Preparation method of nano silicon carbide reinforced aluminum-based composite material

A technology for strengthening aluminum-based and composite materials, which is applied in the direction of improving process efficiency and improving energy efficiency to achieve uniform distribution, excellent mechanical properties, and avoid agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

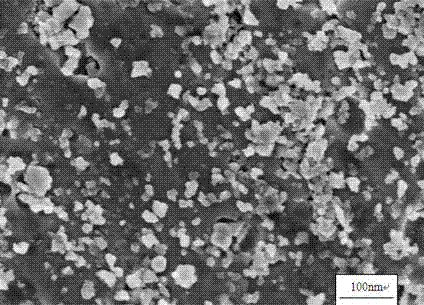

[0022] Step 1: SiC powder with a particle size of 40nm-60nm is mixed with AlSi10Mg powder with a particle size of 15μm-30μm, wherein the content of SiC is 3wt%.

[0023] Step 2: Put the mixed powder above into a Pulverisette-6 single-pot planetary high-energy ball mill produced by Germany Fritsch Company for ball milling. During ball milling, stainless steel balls were used as the ball milling medium, and the ball-to-material ratio was 10:1; argon protection was used to prevent oxidation; the ball mill speed was 300r / min, and the ball milling time was 4h; 4wt% stearic acid (C 18 h 36 o 2 , analytically pure, white granular) as a process control agent (PCA); the ball milling process was carried out by ball milling for 20 minutes and air cooling for 10 minutes.

[0024] Step 3: The SiC / AlSi10Mg nanocomposite powder obtained by ball milling is used for SLM forming. The SLM forming system mainly includes: high-power YLR-200 fiber laser, protective atmosphere device, automatic p...

Embodiment 2

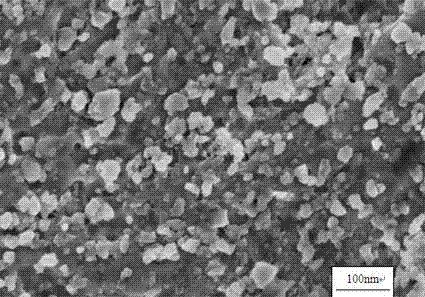

[0031] Step 1: SiC powder with a particle size of 40nm-60nm is mixed with AlSi10Mg powder with a particle size of 15μm-30μm, wherein the content of SiC is 6wt%.

[0032] Step 2: Put the mixed powder above into a Pulverisette-6 single-pot planetary high-energy ball mill produced by Germany Fritsch Company for ball milling. During ball milling, stainless steel balls were used as the ball milling medium, and the ball-to-material ratio was 10:1; argon protection was used to prevent oxidation; the ball mill speed was 300r / min, and the ball milling time was 5h; 4wt% stearic acid (C 18 h 36 o 2 , analytically pure, white granular) as a process control agent (PCA); the ball milling process was carried out by ball milling for 20 minutes and air cooling for 10 minutes.

[0033]Step 3: The SiC / AlSi10Mg nanocomposite powder obtained by ball milling is used for SLM forming. The SLM forming system mainly includes: high-power YLR-200 fiber laser, protective atmosphere device, automatic po...

Embodiment 3

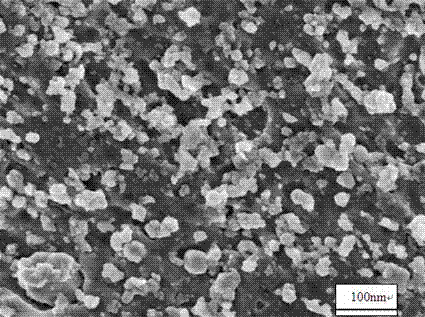

[0040] Step 1: SiC powder with a particle size of 40nm-60nm is mixed with AlSi10Mg powder with a particle size of 15μm-30μm, wherein the content of SiC is 10wt%.

[0041] Step 2: Put the mixed powder above into a Pulverisette-6 single-pot planetary high-energy ball mill produced by Germany Fritsch Company for ball milling. During ball milling, stainless steel balls were used as the ball milling medium, and the ball-to-material ratio was 10:1; argon protection was used to prevent oxidation; the ball mill speed was 300r / min, and the ball milling time was 6h; 4wt% stearic acid (C 18 h 36 o 2 , analytically pure, white granular) as a process control agent (PCA); the ball milling process was carried out by ball milling for 20 minutes and air cooling for 10 minutes.

[0042] Step 3: The SiC / AlSi10Mg nanocomposite powder obtained by ball milling is used for SLM forming. The SLM forming system mainly includes: high-power YLR-200 fiber laser, protective atmosphere device, automatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com