Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4283 results about "Antimony trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony(III) oxide is the inorganic compound with the formula Sb₂O₃. It is the most important commercial compound of antimony. It is found in nature as the minerals valentinite and senarmontite. Like most polymeric oxides, Sb₂O₃ dissolves in aqueous solutions with hydrolysis.

Polyamide composition with flame retardance and thermoplasticity

The invention discloses a polyamide composition with flame retardance and thermoplasticity. The polyamide composition with flame retardance and thermoplasticity comprises the following components in percentage by weight: 30-90% of thermoplastic polyamide resin, 5-40% of a brominated flame retardant, 0.5-15% of a flame-retardant synergist and 0-50% of a reinforcing material. According to the polyamide composition, the brominated flame retardant, the high-efficiency flame-retardant synergist (namely zinc borate) and organic silicon are added in polyamide resin, on the one hand, the polyamide composition can replace antimony trioxide which is a rare material and is limited to be exploited by the nation at present, limited strategic resources of the nation can be saved, and the cost is lowered; and on the other hand, the flame retardance, a CTI (comparative tracking index) value and GWIT (glow wire ignition temperature) of the polyamide composition can be improved greatly, and the safety guarantee is provided for the use of the flame-retardant polyamide product on electronic appliances with high requirements.

Owner:KINGFA SCI & TECH CO LTD +1

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

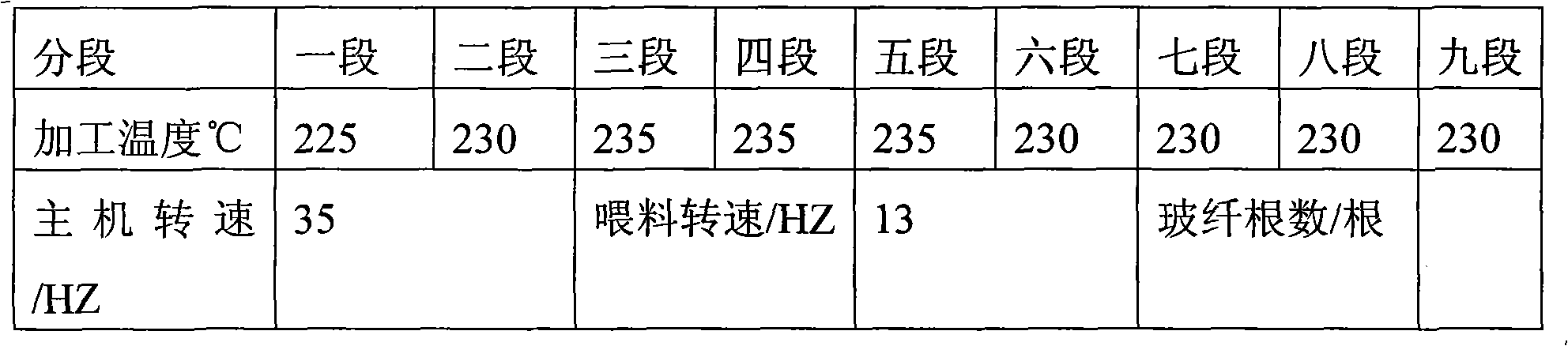

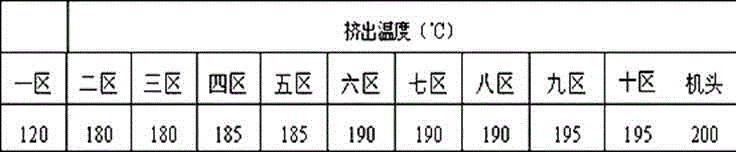

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

Fire resistant fabric material

A fire resistant fabric material comprising a substrate having an ionic charge which is coated with a coating having essentially the same ionic charge. The coating consists essentially of a filler material comprising clay and a binder material. The substrate is preferably fiberglass, the filler material may further comprise at least one additional filler selected from the group consisting of decabromodiphenyloxide, antimony trioxide, fly ash, charged calcium carbonate, mica, glass microspheres and ceramic microspheres and mixtures thereof and the binder material is preferably acrylic latex.

Owner:ELK PREMIUM BUILDING PROD

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

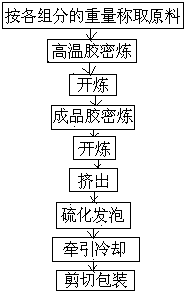

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

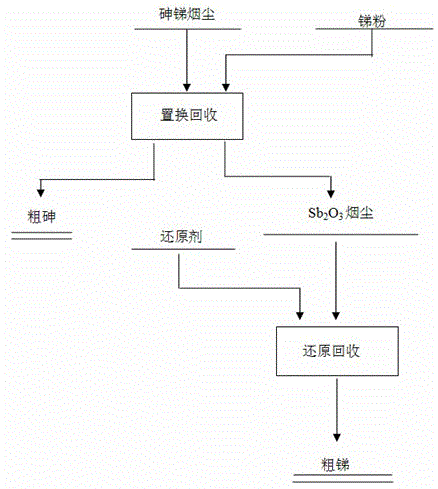

Method for processing arsenic-antimony fume by using replacement-reduction method so as to recover arsenic and antimony

ActiveCN103602835AReduce economic costsLow temperature and easy economic costProcess efficiency improvementDisplacement reactionsAntimony trioxide

The invention relates to a method for processing arsenic-antimony fume by using a replacement-reduction method so as to recover arsenic and antimony, belonging to the field of non-ferrous metallurgy technologies. The method comprises the steps of recovering arsenic by using a replacement method firstly: adding antimony powder into arsenic-antimony fume, and then simultaneously carrying out a displacement reaction on the obtained mixture for 30-120 min at the temperature of 500-800 DEG C and collecting antimony trioxide volatile fume, so that after the reaction is completed, crude arsenic is obtained; recovering antimony by using a reduction method: adding a reducing agent into the antimony trioxide volatile fume obtained in the last step, and then carrying out a reduction reaction on the obtained mixture for 30-180 min at the temperature of 800-1000 DEG C, so that crude antimony is obtained finally, wherein the mass ratio of antimony trioxide to the reducing agent is 10:(1-3). According to the invention, by fully using the characteristic that antimony trioxide is easily volatile at low temperature, arsenic in arsenic-antimony fume is replaced with antimony powder, and antimony trioxide is volatilized, so that crude arsenic is obtained, and then antimony trioxide is subjected to reduction smelting so as to obtain crude antimony, therefore, the method disclosed by the invention is simple in process and has better industrial application prospects.

Owner:KUNMING UNIV OF SCI & TECH

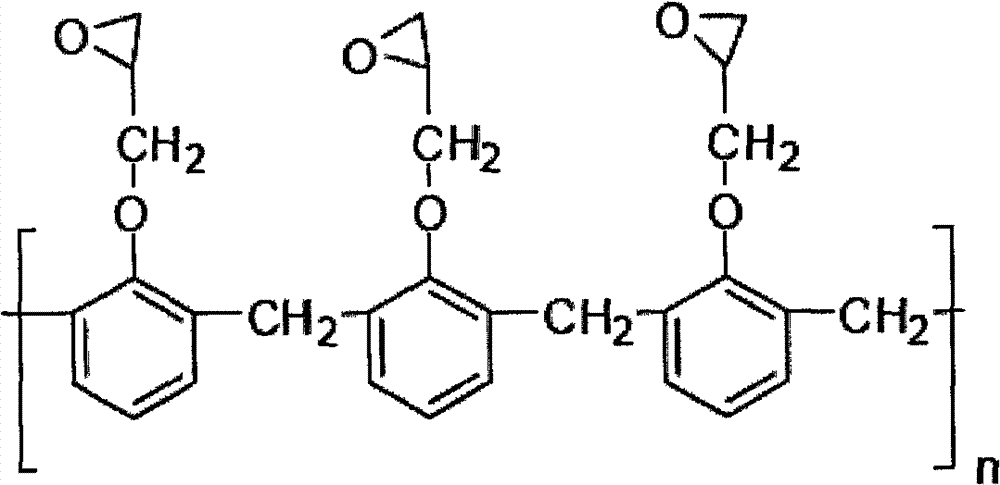

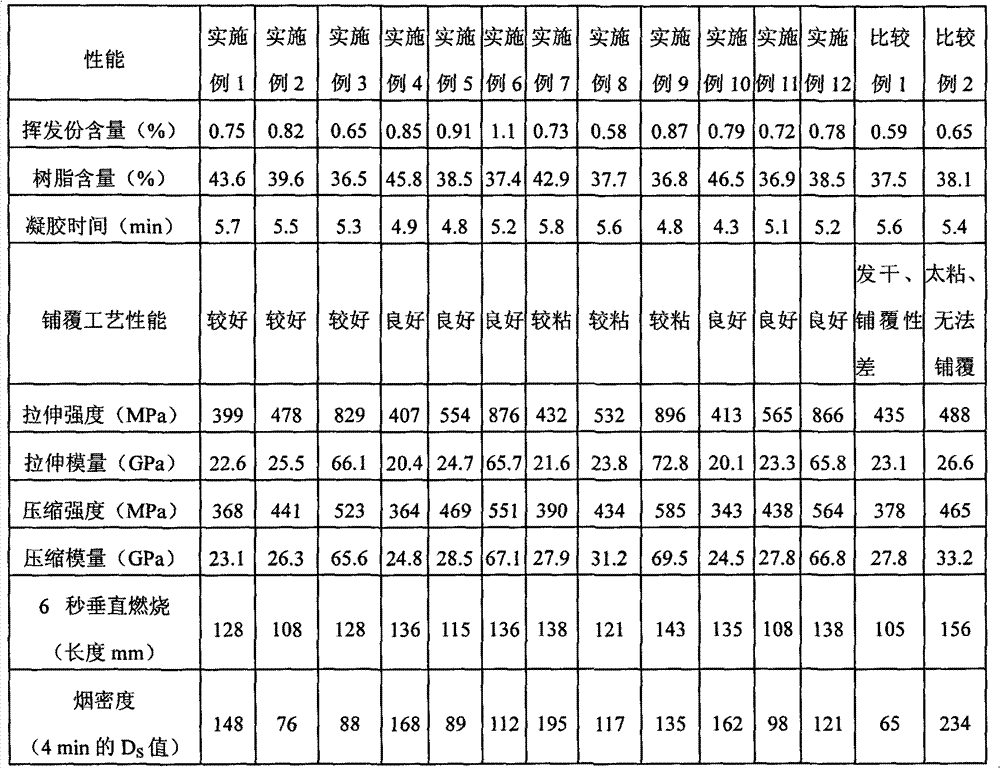

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

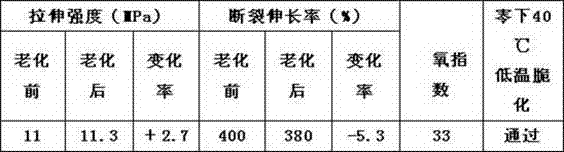

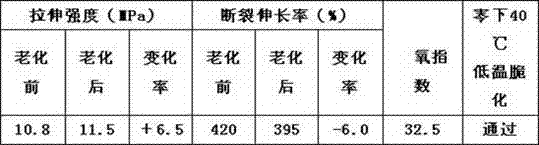

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

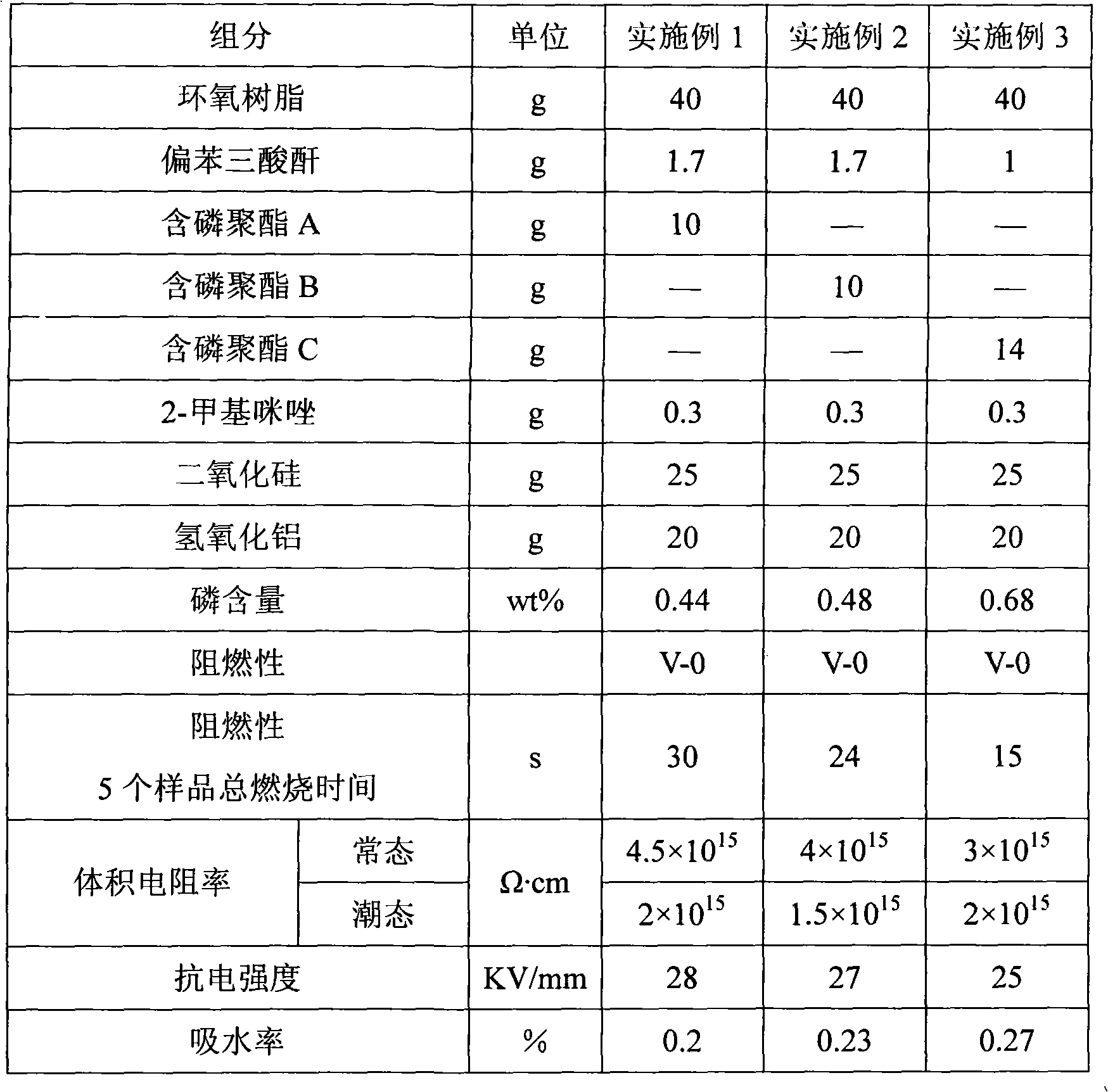

Phosphorus-containing polyester fire retardant epoxy resin composition

InactiveCN101307171AThe synthesis process is simpleStable productionOther chemical processesPolyesterEpoxy

The invention relates to a phosphoric polyester fire-retardant epoxy resin composition. The compositions by mass portion of the phosphoric polyester fire-retardant epoxy resin composition are: 20 to 40 portions of epoxy resin, 5 to 20 portions of phosphoric polyester, 0 to 10 portions of other curing agent, 0.1 to 0.3 portion of curing accelerator and 30 to 70 portions of inorganic filler. The phosphoric polyester fire-retardant epoxy resin composition does not contain harmful substances such as halogen, antimony trioxide and so on; the fire resistance can reach the fire-retardant standard of UL94 V-0; and the phosphoric polyester fire-retardant epoxy resin composition has good fire resistance and electric property.

Owner:天津凯华绝缘材料股份有限公司

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Composite wallpaper containing polyvinyl chloride

ActiveCN102587218AMeet environmental protection requirementsYellow noNon-fibrous pulp additionCoatings with pigmentsPolyvinyl chlorideAntimony trioxide

The invention relates to composite wallpaper containing polyvinyl chloride and discloses composite polyvinyl chloride (PVC) wallpaper with a flame retarding polyvinyl chloride (for short flame retarding PVC) coating or film as a surface layer and flame retarding paper as a bottom layer. Components of the flame retarding PVC surface layer, by weight ratio, comprise PVC resin 100, a plasticizer 0-50, a flame retardant 20-80, a stabilizing agent 0.01-1, filler 40-150, a foaming agent 0-1 and a thinning agent 0-10. Paper which is not flame retarding is soaked, flame retarding liquid is sprayed or brush-coated on the paper which is not flame retarding, and then drying is conducted to obtain the flame retarding paper. Compared with a traditional processing method of adopting antimonous oxide as a PVC surface layer flame retardant and adopting ammonium polyphosphate as a paper base layer flame retardant, the flame retarding PVC wallpaper is environment-friendly, low in toxicity and small in smoke density during burning, oxygen index can reach above 32%, and burning performance can reach a GB8624-2006B level.

Owner:应急管理部四川消防研究所

Grease-proof low-smoke halogen-free flame-proof cable material

The invention discloses a cross-linking type environment-friendly cable insulation material, characterized in oil resistance, low content of smoke, zero halogen and flame resistance. The cable insulation material comprises the components with the following weight portions: 20 to 40 percent of ethylene-vinyl acetate copolymer, 0 to 20 percent of nitrile rubber, 40 to 60 percent of flame retardant, 0.5 to 3 percent of oxidizing agent, 1 to 3 percent of cross-linking sensitizer, 0 to 15 percent of coloring agent and 0.5 to 1 percent of processing agent. The flame retardant is made from one or two of aluminum hydroxide and magnesium hydroxide of which surfaces are treated and one or more of red phosphorus, antimony trioxide, zinc borate or phosphate flame-retardant agent of which surfaces are treated; the invention selects the appropriate macromolecule base stock ethylene-vinyl acetate copolymer to compound with the nitrile rubber and applies the surface treatment to inorganic powders for improving the oil resistance of the material. The cable insulation material characterized in low content of smoke and zero halogen has good oil resistance.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Maintenance-free lead-acid storage battery and preparation method thereof

The invention particularly relates to a maintenance-free lead-acid storage battery and a preparation method thereof. The lead-acid storage battery is prepared from the following anode lead plaster materials: 100kg of lead powder, 1 to 10kg of red lead, 0.02 to 0.15kg of short fiber, 0.02 to 0.15kg of teflon, 0.01 to 0.2kg of stannous mono-sulphate, 0.01 to 0.2kg of antimonous oxide, 6 to 14 weight percent of deionized water, and 5 to 12 weight percent of dilute sulphuric acid, and the following cathode lead plaster materials: 100kg of lead powder, 0.02 to 0.15kg of short fiber, 0.05 to 0.4kg of acetylene black, 0.1 to 1kg of barium sulfate, 0.05 to 0.4kg of lignin, 0.05 to 0.4kg of humic acid, 6 to 14 weight percent of deionized water, and 5 to 12 weight percent of dilute sulphuric acid. The storage battery provided by the invention has good heavy-load discharge performance.

Owner:骆驼集团新疆蓄电池有限公司

Anti-static ceramic brick and production method thereof

ActiveCN102030519AWith anti-static functionCeramic products with antistatic function, it is fireproofBrickAntimony trioxide

The invention discloses an anti-static ceramic brick which is a building ceramic brick taking a glass phase, a quartz phase and an enstatite phase as main bodies. The anti-static ceramic brick is characterized by being mixed with semiconductor oxides, and the semiconductor oxides are stannic dioxide and diantimony trioxide. The anti-static ceramic brick comprises raw materials in percentage by weight: 15-27 clay, 25-52 talc, 0-7 quartz, 10-45 feldspar, 11-35 stannic dioxide and 1-9 diantimony trioxide, and the anti-static ceramic brick comprises chemical components in percentage by weight: 55-72 SiO2, 8-17 Al2O3, 1-9 Sb2O3, 11-35 SnO2, 8-18 MgO, 0.5-5 K2O and 0.2-6 Na2O. The invention also discloses a preparation method of the anti-static ceramic brick. The anti-static ceramic brick has the characteristics of fire prevention, long service life, moisture prevention, water proofing, moth proofing and the like, and the production method is simple and feasible and is beneficial to industrialized production.

Owner:FOSHAN OCEANO CERAMICS +1

Thermal anti-oxidation radiation resistance polyolefine thermal contraction material and preparation method thereof

A thermal anti-oxidation radiation resistance polyolefine thermal contraction material, comprising the following components by weight part: linear low density polyethylene 100-150 part, ethylene copolymer 30-80 part, polyolefine elastomer 20-40 part, cross-link sensibilizer 1-3 part, composite antioxidant 1-10 part, light stabilizer 1-5 part, halogen-containing fire retardant 20-60 part and antimony trioxide 10-30 part. The material is not only used in the nuclear island of the nuclear power station, but also widely used in the fields with higher material performance requirement such as navigation, shipping, nuclear submarine or the like.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

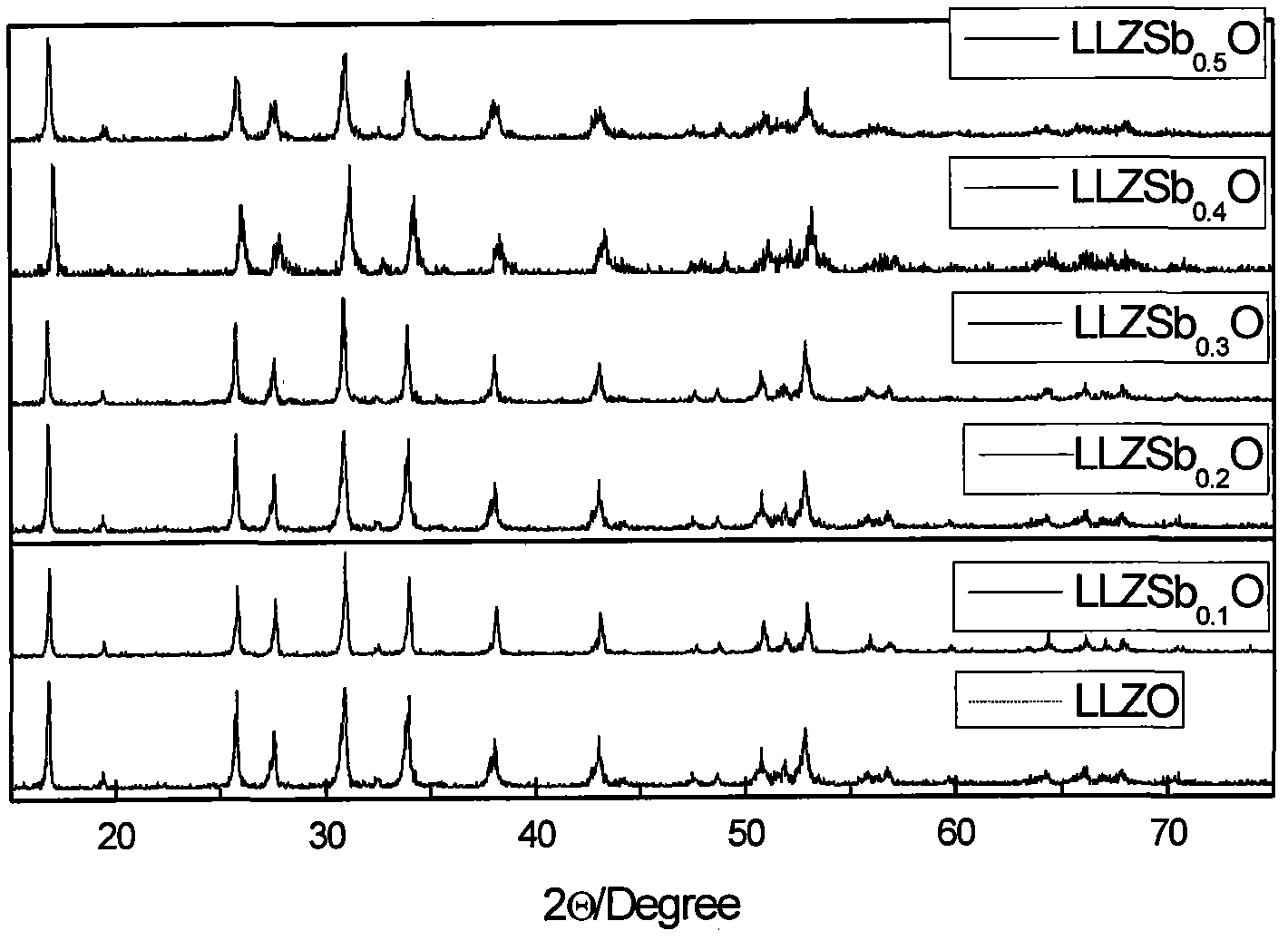

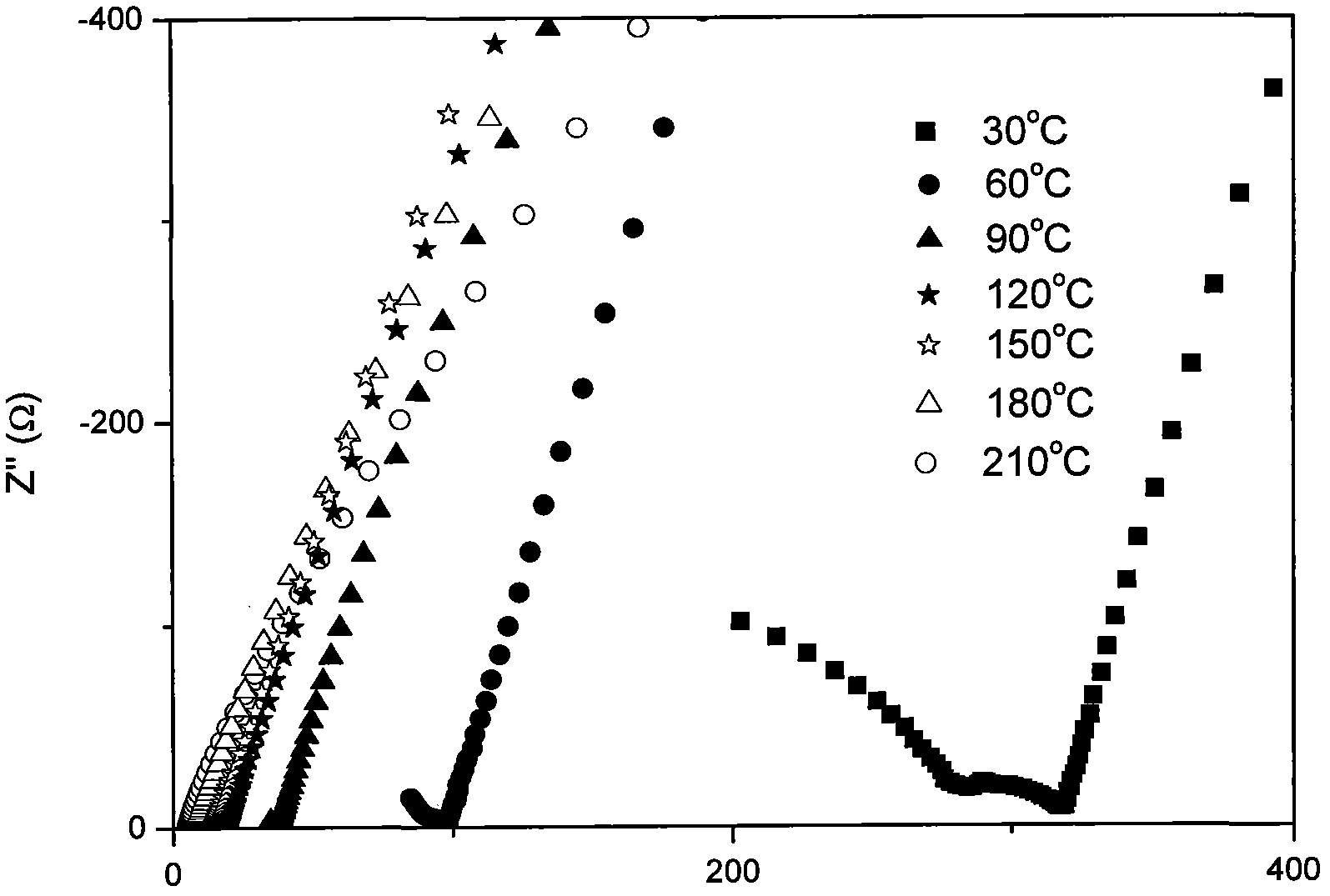

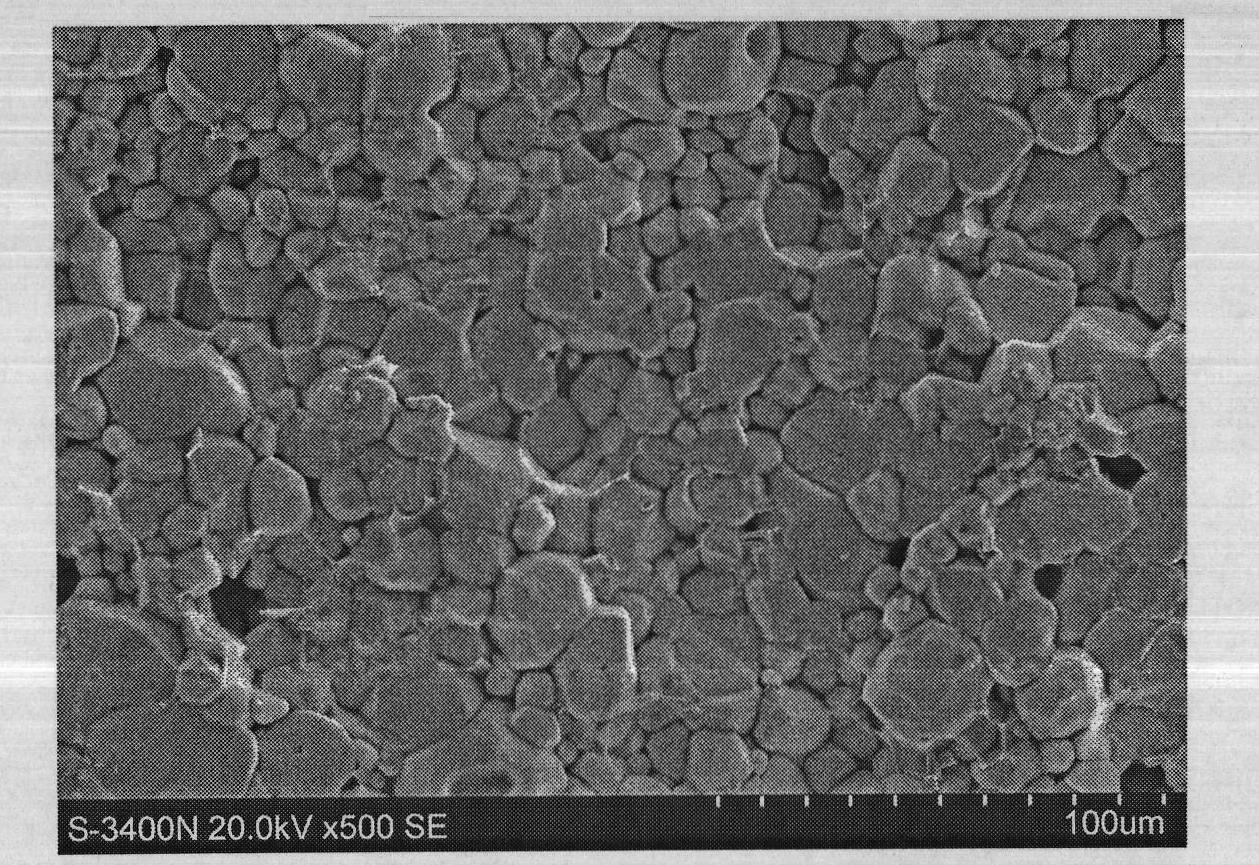

Stibonium-doped quasi garnet-structured lithium ion crystalline-state solid electrolyte material and synthesis method thereof

The invention provides a novel quasi garnet-structured lithium ion conductor (Li7-xLa3Zr2-xSbxO12, wherein x is more than 0 and less than or equal to 0.5) crystalline-state ceramic solid electrolyte material and a synthesis method thereof, and belongs to the field of lithium ion batteries. A novel quasi garnet-structured lithium ion conductor is synthesized by conventional solid-phase reaction. X-ray diffraction (XRD) diffraction peaks of Sb-doped samples show that the Sb-doped samples all have crystalline -state cubic phase quasi garnet-structures in the Sb doped range. The maximum lithium ion conductivity can reach 3.42*10<-4>S / cm at room temperature (30 DEG C). The sample is synthesized by the conventional solid phase method, a preparation process is simple, and sintering time is short. Zr is partially replaced by high-valence Sb, so the lithium ion vacancy is increased, the ionic conductivity is improved obviously, and antimonous oxide is low in price compared with zirconia, so manufacturing cost is reduced. Therefore, the synthesized compact ceramic solid electrolyte material can be probably applied to a lithium ion battery.

Owner:INNER MONGOLIA UNIV OF TECH

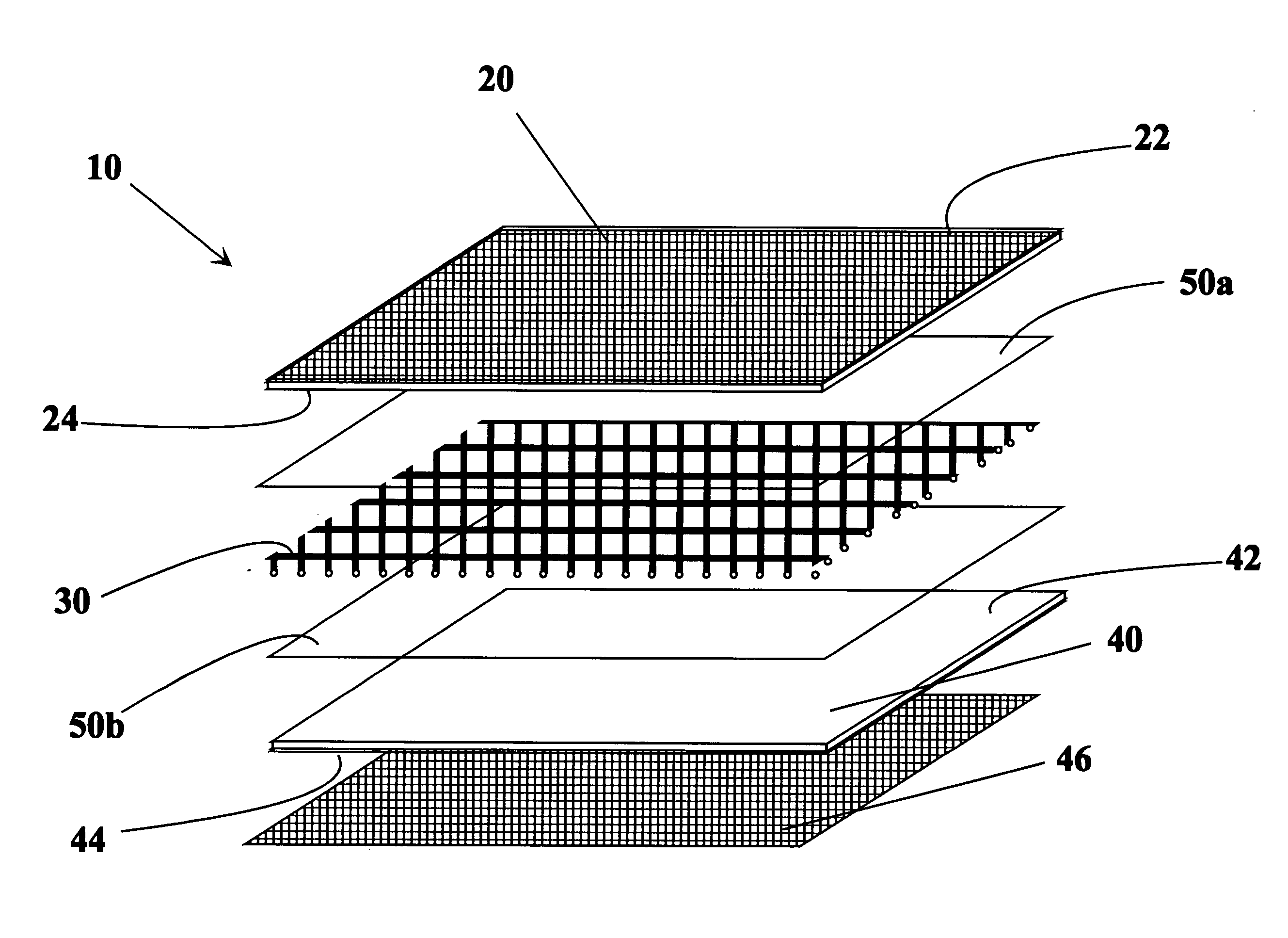

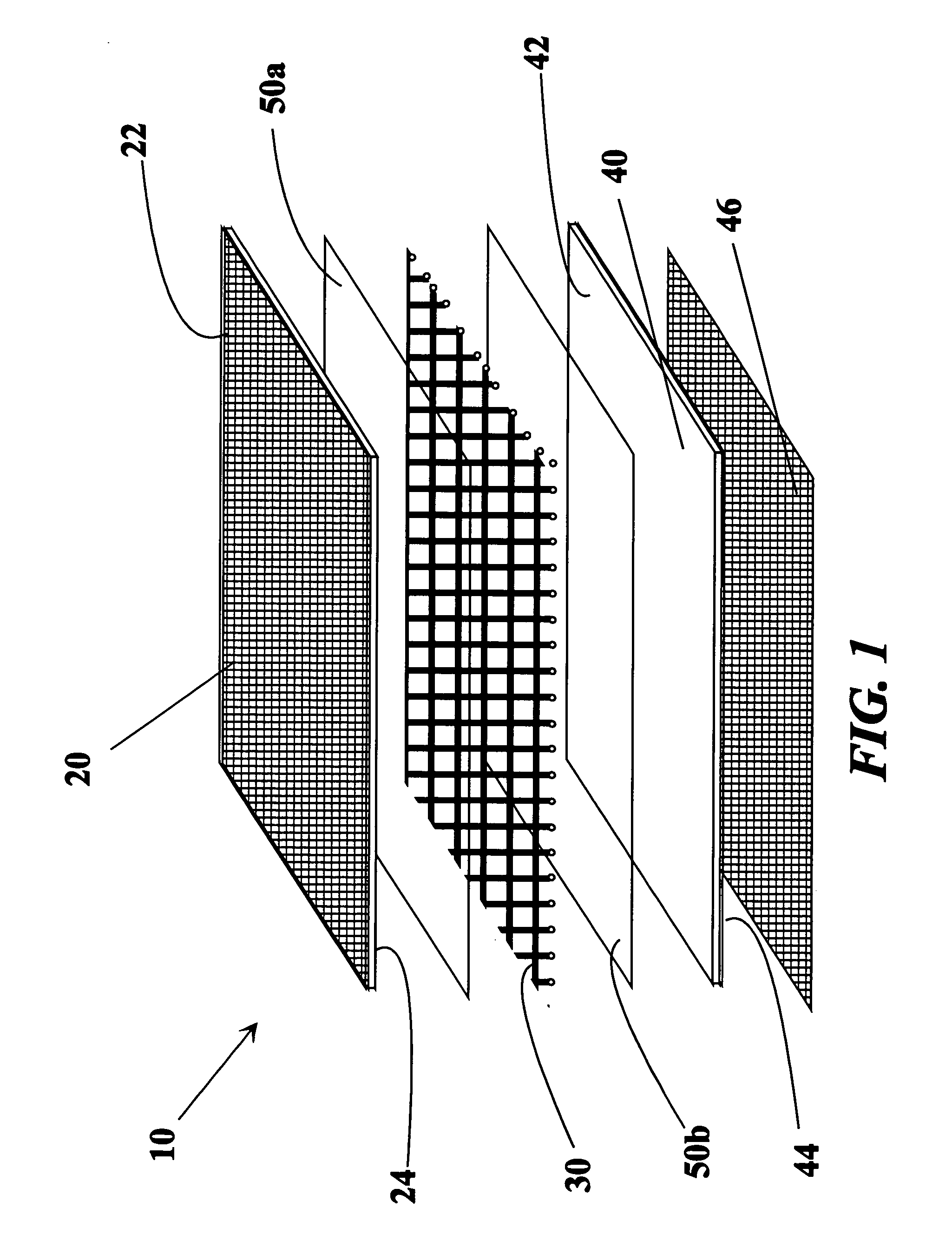

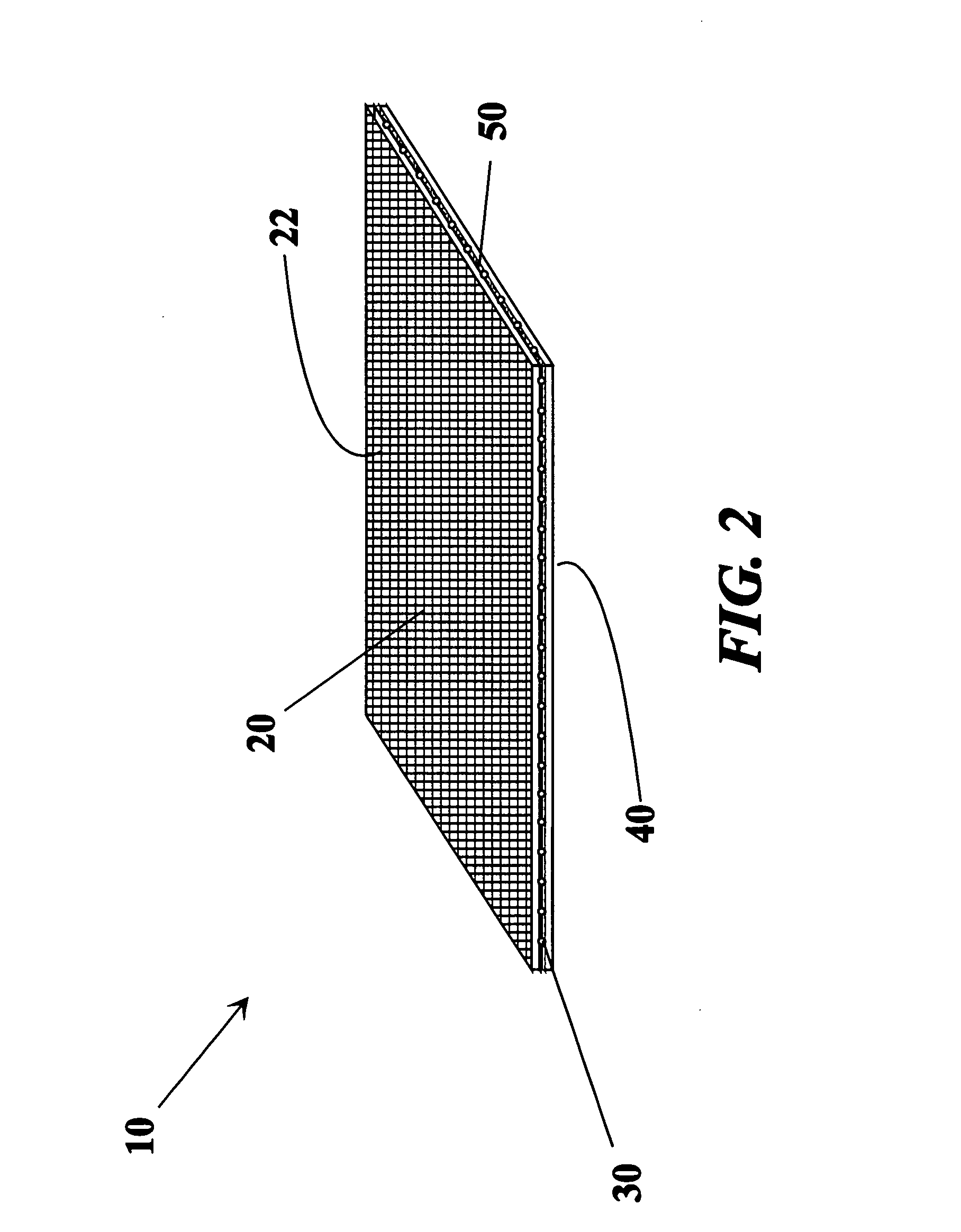

Textured and printed membrane that simulates fabric

InactiveUS20060270298A1Easy to cleanImprove the immunitySynthetic resin layered productsPaper/cardboard layered productsEngineeringAntimony trioxide

A textured and printed membrane has an embossed top layer with a protective coating, a fabric layer, a printed bottom layer with a protective coating, where the layers are adhered with a PVC plastisol. The printing pattern matches the embossing, such that the membrane has the appearance of cloth on both sides. The textured vinyl membrane composite has a thickness of from 10 to 35 mils. The membrane can be fitted on an awning to display illuminated (white / opaque) graphics (lettering or design). The top layer is preferably compounded PVC formulated with a colorant. The bottom layer is also PVC, typically formulated with a flame retardant package, such as antimony trioxide or brominated compounds, aluminum trihydrate, magnesium hydroxide, and the like to suppress the spread of an ignited flame. Both top and bottom layers can have heat stabilizers and lubricants to improve processing of the PVC.

Owner:COOLEY

Benzoic anhydride catalyst and preparation method thereof

ActiveCN101422727AImprove performanceImprove working environmentOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemical industryGas phase

The invention relates to a catalyst that is used in the catalytic oxidation reaction between raw materials of ortho-xylene and / or naphthalin and gas phase that contains molecular oxygen for producing phthalic anhydride, as well as a preparation method of the catalyst. The catalyst comprises an inert imperforated carrier material and a catalytic active substance layer that is coated on the carrier and contains vanadic oxide, diantimony trioxide, titanium dioxide and a cementing agent, etc. In a preparation process of the catalyst, serum is firstly prepared, viscosity of the catalytic active substance serum is controlled, the carrier is heated, the serum is sprayed onto the carrier in a barrate, and the carrier is dried by hot wind. The catalyst is used for the field of chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant agent and flame-retardant resin composition

InactiveUS20140200292A1Improve flame retardant performanceFireproof paintsO-Phosphoric AcidSilicic acid

The present invention provides a composite flame retardant which can be produced without using any toxic metal such as antimony trioxide or any halogen such as bromine and chlorine and can exhibit excellent flame retardancy compared with magnesium hydroxide when added in a smaller amount; and a flame retardant resin composition having excellent flame retardancy and excellent physical properties. The present invention relates to a flame retardant including: (A) 100 parts by mass of a reaction product of piperazine with one phosphorus compound selected from phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; (B) 10 to 1000 parts by mass of a reaction product of melamine with a polyacid selected from cyanuric acid, phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; and (C) 0.1 to 100 parts by mass of a reaction product of calcium or magnesium with silicic acid.

Owner:SAKAI CHEM IND CO LTD

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

High-capacity formation lead paste and preparation method thereof

InactiveCN102931410AIncrease capacityExtended service lifeLead-acid accumulator electrodesFiberPolyester

The invention discloses a high-capacity formation lead paste. An anode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and anode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.6-7.4 parts by weight of dilute sulphuric acid, 10-11 parts by weight of deionized water, 3-5 parts by weight of red lead, 0.1-0.3 part by weight of aquadag, 0.08-025 part by weight of stannous mono-sulphate, 0.03-0.05 part by weight of bismuth trioxide, 0.03-0.05 part by weight of antimonous oxide and 0.06-0.1 part by weight of polyester staple fiber; and a cathode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and cathode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.5-8.5 parts by weight of dilute sulphuric acid, 9-10 parts by weight of deionized water, 0.5-0.8 part by weight of barium sulfate, 0.15-0.25 part by weight of acetylene carbon black, 0.30-0.40 part by weight of humic acid and 0.06-0.1 part by weight of polyester staple fiber. The invention also discloses a preparation method of the high-capacity formation lead paste.

Owner:CHAOWEI POWER CO LTD

Novel environment-friendly polyvinyl chloride cable material

The invention provides a novel environment-friendly polyvinyl chloride cable material. The material consists of polyvinyl chloride WS-1300, plasticizer UN399, stabilizer CZ-756E (105), epoxidized soybean oil, bisphenol A antioxygen, antimonous oxide (SB203), polyethylene (PE), activated light calcium carbonate and carbon black. The chemical substance content of the material is reduced by improving the formula of the cable material, so that the product has the advantages of effectively solving the problem of toxic gases releasing in polyvinyl chloride material heating and plastifying process, reducing the harm to the human bodies in the production process, resisting the temperature of between 40 and 105 DEG C, along with cleanness and environmental protection, light specific gravity, high plasticization degree, no deformation, fracture or aging, superior product performance, and wider application range and field.

Owner:ZHENJIANG HUAYIN INSTR & ELECTRICAL EQUIP

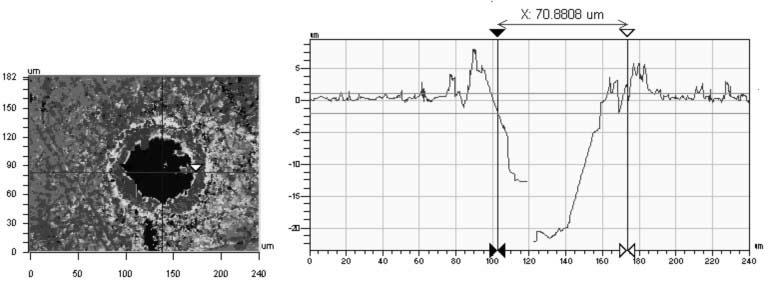

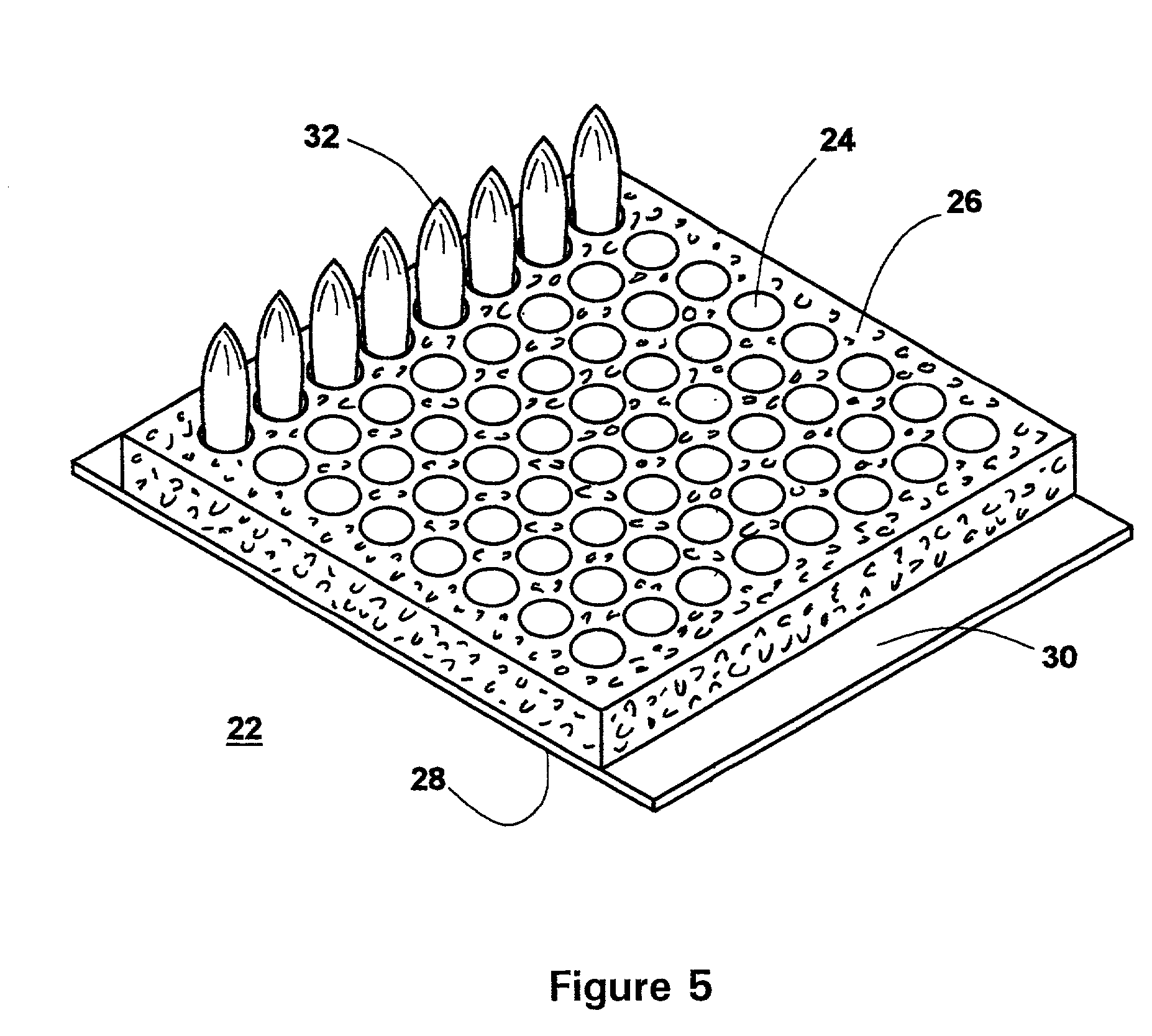

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

Solar super-white rolling glass and preparation method thereof

InactiveCN102219375AReasonable useReduce dependenceGlass furnace apparatusGlass rolling apparatusSolar powerAntimony trioxide

The invention relates to a piece of solar super-white rolling glass which is calculated according to the mass percent of oxide, and comprises the components according to proportions as follows: 72.0%-75.2% of SiO2, 1.0%-2.4% of Al2O3, 13.2%-15.0% of R2O, 8.5%-10.5% of CaO, 0-3.6% of MgO, 0.15%-0.38% of Sb2O3 and Fe2O3 being smaller than or equal to 0.01%. In addition, the invention also relates to a preparation method of the solar super-white rolling glass, and the preparation method comprises the following steps: step one, selecting quartz sand, aluminum hydroxide or aluminum oxide, limestone, calcined soda, sodium sulfate, dolomite, antimony trioxide and cullet as raw materials, and preparing and mixing the raw materials; step two, melting and clarifying; step three, calendaring; and step four, annealing and obtaining the solar super-white rolling glass. The solar super-white rolling glass produced by the preparation method has the advantages of high light transmission, good corrosion resistance and weather resistance, long service life and the like, and can be used for a solar power generating assembly for photoelectric conversion.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Ballistics conditioning

InactiveUS20030078170A1Quick and easy spray-coatingHigh hardnessAmmunition projectilesMoulding toolsHexagonal boron nitrideAcrylic resin

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

The present invention relates to a glass fiber reinforced flame retardant polypropylene material for household appliance products, and belongs to the field of modified polypropylene plastic. The material comprises the following raw materials, by weight: a high-impact-resistance copolymer polypropylene resin, a bromine-based flame retardant agent, antimony trioxide, a flame retardant synergist, alkali-free continuous long glass fibers, a compatibility agent, a toughening agent, a lubricant, a UV absorber and an antioxidant. The present invention provides the glass fiber reinforced flame retardant polypropylene material with higher tensile strength, bending modulus and hardness as well as high impact-resistance, low molding shrinkage, aging resistance and the like. The glass fiber reinforced flame retardant polypropylene material has a high heat deformation temperature, good oxidation resistance at high temperature, and the flame retardant performance up to the level of UL94 V-2, and passes the glow wire test of GWIT: 700 / 3.0. The glass fiber reinforced flame retardant polypropylene material has a low cost and a light weight, and can be used instead of metal or plastic material to produce the household appliance products which need flame retardation and high temperature resistance.

Owner:GUANGDONG JUSHI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com