Wood cutting device with sawdust removing function

A cutting device and wood technology, applied in the direction of clamping device, wood processing equipment, sawing equipment, etc., can solve the problems of wasting resources, wood fixing effect, reducing work efficiency, etc., to improve work efficiency, simple and fast fixing, The effect of reducing the difficulty of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

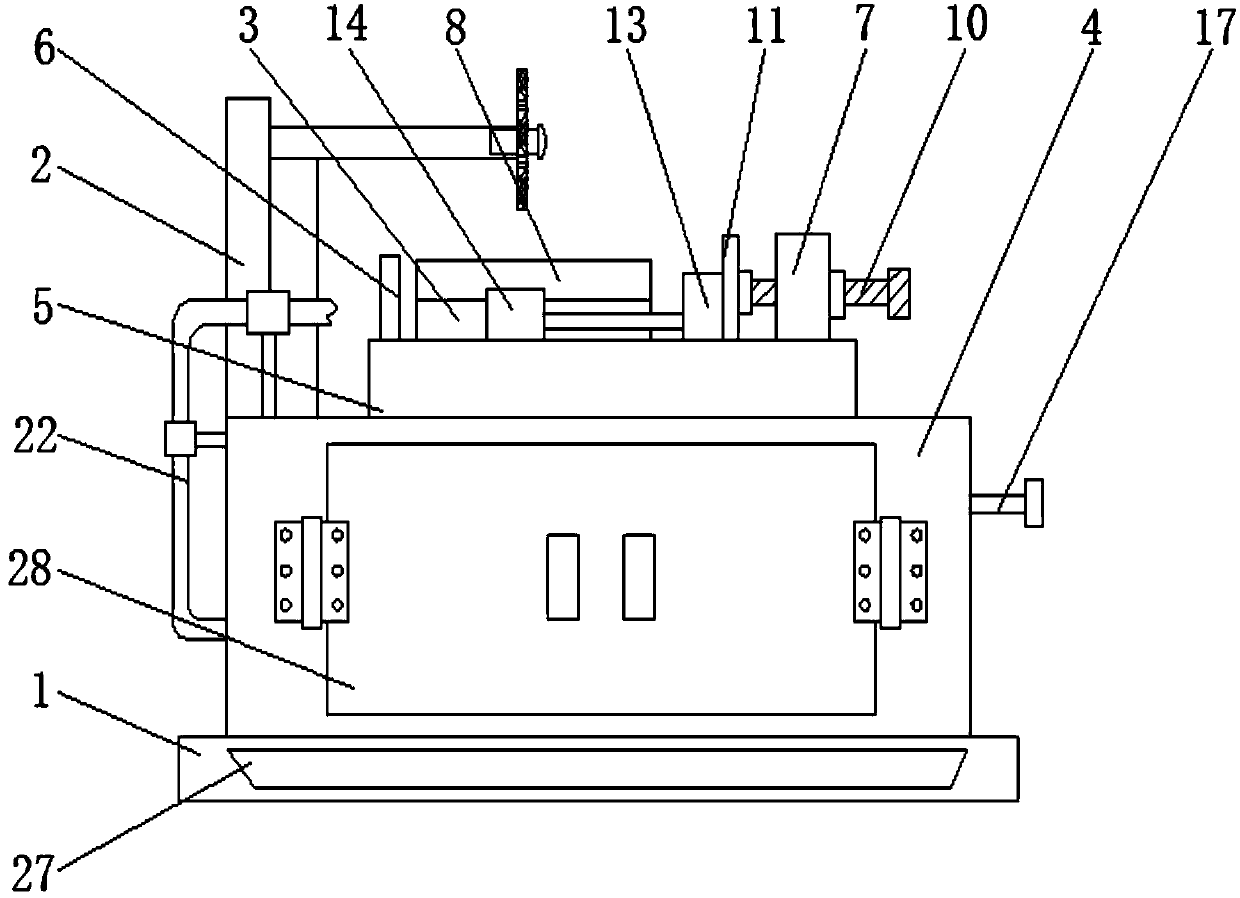

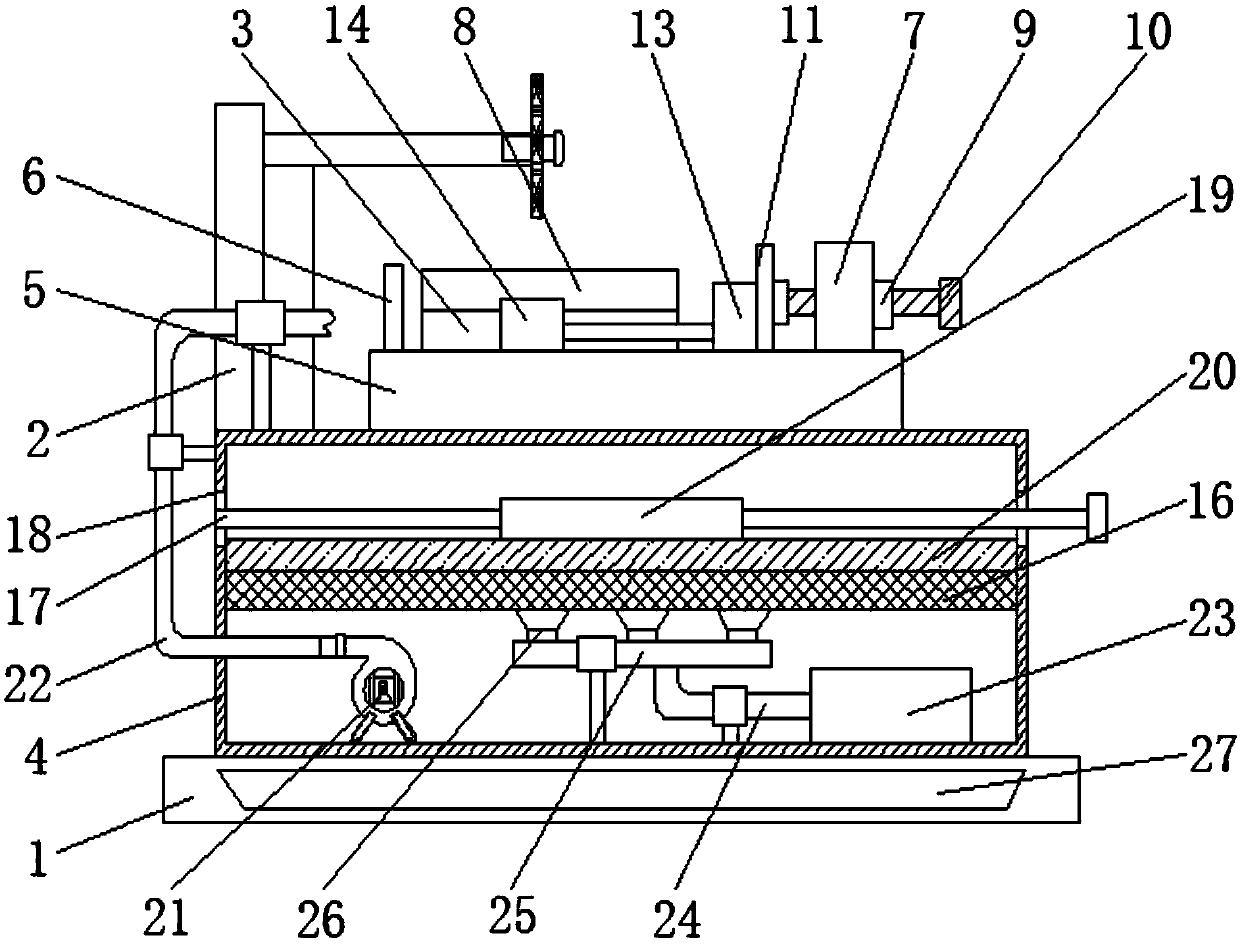

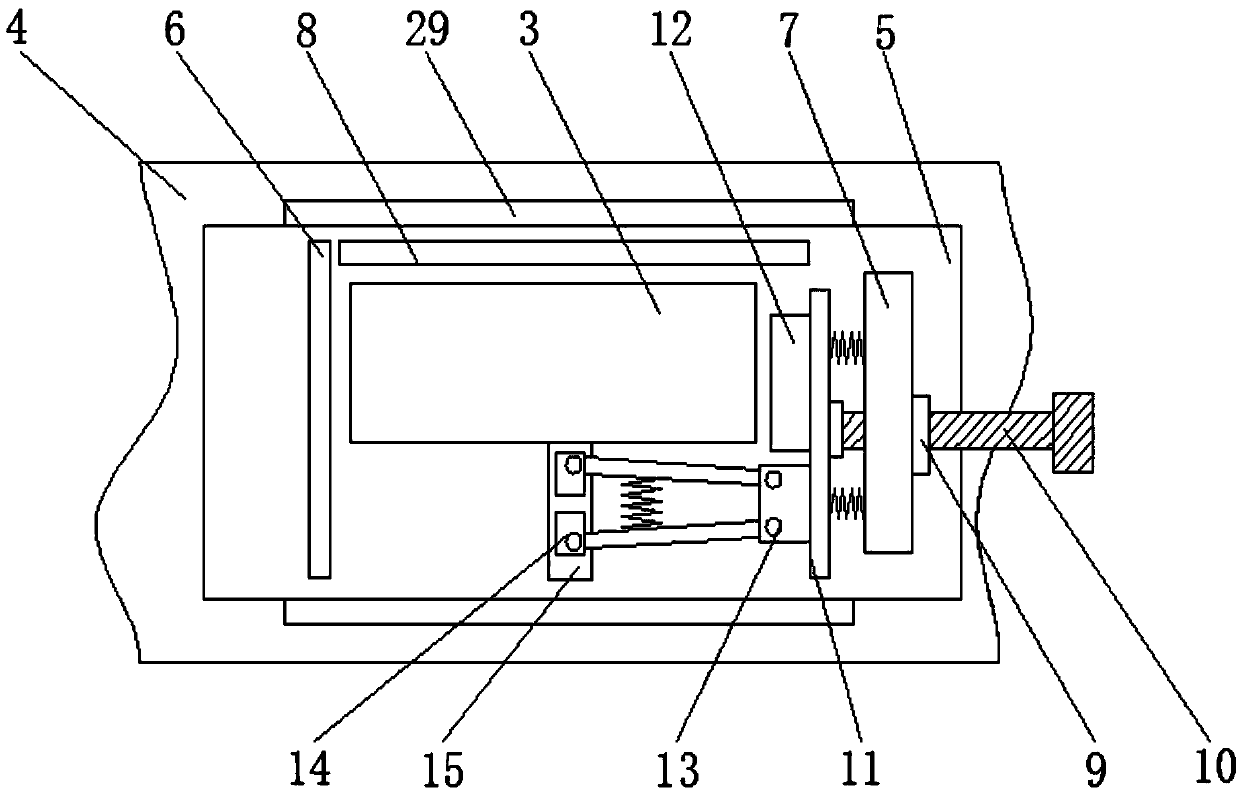

[0015] like Figure 1-Figure 3 As shown, a wood cutting device with chip cleaning function mainly includes a bottom plate 1, a cutting machine body 2, a wood body 3, a box body 4, a workbench 5, a first limiting plate 6, a fixing plate 7, and a second limiting plate 8. Threaded sleeve 9, threaded rod 10, push plate 11, push block 12, fixed block 13, sliding block 14, chute 15, filter screen 16, pull rod 17, transverse groove 18, rectangular block 19, brush 20, The blower 21, the first leather tube 22, the suction fan 23, the second leather tube 24, the shunt pipe 25, the dust suction nozzle 26, the crumb tray 27, the box door 28, the rectangular hole 29, and the front of the bottom plate 1 is fixedly connected with a crumb receiver Disc 27, chip receiving tray 27 can collect and process sawdust in a concentrated manner, and the front of box body 4 is hinged with box door 28 by hinge, and the top of box body 4 is provided with rectangular hole 29, and rectangular hole 29 can le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com