Method for restoring inner bore of gear coupling

A technology of gear coupling and repair method, applied in the direction of metal material coating process, coating, etc., can solve the problems of misalignment of rotation axes, increase maintenance work, increase production cost, etc., to reduce resource and energy consumption, The effect of reducing environmental pollution and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

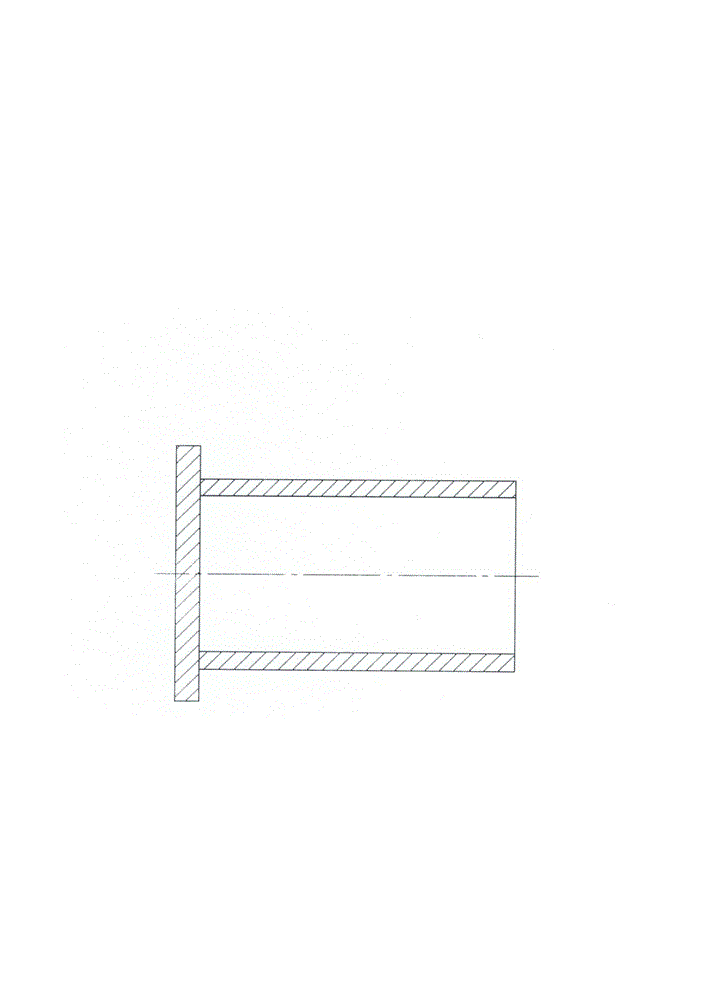

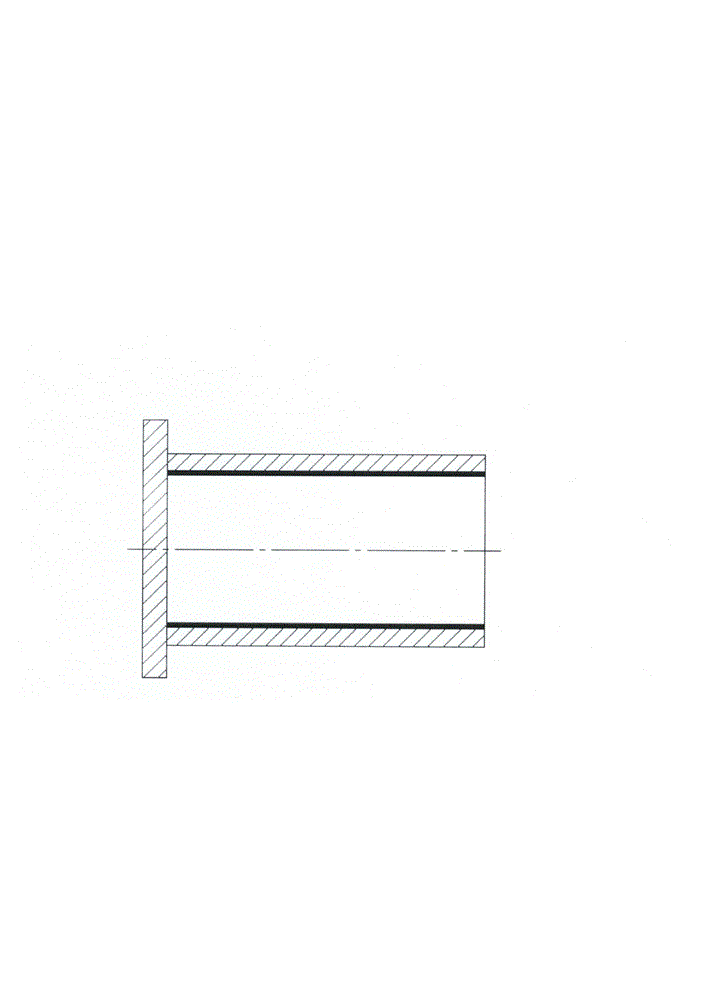

[0026] First, disassemble and disassemble the gear coupling equipment, mark it, clean the workpiece, check the size, and determine if figure 1 The wear part and the wear amount of the inner hole of the gear coupling are shown, and the inner hole of the gear coupling is inspected for radial and end runout, and the failure analysis and life evaluation of the workpiece are carried out, and the gear coupling is measured. Check whether the size of each part is suitable for the laser cladding repair standard, and then remove the 2mm fatigue layer on the surface of the inner hole of the gear coupling to ensure that there are no serious defects such as cracks on the surface of the gear coupling; use the mechanical mixing method to mix the proportioned Ni55 and nano-WC powder into a mechanical powder mixer and fully mixed. The mixing time is 1.5 hours. The mixing ratio of alloy powder is: Ni55 powder accounts for 99% of the total mass, and nano-WC powder accounts for 1% of the total ma...

Embodiment 2

[0028] First, disassemble and disassemble the gear coupling equipment, mark it, clean the workpiece, check the size, and determine if figure 1 The wear part and the wear amount of the inner hole of the gear coupling are shown, and the inner hole of the gear coupling is checked for radial and end runout, and the failure analysis and life evaluation of the workpiece are carried out, and the gear coupling is measured. Check whether the size of each part is suitable for the laser cladding repair standard, and then remove the 2.5mm fatigue layer on the inner hole surface of the gear coupling to ensure that there are no serious defects such as cracks on the surface of the gear coupling; The Ni55 and nano-WC powders were put into a mechanical powder mixer and mixed fully. The mixing time was 1.5 hours. The mixing ratio of the alloy powders was: Ni55 powder accounted for 98.5% of the total mass, and WC powder accounted for 1.5% of the total mass. Shaft powder feeding method, the powd...

Embodiment 3

[0030] First, disassemble and disassemble the gear coupling equipment, mark it, clean the workpiece, check the size, and determine if figure 1The wear part and the wear amount of the inner hole of the gear coupling are shown, and the inner hole of the gear coupling is inspected for radial and end runout, and the failure analysis and life evaluation of the workpiece are carried out, and the gear coupling is measured. Check whether the size of each part is suitable for the laser cladding repair standard, and then remove the 3mm fatigue layer on the surface of the inner hole of the gear coupling to ensure that there are no serious defects such as cracks on the surface of the gear coupling; use the mechanical mixing method to mix the proportioned Ni55 and nano-WC powder into a mechanical powder mixer and fully mixed. The mixing time is 1.5 hours. The mixing ratio of the alloy powder is: Ni55 powder accounts for 98% of the total mass, and WC powder accounts for 2% of the total mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com