Cerium-doped monomolecular layer tungsten disulfide film and preparation method thereof

A tungsten disulfide, monolayer technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of uncontrollable number of layers, low luminous efficiency, huge cost, etc., and achieve the effect of good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

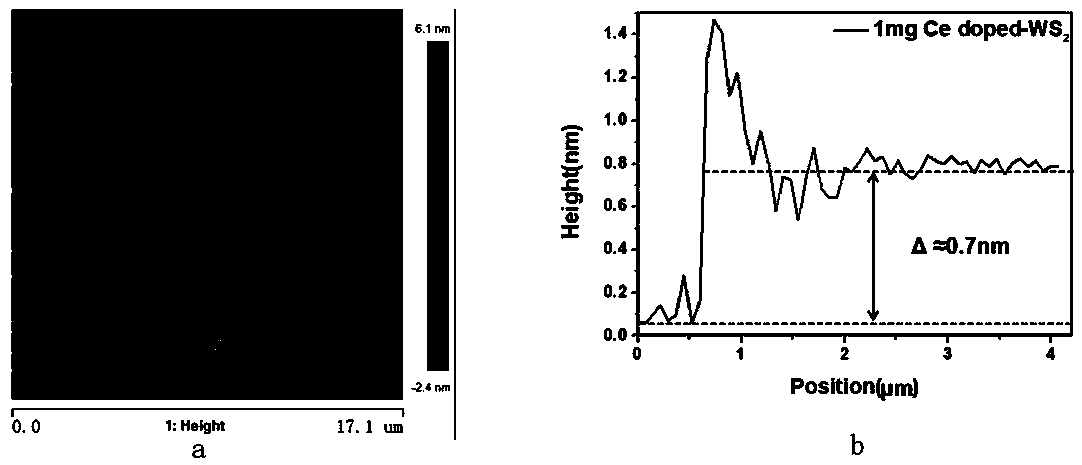

[0025] A typical embodiment of the present invention provides a method for preparing a cerium-doped monomolecular layer tungsten disulfide thin film, using a slide rail type single temperature zone tube furnace, using cerium oxalate as a dopant to prepare the tungsten disulfide thin film Doping includes the following steps:

[0026] Step 1, the substrate is cleaned and dried with ethanol and deionized water, and the substrate is polished flat SiO 2 / Si substrate or sapphire, mica and other substrates.

[0027] Step 2, use the slide rail type single temperature zone tube furnace to fix the WO 2.9 And mix cerium oxalate and WO according to mass ratio 1: (8~12) 2.9 placed in quartz boat 1 (see figure 1 ) and mixed with sodium chloride to form a mixture, the sodium chloride is used as a molten salt, and the mixing quality is WO 2.9 10~20% of the mass (mass ratio) of sodium chloride forms a mixture. The substrate is placed on the quartz boat 1, and the SiO 2 The side is oppos...

Embodiment 1

[0039] The first step, substrate cleaning: use ethanol and deionized water on SiO 2 / Si substrate is cleaned and dried;

[0040] The second step is to use the slide rail type single temperature zone tube furnace to fix the WO 2.9 The quality of 10mg, according to the mass ratio of cerium oxalate and WO 2.9 Placed in quartz boat 1 at a ratio of 1:10 (see figure 1 ) and doped with 2 mg of NaCl, the substrate was placed on a quartz boat, and the SiO 2 The face is opposite to the mixture;

[0041] In the third step, the quartz boat 1 is pushed into the quartz tube, and placed on the side edge of the heating furnace, and the quartz boat 2 with sulfur powder (see figure 1 ) is placed outside the heating furnace, and the distance between the quartz boat 1 and the quartz boat 2 is half of the size of the heating furnace;

[0042] The fourth step is to close the quartz tube and vacuumize for 5 minutes, and set the flow rate to 120 sccm after washing with high-purity argon;

[00...

Embodiment 2

[0052] The first step, substrate cleaning: use ethanol and deionized water on SiO 2 / Si substrate is cleaned and dried;

[0053] The second step is to use the slide rail type single temperature zone tube furnace to fix the WO 2.9 The quality of 8mg, according to the mass ratio of cerium oxalate and WO 2.9 Place in Quartz Boat 1 at a ratio of 1:8 (see figure 1 ) and doped with 1.0 mg of NaCl, the substrate was placed on the quartz boat 1, and the SiO 2 The face is opposite to the mixture;

[0054] In the third step, the quartz boat 1 is pushed into the quartz tube, and placed on the side edge of the heating furnace, and the quartz boat 2 with sulfur powder (see figure 1 ) is placed outside the heating furnace, and the distance between the quartz boat 1 and the quartz boat 2 is half of the size of the heating furnace.

[0055] The fourth step is to close the quartz tube and vacuumize for 5 minutes, and set the flow rate to 80 sccm after washing with high-purity argon;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com