Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Lanthanum sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

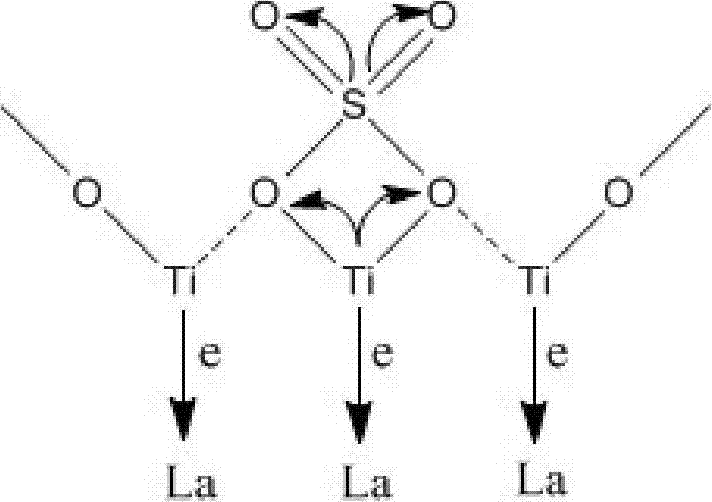

Lanthanum Sulfate is a moderately water and acid soluble Lanthanum source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

Nanometer silicon oxide colloid electrolyte for lead-acid storage battery and its preparing method

InactiveCN1738092AReduce adverse effectsImprove rheologyLead-acid accumulatorsSilicon oxideAgglutination

Disclosed a nanometer monox colloid electrolytic solution of lead-acid storage battery and its preparing method, relates to the manufacturing technique of lead-acid storage battery colloid electrolytic solution special for the electric bicycle. The invention prepares the nanometer monox colloid electrolytic solution by using the lead-acid analytical pure vitriol, vapor phase silica dioxide nanometer powder, salt cake, and the deionized water as main material, which are mixed to be added polyacrylamide and poly-sodium acrylate as gel modifying agent; then, adding litter lanthanum sulfate, cerous sulfate, tungsten oxide, and molybdenum oxide. The invention avoids the disadvantage effect of using sodium silicate colloid; uses vapor phase silica dioxide nanometer powder as gel agent; adds little chemical components, to form the new colloid electrolytic solution which can improve the agglutination property, increase the capacity of accumulator, and prolong the service life of deep discharging cycle. In addition, the invention can be used as electrolytic solution to replace present vitriol water electrolytic solution, to improve the rheological property of colloid electrolytic solution, and control the electrolytic process of water.

Owner:江苏华富能源有限公司

Mixed glue electrolytic liquid of plumbous acid accumulator and production thereof

InactiveCN1747216AIncrease capacityExtended deep discharge cycle lifeLead-acid accumulatorsSilicon dioxidePolypropylene

The mixed gelling electrolyte comprise sulfuric acid, SiO2, sodium sulphate, polyacrylamide, polypropylene sodium, lanthanum sulfate, cerium sulfate, tungsten oxide, molybdenum oxide and deionized water.

Owner:江苏华富能源有限公司

Chromium-free passivation solution for tin plate and method for using same

InactiveCN101638804ALow costSimple processSurface reaction electrolytic coatingChromium freeRare-earth element

The invention relates to an acid metal passivation solution and a method for using the same, in particular to a chromium-free passivation solution for a tin plate and a method for using the same. Thepassivation solution comprises the following components in portion by weight: 5 to 30 portions of inorganic salt of a rare earth element Ce or La, 5 to 40 portions of inorganic salt of ammonium and 1,000 portions of water; the pH value of the passivation solution is between 2 and 7 and can be adjusted by dilute nitric acid or dilute sulfuric acid; the inorganic salt of the rare earth element Ce orLa may be cerous nitrate, cerous sulfate, lanthanum nitrate or lanthanum sulfate; and the inorganic salt of ammonium may be ammonium nitrate or ammonium sulfate. The method for using the passivationsolution comprises that: the tin plate is soaked in the passivation solution for electrochemical processing, and during the processing, the cathodic current density is between 0.1 and 20A / dm<2>, the processing time is between 0.1 and 10s, and the temperature is between 30 and 65 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

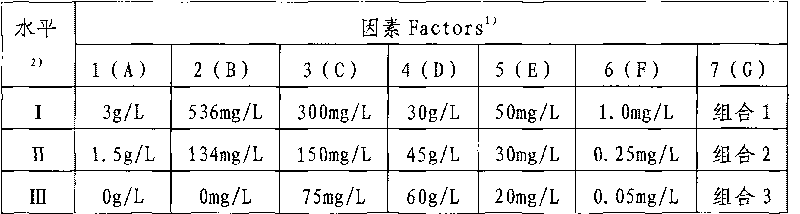

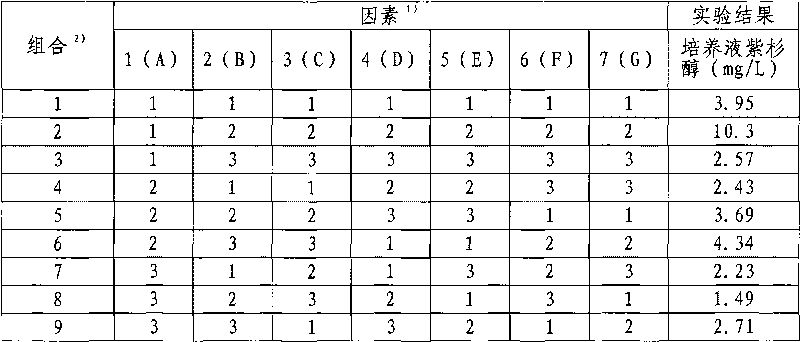

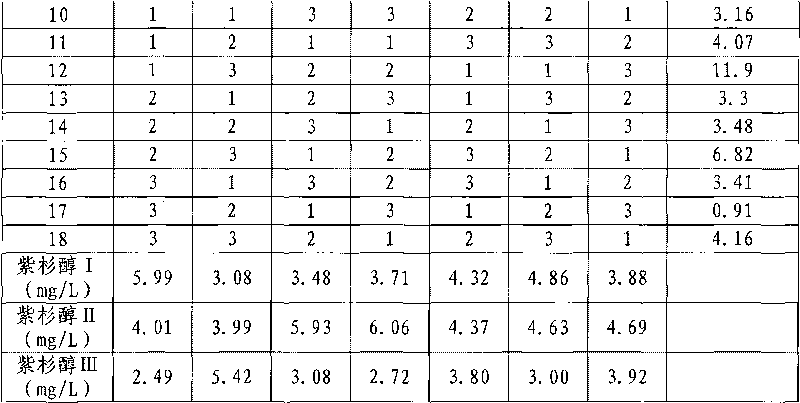

Special culture medium for culturing yew plant cells to produce taxol

The invention discloses a special culture medium for culturing yew plant cells to produce taxol, which is obtained by taking B5 culture medium as a basic formula and utilizing an orthogonal optimization test. When the basic component comparison production is carried out on the special culture medium and the B5 culture medium, the content of the taxol in the special culture medium is 4.2 times that of the B5 culture medium; when high-density of yew plant cells are planted, a combined test is carried out by adding silver nitrate, salicylic acid, chitosan, methyl jasmonic acid, tribasic ammonium citrate, lanthanum sulfate, phenylalanine, glycine, tryptophan and lysine in the culturing process, which can further improve the content of the taxol and shorten the production period of cells; and when the cells are cultured at the thirty-first day, the highest content of the taxol in the special culture medium is 285.15 mg / L which is 81 times the highest content of the taxol in the B5 culture medium, thus the taxol can be effectively produced by using the special culture medium for culturing yew plant cells to produce taxol.

Owner:GUANGDONG KELUN PHARMACEUTICAL CO LTD

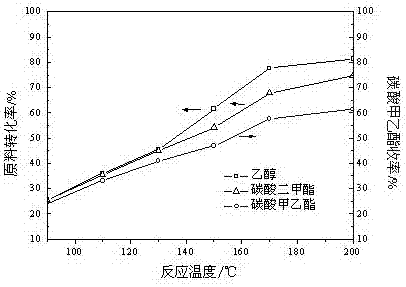

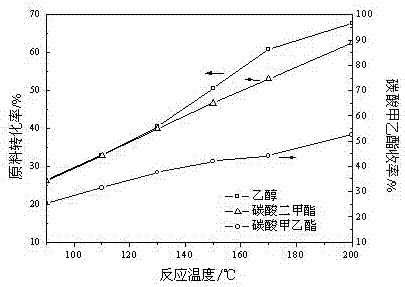

Method for preparation of methyl ethyl carbonate with co-precipitation catalyst

The invention relates to a preparation method of chemical raw materials, in particular to a method for preparation of methyl ethyl carbonate with a co-precipitation catalyst. The method adopts coprecipitation technique to carry one or more of the active components Al2O3, CaO, La2O3, Fe2O3, Mn2O3, Cs2O, MgO, BaO, SrO and K2O, wherein Y is one or more oxides of Si and Al, and Z is one or more oxides of Si, Al and Ti. The invention has the advantages that: macropore can significantly improve the mass transfer effect, and micropore can significantly increase the specific surface area of the carrier and improve the dispersity of the active center. Magnesium nitrate, aluminum chloride and lanthanum sulfate are adopted as the active components and are mixed with a precursor to obtain the 15%MgO-5%Al2O3-3%La2O3 / Al2O3-SiO2 catalyst, which can be applied to dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction. The catalyst active center metal oxide prepared by precipitation method has smaller crystal grains, higher dispersity and surface area, and the prepared catalyst has catalytic effect superior to the catalyst prepared by impregnation method.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for coating hollow microbeads with titanium-lanthanum oxides

InactiveCN102226042AImprove thermal insulation performanceImprove bindingReflecting/signal paintsPigment physical treatmentSurface oxidationRutile

The present invention discloses a method for coating hollow microbeads with titanium-lanthanum oxides. By the method, the surfaces of the hollow microbeads are evenly coated with rutile nano titanium oxide and have a good reflection effect, and the heat-insulation effect of the coating is improved. The method comprises: heating a mixed solution of titanium sulfate solution and lanthanum sulfate solution while stirring to 75-90 DEG C, maintaining the constant temperature and controlling the stirring speed at 500-800 rpm, and simultaneously adding soaked hollow microbeads to the mixed solution at a constant speed within 60-90 minutes; adjusting the pH value of the system to 8.0-9.5, then stirring the system at the stirring speed of 30-80 rpm for 40-90 minutes, and simultaneously ultrasonically vibrating the system; then filtering and washing until the material has a solid content of more than 40%; then carrying out microwave treatment for 15-25 minutes until the material has a solid content of more than 90% and fluffy oxidized surfaces; and heating the material in a roaster to 300 DEG C, maintaining for 1-3 hours, then heating to 900 DEG C and maintaining for 30-60 minutes so that titanium hydroxide coated on the surface of the hollow microbeads is transformed into rutile titanium dioxide.

Owner:TIANJIN HENGSHITONG ENG TECH DEV

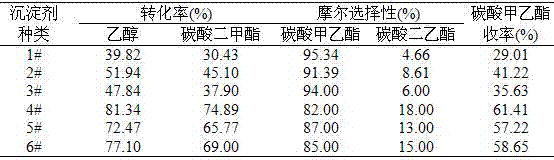

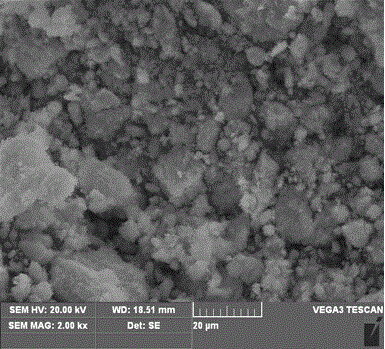

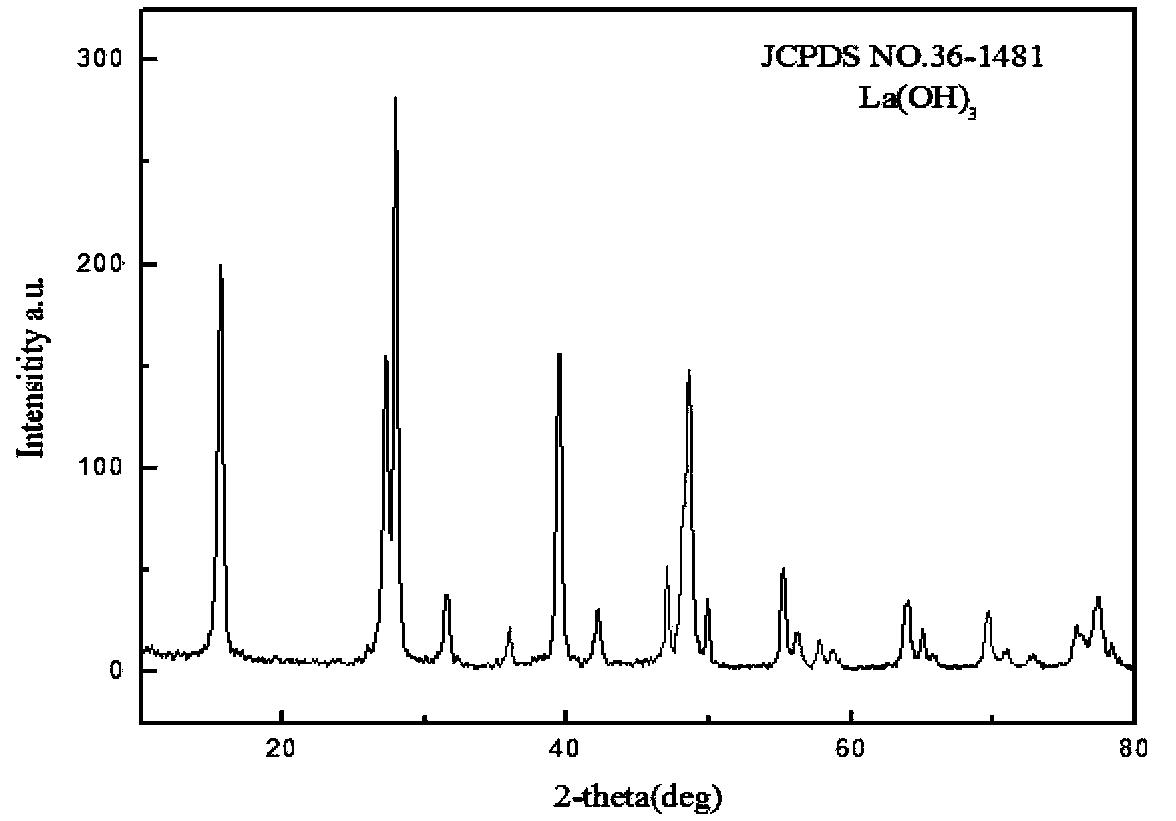

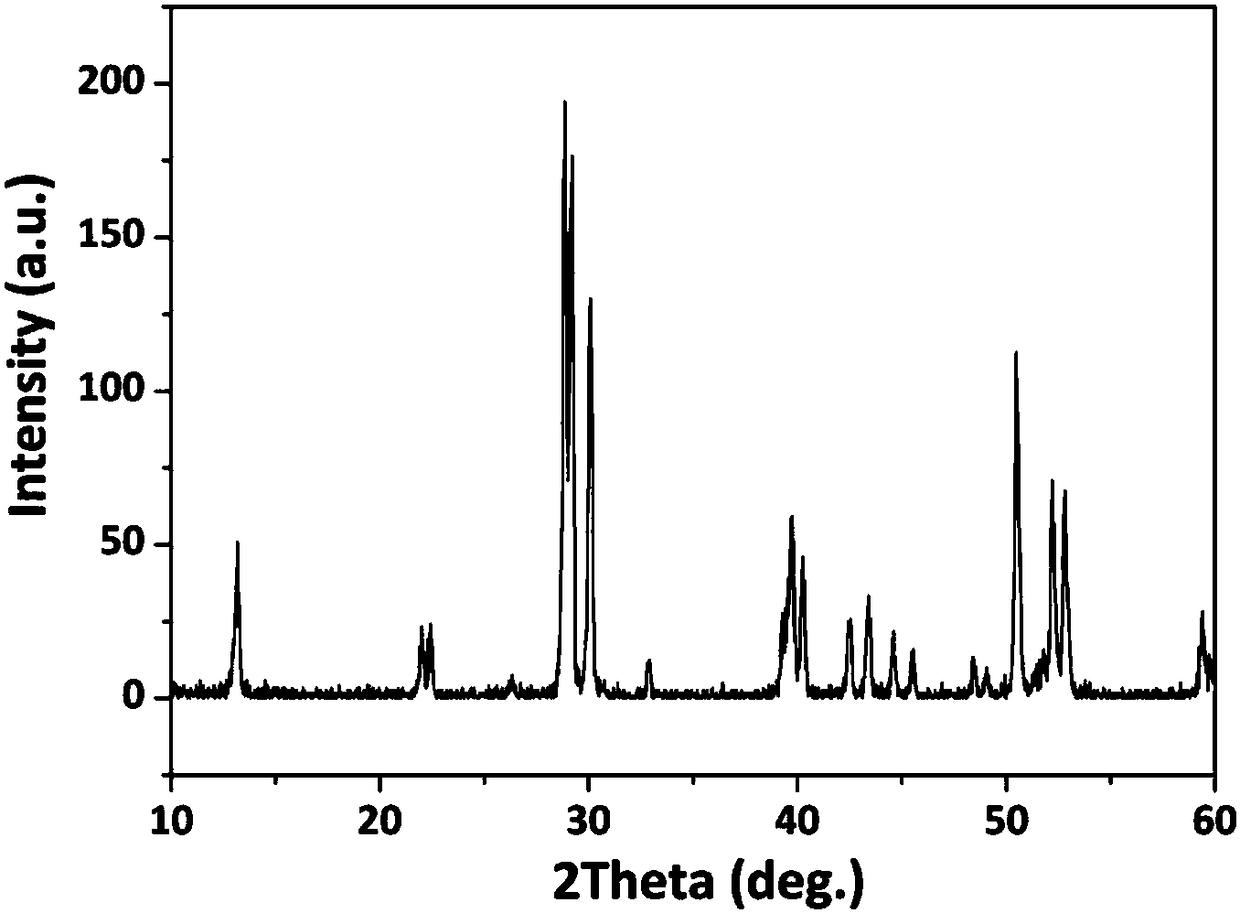

Preparation method of bar-shaped lanthanum hydroxide nanocrystal

ActiveCN102942203AShort reaction timesReduce energy consumptionMaterial nanotechnologyRare earth metal compoundsDispersityEthylenediamine

The invention provides a preparation method of a bar-shaped lanthanum hydroxide nanocrystal. The method comprises the following steps of: adding nona-lanthanum sulfate and ethylenediamine tetraacetic acid into deionized water respectively to obtain a solution B; adjusting the pH of the solution B to 8.0-12.0 with an ammonia water solution to obtain a precursor solution C; pouring the precursor solution C into a four-neck round-bottom flask, putting the four-neck round-bottom flask into a microwave-ultraviolet ray-ultrasonic wave three-in-one synthesis reaction instrument, selecting a microwave heating-ultraviolet irradiation combined reaction in a temperature-time mode, and naturally cooling to the room temperature after the reaction; and centrifugally collecting a product, washing repeatedly with deionized water and absolute ethyl alcohol respectively, and drying to obtain a final product, i.e., bar-shaped lanthanum hydroxide nanocrystal. A simple microwave-ultraviolet ray synthesis method preparation process is adopted, so that the method has the advantages of short reaction time period, low energy consumption, low cost, convenience in operating, one-time completion of a reaction in a liquid phase, and no need of subsequent treatment. La(OH3) particles prepared with the method have bar-shaped structures, are small in size, have high dispersity, and can be applied in the catalysis field and the optics field.

Owner:上海球球云环保科技有限公司

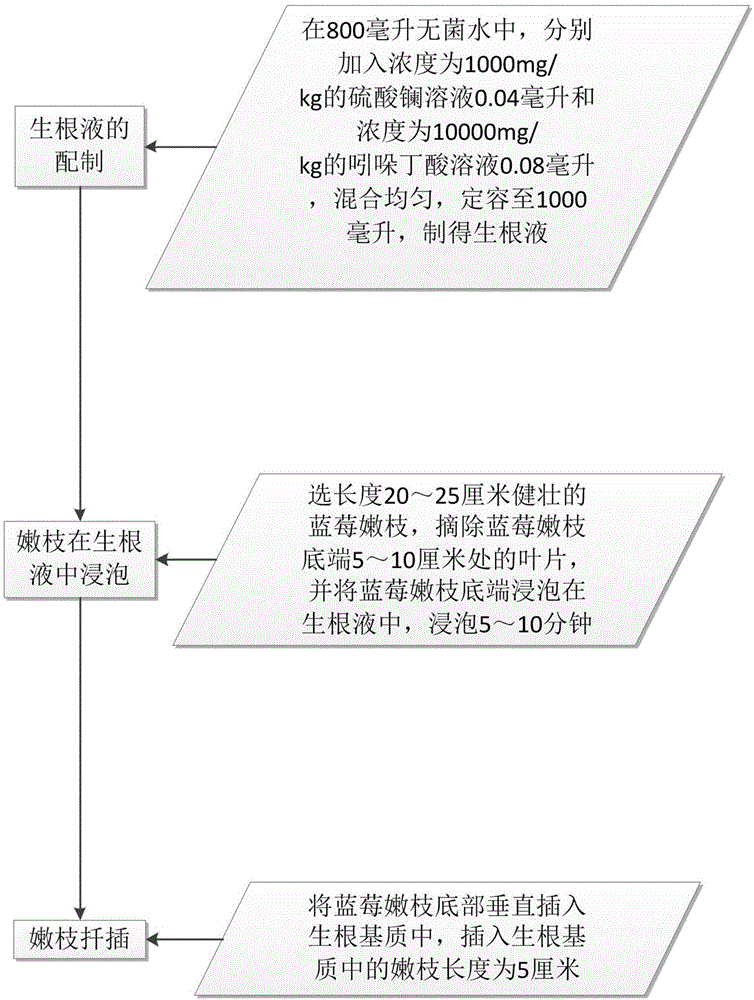

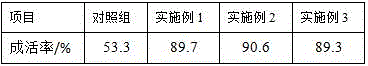

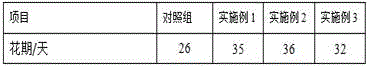

Blueberry twig plant cuttage root-taking cultivation method

InactiveCN102668853AQuality improvementShorten rooting timeHorticultureRelative humidityIndolebutyric Acid

The invention relates to a blueberry twig plant cuttage root-taking cultivation method. The specific cultivation operation comprises the steps of: (1) preparation of a root-taking liquid, to be specific, respectively adding a lanthanum sulfate solution and an indolebutyric acid solution in bacteria free water and mixing uniformly to prepare the root-taking liquid; (2) selecting strong blueberry twigs of 20-25 cm in length, removing leaves at the bottom ends of the blueberry twigs and soaking the bottom ends of the blueberry twigs in the root-taking liquid for 5-10 min; (3) vertically inserting the bottom parts of the blueberry twigs into a root-taking substrate, wherein the root-taking substrate is formed by uniformly mixing turf and fine pearlite according to a volume ratio of 1: 1; and cultivating the blueberry twigs at cultivation conditions including 20-30 DEG C of temperature, 80%-90% of relative humidity and 40%-60% of shading rate for 30 days to obtain new blueberry seedlings. The root-taking time of the blueberry twigs is shortened from 90 days to 30 days, the root-taking rate of the blueberry twigs is more than 80% and the survival rate of the new blueberry seedlings is more than 90%.

Owner:宣城明美蓝莓科技有限公司

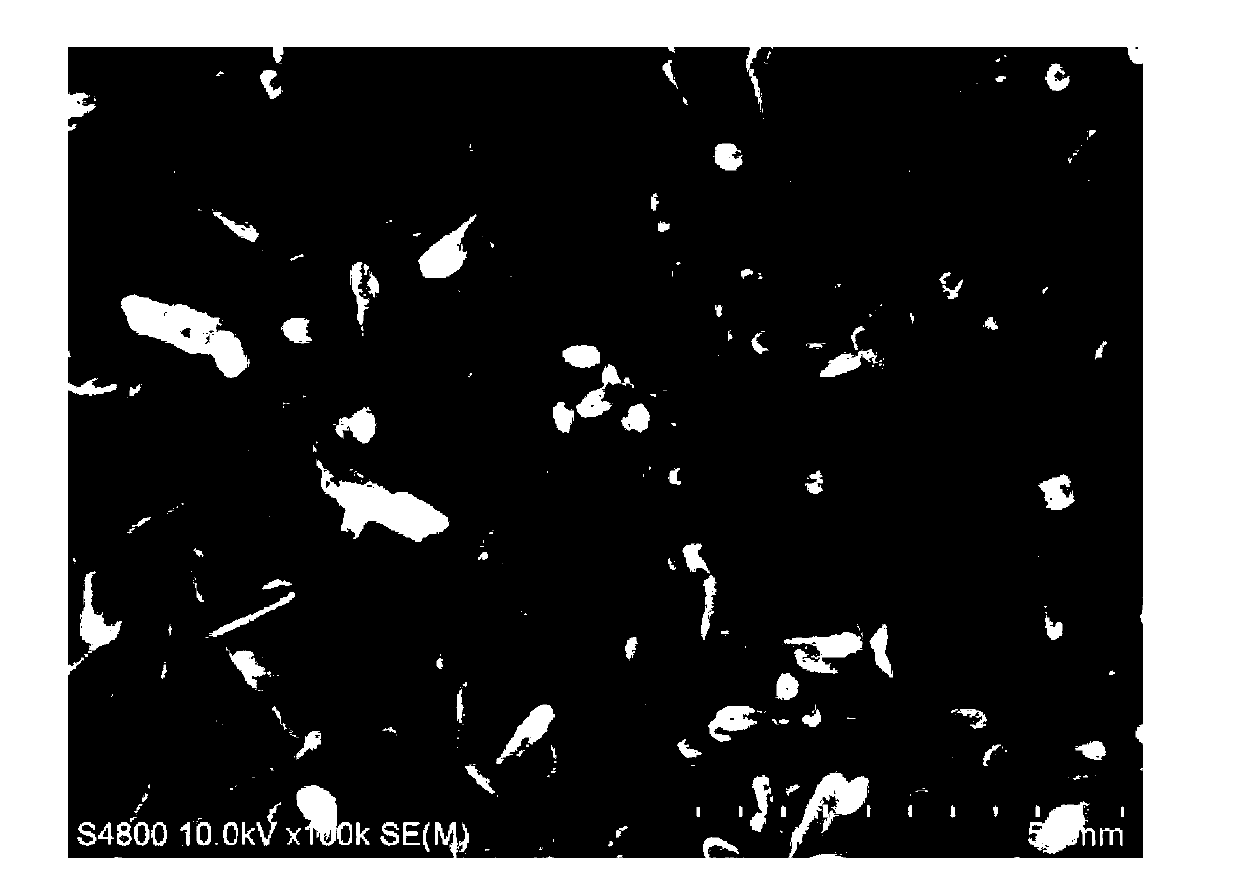

Ni-Cu-La-B quaternary alloy plating solution and method for chemically plating glass fibers by using same

ActiveCN103757617AReduce contentIncreased nickel contentLiquid/solution decomposition chemical coatingEthylenediamineMicroscopic observation

The invention discloses a Ni-Cu-La-B quaternary alloy plating solution. The Ni-Cu-La-B quaternary alloy plating solution comprises the following components: 20-40g / L of nickel chloride, 10-20g / L of copper sulfate, 0.5-10 g / L of lanthanum sulfate, 0.5-3 g / L of sodium borohydride, 40-50g / L of potassium sodium tartrate, 15-30g / L of ethylenediamine and 35-60g / L of sodium hydroxide. A method for chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution comprises the following steps: using sodium borohydride as a reducing agent, adding the water-soluble lanthanum sulfate, and chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution under the conditions of strong base and low temperature; plating layers are Ni-Cu-La-B alloy plating layers, wherein the content of boron is low (only about 0.5-5wt%), the content of nickel in the plating layers is high; the plating layers have good bonding force, electrical conductivity and wear resistance. Through observation with microscopes, the plating layers of the Ni-Cu-La-B quaternary alloy plated glass fibers prepared by using the method are compact; testing with an X-ray energy dispersive spectrometer shows that the surface chemistry components of the Ni-Cu-La-B quaternary alloy plated glass fibers contain 15-50wt% of Ni, 2-15wt% of Cu, 0.5-5wt% of La and 0.5-5wt% of B. The electric conducting glass fibers can be applied to the special fields of electromagnetic wave shielding, microwave absorption, invisibility, anti-static electricity and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

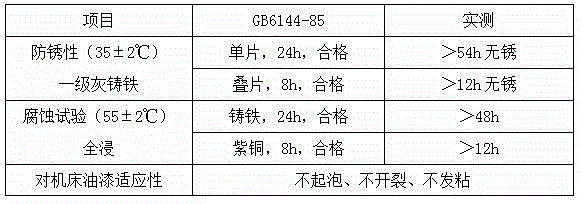

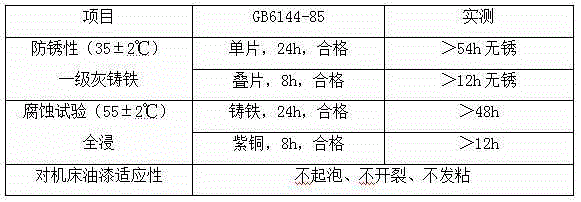

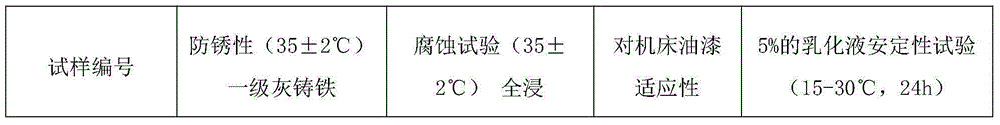

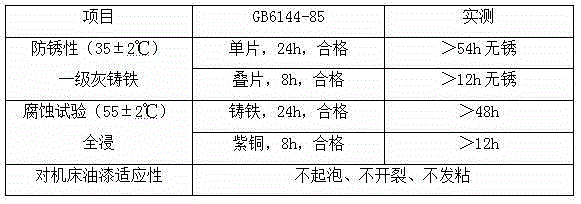

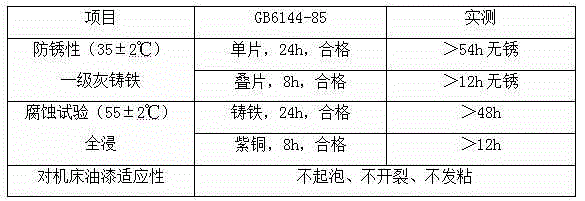

Anti-corrosive cutting fluid

InactiveCN104611119AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene glycolPhytosterol

The invention discloses anti-corrosive cutting fluid. The anti-corrosive cutting fluid comprises the following materials in parts by weight: 0.1-0.2 part of phosphotungstic acid, 0.7-1 part of tetramethylammonium nitrate, 1-2 parts of naphthenic soap, 2-3 parts of toluene diisocynate, 1-2 parts of sodium benzoate, 0.6-1 part of methyl isobutyl ketone, 0.1-0.2 part of zinc cyanurate, 3-5 parts of barium petroleum sulfonate, 0.6-1 part of 8-hydroxyquinoline, 0.8-2 parts of calcium lactate, 0.7-2 parts of isopropyl palmitate, 0.5-1 part of phytosterol, 0.8-1 part of methyl tin mercaptide, 70-80 parts of deionized water, 2-3 parts of polyaniline and 6-7 parts of rare-soil function additives. The anti-corrosive cutting fluid disclosed by the invention has the advantages that in the added rare-soil function additives, alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified, so that the stable anti-rusting effect can be achieved; due to the added nano silicon dioxide, certain lubricity can be achieved, the cutting force, the friction and the power consumption can be reduced; lanthanum sulfate not only has certain anti-corrosive property, but also can improve the anti-corrosive and slow-release effects; and the additives have good oleophilic and hydrophilic properties and high emulsifying and dispersing performances, and the anti-corrosive property, the lubricity, the anti-rusting property and the stability of finished cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

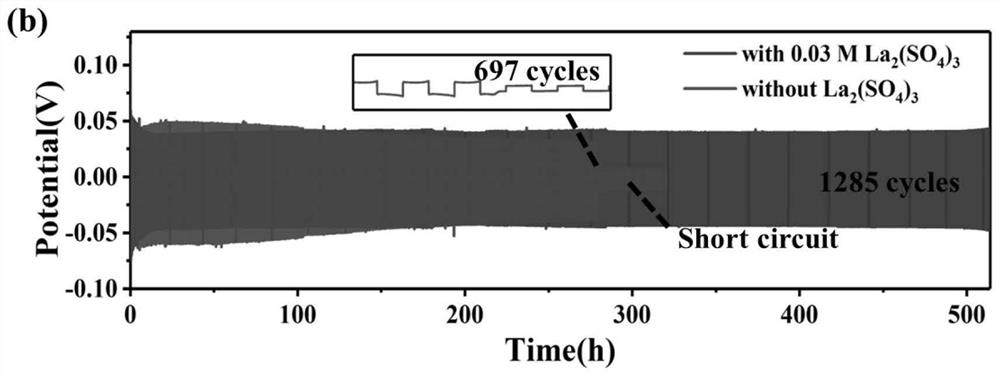

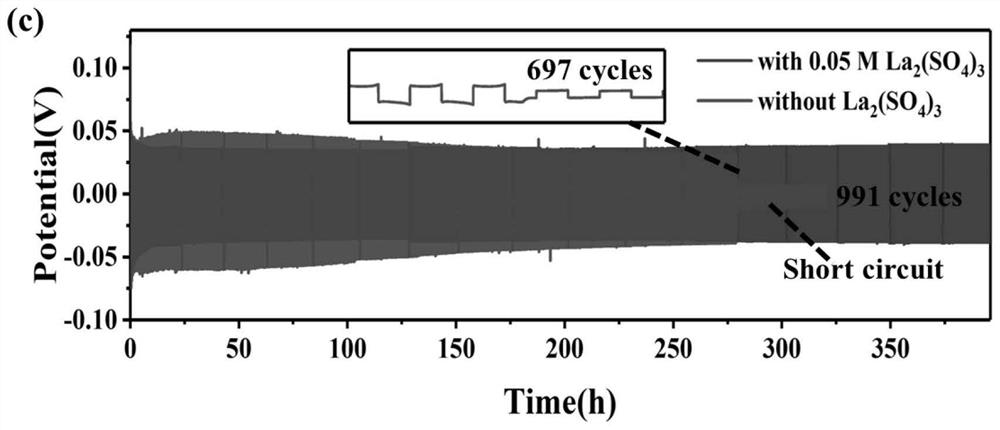

Aqueous zinc ion battery electrolyte containing additive, preparation method of aqueous zinc ion battery electrolyte and battery

ActiveCN113161631AUniform depositionAvoid generatingSecondary cellsAqueous electrolytesElectrolytic agentZinc metal

The invention discloses an additive-containing aqueous zinc ion battery electrolyte, a preparation method thereof and a battery. The electrolyte additive is a lanthanum-containing compound (such as lanthanum sulfate, lanthanum nitrate, lanthanum chloride, lanthanum acetate and hydrates thereof). The electrolyte additive can form a protective layer on a surface of zinc metal through absorption or deposition in the zinc metal deposition process, and the protective layer can adjust the deposition behavior of zinc ions and effectively inhibit generation of zinc dendrites, so the energy utilization rate and cycle stability of the battery are improved; by matching with a high-performance positive electrode material, the industrialization process of the water-based zinc ion battery can be promoted.

Owner:CENT SOUTH UNIV

Cutting fluid for machine tool

InactiveCN104611110AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene glycolDiphenylamine

The invention discloses cutting fluid for a machine tool. The cutting fluid comprises the following materials in parts by weight: 0.5-1 part of alkylated diphenylamine, 2-3 parts of tetrabutyl titanate, 0.6-1 parts of potassium fluotitanate, 3-5 parts of allyl polyethylene glycol, 0.8-1 part of barium stearate, 1-2 parts of methyl pentachlorostearate, 0.3-1 part of 2-bromo-4-methylphenol, 1-2 parts of dioctyl azelate, 1-3 parts of sodium hydrogen sulfite, 0.4-1 part of molybdenum disulfide, 2-3 parts of potassium citrate, 70-80 parts of deionized water, 6-7 parts of rare-soil functional additive and 6-8 parts of boric acid. The cutting fluid disclosed by the invention has the advantages that in the added rare-soil function additives, alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified, so that the stable anti-rusting effect can be achieved; due to the added nano silicon dioxide, certain lubricity can be achieved, and the cutting force, the friction and the power consumption can be reduced; lanthanum sulfate not only has certain anti-corrosive property, but also can improve the anti-corrosive and slow-release effects; and the additives have good oleophilic and hydrophilic properties and high emulsifying and dispersing performances, and the anti-corrosive property, the lubricity, the anti-rusting property and the stability of finished cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Rare earth polymerized silicon aluminum chloride and preparation method thereof

InactiveCN103553192AHigh depigmentationGood removal effectWater/sewage treatment by flocculation/precipitationFlocculationAluminium hydroxide

The invention discloses rare earth polymerized silicon aluminum chloride, wherein the rare earth in the rare earth polymerized silicon aluminum chloride refers to lanthanum rare earth. A method for preparing the rare earth polymerized silicon aluminum chloride according to claim 1 comprises the following steps: (1) putting 1.2-1.5 tons of technical hydrochloric acid with the mass concentration of 10-30%, 50-100kg of sulfuric acid with the mass concentration of 98%, and 0.3-0.6 tons of aluminum hydroxide powder into a reaction kettle, slowly raising the temperature to be 80-100 DEG C, reacting for 1 hour, and cooling down to be 60-70 DEG C; and (2) adding 5-10kg of lanthanum rare earth into the reaction liquid of the step (1), and dropping 100kg of a sodium silicate solution with the mass concentration of 20-30%, raising the temperature to be 100-120 DEG C, reacting for 2 hours and subsequently cooling down to be the room temperature so as to prepare a lanthanum rare earth polymerized silicon aluminum chloride liquid. The lanthanum rare earth is any one or a mixture of lanthanum oxide, lanthanum chloride and lanthanum sulfate. The rare earth polymerized silicon aluminum chloride has the remarkable advantages of high decoloring and flocculation removal rate.

Owner:乔占印

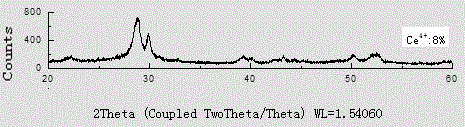

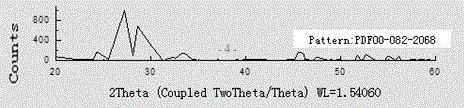

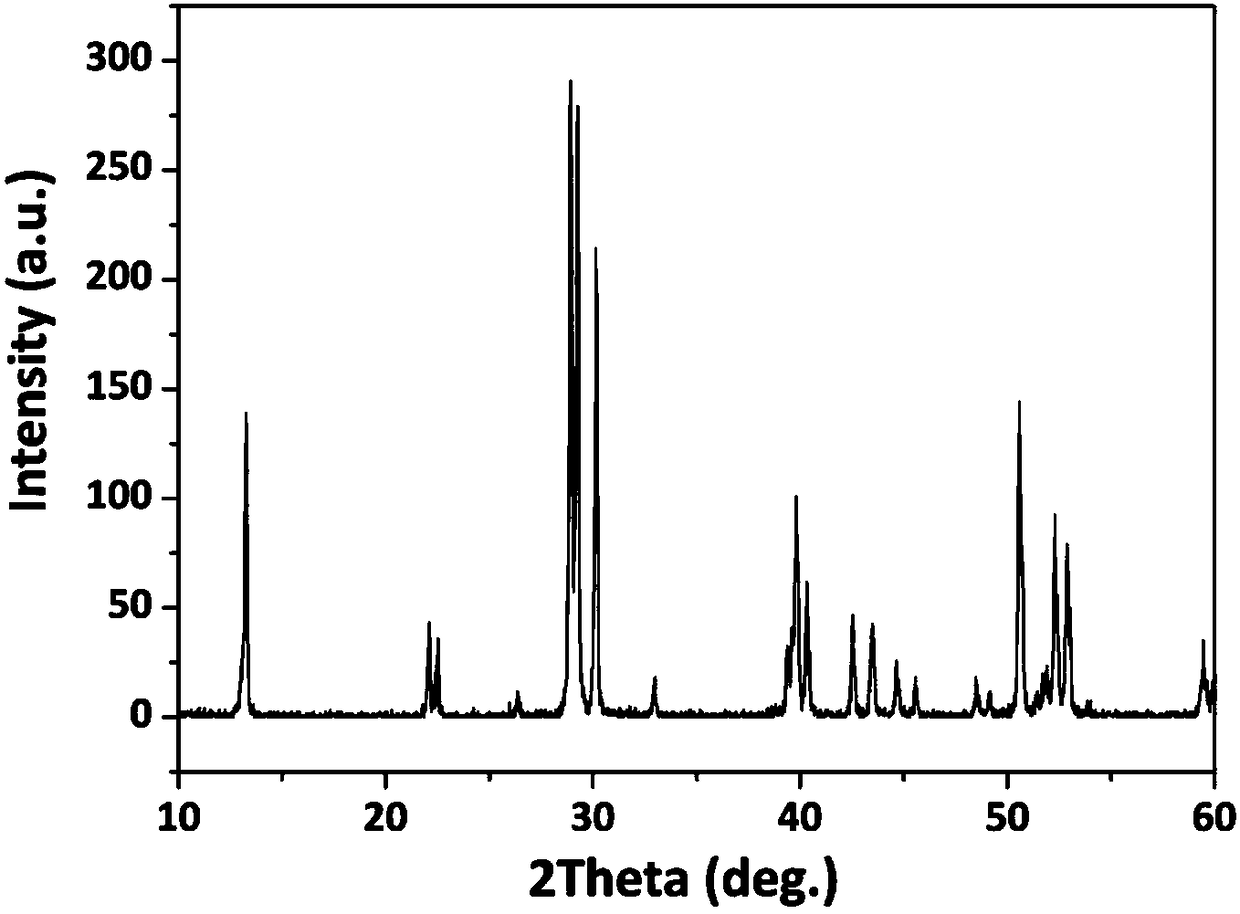

Ultraviolet visual light absorbent and application thereof

ActiveCN105040408APromote absorptionReduce harmCosmetic preparationsToilet preparationsTungstateCeric sulfate

The invention discloses an ultraviolet visual light absorbent and application thereof. The ultraviolet visual light absorbent is obtained with lanthanum sulfate, ammonium tungstate and ceroussulfate serving as raw materials through a coprecipitation method. The structural formula of the ultraviolet visual light absorbent is La2 (WO4)3:Ce4+. Ce4+ accounts for 4% to 8% of the La2 (WO4)3:Ce4+. The ultraviolet visual light absorbent can absorb ultraviolet light to serve as application on the aspect of an ultraviolet absorber. The prepared La2 (WO4)3:Ce4+ has maximum absorption at the wavelength of 240 nm, the absorbing ability of the ultraviolet region is far higher than the adsorbing ability of the visual region, and the ultraviolet visual light absorbent has the advantages of being wide in absorption wavelength range, high in absorption capacity, high in efficiency and capable of absorbing ultraviolet light. The La2 (WO4)3:Ce4+ is easy to prepare, stable in property and high in safety and has good generalizability and market prospects.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Nanometer silicon oxide colloid electrolyte for lead-acid storage battery and its preparing method

Disclosed a nanometer monox colloid electrolytic solution of lead-acid storage battery and its preparing method, relates to the manufacturing technique of lead-acid storage battery colloid electrolytic solution special for the electric bicycle. The invention prepares the nanometer monox colloid electrolytic solution by using the lead-acid analytical pure vitriol, vapor phase silica dioxide nanometer powder, salt cake, and the deionized water as main material, which are mixed to be added polyacrylamide and poly-sodium acrylate as gel modifying agent; then, adding litter lanthanum sulfate, cerous sulfate, tungsten oxide, and molybdenum oxide. The invention avoids the disadvantage effect of using sodium silicate colloid; uses vapor phase silica dioxide nanometer powder as gel agent; adds little chemical components, to form the new colloid electrolytic solution which can improve the agglutination property, increase the capacity of accumulator, and prolong the service life of deep discharging cycle. In addition, the invention can be used as electrolytic solution to replace present vitriol water electrolytic solution, to improve the rheological property of colloid electrolytic solution, and control the electrolytic process of water.

Owner:江苏华富能源有限公司

Preparation method of bar-shaped lanthanum hydroxide nanocrystal

ActiveCN102942203BShort reaction timesReduce energy consumptionMaterial nanotechnologyRare earth metal compoundsEthylenediamineDispersity

The invention provides a preparation method of a bar-shaped lanthanum hydroxide nanocrystal. The method comprises the following steps of: adding nona-lanthanum sulfate and ethylenediamine tetraacetic acid into deionized water respectively to obtain a solution B; adjusting the pH of the solution B to 8.0-12.0 with an ammonia water solution to obtain a precursor solution C; pouring the precursor solution C into a four-neck round-bottom flask, putting the four-neck round-bottom flask into a microwave-ultraviolet ray-ultrasonic wave three-in-one synthesis reaction instrument, selecting a microwave heating-ultraviolet irradiation combined reaction in a temperature-time mode, and naturally cooling to the room temperature after the reaction; and centrifugally collecting a product, washing repeatedly with deionized water and absolute ethyl alcohol respectively, and drying to obtain a final product, i.e., bar-shaped lanthanum hydroxide nanocrystal. A simple microwave-ultraviolet ray synthesis method preparation process is adopted, so that the method has the advantages of short reaction time period, low energy consumption, low cost, convenience in operating, one-time completion of a reaction in a liquid phase, and no need of subsequent treatment. La(OH3) particles prepared with the method have bar-shaped structures, are small in size, have high dispersity, and can be applied in the catalysis field and the optics field.

Owner:上海球球云环保科技有限公司

Method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue

ActiveCN102659559BScientific and rational useSimple recycling processCarboxylic acid salt preparationOXALIC ACID DIHYDRATEHydrogen fluoride

The invention relates to the technical field of material preparation, in particular to a method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue. The method comprises the following steps: reacting to leach the recovered rare earth polishing powder waste residue in concentrated sulfuric acid to obtain a lanthanum cerium sulfate solution; separating the lanthanum cerium sulfate solution from solid residue, and adding oxalic acid to obtain a lanthanum cerium oxalate precipitate; and filtering and separating the lanthanum cerium oxalate precipitate, washing to neutrality, and drying to obtain the finished lanthanum cerium oxalate product. Fluorides such as hydrogen fluoride are not required, the polishing powder waste residue is scientifically and reasonably utilized comprehensively, and the whole recovery process is environment-friendly. The method has the characteristics of small investment, low recovery cost, simple process flow, high recovery rate, environment friendliness and the like.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Rear-earth poly aluminum chloride and production process thereof

The invention discloses rear-earth poly aluminum chloride. The rear-earth poly aluminum chloride comprises poly aluminum chloride, and the rear earth is one of lanthanum oxide, lanthanum chloride and lanthanum sulfate. A process of preparing the rear-earth poly aluminum chloride according to the claim 1 comprises the following steps: (1), placing 0.8-1.4 parts by weight of 10-30wt% food-grade salt into a reaction kettle, slowly adding 0.3-0.6 parts by weight of aluminum hydroxide powder and 0.003-0.008 parts by weight of lanthanum-series rear earth while heating up to 60-130 DEG C; (2), heating up the reaction kettle to 120+ / -10 DEG C to react for 3-6 hours; (3), standing for 2-4 hours after the reaction is ended to prepare liquid poly aluminum chloride. The lanthanum ear earth is one of lanthanum oxide, lanthanum chloride and lanthanum sulfate. The rear-earth poly aluminum chloride disclosed by the invention has the remarkable advantage of being in high in wastewater purifying rate.

Owner:乔占印

Rare-earth polymeric ferrophosphorus sulfate and preparation method thereof

InactiveCN104556323AFast purification and flocculationBig alumWater/sewage treatment by flocculation/precipitationFlocculationSulfate

The invention discloses rare-earth polymeric ferrophosphorus sulfate. The rare-earth polymeric ferrophosphorus sulfate comprises polymeric ferrophosphorus sulfate which is rare-earth polymeric ferrophosphorus sulfate, and rare earth is one or a mixture of lanthanum oxide, lanthanum chloride and lanthanum sulfate. A preparation method comprises steps as follows: placing 1.0-1.5 t of a ferrous sulfate solution with the mass concentration of 30-50% into a reaction kettle, slowly adding 0.1-0.3 t of sulfuric acid with the mass concentration of 98%, 0.05-0.1 t of phosphoric acid with the mass concentration of 31% and 5-10 kg of the lanthanum oxide, the lanthanum chloride or the lanthanum sulfate, and feeding oxygen for reactions at the temperature of 50-90 DEG C for 2-3 h to prepare a dark brown lanthanum rare-earth polymeric ferrophosphorus sulfate liquid. The rare-earth polymeric ferrophosphorus sulfate has the significant advantages of high purification and flocculation speed and large alum floccule.

Owner:乔占印

Metal cutting fluid for machine tool

InactiveCN105087130AImprove anti-corrosion performanceAnti-corrosion hasLubricant compositionWear resistantPolyethylene glycol

The invention discloses metal cutting fluid for a machine tool. The metal cutting fluid consists of the following ingredients in parts by mass: 7 to 10 parts of lanthanum sulfate, 2 to 3 parts of tricresyl phosphate, 5 to 6 parts of tetrabutyl titanate, 0.5 to 0.8 parts of polyglyceryl fatty acid ester, 0.6 to 1 part of potassium fluotitanate, 7 to 9 parts of allyl polyethylene glycol, 0.8 to 1 part of barium stearate, 4 to 6 parts of auxiliary agent, 70 to 80 parts of deionized water, 6 to 8 parts of boracic acid, 8 to 12 parts of petroleum sodium sulfonate and 1 to 2 parts of alkamine, wherein the auxiliary agent is prepared from the following ingredients in parts by mass: 6 to 7 parts of alkenyl succinate, 4 to 5 parts of lanum, 10 to 14 parts of polyethylene glycol, 1 to 2 parts of nanometer silicon dioxide, 120 to 150 parts of deionized water, 5 to 6 parts of high-wear-resistant carbon black and 2 to 3 parts of silicone oil. The invention aims at providing the metal cutting fluid for the machine tool for solving the problems of the poor stability and the poor resistance on bacteria and mildew of cutting fluid on the existing machine tool.

Owner:CHONGQING SHUAICHANG MACHINE MFG

Solid super acid and method for catalyzing and preparing chloracetate by using same

InactiveCN102962081ALow toxicitySimple preparation processPhysical/chemical process catalystsOrganic compound preparationFiltrationSolid particle

The invention relates to a method for preparing solid super acid and a method for catalyzing and synthetizing chloracetate by using the solid super acid. The method comprises the following steps of: adding tetrabutyl titanate, ethanol, acetic acid and water according to the proportion, reacting at the room temperature, continuously stirring for one hour, standing for two days after the end of the reaction, heating to obtain pale yellow dry solid particles by an oil bath, grinding and sieving with a 150-mesh screen, soaking for 14 hours by lanthanum sulfate solution prepared by dissolving lanthanum oxide in sulfuric acid, and placing in a muffle furnace for calcining for 3 hours at 500 DEG C after suction filtration to obtain pale yellow solid which is a catalyst product. According to the method for preparing the chloracetate, azeotropic with-water performance of toluene is utilized, and a solvent secondary adding method is adopted to ensure anhydrous performance of the catalytic process. The solid super acid provided by the invention has good stability and can be repeatedly used. For the method for preparing the chloracetate, the process is simple, by-products do not exist, and the product is less toxic and harmless.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Blueberry cultivation method

InactiveCN106332746AShorten rooting timeQuality improvementCultivating equipmentsSoilless cultivationLanthanum sulfatePearlite

The invention discloses a blueberry cultivation method which comprises the following specific cultivation operation steps: (1) preparing rooting liquid: respectively adding a lanthanum sulfate solution and an indolebutyric acid solution into bacteria free water, and uniformly mixing to prepare the rooting liquid; (2) selecting robust blueberry twigs with the length of 20 to 25 cm, removing leaves at the bottom ends of the blueberry twigs, and soaking the bottom ends of the blueberry twigs in the rooting liquid for 5 to 10 minutes; (3) vertically inserting the bottoms of the blueberry twigs into a rooting substrate which is formed by uniformly mixing turf and fine pearlite according to the volume ratio of 1 to 1, and cultivating under cultivation conditions that the temperature is 20 to 30 DEG C, the relative humidity is 80 to 90 percent and the shade rate is 40 to 60 percent for 30 days to obtain new blueberry seedlings. The rooting time of the blueberry twigs is shortened from 90 days to 30 days, the rooting rate of the blueberry twigs is 80 percent or above, and the survival rate of the new blueberry twigs is 90 percent or above.

Owner:天津显硕科技有限公司

Compression-resistant cutting fluid

InactiveCN104611117AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionLithium hydroxidePolyethylene glycol

The invention discloses a compression-resistant cutting fluid which is prepared from the following raw materials in parts by weight: 3-4 parts of chlorinated paraffin, 0.3-0.5 part of lithium hydroxide, 0.8-1 parts of hexahydrophthalic anhydride, 0.7-1 part of triethanolamine oleic soap, 1-2 parts of hosho oil, 0.5-1 part of zinc naphthenate, 0.8-2 parts of sodium diacetate, 1-2 parts of calcium ricinoleate, 0.6-1 part of 6-tert-butyl-o-cresol, 1-2 parts of bitertanol, 0.4-1 part of allylthiourea, 2-3 parts of oleic acid, 0.4-1 part of dicyclohexylamine carbonate, 5-7 parts of mineral oil, 70-80 parts of deionized water and 6-7 parts of rare earth functional assistants. According to the compression-resistant cutting fluid disclosed by the invention, the rare earth functional assistants are added; alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified first to play a stable rustproof role; the added nano silicon dioxide has certain lubricity so as to reduce the cutting force, friction and power consumption; lanthanum sulfate not only has certain corrosion resistance, but also can be used for improving the rust-proof release effect. The assistants provided by the invention have good hydrophilic and oleophylic characteristics and high emulsion dispersion performance and can be used for effectively improving the corrosion resistance, lubrication, rust prevention and stability of a finished product cutting fluid.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Modified plastic particles with stable mechanical properties and preparation process

The invention discloses modified plastic particles with stable mechanical properties. The plastic particles are prepared from the following substances: epoxy resin, butyl benzyl phthalate, lanthanum sulfate, samarium phosphate, tributyl phosphate, stearic acid, higher alcohol fatty acid ester compound and modified filler. Components of existing plastic particles are specially improved, and finallythe prepared plastic particles have stable performance, good wear resistance, corrosion resistance and tensile resistance, excellent comprehensive quality, long service life, and good popularizationand application value and market competitiveness.

Owner:界首市鑫豪塑胶有限公司

Method for planting silk trees in natural soil of saline and alkaline land by rooting agents containing rice bran extract

InactiveCN106359479ARaise K

<sup>+</sup>

contentIncreased fresh weightBiocidePlant growth regulatorsCalciteSlow Release Formulation

The invention provides a method for planting silk trees in natural soil of saline and alkaline land by rooting agents containing rice bran extract. The method includes the step: broadcasting rooting agents. The rooting agents comprise alpha-naphthylacetic acid, indoleacetic acid, lanthanum sulfate, soil activation agents, slow-release formulation, piperine, rice bran extracts, potash feldspar powder, calcite powder, nicotinic acid, sinapic acid, industrial titanic solution, eel powder, lycine, anti-blocking agents and bal loonflower roots. According to the natural soil planting method, common disease and pest resistance of the silk trees is improved, prevention and treatment rates of the silk trees for common rust diseases, flatheaded borers and long-horned beetles reach 90.6-95.4%, 90.0-94.8% and 88.6-90.8% respectively, any pesticides are omitted, and the method is green and environmentally friendly.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Mud flat silt based slow-release antibacterial agent for cutting propagation and preparation method thereof

InactiveCN108617653AGood waterGood water locking effectBiocideGrowth substratesDihydroxyaluminum aminoacetateAntibacterial agent

The invention relates to a mud flat silt based slow-release antibacterial agent for cutting propagation and a preparation method thereof. The slow-release antibacterial agent is prepared from the following components in parts by weight: 40-60 parts of a fine silt powder, 5-10 parts of sodium polyacrylate, 1-10 parts of crosslinking polyacrylic acid resin, 2-10 parts of nonionic polyacrylamide, 0.5-8 parts of a crosslinking agent, 2-5 parts of a bactericide and 1-3 parts of a tissue protector, wherein the fine silt powder is prepared by treating mud flat silt; the crosslinking agent is dihydroxyaluminum aminoacetate; the bactericide is at least one of copper abietate, potassium permanganate and lanthanum sulfate; the tissue protector is a mixture of oxidized and reduced glutathione. The mudflat silt based slow-release antibacterial agent for cutting propagation and the preparation method thereof disclosed by the invention have the beneficial effects that the slow-release antibacterialagent expands into gel when meeting water and has excellent water gathering and retaining effects; the antibacterial agent is gradually dissolved into water, slowly released or diffused into a cuttingmedium and used for long-term disinfection and sterilization of the cutting medium.

Owner:柯江波

Lubricating cutting fluid

InactiveCN104611112AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene oxidePolyethylene glycol

The invention discloses lubricating cutting fluid. The lubricating cutting fluid is prepared from the following raw materials in parts by weight: 3-4 parts of methacrylic acid, 4-5 parts of di-n-butyl phosphite, 2-3 parts of isopropyl myristate, 1-2 parts of 1-hydroxybenztriazole, 1-2 parts of stearic acid, 3-4 parts of barium ricinoleate, 0.8-1 part of amino trimethylene phosphonic acid, 0.1-0.2 part of dimethylamino propylamine, 4-5 parts of naphthenic oil, 2-3 parts of neutral barium dinonyl naphthalene sulfonate, 0.2-0.4 part of dialkyl p-diphenol, 70-80 parts of deionized water, 6-7 parts of rare-earth functional auxiliaries and 1-2 parts of polyethylene oxide. According to the lubricating cutting fluid, alkenyl succinate, lanolin and polyethylene glycol 4000 are firstly subjected to blended modification by the added rare-earth functional auxiliaries, and a stable anti-rusting effect is achieved; the added nano silica can play a certain role in lubricating, and cutting force, friction and power consumption are reduced; lanthanum sulfate not only has certain corrosion resistance, but also can improve anti-rusting and sustained-release effects; the auxiliaries of the lubricating cutting fluid have good hydrophilic and lipophilic properties and high emulsifying and dispersing properties, and thus, the corrosion resistance, lubricating property, anti-rusting property and stability of the finished product cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

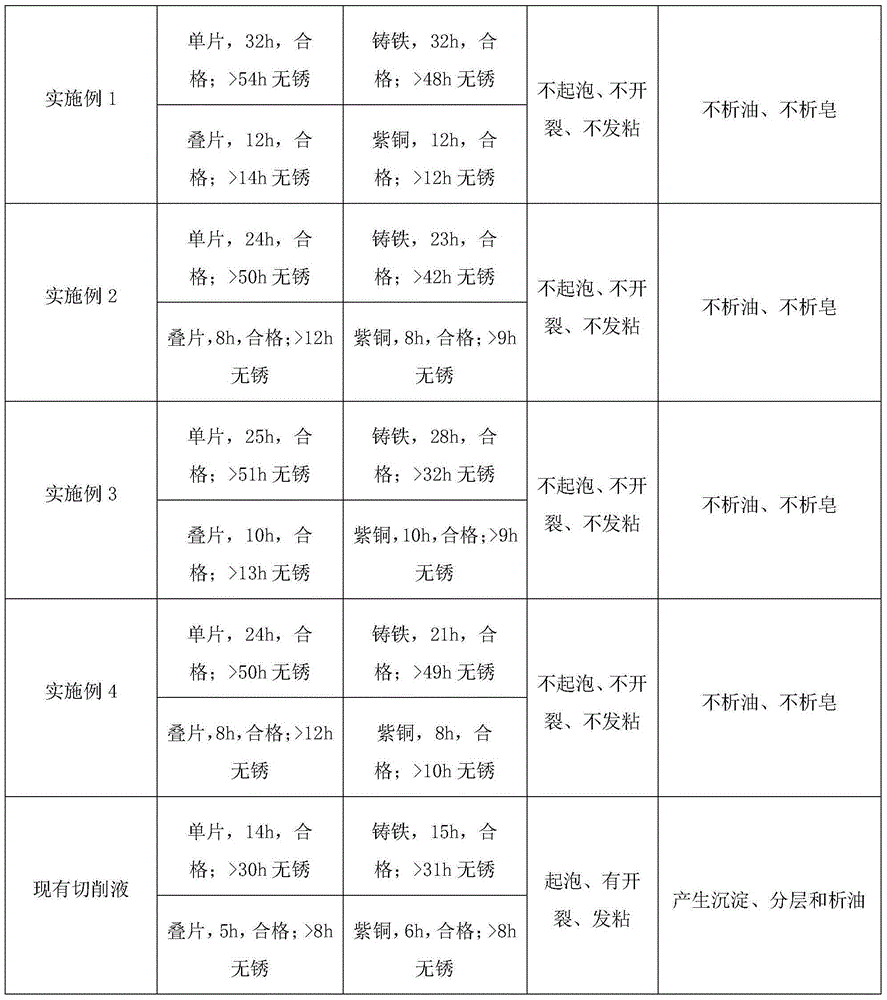

Oxygen-containing lanthanum sulfate thin film and preparation method thereof by layer-by-layer self assembly of nanosheets

ActiveCN108217711ASave rare earth resourcesControl thicknessRare earth metal sulfatesNanotechnologyOxygenLayer by layer self assembly

The invention discloses an oxygen-containing lanthanum sulfate thin film and a preparation method thereof by layer-by-layer self assembly of nanosheets, and belongs to the technical field of materialscience. The oxygen-containing lanthanum sulfate thin film is made of (La, Eu)2O2SO4, and is 5-50nm in thickness. The preparation method of the thin film by layer-by-layer self assembly of the nanosheets comprises the following steps: mixing lanthanum nitrate solution and europium nitrate solution, adding and dissolving ammonium sulfate particles, then adding ammonia water, regulating pH to 6-10,reacting the obtained uniform suspension for 1-48 hours at the temperature of minus 4 to 4 DEG C, thus obtaining a product, separating and drying, and then adding absolute ethyl alcohol, thus obtaining nanosheet sol; adopting a spin-coating technology to spin-coat the nanosheet sol on a sapphire substrate subjected to infiltrating pretreatment, and by layer-by-layer spin-coating self assembly, obtaining a (La, Eu)2(OH)4SO4.nH2O precursor thin film; drying and calcining to obtain the (La, Eu)2O2SO4 thin film. The oxygen-containing lanthanum sulfate thin film and the preparation method disclosedby the invention have the advantages that the thickness of the oxygen-containing lanthanum sulfate thin film can be controlled by controlling the thickness of the precursor thin film; the film formation is convenient, and the film formation quality is high.

Owner:BOHAI UNIV

A kind of ni-cu-la-b quaternary alloy plating solution and the method for glass fiber electroless plating

ActiveCN103757617BIncreased nickel contentImprove bindingLiquid/solution decomposition chemical coatingEthylenediamineMicroscopic observation

The invention discloses a Ni-Cu-La-B quaternary alloy plating solution. The Ni-Cu-La-B quaternary alloy plating solution comprises the following components: 20-40g / L of nickel chloride, 10-20g / L of copper sulfate, 0.5-10 g / L of lanthanum sulfate, 0.5-3 g / L of sodium borohydride, 40-50g / L of potassium sodium tartrate, 15-30g / L of ethylenediamine and 35-60g / L of sodium hydroxide. A method for chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution comprises the following steps: using sodium borohydride as a reducing agent, adding the water-soluble lanthanum sulfate, and chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution under the conditions of strong base and low temperature; plating layers are Ni-Cu-La-B alloy plating layers, wherein the content of boron is low (only about 0.5-5wt%), the content of nickel in the plating layers is high; the plating layers have good bonding force, electrical conductivity and wear resistance. Through observation with microscopes, the plating layers of the Ni-Cu-La-B quaternary alloy plated glass fibers prepared by using the method are compact; testing with an X-ray energy dispersive spectrometer shows that the surface chemistry components of the Ni-Cu-La-B quaternary alloy plated glass fibers contain 15-50wt% of Ni, 2-15wt% of Cu, 0.5-5wt% of La and 0.5-5wt% of B. The electric conducting glass fibers can be applied to the special fields of electromagnetic wave shielding, microwave absorption, invisibility, anti-static electricity and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Microemulsion cutting solution

InactiveCN104611116AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionALUMINUM STEARATESPolyvinyl alcohol

The invention discloses a microemulsion cutting solution. The microemulsion cutting solution is composed of the raw materials in parts by weight as follows: 0.1-0.3 part of diphenyl guanidine chromate, 0.8-1 part of potassium fluotitanate, 0.6-1 part of hexamethyl cyclotrisiloxane, 1-2 parts of aluminum stearate, 0.5-1 part of perluorooctyl acrylate, 2-3 parts of diisocyanate, 0.7-1 part of N-methyldioctylamine, 2-3 parts of polyving akohol, 3-5 parts of sodium dihydrogen phosphate, 0.8-2 parts of chlorthal-dimethyl, 1-2 parts of kieselguhr, 0.5-1 part of hexahydrophthalic anhydride, 70-80 parts of deionized water and 6-7 parts of rare earth function additive, the rare earth function additive is prepared by firstly mixing the alkenyl succinate, wool grease and polyethylene glycol 4000, the rare earth function additive has stable antirust effect, the added nano silica has certain lubricity for reducing the cutting force, friction and power consumption, the lanthanum sulfate has certain anti-corrosive property and the rust proof slow-release effect is raised; the assistant of the microemulsion cutting solution has good hydrophilic and oleophylic character and high emulsifying dispersion performance for effectively raising the anticorrosion, lubrication, rust protection and stability of the finished product cutting solution.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com