Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

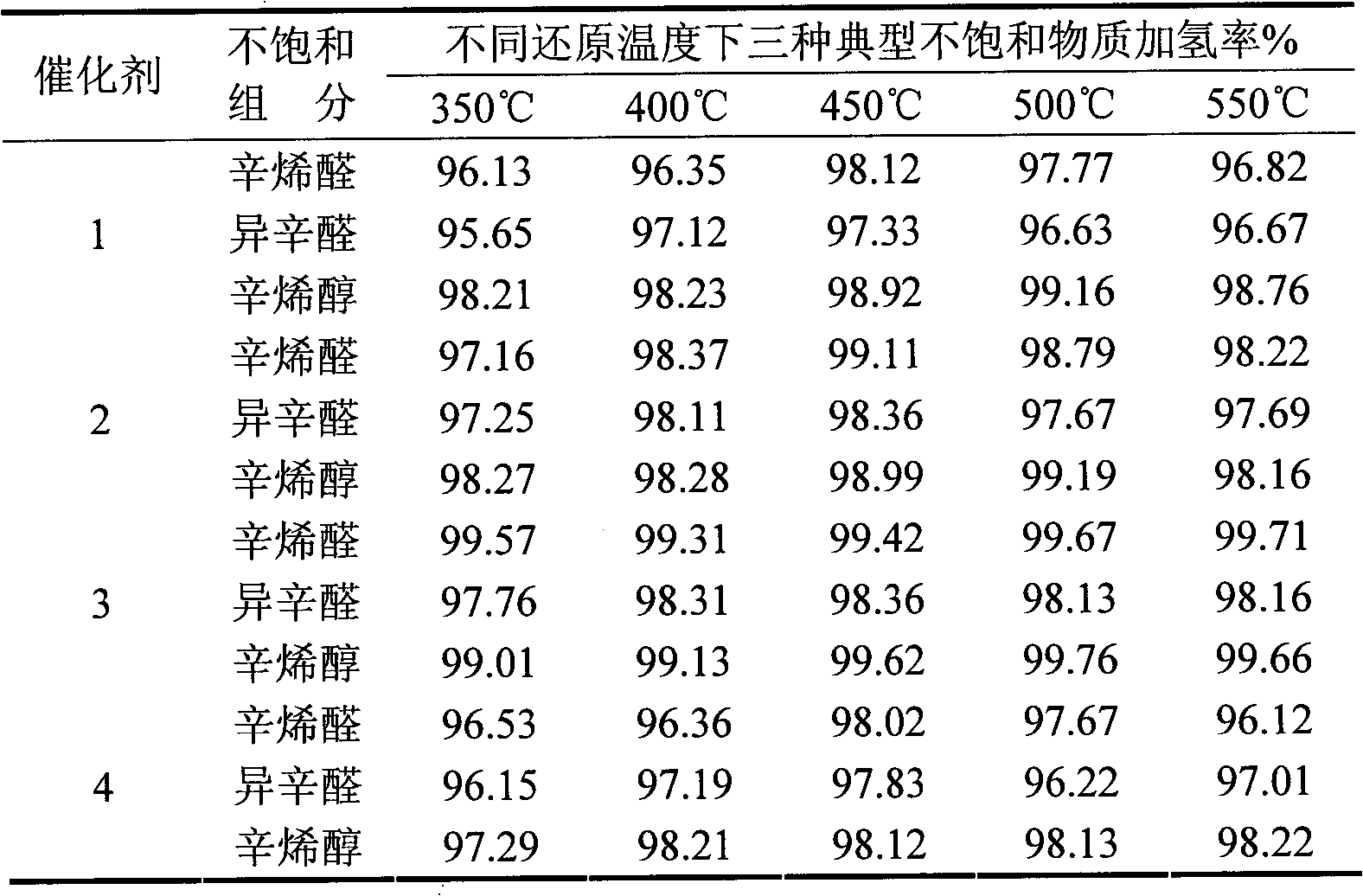

A hydrofining and catalyst technology, which is applied in the direction of catalyst activation/preparation, hydroxyl compound preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of increased preparation cost, unfavorable application of online reduction device, and high activation temperature and other problems, to achieve good industrial application prospects, reduce the formation of solid solutions, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 200g of pseudo-boehmite powder, 3g of turmeric powder, 6g of concentrated nitric acid, and 180g of water, fully knead, and extrude into a D1.0 trilobal strip carrier, and dry the formed carrier at 110°C 10h, and then roasted at 600°C for 3h to obtain the required carrier A; configure 0.05mol / L lanthanum nitrate aqueous solution B, 0.5mol / L copper nitrate aqueous solution C, and 0.5mol / L nickel nitrate aqueous solution D; A is immersed in solution B for 3 hours, dried at 110°C and then roasted at 500°C for 3 hours; then immersed in 10ml of solution C for 3 hours, after the dipping is completed, dried at 110°C and roasted at 500°C for 3 hours; then immersed in 10ml of solution D for 3 hours , and then dried at 110° C.; calcined at 500° C. for 3 hours to obtain a catalyst precursor.

Embodiment 2

[0025]Add 200g of pseudo-boehmite powder, 4g of turmeric powder, 7g of concentrated nitric acid, and 170g of water, fully knead, and extrude into a D1.5 trilobal strip carrier, and dry the formed carrier at 110°C 10h, and then roasted at 600°C for 3h to obtain the required carrier A; configure 0.02mol / L lanthanum acetate aqueous solution B, 0.5mol / L copper acetate aqueous solution C, and 0.5mol / L nickel acetate aqueous solution D; 20g of the carrier A is immersed in solution B for 3 hours, dried at 110°C and then roasted at 500°C for 3 hours; then immersed in 10ml of solution D for 3 hours, after the dipping is completed, dried at 110°C and roasted at 500°C for 3 hours; then immersed in 10ml of solution C for 3 hours , and then dried at 110° C.; calcined at 500° C. for 3 hours to obtain a catalyst precursor.

Embodiment 3

[0027] Add 200g of pseudo-boehmite powder, 5g of fenugreek powder, 8g of concentrated nitric acid, and 160g of water, fully knead, and extrude into a D2.0 trilobal strip carrier, and dry the formed carrier at 110°C 10h, and then roasted at 600°C for 3h to obtain the required carrier A; configure 0.01mol / L lanthanum sulfate ethanol solution B, 0.25mol / L copper sulfate ethanol solution C, and 0.25mol / L nickel sulfate ethanol solution D; 20g of carrier A is first immersed in B solution for 3 hours, dried at 110°C and then roasted at 500°C; then immersed in 10ml of C+10ml D mixed solution for 3h, after impregnation, dried at 110°C; then roasted at 500°C 3h, the catalyst precursor was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com