Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1009 results about "Wood cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Woodcutting (often abbreviated as WC or WCing) is a gathering skill that involves chopping down different types of trees and vegetation. For each type of tree, a minimum Woodcutting level and a hatchet are required to cut it. With each level up, a player will be able to cut trees faster than previously.

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS20060065098A1Increase Section WidthPrevent set collapseMetal sawing devicesMetal sawing toolsEngineeringWood cutting

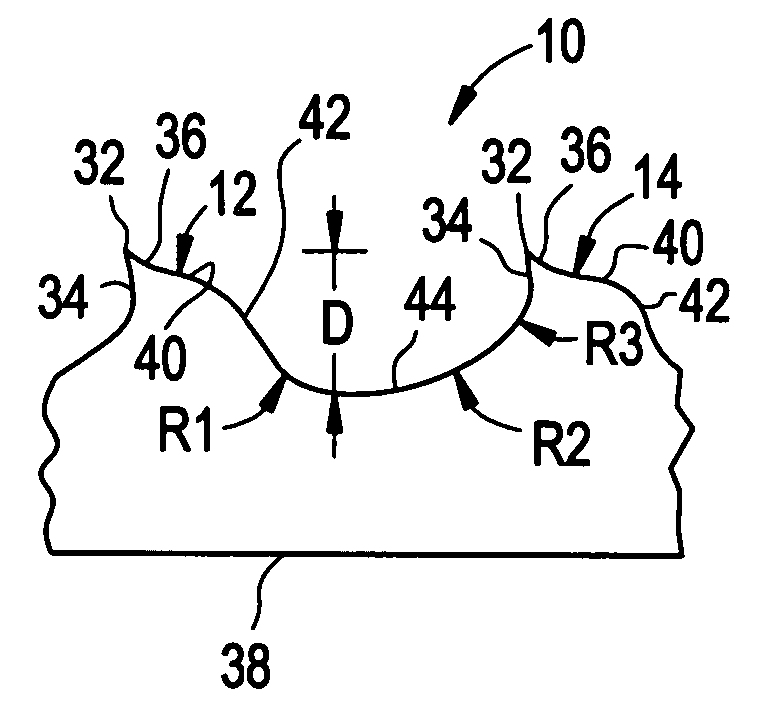

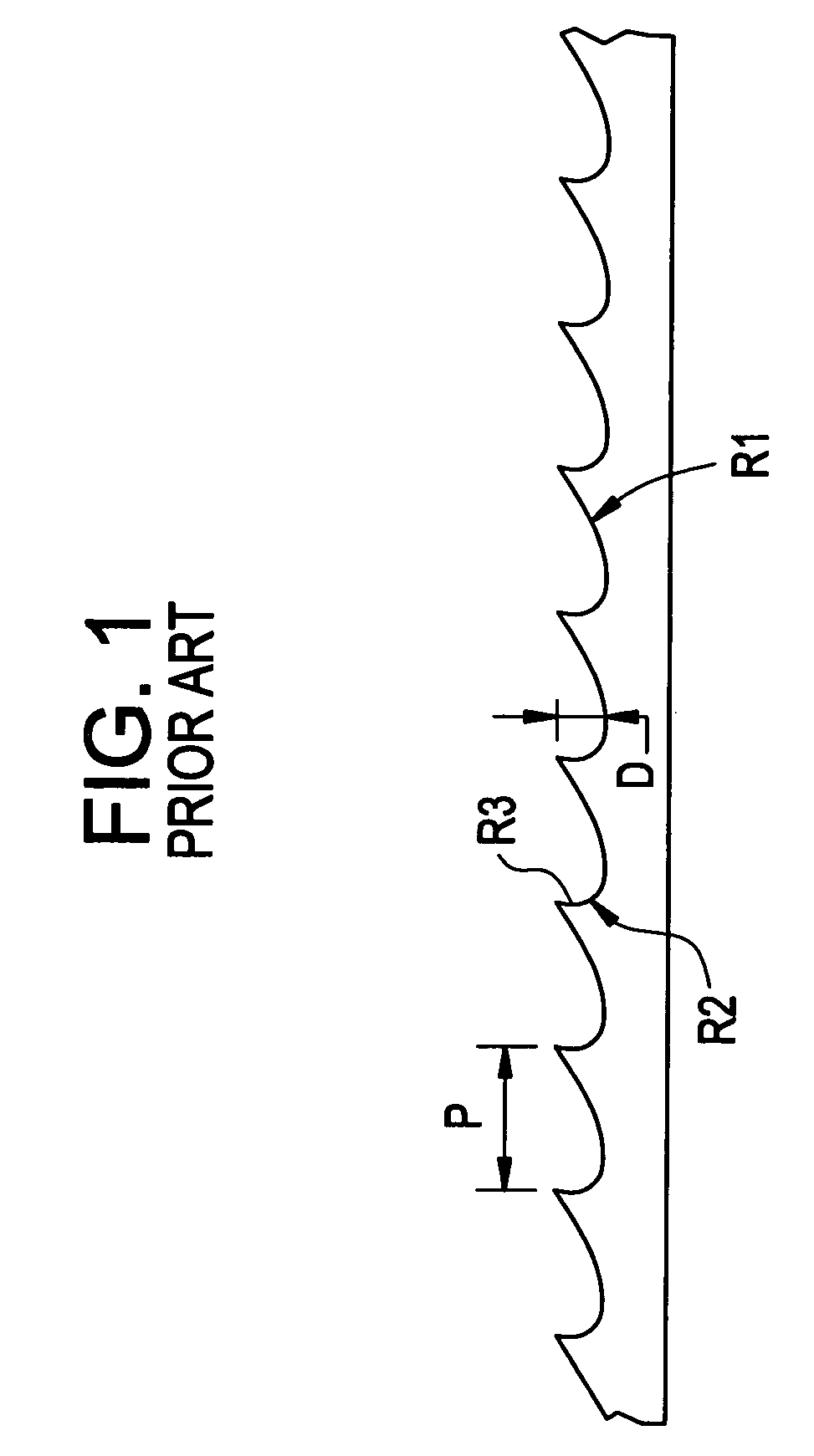

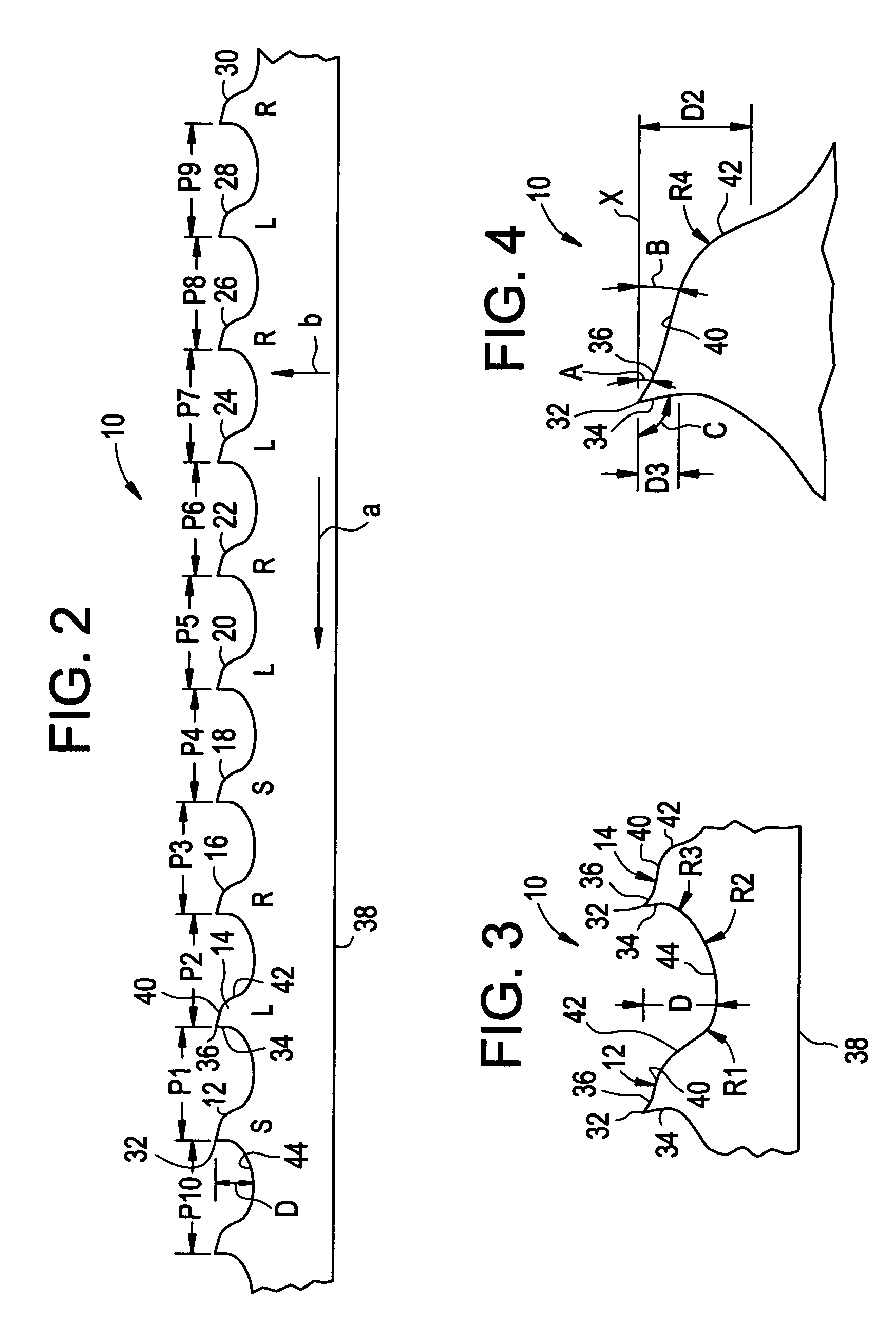

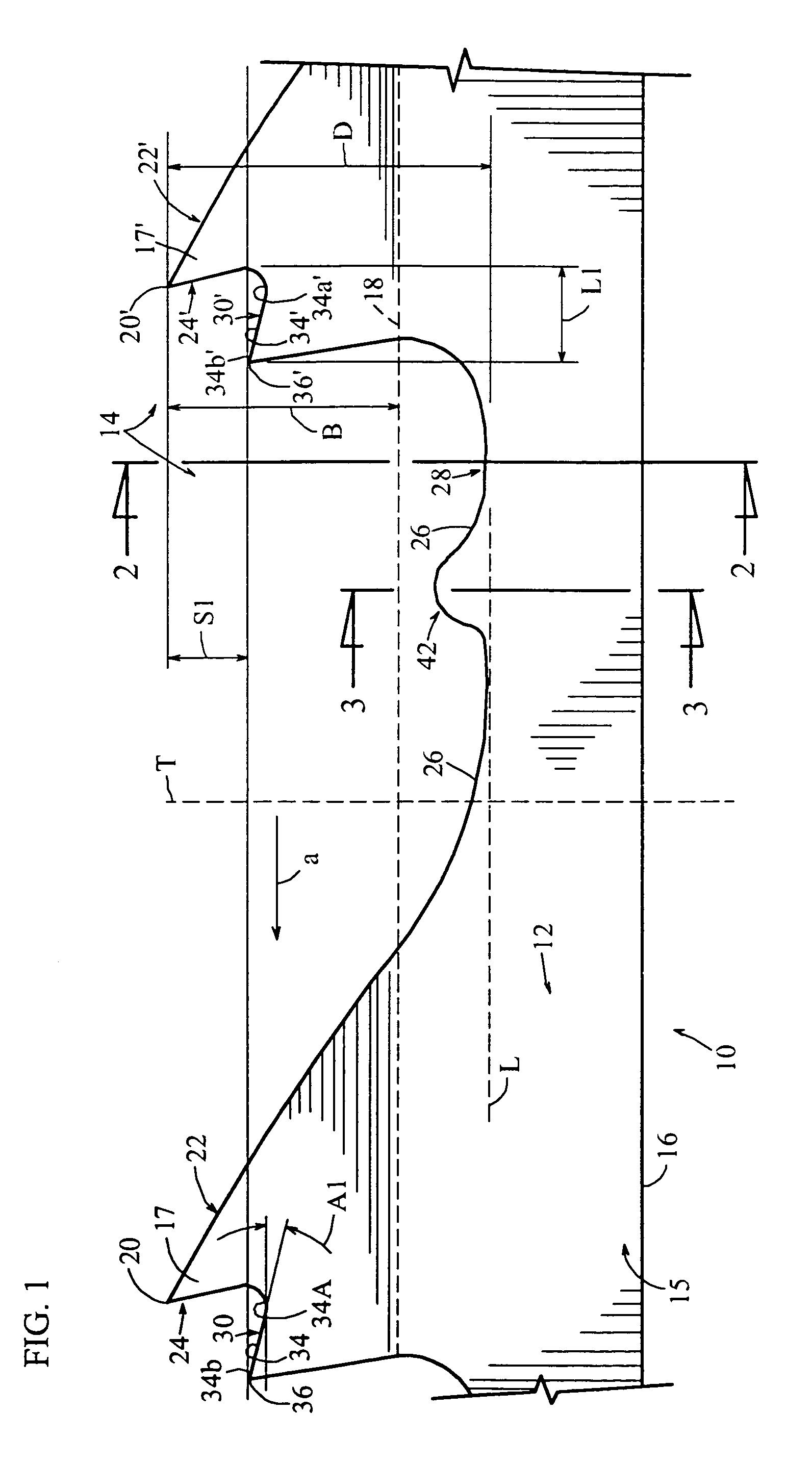

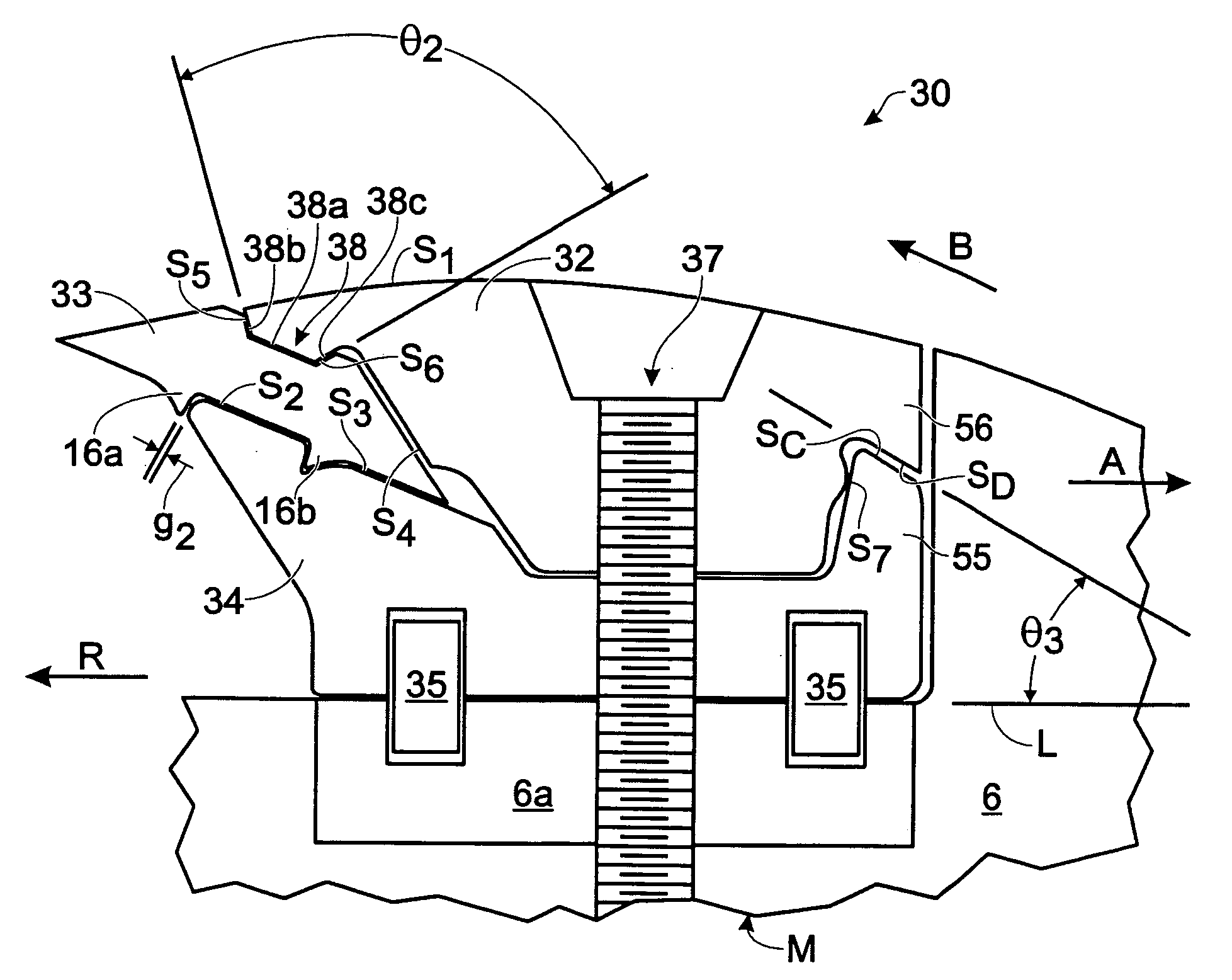

A wood-cutting band saw blade includes a cutting edge defined by a plurality of teeth spaced relative to each other, wherein each tooth includes a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; a tertiary clearance surface formed on an opposite side of the secondary clearance surface relative to the primary clearance surface; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and tertiary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth in a cutting direction of the saw blade. In each tooth, R2>D>R1, D / P is within the range of about 25% to about 35% and R2 / R1≧about 1.4. R1 defines a minimum radius (Rmin) at a base of the gullet and Rmin / D>about 20%.

Owner:IRWIN IND TOOL CO

Wood cutting band saw blade

InactiveUS8113100B1Minimizing dust collectionReadily apparentMetal sawing devicesMetal sawing toolsWood cuttingEngineering

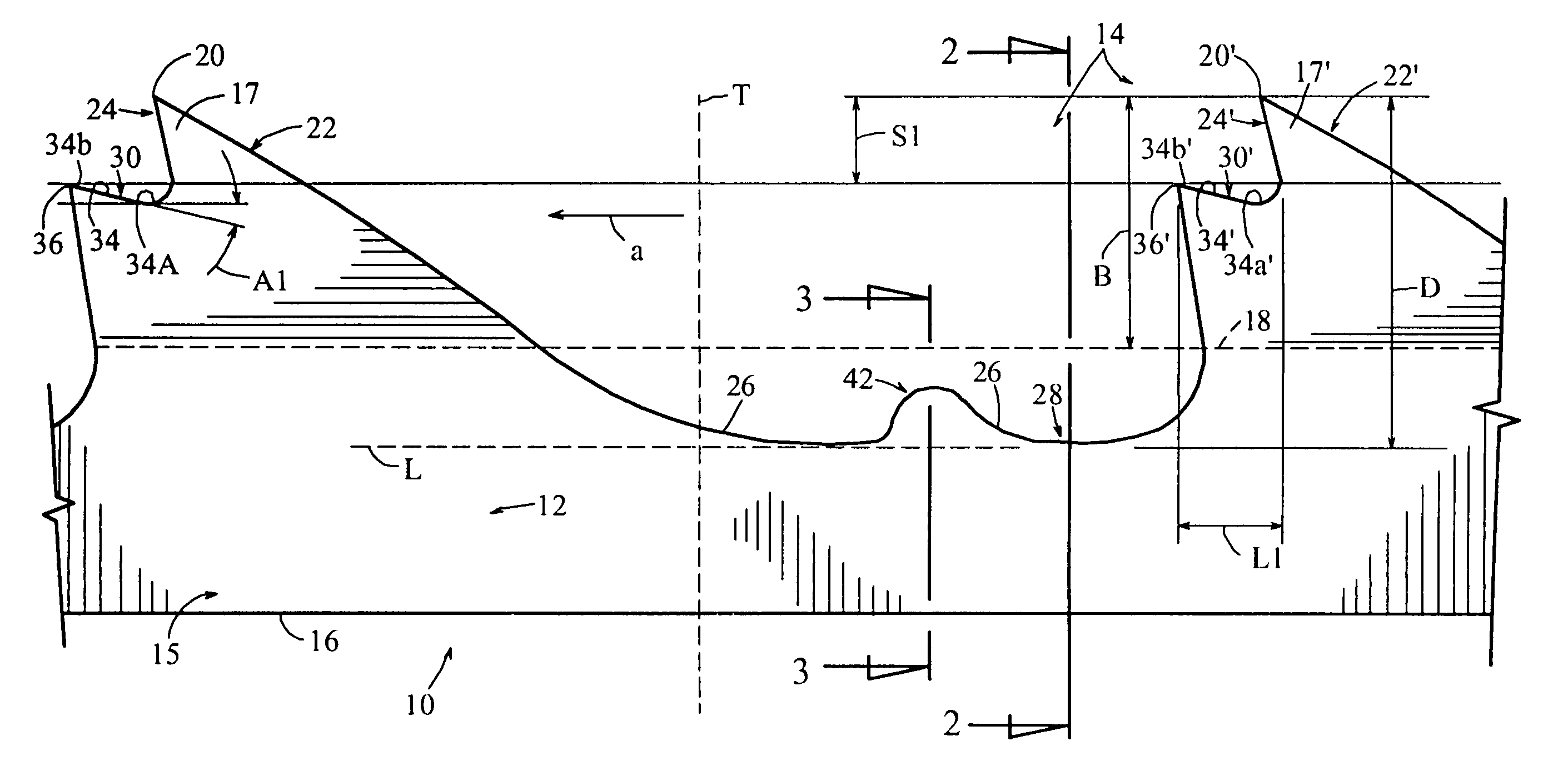

A wood cutting band saw blade includes a cutting edge and a back edge, wherein the cutting edge is defined by a plurality of teeth spaced relative to each other. The plurality of teeth include a plurality of set teeth each having a tip, each defining a bend plane, and each including a shelf located at least partially between the tip and the bend plane for reducing saw dust passing to the kerf and accumulating on the band saw blade. Each of the set teeth may define a relief surface and a cutting surface where the relief surface extends from one side of the tip in a direction opposite that of the movement of the band saw blade and the cutting surface extends from another side of the tip. The shelf includes a shelf surface extending from the cutting surface and may terminate in a shelf tip.

Owner:BLACK & DECKER INC

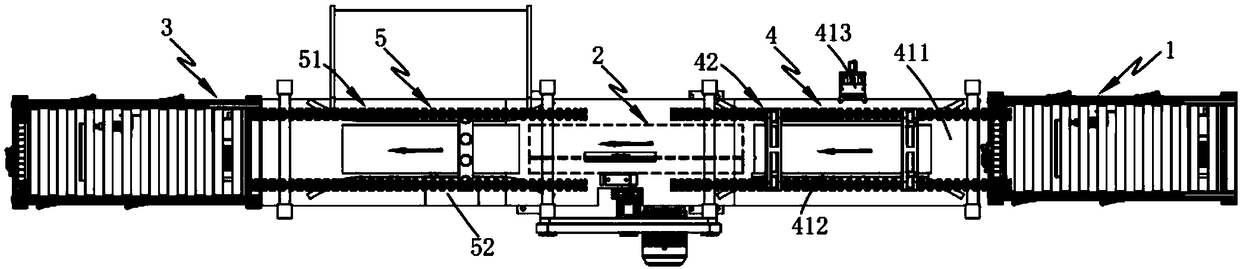

Tiltable infeed and outfeed saw table

InactiveUS6212983B1Precise positioningMinimum elapsed timeMetal sawing devicesAutomatic control devicesCircular sawEngineering

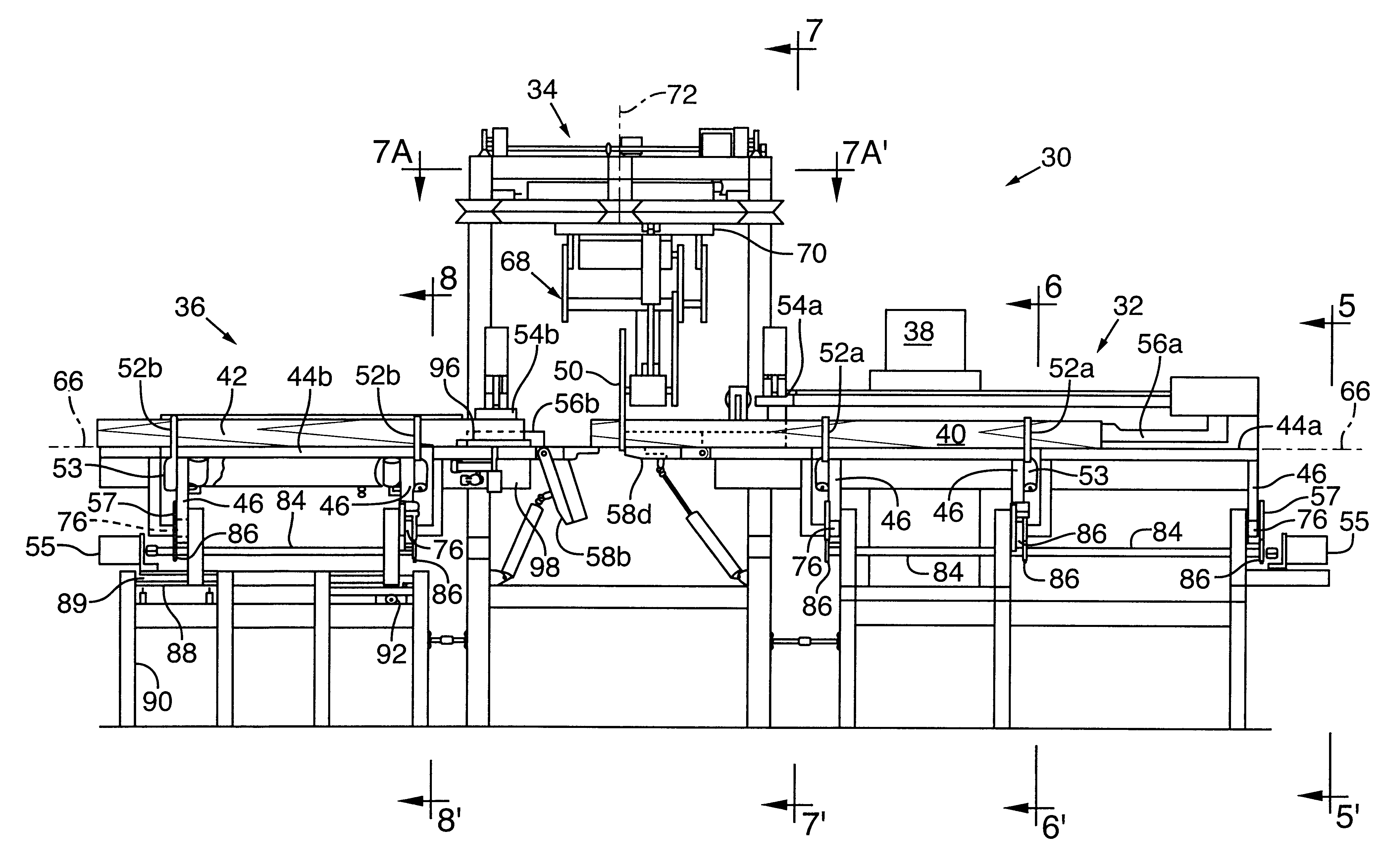

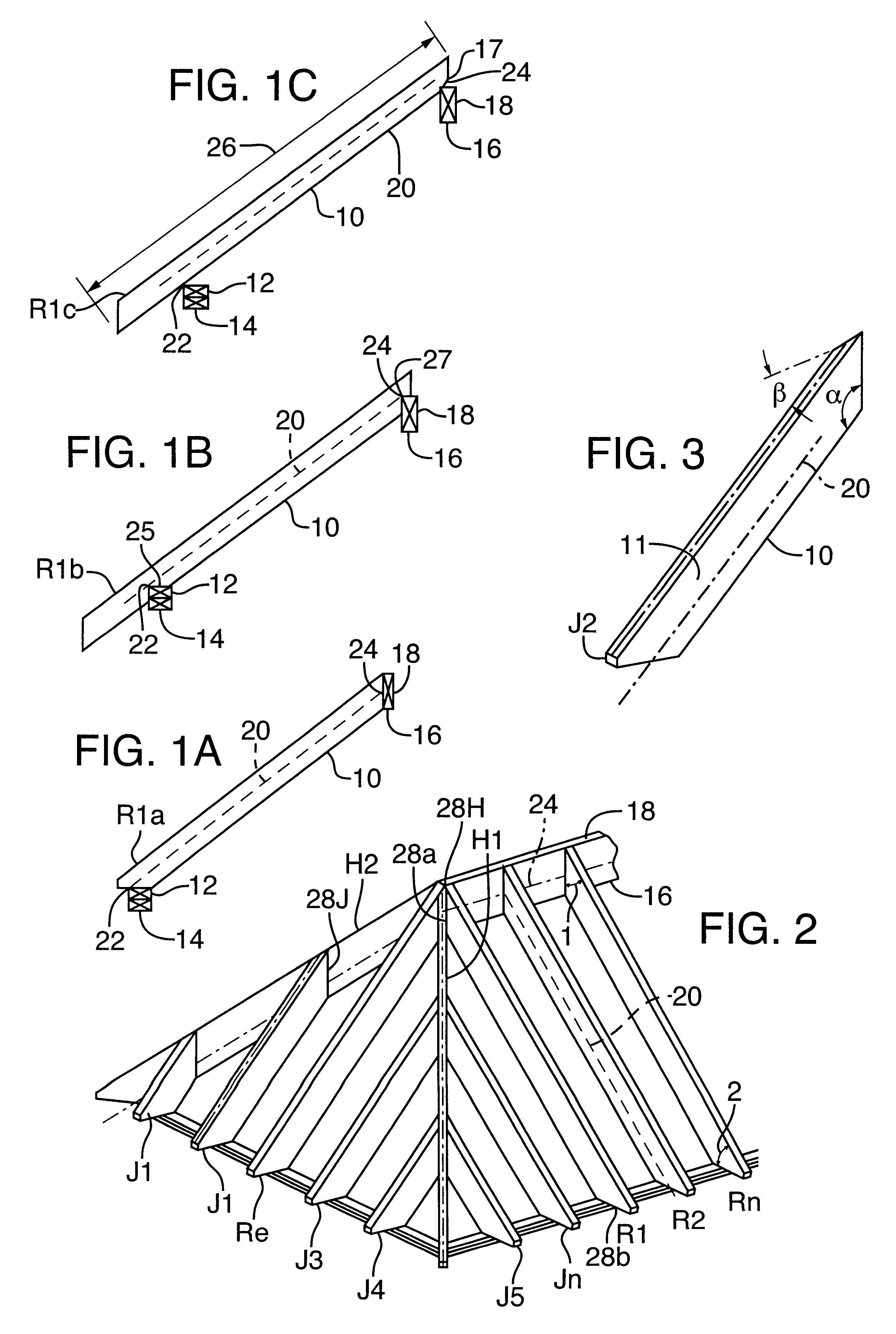

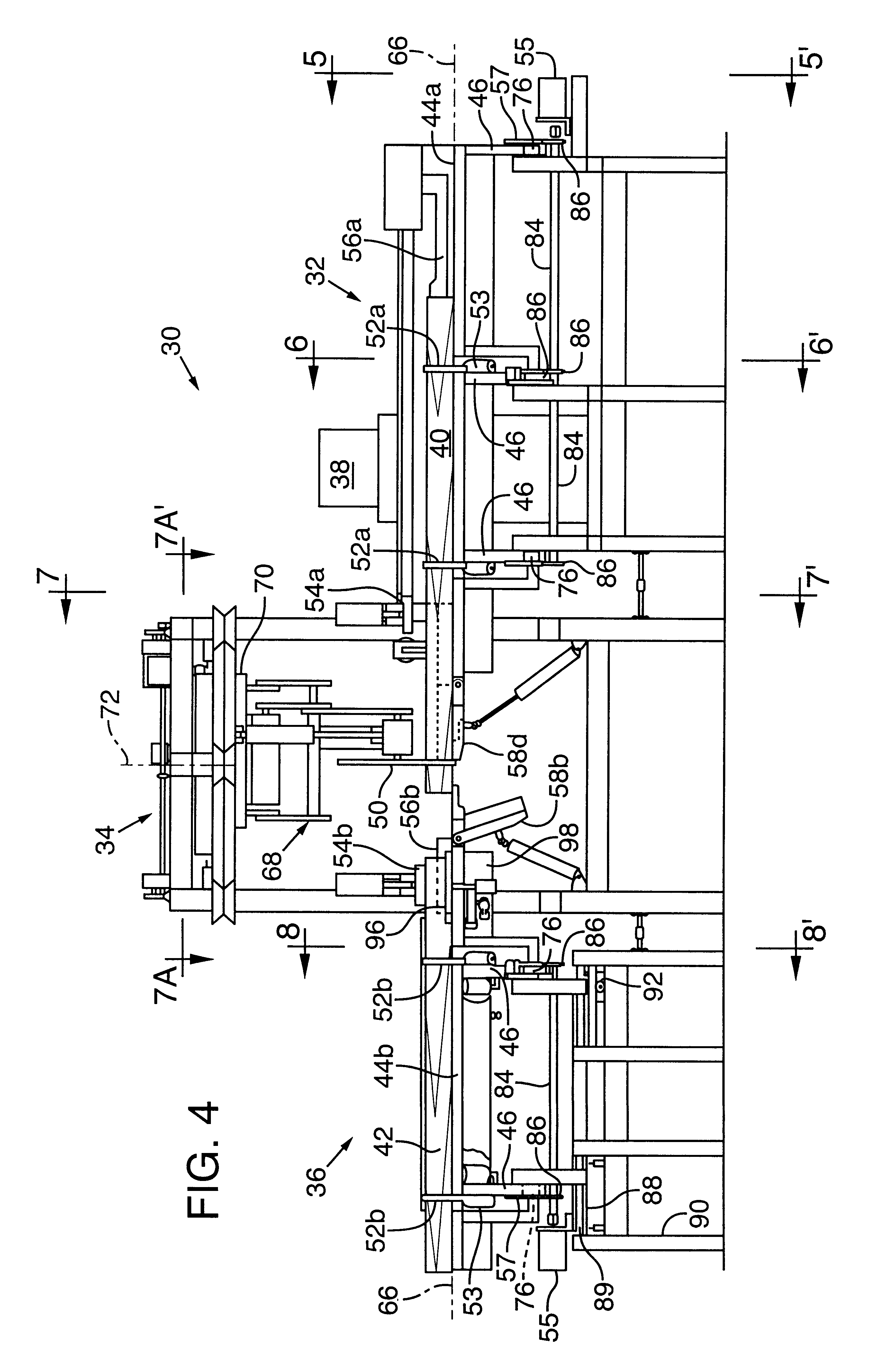

An apparatus for sequentially and automatically cutting a piece of dimension lumber at a number of predetermined angles to produce a building component, such as a rafter or truss web or chord, with composite or compound angles, is disclosed. The apparatus includes infeed and outfeed tables tiltable about a longitudinal axis and equipped with fences along which a workpiece moves longitudinally via moving devices. Clamps hold the workpiece at different positions relative to a cutting station during a cutting operation. A cutter, which for example includes a circular saw blade, is mounted for a positioning movement about a vertical axis at the cutting station, as well as for vertical movement to cut a workpiece at a predetermined composite or compound angle. The entire lumber cutting process at both ends of the workpiece, including lumber movement on the table past the cutting station, angular cutter and table adjustment, cutter movement, and clamping and unclamping, is under the control of a programmable computer operating in conjunction with appropriate sensors and pulse counters on the equipment.

Owner:STODDARD H PYLE REVOCABLE LIVING TRUST DATED JULY 17 1991

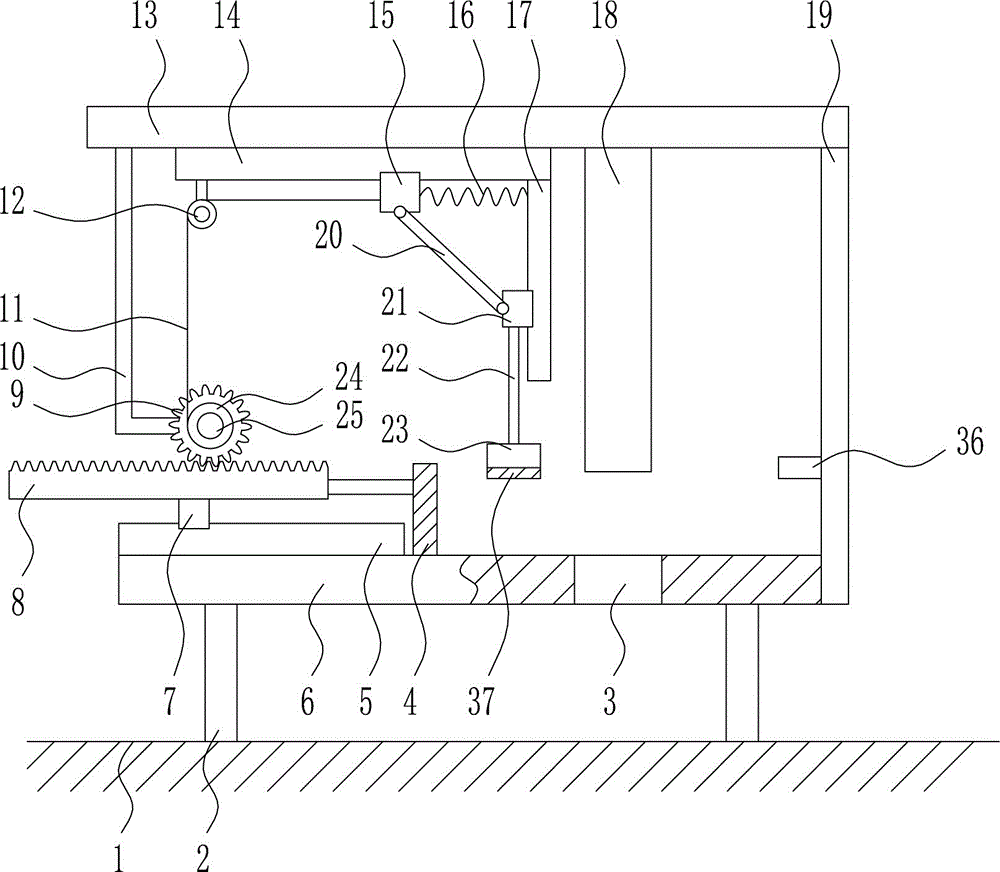

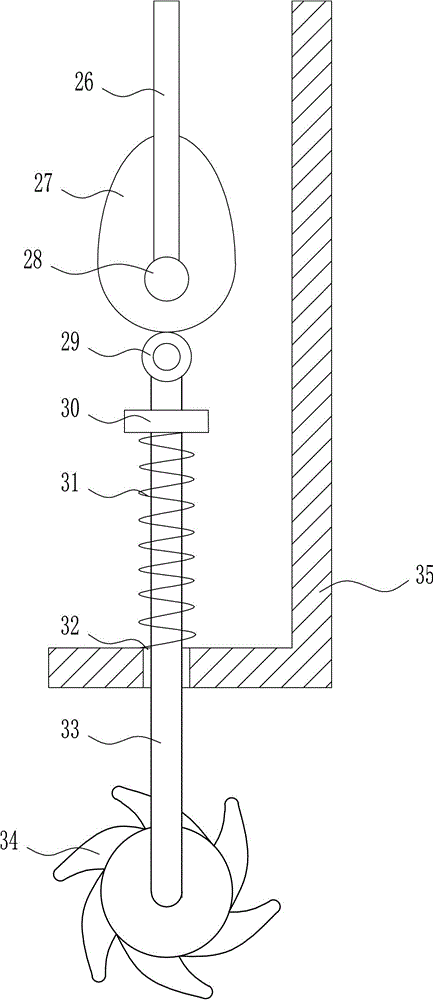

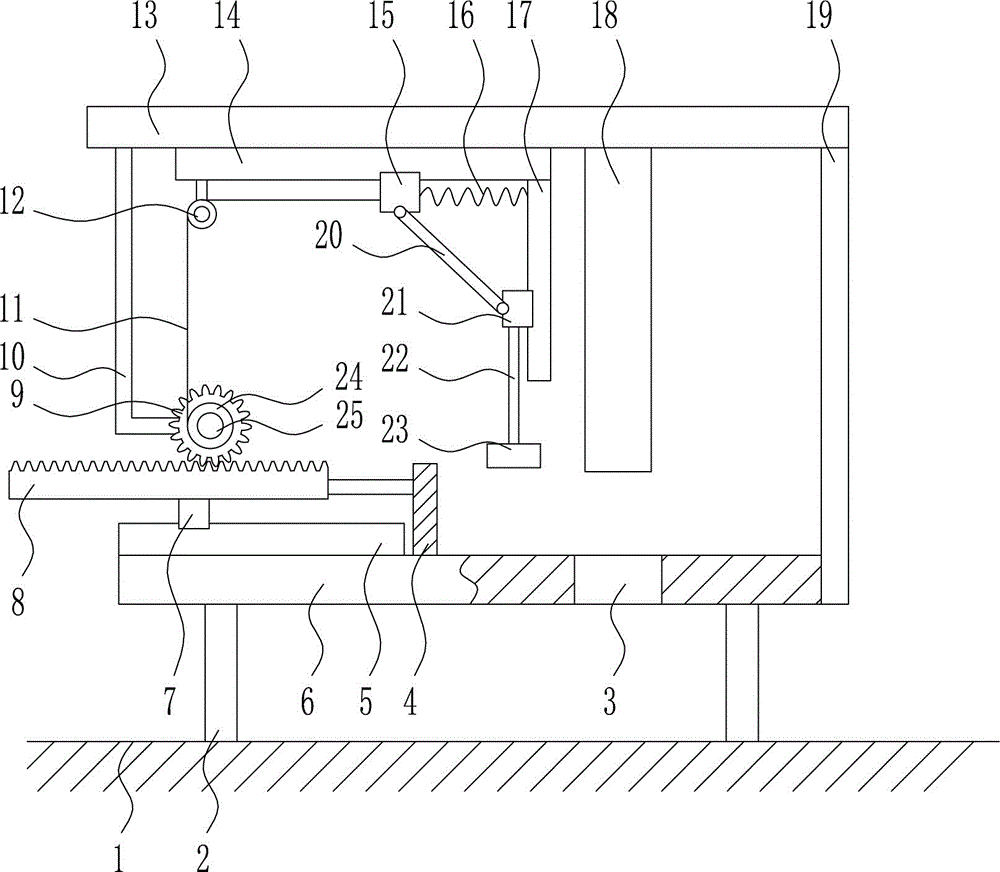

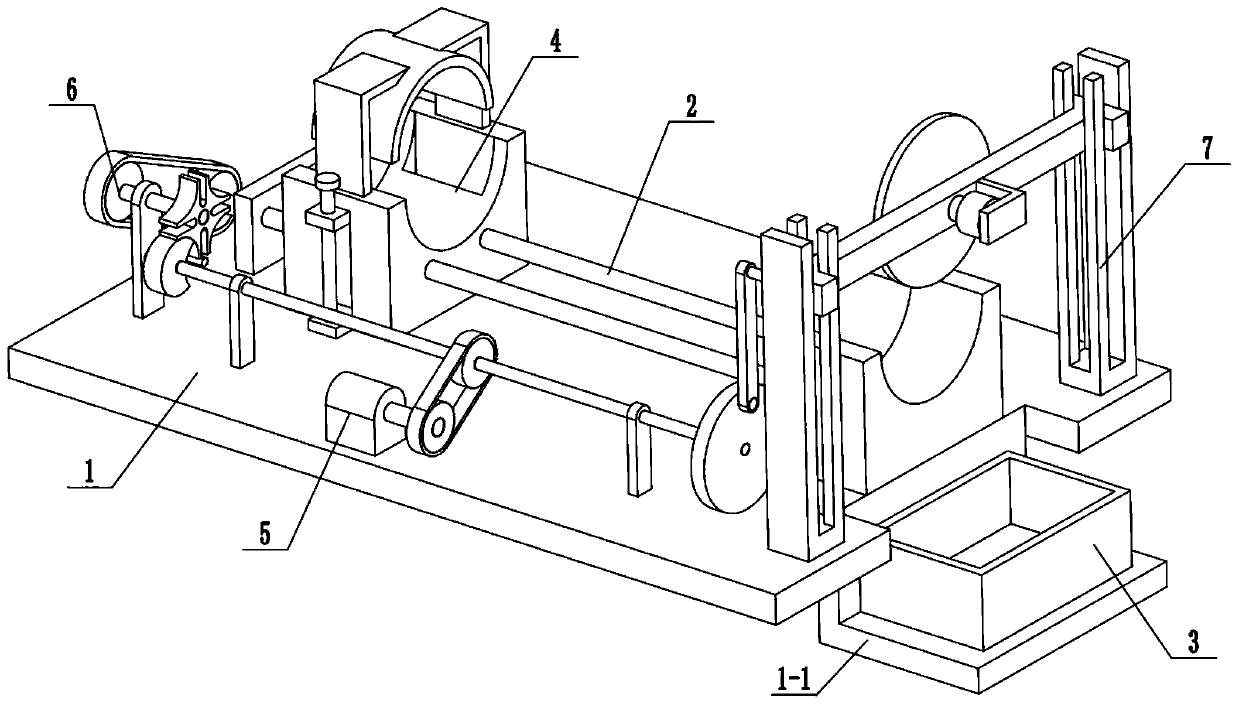

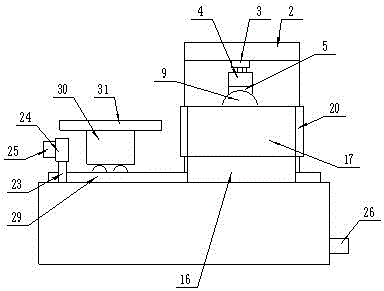

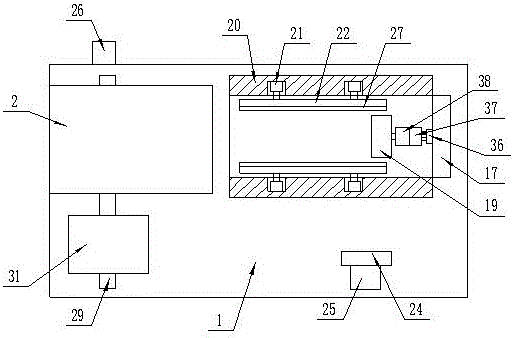

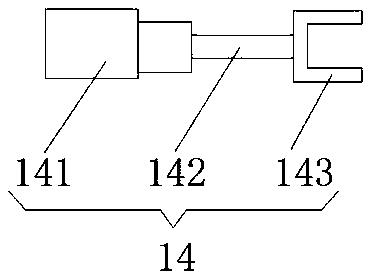

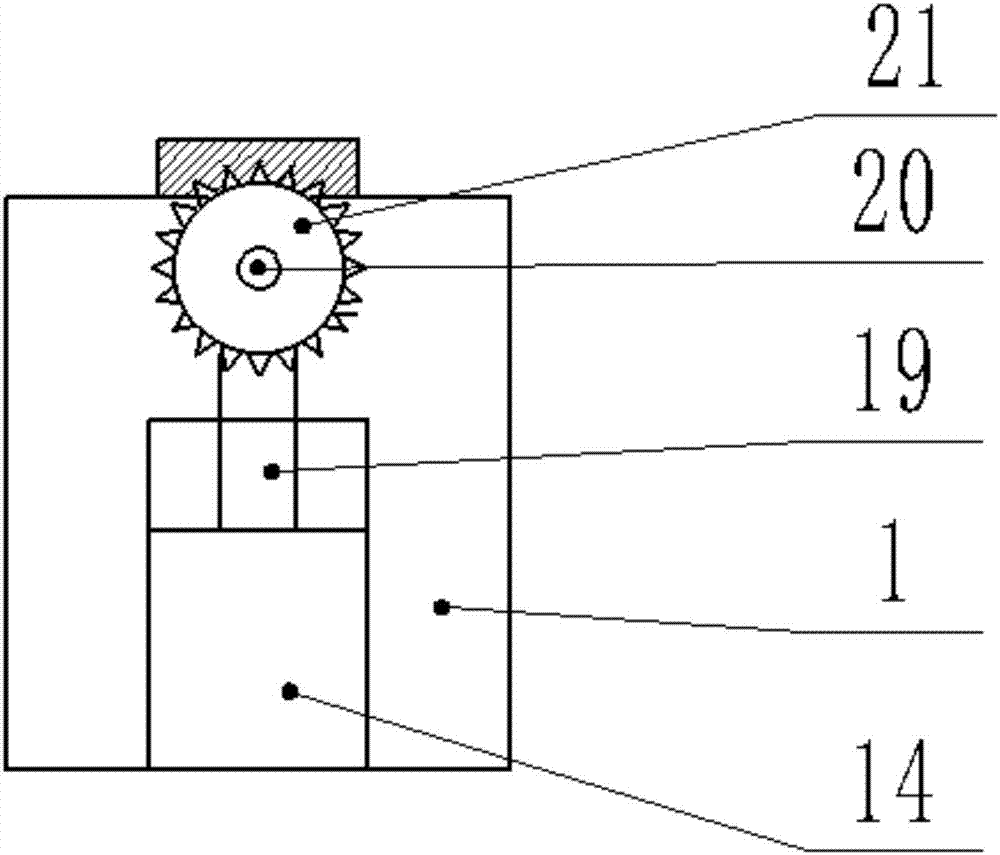

Efficient wood cutting device for construction site

ActiveCN106827097AEasy to cutIntegrity guaranteedProfiling/shaping machinesArchitectural engineeringWood cutting

The invention relates to a cutting device, in particular to an efficient wood cutting device for a construction site, and aims to provide an efficient wood cutting device with high wood cutting efficiency for a construction site. The efficient wood cutting device for the construction site comprises a support rod, a push block, a first slide rail, a cutting table, a first slide block, a rack, a gear, a connecting rod, a stay cord, a fixed pulley, a top plate, a second slide rail, a second slide block and the like, wherein the cutting table is arranged at the top end of the support rod; the cutting table is provided with a through hole; the left side of the top of the cutting table is provided with the first slide rail; the first slide rail is provided with the first slide block; the top of the first slide block is provided with the rack. By adopting the efficient wood cutting device, the aim of rapidly cutting wood for the construction site is fulfilled; meanwhile, the problems of waste in time and force, low cutting efficiency and uneven cutting caused by manual wood cutting are solved through an electric cutting wheel.

Owner:XUZHOU CAMRY WOOD CO LTD

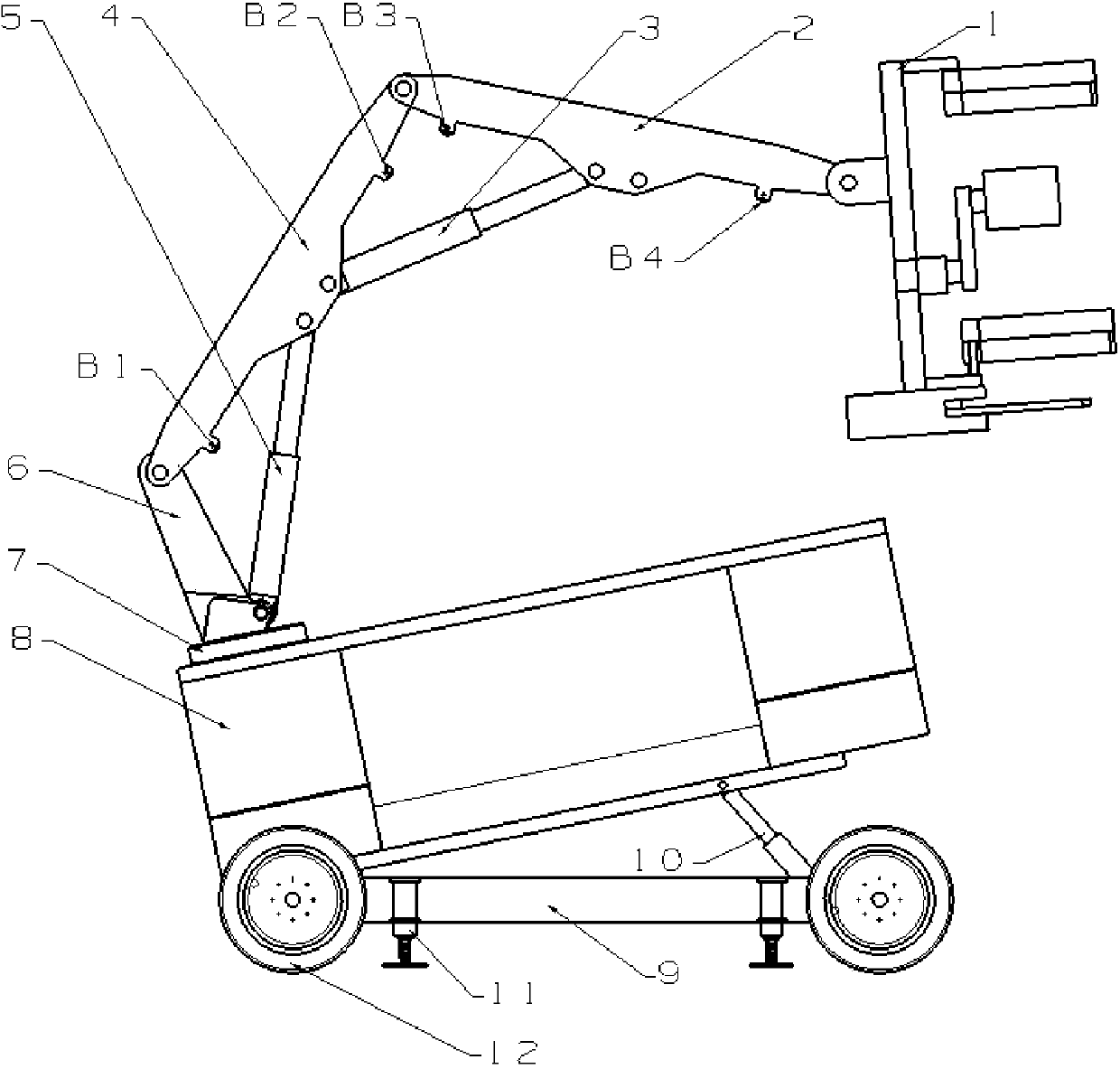

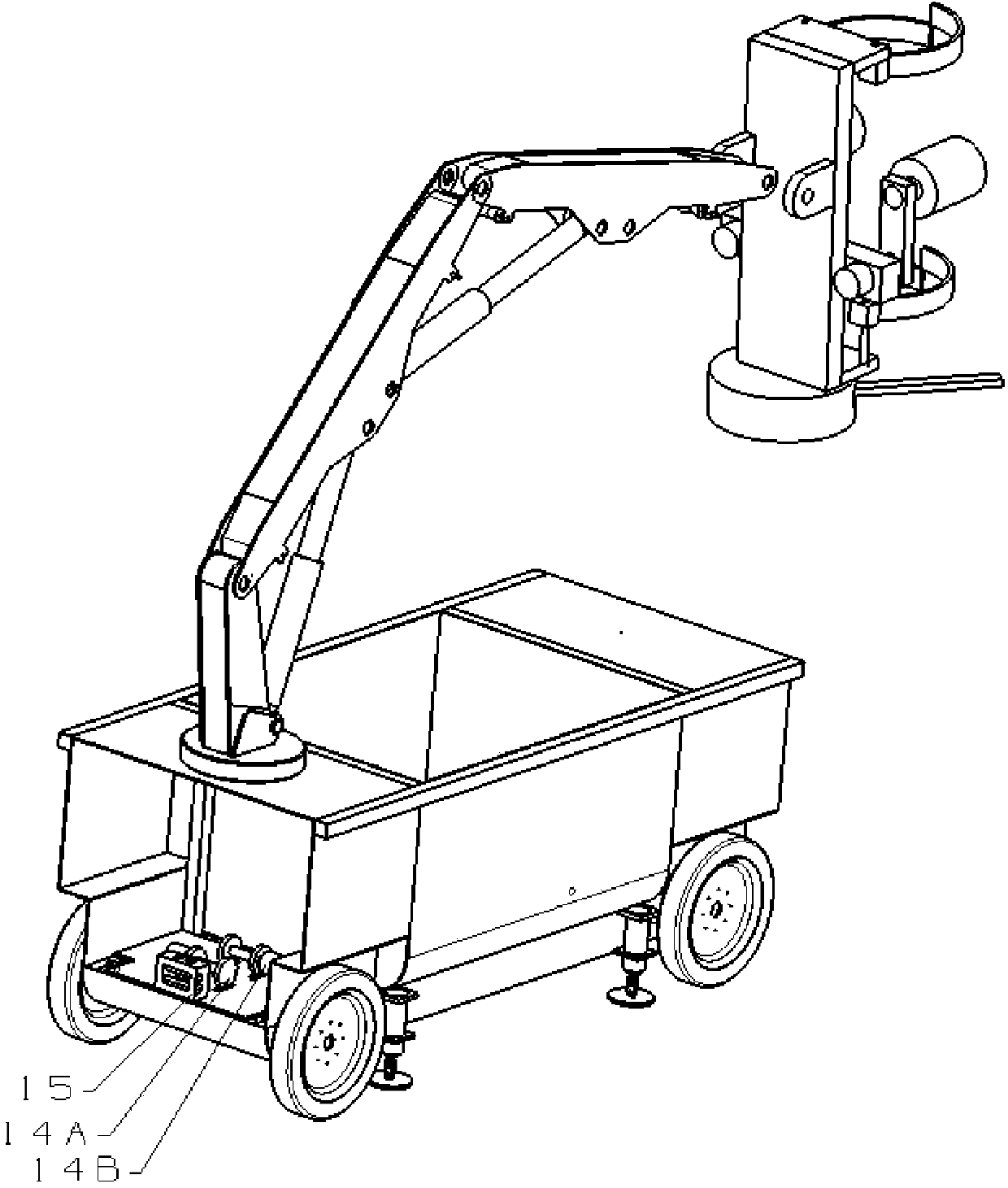

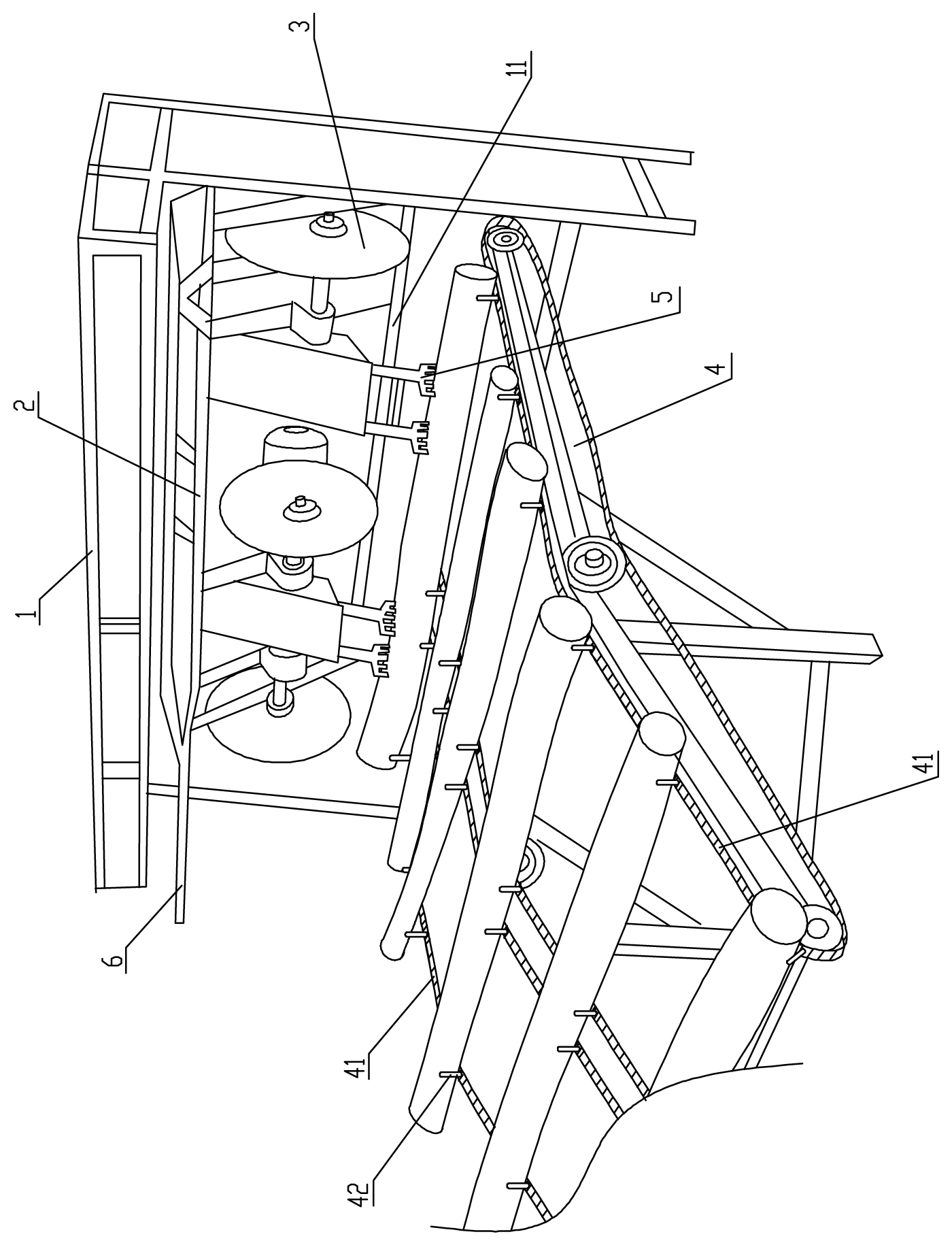

Wood cutting, loading, conveying and unloading all-in-one machine

ActiveCN104170702AFlexible moving processImprove securityForestryCranesPulp and paper industryWindlass

The invention discloses a wood cutting, loading, conveying and unloading all-in-one machine. One end of a wood collecting compartment is hinged to an underframe, the other end of the wood collecting compartment is hinged to a hydraulic balancing device, and the other end of the hydraulic balancing device is hinged to the underframe; the wood collecting compartment is provided with a swing driving device connected with a main arm, the main arm is hinged to a middle arm, the middle arm is hinged to an auxiliary arm, and the auxiliary arm is connected with a feller; an auxiliary arm hydraulic device is mounted between the auxiliary arm and the middle arm, a middle arm hydraulic device is mounted between the middle arm and the main arm, and the two ends of the middle arm and the auxiliary arm are respectively provided with rollers; two windlasses are mounted on the wood collecting compartment, a wire cable of one of the windlasses bypasses the four rollers to be connected with a hook after penetrating a wood unloading wire cable penetration hole site, and the end of a wire cable of the other windlass can be connected with an additionally arranged fixed support; four wheels are mounted below the underframe. The machine provided by the invention integrates four procedures of wood cutting, loading, conveying and unloading to meet the requirements for wood cutting, loading, conveying and unloading in various harsh environments.

Owner:周泓宇 +1

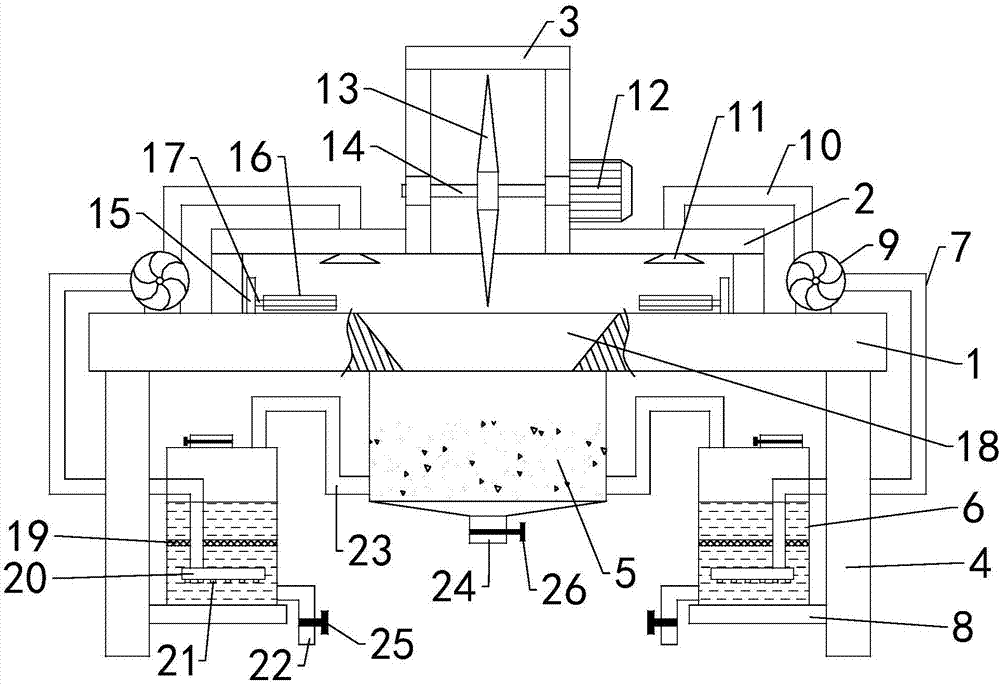

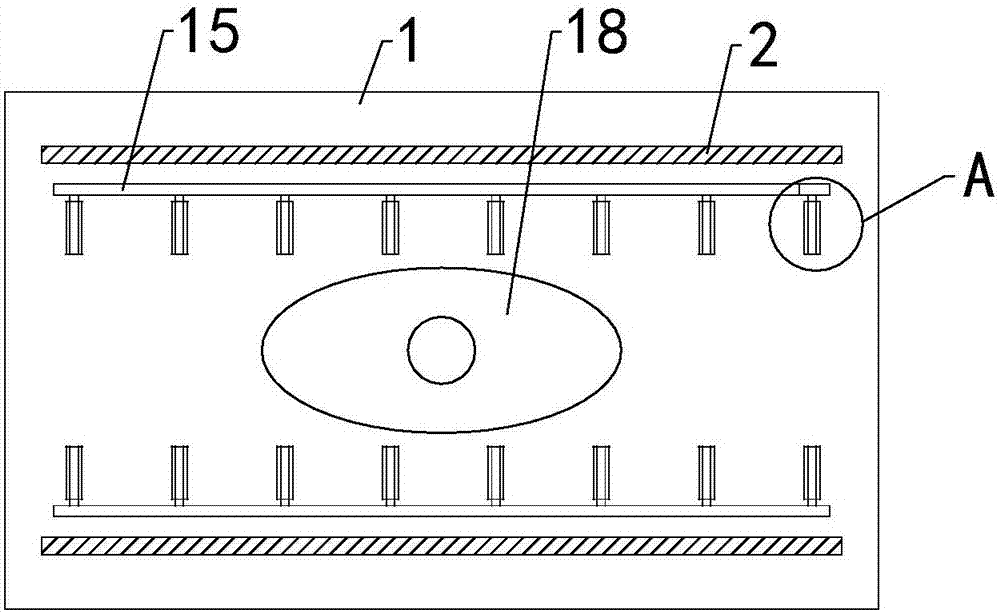

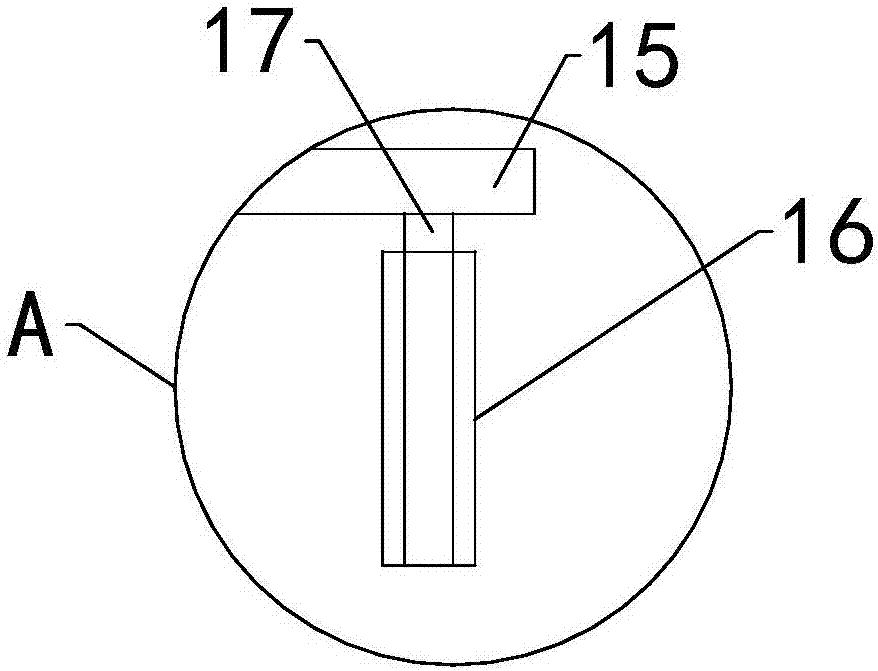

Dust sucking type wood processing cutting device

InactiveCN107214777APrevent accidental touchEasy to processProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningPulp and paper industry

The invention discloses a vacuum-type wood processing and cutting device, which comprises a working table, a protective box, a protective cover, a sawdust collection box and a water tank. The upper surface of the working table is symmetrically fixed and welded. There are a number of rotating shafts on the inner wall of the plate, each rotating shaft is equipped with a conveying roller, and two fans are symmetrically arranged on the upper surface of both ends of the workbench, and the air inlet of each fan is connected. There is an air intake pipeline, the air intake end of the air intake pipeline is connected with the dust collection hood, the lower part of the inner cavity of the water tank is provided with an annular exhaust pipe, and the annular exhaust pipe is connected with the outlet end of the ventilation pipeline, and the inlet of the ventilation pipeline The gas end is connected with the gas outlet of the blower fan, and the upper part of the inner cavity of the water tank is connected with the lower inner cavity of the sawdust collection box through a connecting pipe. The invention has simple structure, high safety, is convenient for processing and cutting wood boards, can effectively absorb dust and collect sawdust, and is suitable for popularization and use.

Owner:张翔

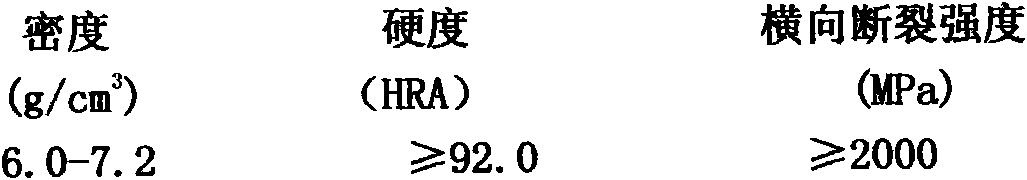

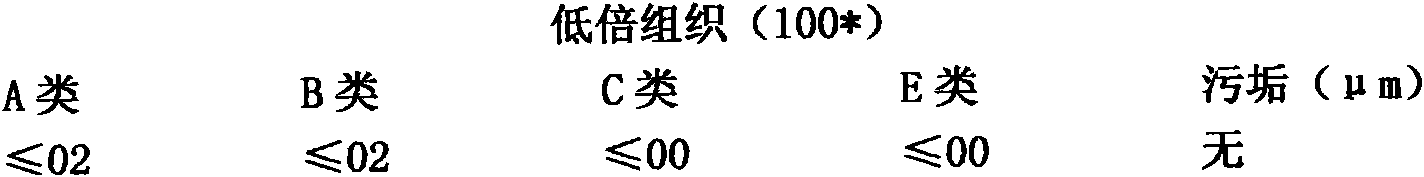

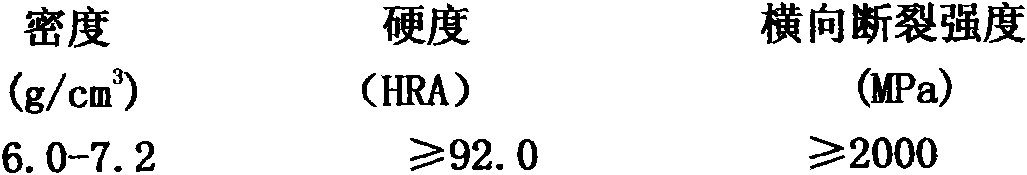

Wood cutting tool material of Ti(CN) cermet and preparation method thereof

The invention provides a wood cutting tool material of Ti(CN) cermet and a preparation method thereof, relating to the technical field of wood cutting tool materials. The Ti(CN) cermet comprises 50 to 65% of Ti(CN) powder, 5 to 10% of cobalt powder, 5 to 10% of nickel powder, 8 to 15% of molybdenum powder, 10 to 20% of tungsten carbide powder, 4 to 8% of tantalum carbide powder and 0 to 1.0% of chromium carbide and vanadium carbide powder. The preparation method comprises the steps of preparation of materials, ball milling, spray drying, compacting, pressure sintering and obtainment of a finished product. Compared to other cutter materials, a cutter prepared in the invention has durability and a service life increased by 1 to 10 times, a cutting speed increased by 1.5 to 3 times and cost for cutting processing reduced by 20% to 40%, and has a wide application prospect in processing of wood composite materials by using cermet cutters.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

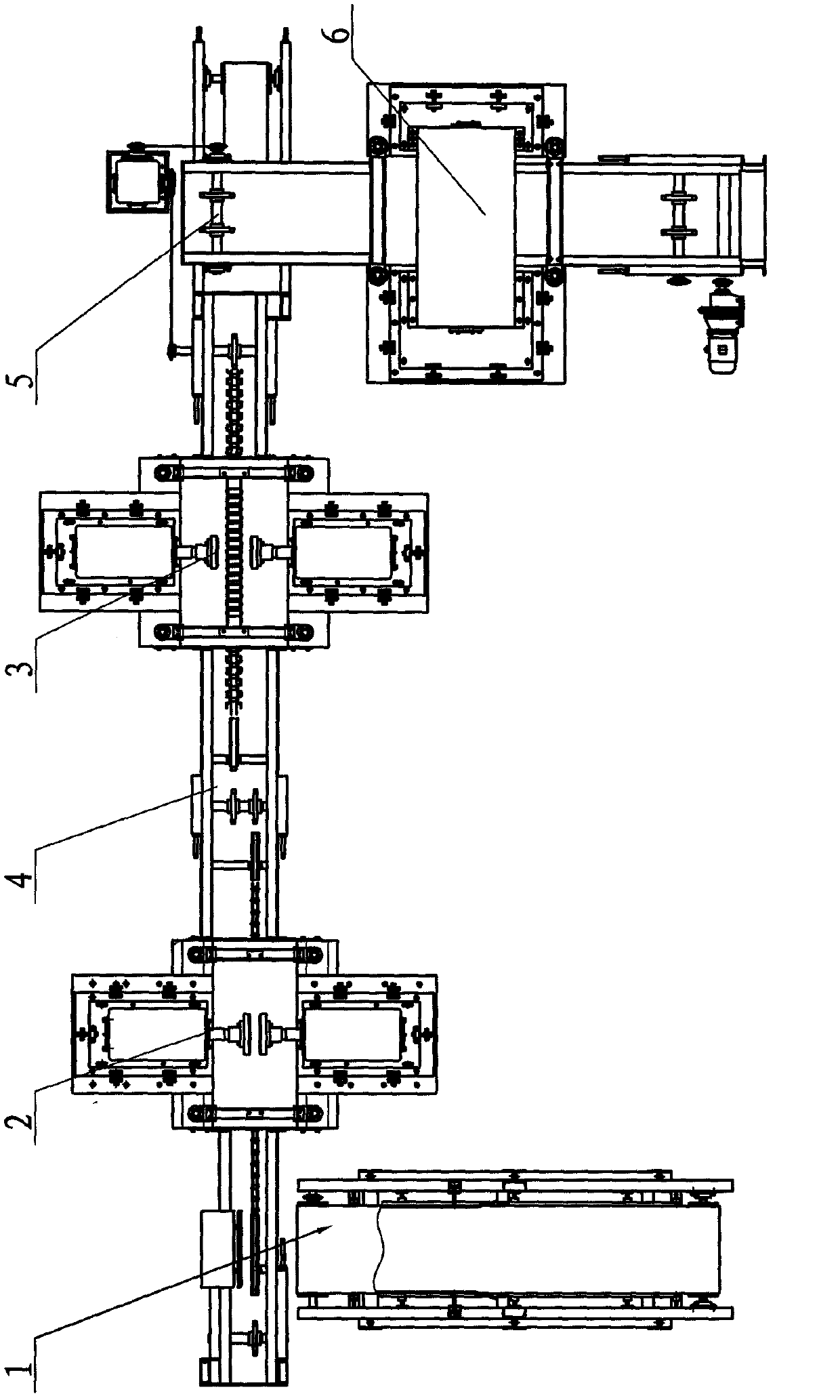

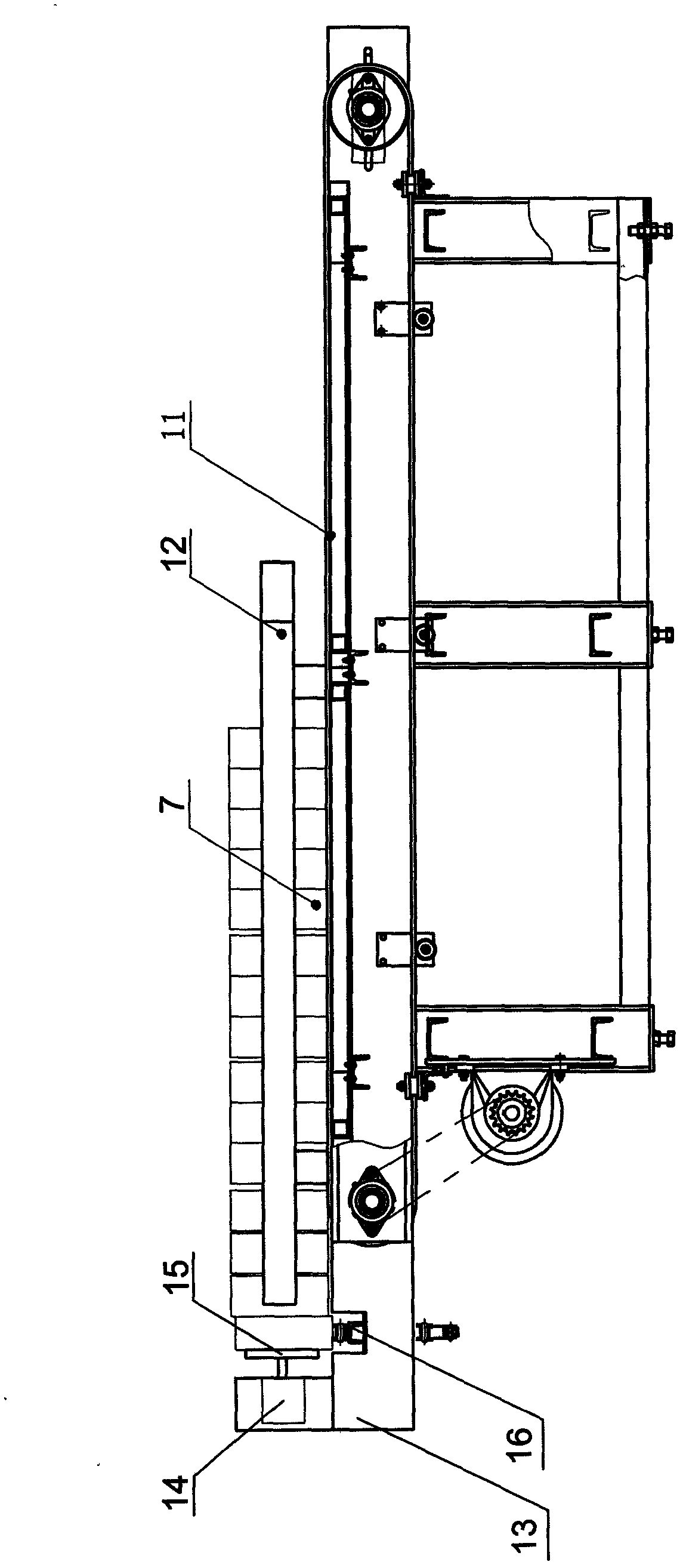

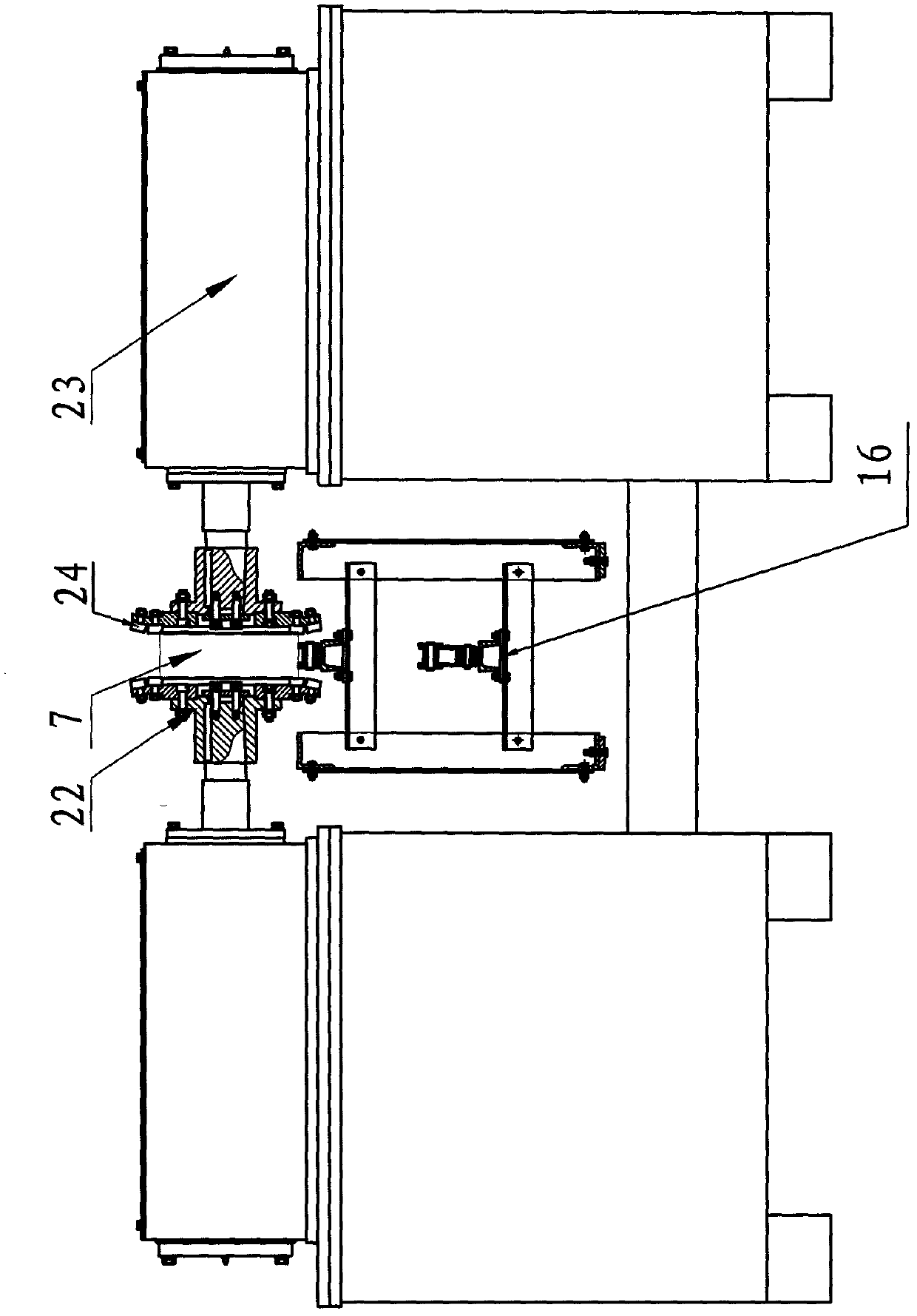

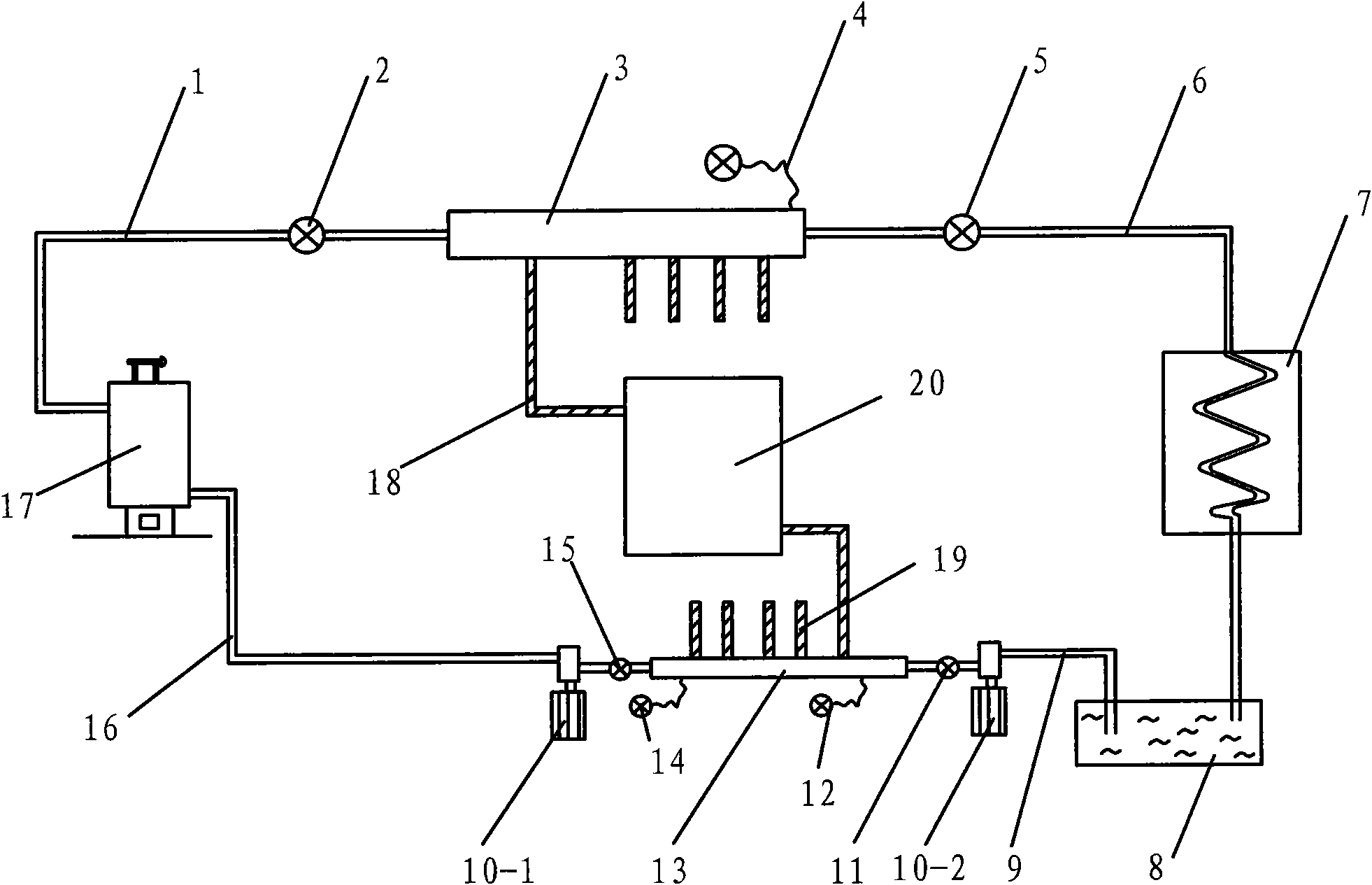

Automatic grinding/slitting system for refractory bricks

InactiveCN102601699AReduced structureSimple structureCeramic shaping apparatusPlane surface grinding machinesBrickWood cutting

The invention belongs to the field of refractory brick manufacturing, and relates to an automatic grinding / slitting system for refractory bricks, which comprises an automatic blank feeding device, a first refractory brick double-face grinding device, a second refractory brick double-face grinding device, a refractory brick blank turnover device, a refractory brick blank synchronous steering device and an automatic slitting system. The automatic blank feeding device is used for intermittently feeding a refractory brick grinding device, the first refractory brick double-face grinding device and the second refractory brick double-face grinding device are used for continuously grinding refractory brick blanks, the refractory brick blank turnover device is used for automatically overturning large faces of the refractory brick blanks from vertical to horizontal, the refractory brick blank synchronous steering device enables the conveying direction of the refractory brick blanks to horizontally turn left or right by 90 degrees and then be conveyed continuously, and the automatic slitting system is used for cutting or slitting the refractory brick blanks. A brick blank conveying mechanism is used as a main moving part of the refractory brick cutting machine, and the refractory bricks are continuously processed in a way similar to wood cutting. The cutting machine is greatly structurally simplified, the problems of high abrasion, complex structure and low operating efficiency of an existing fixed cutting machine are solved, and the automatic grinding / slitting system has the advantages of simple structure, convenience in mounting and maintenance and high machining efficiency.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

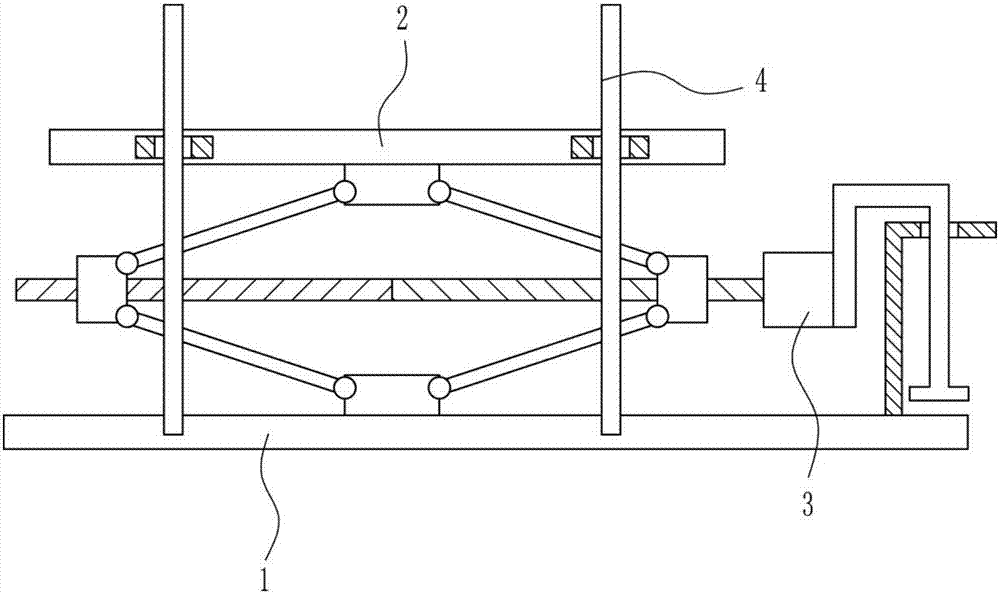

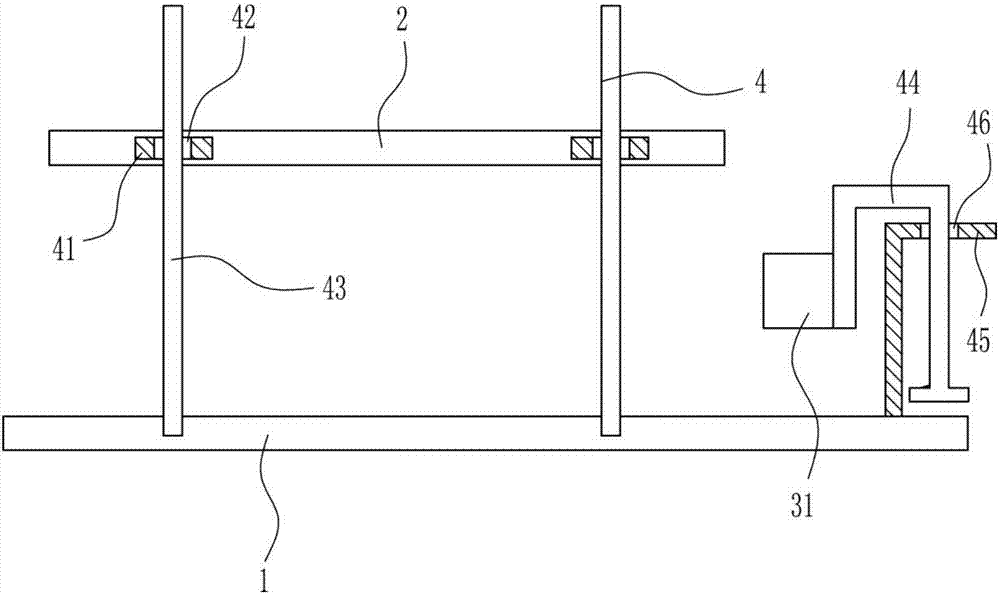

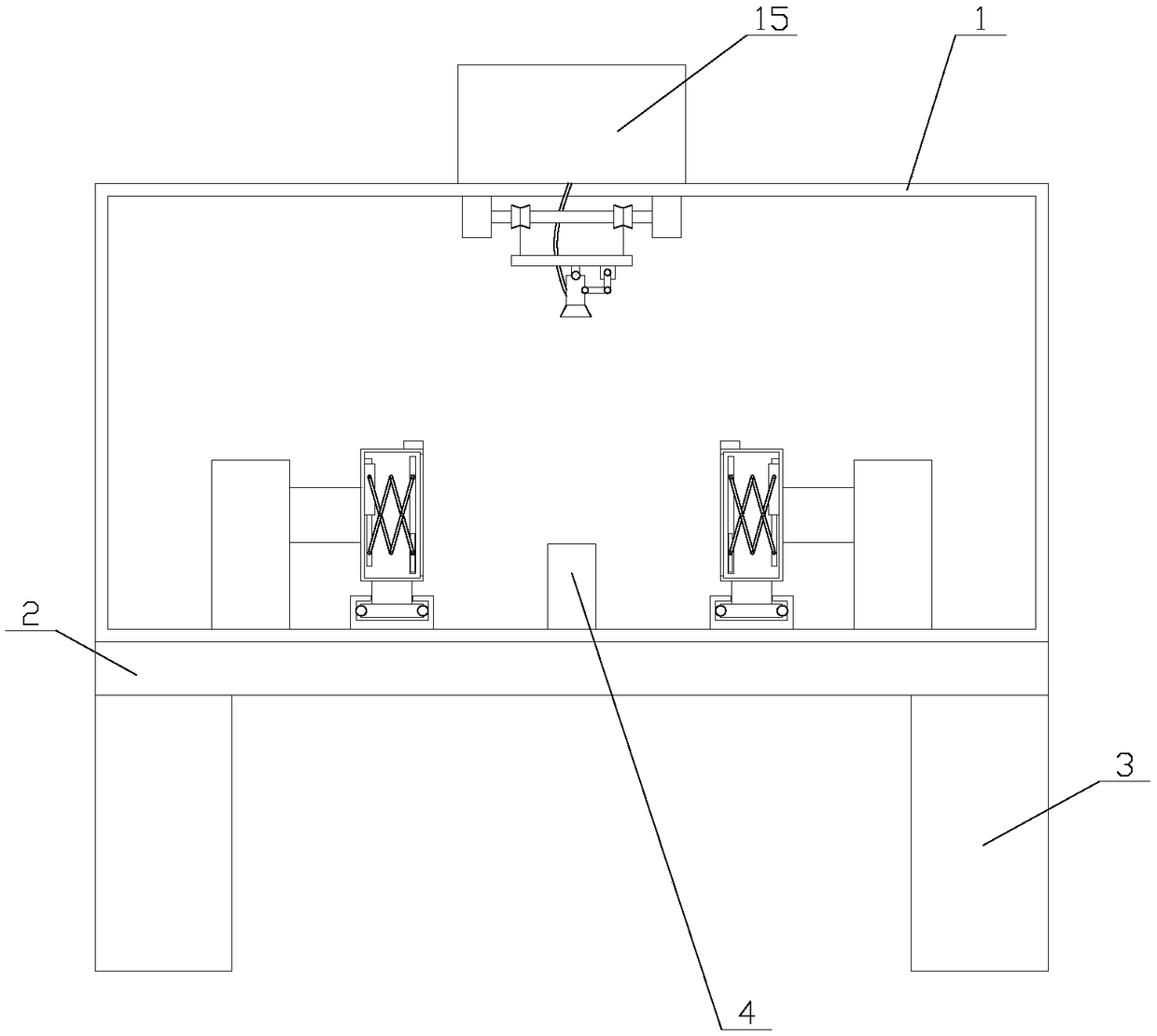

Lifting-type working table used for cutting wood

The invention relates to a lifting-type working table, in particular to a lifting-type working table used for cutting wood. Through the lifting-type working table used for cutting the wood, the height of the working table can be adjusted, and residual wood scraps are convenient to clean. The lifting-type working table used for cutting the wood comprises a first installation base and others; a working table body is arranged above the first installation base, a lifting mechanism is connected between the first installation base and the working table body, and a guiding mechanism is connected to the first installation base, the working table body and the lifting mechanism. The lifting-type working table used for cutting the wood achieves the effects that the height of the working table body can be adjusted, and the residual wood scraps are convenient to clean.

Owner:菏泽中创智慧消防器材有限公司

Wood cutting knife assembly providing improved knife stability

ActiveUS7069969B2Improve stabilityMulti-purpose machinesProfiling/shaping machinesWood cuttingEngineering

Owner:KEY KNIFE

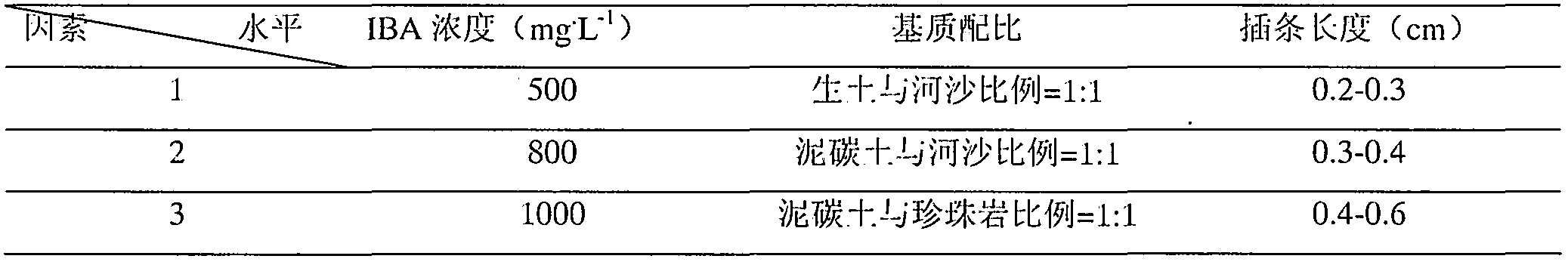

Propagation method for hard wood cutting of 'golden common vetch'

The invention provides a 'propagation method for the hard wood cutting of 'golden common vetch''. The propagation method is characterized by comprising the following steps of: selecting the annual 'golden common vetch' branches free of plant diseases and insect pests and with the coarseness within the range of 0.2-0.6cm in March, shearing into cutting slips with the lengths of 5-10cm, and soaking in water for 12-24 hours; dipping the roots of the cutting slips at 1.5-3.0cm for 10-20s by 75% ethyl alcohol, washing by clean water for 2-3s, inserting into 800-1000mg.L<-1> IBA (iso butyl alcohol) solution for 30-50s, and inserting into a matrix mixed by mire soil and perlite according to the proportion of 1:1, wherein the cottage depth is 1 / 2 of the length of the cutting slips, and one golden common vetch is inserted into every one hole disc; spraying water after cottage, so that the branches are tightly contacted with the matrix; and entering a seedling exercising period when the rooting percentage of the cutting slips reaches up to 60-70% of a sword, and planting when the seedling exercising time is 10-15d. The survival percentage of the cutting slips of 'golden common vetch' propagated by the method disclosed by the invention can reach to be more than 80% of the sword under the condition of a fog system, and the method is ordered in nursery stock, enough in delayed effect, and extremely good in commodity.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

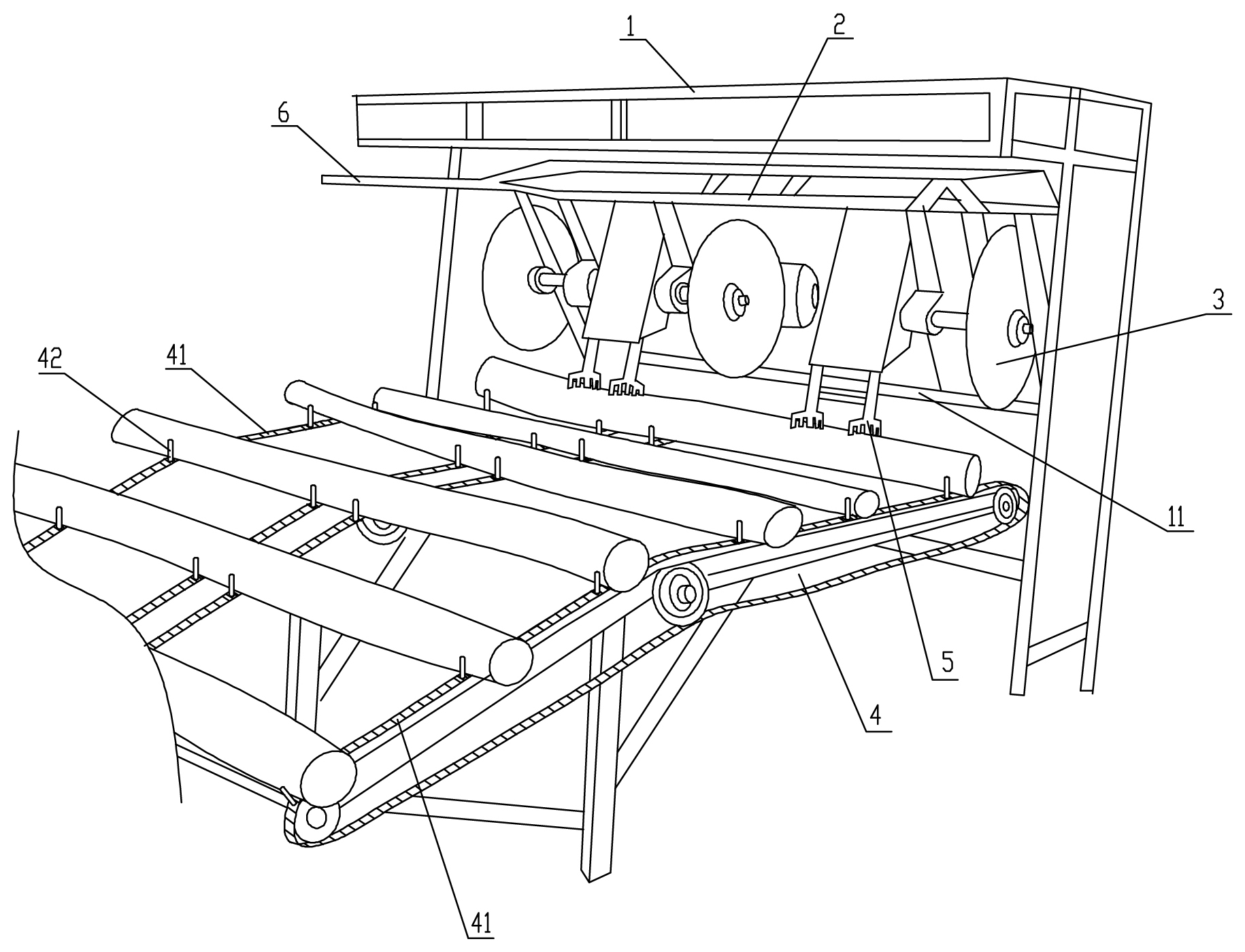

Wood cutting device

InactiveCN103659940AEasy feedingGuaranteed to proceed normallyProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringWood cutting

The invention provides a wood cutting device, which comprises a frame, a plurality of feeding rollers, a bracket, a spindle, cutting knives and a plurality of discharge rollers. The feeding rollers are arranged on the bracket, the bracket is fixed on the frame, the spindle is uniformly provided with a plurality of cutting knives, a discharging end of the frame is provided with a belt conveyor for conveying wood, both ends of the belt conveyor are provided with rollers for driving the conveyer belt to rotate, the discharge rollers are arranged above the belt conveyor, the feeding rollers are provided with damping springs, and the damping springs are arranged between the feeding rollers and the bracket. The wood cutting device can guarantee the stability of feeding and avoid influence of vibration of wood on cutting accuracy in the cutting process. During the whole cutting process, the device can realize automatic feeding, cutting and discharging; and the spindle is evenly provided with the plurality of cutting knives, so as to effectively improve the cutting efficiency.

Owner:简厚诚

Method for propagating vigorous clonal Malus prunifolia own-rooted stock seedlings of apple trees

InactiveCN104126396AImprove uniformitySolve the problem of large quality differencesHorticultureSeedlingWood cutting

The invention relates to a method for propagating vigorous clonal Malus prunifolia own-rooted stock seedlings of apple trees. According to the method, Malus prunifolia cutting seedlings are propagated first based on the Malus prunifolia hard wood cutting technology, and the cutting seedlings are kept at the origin position to serve as stock plants; a Malus prunifolia own-rooted stock seedling layering propagation garden is built according to the vertical layering method, and the Malus prunifolia own-rooted stock seedlings are propagated in batches every year afterwards; after the Malus prunifolia own-rooted stock seedling vertical-layering propagation garden is built, the clonal Malus prunifolia own-rooted stock seedlings can be continuously harvested in 15-20 years. By means of the method, the operation of carrying out Malus prunifolia hard wood cutting propagation by crop rotation and land search every year is not needed, and more than 1 / 3 of nursery land is saved for propagating dwarf interstock apple seedlings.

Owner:NORTHWEST A & F UNIV

Cuttage rapid-propagation seedling culture method for elevated sand bed camphora wood cutting orchard tissue culture seedling twigs

ActiveCN102301883ALow costGood genetic traitsGreenhouse cultivationCultivating equipmentsSocial benefitsPlantlet

The invention discloses a cuttage rapid-propagation seedling culture method for elevated sand bed camphora wood cutting orchard tissue culture seedling twigs. The method comprises the following steps: taking semi-lignified twigs formed by camphora wood cutting orchard tissue culture seedling planted on the elevated sand bed as a cutting wood; treating the cutting wood by greenplant growth regulator-ABT6 rooting solution; inserting the treated cutting wood into a mixed medium which contains peat soil and coconut bran in a weight ratio of 3:(1-1.5); culturing on a pressure lifting seedling culture bed capable of automatically controlling temperature, controlling moisture and controlling light; controlling parameters of air humidity to 85%, medium moisture content to 50% and illumination intensity to 1500lux; and after one month, causing the cutting wood to form an integral plant, wherein the cuttage survival rate is 80-85%. The method has the advantages of scientific seedling culture facility, high propagation speed, large seedling culture amount, short seedling culture time, high afforestation survival rate, low wood culture cost, good economic benefit and social benefit and the like, offspring can keep the excellent hereditary character of a stock plant, and the asexual seedling culture of camphora fine variety is achieved.

Owner:GUANGXI FORESTRY RES INST

Wood cutting device for forestry engineering

ActiveCN109732707ASmooth cutNot easy to shiftFeeding devicesGripping devicesEngineeringMaterials processing

The invention relates to the field of building material processing equipment, in particular to a wood cutting device for forestry engineering. A rectangular through slot is formed in the middle end ofthe right end of a base; an L-shaped seat plate is fixedly connected into the rectangular through slot; a wood collecting box is placed onto the L-shaped seat plate; a feeding slide base is fixedly connected onto the base; the wood collecting box is positioned below the right end of the feeding slide base; a wood fixed slide base is connected on the feeding slide base; a power device is fixedly connected to the front end of the base; the power device is in transmission connection to a cutting assembly through a belt; and the cutting assembly is fixedly connected to the right end of the base.The wood cutting device can fix wood, and the fixed wood is not liable to deviate, so that wood cutting is more smooth, wood scrap is avoided, and waste of wood resources is avoided; and an intermittent feeding mechanism can automatically feed the fixed wood to cut, so that a constructor is prevented from risk during operation.

Owner:陈芬芬

Red globe grape seedling raising method

A red globe grape seedling raising method comprises the following steps of collection of cuttings: collecting branches which are trimmed in the winter, are pure in variety, have full buds, are mature and robust, do not have quarantine pests, and are 0.8-1.2 centimeters in thickness as cuttings, and using an electric heating line cutting forcing method; root cutting: forming holes in a seedbed by using a root cutting awl with the thickness of 2cm in the last ten-day of April, and slowly placing the treated cuttings in the holes; bud control: (a) trimming in winter: reserving a main stem by 1.6-1.9m, selecting branches which grow sufficiently, are high in maturity and do not have plant diseases or insect pests as final mother branches, and reserving 3-5 final mother branches per meter; and construction of a shed frame: using a T-shaped shed frame, pulling a first steel wire on each perpendicular concrete pole at a position distant from the ground by 1.2-1.4 meters, sleeving bags outside clusters one by one from the young fruit period to the fruit mature period in a grape growing process, sealing openings of the bags, and reserving air vents in bag bodies.

Owner:张家港市塘桥果艺园

Wood floor carbonizing processing method

InactiveCN101570031AEasy to operateQuality improvementWood compressionWood charring/burningEngineeringWood plank

The invention refers to the field of wood floor processing, in particular to a wood floor carbonizing processing method. The method comprises the following steps: (1) pretreatment: cutting wood into the shape of floor to obtain floor planks; (2) heat pressing carbonizing: putting the floor plank into a heat pressing machine for high temperature carbonizing to obtain carbonized wood planks; (3) cooling: putting the carbonized wood planks into the heat pressing machine to be cooled to lower than 160 DEG. C by the cold oil device of the heat pressing machine; (4) finish product producing: withdrawing the cooled carbonized wood plank from the heat pressing machine and executing post-treatment to obtained finished carbonized wood floor product. This method finishes carbonizing and cooling directly in the same heat pressing machine, thus causing the operation to be simple and convenient and the whole carbonizing process to be safe and controllable with higher yielding rate and higher quality of the finished floor product.

Owner:周发荣

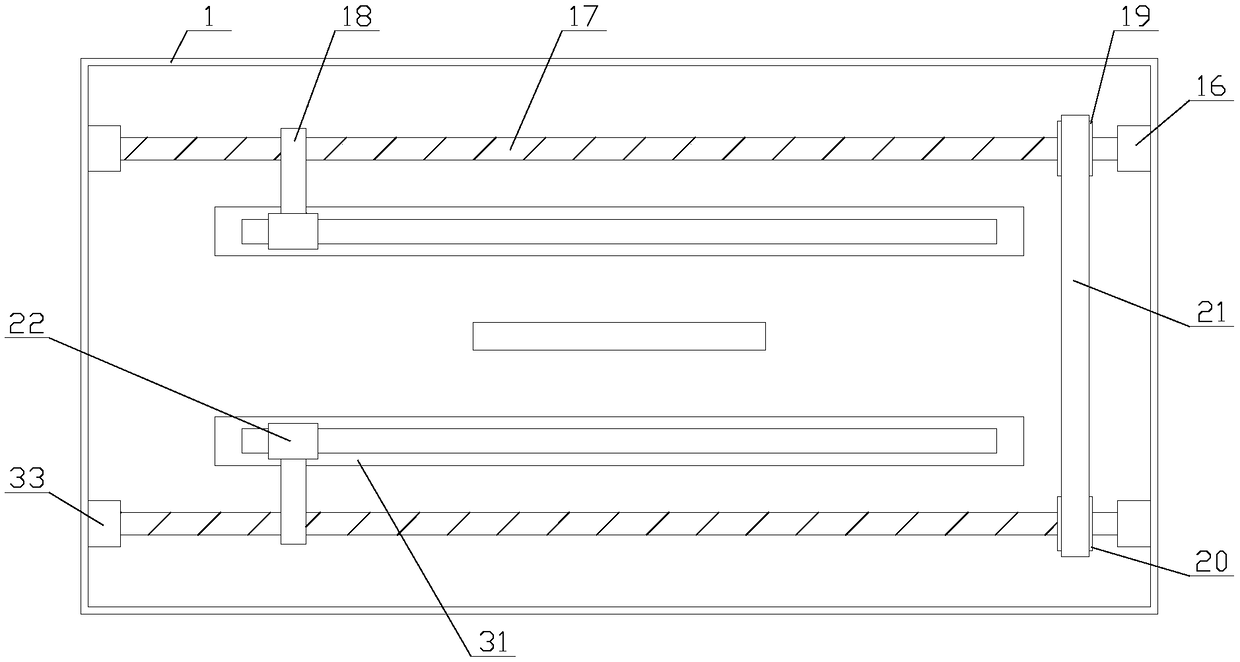

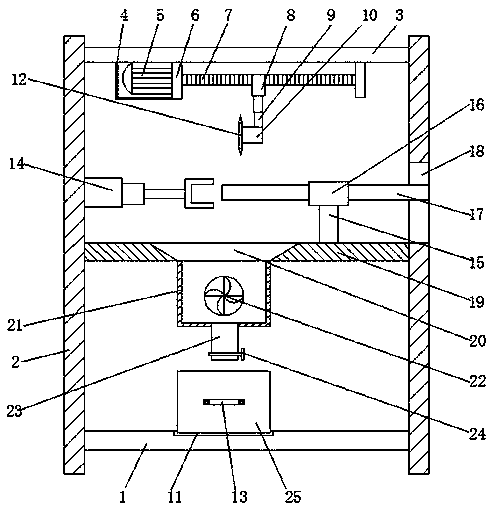

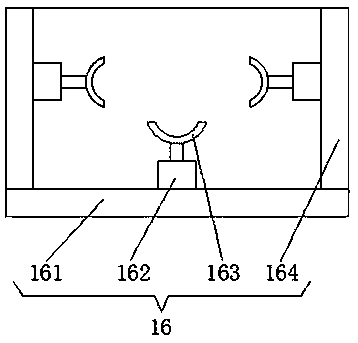

Automatic wood cutting machine

InactiveCN107053344AImprove securityImprove clamping effectFeeding devicesGripping devicesFixed frameSlide plate

The invention relates to the field of furniture manufacturing, in particular to an automatic wood cutting machine. The automatic wood cutting machine comprises a fixed frame and a movable frame. The movable frame is arranged above the fixed frame. A guide rail and a lead screw are arranged between the fixed frame and the movable frame. The fixed frame comprises a top plate, a cutting mechanism and a discharging mechanism. The discharging mechanism comprises a discharging outlet formed in the top plate and a discharging slide. The cutting mechanism is a cutting machine body fixed to the lower portion of the top plate. The top of a cutting blade of the cutting machine body is higher than the top of the top plate. The movable frame comprises a cutting area located above the discharging outlet, a clamping mechanism, a length positioning mechanism and a pushing mechanism. The clamping mechanism, the length positioning mechanism and the pushing mechanism are sequentially arranged. The cutting area is arranged between the clamping mechanism and the length positioning mechanism. The clamping mechanism is connected with the top of the length positioning mechanism through a connecting rod. The clamping mechanism is connected with the bottom of the pushing mechanism through a sliding plate.

Owner:ZOY HOME FURNISHING CORP

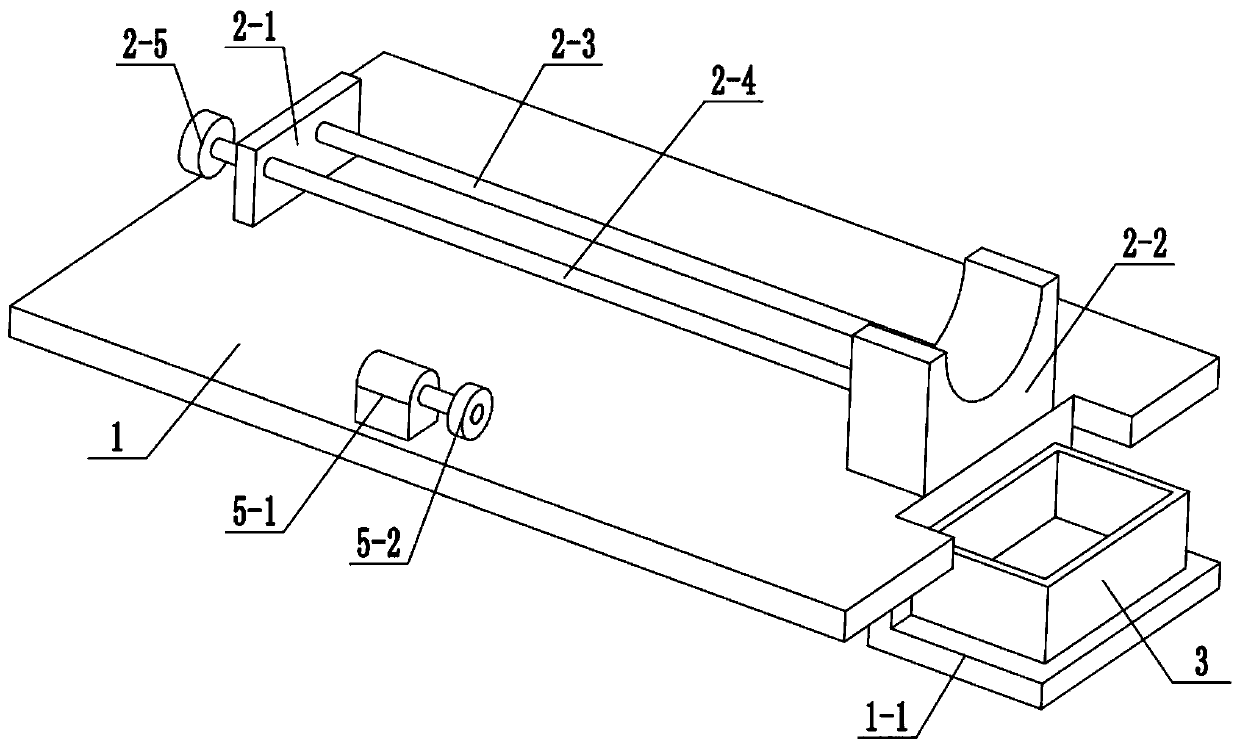

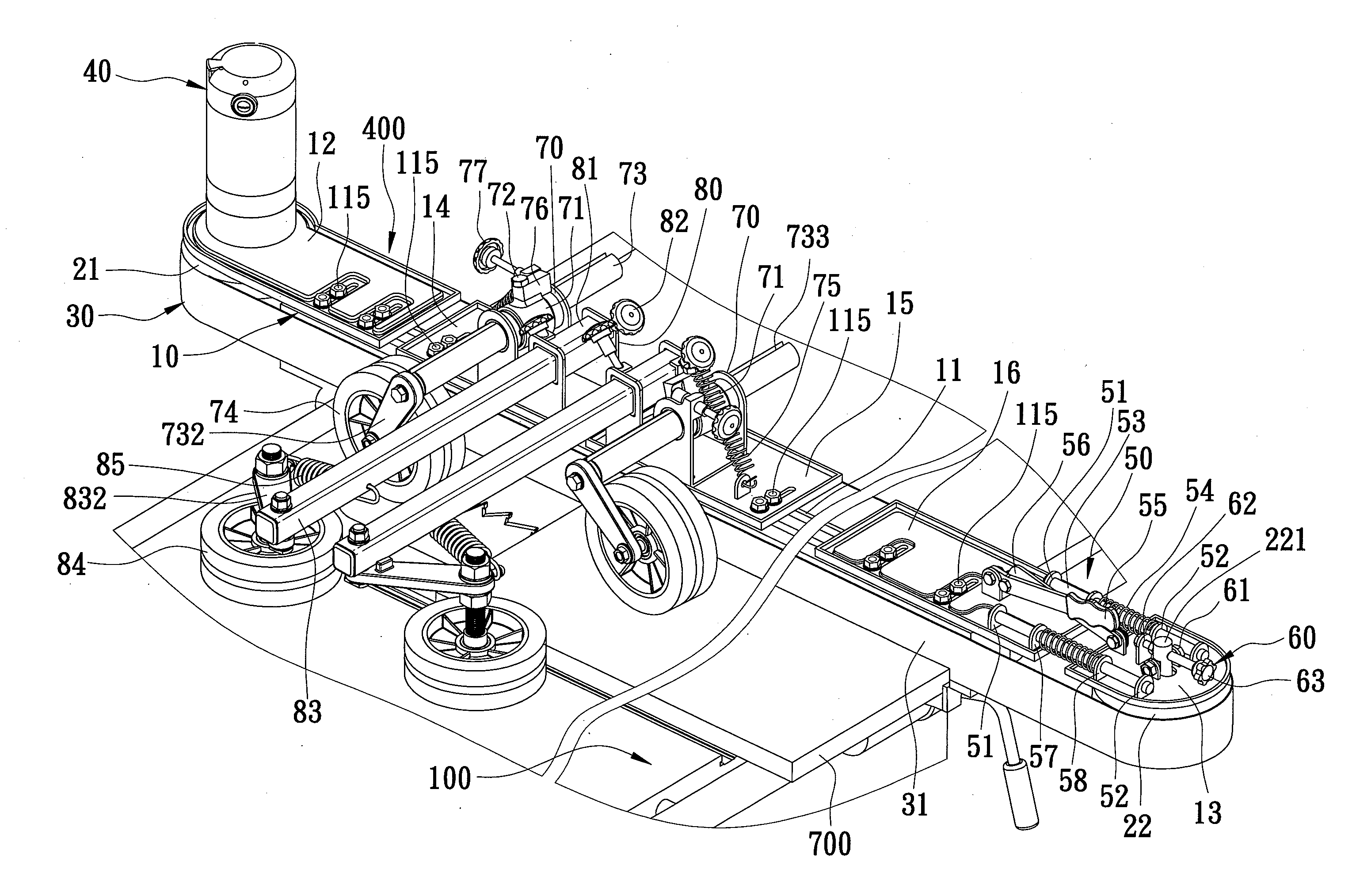

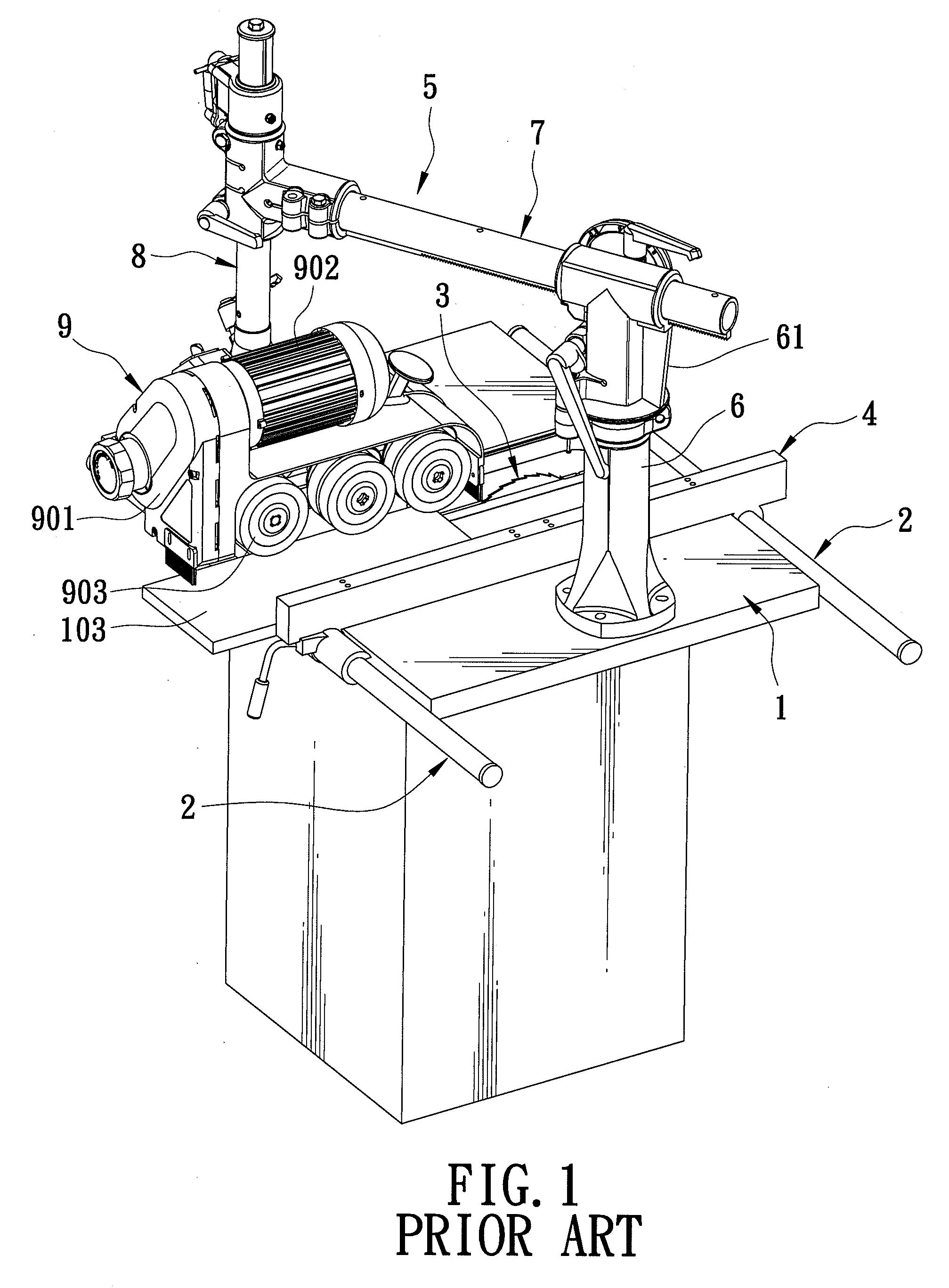

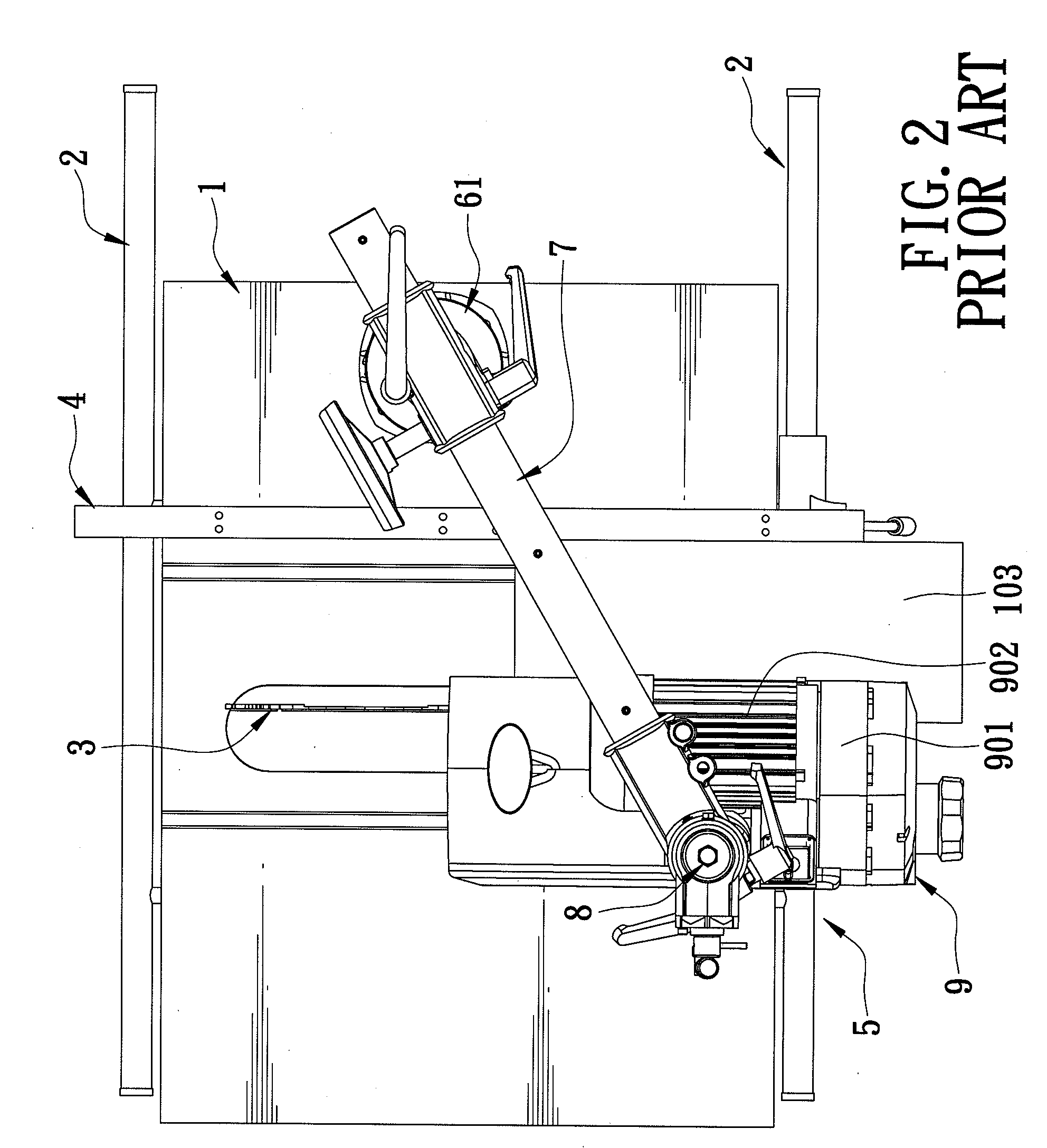

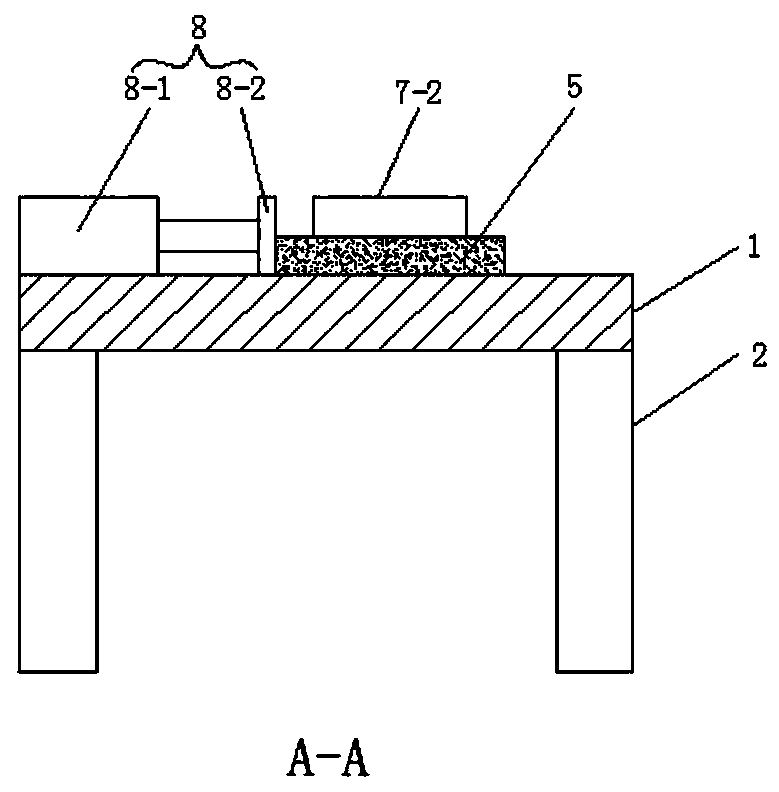

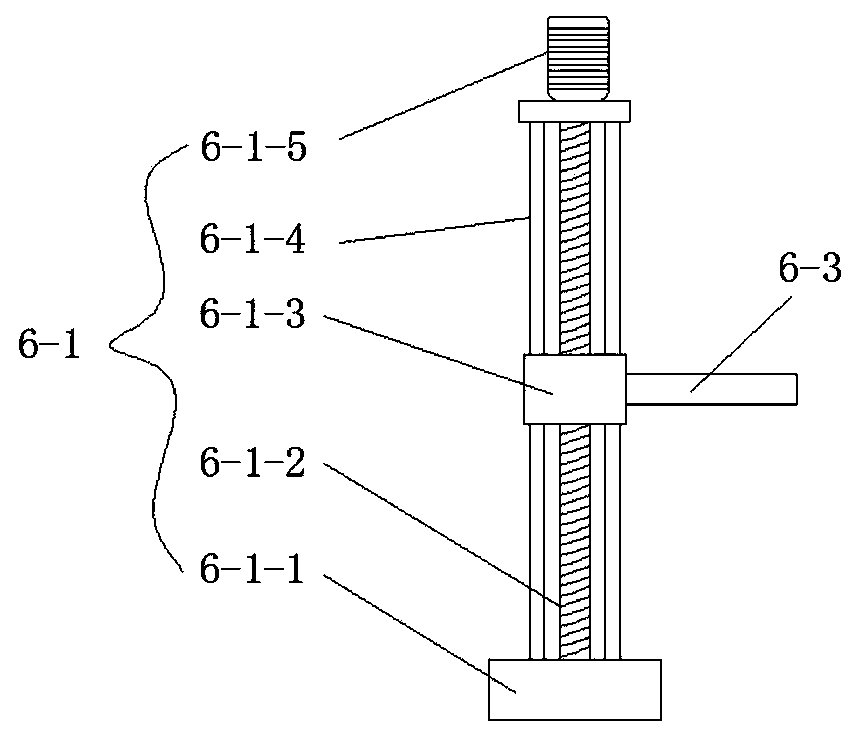

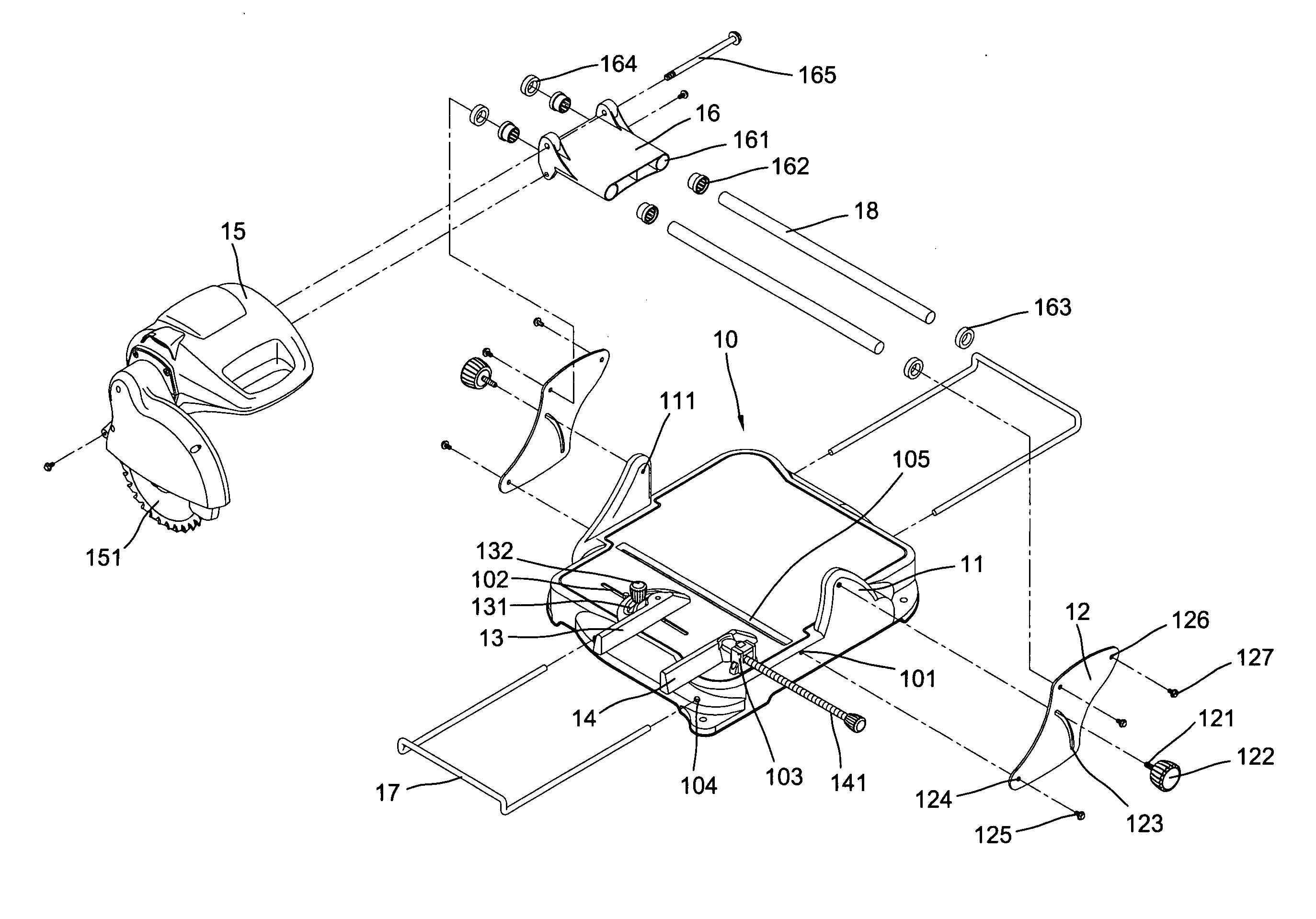

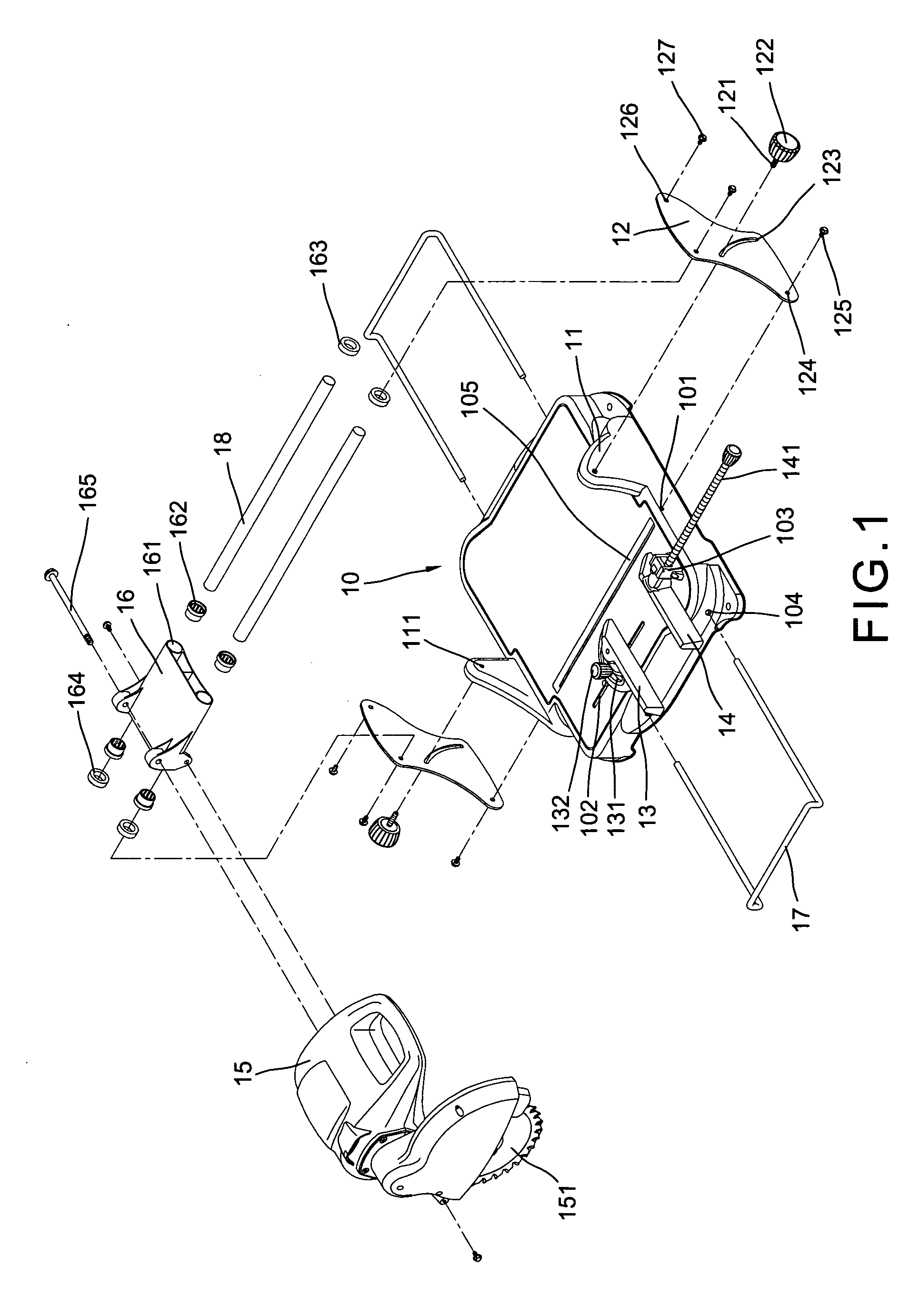

Workpiece-Advancing Device for a Wood Cutting Apparatus

InactiveUS20090049969A1Prevent deviationWood feeding arangementsFeeding devicesEngineeringWood cutting

A workpiece-advancing device includes: a slider mounted on a worktable; a workpiece-driving unit mounted on the slider and including a pair of driving rollers and a belt trained on the driving rollers and having a portion adapted to abut against a workpiece and movable relative to the slider for driving movement of the workpiece on the worktable; and a positioning mechanism including an urging unit, a supporting arm unit mounted on the slider and passing through a lateral side of the slider, and an abutting unit mounted on the supporting arm unit and urged by the urging unit so as to be adapted to abut against the workpiece and so as to prevent the workpiece from deviating from a predetermined cutting path.

Owner:LIN CHING CHI

Flower seedling wood cutting medium

The invention discloses a flower seedling wood cutting medium, and belongs to the technical field of soilless culture. The medium comprises the following components in percentage by volume: 30 to 50 percent of vinegar residues, 10 to 20 percent of manioc waste, 10 to 15 percent of plant ash, 10 to 20 percent of vermiculite, 10 to 20 percent of turf, wherein the water content of the medium is between 25 and 40 percent, the total porosity is between 65 and 90 percent, the organic matter content is more than or equal to 20 percent, the total nutrition content is between 1 and 3 percent, the grain diameter is between 0.1 and 3.5mm, the volume weight is between 0.2 and 0.8g / cm3, the gas-water ratio is 1:(2-4), the EC (nutrient liquid concentration) value is between 1 and 3mS / cm, and the pH is between 6 and 7.5. According to the flower seedling wood cutting medium, organic wastes are mainly used as raw materials and fermented at high temperature to produce soilless culture medium, so that waste materials are changed into valuable things, and harmful substances are changed into benefits things. The medium is low in cost, light in weight and comprehensive in nutrition, is suitable for flower seedling wood cutting seedling, and is an excellent medium for soilless culture of garden crops.

Owner:江苏培蕾基质科技发展有限公司

Adjustable wood board cutting processing device

InactiveCN107839021ASimple structureEasy to operateGuide fencesFeeding devicesConnection tableAgricultural engineering

The invention discloses an adjustable wood board cutting processing device and relates to the technical field of board processing equipment. The adjustable wood board cutting processing device comprises a workbench, the four corners of the lower end of the workbench are provided with supports correspondingly, a push mechanism, two side plates for positioning boards, a cutting mechanism and a limiting mechanism are sequentially arranged on the workbench from left to right, the push mechanism comprises a lead screw arranged inside the workbench, the lead screw is provided with a nut base, the nut base is sleeved with a push block which can slide on the workbench, the lead screw is connected with a stepping motor arranged on the outer side of the workbench, the cutting mechanism comprises a lifting mechanism arranged on the workbench, the lifting mechanism is connected with a supporting plate capable of moving on the lifting mechanism, the supporting plate is provided with a motor, the motor is connected with a saw blade, the limiting mechanism comprises an air cylinder arranged on the workbench, and a piston rod of the air cylinder is connected with a baffle. The adjustable wood board cutting processing device has the advantages of being simple in structure, convenient to operate and easy to adjust.

Owner:SICHUAN GUANTENG TECH CO LTD

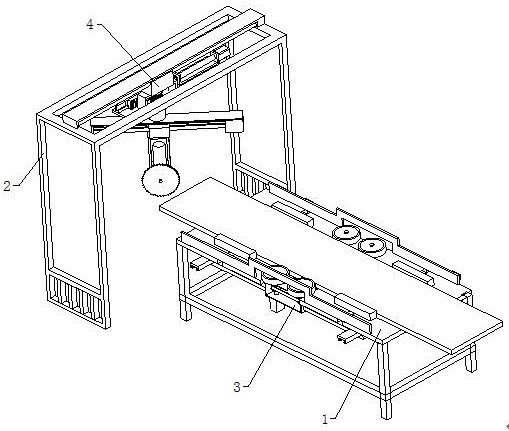

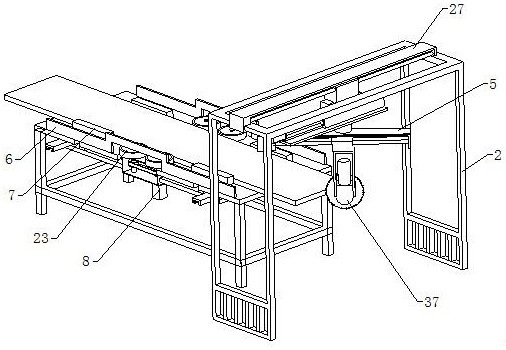

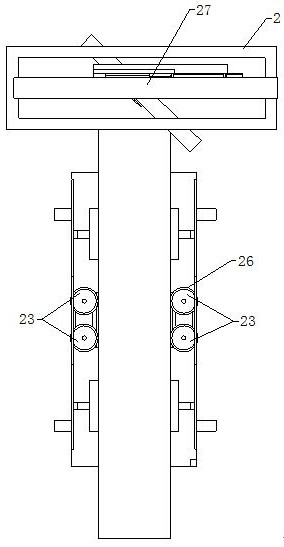

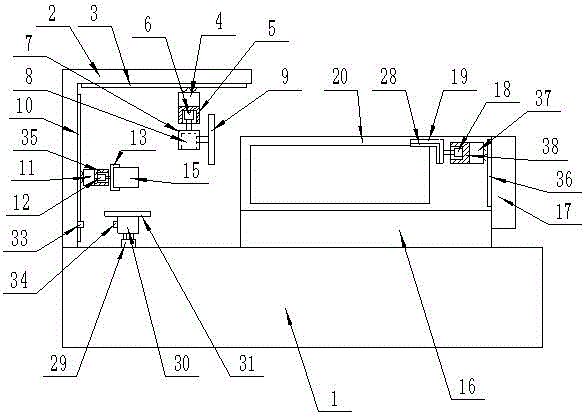

Construction wood-cutting machine with adjustable angle

InactiveCN112140241AReduce labor costsImprove cutting efficiencyFeeding devicesGripping devicesAgricultural engineeringWood machining

The invention relates to the technical field of construction wood cutting, in particular to a construction wood-cutting machine with an adjustable angle. The construction wood-cutting machine with theadjustable angle comprises a conveying table, a portal frame vertically erected at one end of the conveying table, a conveying and positioning mechanism which is arranged on the conveying table and used for transferring wood to a processing portion of the portal frame and conducting positioning, and a rotary adjusting and cutting mechanism which is arranged on the portal frame and used for conducting angle cutting on processing ends of the wood conveyed by the conveying and positioning mechanism, and the construction wood-cutting machine with the adjustable angle is characterized in that therotary adjusting and cutting mechanism comprises a horizontal overturning board which is horizontally arranged at the upper end of the interior of the portal frame and can horizontally rotate. By means of the construction wood-cutting machine with the adjustable angle, the wood can be automatically conveyed and positioned, and cutting is conducted with the angle of a cutting machine body automatically adjusted according to angles needed for wood cutting, so that the labor cost is reduced, and the cutting efficiency is improved.

Owner:潘长艳

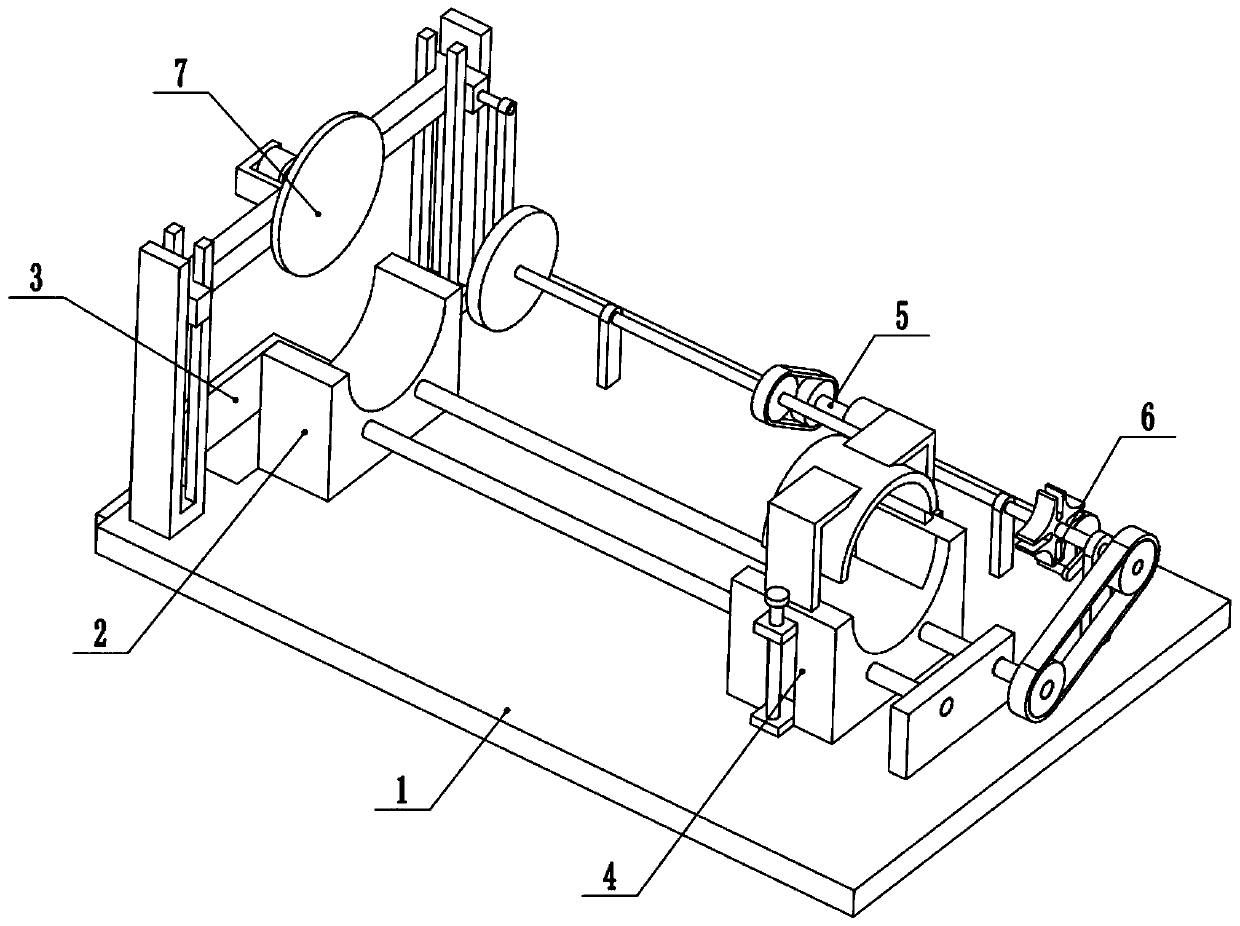

Wood cutting and transporting device

ActiveCN106378831AEasy to operateReduce maintenance costsProfiling/shaping machinesHydraulic cylinderElectricity

The invention discloses a wood cutting and transporting device. The wood cutting and transporting device comprises a workbench. A fixed cutting mechanism is arranged on the upper surface of the workbench. A vertical rod is arranged on the upper surface of the workbench and located in front of a fixing table. A third vertical installing plate is arranged on the upper surface of the vertical rod. A controller is arranged on the front surface of the third vertical installing plate. A commercial power interface is arranged on the rear surface of the workbench. A supply terminal of the controller is connected with the commercial power interface through a wire. The output end of the controller is connected with a first electric trolley, a fourth electric trolley, a hydraulic cylinder, a rotation motor, a second electric trolley, an electric push rod, a mini-type linear motor, a second electric push rod and a third electric push rod through wires. The wood cutting and transporting device has the beneficial effects that semiautomatic promoted and fixed cutting is achieved, the cutting speed is high, automatic transporting is achieved, manpower is liberated, potential safety hazards are reduced, the work efficiency is improved, using is convenient, and novelty is high.

Owner:徐州融创达电子科技有限公司

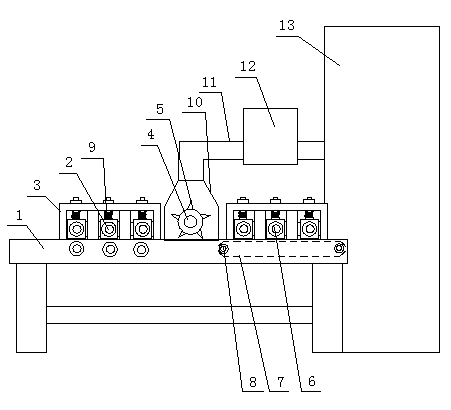

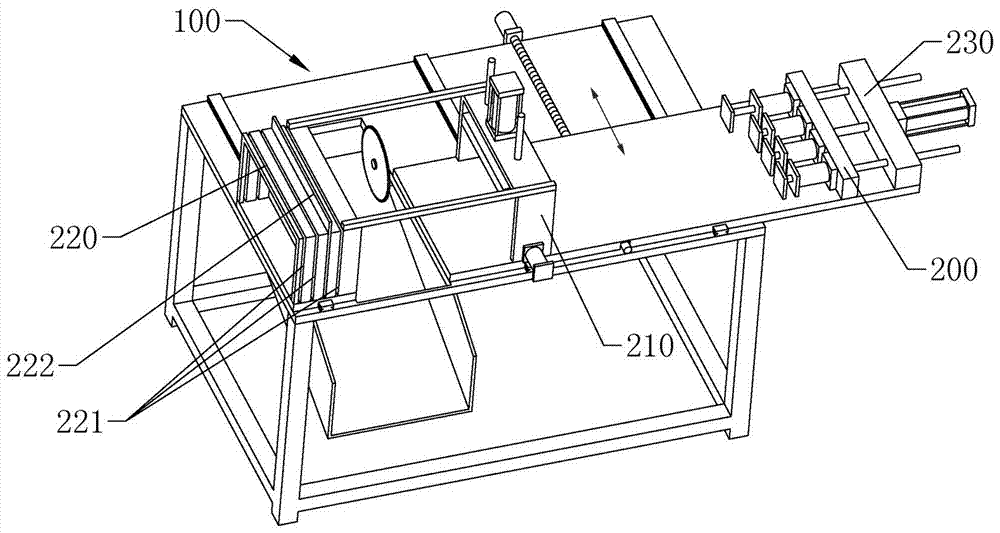

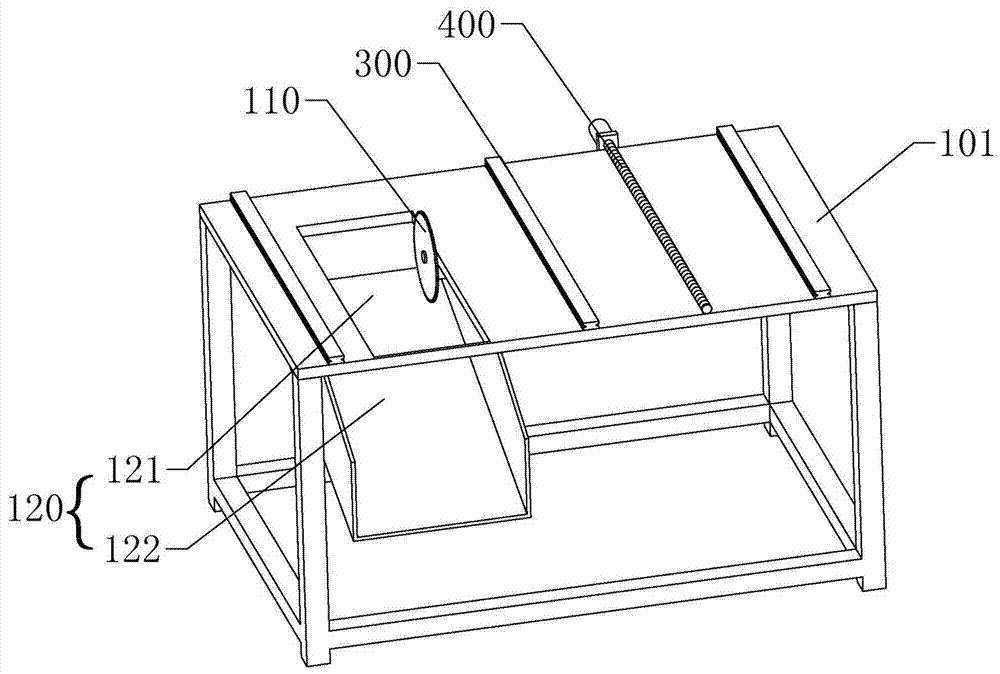

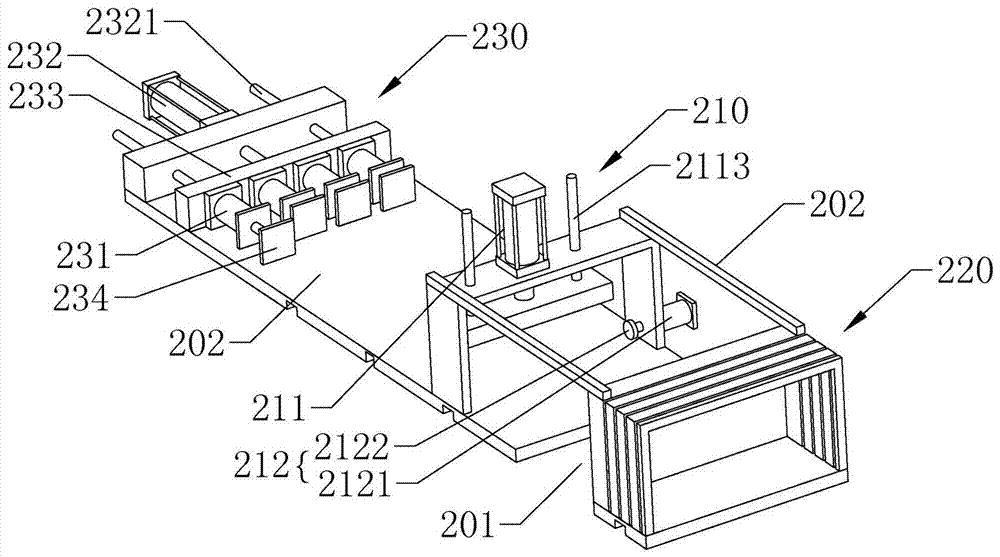

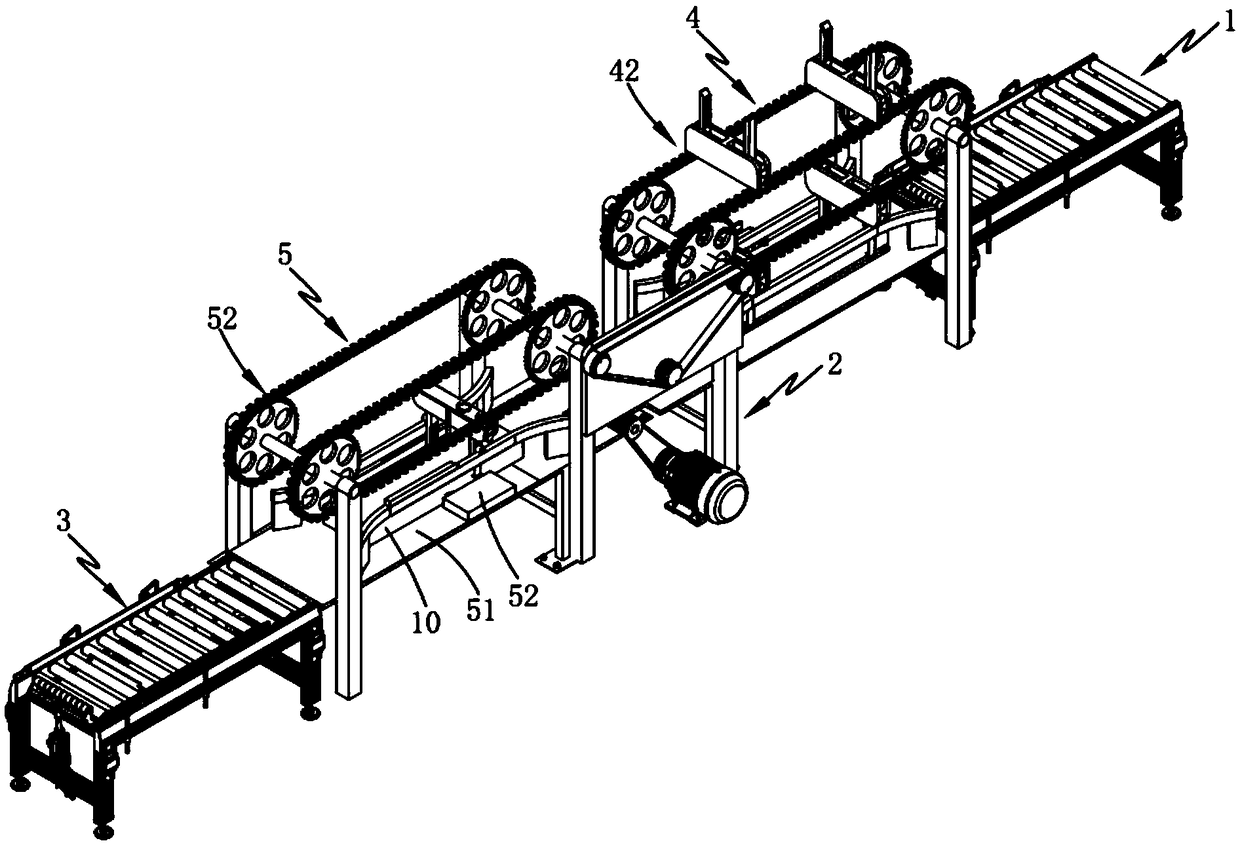

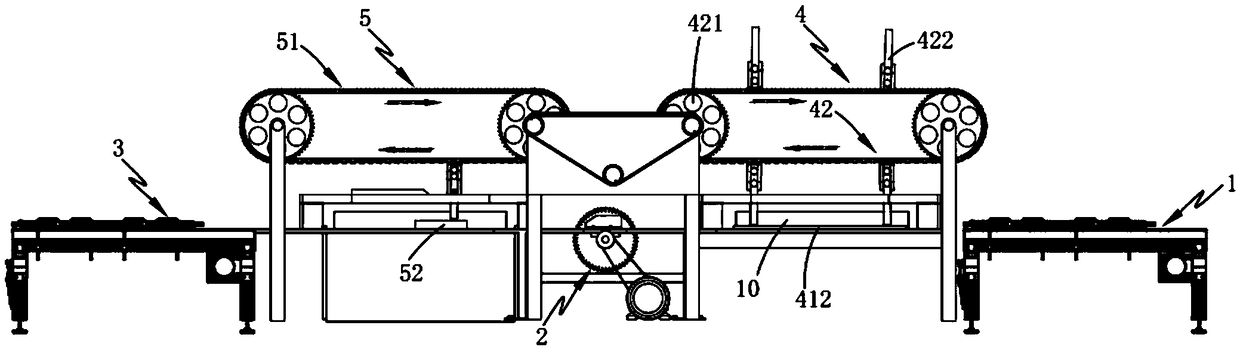

Continuous automatic processing production line for wood of furniture manufacturing

ActiveCN109291140ARealize fully automatic cuttingAchieve separationFeeding devicesGripping devicesProduction lineReciprocating motion

The invention provides a continuous automatic processing production line for wood of furniture manufacturing. The production line comprises a feeding device, a cutting device, an output device, a clamping and feeding device and a waste separating device, wherein the clamping and feeding device is arranged between the feeding device and the cutting device, and comprises a wooden block positioning mechanism and a clamping and transporting mechanism; and the waste separating device is arranged between the cutting device and the output device, and comprises a separating workbench, a clamping staggering mechanism and a separating mechanism. After the clamping and feeding device clamps wooden blocks in a mode of reciprocating motion, the stepwise feeding and cutting are carried out in the cutting device; after the cutting of the wooden blocks is completed, the clamping and feeding device is fitted with the waste separating device to carry out the staggering separation of finished products and waste, so that the full-automatic cutting and the waste separating of the wooden blocks are realized; and in this way, an original manual wooden block feeding and cutting method is replaced, so thatthe problem that the leftward and rightward swaying of the wood results in irregular wood cutting surfaces and the imprecise cutting in the prior art is solved.

Owner:佛山市顺德区博领家具有限公司

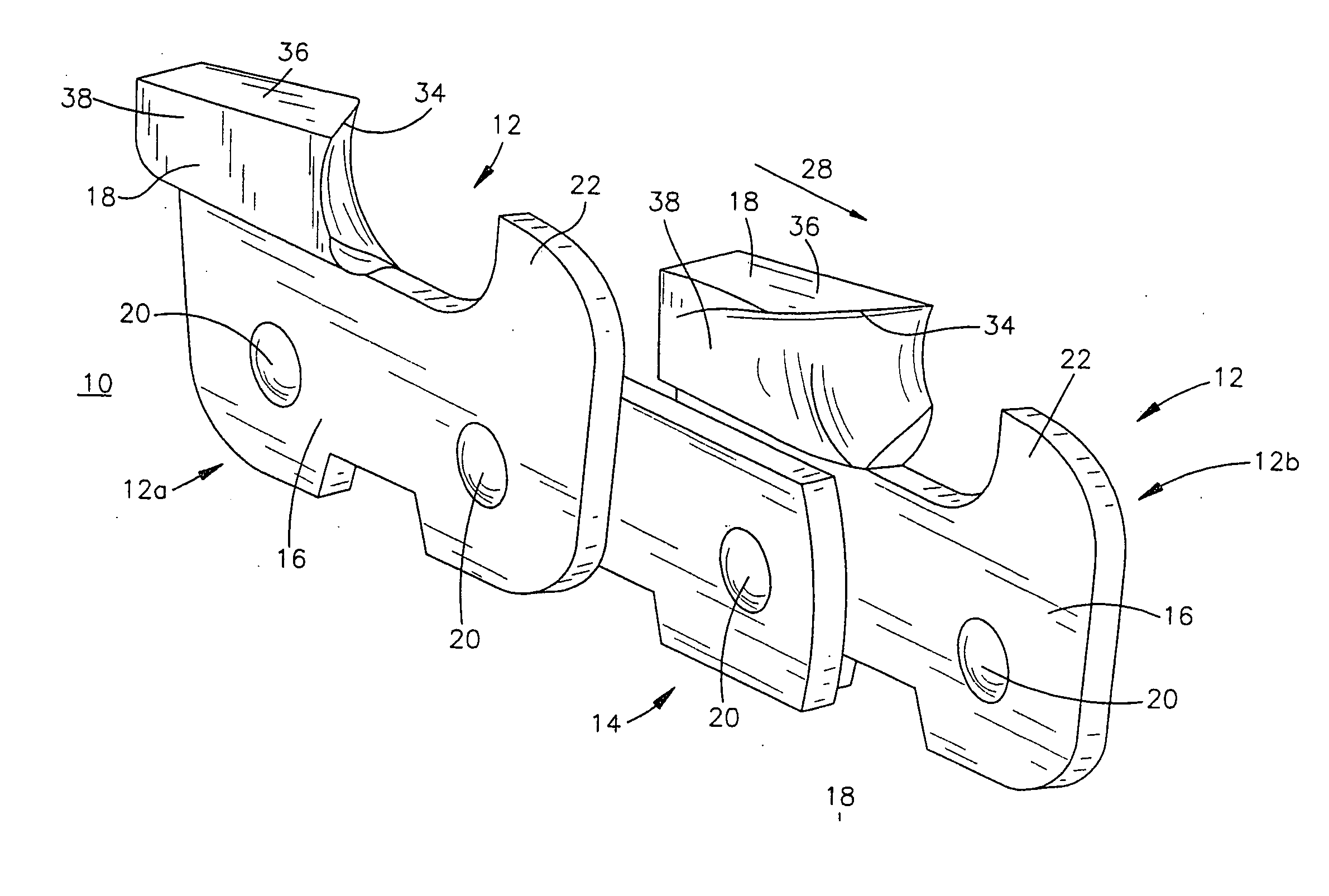

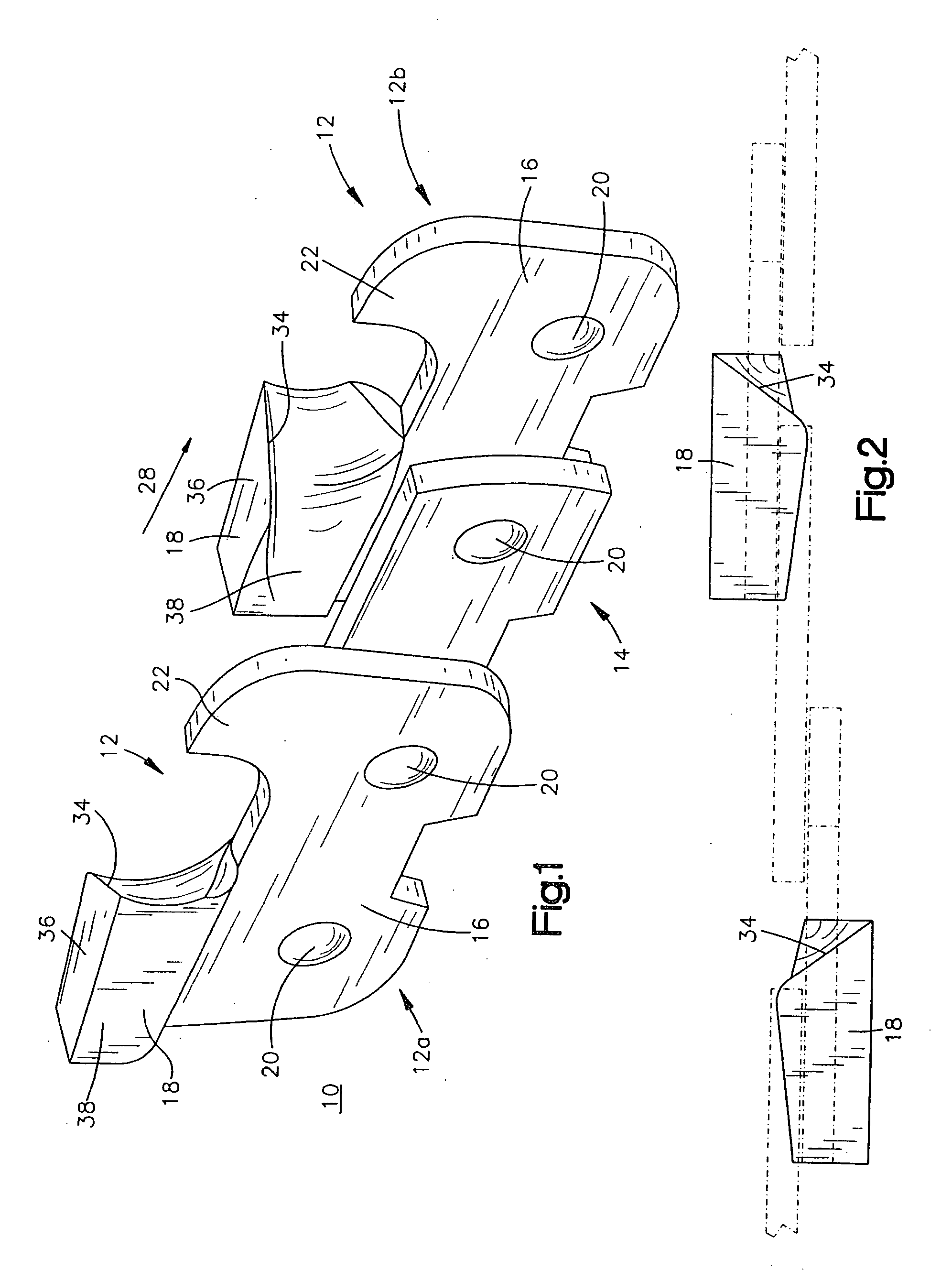

Wood cutting saw chain and replaceable cutting members

PendingUS20050178263A1Effective and strong self-locking connectionSafe and effective installationMetal sawing devicesMetal sawing toolsSelf lockingWood cutting

A quick change cutting link of saw chain for cutting wood comprises a base member adapted to be pivotally connected to other links of the saw chain. The base member comprises a seat surface. A cutting member comprising a cutting edge releasably engages the seat surface of the base member. The cutting member includes sintered and compacted particles of abrasion resistant material. In particular, in one design the base member seat surface has a first taper and the cutting member includes a surface having a second taper. The first and second tapers extend at an angle ranging from about 0.5° to about 45° relative to a direction of chain travel at a close tolerance effective to cause self-locking engagement of the first taper of the seat surface and the second taper of the cutting member surface. The close tolerance is characterized by variation in the angle being not more than about 1° and, in particular, not more than 0.5°. The invention is also directed to the cutting member itself, including a design in which one of the cutting member and seat surface includes an inverted-L shaped protrusion and the other includes an inverted-L shaped recess for receiving the inverted-L shaped protrusion. The inverted L-shaped protrusion and recess may be designed so as to form a wedge. Also included is wood-cutting saw chain containing the inventive cutting link such as saw chain adapted for use on a chain saw, timber harvester and the like.

Owner:SZYMANSKI DAVID

Wood cutting machine and wood cutting and processing method

InactiveCN101774189AImprove cutting efficiencyImprove securityCircular sawsCentre of rotationElectric machinery

The invention relates to a wood cutting machine, which comprises a fixed stander, wherein the fixed stander is rotatably provided with a movable rack through a rotating shaft, and the movable rack is provided with at least two cutting blades driven by a motor to rotate; the cutting blades are sequentially distributed along the rotating central line, and the fixed stander is provided with a bracket for placing round wood below the cutting blades; and the fixed stander is also provided with retractable metal pressing pieces below the cutting blades, and the round wood is pressed by the metal pressing pieces when the metal pressing pieces extend outwards and is cut off by the cutting blades. When processing, the metal pressing pieces are used to press the round wood, and the movable rack rotates to press downwards, and the cutting blades are used to cut off the round wood; and the wood cutting process is fully completed by mechanical devices so as to improve the safety of the construction process and greatly improve the cutting and processing efficiency of wood. The invention also discloses a wood cutting and processing method.

Owner:刘汉权

Safe type wood cutting machine with dustproof function

InactiveCN108714941AImprove securityImprove practicalityProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringWood cutting

The invention relates to a safe type wood cutting machine with a dustproof function. The cutting machine comprises a main body, a supporting plate, a cutting device and four supporting legs, and further comprise a dust prevention mechanism and a feeding mechanism, wherein the dust prevention mechanism comprises a waste box, a lifting assembly and a collecting assembly, the lifting assembly comprises a first motor, a rotating shaft, a lifting plate and two lifting units, the lifting units comprise wire winding spools and pull wires, the collecting assembly comprises a supporting shaft, a suction nozzle, a hose and an adjusting unit, the feeding mechanism comprises a moving assembly and two clamping chambers, and stretchable assemblies are arranged in the clamping chambers, and comprise driving units, stretchable frames, clamping plates, hinging blocks and sliding blocks. According to the safe type wood cutting machine with the dustproof function, the dust prevention mechanism is arranged so that the collection work of wood chippings can be carried out on the interior of the main body, the wood chippings are prevented from flying around, and the body health of a user is prevented from being threatened; and the feeding mechanism is arrange so that wood can be automatically moved to the cutting device for cutting, the user can be prevented from being cut by the cutting device whenmanual feeding is carried out.

Owner:福建奕圣科技有限公司

Saw blade angular adjustment device for a metal and wood cutting machine

InactiveUS20060266189A1Quick decisionMetal sawing devicesMetal working apparatusEngineeringWood cutting

A saw blade angular adjustment device for a metal and wood cutting machine includes a rectangular working platform having a pair of symmetrically arranged triangular support arms on lateral sides each including a screw hole in the top engaged with an arcuate slit in the middle portion of a pair of pillow shaped pivotal plates which is rotatably secured to the arms by bolt, a pair of sliding bars parallel secured to the top of the pivotal plates, a saw blade angular adjustment assembly slidably engaged onto the sliding bars including a seat and a guarded saw bladed which is operated by a motor inside the seat a pair of first and second clamping plate parallel disposed on the front portion of the platform and a pair of U-shaped rods respectively inserted into the front and rear end of the platform. The feature is that both of the saw blade and the clamping plate can be adjusted a certain degree of angle.

Owner:CHEN YUEHTING

Wood cutting device for furniture manufacturing

InactiveCN108789658AEasy to operateImprove working environmentProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningWorking environment

The invention provides a wood cutting device for furniture manufacturing. The device comprises a base plate; support plates are fixedly mounted at the two ends of the base plate; a cover plate is fixedly mounted on the upper sides of the support plates; a motor box is fixedly mounted on the left side of the cover plate; a first servo motor is arranged in the motor box; two bearing bases are arranged on the right side of the first servo motor; a lead screw is arranged between the two bearing bases, and is slidingly connected with a slide block; a first electric extension rod is fixedly mountedat the top of the slide block; a second servo motor is fixedly mounted at the end, far from the slide block, of the first electric extension rod; and the invention relates to the field of wood machining. The wood cutting device for furniture manufacturing is provided with a wood chip collecting box and a wood chip storage box, so that wood chips and dust are sucked into the wood chip collecting box through an electric blower and fall into the wood chip storage box through a discharge pipe, the wood chips are convenient to collect, both time and manpower are saved, and the improvement of the working environment is facilitated.

Owner:刘闪闪

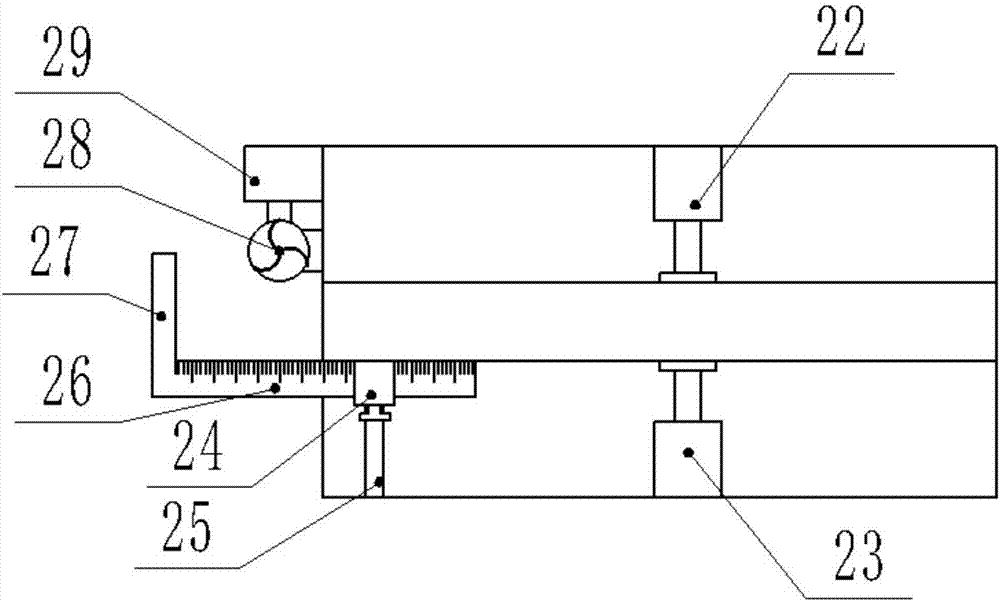

Automatic equal-distance building wood cutting device

InactiveCN107116623AAvoid flyingAffect healthProfiling/shaping machinesBark-zones/chip/dust/waste removalDrive wheelEngineering

The invention discloses an automatic equal-distance building wood cutting device. The automatic equal-distance building wood cutting device comprises a cutting table, a top plate, a driving wheel, a lifting device, a cutting motor, a cutting wheel, a dividing ruler and a scrap collecting device. The driving wheel is fixedly arranged on an output shaft of a first drive motor. The lifting device is further arranged in the cutting table. The dividing ruler is arranged in the sliding block in a sliding manner. A stop block is fixedly arranged at the left end of the dividing ruler. A suction fan is fixedly arranged at the upper left corner of the cutting table. The scrap collecting device is fixedly arranged on the upper side of the suction fan. The driving wheel is set to be an irregular wheel, and accordingly intermittent equal-distance cutting is achieved. A hydraulic machine A is matched with the rack, the distance between the driving wheel and a driven wheel is adjusted, and accordingly cutting of wood different in thickness is achieved. Through the arrangement of the suction fan and the scrap collecting device, wood scraps are prevented from flying all around, and the situation that operators inhale the wood scraps, and health is influenced is avoided.

Owner:长沙装研智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com