Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2435 results about "Carbonate ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

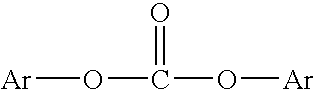

Inventor

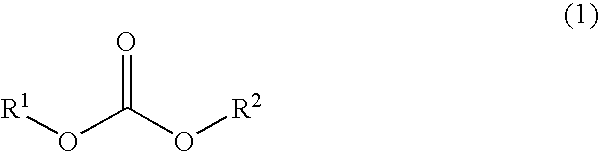

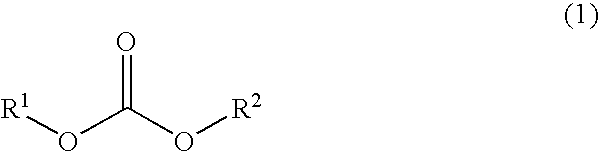

A carbonate ester (organic carbonate or organocarbonate) is an ester of carbonic acid. This functional group consists of a carbonyl group flanked by two alkoxy groups. The general structure of these carbonates is R₁O(C=O)OR₂ and they are related to esters R₁O(C=O)R and ethers R₁OR₂ and also to the inorganic carbonates.

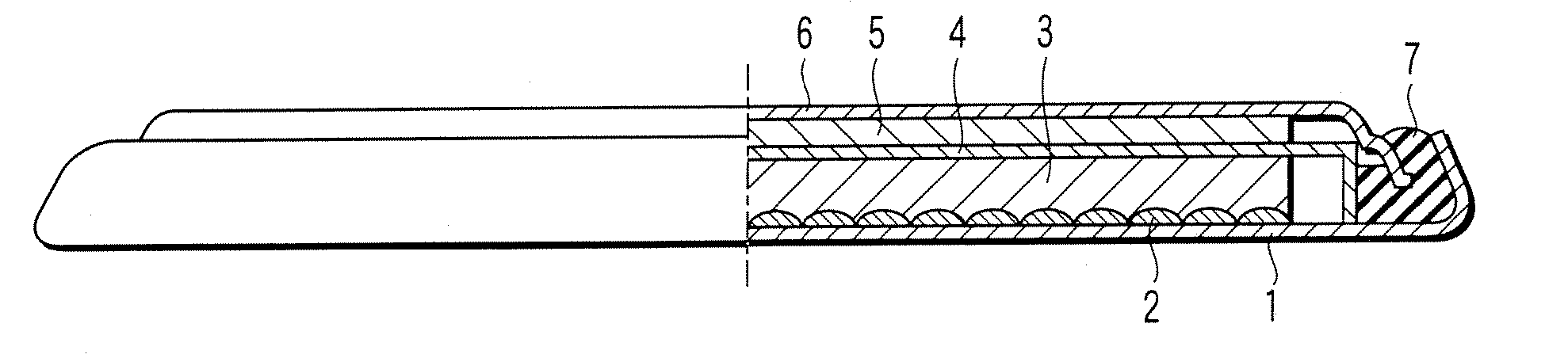

Magnetic recording medium

InactiveUS20090087689A1Improve high-speed running stabilityMaintain good propertiesMagnetic materials for record carriersRecord information storageAtomic force microscopyMagnetic force microscope

The magnetic recording medium comprises a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support. In the magnetic recording medium, a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 500 / 1,600 μm2, the binder comprises a polyurethane resin with a weight average molecular weight ranging from 100,000 to 200,000, and the magnetic layer further comprises a carbonic ester having a molecular weight ranging from 360 to 460.

Owner:FUJIFILM CORP

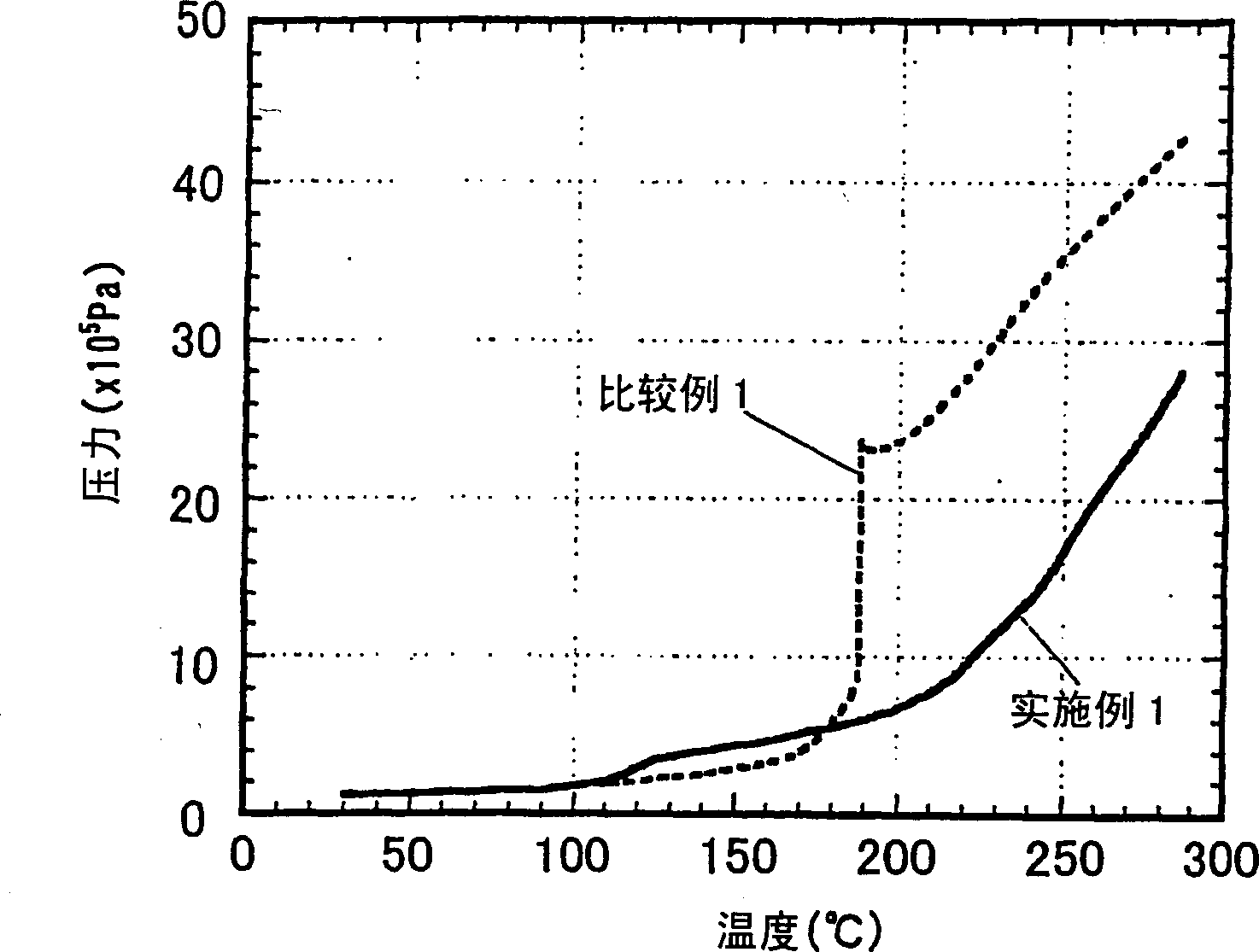

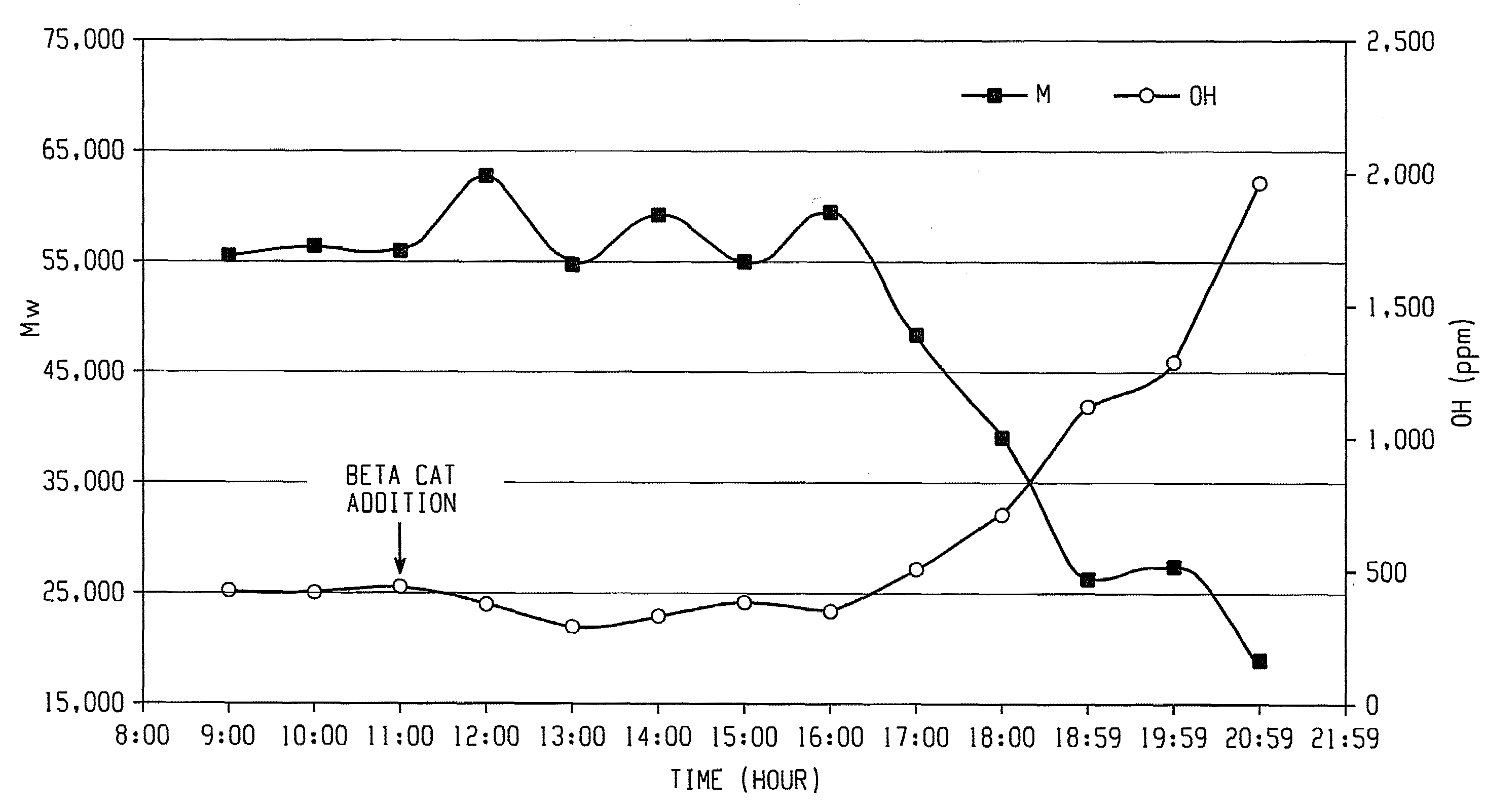

Polycarbonate polyol compositions and methods

ActiveUS20110230580A1Efficient productionIncrease ratingsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupPolycarbonate

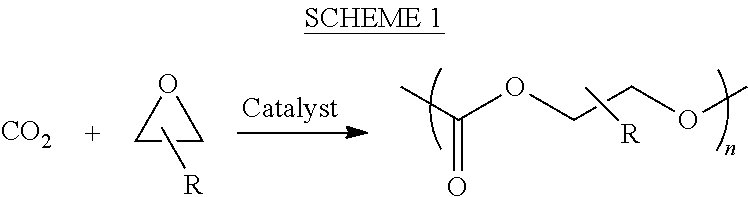

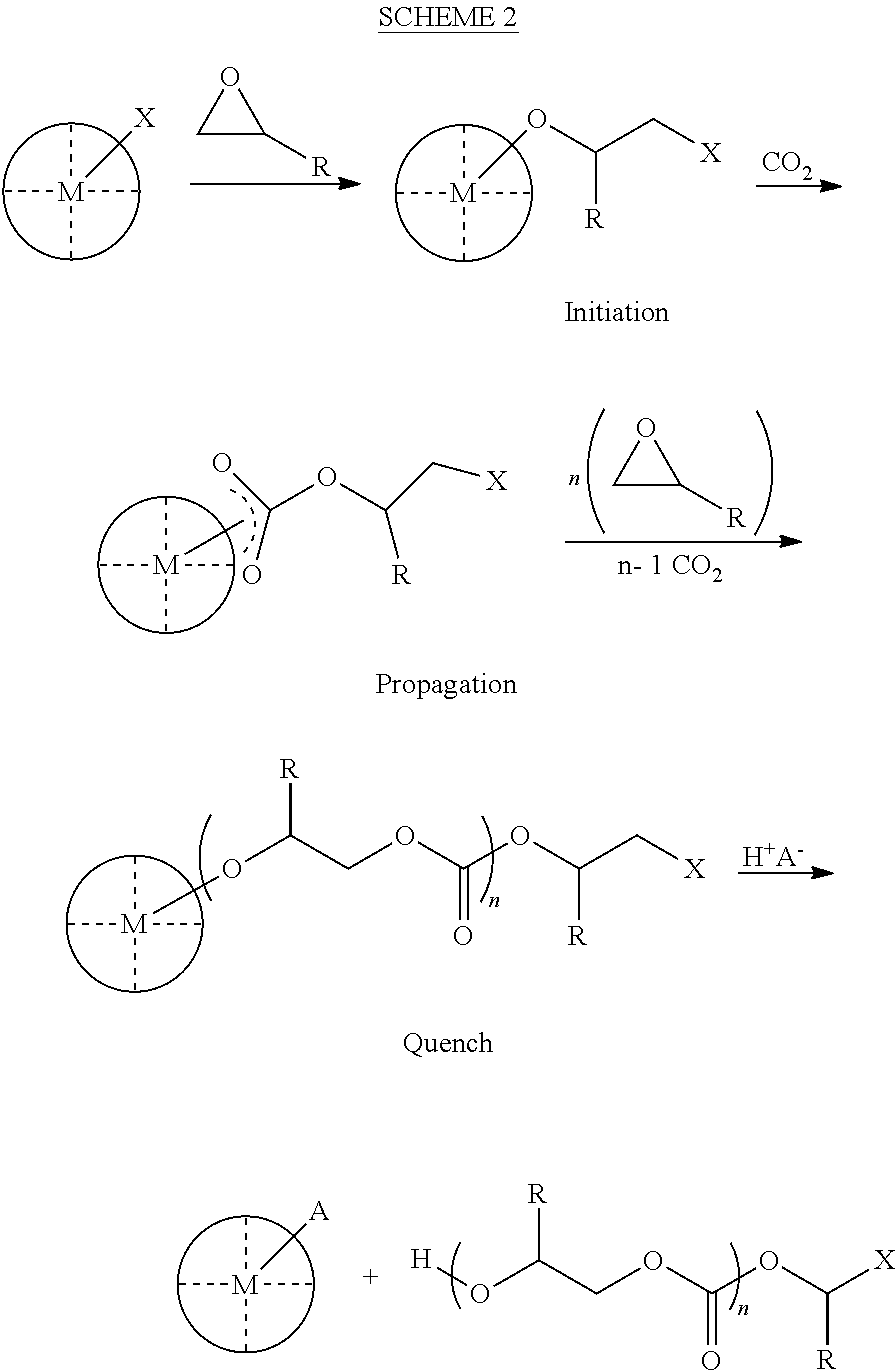

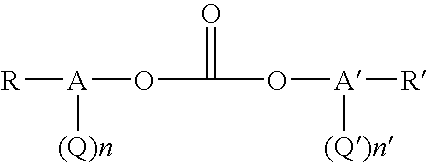

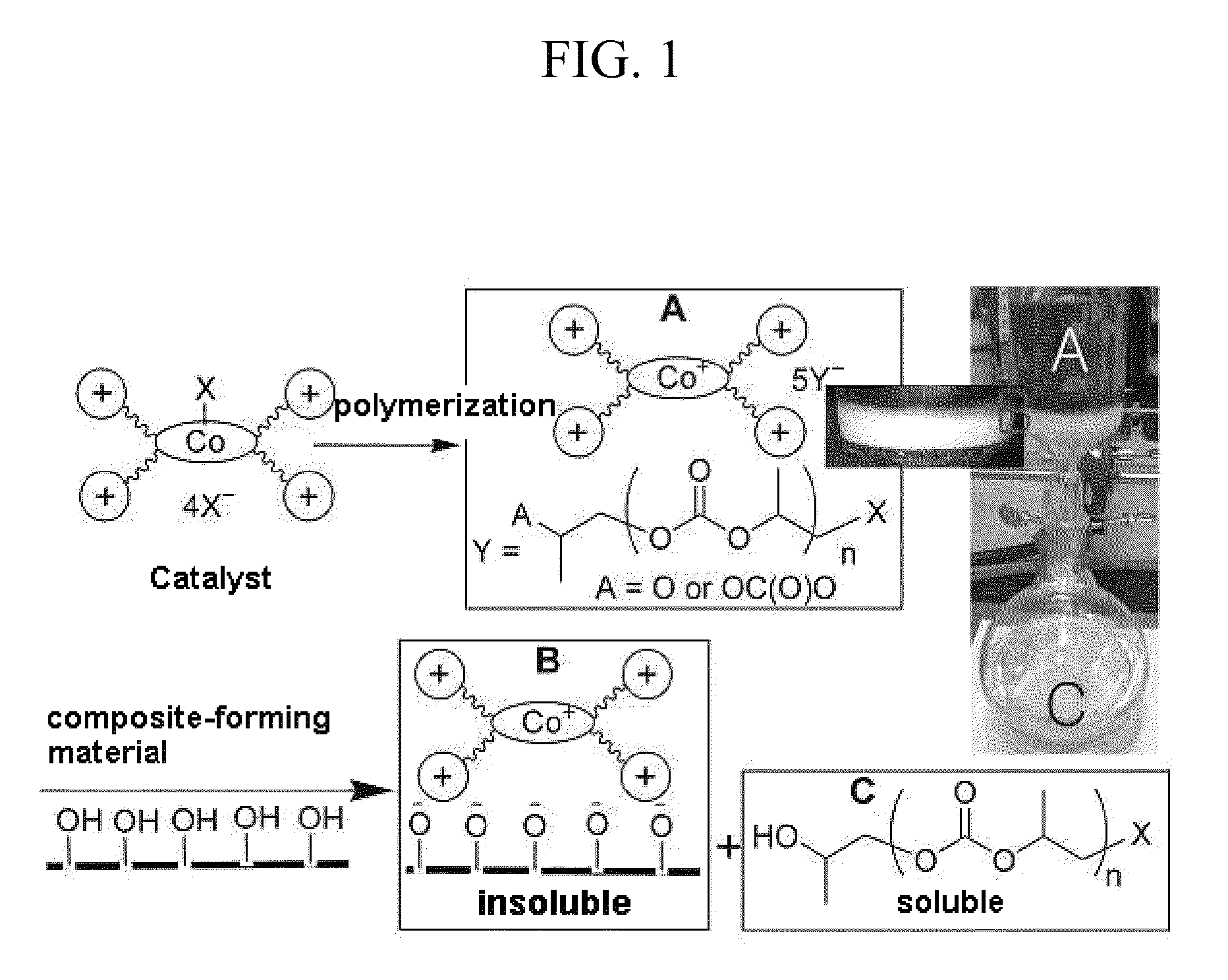

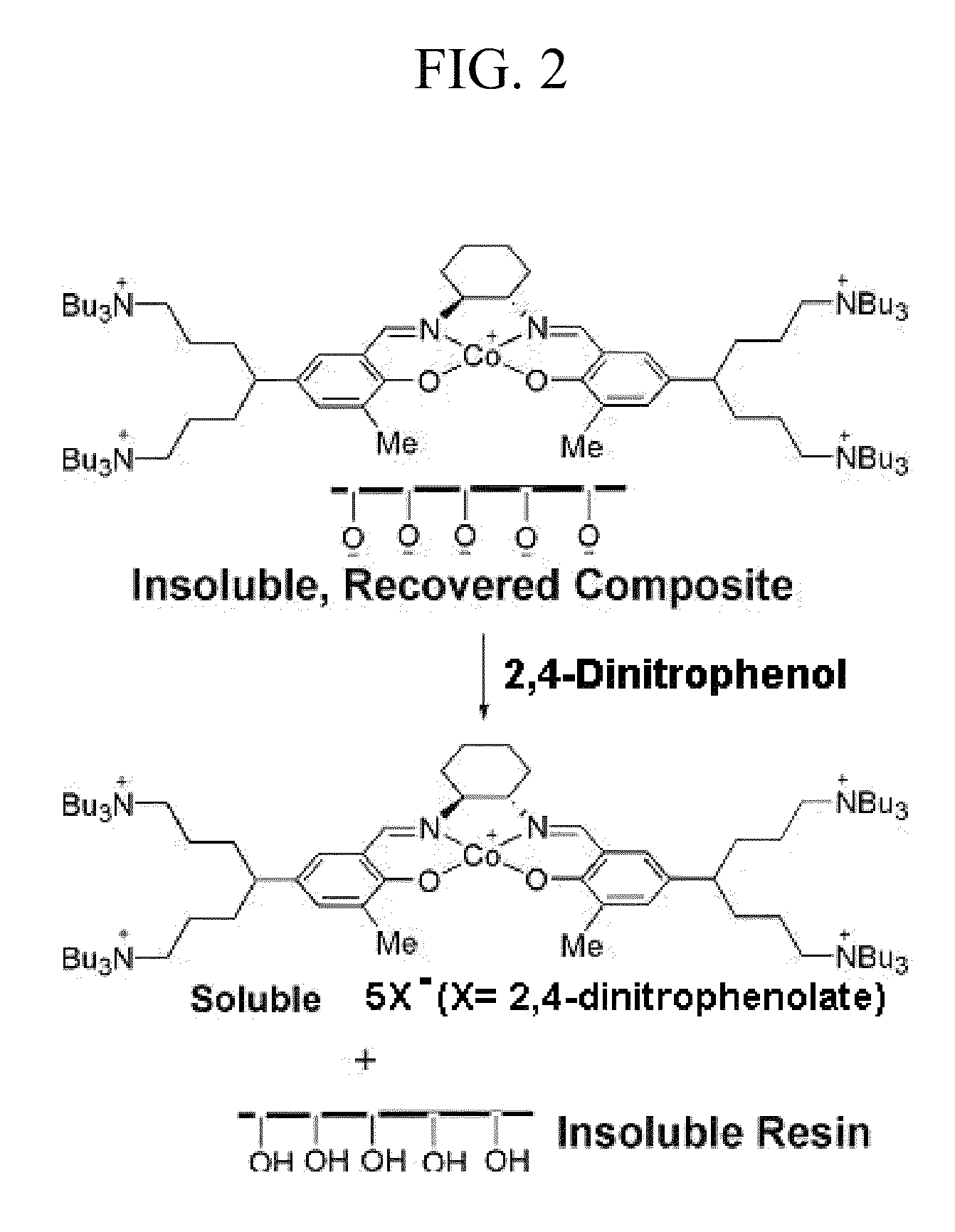

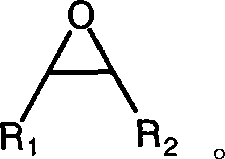

In one aspect, the present disclosure encompasses polymerization systems for the copolymerization of CO2 and epoxides comprising 1) a catalyst including a metal coordination compound having a permanent ligand set and at least one ligand that is a polymerization initiator, and 2) a chain transfer agent having two or more sites that can initiate polymerization. In a second aspect, the present disclosure encompasses methods for the synthesis of polycarbonate polyols using the inventive polymerization systems. In a third aspect, the present disclosure encompasses polycarbonate polyol compositions characterized in that the polymer chains have a high percentage of —OH end groups and a high percentage of carbonate linkages. The compositions are further characterized in that they contain polymer chains having an embedded polyfunctional moiety linked to a plurality of individual polycarbonate chains.

Owner:SAUDI ARAMCO TECH CO

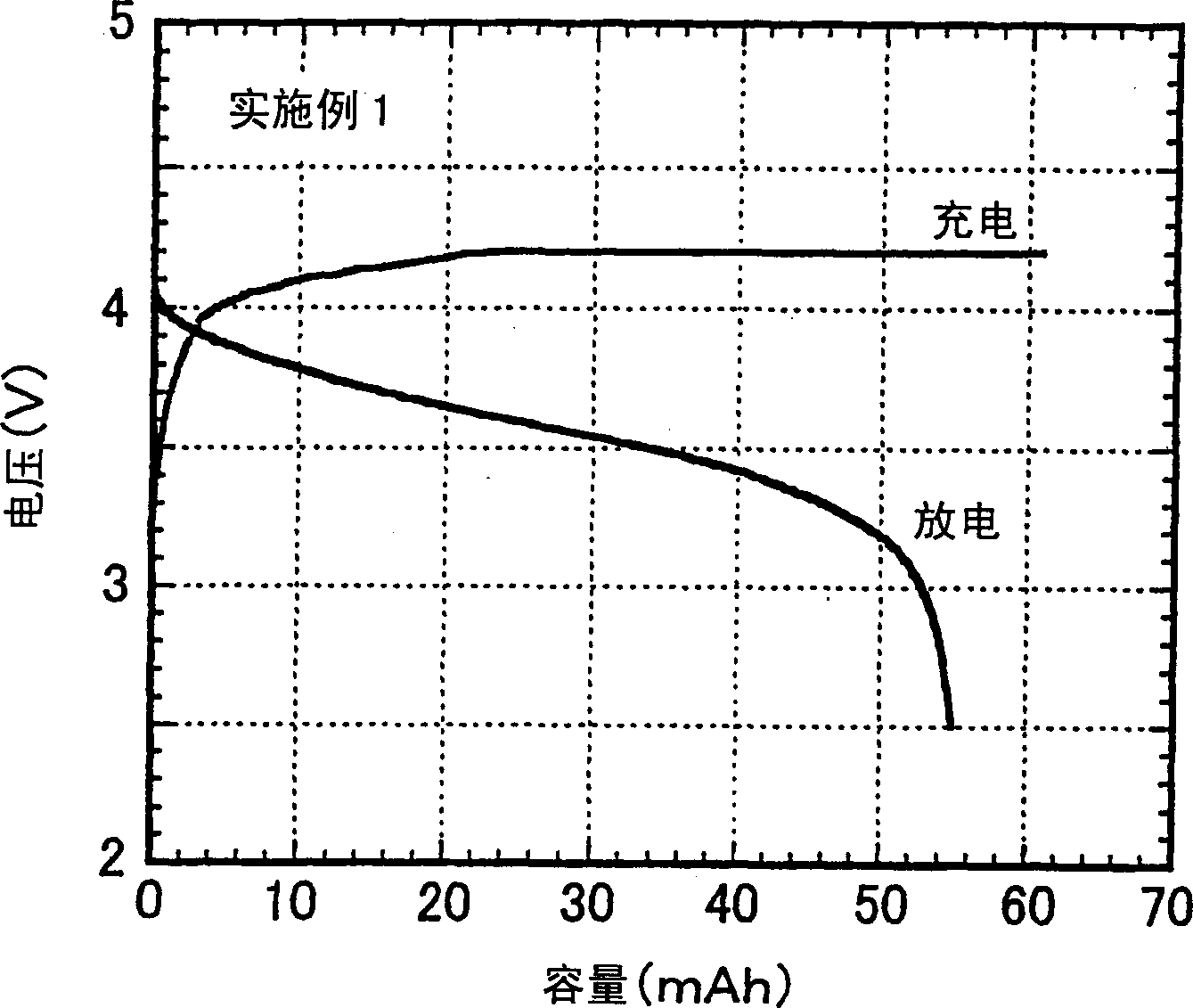

Lithium secondary battery and electrolyte thereof

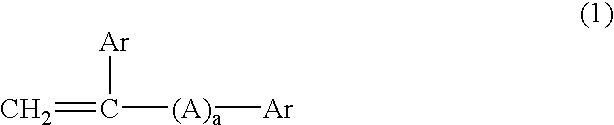

InactiveUS6033809AImprove featuresWithout adversely affecting normal reactionCell electrodesOrganic electrolyte cellsArylHydrogen atom

A non-aqueous electrolyte lithium secondary battery comprising a cathode, an anode and a non-aqueous electrolyte comprising an electrolyte dissolved in a non-aqueous solvent, wherein the cathode is composed of a material containing a lithium complex oxide, the anode is composed of a material containing graphite and the non-aqueous solvent contains, as main components, a cyclic carbonate and a linear carbonate and 0.1 to 4% by weight, based upon the total weight of the non-aqueous solvent, of a sultone derivative having the general formula (I): wherein R1, R2, R3, R4, R5 and R6 independently represent an alkyl group having 1 to 12 carbon atoms, a cycloalkyl group having 3 to 6 carbon atoms, an aryl group having 6 to 12 carbon atoms or a hydrogen atom and n is an integer of 0 to 2.

Owner:UBE IND LTD

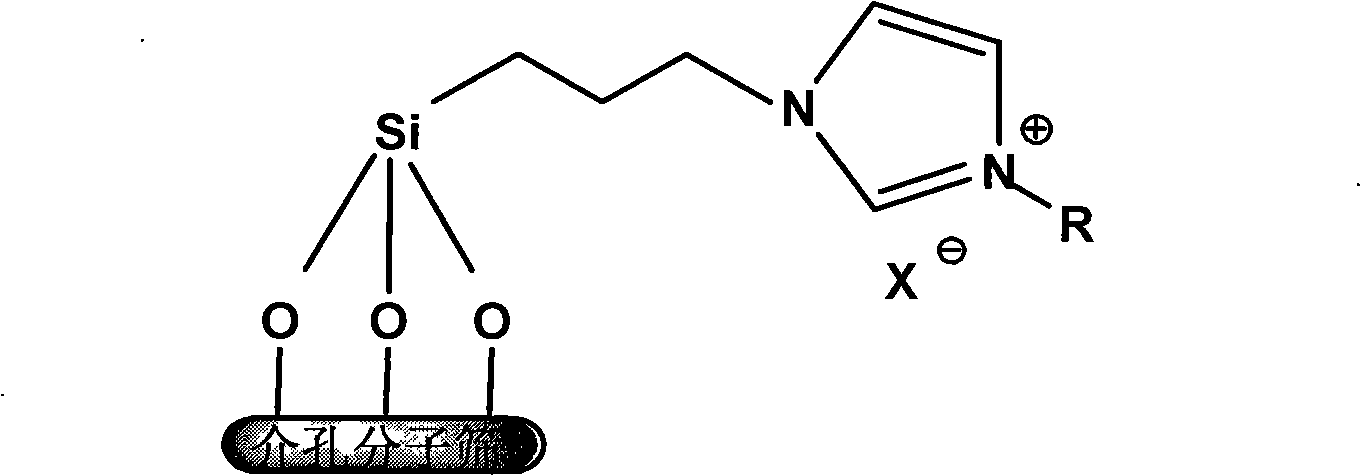

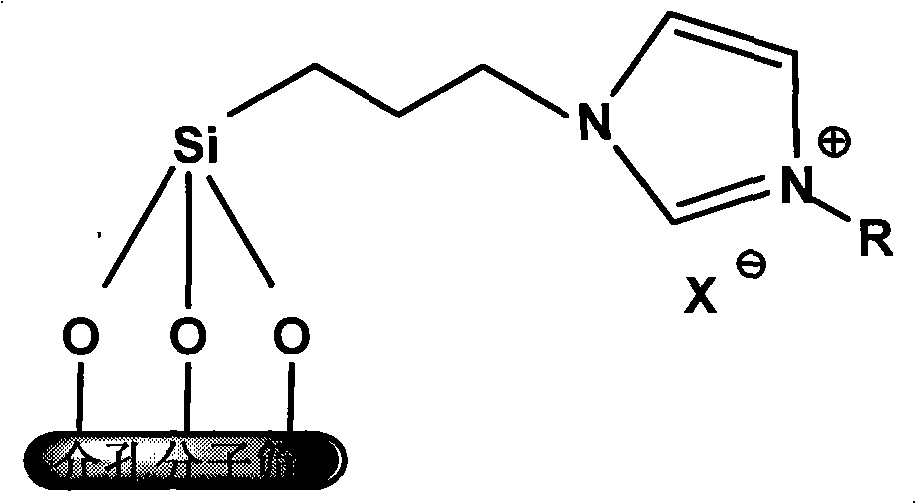

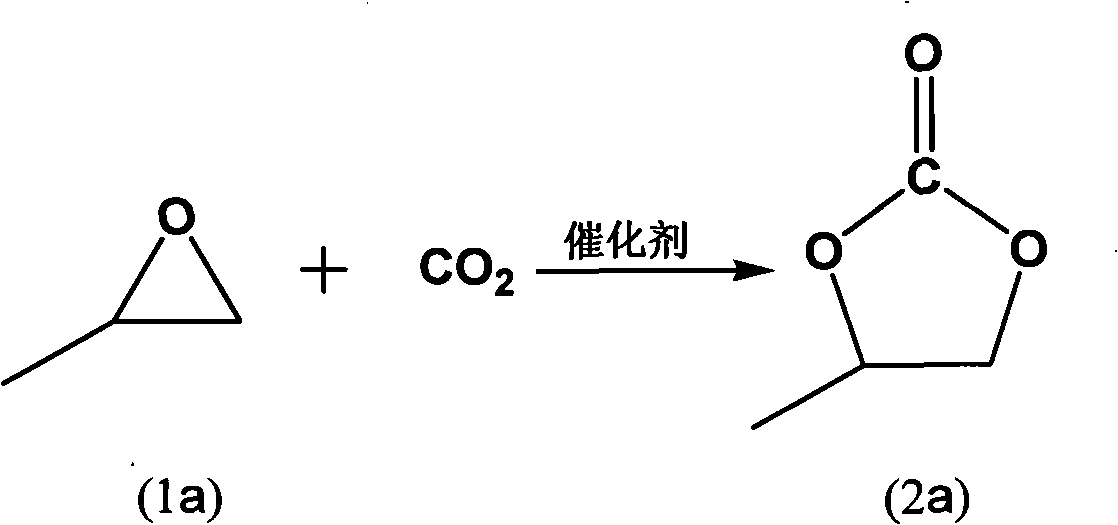

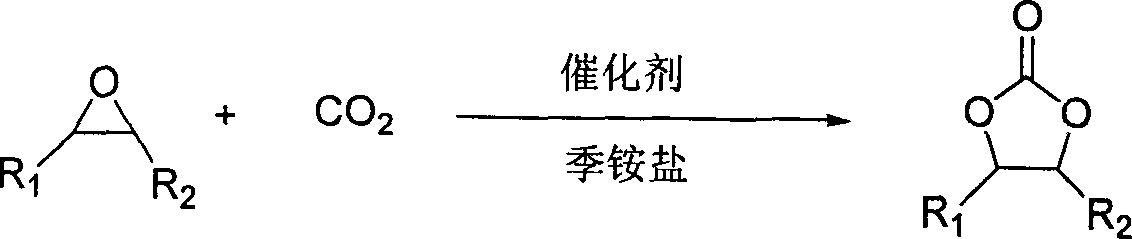

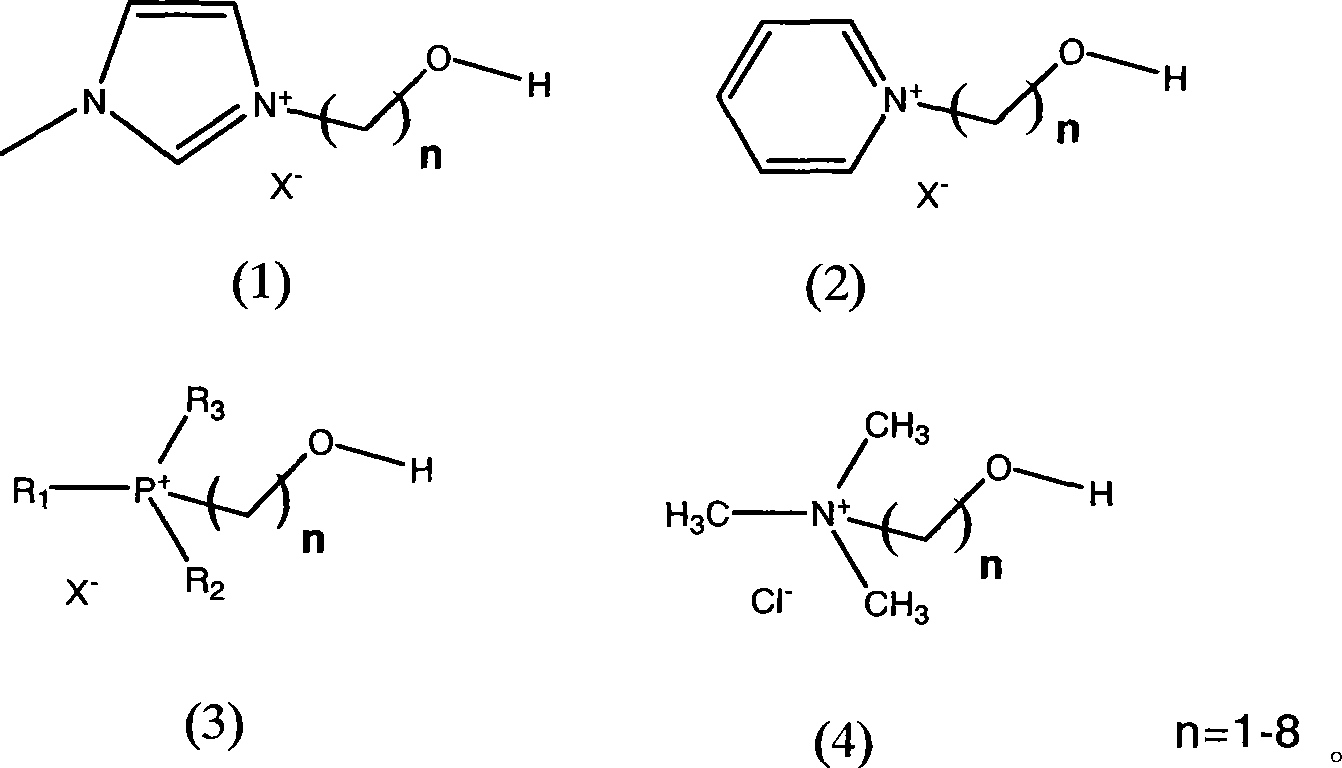

Process for synthesizing cyclic carbonate with catalysis of solid carried ion liquid catalyst

ActiveCN101318949AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveCarbonate ester

The invention relates to a method for synthesizing a cyclic carbonate ester by the catalysis of immobilized ionic liquid. The invention is characterized by utilizing a chemical method to prepare an immobilized ionic liquid catalyst. In the method, a mesoporous molecular sieve is used as a carrier; and the immobilized ionic liquid catalyst is prepared through different steps and catalyzes an epoxy compound to produce the cyclic carbonate ester. Compared with the prior immobilized catalyst, the immobilized catalyst is utilized to greatly improve a yield rate and selectivity in a short reaction time under a lower reaction temperature and a lower reaction pressure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparing method of poly (carbonic ester-ether) polyalcohol

ActiveCN102617844AIncreased content of carbonate unitsSuppression of continuous insertionCyanidePolyol

The invention discloses a preparing method of poly (carbonic ester-ether) polyalcohol. Rare-earth doped bi-metal cyanides based on Zn3[Co(CN)6]2 serve as catalysts, carboxylic acids serve as chain transfer agents, and carbon dioxide and epoxy compounds are performed with a copolymerization reaction to obtain the poly (carbonic ester-ether) polyalcohol. Compared with the prior art, the carboxylic acids serve as chain transfer agents, and due to the fact that the carboxylic acids are strong in coordination capability, faster in chain transfer, capable of restraining continuous inserting of epoxy monomers and free of ether structure, unit content of carbonic ester is improved, and the prepared poly (carbonic ester-ether) polyalcohol has higher carbonic ester unit content. Experimental results indicate that molecular weight of the prepared poly (carbonic ester-ether) polyalcohol is 1500g / mol-5000g / mol, molecular weight distribution is 1.11-1.50, unit content of the carbonic ester is 40%-80%, catalytic activity is larger than 1.0kg / gLn-DMC, and cyclic carbonic ester content is less than 10wt%.

Owner:南通华盛高聚物科技股份有限公司

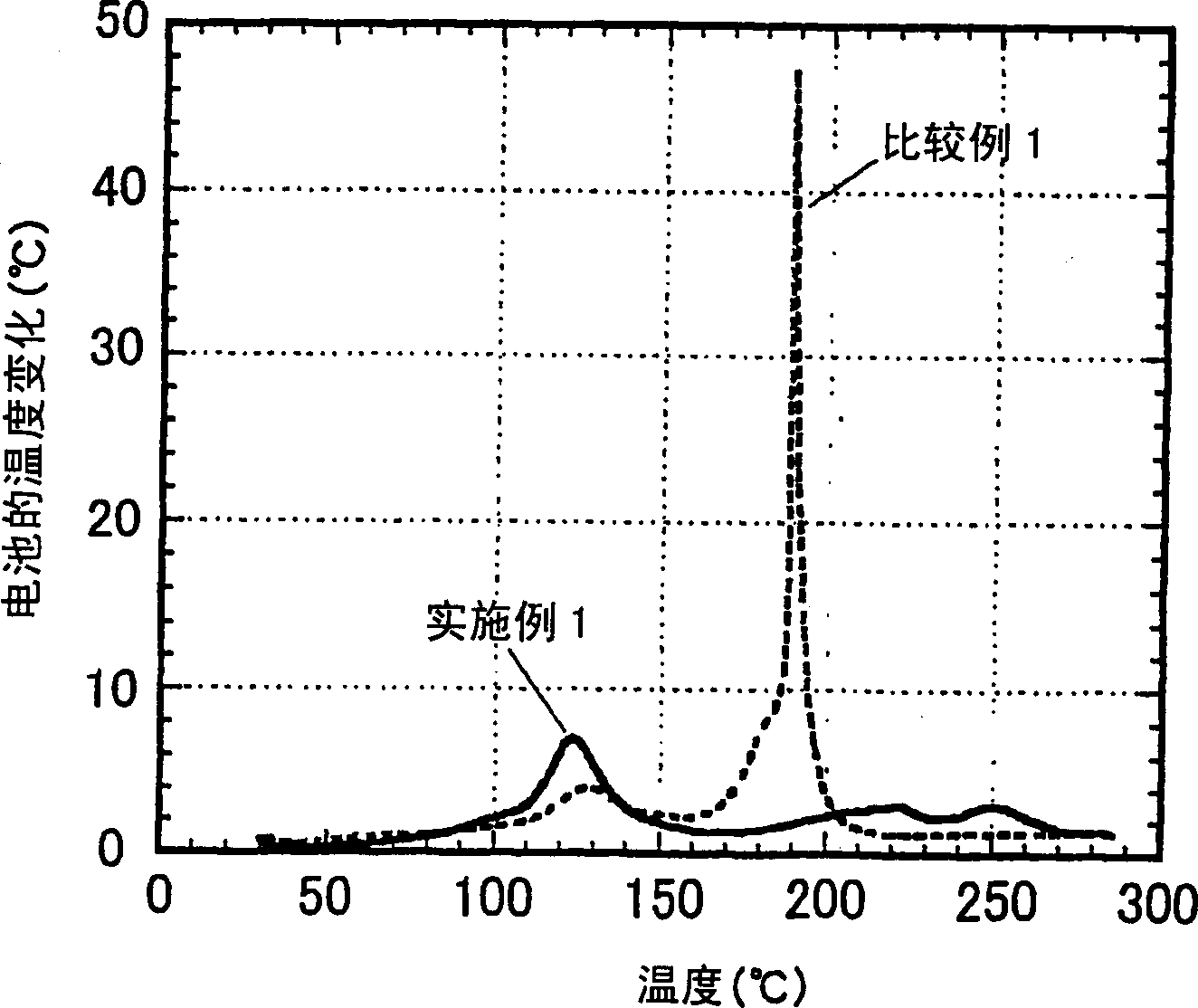

Thermopolymerizable composition for battery use

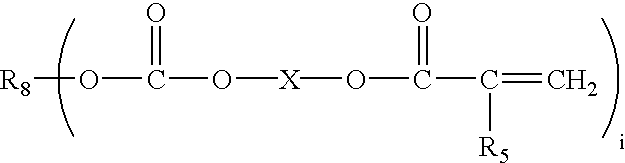

InactiveUS6562513B1Good storage stabilityHigh strengthCell electrodesFinal product manufactureMeth-Carbonate ester

The present invention provides (1) a thermopolymerizable composition containing a thermopolymerizable compound having (meth)acrylate having a moiety consisting of oxyalkylene, fluorocarbon, oxyfluorocarbon and / or carbonate group within the molecule, an electrolyte salt, an organic polymerization initiator having no benzene ring, and a polymerization retarder having vinyl group within the molecule, (2) a solid electrolyte obtained by heat-curing the composition, (3) a primary battery, a secondary battery and an electric double-layer capacitor each using the solid electrolyte, and processes for manufacturing the same.

Owner:SHOWA DENKO KK

Non-aqueous electrolyte for high-voltage lithium ion batteries

ActiveCN103268956ASimple compositionPromote circulationSecondary cellsHigh voltage batteryPropylene carbonate

The invention relates to a non-aqueous electrolyte for high-voltage lithium ion batteries, which is prepared from the following raw materials in percentage by weight: 70-85% of carbonate, 3-20% of functional additive and 11-17% of lithium hexafluorophosphate. The carbonate is one or mixture of more of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate, diethyl carbonate, dipropyl carbonate, methylethyl carbonate, methyl propyl carbonate and methyl butyl carbonate; and the functional additive is one or mixture of more of 0.5-10% of negative pole film-forming additive, 0.5-10% of high-temperature additive, 0.5-10% of positive pole film-forming additive, 0.5-10% of high-voltage additive and 0.001-2% of stability additive. The invention solves the problem of adaptation of the lithium ion battery electrolyte to the 4.35V high-voltage battery positive / negative pole, and provides an electrolyte for high-voltage batteries, which has the advantages of high cycle life, low inflation rate and favorable high-temperature properties.

Owner:广东金光高科股份有限公司

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

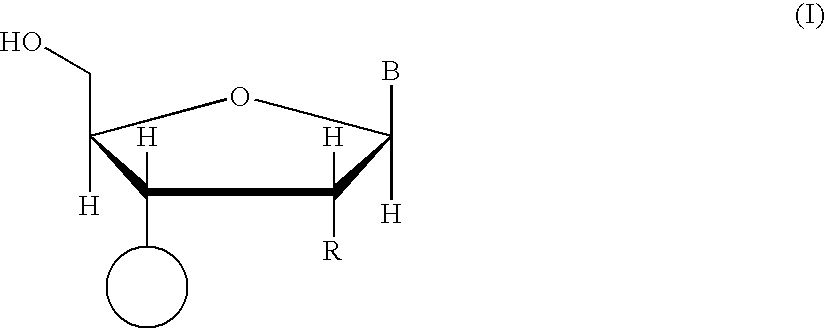

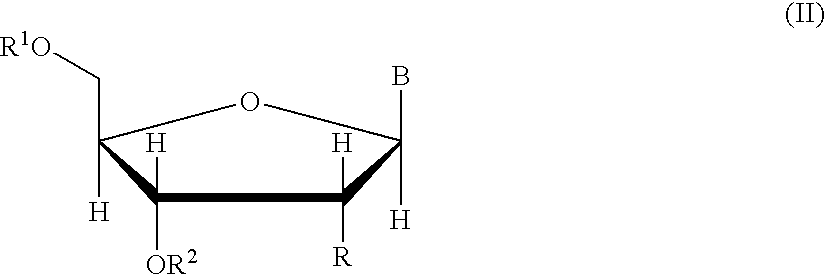

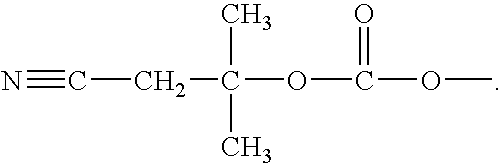

Methods of synthesizing oligonucleotides using carbonate protecting groups and alpha-effect nucleophile deprotection

The invention provides methods for synthesizing oligonucleotides using nucleoside monomers having carbonate protected hydroxyl groups that are deprotected with α-effect nucleophiles. The α-effect nucleophile irreversibly cleave the carbonate protecting groups while simultaneously oxidizing the internucleotide phosphite triester linkage to a phosphodiester linkage. The procedure may be carried out in aqueous solution at neutral to mildly basic pH. The method eliminates the need for separate deprotection and oxidation steps, and, since the use of acid to remove protecting groups is unnecessary, acid-induced depurination is avoided. Fluorescent or other readily detectable carbonate protecting groups can be used, enabling monitoring of individual reaction steps during oligonucleotide synthesis. The invention is particularly useful in the highly parallel, microscale synthesis of oligonucleotides.

Owner:AGILENT TECH INC +1

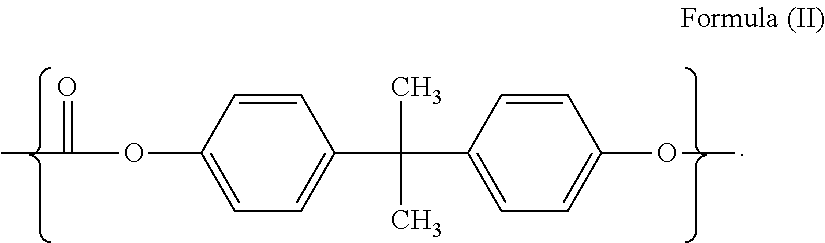

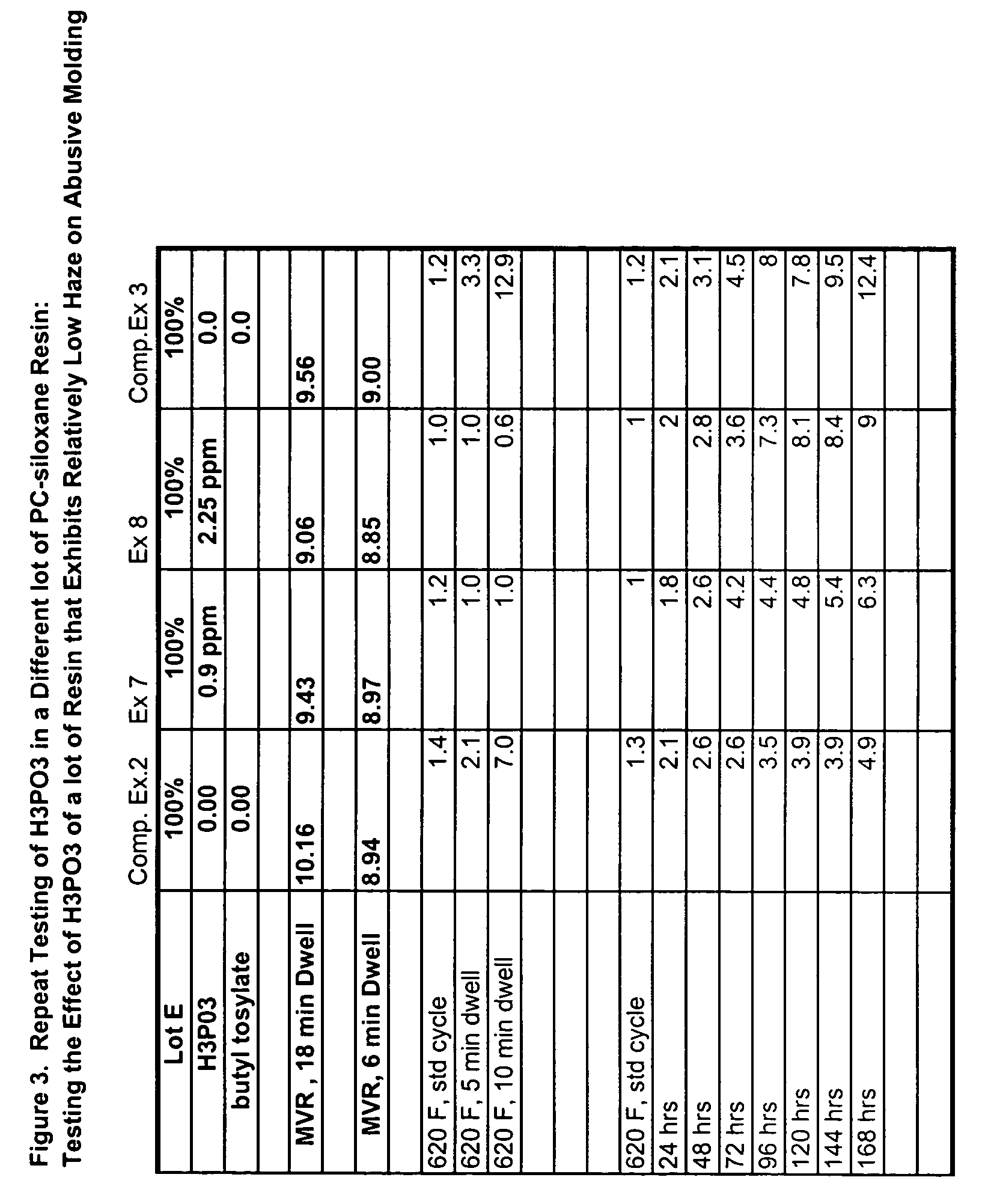

Low smoke polycarbonate composition, method of manufacture and product made therefrom

A composition containing a polycarbonate, a polycarbonate-polysiloxane copolymer, an impact modifier, and a polyetherimide, wherein the polycarbonate comprises greater than or equal to about 50% by weight of the combined weights of the polycarbonate, polycarbonate-polysiloxane copolymer, impact modifier and polyetherimide and wherein a 3.2 millimeter thick, 7.6 centimeter square sample of the composition produces a smoke density (Ds) of less than 275 after a 4-minute burn, measured according to ASTME 662-03. In one embodiment, a composition may contain about 60 to about 85 wt. % polycarbonate, about 8 to about 20 wt. % polycarbonate-polysiloxane copolymer, about 0.5 to about 20 wt. % impact modifier, and about 1 to about 10 wt. % polyetherimide.

Owner:SABIC GLOBAL TECH BV

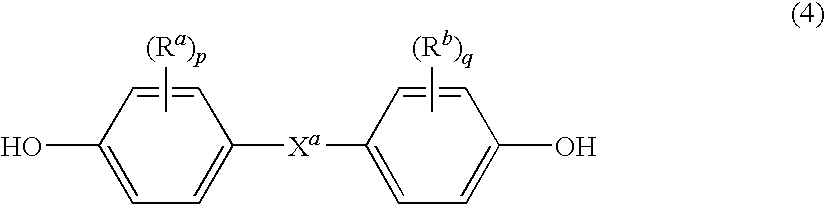

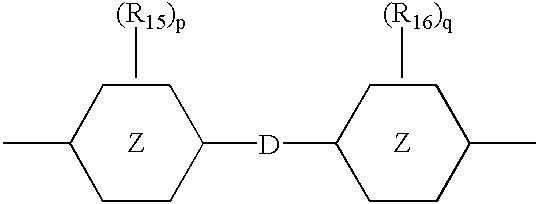

Clear silicone polycarbonate elastomeric copolymers

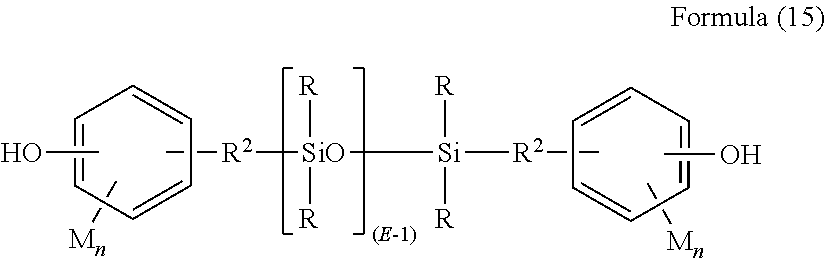

Silicone polycarbonate block copolymers are disclosed that have a high elongation before yield, are clear, and have elastomeric properties. Generally, the silicone blocks are very short (less than about 50 organosiloxane repeat units) and the silicone blocks are substantially isolated from each other by bisphenol carbonate spacers.

Owner:SHPP GLOBAL TECH BV

Process to make polycarbonate from bismethylsalicylcarbonate (BMSC)

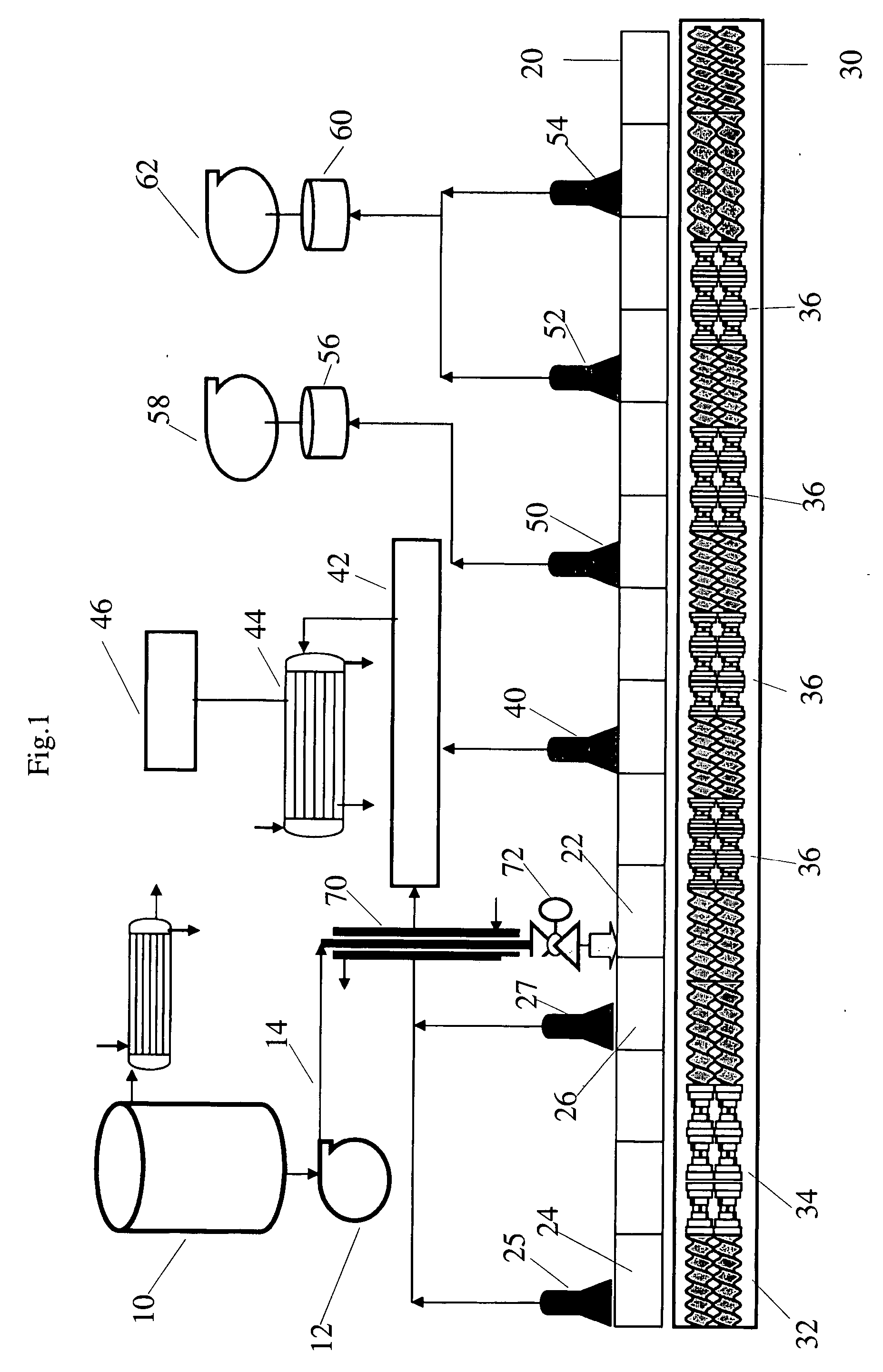

ActiveUS20060069228A1Superior polycarbonate productionMinimizing residence timeCeramic shaping apparatusTrans esterificationPolymer science

The present invention relates to a method of preparing polycarbonate comprising the steps of: (i) introducing to an extruder through a feed port a plurality of reaction components comprising a polycarbonate oligomer, an activated carbonate residue, and a transesterification catalyst, wherein the extruder comprises the feed port, a first back vent port, and a polycarbonate exit port, wherein the feed port is located between the first back vent port and the polycarbonate exit port, and wherein the resistance to flow of the reaction components from the feed port to the first back vent port is less than or equal to the resistance to flow of the reaction components from the feed port to the polycarbonate exit port; and (ii) extruding the reaction components at one or more temperatures in a range between 100° C. and 400° C., wherein during the extrusion of the reaction components, activated carbonate residue is removed through the first back vent port, thereby preparing a polycarbonate.

Owner:SHPP GLOBAL TECH BV

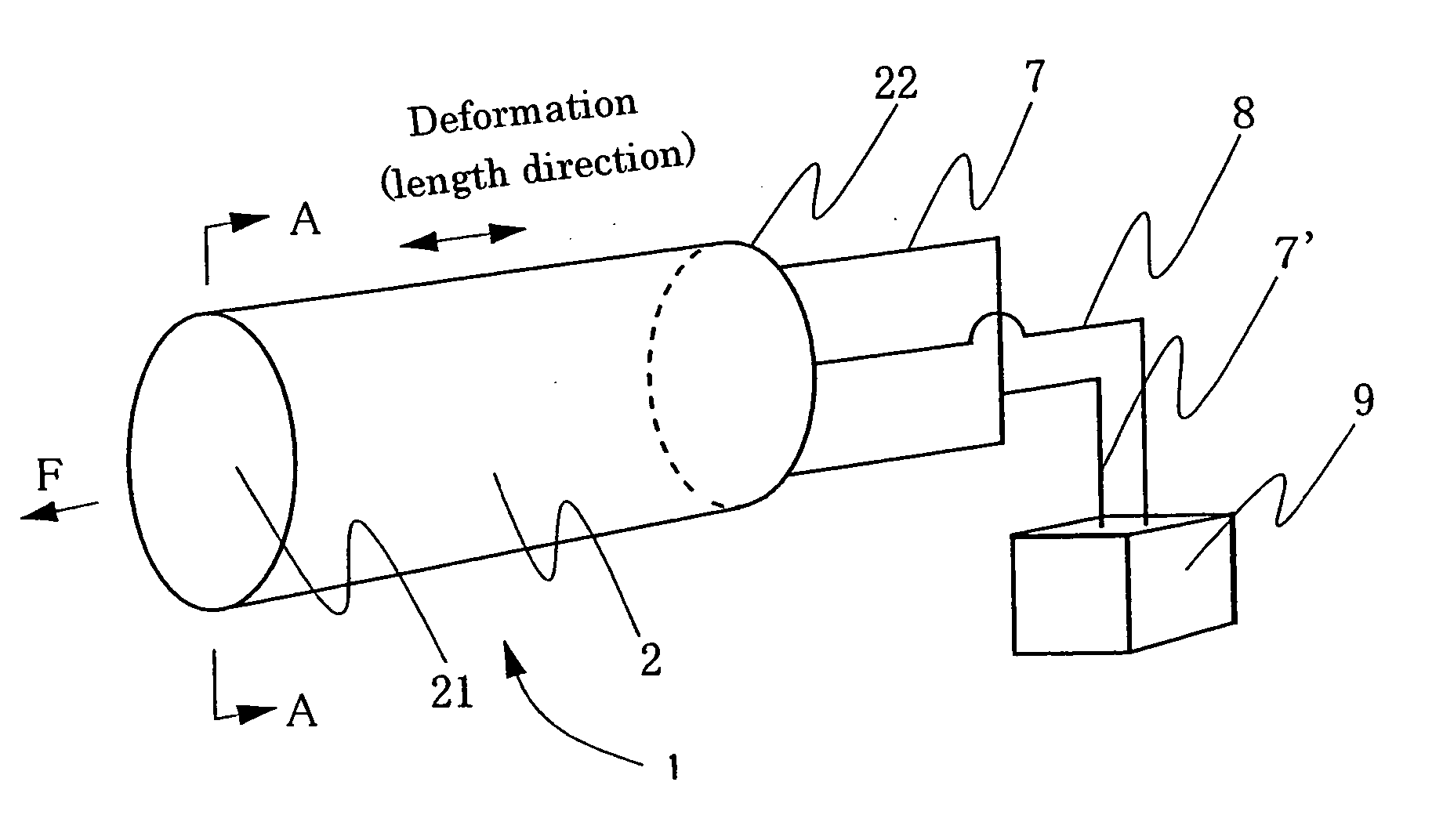

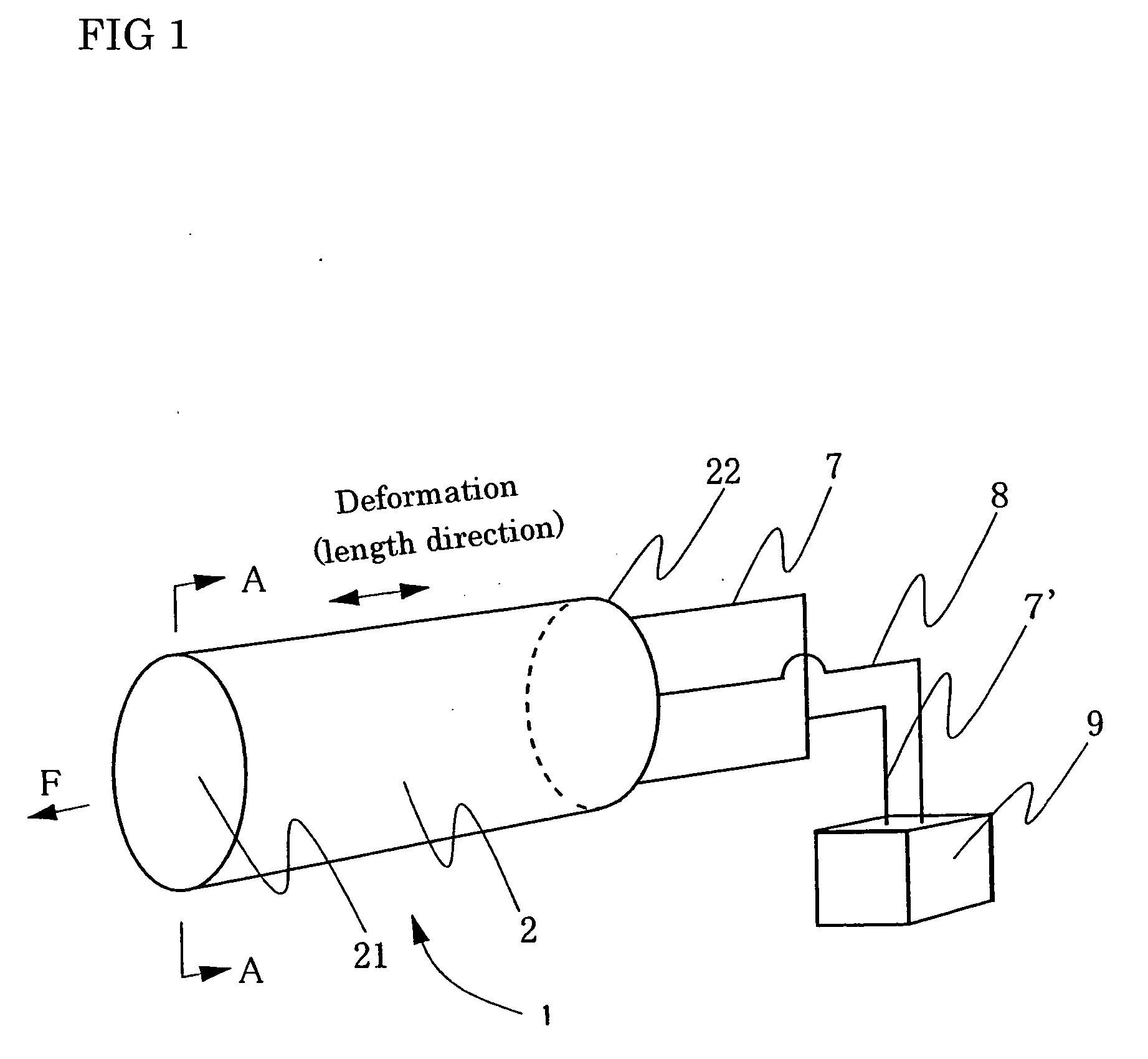

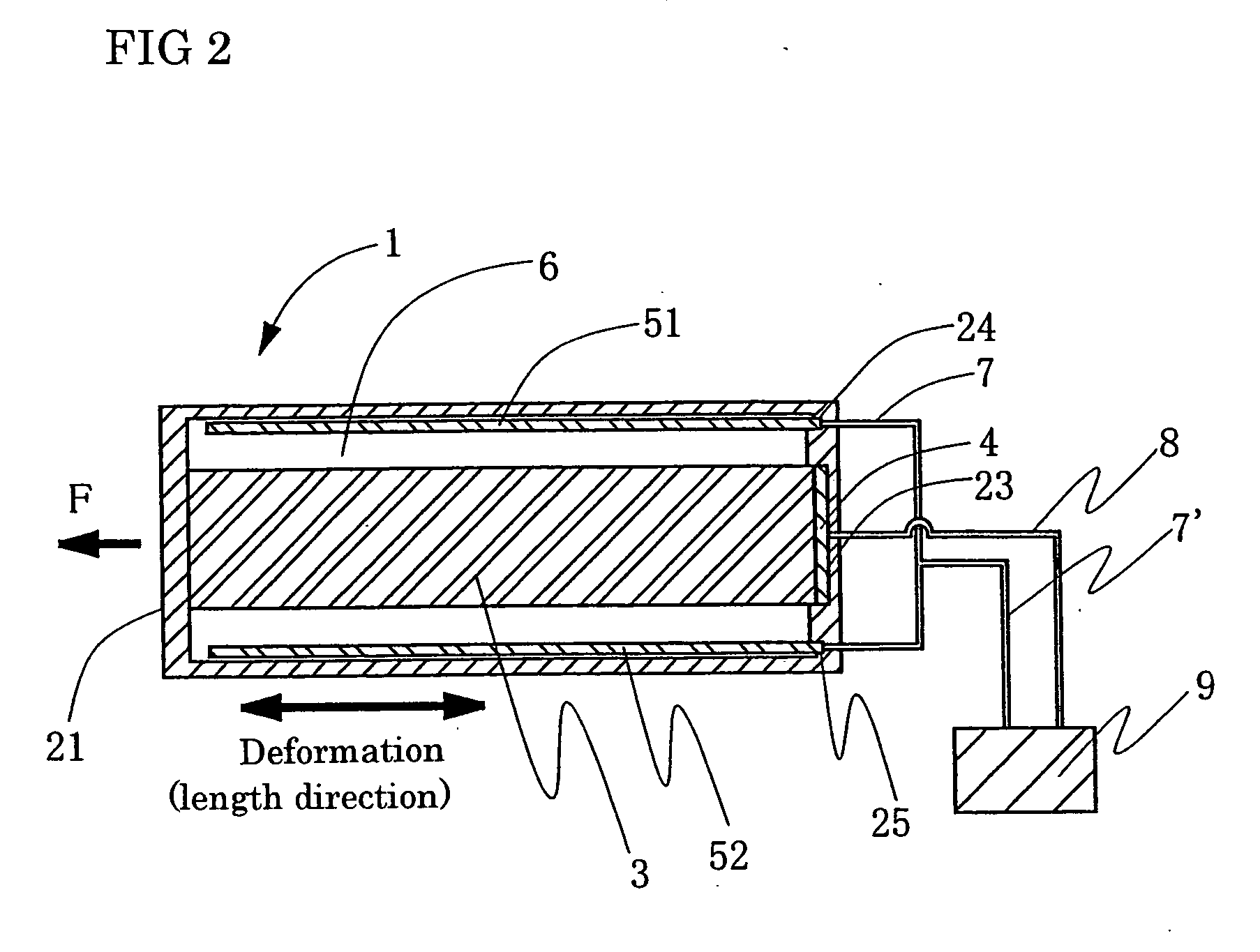

Process for producing conductive polymer

A process for producing conductive polymers with excellent electrochemical strain per redox cycle is provided. A process for producing conductive polymers by an electrochemical polymerization method, wherein said conductive polymers have deformation property by electrochemical redox, said electrochemical polymerization method is a polymerization method using electrolyte including organic compounds as solvents, and wherein said organic compounds include (1) chemical bond species selected at least one from a group composed of the chemical bond consisting of ether bond, ester bond, carbon-halogen bond, and carbonate bond and / or (2) functional groups selected at least one from a group composed of functional groups consisting of hydroxyl group, nitro group, sulfone group, and nitryl group in a molecule, and said electrolyte includes anions which include trifluoromethanesulfonate ion and / or plural of fluorine atoms which bond to central atom is used.

Owner:EAMEX

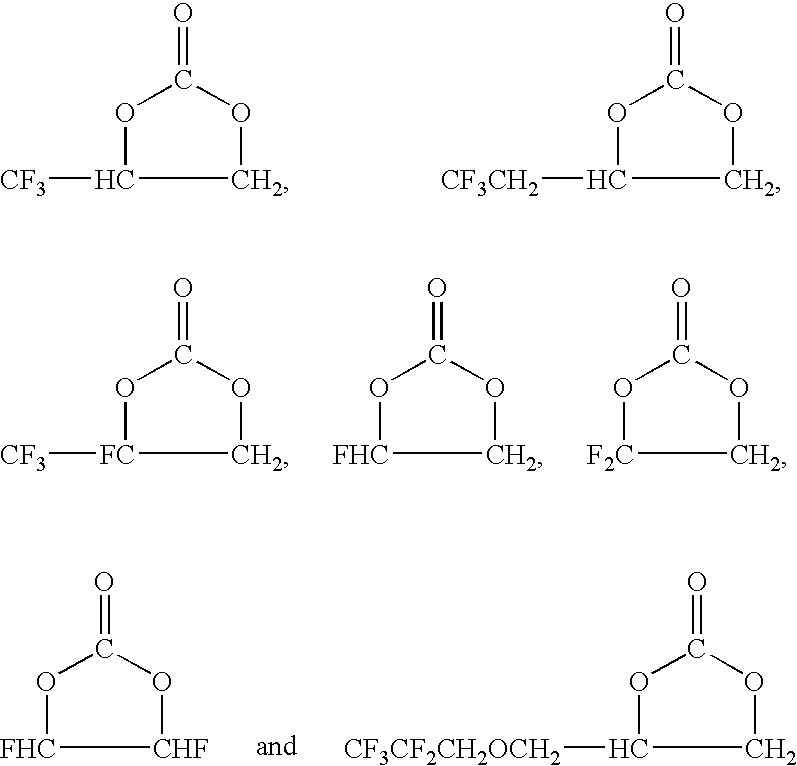

Non-aqueous electrolytic solution

ActiveUS20100062344A1Excellent non-flammabilitySuitableOrganic electrolyte cellsPositive electrodesLithiumSolvent

There is provided a non-aqueous electrolytic solution comprising an electrolyte salt, a specific fluorine-containing solvent and a fluorine-containing cyclic carbonate represented by the formula (A1):wherein X1 to X4 are the same or different and each is —H, —F, —CF3, —CHF2, —CH2F, —CF2CF3, —CH2CF3 or —CH2OCH2CF2CF3; at least one of X1 to X4 is —F, —CF3, —CF2CF3, —CH2CF3 or —CH2OCH2CF2CF3, and the non-aqueous electrolytic solution has further excellent noncombustibility and is suitable for lithium secondary batteries.

Owner:DAIKIN IND LTD

Nonaqueous electrolytic liquid and lithium secondary battery employing same

InactiveCN1411619AExcellent charge and discharge characteristicsImprove conductivityOrganic electrolyte cellsNegative electrodesPhosphoric Acid EstersCarbamate

Nonaqueous electrolytic liquids for lithium secondary batteries which have flame retardancy (self-extinguishing characteristics) or incombustibility (no flash point), have a high conductivity, and are electrochemically stable. One of the nonaqueous electrolytic liquids comprises a nonaqueous solvent comprising as an essential ingredient at least one phosphate (a) selected among chain phosphoric esters (a1) and cyclic phosphoric esters (a2). The nonaqueous solvent may further contain a cyclic carboxylic ester (b1) and a cyclic carbonic ester (b2). Another nonaqueous electrolytic liquid comprises the nonaqueous solvent and incorporated therein at least either a vinylene carbonate compound (c1) or a vinylethylene carbonate compound (c2) and one or more compounds selected from the group consisting of cyclic amide compounds (d1), cyclic carbamate compounds (d2), and cyclic hetero-compounds (d3).

Owner:MITSUBISHI RAYON CO LTD

Aliphatic diol-based polycarbonates, method of making, and articles formed therefrom

Owner:SABIC INNOVATIVE PLASTICS IPBV

Process for the start-up of an epoxidation process, a process for the production of ethylene oxide, a 1,2-diol, a 1,2-diol ether, a 1,2-carbonate, or an alkanolamine

InactiveUS20090281339A1Improve catalytic selectivityHigh selectivityProductsOrganic compound preparationOrganic chloride compoundOxygen

A process is provided for the start-up of an ethylene epoxidation process comprising: (a) contacting a catalyst bed comprising a high selectivity epoxidation catalyst with a feed comprising ethylene, oxygen and an organic chloride for a period of time until an increase of at least 1×10−5 mole-% of vinyl chloride (calculated as the moles of vinyl chloride relative to the total gas mixture), preferably 2×10−5 mole-% of vinyl chloride is detected in a reactor outlet gas or a recycle gas loop; and (b) subsequently adjusting the quantity of organic chloride in the feed to a value sufficient to produce ethylene oxide at a substantially optimum selectivity.

Owner:SHELL OIL CO

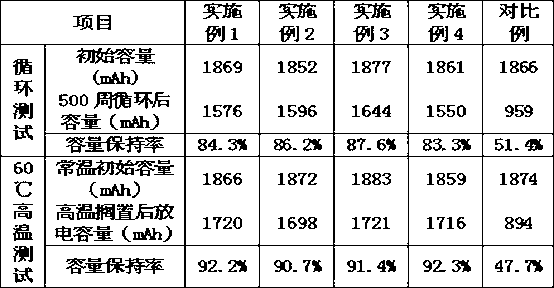

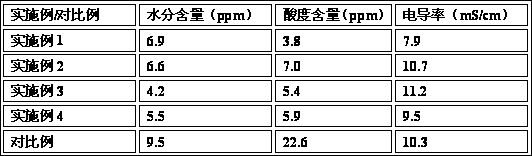

Lithium ion battery electrolyte with both high and low temperature performances

The invention relates to the technical field of lithium ion electrolytes, and in particular relates to a lithium-ion battery electrolyte with both high and low temperature performances. The electrolyte comprises lithium hexafluorophosphate, mixed organic solvents, filming additives, additives for improving the dielectric constant and the low temperature infiltration capability, and a lithium salt type additive, wherein the mixed organic solvents comprise a carbonic ester solvent and a linear carboxylic ester solvent; the linear carboxylic ester solvent in the mixed organic solvents is one or a mixture of more than two of ethyl propionate, propionic acid n-propyl ester, n-propyl acetate, acetic acid n-butyl ester and isobutyl acetate; and the additives for improving the dielectric constant and the low temperature infiltration capability are one or a mixture of more than two of fluoro ethylene carbonate, difluoro ethylene carbonate and 4-trifluoromethyl ethylene carbonate. A battery prepared from the lithium-ion battery electrolyte with both high and low temperature performances is long in service life, and both the good low temperature discharge performance of the battery is ensured, and the storage performance of the battery at the high temperature of 60 DEG C is effectively considered.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

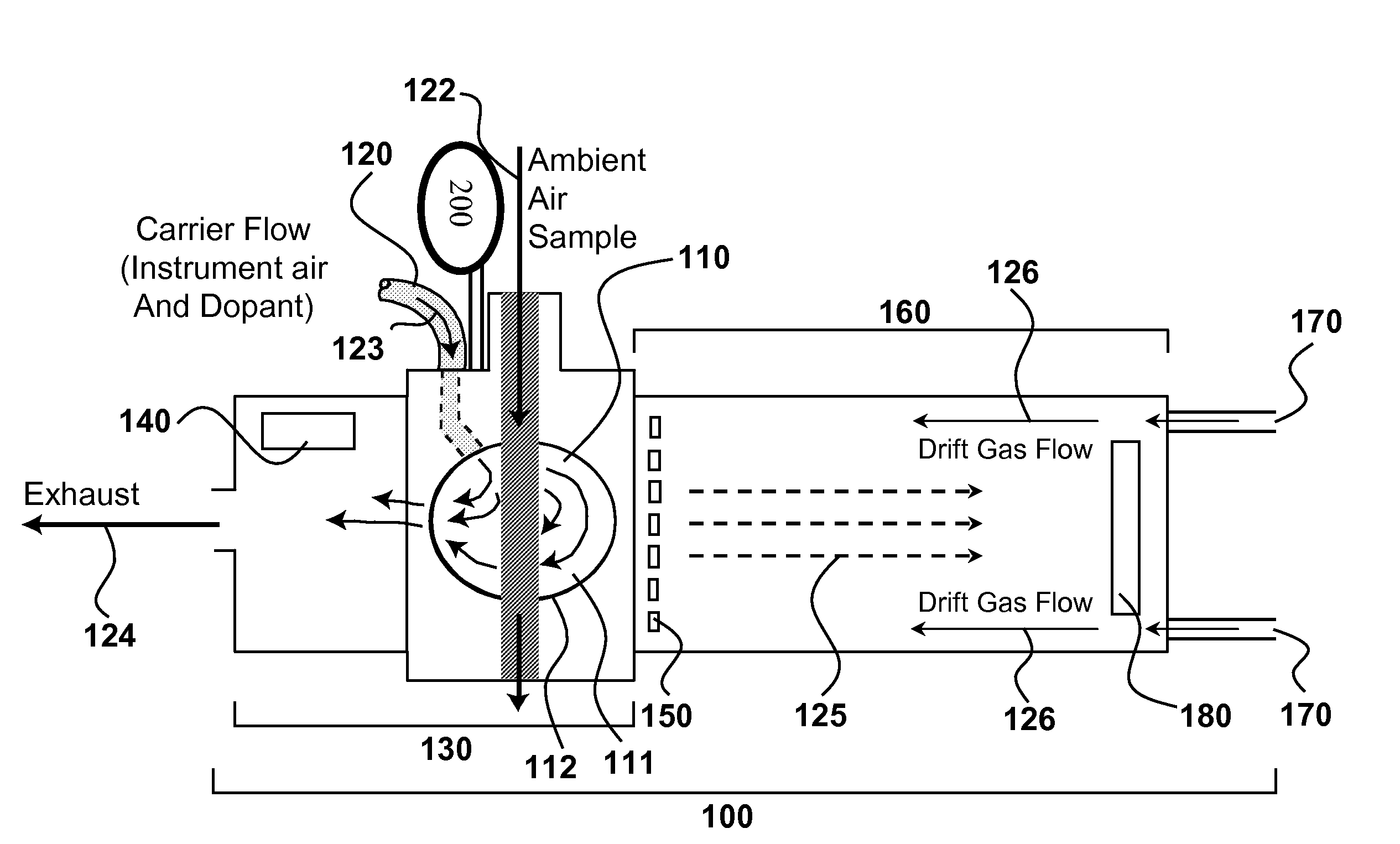

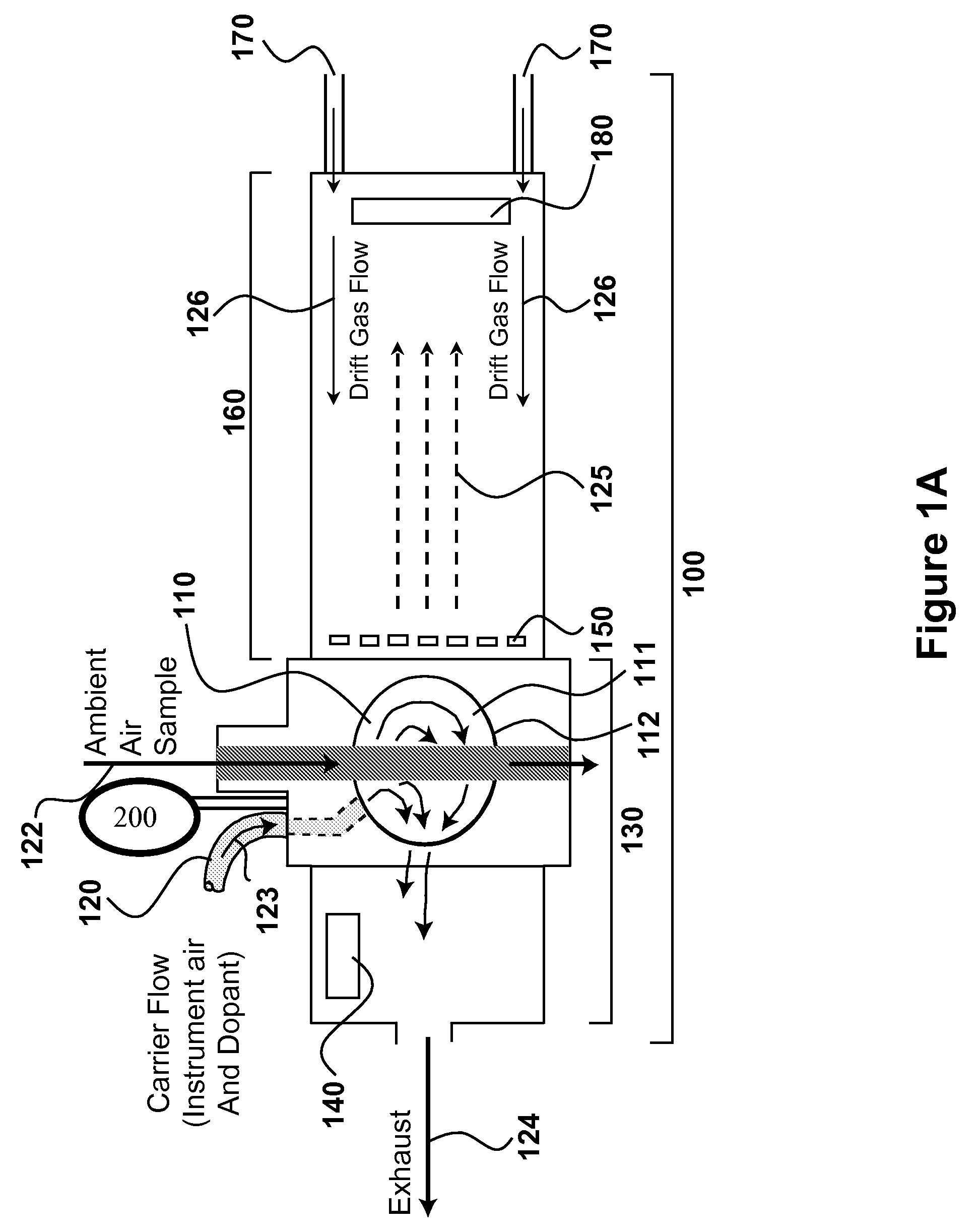

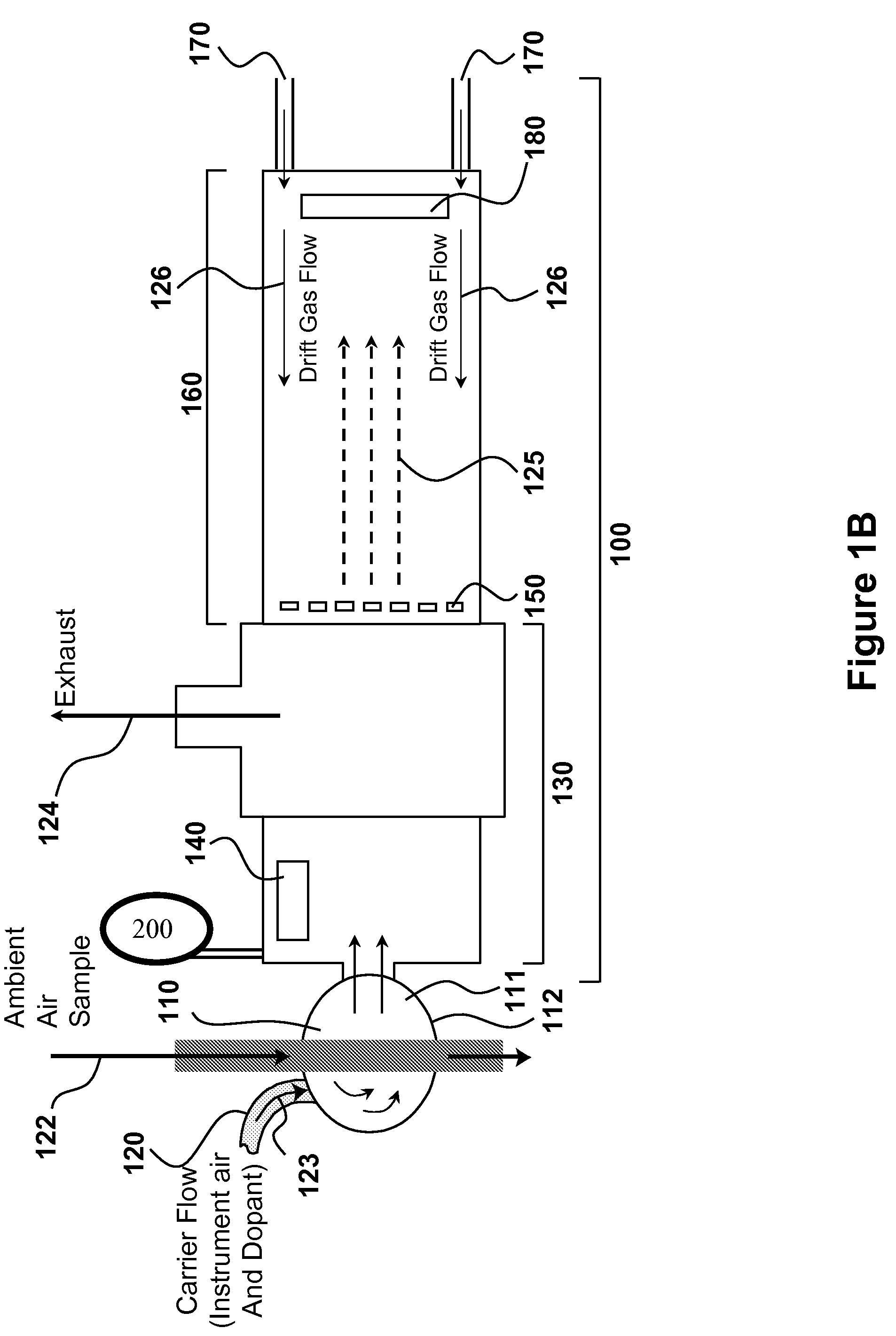

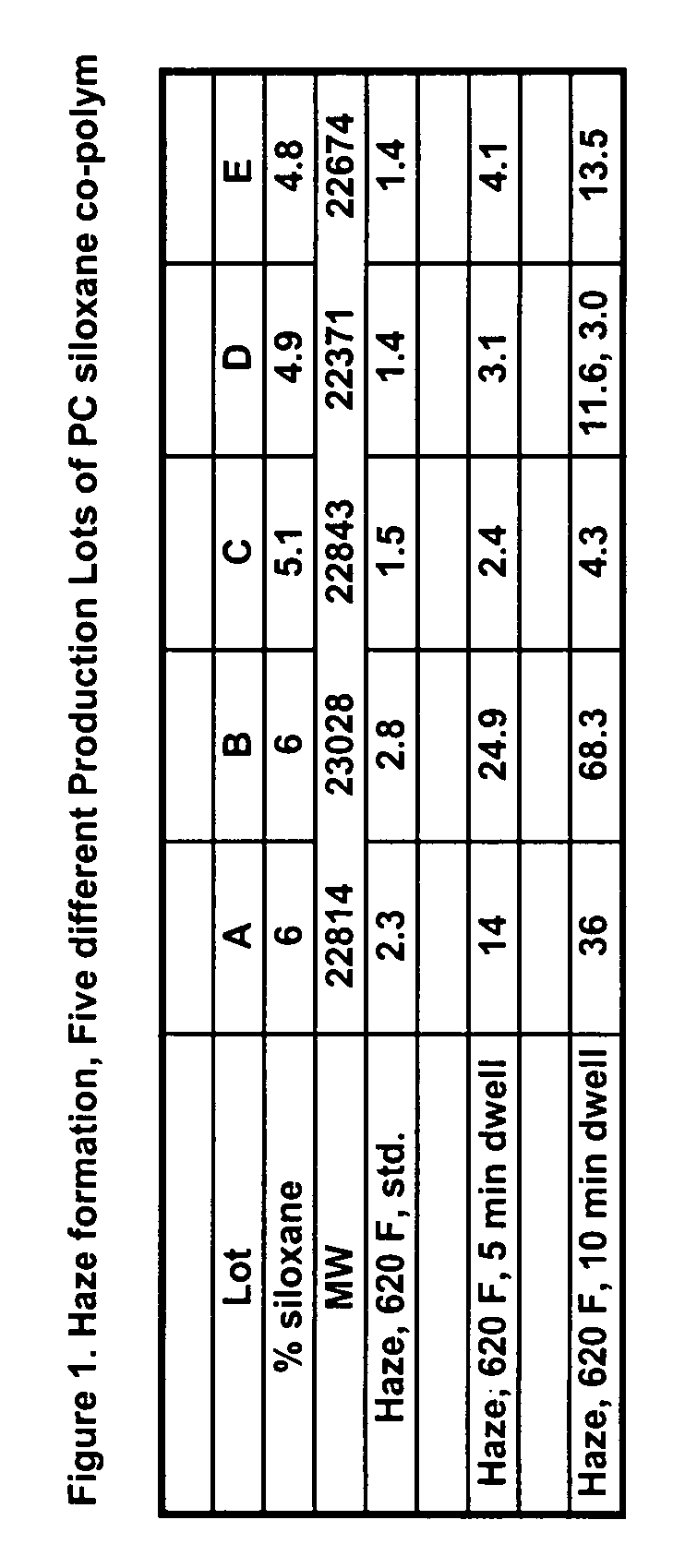

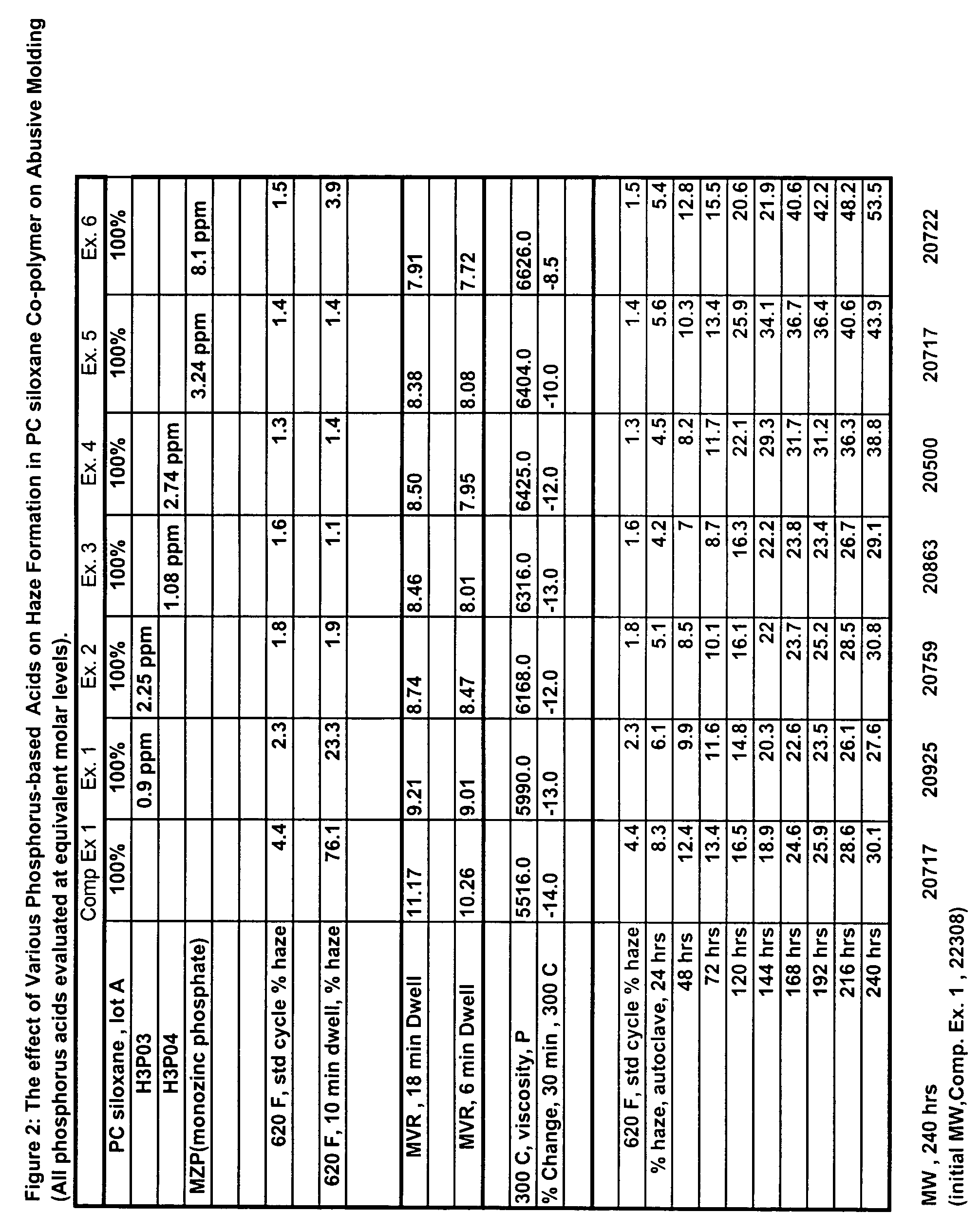

Ion mobility spectrometry analyzer for detecting peroxides

InactiveUS20090078862A1Improved sensitivity and selectivityAccurate measurementParticle separator tubesMaterial analysis by electric/magnetic meansCarboxylic acidIon-mobility spectrometry

The present invention provides IMS analyzers and methods for detecting, identifying, and characterizing (e.g., measuring the concentration of) peroxides in samples. Methods and systems of the present invention utilize sample inlet conditions and dopant strategies providing an enhancement in selectivity and sensitivity for the detection of peroxide compounds relative to conventional IMS analyzers. Dopants of the present invention include, but are not limited to, substituted aryl compounds or substituted cyclic dienes; wherein the substituted aryl compound or the substituted cyclic diene has at least one substituent selected from the group consisting of a hydroxyl group, a carbonyl group, an aldehyde group, an ester group, a carboxylic acid group and a carbonate ester group. The present IMS analyzers and methods are versatile and enable selective detection of a broad class of peroxides and derivatives thereof, including hydrogen peroxide, hydroperoxides, organic peroxides and derivatives thereof.

Owner:PARTICLE MEASURING SYST

Transparent and high-heat polycarbonate-polysiloxane copolymers and transparent blends with polycarbonate and a process for preparing same

Owner:SHPP GLOBAL TECH BV

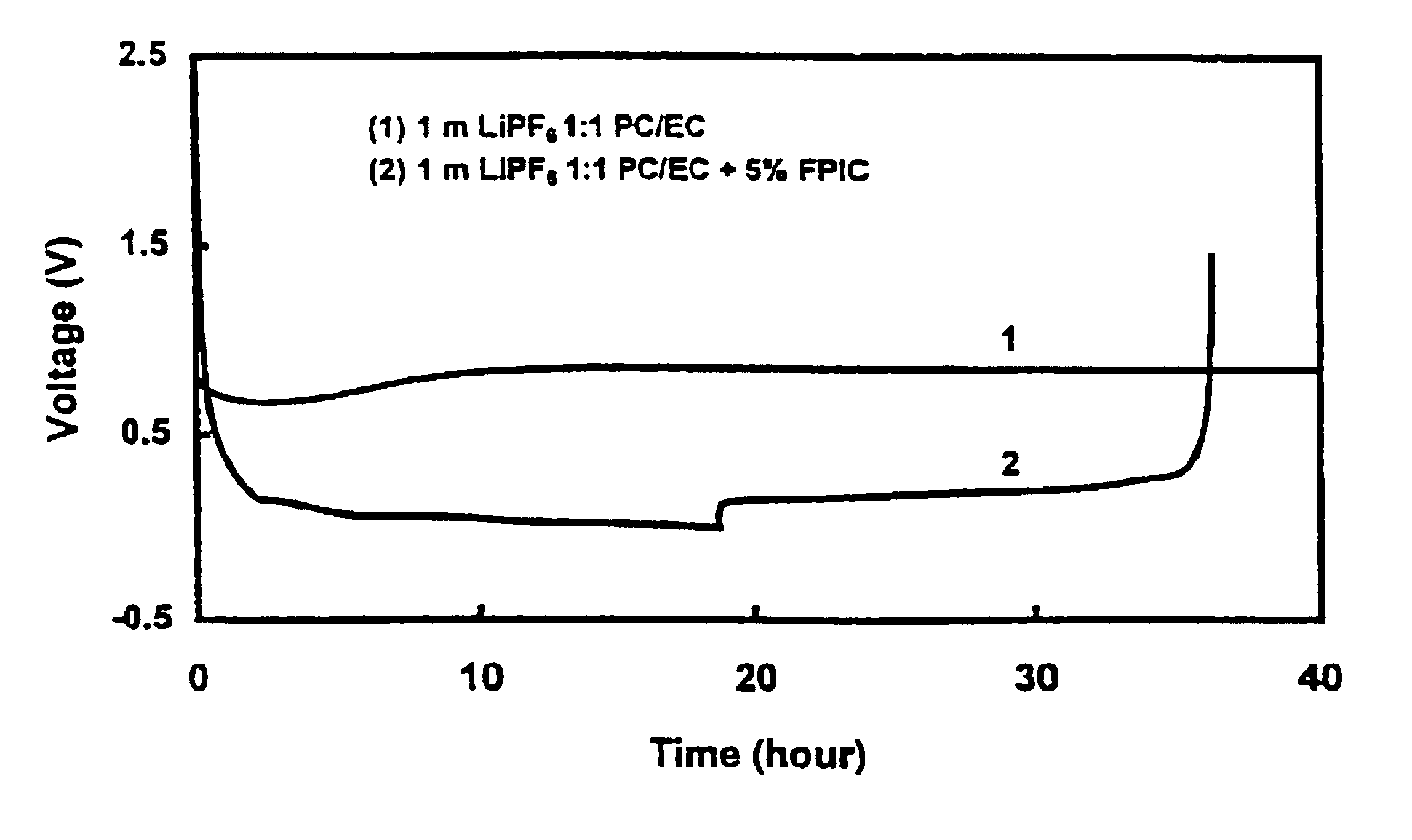

Non-aqueous electrolyte solutions comprising additives and non-aqueous electrolyte cells comprising the same

InactiveUS6905762B1Improve abilitiesImprove protectionOrganic electrolyte cellsSolid electrolyte cellsHydrogen atomHydrogen

A non-aqueous electrolyte to be used in a Li-ion battery includes a lithium salt, a cyclic carbonate, a linear carbonate and an isocyanate-based additive, with the following general formulaR1—N═C═Owherein R1 represents linear or branched alkyl groups which have 1 to 7 carbon atoms, or aromatic groups having the following general formula wherein R2 and R3, which may be the same or different and located at any positions of carbons 2, 2′, 3, 3′ and 4 in the benzyl ring, represent hydrogen atoms or halogen atoms, isocyanate groups, either groups, ester groups or alkyl groups, having 1 to 3 carbon atoms, and are optionally substituted with halogen atoms.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Electrochemical device

InactiveUS20060210876A1Excellent in charge-discharge cycle characteristicHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorLamellar crystalsHydrogen atom

An electrochemical device includes a case, a nonaqueous electrolyte filled in the case and containing a room temperature molten salt in an amount of 1 to 50 vol %, a first electrode housed in the case, and a second electrode housed in the case and containing a substance having a lamellar crystal structure. The room temperature molten salt contains a cation represented by formula (1) or formula (2) given below. R1 includes a carbonic acid ester group. Each of R2 and R3 denotes a substituent having an acyclic structure and having 4 or less carbon atoms, or R2 and R3 are combined to denote a substituent having a cyclic structure and having 4 or 5 carbon atoms. R4 includes a carbonic acid ester group, R5 has an acyclic structure and has 4 or less carbon atoms, and R6 denotes a hydrogen atom or a methyl group.

Owner:KK TOSHIBA

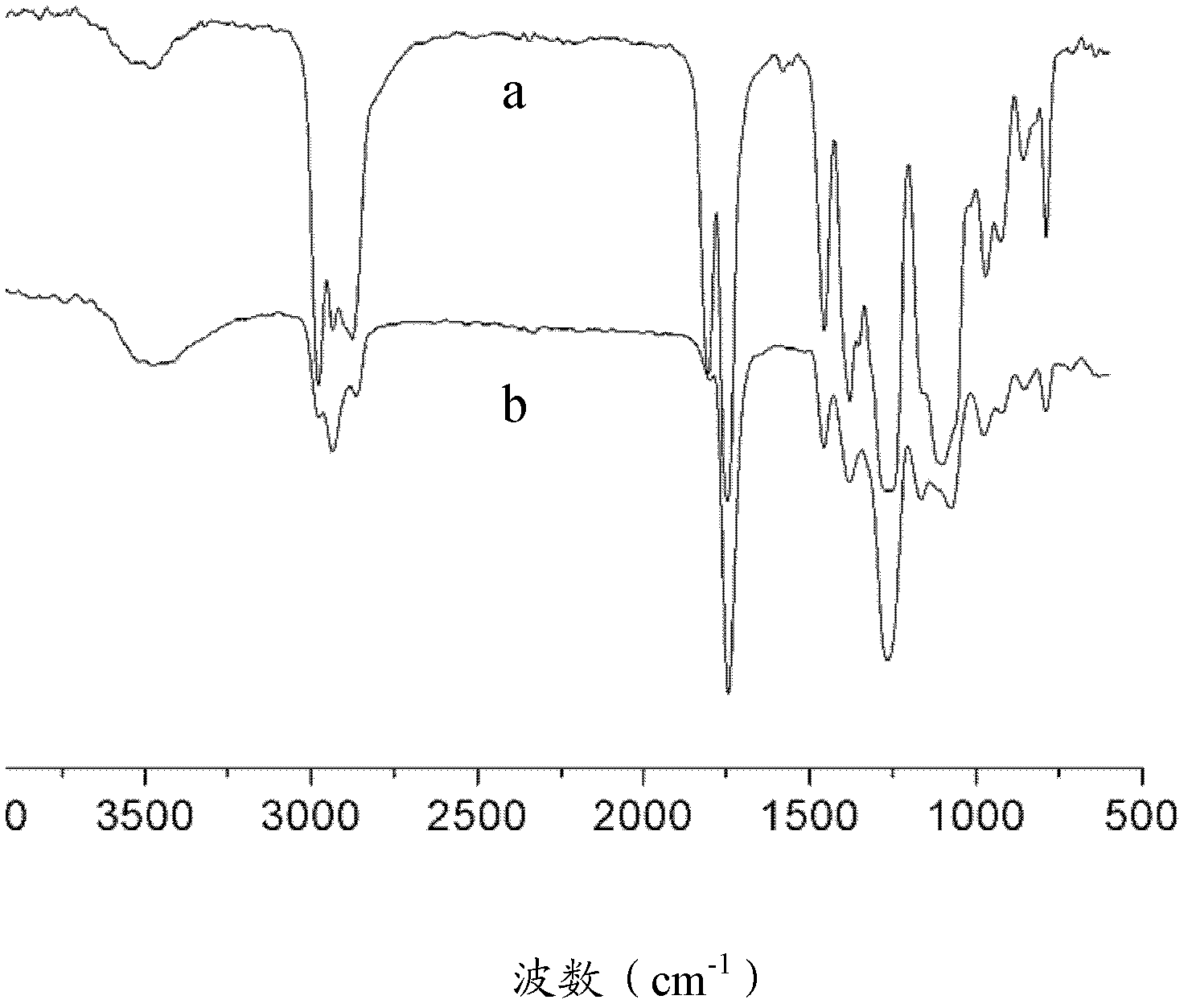

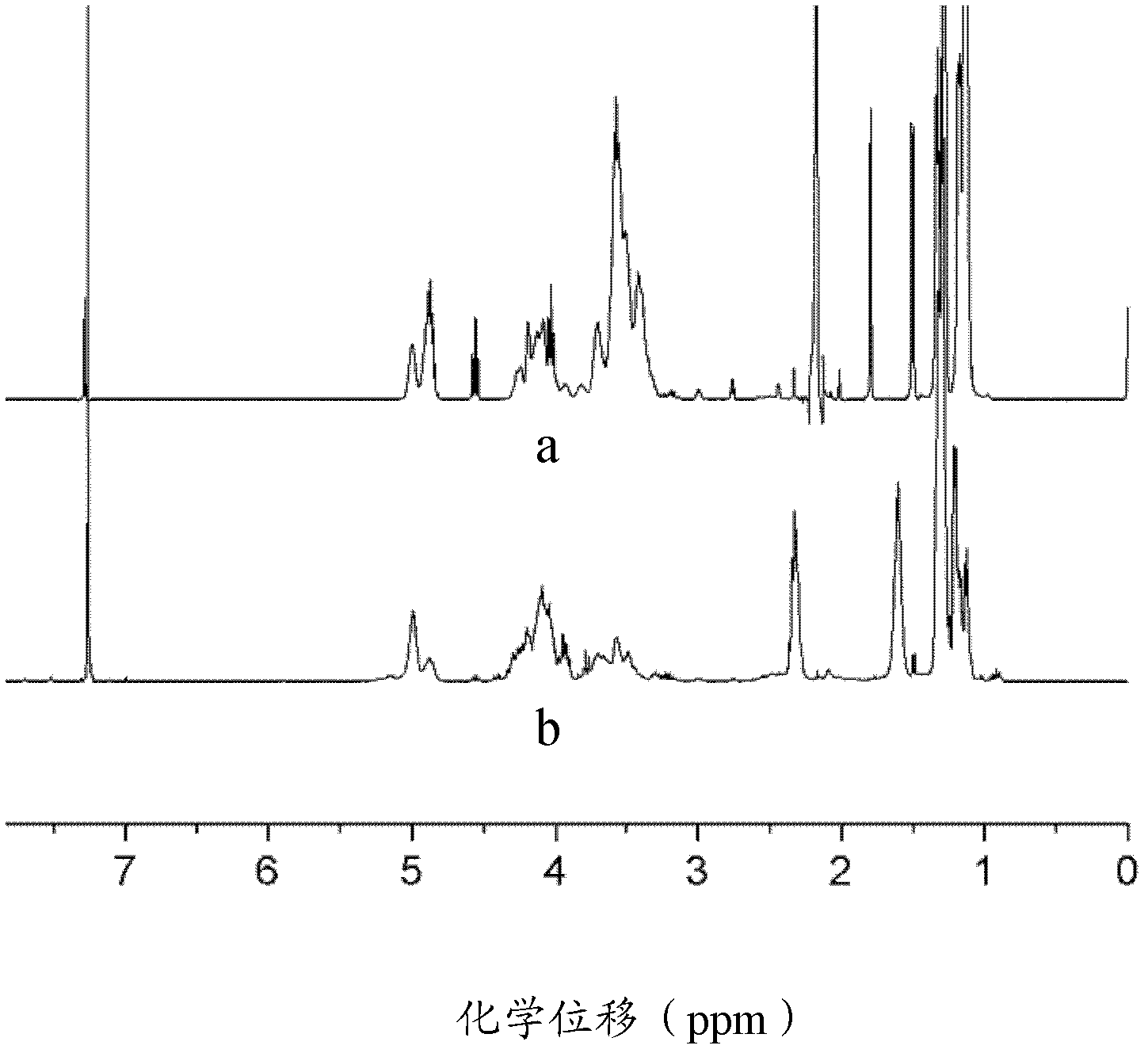

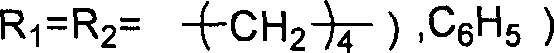

Method for synthesizing cyclic carbonate from carbon dioxide and epoxy compound through reaction of cycloaddition

ActiveCN1796384AMild reaction conditionsSimple processOrganic chemistryChemical recyclingOrganic solventSynthesis methods

This invention relates to a cycloaddition synthesis method for cyclic carbonates from carbon dioxide and epoxides. In this method, both supported catalysts and cocatalysts are adopted and the cycloaddition reaction is kept at a temperature of 50~200 deg.C and a carbon dioxide pressure of 0.1~10MPa for 0.5~10 hours. Qualitative and quantitative analysis with 6890 / 5973 chromatography-MS and NMR shows that the product purity is over 99% and the highest separation yield can be up to 95%. Compared to current methods, no organic solvents are adopted in this invention and therefore it is free from the toxicity of bezene, dichloromethane, and so on.

Owner:江苏华昌新材料技术研究有限公司

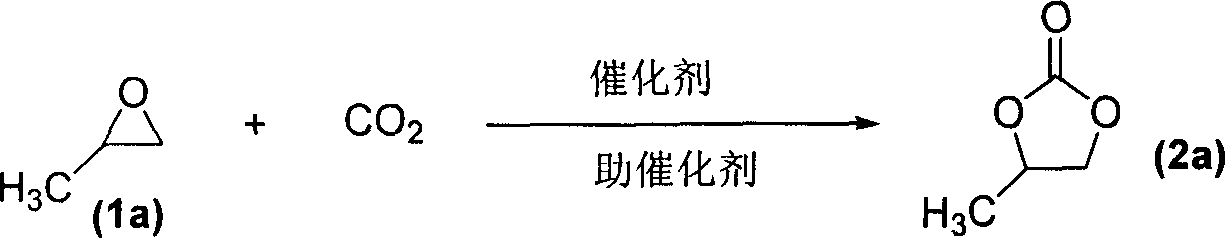

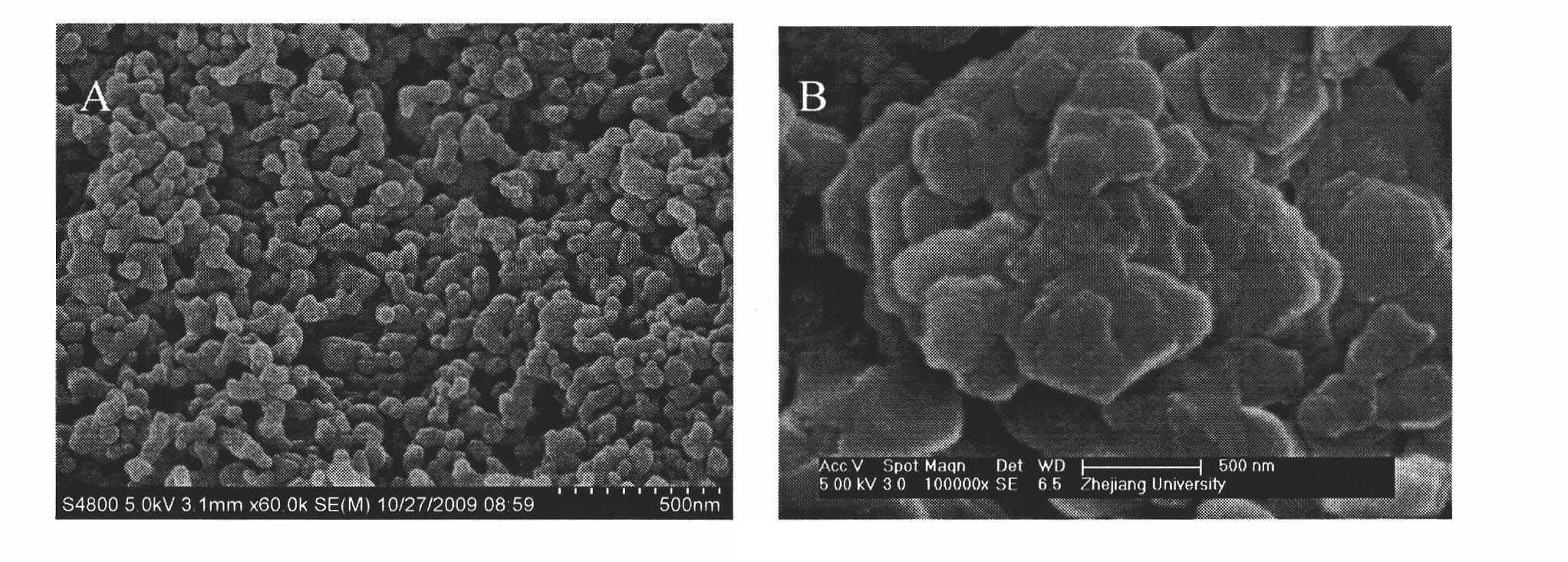

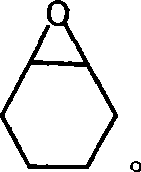

Method for preparing aliphatic polycarbonates by catalyzing by metal cyanide coordination catalyst

The invention discloses a method for preparing aliphatic polycarbonates by catalyzing by the metal cyanide coordination catalyst. In a high pressure reactor, the metal cyanide coordination catalyst is utilized to catalyze epoxide and carbon dioxide body or solution copolymerization, wherein, the copolymerization temperature is 20-150 DEG C; the carbon dioxide pressure is 0.5-10MPa; the reaction time is 1-48h; the catalyst concentration is 1-100kg epoxide / g catalyst; the polymerization activity is more than 1.0kg of polymer / g catalyst; the weight-average molecular weight of the copolymer is more than 80 thousand; the molecular weight distribution is 1.5-4; the alternation degree of the copolymer is more than 90%; the cyclic carbonate by-product is less than 5wt%; the CO2 fixed rate of CO2 / epoxypropane copolymer is more than 40wt%; and the CO2 fixed rate of CO2 / cyclohexene oxide copolymer is more than 30wt%.

Owner:ZHEJIANG UNIV

Process for producing polycarbonates and a coordination complex used therefor

ActiveUS8163867B2Silicon organic compoundsIsocyanic acid derivatives preparationPolymer scienceCarbonate ester

The complex of the present invention containing an onium salt and a central Lewis acidic metal has a high catalytic activity at a high temperature for the copolymerization of an epoxide and carbon dioxide to produce a high molecular weight poly-carbonate.

Owner:SK INNOVATION CO LTD

Method for producing ring carbonic acid ester with hydroxyl ion liquid

ActiveCN101130537AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyThermal stability

The invention discloses a making method of annular carbonate through hydroxy ion liquid, which comprises the following steps: adopting epoxy compound and carbon dioxide as reactant; using catalyst from one of hydroxy ion liquid; making the quantity of catalyst between 1X10-3 and 1. 5X10-2mol corresponding to epoxy compound; setting the reacting pressure at 0. 1-10. 0Mpa under 323. 15-483. 15K for 0. 3-5h; obtaining the product under mild reacting condition. The invention saves cost due to using mono-component catalyst with high selectivity, which displays good water and thermal stability to be used reciprocally.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

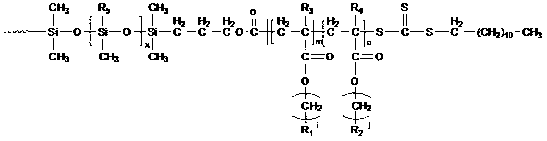

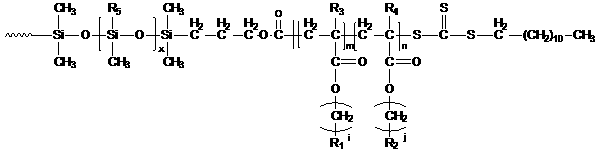

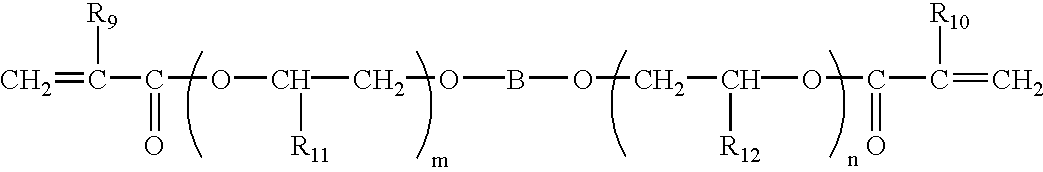

POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and preparation method thereof

InactiveCN102775567AMild surface energyLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceCopolymer

The invention discloses a POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and a preparation method thereof. The preparation method includes subjecting hydrogen-terminated polysiloxane and vinylcarbinol to reaction to obtain hydroxy-terminated polysiloxane; subjecting the hydroxy-terminated polysiloxane and carboxyl thiocarbonic acid ester to reaction to obtain polysiloxane macromolecular RAFT (reversible addition-fragmentation chain transfer polymerization) reagent; polymerizing the polysiloxane macromolecular RAFT reagent, acrylate monomer and POSS monomer with initiator to prepare the POSS contained polyacrylate-polysiloxane block copolymer. The method has the advantages of simple operation and mild reaction conditions, reaction products have better surface performance and bonding performance with substrates, and further, the reaction products can be used in low-surface-energy lyophobic coating materials and used for preparing ice and snow preventive and antifouling coatings.

Owner:TIANJIN UNIV

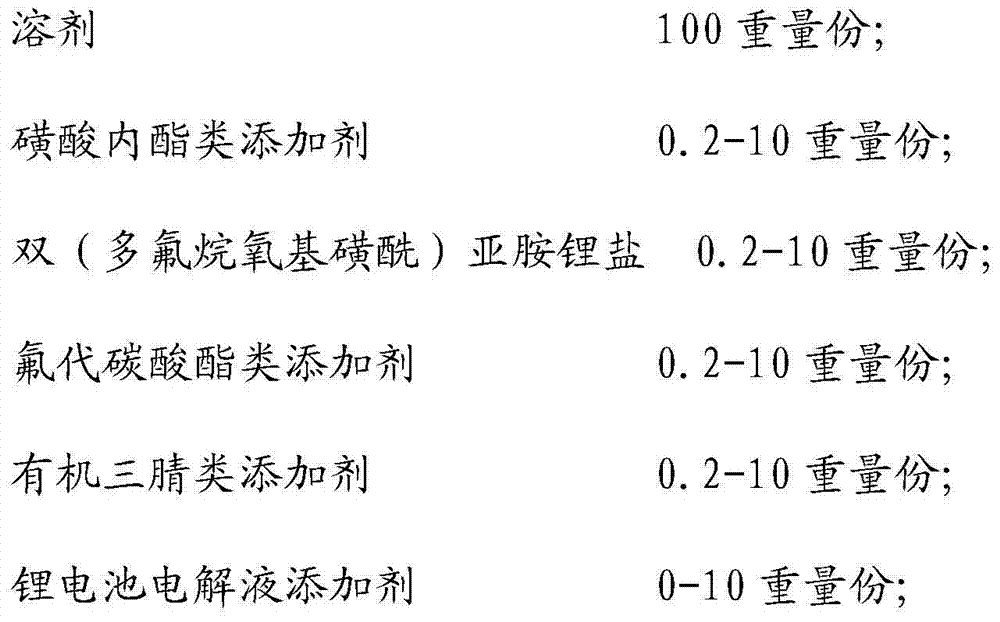

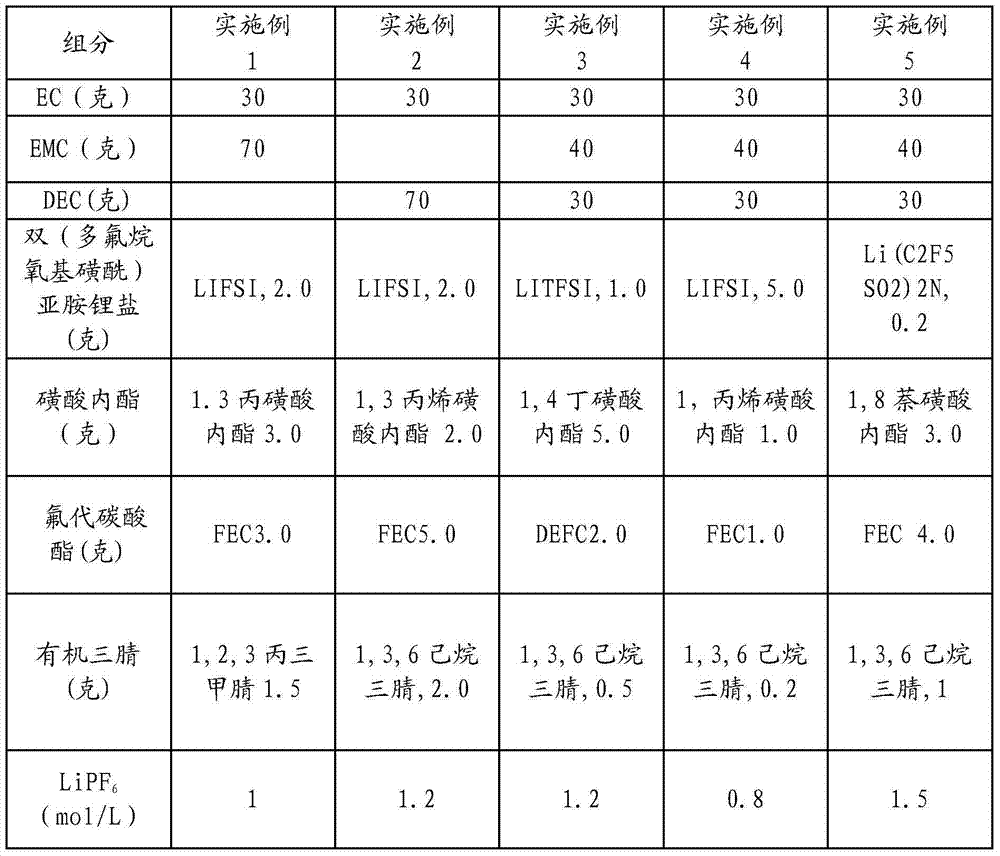

Nonaqueous electrolyte for high-voltage lithium ion battery

ActiveCN104505535AImprove wettabilityImprove oxidation resistanceSecondary cellsCarbonate esterCombined use

The invention discloses nonaqueous electrolyte for a high-voltage lithium ion battery. The nonaqueous electrolyte consists of a solvent, an inorganic lithium salt, a fluoro-ester additive, a sultone additive, an organic tri-nitrile additive, a bi(polyfluoroalkoxy sulfonyl) imine lithium salt and a lithium battery electrolyte additive, wherein the addition amount of the solvent is 100 weight parts; the addition amount of the fluoro-carbonate additive is 0.2-10 weight parts; the addition amount of the nitrile additive is 0.2-10 weight parts; the addition amount of the bi(polyfluoroalkoxy sulfonyl) imine lithium salt is 0.2-10 weight parts; the addition amount of the common lithium battery electrolyte additive is 0-10 weight parts; the solvent refers to cyclic carbonate and / or chain carbonate; and the molar concentration of the inorganic lithium salt in the solvent is 0.8-1.5mol / L. According to combined use of the sultone additive, the fluoro-ester carbonate additive, the bi(polyfluoroalkoxy sulfonyl) imine lithium salt and the organic tri-nitrile additive, the oxidation resistance of the SEI film during primary formation of the electrolyte can be improved, and the normal-temperature and high-temperature cycle performance of the high-voltage electrolyte is obviously improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Process for synthesizing cyclic carbonate

InactiveCN1343668AEasy to separateHigh purityOrganic chemistryEpoxyNitrogenous heterocyclic compound

A process for preparing cyclic carbonate features that catalytic cycloaddition reaction of CO2 on epoxy compound at 100-140 deg.C and 1.5-4.5 MPa for 4-8 hrs under the existance of the catalyst whichis composed of azacyclic compound (halogenated alkylpyridine or halogenated 1,3-dialkyl imidazole) and non-metal halide, and the cocatalyst which is alkali-metal halide or ammonium tetrebutyl bromide. Its advantages are high catalytic activity, smooth reaction condition, easy separation of resultant from catalyst, and cyclic use of catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Photochromic polymerizable compositions

Described is a polymerizable composition of a photochromic amount of at least one photochromic compound, at least one material having at least one carbonate group and at least one hydroxyl group, and at least one monoisocyanate containing material having at least one unsaturated group. The polymerizable composition optionally contains copolymerizable monomers. Also described are photochromic polymerizates, e.g., photochromic optical elements such as ophthalmic lenses, prepared from the polymerizable composition of the present invention.

Owner:TRANSITIONS OPTICAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com