Piston aluminum ingot used for turbo charger car

A technology of turbocharging and aluminum ingots, applied in the field of piston aluminum ingots, can solve the problems of poor mechanical properties of aluminum alloy pistons, waste of aluminum scraps, etc., and achieve the effects of improving drying effect, stable combustion, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

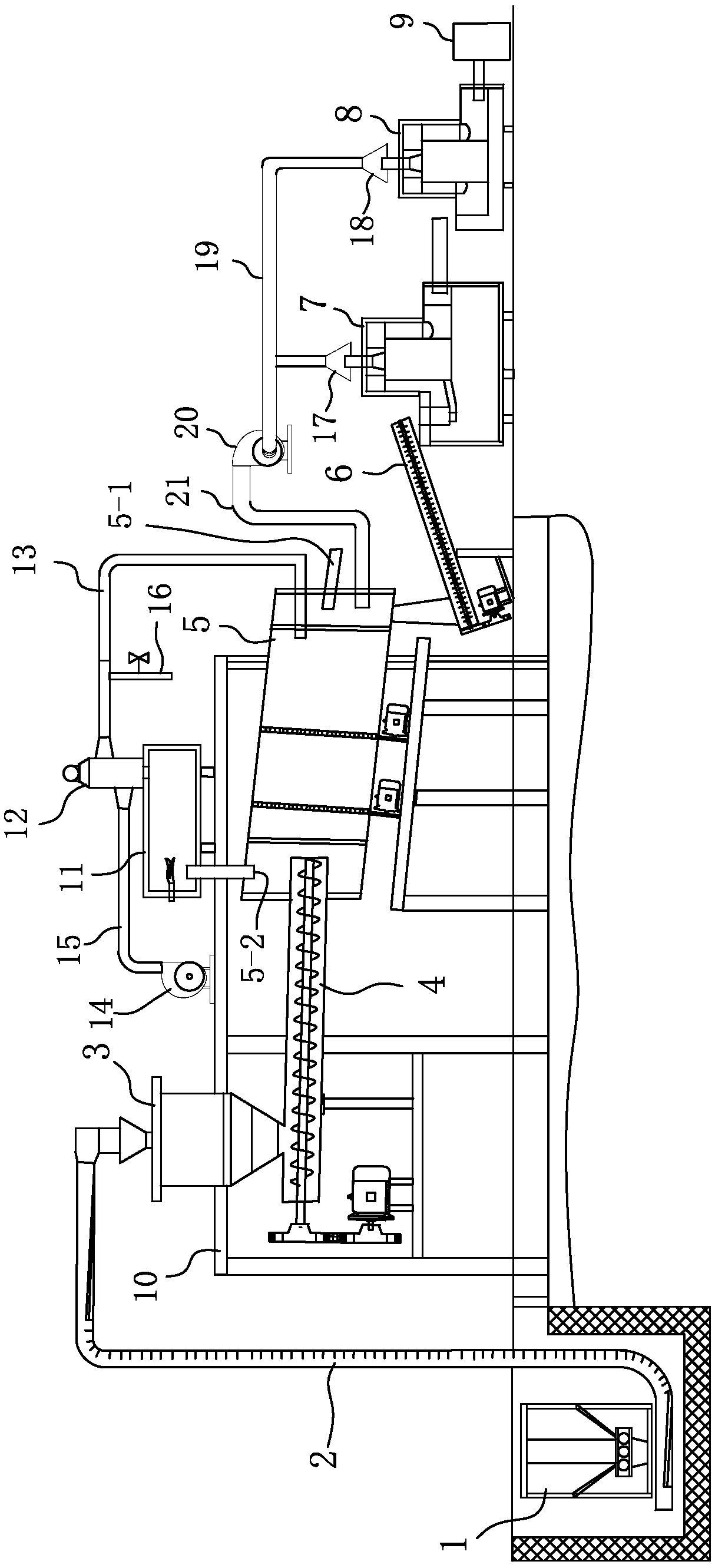

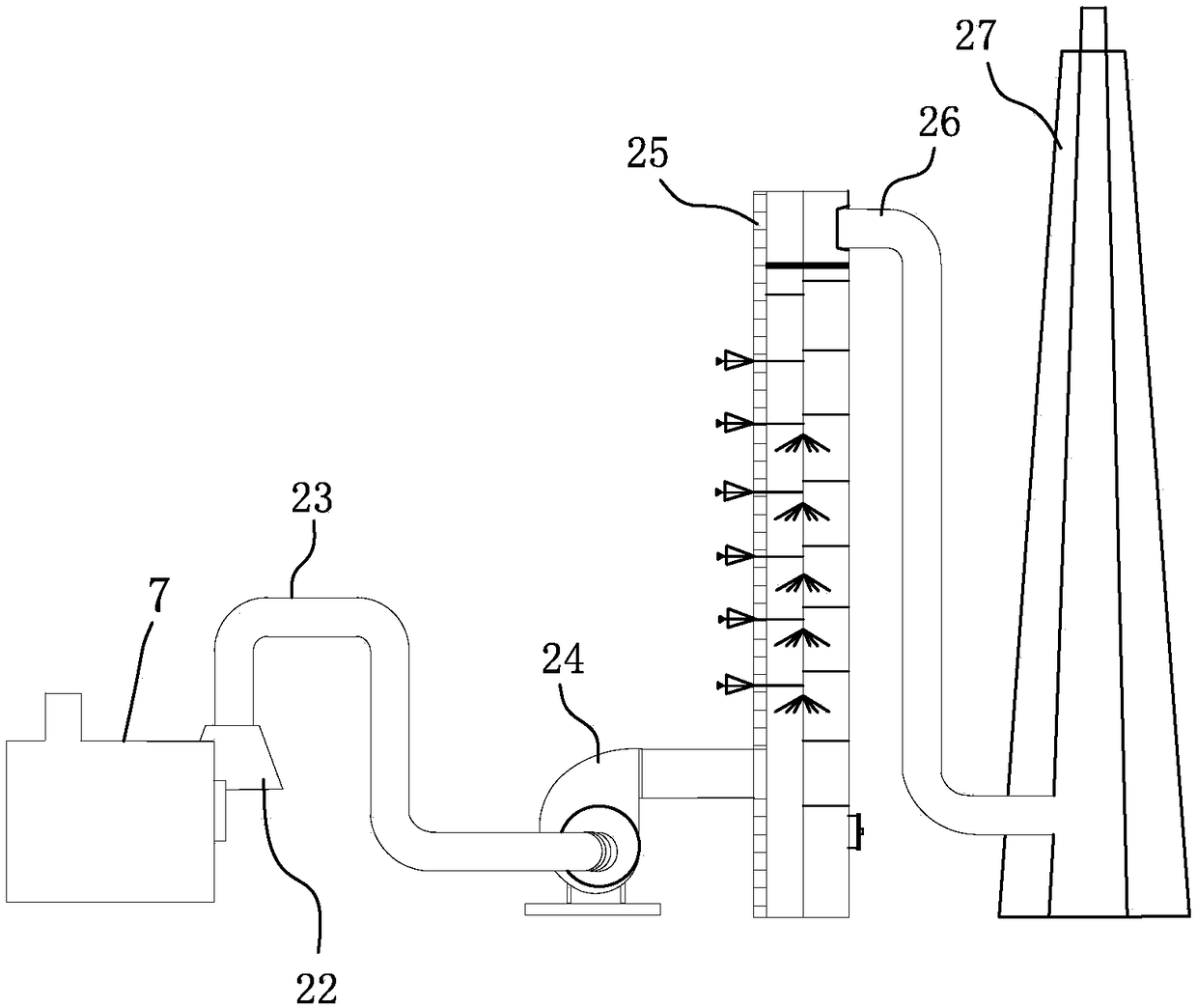

[0067] The process method for producing aluminum ingots using the aforementioned production equipment for aluminum ingots for piston processing includes the following steps:

[0068] The first step is to collect the aluminum scraps generated during the machining of the Al-Si-Cu-Ni-Mg alloy piston, and prepare the aluminum ingots, metal ingredients, chemical reagents and production tools for remelting. Chemical reagents and metal ingredients are commercially available. Blagging agent, degassing agent, nitrogen gas and decalcifying agent can all be purchased from the market, and slagging agent, degassing agent and decalcifying agent can be purchased from Zhangjiagang Jieya Metallurgical Application Technology Co., Ltd. The aluminum ingot for remelting adopts the aluminum ingot for remelting with the grade of Al99.70 produced by Shaanxi Nonferrous Yulin New Materials Co., Ltd., and its chemical composition table is as follows:

[0069]

[0070] The second step is to use a pul...

Embodiment 2

[0086] The process method for producing aluminum ingots using the aforementioned production equipment for aluminum ingots for piston processing includes the following steps:

[0087] The first step is to collect the aluminum scraps generated during the machining of the Al-Si-Cu-Ni-Mg alloy piston, and prepare the aluminum ingots, metal ingredients, chemical reagents and production tools for remelting. Chemical reagents and metal ingredients are commercially available. The aluminum ingot for remelting adopts the aluminum ingot for remelting with the grade of Al99.70 produced by Shaanxi Nonferrous Yulin New Materials Co., Ltd., and its chemical composition table is as follows:

[0088]

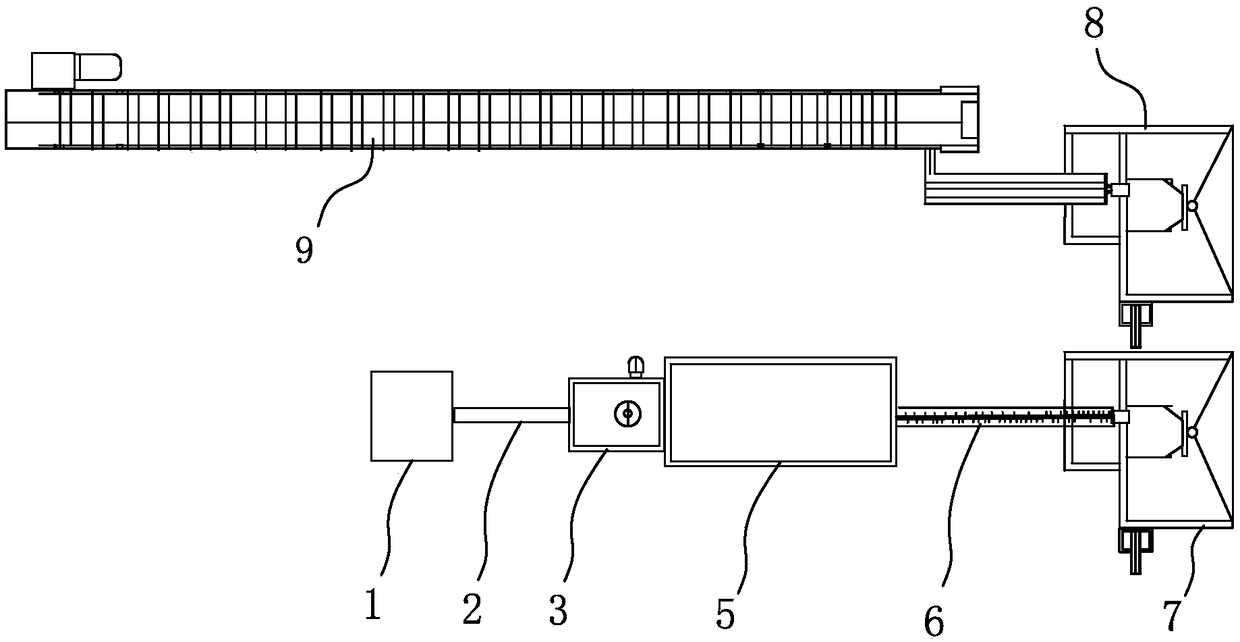

[0089] The second step is to use a pulverizer to cut and pulverize the aluminum chips.

[0090] The third step is to pour the crushed aluminum scraps into the scrap box 1.

[0091] In the fourth step, the scraper elevator 2 works to transport the crushed aluminum scraps in the chip collecti...

Embodiment 3

[0105] The process method for producing aluminum ingots using the aforementioned production equipment for aluminum ingots for piston processing includes the following steps:

[0106] The first step is to collect the aluminum scraps generated during the machining of the Al-Si-Cu-Ni-Mg alloy piston, and prepare the aluminum ingots, metal ingredients, chemical reagents and production tools for remelting. Chemical reagents and metal ingredients are commercially available. The aluminum ingot for remelting adopts the aluminum ingot for remelting with the grade of Al99.70 produced by Shaanxi Nonferrous Yulin New Materials Co., Ltd., and its chemical composition table is as follows:

[0107]

[0108] The second step is to use a pulverizer to cut and pulverize the aluminum chips.

[0109] The third step is to pour the crushed aluminum scraps into the scrap box 1.

[0110] In the fourth step, the scraper elevator 2 works to transport the crushed aluminum scraps in the chip collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com