Metal composite plate with fireproof interlayer and manufacturing method thereof

A technology of metal composite board and sandwich layer, which is applied in the field of building decoration materials, can solve the problems of poor fire resistance and achieve light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

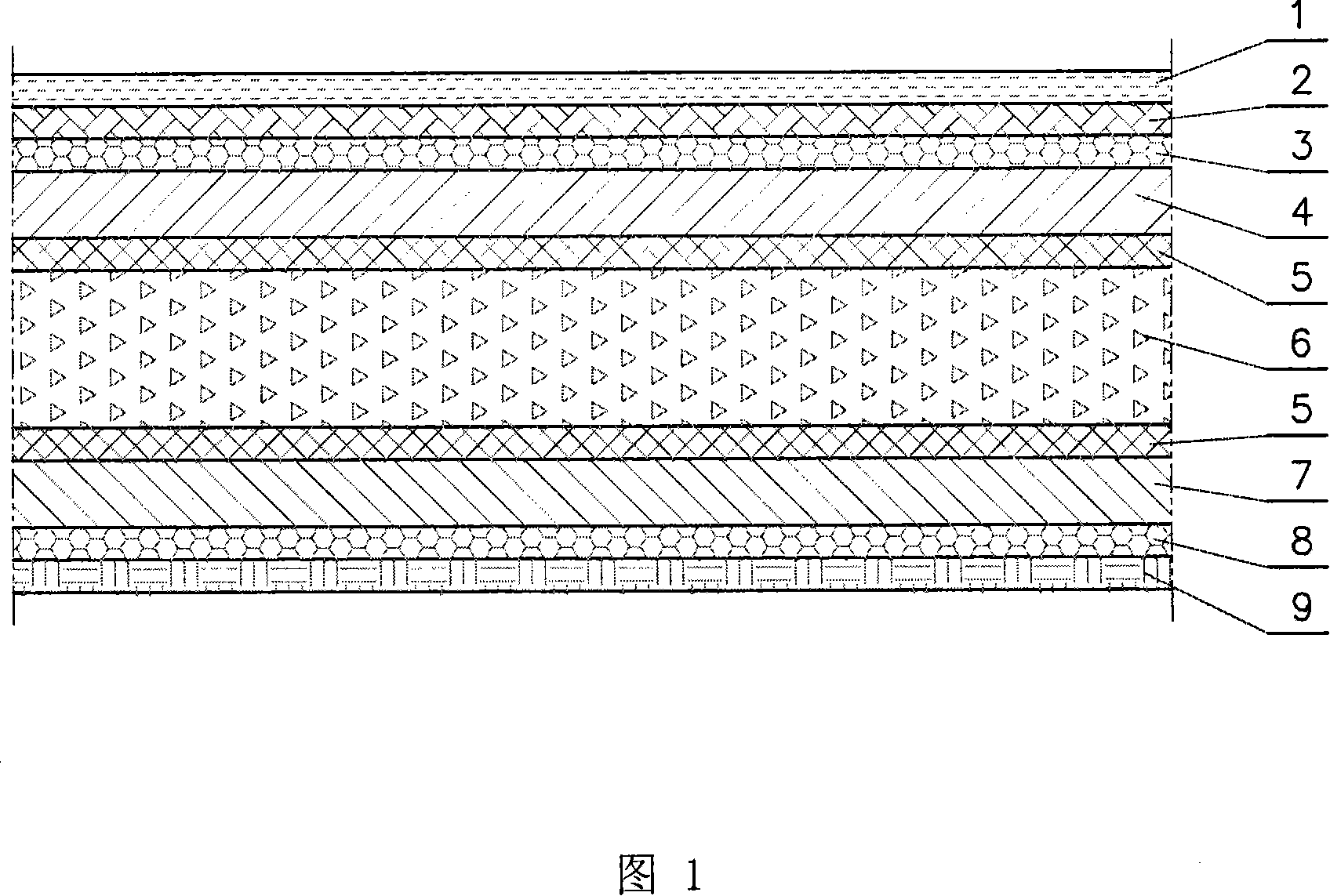

[0020] Embodiment 1 is shown in accompanying drawing 1: a kind of thickness is 4mm and is used for interior and exterior wall decoration with fireproof sandwich layer aluminum alloy composite board, and it is made of polyethylene protective film 1, fluorocarbon resin baking paint layer 2, chemical conversion treatment skin film Layer 3, upper aluminum alloy plate 4 with a thickness of 0.5mm, polyurethane adhesive layer 5, flame-retardant core plate 6 and polyurethane adhesive layer 5, lower aluminum alloy plate with a thickness of 0.5mm 7, chemical conversion treatment film layer 8 and anti-rust bottom The lacquer layers 9 are stacked successively to form a whole.

[0021] The flame retardant core board 6 is made of quartz sand with a particle size of 80-150 mesh, silicon dioxide, perlite with a particle size of 40-100 mesh, flame retardant, coupling agent, and binder, and then hot-pressed. Sheets with a thickness of 3mm.

Embodiment 2

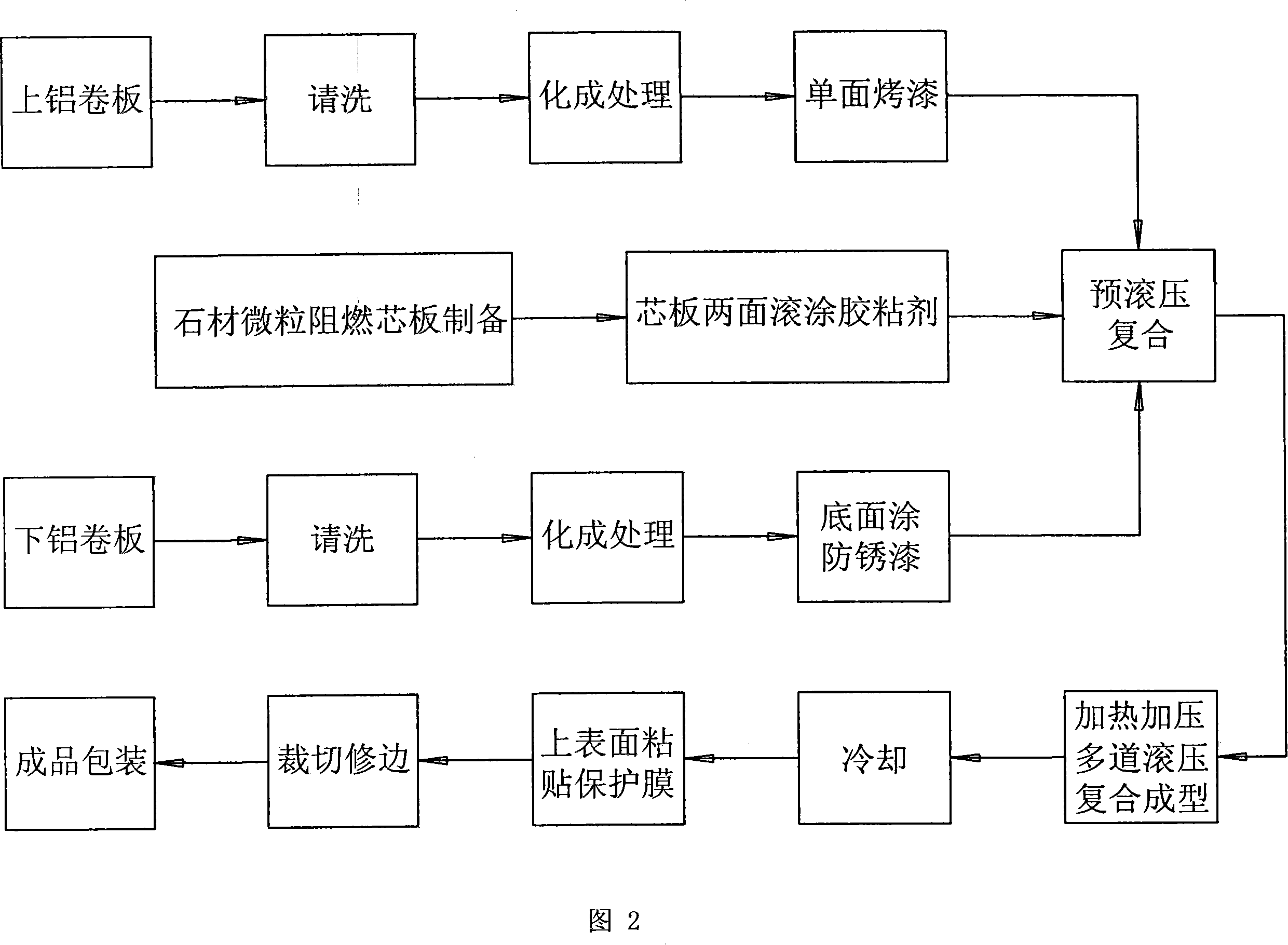

[0022] Embodiment 2 is shown in accompanying drawing 2: a kind of thickness is 4mm, is used for the manufacture method of the aluminum alloy composite panel with fireproof sandwich layer of interior and exterior wall decoration, comprising:

[0023] ① Preparation of flame retardant core board 6;

[0024] A. select quartz sand, silicon dioxide and perlite with a particle size of 80 to 150, and the mixed weight components account for 60% of the total weight of the core material;

[0025] B. Select aluminum hydroxide, magnesium hydroxide and 1000 order decabromodiphenyl ether as flame retardant for use, and its weight components account for 10% of the core material gross weight;

[0026] C. select glass fiber and silane coupling agent for use, and its weight component accounts for 3% of core material gross weight;

[0027] D. select polyurethane and vinyl acetate latex synthetic binding agent for use, and its weight component accounts for 27% of core material gross weight;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com