Phosphorus-containing polyester fire retardant epoxy resin composition

A technology of epoxy resin and composition, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of restricting the use of added flame retardants, dispersibility, compatibility, and low flame retardant efficiency, and achieves Good electrical properties, excellent flame retardancy, and simple synthesis process

Inactive Publication Date: 2008-11-19

天津凯华绝缘材料股份有限公司

View PDF1 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the process of additive phosphorus flame retardants is simple, but the flame retardant efficiency is low, the amount of addition is large, and there are problems such as dispersion and compatibility, which limits the use of additive flame retardants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The present invention will be described in further detail below with reference to specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Login to View More

Abstract

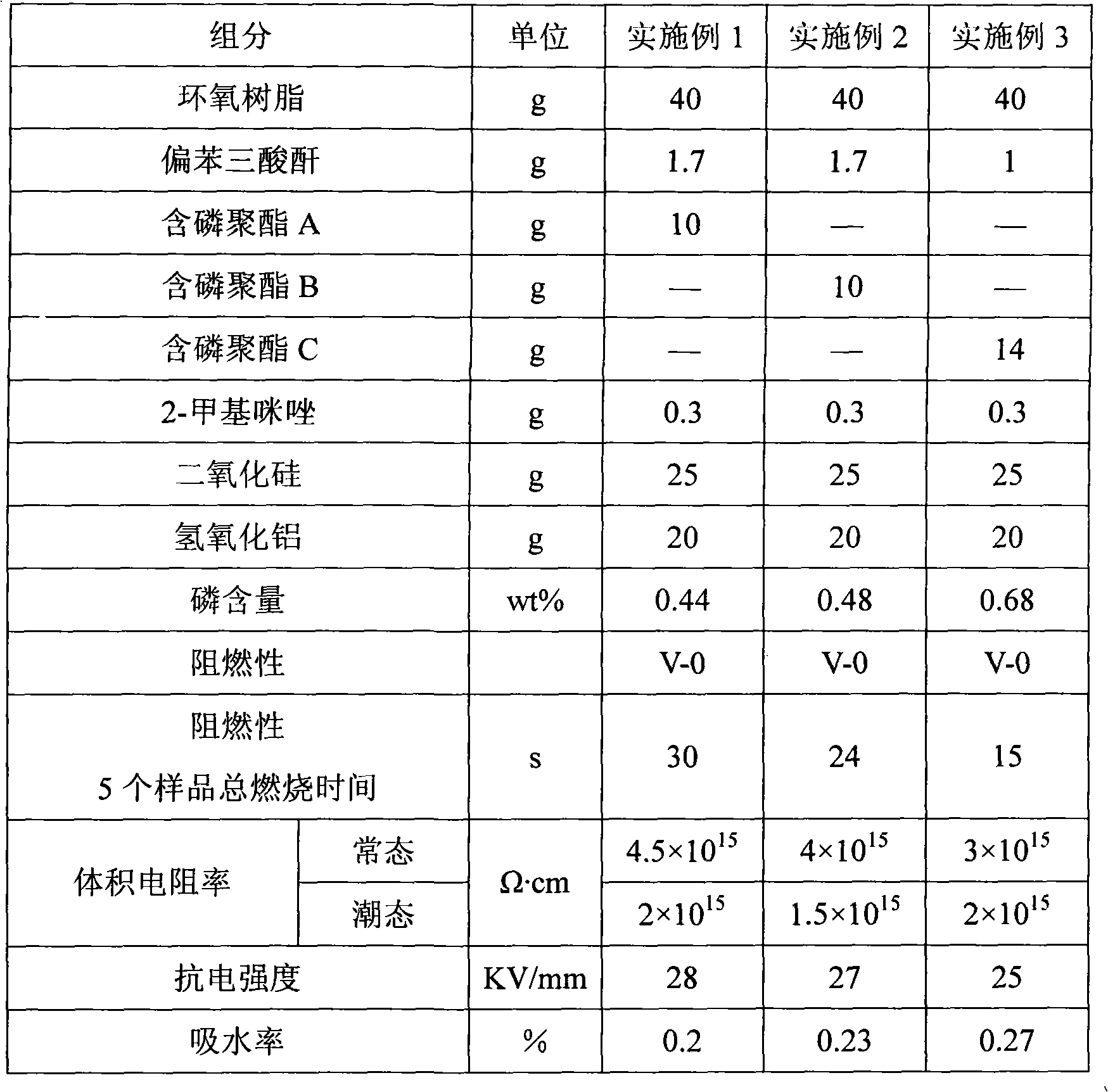

The invention relates to a phosphoric polyester fire-retardant epoxy resin composition. The compositions by mass portion of the phosphoric polyester fire-retardant epoxy resin composition are: 20 to 40 portions of epoxy resin, 5 to 20 portions of phosphoric polyester, 0 to 10 portions of other curing agent, 0.1 to 0.3 portion of curing accelerator and 30 to 70 portions of inorganic filler. The phosphoric polyester fire-retardant epoxy resin composition does not contain harmful substances such as halogen, antimony trioxide and so on; the fire resistance can reach the fire-retardant standard of UL94 V-0; and the phosphoric polyester fire-retardant epoxy resin composition has good fire resistance and electric property.

Description

technical field [0001] The invention belongs to the field of electronic packaging materials, in particular to a phosphorus-containing polyester flame retardant epoxy resin composition. Background technique [0002] Epoxy resin is one of the most widely used matrix resins in polymer matrix composites. It has excellent adhesion, chemical resistance, electrical insulation properties, mechanical properties, as well as easy processing, low shrinkage, and low coefficient of linear expansion. It has the advantages of low cost and low cost, and is widely used in the packaging of electronic components such as varistors, ceramic capacitors, diodes, and triodes. Since the limiting oxygen index (LOI) of epoxy resin is low, only 19.5, it is a flammable substance, so it needs to be flame-retardant. Usually, the method to improve the flame retardancy of epoxy resin is to introduce halogen-containing flame retardant into the epoxy resin, and mix it with flame retardant auxiliary such as an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L63/00C08L67/00C08K13/02C08G63/692C09K3/10

Inventor 沈纪洋席小悦

Owner 天津凯华绝缘材料股份有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com