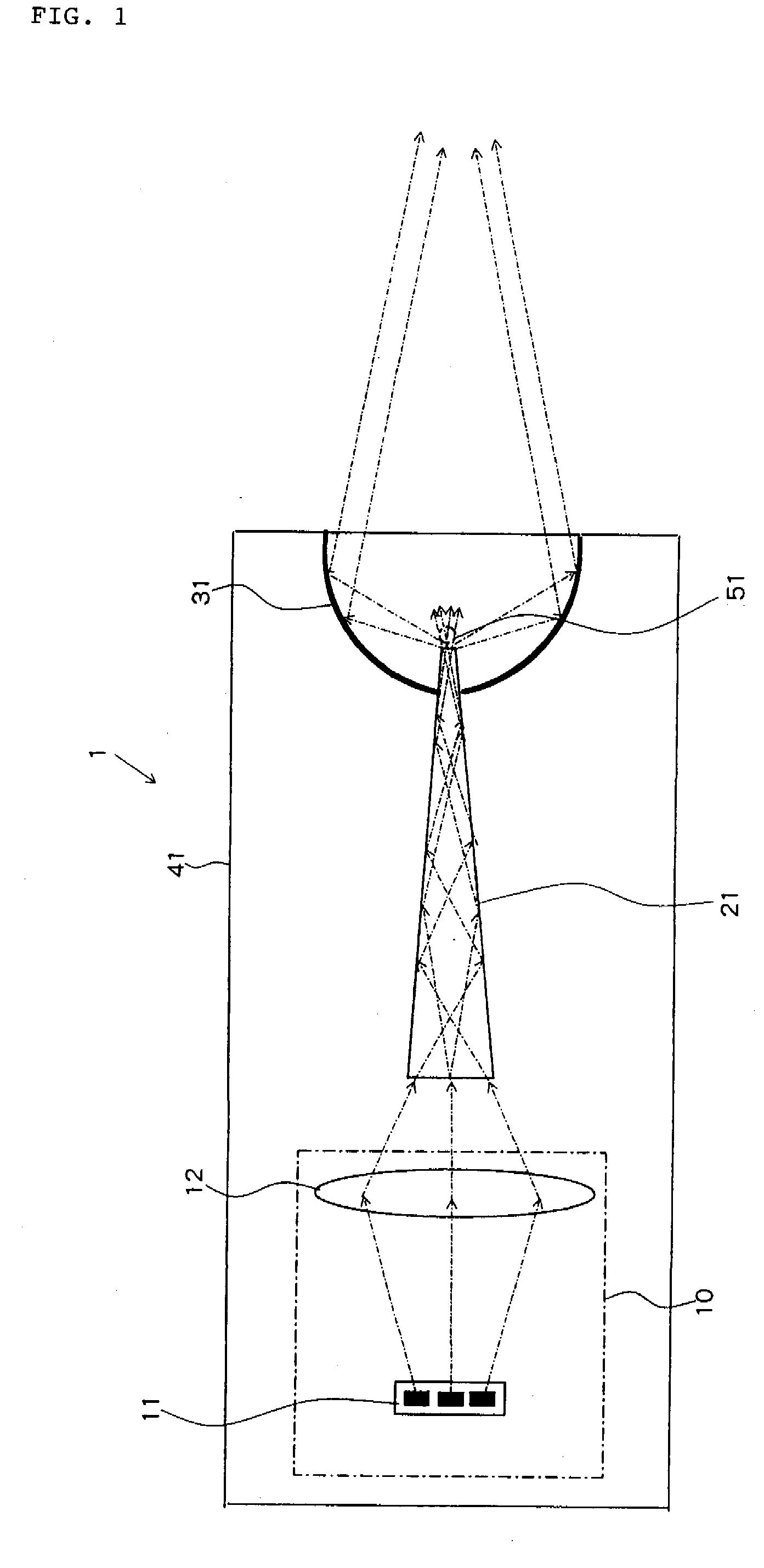

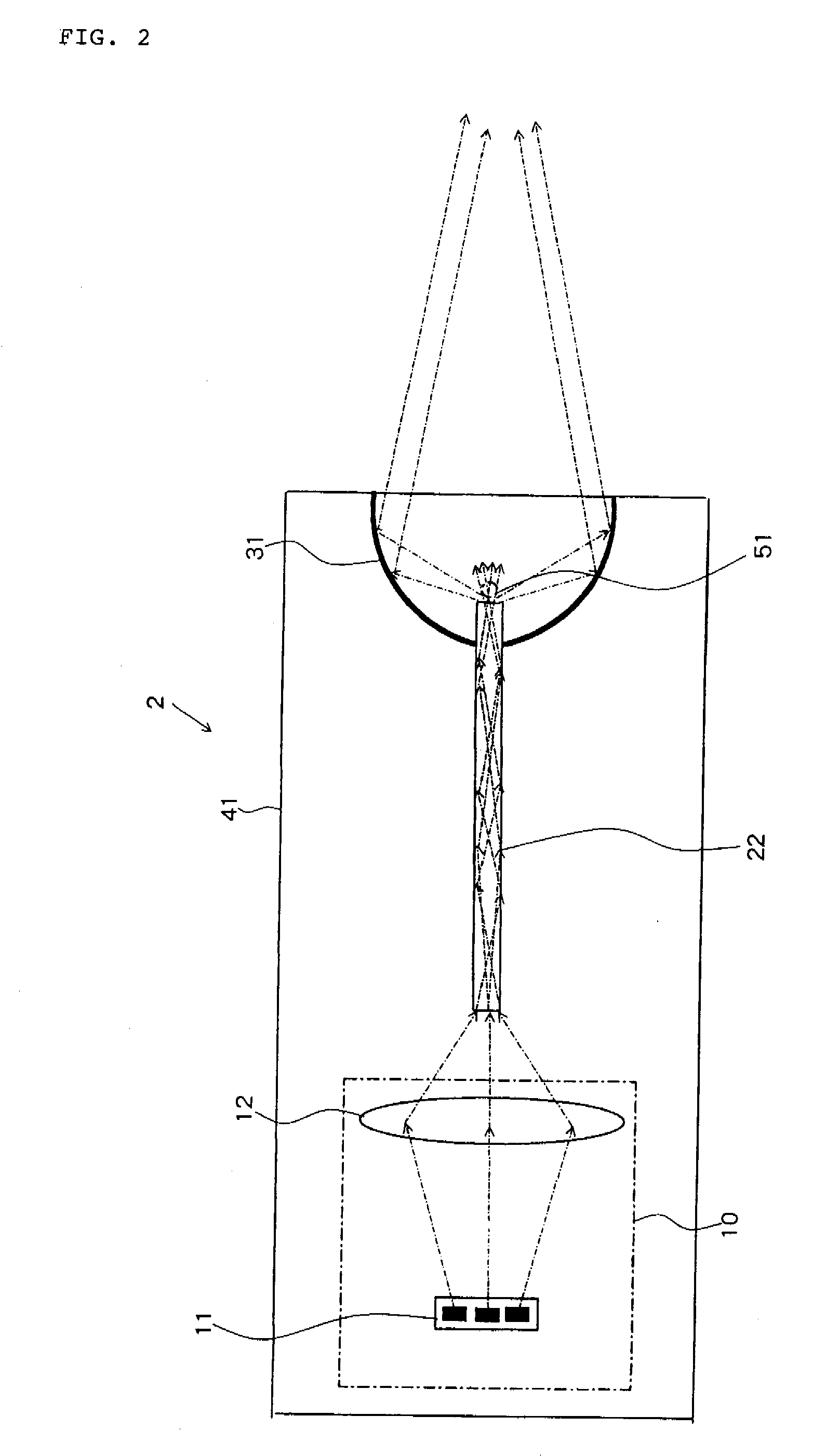

LED spotlight

InactiveUS20090052189A1Easily designedReduced color irregularityLight source combinationsVehicle headlampsPhysicsColor mixing

An LED spotlight includes: a light source unit including an RGB-LED light source composed of R, G and B LEDs, and a condenser lens for condensing light beams of mixed color projected from the RGB-LED light source on an entrance end face of a rod lens; a pyramid rod lens whose cross-sectional area converges from an entrance end face to an exit end face; and a reflector for condensing rays of exiting light exiting as a point light source from the exit face of the pyramid rod lens on an axial line of the pyramid rod lens. A light beam incident on the pyramid rod lens progresses while repeatedly internally reflected several times, thereby brightness irregularity at the exit end of the rod lens is lowered, and color mixture is accelerated, so that a light beam is emitted as a point light source of white light whose color is observed as the same color, seen from any direction, and the light beams are condensed as a spotlight on the axial line of the pyramid rod lens by the reflector.

Owner:NEC LIGHTING

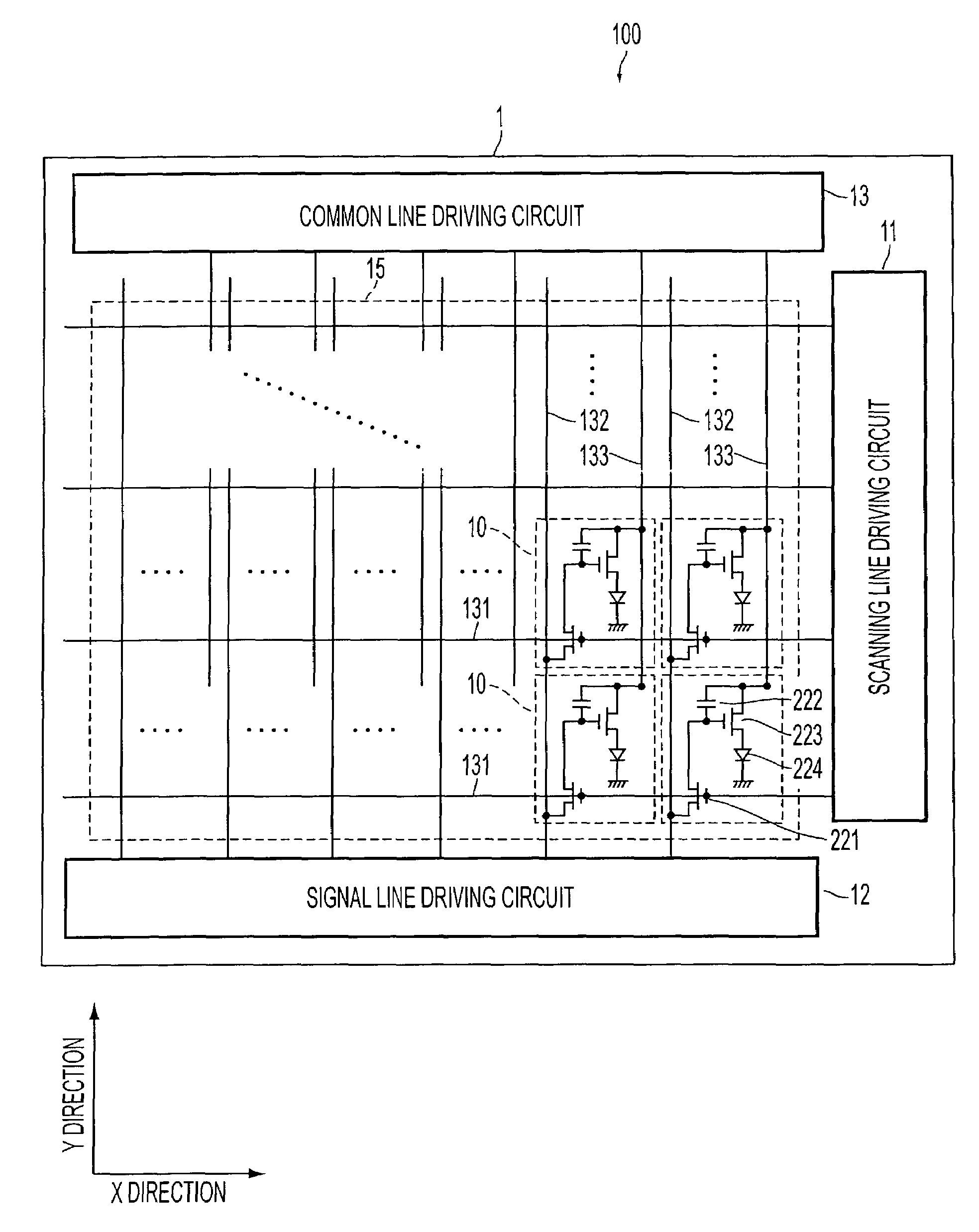

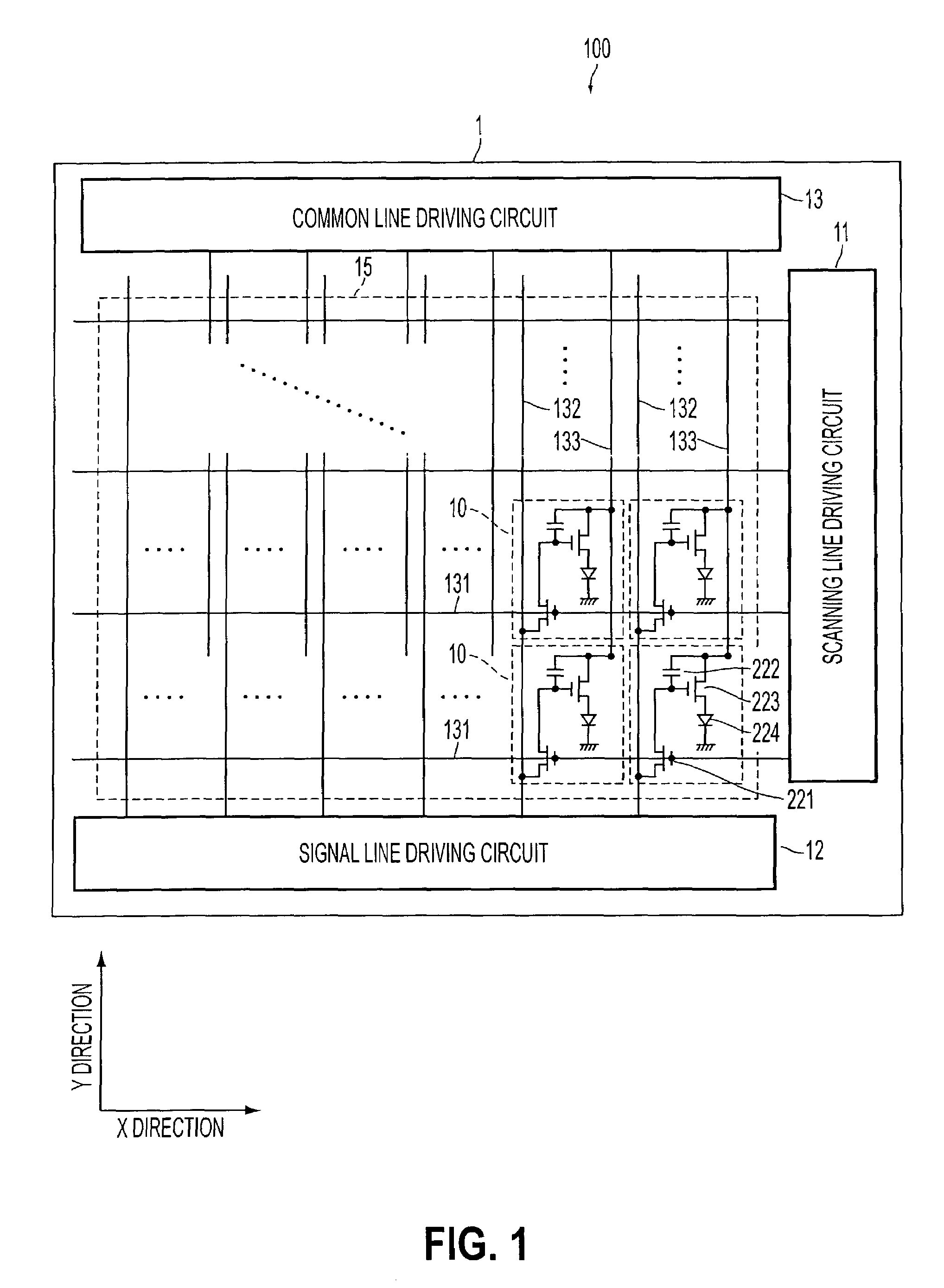

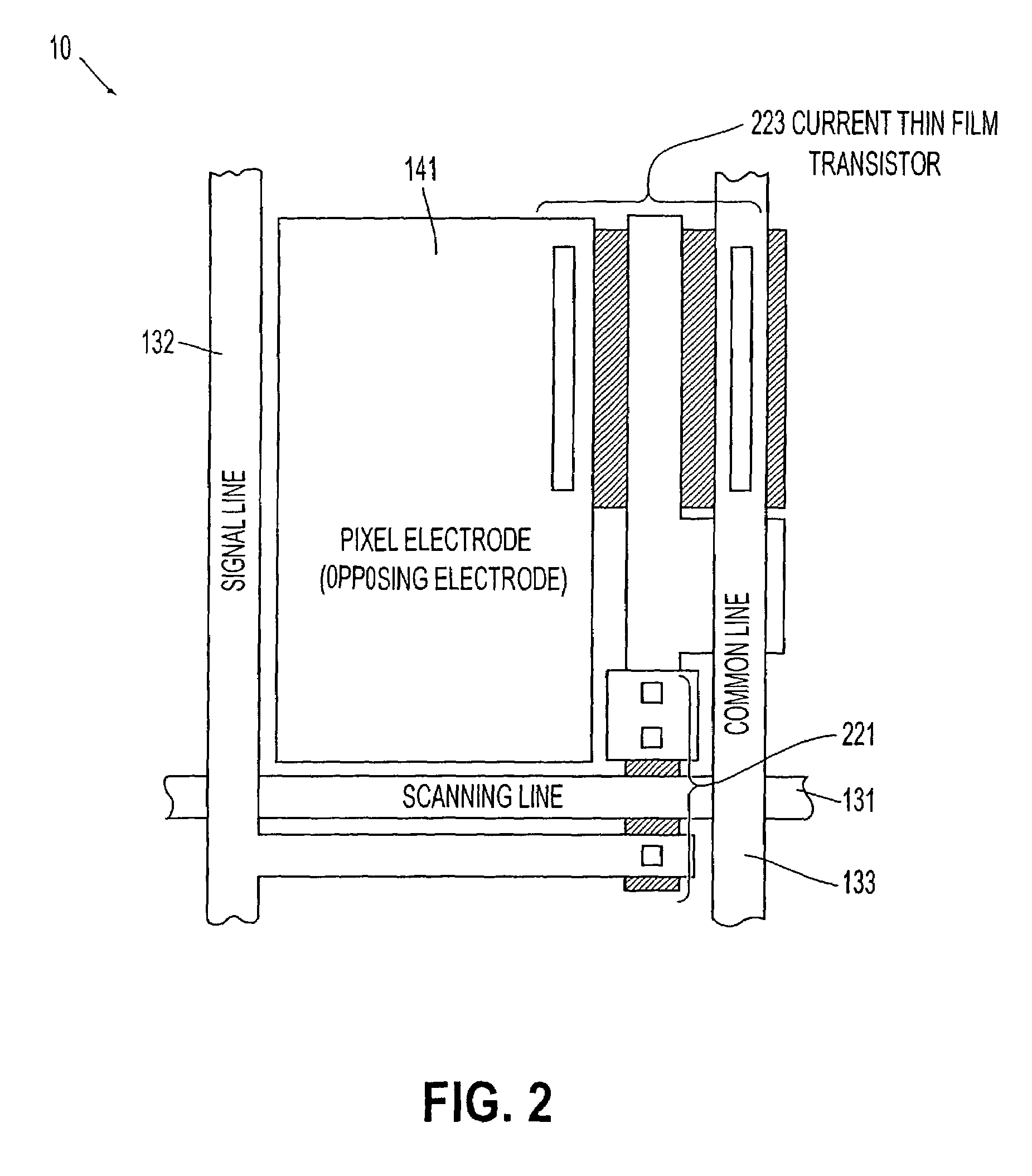

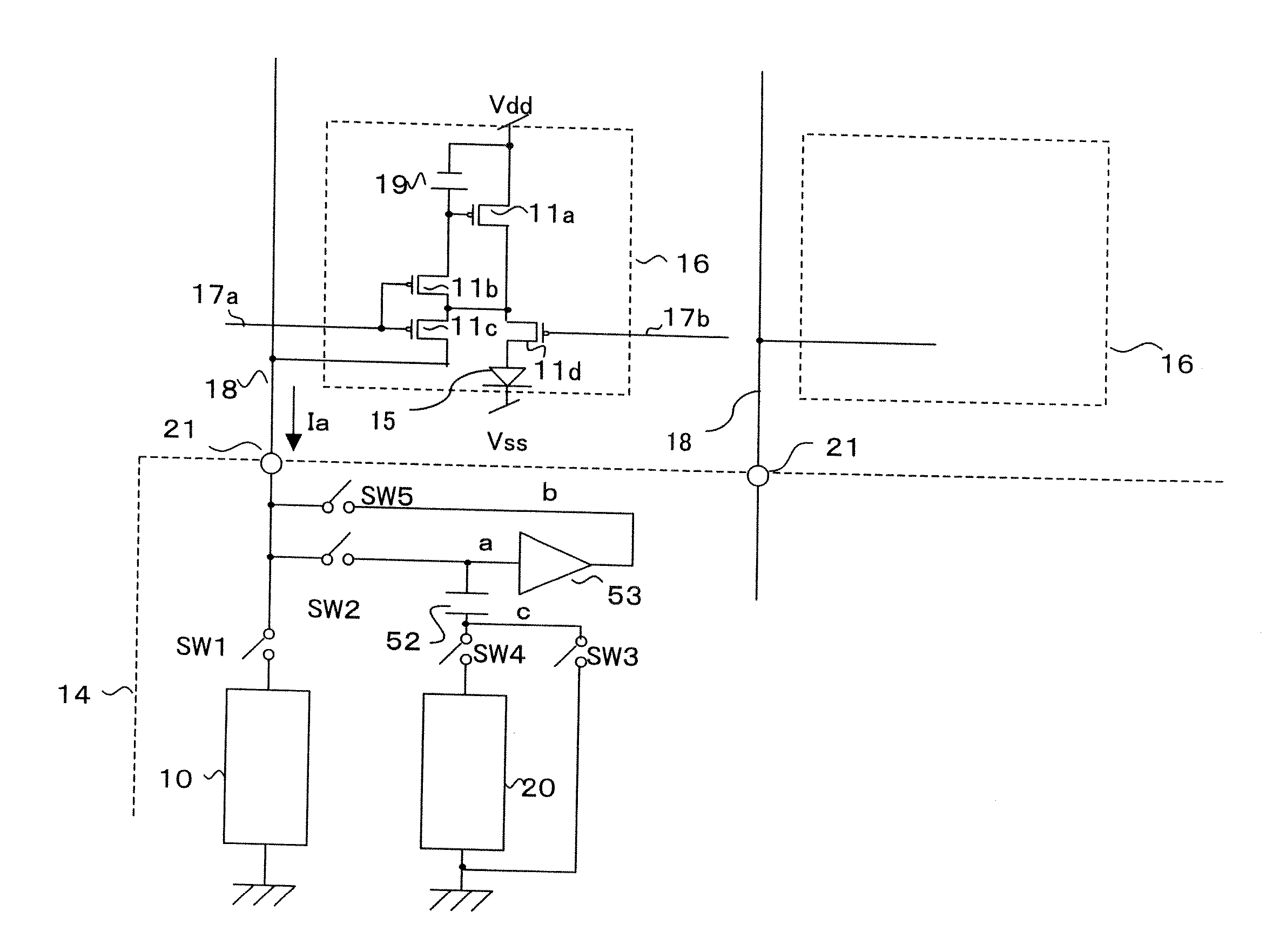

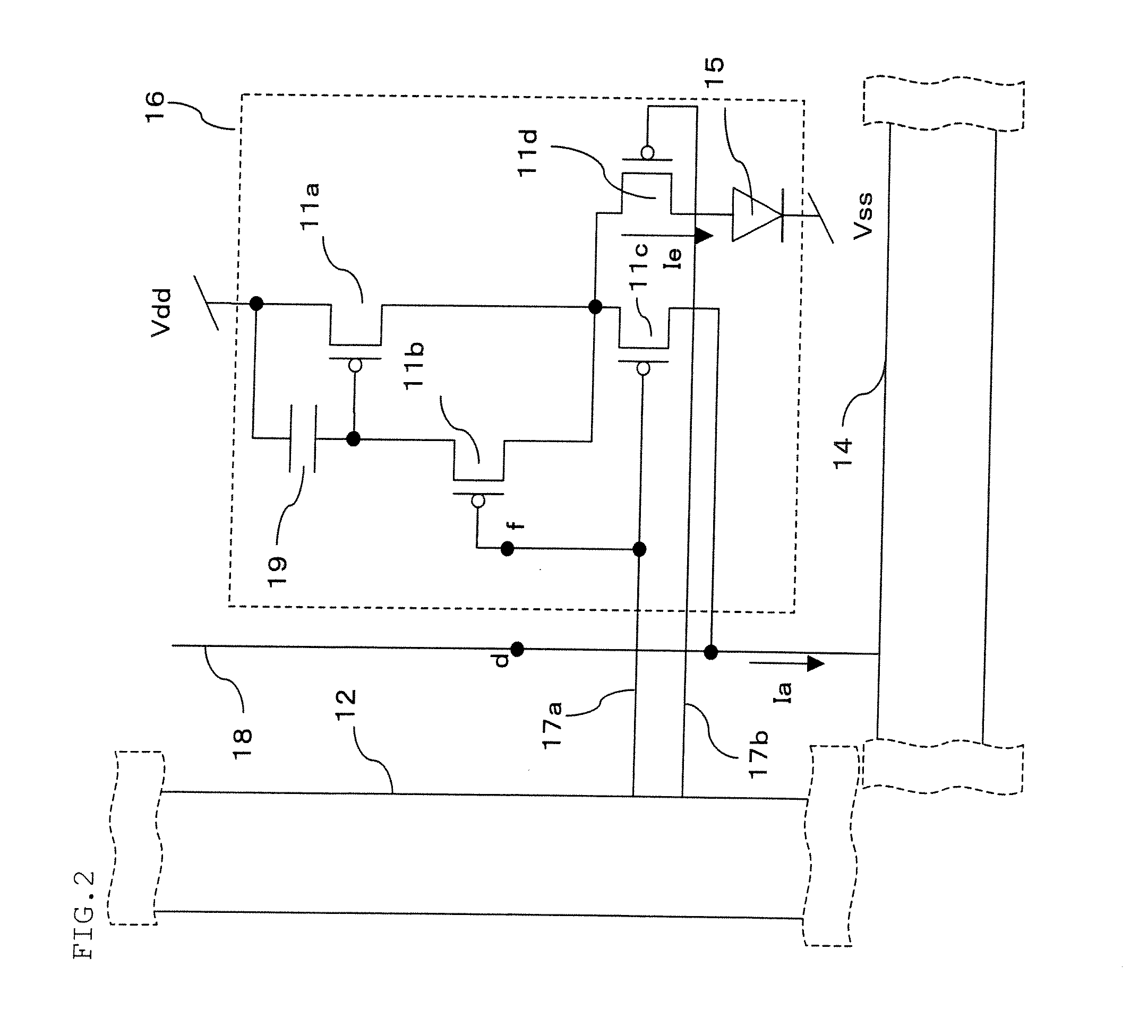

Pixel circuit, display apparatus and electronic apparatus equipped with current driving type light-emitting device

InactiveUS7362322B2Reduction in display luminanceReduction in screen irregularityElectroluminescent light sourcesSolid-state devicesVoltage regulationEngineering

A display apparatus is provided with a current driving type light-emitting device and a driving device for controlling a driving current flowing through the light-emitting device for each pixel of the display apparatus. The display apparatus consists of power source units for supplying power for causing a driving current to flow via the driving device to the light-emitting device via a power source wire, and signal wire driving units for supplying a data signal to the driving device via signal wires. In addition, voltage adjusting units adjust a voltage for the power source units or a data signal from the signal wire driving units so that a quantity of a driving current flowing through the light-emitting device when a data signal of a predetermined voltage is supplied to the driving device via signal wires or a quantity of emitted light emitted from the light-emitting device comes close to a predetermined reference value.

Owner:SEIKO EPSON CORP

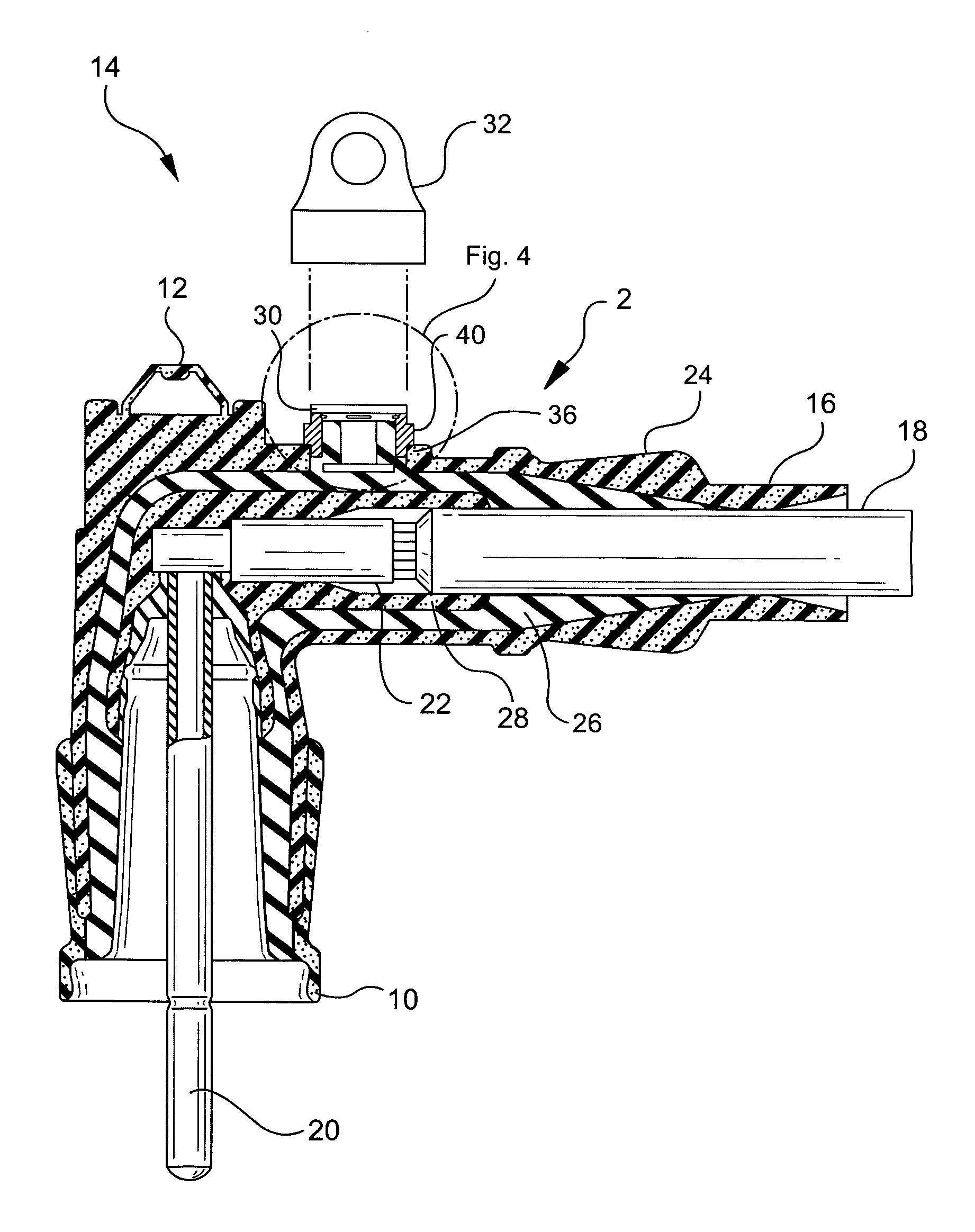

Method for forming an electrical connector with voltage detection point insulation shield

ActiveUS7150098B2Reduce frictionReduce irregularitiesContact member manufacturingRelieving strain on wire connectionThermoplasticElectrical conductor

In a method for forming an electrical cable connector having a voltage detection test point, an insulative shield is first molded from a thermoplastic and a conductive voltage detection test point terminal is inserted within the plastic insulative shield. After the pre-assembled insulative plastic shield and test point terminal are positioned adjacent the opening of the conductive outer shield, and after the conductive outer shield and an internal conductor are positioned within a mold cavity, an inner insulative housing is molded within the conductive outer shield and around the internal conductor.

Owner:THOMAS & BETTS INT INC

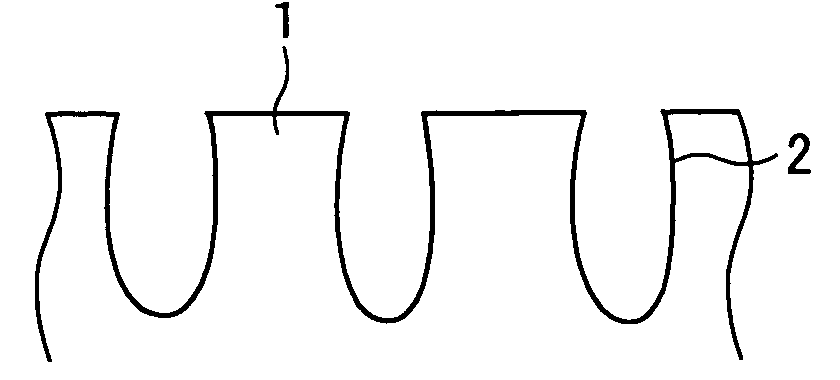

Sheet conveying apparatus

InactiveUS20070023995A1Improve accuracyWeaken influenceRegistering devicesFunction indicatorsLeading edgeEngineering

A sheet conveying apparatus for conveying a sheet to an image forming portion has a first aligning member for effecting the alignment of the sheet with one of the opposite side edges of the sheet parallel to a sheet conveying direction as a reference, a second aligning member for effecting the alignment of the sheet with the leading edge of the sheet orthogonal to the sheet conveying direction as a reference, and an aligning operation controlling device for selectively operating one of the first aligning member and the second aligning member on the basis of at least one of image information, sheet information and sheet processing information.

Owner:CANON KK

El display apparatus and method for driving el display apparatus

InactiveUS20070126667A1Reduce irregularitiesElectrical apparatusStatic indicating devicesEngineeringSignal lines

An EL display apparatus in which pixels having EL elements are formed in a matrix, has a constant current circuit which generates a predetermined constant current; and a gradation voltage circuit which generates a gradation voltage; wherein the constant current generated by the constant current circuit is supplied to the pixels via a source signal line; and the gradation voltage generated by the gradation voltage circuit is supplied to the pixels via the source signal line.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

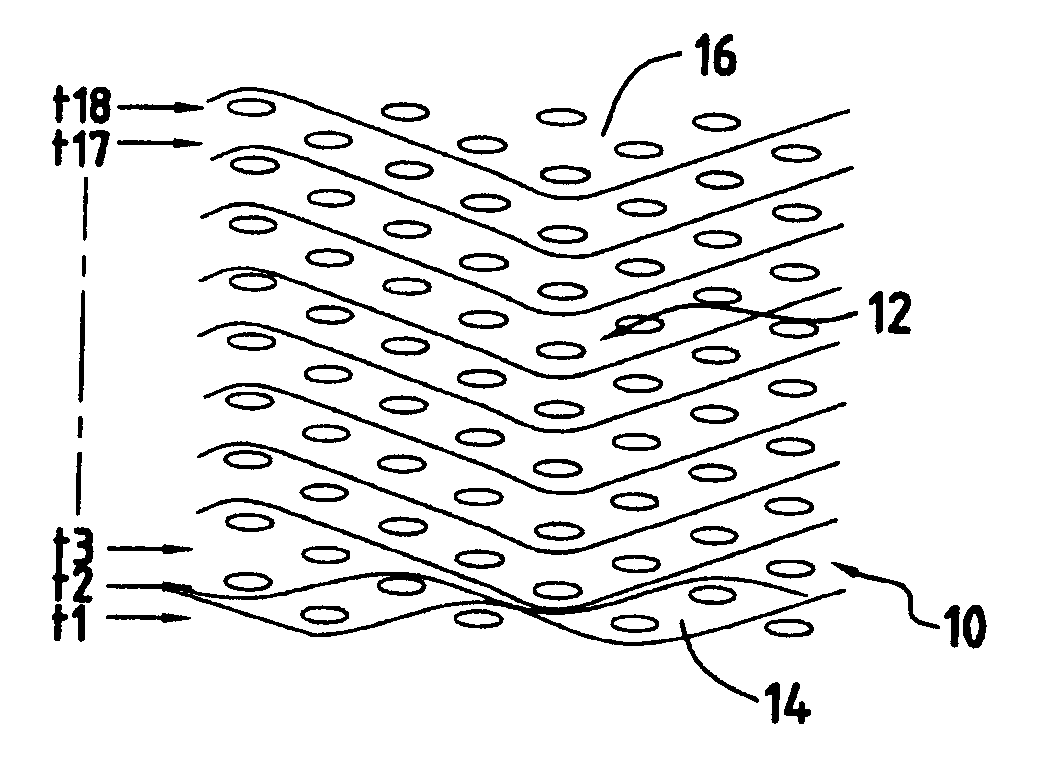

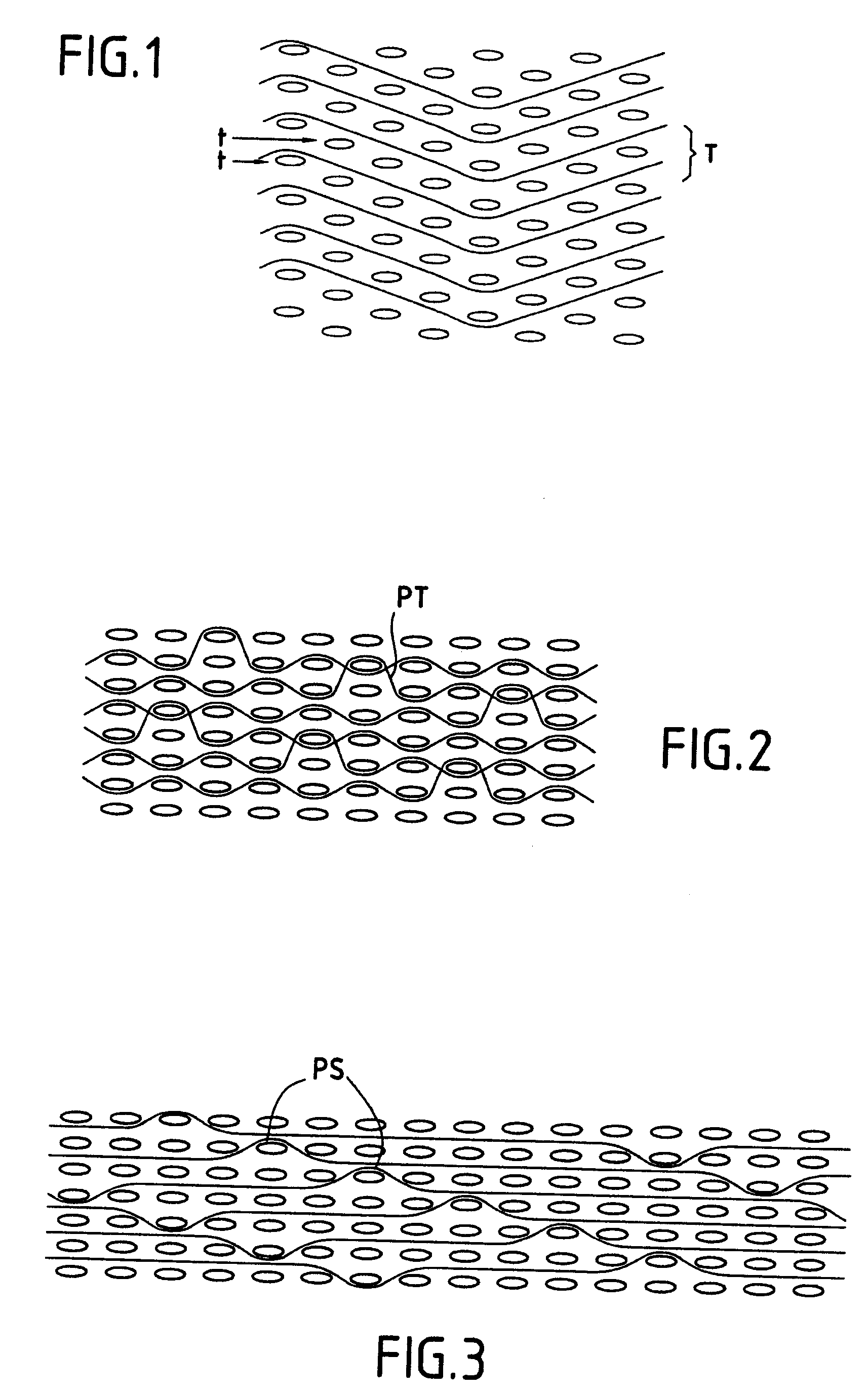

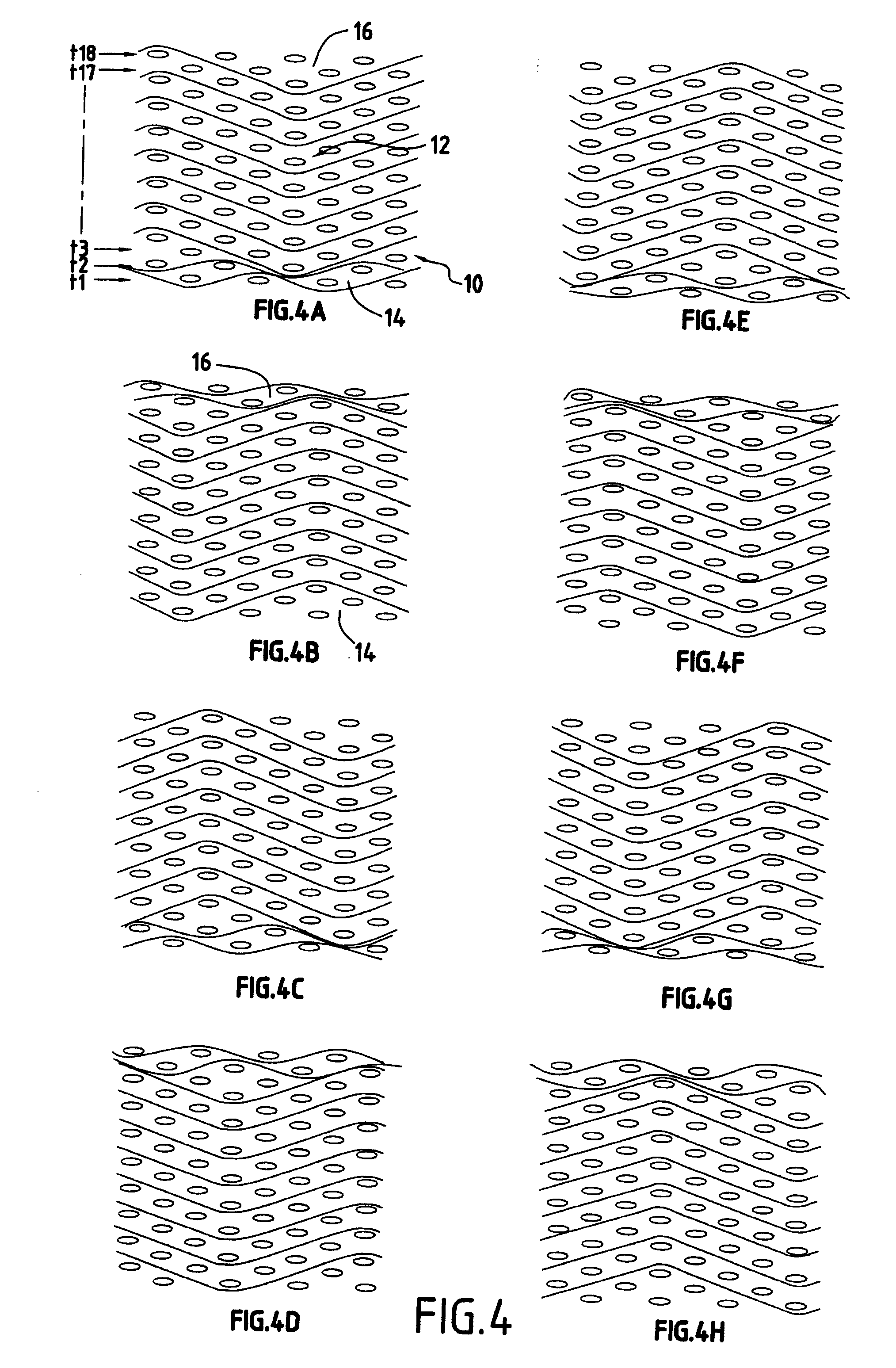

Reinforcing fibrous structure for a composite material and a part containing said structure

ActiveUS20100144227A1Easy accessReduce irregularitiesConnecting rodsMulti-ply fabricsBiomedical engineeringFiber structure

A woven fibrous structure embodied in one piece, used for producing a composite material part and comprising an internal part or a core (72) and a part adjacent to the external surface thereof or a skin (74, 76), is formed by three-dimensional core weaving with at least one weave selected from interlock and multilayer weaves and by skin weaving with a weave which differs from the core weave and selected from a multilayer weave and a two-dimensional weave. It can be also formed by three-dimensional weaving with at least one core interlock weave (72) and weaving with a fabric-, satin or skin twill-type weave, wherein skin weaving is of a multilayer or two-dimensional type.

Owner:GERAKL

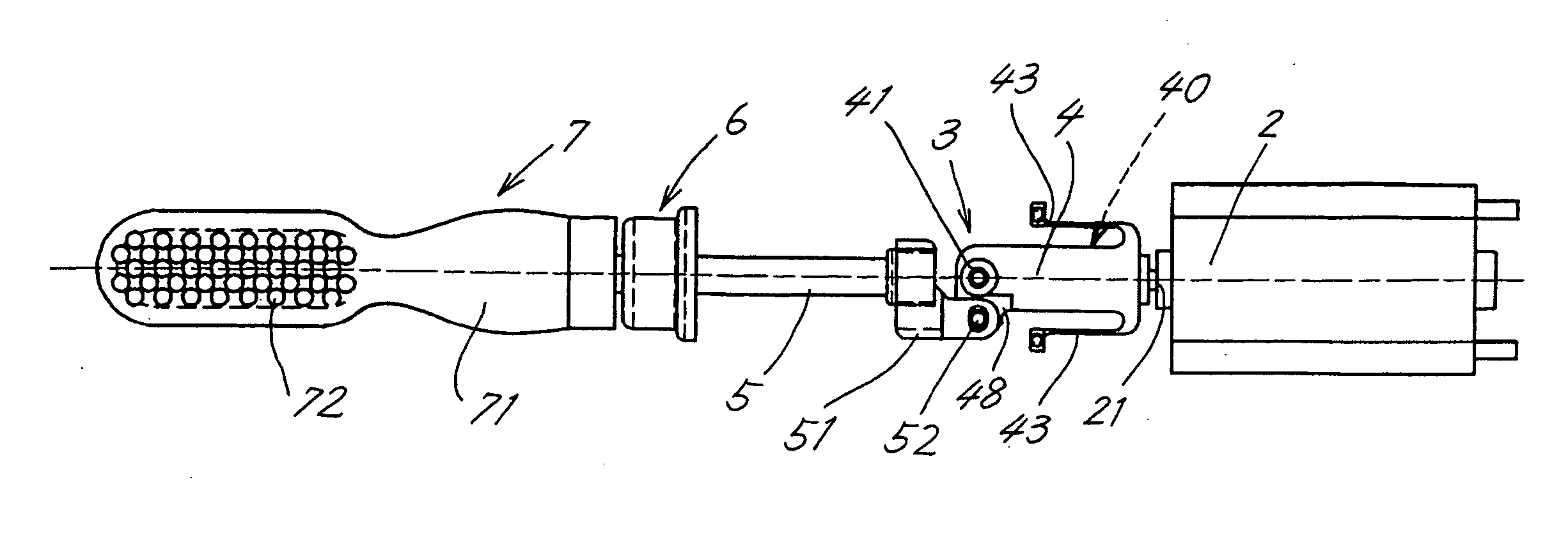

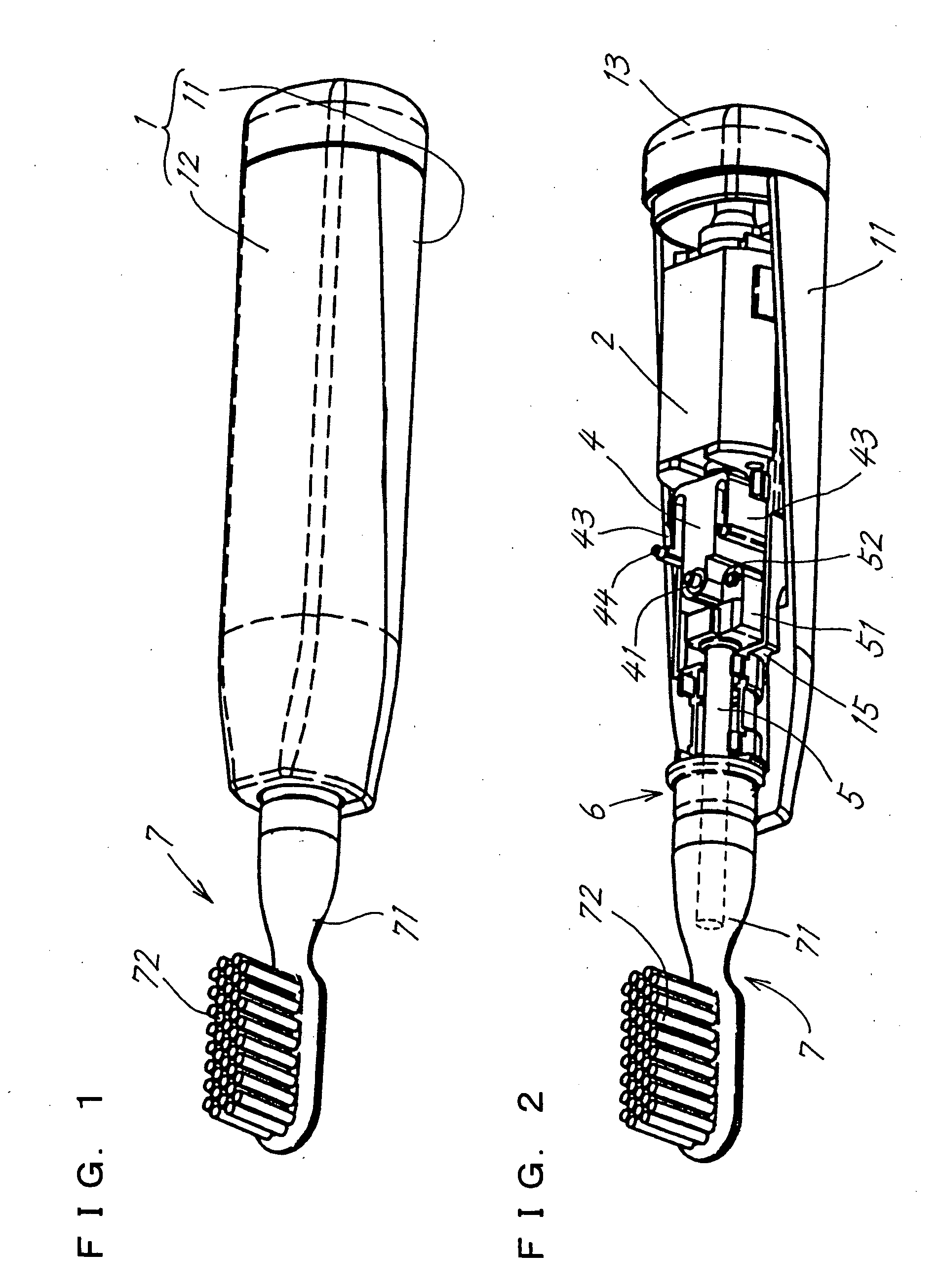

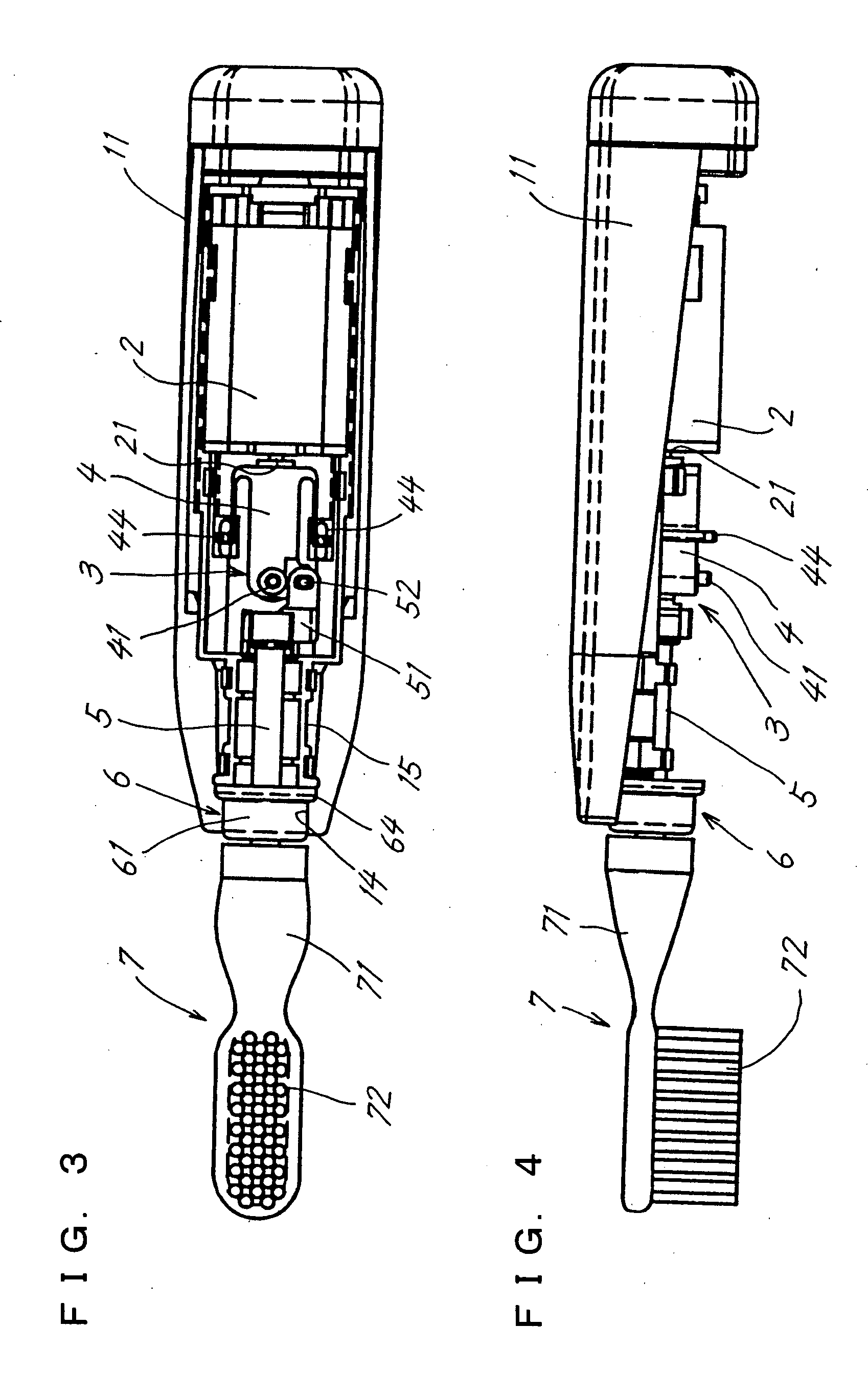

Electric toothbrush

InactiveUS20060101598A1Reduce irregularitiesRemove noiseMechanical apparatusCarpet cleanersReciprocating motionElectric machine

An electric toothbrush wherein the number of revolution of a motor shaft is in match with the frequency of reciprocating motion of the brush. A motor (2) housed in a tubular case (1) is coupled to a reciprocating shaft (5) slidably extending through the forward end of the case by a scotch yoke mechanism (40) for converting one turn of rotation of the motor shaft (21) into one stroke of reciprocating pivotal movement of a pivotal body (4), and by motion conversion means (3) for converting one stroke of reciprocating movement of the pivotal body (4) into one stroke of linear reciprocating motion of the reciprocating shaft (5).

Owner:SANYO ELECTRIC CO LTD

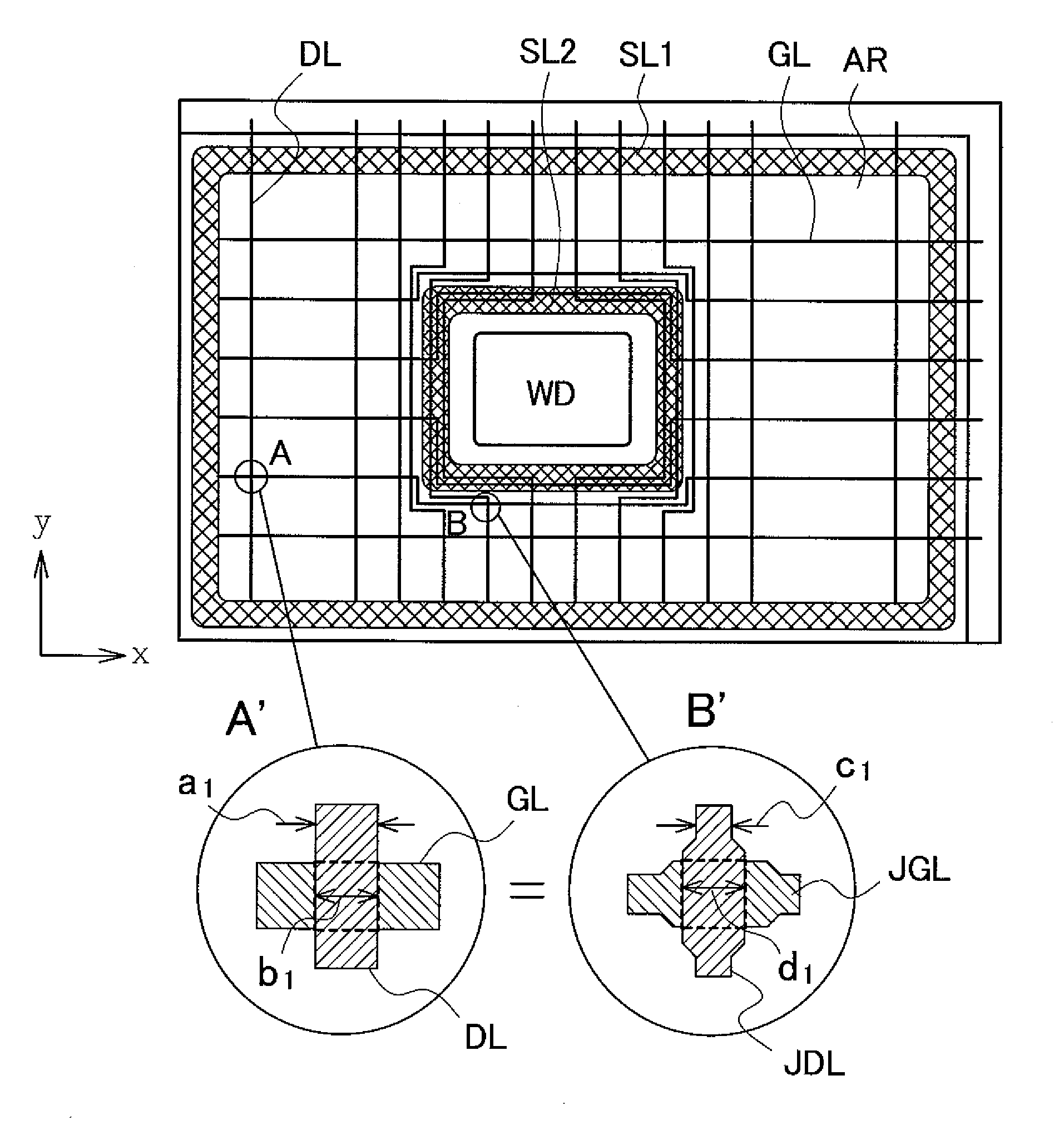

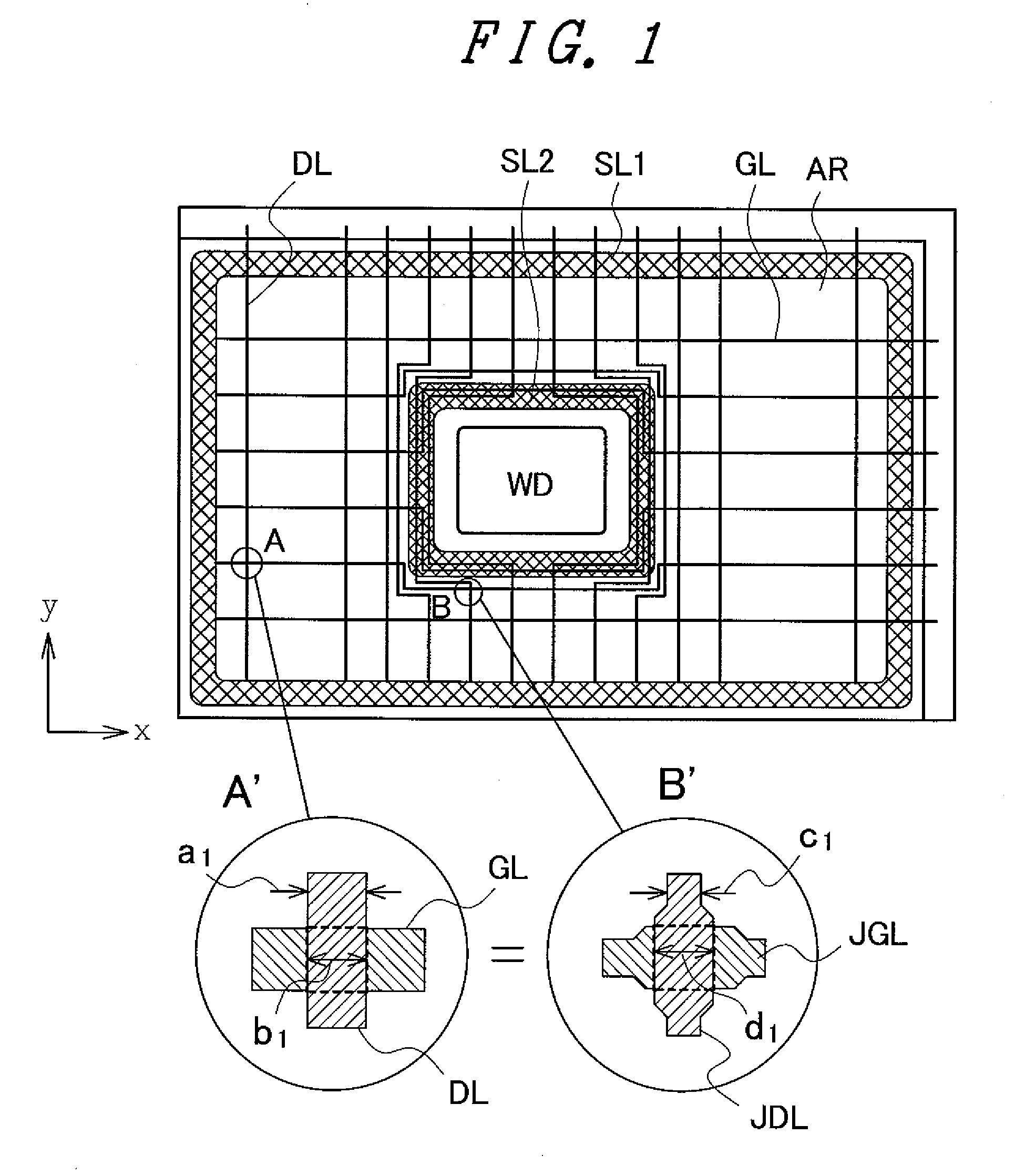

Display Device

InactiveUS20100053058A1Capacitance differenceSmall differenceStatic indicating devicesDisplay deviceEngineering

A display device in which a non-display region where drain lines, gate lines and pixels are not formed is formed at a portion within a display region which is constituted of a mass of the pixels, drain route-around lines and gate route-around lines are formed by routing the drain lines and the gate lines separated by the non-display region around the non-display region, a line width of at least one of the drain route-around line and the gate route-around line is set such that the line width at an intersecting portion where the drain route-around line and the gate route-around line intersect with each other differs from the line width at a non-intersecting portion.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

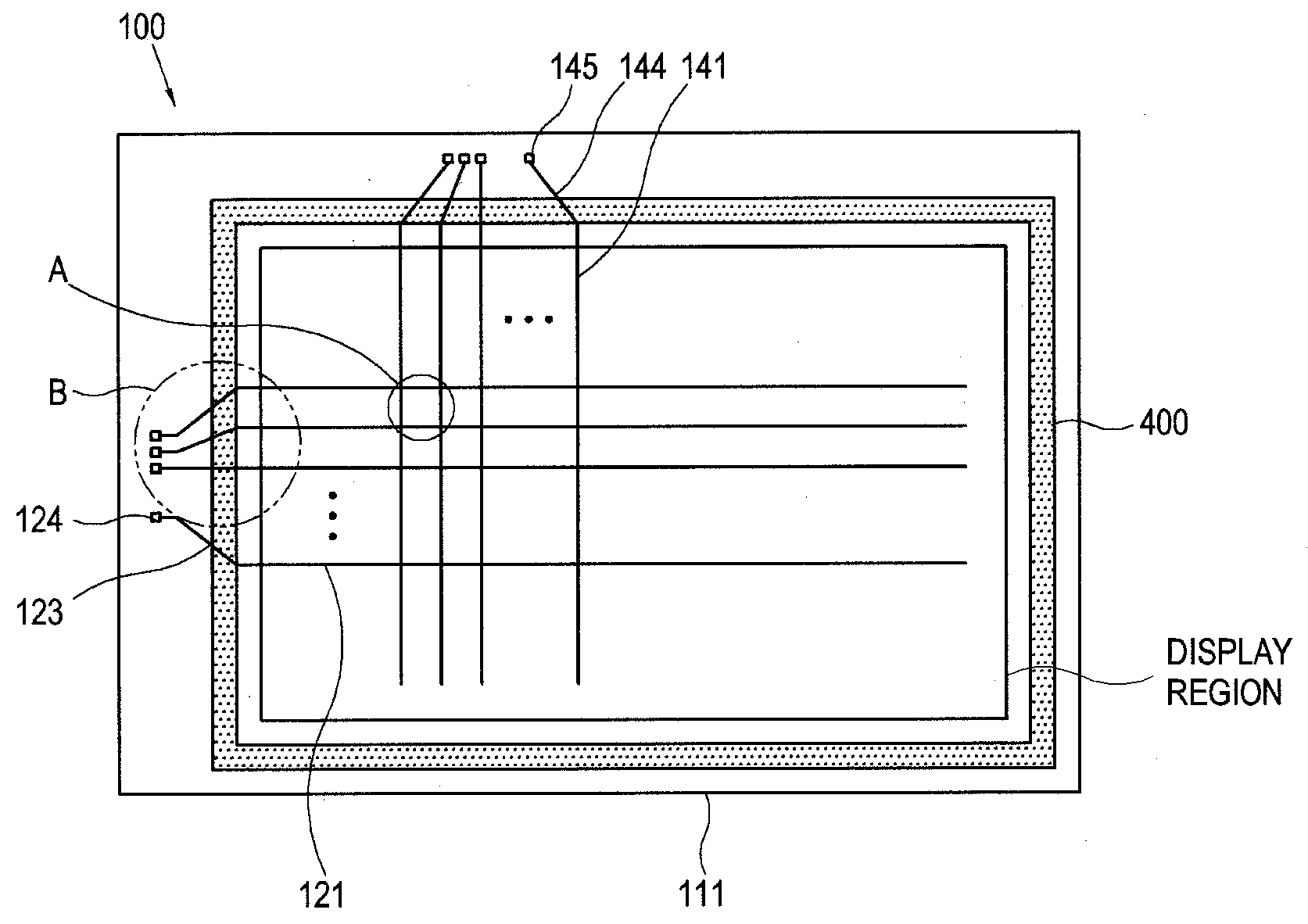

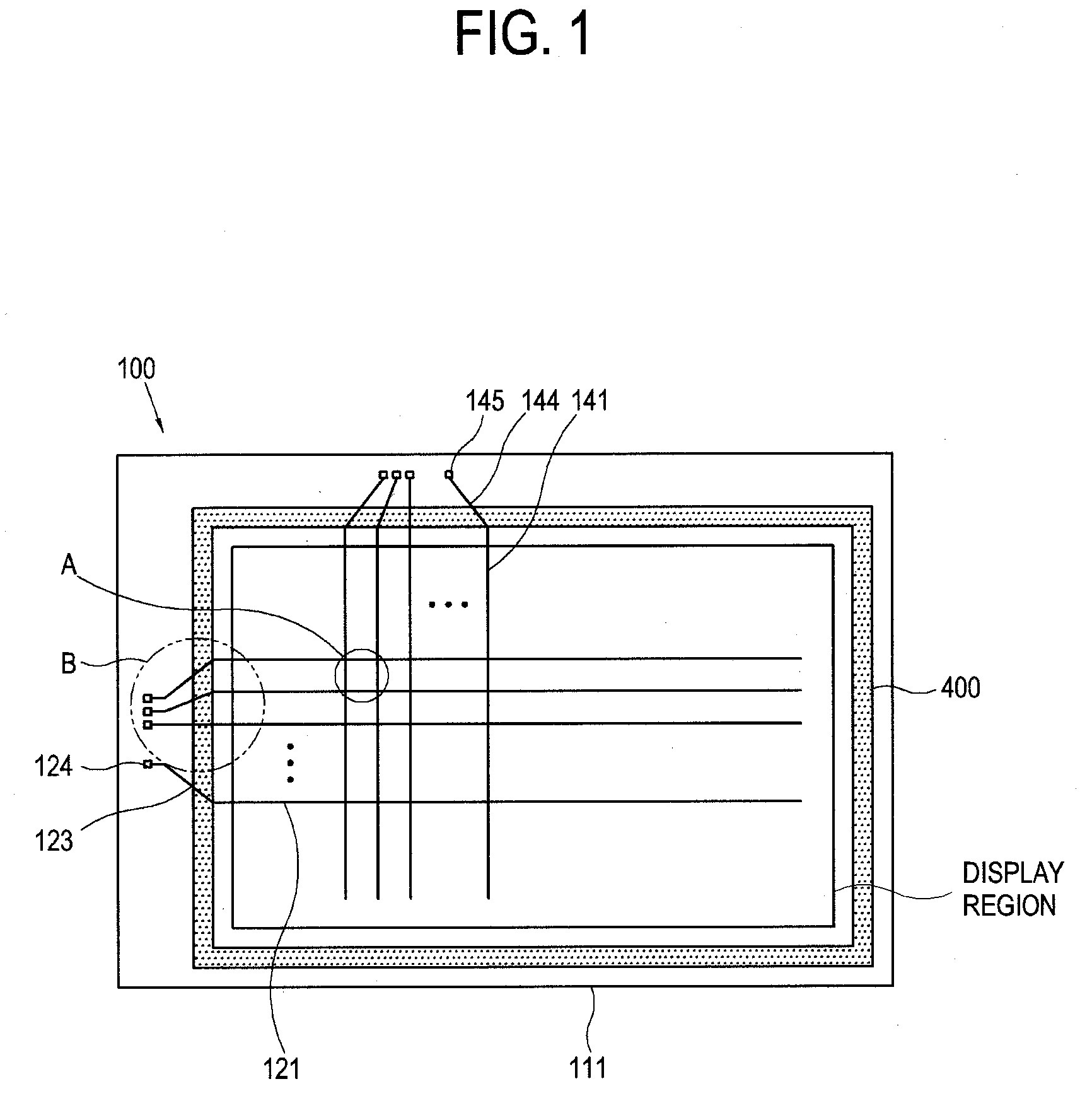

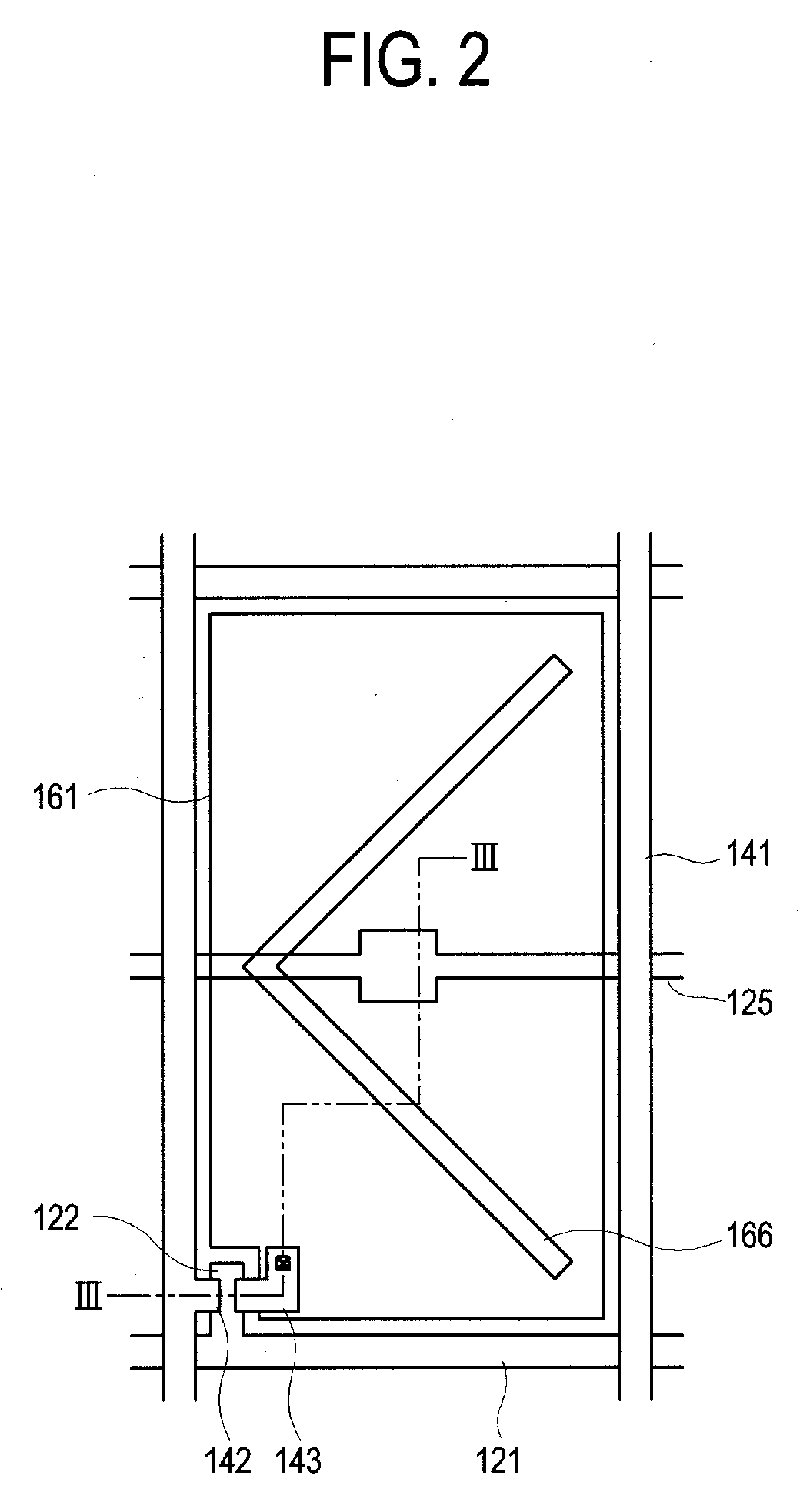

Liquid crystal display device having delay compensation

ActiveUS20080049156A1Reduce irregularitiesSmall valueStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes: a first substrate having a display region; a second substrate facing the first substrate; and a liquid crystal layer disposed between the first substrate and the second substrate, the first substrate comprising: a gate main line which is disposed in the display region; a gate pad which is disposed out of the display region; and a ballasting resistor which electrically connects the gate main line and the gate pad, and comprises a material having a larger resistivity than that of a predominant conductive material defining the gate main line.

Owner:SAMSUNG DISPLAY CO LTD

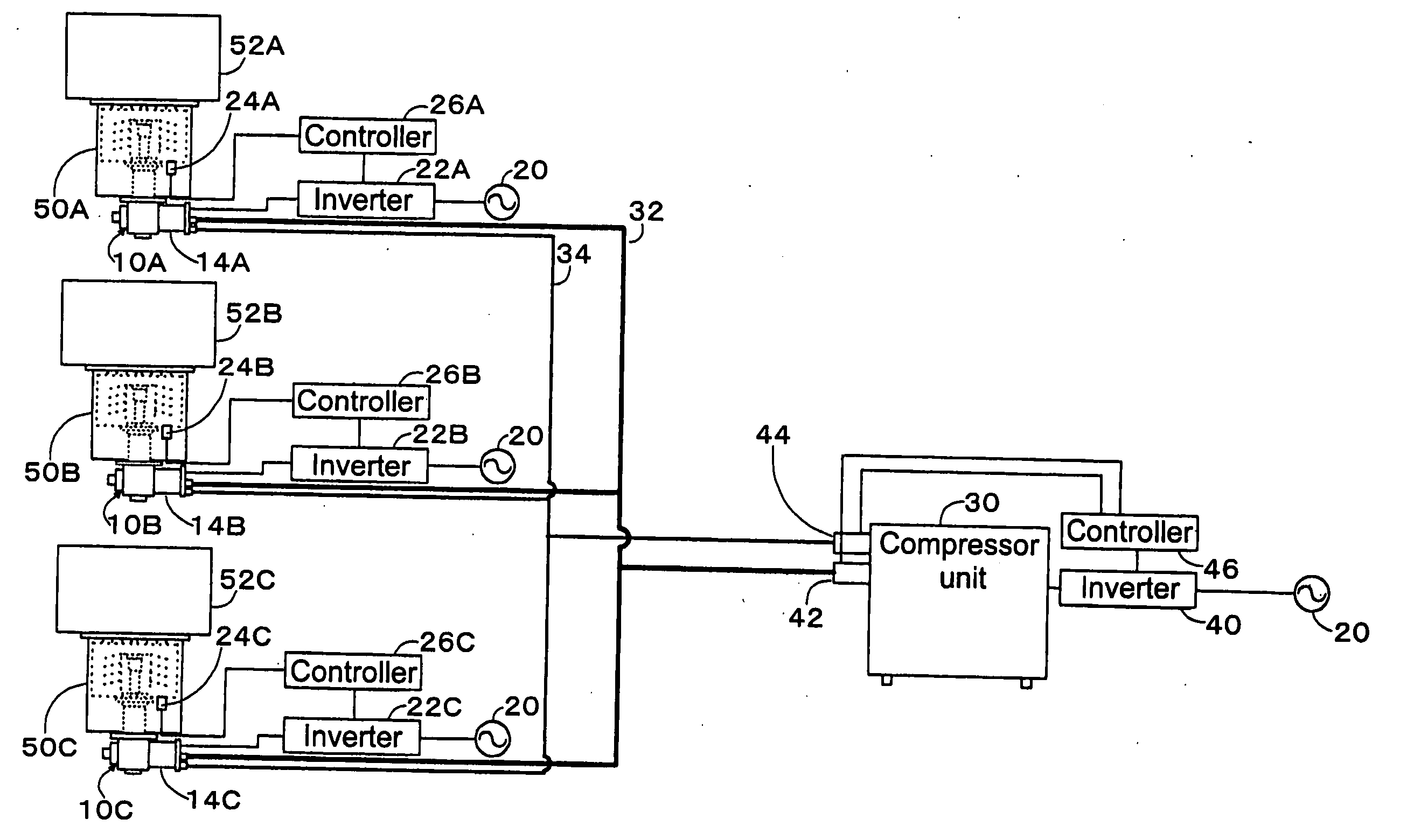

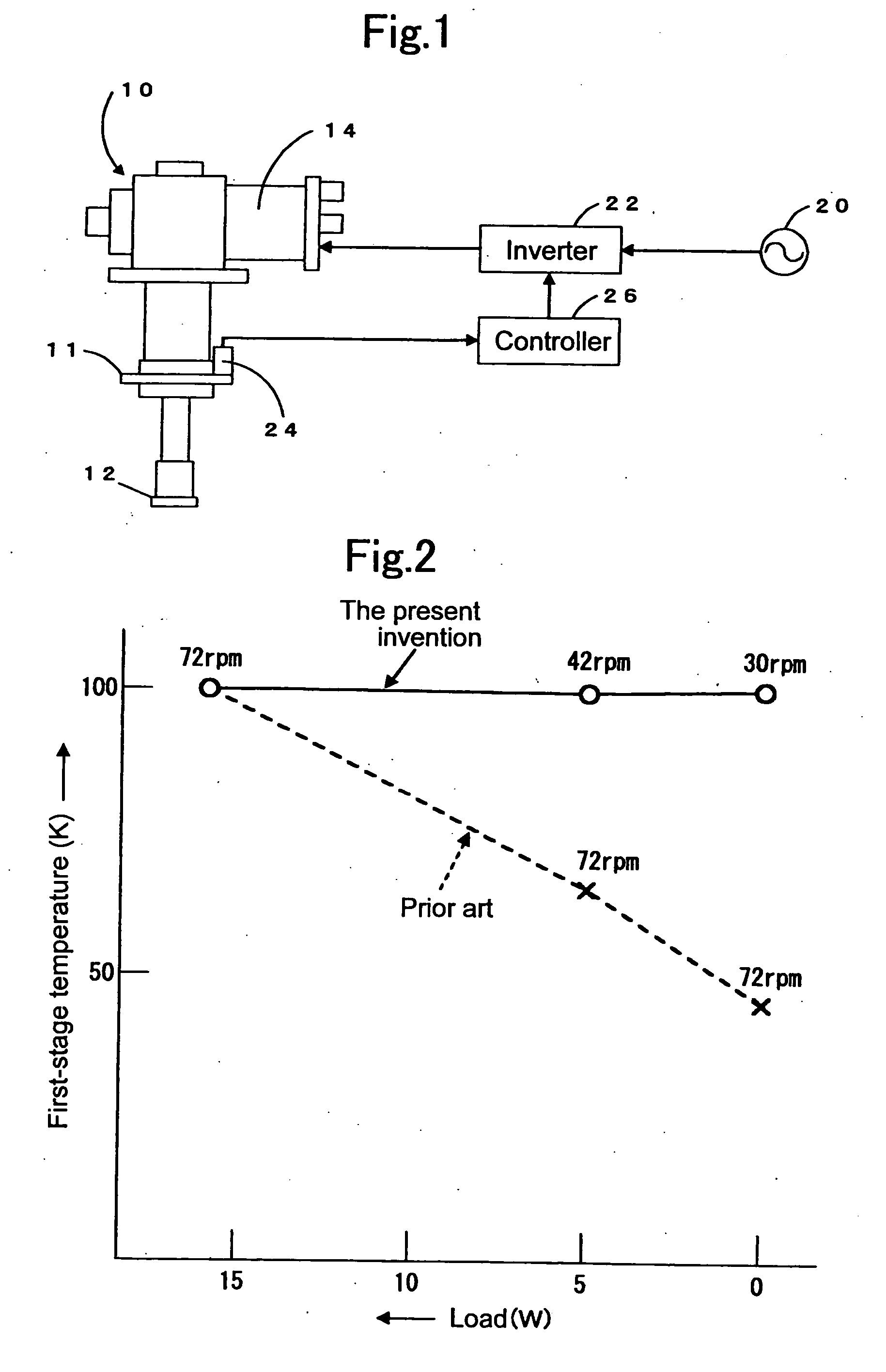

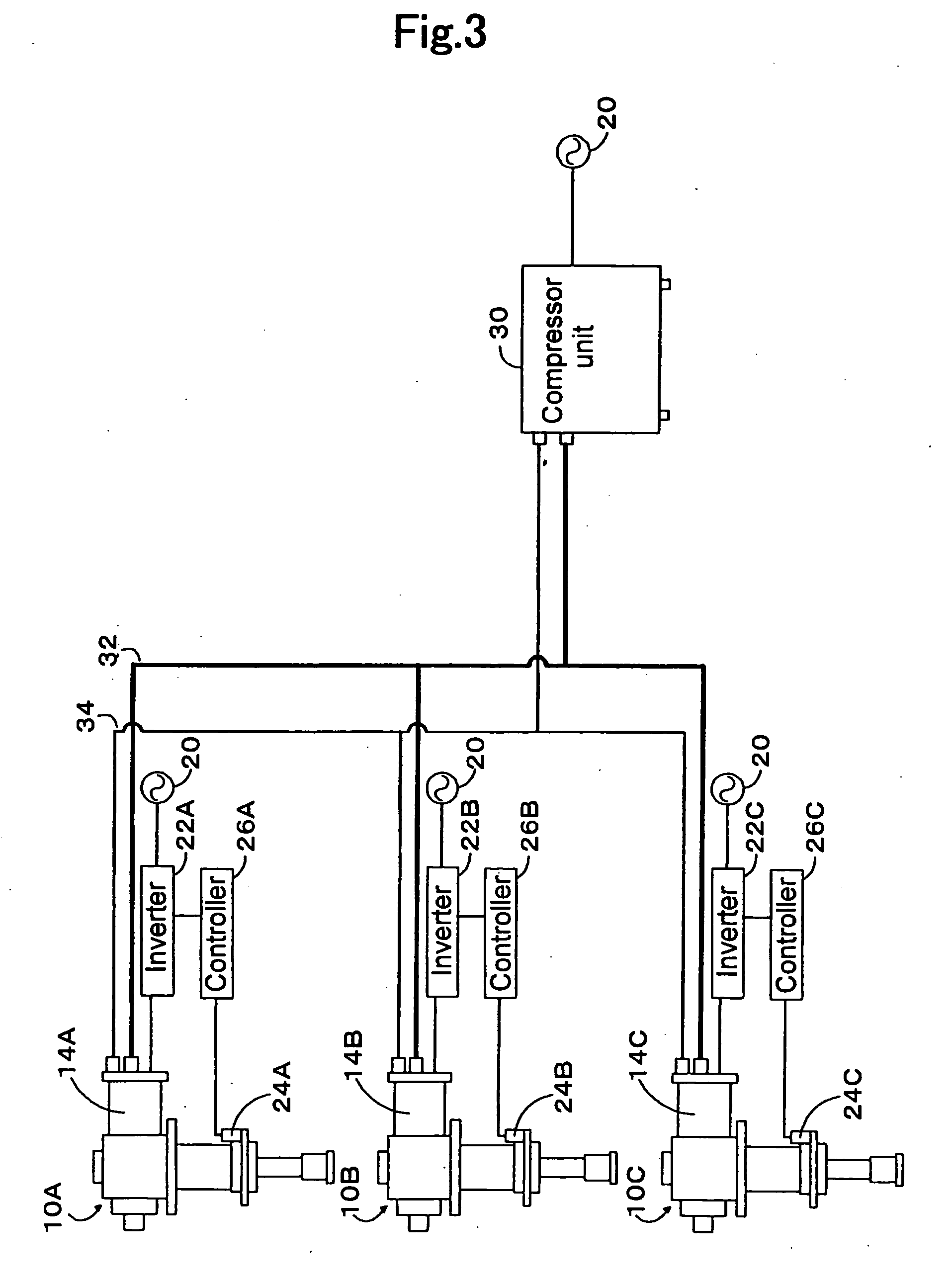

Very low temperature refrigerator

An inverter (22) is provided between a power source (20) and a suction / discharge valve driving motor (14) that controls cycle time of suction and discharge of a refrigerator unit (10). An output frequency of the inverter (22) is controlled in accordance with output of a sensor (24) that detects temperature of a thermal load portion (11) of the refrigerator unit (10). This enables temperature adjustment of individual refrigerators with a highly reliable method without using an electric heater.

Owner:SUMITOMO HEAVY IND LTD

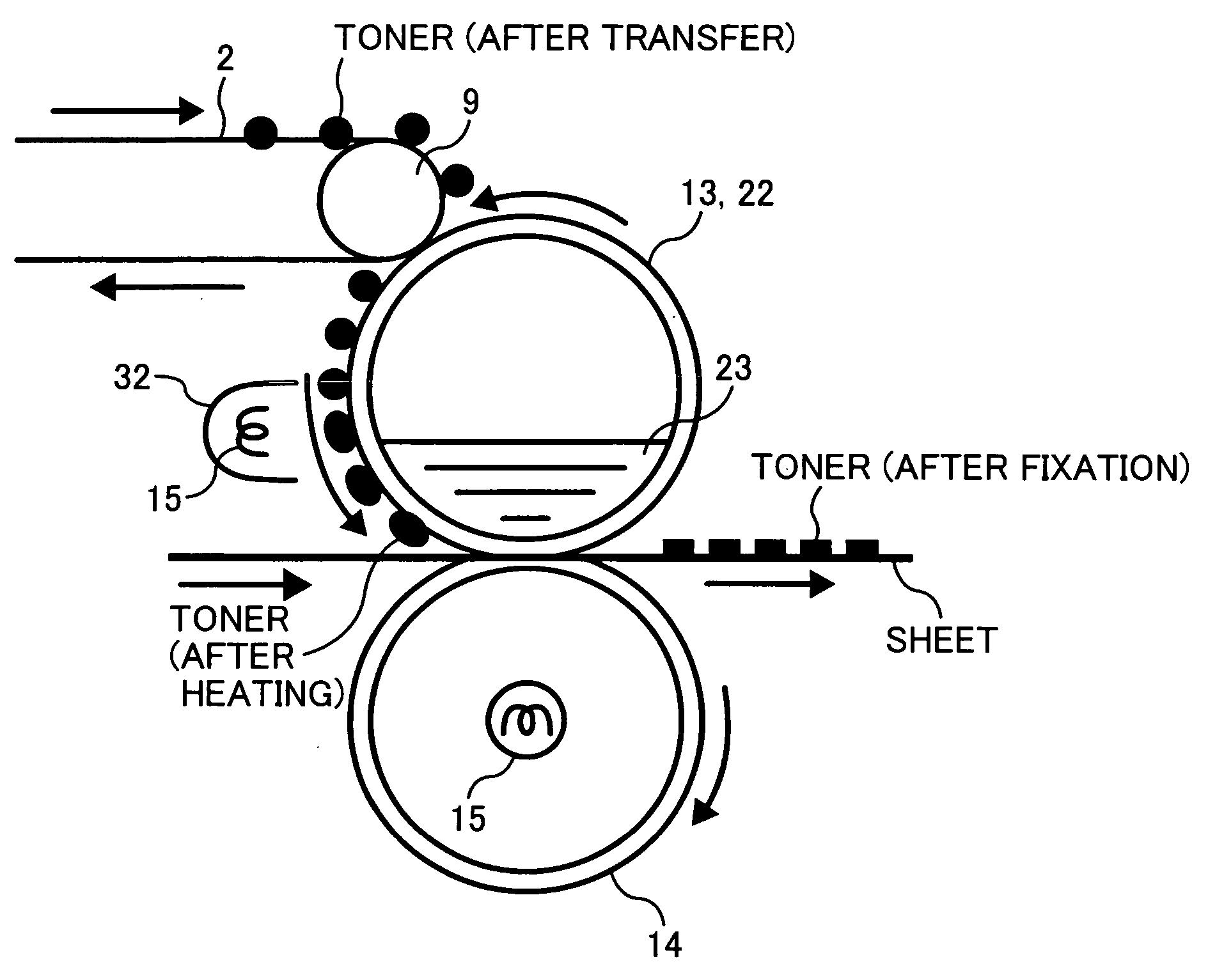

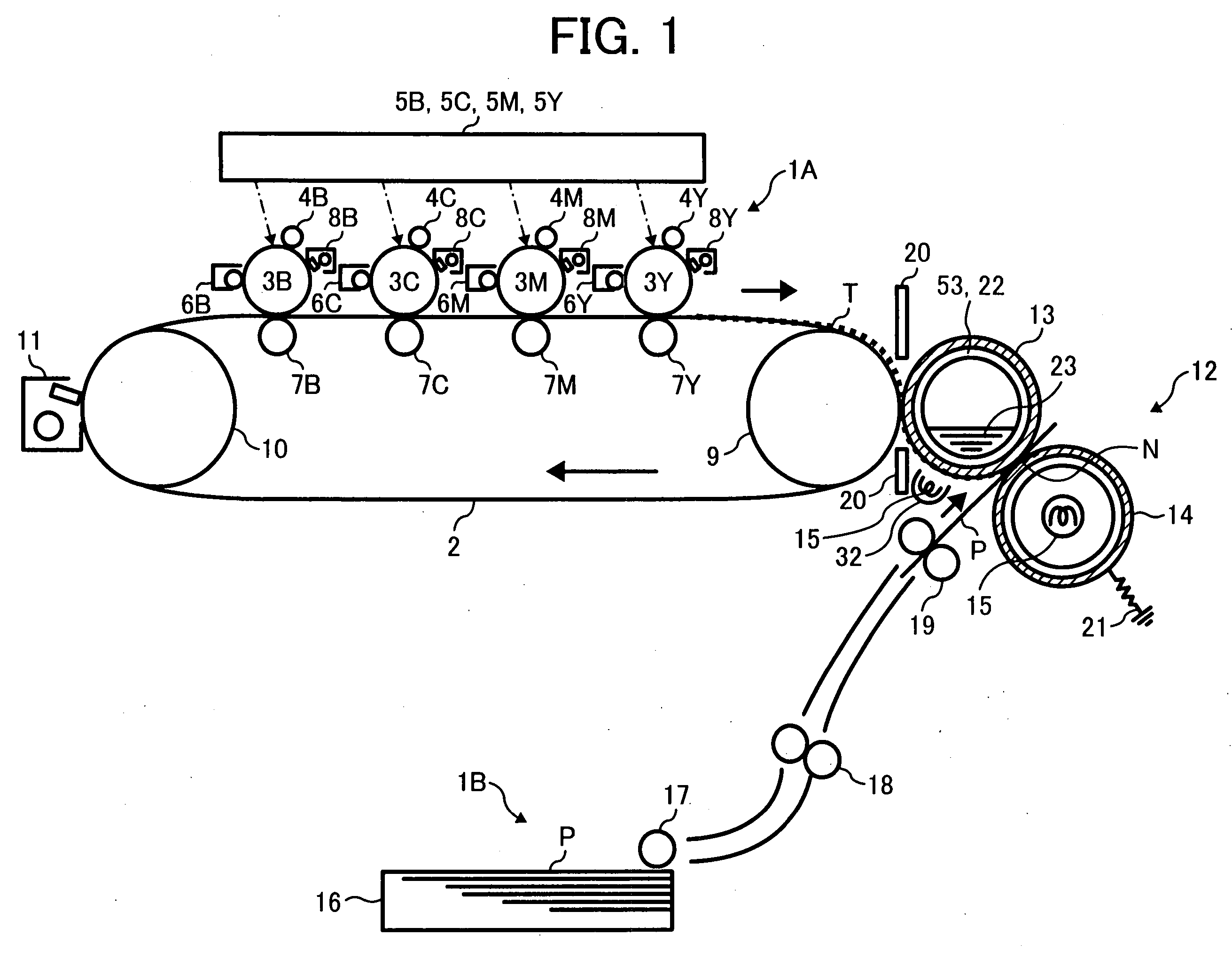

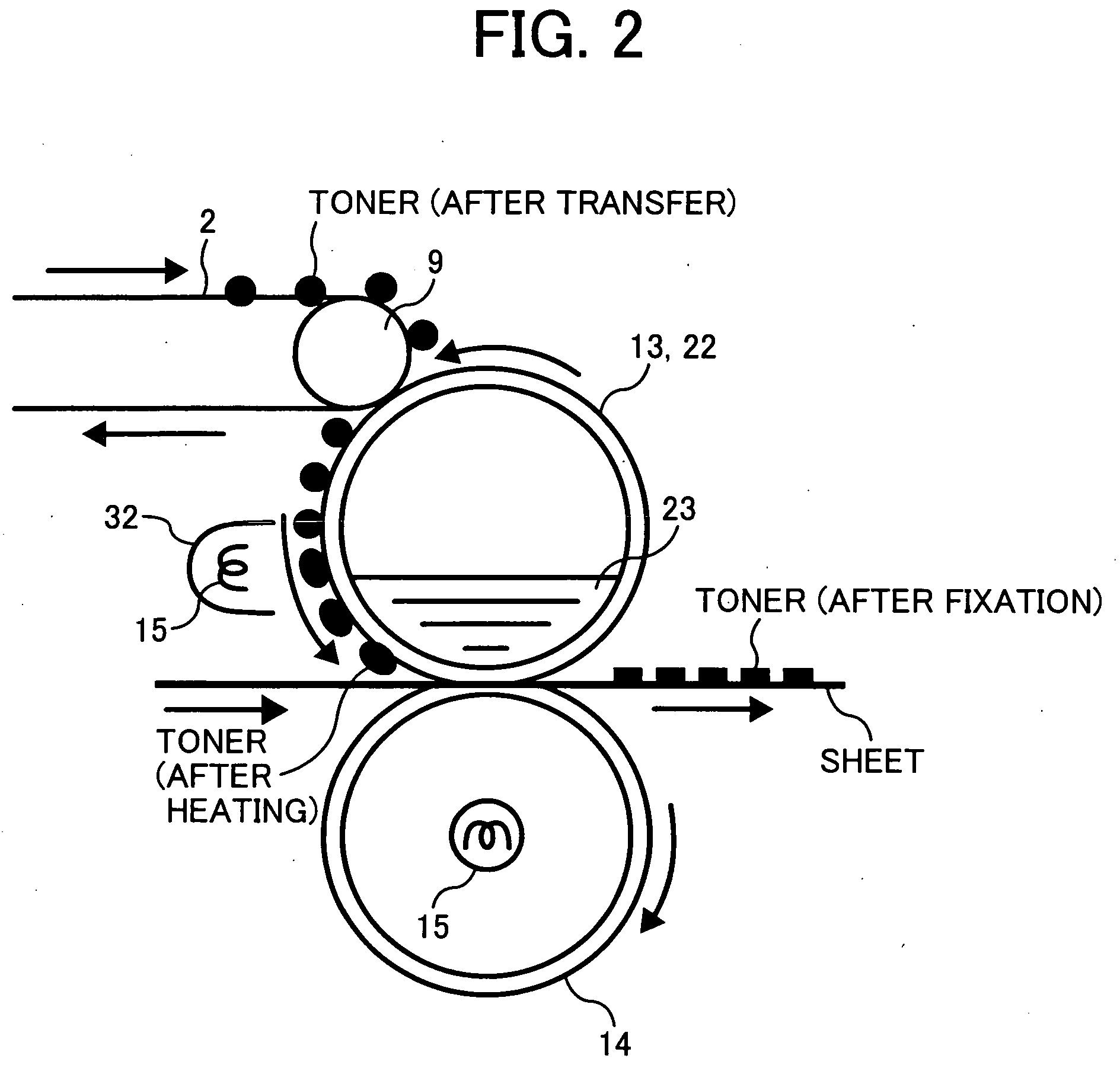

Fixing device and image forming apparatus using the same

InactiveUS20060140689A1Shorten warm-up timeReduce irregularitiesElectrographic process apparatusImage formationEngineering

A fixing device for fixing image information on a recording medium passing a nip of the present invention includes a rotatable member for transferring and conveying a non-fixed image, a first heating means for heating an image present on the rotatable member and a rotatable pressing member forming a nip in combination with the rotatable member. A heat pipe extends in parallel to the axis of the rotatable member. A radiating member is positioned at one end of the heat pipe while a heating member is positioned at the other end of the heat pipe.

Owner:RICOH KK

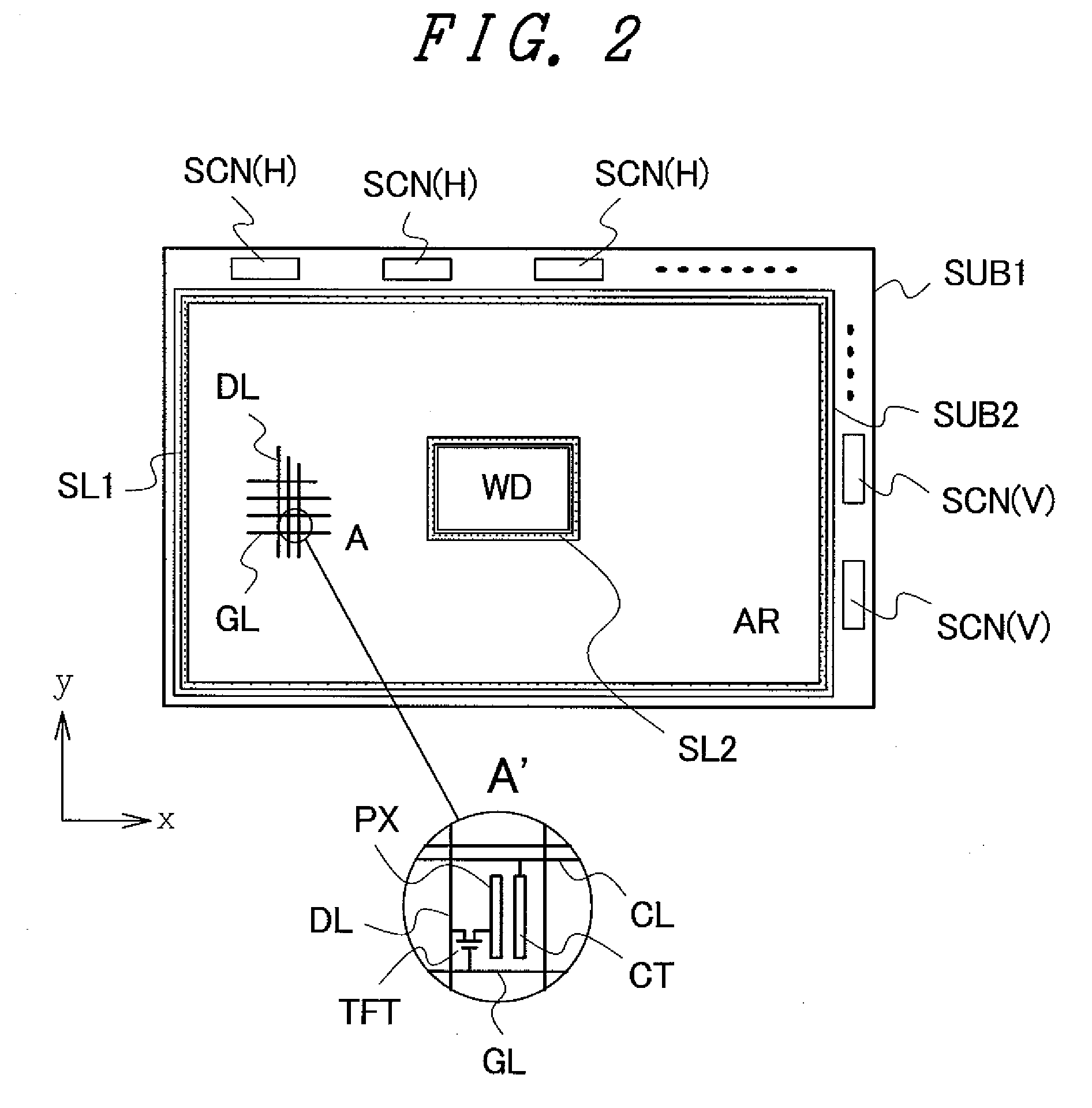

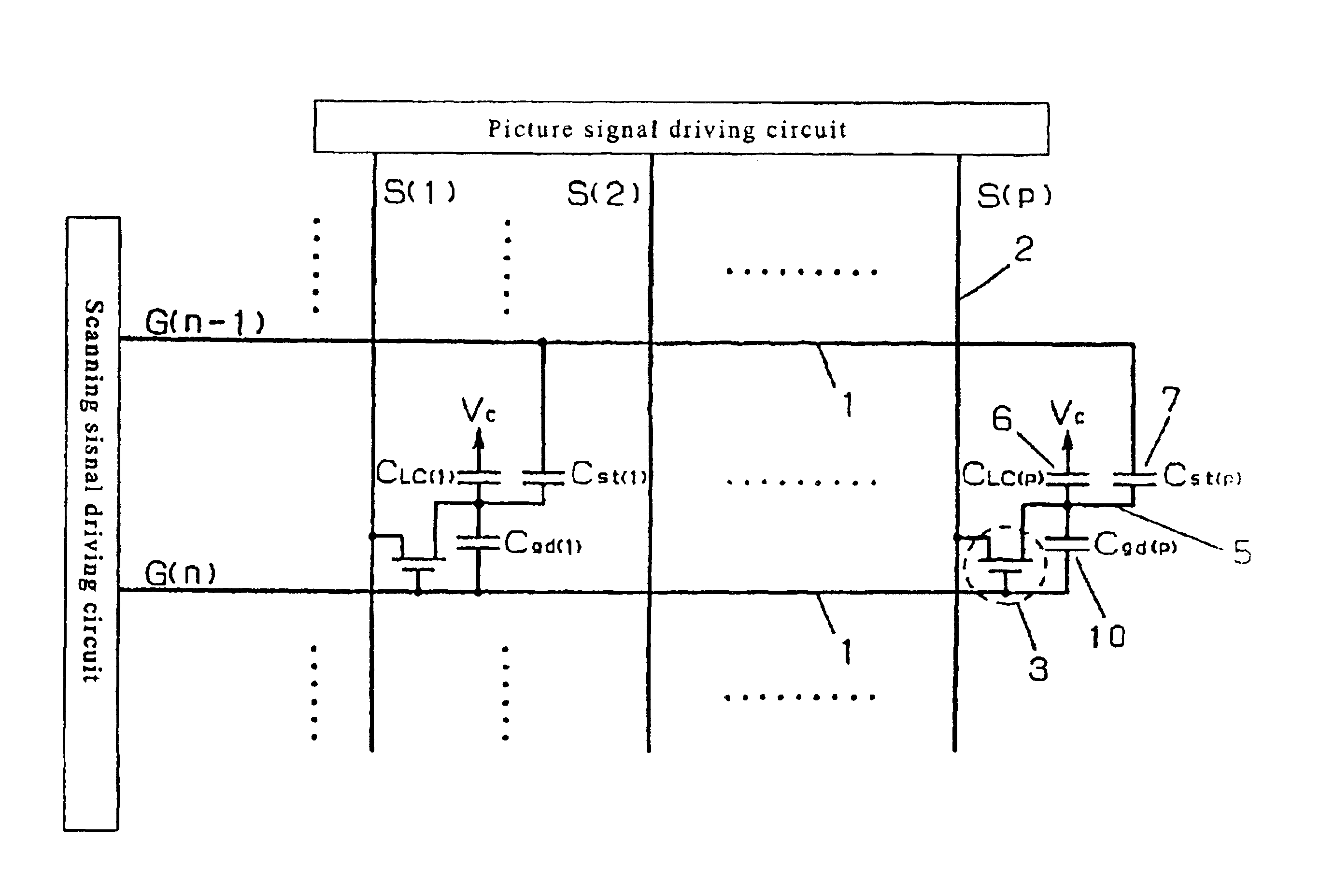

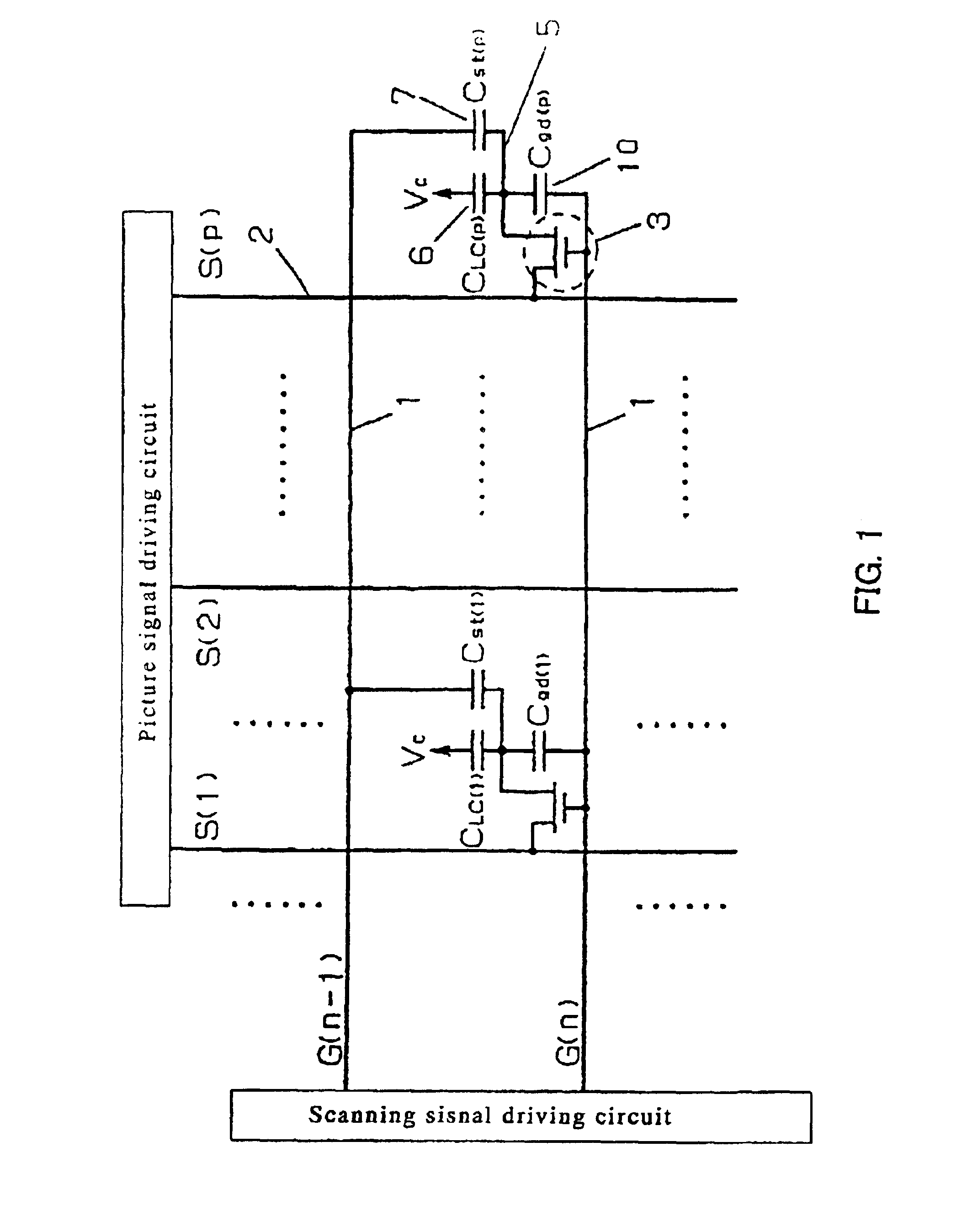

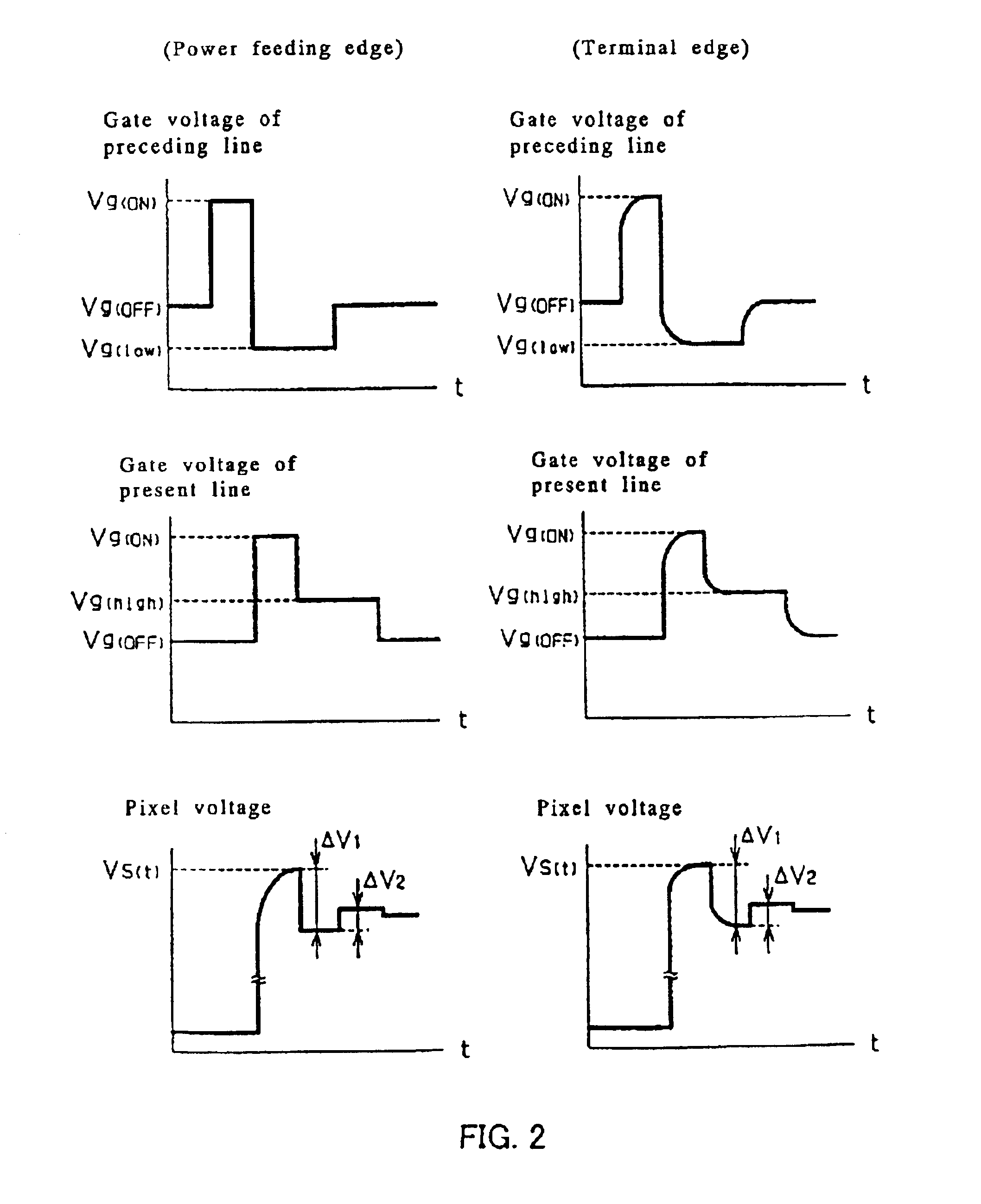

Display unit and drive method therefor

InactiveUS6909415B2Not be increaseHigh resolution-typeCathode-ray tube indicatorsNon-linear opticsCapacitanceEngineering

The present invention provides a display apparatus that can reduce a voltage irregularity and a brightness irregularity accompanied by making an enlarged and a high resolution type display apparatus. The display apparatus comprises plural pixel electrodes 5 arranged in a matrix, a switching element 3 connected with the pixel electrode, a scanning electrode 1, a picture signal electrode 2, an opposite electrode forming a capacitance with the pixel electrode 5, and further comprising; a storage capacitance 7 between the pixel electrode 5 and the scanning electrode 5 other than the scanning electrode 1 of the present line; more than two capacitance elements connected with the pixel electrode 5, including at least one of a gate-drain inter-electrode capacitance 4 of the switching element 3 and the storage capacitance 7, having a different value according to the distance from the power feeding edge of the scanning electrode 1; wherein, each capacitance in each pixel is set so that, when all capacitance connected with the pixel electrode 5 in a pixel is denoted as Ctot, a first capacitance ratio α gd=Cgd / Ctot increases continuously or in stages according to the distance from the power feeding edge of the scanning electrode 1, or a second capacitance ratio α st=Cst / Ctot is substantially constant.

Owner:PANASONIC CORP

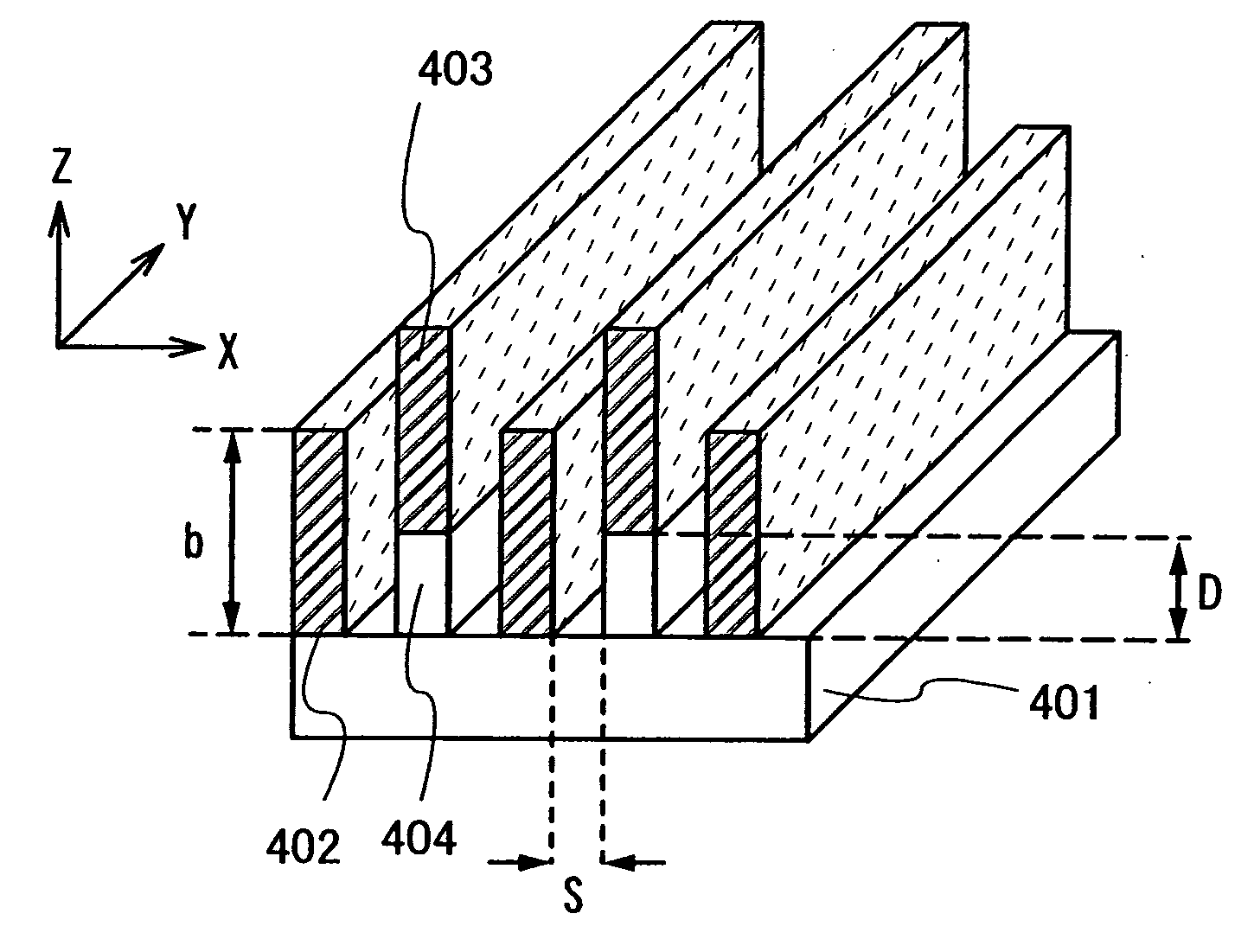

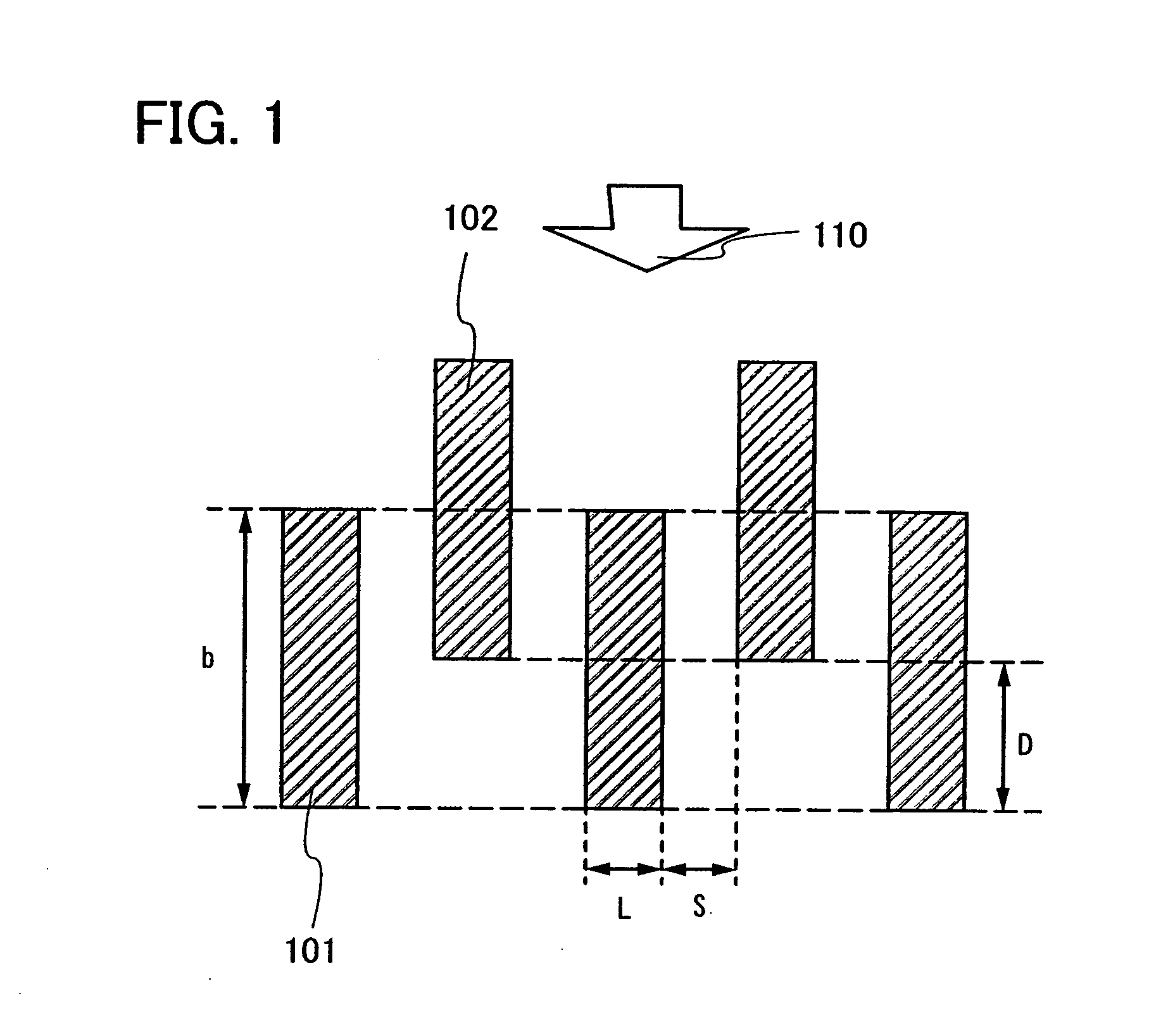

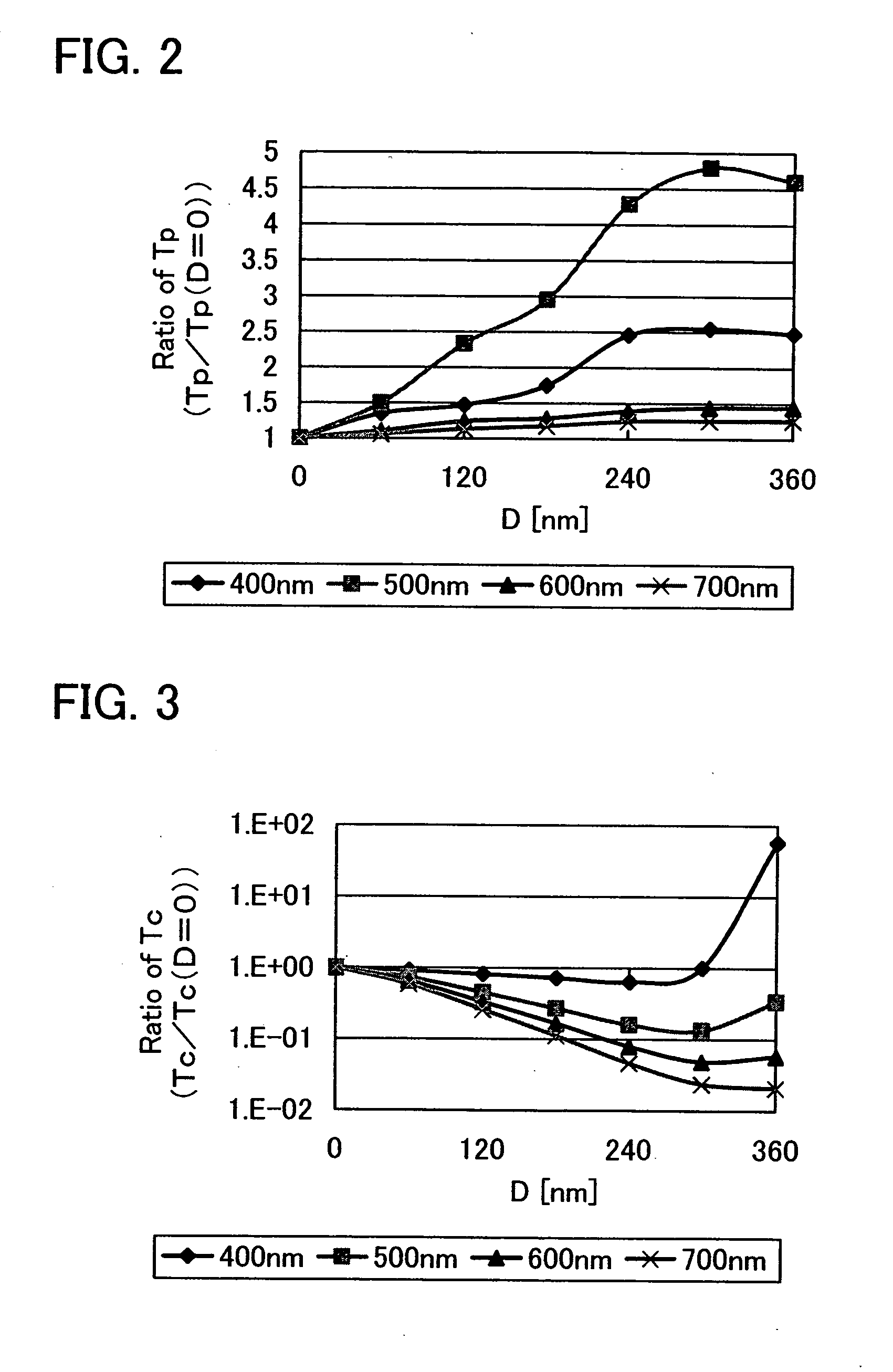

Polarizer and display device including polarizer

ActiveUS20090009865A1Good optical performanceHigh mechanical strengthPolarising elementsSpecial surfacesTransmittanceDisplay device

A polarizer in which parallel transmittance TP is increased and crossed transmittance TC is provided. Instead of arranging a plurality of all metal wires on one plane, a plurality of metal wires is separately formed on at least two different parallel planes, and adjacent meal wires among the plurality of metal wires are staggered in the polarizer. The heights of a first group of metal wires formed on a first plane and a second group of metal wires formed on a second plane, from a surface of the light-transmitting substrate are different. Further, a metal wire of the second group is provided to be more distant from the light-transmitting substrate than the first group of metal wires by distance D, and the distance D is smaller than the thickness of the first group of metal wires.

Owner:SEMICON ENERGY LAB CO LTD

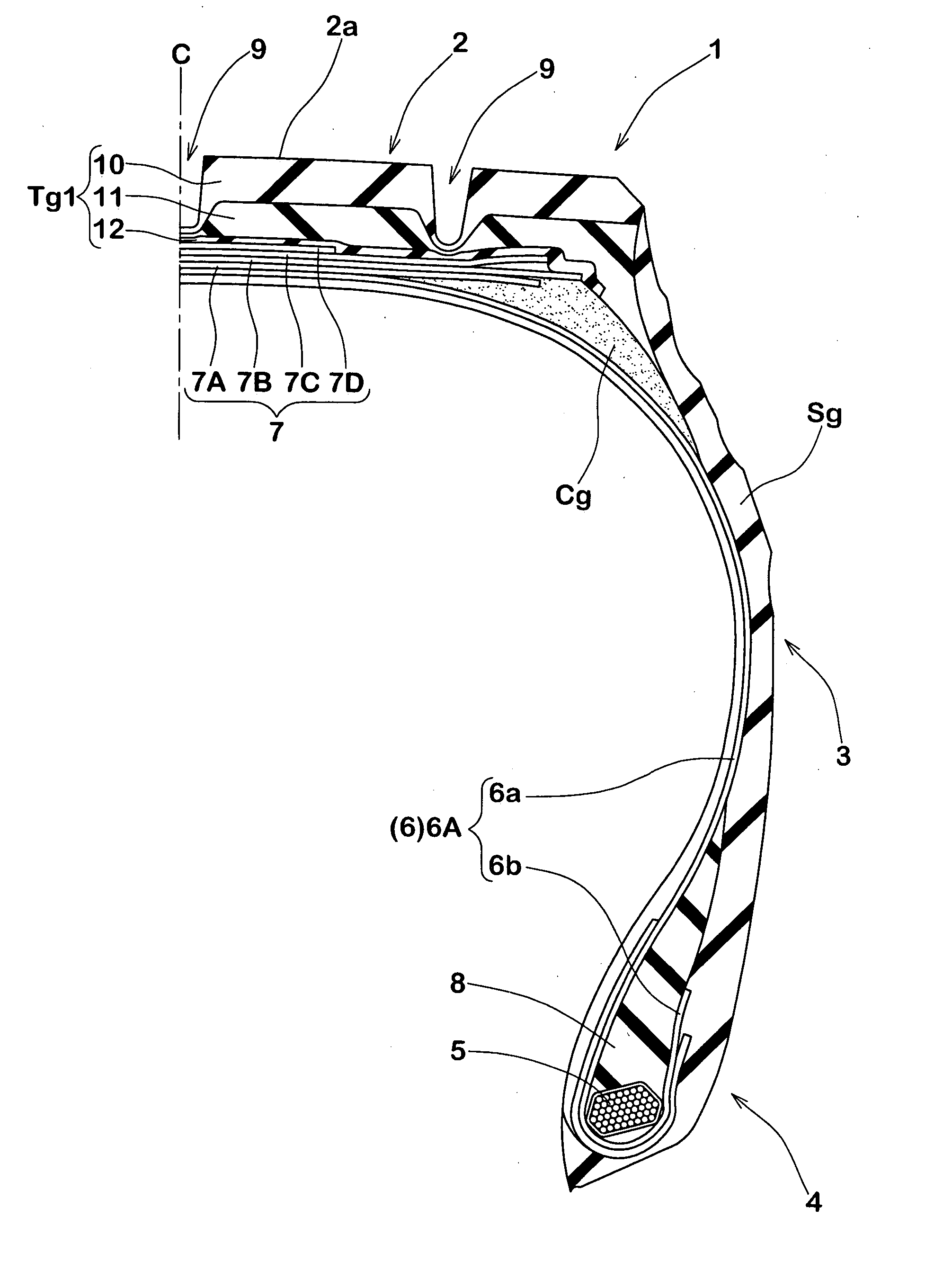

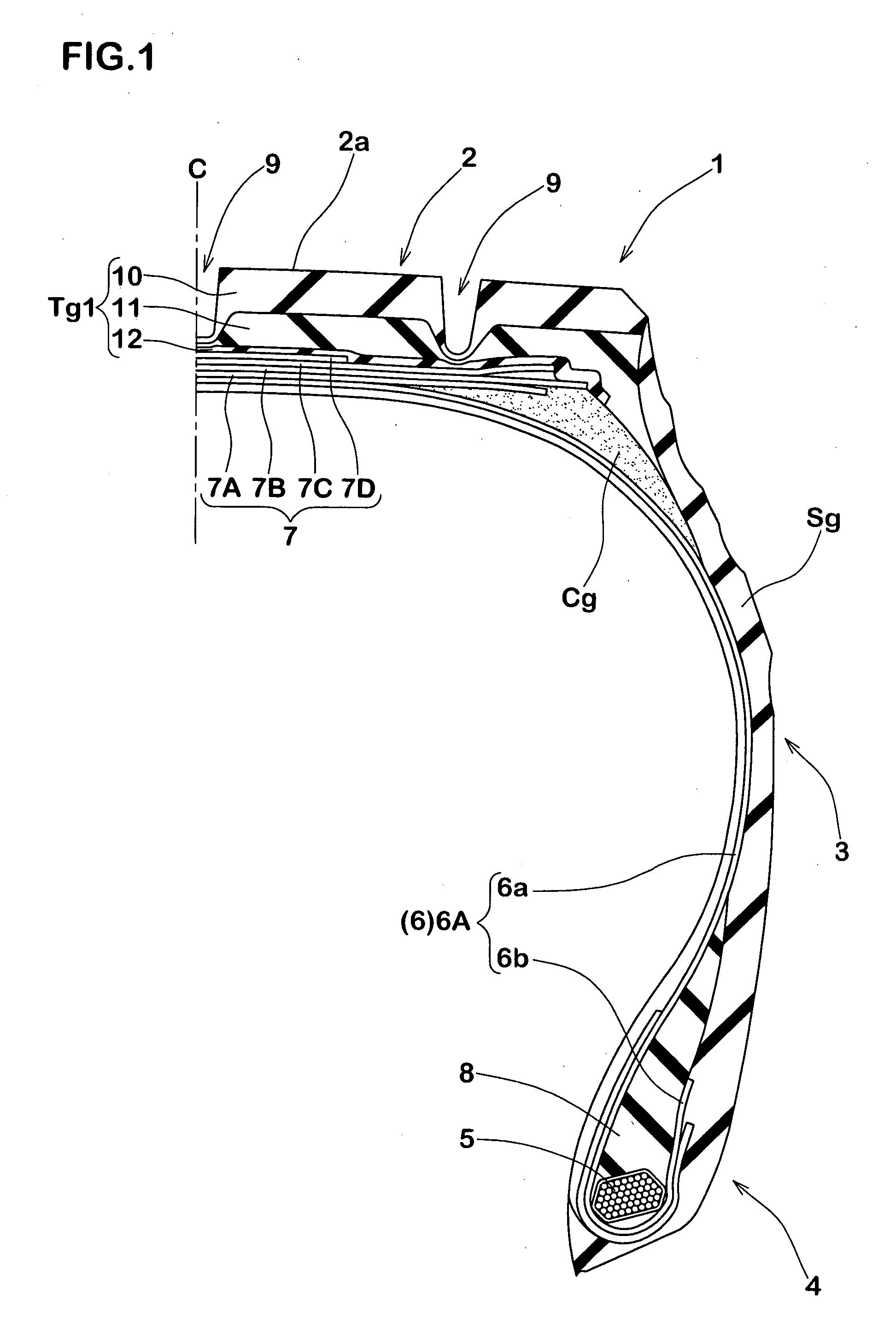

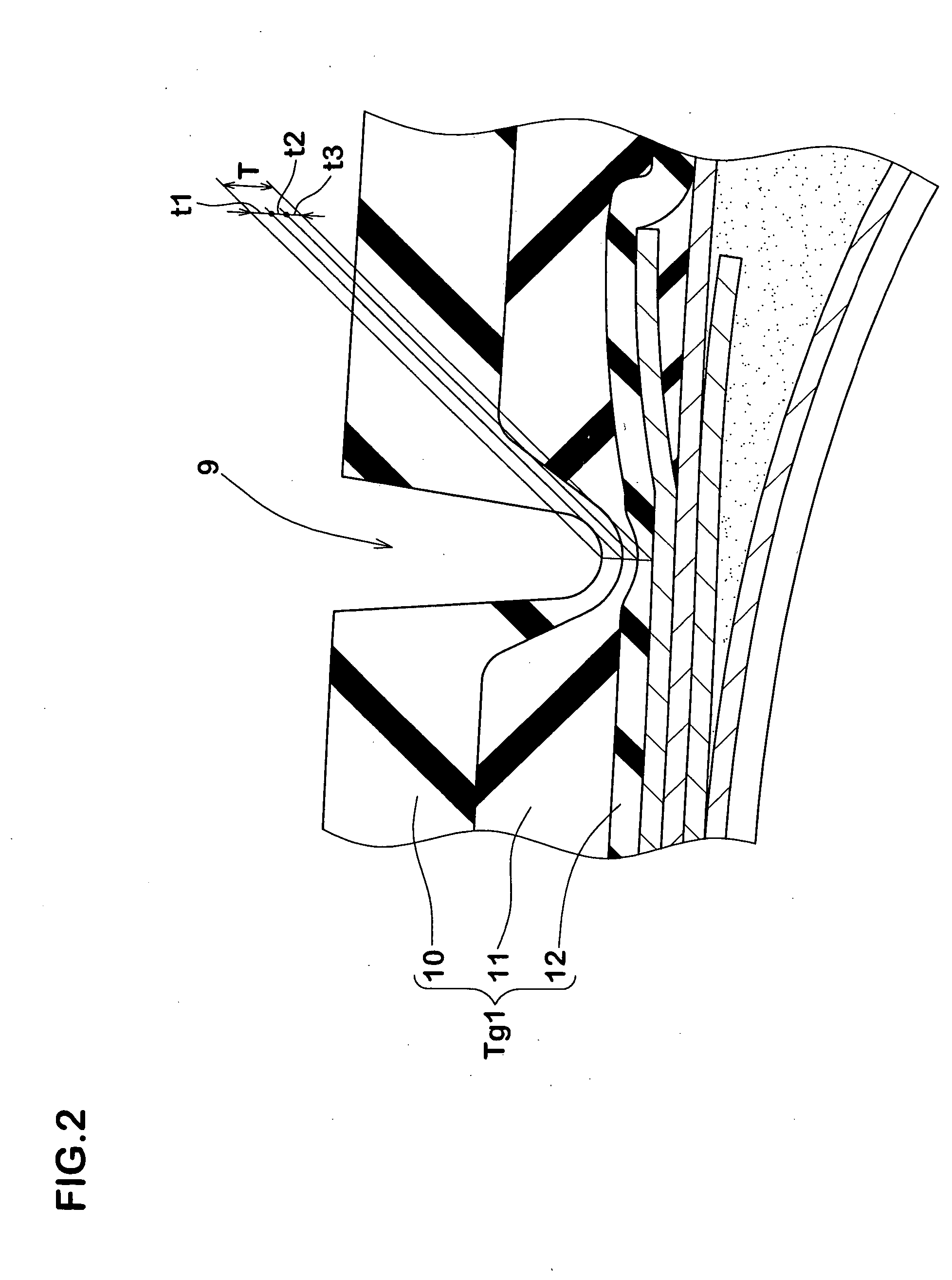

Heavy-duty pneumatic tire

An object of the present invention is to provide a heavy-duty pneumatic tire and a method for manufacturing the same capable of effectively preventing occurrence of wrinkles and cracks on groove bottoms of main grooves. The heavy-duty pneumatic tire 1 includes a carcass 6 made of steel cords and a belt layer 7. A tread rubber Tg1 thereof is comprised of a cap layer 10 disposed on an outermost side in a radial direction and is made of cap rubber having viscoelastic properties with a complex elastic modulus E*1 of 5.0 to 7.0 MPa and a loss tangent tanδ of 0.08 to 0.15, a base layer 12 having different viscoelastic properties as those of the cap rubber and that is disposed on an innermost side in the radial direction, and a middle layer 11 that is disposed between the cap layer 10 and the base layer 12 and that exhibits viscoelastic properties different from those of both. The respective layers are comprised of strip laminated bodies in which tape-like non-vulcanized rubber strips are spirally wound.

Owner:SUMITOMO RUBBER IND LTD

Sheet conveying apparatus

InactiveUS7445208B2Improve accuracyWeaken influenceRegistering devicesFunction indicatorsLeading edgeEngineering

A sheet conveying apparatus for conveying a sheet to an image forming portion has a first aligning member for effecting the alignment of the sheet with one of the opposite side edges of the sheet parallel to a sheet conveying direction as a reference, a second aligning member for effecting the alignment of the sheet with the leading edge of the sheet orthogonal to the sheet conveying direction as a reference, and an aligning operation controlling device for selectively operating one of the first aligning member and the second aligning member on the basis of at least one of image information, sheet information and sheet processing information.

Owner:CANON KK

Microstructures and method of manufacture

InactiveUS20060060472A1High sensitivityGood reproducibilitySurface reaction electrolytic coatingResonanceSurface roughness

In order to provide a structure which has a sufficiently large signal strength and generates local plasmon resonance of excellent reproducibility, the invention provides a process for manufacturing a structure at least a portion of which is an aluminum member having on a surface thereof an anodized layer having a plurality of micropores, the process comprising the steps of, in order, anodizing a surface of an aluminum member so as to form an anodized layer having micropores present therein, sealing the micropores in the anodized layer by filling the micropores with metal, surface-treating the sealed anodized layer so as to remove at least a portion of upper layer surface thereof and set the average surface roughness (Ra) to at most 30 nm, and subjecting the surface-treated anodized layer to electrodeposition so as to form metal particles on the metal filled into the micropores during sealing.

Owner:FUJIFILM HLDG CORP +1

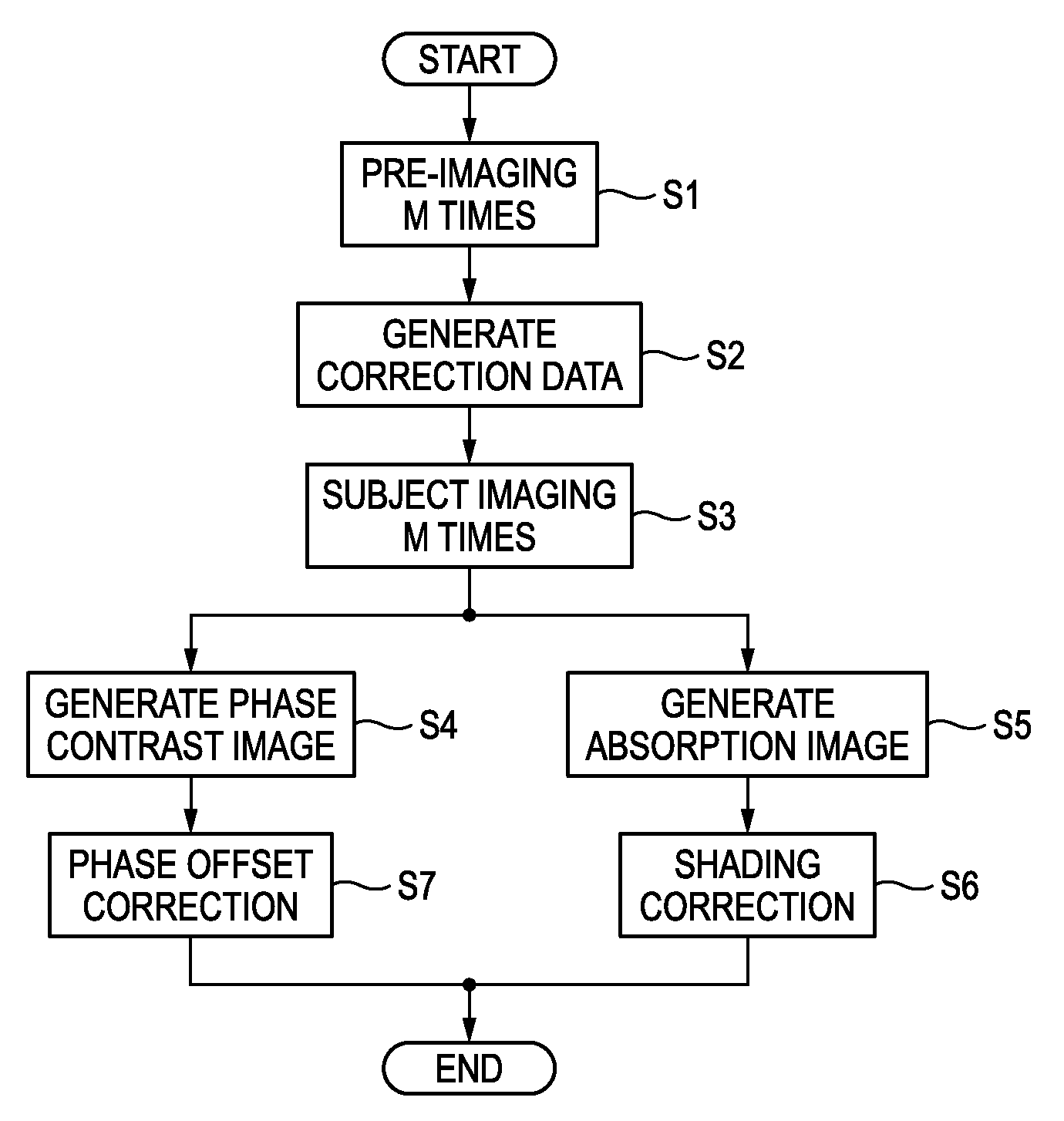

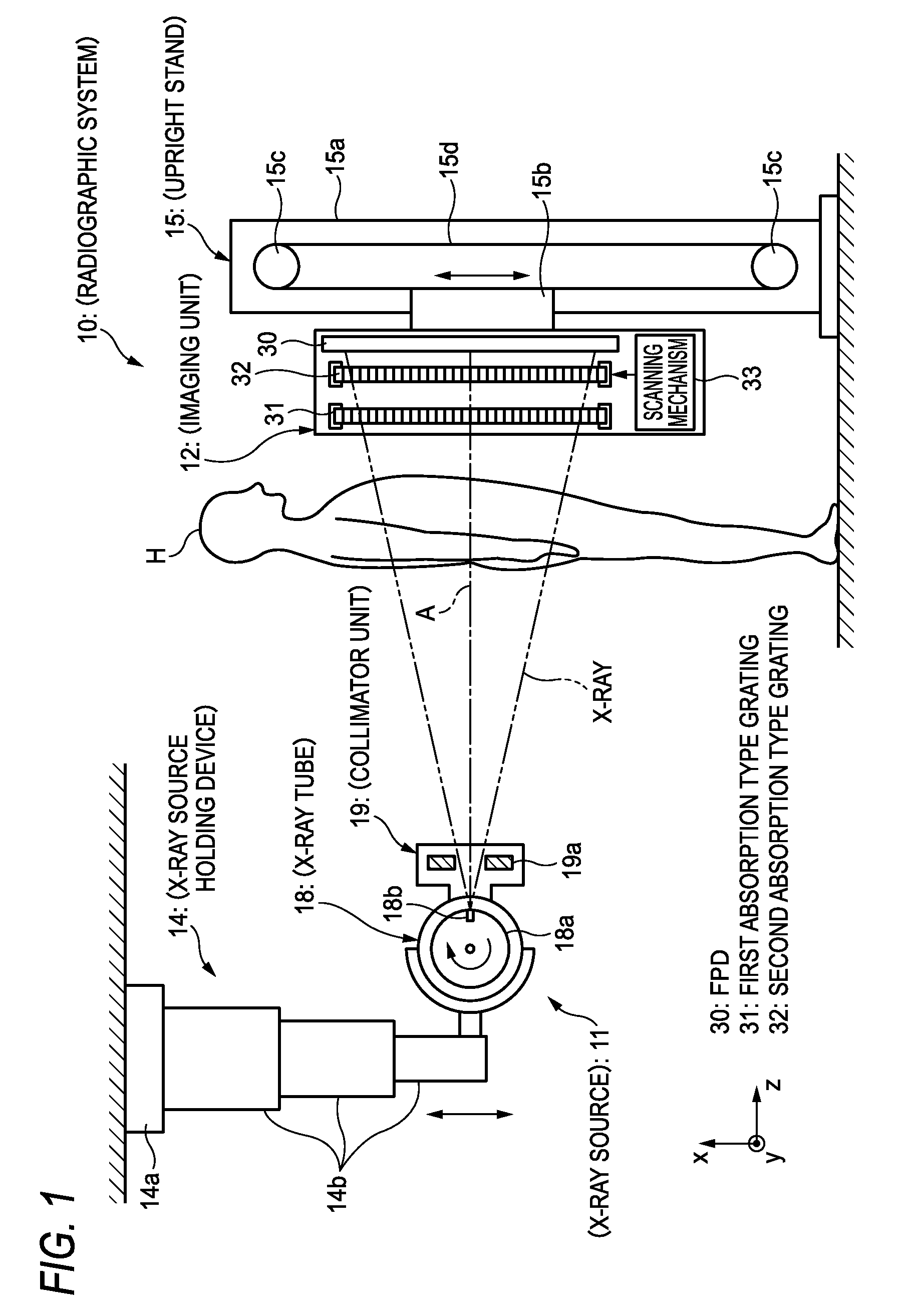

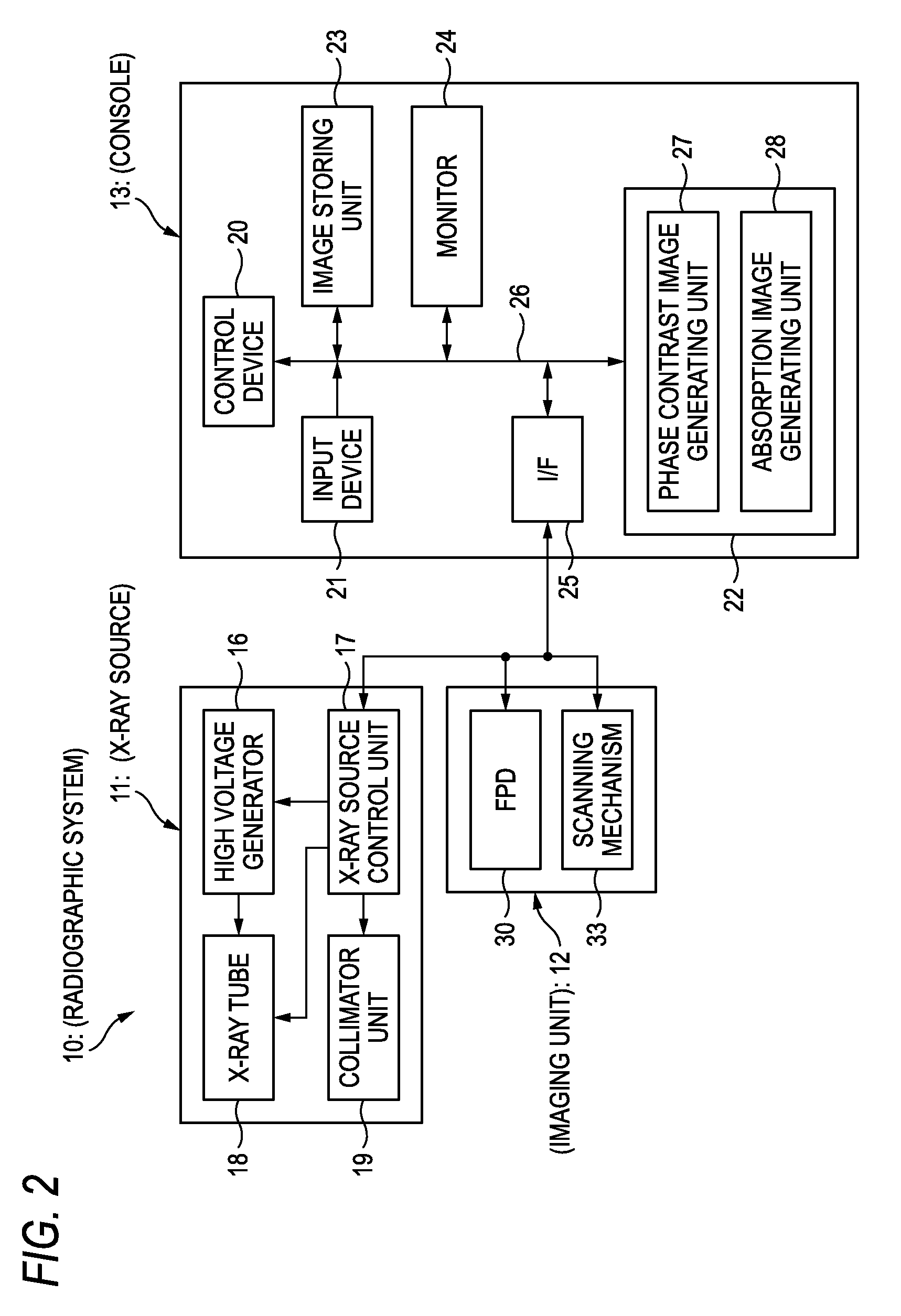

Radiographic system and radiographic image generating method

InactiveUS8903042B2Favorable overlayingReduce the burden onMammographyMaterial analysis by transmitting radiationComputer scienceImaging data

In a radiographic system and a radiographic image generating method that generate a phase contrast image and an absorption image of an subject, the absorption image in which density irregularity is removed or reduced is generated on the basis of a plurality of pieces of image data obtained for generating the phase contrast image.

Owner:FUJIFILM CORP

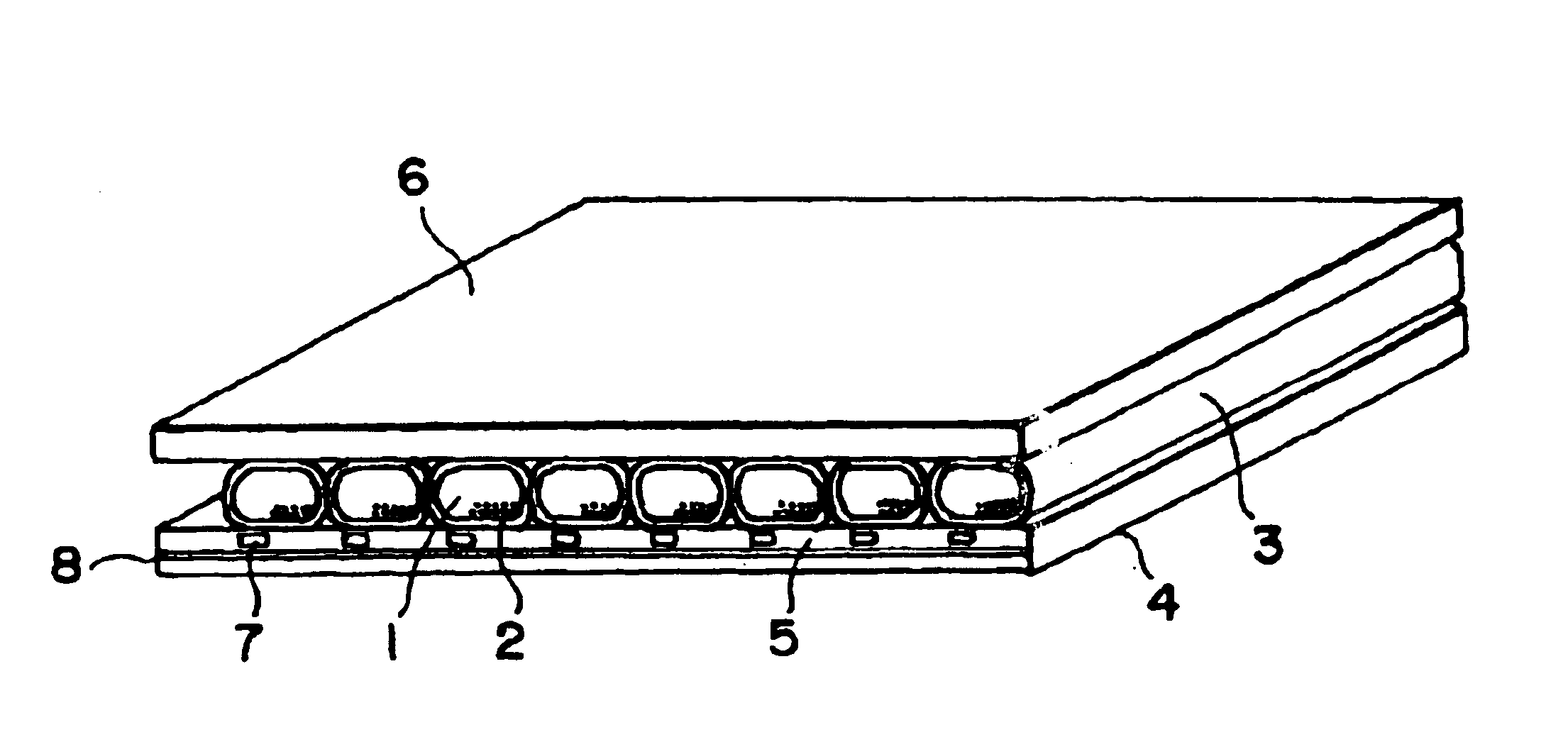

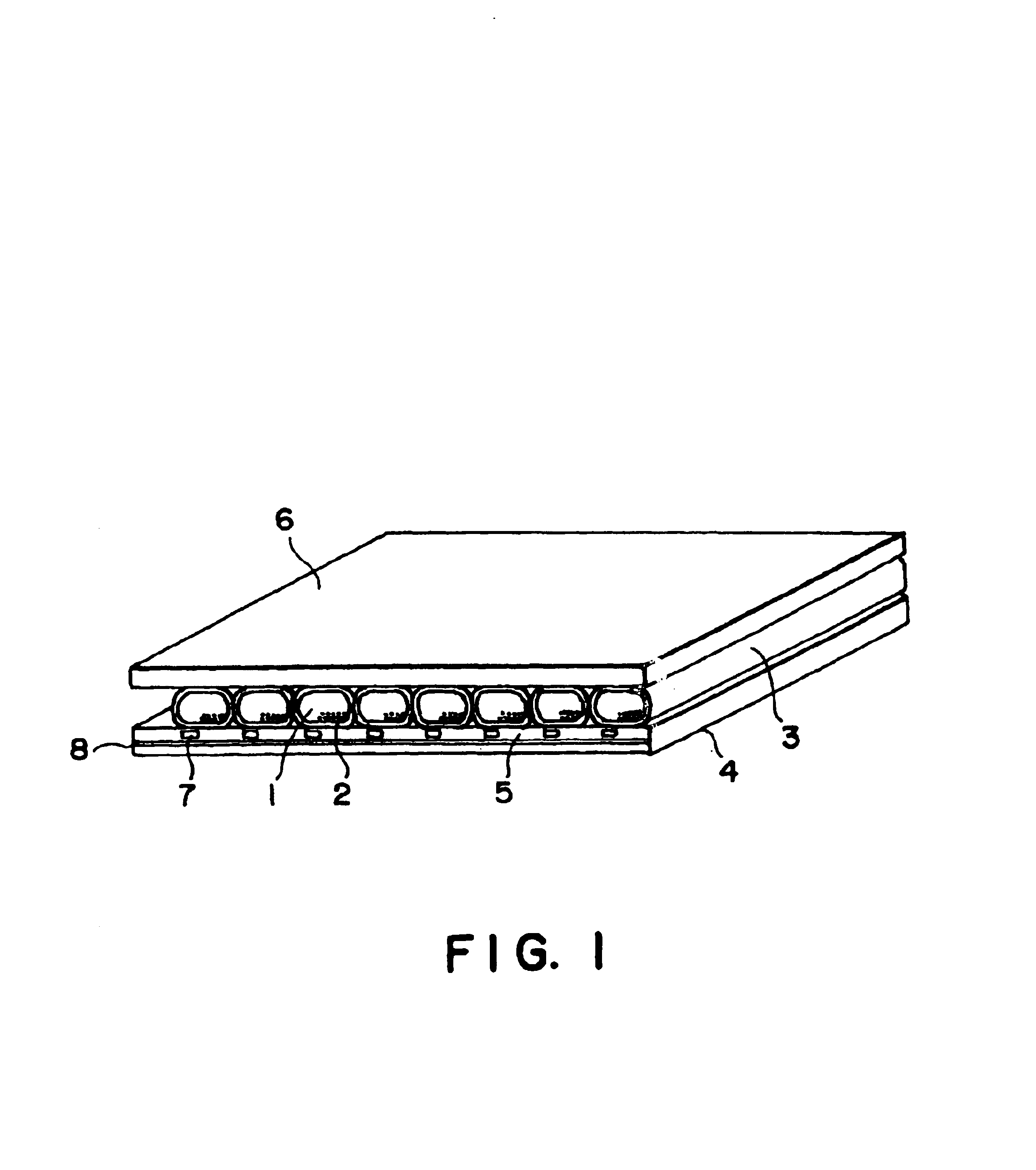

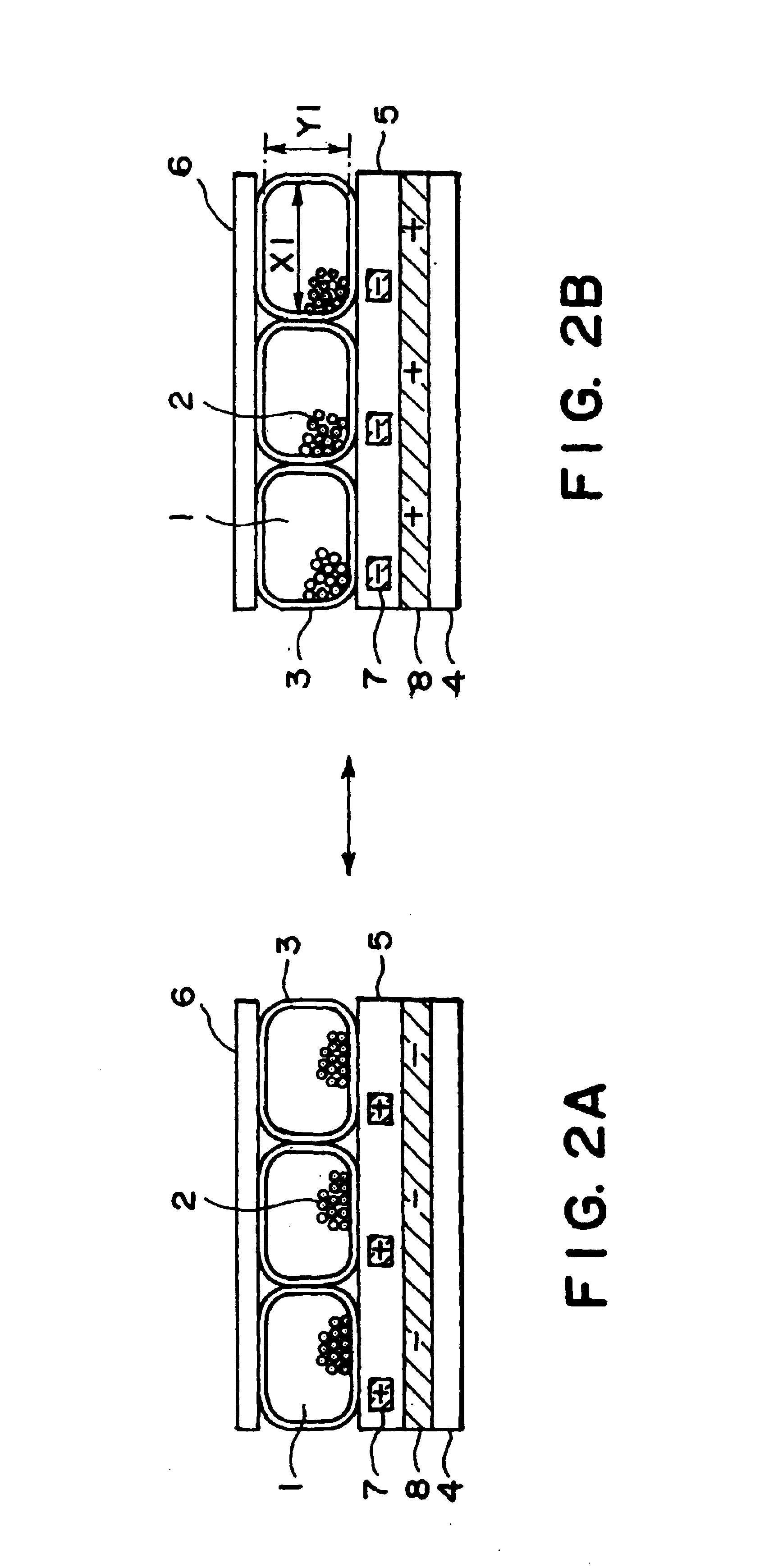

Display device and process for production thereof

InactiveUS6876476B1Reduce irregularitiesLow costCathode-ray tube indicatorsNon-linear opticsDisplay deviceEngineering

A display device includes a first substrate and a second substrate disposed opposite to each other, and a display medium including an insulating liquid and electrophoretic colored particles dispersed therein and disposed between the first and second substrates. A first electrode and a second electrode are provided for applying a voltage to the display medium so as to move the colored particles between the first and second electrodes to effect a display depending on a voltage applied to the first and second electrodes. The electrophoretic colored particles are distributed uniformly without localization by incorporating the display medium in a plurality of light-transmissive tubes, and disposing and fixing the plurality of tubes in intimate contact with each other between the first and second substrates.

Owner:CANON KK

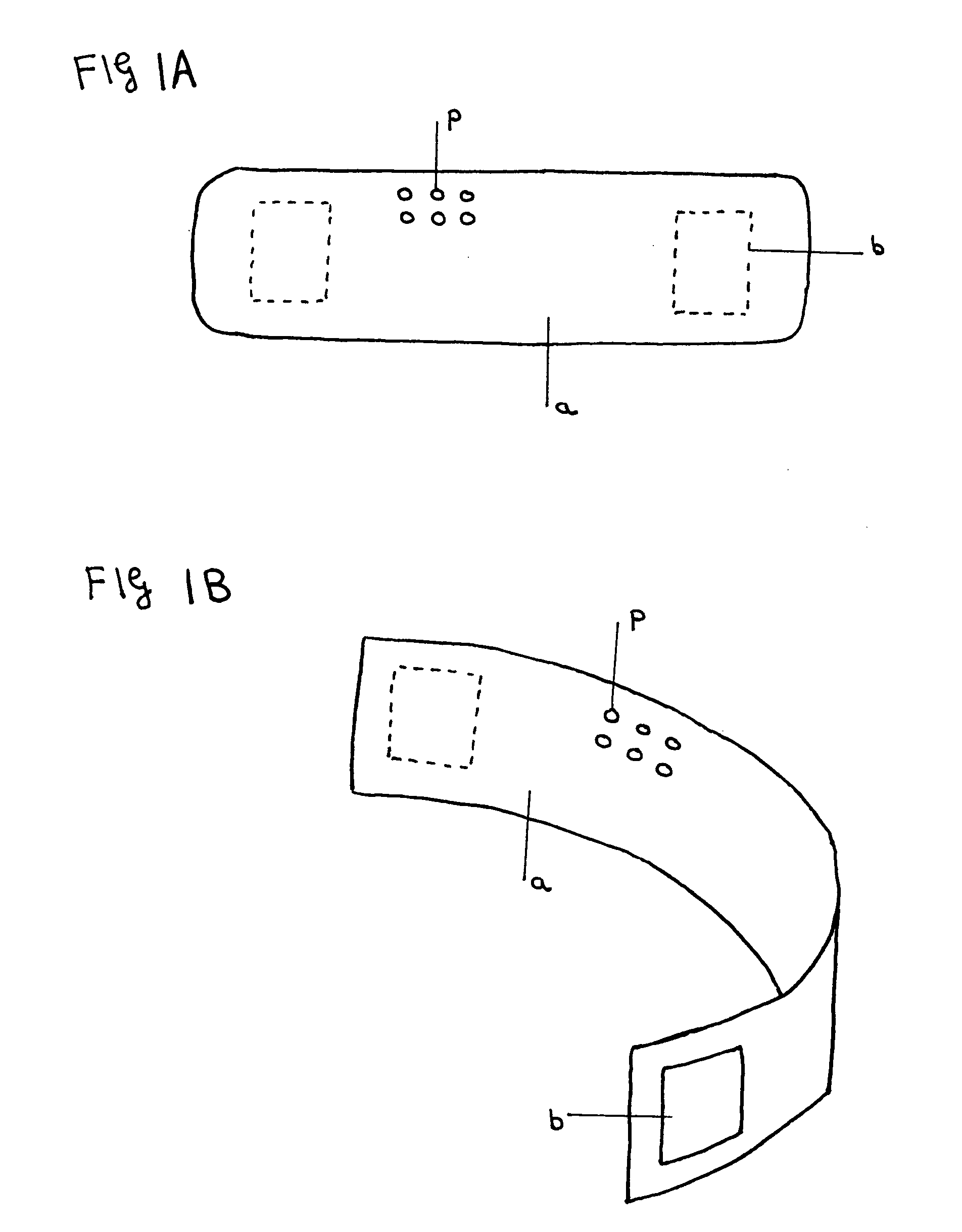

Friction reducing barrier

InactiveUS20080301860A1Reduce frictionDirect contact guaranteeChemical protectionHeat protectionPhysical BarrierProtection Skin

Disclosed herein is a device for reducing friction, caused due to contact or rubbing of the rear portion of a foot heel with the inner portion of footwear. The device is composed of a thin, smooth, and flexible material with a low coefficient of friction. The material of the device is molded into different shapes and sizes to fit different portions of a shoe of any shape and size. The device may be attached temporarily or embedded permanently to the inner heel portion of the shoes, or socks of the user. The device may also be used in any article of clothing or protective covering to reduce the effects of friction. Disclosed herein are various methods of attaching or affixing the device to the inner heel portion of the shoes, socks, and any other article of clothing or protective covering. Also, disclosed is a method to hold the device in place without using any kind of adhesive material on the device itself. The device avoids formation of blisters, calluses, and other irritations caused due to friction between any external garment or surface such as a shoe and the part of the body such surfaces come in contact with. In addition to reducing the effects of friction, this device also acts as a very tough yet comfortable physical barrier between the body and an external garment or surface such as a shoe; doing so this device protects the skin from any physical irritants, e.g. sharp edges and points in the shoe.

Owner:IQBAL HASAN

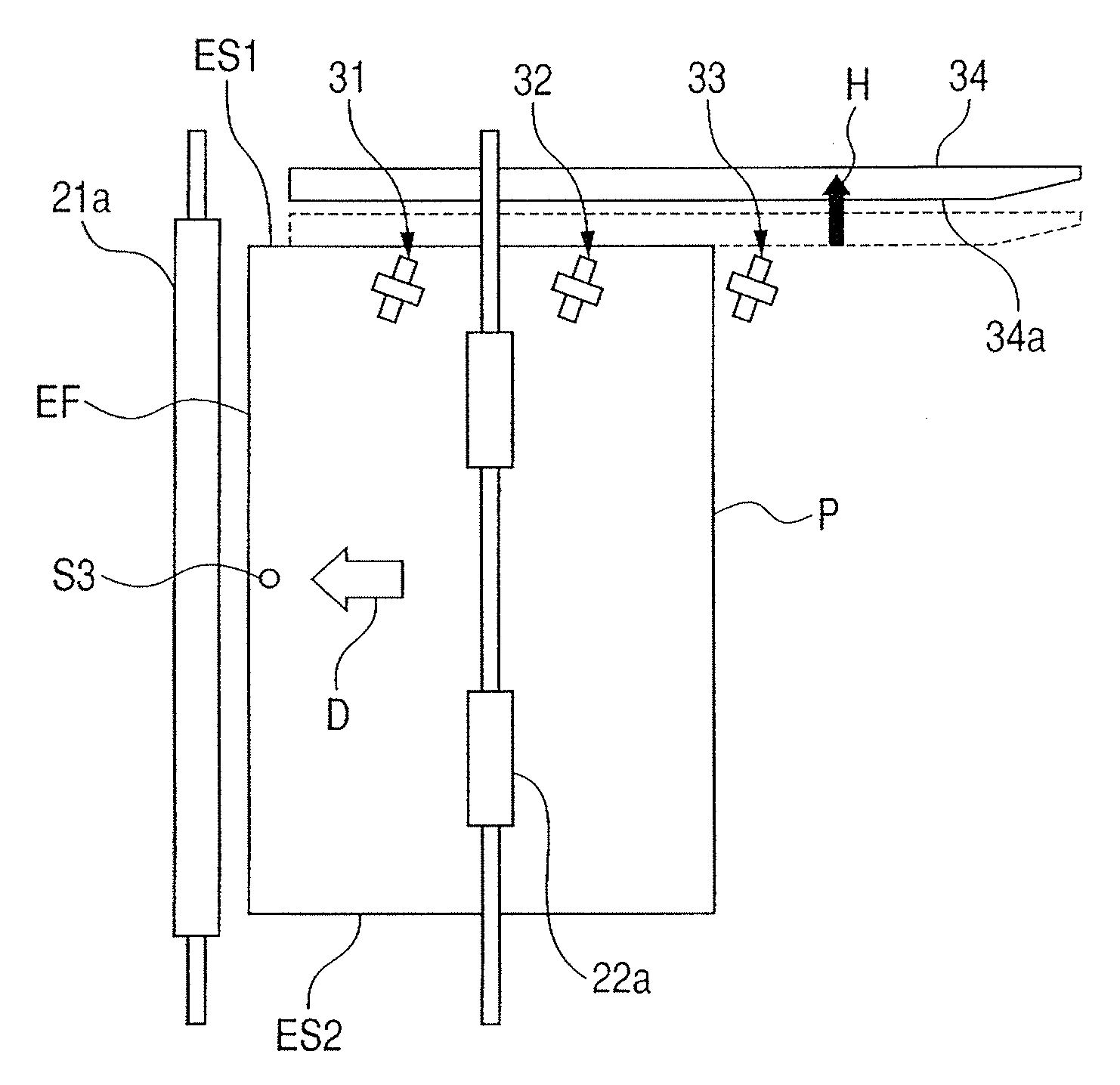

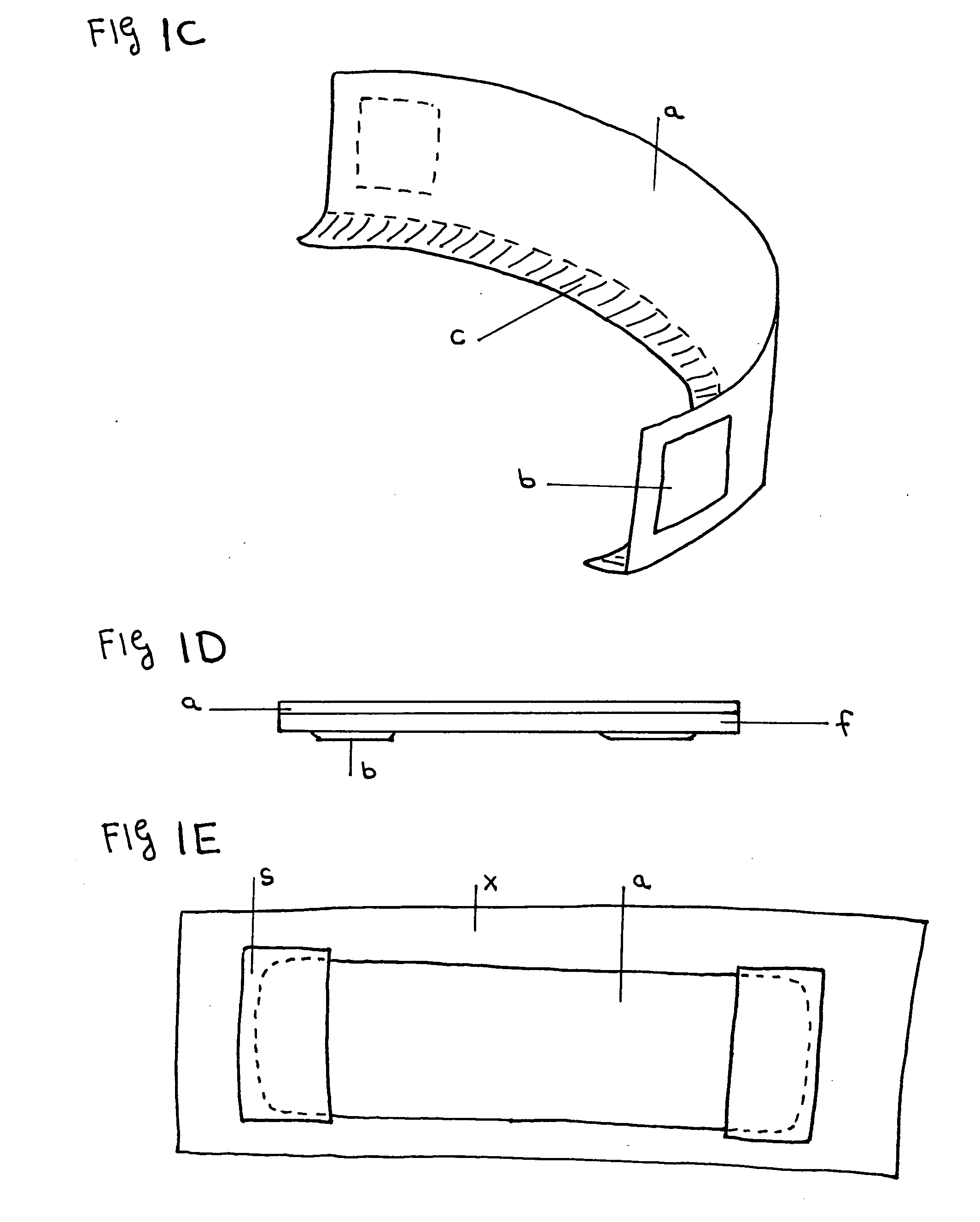

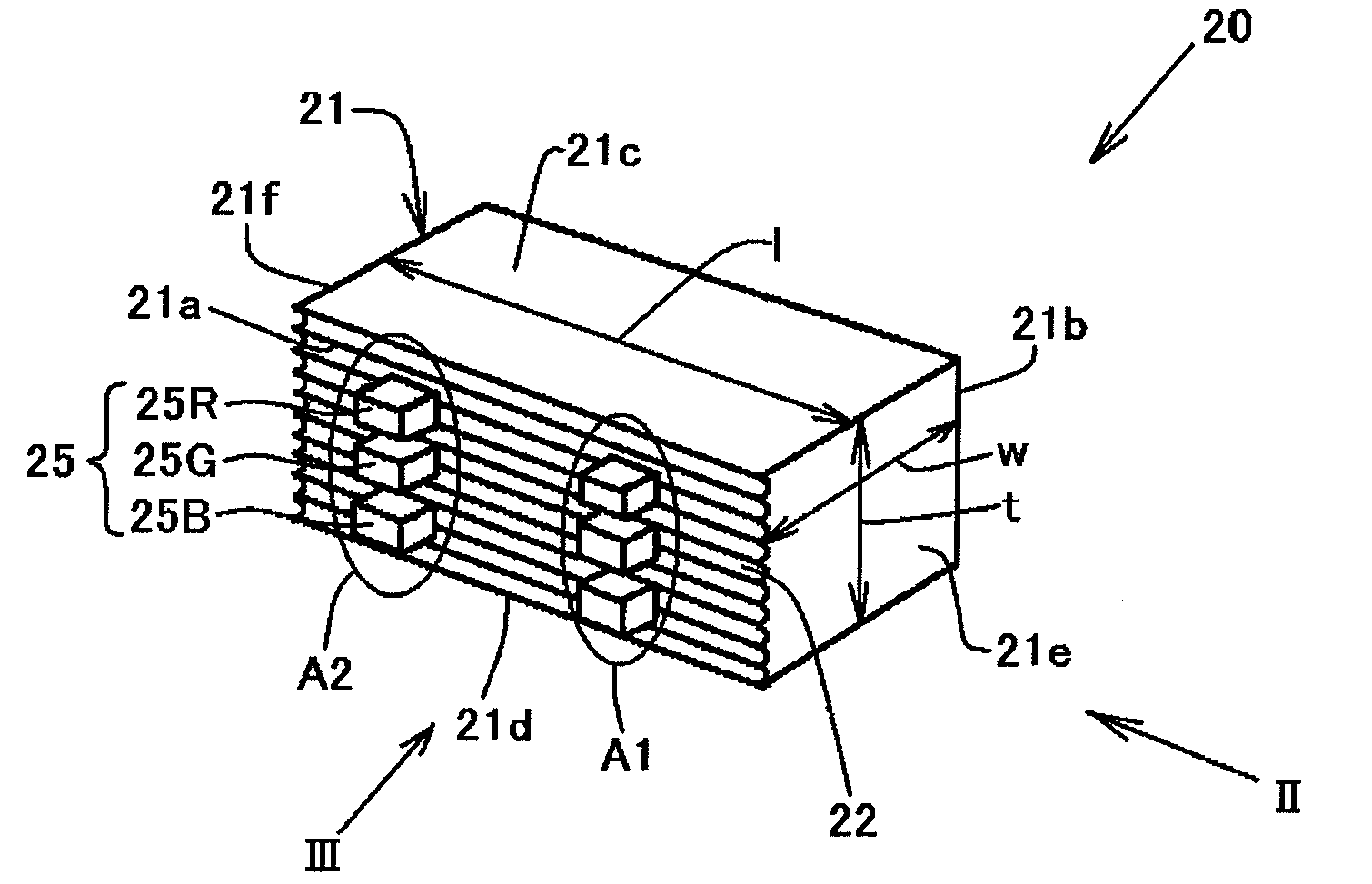

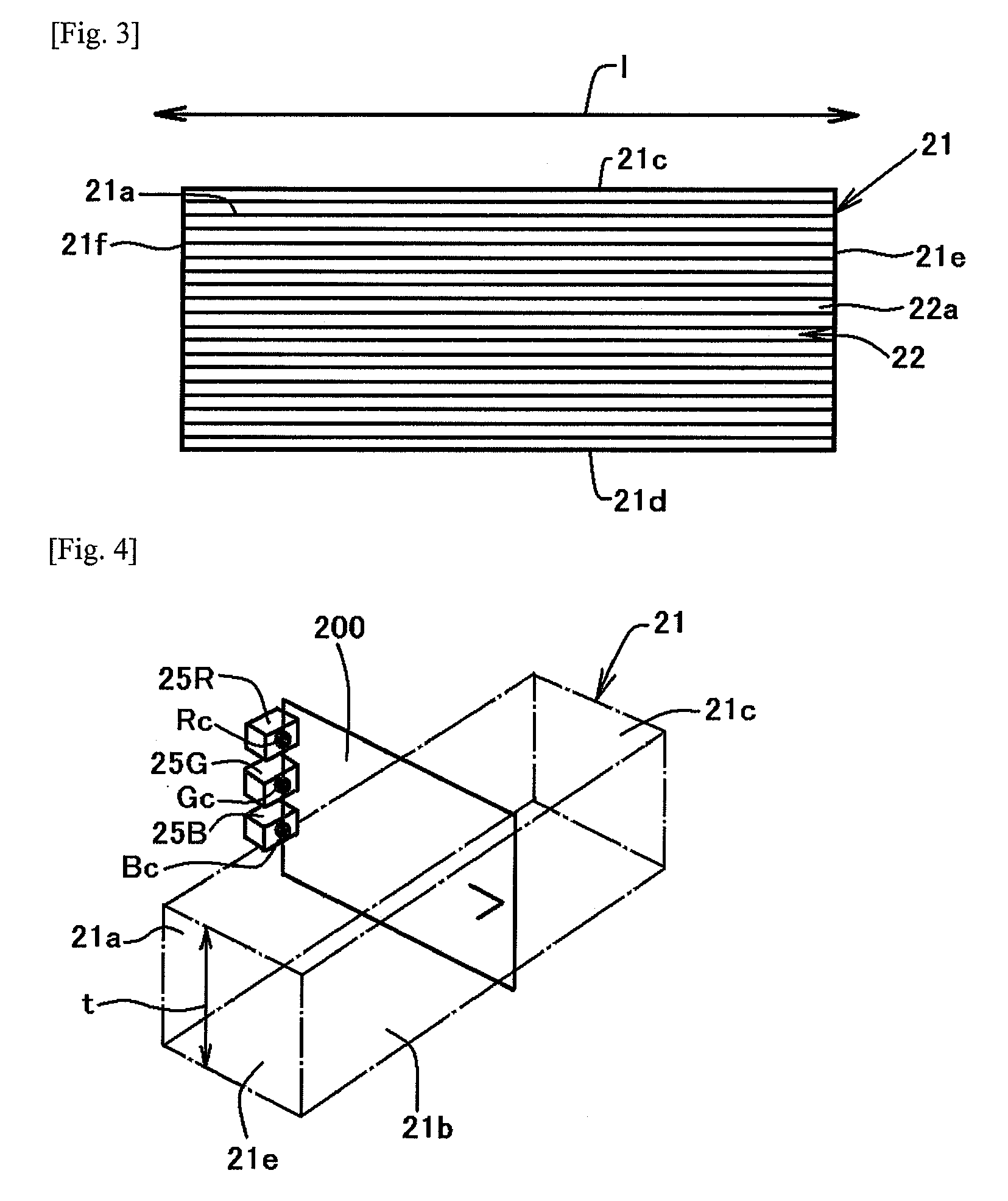

Light source unit, backlight unit and display apparatus having the same

InactiveUS20080151142A1Reduced color irregularityImprove color mixingPlanar/plate-like light guidesSpectral modifiersEffect lightLength wave

A light source unit capable of obtaining white light with reduced color irregularity includes a plurality of light-emitting diodes (25R, 25G and 25B) having different emission spectrum peak wavelengths, and a light mixing member (21) that receives lights from the light-emitting diodes through an entrance surface (21a) and that allows lights to mix together before exiting through an exit surface (21b). The light mixing member (21) has anisotropic diffusing elements (22) that diffuse incident lights from the light-emitting diodes in a specific plane to effect light mixing.

Owner:CITIZEN ELECTRONICS CO LTD

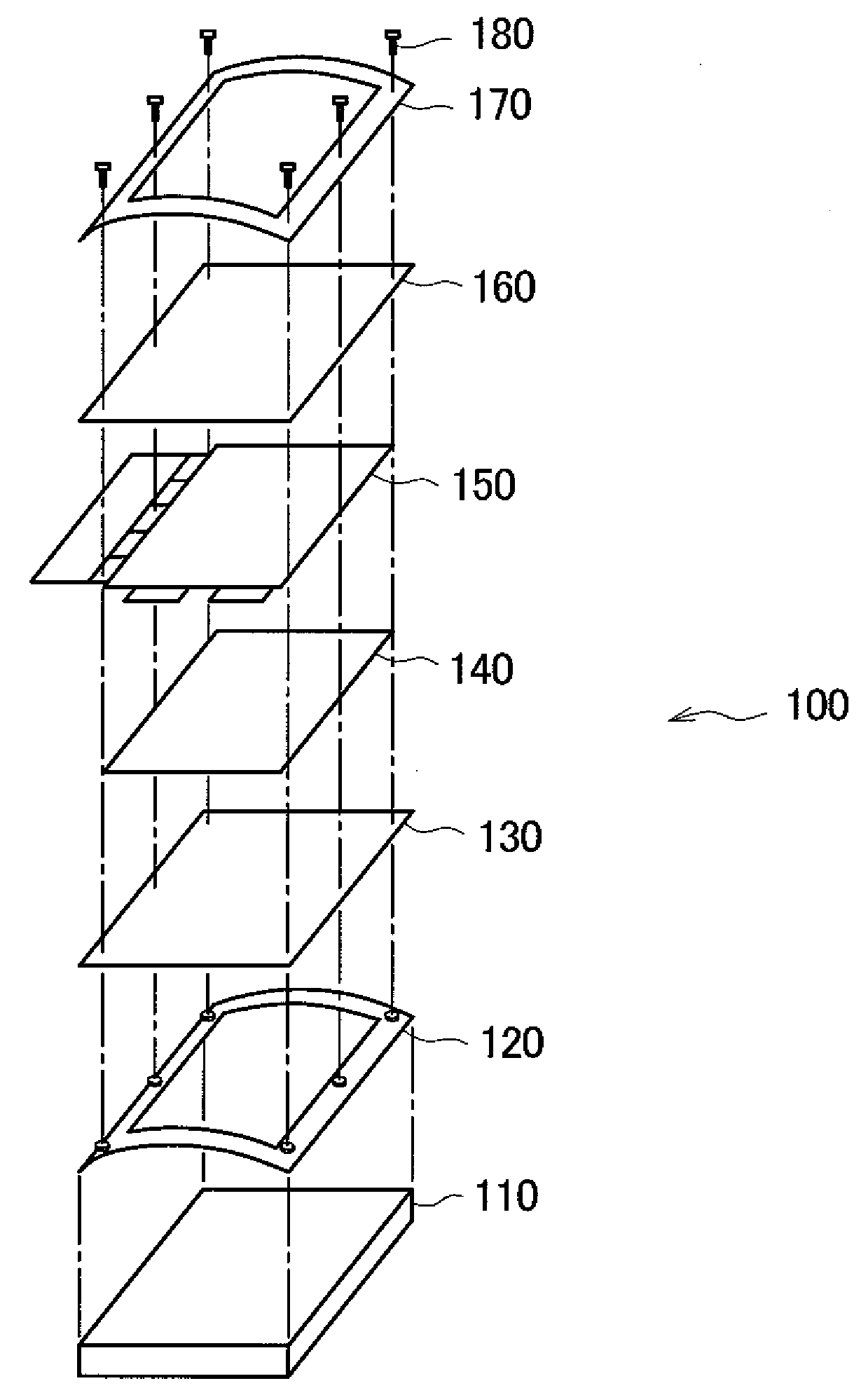

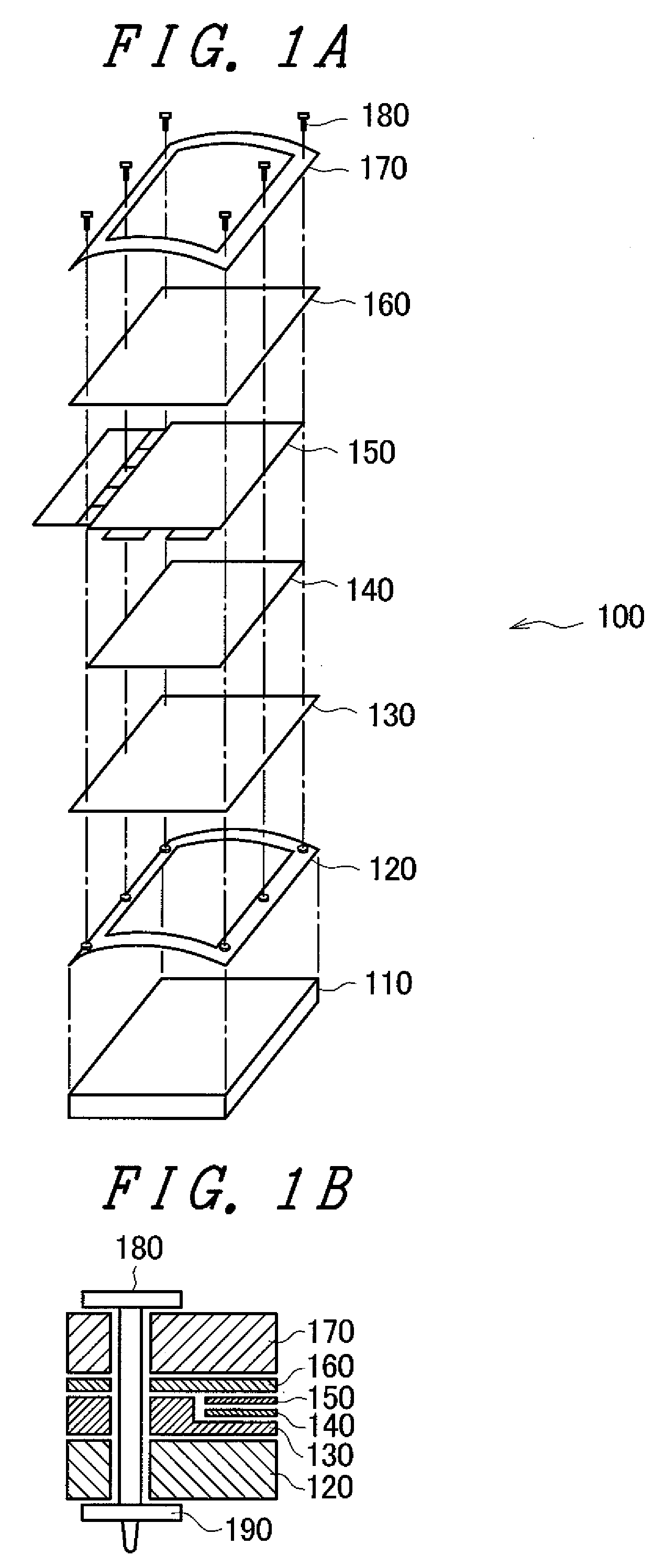

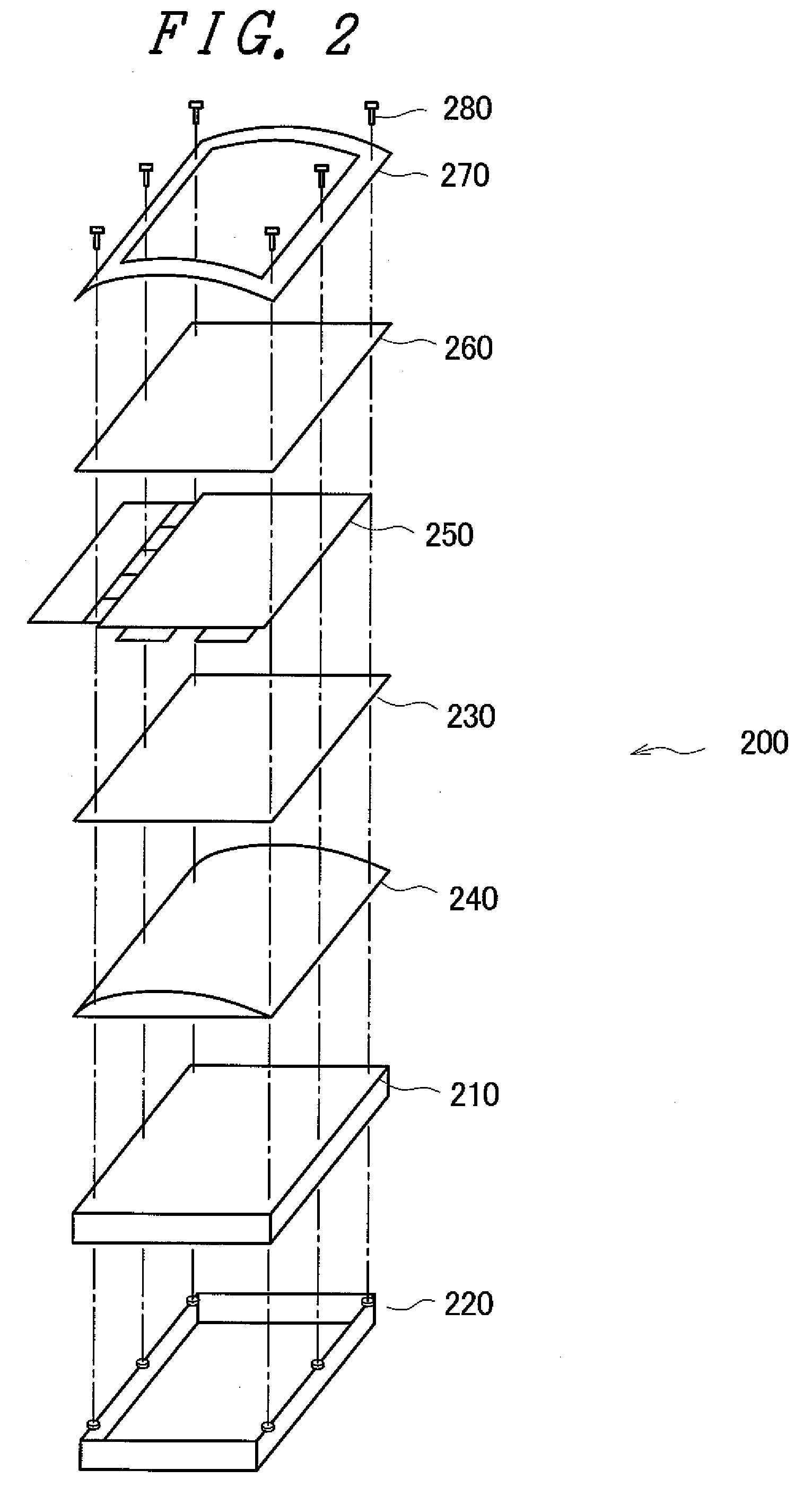

Liquid Crystal Display Device

InactiveUS20100033648A1Increase lengthReduce irregularitiesNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display device includes: a liquid crystal panel which includes a liquid crystal layer and a pair of resilient substrates which sandwiches the liquid crystal layer therebetween; and a curving holding means (a lower frame, an upper frame, a plurality of bolts, and a plurality of nuts) which clamps an outer peripheral portion of the liquid crystal panel from a front surface and a back surface of the liquid crystal panel so as to hold the liquid crystal panel in a state that the liquid crystal panel is curved in one direction, wherein a clamping force applied to a non-curved outer peripheral portion of the liquid crystal panel by the curving holding means is set larger than a clamping force applied to a curved outer peripheral portion of the liquid crystal panel by the curving holding means.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com