Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Strengthened grain boundaries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood cutting tool material of Ti(CN) cermet and preparation method thereof

The invention provides a wood cutting tool material of Ti(CN) cermet and a preparation method thereof, relating to the technical field of wood cutting tool materials. The Ti(CN) cermet comprises 50 to 65% of Ti(CN) powder, 5 to 10% of cobalt powder, 5 to 10% of nickel powder, 8 to 15% of molybdenum powder, 10 to 20% of tungsten carbide powder, 4 to 8% of tantalum carbide powder and 0 to 1.0% of chromium carbide and vanadium carbide powder. The preparation method comprises the steps of preparation of materials, ball milling, spray drying, compacting, pressure sintering and obtainment of a finished product. Compared to other cutter materials, a cutter prepared in the invention has durability and a service life increased by 1 to 10 times, a cutting speed increased by 1.5 to 3 times and cost for cutting processing reduced by 20% to 40%, and has a wide application prospect in processing of wood composite materials by using cermet cutters.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

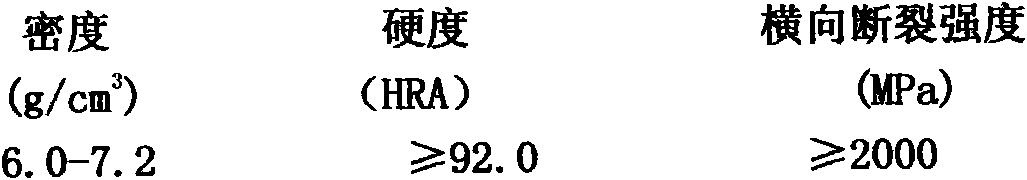

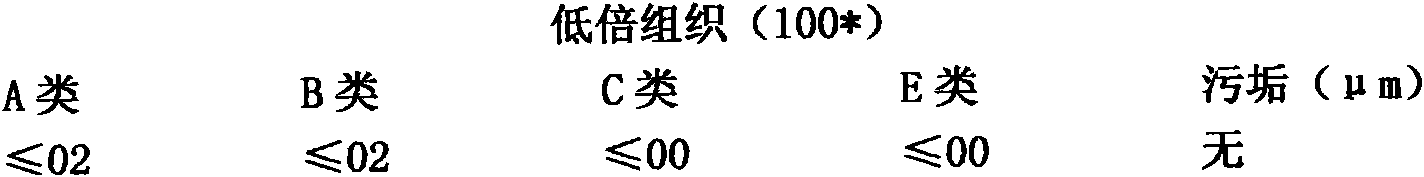

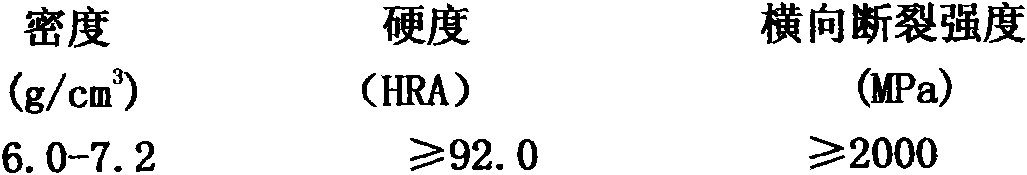

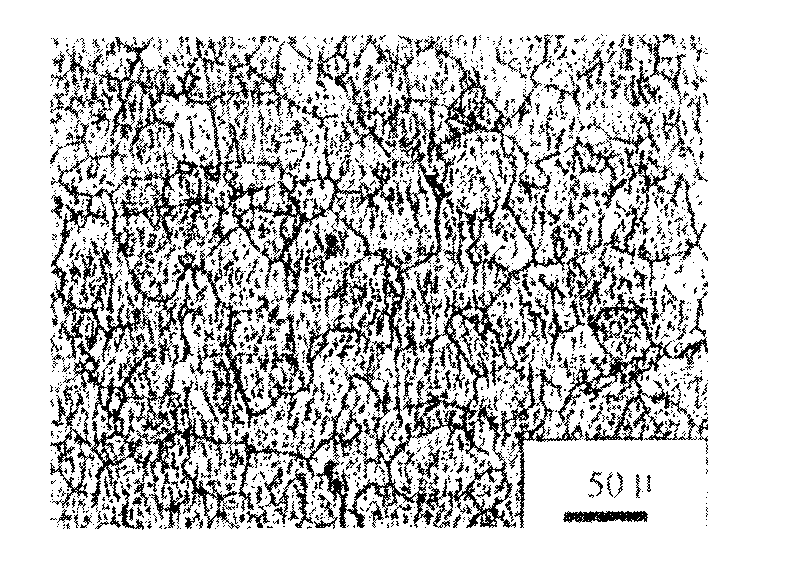

Nano WC-Co composite powder modified Ti(CN) based metal ceramic and preparation thereof

The invention discloses a nanometer WC-Co composite powder modified Ti(CN) based cermet and the preparing method thereof. Titanium carbonitride is used as the main parent metal, metal cobalt and / or nickel are / is used as the binder of raw material powder, carbide and tantalum-niobium sosoloid are used as the additive. The cermet is characterized in: the cermet is added with 6.0% to 27% by weight of raw material power nanometer WC-Co composite powder; the cermet is prepared with the raw material powder by ball grinding crushing, dispersing the nanometer WC-Co composite powder, uniformly mixing, press forming, vacuum or pressure sintering, etc. Compared with traditional cermet, since the cementing phase and the crystal boundary are strengthened, the nanometer WC-Co composite powder modified Ti(CN) based cermet has better wearing resistance, higher strength, fracture toughness and red hardness, thus a tool bit manufactured with the cermet has superior cutting property.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Micro-alloying compound cored wire for high-strength steel

The invention relates to a micro-alloying compound cored wire for high-strength steel, comprising a carbon steel sheath and a powdery core, wherein the core is prepared from the following chemical components by weight percent: 23 to 28 wt% of Ca, 51 to 55 wt% of Si, 0.65 to 1.5 wt% of Mg, 1.3 to 2.5 wt% of Ba, 0.6 to 1.0 wt% of Re, 0.6 to 1.2 wt% of B, 1.6 to 3.5 wt% of Zr, 1.3 to 2.8 wt% of Ti, 0.6 to 1.2 wt% of Nb, and balance of ferrum and inevitable impurities. The invention reduces the content of C in high-strength steel through reasonably designing the chemical components and simultaneously and greatly enhances the grain sizes in continuous casting billets so that the grains are refined. The mechanical properties of the steel can be obviously improved, and the transverse impact properties of the steel are obviously enhanced to approximate to longitudinal impact value. Besides, the invention well solves the problems of center segregation and center porosity of the continuous casting billets, nonuniform impurity distribution, and the like.

Owner:HUBEI KMK WELDING MATERIALS

Method for preparing proppant in high intensity

The present invention provides a preparation method of high-strength proppant. Said method includes the following steps: mixing bauxite raw ore powder, rare earth concentrate, combustible substance and binding agent according to a certain mixing ratio, grinding them into powder material, sphere-forming to obtain blank spheres, screen to obtain semi-finished product spheres, roasting at 1250-1500 deg.C, further screening, polishing, removing dust, finally covering the spheres with phenol-formaldehyde resin so as to obtain finished product. Said invention also provides its application range.

Owner:关昌烈 +1

Titanium alloy laser cladding surface reinforcing method

ActiveCN103668186AImprove surface qualityImprove organizationMetallic material coating processesHardnessWear resistance

The invention relates to a titanium alloy laser cladding surface reinforcing method which comprises the following steps: mixing the following components by weight: 50-100% of Co42 cobalt-based self-fluxing alloy powder, 0-50% of B4C0, 0-50% of SiC, 0-39% of TiN, 0-1.5% of Y2O and 0-1.5% of CeO2, uniformly blending the mixture powder into paste by using a sodium silicate solution, uniformly coating the paste mixture powder on the surface of a titanium alloy, keeping the coating uniform in thickness, drying in air naturally, and performing laser cladding on the coating on the surface of the titanium alloy. By the adoption of the method provided by the invention, the microstructure of a cladding layer can be improved, and the hardness and the wear-resistance of the cladding layer can be further improved.

Owner:SHANDONG UNIV

Wear-resistant white cast iron material and preparation method thereof

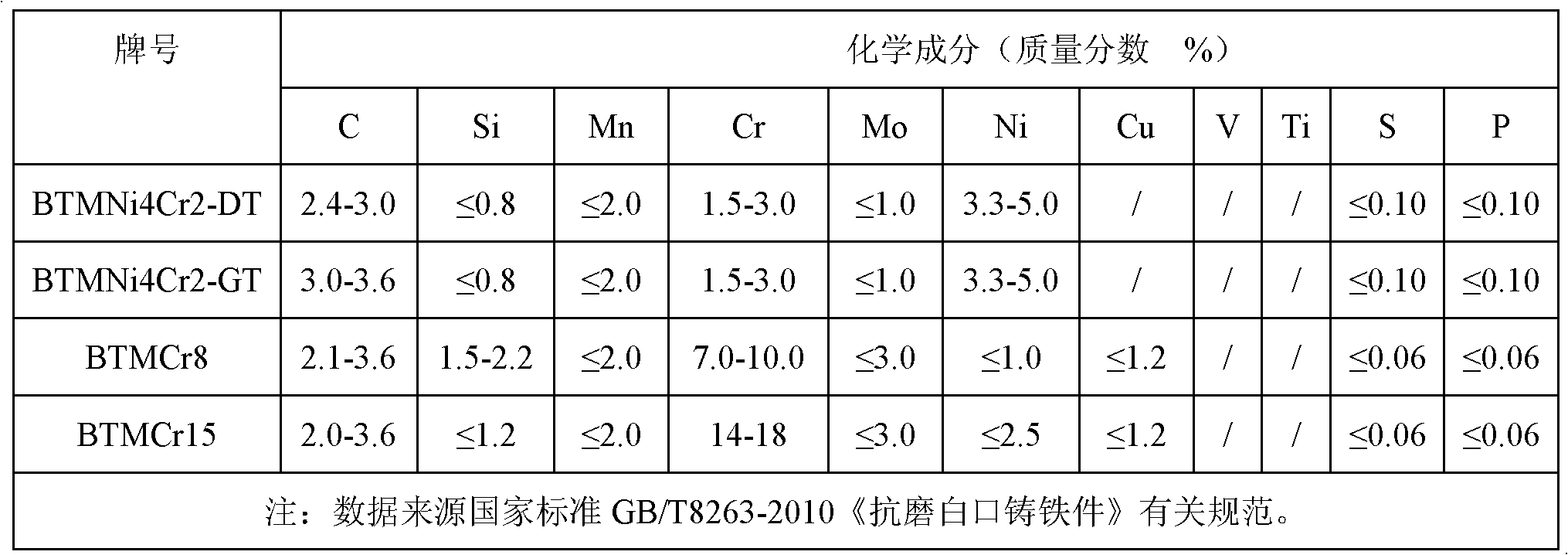

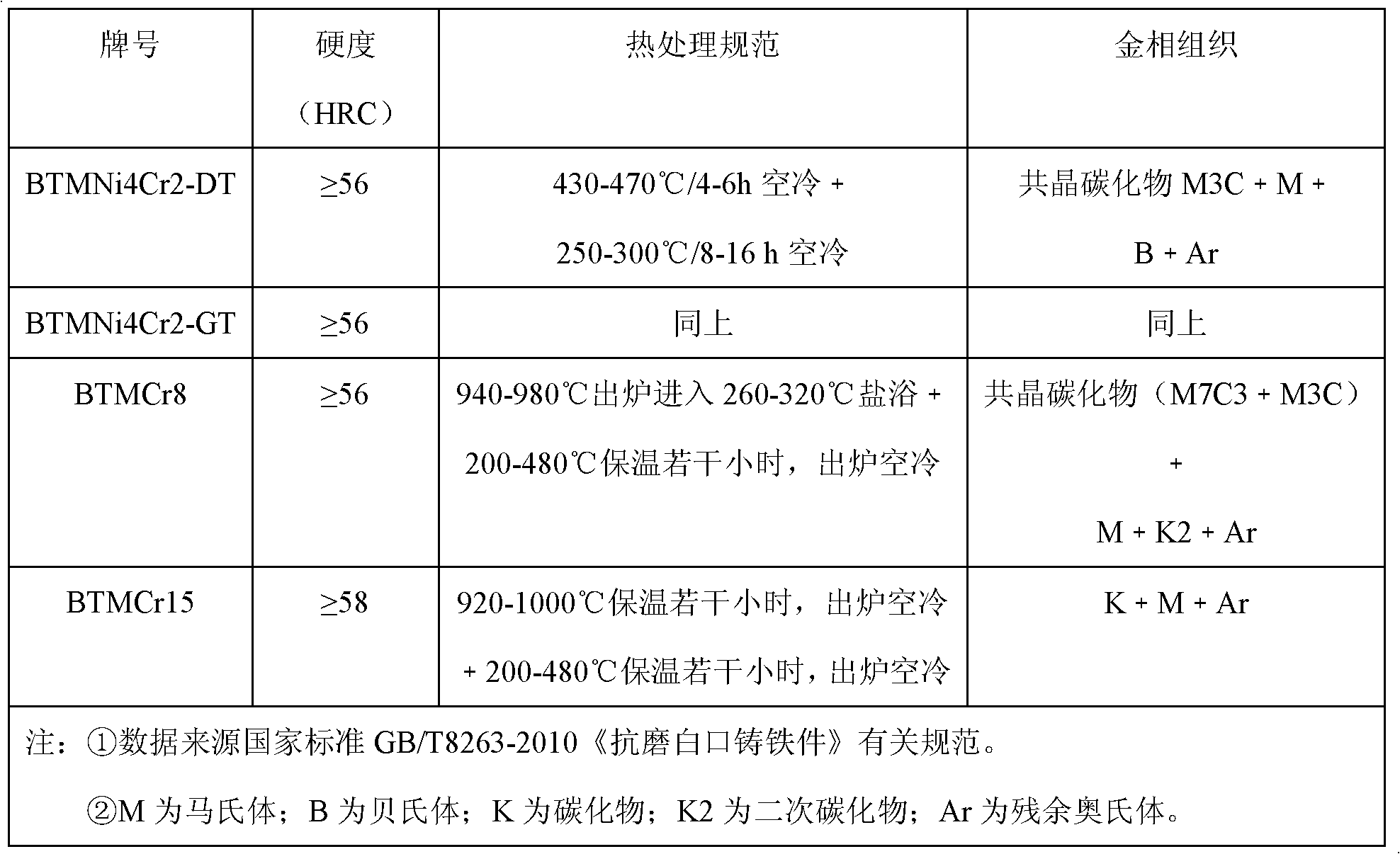

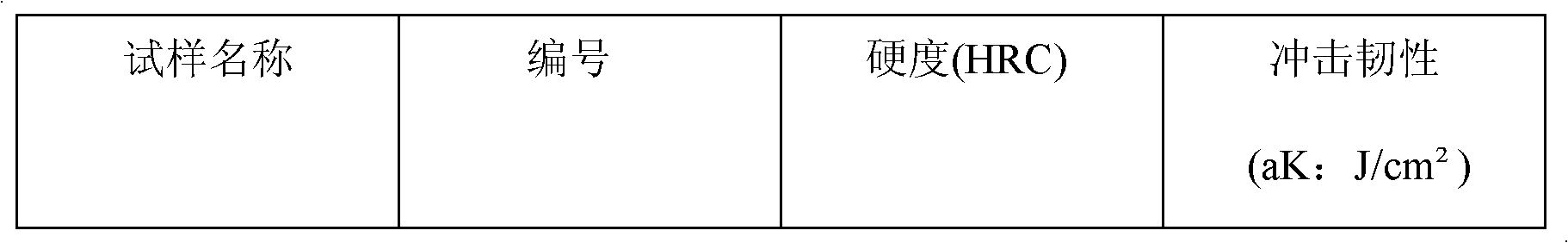

The invention discloses a wear-resistant white cast iron material, which consists of the following elements in percentage by weight: 2.2 to 3.2 percent of C, less than or equal to 1.2 percent of Si, 2.0 to 3.5 percent of Mn, 7.0 to 10.0 percent of Cr, 0.2 to 1.2 percent of Cu, 0.06 to 0.3 percent of V, 0.02 to 0.15 percent of Ti, 0.001 to 0.003 percent of B, 0.02 to 0.06 percent of Al, 0.02 to 0.15 percent of RE, less than or equal to 0.06 percent of S, less than or equal to 0.06 percent of P, and the balance of Fe. The wear-resistant white cast iron material has the hardness (HRC) of more than or equal to 56, the impact toughness aK of more than or equal to 6J / cm<2>, and a metallographic structure consisting of martensite, carbide (M7C3+a small amount of M3C), secondary carbide and a small amount of retained austenite. The wear-resistant white cast iron material does not contain noble metals such as molybdenum, nickel and the like; and compared with the traditional medium-chromium cast iron material, the wear-resistant white cast iron material has the advantages that the production cost can be greatly saved and the material has good economic benefit.

Owner:驻马店市三山耐磨材料有限公司

Method for improving thermoplasticity of super austenitic stainless steel

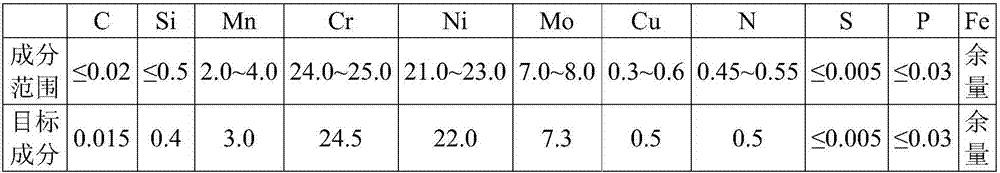

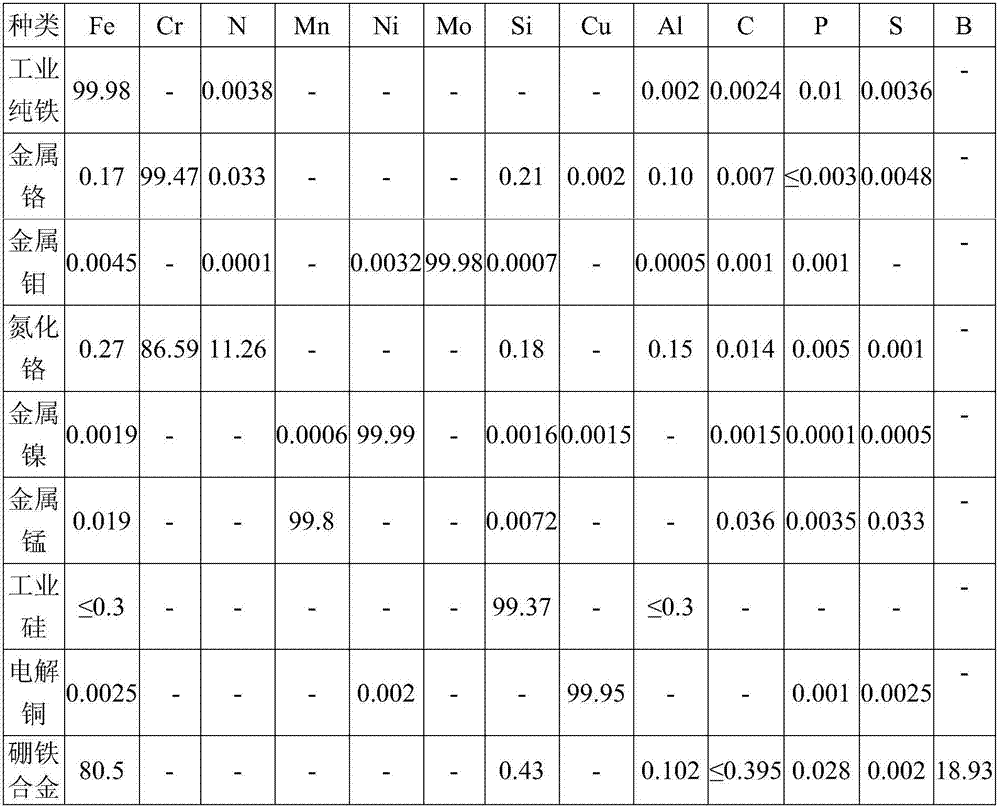

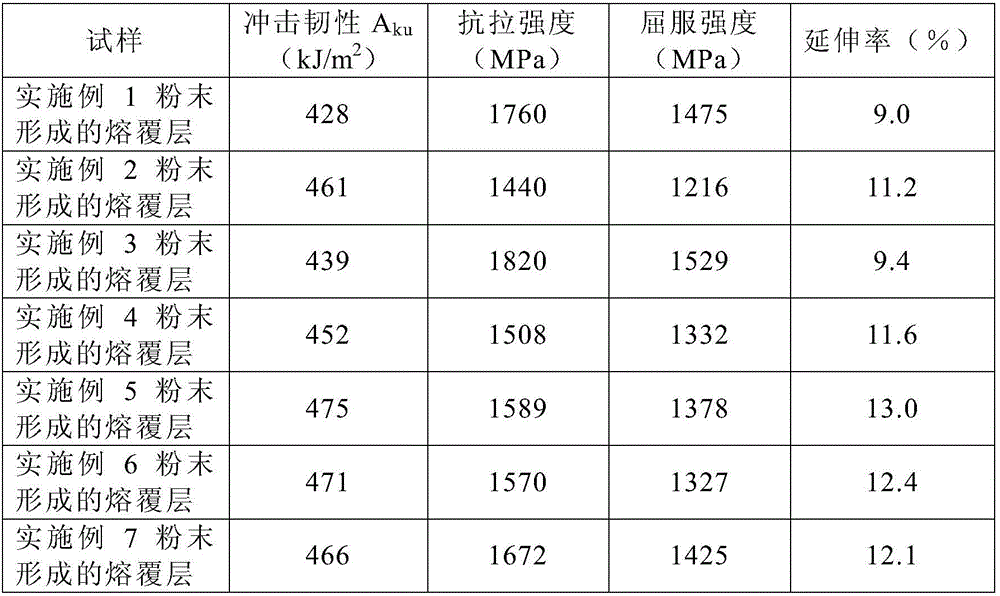

The invention belongs to the field of super austenitic stainless steel smelting and processing and provides a method for improving the thermoplasticity of super austenitic stainless steel. The method is suitable for smelting the super austenitic stainless steel with smaller than or equal to 0.02% of C, smaller than or equal to 0.5% of Si Mn, 2.0-4.0% of Mn, 24.0-25.0% of Cr, 21.0-23.0% of Ni, 7.0-8.0% of Mo, 0.3-0.6% of Cu, 0.45-0.55% of N, smaller than or equal to 0.005% of S, smaller than or equal to 0.03% of P and the balance Fe and other inevitable impurity elements, and 0.01-0.10% of rare earth and 0.001-0.008% of boron are added into the steel on the basis. The method is characterized by comprising the steps of preparing and placing materials; vacuumizing a furnace until the pressure is less than 5 Pa, and electrifying and heating the furnace; introducing nitrogen into the furnace after melting down until the pressure is 0.08-0.10 MPa, and sequentially adding chromium nitride, a deoxidizing agent and a desulfurizing agent; after deep deoxidation and desulfurization, sequentially adding the rare earth and the boron; and filling the furnace with the nitrogen again until the pressure is 0.10-0.12MPa, and carrying out casting. The method has the advantages that by adopting the mode of compound addition of the boron and the rare earth, the plasticity of the steel is remarkably improved, the hot working performance of the steel is improved, the technical bottleneck of hot rolling cracking is broken through, and a technical support is provided for obtaining a super austenite stainless steel product with high surface quality and excellent performance.

Owner:NORTHEASTERN UNIV

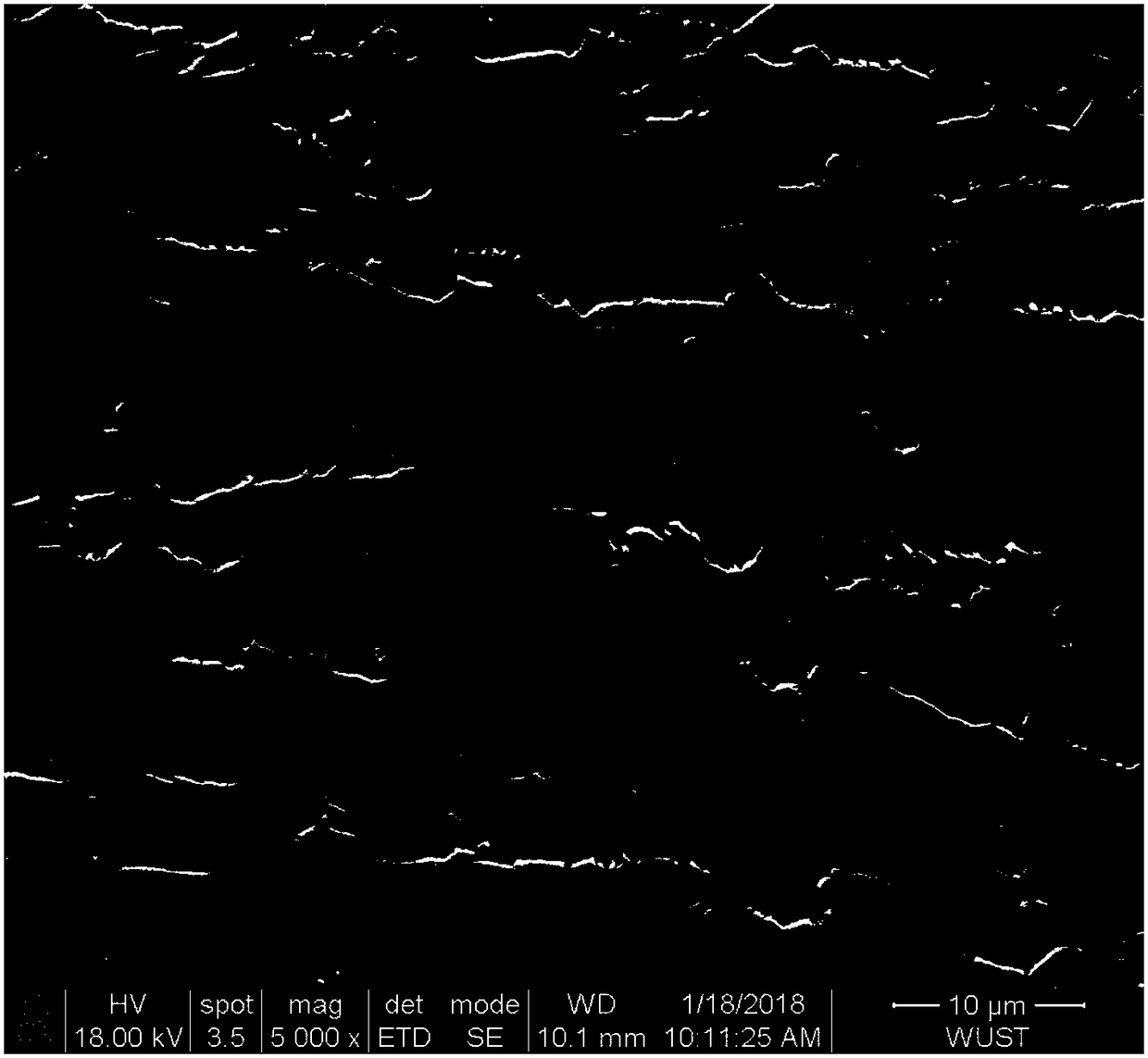

Graphene ceramic composite material prepared based on 3D printing and preparation method thereof

PendingCN112125653AEvenly dispersedUniform performanceAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicCeramic composite

The invention provides a graphene ceramic composite material prepared based on 3D printing and a preparation method thereof, and belongs to the field of preparation of ceramic composite materials. Thegraphene ceramic composite material is prepared from three raw materials, namely Al2O3, SiC particles and graphene. The preparation process mainly comprises the steps of ball-milling mixing, slurry preparation, 3D printing, drying and microwave sintering. The preparation method has the main advantages that a method combining a 3D printing technology and microwave pressure sintering is adopted, after sintering, aluminum oxide and silicon carbide form a nano ceramic composite material, graphene modifies silicon carbide aluminum oxide ceramic, and the prepared composite material has good fracture toughness, electrical conductivity, thermal conductivity and the like. The ceramic composite material prepared by the method is simple in process and high in universality, the mold-free additive manufacturing of the ceramic composite material is realized, the production cost is greatly reduced, and the economic benefit is good.

Owner:JIANGSU UNIV

Laser cladding powder for 30CrMnSiNi2A steel and preparation method

ActiveCN106480363AHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthUltimate tensile strength

The invention relates to laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The laser cladding powder is prepared from the following components in weight percent: 0.8% to 1.0% of Cr, 0.75% to 1.10% of Mn, 0.65% to 1.10% of Si, 2.0% to 3.2% of Ni, 0.16% to 0.22% of C, 0.15% to 0.20% of Cu, 0.015% to 0.020% of P, 0.01% to 0.015% of S, 0.001% to 0.015% of rare earth and the balance of Fe. The invention further provides the preparation method of the laser cladding powder, the laser cladding powder is exclusively used in a laser cladding technique of the 30CrMnSiNi2A steel, excellent bonding strength and low metallurgical defects and dilution rate of a cladding interface are guaranteed, the toughness of a cladding layer is increased, the wettability of the cladding powder is improved, the cracking of the cladding layer is inhibited, and the crack growth rate is reduced.

Owner:国营芜湖机械厂

Piston aluminum ingot used for turbo charger car

The invention relates to a piston aluminum ingot used for a turbo charger car. The piston aluminum ingot solves the technical problem that the mechanical property of an aluminum alloy piston in an engine of an existing car is poor, and aluminum scraps generated in the mechanical finishing process of the piston are wasted. Chemical components of the piston aluminum ingot comprise, by weight percent, 11.8-12.8% of Si, 3.0-3.5% of Cu, 0.7-1.0% of Mg, 2.0-2.5% of Ni, 0.1-0.2% of Ti, 0.09-0.2% of Zr, 0.09-0.18% of V, 0.006-0.02% of P, smaller than or equal to 0.5% of Fe, smaller than or equal to 0.2% of Mn, smaller than or equal to 0.12% of Zn, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.01% of Pb, smaller than or equal to 0.02% of Sn, smaller than or equal to 0.002% of Sr,smaller than or equal to 0.001% of Na, smaller than or equal to 0.005% of Ca, smaller than or equal to 0.005% of Sb and the balance Al. The piston aluminum ingot is widely applied to the car with theturbo charger structure and a plug-in hybrid power car.

Owner:文登皇利压铸化工材料有限公司

Low-silver-copper-phosphorus brazing material containing trace indium

InactiveCN105149813AMobility is suitableSuitable brazing temperatureWelding/cutting media/materialsSoldering mediaIndiumSilver copper

The invention relates to a low-silver-copper-phosphorus brazing material containing trace indium. The low-silver-copper-phosphorus brazing material is characterized by comprising the following components in percentage by weight: 1.0-3.0% of silver, 6.7-8% of phosphorus, 0.05-0.2% of indium, 0.01-0.05% of mixed rare earth and the balance of copper, wherein the melting temperature range of the brazing material is 600-780 DEG C. The low-silver-copper-phosphorus brazing material has the advantages that the low-silver-copper-phosphorus brazing material can be used for replacing a BCu80AgP copper-based brazing material during brazing copper alloys, the content of the silver is reduced, the low-silver-copper-phosphorus brazing material has appropriate spreadability and liquidity, the low-silver-copper-phosphorus brazing material has appropriate liquidity during brazing copper and copper alloys, the brazing process is high in performance, stable in quality and smooth in surface, the technique performance index is equivalent to that of the Bag15CuP copper-based brazing material, and the brazing material can be prepared into various forms such as filaments, rings and strips by improving the molding technique.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

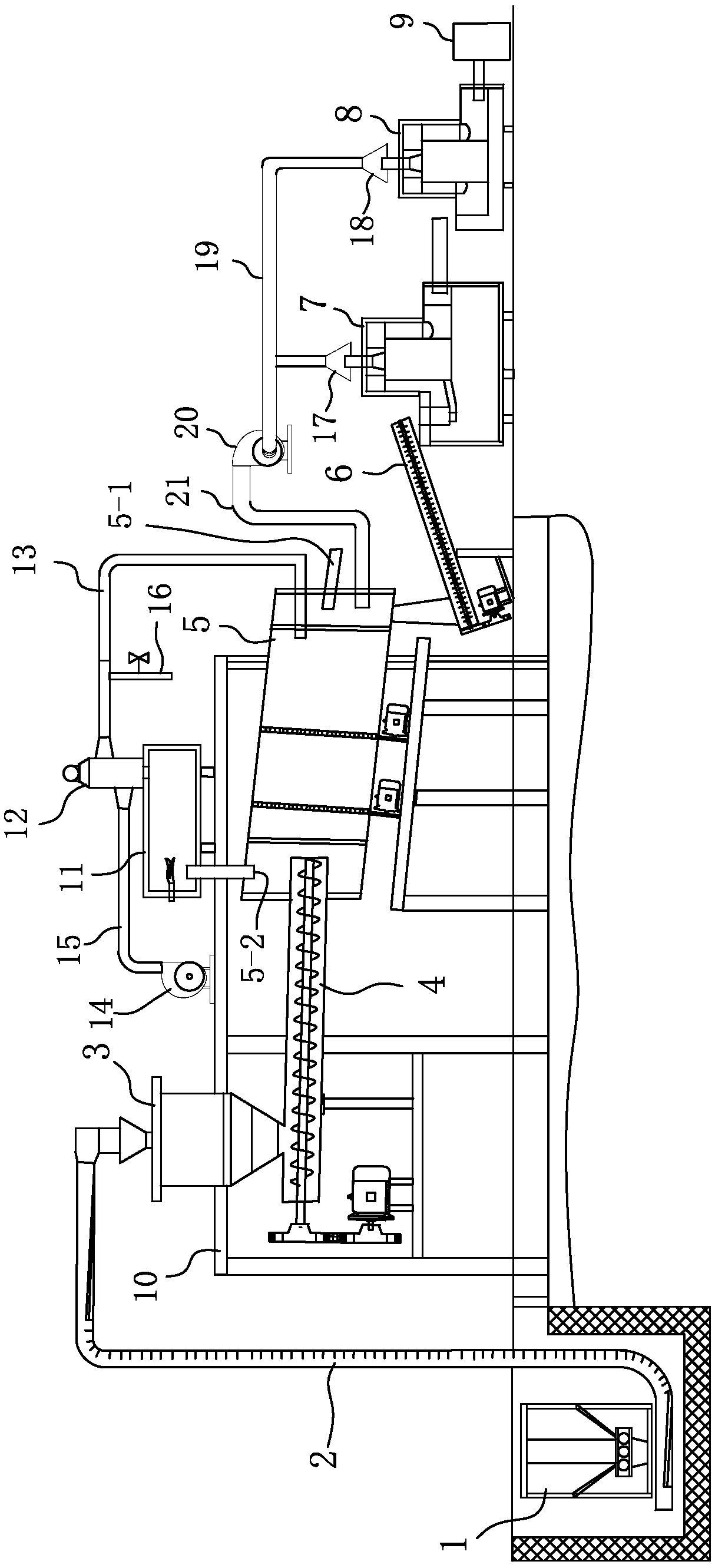

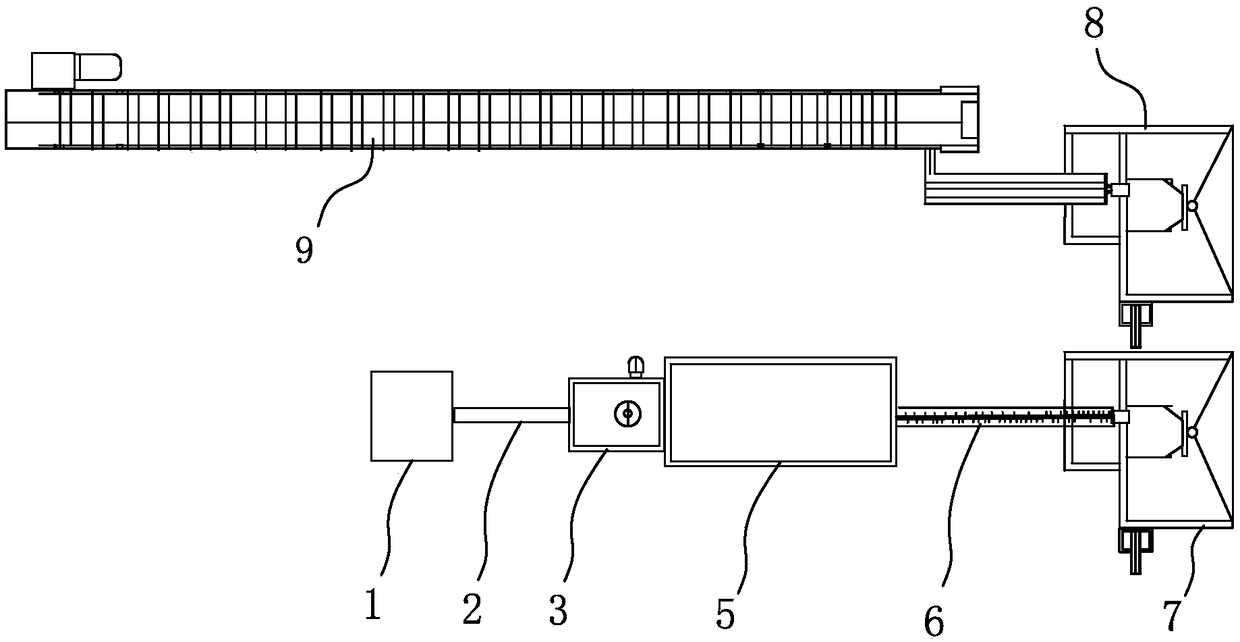

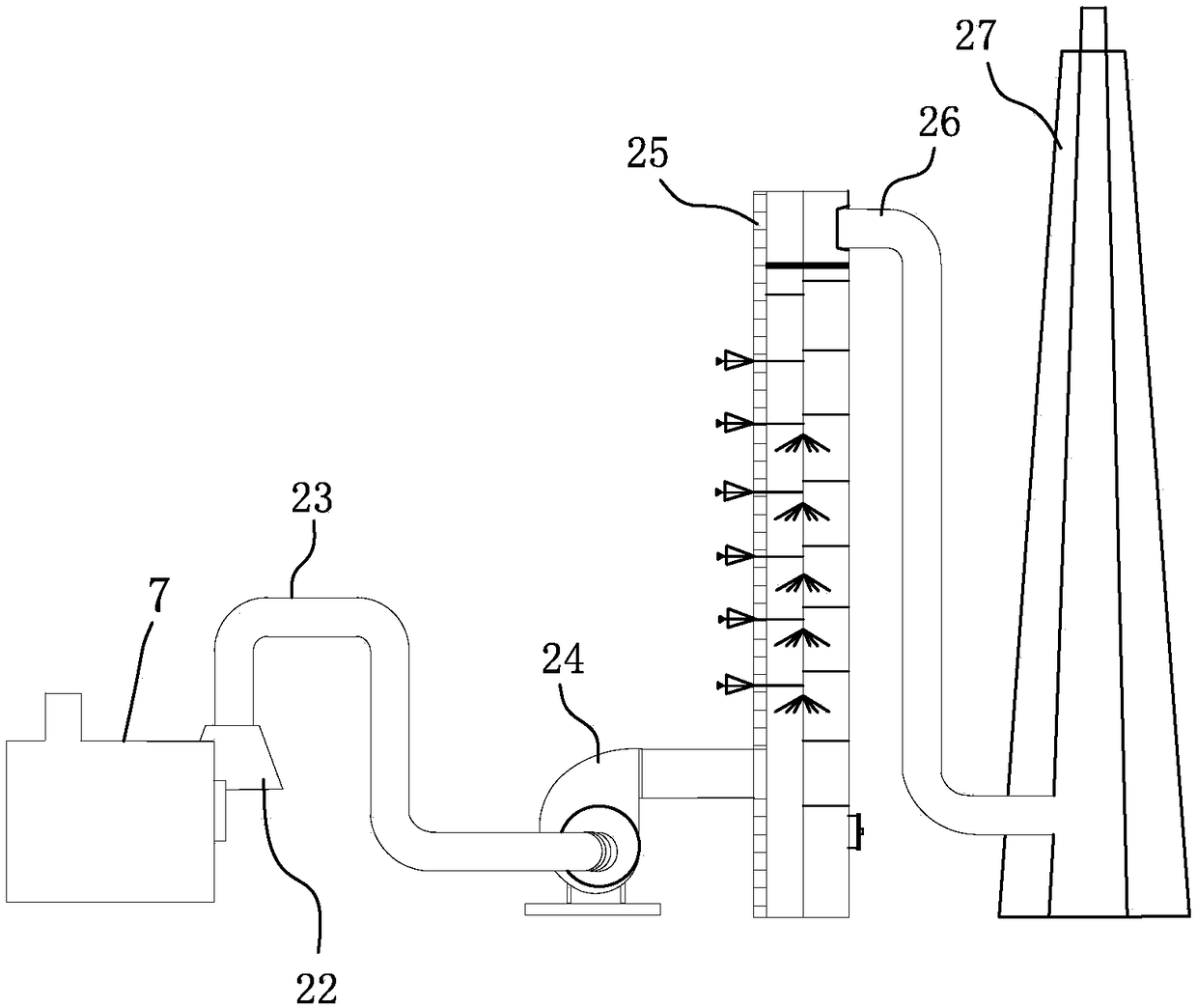

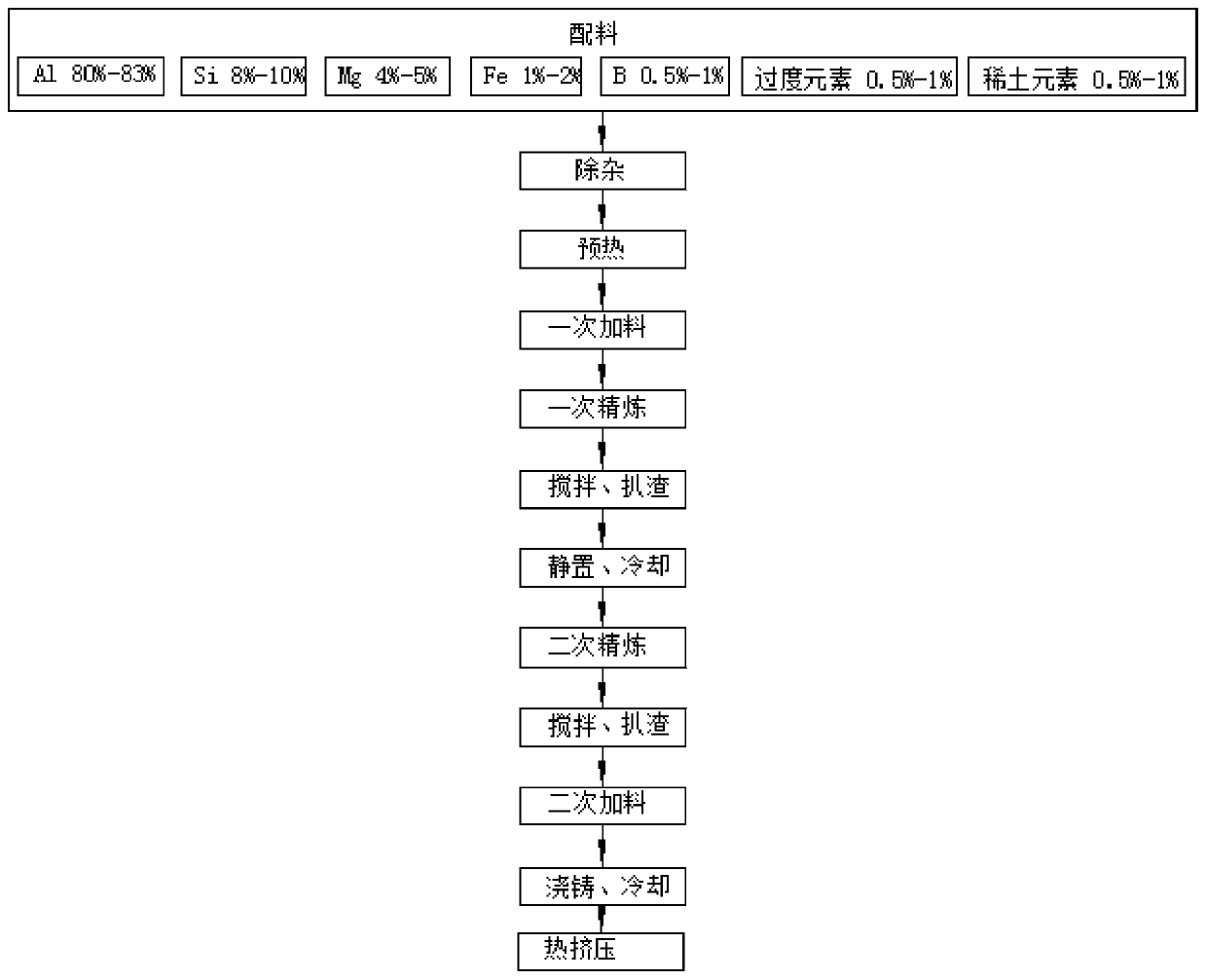

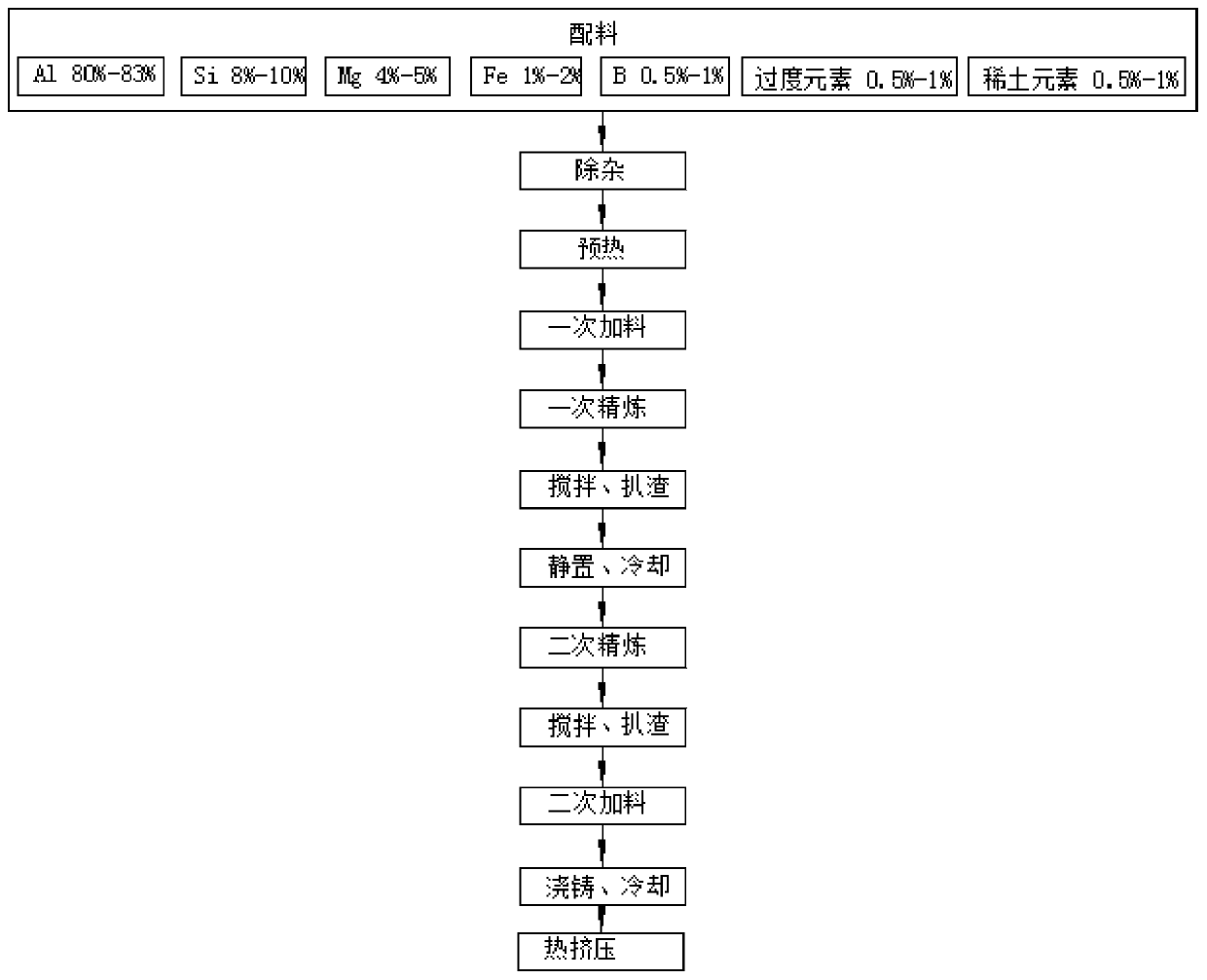

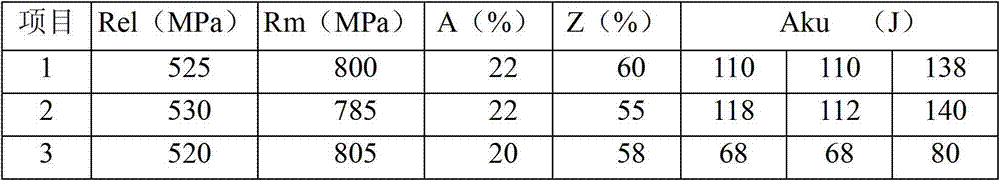

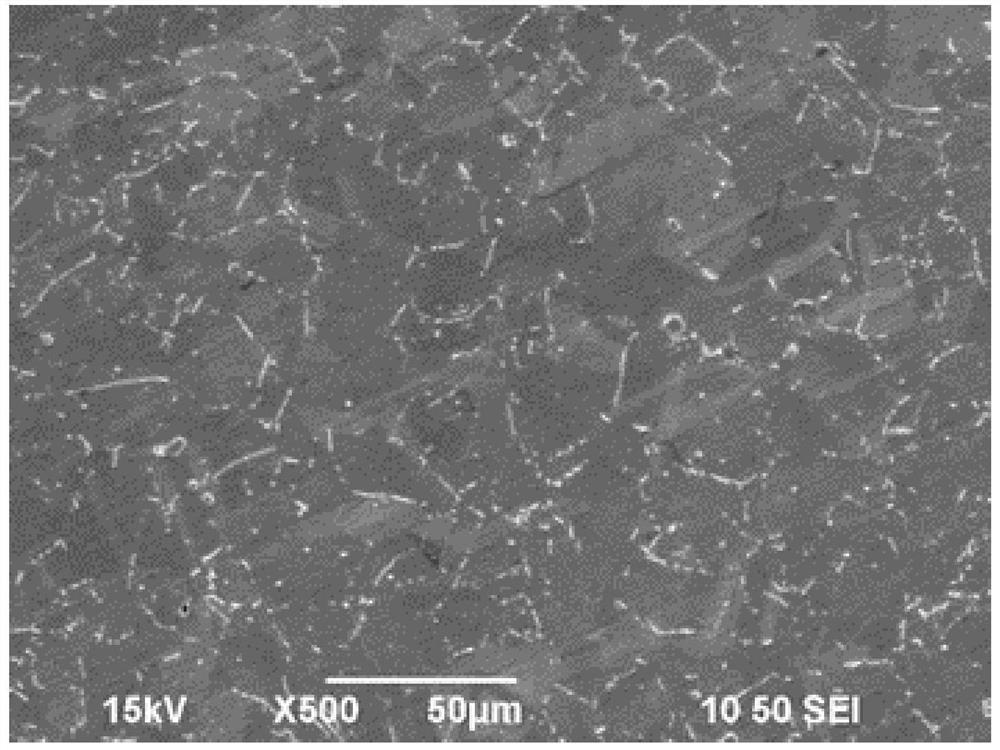

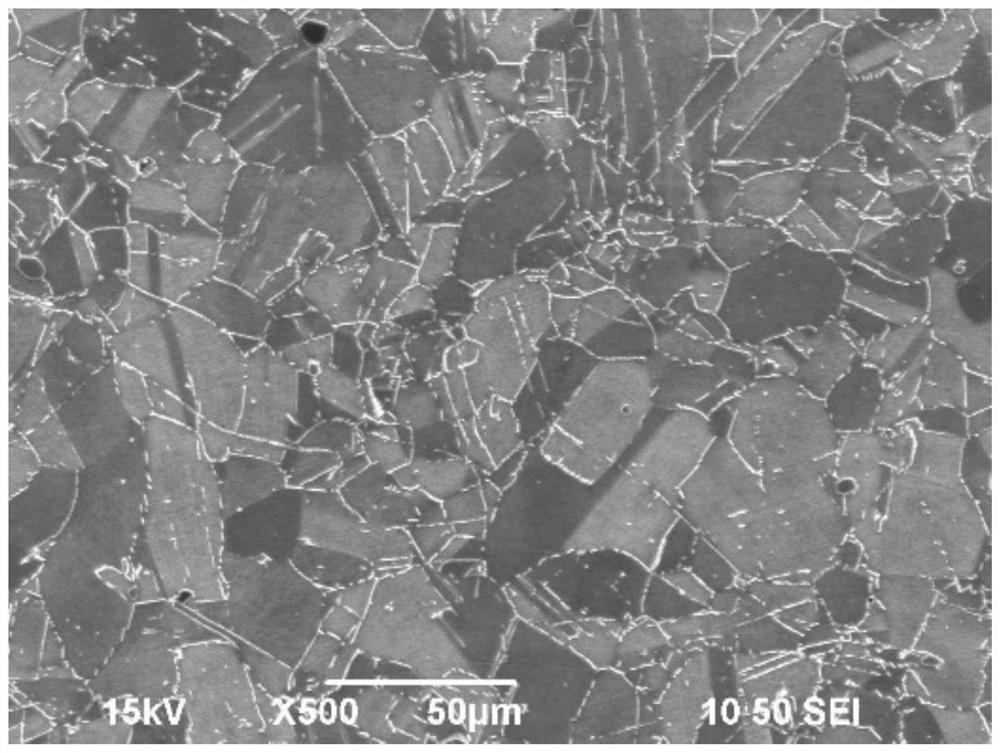

High-temperature-resistant aluminum alloy material and preparation method thereof

ActiveCN110029251AHigh temperature resistanceImprove high temperature resistanceRare-earth elementTemperature resistance

The invention discloses a high-temperature-resistant aluminum alloy material and a preparation method thereof. The high-temperature-resistant aluminum alloy material is prepared from the following rawmaterials in mass ratio: 80 percent to 83 percent of Al, 8 percent to 10 percent of Si, 4 percent to 5 percent of Mg, 1 percent to 2 percent of Fe, 0.5 percent to 1 percent of B, 0.5 percent to 1 percent of transition element, and 0.5 percent to 1 percent of rare earth element. The preparation method of the high-temperature-resistant aluminum alloy material comprises the following steps of (1) burdening; (2) purifying; (3) preheating; (4) refining for the first time; (5) refining for the second time; (6) cooling; and (7) carrying out hot extrusion. According to the high-temperature-resistantaluminum alloy material and the preparation method thereof provided by the invention, a crystal boundary can be effectively strengthened, and the high temperature resistance is improved.

Owner:中力鸿(深圳)新材料科技有限公司

Preparation method of ceramic alloy composite wear-resistant material for brake block

ActiveCN107034406AHigh temperature resistantHigh temperature and thermal decay resistanceTransportation and packagingMetal-working apparatusWear resistantRare earth

The invention relates to a preparation method of a ceramic alloy composite wear-resistant material for a brake block. All ceramic fine powder, all silicon carbide fine powder, all titanium carbonitride fine powder, all chromite fine powder and half molybdenum tungsten rare earth alloy powder are evenly mixed, a binder is added to prepare slurry, and spraying mist drying and prilling are carried out; and a special die capable of conducting chamfering is used for hot press molding, a pressing material is obtained, half of remaining molybdenum tungsten rare earth alloy powder is used for spraying all surfaces of the pressing material, sintering is carried out after spraying, repeated spraying is carried out, sintering is carried out multiple times until a molybdenum tungsten rare earth alloy layer is formed on the surface, and the ceramic alloy composite wear-resistant material for the brake block is manufactured. According to the preparation method of the ceramic alloy composite wear-resistant material for the brake block, the brake block manufactured through the method has the beneficial effects of high temperature resistance, corrosion resistance, comfortable braking, environmental protection and noise reduction, and the problems of brake failures, large brake noise, serious abrasion and the like caused by brake block heat fading are solved.

Owner:洛阳鹏飞耐磨材料股份有限公司

AlN-based composite ceramic and preparation method thereof

InactiveCN107651964AStrengthened grain boundariesHigh thermal conductivityComposite ceramicMechanical property

The application belongs to the technical field of ceramics and specifically relates to an AlN-based composite ceramic and a preparation method thereof. The AlN-based composite ceramic comprises AlN and an additive, wherein the additive comprises Re2O3 and ZrO2; Re is selected from Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu. In the AlN-based composite ceramic, the densifying of AlN is promoted by introducing the Re2O3; in addition, the ZrO2 is introduced, and ZrN is generated by performing a high-temperature reaction on the ZrO2, so as to intensify the crystal boundaryof the AlN-based composite ceramic. The invention also provides the preparation method of the AlN-based composite ceramic. Hot pressed sintering is performed by taking the AlN as the basic raw material and the Re2O3 as a sintering additive and adding the appropriate amount of nano-sized ZrO2. The AlN-based composite ceramic obtained by the preparation method has comparatively good heat conductivity and breaking tenacity and good mechanical property. Therefore, the AlN-based composite ceramic can be widely applied in various fields of the ceramics, metallurgy, electronics, chemical engineeringand the like.

Owner:GUANGDONG UNIV OF TECH

Aluminum oxide ceramic ball with high wear resistance and preparation method thereof

The invention discloses an aluminum oxide ceramic ball with high wear resistance. The aluminum oxide ceramic ball is prepared from, by weight, 100 parts of high bauxite, 5-12 parts of titanium carbonitride, 0.2-0.8 part of chromium powder, 5-15 parts of electro-fused zirconia powder, 1-5 parts of wollastonite, 2-10 parts of activated clay, 3-12 parts of kaolin, 0.5-1.5 parts of calcium carbonate, 0.2-1.5 parts of lithium carbonate, 0.1-0.5 part of lanthanum oxide, 0.1-0.5 part of yttrium oxide, 0.1-0.5 part of europium oxide, 0.2-1 part of tetraterbium heptaoxide, 0.3-0.8 part of holmium oxide and 0.1-0.5 part of copper oxide. According to the aluminum oxide ceramic ball with the high wear resistance and a preparation method thereof. The preparation method is simple in process and mild in condition, and the obtained aluminum oxide ceramic ball is excellent in anti-impact property and good in wear resistance and can meet the use requirements of a cement grinding system.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Dispersion strengthening copper-based composite material for spot-welding electrode and preparation method of dispersion strengthening copper-based composite material

The invention discloses a dispersion strengthening copper-based composite material for a spot-welding electrode and a preparation method of the dispersion strengthening copper-based composite material, and belongs to the technical field of metal-based composite materials. The dispersion strengthening copper-based composite material for the spot-welding electrode is composed of, by mass, 5%-10% of TiC, 0.5%-1% of Ce, 0.5%-1% of La2O3, 0.1%-1% of Al2O3 and the balance Cu. The TiC has the characteristics of being high in hardness, high in melting point and good in heat stability. The TiC and the Cu are not subjected to solid solution with each other. The prepared composite material not only has the TiC characteristics of being high in strength, high in hardness and high in melting point but also has the Cu characteristics of being high in electrical conductivity, high in thermal conductivity and the like. Furthermore, the strength, abrasion resistance and high-temperature resistance of copper can be improved through the TiC. The light rare earth element Ce and the light rare earth oxide La2O3 have the effects of strengthening the grain boundary and refining crystal grains, and thus the strength and machinability of the composite material can be improved.

Owner:HENAN UNIV OF SCI & TECH

Rare-earth-containing 34Mn2V high-pressure gas bottle blank and production method thereof

The invention relates to a rare-earth-containing 34Mn2V high-pressure gas bottle blank and a production method thereof, belonging to the technical field of metallurgy of iron and steel. The production process provided by the invention comprises the following steps: feeding molten iron into a blast furnace, pretreating the molten iron, performing converter smelting, performing LF (ladle furnace) refinement, performing VD (vacuum degasser) vacuum degasification, performing calcium treatment, adding rare earth, performing continuous bloom casting, rolling to obtain a finished blank of 200mm*200mm, sampling, performing heat treatment on the sample, and inspecting. By adopting the technical scheme, the invention has the following advantages in comparison with the traditional technology: the 34Mn2V high-pressure gas bottle blank is low in gas content of H, O and N, and the steel quality is clean; the cross section of the blank is light in carbon segregation degree and manganese segregation degree; the macroscopic structure is compact, the metallurgical structure is pearlite plus ferrite, the grain fineness is Level 7-9, and the level of inclusion in steel is low; the 34Mn2V high-pressure gas bottle blank is uniform in composition, structure and performance; the bottle punching process is fine in performance, is suitable for producing a high-pressure gas bottle through punching and is safe to use; the 34Mn2V high-pressure gas bottle is stable and uniform in performance, high in plasticity and impact property reservation margin and fine in comprehensive mechanical property.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Heat treatment method for GH4169 high-temperature alloy wire after cold deformation

InactiveCN112593170AInhibit growthMeeting Organizational Performance NeedsHeat conservationSuperalloy

The invention discloses a heat treatment method for a GH4169 high-temperature alloy wire after cold deformation, belongs to the technical field of high-temperature alloy wire preparation, and providesan intermediate heat treatment method for the GH4169 high-temperature alloy wire after cold deformation, wherein the method realizes optimal control of cold drawing deformation and a heat treatment process. The method specifically comprises the following steps of carrying out solid solution heat treatment on an obtained cold-drawn wire, and carrying out heat preservation at 1000-1020 DEG C for 5-20 minutes; cooling to 960 DEG C at a cooling rate of 20 DEG C / min, and keeping the temperature for 60 minutes; finally, filling argon for air cooling; and enabling the vacuum degree to be less than 10<-3>Pa in the solid solution heat treatment process. By means of the method, the cold-drawn wire is obtained, ideal recrystallized grains and precipitated phase structures are obtained according to the optimal control over the cold-drawn deformation and the corresponding heat treatment temperature, precipitated phases are separated out along grain boundaries, the effects of inhibiting grain growth and strengthening the grain boundaries are achieved, and the structure performance requirements of GH4169 alloy wires for aerospace fasteners and spring wires are met.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Rare earth microalloyed anti-seismic and hot-rolled H-shaped steel and preparation method of H-shaped steel

The invention discloses a preparation method of a rare earth microalloyed shock-resistant hot-rolled H-shaped steel, which includes: during the smelting process of the converter, controlling the w[S] of the molten iron in the converter to be ≤ 0.009%, increasing the tapping temperature of the converter to about 1600°C, Control the amount of slag in the converter; extend the refining time of the LF furnace during the LF refining process; during the VD vacuum refining process, the argon blowing time of the VD furnace should not be less than 10 minutes; the casting speed range of the continuous casting machine is 0.80m / min~0.9m / min, The superheat degree of the steel type is less than 25°C; in the rolling process, the heating temperature is 1210-1250°C, the starting rolling temperature is ≤1200°C, and the final rolling temperature is 870-890°C to obtain H-shaped steel. The invention also discloses a rare earth micro-alloyed shock-resistant hot-rolled H-shaped steel. The invention adopts the narrow component design, and the obtained H-shaped steel can meet the requirements of the yield strength and tensile strength of the shock-resistant hot-rolled H-shaped steel.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Rare-earth-containing 37Mn high-pressure gas bottle blank and production method thereof

The invention relates to a rare-earth-containing 37Mn high-pressure gas bottle blank and a production method thereof, belonging to the technical field of metallurgy of iron and steel. The production process provided by the invention comprises the following steps: feeding molten iron into a blast furnace, pretreating the molten iron, performing converter smelting, performing LF (ladle furnace) refinement, performing VD (vacuum degasser) vacuum degasification, performing calcium treatment, adding rare earth, performing continuous bloom casting, rolling to obtain a finished blank of 200mm*200mm, sampling, performing heat treatment on the sample, and inspecting. By adopting the technical scheme, the invention has the following advantages in comparison with the traditional technology: the 37Mn high-pressure gas bottle blank is low in gas content of H, O and N, and the steel quality is clean; the cross section of the blank is light in carbon segregation degree and manganese segregation degree; the macroscopic structure is compact, the metallurgical structure is pearlite plus ferrite, the grain fineness is Level 7-9, and the level of inclusion in steel is low; the 37Mn high-pressure gas bottle blank is uniform in composition, structure and performance; the bottle punching process is fine in performance, is suitable for producing a high-pressure gas bottle through punching and is safe to use; the 37Mn high-pressure gas bottle is stable and uniform in performance, high in plasticity and impact property reservation margin and fine in comprehensive mechanical property.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

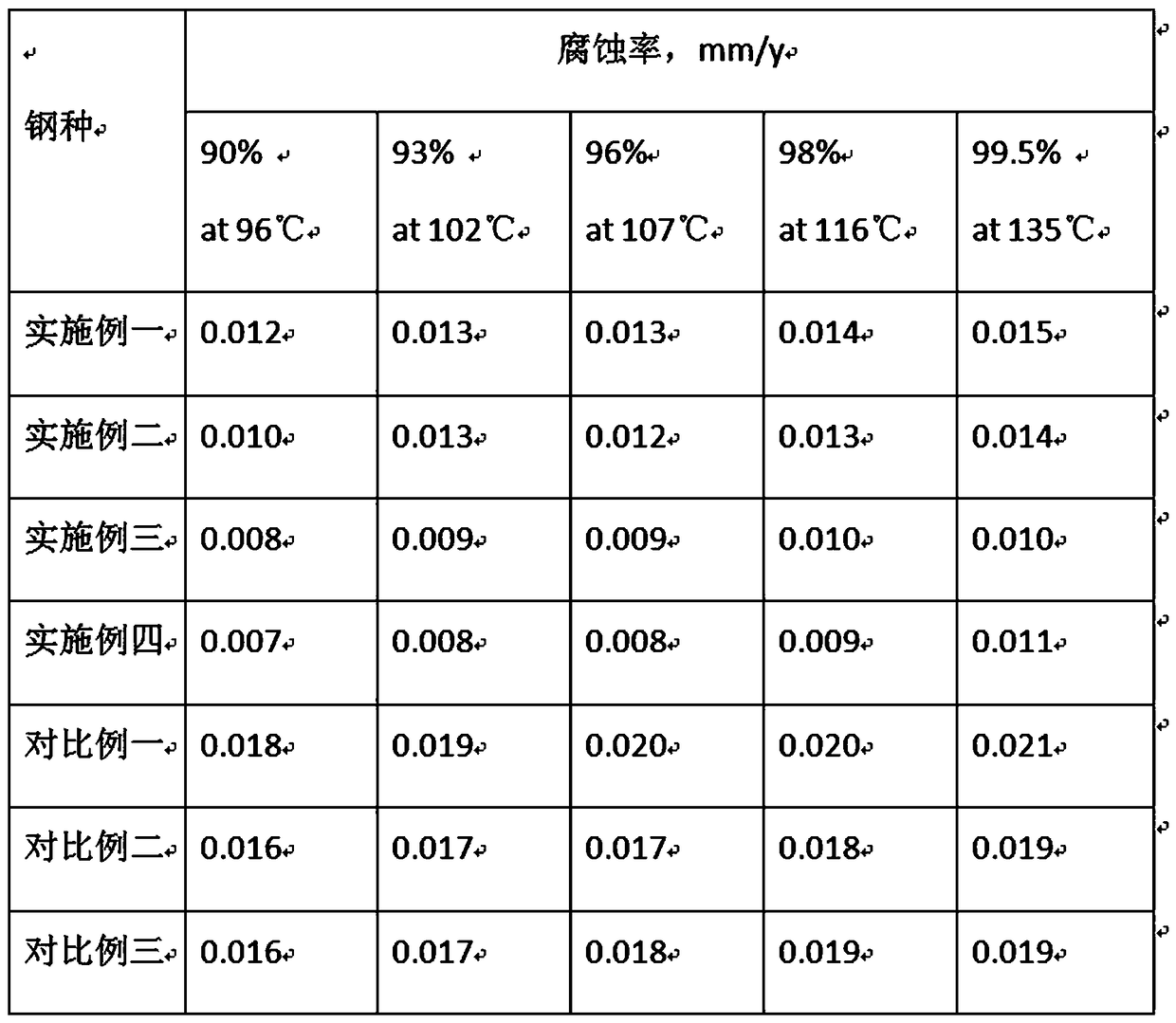

Austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid

The invention relates to an austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid and belongs to the technical field of austenitic stainless steel. The austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid comprises, by weight, 13-19.5% of Cr, 13-22% of Ni, 4.5-6.5% of Si, 0.30-1.5% of Cu, 0.75-2.5% of Mo, 0.07% or less of C, 2% or less of Mn, 0.015% or less of S, 0.03% or less of P, 0.3% or less of Al, inevitable impurities, and the balance Fe. Among steel varieties in the prior art, Zecor, Saramet35 and sandvik SX developed by foreign companies are similar to the austenitic stainless steel on the aspects of material design and overall performance, and compared with the steel of foreign countries, the austenitic stainless steel has more obvious advantages on the aspects of material manufacturing process, yield improvement, corrosion resistance and the like.

Owner:YONGXING SPECIAL STAINLESS STEEL

Alloy powder for die steel laser cladding remanufacturing and preparation method of alloy powder

InactiveCN110238383AImprove high temperature mechanical propertiesGood high temperature mechanical propertiesMetallic material coating processesCrack resistanceAlloy

The invention discloses alloy powder for die steel laser cladding remanufacturing and a preparation method of the alloy powder. The alloy powder comprises the following components of, in percentage by weight, 0.45%-0.60% of C, 4.20%-8.50% of Co, 3.20%-4.80% of Cr, 1.20%-3.35% of Mo, 0.60%-2.40% of Mn, 0.40%-0.85% of Nb, 0.50%-2.40% of Si, 0.8%-3.2% of B, 0.01%-0.03% of Y2O3, 0.01%-0.03% of La2O3, less than or equal to 0.035% of P, less than or equal to 0.025% of S and the balance Ni. According to the alloy powder for die steel laser cladding remanufacturing and the preparation method of the alloy powder, the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in the laser cladding process can be improved, the high-temperature mechanical property of 4Cr5Mo3V die steel is improved, the service life of the 4Cr5Mo3V steel is prolonged, and the economical efficiency is good.

Owner:CHANGSHAN SHUANGMING BEARING

High-strength and rapid-corrosion magnesium alloy and preparation method thereof

InactiveCN110016598AHigh strengthIncrease corrosion rateConstructionsFluid removalMetal alloyPotassium

The invention relates to the technical field of metal alloy materials, and particularly relates to a high-strength and rapid-corrosion magnesium alloy, and a preparation method thereof. The alloy is composed of the following components in percentage by weight: 2%-8% of Al, 0.5%-7% of Ge and the balance magnesium. According to the high-strength and rapid-corrosion magnesium alloy, and the preparation method thereof, the strength and the corrosion speed of the magnesium alloy are increased by adequately utilizing the action of the elements Al and Ge, and the mechanical property of the magnesiumalloy is remarkably improved, and the corrosion speed of the magnesium alloy is remarkably increased through few alloy element adding types and low adding amounts. The compressive strength of the magnesium alloy is capable of reaching 416-431MPa; the corrosion speed in 3% potassium chloride solution at 90 DEG C is capable of reaching 537-582 mm / a; the performance requirement of a fractured ball can be met; and the magnesium alloy can be used as a structural member, and can also be rapidly dissolved under a specific condition.

Owner:TAIYUAN UNIV OF TECH

Preparation method of austenitic stainless steel resisting high-temperature and high-concentration sulfuric acid

InactiveCN108118237APreferential oxidationReduce oxidationProcess efficiency improvementMaterials preparationHigh concentration

The invention relates to a preparation method of austenitic stainless steel, in particular to the preparation method of the austenitic stainless steel resisting high-temperature and high-concentrationsulfuric acid and belongs to the technical field of the austenitic stainless steel. The method sequentially comprises the process steps of burdening, oxygen blowing decarburization, reduction, steeltapping, ladle refining, casting, cogging, hot rolling and the like. The invention discloses the austenitic stainless steel resisting the high-temperature and high-concentration sulfuric acid. By query and comparison, steel grades in the prior art, namely Zecor, Saramet35 and sandvik SX developed by foreign companies are similar to a steel grade disclosed by the invention in material design and overall performance; compared with the foreign steel grades, the steel grade disclosed by the invention has more obvious advantages in the aspects of a material preparation process, yield improvement, corrosion resistance and the like.

Owner:YONGXING SPECIAL STAINLESS STEEL

Method for preparing Al-Mg3Sb2 composite coating on surface of magnesium alloy

InactiveCN105908118ASimple methodSuitable for mass productionMolten spray coatingAl powderHeat stability

The invention discloses a method for preparing an Al-Mg3Sb2 composite coating on the surface of magnesium alloy. After being mixed, Mg powder and Sb powder are ball-milled in a ball milling machine, so that Mg chemically reacts with Sb to form an Mg3Sb2 intermetallic compound, Mg3Sb2 powder and granulated Al powder are thermally sprayed to the surface of a magnesium alloy workpiece subjected to sandblasting treatment, and the Al-Mg3Sb2 composite coating is obtained; after the Al-Mg3Sb2 composite coating is heated, the coating is hot-pressed on a press machine. The Mg powder and the Sb powder have a solid-phase reaction in the ball milling process to generate the Mg3Sb2 intermetallic compound, Mg3Sb2 melting point is high, heat stability is good, dislocation movement can be effectively hindered, a substrate and a grain boundary are remarkably reinforced, and high-temperature mechanical properties and creep resistance of the workpiece are improved. Pores and layered structures in the thermally sprayed Al-Mg3Sb2 composite coating disappear in the hot press process because the composite coating plastically deforms and is compacted, compactness of the coating is remarkably improved, and the high-temperature mechanical properties and creep resistance are given full play to.

Owner:HUBEI UNIV OF TECH

Electrode materials of composite rare-earth iridium alloy and sparking plug of using the electrode materials

ActiveCN101550499AImprove high temperature durabilityImprove heat resistanceSparking plugsIridiumHigh pressure

The present invention discloses an electrode materials of composite rare-earth iridium alloy that is a noble metal alloy containing Ir. The noble metal alloy contains 99.5-99.9 wt% Ir and 0.10-0.50 wt% X; the X is one or a mixture of some of the La, Nd, Pr, Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ce; the noble metal alloy can also contains Th and Al added at the same time. The invention also discloses a sparking plug of composite rare-earth iridium alloy, includes a center electrode and at least a lateral electrode, ignition tip of the center electrode and / or the lateral electrode is the noble metal alloy. The invention provided electrode materials has advantage of high-temperature resistance, strong high-temperature corrosion resistance and excellent performance price ratio; sparking plug of using the electrode materials can provide strong spark on time even the motor is in high-speed, high-temperature high-pressure condition.

Owner:昆明富尔诺林科技发展有限公司

ZTA ceramic material preparation method and material prepared from method

ActiveCN110015889ARaise the sintering temperatureImprove the performance of sintered bodyChromium(III) hydroxideHardness

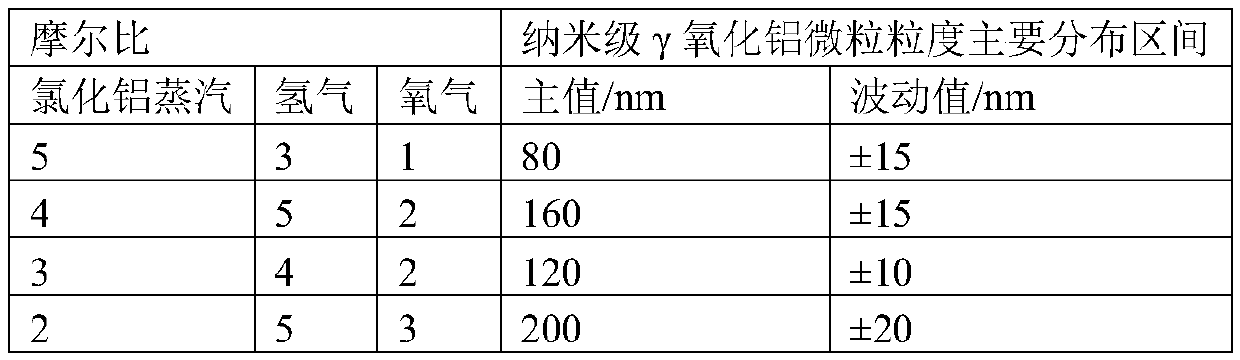

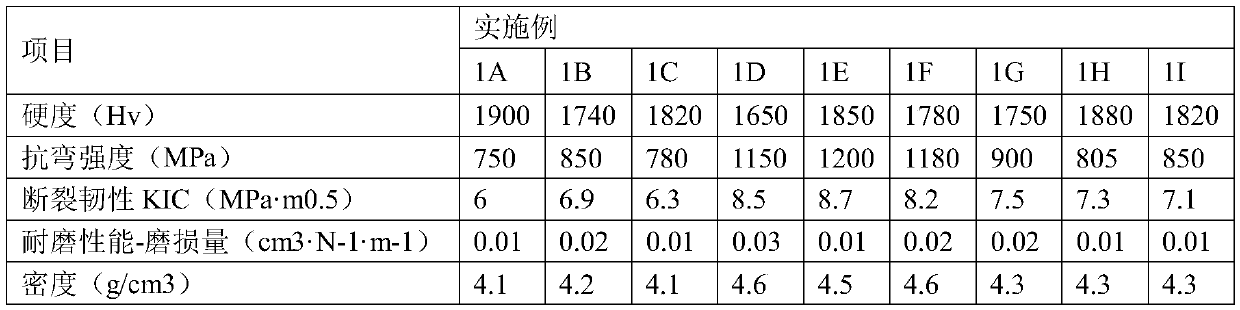

The invention relates to a zirconia toughened alumina (ZTA) ceramic material, and discloses a ZTA ceramic material preparation method and a material prepared from the method. The preparation method comprises the following steps: mixing independently prepared chromium hydroxide gel, gamma alumina particles and nano 2Y hydrated zirconia gel to prepare a mixed gel, then carrying out calcining, carrying out airflow crushing, carrying out grinding to obtain slurry, and carrying out spray granulation to obtain raw material ZTA composite ceramic powder, carrying out isostatic pressing molding on theraw material ZTA composite ceramic powder to obtain a ZTA ceramic blank, and then carrying out high-temperature sintering to obtain the ZTA ceramic material. The particle sizes of the nanoscale gammaalumina particles and the 2Y hydrated zirconia gel are controlled, and the nanoscale gamma alumina particles are prepared by mixing aluminum chloride steam with hydrogen and oxygen and then carrying out combustion. The ratio of the aluminum chloride steam to the hydrogen and oxygen are controlled during combustion and the gas pressure during combustion are controlled, so that particle size fluctuation is reduced, the mixing uniformity degree and the granularity of components in coarse ZTA ceramic powder and the raw material ZTA composite ceramic powder are controlled, and properties such as strength, hardness, wear resistance and the like of the toughened ZTA ceramic material obtained by sintering are improved.

Owner:NINGBO TOPTEK ADVANCED CERAMICS CO LTD

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel and preparation method thereof

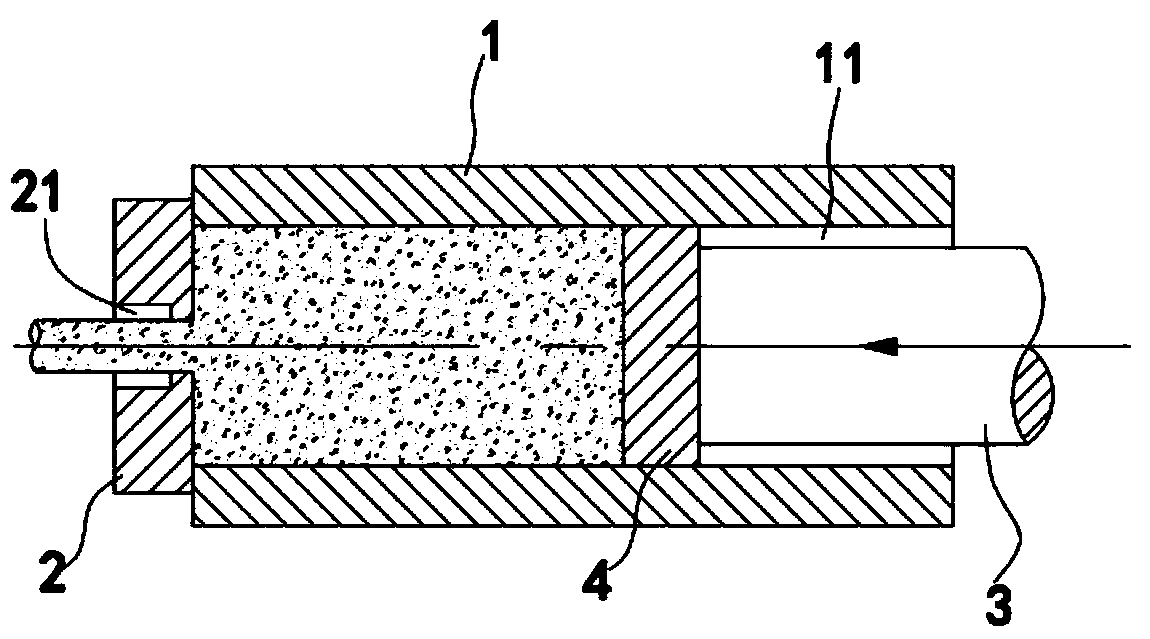

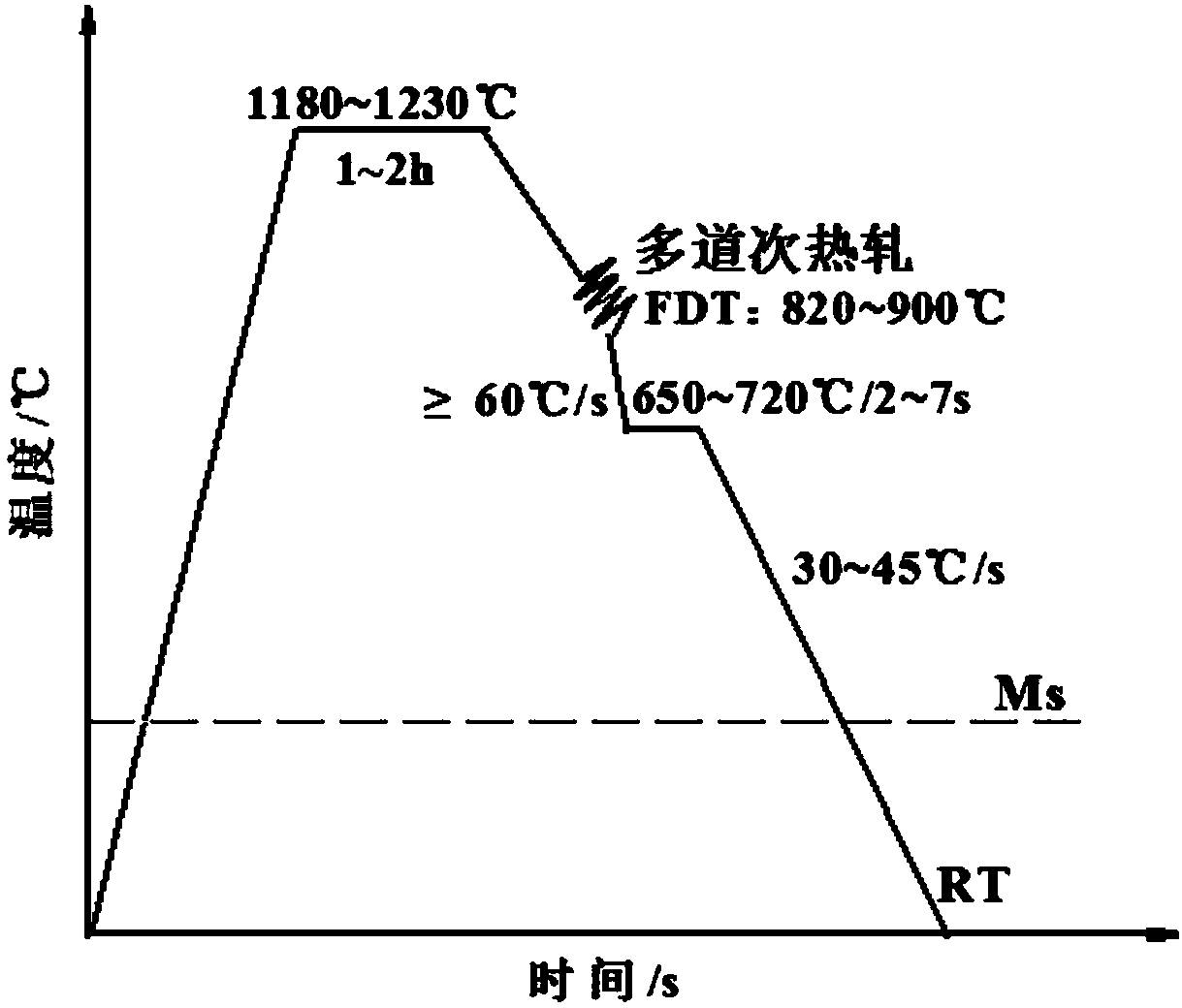

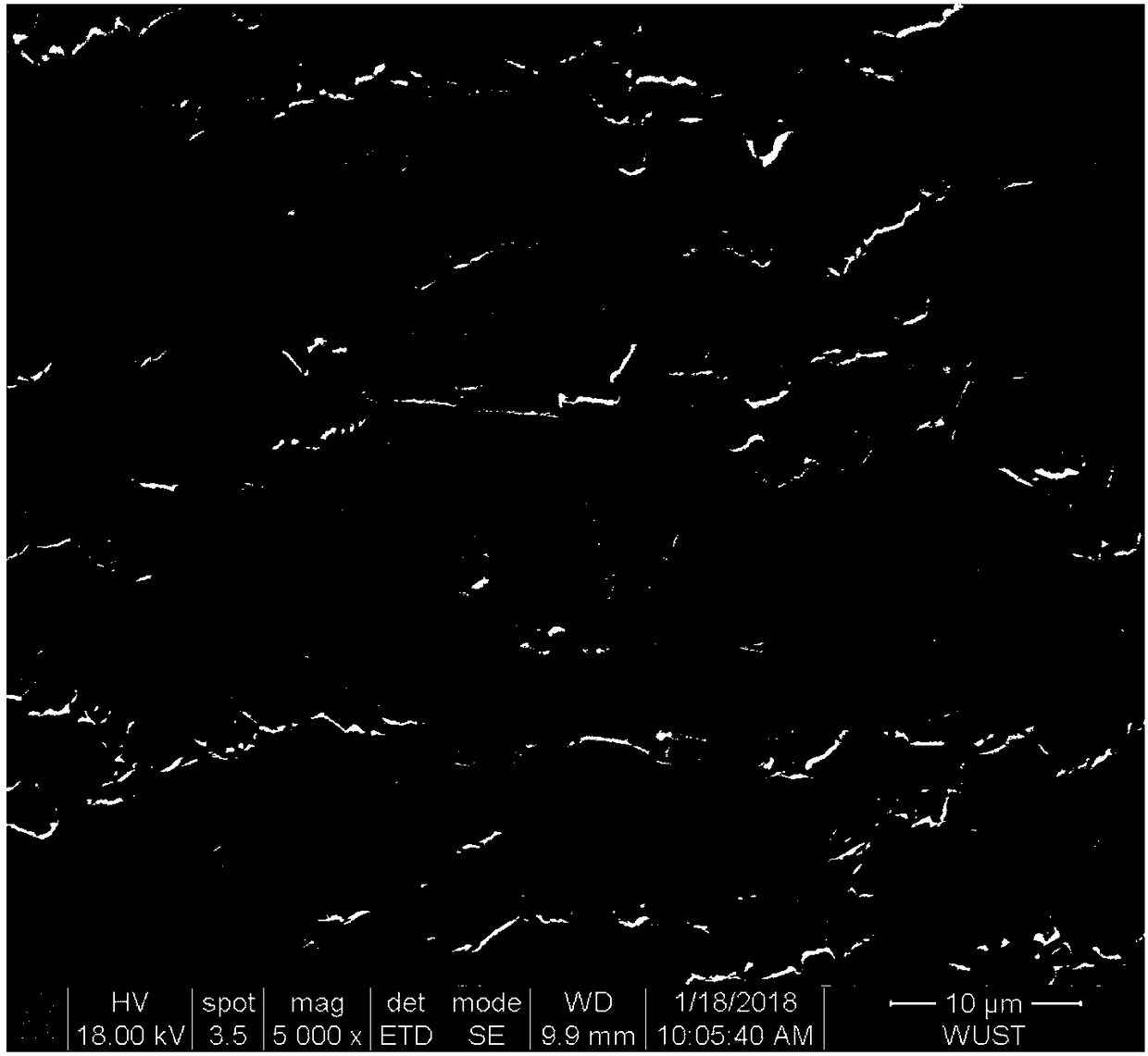

The invention relates to 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel and a preparation method of the 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel. According to the technical scheme, the low-carbon hot-rolled dual-phase steel comprises the chemical components of 0.17-0.22 wt% of C, 0.2-0.8 wt% of Si, 1.4-2.0 wt% of Mn, 0.03-0.06 wt% of Al, 0.03-0.06wt% of Nb, 0.001-0.004 wt% of B, not larger than 0.020 wt% of P, not larger than 0.005 wt% of S and the balance Fe and inevitable impurities. According to the preparation method, the chemical components are smelted, refining and blank casting are conducted, the blank is placed in a heating furnace, the charging temperature is 700-850 DEG C, and the temperature is kept at 1180-1230 DEG C for 1-2 h;large reduction is adopted during the first three passes, the reduction rate is 40%-60%, and the finish rolling temperature is 820-900 DEG C; after finish rolling, the rolled blank is rapidly cooledto 650-720 DEG C, air cooling relaxation is conducted for 2-7 s so as to separate out ferrite, then the obtained steel is water cooled to the indoor temperature, and therefore the 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel is obtained. The technology is simple, the production cost is low, the strength, plasticity and tenacity of the obtained product match well, and the formation performance is excellent.

Owner:WUHAN UNIV OF SCI & TECH

Aluminium piston alloy

The invention discloses an aluminium piston alloy, relating to the technical field of alloy material. The aluminium piston alloy comprises the following chemical components in percentage by mass: 1.0-1.5% of Cu, 0.4-1% of Mg, 11-13% of Si, 0.6-1% of Fe, 0.3-0.9% of Mn, 0.8-1.4% of Re, 0.001-0.005% of Sn, 0.001-0.005% of Pb, 0.01-0.15% of Zn, 0.01-0.09% of Cr, 0.06-0.18% of Ti and the balance of Al and inevitable impurities. Compared with the prior art, the aluminium piston alloy has the advantages that the strength and hardness are increased, the volume stability and cutting property are enhanced; after standing for a period of time, a finished aluminium piston hardly deforms, so that the yield of qualified products is increased.

Owner:LIUZHOU KAITONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com