Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Cerium oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium(III) oxalate (cerous oxalate) is the inorganic cerium salt of oxalic acid. It is a white crystalline solid with the chemical formula of Ce₂(C₂O₄)₃. It could be obtained by the reaction of oxalic acid with cerium(III) chloride.

Apparatus and process for treating an aqueous solution containing chemical contaminants

Apparatus, process and article for treating an aqueous solution containing a chemical contaminant. The process includes contacting an aqueous solution containing a chemical contaminant with an aggregate composition comprising an insoluble rare earth-containing compound to form a solution depleted of chemical contaminants. The insoluble rare earth-containing compound can include one or more of cerium, lanthanum, or praseodymium. A suitable insoluble cerium-containing compound can be derived from a cerium carbonate, cerium oxalate and / or a cerium salt. The aggregate composition can include more than 10.01% by weight of the insoluble rare earth-containing compound, and in a particular embodiment consists essentially of one or more cerium oxides, and optionally a binder and / or flow aid. Although intended for a variety of fluid treatment applications, such applications specifically include removing or detoxifying chemical contaminants in water.

Owner:MOLYCORP MINERALS

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777AEasy to control abrasion resistanceImprove control stabilityOther chemical processesPolishing compositions with abrasivesCerium oxalateGranularity

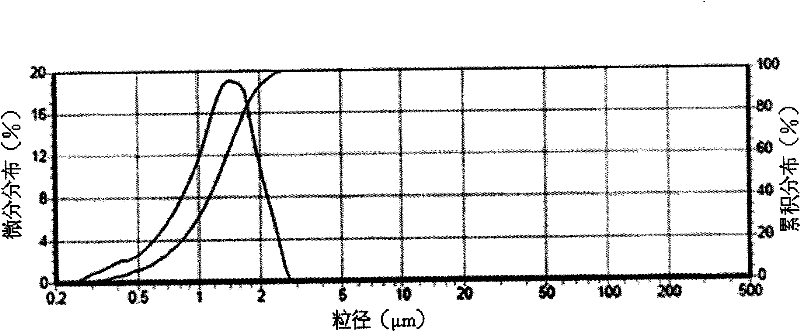

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

Apparatus and process for treating an aqueous solution containing biological contaminants

InactiveUS20090107925A1Material nanotechnologyWater treatment parameter controlCerium oxalateLanthanum

Process, apparatus and article for treating an aqueous solution containing biological contaminants. The process includes contacting an aqueous solution containing a biological contaminant with an aggregate composition comprising an insoluble rare earth-containing compound to form a solution depleted of active biological contaminants. The aggregate includes mote than 10.01% by weight of the insoluble rare earth-containing compound. The insoluble rare earth-containing compound can include one or more of cerium, lanthanum, or praseodymium. A suitable insoluble cerium-containing compound can be derived from a cerium carbonate, a cerium oxalate or a cerium salt. The composition can consist essentially of cerium oxides, and optionally, a binder and / or flow aid. The aggregate includes no more than two elements selected from the group consisting of yttrium, scandium, and europium when the aggregate is to be sintered. Although intended for a variety of fluid treatment applications, such applications specifically include removing or deactivating biological contaminants in water.

Owner:SECURE NATURAL RESOURCES LLC

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

Method for separating rare earth oxides from rare earth ore by using ammonium chloride-potassium chloride gas phase transmission

InactiveCN101638731AAvoid separationReduce usageProcess efficiency improvementGas phaseDecomposition

The invention provides a method for separating rare earth oxides from rare earth ore by using ammonium chloride-potassium chloride gas phase transmission. The main technical characteristic of the method is as follows: mixing rare earth ore and sodium carbonate to roast; dissolving the decomposition product obtained by roasting in water, drying and grinding insoluble substance to mix with ammoniumchloride and perform chlorination reaction; dissolving the chlorinate to obtain filtrate, adding BaCl2 and H2SO4 in the filtrate to separate precipitates such as ThO2, Fe2O3, U2O3 and the like; treating the filtrate through evaporating, oxidizing and calcining, chlorhydric acid leaching and drying in turn, then adding NH4Cl and KCl to perform chemical gas phase transmission for 20-25 times; dissolving the obtained product with water, adding oxalic acid to obtain lanthanum oxalate, praseodymium oxalate, neodymium oxalate and other rare earth oxalates except for cerium oxalate; then igniting theoxalates above 800 DEG C to obtain corresponding rare earth oxides. The method has the advantages that the problem of separating radioactive elements can be effectively solved, the use of chlorine gas and the emission of wastewater and effluent gas can be reduced in the production process, and the discharged gas can be recyled for reproduction.

Owner:SHENYANG POLYTECHNIC UNIV

Apparatus and process for treating an aqueous solution containing chemical contaminants

Owner:MOLYCORP MINERALS

Method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue

ActiveCN102659559ANo pollution in the processScientific and rational useCarboxylic acid salt preparationHydrogen fluorideCerium oxalate

The invention relates to the technical field of material preparation, in particular to a method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue. The method comprises the following steps: reacting to leach the recovered rare earth polishing powder waste residue in concentrated sulfuric acid to obtain a lanthanum cerium sulfate solution; separating the lanthanum cerium sulfate solution from solid residue, and adding oxalic acid to obtain a lanthanum cerium oxalate precipitate; and filtering and separating the lanthanum cerium oxalate precipitate, washing to neutrality, and drying to obtain the finished lanthanum cerium oxalate product. Fluorides such as hydrogen fluoride are not required, the polishing powder waste residue is scientifically and reasonably utilized comprehensively, and the whole recovery process is environment-friendly. The method has the characteristics of small investment, low recovery cost, simple process flow, high recovery rate, environment friendliness and the like.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Apparatus and process for treating an aqueous solution containing biological contaminants

Process, apparatus and article for treating an aqueous solution containing biological contaminants. The process includes contacting an aqueous solution containing a biological contaminant with an aggregate composition comprising an insoluble rare earth-containing compound to form a solution depleted of active biological contaminants. The aggregate includes more than 10.01% by weight of the insoluble rare earth-containing compound. The insoluble rare earth-containing compound can include one or more of cerium, lanthanum, or praseodymium. A suitable insoluble cerium-containing compound can be derived from a cerium carbonate, a cerium oxalate or a cerium salt. The composition can consist essentially of cerium oxides, and optionally, a binder and / or flow aid. The aggregate includes no more than two elements selected from the group consisting of yttrium, scandium, and europium when the aggregate is to be sintered. Although intended for a variety of fluid treatment applications, such applications specifically include removing or deactivating biological contaminants in water.

Owner:MOLYCORP MINERALS

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777BImprove control stabilitySmall median diameterOther chemical processesPolishing compositions with abrasivesCerium oxalateRare earth

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

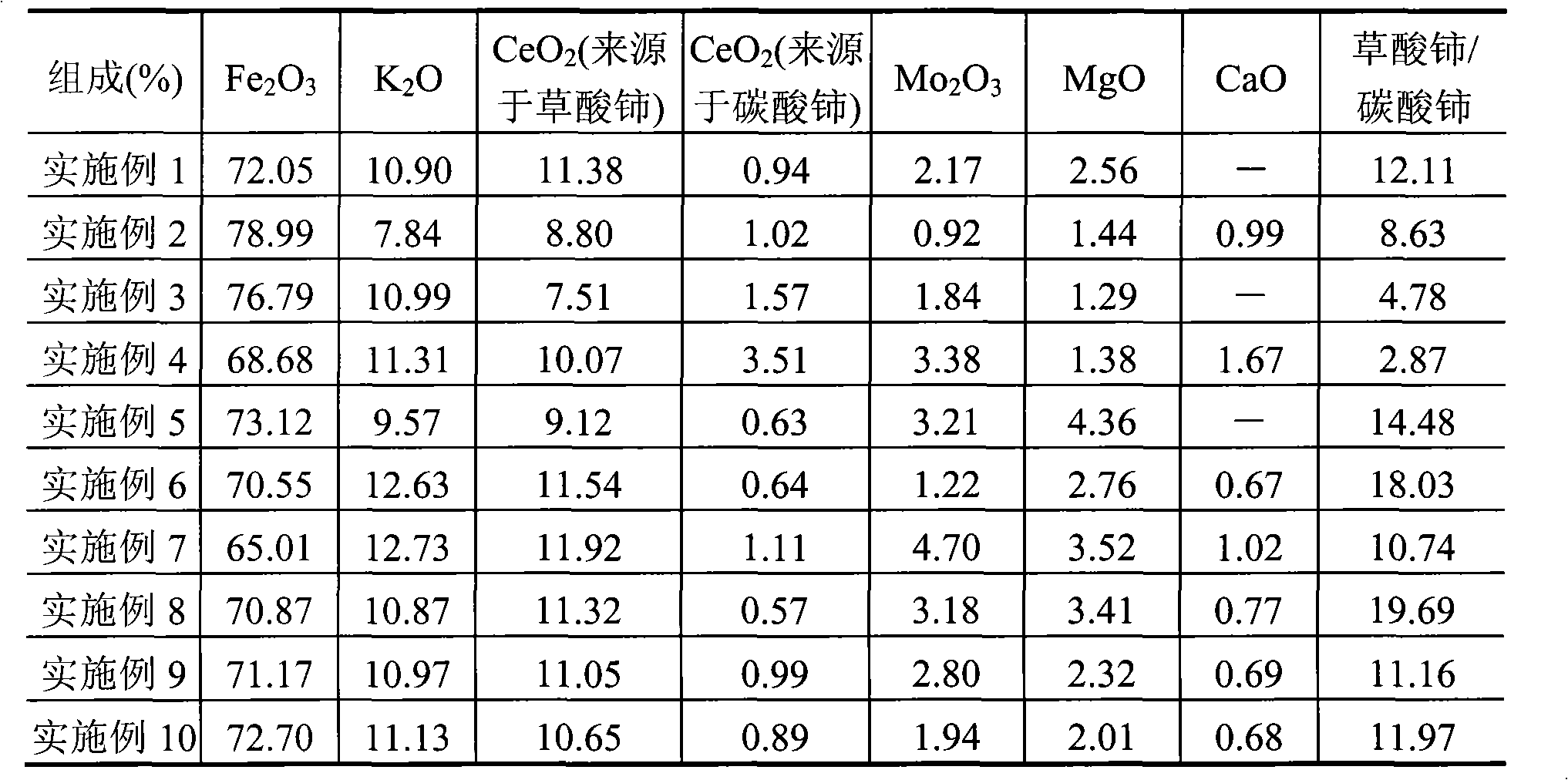

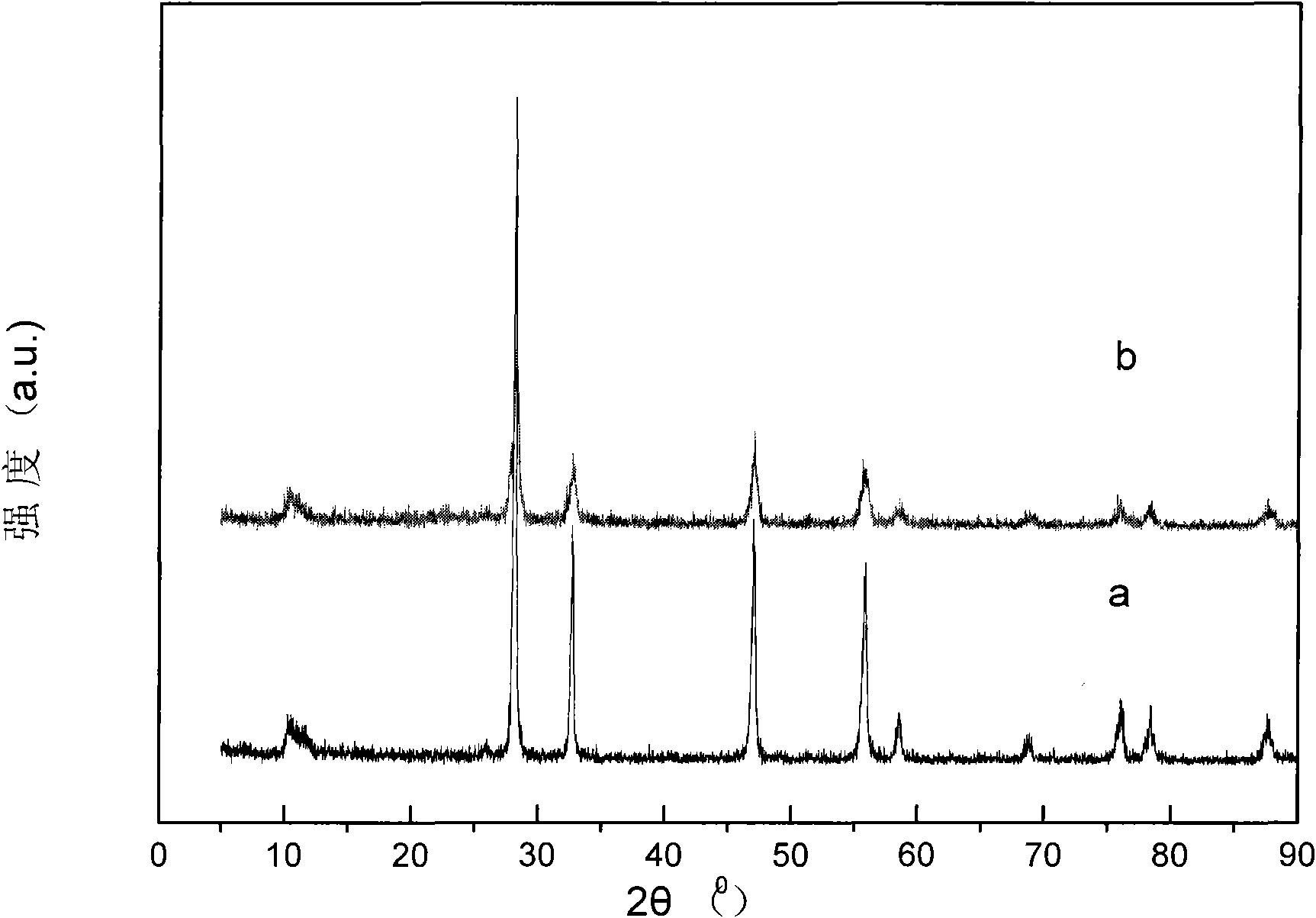

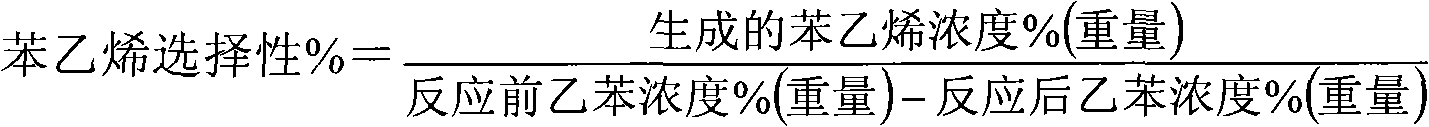

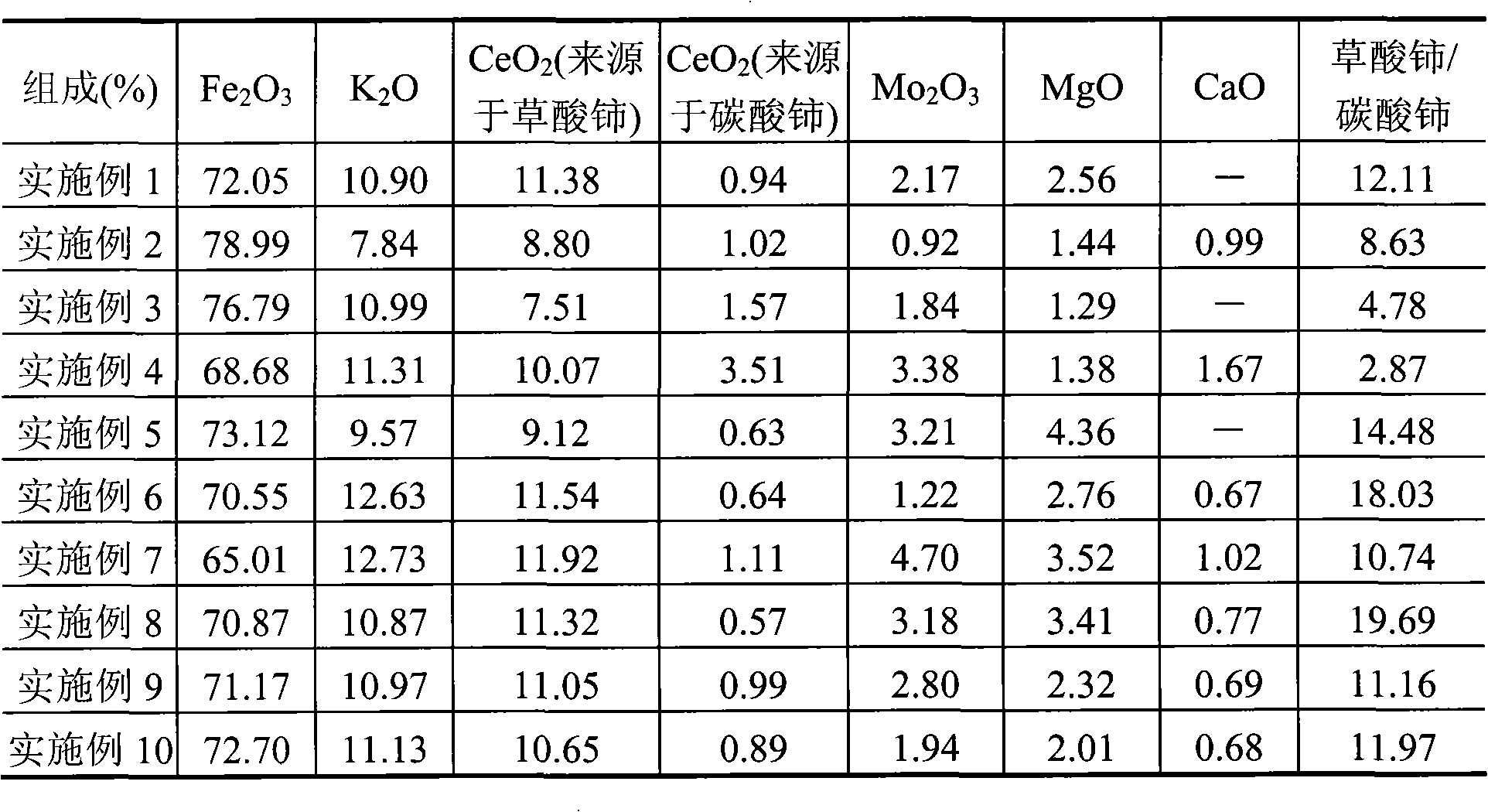

Catalyst for preparing styrene by dehydrogenizing ethylbenzene and preparation method thereof

ActiveCN101992092AIncrease alkalinityStabilize and disperse the active phaseCatalyst activation/preparationHydrocarbonsCalcium silicatePotassium

The invention relates to a catalyst for preparing styrene by dehydrogenizing ethylbenzene and a preparation method thereof, mainly solving the technical problem that the low mechanical strength of a low-potassium catalyst causes the reduction of the catalyst stability under the condition of not adding ordinary calcium silicate cement in the prior art. In the invention, a cerium source, an iron source, a potassium source, a molybdenum source, an alkaline earth metallic oxide and a hole forming agent with required quantities are selected in an iron-potassium-cerium-molybdenum-magnesium catalystsystem and uniformly mixing; and molding, drying and roasting to prepare a catalyst, wherein the technical scheme of adopting cerium oxalate and cerium carbonate as raw materials of the cerium sourceand adding the cerium source to the catalyst better solves the problem. The invention can be applied to the industrial production of preparing the styrene by dehydrogenizing the ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus and process for treating an aqueous solution containing biological contaminants

Process, apparatus and article for treating an aqueous solution containing biological contaminants. The process includes contacting an aqueous solution containing a biological contaminant with an aggregate composition comprising an insoluble rare earth-containing compound to form a solution depleted of active biological contaminants. The aggregate includes more than 10.01% by weight of the insoluble rare earth-containing compound. The insoluble rare earth-containing compound can include one or more of cerium, lanthanum, or praseodymium. A suitable insoluble cerium-containing compound can be derived from a cerium carbonate, a cerium oxalate or a cerium salt. The composition can consist essentially of cerium oxides, and optionally, a binder and / or flow aid. The aggregate includes no more than two elements selected from the group consisting of yttrium, scandium, and europium when the aggregate is to be sintered. Although intended for a variety of fluid treatment applications, such applications specifically include removing or deactivating biological contaminants in water.

Owner:MOLYCORP MINERALS

Method for producing ammonium metavanadate by using waste catalytic cracking catalyst in oil refinery

InactiveCN104495924AImprove recycling efficiencyVanadium compoundsAmmonium sulfideAluminum ammonium sulfate

The invention relates to a method for producing ammonium metavanadate by using a waste catalytic cracking catalyst in an oil refinery. The method comprises the following steps: mixing the waste catalyst with sulfuric acid, calcium fluoride and water in a mixer, feeding into a curing cabin, and curing in the curing cabin; pulpifying the mixed materials with water; pumping the pulpified liquid into a leaching tank, and heating and stirring for leaching; pumping into a plate filter press for liquid-solid separation, feeding the leachate into a crystallization tank, and adding ammonium sulfate to crystallize; and performing liquid-solid separation, thereby obtaining an aluminum ammonium sulfate product and crystallization master batch; and adding ammonium carbonate into the crystallization master batch to adjust the pH value, adding ammonium persulfate, adding ammonium carbonate to adjust the pH value, heating to react, pumping into the filter press, and performing liquid-solid separation, thereby obtaining ammonium metavanadate. The separated liquid can be also fed into a lanthanum-cerium deposition tank, and ammonium oxalate is added to react to obtain lanthanum oxalate and cerous oxalate, or the separated liquid is fed into a nickel deposition tank, and ammonium sulfide is added to react to obtain nickel sulfide. By adopting the method, the waste catalytic cracking catalyst in the oil refinery can be reused for producing ammonium metavanadate, the problems that the environment can be polluted by the waste catalyst and the land can be occupied are effectively solved, the purity of the produced ammonium metavanadate is even greater than 99%, and the recycling efficiency is high.

Owner:武汉源宸再生资源科技有限公司

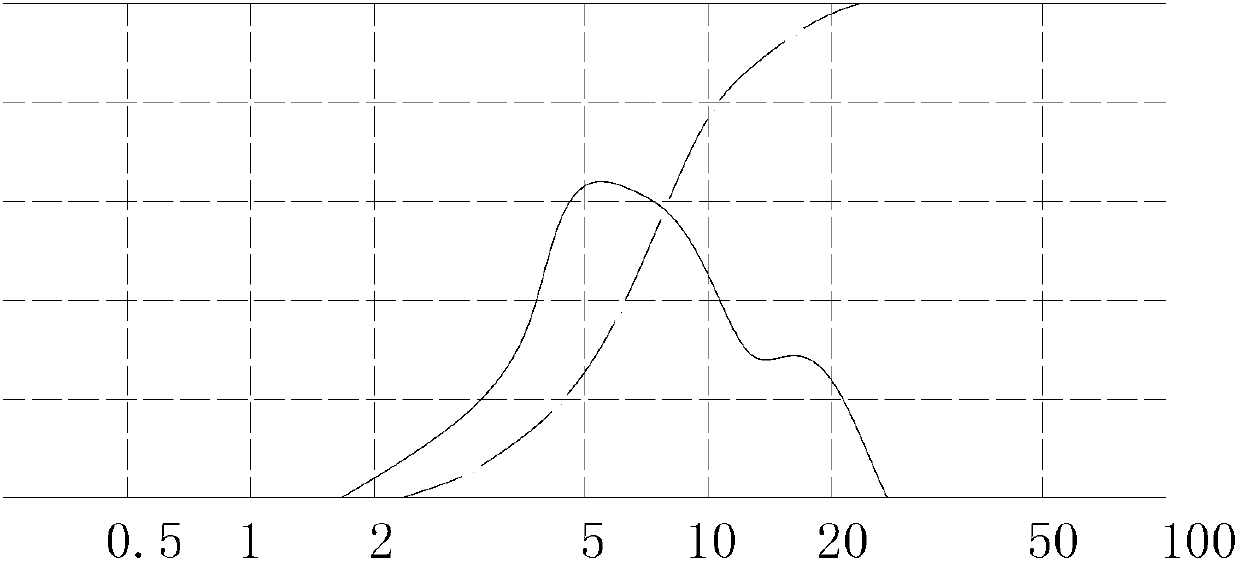

Preparation method of low polished cerium oxide polishing powder

InactiveCN103130262AEasy to prepareReduce manufacturing costOther chemical processesRare earth metal compoundsCerium nitrateCerium oxalate

The invention relates to a preparation method of a low polished cerium oxide polishing powder, which comprises the following steps: adding a cerium nitrate solution in a reaction vessel, under stirring condition, adding a certain amount of cerous oxalate, then heating the materials in the reaction vessel, keeping the material temperature of 45-60 DEG C, adding an oxalate solution at the temperature, after finishing the dropping of the oxalic acid liquid, continuously stirring for 20-45 minutes, stopping the stirring , depositing a cerous oxalate precursor and standing for 15-30 minutes, washing to the pH value of 6.5-7.0, spin-drying on the sediment to form a loosely granular cerous oxalate material; then insulating the spin-dried cerous oxalate material, cooling, and sieving to remove the impurities to obtain the cerium oxide polishing powder with average particle size at 7-10mum and maximum particle size controlled in 30 mum, The oxalic acid is used for depositing high purity cerium nitrate as the precursor, the preparation method is simple, the production cost is low, and the obtained polishing powder has the effect of high fineness and stable aperture of an optical element.

Owner:XIAN SICONG FINE CHEM

Modified chitosan pakchoi concentrated fertilizer with high infectious microbe inhibiting activity and preparation method thereof

InactiveCN105481571AEfficient cultivationImprove antibacterial propertiesBioloigcal waste fertilisersFertilizer mixturesO carboxymethyl chitosanMicrobial agent

The invention discloses modified chitosan pakchoi concentrated fertilizer with high infectious microbe inhibiting activity. The modified chitosan pakchoi concentrated fertilizer with high infectious microbe inhibiting activity comprises the following components in parts by weight: chitosan cationic solution, cinnamic acid, cerium oxalate, humulone, algin, shrimp and crab shells, tremolite, iron-containing waste residue, nano carbon, EM microbial agent, zinc methionine complex, ethoxy quinoline, porous high-activity humic acid, superfine glass fibers with micropores, O-carboxymethyl chitosan and right amount of weakly acidic small molecular group activated water. The modified chitosan pakchoi concentrated fertilizer with high infectious microbe inhibiting activity adopts chitosan rare earth cerium copolymer carried by the superfine glass fibers, supplement of cerium oxalate and antibacterial cultivation on the pakchoi are realized, and the weakly acidic small molecular group activated water and O-carboxymethyl chitosan treated cinnamic acid are combined, so that antibacterial, disease-resistant and high-efficiency cultivation is promoted, and natural environment-friendly cultivation is realized; meanwhile, shrimp and crab shell waste, tremolite, sandy soil and iron-containing waste residue are combined for composting, and the fertilizer has good permeability, is rich in nutrients and can promote high-efficiency cultivation of the pokchoi.

Owner:WUHU RUNLAN BIOTECH CO LTD

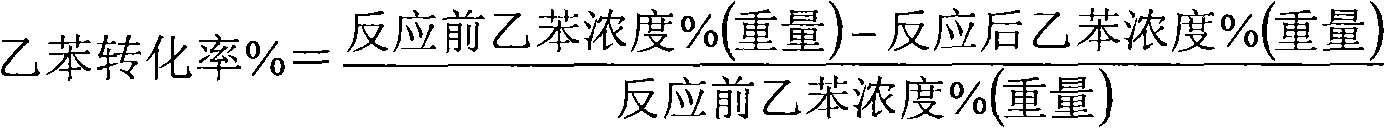

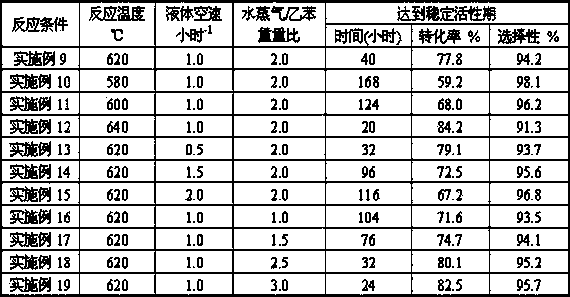

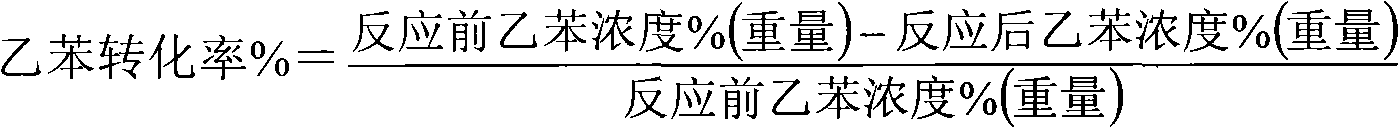

Method for preparing styrene by dehydrogenation of ethylbenzene

ActiveCN102040465AIncrease alkalinityStabilize and disperse the active phaseHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCalcium silicateWater vapor

The invention relates to a method for preparing styrene by dehydrogenation of ethylbenzene, and mainly solves the technical problem existing in the prior art that the mechanical strength of low potassium catalyst is low without the addition of common calcium silicate cements such that the stability decreases. According to the invention, ethylbenzene is adopted as a raw material, and styrene is prepared by contacting the raw material with a catalyst in a weight ratio of water vapor to ethylbenzene of 1.0-3.0 at normal pressure, a temperature of 580-640 DEG C, and a liquid space velocity of 0.5-2.0 h<-1>, wherein the catalyst used is the iron-potassium-cerium-molybdenum-magnesium catalyst and the mixture of cerium oxalate and cerium carbonate is adopted as a raw material for cerium source. The technical scheme solves the technical problem well and is applicable to the industrial production of preparing styrene by dehydrogenation of ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminum alloy natural color chromate-free passivation treatment agent and preparation method thereof

ActiveCN109609944AImprove corrosion resistanceSimple processMetallic material coating processesPotassium persulfateAluminium alloy

The invention discloses an aluminum alloy natural color chromate-free passivation treatment agent. The aluminum alloy natural color chromate-free passivation treatment agent is prepared from, by weight percentage, 5-10% of potassium persulfate, 1-5% of sorbitol, 0.5-1.5% of ammonium metavanadate, 0.1-0.5% of sodium diisobutyl naphthyl sulfonate, 0.1-0.5% of potassium zirconium carbonate, 0.05-0.08% of polyoxyethylene 10 lauryl ether, 0.01-0.05% of sodium pyrrolidone carboxylate, 0.05-0.1% of cerium salt, 3-10% of inorganic acid, 0.5-2% of organic acid and the balance water. The cerium salt isone or a mixture of cerium oxalate, cerium zincate, cerium formate and cerium acetate. The inorganic acid is one of hexafluorozirconic acid and hexafluorotitanic acid or a mixture of both. The organicacid is one of formic acid, acetic acid and oxalic acid. According to the chromate-free passivation treatment agent, a chromate-free passivation film formed on the surface of aluminum alloy is colorless and transparent, and the natural color of the aluminum alloy is not changed; and after treatment is conducted through the aluminum alloy natural color chromate-free passivation treatment agent, the corrosion resistance of the aluminum alloy is greatly improved, and the treatment agent can be applied to occasions without surface coating.

Owner:LINYI JINHU COLOR COATING ALUMINUM IND

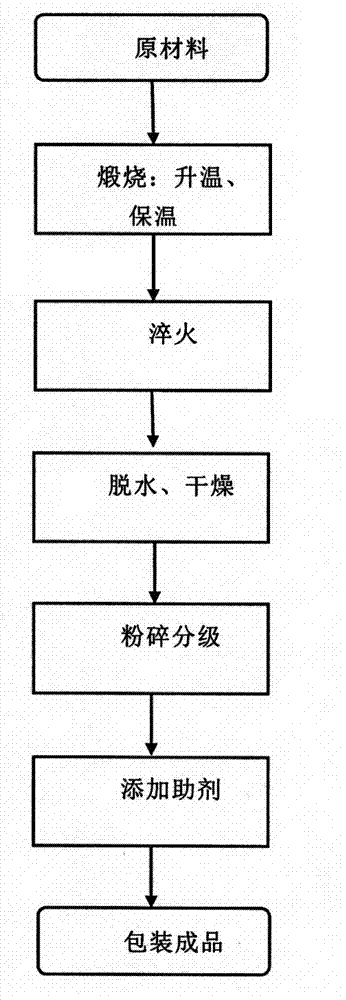

A producing process for preparing cerium oxide polishing powder

InactiveCN104261454AFast polishingReduced service lifeOther chemical processesRare earth metal compoundsCerium oxalateHeat conservation

The invention relates to the technical field of chemical production and particularly relates to a producing process for preparing cerium oxide polishing powder. Producing processes at present for cerium oxide polishing powder have disadvantages that: the environment is polluted; energy resources are wasted; and the polishing efficiency namely the cutting rate, polishing quality and service lifetime of the obtained cerium oxide polishing powder by the processes at present fail to meet requirements. The producing process adopts high-purity cerium oxide or cerous carbonate or cerous oxalate as a raw material, and by steps of heating, maintaining the temperature, performing secondary heating, performing secondary temperature maintaining, quenching, calcinating, removing water, drying, smashing and grading to obtain the polishing powder. A product of the producing process has advantages of high polishing speed, long service lifetime, good polishing quality, simple process, low raw material cost, energy conservation and environment protection.

Owner:ZHENGZHOU PUMING NEW MATERIAL

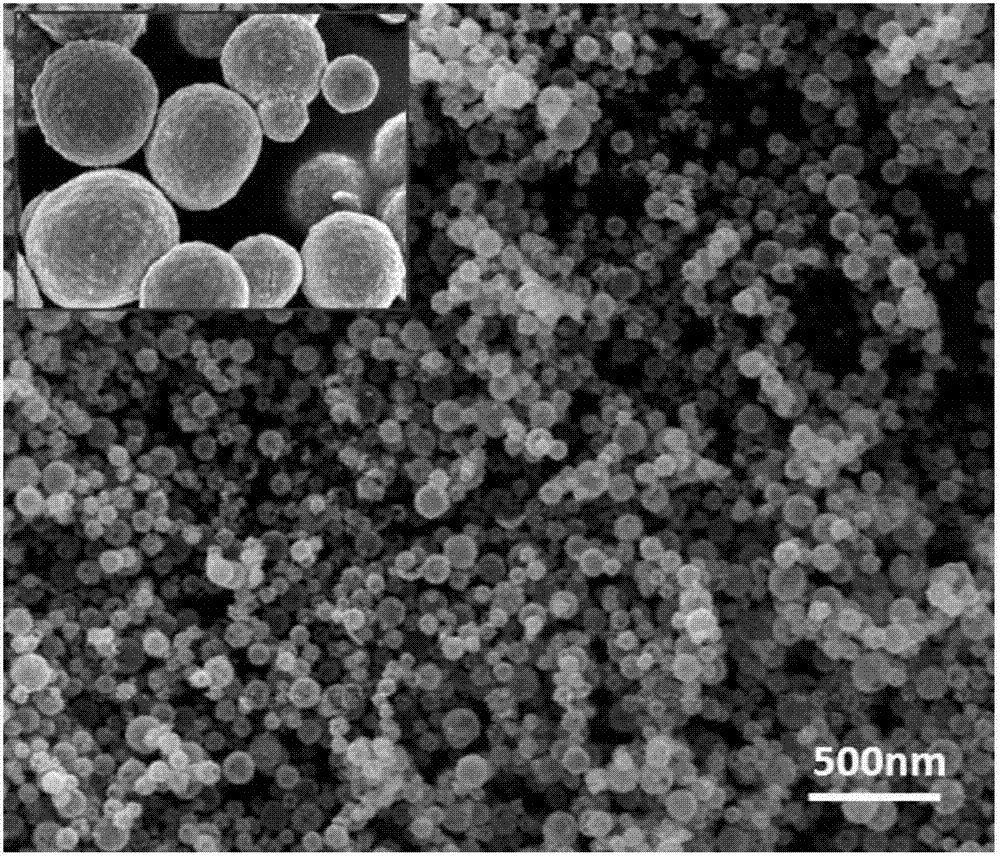

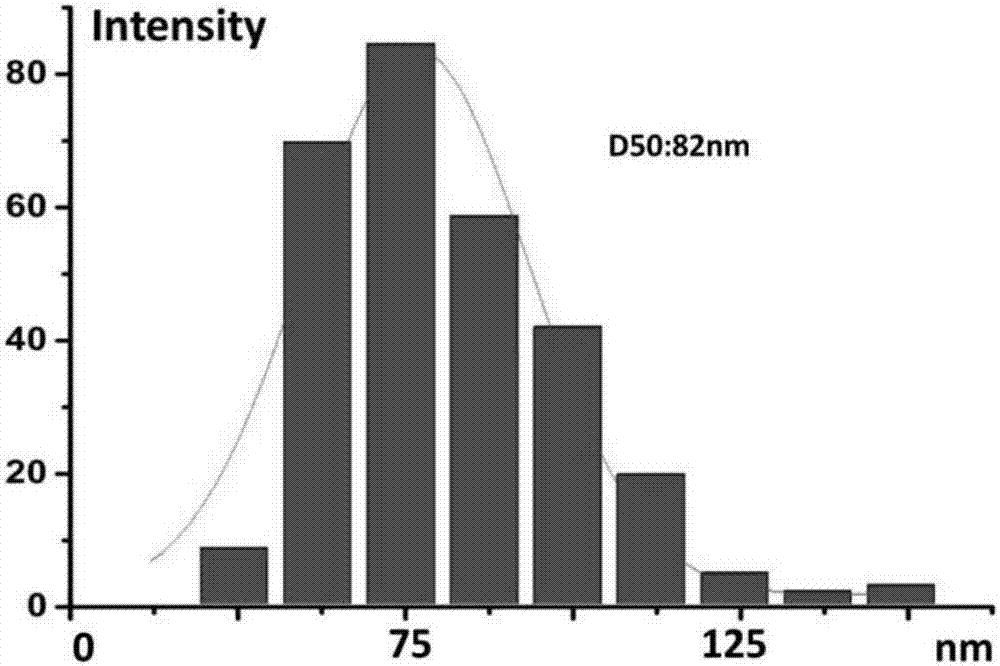

Preparation method of nano spherical cerium-group light rare earth oxide

ActiveCN107188216AInhibit growthFast nucleationRare earth metal oxides/hydroxidesMaterial nanotechnologySodium bicarbonateFiltration

The invention relates to a preparation method of a nano spherical cerium-group light rare earth oxide. The preparation method comprises the following steps: (1) respectively weighing sodium hydrogen carbonate and rare earth salt serving as reaction raw materials, wherein the rare earth salt is lanthanum salt, cerium salt, praseodymium salt, neodymium salt, promethium salt, samarium salt or europium salt; then, weighing right amount of hexadecyl trimethyl ammonium bromide; (2) mixing the reaction raw materials with the hexadecyl trimethyl ammonium bromide and right amount of anhydrous ethanol, and then carrying out planetary ball milling; (3) carrying out extraction filtration on an obtained product, washing, and then adding right amount of the anhydrous ethanol so as to obtain precursor slurry; (4) carrying out thermal decomposition on the precursor slurry by using a spray pyrolysis method. The preparation method provided by the invention has the advantages of being low in raw material cost, simple in equipment technology and operation, easy in realization of industrialization, and the like, and can be used for preparing the nano solid spherical cerium-group light rare earth oxide which is good in morphology, uniform in distribution, small in particle size, high in purity and high in particle spheroidization rate.

Owner:CHONGQING UNIV OF ARTS & SCI +1

Method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue

ActiveCN102659559BScientific and rational useSimple recycling processCarboxylic acid salt preparationOXALIC ACID DIHYDRATEHydrogen fluoride

The invention relates to the technical field of material preparation, in particular to a method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue. The method comprises the following steps: reacting to leach the recovered rare earth polishing powder waste residue in concentrated sulfuric acid to obtain a lanthanum cerium sulfate solution; separating the lanthanum cerium sulfate solution from solid residue, and adding oxalic acid to obtain a lanthanum cerium oxalate precipitate; and filtering and separating the lanthanum cerium oxalate precipitate, washing to neutrality, and drying to obtain the finished lanthanum cerium oxalate product. Fluorides such as hydrogen fluoride are not required, the polishing powder waste residue is scientifically and reasonably utilized comprehensively, and the whole recovery process is environment-friendly. The method has the characteristics of small investment, low recovery cost, simple process flow, high recovery rate, environment friendliness and the like.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Acid brilliant pink-calcium oxalate adsorbing material and its preparation method

InactiveCN101306346AImprove adsorption capacityShort adsorption timeOther chemical processesWater/sewage treatment by sorptionVolumetric Mass DensitySolvent

The invention provides an acid brilliant pink and calcium oxalate absorbing material as well as the preparation method thereof, and relates to an absorbing material which can separate the coloring matter, the organic matter and the heavy metal in waste water as well as the preparation method thereof. The absorbing material is composed by compounding a calcium oxalate framework material (1) and an acid red 138 inclusion material (2). 4 parts of 5-20 percent (w / w) calcium solution with the pH valve of 5-7, 1 part of 2-5 percent (w / w) oxalate solution, 2 parts of 10-20mM acid red 138 inclusion material and 4 parts of colloidize solvent are weighed out, then the inclusion solution and the colloidize solvent are added into the calcium solution, after mixing, the oxalate solution is added under the condition of stirring, and then after the reaction lasts for 10 to 30 minutes, the product is obtained by settling and washing the sediment, the appearance of the product is red, the density is 1800 to 2200 kg / m<3>, and the product is insoluble in water and alcohol, and is soluble in the suspension liquid of concentrated sulfuric acid; or the solid product can be prepared by centrifugally separating, drying and crushing. The invention treats a waste with another waste, the cost is low, and the process is simple; the product can be used for absorbing the coloring matter, the organic compounds and the heavy metal in the waste water with the efficiency being more than 90 percent, thereby having worshipfully economic and social benefits.

Owner:TONGJI UNIV

Method for preparing styrene employing ethylbenzene dehydrogenation

InactiveCN103664496AHigh initial activityShort initial activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPotassiumDehydrogenation

The invention relates to a method for preparing styrene employing ethylbenzene dehydrogenation, and mainly solves the problems of low initial activity and long induction period of a catalyst in the prior art. The method adopts the technical scheme as follows: a cerium source adopts ceric ammonium nitrate and cerous oxalate as raw materials and then the raw materials are added to the catalyst according to the required ratio in an iron-potassium-cerium-molybdenum or tungsten catalyst system, and meanwhile, the catalyst obtained from a cerium active component by adopting a mode of leading to the catalyst employing a sub-step method is applied to preparation of styrene employing ethylbenzene dehydrogenation, so that the problem is well solved, and the method can be applied to industrial production of styrene preparation employing ethylbenzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydrogenation catalyst for preparing alkyl alkenyl arene

ActiveCN1915503AHigh activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCerium oxalate

Owner:CHINA PETROLEUM & CHEM CORP +1

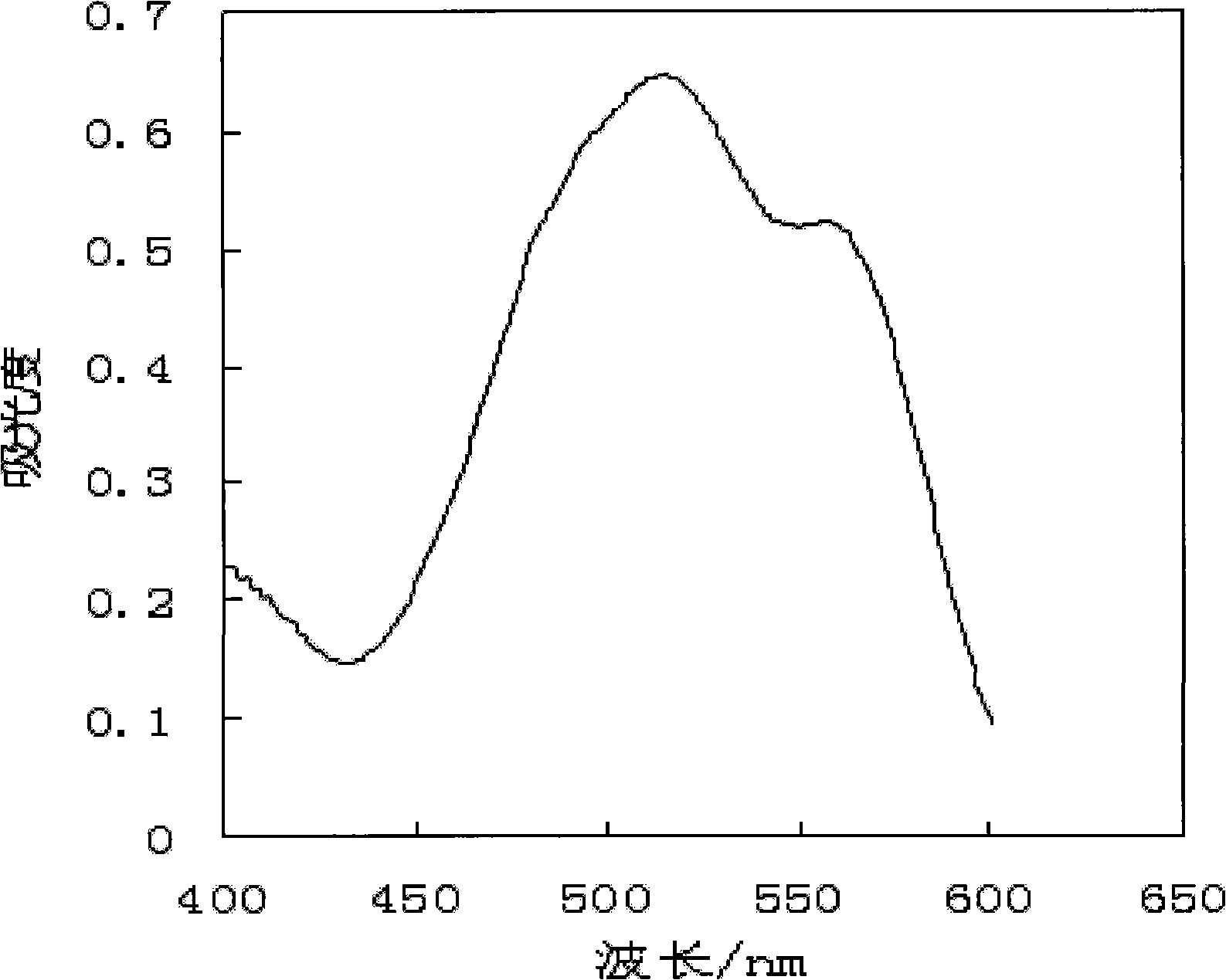

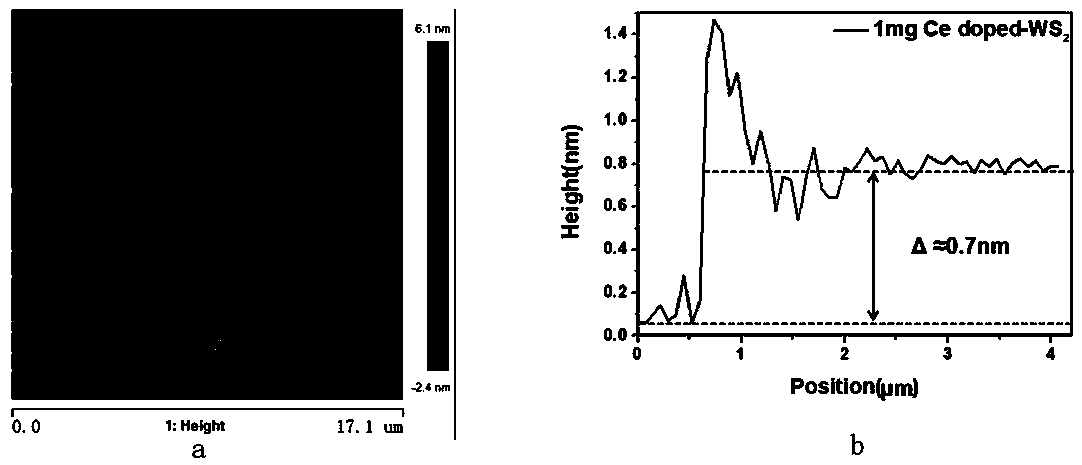

Cerium-doped monomolecular layer tungsten disulfide film and preparation method thereof

ActiveCN110668499AEvenly dopedImprove crystal qualityTungsten compoundsCerium oxalatePhysical chemistry

The invention relates to a cerium-doped monomolecular layer tungsten disulfide film and a preparation method thereof. Through a CVD system of a single temperature area, cerium oxalate and WO2.9 are placed in a quartz boat and doped with sodium chloride to form a mixture, the mixture is placed at the edge of one side of a heating hearth, and the quartz boat with placed sulfur powder is placed on the outer side of the heating hearth; a quartz tube is closed and vacuumized, and high-purity argon serves as carrier gas; the temperature of the temperature area is increased to 1050-1200 DEG C and kept, and the heating hearth is continuously moved in the period; annealing is conducted at the cooling rate of 50 DEG C per minute, and the temperature is decreased to 1040 DEG C and kept for 5-10 minutes; and then natural cooling is conducted to obtain the cerium-doped monomolecular layer tungsten disulfide film. By controlling various parameters related to the experimental process, the cerium-doped monomolecular layer tungsten disulfide film which is good in crystal quality and uniform is prepared.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method of quadrivalent uranium-cerium-oxygen solid solution

InactiveCN101807445AAvoid repaymentEnsure safetyUranium dioxideRare earth metal compoundsElectrolysisOxygen

The invention relates to a preparation method of a quadrivalent uranium-cerium-oxygen solid solution, wherein uranium nitrate is prepared by an electrolytic reduction method, and the quadrivalent uranium-cerium-oxygen solid solution is prepared by adopting a coprecipitation method; the method comprises the following steps: using a uranyl nitrate solution as a cathode electrolyte, using a nitric acid solution as an anode electrolyte, using a platinum-plated titanium electrode as an anode, and using a titanium net as a cathode; electrolyzing under the condition that the current density is 20 to 80 mA.cm-2 to obtain a uranium nitrate solution; then adopting the coprecipitation method, using oxalic acid as a precipitator, adding a mixed solution of the uranium nitrate and cerous nitrate obtained through electrolytic reduction, and coprecipitating to obtain a uranium-cerium oxalate deposit; and finally calcining at the temperature of 1173 to 1473K under argon protection to obtain the quadrivalent uranium-cerium-oxygen solid solution. The invention avoids leading reductive gas under the condition of high temperature, and the quadrivalent uranium-cerium-oxygen solid solution is prepared under a milder condition.

Owner:TSINGHUA UNIV

Pig feed with cassava as raw material and preparation method thereof

InactiveCN106974073AEliminate potential safety hazardsImprove disease resistanceFood processingAnimal feeding stuffBiotechnologyYeast

The invention relates to pig feed with cassava as a raw material, prepared from the following raw materials in parts by weight: 86-126 parts of cassava, 77-117 parts of corn, 73-113 parts of soy beans, 55-95 parts of shelled shrimps, 50-90 parts of artemisia vulgaris, 50-90 parts of water chestnuts, 48-88 parts of cassava leaves, 48-88 parts of bran coat, 40-80 parts of peanuts, 36-76 parts of medical stone, 32-72 parts of orange peel, 24-64 parts of cat beans, 19-59 parts of Xiasangju, 5-45 parts of cerium oxalate, 5-45 parts of peach leaves and 15-35 parts of yeast. The invention also discloses a preparation method of the pig feed. The pig feed ensures healthy growth of pigs, improves the growth efficiency of pigs, and improves the meat quality, palatable taste and fragrance of pork pigs to obtain compact meat quality, good mouthfeel, palatable taste and subtle fragrance. The cassava accounts for the most part of the pig feed, and the cassava is cheap, thereby reducing the feeding cost, improving economic benefit and solving the problem of dull sale due to seasonal harvest of cassava.

Owner:GUANGXI UNIV

Catalyst for preparing styrene by dehydrogenizing ethylbenzene and preparation method thereof

ActiveCN101992092BIncrease alkalinityStabilize and disperse the active phaseCatalyst activation/preparationHydrocarbonsCalcium silicatePotassium

The invention relates to a catalyst for preparing styrene by dehydrogenizing ethylbenzene and a preparation method thereof, mainly solving the technical problem that the low mechanical strength of a low-potassium catalyst causes the reduction of the catalyst stability under the condition of not adding ordinary calcium silicate cement in the prior art. In the invention, a cerium source, an iron source, a potassium source, a molybdenum source, an alkaline earth metallic oxide and a hole forming agent with required quantities are selected in an iron-potassium-cerium-molybdenum-magnesium catalystsystem and uniformly mixing; and molding, drying and roasting to prepare a catalyst, wherein the technical scheme of adopting cerium oxalate and cerium carbonate as raw materials of the cerium sourceand adding the cerium source to the catalyst better solves the problem. The invention can be applied to the industrial production of preparing the styrene by dehydrogenizing the ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

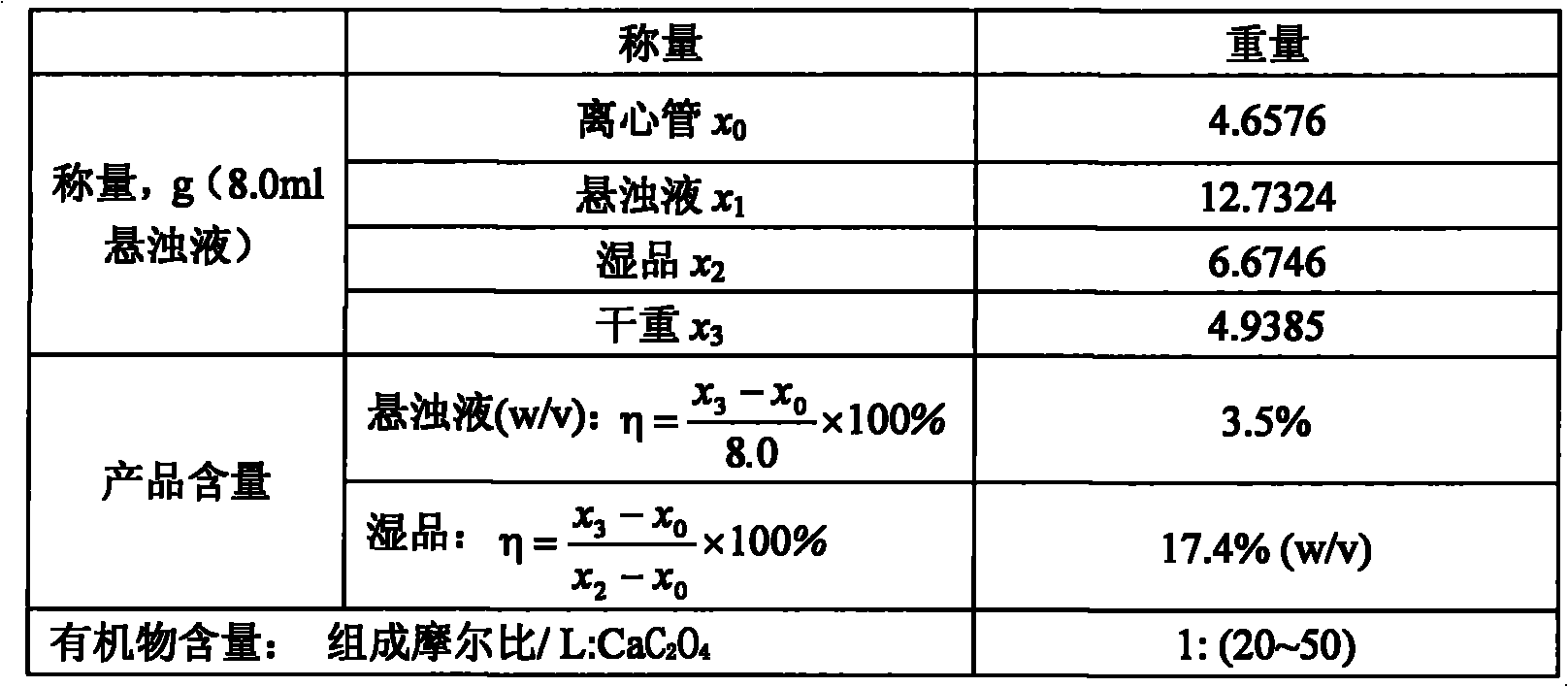

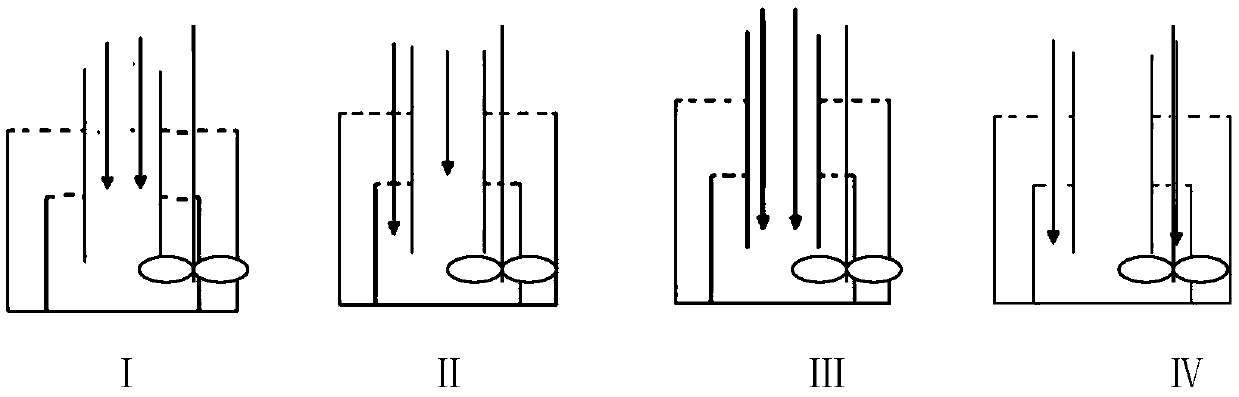

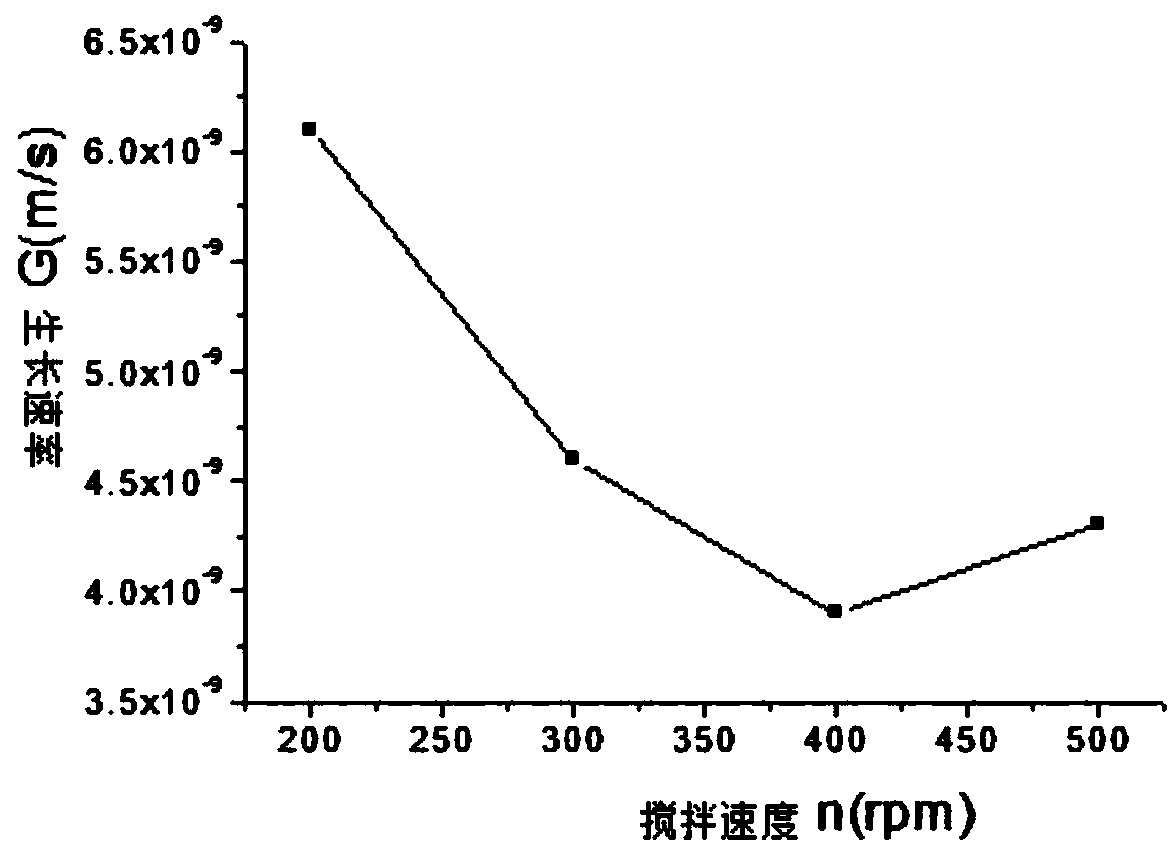

Preparation method of large-granule cerous oxalate precursor

InactiveCN105503917AGood effectGood nucleation rateGroup 3/13 organic compounds without C-metal linkagesCerium oxalateReaction temperature

The invention discloses a preparation method of a large-granule cerous oxalate precursor, which comprises the following steps: preparing a cerous carbonate solution with the Ce(NO3)3 concentration of 0.02 mol / L; preparing a precipitant oxalic acid solution with the H2C2O4.2H2O concentration of 0.15 mol / L; in the nucleation stage, adding the cerous carbonate solution into a nucleation device, and dropwisely adding the oxalic acid solution into the nucleation device while continuously stirring, wherein the dropwise addition rate is 10ml / minute, and the reaction temperature is 298K; meanwhile, starting a stirring paddle in an electric heating reaction kettle, wherein the stirring rate is 200 rpm, and the reaction time is 15.97 minutes; and filtering the granules generated in the solution, and drying to obtain the cerous oxalate large-granule precursor. The method has favorable effects on nucleation rate and growth rate in the rare-earth cerium oxide precursor cerous oxalate preparation process, and can be used for preparing the large-granule precursor cerous oxalate.

Owner:李荣

SCR flue gas denitration catalyst regeneration liquid and preparation method thereof

PendingCN111318316ARestore activityEnhanced anti-toxicityGas treatmentDispersed particle separationPtru catalystCerium oxalate

The invention relates to an SCR flue gas denitration catalyst regeneration liquid and a preparation method thereof, the regeneration liquid comprises an activity recovery liquid, an antitoxic inhibition liquid and a cleaning liquid, and the weight ratio of the activity recovery liquid to the antitoxic inhibition liquid to the cleaning liquid is 1: 0.3: 5; wherein the activity recovery liquid is prepared from vanadyl acetate, ammonium metatungstate, cerium oxalate, lanthanum nitrate, a surface penetrating agent and deionized water; wherein the antitoxic inhibition liquid is prepared from ammonium tungstate pentahydrate, cesium nitrate, ceric ammonium sulfate and deionized water; the cleaning liquid is composed of acid, a surfactant, a dispersing agent and deionized water. The regeneration liquid provided by the invention can be used for regenerating the deactivated catalyst, has the advantages of good regeneration effect, low SO2 / SO3 conversion rate and the like, and the regenerated catalyst has better anti-toxic performance, so that the service life of the regenerated catalyst is prolonged.

Owner:JIANGSU FENGYE TECH ENVIRONMENTAL PROTECTION GRP CO LTD

Preparation method of TiO2/rare earth/HY molecular sieve photocatalytic material

InactiveCN108514890AImprove photocatalytic activityNot easy to loseGas treatmentWater/sewage treatment by irradiationMolecular sieveAcetic acid

The invention provides a preparation method of a TiO2 / rare earth / HY molecular sieve photocatalytic material. The preparation method comprises following steps: mixing ethyl titanate and anhydrous ethanol, stirring continuously, dropwise adding cerium oxalate, neodymium nitrate, and yttrium carbonate hydrate under stirring; after addition, heating the mixture to a temperature of 70-90 DEG C, continuously stirring for 30 to 50 minutes; then dropwise adding 2-5 drops of glacial acetic acid to obtain an impregnation liquid; burning HY molecular sieves at a temperature of 180 to 220 DEG C to carry out reactions for 30 to 40 minutes, saving HY molecular sieves for later use; adding preprocessed HY molecular sieves into the impregnation liquid, wherein the solid / liquid ratio is 1:20-40; heating the solution to a temperature of 150-180 DEG C at a speed of 2-5 DEG C / min, carrying out reactions for 1 to 2 hours at a stirring speed of 500-700 r / min; then heating the solution to a temperature of 220-260 DEG C at a speed of 1-3 DEG C / min, carrying out impregnation reactions for 1-2 hours, cooling, washing the reaction product by distilled water, and burning the reaction product to obtain the photocatalytic material.

Owner:SUZHOU JUKANG NEW MATERIAL TECH

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711BTotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationCerium(IV) oxideRare earth

Owner:CHAOZHOU THREE CIRCLE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com