1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel and preparation method thereof

A hot-rolled dual-phase steel and micro-alloying technology, which is applied in the field of low-carbon hot-rolled dual-phase steel, can solve problems such as unfavorable stamping of structural parts, difficulty in industrialized large-scale production, and increased production costs, so as to improve plastic toughness and increase production costs. Effect of strengthening grain boundaries and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. These examples are only descriptions of the best implementation modes of the present invention, and do not limit the protection scope of the present invention.

[0033] A 1400MPa grade B microalloyed low-carbon hot-rolled dual-phase steel and a preparation method thereof. The chemical composition of the 1400MPa grade B microalloyed low-carbon hot-rolled dual-phase steel is: C is 0.17-0.22wt%, Si is 0.2-0.8wt%, Mn is 1.4-2.0wt%, and Al is 0.03-0.06 wt%, Nb is 0.03-0.06wt%, B is 0.001-0.004wt%, P≤0.020wt%, S≤0.005wt%, and the balance is Fe and unavoidable impurities.

[0034] Preferably: B is 0.002-0.003wt%.

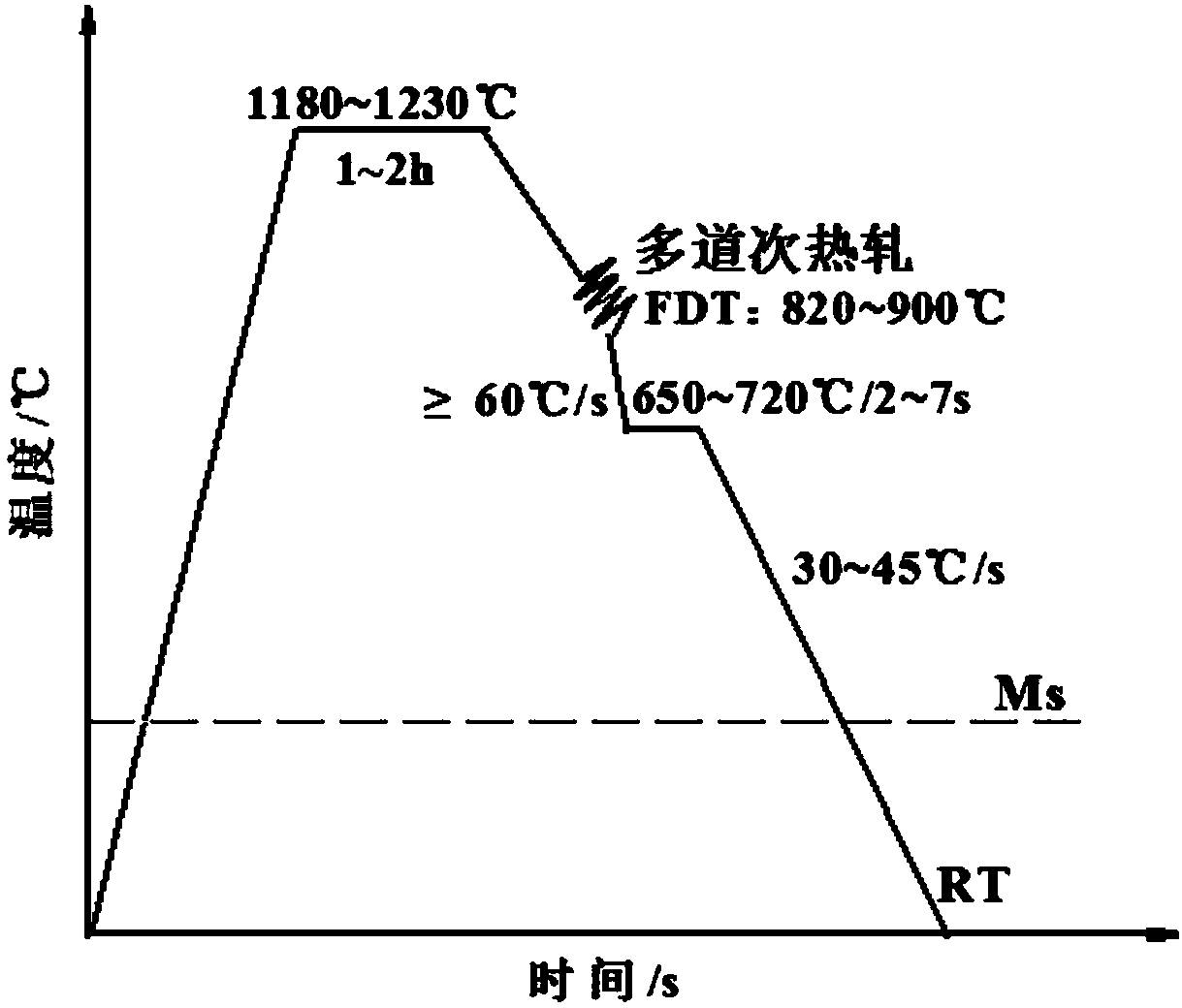

[0035] figure 1 For the process schematic diagram of this specific embodiment, from figure 1 It can be seen that the preparation method steps of the 1400MPa grade B microalloyed low-carbon hot-rolled dual-phase steel are:

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com