Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Avoid cold cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding method for Q345qDNH weather-resisting steel for bridge

ActiveCN102837105AGood mechanical propertiesEasy to upgradeArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingButt joint

The invention discloses a welding method for Q345qDNH weather-resisting steel for a bridge. According to the welding method provided by the invention, specific to the special chemical components, suitable technical conditions and different slab thickness of the Q345qDNH weather-resisting steel for the bridge, a welded joint is jointed in a butt-jointed or T-shaped corner jointed form. According to the welding method, submerged-arc welding, drug core CO2 gas shielding semi-automatic welding or shielded metal arc welding is adopted and the weld preheating temperature is confirmed according to the different slab thickness. According to the welding method provided by the invention, the joint form and the thickness size of a bridge structure are completely covered; the technical scheme is simple and the applicability is strong; the implementing effect meets the technical demands of the present related standard for the construction of the bridge steel and the bridge structure; and the welding method can be practically applied to the welding of the Q345qDNH weather-resisting steel bridge structure.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

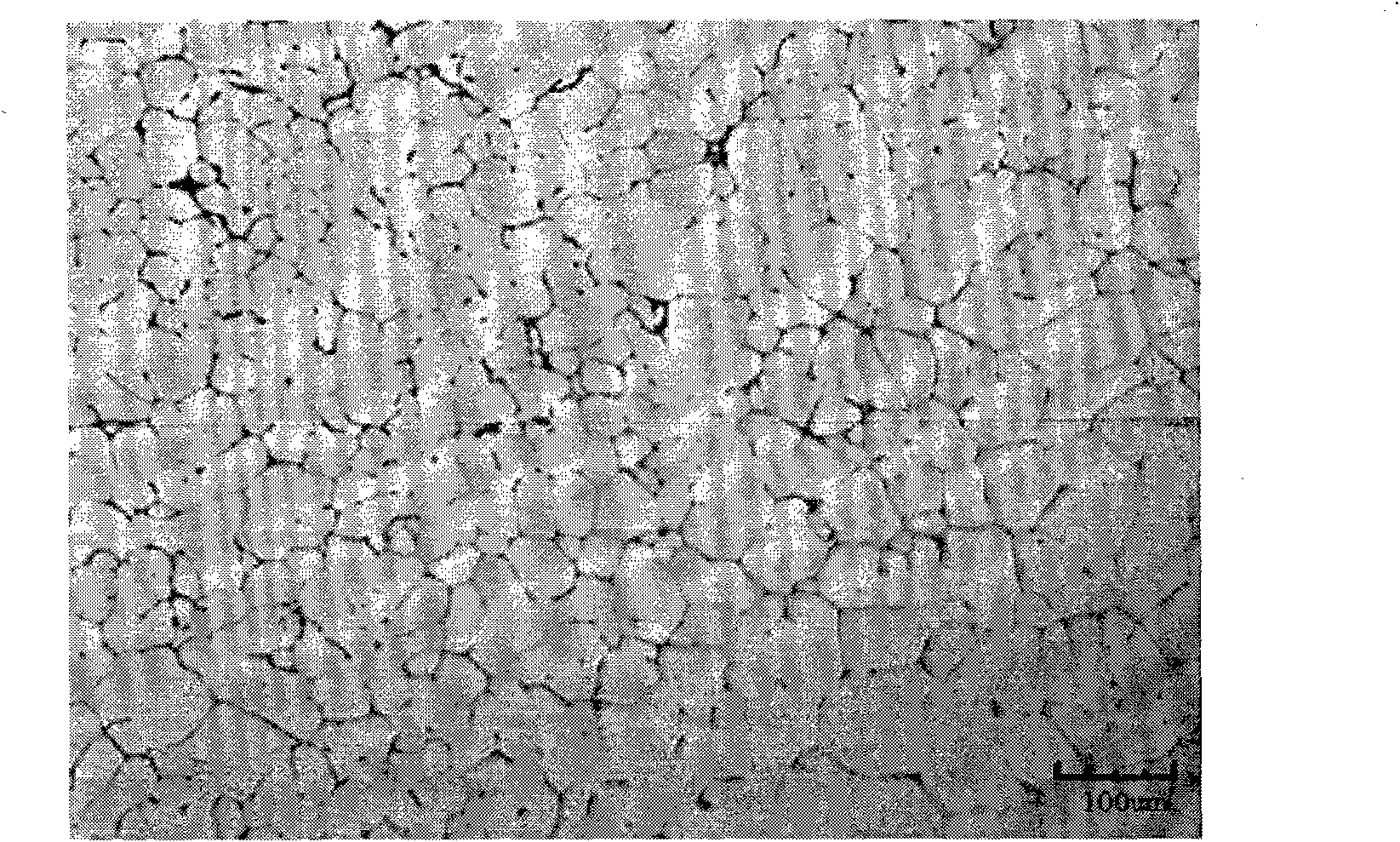

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots and solving the problems of easy cracking and difficult forming during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO.1 flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials in the smelting furnace are smelted; adding magnesium ingots and then smelting; then refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the prepared ingot is 500-600mm, the width is 600mm, and the length is 2,000-3,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 90.5 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

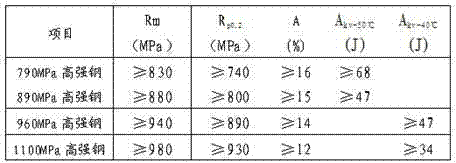

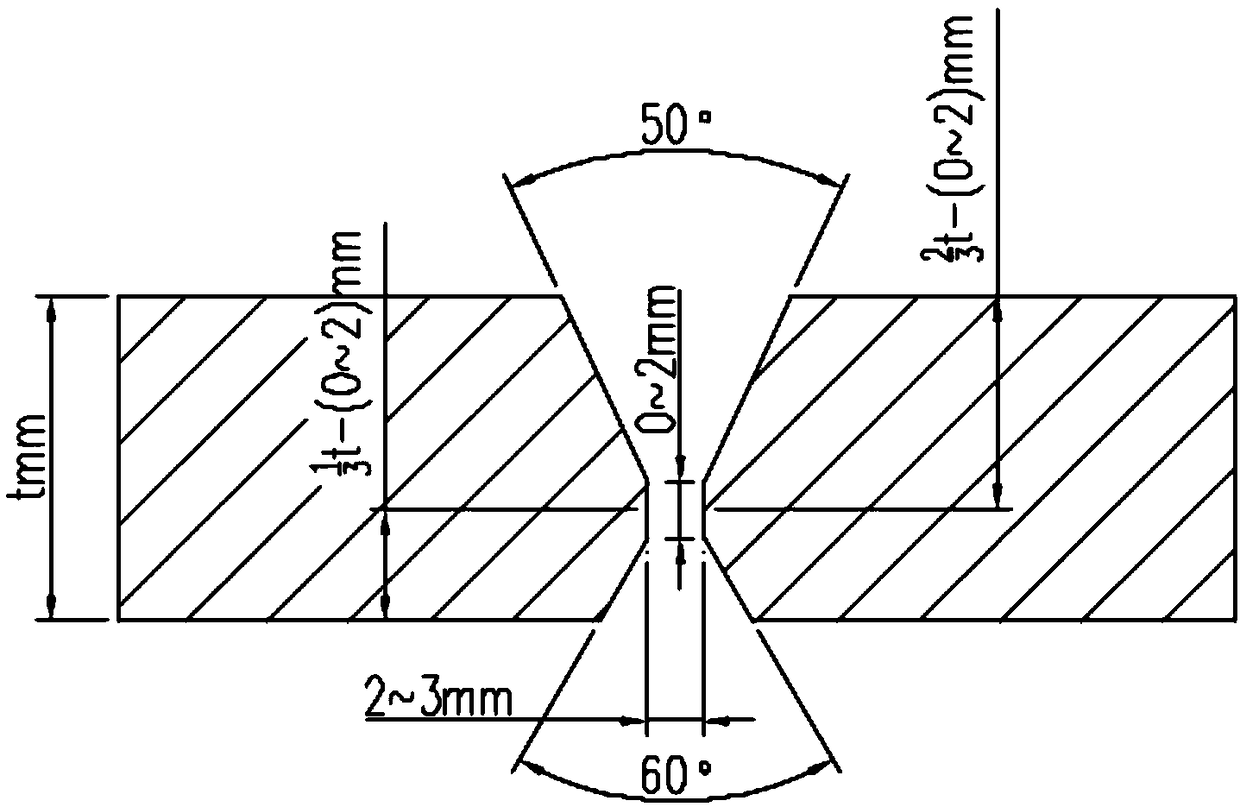

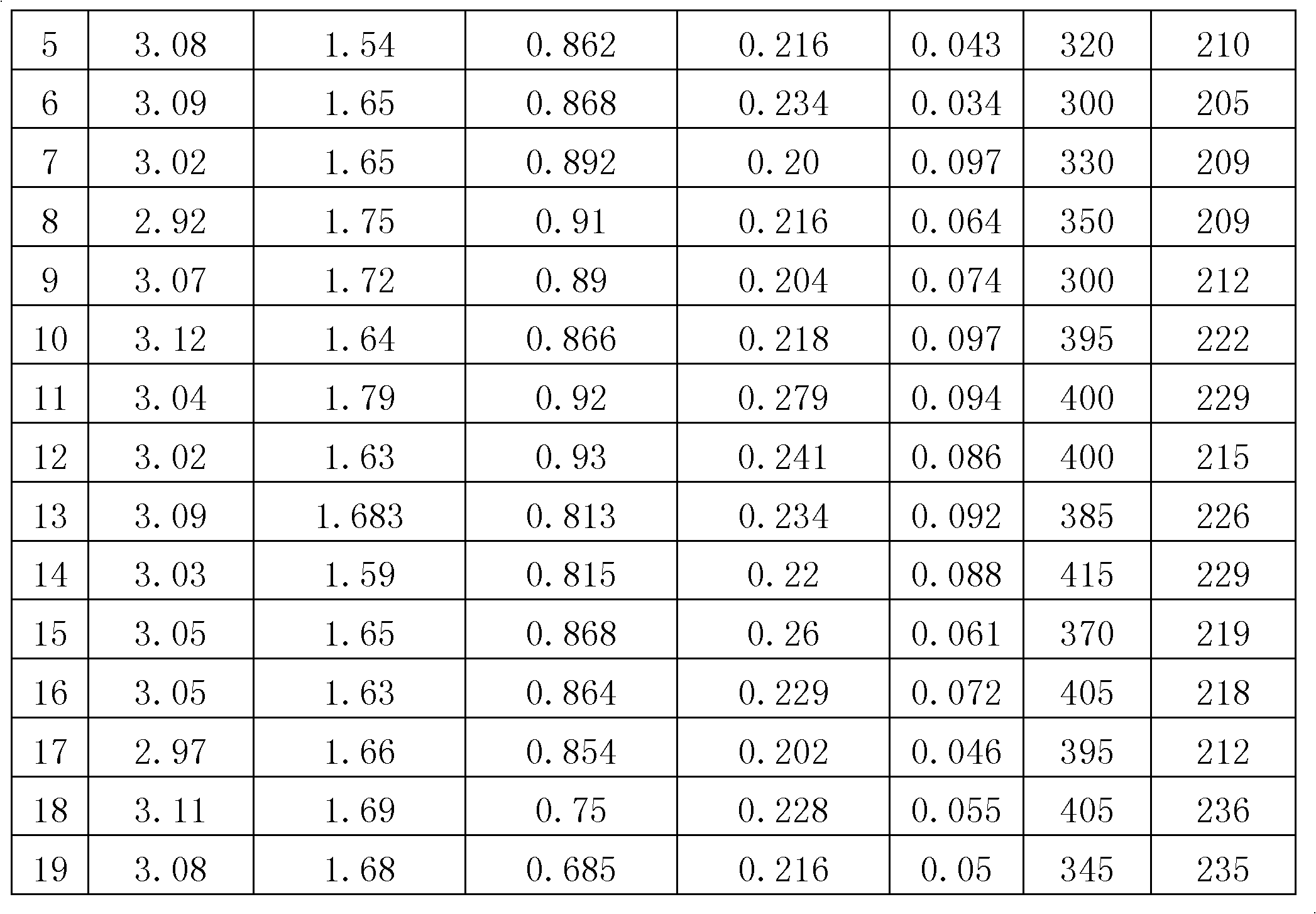

Gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates

ActiveCN106270957AHigh strengthGuaranteed toughness and plasticityArc welding apparatusWelding/cutting media/materialsEngineeringSlow cooling

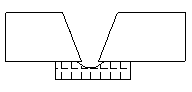

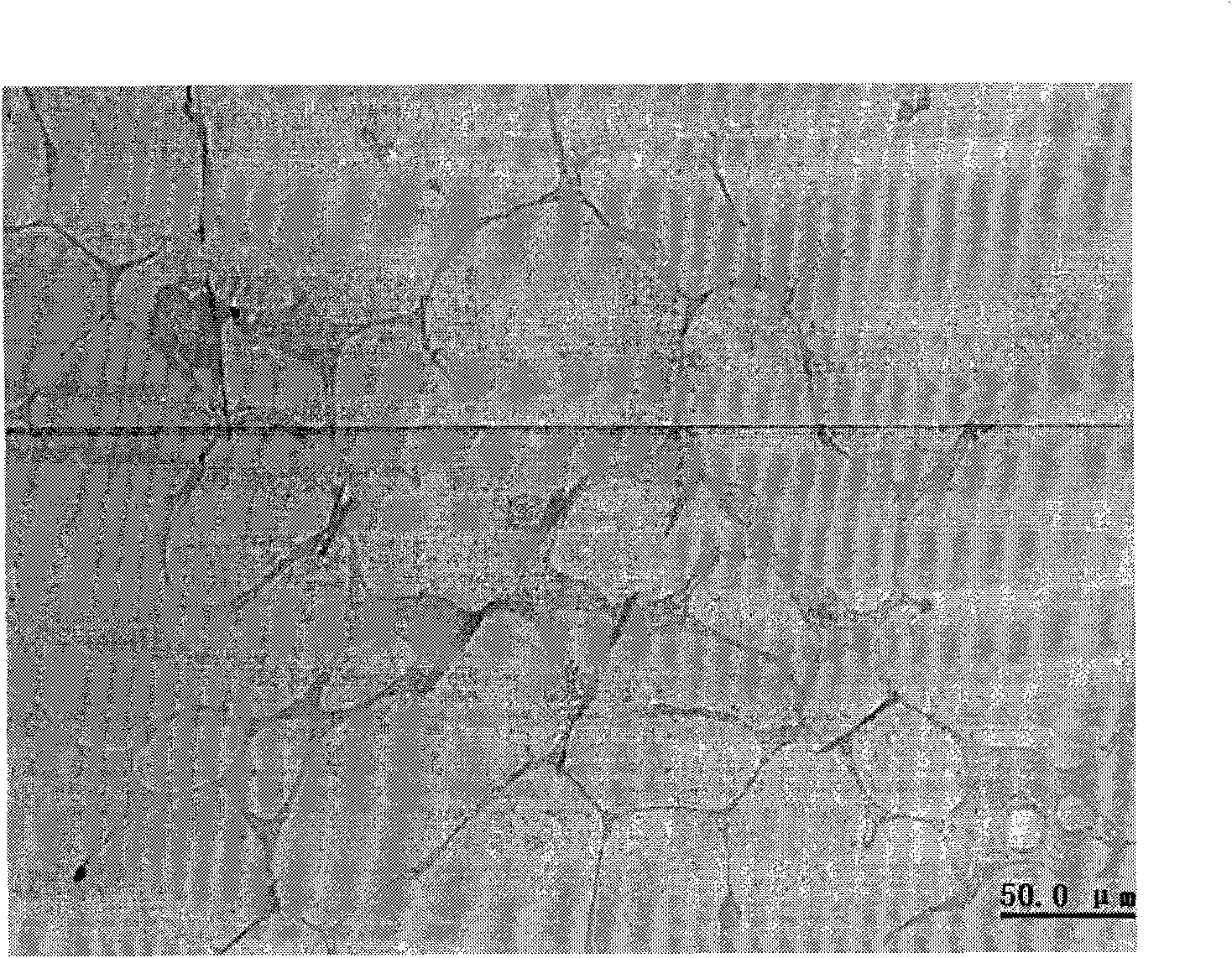

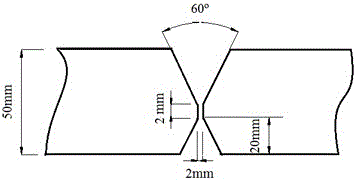

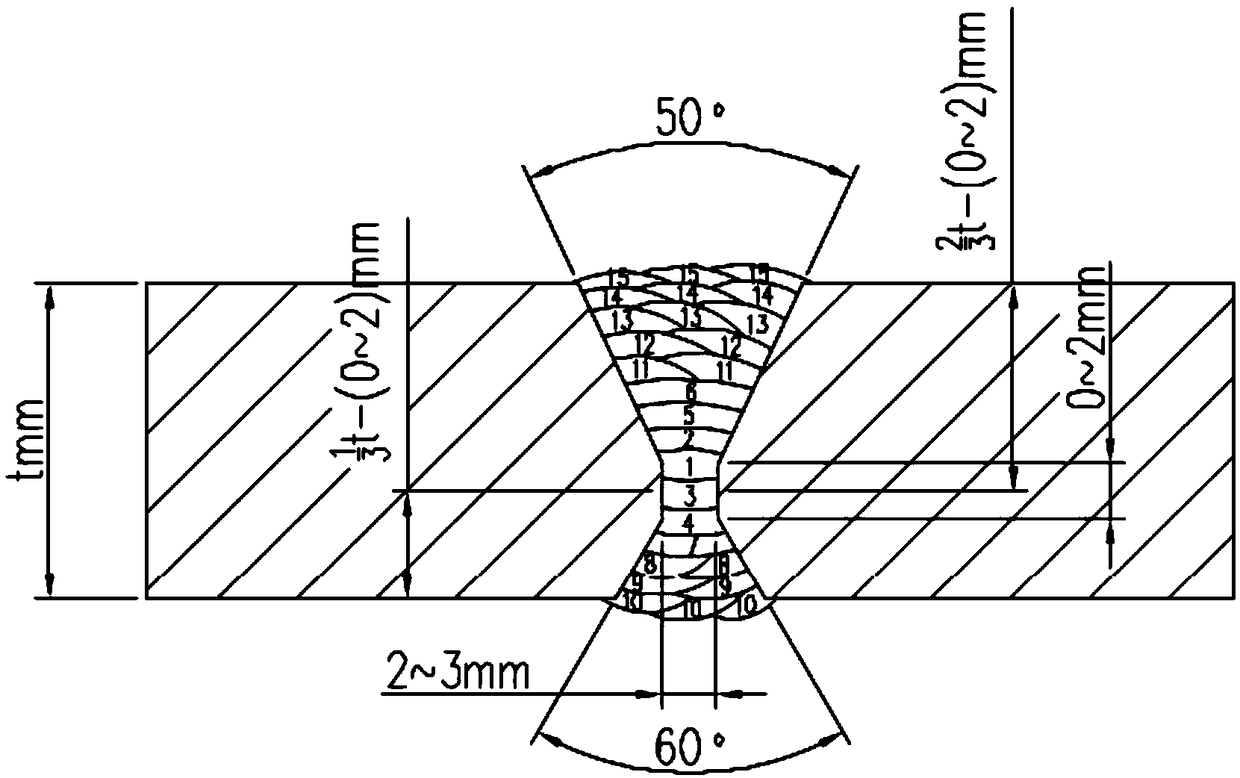

The invention provides a gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates. Welding base materials are Rm1000-1100 MPa engineering machine quenched and tempered steel plates in equal-thickness flat plate butt joint, a groove is a double-side V-shaped asymmetric groove, the angle of the groove is 60 degrees, a truncated edge is 2-3 mm long, and an assembly gap is 2 mm wide. According to welding materials, bottoming welding wires are 700 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm, and filling and surface covering welding wires are 1000 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm. The welding method includes the welding steps that bottoming welding is conducted, filling welding is conducted, surface covering welding is conducted, slow cooling is conducted after welding, and joint areas in the range of 300 mm on the two sides of a weld joint are covered with asbestos cloth. Preheating is not needed, after-heating is not conducted, strength and toughness of a joint are ensured, the variety of welding gas and replacement frequency of equipment and the welding wires are reduced, the high-strength advantage of high-strength steel can be fully achieved, and maneuverability is high.

Owner:武汉钢铁有限公司

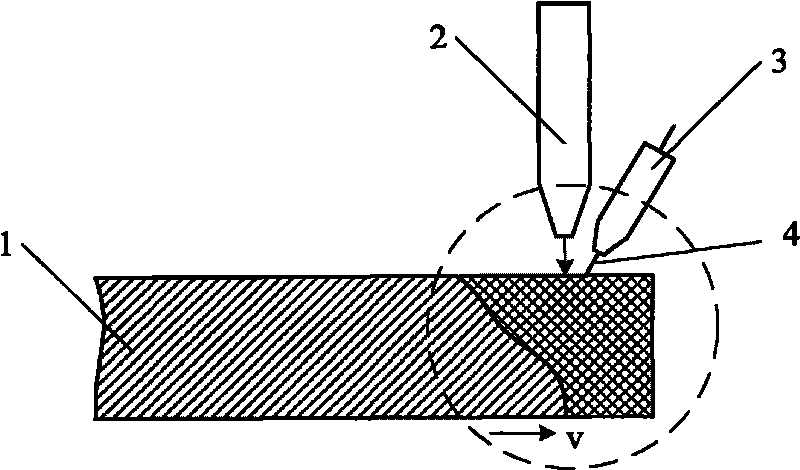

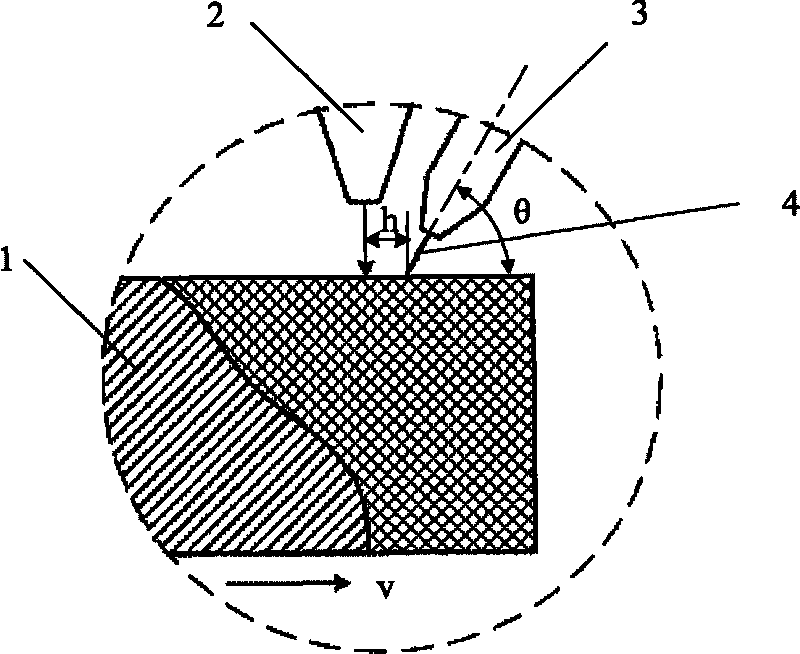

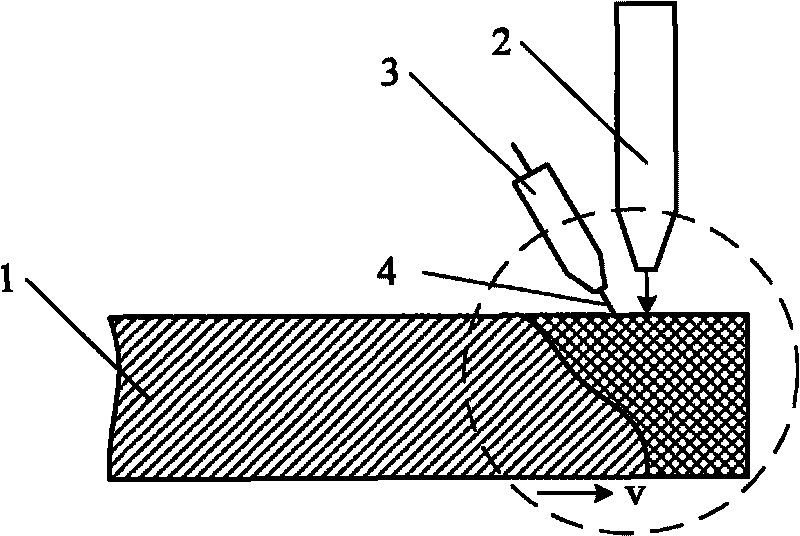

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

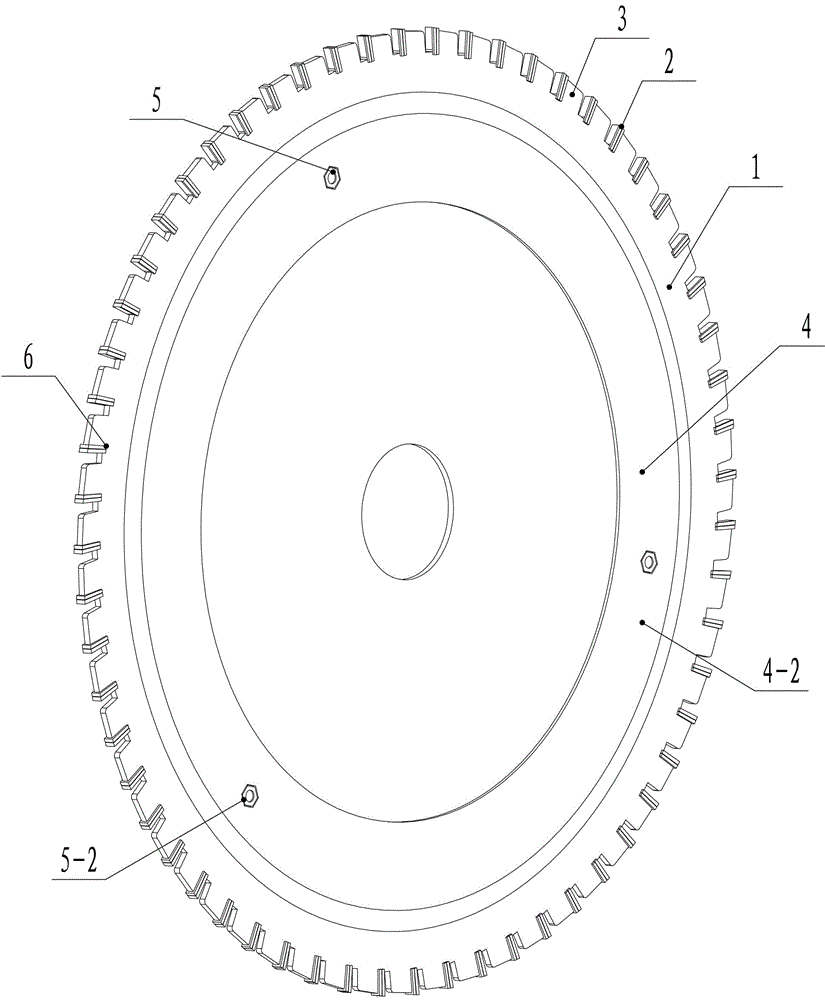

Saw web used for both cutting and grinding

ActiveCN106424940ARepair smoothImprove verticalityEdge grinding machinesMetal sawing toolsEngineeringGrinding wheel

The invention relates to a saw web used for both cutting and grinding. The saw web comprises a saw web body, double-layer cutter heads, tooth backs and a grinding wheel. Grooves are formed in the positions, on the same sides of the tooth backs, of the saw web body. The double-layer cutter heads are welded in the grooves. The grinding wheel comprises an upper grinding wheel body and a lower grinding wheel body. The upper grinding wheel body and the lower grinding wheel body are annular and arranged on the both sides of the saw web body correspondingly. The saw web body, the upper grinding wheel body and the lower grinding wheel body are provided with bolt through holes in fit with one another. The upper grinding wheel body and the lower grinding wheel body are fixed to the saw web body through bolts. By adoption of the saw web used for both cutting and grinding, a cut surface can be cut and ground at the same time, the efficiency is greatly improved, the flatness of the ground surface is improved, and the perpendicularity of the ground surface and a profile is improved; and meanwhile, by designing the embedded cutter heads, the impact resistance of saw web cutter teeth of the saw web to to-be-cut materials during cutting is greatly improved, and the cutter heads are not prone to falling off.

Owner:HEBEI JIMEIDA TOOLS CO LTD

Method for restoring inner bore of gear coupling

InactiveCN102747364AExtended service lifeImprove wear resistanceMetallic material coating processesLaser coatingHigh power lasers

A method for restoring the inner bore of a gear coupling is disclosed. Dimensions of all parts of the gear coupling are measured to check whether all the dimensions satisfy laser coating restoration standards, the surface fatigue layer of the inner bore of the gear coupling is removed, Ni55 and nanometer WC powder which are prepared in proportion are fully mixed in a mechanical powder mixer through adopting a mechanical mixing method, the Ni55 and the nanometer WC powder are coated on the surface of the inner bore of the gear coupling through adopting a coaxial powder sending method and through scanning by adopting a large-power CO2 laser, and the gear coupling undergoes heat treatment and then is slowly cooled with a furnace; and the inner bore of the cooled gear coupling is machined to obtain the gear coupling with the dimensions and the surface process which satisfy requirements, the gear coupling undergoes processing precision detection, and finally the gear coupling is packaged. Compared with the prior art, the method disclosed in the invention has the advantages of continuous use, better performances and long service life of the gear coupling, simple technology, strong controllability, less energy consumption and the like.

Owner:YANSHAN UNIV

Non-preheating and non-copper-plating automatic low-alloy-steel welding wire for ships and production technology of wire

ActiveCN102922171ALow elemental contentImprove cleanlinessWelding/cutting media/materialsSoldering mediaChemical compositionCopper plating

The invention relates to a non-preheating and non-copper-plating automatic low-alloy-steel welding wire for ships. The welding wire comprises the following chemical compositions: 0.02%-0.1% of C, 2%-4% of Mn, 2%-4% of Ni, 0.5%-1% of Mo, 0.5%-0.8% of Si, 0-0.5% of Cu, 0-1.2% of Cr, 0-0.12% of V and 0-0.05% of Ti; and the drawing diameter of the welding wire ranges from phi 4.0mm to phi 1.0mm. The non-preheating and non-copper-plating automatic low-alloy-steel welding wire can be used for welding steel with high strength and high toughness without preheating, can avoid cold cracks during welding of a modern ship structure, can simplify a production technology, reduce the production cost and improve the production efficiency during the welding process, and can reduce the production cost and prevent impurities containing copper from being mixed to influence a welding effect since the welding wire does not need to be stored in a copper plating way.

Owner:JIANGSU TIANYE ALLOY MATERIAL

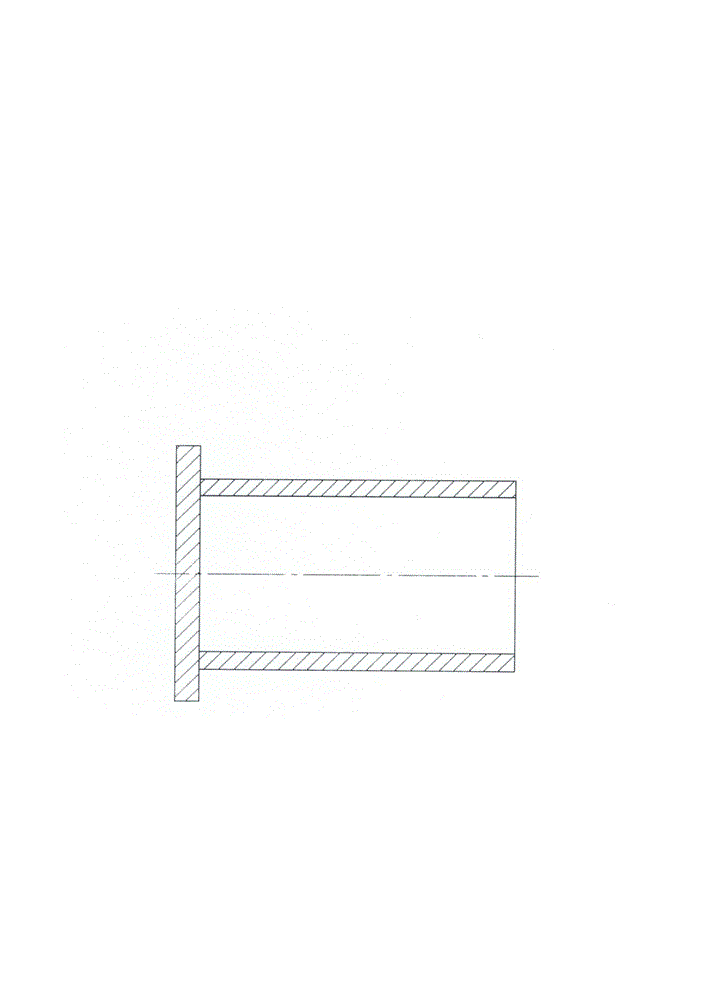

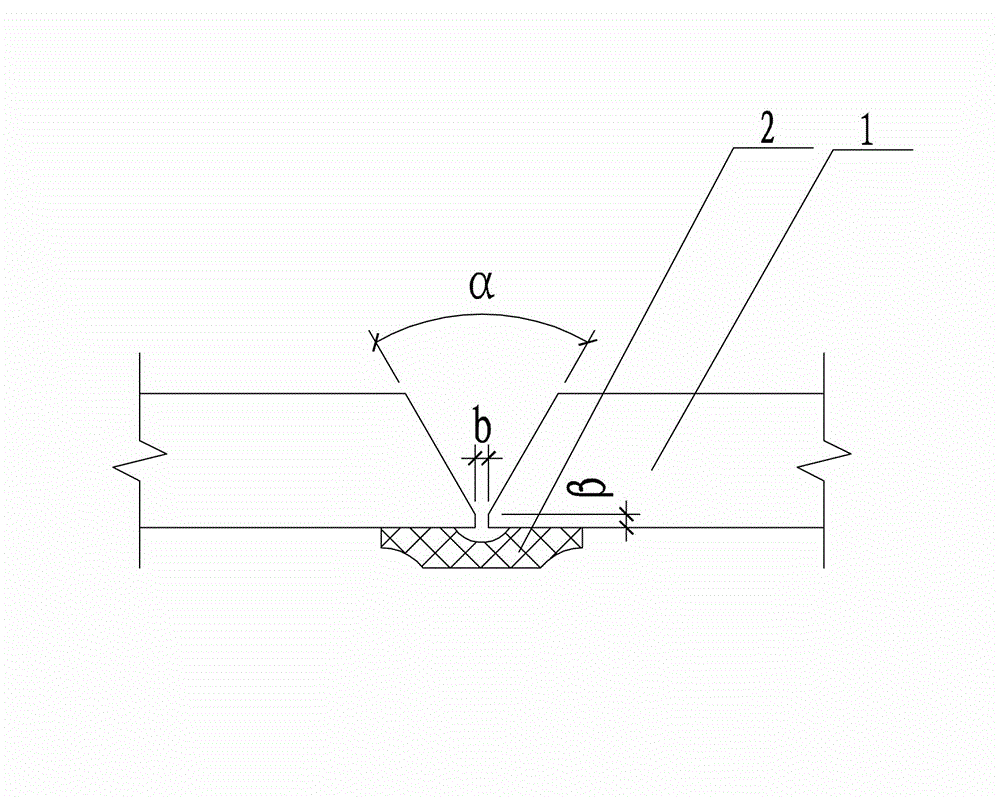

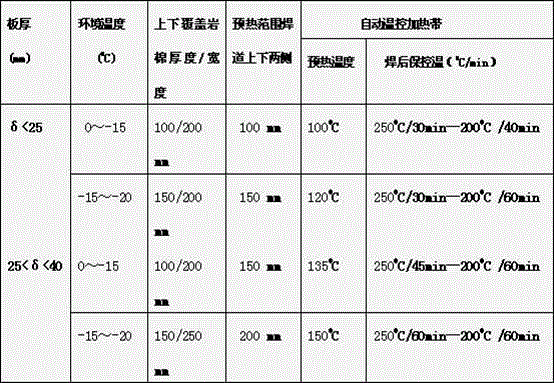

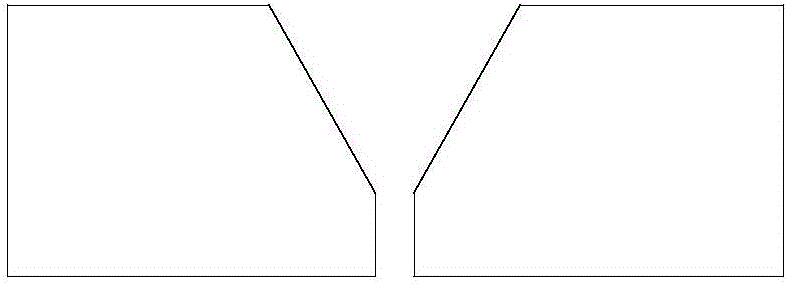

Low-temperature welding technology of low alloy bridge steel

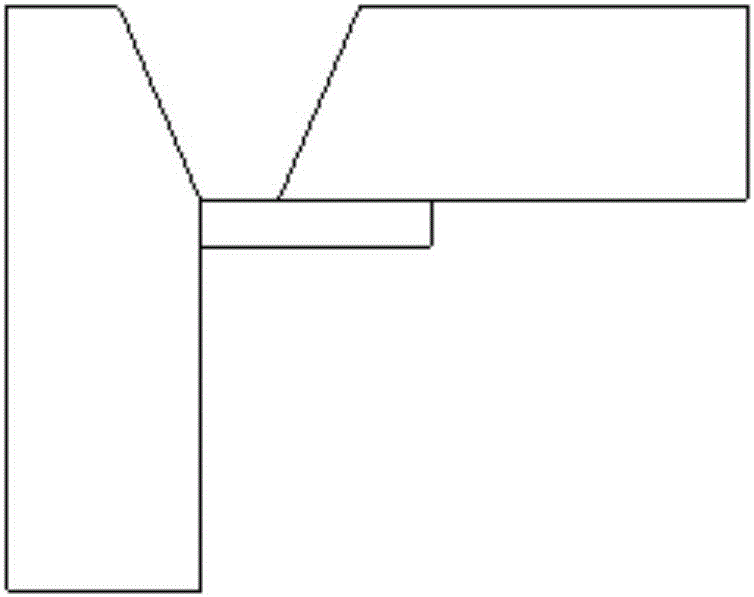

InactiveCN102873463AEffective precipitationAvoid cold cracksWelding/cutting auxillary devicesAuxillary welding devicesTemperature controlAlloy

The invention relates to a low-temperature welding technology of low alloy bridge steel. The technology comprises the steps of processing welding bead grooves, preheating before welding and insulating after welding, and is characterized in that high temperature resistant ceramic backings are adhered at the bottom of ''Y-shaped'' groove welding beads of two butted parent materials of the low alloy bridge steel; a double-side formation with one-side welding is adopted by the welding; meanwhile, an insulation rockwool is adopted; and an automatic temperature control heating tape is used for carrying out the preheating before welding, the temperature control during welding and the preheating, the temperature control and the insulation after welding, and finally carrying out retarded cooling. The technology has the advantages that: as the heat automatic temperature control heating tape and a thermocouple temperature measurement probe are adopted, the accurate control can be conducted on the temperature and the time of the preheating before welding, and the insulation and the retarded cooling after welding at different thicknesses and different environmental temperatures of the steel, thereby ensuring effective precipitation of hydrogen. Furthermore, the occurrence of low-temperature welding cold cracks and low-temperature brittle phenomena can be avoided effectively.

Owner:EAST STEEL STRUCTURE BRIDGE

Gas shielded welding method of bridge steel with tensile strength Rm greater than or equal to 810 MPa

ActiveCN109128550AGive full play to the advantages of high strengthImprove the construction environmentArc welding apparatusWelding/soldering/cutting articlesHeat-affected zoneButt joint

The invention relates to a gas shielded welding method of bridge steel with tensile strength Rm greater than or equal to 810 MPa. Base materials: ReL is greater than or equal to 690 MPa, Rm is greaterthan or equal to 810 MPa, A is greater than or equal to 14%, and the impact work KV2 at -40 DEG C is greater than or equal to 120 J; double-faced V-shaped symmetrical grooves are adopted; and a backing welding wire adopts a solid gas shielded welding wire of which the tensile strength is 550 MPa, and a filling and covering welding wire adopts a solid gas shielded welding wire of which Rm is greater than or equal to 810 MPa. A welding process comprises the steps of performing backing welding first by adopting CO2 gas shielded welding, and welding front and back surfaces respectively for one pass without back chipping; then performing filling and covering gas welding. According to a butt joint welded by adopting the gas shielded welding method, the impact work KV2 of a three-area impact work welding beam at 20 DEG C is 147 to 167 J, the impact work KV2 of a fusion line at 20 DEG C is 214 to 224 J, the impact work KV2 of a heat affected area (1 mm) at 20 DEG C is 215 to 227 J, the impactwork KV2 of the welding beam at -20 DEG C is 126 to 134 J, the impact work KV2 of the fusion line at -20 DEG C is 132 to 144 J, the impact work KV2 of the heat affected area (1 mm) at -20 DEG C is 142 to 159 J, the impact work KV2 of the welding beam at -40 DEG C is 96 to 108 J, the impact work KV2 of the fusion line at -40 DEG C is 125 to 139 J, the impact work KV2 of the heat affected area (1 mm) at -40 DEG C is 134 to 158 J, and the corrosion resistant index I of the welding seam is 8.89 to 9.46.

Owner:武汉钢铁有限公司

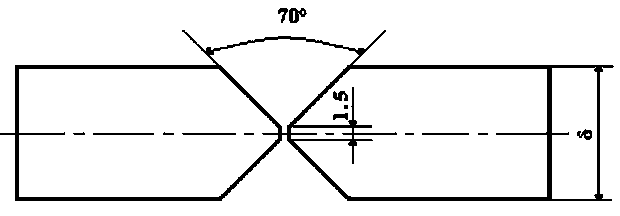

GMAW-Ar welding method for Q420B steel plate

InactiveCN109352142AAvoid cold cracksReduce hardnessArc welding apparatusWelding/cutting media/materialsSheet steelSlag

The invention provides a GMAW-Ar welding method for a Q420B steel plate. The GMAW-Ar welding method for the Q420B steel plate comprises the following steps: S1: making asymmetric X-shaped grooves in specimens, S2: grinding the groove surface and the periphery of the grooves within 20 mm with a grinding wheel machine, S3: assembling the ground specimens, S4: position welding the assembled specimens, S5: preheating the specimens by a flame heating method before welding, S6: welding the bottom by adopting the GMAW-Ar method, S7: carrying out welding through the GMAW-Ar method, S8: cleaning root of a bottom welding pass by carbon arc air gouging, S9: controlling the interlayer temperature between 150 and 200 DEG C by the flame heating method, S10: cleaning up slag and spatter during welding, and S11: detecting flaw. The GMAW-Ar welding method for the Q420B steel plate can effectively control the cold crack and the laminar tearing tendency and improve the welding quality.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

Automatic submerged arc welding method for pearlitic heat-resistant steel composite board

ActiveCN105665898AReduce fillingReduce the amount of weldingArc welding apparatusWelding/soldering/cutting articlesWeld seamEngineering

The invention discloses an automatic submerged arc welding method for a pearlitic heat-resistant steel composite board. The significant advantages are achieved by changing the welding method and the groove type and adjusting the welding sequence. The automatic submerged arc welding method has the significant advantages that by optimizing the groove type, the welding material filling quantity is reduced, and the welding efficiency is improved; a mechanical mode is adopted to conduct groove machining and welding seam back chipping, parent metal hardening caused by rapid heating and rapid cooling of thermal cutting or carbon arc air gouging is effectively avoided, and the rolling machining and welding quality of a barrel is improved; outer edge back chipping is conducted immediately after inner edge base layer welding is completed, welding stagnation and reheating in the middle can be effectively avoided, and the welding quality is guaranteed; transition layer welding is conducted immediately after base layer welding is completed, composited layer welding is conducted after crack detection is qualified, repeated preheating and transition layer welding which are conducted after nondestructive detection of previous base layer welding is completed and qualified can be effectively avoided, and the composited layer welding quality is improved.

Owner:LUXI IND EQUIP

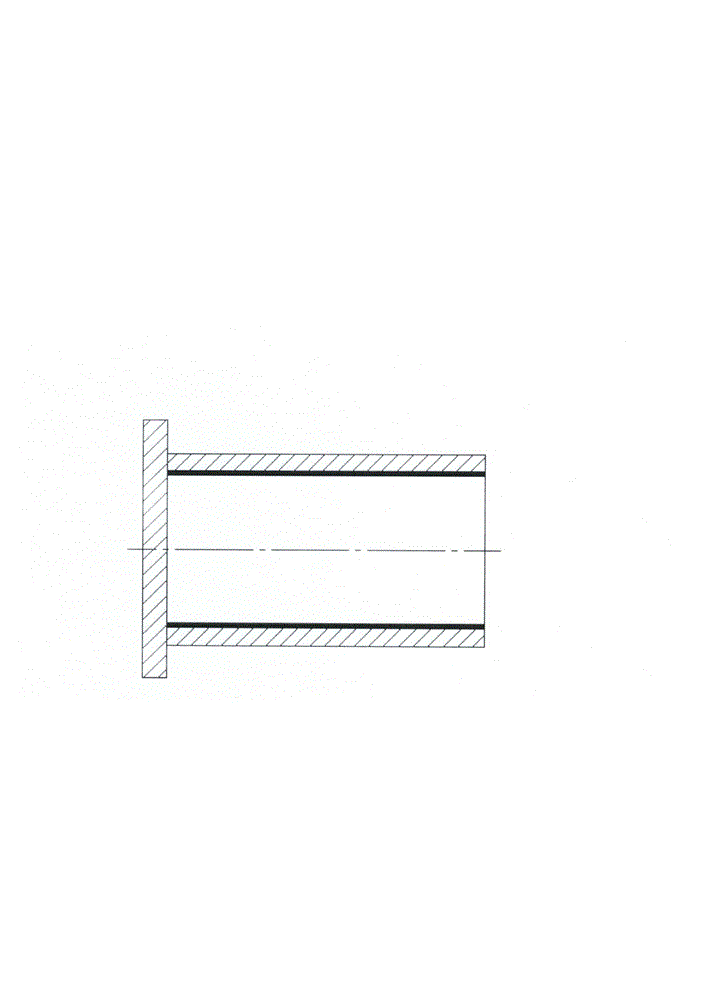

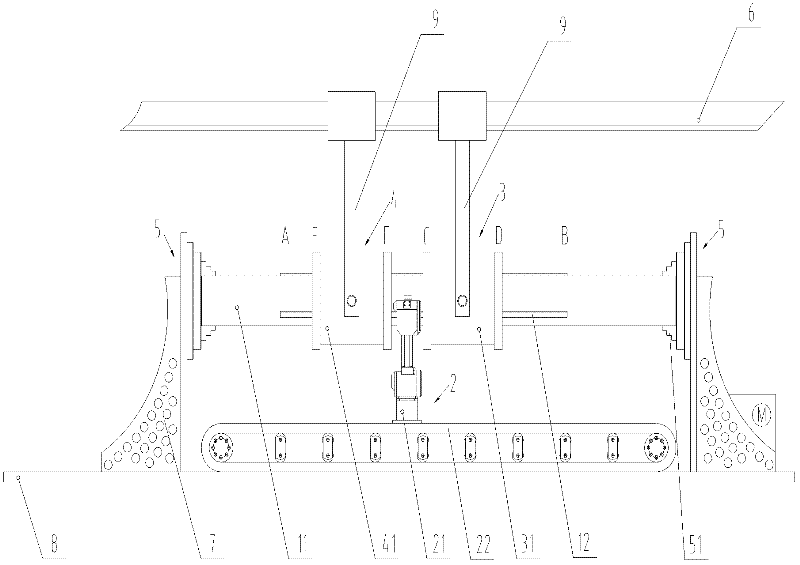

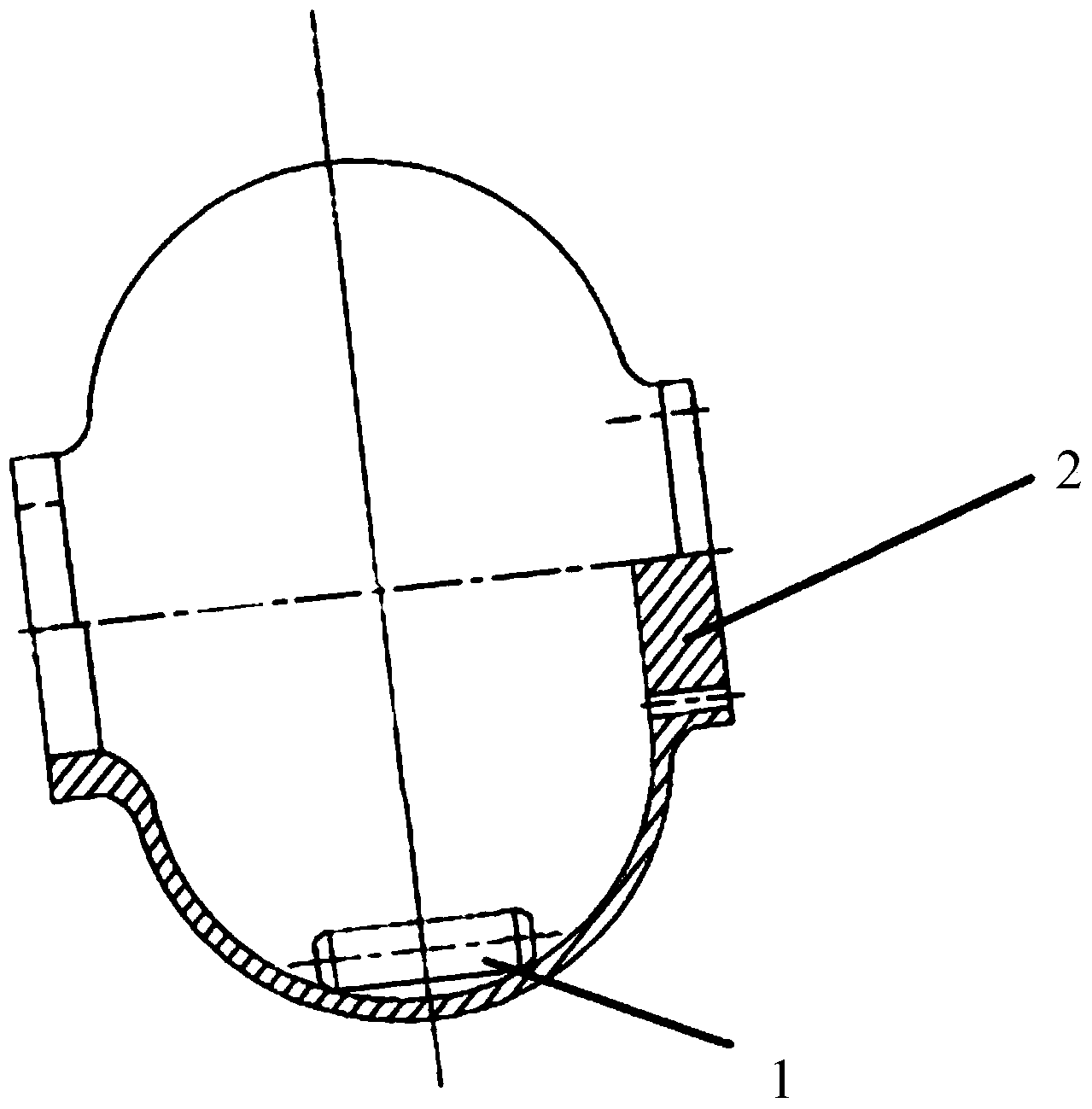

Method and device for welding drill pipe body for rotary drilling and outer keys

ActiveCN102500966AReduce local temperature variationsAvoid cold cracksWelding/cutting auxillary devicesAuxillary welding devicesWeld seamWelding deformation

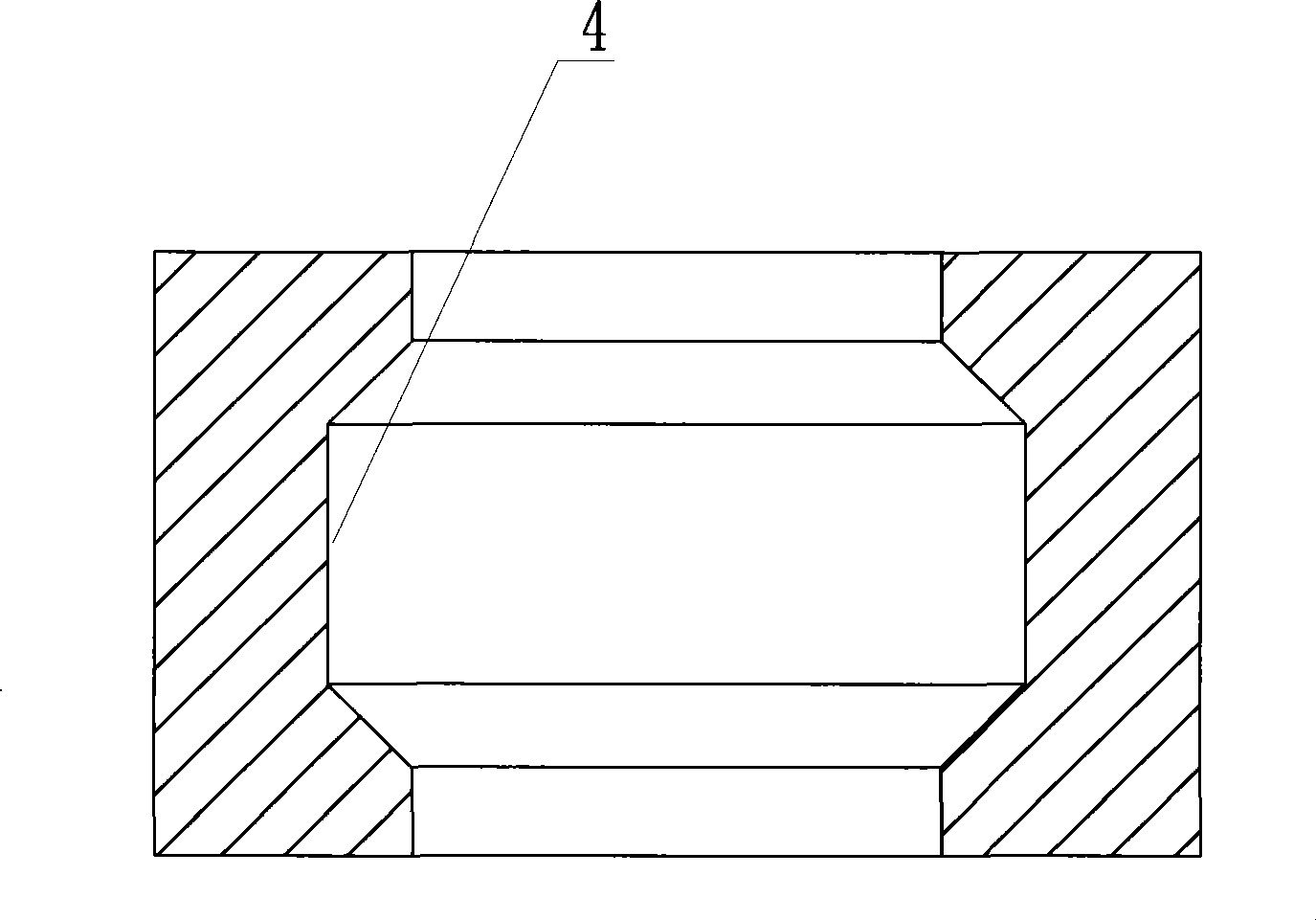

The invention discloses a method and a device for welding a drill pipe body for rotary drilling and outer keys. The method comprises the following steps of: a preheating step: preheating a welding area (13) between the drill pipe body (11) and each outer key (12); a welding step: welding the welding area (13) between the drill pipe body (11) and each outer key (12) to form a welding seam; and a post-heating step: heating the welding seam formed between the drill pipe body (11) and each outer key (12) after the welding step. The invention also discloses a device for welding the drill pipe body for the rotary drilling and the outer keys, which comprises a preheating unit (3), a welding unit (2) and a post-heating unit (4). By the technical scheme, the cold breaking phenomenon during the welding process of the drill pipe body and the outer keys can be effectively avoided. In addition, the welding stress and the welding deformation of the drill pipe body and the outer keys, caused after the preheating step and the post-heating step, can be effectively eliminated.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

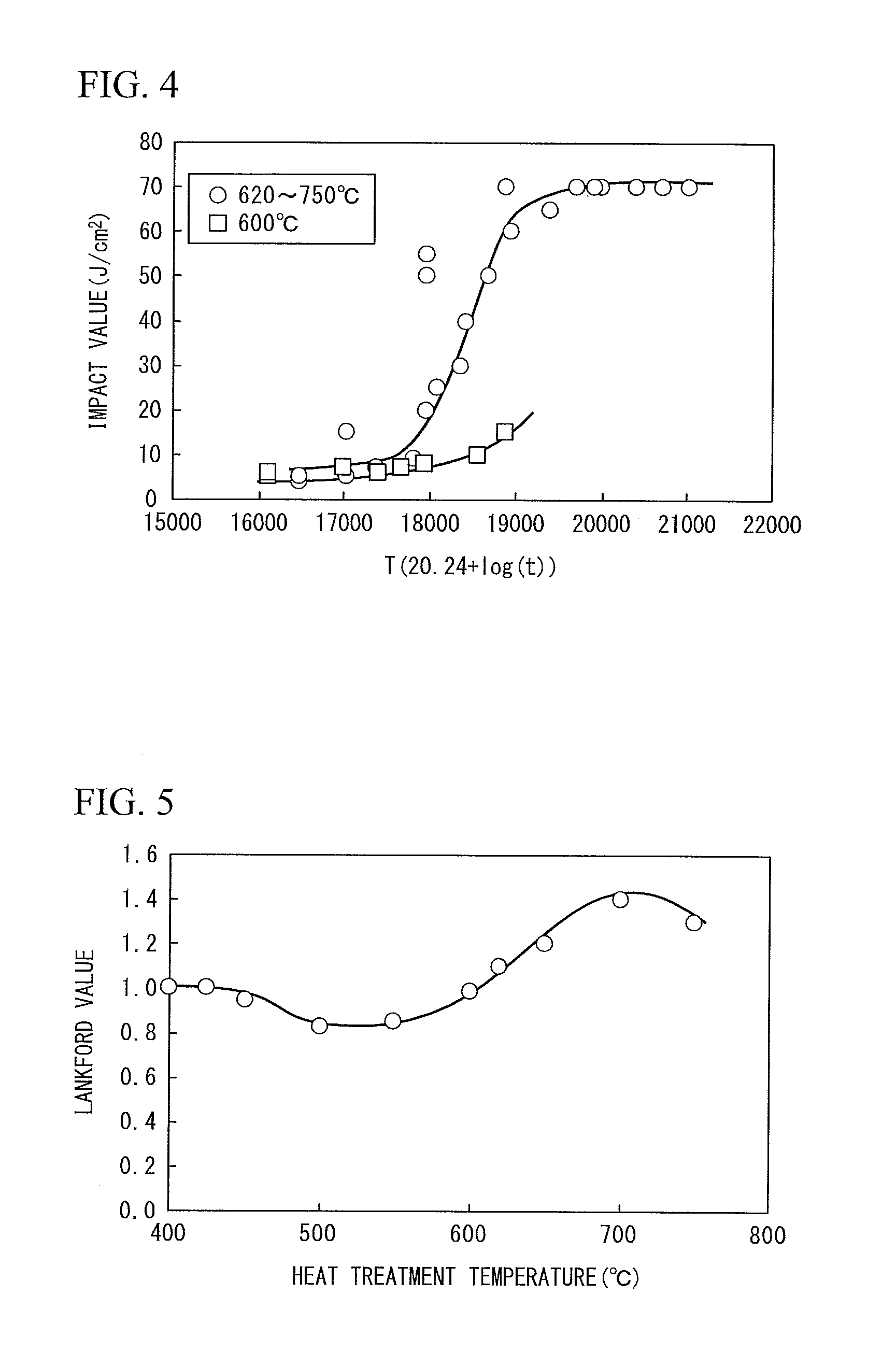

Hot rolled ferritic stainless steel sheet, method for producing same, and method for producing ferritic stainless steel sheet

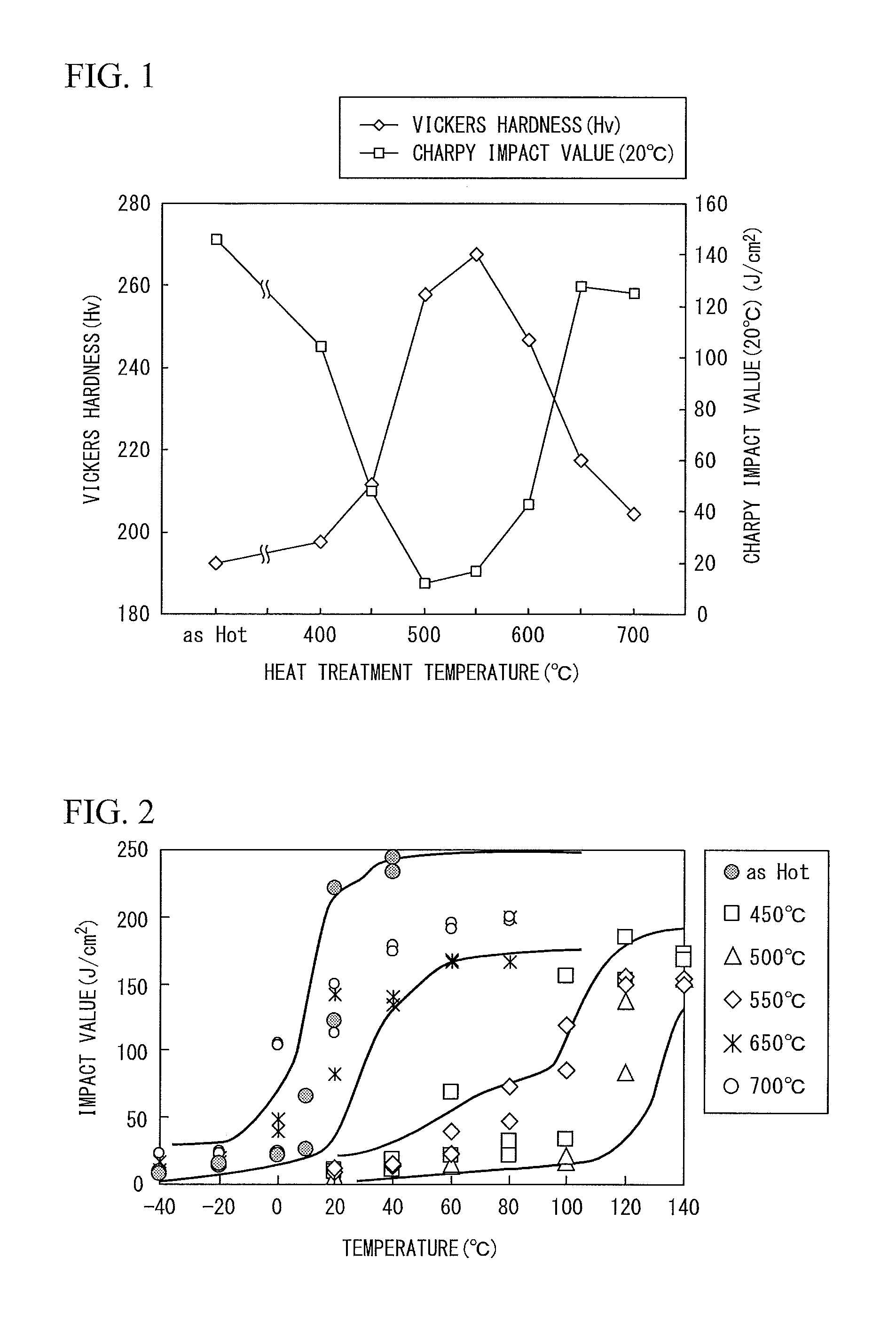

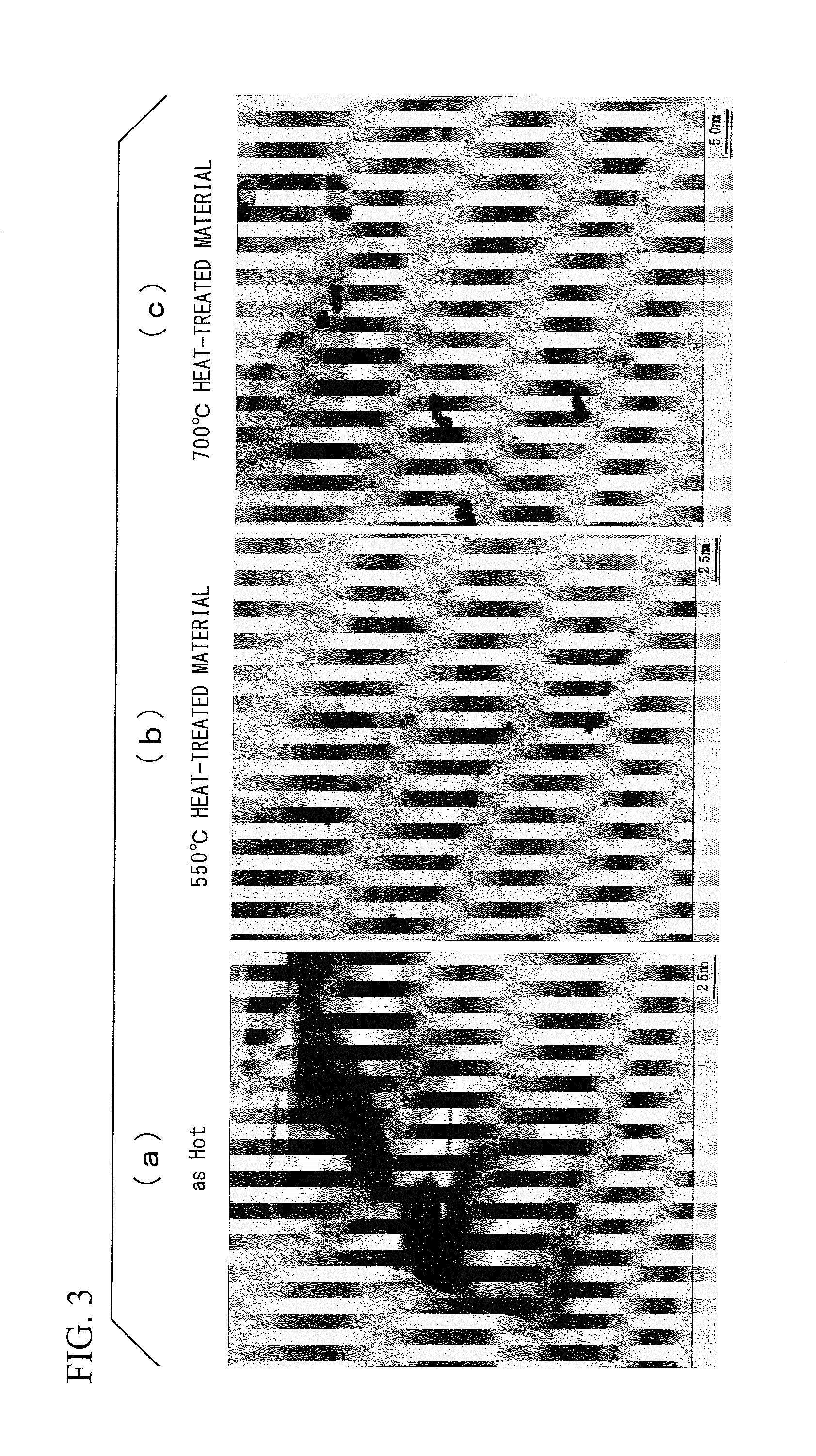

ActiveUS20130306204A1Improve heat resistanceAdjustable hardnessFurnace typesMetal rolling arrangementsMetallurgyMaterials science

This hot-rolled ferritic stainless steel sheet has a steel composition containing, in terms of % by mass: 0.02% or less of C; 0.02% or less of N; 0.1% to 1.5% of Si; 1.5% or less of Mn; 0.035% or less of P; 0.010% or less of S; 1.5% or less of Ni; 10% to 20% of Cr; 1.0% to 3.0% of Cu; 0.08% to 0.30% of Ti; and 0.3% or less of Al, with the balance being Fe and unavoidable impurities, and the hot-rolled ferritic stainless steel sheet has a Vickers hardness of less than 235 Hv.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Gas protection welding wire for low-magnetic steel

InactiveCN106238959AAvoid cold cracksReduce sensitivityWelding/cutting media/materialsSoldering mediaTungstenAluminium

The invention discloses a gas protection welding wire for low-magnetic steel, and belongs to the field of welding materials. The welding wire comprises components including, by mass percent, 0.15% to 0.35% of C, 4% to 10% of Mn, 0.30% to 1.0% of Si, 13% to 20% of Ni, 3% to 7% of Mo, 0.1% to 0.4% of Ti, 10% to 26% of Cr, smaller than 0.005% of S, smaller than 0.015% of P and the balance Fe. When the disclosed welding wire is used for argon tungsten-arc welding or metal inert gas protection welding of the low-magnetic steel, an obtained welding line has the good mechanical property, the low magnetic conductivity can be ensured, and the welding wire is particularly suitable for welding of working welding lines, with the requirement for the service environment without magnetism or with the low magnetism, of manganese aluminum low magnetic steel.

Owner:SHANGHAI JIAO TONG UNIV

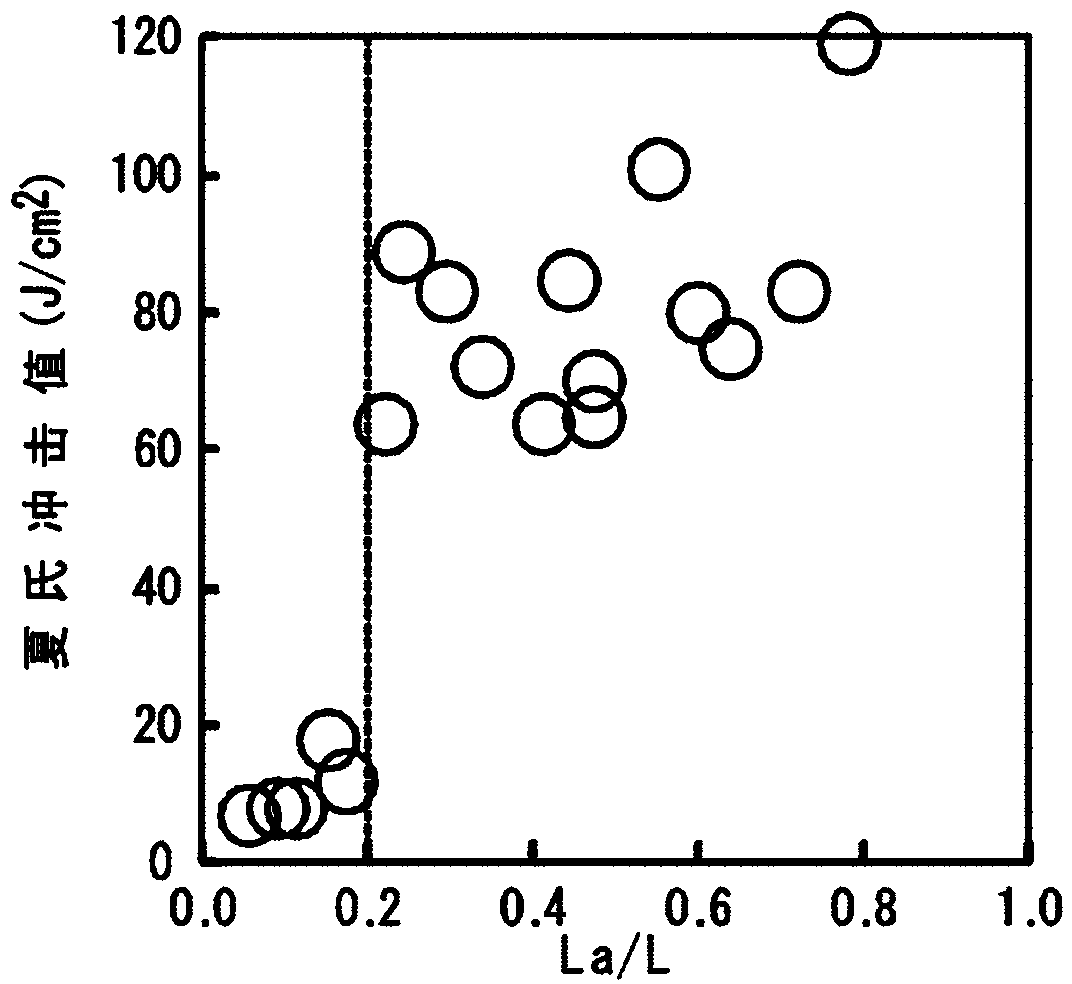

Hot-rolled ferritic stainless steel sheet with excellent cold cracking resistance and manufacturing process therefor

ActiveCN103857812AAvoid cold cracksRaise the ratioFurnace typesMetal rolling arrangementsHot rolledMisorientation

Owner:NIPPON STEEL STAINLESS STEEL CORP

Machining method for spherical surface roller pin free of edge angles

ActiveCN103659562ANot easy to scratchAvoid breakingEdge grinding machinesPolishing machinesPulp and paper industryLantern

The invention discloses a machining method for a spherical surface roller pin free of edge angles. The method includes the following steps of A roll polishing, B heat treating and C modified line machining and further includes the following step of edge angle removal machining, wherein after roll polishing in the step A, an arc lantern-shaped rolling barrel is manufactured according to the size and the shape of a roller pin, the rolling barrel is horizontally arranged on a support with an adjustable dip angle, the roller pin after roll polishing is thrown into a barrel body of the rolling barrel through a throwing opening, the two ends of a roller pin blank make contact with the barrel wall in the barrel body, the rolling barrel rotates in the circumferential direction around the axis of the barrel body through an external power source, and in the rotating process, the roller pin blank is grinded in a 360-degree rolling-polishing mode along the barrel wall in the barrel body, so that the edge angles at the two ends of the roller pin are machined to be arc angles. The method solves the problem that the edge angles exist in the connecting positions of the two ends of the outer side wall and the semicircular ends of the roller pin, and the roughness of the semicircular ends at the two ends of the roller pin is small.

Owner:NINGBO ZHONGHE AUTO PATS

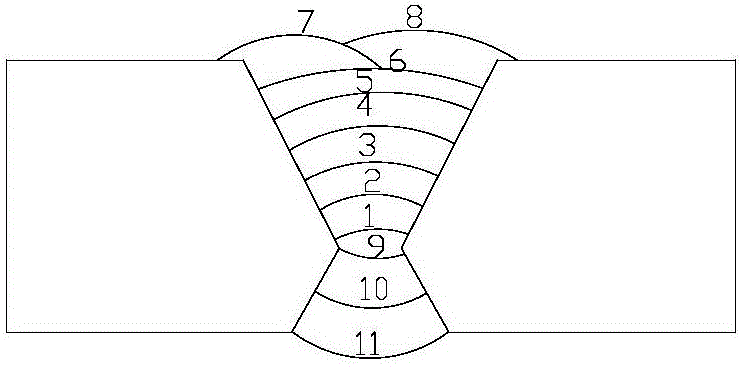

Surfacing method of alloy steel gear-wheel gear-ring transition layer

InactiveCN101396752AImprove solderabilityAvoid cold cracksArc welding apparatusRotary machineAlloy steel

The invention discloses a method for resurfacing-welding a transition layer of alloy steel gear and gear ring, including the following concrete steps: a machine tooling method is adopted for processing a groove of the transition layer in the alloy steel gear and gear ring, and the groove is cleaned out; the alloy steel gear and gear ring are put in a far-infrared oven for preheating, the preheating temperature is 325 DEG C to 375 DEG C, and the temperature is preserved for 3.5 to 4.5 hours; the alloy steel gear and gear ring are taken out from the far-infrared oven, and multi-layer multi-run welding is carried out by using CO2 gas shield welding; the alloy steel gear and gear ring are put in the oven immediately after welding for heating till being 325 DEG C to 375 DEG C, the temperature is preserved for 1 to 2 hours, and the alloy steel gear and gear ring are cooled to room temperature slowly along with the oven and taken out from the oven. The transition layer is cleared and polished, and then the inner diameter of the gear ring is processed by using a rotary machine tool; after processing, 20% of the gear rings are drawn for ultrasonic inspection examination. The method has the following beneficial effects: after the transition layer of the alloy steel gear and gear ring is resurfacing-welded by using the method, the weldability of the alloy steel gear and gear ring can be greatly enhanced, thereby being capable of avoiding the generation of cold cracks while welding.

Owner:JIER MACHINE TOOL GROUP

Welding method for steel Q390GJC for building structure

ActiveCN106363281ASolve Welding ProblemsAvoid cold cracksArc welding apparatusWelding/soldering/cutting articlesButt jointEngineering

The invention relates to a welding method for steel Q390GJC for a building structure. A welding joint type adopts butt-joint flat welding, butt-joint transverse welding, angular butt-joint flat welding, T-shaped angle joint transverse welding, and T-shaped angle joint ship type non-penetration flat welding; submerged automatic arc welding and CO2 gas shielded welding are adopted; the steel Q390GJC is preheated before being welded, wherein the preheating temperature is 60 DEG C; multi-layer and multi-pass welding is adopted, and the interlayer temperature is 150 to 200 DEG C. The welding method has the advantages that: welding problems of the steel are solved aiming at the component ranges of the steel Q390GJC and technical conditions; the welding problems specifically comprise: (1) preheating the steel to a temperature before welding so as to avoid cold cracks at a joint part; (2) proposing reasonable groove types and welding methods according to joint types and plate thickness; (3) selecting proper welding materials aiming at joint types, groove types and welding methods; (4) proposing proper welding process parameters. The steel Q390GJC is welded by adopting the technical scheme; the welding joint can achieve the same mechanical property as that of a base material, and meets using requirements of a project.

Owner:鞍钢钢结构(营口)有限公司

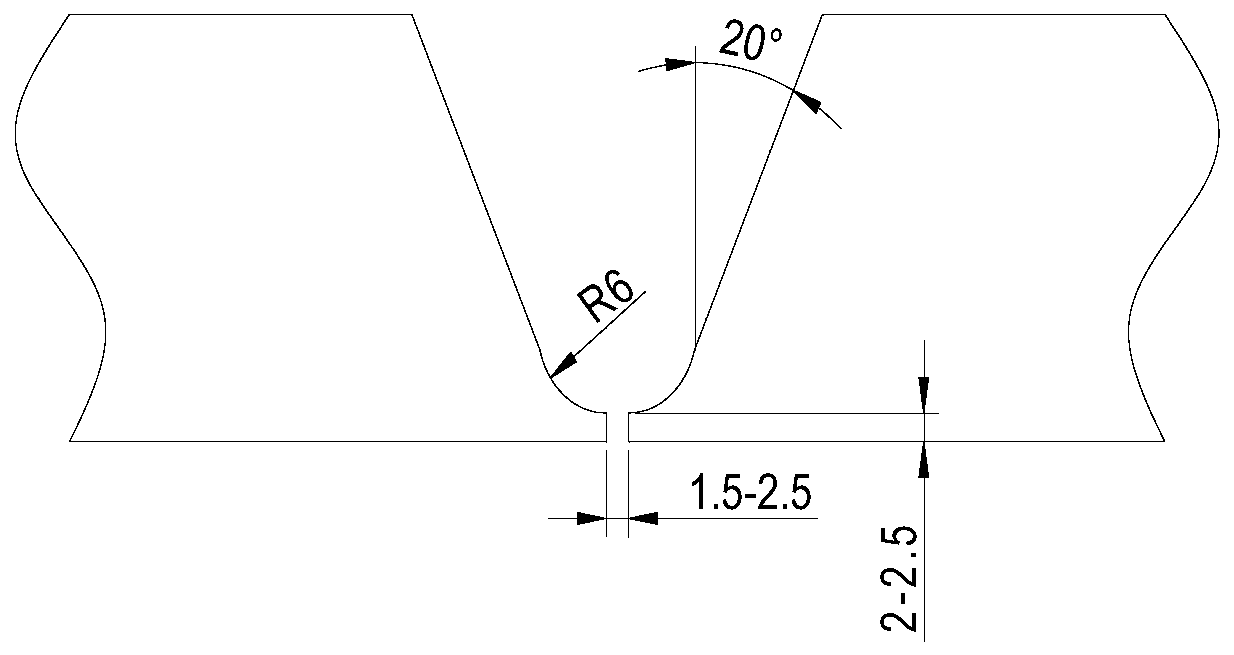

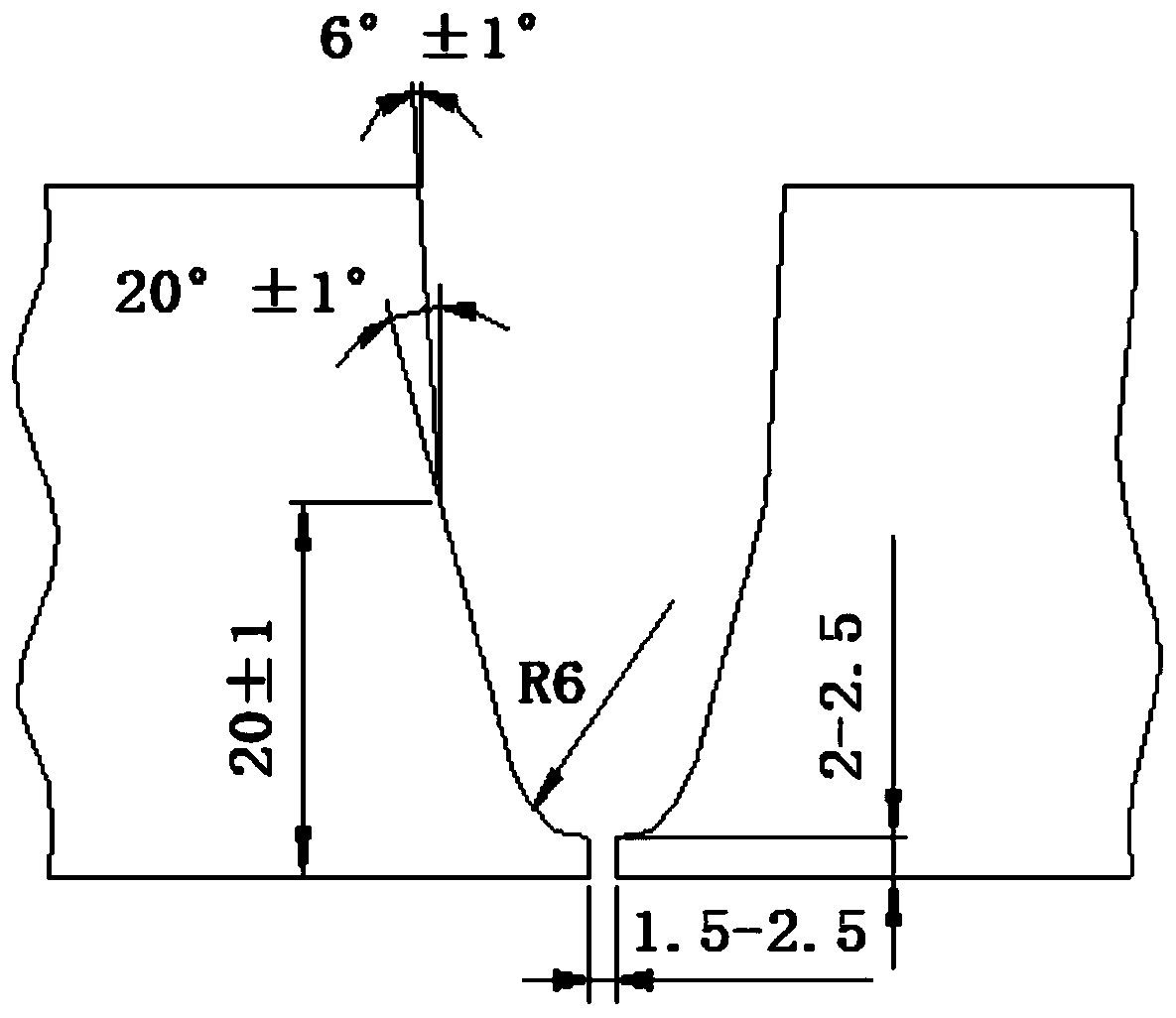

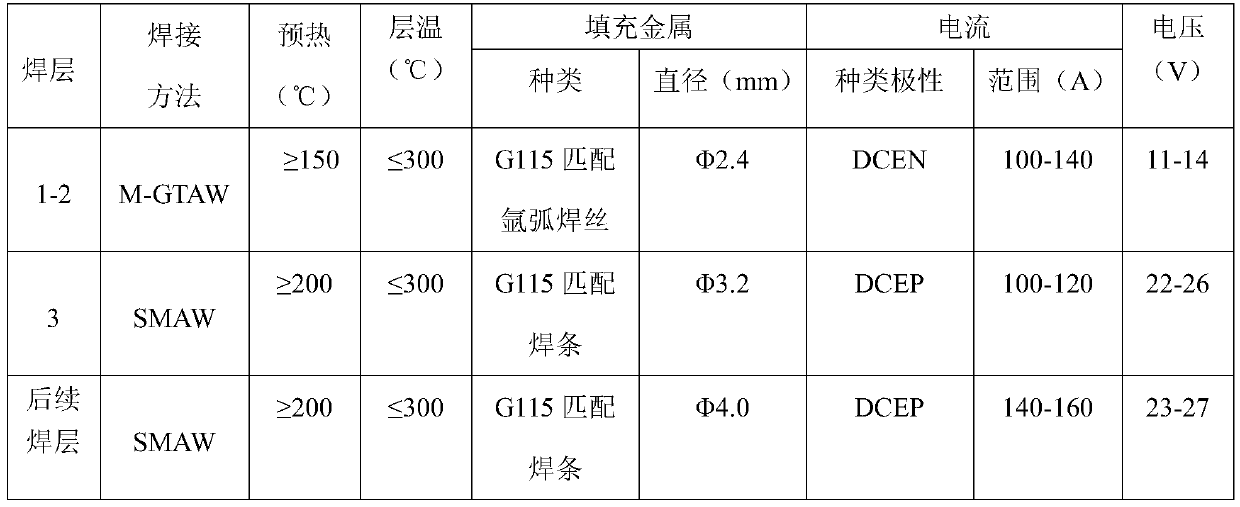

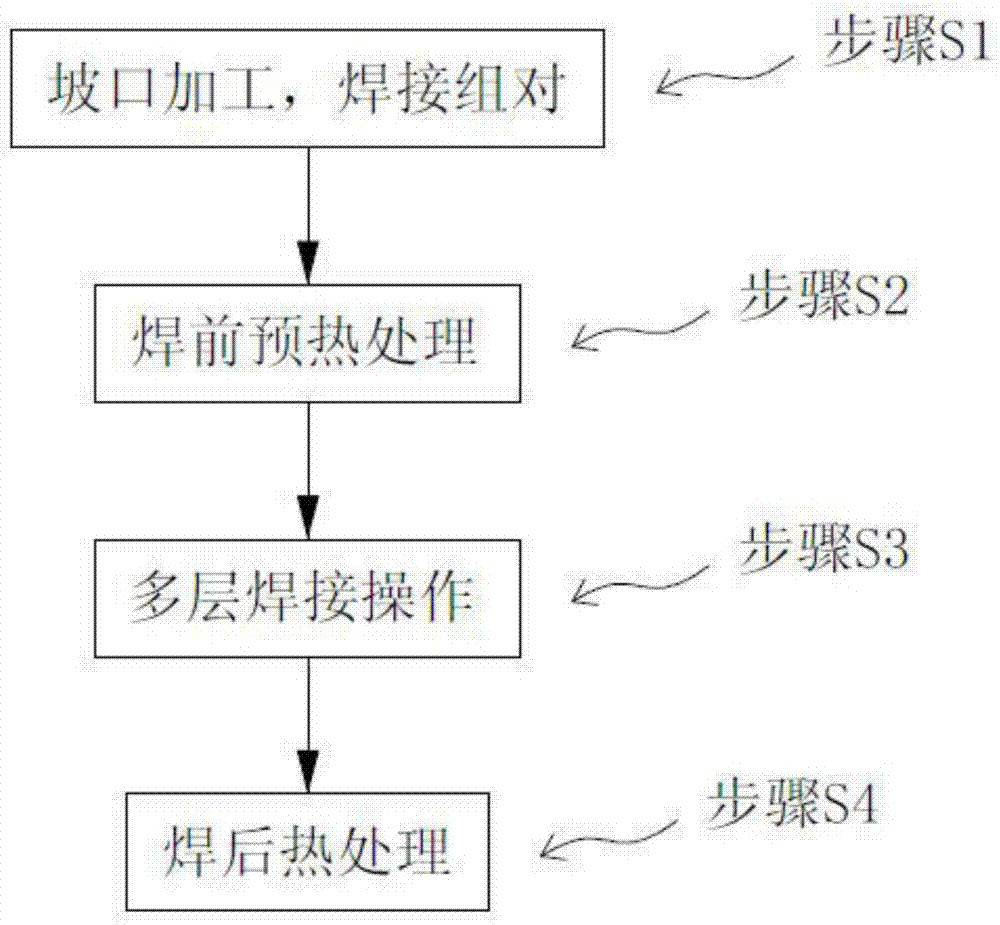

Manual argon tungsten-arc welding and welding rod electric-arc welding combined welding method of G115 large-diameter pipe

ActiveCN109865955AGuarantee welding qualitySolve cold and hot cracksArc welding apparatusEngineeringTungsten

The invention provides a manual argon tungsten-arc welding and welding rod electric-arc welding combined welding method of a G115 large-diameter pipe, relates to the technical field of pipe welding, and aims at solving the method that a G115 large-diameter pipe is easily subjected to cold and hot racks and poor weld penetration in an existing welding technology and weld joints with high mechanicalperformance and good formation cannot be ensured. The method comprises the steps of 1, preparing before welding, namely, preparing a groove of the G115 large-diameter pipe, and aligning the groove and assembling; 2, welding, namely, preheating the G115 large-diameter pipe; performing manual argon tungsten-arc welding on a first layer and a second layer; and performing electric arc welding on a third layer and the following welding layers through welding bars; and 3, heat treatment after welding, namely, cooling the G115 large-diameter pipe after welding; increasing the temperature; and continuously increasing the temperature. The method is applicable to welding of the G115 large-diameter pipe.

Owner:HARBIN BOILER

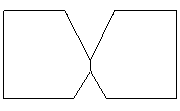

Laser welding method for titanium alloy blade

ActiveCN106513998AImprove connection strengthAvoid shrinkage and shrinkage defectsWelding/soldering/cutting articlesLaser beam welding apparatusTitanium alloyUltimate tensile strength

The invention discloses a laser welding method for a titanium alloy blade. The laser welding method for the titanium alloy blade comprises the following steps: processing a groove in a joint, wherein the groove is a Y-shaped groove; and respectively processing T-shaped interlocking components on inclined surfaces of two sides of the groove. Each T-shaped component comprises a first end and a second end, a position where each first end is connected with the corresponding second end is in fillet transition, the T-shaped components are alternately distributed on the surfaces of two sides of the groove, the distance between each two T-shaped components is 4-8 mm, an interlocking structure is formed during welding, a mechanical interlocking structure can be formed between a blind hole filled with welding flux and a base material during welding, therefore, the strength of a welding position is improved remarkably, repeated design experiments of the groove are avoided, and the time is saved.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

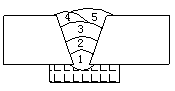

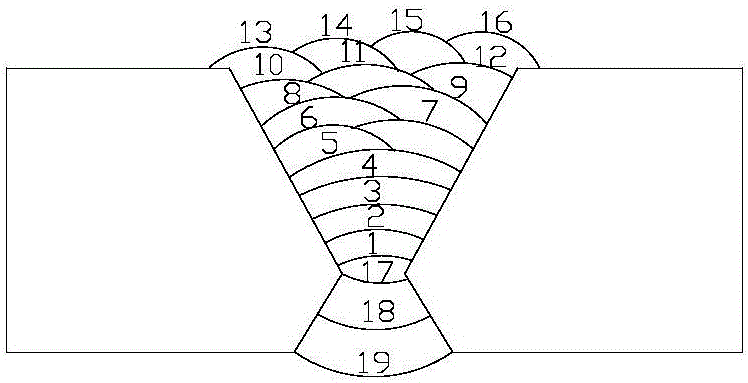

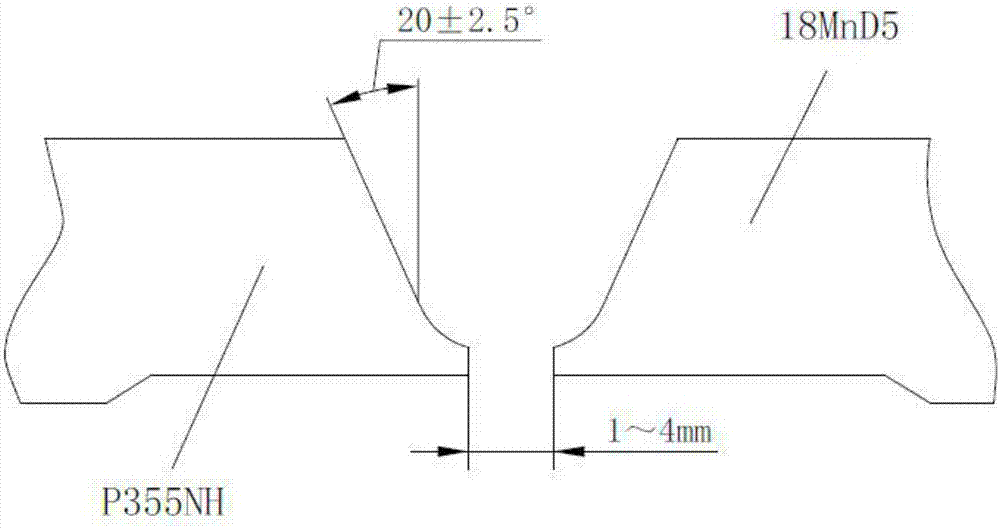

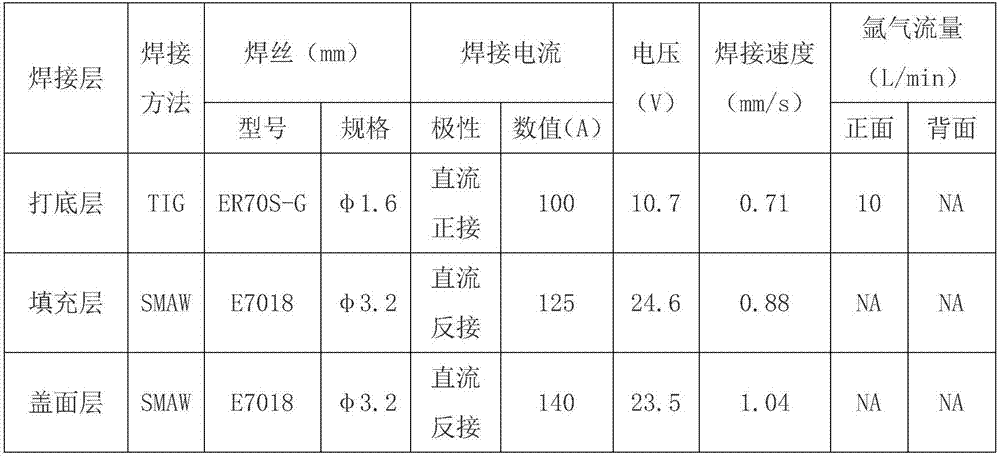

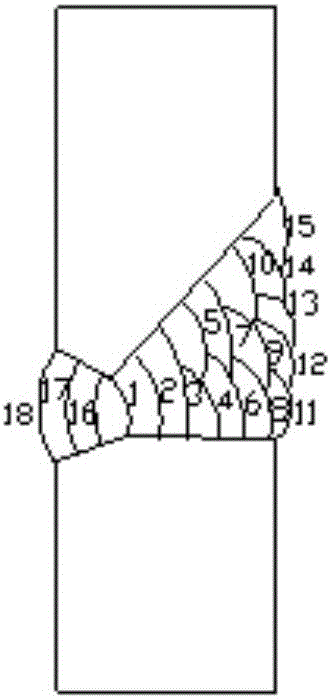

Welding method for P355NH and 18MnD5 dissimilar steel

InactiveCN107498143AControl cooling rateReduced tendency to crackArc welding apparatusBrittle fractureHeat treated

The invention belongs to the technical field of welding of dissimilar steel, particularly relates to a welding method for P355NH and 18MnD5 dissimilar steel, and discloses a welding method for P355NH and 18MnD5 dissimilar steel in order to solve the problem that welding cracks and brittle fracture are likely to be produced in a welding joint area of P355NH and 18MnD5 when the P355NH and the 18MnD5 are welded. The method comprises the steps that 1, edge preparation and welding assembling are carried out on P355NH and 18MnD5 dissimilar steel base metal to be welded; 2, preweld preheat treatment is carried out on the P355NH and 18MnD5 dissimilar steel base metal to be welded; 3, multi-layer welding operation is carried out on the P355NH and 18MnD5 dissimilar steel base metal, wherein the multi-layer welding operation sequentially comprises base coat welding, filling layer welding and cover face layer welding; and 4, a P355NH and 18MnD5 dissimilar steel welding joint obtained after welding is subjected to postweld heat treatment. In the welding method, the parameters in the welding operation process are selected and controlled, so that welding for P355NH and 18MnD5 dissimilar steel is completed, and the welding joint with the excellent welding performance is obtained.

Owner:CHINA NUCLEAR IND 23 CONSTR

Welding method of Q460GJC steel used for architectural structure

InactiveCN106270928AAvoid cold cracksAvoid it happening againArc welding apparatusWelding/soldering/cutting articlesRoom temperatureEngineering

The invention relates to a welding method of Q460GJC steel used for an architectural structure. The welding method comprises the steps that a plate blank which is 3-40 mm thick is welded at the room temperature of -10-0 DEG C through automatic submerged-arc welding or CO2+Ar gas shielded welding, specifically, (1) preheating is conducted before welding so that cold cracks can be prevented from being produced at the joint portion; (2) a reasonable groove mode and a welding method are put forward according to the joint mode and the thickness of the plate blank; (3) an appropriate welding material is selected and used according to the joint mode, the groove mode and the welding method; and (4) corresponding appropriate welding process parameters are presented. Making of the technical scheme of the welding method is based on a welding procedure qualification test, and the welding method has sufficient objectivity and reasonability; and the Q460GJC steel is welded through the technical scheme, a welded joint has mechanical properties equivalent to a parent material and meets the welding quality requirements of engineering.

Owner:鞍钢钢结构(营口)有限公司

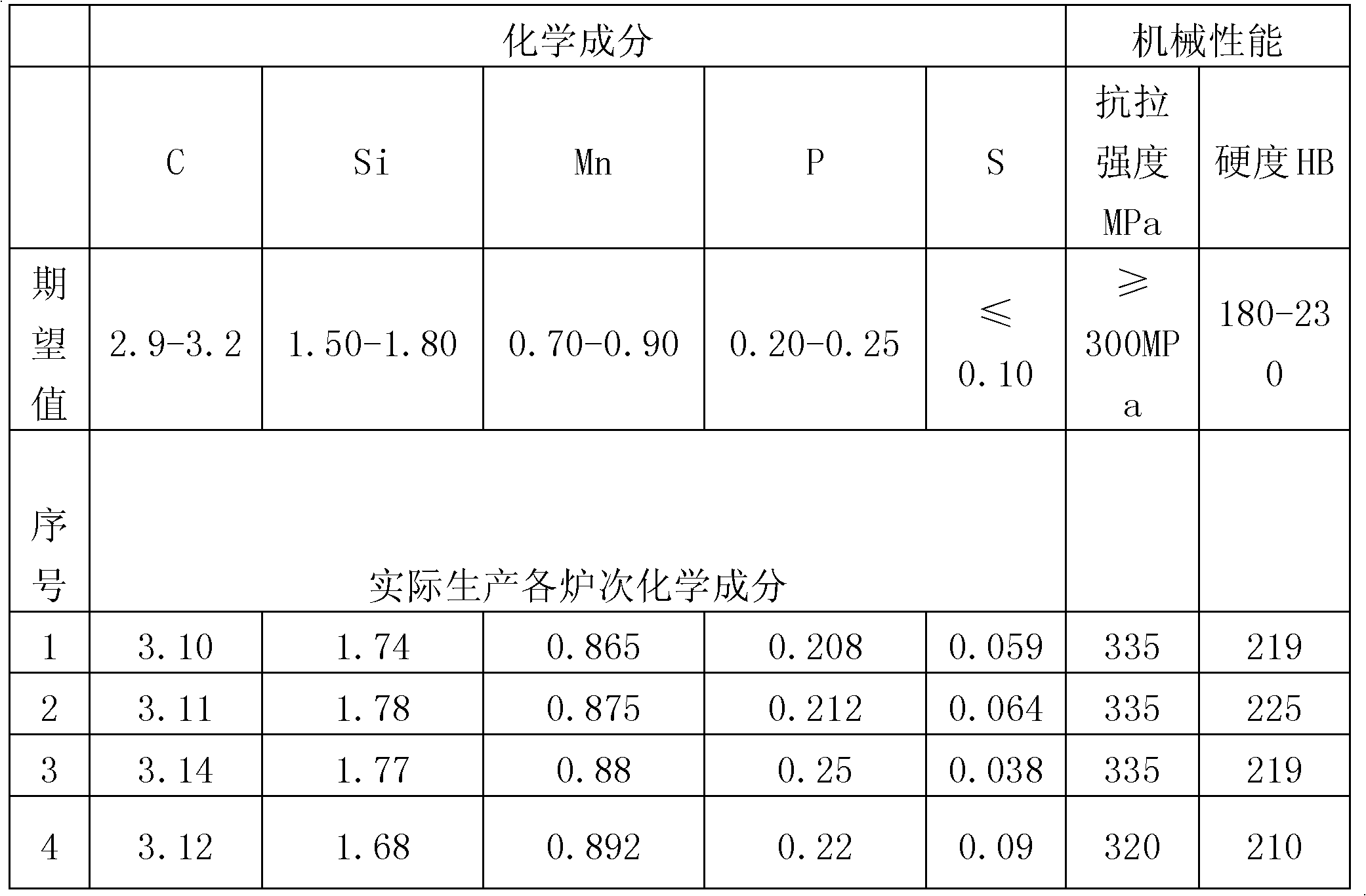

Production technology of high-phosphorus iron casting

The invention provides a production technology of a high-phosphorus iron casting so as to solve the technical problems such as poor mechanical property, obvious cooling crack and high production cost of the high-phosphorus iron casting in the background technology. The production technology of the high-phosphorus iron casting includes the steps as follows: firstly, adding scrap steel and recarburizer into an induction intermediate frequency furnace; secondly, adding foundry returns; thirdly, adding pig iron; fourthly, adding ferrophosphorus, ferrosilicon and ferromanganese in sequence; fifthly, after 18-20min, raising the furnace temperature to 1480-1520 DEG C and conducting inoculation for multiple times by adopting Fe-Si and Si-Ba series; and sixthly, by a stream pouring inoculation way, finally obtaining the pearlite high-phosphorus iron casting with high strength under the condition of CE (carbon equivalent) higher or equal to 3.5%. The mechanical property and metallographic structure (graphite form, type A and pearlite) of the high-phosphorus iron casting prepared by the technology are both superior to the technique data of the product obtained under higher technology cost.

Owner:江西德辰科技有限公司

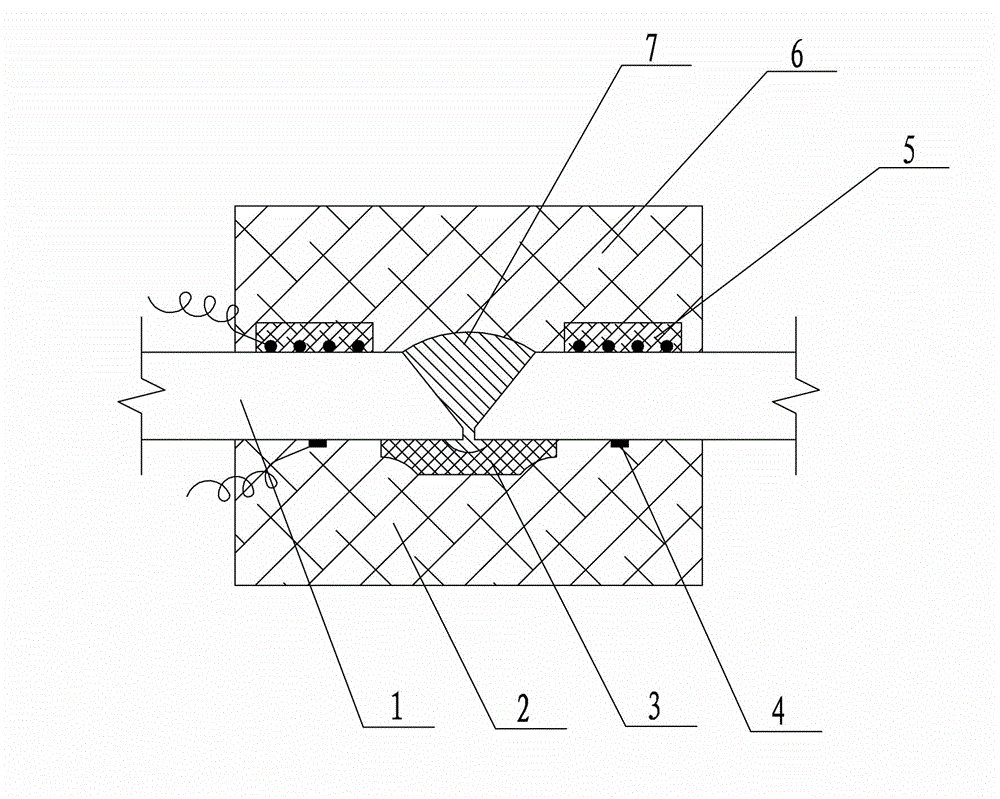

Laser welding method for ultrahigh strength armor steel

InactiveCN108672929AOvercoming extreme cold hardeningMeet performance requirementsLaser beam welding apparatusEngineeringToughness

The invention discloses a laser welding method for ultrahigh strength armor steel. The laser welding method comprises the following steps that step 1, preparation before welding is carried out; step 2, two to-be-welded workpieces are installed on a tool fixture; and step 3, a welding line between the two to-be-welded workpieces is welded, wherein welding parameters are that laser power is 2500-2700W, the welding speed is 600mm / min, pure argon gas protection is needed, the welding environment temperature is no less than 15 DEG C, the welded position preheating temperature is between 50 DEG C-100DEG C, and the wind speed of the welded area is limited below 1m / s, otherwise a wind blocking device is needed. The cooling speed of a connector is decelerated, brittleness of the connector is reduced, shaping toughness is improved, cold crack is avoided, and usability requirements of the connector to a vehicle are guaranteed.

Owner:内蒙古第一机械集团股份有限公司

Production technology for automatic low alloy steel welding wire for ship

InactiveCN104625489ALow elemental contentImprove cleanlinessWelding/cutting media/materialsSoldering mediaWire rodCopper plating

The invention relates to a production technology for an automatic low alloy steel welding wire for a ship, wherein preheating and copper plating are not needed. The production technology is characterized in that the welding wire comprises 0.02-0.1% of C, 2-4% of Mn, 2-4% of Ni, 0.5-1% of Mo, 0.5-0.8% of Si, 0-0.5% of Cu, 0-1.2% of Cr, 0-0.12% of V and 0-0.05% of Ti. The production technology comprises the steps of vacuum melting, forging, steel rolling, wire rod hot rolling, mechanical dust removal, chlorohydric acid pickling, neutral water washing, high-pressure water cleaning, alkali neutralization, boronizing, saponification with liquid soap, drying, primary cold drawing, recrystallization annealing, chlorohydric acid pickling, neutral water washing, high-pressure water cleaning, alkali neutralization, boronizing, saponification with liquid soap, drying, secondary cold drawing, chlorohydric acid pickling, neutral water washing, high-pressure water cleaning, alkali neutralization, saponification with liquid soap, brilliant polishing and drawing and rust-proof liquid coating.

Owner:JIANGSU TIANYE ALLOY MATERIAL

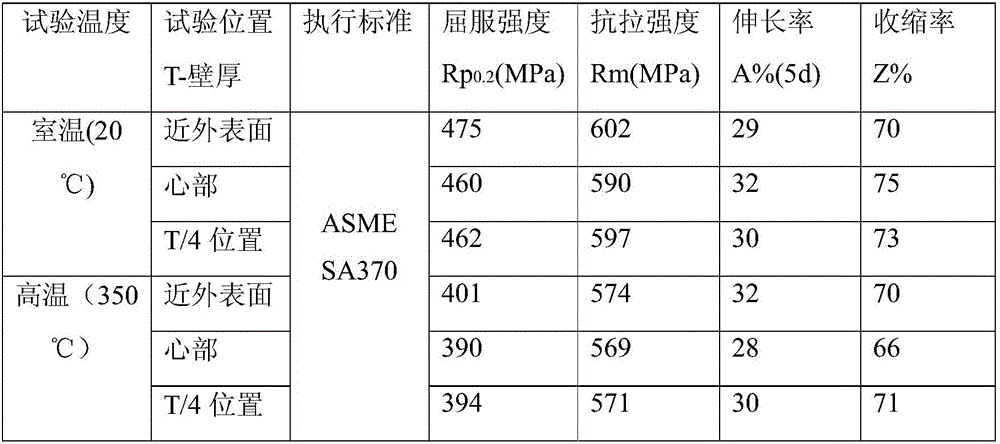

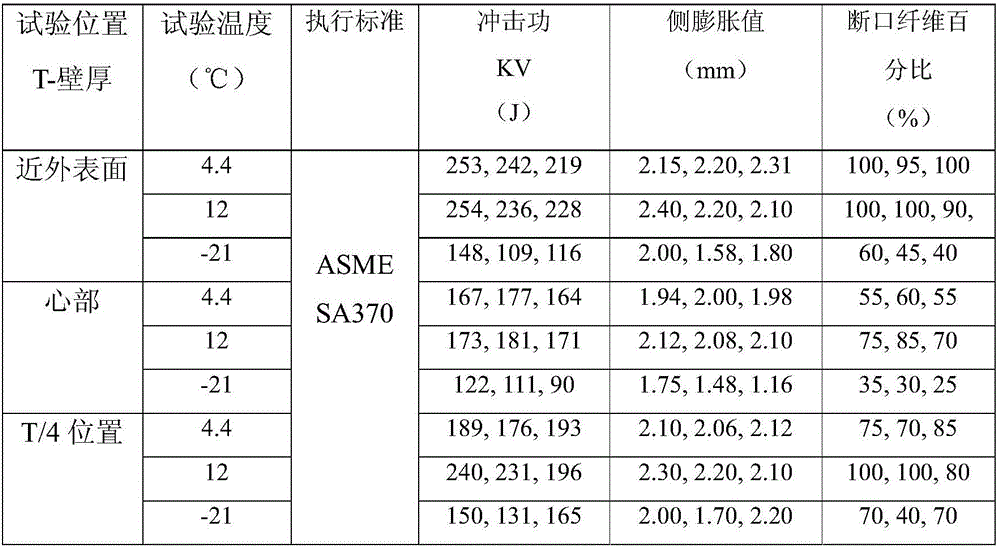

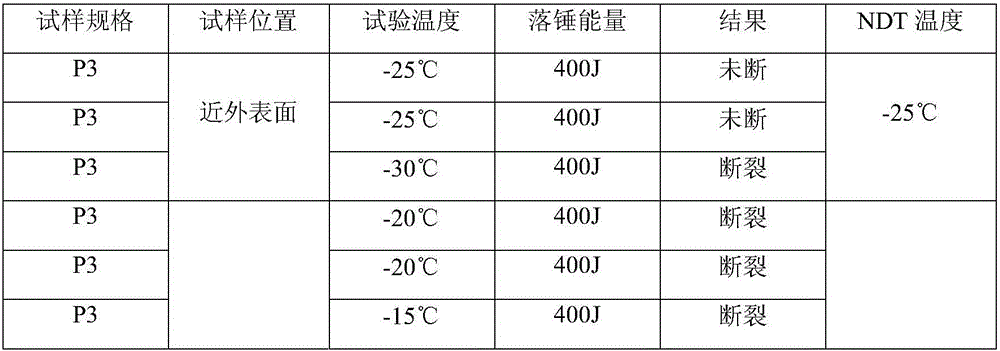

Heat treatment method of nuclear island ultralarge section forging

ActiveCN106222387AFully austenitizedImprove pass rateFurnace typesHeat treatment furnacesRoom temperatureWater cooling

The invention relates to a heat treatment method of a nuclear island ultralarge section forging. The method comprises the following steps: (b) preheating treatment: the nuclear island ultralarge section forging is heated from room temperature to 880-910 DEG C for insulation, and then is dipped in water for cooling; (c) thermal refining: scales on the surface of the nuclear island ultralarge section forging treated in the step (b) are removed; and the nuclear island ultralarge section forging is heated from room temperature to 740-890 DEG C for insulation, and then is cooled by water; and (d) tempering: the nuclear island ultralarge section forging treated by the step (c) is heated from room temperature to 615-645 DEG C for insulation, and then is cooled along with a furnace to reach the room temperature. The method can guarantee full austenitizing of the part with the largest thickness, is finer in grains, can effectively prevent hot cracks and cold cracks, and greatly improves the yield of finished products.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Welding process of three-way valve seat and valve body

ActiveCN102990200AReduce toughnessReduced crack resistanceArc welding apparatusHeat-affected zonePower flow

The invention relates to a welding process of a valve seat and a valve body, in particular to a welding process of a three-way valve seat and a valve body of a supercritical thermal power unit; the welding process comprises the following steps that the beneficial impact of multi-layer welding is fully utilized, multi-layer welding is adopted, and a latter layer plays the roles of dehydrogenating and improving the tissue of a heat affected zone to a former layer; heat input is controlled through a method in which low welding current welds more quickly, and the heat input of welding is strictly controlled; and high-strength steel is more sensitive to the heat input of welding, and over heat input can reduce the toughness of a welding connector and thus reduce the anti-cracking performance. Post heat treatment is carried out soon after welding, so that cold cracks are prevented from generating in a period of time after welding, and the welding requirements are met. According to the welding process, the problem that WB36 and F6a special steel welding is difficult is fully solved, cracking and other phenomena after welding are avoided, and the weld seam quality can be fully ensured.

Owner:DALIAN DAGAO VALVE

Welding method for Q345qDNH weather-resisting steel for bridge

ActiveCN102837105BSolve welding process problemsAvoid cold cracksArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingButt joint

The invention discloses a welding method for Q345qDNH weather-resisting steel for a bridge. According to the welding method provided by the invention, specific to the special chemical components, suitable technical conditions and different slab thickness of the Q345qDNH weather-resisting steel for the bridge, a welded joint is jointed in a butt-jointed or T-shaped corner jointed form. According to the welding method, submerged-arc welding, drug core CO2 gas shielding semi-automatic welding or shielded metal arc welding is adopted and the weld preheating temperature is confirmed according to the different slab thickness. According to the welding method provided by the invention, the joint form and the thickness size of a bridge structure are completely covered; the technical scheme is simple and the applicability is strong; the implementing effect meets the technical demands of the present related standard for the construction of the bridge steel and the bridge structure; and the welding method can be practically applied to the welding of the Q345qDNH weather-resisting steel bridge structure.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Valve seat and valve body welding process

InactiveCN105364268AControl heat inputReduce toughnessWelding/cutting auxillary devicesArc welding apparatusHeat-affected zonePower flow

The invention relates to a valve seat and valve body welding process and specifically relates to a valve seat and valve body assembly welding process for a supercritical thermal power unit. The positive effect of multilayer welding is fully utilized; by utilizing multi-layer welding, the following layer has the effects of hydrogen removal and heat affected zone microstructure improvement on the previous layer. The method of relatively rapid welding of small welding current is used for controlling thermal input; thermal input of welding is strictly controlled; high-strength steel is relatively sensitive to thermal input of welding and excessive thermal input causes reduction of the toughness of a welding joint and reduces the anti-cracking performance. After-heat treatment is performed immediately after welding, so that the problem that cold cracks appear some time after welding is solved and the welding requirement is met. The welding process completely solves the problem of difficulty in welding of WB36 and F6a dissimilar steel, prevents post-welding cracking and can totally guarantee the welding quality.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com