Biomass energy prepared by one-step method of microalgae

A technology of microalgae and biodiesel, applied in microorganisms, microorganism-based methods, biofuels, etc., can solve the problems of unsuitable industrial production, incapability of large-scale use, short catalytic life, etc., to reduce losses and costs, and simplify process steps. and equipment, the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

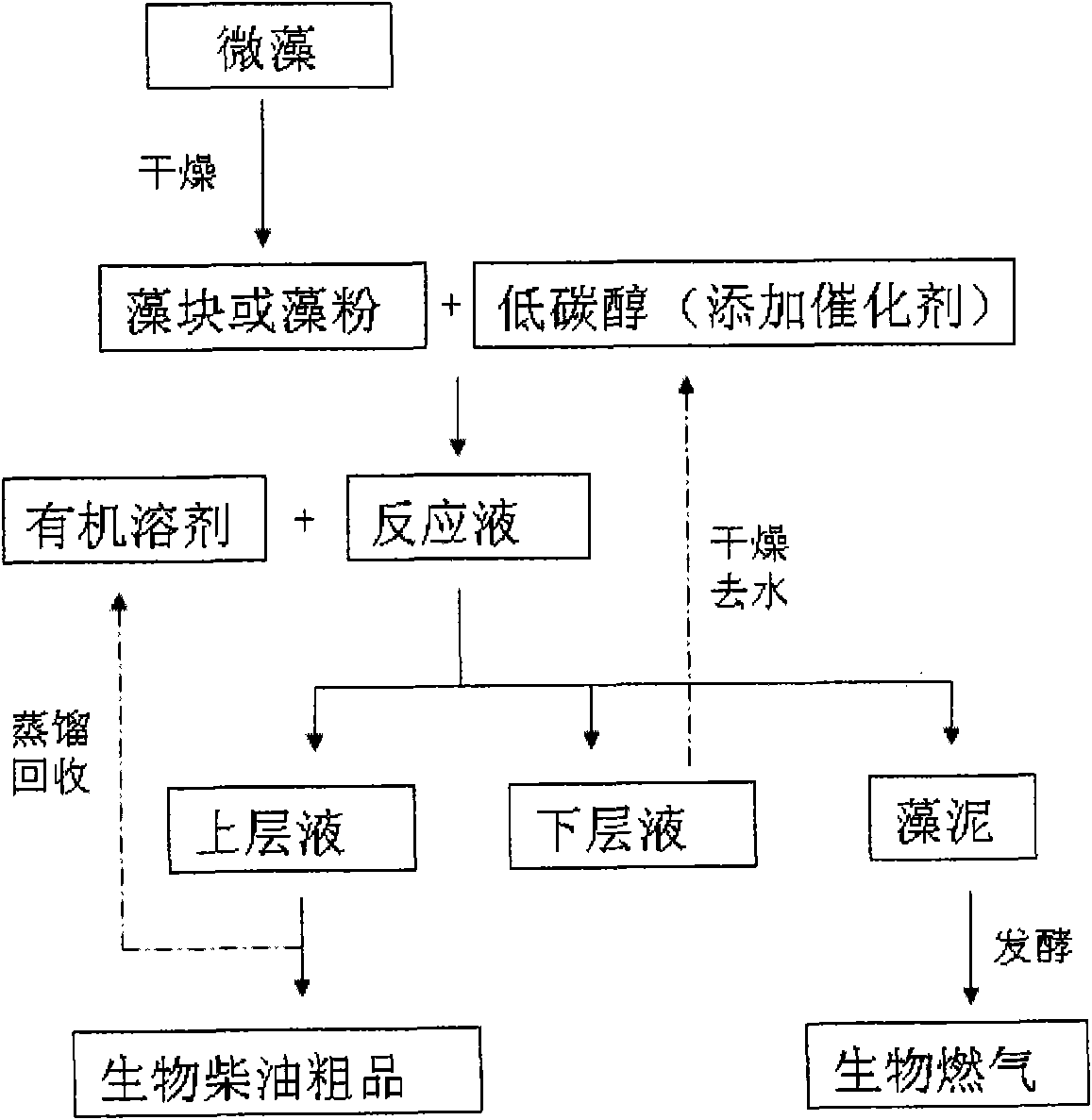

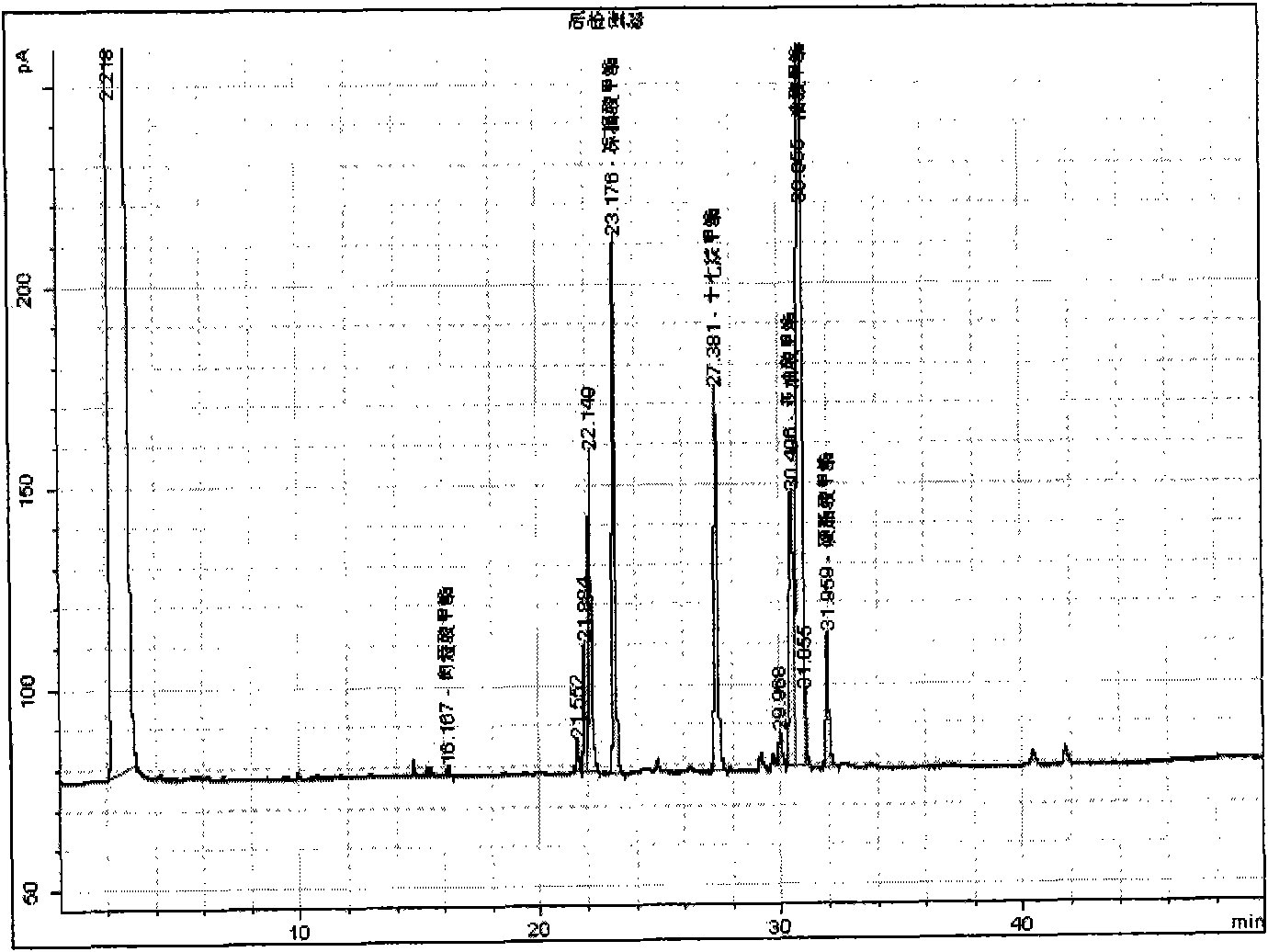

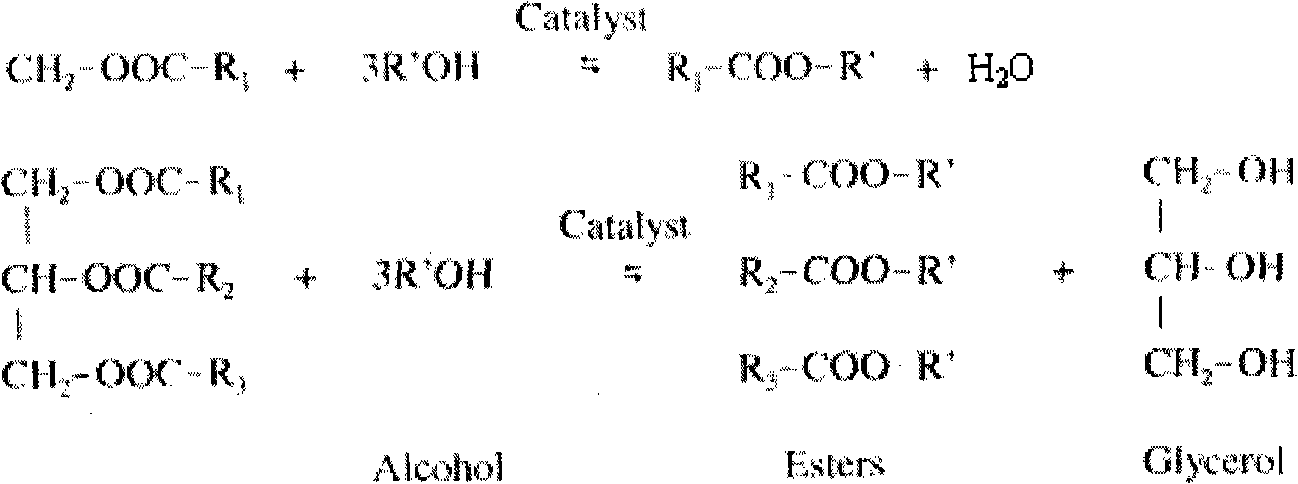

[0051] Embodiment 1, chlorella methyl esterification prepares biodiesel

[0052] Naturally air-dried Chlorococcum sp. (No. FACHB-957) (purchased from China Freshwater Algae Species Bank, Wuhan Institute of Hydrobiology, Chinese Academy of Sciences), medium BG-11, reference: Esra IMAMOGLU, Fazilet VARDAR SUKAN , Meltem CONK DALAY, International Journal of Natural and Engineering Sciences 1 (3): 05-09, 2007, the algal block or algae powder (water content is 8%) 3.3g and methanol 30ml join in In a four-necked flask, add 3 ml of catalyst 98% concentrated sulfuric acid dropwise from a constant pressure dropping funnel, seal the four-necked flask, and stir to reflux. The four-neck flask was heated in an oil bath at 70°C for 8 hours to stop the reaction.

[0053] Then add 30ml of n-hexane to the four-necked flask, increase the stirring properly, and use the remaining temperature of the previous reaction or maintain a certain temperature (below 60°C) to promote the extraction. After ...

Embodiment 2

[0067] Embodiment 2, the dehydration reuse of methanol and sulfuric acid

[0068] After the extraction was stopped in Example 1, the reaction solution was divided into upper layer liquid (organic solvent phase for extraction), lower layer liquid (methanol plus water phase) and algae mud in the reaction liquid. Add solid desiccant (such as alumina, silica gel, molecular sieve, etc.) to the lower layer liquid to remove water and dry it, then re-add algae powder to continue methyl esterification, and add methanol appropriately according to the reaction ratio in Example 1 (methanol 30ml). Chlorophyll mostly dissolves in this layer, but it does not affect reuse. At the same time, the desiccant can also play a certain role in decolorization.

Embodiment 3

[0069] Embodiment 3, algal mud preparation biogas

[0070] After the extraction in Example 1 is stopped, it is divided into three layers, and the algae mud in the lower layer can be used for fermentation to prepare biogas. The basic conditions are as follows: the temperature of hydrogen-producing acetate fermentation in the first stage is controlled at 30-40°C, and the pH is adjusted to 4.0-4.5; the temperature of the second-stage methane-producing fermentation is maintained at 35-40°C, and the pH is adjusted to 6.8-7.5. The gas produced is hydrogen and / or methane, which is biogas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com