Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215results about How to "Excellent non-flammability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

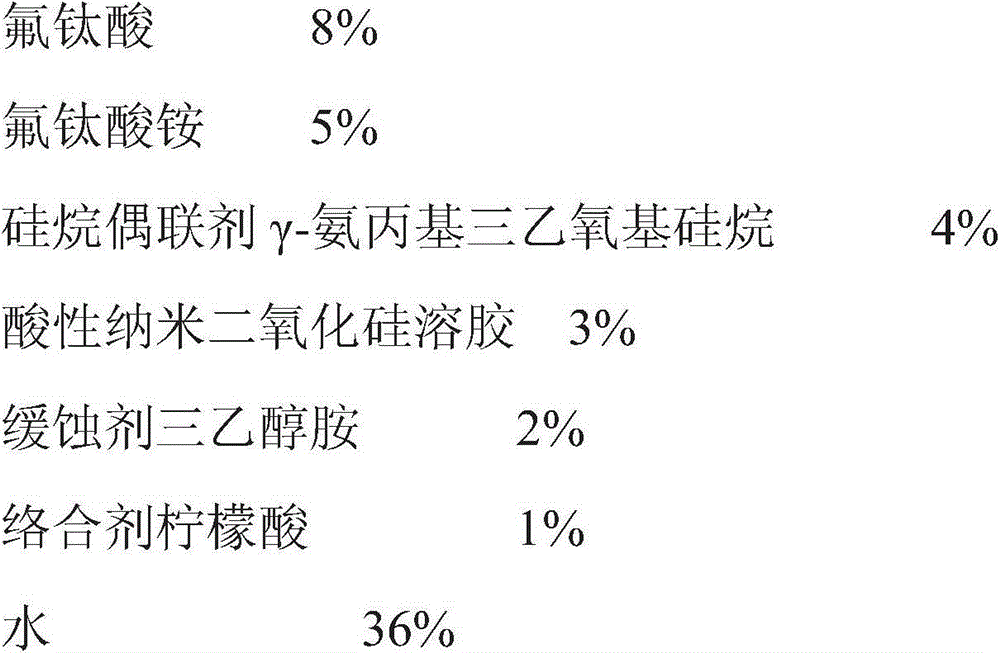

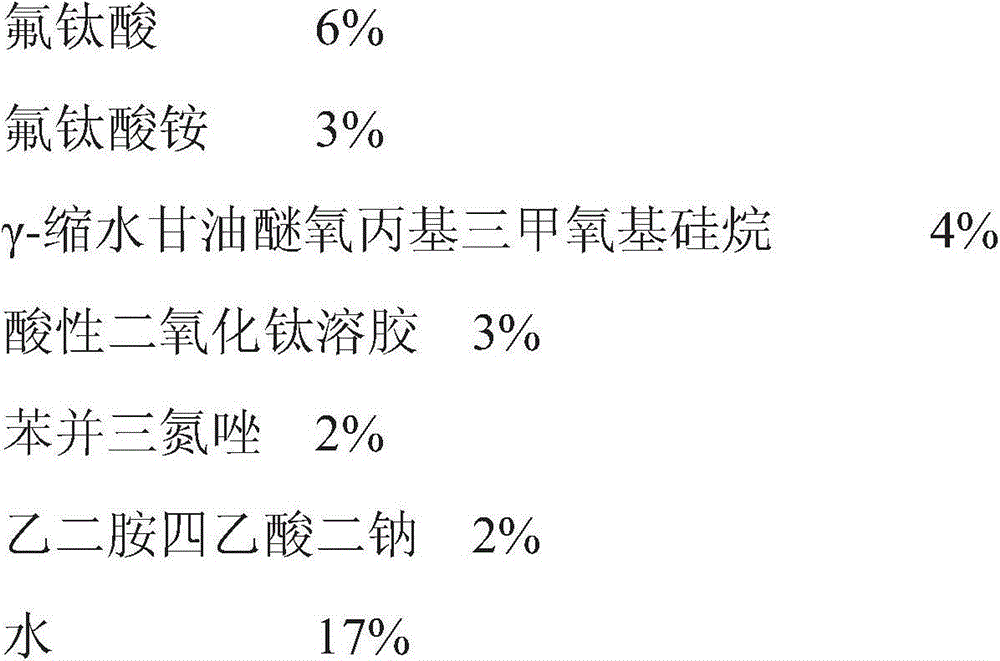

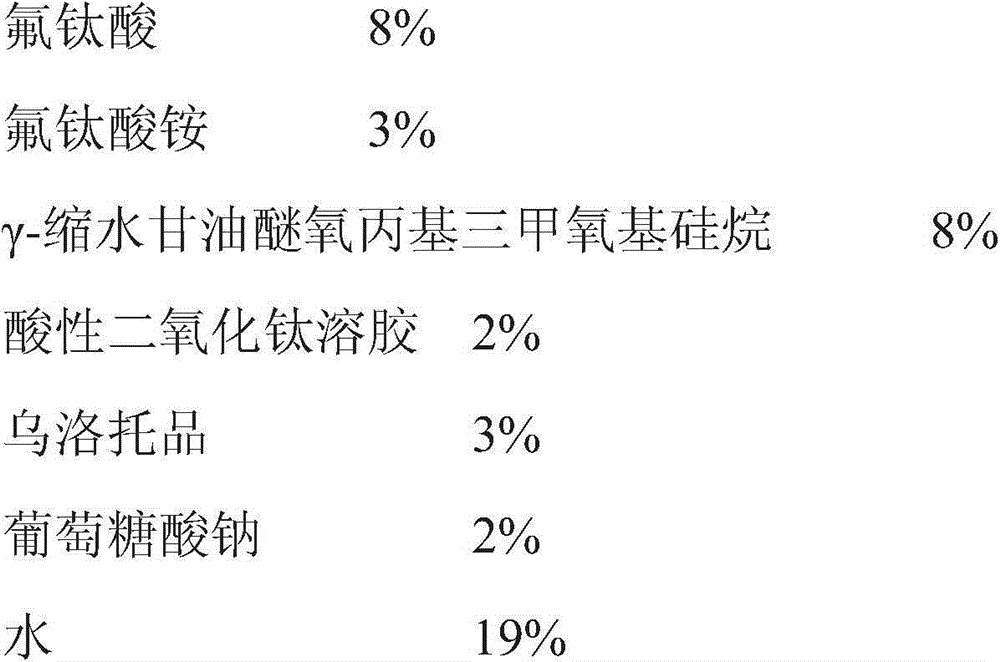

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

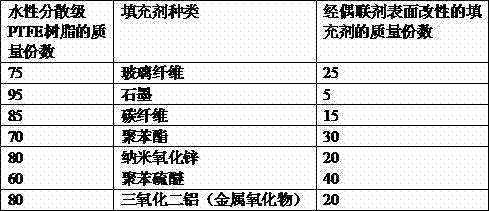

Fluorine-containing polymer mixing material and method for preparing bulb buffer ball keyway by same

InactiveCN102952360AGood chemical stabilityGood self-lubricating performanceControl armMixed materials

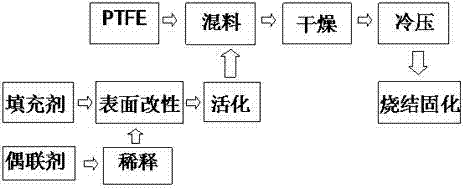

The invention discloses a fluorine-containing polymer mixing material and a method for preparing a bulb buffer ball keyway by the same. The fluorine-containing polymer mixing material is prepared by mixing fluorine-containing polymer resin with filler modified by a coupler, and comprises the materials in parts by mass as follows: 60-99 parts of fluorine-containing polymer resin and 1-40 parts of modified filler. The filler meets the condition that the filler is stably sintered at a temperature above the melting temperature of the resin and the granularity is smaller than or equal to 150 microns; the filler does not absorb moisture; and the filler is not clustered under the sintering condition and is not reacted with the polymer. The coupler accounts for 5-40% of the filler by mass percentage. The material has excellent chemical stability, self-lubricating property, noninflammability, resistance to atmospheric aging and high and low temperature adaptability and the like as well as higher mechanical strength. The hardness can be improved through modification and the material is used to prepare wear-resisting products. The bulb buffer ball keyway is prepared from the material so that a suspension type direction control arm assembly of an automobile with high mechanical strength, good wear-resistance and a long service life is further obtained.

Owner:浙江国威汽车配件有限公司

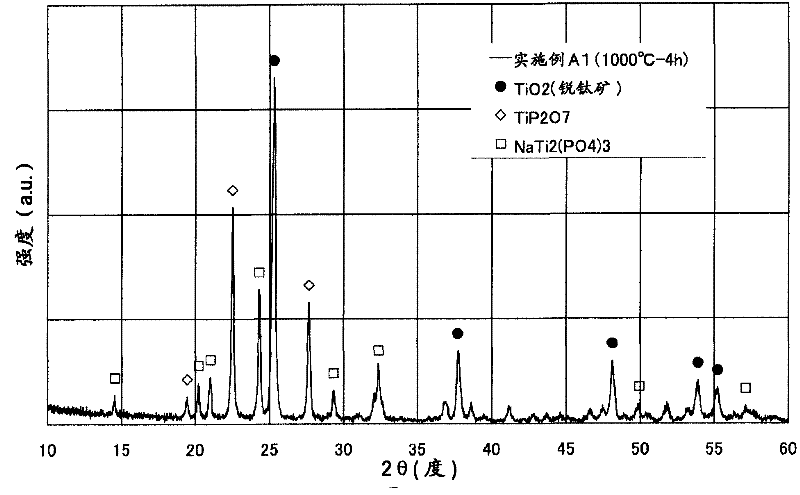

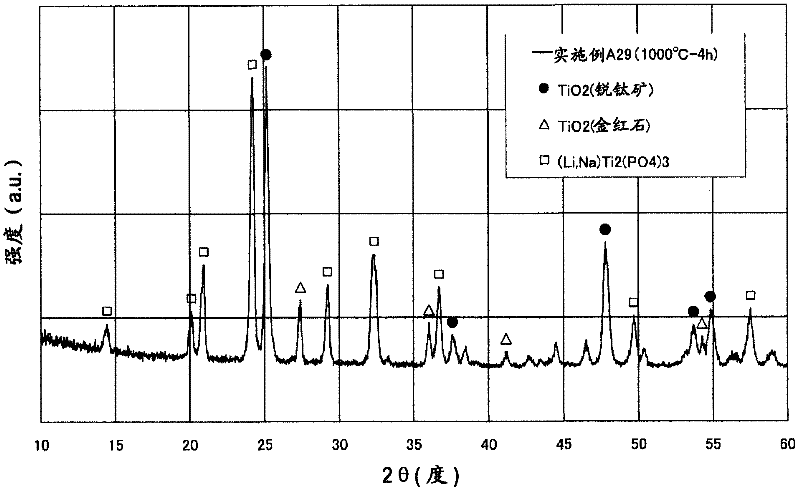

Glass ceramics and process for production thereof, process for producing sintered glass ceramics, process for producing complex, molded article having photocatalytic function, and hydrophilic molded article

InactiveCN102177102APromote precipitationCatalytic performance does not deterioratePhysical/chemical process catalystsBrookiteTitanium

Disclosed is a process for producing a glass ceramics which has a surface having excellent durability and has at least one titanium oxide crystal phase selected from those of anatase type, rutile type and brookite type. Also disclosed are a molded article having a photocatalytic function and a hydrophilic molded article each of which comprises the glass ceramics produced by the process. The glass ceramics comprises 15.0 to 95.0% by mol inclusive of a TiO2 component and 3.0 to 85.0% by mol inclusive of a P2O5 component and / or an SiO2 component in terms of oxide contents relative to the total amount of the glass ceramics.

Owner:OHARA

Refrigerant mixture for low back pressure condition

InactiveUS20030178597A1Excellent coefficientImprove securityDomestic cooling apparatusLighting and heating apparatusIodideTrifluoromethyl

There is provided a composition of refrigerant mixtures for low back pressure condition, comprising isobutane, 1,1-difluoroethane and, optionally, additive selected from the group consisting of carbon oxide, trifluoromethyl iodide and mixture thereof. The composition according to the present invention is environment-friendly and can be directly drop in the conventional refrigerator system adopting CFC-12 refrigerant without any systemic change.

Owner:ACM TECH

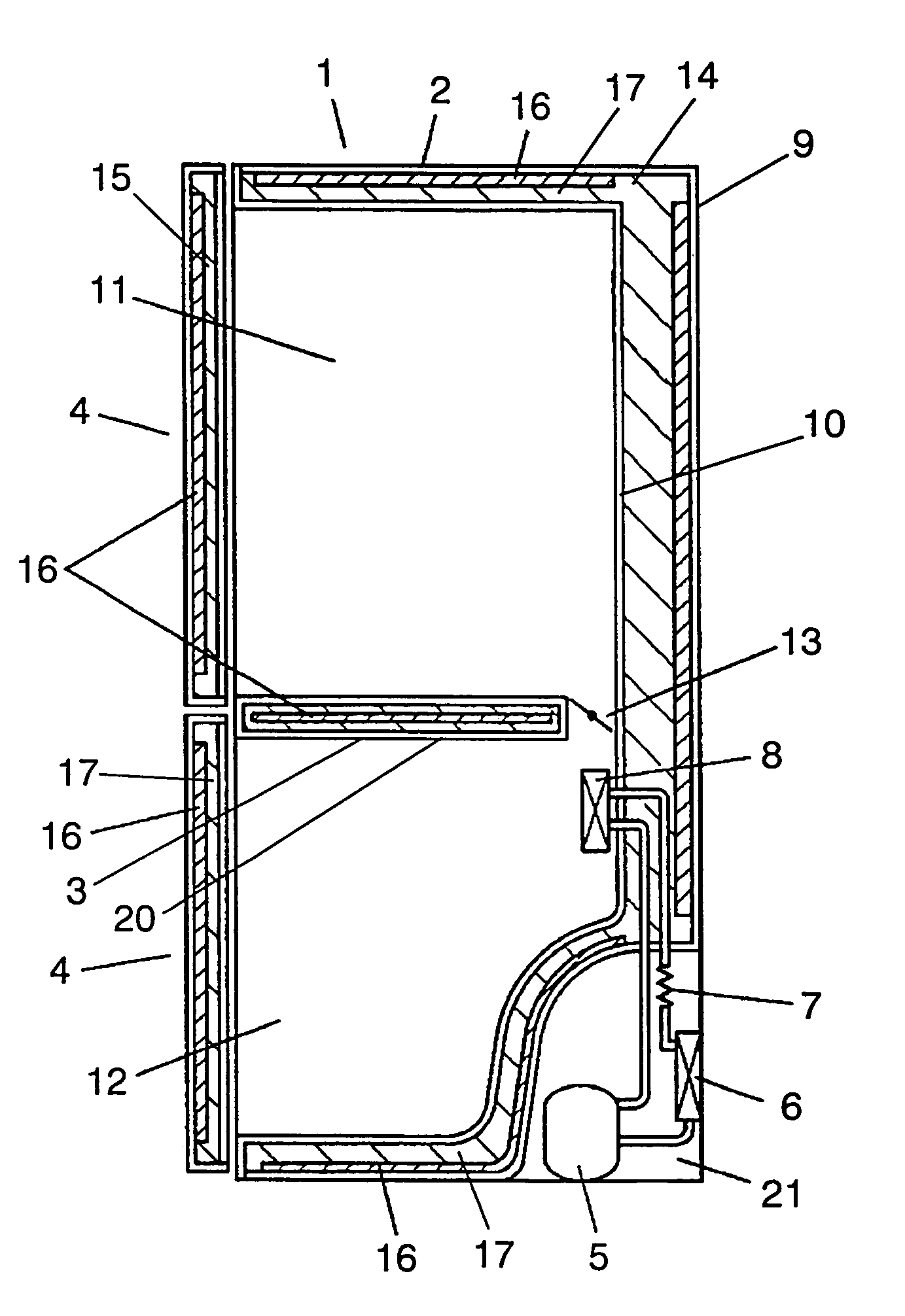

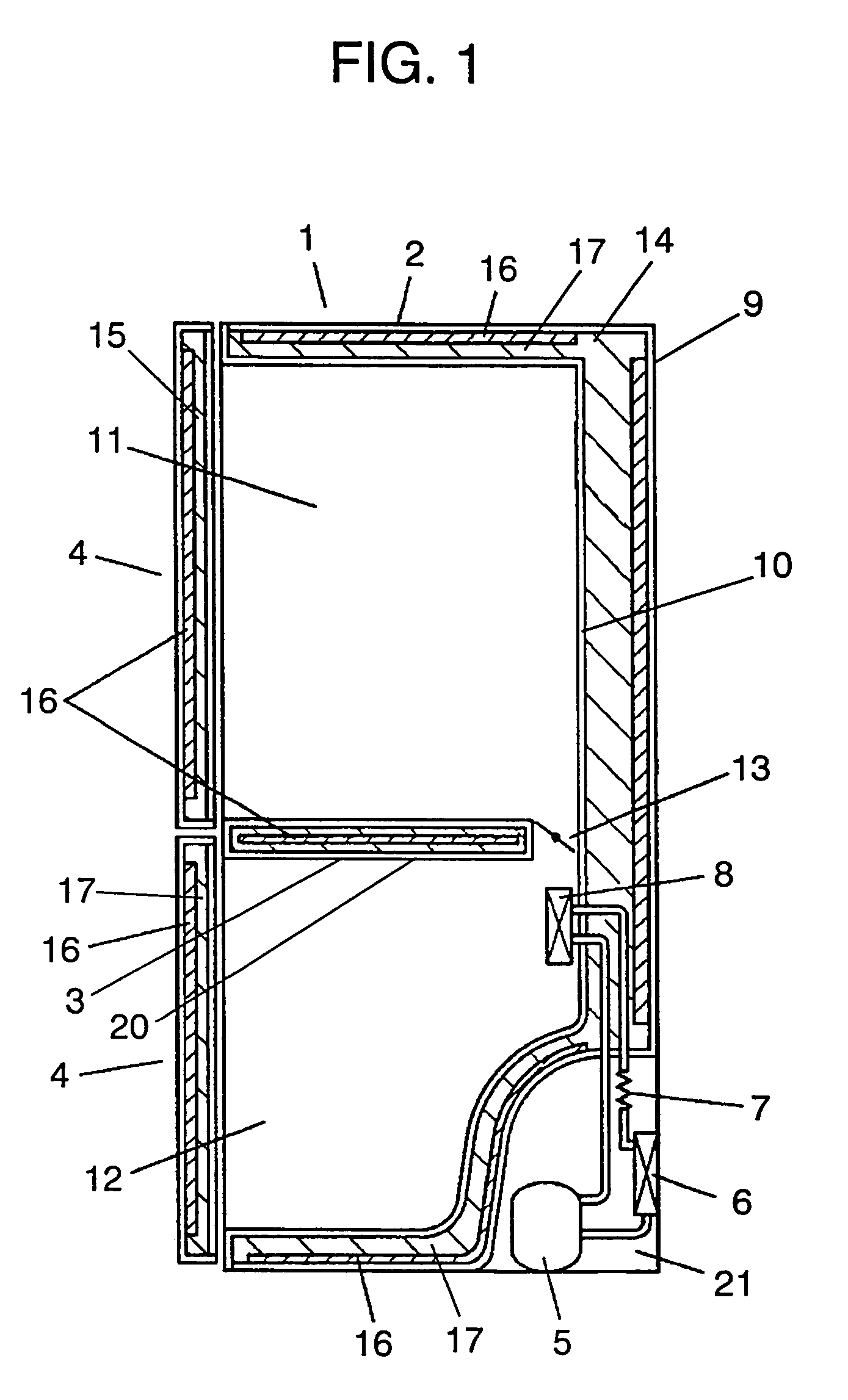

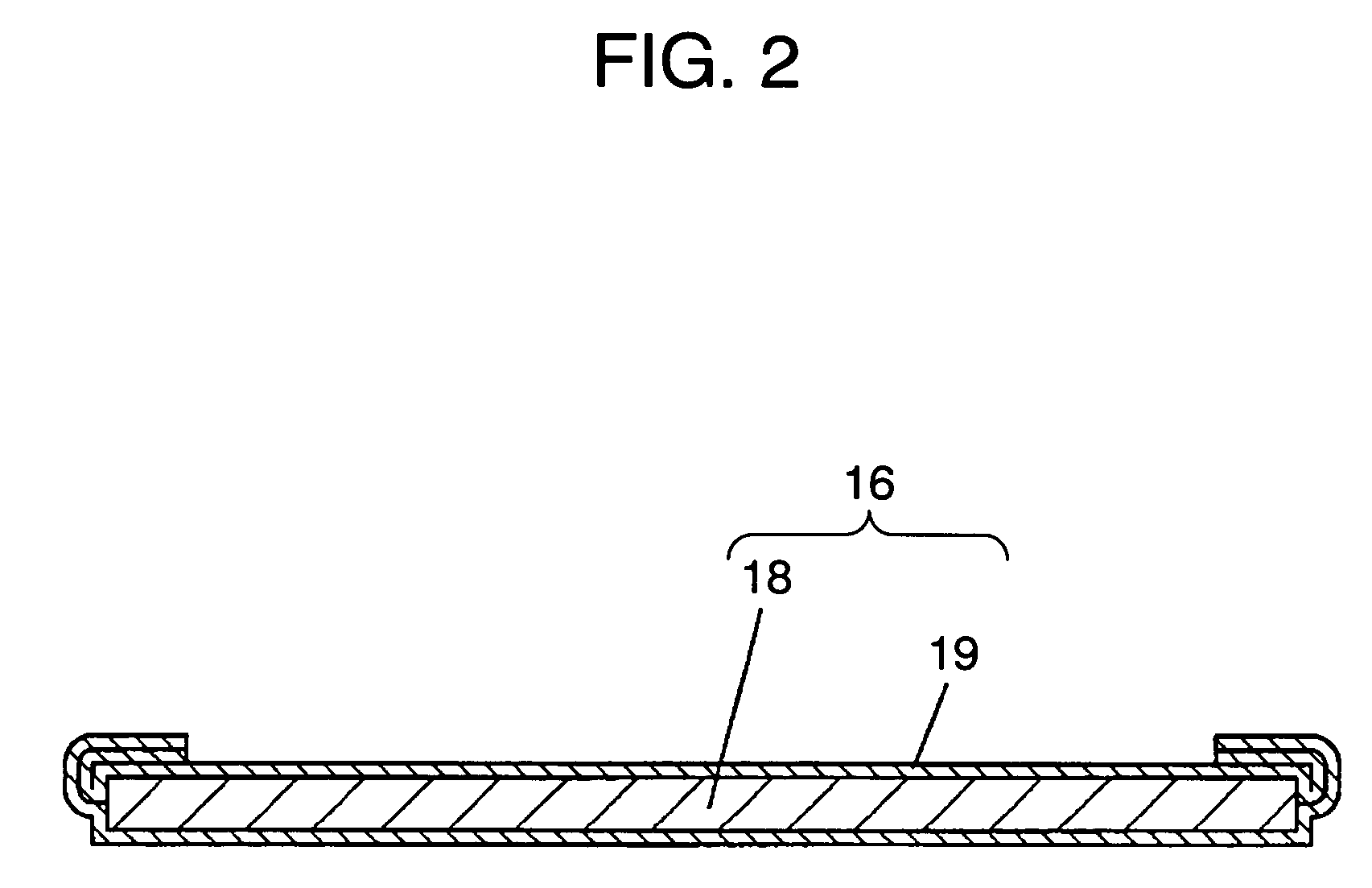

Refrigerator

InactiveUS7278279B2Improve securityNon-flammability of the heat-insulating box is enhancedLighting and heating apparatusDomestic refrigeratorsRefrigerator carFiber

A heat insulating box of a refrigerator includes a non-flammable heat-insulator particularly a vacuum heat-insulator made of a board-shape molded inorganic fiber. Therewith non-flammability of the heat insulator is ensured and a refrigerator box prevented from catching an outside caused fire is achieved, thus a refrigerator which is safe even when a flammable refrigerant is used and which is high in energy-saving is provided.

Owner:PANASONIC CORP

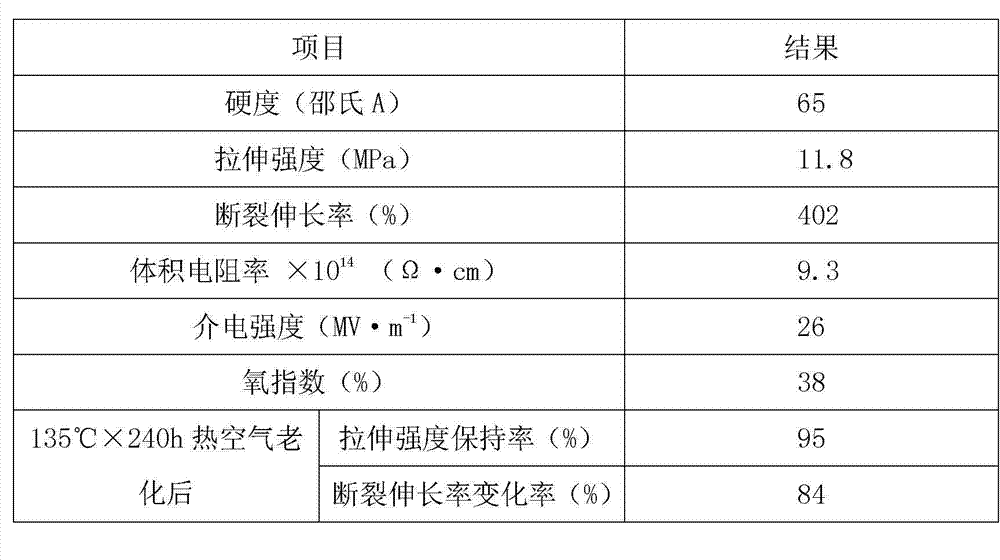

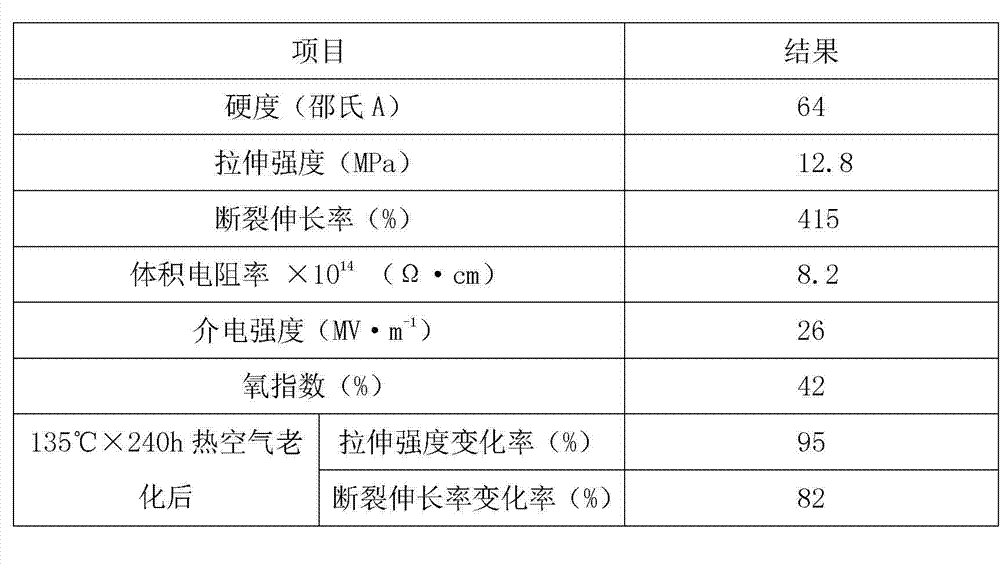

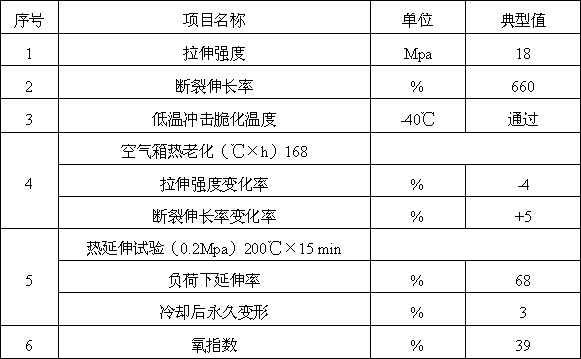

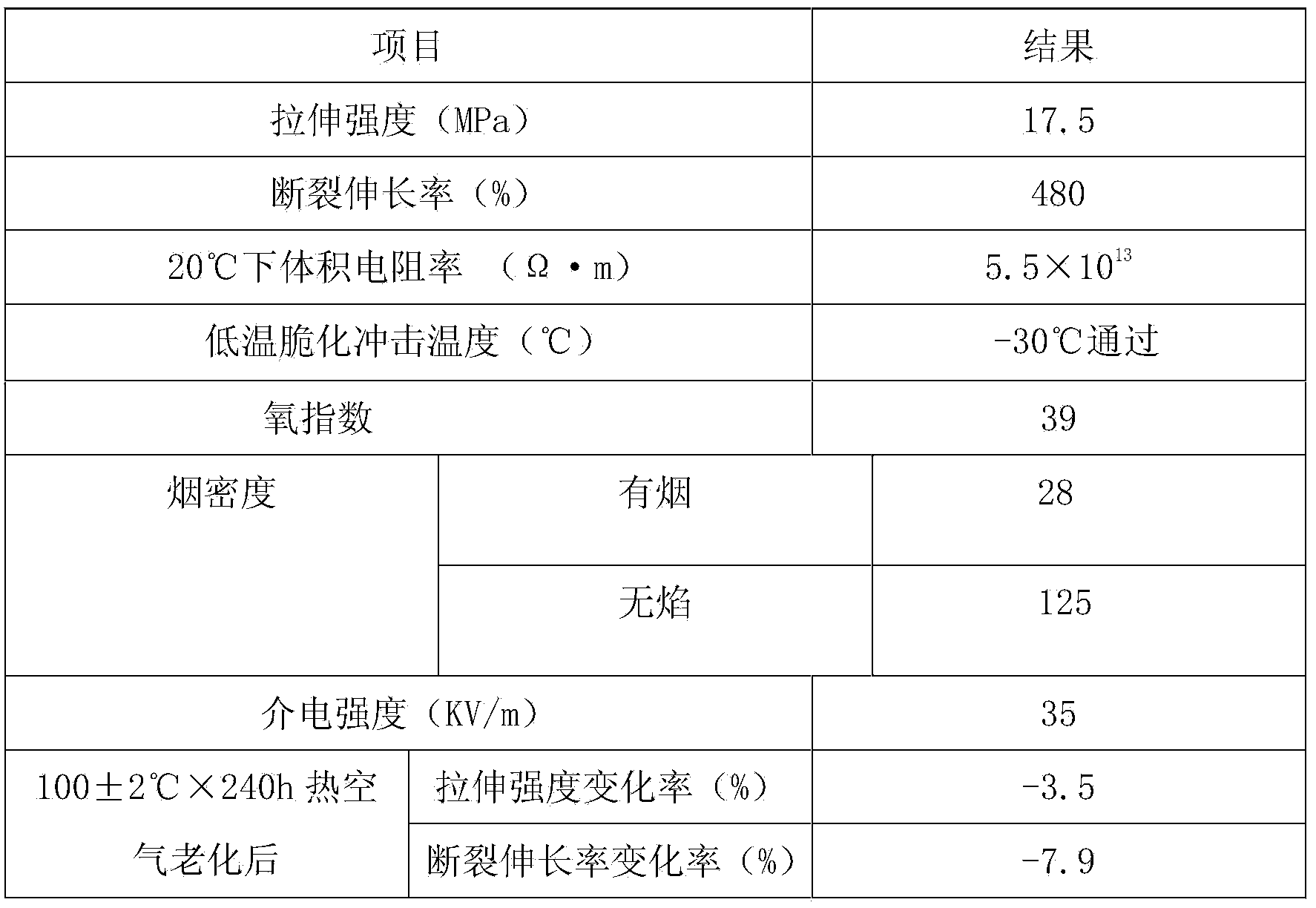

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

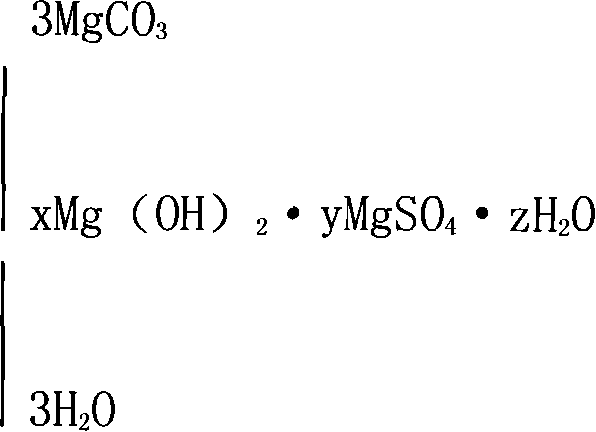

High-strength waterproof magnesium oxysulfate fireproof board and manufacturing method thereof

InactiveCN105036692AImprove water resistanceImprove toughnessSolid waste managementLaminationFiberSlurry

The invention discloses a high-strength waterproof magnesium oxysulfate fireproof board. The high-strength waterproof magnesium oxysulfate fireproof board comprises a fiber layer and slurry, wherein the slurry comprises a bottom material, an intermediate material and a surface material; the bottom material, the intermediate material and the surface material respectively comprise the following components in parts by weight: 80-240 parts of magnesium sulfate solution having the baume degree being 23-28 degrees, 100-300 parts of 85% light calcined magnesia, 0.1-5 parts of tartrate, 2-10 parts of butylbenzene emulsion, 0-100 parts of heavy-weight filler, 0-100 parts of lightweight filler and 0.1-5 parts of water reducing agent. The high-strength waterproof magnesium oxysulfate fireproof board has the advantages of low thermal expansion and shrinkage rate, low heat conduction coefficient, high strength, excellent waterproof property, no warping and deformation, over 0.95 softening coefficient, no halogenation, no scumming, excellent freezing resistance and noninflammability and the like.

Owner:郑春科

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Inorganic thermal-insulation mortar used for building exterior walls of buildings and preparation method thereof

InactiveCN101863639AGood chemical stabilityGood weather resistanceSolid waste managementHigh resistanceWeather resistance

The invention relates to inorganic thermal-insulation mortar used for building exterior walls of buildings and a preparation method thereof. The invention is characterized in that the thermal-insulation mortar comprises the following components in part by weight: lightweight aggregate 100-150, binding material 100-150, fly ash 10-60, and additive 8.72-11.36. Compared with the prior art, the inorganic thermal-insulation mortar has the advantages of high weather resistance, high aging resistance, long service life, high fireproofing and flame-retarding performance, energy conservation and environment protection.

Owner:SHANGHAI MINJIANG TONG PROD

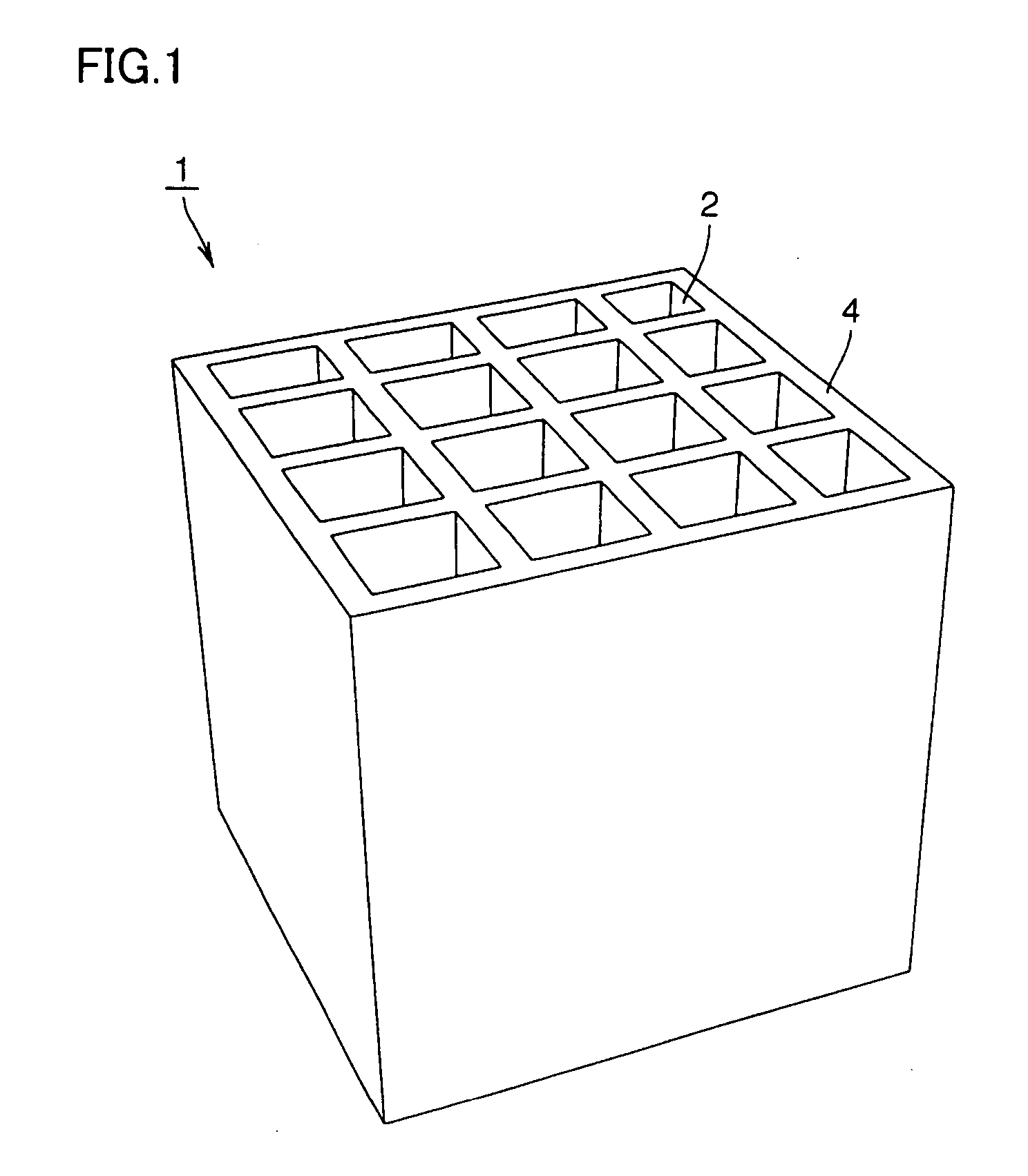

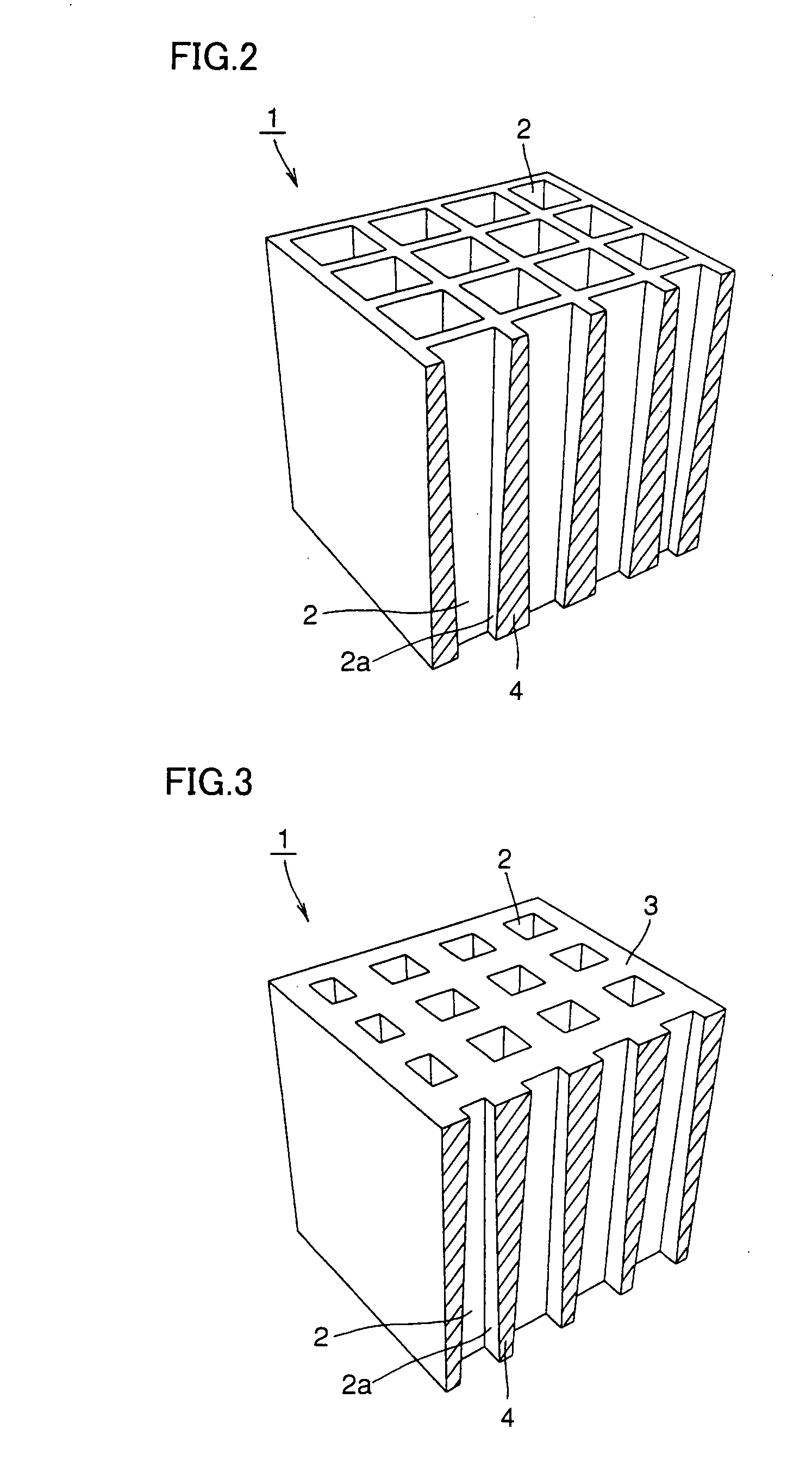

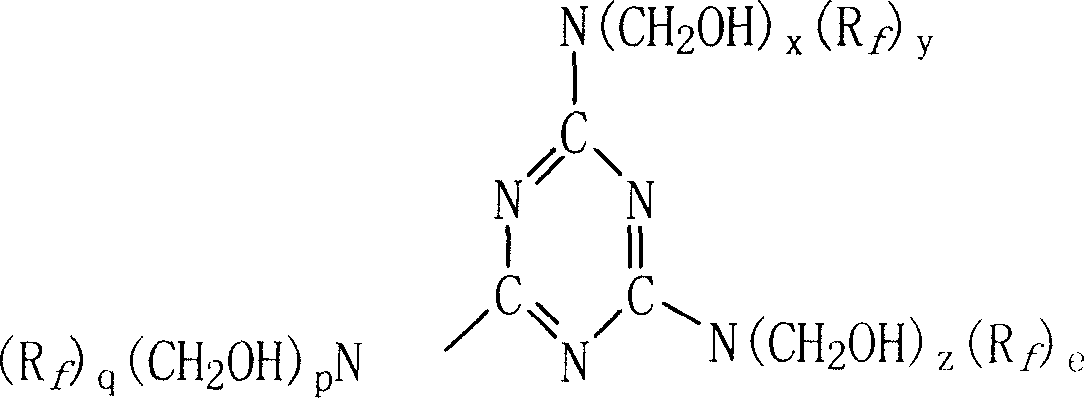

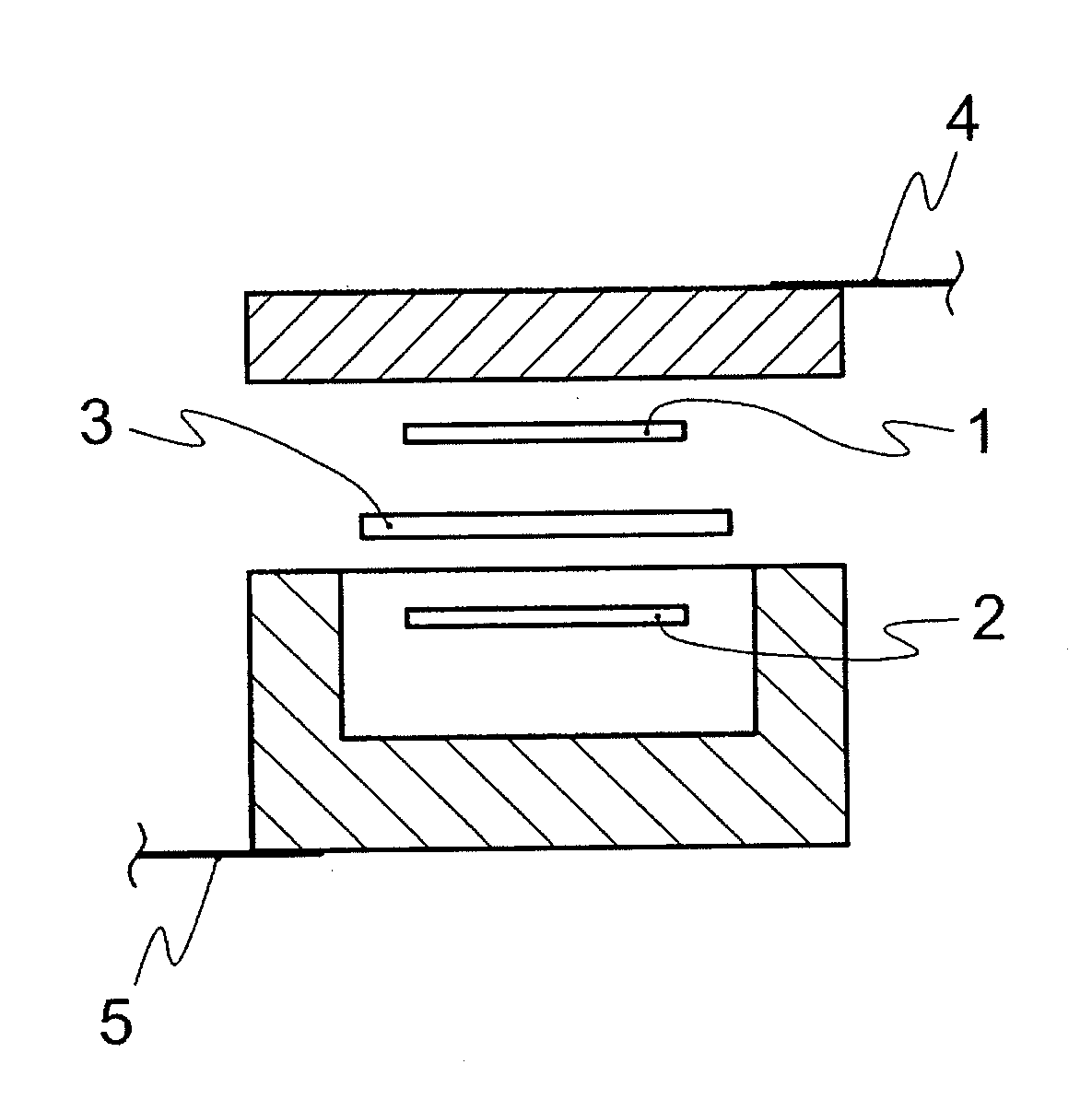

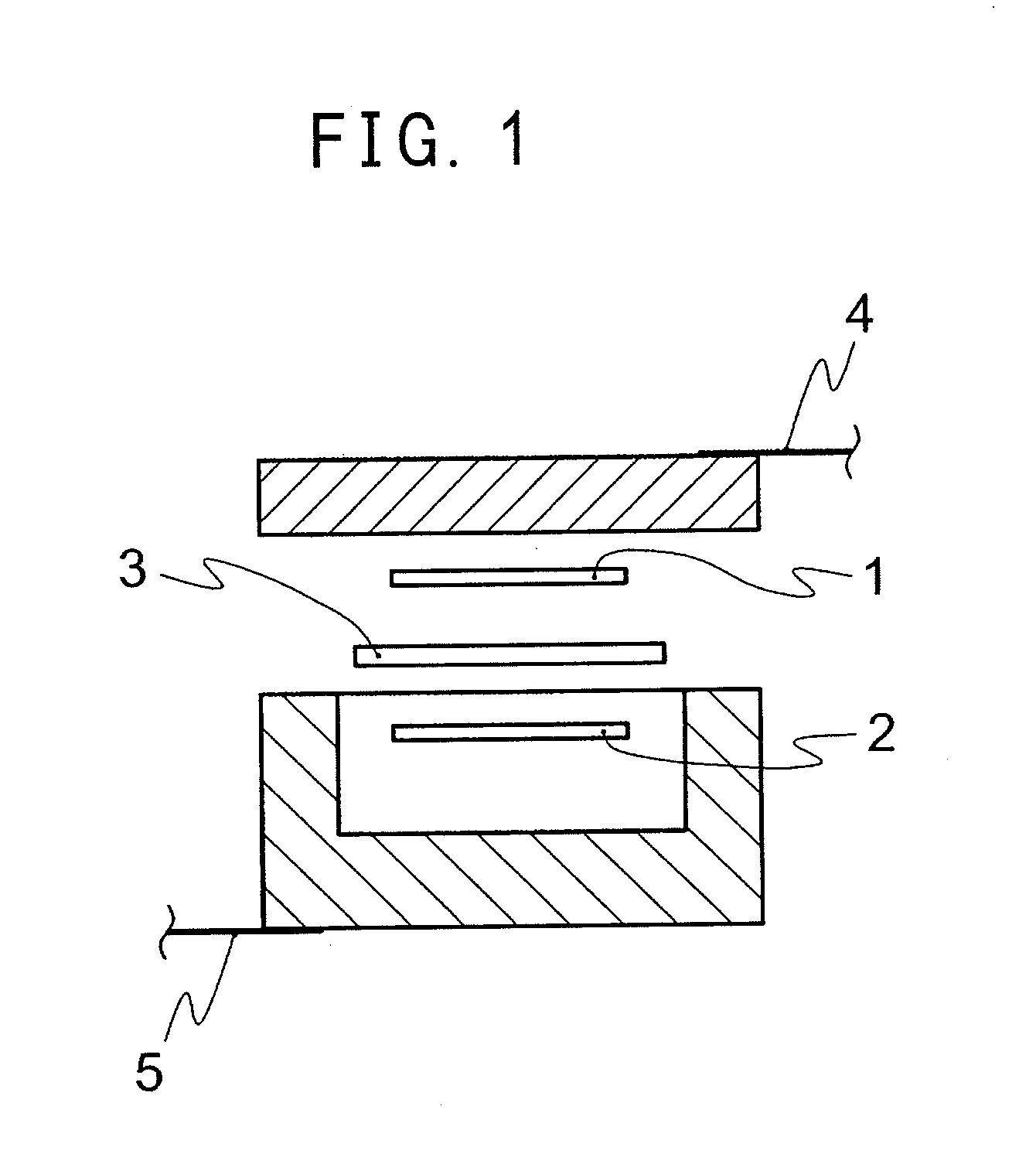

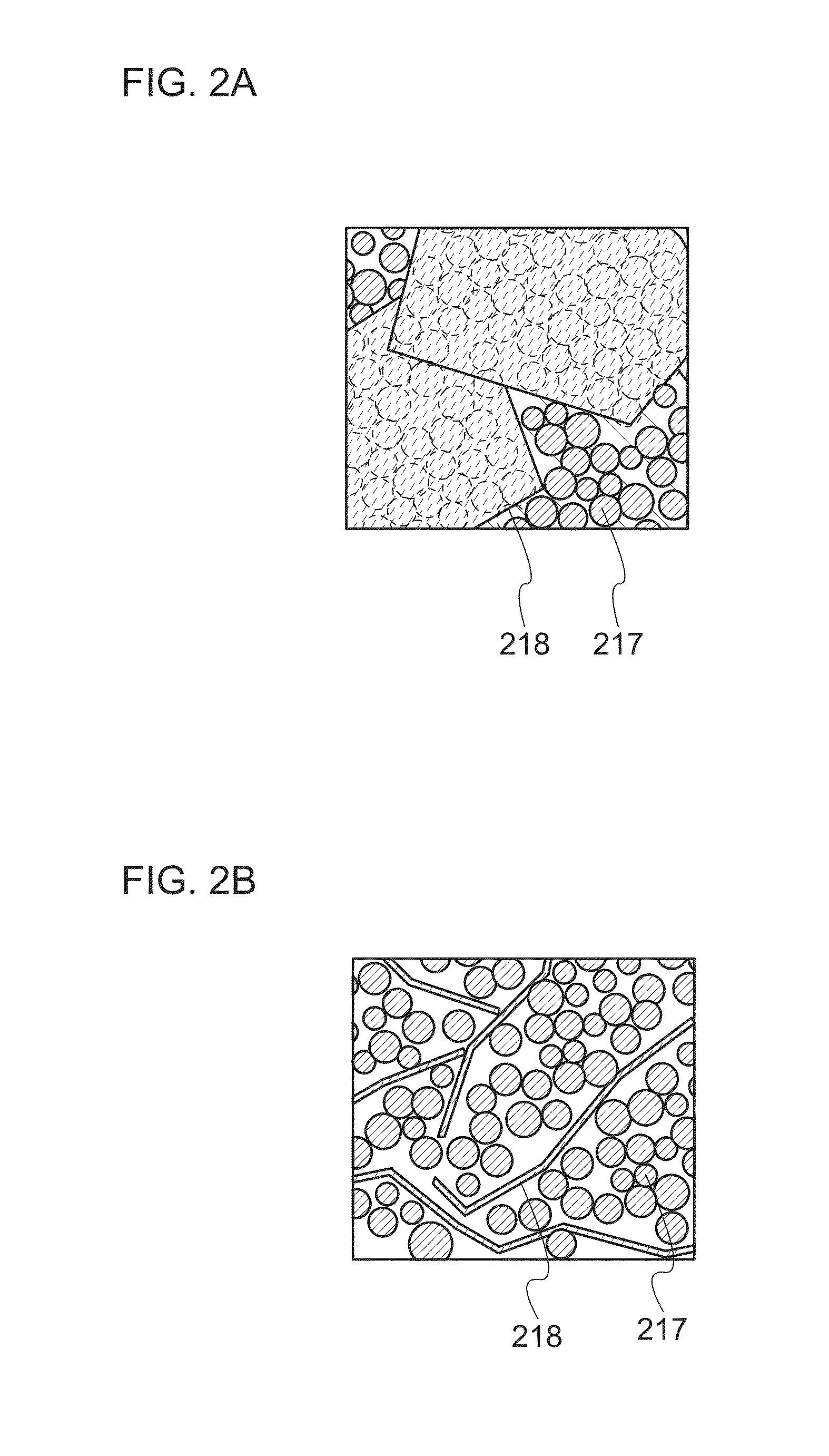

Electromagnetic wave absorption complex, and method of producing the same

InactiveUS20060202882A1Improved yieldSimplify processRadiation/particle handlingMagnetic/electric field screeningEngineeringInjection moulding

An electromagnetic wave absorber is formed by injection-molding a thermoplastic resin blended with approximately 20-60% by volume of soft magnetic material powder, and blended with a molding assistant and a kneading assistant. The electromagnetic wave absorber includes a unit cell having a bore extending from a top face to a bottom face. A portion of the bore located more adjacently to the bottom face than to the top face has a smaller cross-sectional area than the bore at the top face, and a height of the unit cell from the bottom face to the top face is approximately at least 1.2 times and approximately at most 10 times as large as the maximum width of the bore at the top face of the unit cell.

Owner:MIYAGAWA KASEI IND

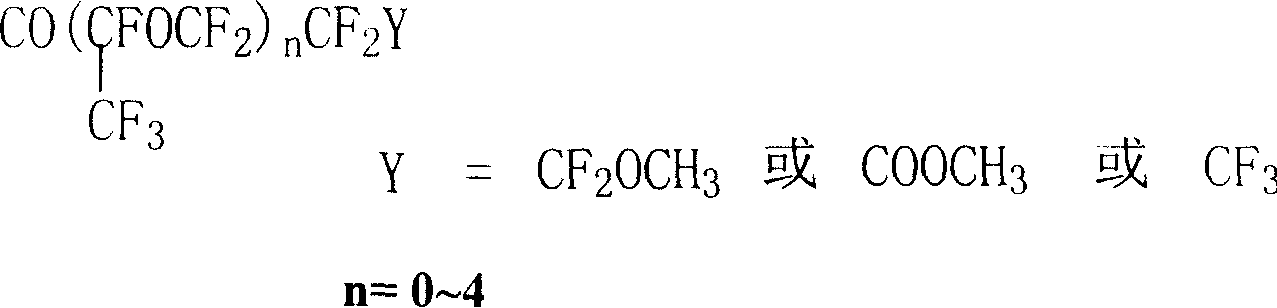

Functional end group containing fluorine-containing chain hydrocarbon melamine derivative and its preparation method

ActiveCN1955166AGood chemical stabilityImprove heat resistanceOrganic chemistryCross-linkPolymer science

This invention discloses a category of fluorinated hydrocarbons chain melamine derivate which has functional end group and its preparation. Cyanuramide derivate containing esterfunction or its functional end group has perfluoro-aliphatic hydrocarbon, is produced by condensation reaction of monomer containing fluorine acyl fluoride which has functionality end and hexamethylolmelamine. This derivate can be used as cross linking agent that contains fluorine, lubricant, high-grade paint, flame retardant, special material assistant, intermedium of organism containing fluorine materials, fabric unscrambling agent and ao on. Its structural formula is formula I, x,p,z=0,1,2;And x+y=2,p+q=2,e+z=2 but x,p,z does not equal 2 at the same time, among them Rf is formula II, Y=CF2OCH3 or COOCH3 or CF3n=0-4.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

High cold-resistance ethylene propylene diene copolymer insulated cable material and preparation method thereof

ActiveCN102964698AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsPolymer scienceBenzoyl peroxide

The invention discloses a high cold-resistance ethylene propylene diene copolymer insulated cable material and a preparation method thereof. The cable material is made of the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland 9650 ethylene propylene diene copolymer, 20-30 parts of active chlorine type acrylic rubber AR-400, 10-15 parts of duprene rubber CR121, 10-15 parts of di-butyl nylonic acid ester, 5-10 parts of trioctyl trimellitate, 5-10 parts of triethyl phosphate, 1-2 parts of sulphur, 2-4 parts of benzoyl peroxide, 1-2 parts of triallyl isocyanurate and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

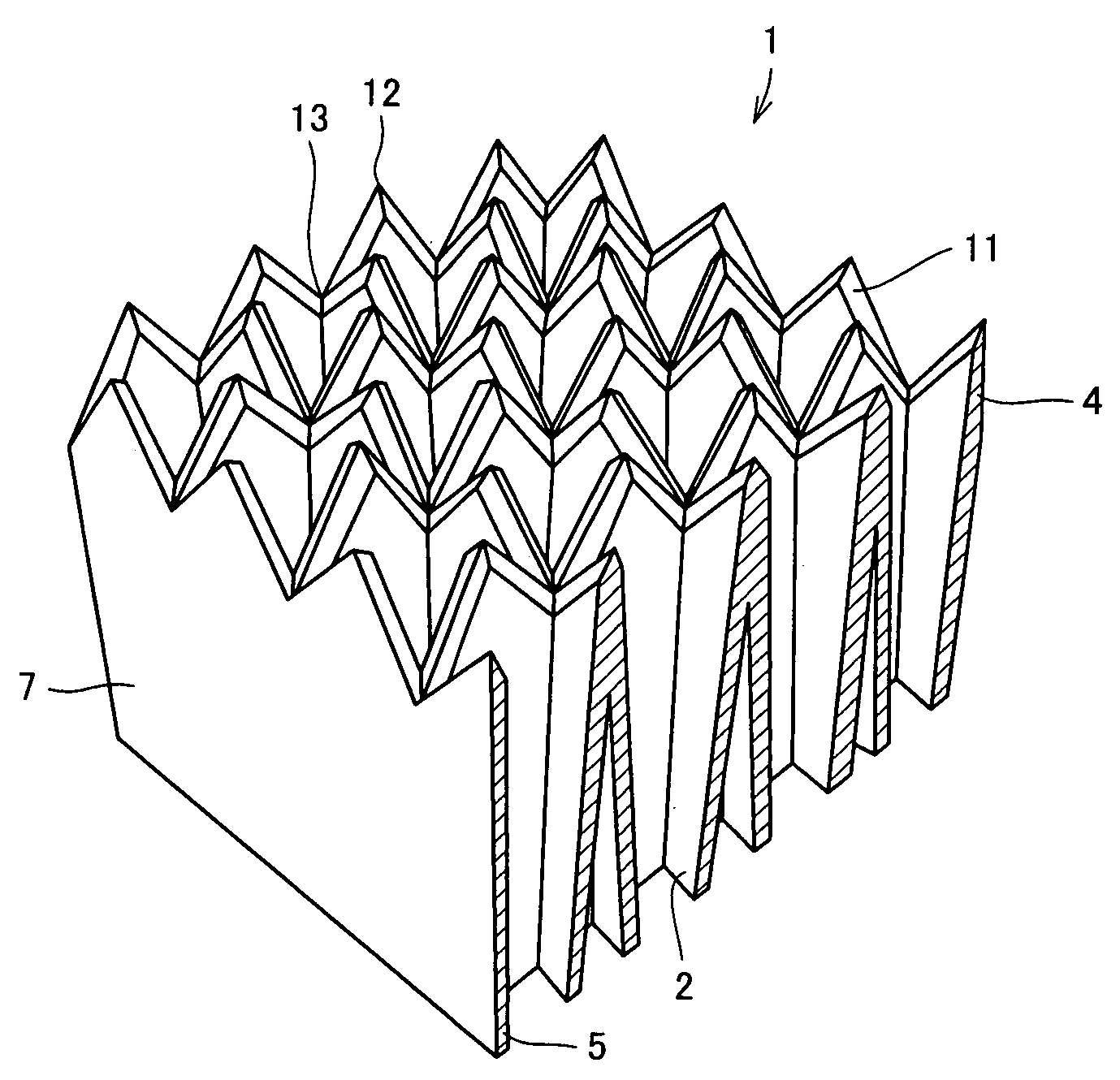

Compound filter material, method and application thereof

InactiveCN101596384AExtended service lifeHigh acid and alkali resistanceFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiber and the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

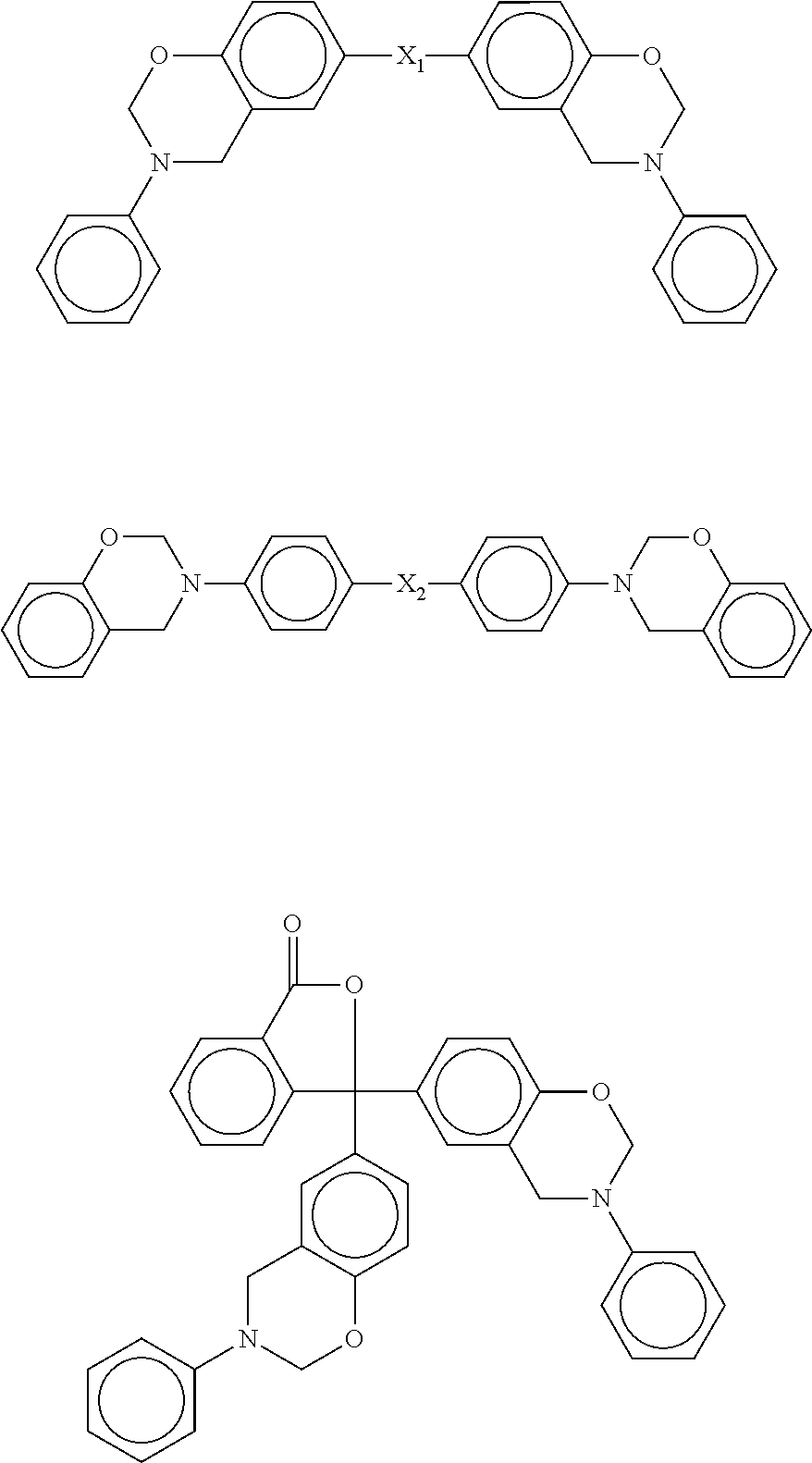

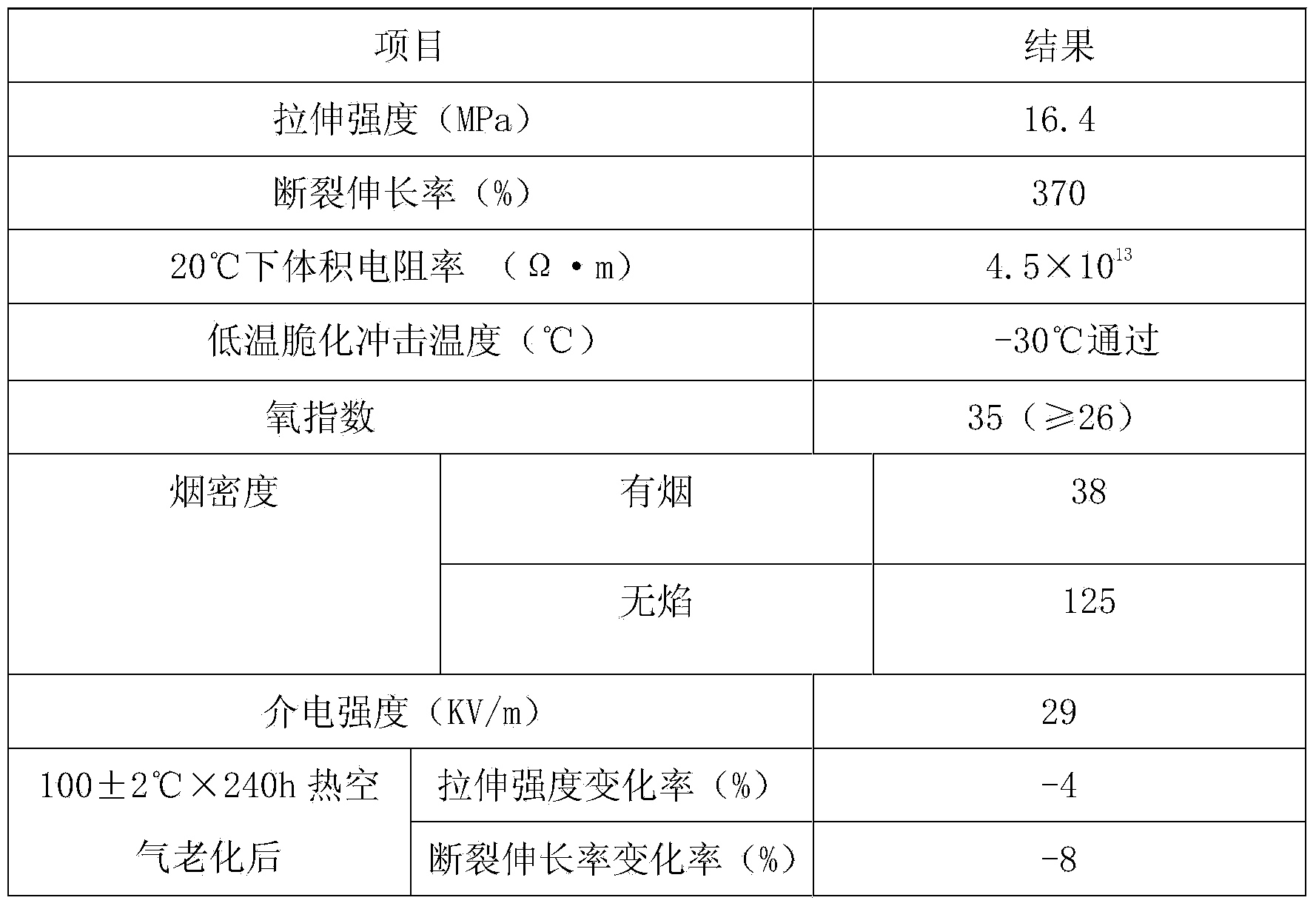

Halogen-free resin composition

ActiveUS20130316155A1Low dielectric constantImprove heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyDielectric loss factor

A halogen-free resin composition includes 100 parts by weight of epoxy resin; 10 to 100 parts by weight of benzoxazine resin; 10 to 100 parts by weight of styrene-maleic anhydride copolymer; and 10 to 90 parts by weight of dicyclopentadiene phenol novolac resin. The halogen-free resin composition features specific ingredients and proportions thereof to attain low dielectric constant (Dk), low dielectric dissipation factor, high heat resistance and high non-flammability and produce prepregs or resin film, and is thus applicable to copper clad laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles, and its preparation method

ActiveCN102977610AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsElastomerLinear low-density polyethylene

The invention provides a cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles. The cable material is prepared from the following raw materials, by weight, 100 parts of methyl-vinyl silicone rubber, 40-50 parts of isoprene rubber, 60-80 parts of linear low-density polyethylene, 9-11 parts of a styrene type thermoplastic elastomer SEBS, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black 550, 10-13 parts of modified diatomite, 0.5-1.0 part of an antioxidant D, 0.1-0.3 parts of an antioxidant 4010NA, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weather resistance, good abrasion resistance and good insulation property.

Owner:蚌埠尚维知识产权运营有限公司

Magnesium cement fireproof board having excellent water-resistance and preparation thereof

InactiveCN101250062ASmall coefficient of thermal expansionNot easy to warp and deformFiberThermal expansion

The invention reltes to a fireproof board, belonging to the technical field of building material, decorative material, traffic facility, fireproof product, abrasive, abrasive tool and wood furniture. According to the formula of the invention, a preparation method comprises adding 80 portions of magnesium sulfate and 1 portion of tartaric acid into a mixer, adding water of suitable amount, mixing and adjusting the Baume degree of the magnesium sulfate and tartaric acid to 26, adding 150 portions of 85% light magnesium oxide, 12 portions of perlite, 120 portions of heavy calcium carbonate and 22 portions of sawdust, mixing for 5min, emptying, shaping the materials on a fireproof board product line provided with two layers of dual fiber net bags, removing mould and cutting when the product reaches a suitable strength, to obtain the magnesium cement fireproof board with better water resistance. The inventive fireproof board has low thermal expansion factor, non warping deformation, softening factor higher than 0.9, non recurrent halogen, non frost mist, better freezing resistance and non combustibility.

Owner:李锦富

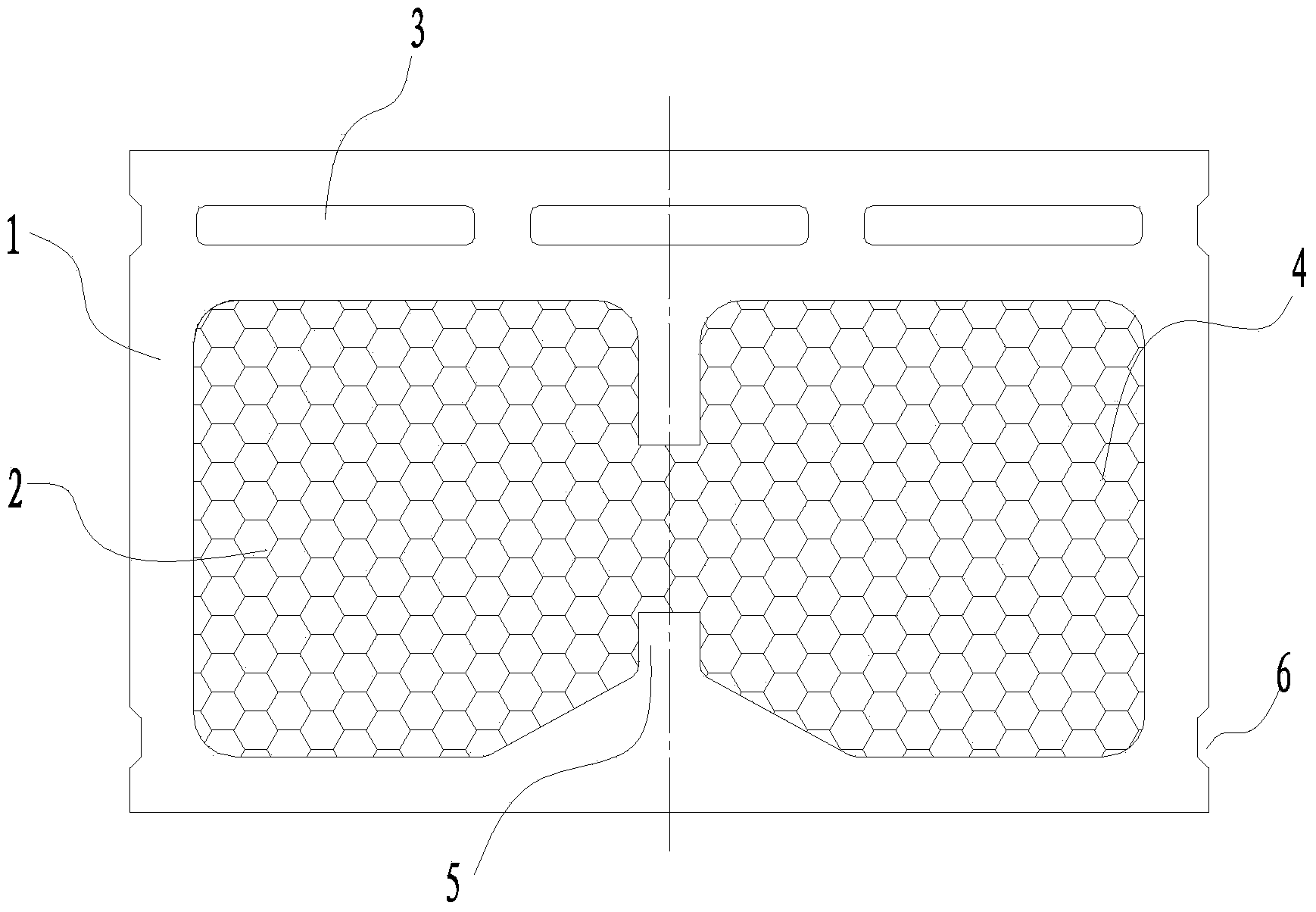

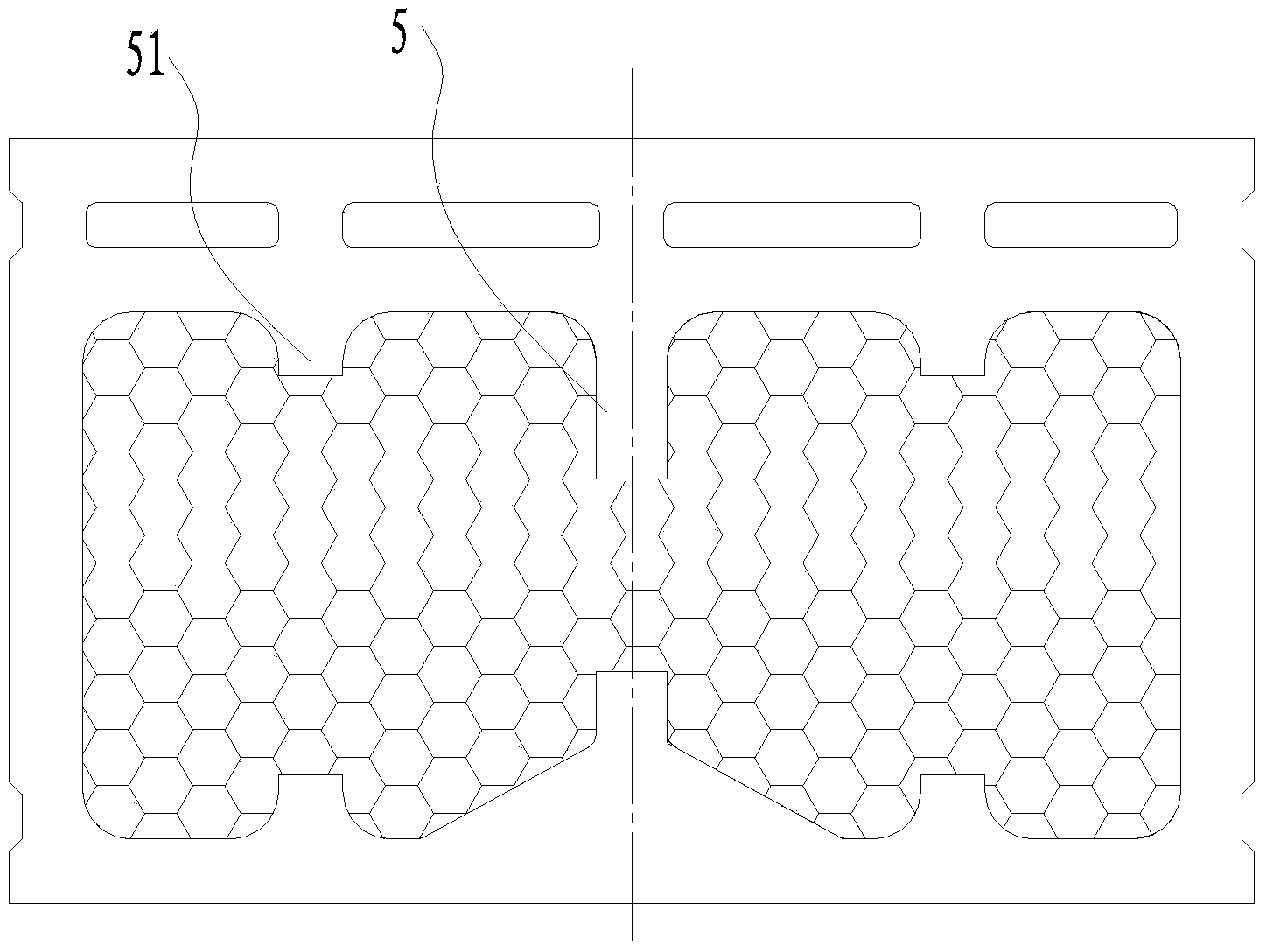

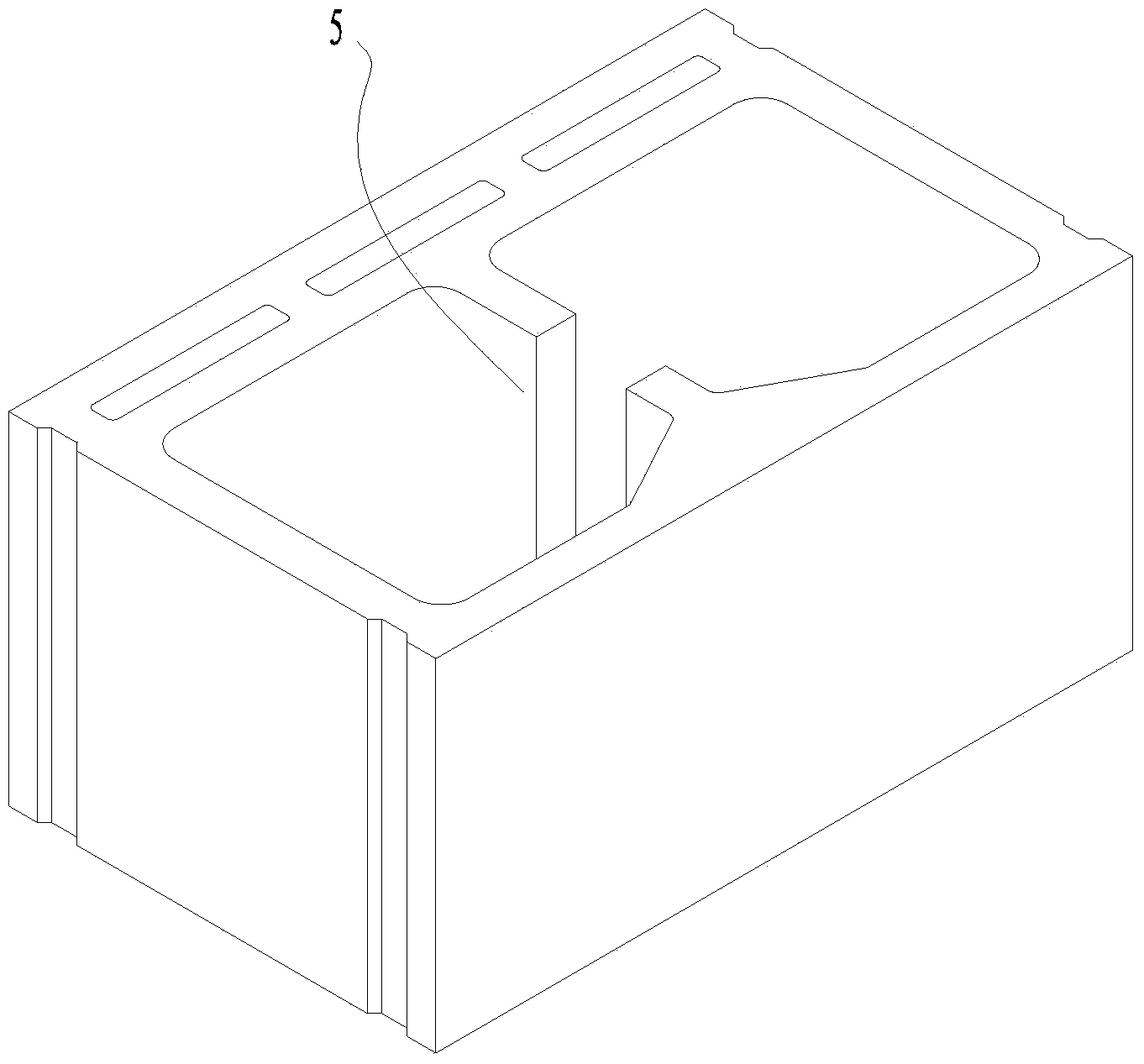

Foam cement filling type concrete composition heat preservation building block and manufacturing method thereof

ActiveCN103643760AGood dimensional stabilityHigh strengthConstruction materialCeramicwareThermal insulationBuilding material

The invention discloses a foam cement filling type concrete composition heat preservation building block and a manufacturing method of the foam cement filling type concrete composition heat preservation building block, which belongs to the technical field of energy-saving building materials. The building block comprises a concrete base body with a cavity, wherein at least one air space which passes through the base body is formed in the inner side of at least one outer surface; at least one cavity of which the cross section area is greater than the cross section area of the air space is further formed inside the base body; a foam cement filling body is arranged in the cavity. Due to the concrete base body, the concrete composition heat preservation building block has good physical and mechanical properties and durability, due to the air space and the foam cement, the concrete composition heat preservation building block has good thermal performance, and meanwhile a manufactured product is conveniently transferred, built, decorated and constructed because of the air space. The foam cement filling type concrete composition heat preservation building block has the characteristics of light weight, good heat preservation, thermal insulation and sound insulation effects, high strength, non-combustibility, anti-permeability and the like, and can be widely applied to internal and external walls of urban frame structure buildings and rural buildings. The building block is convenient to construct and stable in performance, and the working intensity and the construction cost are greatly alleviated and lowered.

Owner:CHINA BUILDING MATERIALS ACAD

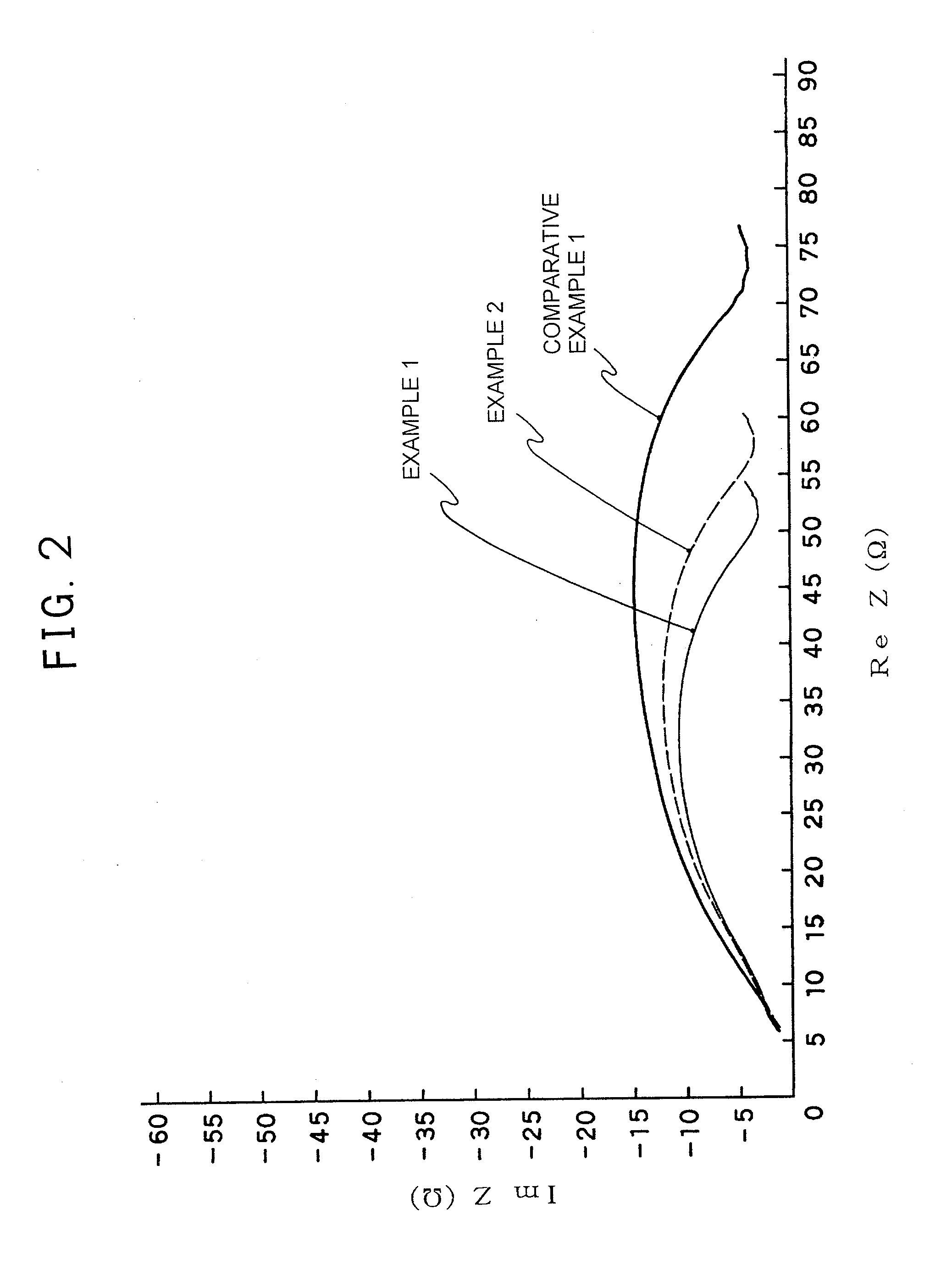

Solvent for dissolving electrolyte salt of lithium secondary battery

ActiveUS20100310943A1Excellent non-flammabilityIncrease capacityOrganic electrolyte cellsElectrolytesCarbonate esterEther

There are provided a solvent for dissolving an electrolyte salt of lithium secondary battery comprising at least one fluorine-containing solvent (I) selected from the group consisting of a fluorine-containing ether, a fluorine-containing ester and fluorine-containing chain carbonate, 1,2-dialkyl-1,2-difluoroethylene carbonate (II) and other carbonate (III), a non-aqueous electrolytic solution comprising the solvent and an electrolyte salt, and a lithium secondary battery using the non-aqueous electrolytic solution. The solvent for dissolving an electrolyte salt provides a lithium secondary battery being excellent particularly in discharge capacity, rate characteristic and cycle characteristic and has enhanced incombustibility (safety) and the non-aqueous electrolytic solution comprises the solvent and an electrolyte salt.

Owner:DAIKIN IND LTD

Flame-retardant, environmentally-friendly and safe polyolefin sheath material and its preparation method

ActiveCN102977466AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntimony trioxide

The invention provides a flame-retardant, environmentally-friendly and safe polyolefin sheath material. The polyolefin sheath material is prepared from the following raw materials, by weight, 20-30 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of a rubber smoked sheet, 0.5-1.0 part of bisphenol A, 1-3 parts of modified tree ash, 20-30 parts of triethyl citrate, 4-6 parts of magnesium oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.0 part of a promoter MBTS, 0.2-0.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenylethane, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The polyolefin sheath material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, good abrasion resistance, and good prevention performance.

Owner:宝新高分子科技(广州)有限公司

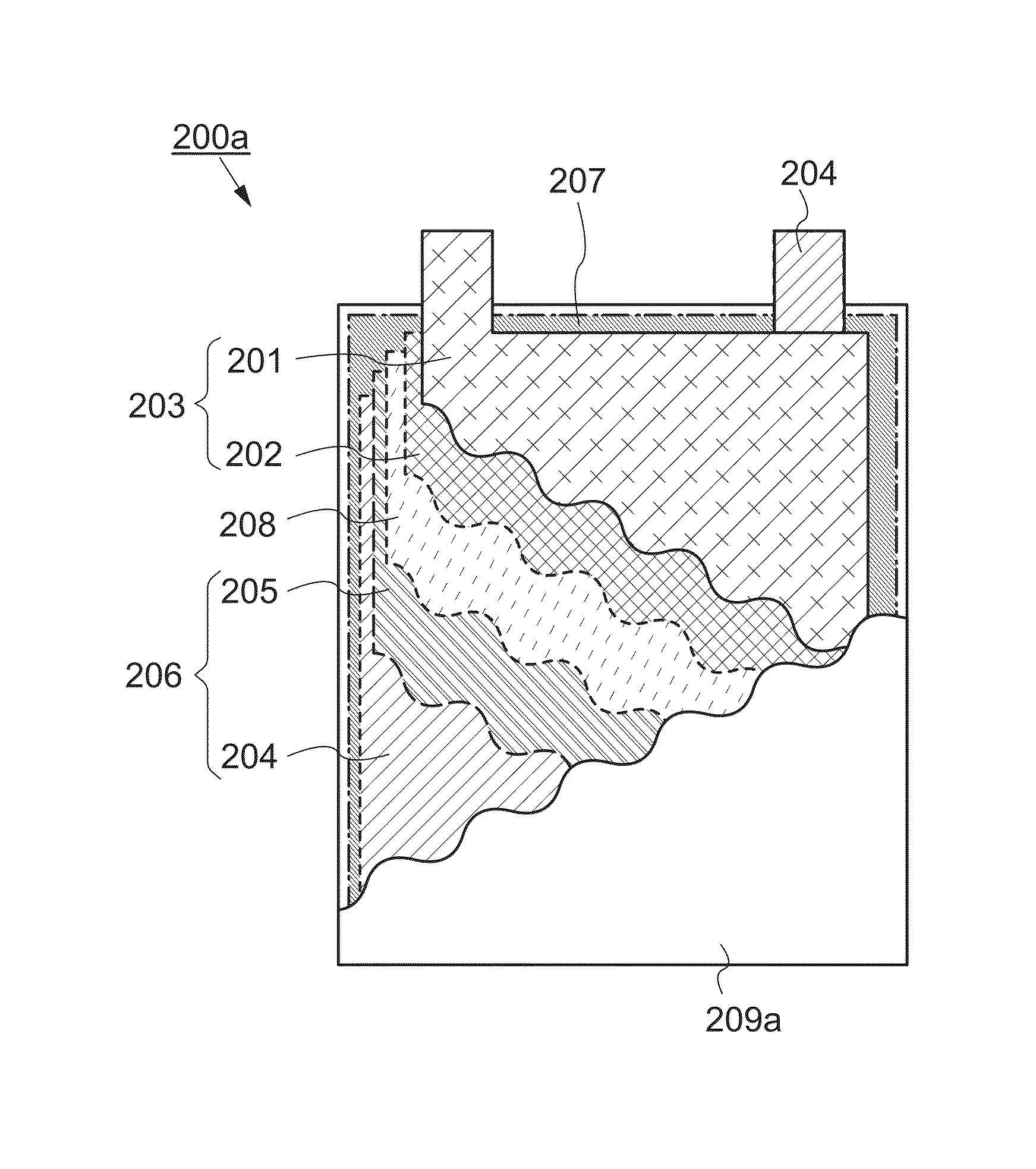

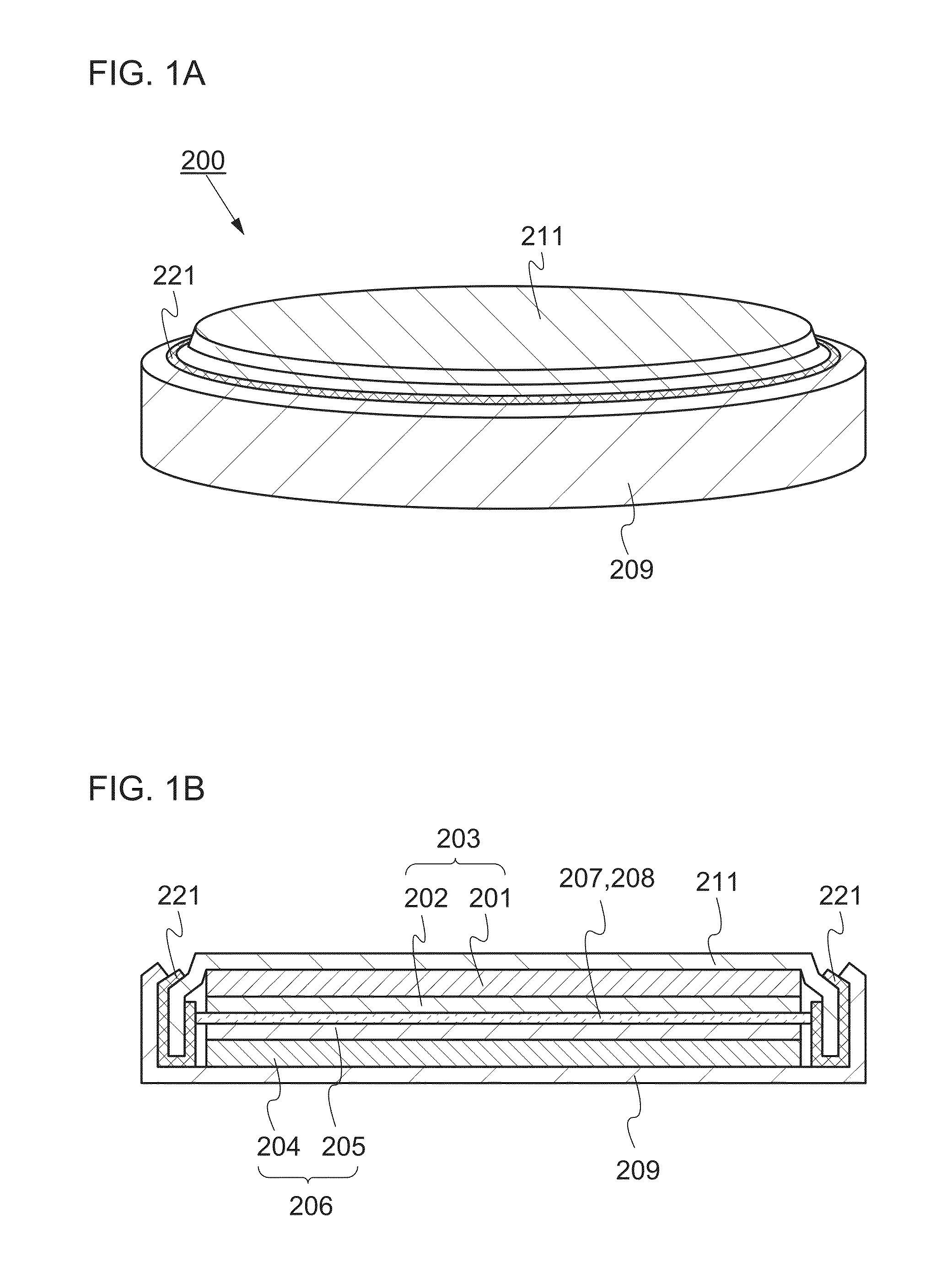

Non-aqueous electrolyte and non-aqueous electrolyte secondary power source comprising the same

InactiveUS20100285373A1Excellent non-flammabilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsAlkoxy groupSolvent

This invention relates to a non-aqueous electrolyte having high non-combustibility and a non-aqueous electrolyte secondary power source having high safety and exhibiting stable performance even under high load conditions or low-temperature conditions, and more particularly to a non-aqueous electrolyte characterized by comprising a cyclic phosphazene compound represented by the following general formula (I):(NPR2)n (I)[wherein Rs are independently fluorine, an alkoxy group or an aryloxy group and n is 3-4], a non-aqueous solvent, LiPF6 and at least one lithium amide selected from the group consisting of Li(FSO2)2N, Li(CF3SO2)2N and Li(C2F5SO2)2N, as well as a non-aqueous electrolyte secondary power source comprising the non-aqueous electrolyte, a positive electrode and a negative electrode.

Owner:BRIDGESTONE CORP

Oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats, and its preparation method

ActiveCN102977609AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsMeth-Carbamate

The invention provides an oil and low-temperature resistant low-smoke and halogen-free flame retardant cable material for boats. The cable material is prepared from the following raw materials, by weight, 20-30 parts of polyurethane, 60-80 parts of methyl vinyl silicone rubber, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of magnesium hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of barium stearate, 8-12 parts of triglycol dioctate, 4-6 parts of copper oxide, 0.5-1.0 parts of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of modified argil, 0.5-1.0 part of an antioxidant H, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter NOBS, 0.2-0.5 parts of a vulcanizing agent DCBP, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance.

Owner:广东蓝宇塑料制品有限公司

Flame-retardant cable material and preparation method

ActiveCN103524933AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsPolyolefinPhosphoric acid

The invention provides a flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 80-90 parts of PVC resin, 15-18 parts of buna-N rubber / nano calcium carbonate composite powder rubber, 2.5-5 parts of chlorinated polyethylene, 5-10 parts of polystyrene, 5-10 parts of polyolefin, 3-5 parts of nano jade powder, 10-15 parts of mica powder, 10-12 parts of ammonium polyphosphate, 20-30 parts of DIDP, 0.4-1.0 part of tribasic lead sulfate, 1-2 parts of polyethylene wax, 15-25 parts of aluminum hypophosphite, 1-2 parts of calcium stearate, 1-2 parts of pentaerythritol, 1-2 parts of polytetrafluoroethylene and 5-10 parts of modified filling materials. The cable material has excellent flame resistance and incombustibility. The generated smoke is little during burning, no toxic gas is generated, and no corrosive gas is generated. The cable material has high tensile strength and good rebound resilience.

Owner:苏州华盟塑化有限公司

Ceramic silicone rubber cable material and preparation method thereof

InactiveCN103525092ASo as not to damageImprove flame retardant performanceRubber insulatorsInsulated cablesPhosphoric acidAntimony trioxide

The invention provides a ceramic silicone rubber cable material. The cable material is prepared by using the following raw materials, by weight, 80-90 parts of silicone rubber, 10-20 parts of natural rubber, 20-30 parts of mineral silicate, 10-15 parts of diantimony trioxide, 10-20 parts of ammonium polyphosphate, 4-6 parts of zinc oxide, 1-2 parts of an antioxidant DTPD, 20-30 parts of spraying carbon black, 10-20 parts of light calcium carbonate, 14-16 parts of aluminum hypophosphite, 1-2 parts of calcium stearate, 1-2 parts of pentaerythritol, 1-2 parts of talcum powder, and 12-14 parts of a modification filler. The cable material has the advantages of excellent flame retardancy, and very small smoke amount and no generation of toxic gases or corrosive gases during combustion, and forms a hard shell after the combustion, and the hard shell does not shed and protects a combusted cable from damages to guarantee normal power transmission.

Owner:广东新成硅胶实业有限公司

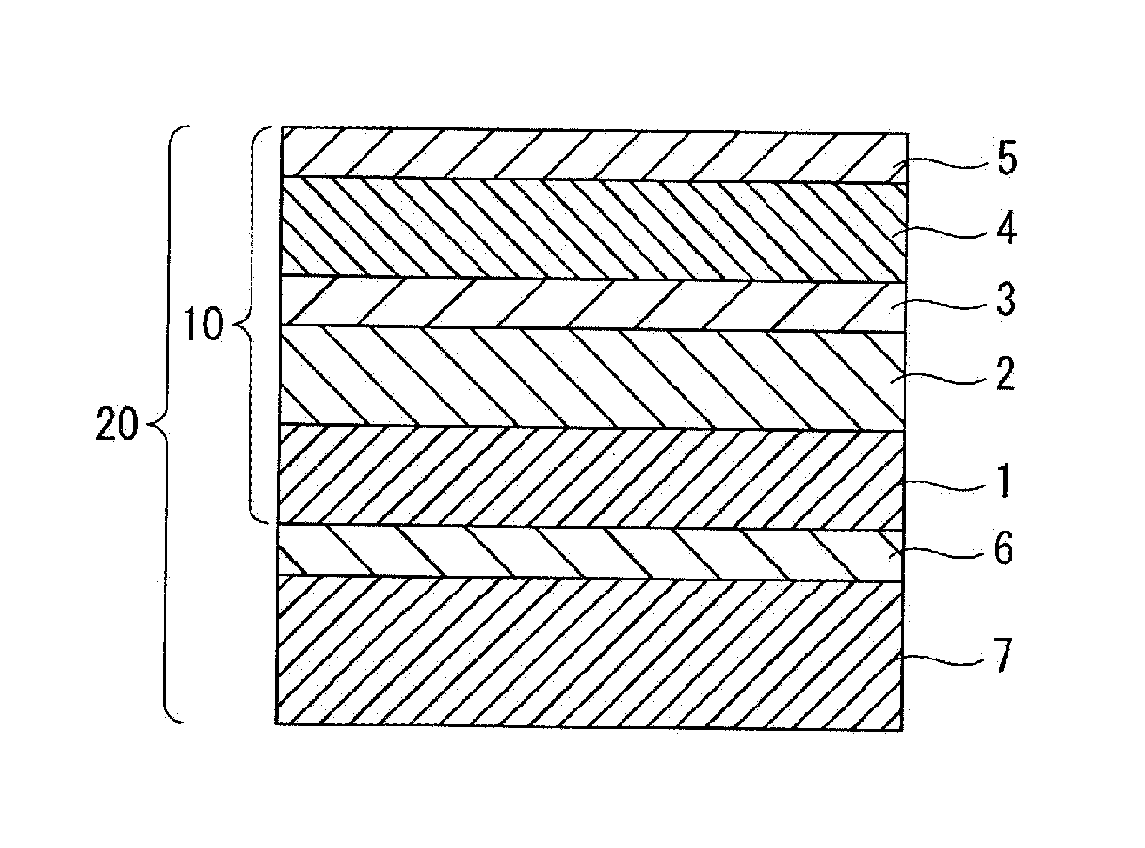

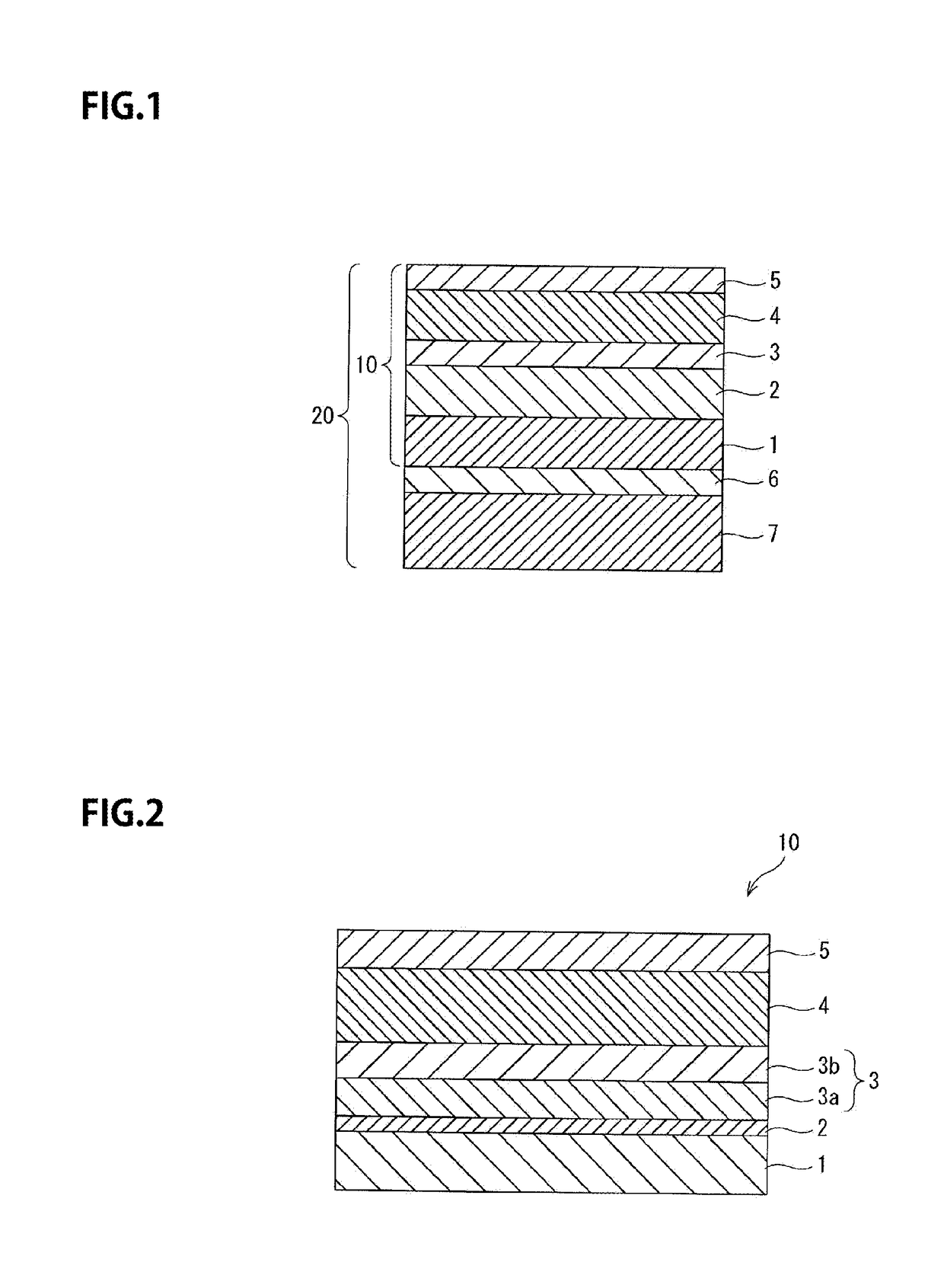

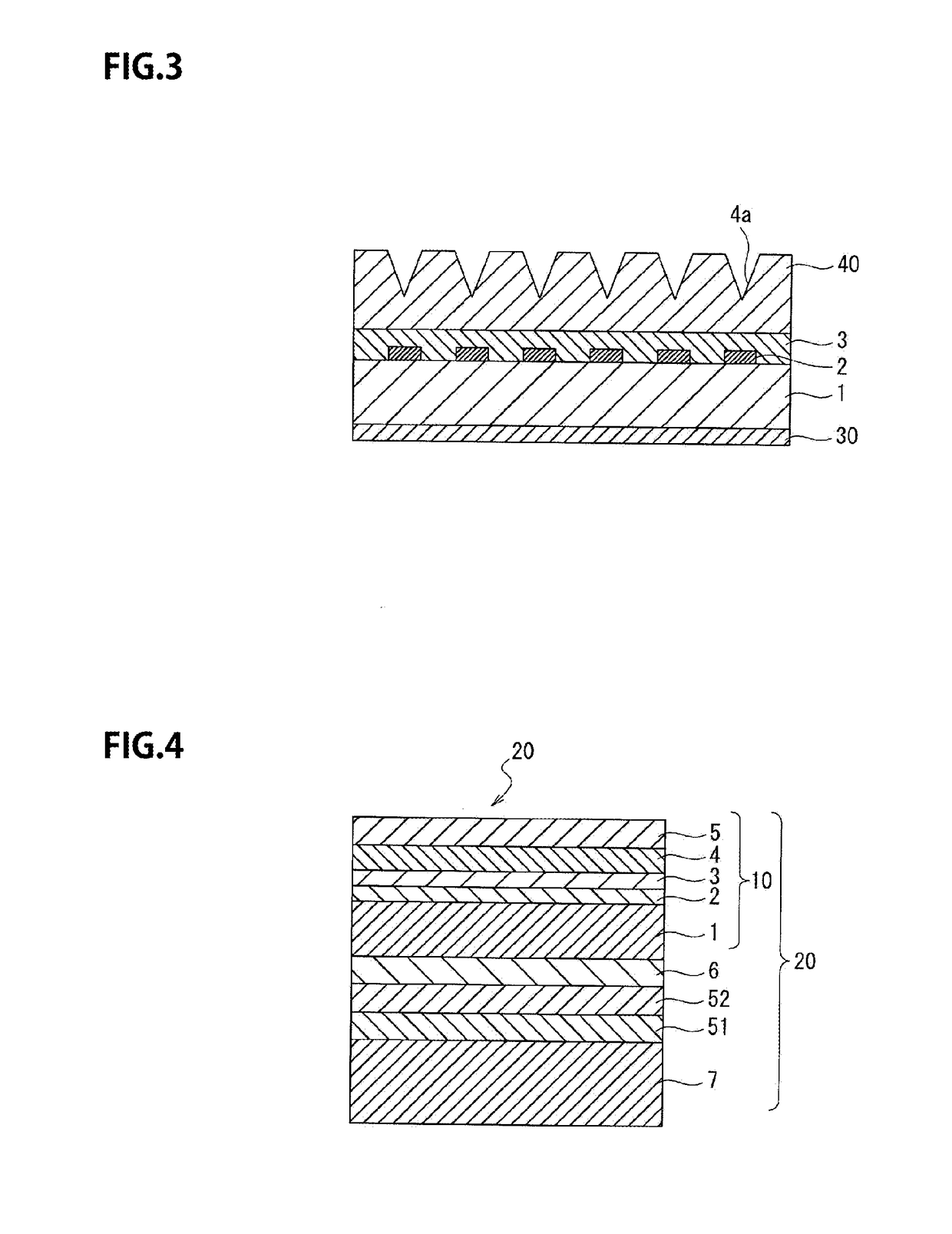

Incombustible decorative sheet, metal decorative member and method for fabricating a metal decorative member

ActiveUS20170297307A1Incombustibility be goodEasy to processCovering/liningsLamination ancillary operationsAcrylic resinChemistry

A decorative sheet which ensures good incombustibility, processability and weatherability along with weatherability, contamination resistance and solvent resistance. An incombustible decorative sheet having incombustibility includes a weather-resistant resin layer and a fluorine resin layer laminated on a substrate layer in this order, wherein the weather-resistant resin layer is made of a mixture of an acrylic resin and an acrylic resin-based rubber having a ratio by mass between the acrylic resin-based rubber and the acrylic resin within a range of 30:70 to 60:40. The ratio between the fluorine resin layer and the weather-resistant resin layer is within a range of 10:90 to 40:60.

Owner:TOPPAN PRINTING CO LTD

Nano-kieselguhr modified chlorosulfonated polyethylene rubber cable material

ActiveCN102964705AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsDiphenyl phosphatePolymer science

The invention discloses a nano-kieselguhr modified chlorosulfonated polyethylene rubber cable material. The cable material is prepared from the following raw materials in parts by weight: 100-120 parts of chlorosulfonated polyethylene rubber CSM2305, 20-30 parts of duprene rubber CR322, 10-20 parts of ethylene-vinyl acetate rubber, 5-10 parts of di-n-hexyl adipate, 5-10 parts of isopropylphenyl diphenyl phosphate, 4-6 parts of di(2-Ethylhexyl)-4,5-epoxytetrahydrophthalate, 1-2 parts of nonsoluble sulfur, 4-6 parts of butyl perbenzoate, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Solar energy thermal insulation material

ActiveCN101280052AUnique acid resistanceUnique alkali resistanceOther chemical processesThermal insulationIsocyanate compound

The invention relates to green environment-friendly polyurethane insulation material which will not destroy the atmospheric ozone layer. The insulation material is made from the raw materials with the following weight proportions and through the following method: (1) 92-96% of polyether, 0.5-2% silicone oil, 0.5-2% foam stabilizer, 1-4% catalyst and 1-4% of additive are fully mixed through a reactor to obtain the mixed material A; (2) according to the weight ratio of 1:0.05-0.3 between the mixed material A and HFC-245fa, the raw materials are evenly mixed to prepare the mixed material B; (3) based on the weight ratio of 1-1.1:1 between isocyanate and the mixed material B, the raw materials are mixed and foamed under high pressure so as to obtain the polyurethane solar energy insulation material after high-temperature solidification. The insulation material is green environment-friendly material which will not destroy the atmospheric ozone layer and has insulation and fire-retardant effects.

Owner:SHANDONG LINUO PARADIGMA

Nonaqueous solvent, nonaqueous electrolyte, and power storage device

InactiveUS20140377644A1Improve conductivityLess likely to volatilizeOrganic electrolyte cellsSecondary cellsQuaternary ammonium cationSolvent

A nonaqueous solvent that includes an ionic liquid and has at least one of the following characteristics: high lithium ion conductivity, high lithium ion conductivity in a low temperature environment, high heat resistance, a wide available temperature range, a low freezing point (melting point), low viscosity, and the like. The nonaqueous solvent includes an ionic liquid and a fluorinated solvent. The ionic liquid contains an alicyclic quaternary ammonium cation which has a substituent and a counter anion to the alicyclic quaternary ammonium cation which has the substituent.

Owner:SEMICON ENERGY LAB CO LTD

Electrolyte of flame-retarded lithium ion battery

ActiveCN102082296AExcellent non-flammabilityHigh viscositySecondary cells servicing/maintenanceBenzeneOrganic solvent

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

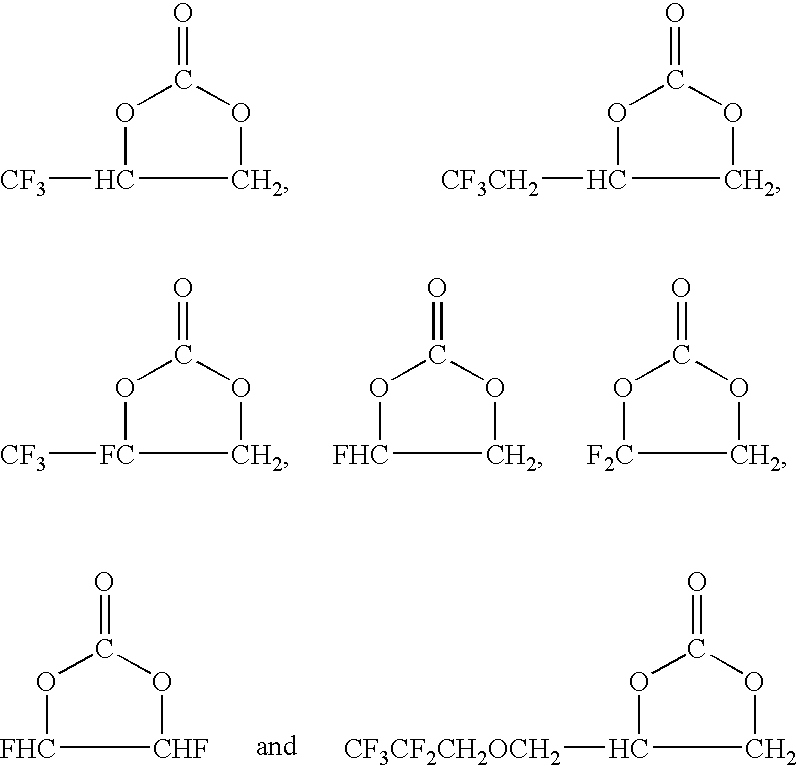

Non-aqueous electrolytic solution

ActiveUS8871384B2Excellent non-flammabilitySuitableElectrolytic capacitorsOrganic electrolyte cellsLithiumSolvent

There is provided a non-aqueous electrolytic solution comprising an electrolyte salt, a specific fluorine-containing solvent and a fluorine-containing cyclic carbonate represented by the formula (A1):wherein X1 to X4 are the same or different and each is —H, —F, —CF3, —CHF2, —CH2F, —CF2CF3, —CH2CF3 or —CH2OCH2CF2CF3; at least one of X1 to X4 is —F, —CF3, —CF2CF3, —CH2CF3 or —CH2OCH2CF2CF3, and the non-aqueous electrolytic solution has further excellent noncombustibility and is suitable for lithium secondary batteries.

Owner:DAIKIN IND LTD

Irradiation crosslinking low-smoke and halogen-free flame retardant cable material and its preparation method

InactiveCN102977468AImprove flame retardant performanceExcellent non-flammabilityElastomerPolymer science

The invention provides an irradiation crosslinking low-smoke and halogen-free flame retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 9-11 parts of a maleic anhydride grafted polyolefin elastomer, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 10-20 parts of an EVA resin, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of zinc stearate, 0.2-0.5 parts of dicumyl peroxide (DCP), 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black N3393, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of an antioxidant 4020, 0.1-0.3 part of an antioxidant MB, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weatherability, good abrasion resistance, good insulation property, and ultraviolet resistance.

Owner:武汉爱邦高能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com