Friction reducing barrier

a friction barrier and friction technology, applied in the field of footwear, can solve the problems of blisters, abrasions, calluses, other irritations of feet, and the inability to meet the needs of reducing and achieve the effect of reducing friction, preventing blisters, abrasions, calluses,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

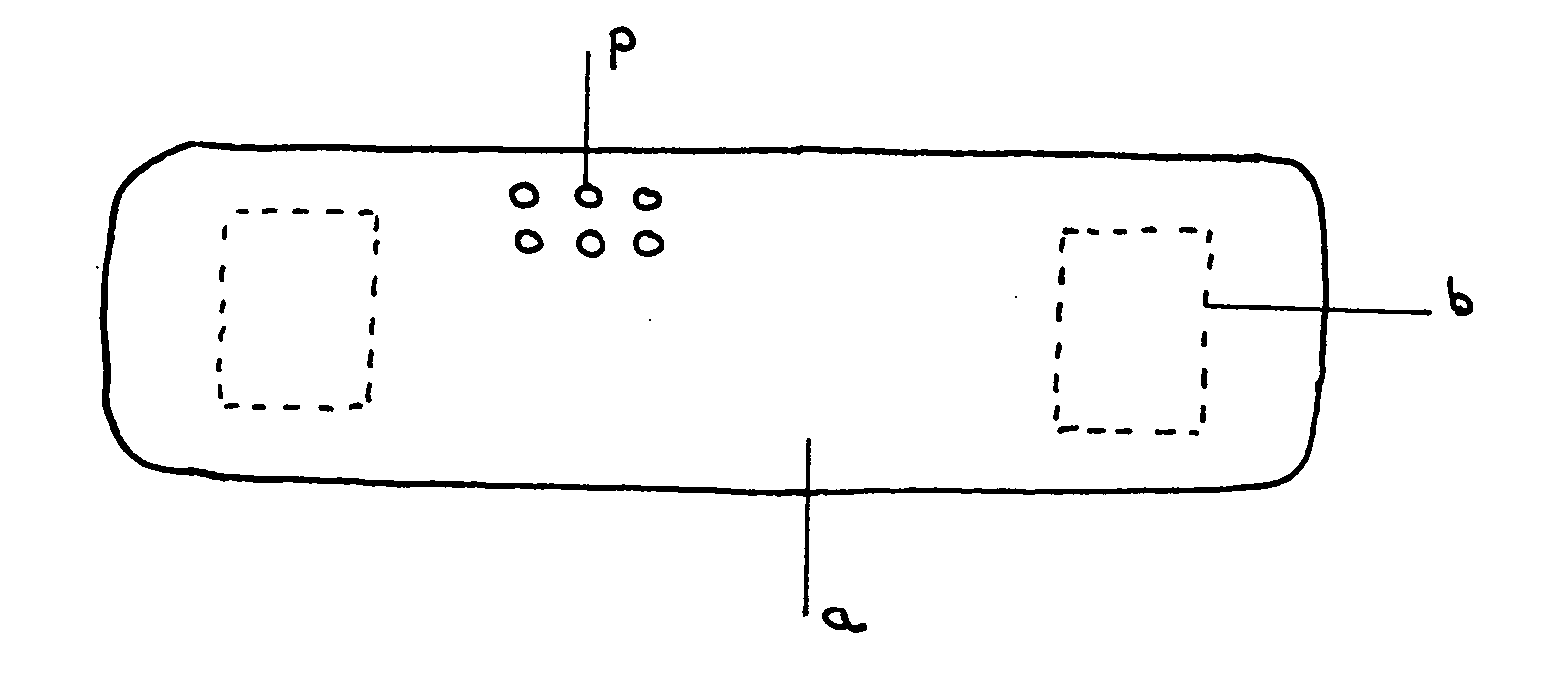

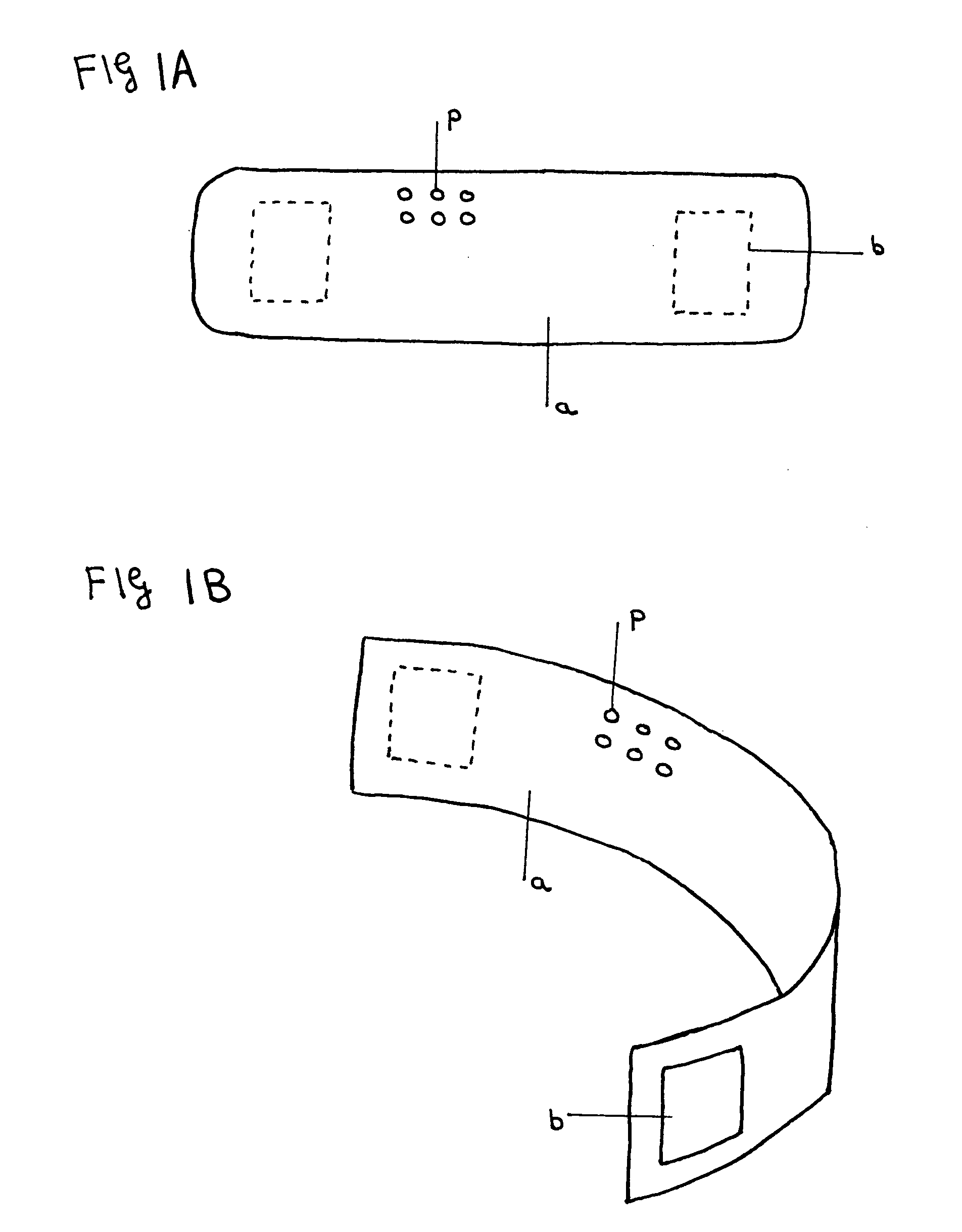

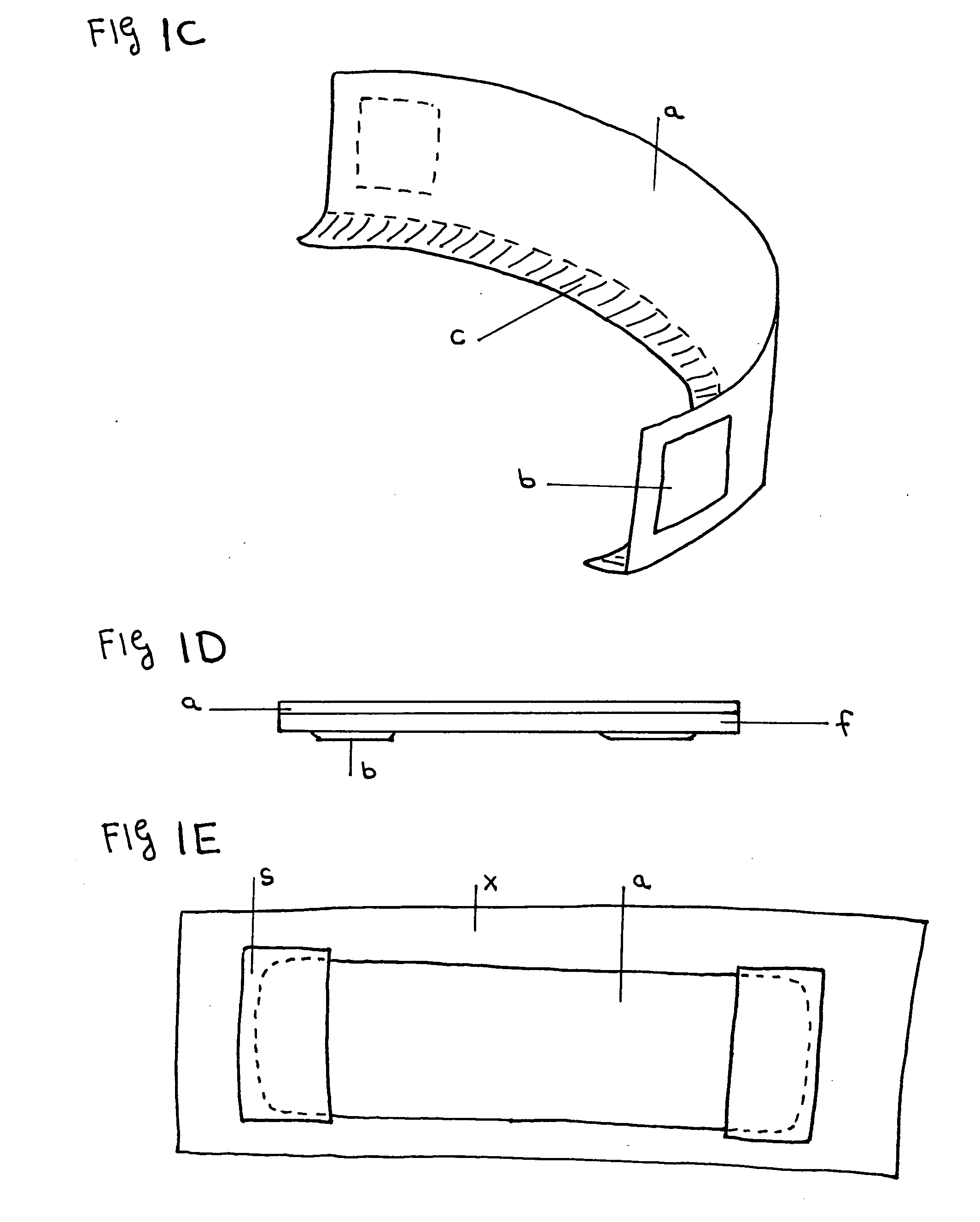

[0039]Disclosed herein is a device for reducing friction, such as caused due to rubbing of the rear portion of a foot heel with the inner surface of a shoe. The device is composed of a thin, smooth, and flexible material with a low coefficient of friction. The material with a low coefficient of friction used in the device can belong to any group of plastics or any other material as long as the material can be transformed into a thin, smooth, slippery, and flexible form. Additionally, the thin, smooth, and flexible material with a low coefficient of friction can be applied / painted with a low friction paint / enamel. Also the thin, smooth, and flexible material with a low coefficient of friction can be applied over a cushioning material such as a foam or silicon gel or like. Neither the low friction paint / enamel nor the cushioning material is a must, however these may enhance the function of the device. Also, the device may have plurality of perforations for the easy release and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com