Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1644 results about "Trans esterification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

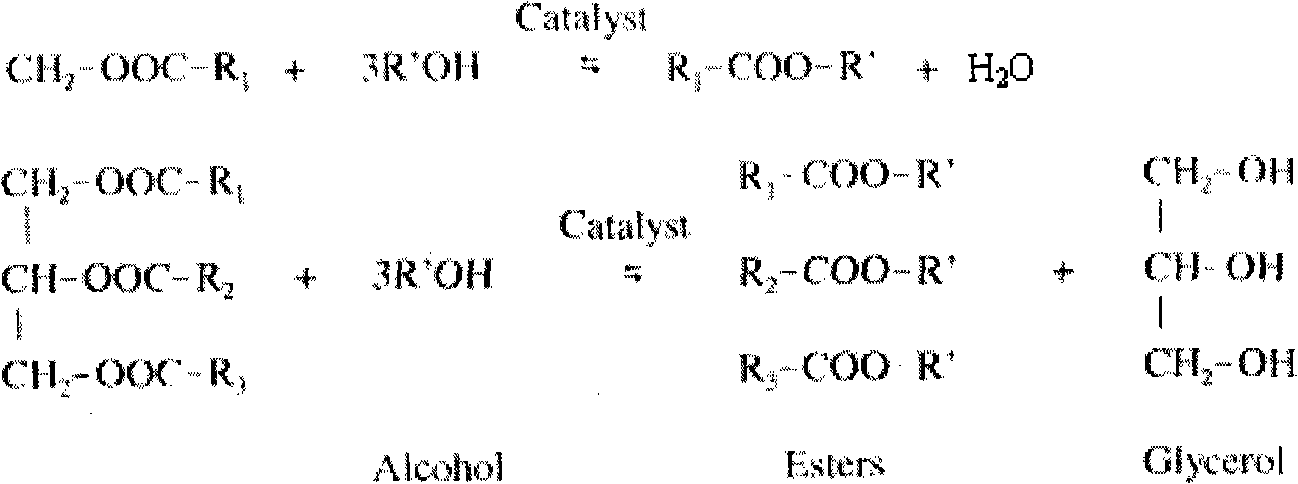

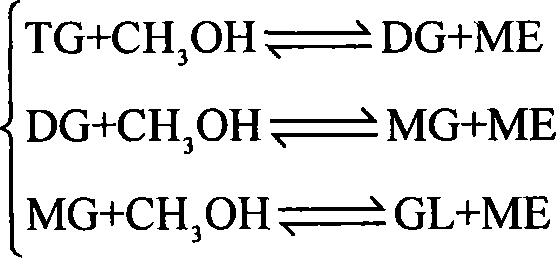

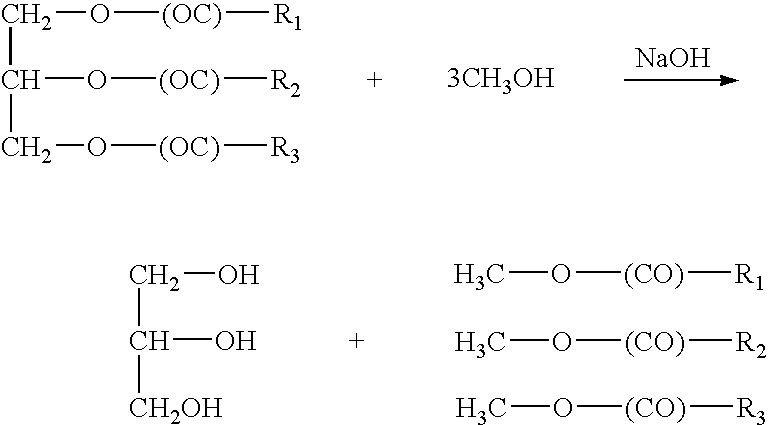

Transesterification is an important class of organic equilibrium exchange reaction in which one ester is transformed into another by the interchange of the alkoxy moiety.

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

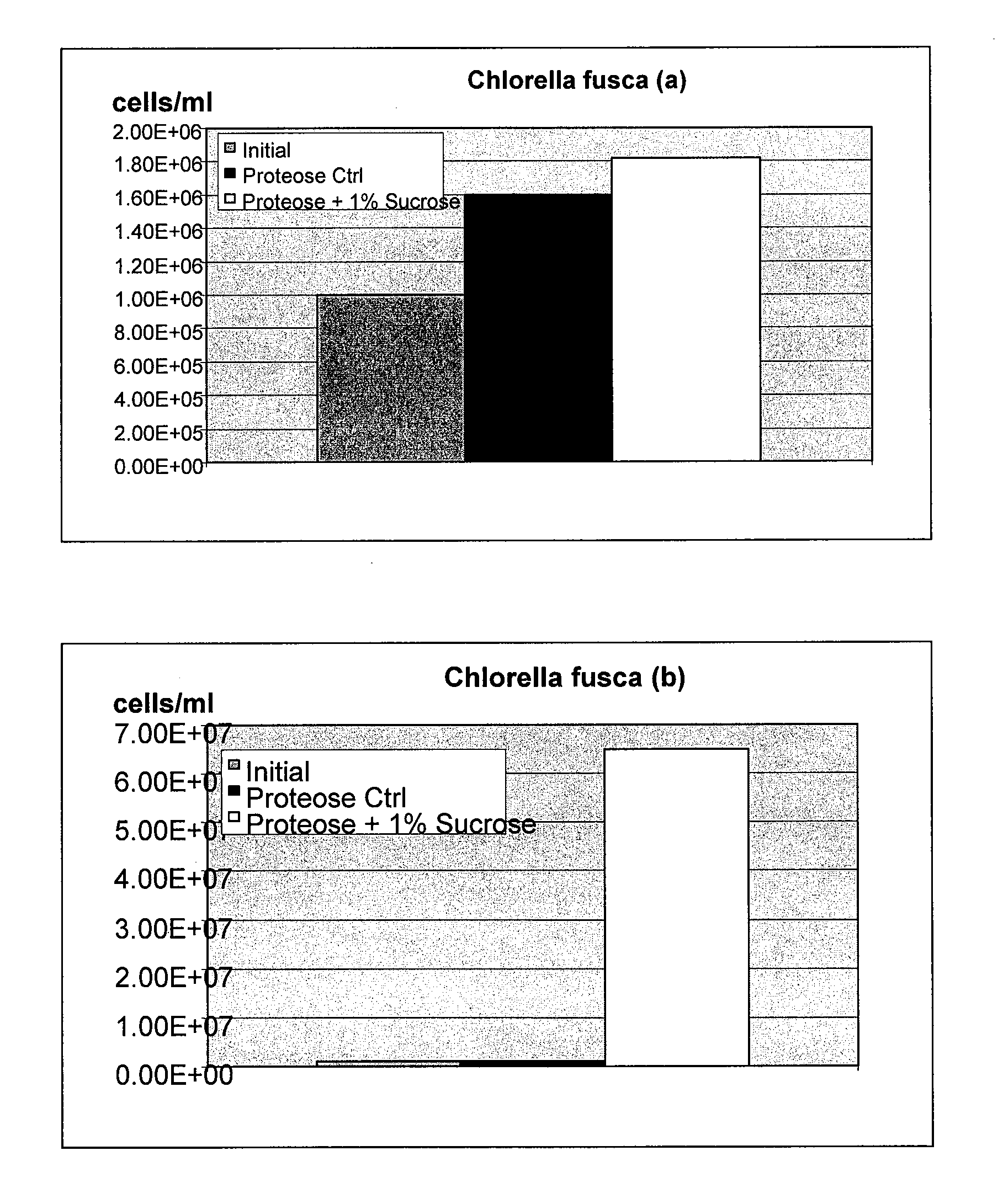

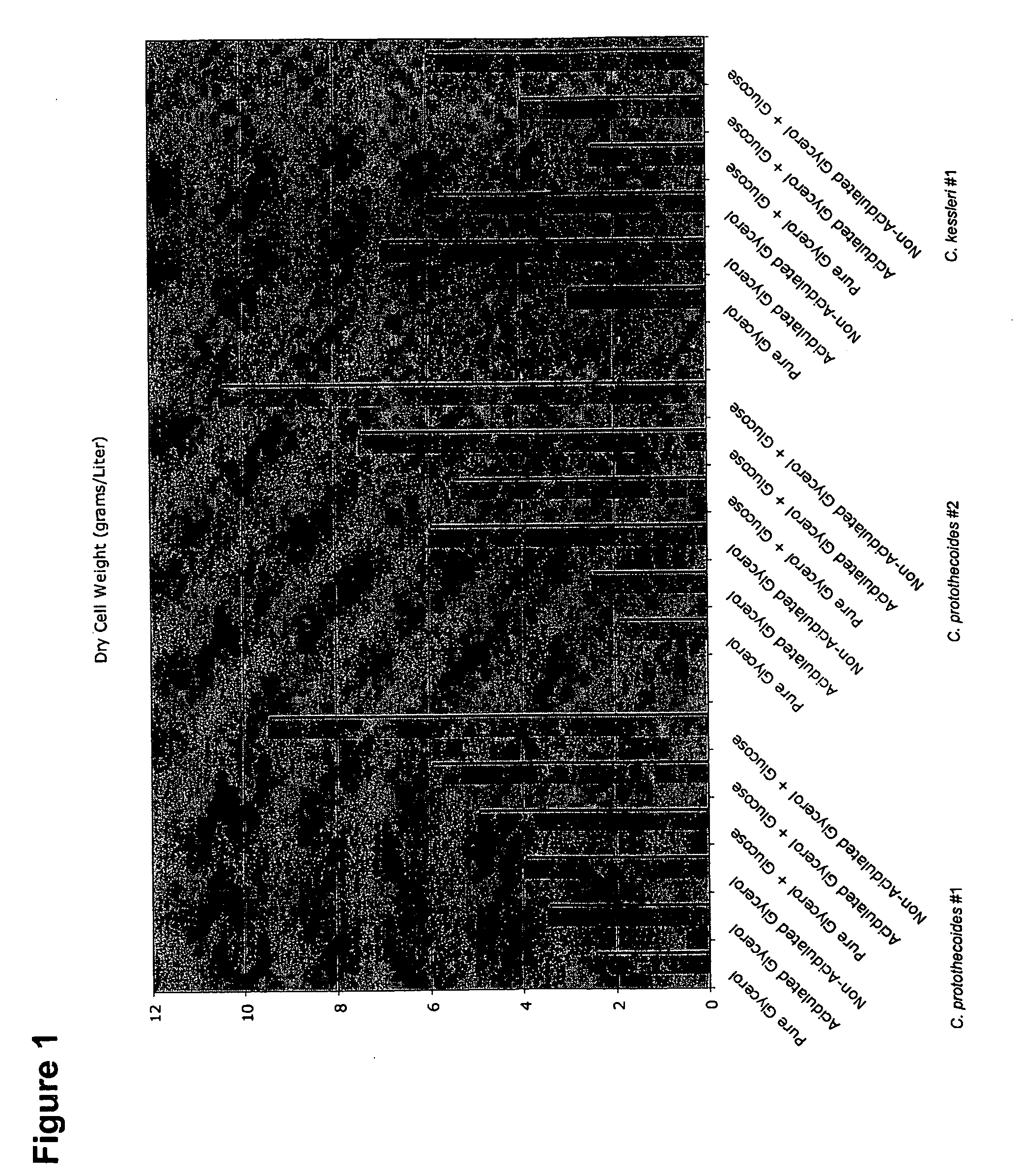

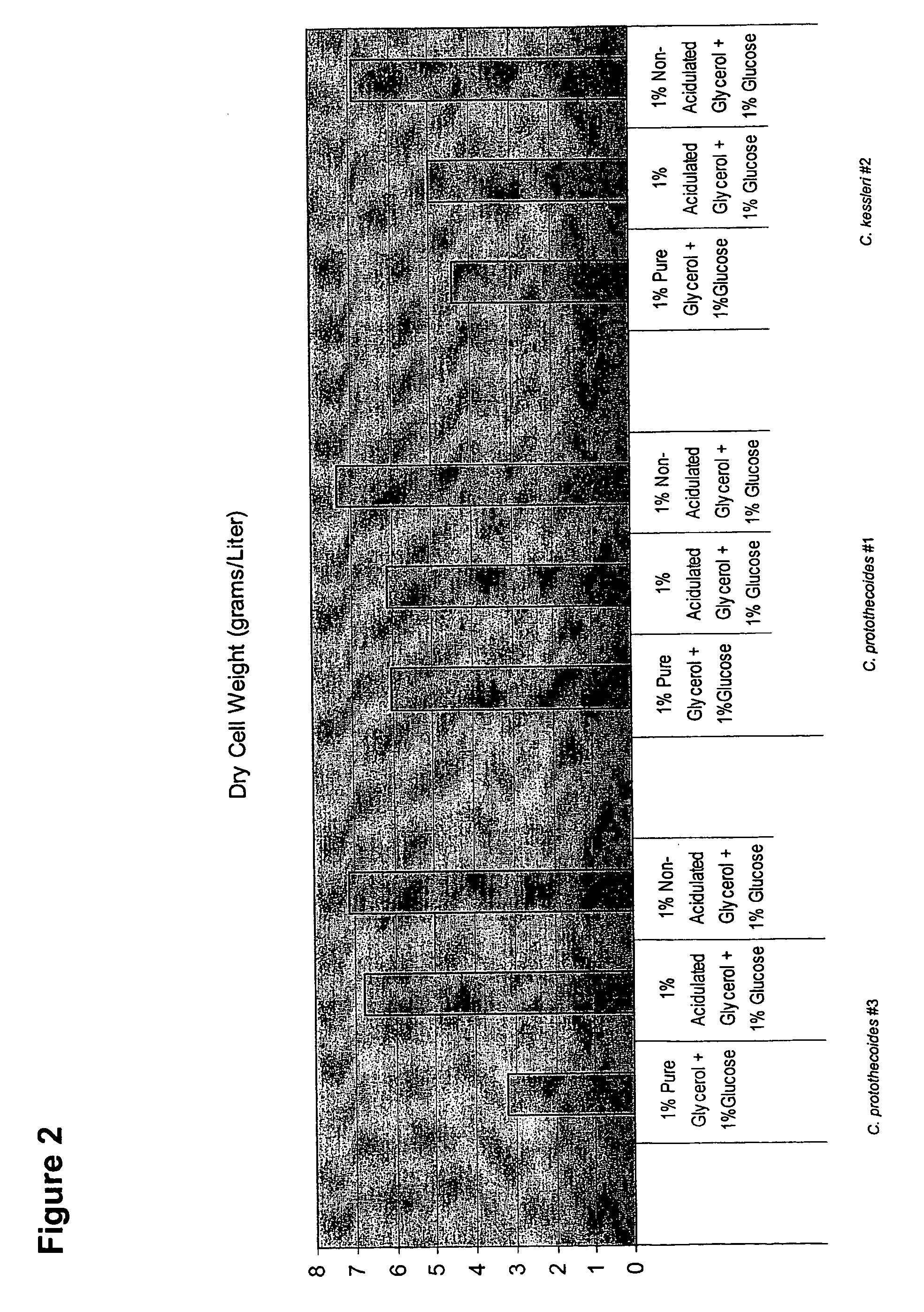

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

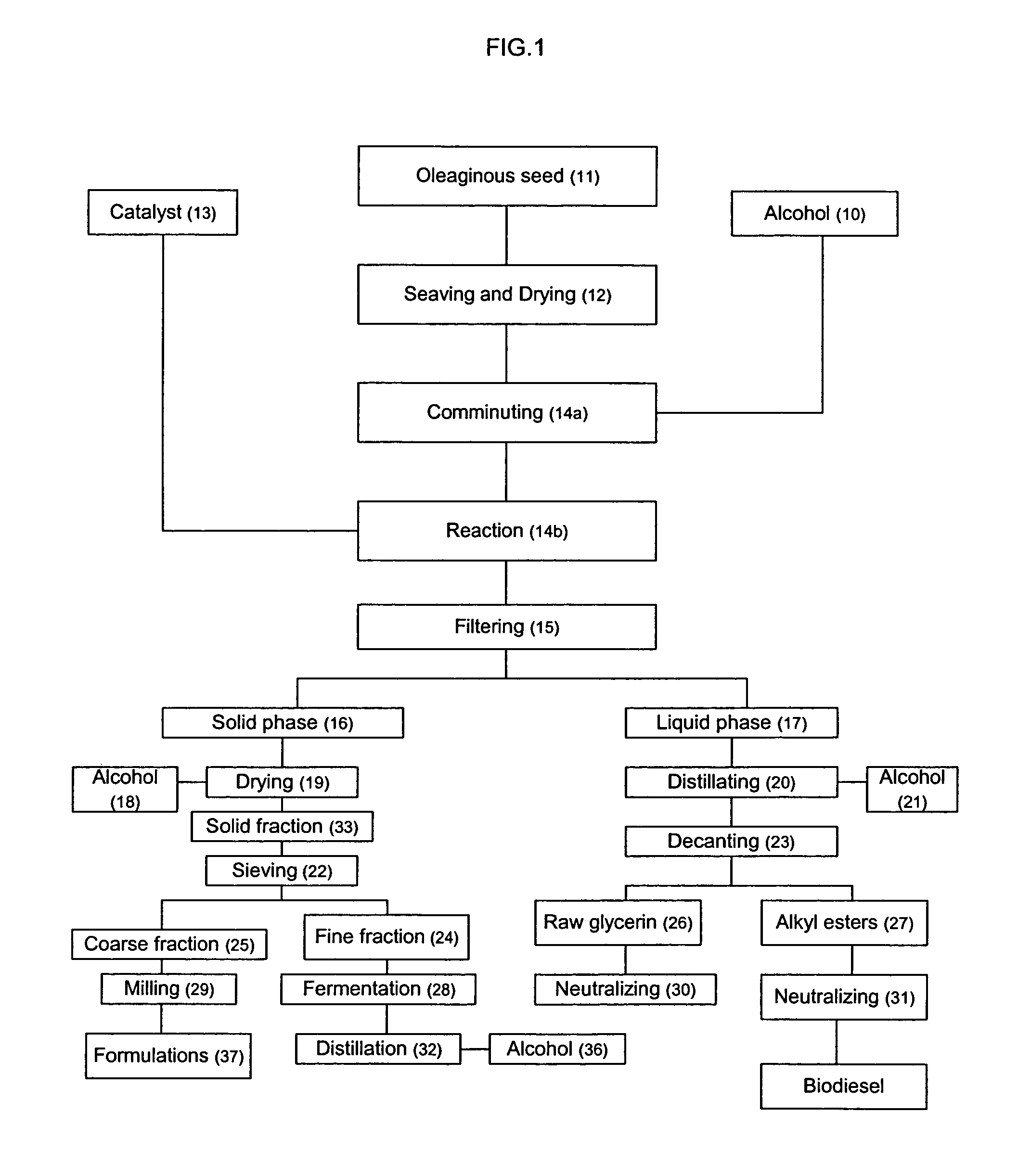

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

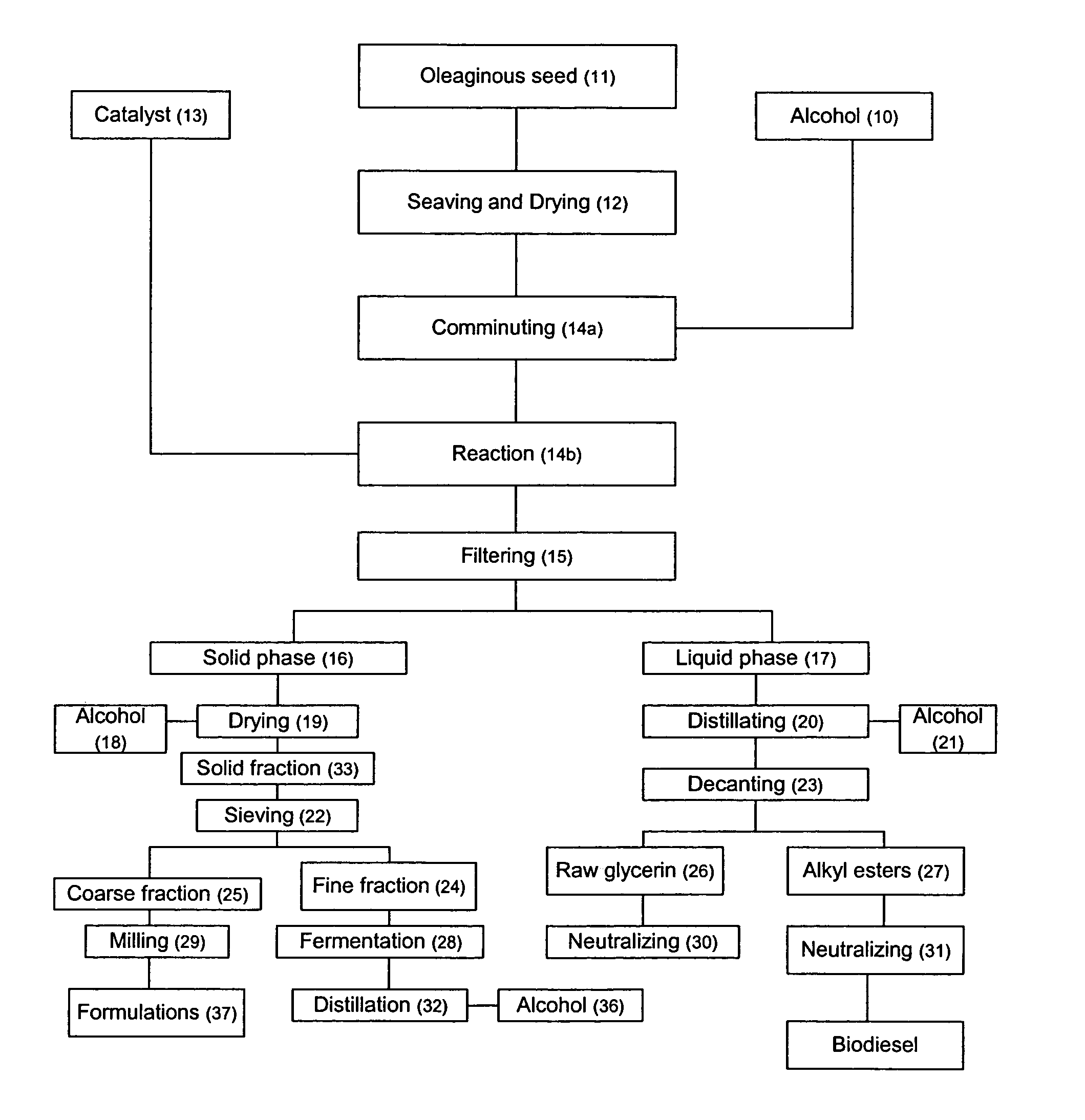

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

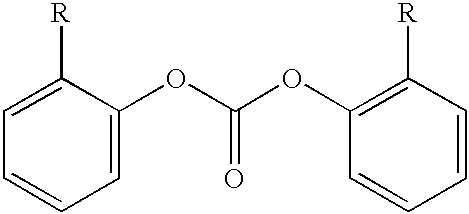

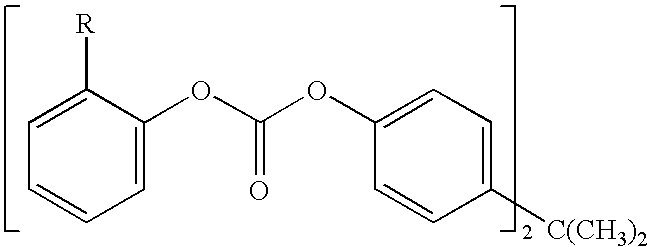

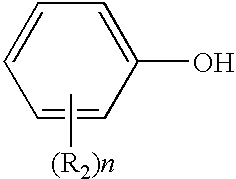

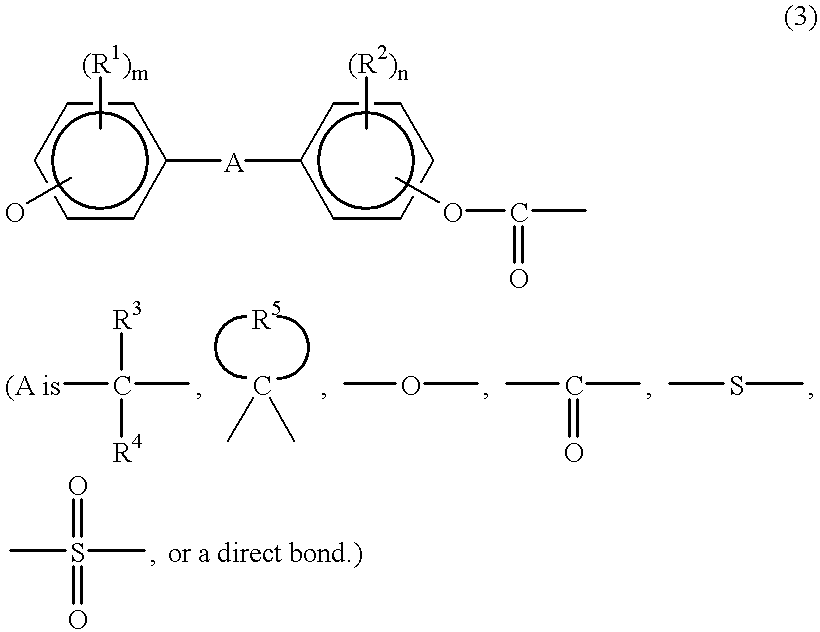

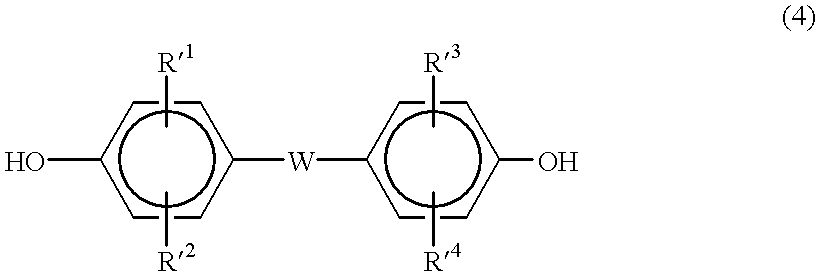

Method for end-capping polycarbonate resins and composition for use in same

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of: (a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

Polycarbonate diol and producing method thereof, and polyurethane and active energy ray-curable polymer composition both formed using same

ActiveUS20130109804A1Improves stain resistanceHigh hardnessOrganic chemistryPolyureas/polyurethane adhesivesMethacrylateElastomer

A novel polycarbonate diol is useful as a raw material for producing a polycarbonate diol-based polyurethane with a high degree of hardness, superior abrasion resistance, and superior hydrophilicity. The polyurethane is useful in paints, coating agents, synthetic leathers, artificial leathers, and highly-functional elastomers, or the like. The polycarbonate diol is also useful for producing an active-energy radiation curable polymer composition giving a cured film having superior contamination resistance and high degree of hardness. The curable polymer composition contains a urethane(meth)acrylate oligomer obtained from the polycarbonate diol. The polycarbonate diol is obtained, for example, by reacting two specific types of diols with diester carbonate in the presence of a transesterification catalyst. The catalyst has a metal of Group 1 or 2 on the periodic table. A metal content of the transesterification catalyst is 100 weight ppm or less.

Owner:MITSUBISHI CHEM CORP

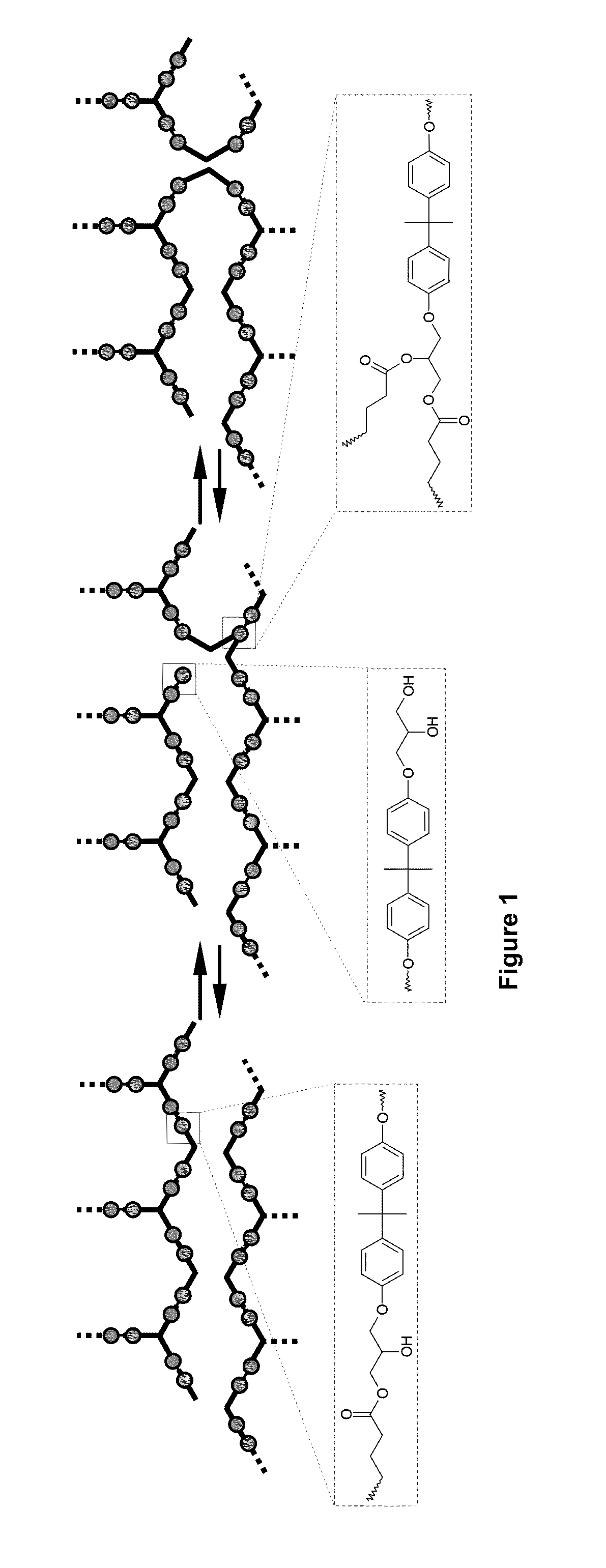

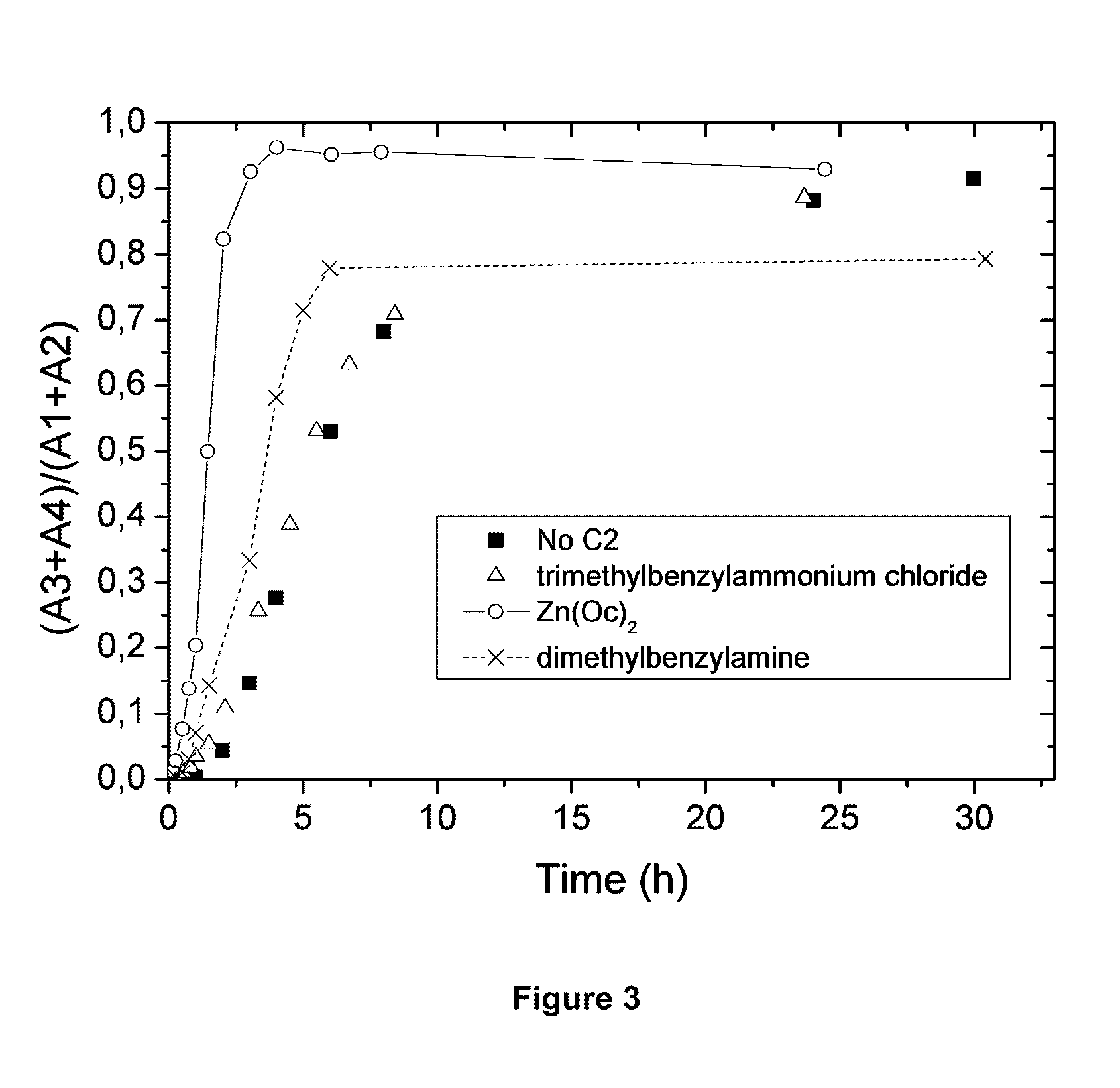

Epoxy Acid Thermoset Resins and Composites that Can Be Hot-Fashioned and Recycled

Resins and thermoset composites comprising them, these materials being able to be hot-fashioned. These compositions resulting from placing at least one thermosetting resin precursor, this thermosetting resin precursor comprising hydroxyl functions and / or epoxy groups, and optionally ester functions, in contact with at least one hardener chosen from carboxylic acids, in the presence of at least one transesterification catalyst whose total molar amount is between 5% and 25% of the total molar amount of hydroxyl and epoxy contained in the thermosetting resin precursor. Process for manufacturing these materials, process for transforming and process for recycling these materials. New solid forms of resins and of thermoset composites that may be used in the implementation of these processes.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Stabilized aromatic polycarbonate

The relative intensity of fluorescent light of a melt-polycondensed aromatic polycarbonate produced by the transesterification process (melt polymerization process) of an aromatic dihydroxy compound and a carbonic acid diester in the presence of a catalyst comprising a basic nitrogen compound and / or a basic phosphorus compound in combination with an alkali metal compound is suppressed to 4.0x10-3 or below at a wavelength of 465 nm based on a standard substance in a fluorescent light spectrum obtained by the excitation wavelength of 320 nm. An aromatic polycarbonate having good color stability, especially good stability to the deterioration of the chip color during storage of the chip in air at room temperature can be produced by the present invention.

Owner:TEIJIN LTD

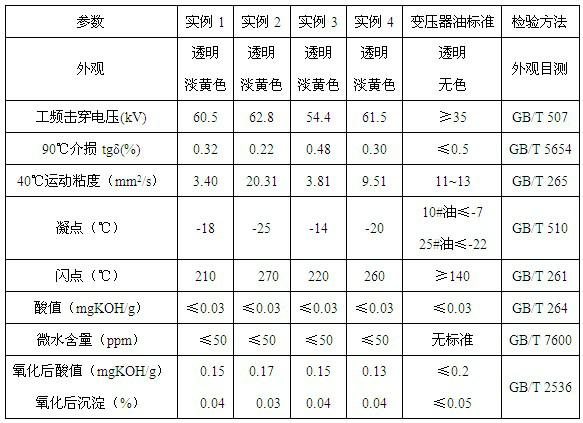

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

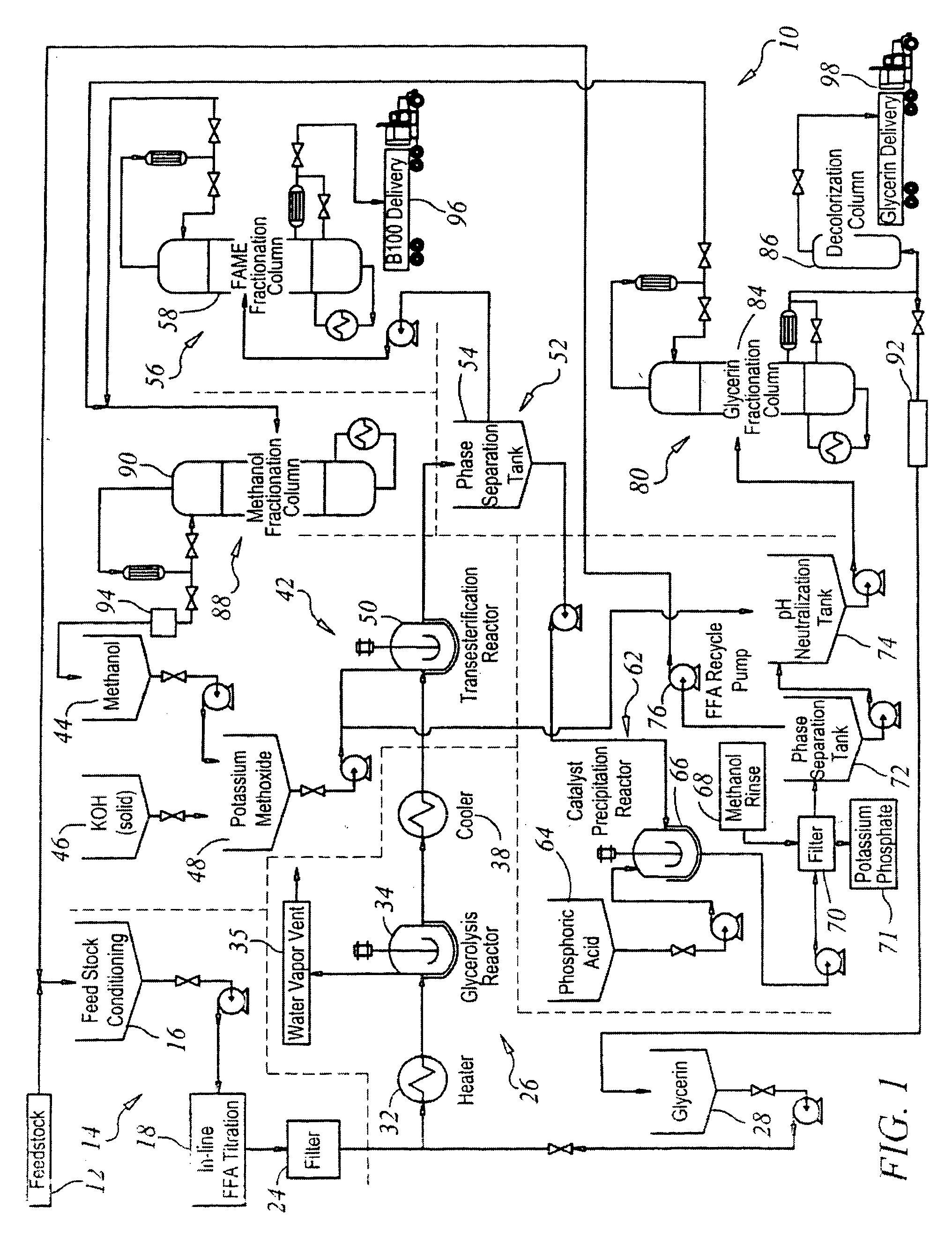

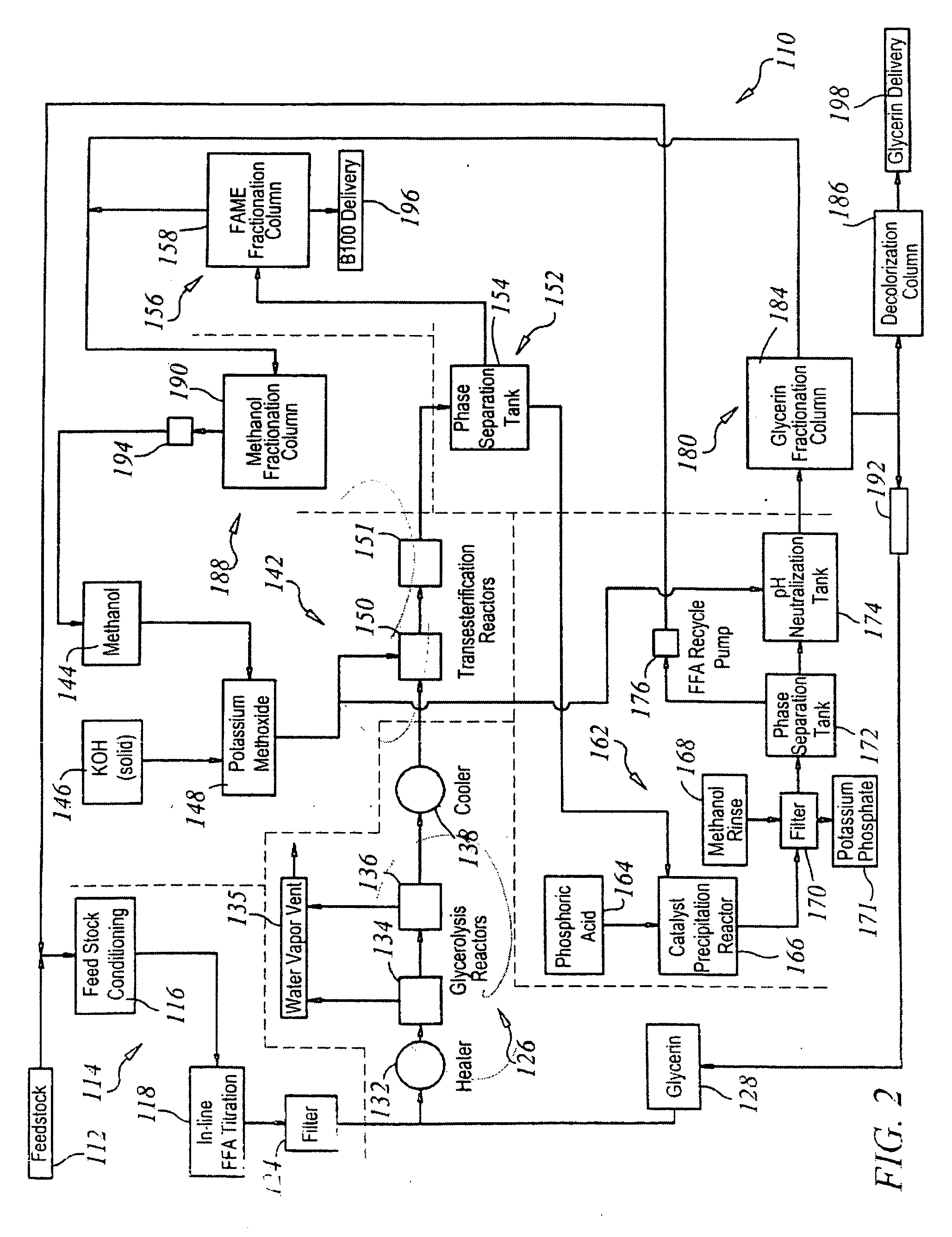

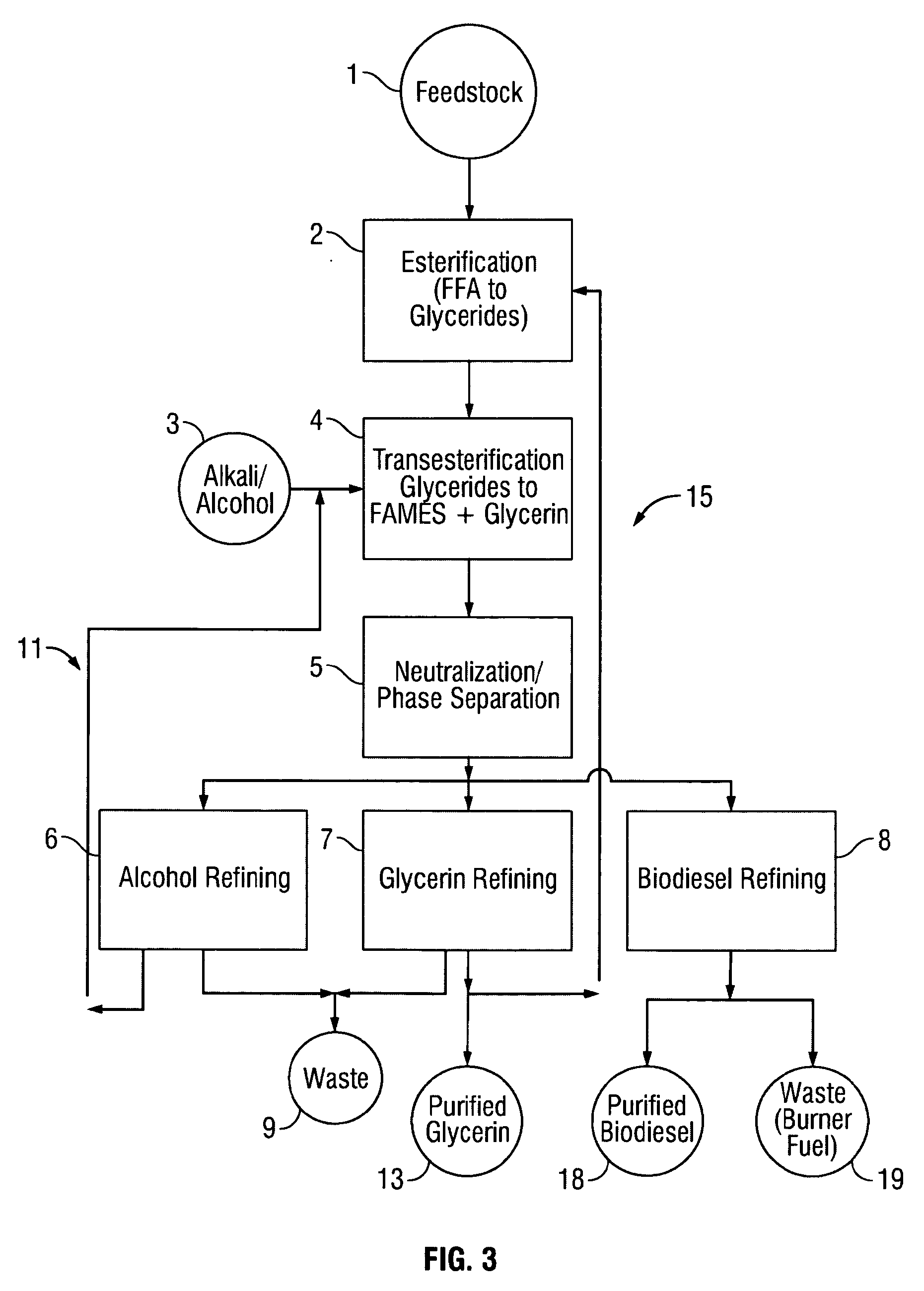

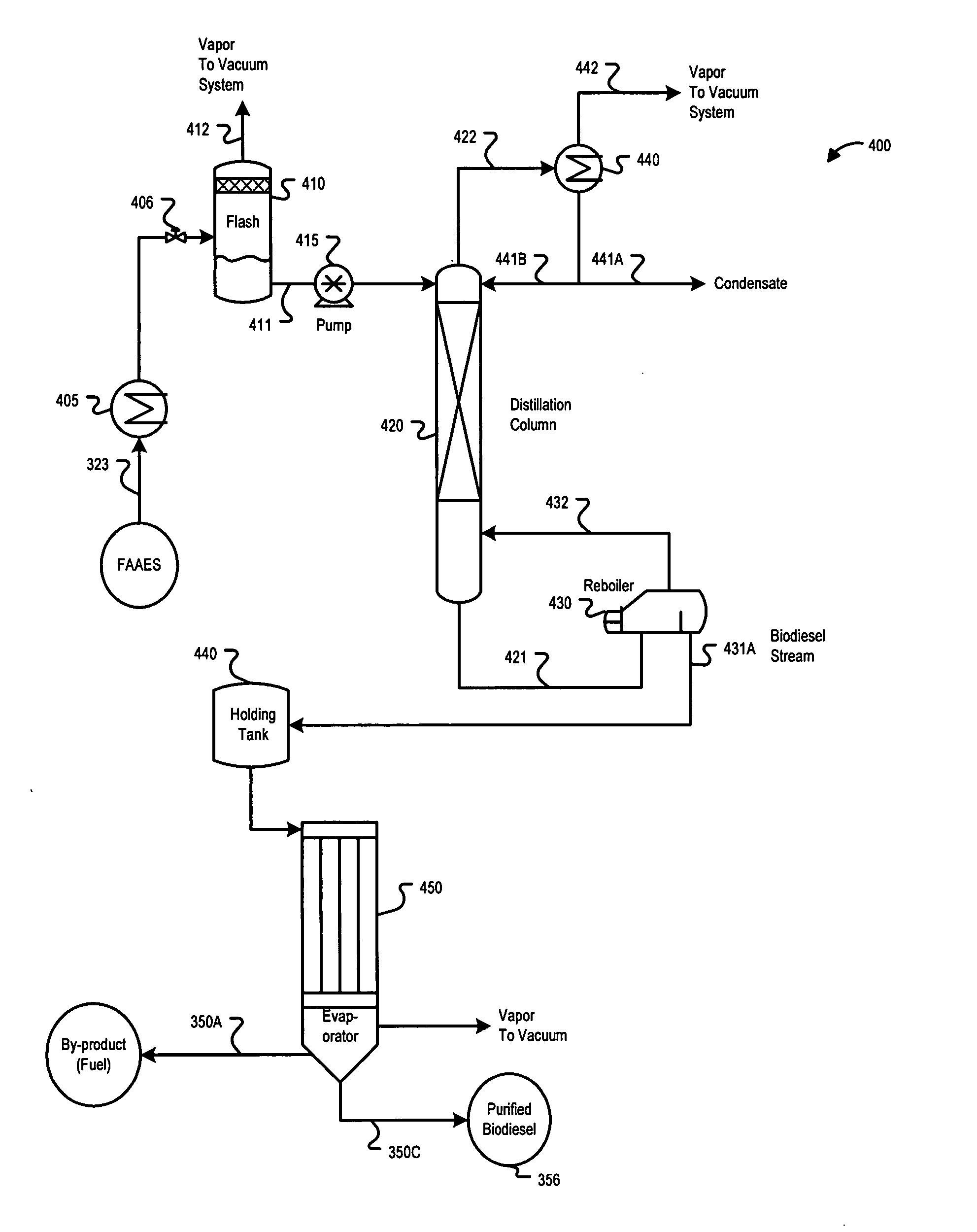

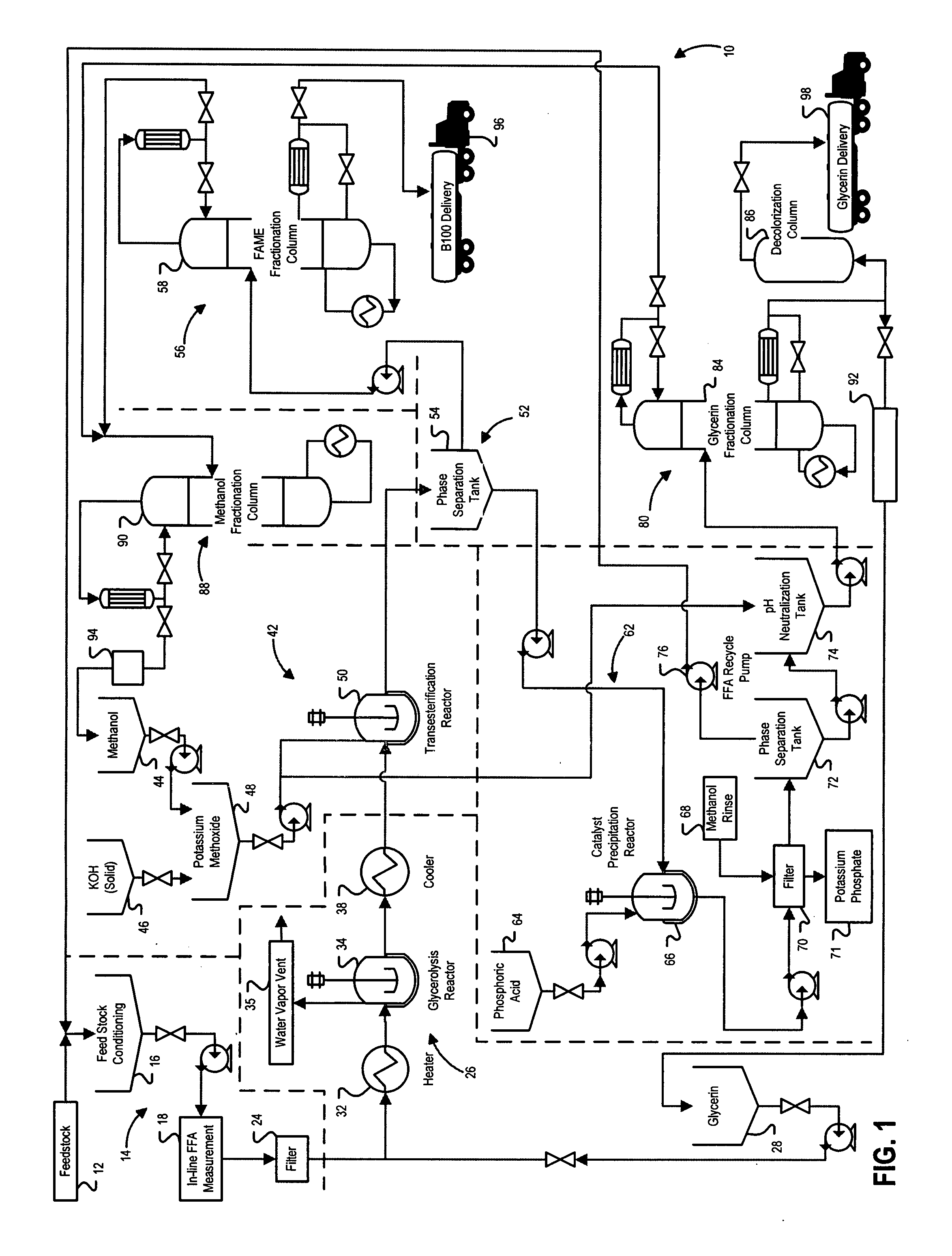

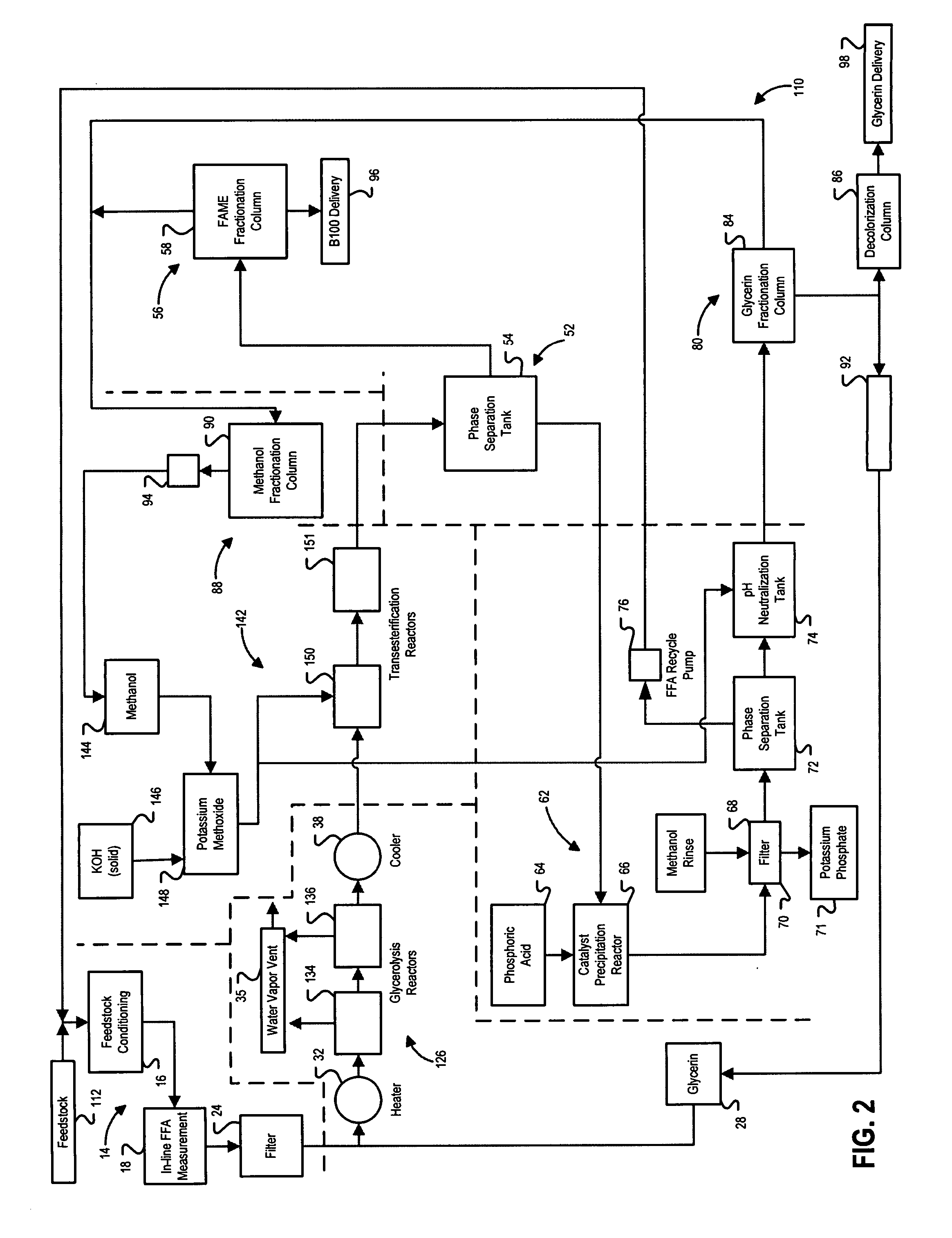

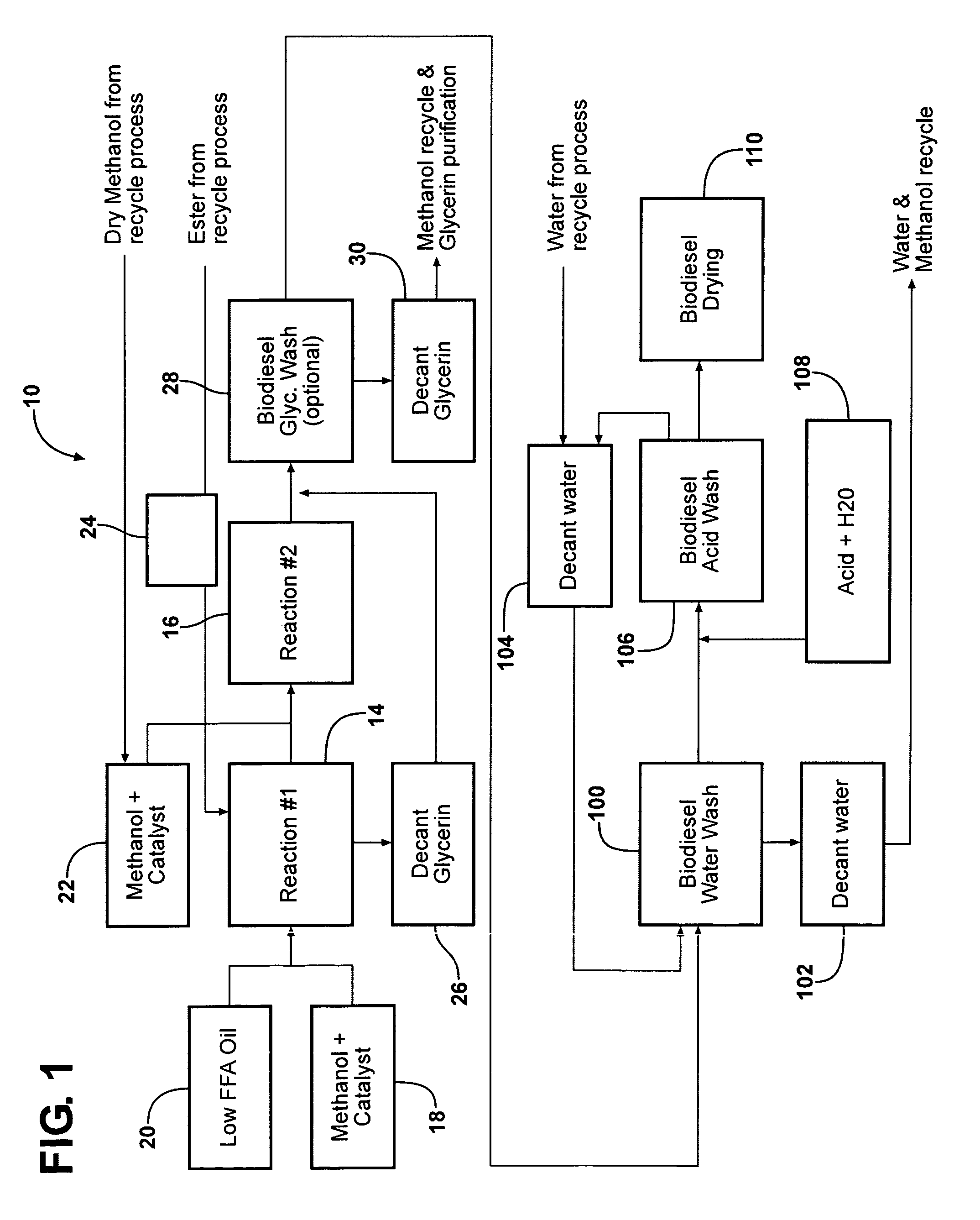

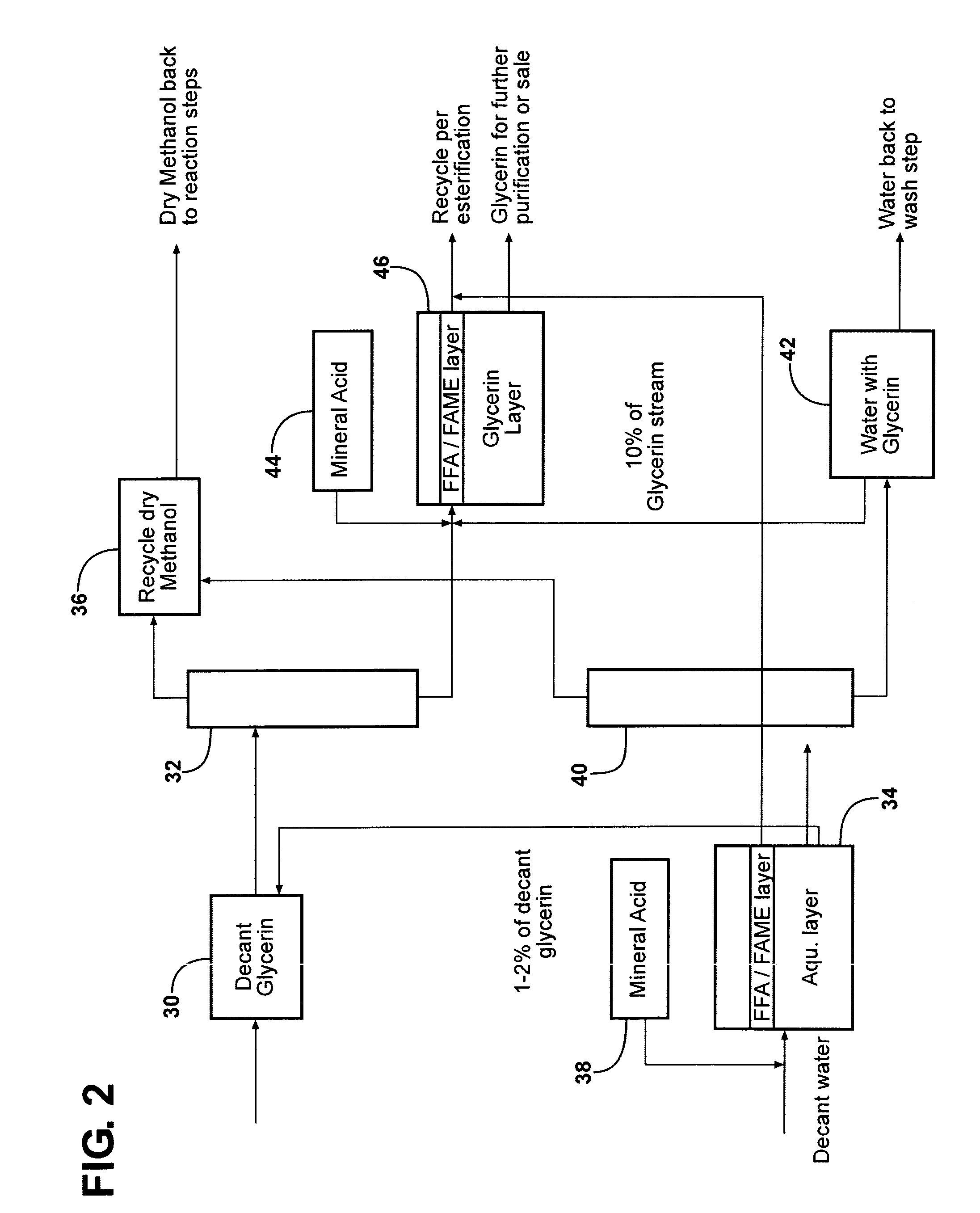

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277430A1Increase productionHigh purityFatty acid esterificationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

A system and method for the conversion of free fatty acids to glycerides and the subsequent conversion of glycerides to glycerin and biodiesel includes the transesterification of a glyceride stream with an alcohol. The fatty acid alkyl esters are separated from the glycerin to produce a first liquid phase containing a fatty acid alkyl ester rich (concentrated) stream and a second liquid phase containing a glycerin rich (concentrated) stream. The fatty acid alkyl ester rich stream is then subjected to distillation, preferably reactive distillation, wherein the stream undergoes both physical separation and chemical reaction. The fatty acid alkyl ester rich stream is then purified to produce a purified biodiesel product and a glyceride rich residue stream. The glycerin rich second liquid phase stream may further be purified to produce a purified glycerin product and a (second) wet alcohol stream. Neutralization of the alkaline stream, formed during the alkali-catalyzed transesterfication process, may proceed by the addition of a mineral or an organic acid.

Owner:REG SENECA LLC +3

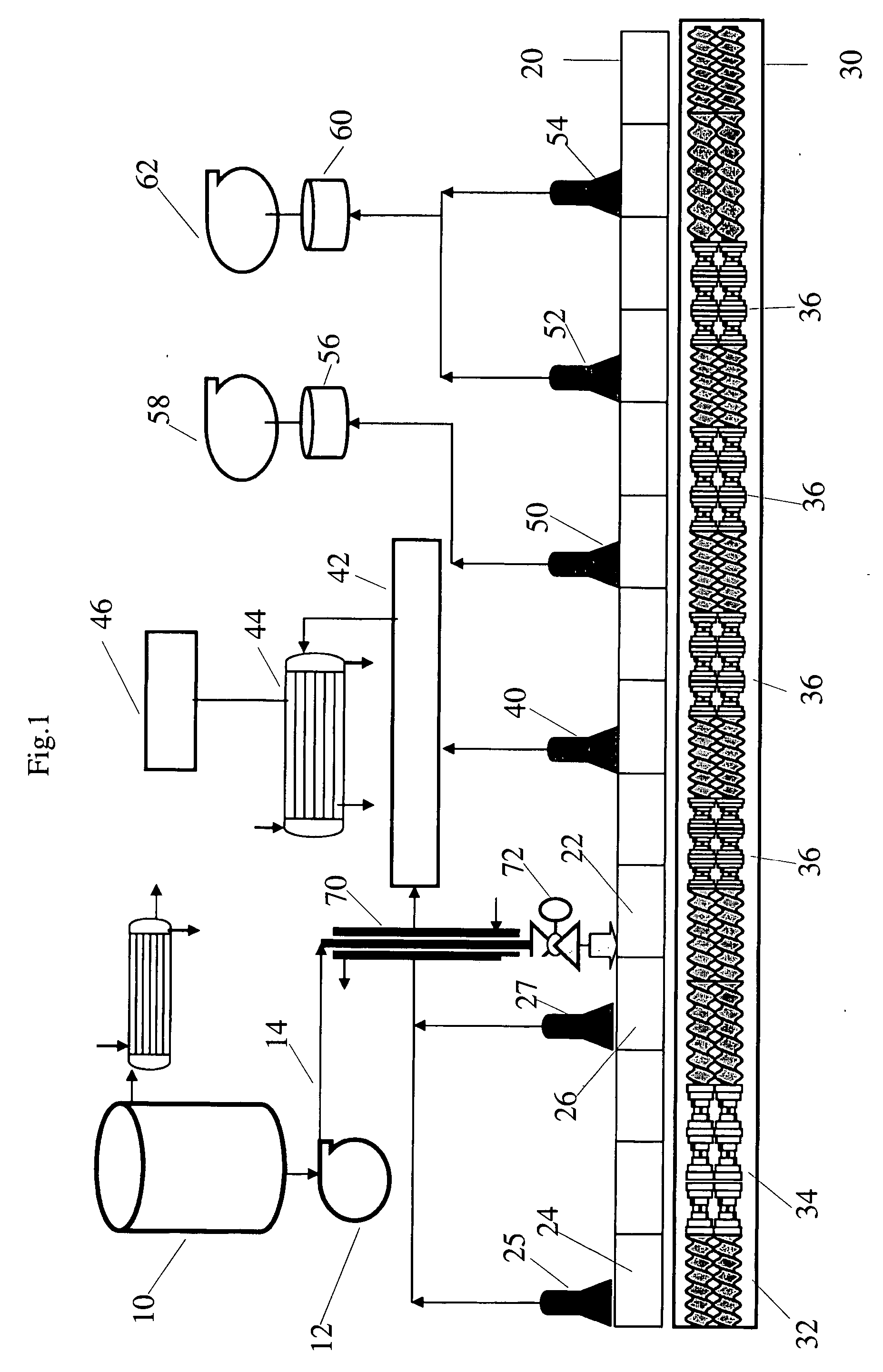

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS7666234B2Speed up the processFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationTriglyceride

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

Process to make polycarbonate from bismethylsalicylcarbonate (BMSC)

ActiveUS20060069228A1Superior polycarbonate productionMinimizing residence timeCeramic shaping apparatusTrans esterificationPolymer science

The present invention relates to a method of preparing polycarbonate comprising the steps of: (i) introducing to an extruder through a feed port a plurality of reaction components comprising a polycarbonate oligomer, an activated carbonate residue, and a transesterification catalyst, wherein the extruder comprises the feed port, a first back vent port, and a polycarbonate exit port, wherein the feed port is located between the first back vent port and the polycarbonate exit port, and wherein the resistance to flow of the reaction components from the feed port to the first back vent port is less than or equal to the resistance to flow of the reaction components from the feed port to the polycarbonate exit port; and (ii) extruding the reaction components at one or more temperatures in a range between 100° C. and 400° C., wherein during the extrusion of the reaction components, activated carbonate residue is removed through the first back vent port, thereby preparing a polycarbonate.

Owner:SHPP GLOBAL TECH BV

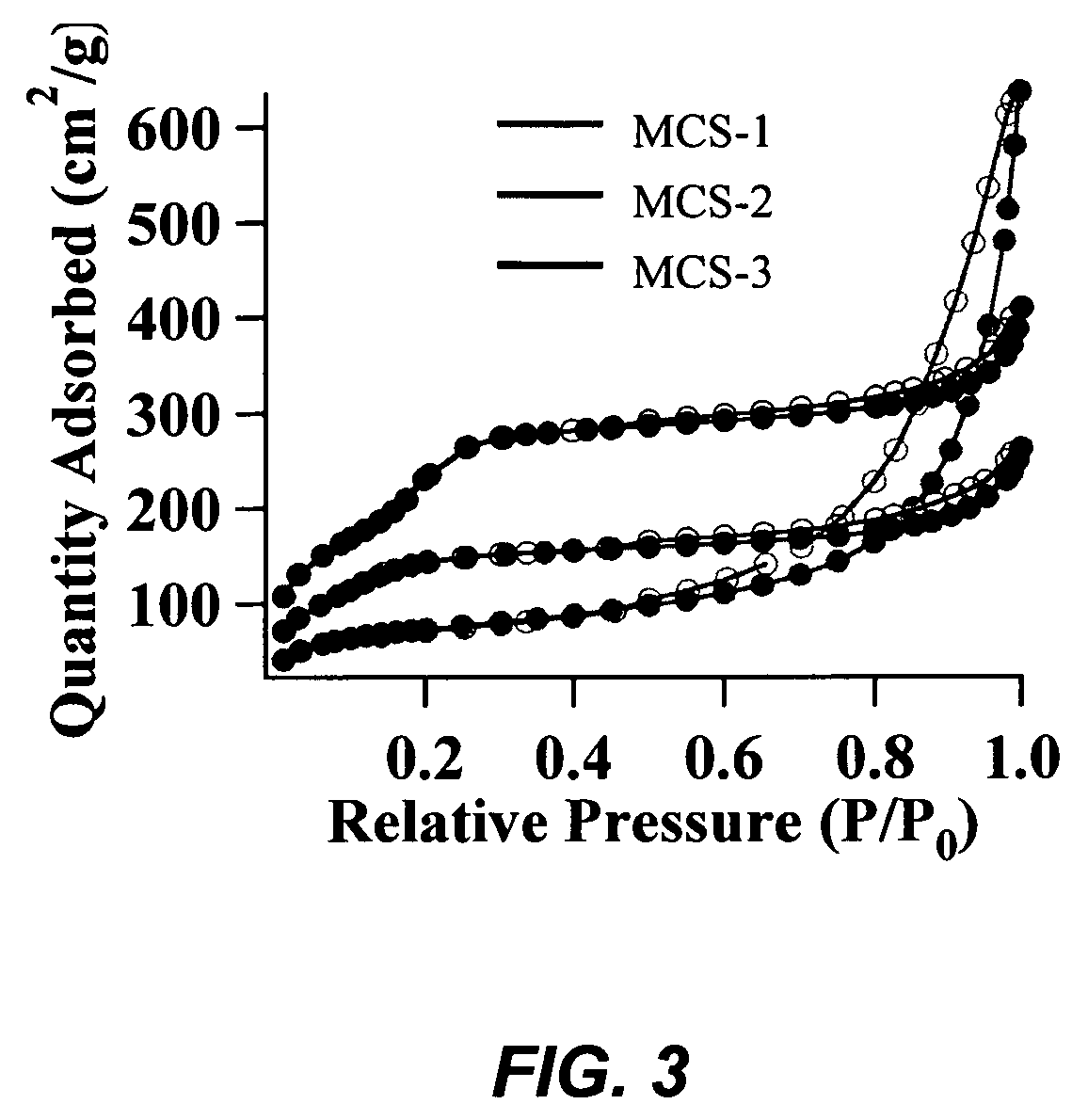

Porous silica and metal oxide composite-based catalysts for conversion of fatty acids and oils to biodiesel

ActiveUS7790651B2Easy to separateEasy to recycleFatty oils/acids recovery from wasteNanotechMETHYL SOYATEVegetable oil

A recyclable esterification or transesterification catalyst and methods for making and using the same are provided herein. The catalyst can be used to prepare biodiesel or methyl soyate from various feedstocks, including vegetable oils and animal fats. The catalyst can both esterify free fatty acids and transesterify mono-, di-, and triglycerides. The catalyst can also be combined with a metal oxide, and optionally calcined, prior to carrying out a catalytic reaction.

Owner:IOWA STATE UNIV RES FOUND

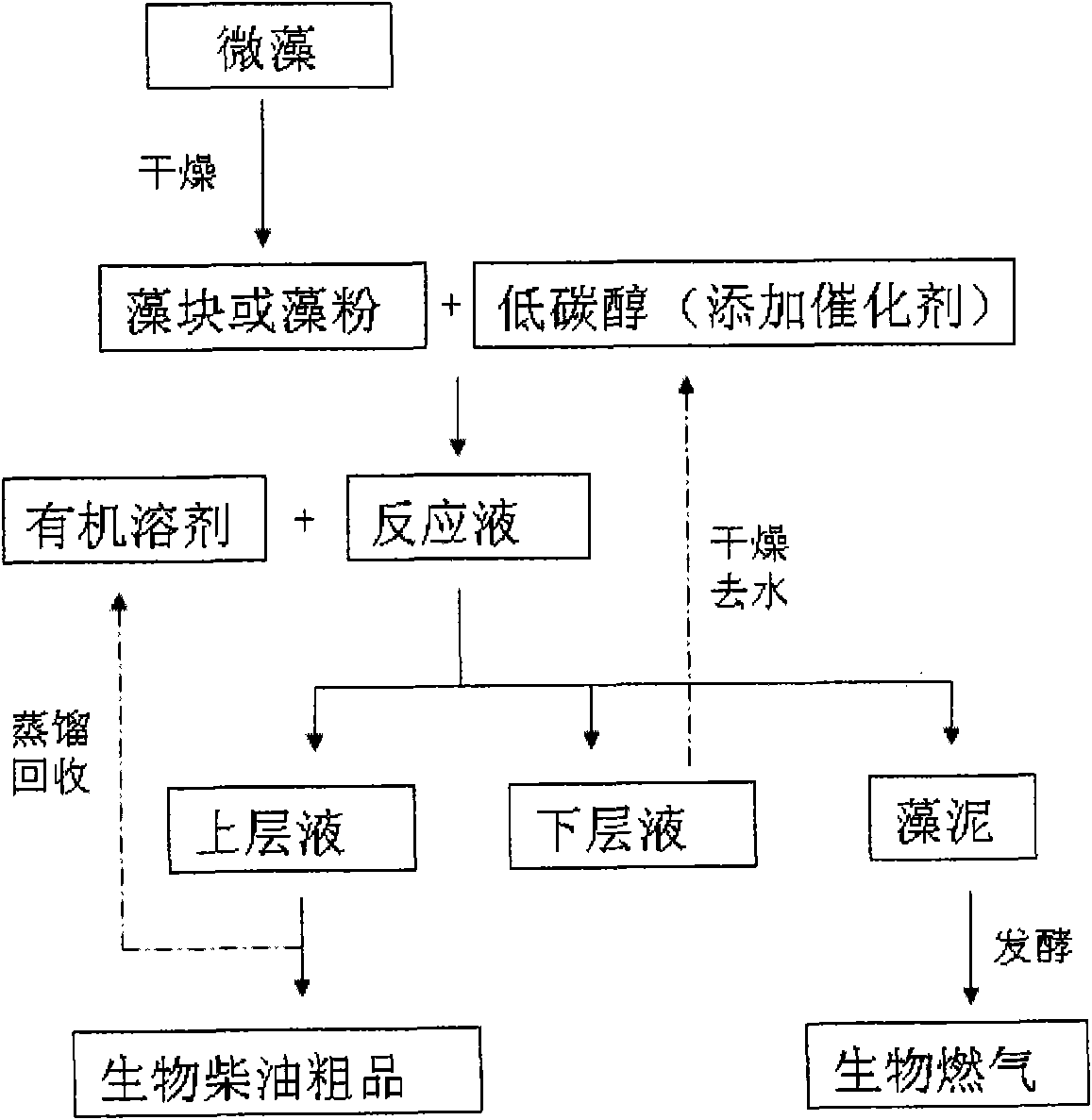

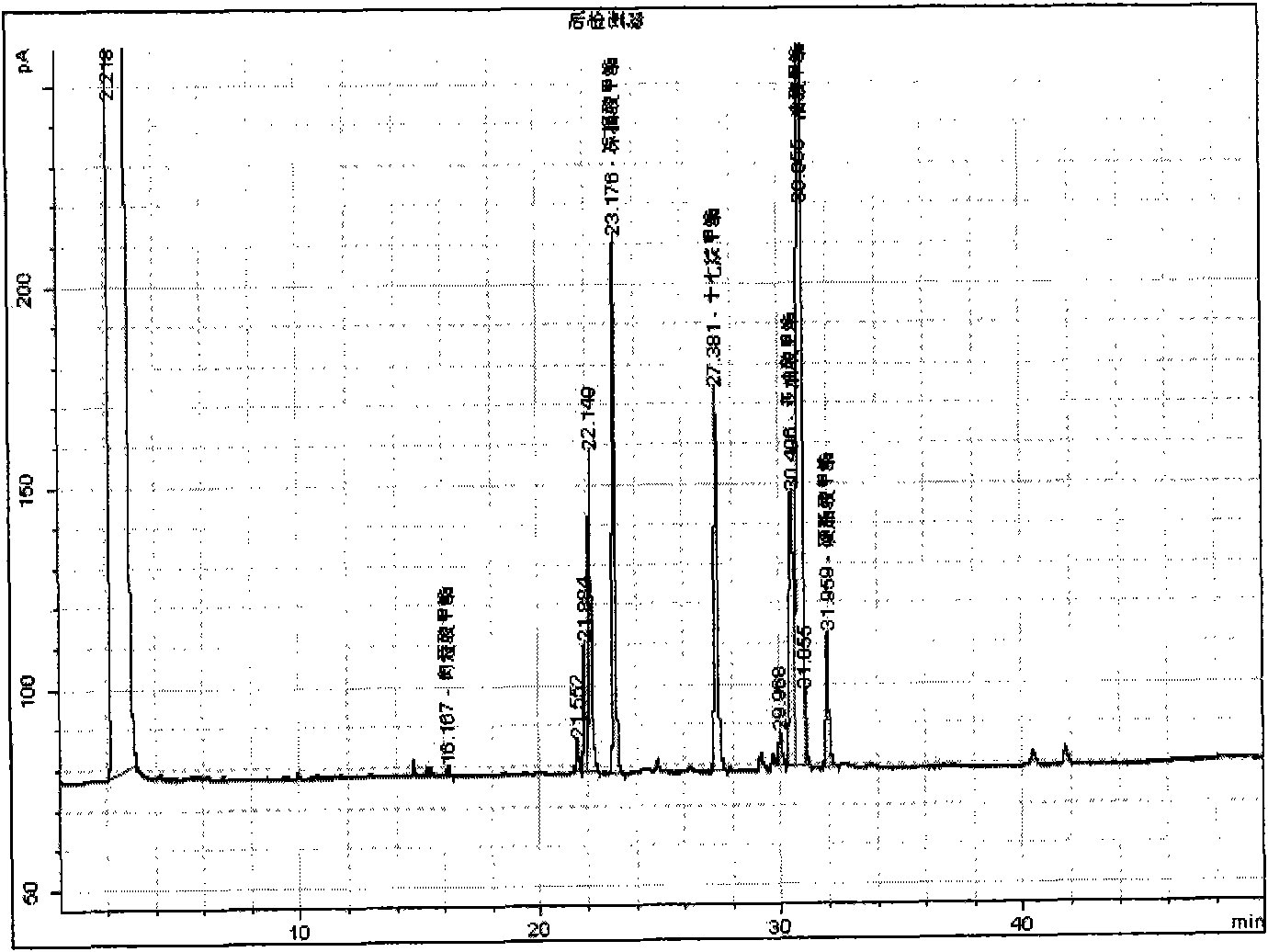

Biomass energy prepared by one-step method of microalgae

ActiveCN101580857AWon't happenRelieve pressurePreparation by ester-hydroxy reactionBiofuelsDownstream processingBiodiesel

The invention provides a method for preparing biodiesel from microalgae. The method comprises the following steps of: a. changing collected microalgae from the wet algae into algae block or algae powder; b. mixing a catalyst into low-carbon alcohol, directly adding the algae block or the algae powder obtained by the step a, and carrying out ester exchange reaction to prepare the biodiesel; c. after the reaction is stopped, adding an organic solvent for extracting reaction solution which is divided into organic solvent phase used for extraction, low-carbon alcohol water-adding phase and algae mud; and d. after the extraction is completed, collecting the organic solvent phase used for extraction, removing the organic solvent by distillation, and obtaining oily liquid, namely crude products of the biodiesel. After preparing the biodiesel, the steps that the low-carbon alcohol water-adding phase is used circularly after dewatered by a solid drying agent, and the produced algae mud is used for producing biogas by biological fermentation are added. The invention completes the oil extraction of microalgae and biodiesel production by one step, simplifies the technique steps and equipment, saves cost; the sulphuric acid and low-carbon alcohol used for production can be recovered, then dewatered by drying, then utilized repeatedly, the cost is reduced, the final product is neutral, does not need washing and reduces the downstream processing pressure; and simultaneously, chlorophyll is mainly concentrated in the low-carbon alcohol, reduces the interference of the chlorophyll to the color of the product and does not need the step of decoloring.

Owner:ENN SCI & TECH DEV

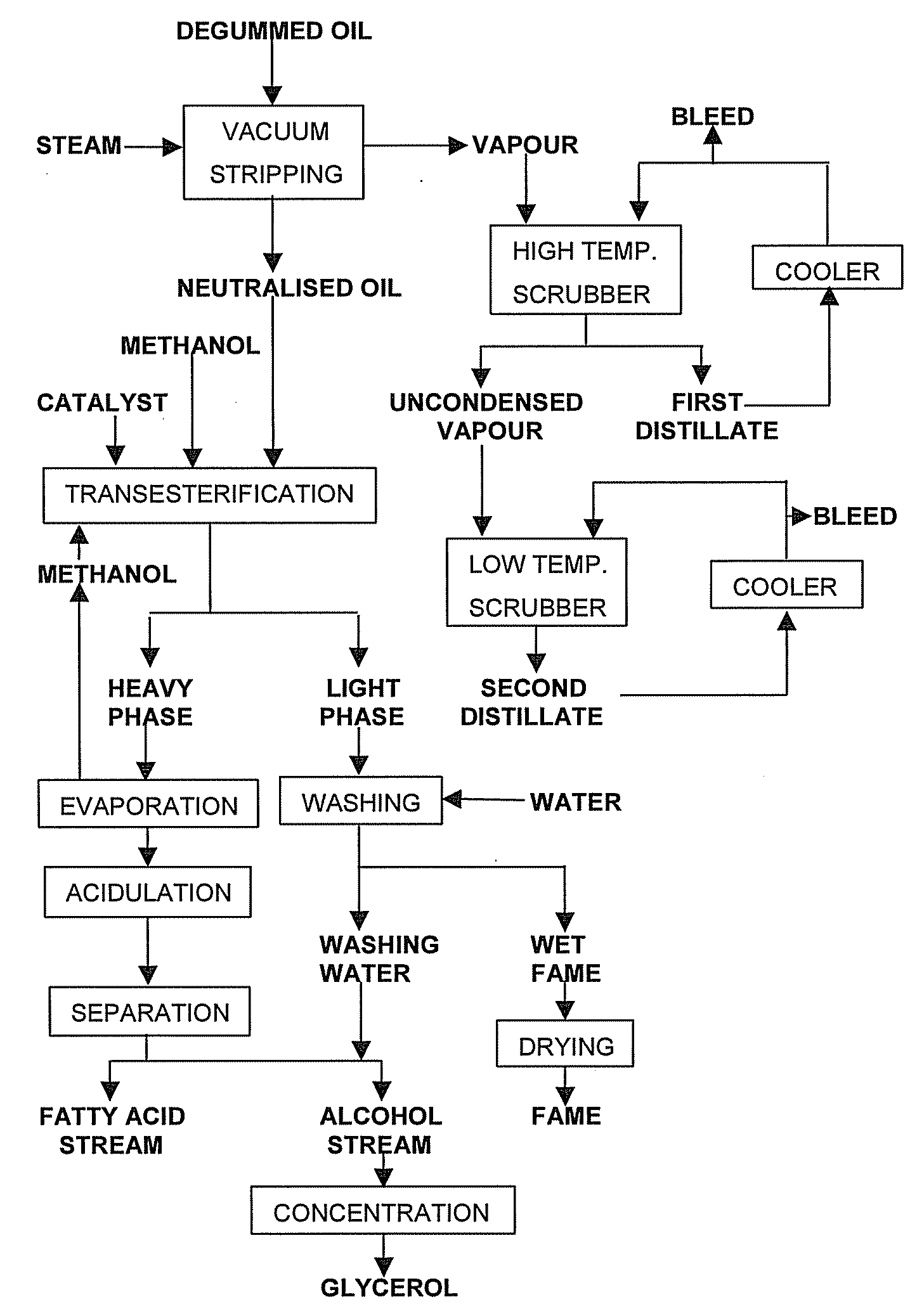

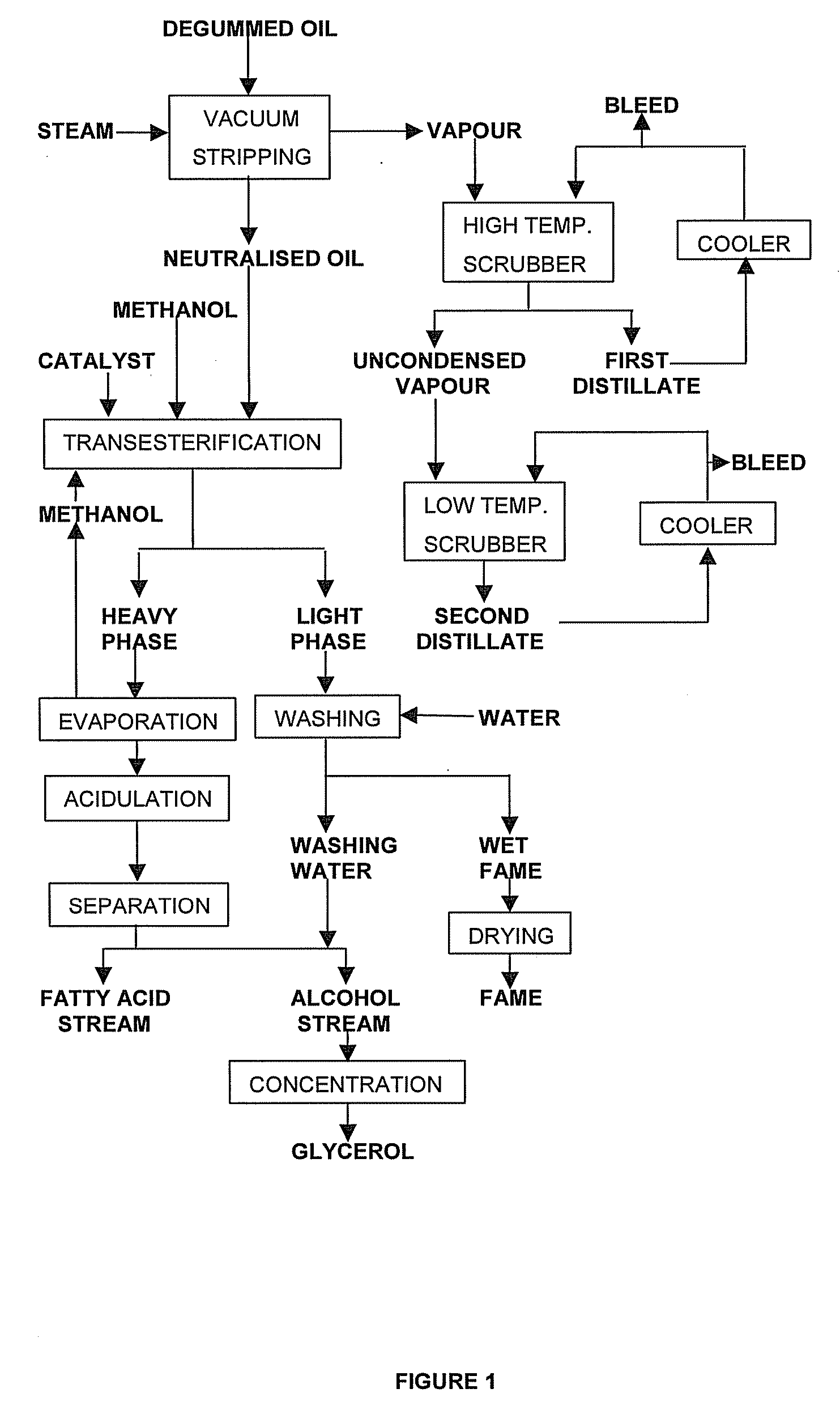

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

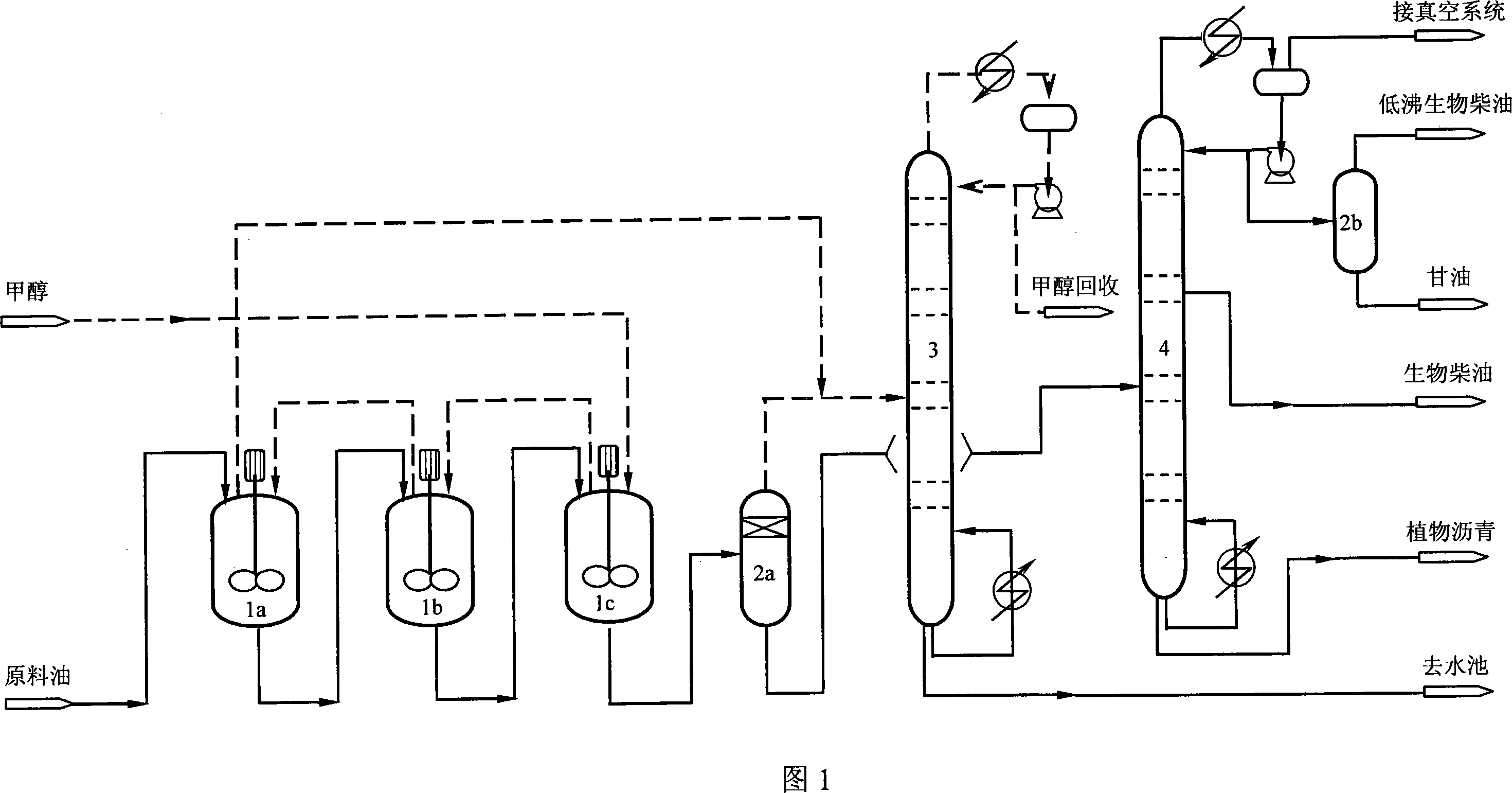

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

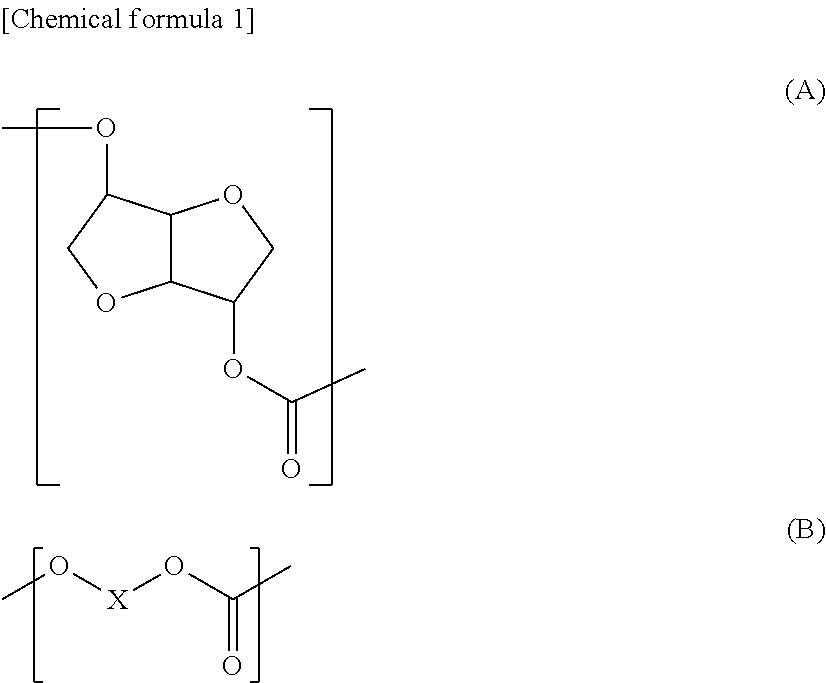

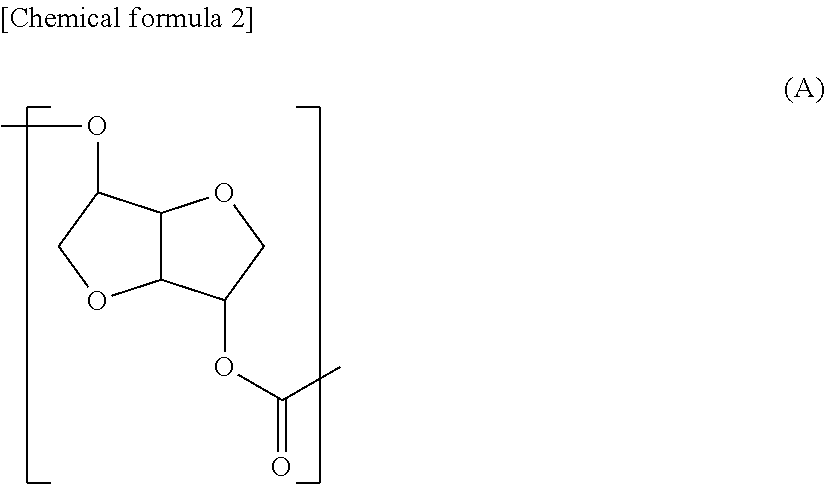

Process for producing polyester resins

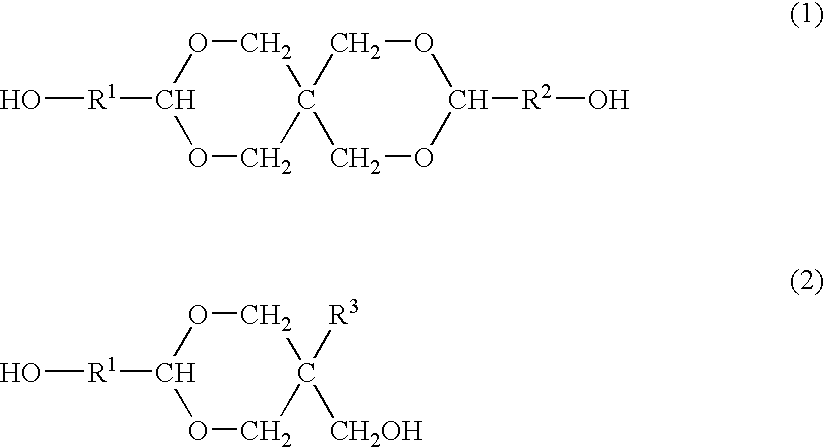

The process of the present invention for producing a polyester resin comprising a dicarboxylic acid constitutional unit and a diol constitutional unit having a cyclic acetal skeleton comprises a step (1) of subjecting a diol (A) having a cyclic acetal skeleton and an ester (D) to transesterification reaction and a step (2) of mainly converting the resultant oligomer into a high polymer. The step (1) simultaneously satisfies the requirements (i) to (iv) as described in the specification. In the process of the present invention, the polyester resins having excellent moldability and mechanical properties are stably produced by a transesterification method which is less detrimental to environments.

Owner:MITSUBISHI GAS CHEM CO INC

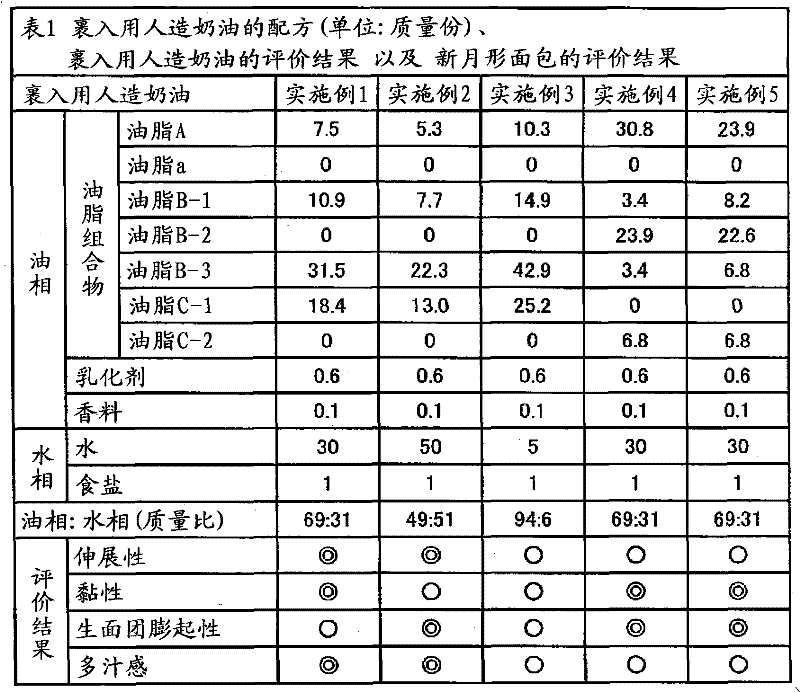

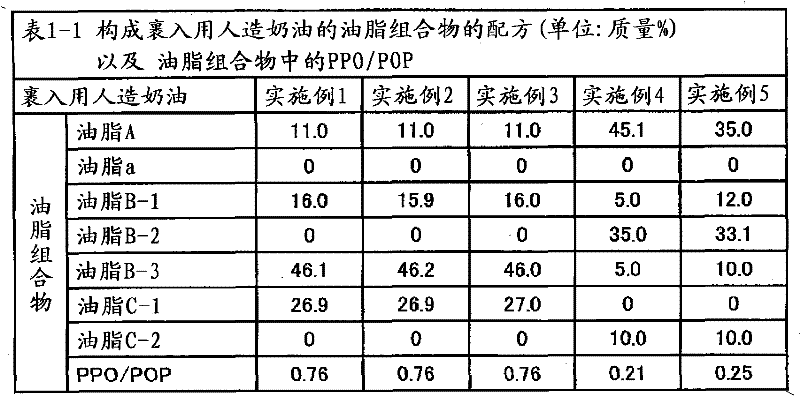

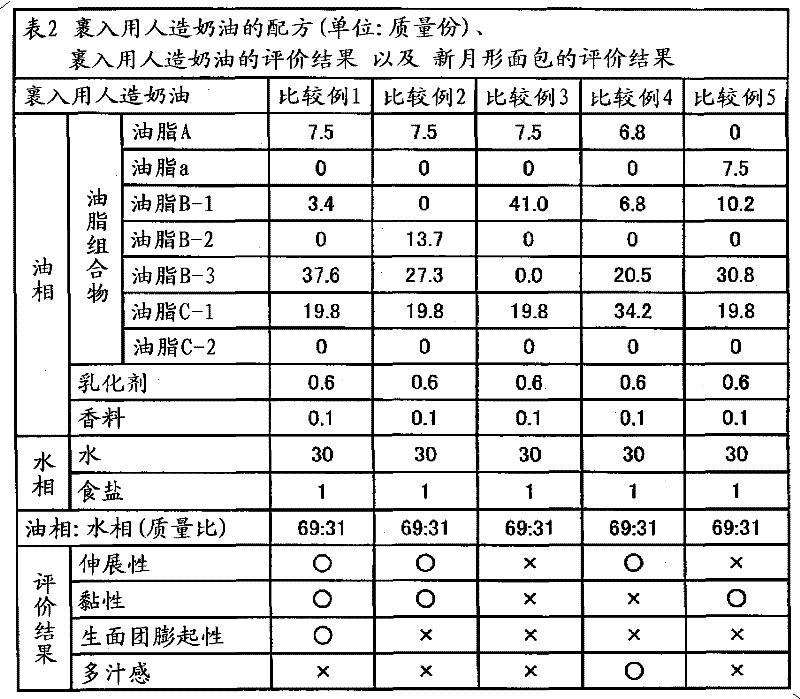

Plastic fat composition

ActiveCN102056493AEasy to stretchEasy to operateSpread compositionsFatty acid esterificationStearic acidOleic Acid Triglyceride

Provided are a plastic fat composition having a small trans fatty acid content, which is suitable for roll-in, spreading, kneed-in and similar purposes, and a fat composition to be used in the preceding plastic fat composition. A fat composition which contains the following fats A, B and C and satisfies the following requirements (a) to (c): fat A: a fat which contains 20 to 60% by mass of a saturated fatty acid having 12 to 14 carbon atoms and 40 to 80% by mass of a saturated fatty acid having 16 to 18 carbon atoms in the total constituting fatty acids thereof, and in which the fats have been obtained by ester exchange; fat B: a fat which contains 20 to 60% by mass of palmitic acid, 0.5 to 6% by mass of stearic acid and 30 to 60% by mass of oleic acid in the total constituting fatty acids thereof; and fat C: a liquid oil; (a) the content of fat A in the fat composition being 0.1 to 50% by mass; (b) the content of fat B in the fat composition being 0.1% by mass or more but less than 40% by mass; and (c) the PPO / POP of the fat composition being 0.15 to 1.00.

Owner:THE NISSHIN OILLIO GRP LTD

Synthesis of higher polyol fatty acid polyesters by transesterification

InactiveUS6504003B1Process economyHigh degree of esterificationEsterified saccharide compoundsSugar derivativesPolyesterTrans esterification

A process for synthesizing polyol fatty acid polyesters comprising the steps of (1) mixing ingredients comprising (a) unesterified first polyol having hydroxyl groups, (b) second polyol esterified with fatty acids, (c) basic catalyst, and (d) emulsifying agent to form a mixture of ingredients; (2) reacting the mixture of ingredients at a temperature sufficient to obtain a transesterification reaction products and by-products; and (3) removing at least a portion of the by-products from the transesterification reaction mixture; and (4) further heating the transesterification reaction products and ingredients from step (3) at a temperature and for a time sufficient to esterify at least about 50% of the hydroxyl groups of the first polyol.

Owner:THE PROCTER & GAMBLE COMPANY

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277432A1Maximize recoveryQuality improvementFatty acid chemical modificationOrganic compound preparationOrganic acidChemical reaction

A system and method for the conversion of free fatty acids to glycerides and the subsequent conversion of glycerides to glycerin and biodiesel includes the transesterification of a glyceride stream with an alcohol. The fatty acid alkyl esters are separated from the glycerin to produce a first liquid phase containing a fatty acid alkyl ester rich (concentrated) stream and a second liquid phase containing a glycerin rich (concentrated) stream. The fatty acid alkyl ester rich stream is then subjected to distillation, preferably reactive distillation, wherein the stream undergoes both physical separation and chemical reaction. The fatty acid alkyl ester rich stream is then purified to produce a purified biodiesel product and a glyceride rich residue stream. Biodiesel may be further recovered from the glyceride rich residue stream, by further separation of and / or processing of glycerides / free fatty acids contained therein. The glycerin rich second liquid phase stream may further be purified to produce a purified glycerin product and a (second) wet alcohol stream. Neutralization of the alkaline stream, formed during the alkali-catalyzed transesterification process, may proceed by the addition of a mineral or an organic acid.

Owner:REG SENECA LLC

Solid alkali catalyst, preparation and use thereof

InactiveCN1680514AOvercoming defects that are not easy to reproduceReduce adverse effectsBiofuelsCatalyst activation/preparationAlkali soilBiodiesel

A solid alkali catalyst is used to ester exchange of producing biological diesel fuel. The catalyst which is solid or multihole particle is made up of oxidant of the alkali soil and alkali metal. The process has dissolved the difficult of reuse and separate of the catalyst. The yield of the product can reach to 85%. It can be used to different biological diesel fuel.

Owner:TSINGHUA UNIV

Aromatic polycarbonate resin composition

InactiveUS6355767B1High impact strengthImprove hydrolysis resistanceTrans esterificationPolymer science

An aromatic polycarbonate resin composition comprising:(1) 10 to 90 wt % of an aromatic polycarbonate resin (component A) which is obtained from an ester exchange reaction between a diphenol and a dicarbonate ester and has a terminal hydroxyl group concentration of 10 to 70 mol % based on 100 molt of the total of all the terminal groups; and(2) 90 to 10 wt % of a thermoplastic graft copolymer resin (component B) which is obtained by grafting a vinyl cyanide monomer component and an aromatic vinyl monomer component to a diene-based rubber, the proportion of the vinyl cyanide monomer component to the copolymer resin being 10 to 27 wt % and the amount of a vinyl cyanide monomer contained in the copolymer resin being 200 ppm or less. According to the present invention, there is provided an aromatic polycarbonate resin composition which has excellent mechanical strength, particularly falling weight impact strength and improved hydrolysis resistance under a moist heat environment.

Owner:TEIJIN KASEK KK

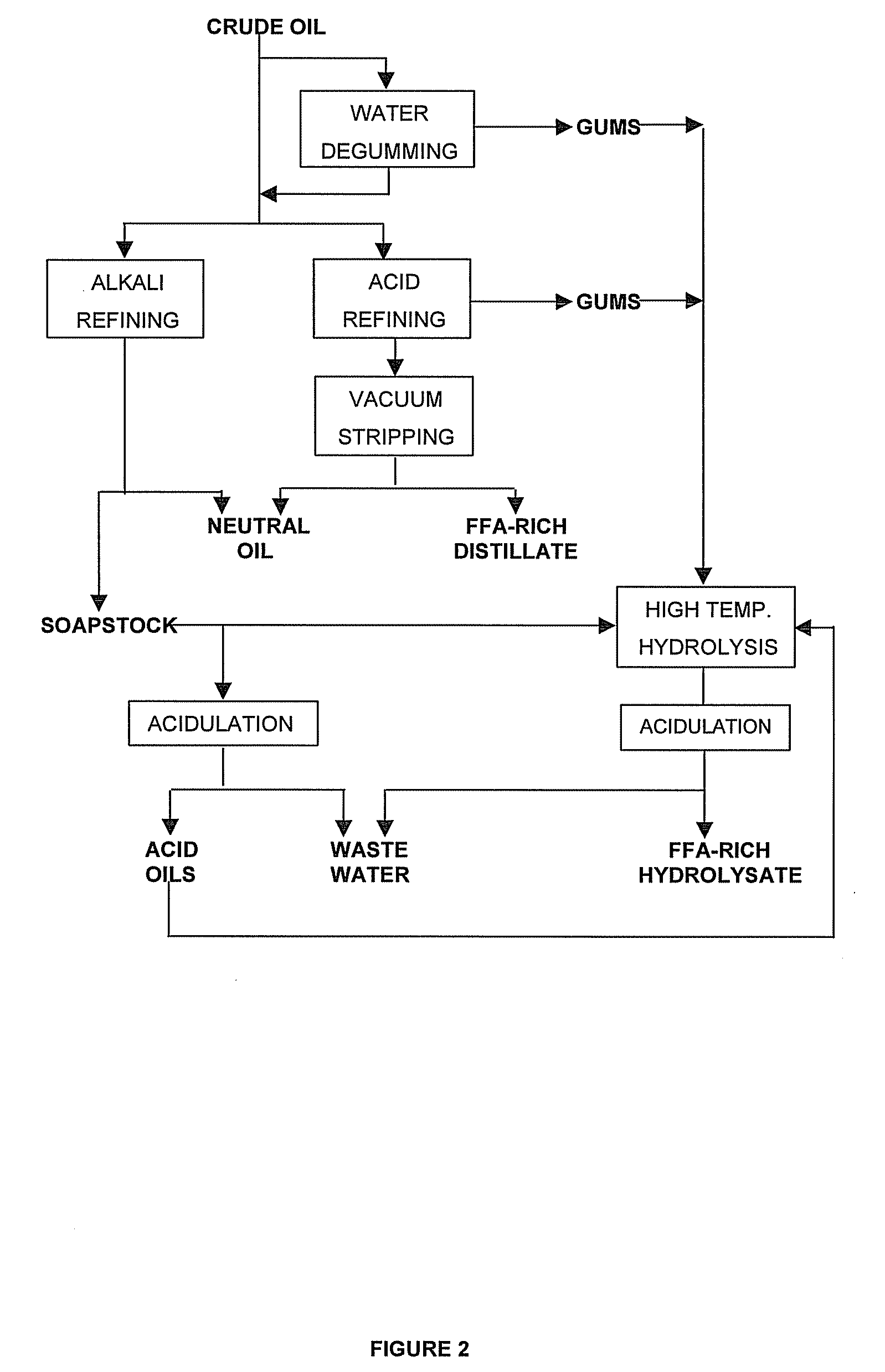

Integrated process for the manufacture of biodiesel

InactiveUS20070260078A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationAnimal oil

The present application describes an integrated process for the manufacture of biodiesel from vegetable or animal oils using a solid, transesterification catalyst and a solid, etherification catalyst.

Owner:MILLENNIUM RES LAB

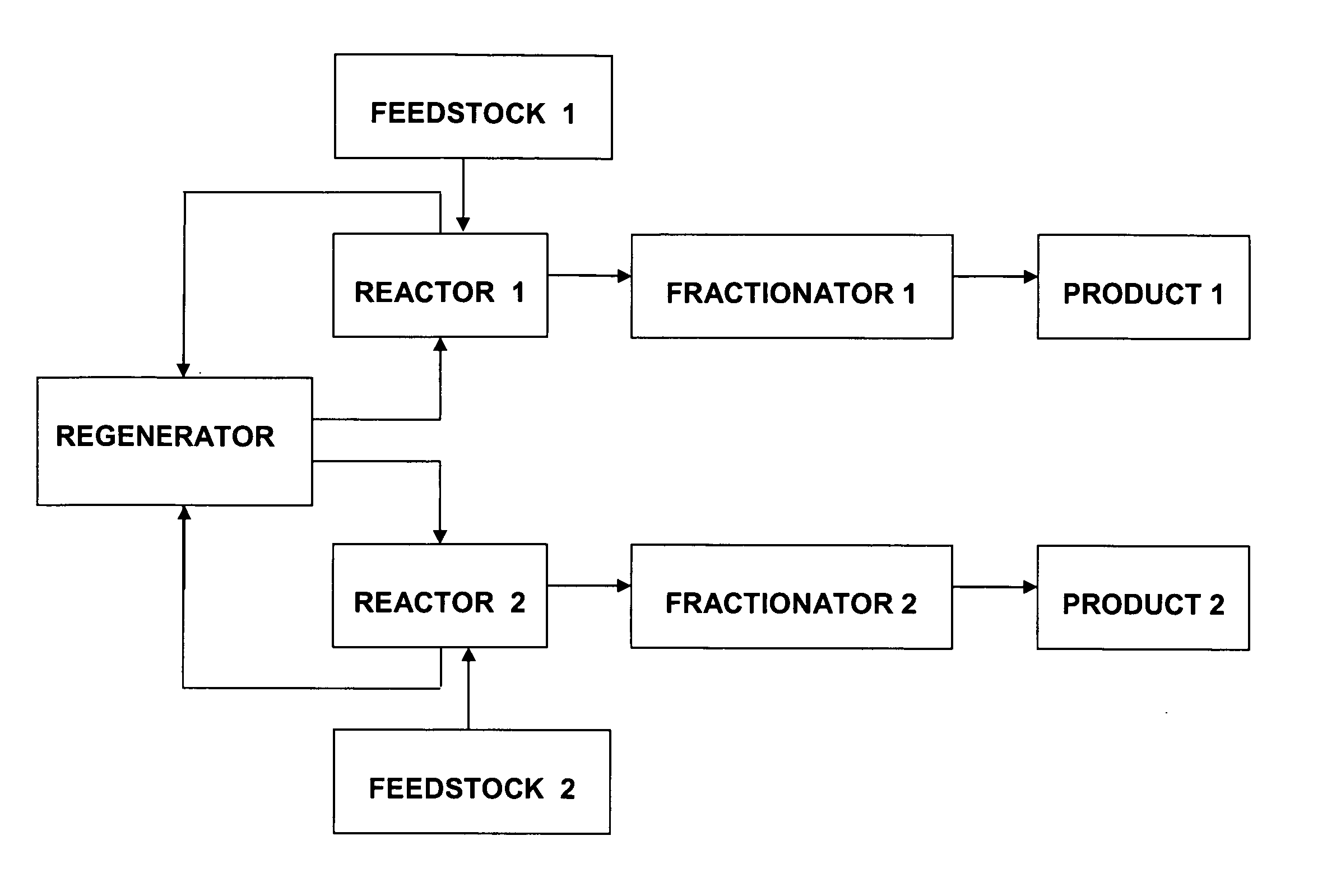

Catalytic cracking process for the production of diesel from vegetal oils

ActiveUS20070007176A1Increase cetane numberCatalytic crackingCatalytic naphtha reformingHydrocotyle bowlesioidesTransesterification

The present invention comprises a thermo catalytic process to produce diesel oil from vegetal oils, in refineries which have two or more Catalytic Cracking (FCC) reactors. At least one reactor processes heavy gasoleum or residue in conventional operation conditions while at least one reactor processes vegetal oils in proper operation conditions to produce diesel oil. This process employs the same catalyst employed in the FCC process, which processes conventional feedstocks simultaneously. This process transforms high heat content raw materials into fuel hydrocarbons. It shows excellent efficiency for the obtention of highly pure products and do not yield glycerin, one by-product of the transesterification process. The diesel oil produced by said process presents quality superior and cetane number higher than 40. Once cracking reactions occur at lower temperatures, it forms less oxidized product, which is consequently purer than those obtained by existent technology are.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

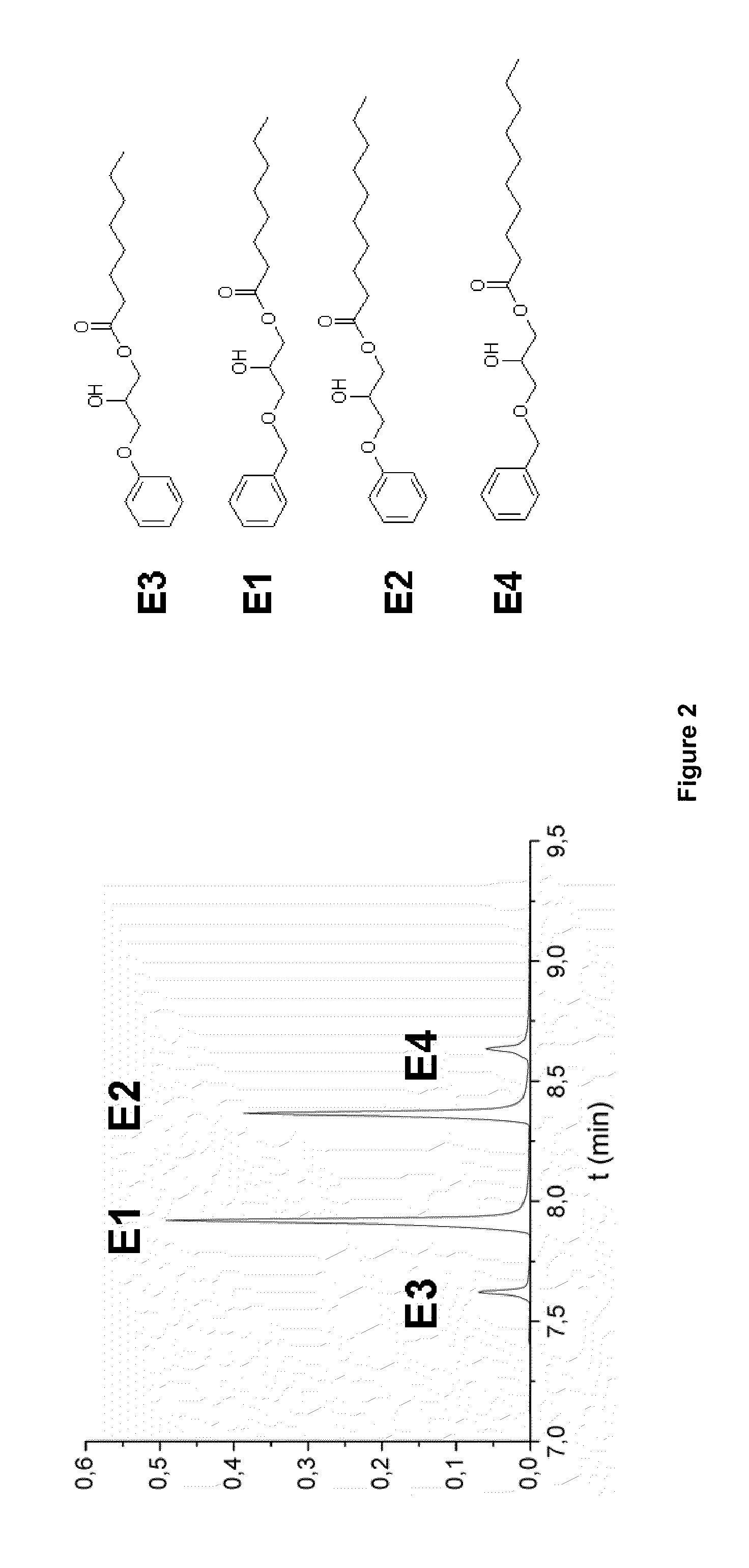

Method for the extraction and analysis of contents made from organic material

InactiveUS7311838B2Guaranteed smooth progressComponent separationIon-exchanger regenerationAlcoholOrganic solvent

The present invention relates to a process for isolating constituents from organic material, comprising the following process steps:a) freeze-drying of the organic material;b) extracting the constituents with a polar solvent or solvent mixture (A) and an organic solvent or solvent mixture (B), it being possible for the extracts of the extraction with (A) and (B) to form one phase;c) combining the extracts (A) and (B) to give one phase; andd) carrying out an esterification / transesterification in the unpolar phase with an alcohol, the esterification / transesterification being carried out in the presence of a volatile acid;the process being a high-throughput process.

Owner:METANOMICS GMBH

Method for manufacture of esters by transesterification

InactiveUS7696376B2Fatty oils/acids recovery from wastePreparation by ester-hydroxy reactionPtru catalystSolid acid

A method for the manufacture of an ester by transesterification allows the transesterification reaction to proceed within a short reaction time and under a pressure of the order of normal pressure. It was found that transesterification proceeds when a starting material ester and an alcohol are brought into contact with a catalyst comprising (A) an amorphous zirconium oxide and (B) an oxide of a Group II element, an oxide of a Group V element, and / or an oxide of a Group IV element other than zirconium and hafnium. In this method, it is preferred that the starting material ester in a liquid-phase state and the alcohol in a vapor-phase state be brought into contact with a solid acid catalyst comprising the above components (A) and (B), the starting material ester be an oil or fat, and the alcohol be methanol or ethanol. An oxide of titanium, silicon, germanium, or tin is the preferred oxide of the Group IV element other than zirconium and hafnium.

Owner:JAPAN ENERGY CORP

Terephthalic acid oxidation residue recovery and utilization method

ActiveCN1611482AOrganic compound preparationCarboxylic acid esters preparationChemical industryBenzoic acid

The invention relates to a kind of recycling method of tere phthalic acid (TPA) oxidizing residue. The invention uses the processes such as twice methyl ester reaction, rectification for separating, recrystallization for refining, interesterification reaction, and so on, to recycle tere phthalic acid (TPA), M-phthalic acid, and benzoic acid in petroleum chemical industry production residue. The invention solves problems such as low recycling ratio and more impurity of the product and so on in existing technique. The method is mainly used in recycling of tere phthalic acid (TPA) oxidizing residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process For Preparing Fatty Acid Alkylesters Using As Biodiesel

InactiveUS20070282118A1Increase concentrationFatty acid esterificationOrganic compound preparationAlcoholVegetable oil

Fatty acid alkyl esters suitable for use as biodiesel are produced by a single step esterification of free fatty acids and transesterification of triglycerides from vegetable oils or animal fats or combinations thereof with a lower alcohol (e.g. methanol) in presence of alkyl Tin oxide as catalyst. The ester thus produced is purified by distillation, treatment with an adsorbent, washing with water or combination thereof to give esters suitable for use as biodiesel.

Owner:COUNCIL OF SCI & IND RES

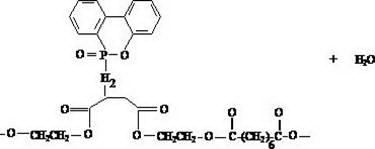

Preparation method of phosphorus-containing halogen-free environmentally-friendly flame-retardant polyester polyol

The invention provides a preparation method of phosphorus-containing halogen-free environmentally-friendly flame-retardant polyester polyol. The method comprises the steps that with DOPO being starting material, firstly, the DOPO reacts with dibasic acid or dibasic acid anhydride to generate a DOPO complex intermediate; secondly, esterification dehydration reaction is performed on the generated intermediate, small-molecules polyol and dibasic acid or dibasic acid anhydride at 150 DEG C-160 DEG C; after the dehydration reaction is over, the temperature is raised to 200 DEG C-250 DEG C for transesterification, wherein the reaction time is 1 h-3 h, and in this way, the polyester polyol is obtained. The prepared polyester polyol is not conventional polyester polyol but the polyester polyol containing the phosphorus element, has the reactivity with isocyanate and can be used for permanent flame retardant modification of polyurethane products. As the phosphorus element is introduced to the polyester polyol, the polyester polyol contains phosphorus and is free of halogen, environmentally friendly and capable of inflaming retarding.

Owner:XUCHUAN CHEM SUZHOU

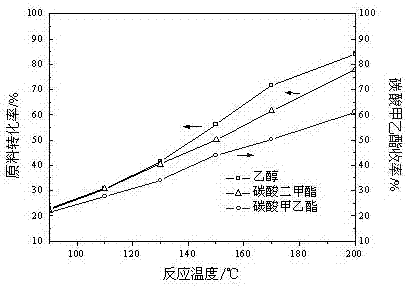

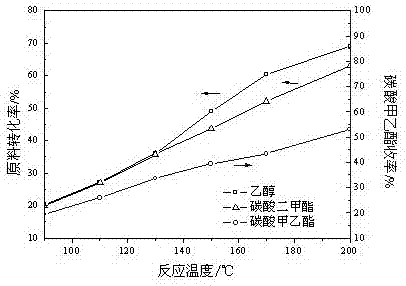

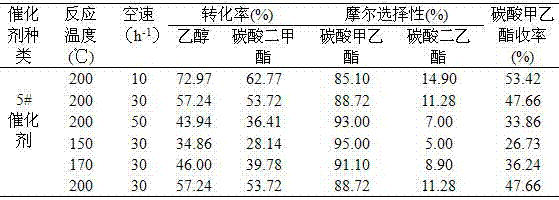

Method for preparing ethyl methyl carbonate through ester exchange method

InactiveCN107473968AGood dispersionImprove mass transfer effectPhysical/chemical process catalystsPreparation from organic carbonatesDispersityMethyl carbonate

The invention provides a method for preparing ethyl methyl carbonate through an ester exchange method, and relates to a method for preparing a chemical raw material. A first catalyst prepared by the method simultaneously has macropore and micropore structures, wherein the macropores can obviously improve the mass transfer effect; and the micropores can obviously improve the specific surface area of a carrier and simultaneously improve the dispersity of active centers. Meanwhile, the prepared first catalyst simultaneously has an alkali active center and a Lewis acid catalytic active center. The prepared 15%MgO-5%MgCl2-2%La2O3 / Al2O3-SiO2 is used in a dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction; when the reaction temperature is 200 DEG C and the space velocity is 30h<-1>, the catalyst is not inactivated after 5000h of continuous reaction, the dimethyl carbonate conversion rate can be kept at 70%, the ethanol conversion rate can be kept at 80%, and the yield of the product ethyl methyl carbonate is 56%; and after the reaction, the catalyst can be reused through simple filtration treatment, and the activity of the catalyst can still be kept unchanged after the catalyst is reused for multiple times.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Purification of glycerin obtained as a bioproduct from the transesterification of triglycerides in the synthesis of biofuel

InactiveUS7718833B2Lower bottom temperatureInhibition formationOrganic compound preparationOxygen compounds purification/separationBioproductsAlcohol

Methods for purifying glycerin contaminated with one or more lower boiling alcohols such as methanol, ethanol, straight, branched or cyclic C3-C6 alcohols, and the like. The methods are particularly useful for purifying crude glycerin phases recovered from the synthesis of biofuels. The present invention uses distillation techniques to strip alcohol contaminants from glycerin. In contrast to conventional methods that carry out distillation either under substantially anhydrous or very wet conditions, the present invention carries out distillation in the presence of a limited amount of water, e.g., from about 0.8 to about 5 parts by weight of water per 100 parts by weight of contaminated glycerin to be purified.

Owner:JOHANN HALTERMANN

Thermoplastic polyolefins with high flowability and excellent surface quality produced by a multistage process

InactiveUS20110086970A1Improve liquidityImprove surface qualityOrganic-compounds/hydrides/coordination-complexes catalystsMixingElastomerPolymer science

Reactor grade thermoplastic polyolefins with high flowability and excellent surface quality comprising (A) 40-90 wt % of a propylene homo- or copolymer matrix with an MFR in accordance with ISO 1 133 (230° C., 2.16 kg load) of >200 g / 10 min and (B) 2-30 wt % of an elastomeric ethylene-propylene copolymer having an intrinsic viscosity IV (according to ISO 1628 with decalin as solvent) of ≦2.8 dl / g and an ethylene content of >50 to 80 wt % and (C) 8-30 wt % of an elastomeric ethylene-propylene copolymer having an intrinsic viscosity IV (according to ISO 1628 with decalin as solvent) of 3.0-6.5 dl / g and an propylene content of 50 to 80 wt %, the reactor grade thermoplastic polyolefins being obtainable by a multistage polymerization process with at least 3 polymerization steps in the presence of a catalyst system comprising (i) a Ziegler-Natta procatalyst which contains a trans-esterification product of a lower alcohol and a phthalic ester and (ii) an organometallic cocatalyst and (iii) external donor represented by formula (I) Si(OCH2CH3)3(NR1R2) wherein R1 and R2 can be the same or different a represent a hydrocarbon group having 1 to 12 carbon atoms, as well as the use of these reactor grade thermoplastic polyolefins and molded articles produced from them.

Owner:BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com