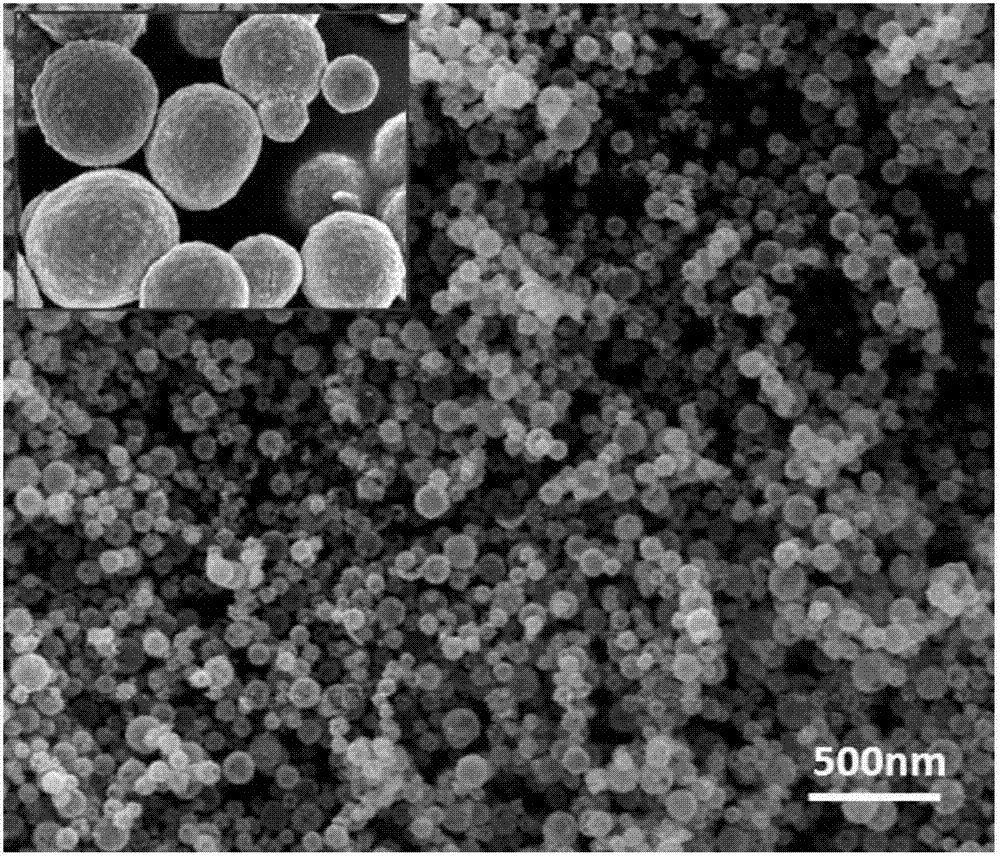

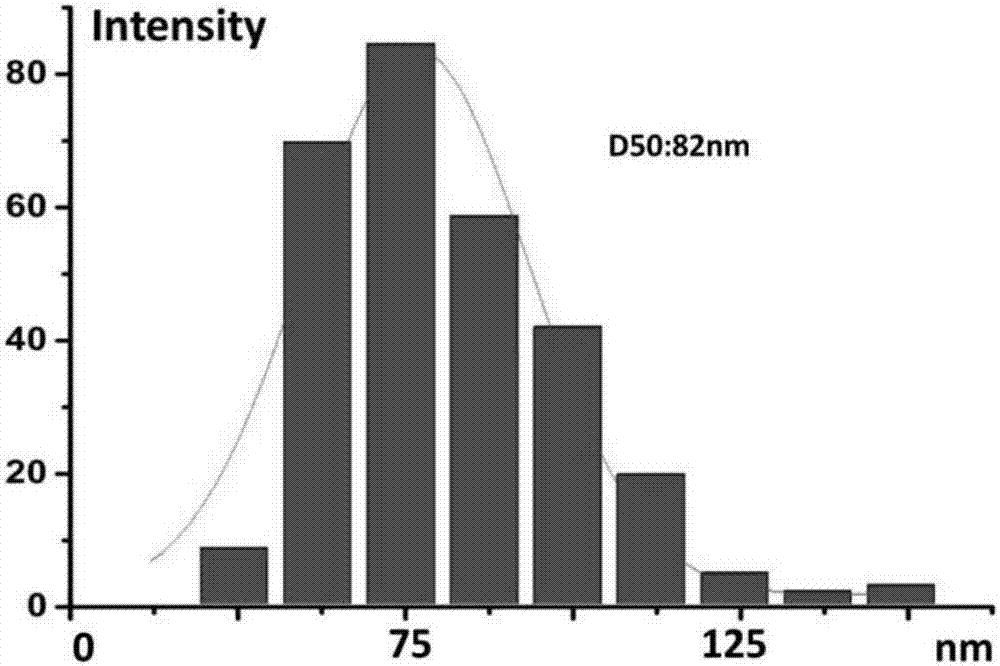

Preparation method of nano spherical cerium-group light rare earth oxide

A light rare earth oxide and spherical technology, applied in the direction of rare earth metal oxides/hydroxides, rare earth metal compounds, chemical instruments and methods, etc., can solve the problem of inability to effectively maintain products, complex preparation process and equipment, and limited material performance Effects and other issues, to achieve the effect of low raw material and processing costs, reduced mixing time of ball milling, equipment technology and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing nano-spherical cerium group light rare earth oxides, comprising the following steps:

[0026] 1. Ingredients

[0027] According to the stoichiometric ratio of each element in the reaction equation, the corresponding sodium bicarbonate (NaHCO 3 )2mol, rare earth salt cerium nitrate (Ce(NO 3 ) 2 ·6H 2 (2) 1mol is used as reaction raw material; Then take by weighing the surfactant cetyltrimethylammonium bromide (CTAB) that accounts for 2% of reaction raw material gross mass;

[0028] 2. Planetary ball mill

[0029] NaHCO to be weighed 3 , Ce(NO 3 ) 2 ·6H 2 O, CTAB is mixed with an appropriate amount of absolute ethanol, and is packed into an agate jar together with agate balls, wherein the weight ratio of the reaction raw materials to the agate balls is 1:5, and then planetary ball milling is carried out, and the ball milling speed is 300 revolutions per minute, and ball milling After 5 hours, the obtained product was suction filtered and th...

Embodiment 2

[0047] A method for preparing nano-spherical cerium group light rare earth oxides, comprising the following steps:

[0048] 1. Ingredients

[0049] According to the stoichiometric ratio of each element in the reaction equation, take corresponding 3mol sodium bicarbonate (NaHCO 3 ), 2mol rare earth salt lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) as reaction raw material; Then take by weighing the surfactant cetyltrimethylammonium bromide (CTAB) that accounts for 3.5% of reaction raw material gross mass;

[0050] 2. Planetary ball mill

[0051] NaHCO to be weighed 3 , La(NO 3 ) 3 ·6H 2 O, CTAB is mixed with an appropriate amount of absolute ethanol, and is packed into an agate jar together with agate balls, wherein the weight ratio of the reaction raw materials to the agate balls is 1:6, and then planetary ball milling is carried out at a ball milling speed of 400 revolutions per minute. After 7.5 hours, the obtained product was suction filtered and then washed 4 times wit...

Embodiment 3

[0055] A method for preparing nano-spherical cerium group light rare earth oxides, comprising the following steps:

[0056] 1. Ingredients

[0057] According to the stoichiometric ratio of each element in the reaction equation, the corresponding sodium bicarbonate (NaHCO 3 )3mol, rare earth salt samarium sulfate (Sm 2 (SO 4 ) 3 ) 2mol as reaction raw material; Then take by weighing the surfactant cetyltrimethylammonium bromide (CTAB) that accounts for 4.5% of reaction raw material gross mass;

[0058] 2. Planetary ball mill

[0059] NaHCO to be weighed 3 、Sm 2 (SO 4 ) 3 , CTAB is mixed with an appropriate amount of absolute ethanol, and put into an agate jar together with agate balls. The weight ratio of the reaction raw materials to the agate balls is 1:8, and then planetary ball milling is carried out. The ball milling speed is 480 revolutions per minute, and the ball milling time is After 9.5 hours, the obtained product was suction filtered and then washed 5 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com