Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

A technology of char-forming agent and polyphosphazene, which is applied in the field of hyperbranched polyphosphazene flame-retardant char-forming agent and its preparation, can solve the problems of poor thermal stability, poor water resistance and durability, complex synthesis process, etc., and achieve good processing performance , excellent flame retardant effect, the effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

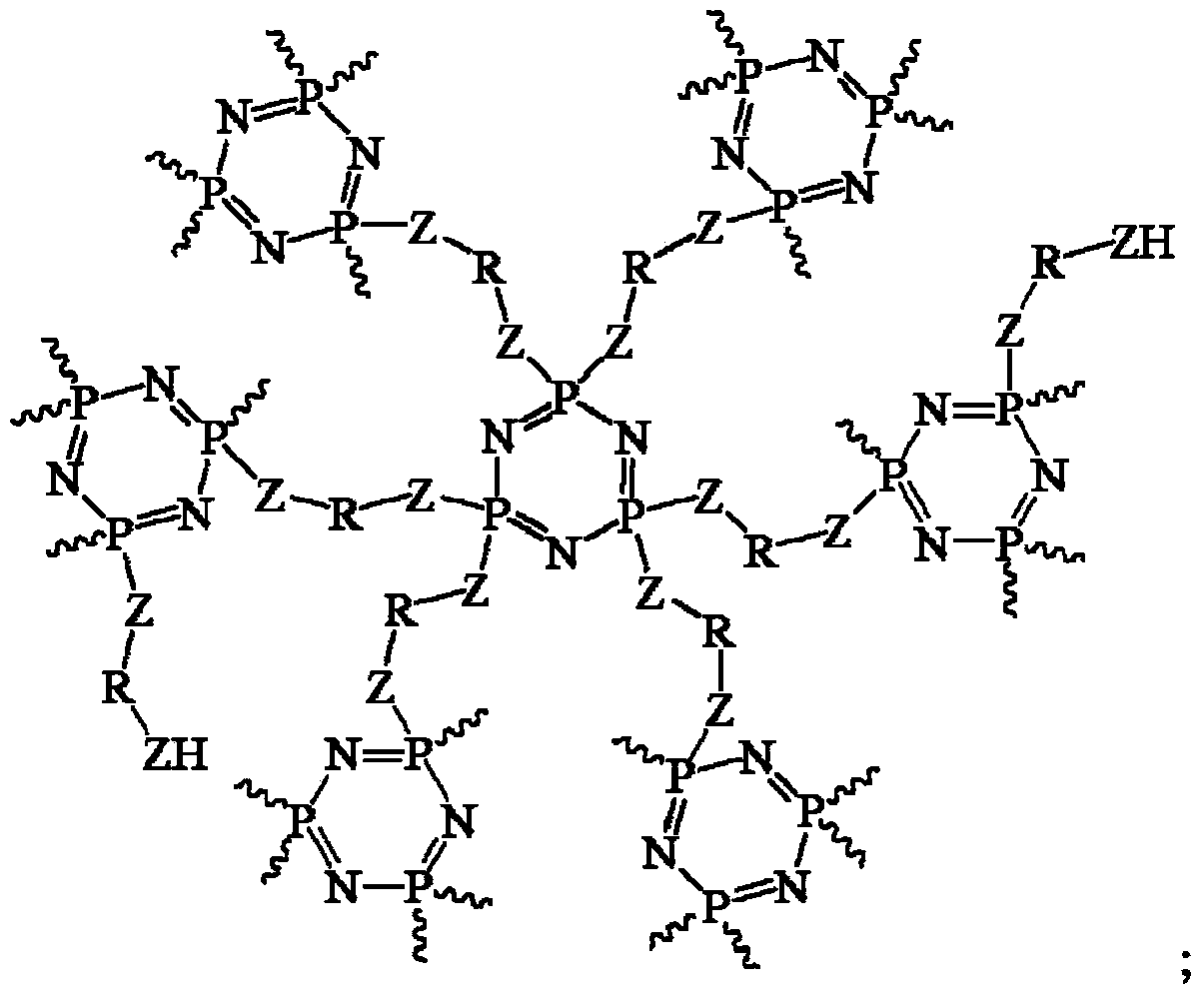

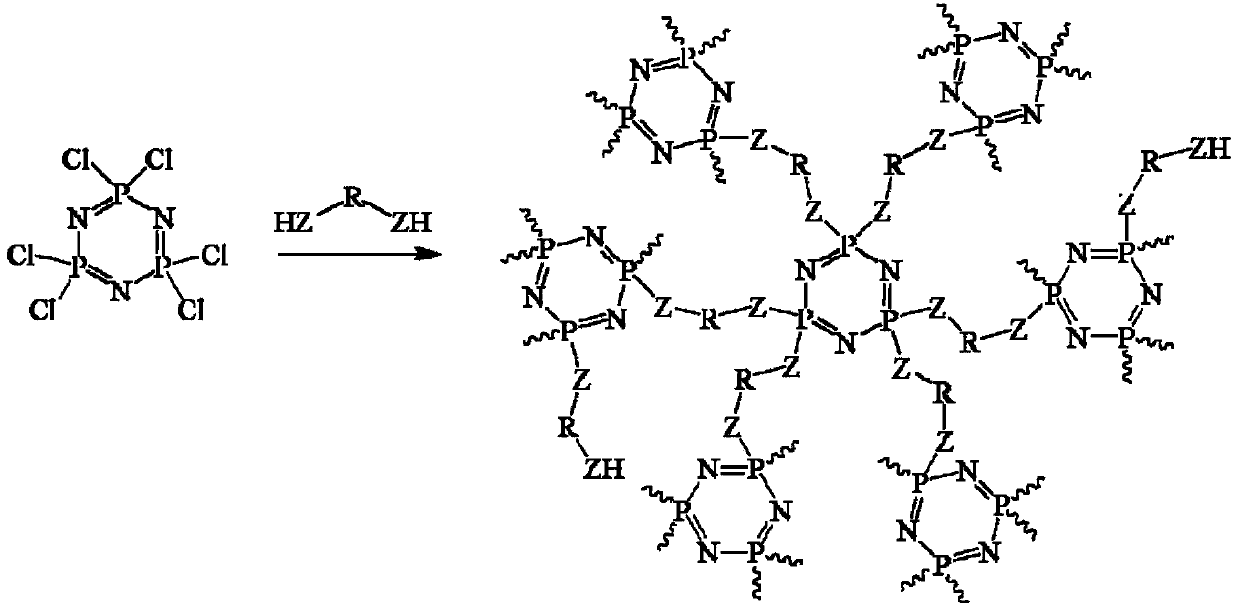

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 0.2mol piperazine in 70mL ethanol, add it into a 500mL three-neck flask equipped with a reflux condenser, a constant pressure dropping funnel, and a stirrer, and start stirring; dissolve 0.05mol hexachlorocyclotriphosphazene in 100mL dioxane and dropwise added to the above piperazine solution through a constant pressure dropping funnel, keeping the temperature at 0°C for 4 hours; then raising the reaction temperature to 50°C, dissolving 0.3mol NaOH in 20mL of water, and slowly dropping Add it to the above reaction system, and continue to react at this temperature for 6 hours; finally, raise the reaction temperature to 95°C, continue to react for 9 hours, stop stirring, suction filter while hot, wash with water 3 times, and vacuum dry at 80°C for 8 hours. 22.54 g of the product were obtained as a yellowish solid.

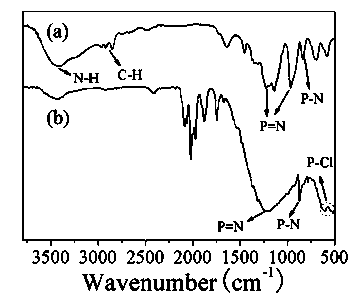

[0035] The obtained product was subjected to elemental analysis, and the results showed that the measured mass percentages of C, N, and H in the samp...

Embodiment 2

[0039] Dissolve 0.25mol of ethylenediamine in 25mL of water, add it to a 500mL three-necked flask equipped with a reflux condenser, a constant pressure dropping funnel, and a stirrer, and then dissolve 0.05mol of hexachlorocyclotriphosphazene in 10mL of tetrahydrofuran, Add dropwise to the above aqueous solution of ethylenediamine, react at 10°C for 1 hour; then raise the temperature to 70°C, add 0.32mol of Na 2 CO 3 Dissolve in 40mL of water, slowly add dropwise to the system, and continue to react at this temperature for 3 hours, and finally raise the temperature to 150°C, and react for 6 hours; stop stirring, suction filter while hot, and wash with water 3 times. After drying for 2 hours, 8.79 g of a yellowish solid product was obtained with a yield of 93.2%. The elemental analysis results of the product obtained in this example show that the theoretical percentages of C, N, and H in the hyperbranched polyphosphazene flame-retardant char-forming agent are respectively 28.4...

Embodiment 3

[0041] Dissolve 0.3mol of p-phenylenediamine in 100mL of ethanol, add it to a 500mL three-neck flask equipped with a reflux condenser, a constant pressure dropping funnel, and a stirrer, and then dissolve 0.05mol of hexachlorocyclotriphosphazene in 5mL of benzene Add dropwise to the above p-phenylenediamine solution, and react at 5°C for 3 hours; then raise the reaction temperature to 30°C, dissolve 0.35mol of KOH in 50mL of water, and slowly add dropwise to the reaction system, and continue to react at this temperature for 8 hours, and finally raise the temperature to 150°C, and react for 10 hours; stop stirring, suction filter while hot, wash with water 3 times, and vacuum dry at 50°C for 10 hours to obtain a light yellow solid product 36.7 g, the yield is 94.6%. The elemental analysis results of the product obtained in this example show that in the hyperbranched polyphosphazene char-forming agent, the theoretical percentages of C, N, and H are respectively 51.8%, 27.7%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com