Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

282results about How to "Solve Welding Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

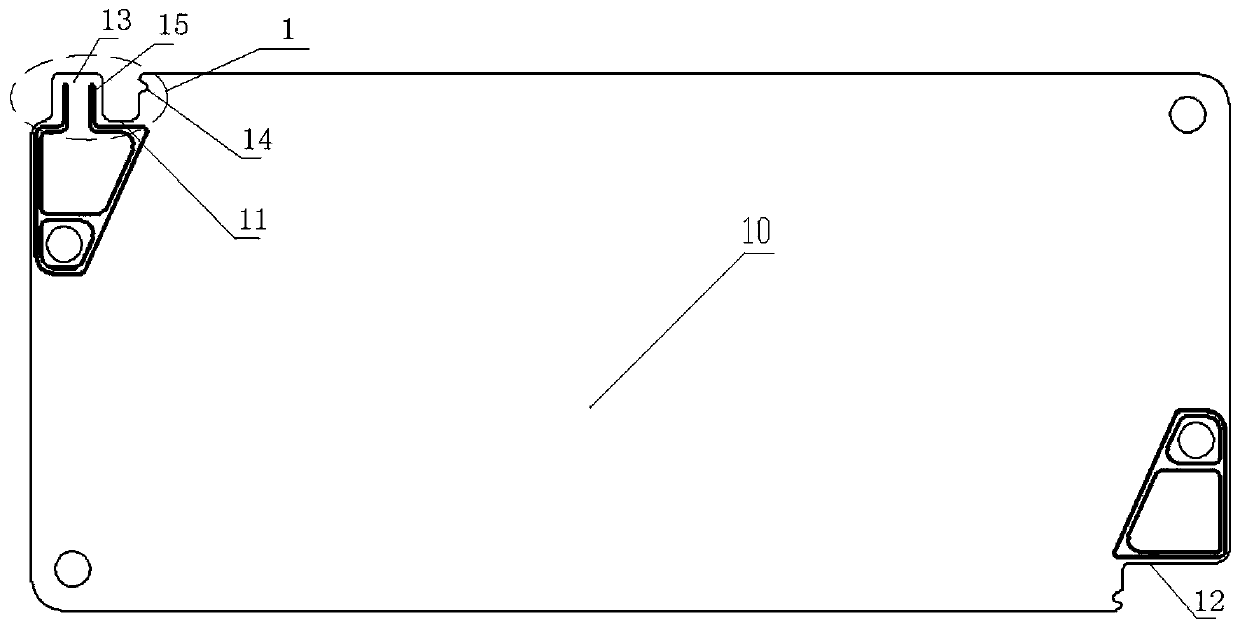

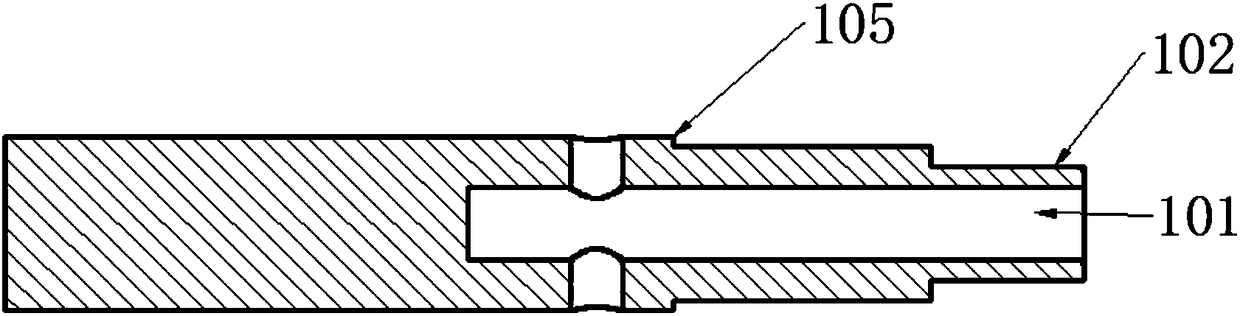

Fuel cell bipolar plate and fuel cell voltage routing inspection insertion part

PendingCN110323463AImprove seismic performanceReduce manufacturing difficultyElectrical testingCollectors/separatorsFuel cellsVoltage

The invention provides a fuel cell bipolar plate which comprises a routing inspection insertion part connection structure for connecting a routing inspection insertion part. The routing inspection insertion part connection structure comprises an anti-off buckle and a contact terminal, wherein the anti-off buckle is formed by protruding or sinking along a direction which is not parallel to an insertion direction of the routing inspection insertion part; and the contact terminal is formed by protruding outwards along a direction in parallel to the insertion direction of the routing inspection insertion part at the edge of the bipolar plate. The technical scheme of the invention solves problems of existing connection modes between the routing inspection insertion part and a reactor core assembly, such as welding or insertion and extraction and the like.

Owner:SUNRISE POWER CO LTD

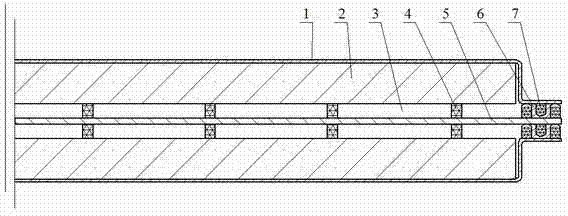

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

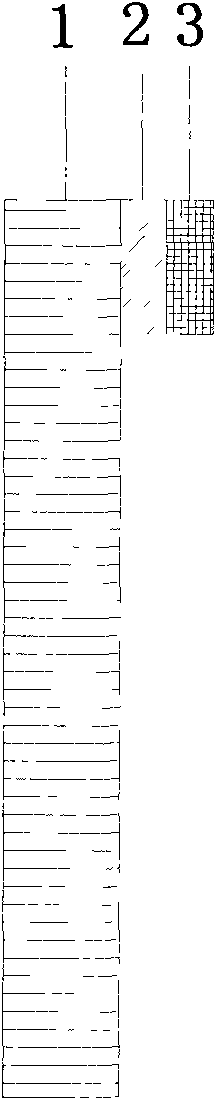

Tab material of flexible-packaging lithium battery as well as electroplating method and application method thereof

ActiveCN101771142ASolve Welding ProblemsWon't hurtSmall-sized cells cases/jacketsElectrode carriers/collectorsElectrical batteryMetallic materials

The invention discloses a tab material of a flexible-packaging lithium battery as well as an electroplating method and an application method thereof, wherein the tab material and the application method thereof are suitable for preparing an anode tab and a cathode tab of the flexible-packaging lithium battery and welding a circuit board. For the tab material, an SUS430 stainless steel band, a copper band, an aluminum band, a nickel band and other conduction materials as the substrate, a nickel-plated layer is firstly plated at one side end of the substrate, and then a tin-plated layer is plated on the nickel-plate layer (the tin-plated layer is directly plated on the nickel band), so as to obtain the tab material with lower production cost, good weldability and appropriate thermal conductivity. For the application method, at the position of the tab material double layers of nickel and tin, laser heating is carried out on one side of the position without being plated, and the tab material is heated to the tin melting point instantly, so that the tab material is welded on a metal material to be welded. With the adoption of the invention, the anode tab and the cathode tab are simultaneously welded, and less heat can be generated in the welding process, thereby ensuring the weldability with high strength and protecting the battery.

Owner:力佳电源科技(深圳)股份有限公司 +4

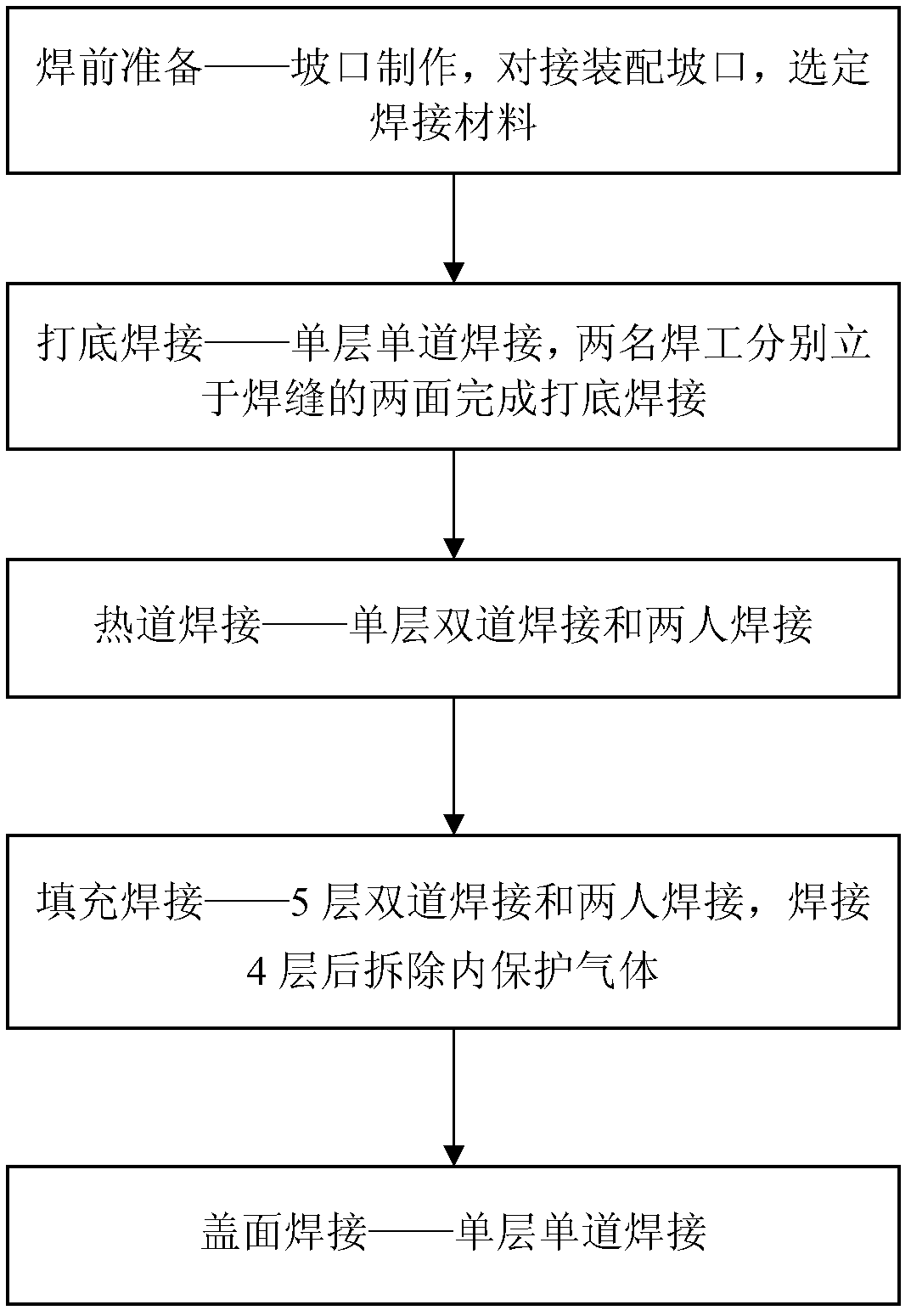

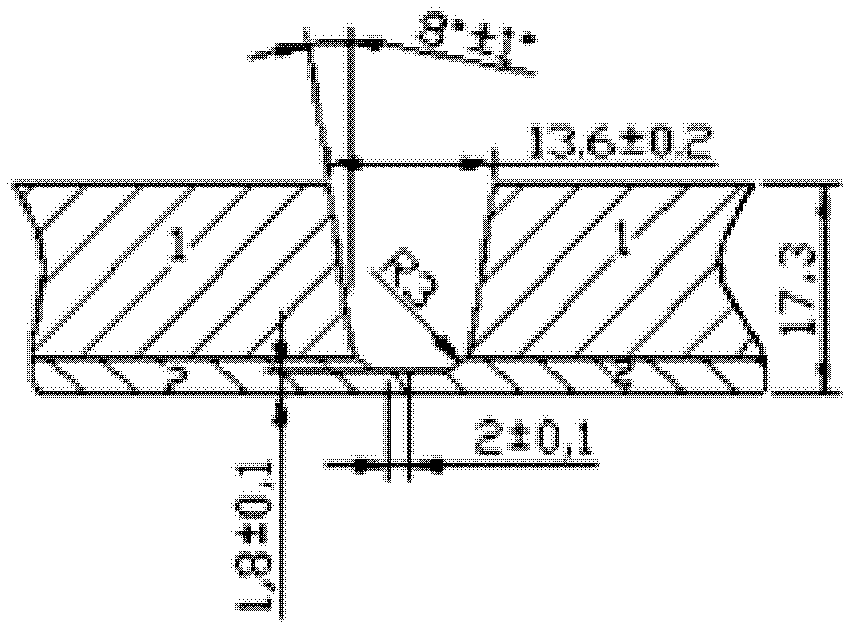

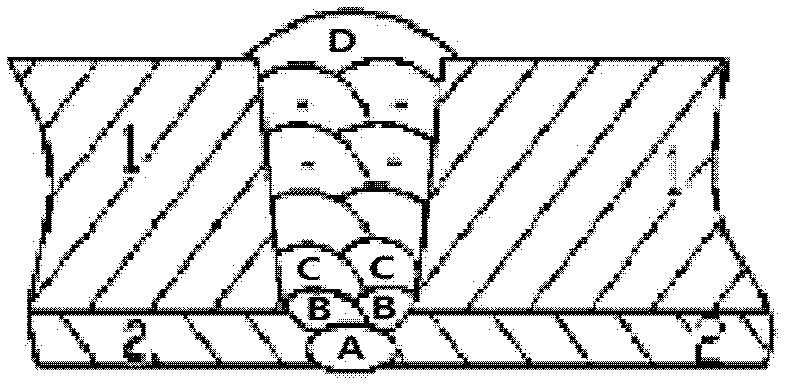

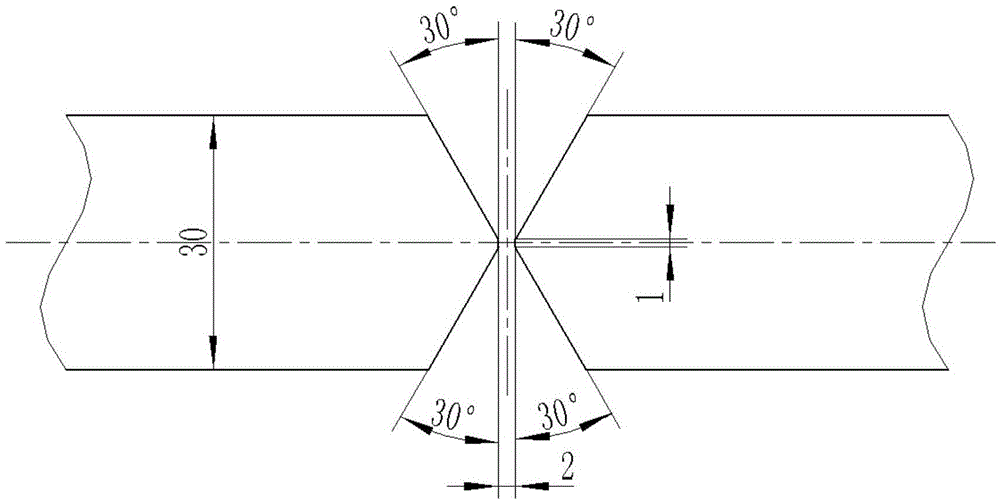

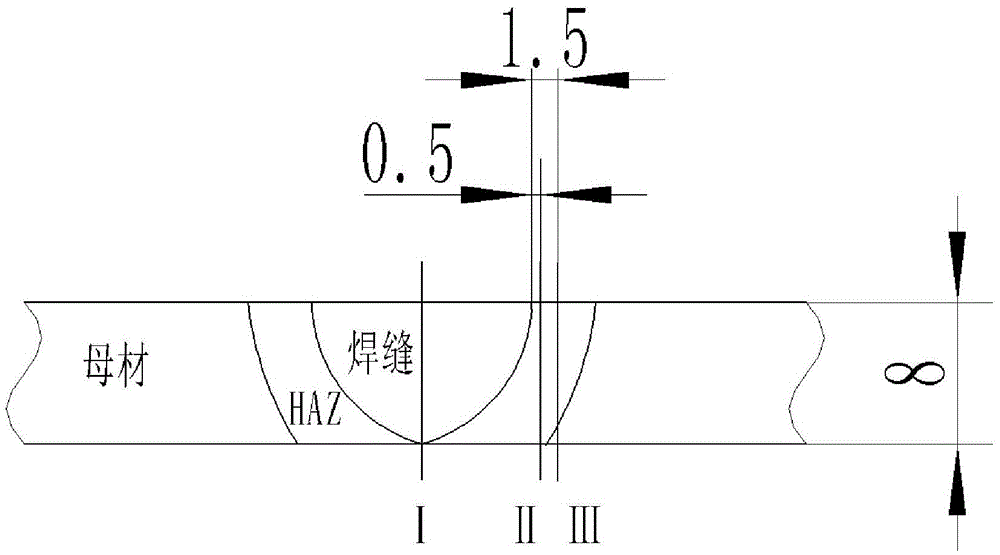

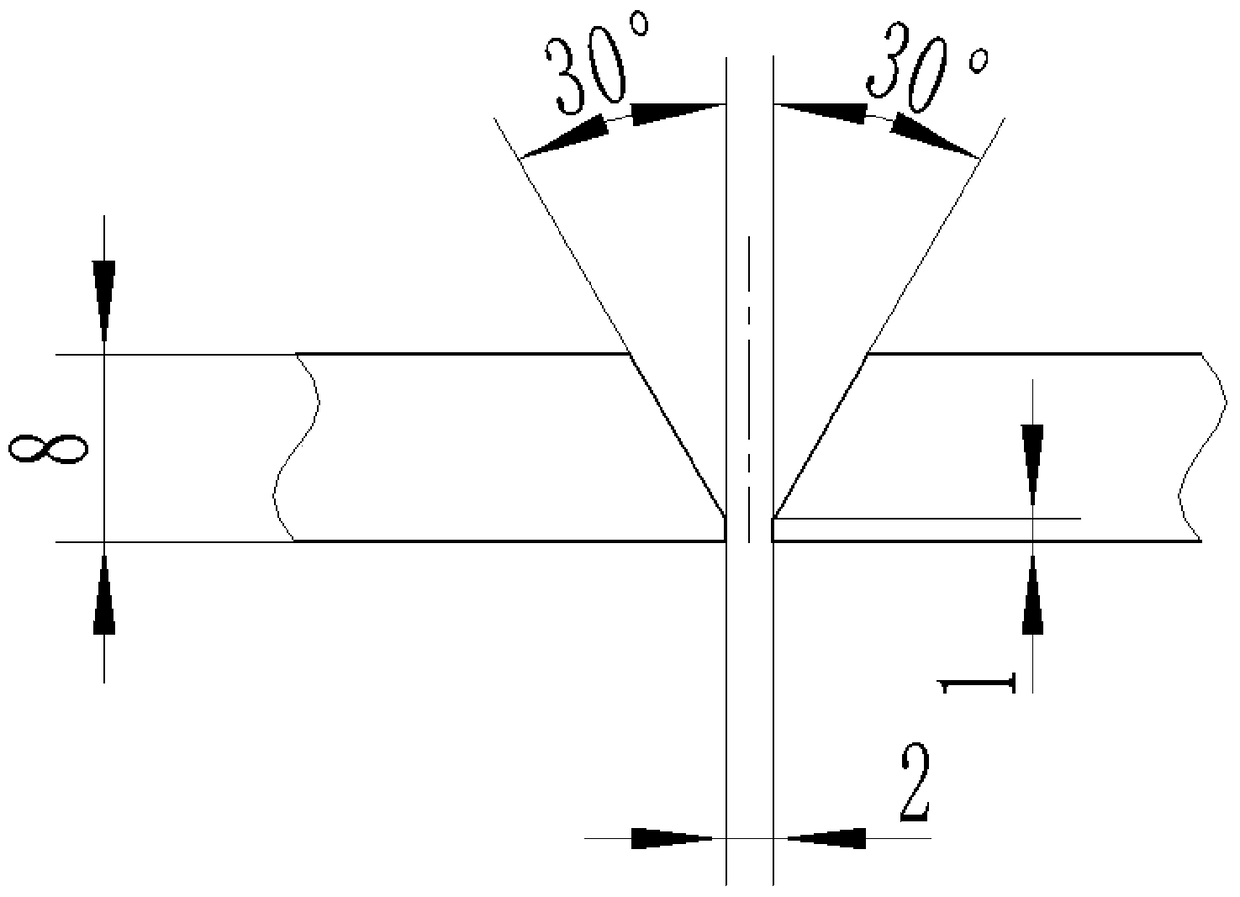

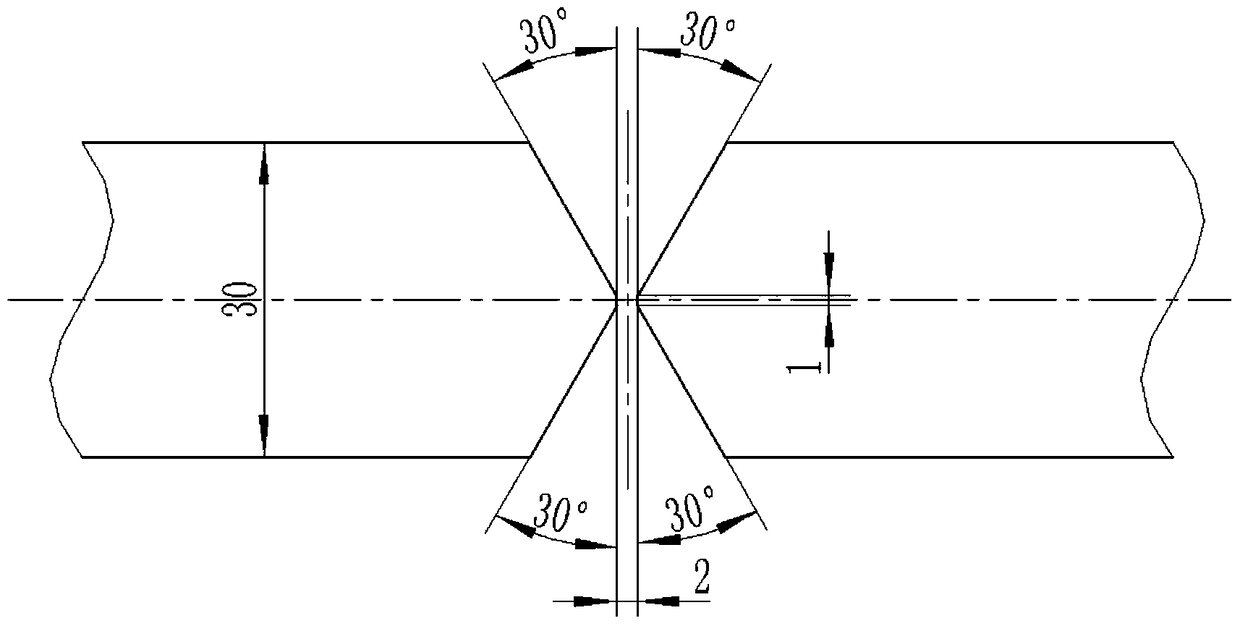

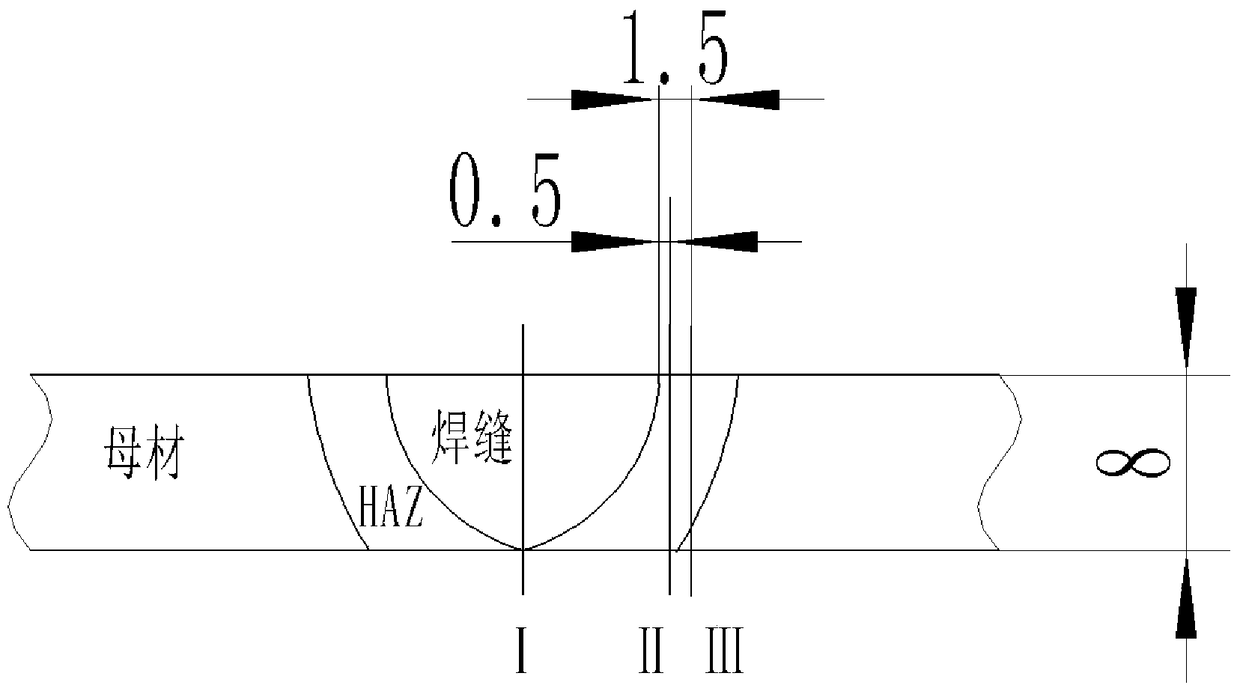

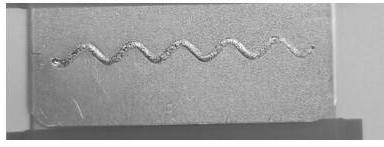

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

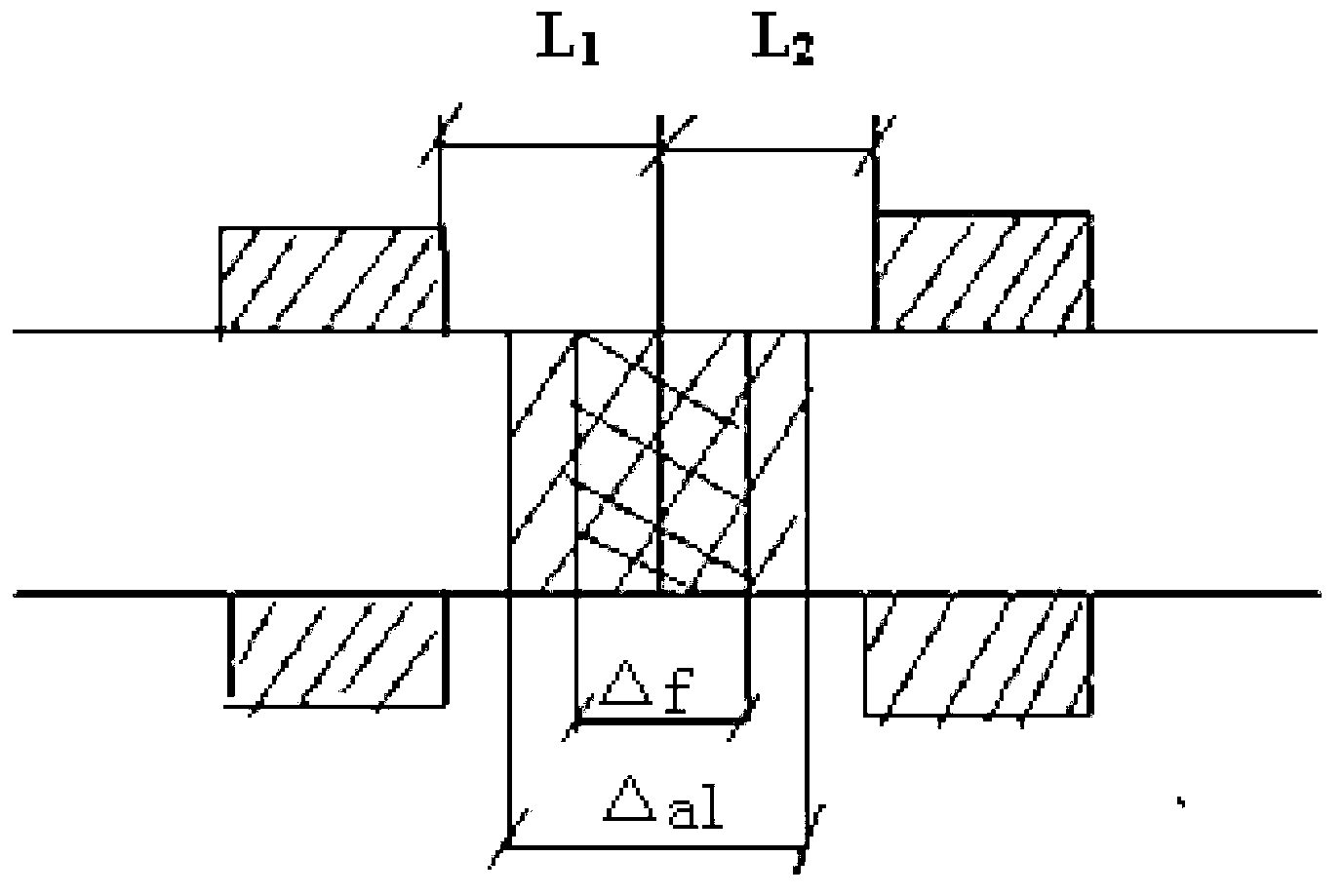

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

Induction welding method for aluminum water-cooling base plate and stainless joint

ActiveCN101642840ASolve Welding ProblemsFull shapeWelding/cutting media/materialsSoldering mediaIgbt power modulesInduction welding

The invention relates to an induction welding method for an aluminum water-cooling base plate and a stainless joint, which mainly comprises the following steps: processing the stainless joint and thewater-cooling base plate by sodium hydroxide and sulfuric acid solution and drying; bending a zinc-aluminum alloy flux-cored welding wire with a melting point of 420-480 DEG C into a circle and placing the zinc-aluminum alloy flux-cored welding wire to the root part of the stainless joint exposing out of the end surface of the water-cooling base plate and the chamfering position of a screw hole ofthe end surface of the water-cooling base plate; connecting an induction coil of the water-cooling base plate with one induction heating power supply and placing the water-cooling base plate into theinduction coil; connecting an induction coil of the stainless joint with the other high frequency induction heating power supply and placing the stainless joint into the induction coil. The temperature in the welding position of the water-cooling base plate rises to 450-480 DEG C and the temperature in the welding position of the stainless joint rises to 500-550 DEG C during welding. The invention more ideally solves the problem of welding two different material components of aluminum and stainless steel; welded brazing filler metal has full and even appearance and completely fills a seam andcan lead the welding position to be sealed permanently; and the stable working state of an IGBT power module is ensured.

Owner:CRRC DALIAN INST CO LTD

Welding method for low-alloy and ultrahigh-strength steel with yield strength being 1100 MPa

ActiveCN105522262AAvoid welding cold cracksGood toughnessArc welding apparatusWelding/soldering/cutting articlesCarbon dioxideWeld bead

Owner:NORTHEASTERN UNIV +1

Welding technique of G115 steel used for boiler pipelines

The invention discloses a welding technique of G115 steel used for boiler pipelines. The welding technique is characterized by comprising the following steps that the pipelines are prepared from G115 novel martensitic heat-resistant steel supplied in the normalized condition and the tempering condition; beveled edges are prepared in the two pipelines needing to be welded correspondingly, through polishing, the beveled edges and the two sides of the inner walls and the outer walls of the beveled edges are cleared, and then the two pipelines needing to be welded are subjected to aligned assembly; manual argon arc welding and manual electric-arc welding are adopted to conduct welding; and after butt girth welding is conducted, heat treatment is conducted at the temperature of 760-780 DEG C, and the heat preservation time is seven hours or more. According to the welding technique of the G115 steel used for the boiler pipelines, the problems that which welding material is adopted for welding of the G115 steel and how heat treatment is conducted after the G115 steel is welded are solved, and the welding technique of the G115 novel martensitic heat-resistant steel is completely provided and has great significance for reference on solving the welding problem of the same martensitic heat-resistant steel.

Owner:SHANGHAI BOILER WORKS +1

Vertically compensated stirring friction welding technique

ActiveCN103962715AQuality improvementSolve Welding ProblemsNon-electric welding apparatusFriction weldingButt joint

The invention relates to a vertically compensated stirring friction welding technique. Two welding pieces are placed on the same horizontal plane; a certain gap is formed between the two welding pieces; a vertically compensated material is placed in the gap; a stirring gap is controlled to rotate at a rotating speed of 500-5000 rpm; a stirring needle is stabbed into a to-be-welded portion of each welding piece; when reaching a set stabbing depth, the stirring needle stops stabbing and continues to rotate for 1-5 minutes; and the stirring head forwards moves along the horizontal direction of a connection surface of the welding pieces at a speed of 50-1500mm / min until welding is finished. The size of a shaft shoulder of the stirring head and the size of the stirring needle of the stirring head can be changed along with change of the size of the compensating material; the material has sufficient heat input and flows in a welding process, and a welding head with the excellent quality is obtained; and by using the stirring head, the compensating material and a to-be-welded material are sufficiently stirred and mixed, and welding, which is difficultly realized by using the conventional stirring friction method, on a large-gap butt joint can be realized.

Owner:CRRC QINGDAO SIFANG CO LTD

Laser welding head with coaxial light path

PendingCN108044231ASolve Welding ProblemsEasy to operateLaser beam welding apparatusTemperature controlLight spot

The invention discloses a laser welding head with a coaxial light path. The laser welding head comprises a light path cavity, a laser emitting head, a laser optical fiber used for providing laser beams, an infrared temperature measuring optical fiber used for collecting infrared temperature measuring light beams and a camera used for providing visual positioning and monitoring light beams, whereinthe laser optical fiber, the infrared temperature measuring optical fiber and the camera are correspondingly connected to the light path cavity; the light path cavity combines the laser beams, the infrared temperature measuring light beams and the visual positioning and monitoring light beams into a three-in-one coaxial light beam, and the coaxial light beam passes through the laser emitting headso as to perform laser welding, temperature measuring and visual positioning on the position of a welding spot located at the laser emitting head; and the laser emitting head is internally provided with a laser focusing lens used for transmitting the three-in-one coaxial light beam and focusing the laser beams. According to the laser welding head, the coaxial light beam makes temperature controland vision positioning play effective roles at the special welding spot position, the control is accurate, the reliability is higher, therefore, the problem that the temperature control detection canbe easily interfered is solved; and moreover, the size of the light spot at the focal point of the laser can be adjusted so as to be suitable for bonding pads with different sizes.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

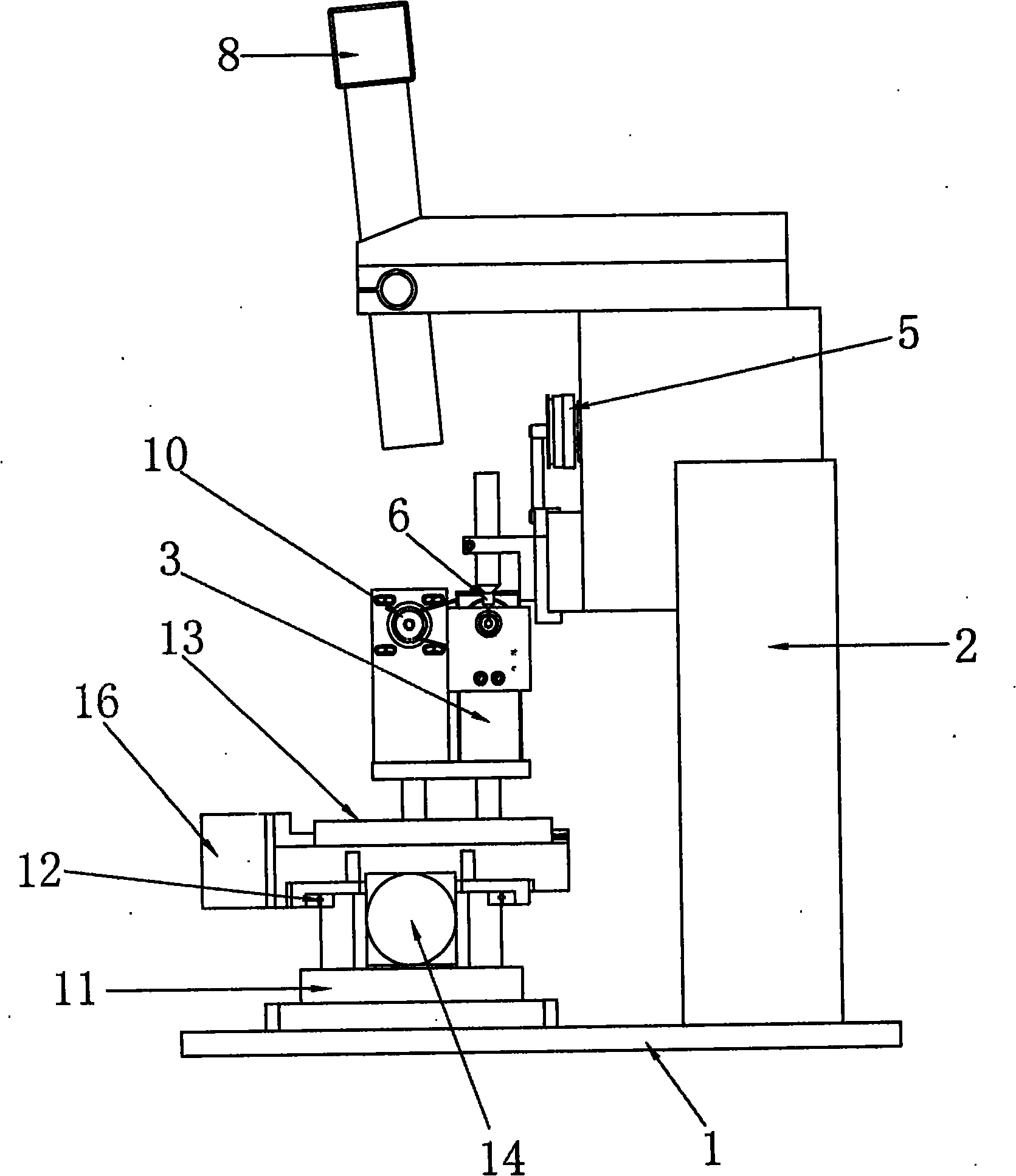

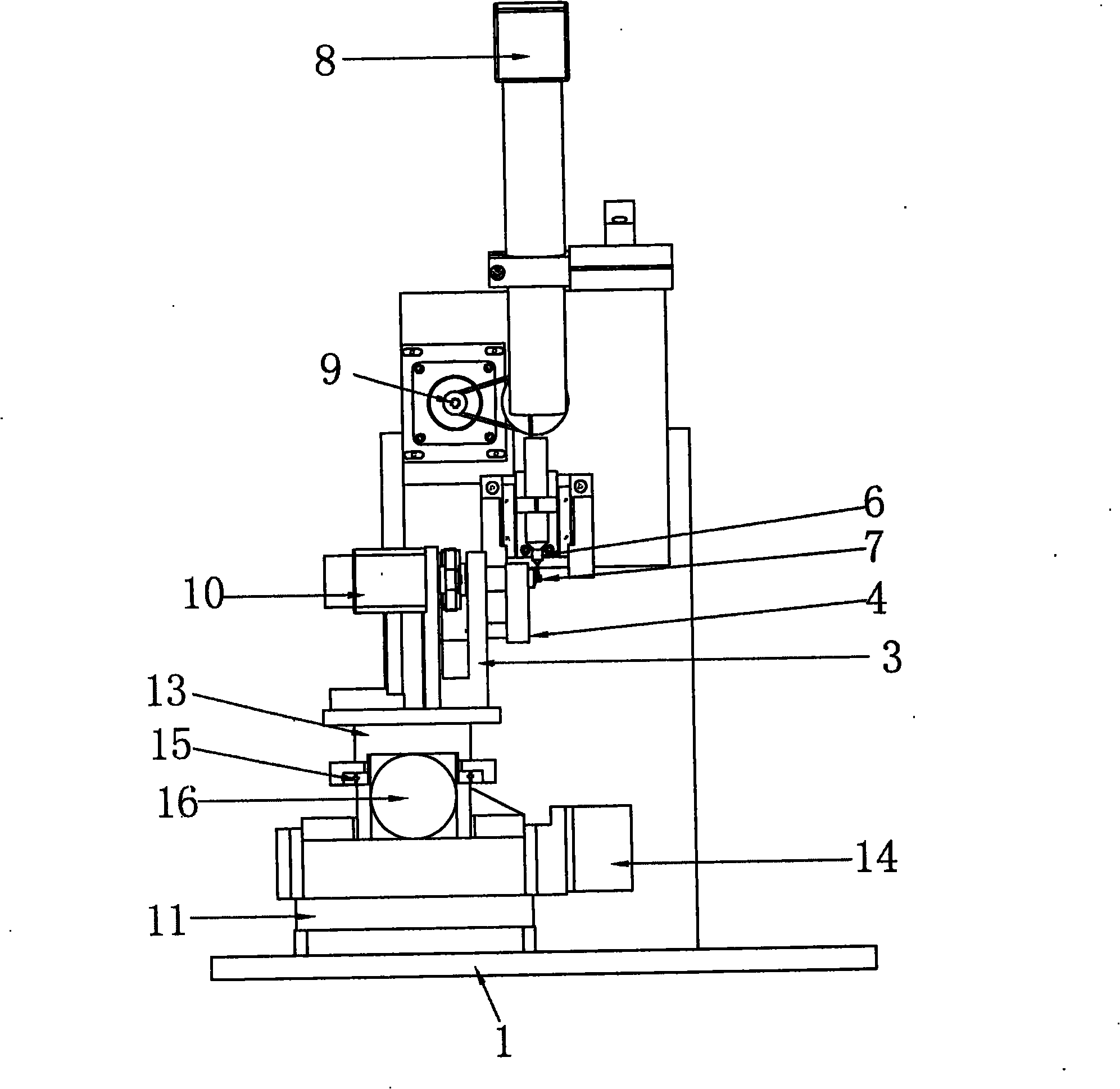

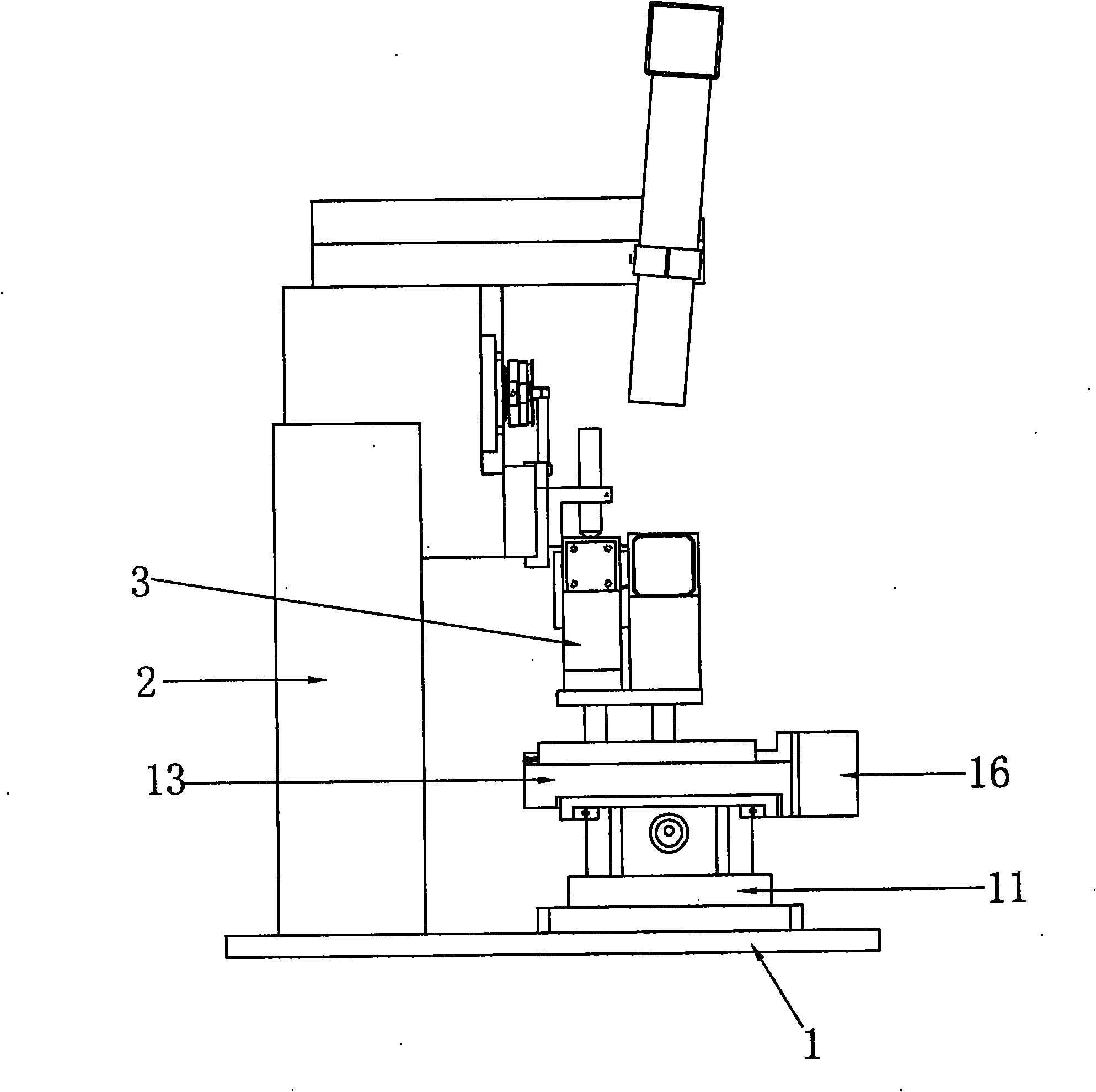

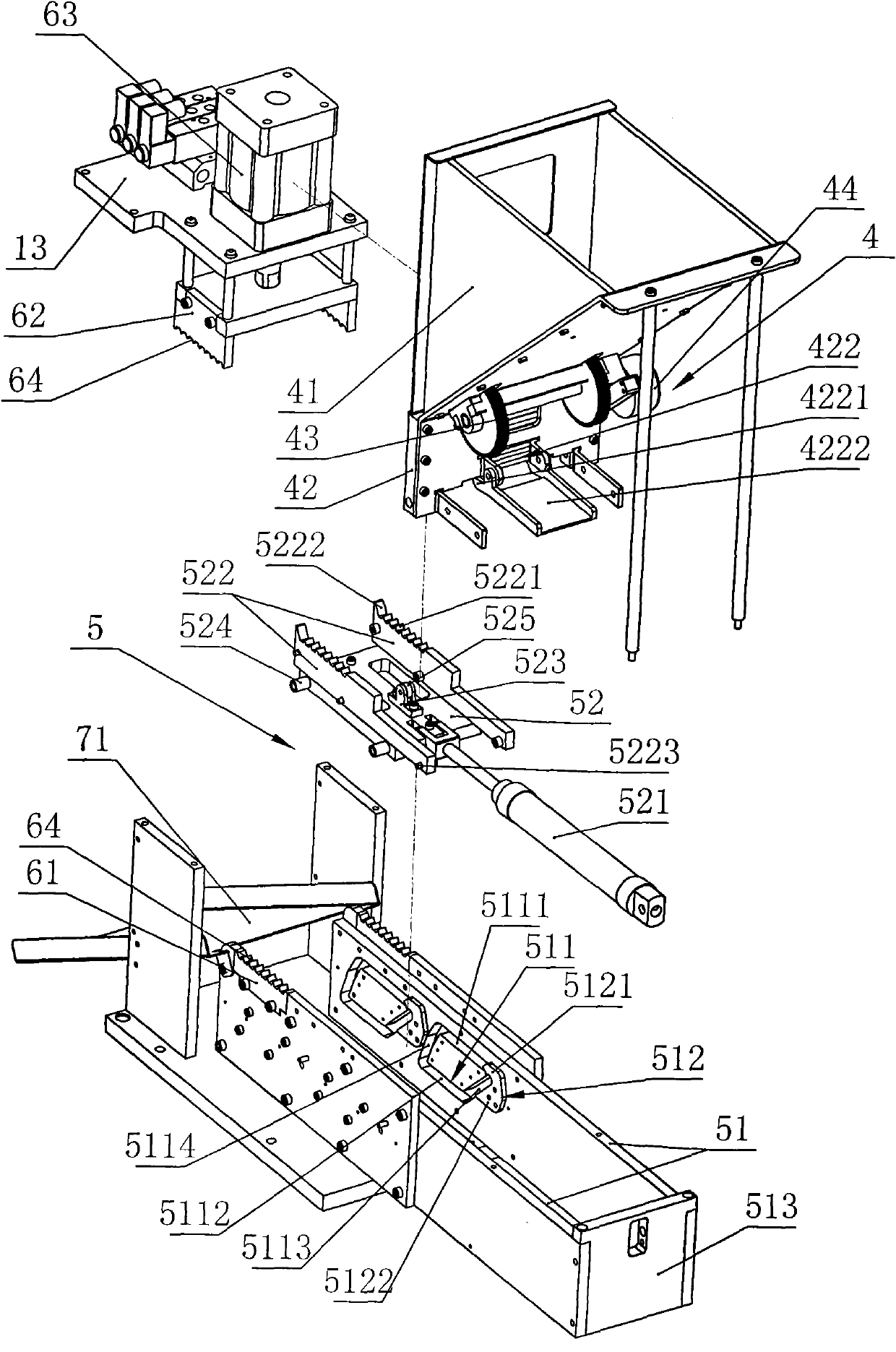

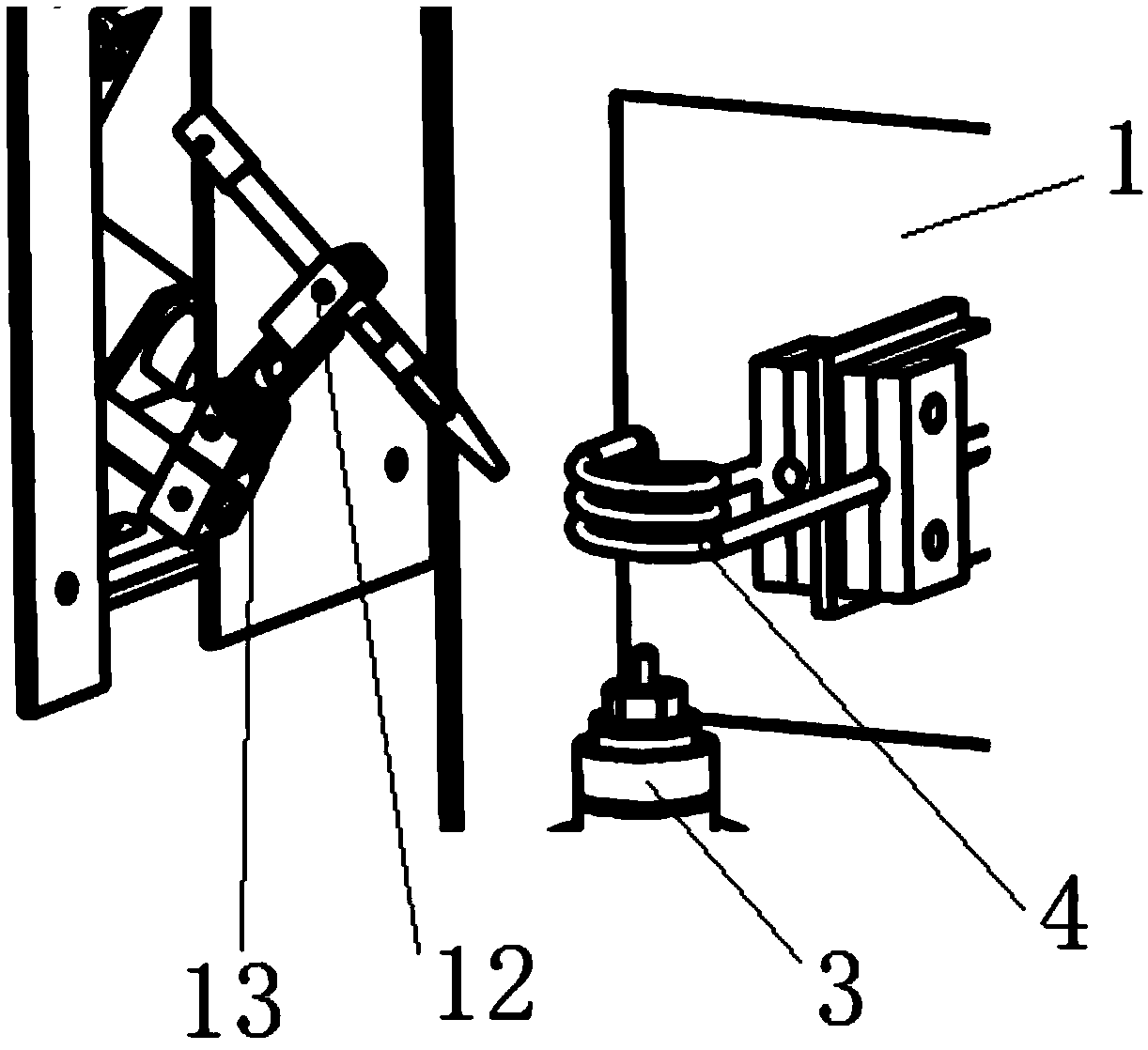

Numerical control rotating three-dimensional ultrasonic gold wire bonder

InactiveCN101774077ASolve Welding ProblemsShorten welding timeNon-electric welding apparatusEngineeringSpot welding

The invention discloses a numerical control rotating three-dimensional ultrasonic gold wire bonder, which is characterized by comprising a bottom plate, a base and a numerical control system, wherein the bottom plate is provided with X and Y axis mobile platforms; the X and Y axis mobile platforms are provided with a device clamp seat; the device clamp seat is provided with a heating block; the base is provided with a Z-axis worktable; the Z-axis worktable is provided with spot welding heads; the device clamp seat and the heating block are provided with device clamps; the positions of the spot welding heads correspond to those of the device clamps; the base is provided with a camera which can carry out camera shooting on devices on the device clamps and feeds back the shot information to the numerical control system; and the X and Y axis mobile platforms and the Z-axis worktable are connected with the numerical control system. Through the numerical control rotating three-dimensional ultrasonic gold wire bonder, the welding time can be shortened, the welding efficiency can be improved, a mass of human resources are saved and the problem that the conventional gold wire bonding machine cannot weld the internal leads of the polyhedral or irregular polyhedral large or small power devices is solved.

Owner:周志坚

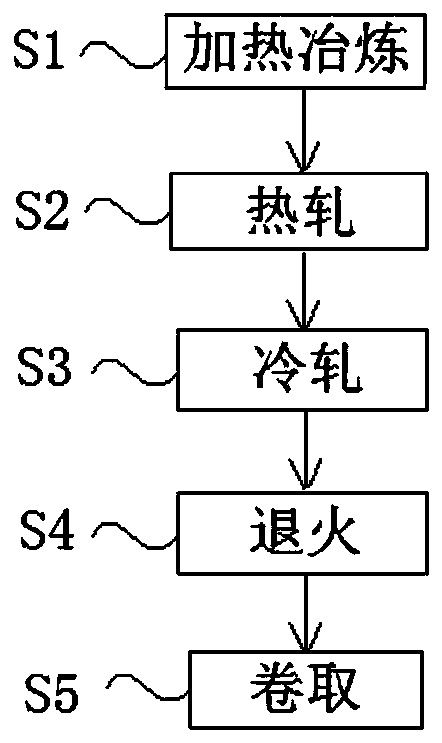

Low-density and high-strength steel for automobiles and preparation method thereof

Owner:SHOUGANG CORPORATION

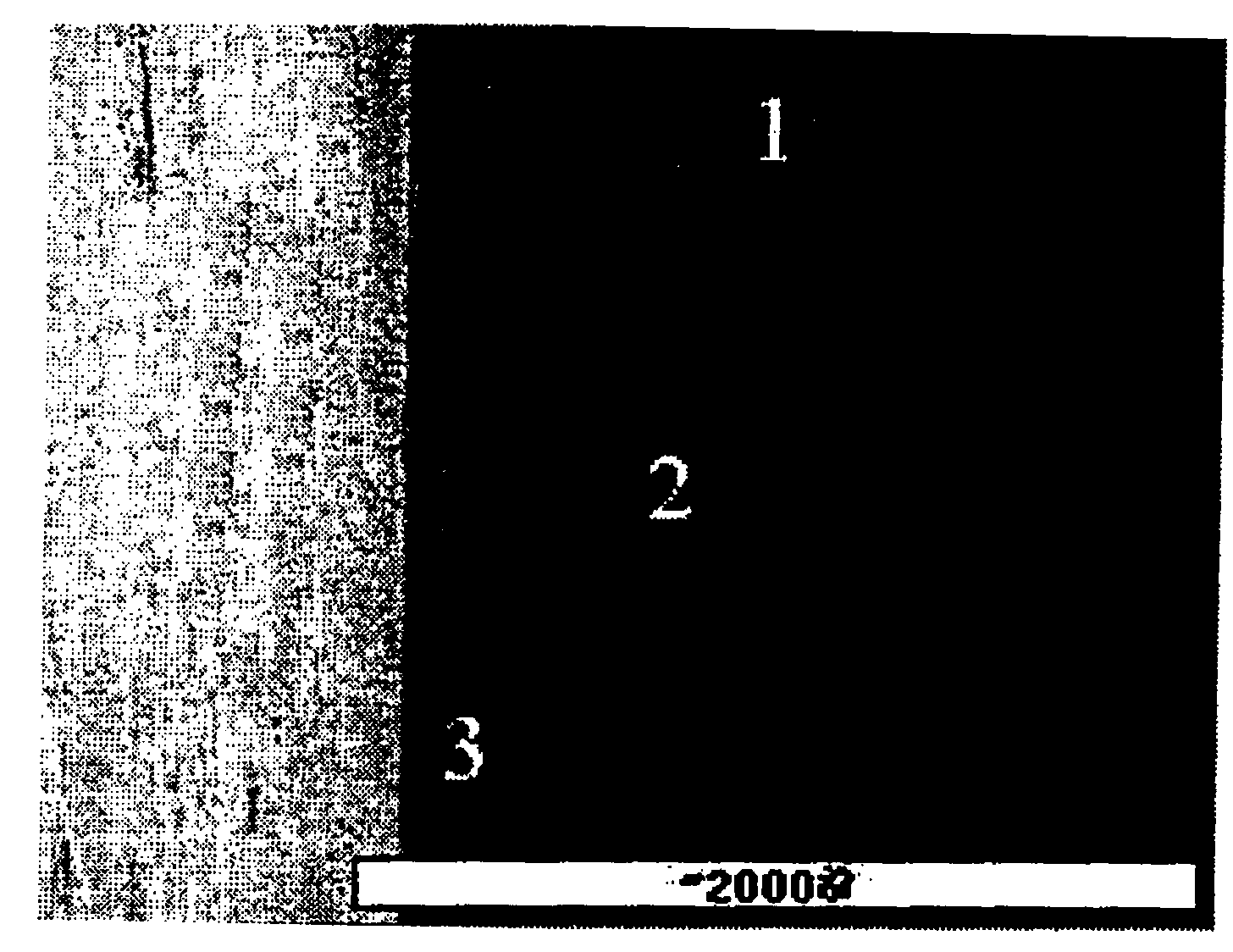

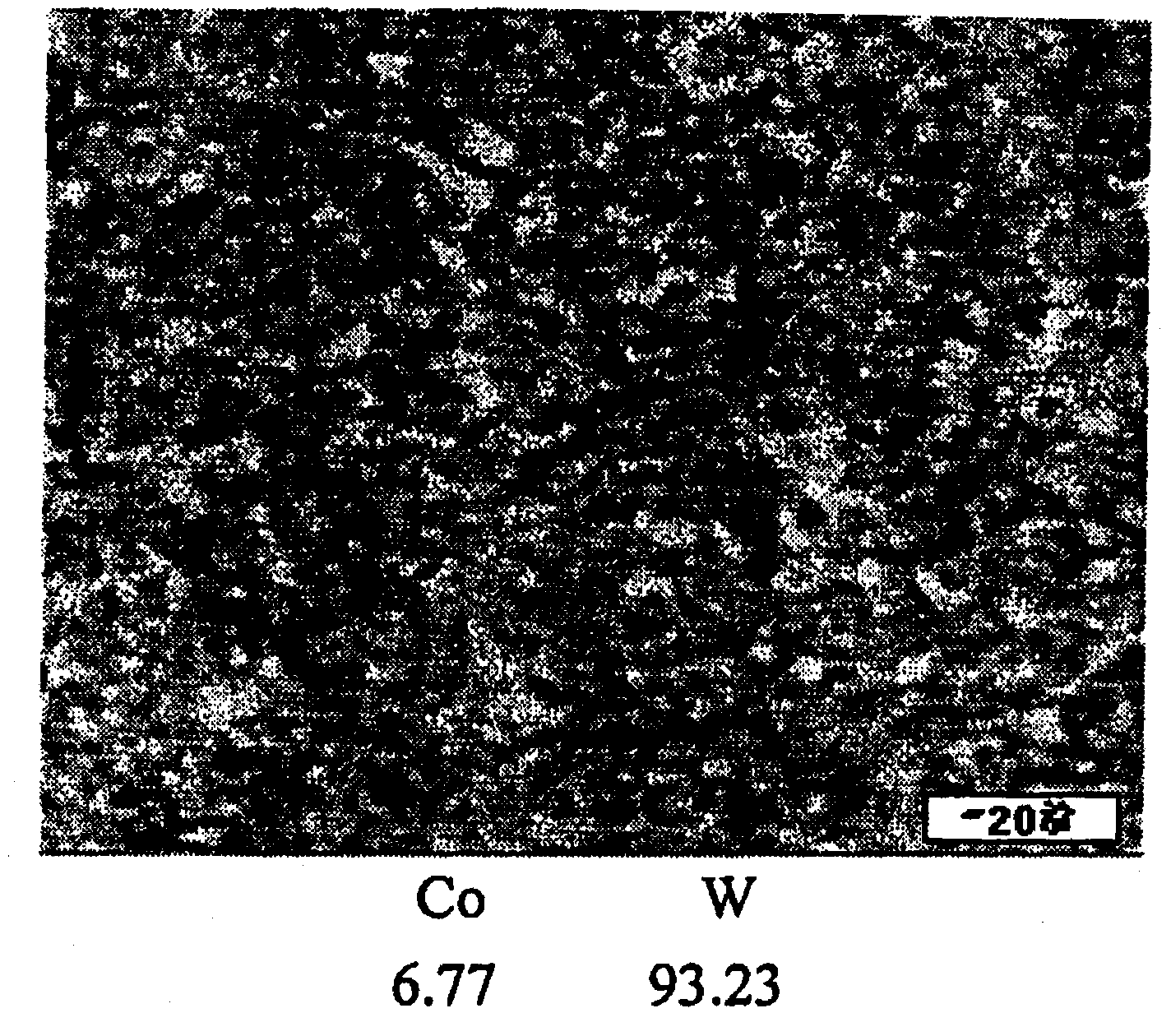

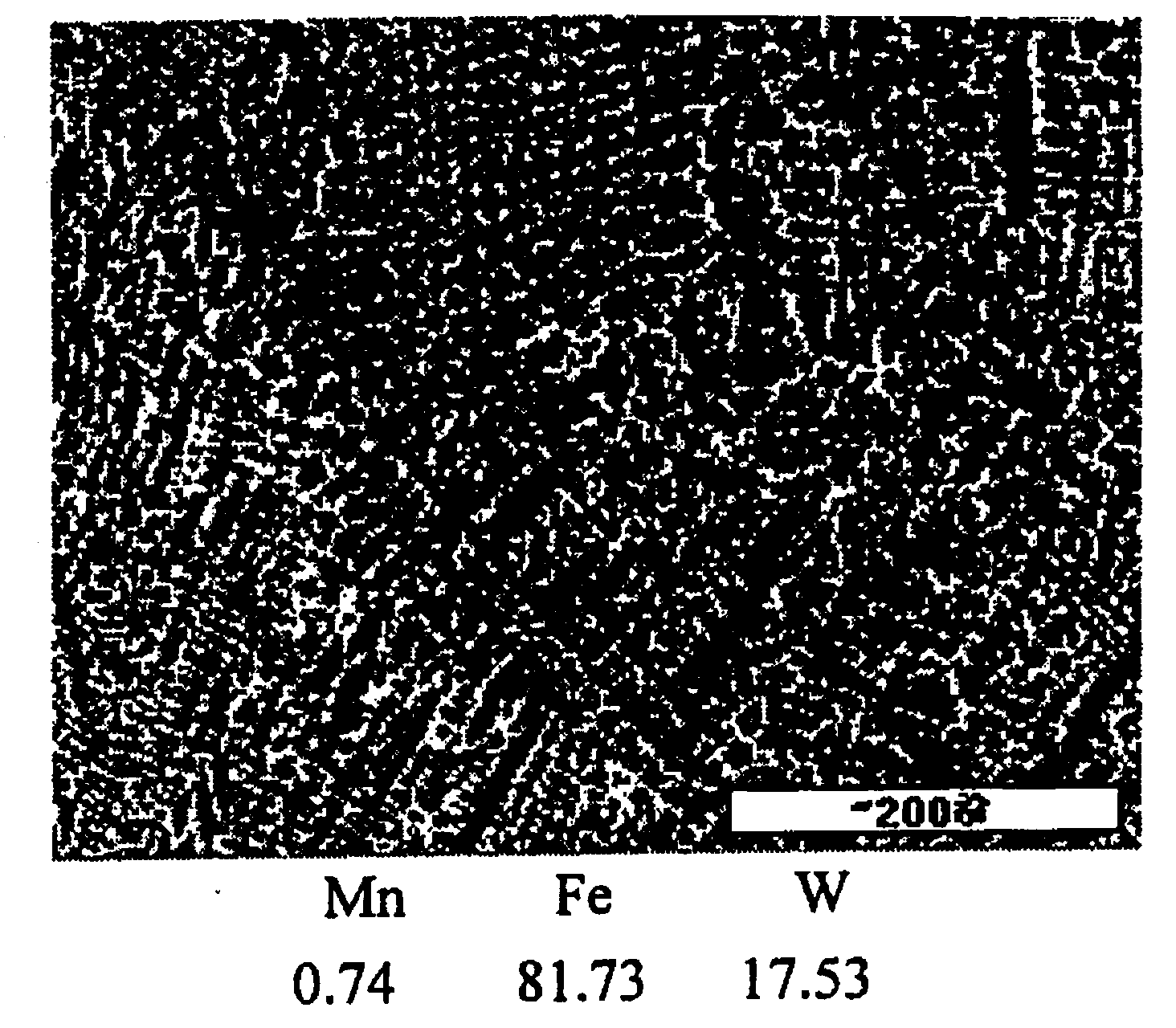

Welding rod for welding hard alloy and steel parts and welding method thereof

InactiveCN101585117ASolve Welding ProblemsSimple welding processWelding/cutting media/materialsSoldering mediaIron powderRare earth

The invention is a welding rod for welding hard alloy and steel parts and welding method thereof, belonging to the field of welding material. The invention is characterized in that the coating compositions of the welding rod according to parts by weight are as follows: 50 to 53 parts of W, 24 to 27 parts of CaCO3, 9 to 12 parts of CaF2, 2 to 4 parts of TiO2, 2 to 4 parts of SiO, 2 to 4 parts of C, 1.5 parts of rare earth, and remainder being iron powder. The welding metal in the invention has red hardness and endurance at the temperature of 500 to 600 DEG C, thereby solving the welding problem applied between alloy and steel at high temperature; the welding rod has good welding technological property, stable electric arc and beautiful modeling.

Owner:WUHAN MARINE MACHINERY PLANT

Thick-wall red copper and austenitic stainless steel non-prewarming arc melting and welding method

InactiveCN101323044ASolve Welding ProblemsSolve the problem of hot cracking tendencyArc welding apparatusWelding/soldering/cutting articlesCrazingShielding gas

The invention discloses a non-preheating electric arc melting welding method of thick-wall red copper and austenitic stainless steel, which includes the following processing steps: 1. the method adopts tungsten electrode helium arc welding added with nickel-copper alloy welding wires of Phi 2 to 4mm for welding; the welding current is 180 to 400A; protective gas is pure helium, the flow volume of which is 10 to 15L per minute; the diameter of the tungsten electrode is Phi 4 to 5mm; the length for positioned welded joints is 10 to 15mm and the distance between the two welded joints is 100 to 150mm; 2. the method adopts the tungsten electrode helium arc welding added with the nickel-copper alloy welding wires of Phi 2 to 4mm for welding under the non-preheating condition; the welding current is 180 to 400A; the protective gas is helium, the flow volume of which is 10 to 15L / min; 3. after the backing welding, the non-preheating welding is used for filling the welded joint. The method solves the problems of the non-preheating welding of the thick-wall red copper and austenitic stainless steel and the hot cracking trend, which improves the solidification temperature, strength and plasticity of the welded joint and prevents the hot cracking and stomata by adding the nickel-copper alloy welding wire by hand.

Owner:中国船舶集团渤海造船有限公司

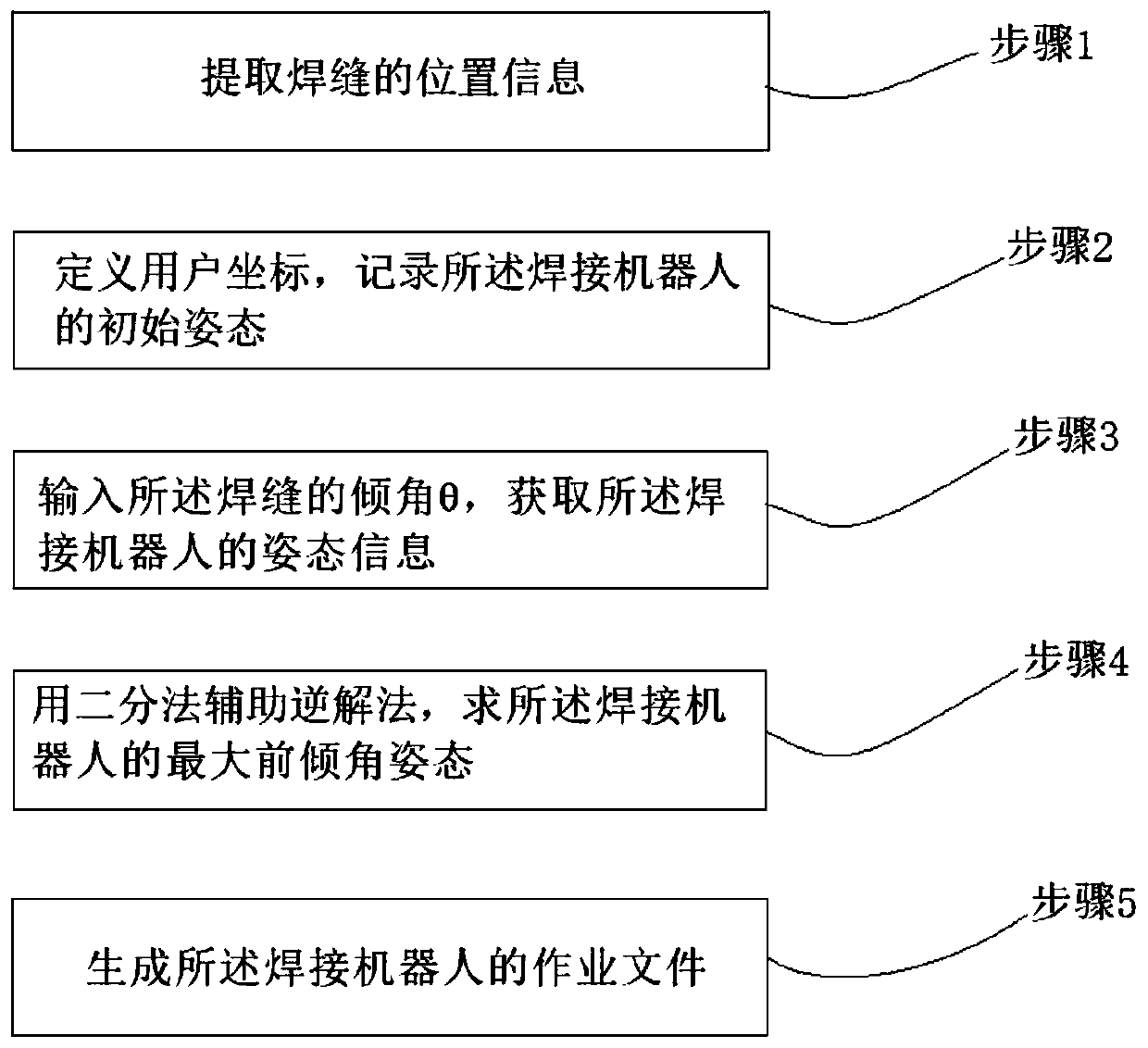

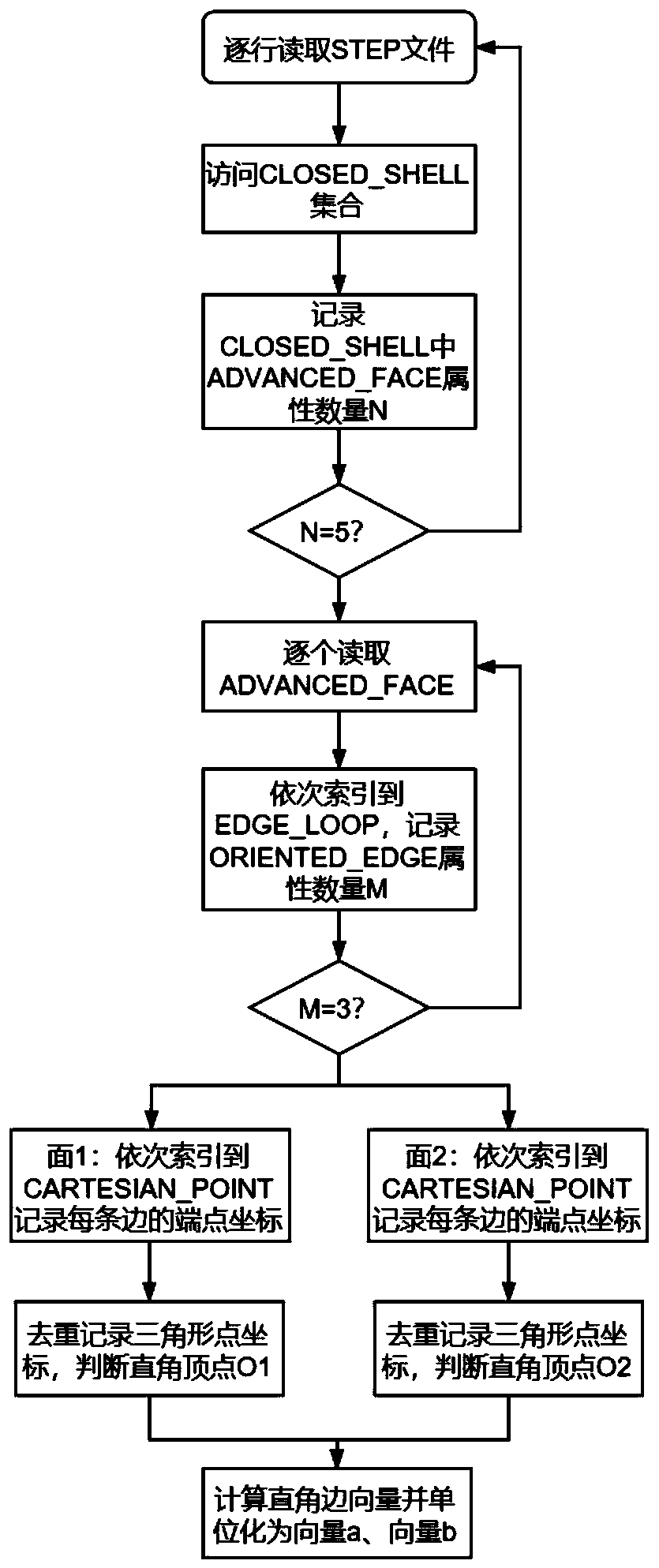

Welding robot track automatic planning method

ActiveCN110370298AIncrease productivitySolve Welding ProblemsProgramme-controlled manipulatorSimulationWeld seam

The invention discloses a welding robot track automatic planning method, and relates to the field of welding robot offline programming and track planning. The method comprises the following steps of 1, extracting position information of a welding seam; 2, defining user coordinates, and recording the initial attitude of a welding robot; 3, inputting a tilt angle theta of the welding seam, and acquiring attitude information of the welding robot; 4, utilizing a dichotomy method to assist an inverse solution to obtain the maximum forward tilt angle attitude of the welding robot; and 5, generatinga job file of the welding robot. According to the welding robot track automatic planning method, a three-dimensional model of a workpiece is provided, the track planning during a welding process can be completed as long as a set welding angle is input, and in this way, a complicated teaching process is replaced so that the production efficiency is improved; and in addition, a large number of related calculation processes can be obtained through compiling a calculation program, and corresponding parameters are changed such as changing sizes of mechanical arms of an algorithm of different robots, so that similar welding problems can be solved.

Owner:SHANGHAI JIAO TONG UNIV

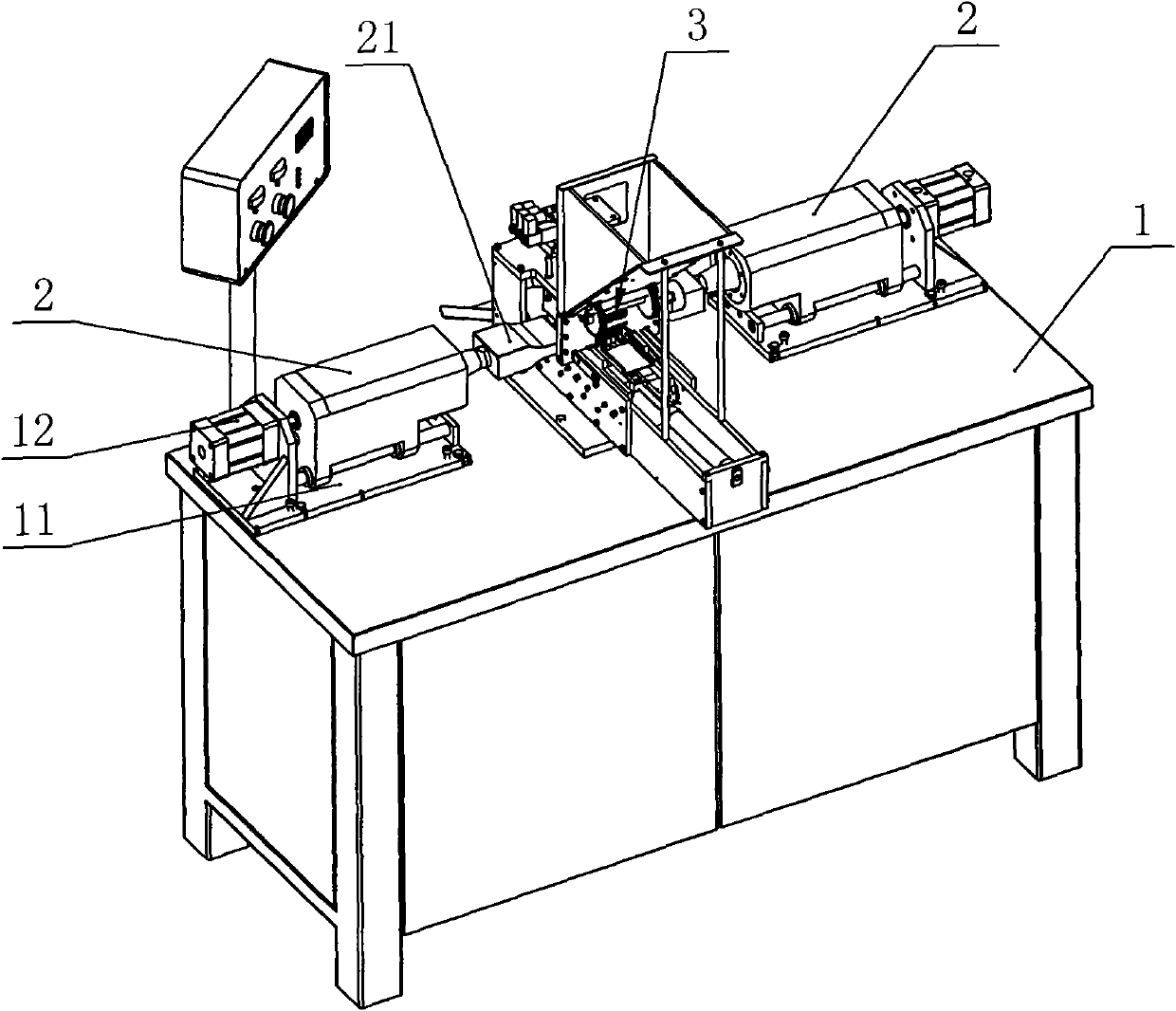

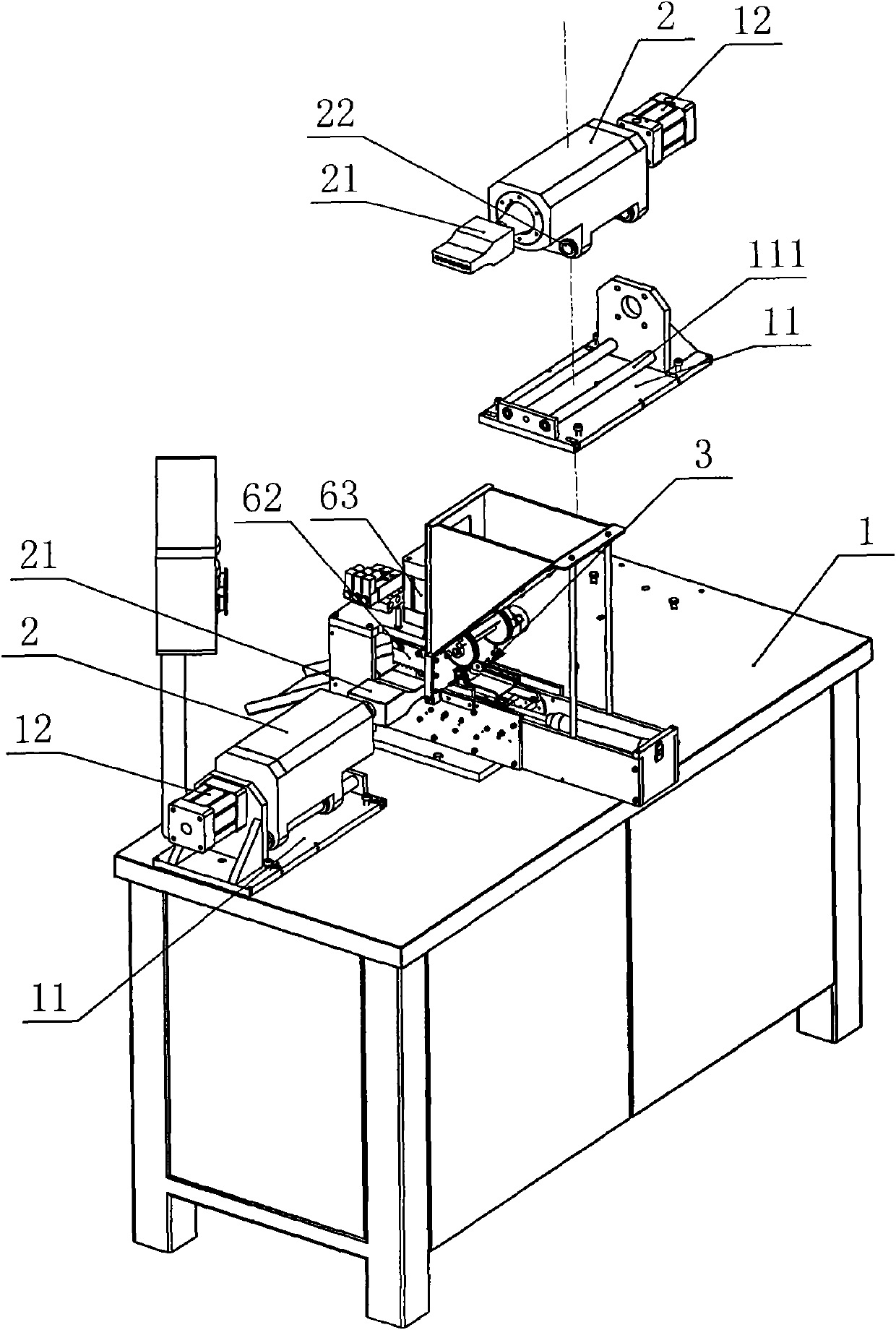

Full automatic ultrasonic welding machine for plastic pen

The invention discloses a full automatic ultrasonic welding machine for a plastic pen. The full automatic ultrasonic welding machine for the plastic pen comprises a mounting rack, an ultrasonic generator, energy converters and energy converter guide rail brackets, wherein an energy converter sliding power mechanism is arranged on the energy converter guide rail brackets; the symmetric center position of the two energy converter guide rail brackets is provided with a welding mechanism for two ends of the plastic pen; the welding mechanism for two ends of the plastic pen comprises a one-by-one pen feeding mechanism, a delivery mechanism, a plastic pen clamping welding mechanism and a pen arranging mechanism; the plastic pen clamping welding mechanism comprises a lower mould, an upper mould, and a power mechanism for joining and separating the moulds; the lower mould and the upper mould are correspondingly provided with a plurality of mould dents matched with the plastic pen; and the left side and the right side of the joint position of the lower mould and the upper mould, and the left ultrasonic welding head and the right ultrasonic welding head which are arranged on the left energy converter and the right energy converter are oppositely arranged in a matching way. The full automatic ultrasonic welding machine for the plastic pen has the advantages of high work efficiency and beautiful weld appearance.

Owner:WENZHOU DONGFENG JINGGONG ELECTRONICS INSTR FACTORY

High-frequency welding mechanism and method of wire feeding machine

ActiveCN107617801AFully automatedImprove work efficiencyIncreasing energy efficiencySolder feeding devicesControl systemSingle station

The invention discloses a high-frequency welding mechanism and a method of a wire feeding machine. A workpiece tool, a cylinder adjusting mechanism, a wire feeding mechanism and a brazing device are arranged on a worktable; workpieces to be machined are fixed on the workpiece tool positioned at the lower end of an induction coil; the electromagnetic induction heating is performed on the workpiecesto be machined through the induction coil on the brazing device; a control system controls a cylinder device on the cylinder adjusting mechanism to feed a wire feeding nozzle onto the workpieces to be machined; a force sensor induces if welding wires are molten to achieve accurate wire feeding; the wire feeding mechanism, the brazing device and the force sensor are matched to realize precise matching between the welding wires and welded parts, so that the operation efficiency and the convenience are improved; a control system is adopted to replace manual control, so that full automation of all actions is guaranteed; the welded parts and the welding wires are precisely matched to reach optimal product quality; and the mechanism can adopt single-station and multi-station welding operations,can perform mated use according to actual scene conditions, and solves the product welding problems.

Owner:深圳市北辰亿科科技有限公司

Method for welding large-size tantalum strips

The invention relates to a method for welding rolled tantalum strips in a flash butt welding mode, in particular to a method for welding large-size tantalum strips. The method is characterized by comprising the following steps that two tantalum strips which are rolled are combined to form a butt welding head, two ends of the butt welding head are respectively clamped tightly by two electrodes of a but welding machine, upsetting force is exerted to the two ends of the butt welding head, the end faces of the but welding machine gradually move closely to achieve partial contact, a power source is then connected, a resistance heat heating contact is used for generating flash to melt the contacted end faces, and when a preset temperature is reached, and the upsetting force is exerted quickly to the two ends of the butting welding head so that welding can be completed. Cold welding is adopted in a traditional method for welding the tantalum strips belongs to, and due to the fact that tantalum strips with sizes lower than pi 3mm are only suitable for domestic cold welding devices, tantalum strips with sizes higher than pi 4mm or 4*4mm cannot be welded. The problem of welding of the tantalum strips with the sizes higher than pi 4mm or 4*4mm is resolved and feasibility is provided for continuous rolling or drawing of the large-size tantalum strips.

Owner:NINGXIA ORIENT TANTALUM IND

Welding device of superconduction cable connector

ActiveCN108321556ASolve Welding ProblemsEfficient weldingLine/current collector detailsSoldered/welded conductive connectionsElectrical conductorInsulation layer

The invention provides a welding device of a superconduction cable connector. The welding device comprises a welding connector, a red copper sheath and a heating aluminum block, wherein the red coppersheath and the heating aluminum block are connected in a clearance fit manner and sleeve the welding connector, a framework corrugated pipe in a superconduction cable is fastened with the welding connector by a thread, a superconduction belt of which a surface insulation layer is stripped is plugged into a gap between the red copper sheath and the welding connector, the gap is filled with a welding material, a gap between the other end of the red copper sheath and the welding connector is sealed, a heating rod is inserted into a heating hole of the heating aluminum block during the sealing process so as to heat the welding material, and the superconduction belt, the welding connector and the red copper sheath can be welded to form a whole after the welding material is molten. In the welding device of the superconduction cable connector provided by the invention, an end part of a superconduction cable energization conductor can be effectively welded to form the whole by arranging the welding connector, the red copper sheath and the heating aluminum block, and the problem of welding of the superconduction cable connector is solved.

Owner:BEIJING JIAOTONG UNIV

Traction transformer series-connected in one box by two low voltage winding layers for AT (Auto-Transformer) power supply

InactiveCN101964246ASimple designSimple structureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresSingle phaseTraction transformer

The invention discloses a traction transformer series-connected in one box by two low voltage winding layers for AT (Auto-Transformer) power supply, relating to traction transformers. The ordinary traction transformer for AT power supply comprises a T single phase traction transformer and an M single phase traction transformer, the two transformers are necessarily and independently designed, the structure is complex, the manufacturing difficulty is big, and design requirements are difficultly satisfied. The traction transformer is characterized in that a core limb group comprises four core limbs, and three winding layers are sleeved on the core limbs from inside to outside; the first winding layers of the first core limb and the third core limb are power supply side windings, and the second winding layer is a feed side winding; the first winding layers of the second core limb and the fourth core limb are the feed side windings, and the second winding layer is a power supply side winding; and the power supply side windings on the first core limb and the second core limb and the power supply side windings on the third core limb and the fourth core limb are respectively connected in series. In the invention, because the T single phase traction transformer and the M single phase traction transformer are uniformly designed into the traction transformer, the structure is simple, the design requirement is satisfied, and the design cost and the production cost are reduced.

Owner:WOLONG ELECTRIC GRP CO LTD +1

Double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials

ActiveCN108436234AImprove welding qualityControl soldering temperatureArc welding apparatusWelding/soldering/cutting articlesThree-dimensional spaceHeat losses

The invention discloses a double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials, and belongs to the field of metal material welding. Whenwelding the large thermal conductivity mismatched metal materials, the method adopts two heat sources to simultaneously heat the front and back sides of joints and optimizes energy distribution of the joints by controlling energy parameters and positional parameters of the two heat sources, side heat input of high thermal conductivity metal is increased, the heat loss caused by the higher thermalconductivity is compensated, the low thermal conductivity metal side welding temperature is controlled, and the problem of large thermal conductivity mismatched metal material welding forming is solved and the joint welding quality is improved. The preheating effect of the joints is obtained by tilting the two heat sources on the front and back sides at a certain angle in the welding direction, and the single-pass welding double-sided forming of the joints is realized under auxiliary measures such as no chamfering and pre-weld preheating. The welding device can effectively adjust and controlthe heat distribution of the joints by precisely controlling the position of the welding heat sources in the three-dimensional space, and efficient and reliable connection of the large thermal conductivity mismatched metal materials is realized.

Owner:UNIV OF SCI & TECH BEIJING

Fast connecting and positioning device for L-shaped rotary tire and follow fixture of robot and working method of fast connecting and positioning device

ActiveCN105014290AReduce the number of tooling manufacturingReduce deformation and robot positioning errorRailsWelding/cutting auxillary devicesManipulatorSelf locking

The invention provides a fast connecting and positioning device for an L-shaped rotary tire and a follow fixture of a robot and a working method of the fast connecting and positioning device. A base is provided with symmetric follow fixture fast connector devices. The follow fixture fast connector devices comprise bayonet pins, bayonet pin seats and sliding rails. The sliding rails are arranged on the base. The bayonet pin seats freely slide on the sliding rails in the horizontal direction. The bayonet pin seats are connected with self-locking lead screw mechanisms or hydraulic jacking mechanisms. The bayonet pins are fixed to the bayonet pin seats. The bayonet pins are each of a blocky structure. The bottom faces of the bayonet pins are provided with slopes or wedge-shaped surfaces, and the slopes or the wedge-shaped surfaces and the wedge-shaped surface of the follow fixture are fast positioned. The base is provided with transverse and longitudinal positioning blocks with slopes. Dowel seats are arranged on the outer sides of the bayonet pin seats. The dowel seats are internally provided with part of spherical or semi-spherical dowels, and the part of spherical or semi-spherical dowels and the concave surface of the follow clamp are matched and fast positioned. Stopping blocks can be arranged at the inward ends of the bayonet pin seats in the longitudinal direction. Automatic welding and automatic grinding of a side beam mechanical arm and work fixture following are achieved, and the workpiece dismounting and mounting frequency and the problems of beam body welding deformation caused after dismounting and mounting are finished are effectively reduced.

Owner:CRRC QINGDAO SIFANG CO LTD

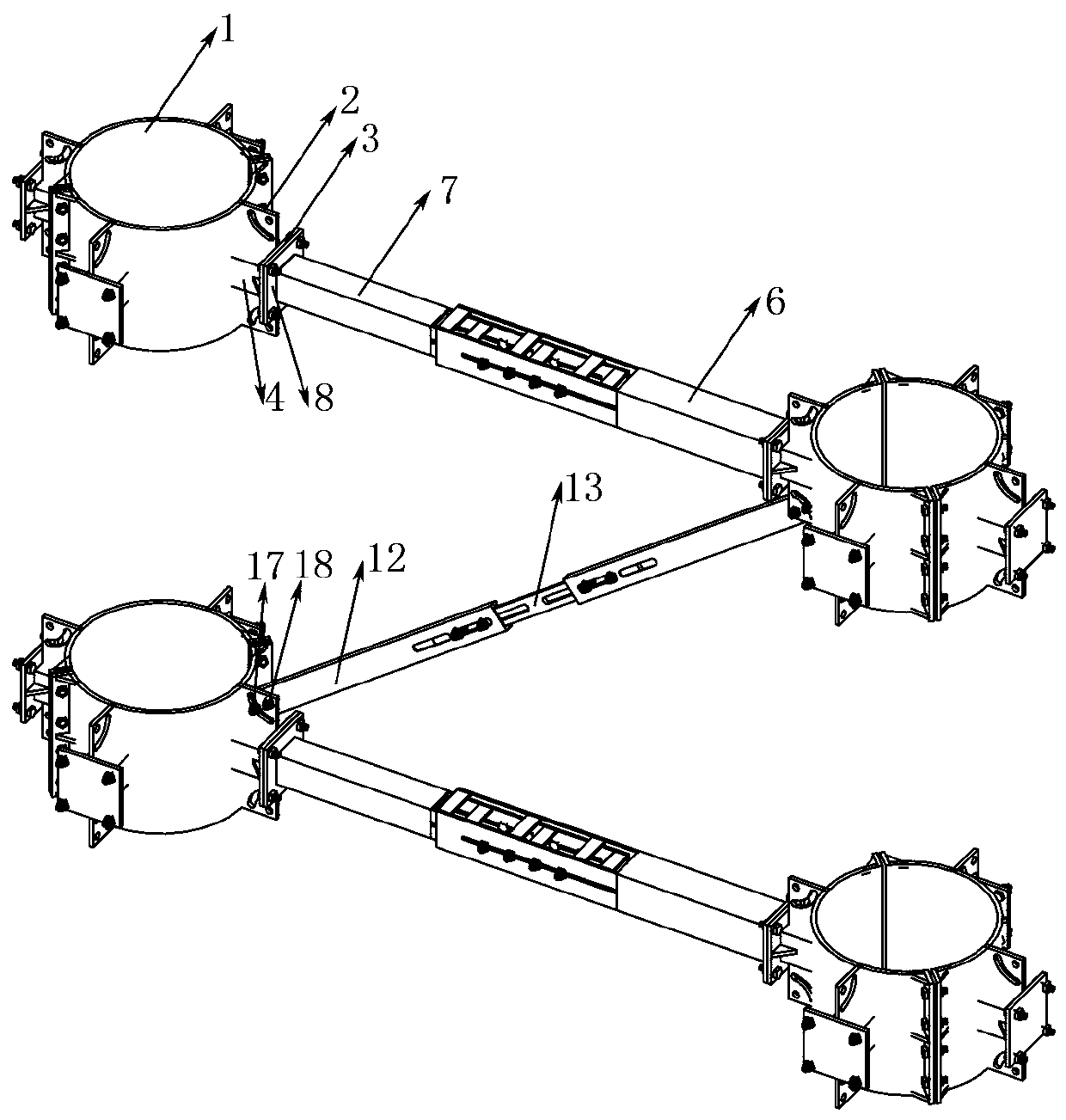

Multi-serial and multi-parallel cylindrical lithium ion battery combination body

ActiveCN103682478ASolve Welding ProblemsCell component detailsSecondary cells servicing/maintenancePower stationDrive motor

The invention discloses a multi-serial and multi-parallel cylindrical lithium ion battery combination body. The multi-serial and multi-parallel cylindrical lithium ion battery combination body comprises a plurality of single cylindrical lithium ion batteries which are connected to form a serial connection body by spot welding through connection sheets; serial connection combined units are formed by assembling special end brackets and middle connecting and splicing brackets. The plurality of serial connection combined units are spliced to form sheet-shaped multi-serial and multi-parallel combination bodies of the plurality of sets of serial connection combined units by swallow tail slots in the middle connecting and splicing brackets. U-shaped double metal sheets are inserted in the middle connecting and splicing brackets and the plurality of sheet-shaped multi-serial and multi-parallel combination bodies are overlapped and spliced together to be assembled into the multi-serial and multi-parallel cylindrical lithium ion battery combination body, so that the safety protection on the whole set of the multi-serial and multi-parallel cylindrical lithium ion battery combination body is realized. The battery combination body is applicable to manufacturing of large-capacity battery modules for driving motors or energy-storage power stations.

Owner:江苏海四达电源有限公司 +1

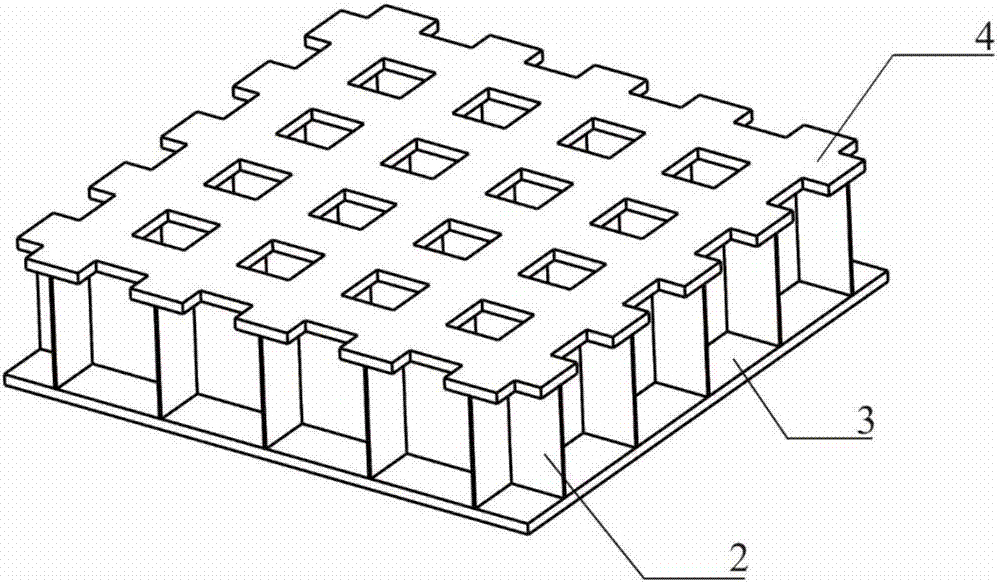

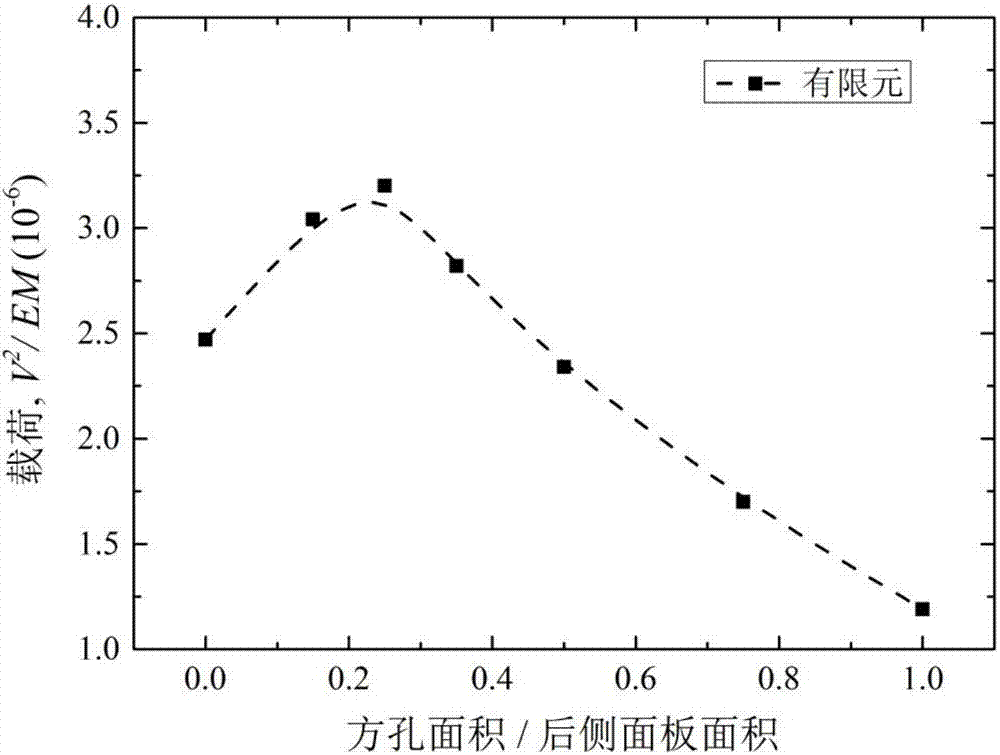

Square honeycomb interlayer structure and preparation method thereof

InactiveCN107199439ASolve Welding ProblemsMature technologyElongated constructional elementsHoneycombEngineering

The invention discloses a square honeycomb interlayer structure and a preparation method thereof. A square honeycomb core body is prepared through an interlocking technology, through the cell-element position of the core body, the position of an opening in a unilateral panel is determined, and the opened square hole coincides with the geometric center of a square honeycomb unit cell. The square honeycomb interlayer structure is formed by welding the core body, a front side panel and a rear side panel through brazing or argon arc welding. Compared with a traditional square honeycomb interlayer structure, the improved square honeycomb interlayer structure is easier to prepare and more convenient to maintain and meanwhile facilitates mass production under the condition that it is ensured that the bearing property and shock-resistant property are equal and has wide application prospects in the fields such as transportation, safety protection and military science.

Owner:XI AN JIAOTONG UNIV

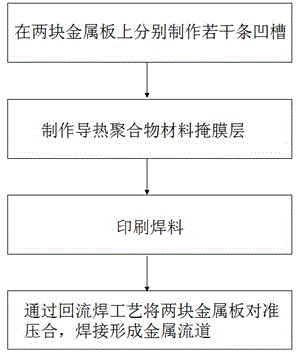

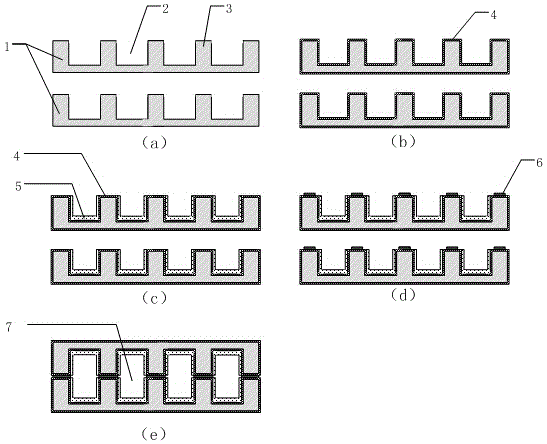

Manufacturing method of metal runners used for liquid cooling and liquid cooling metal runner cold plate

ActiveCN105636411AEasy to processGood process repeatabilityCooling/ventilation/heating modificationsHeat conductingMetallurgy

The invention discloses a manufacturing method of metal runners used for liquid cooling and a liquid cooling metal runner cold plate. The manufacturing steps are listed as follows: 1) multiple grooves of the same structure are respectively manufactured on two metal plates and rib strips of which the number is more than one of the number of the grooves are formed, and a metal weldable layer is manufactured on the upper surface of the rib strips and the bottom part and the side wall of the grooves; 2) a heat-conducting polymer material mask layer is manufactured on the metal weldable layer of the bottom part and the side wall of the grooves; 3) a welding flux layer is manufactured on the upper surface of the rib strips; and 4) the two metal plates are buckled together and the grooves and the rib strips arranged on the two metal plates are corresponding in a one-to-one way, and the welding flux layers of the rib strips of the two metal plates are correspondingly welded through a reflow welding technology so that the metal runners are formed. The manufacturing method is simple in manufacturing, and the manufactured runners are high in reliability and great in heat radiation.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

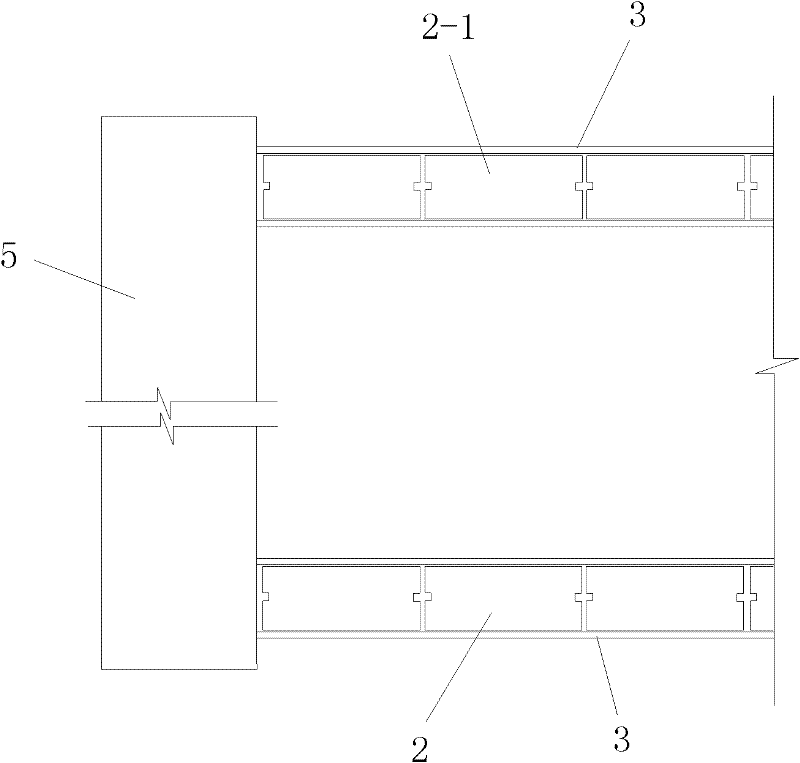

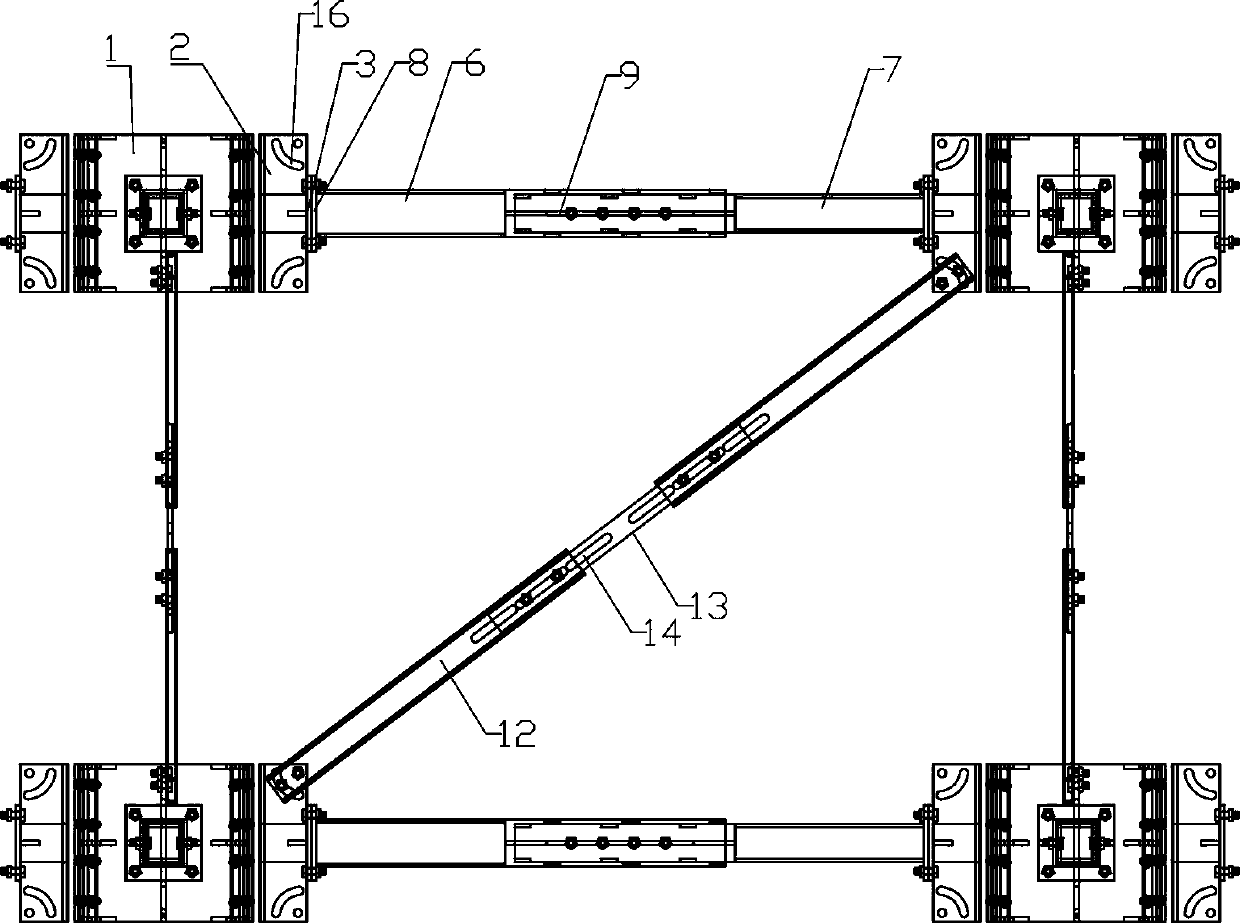

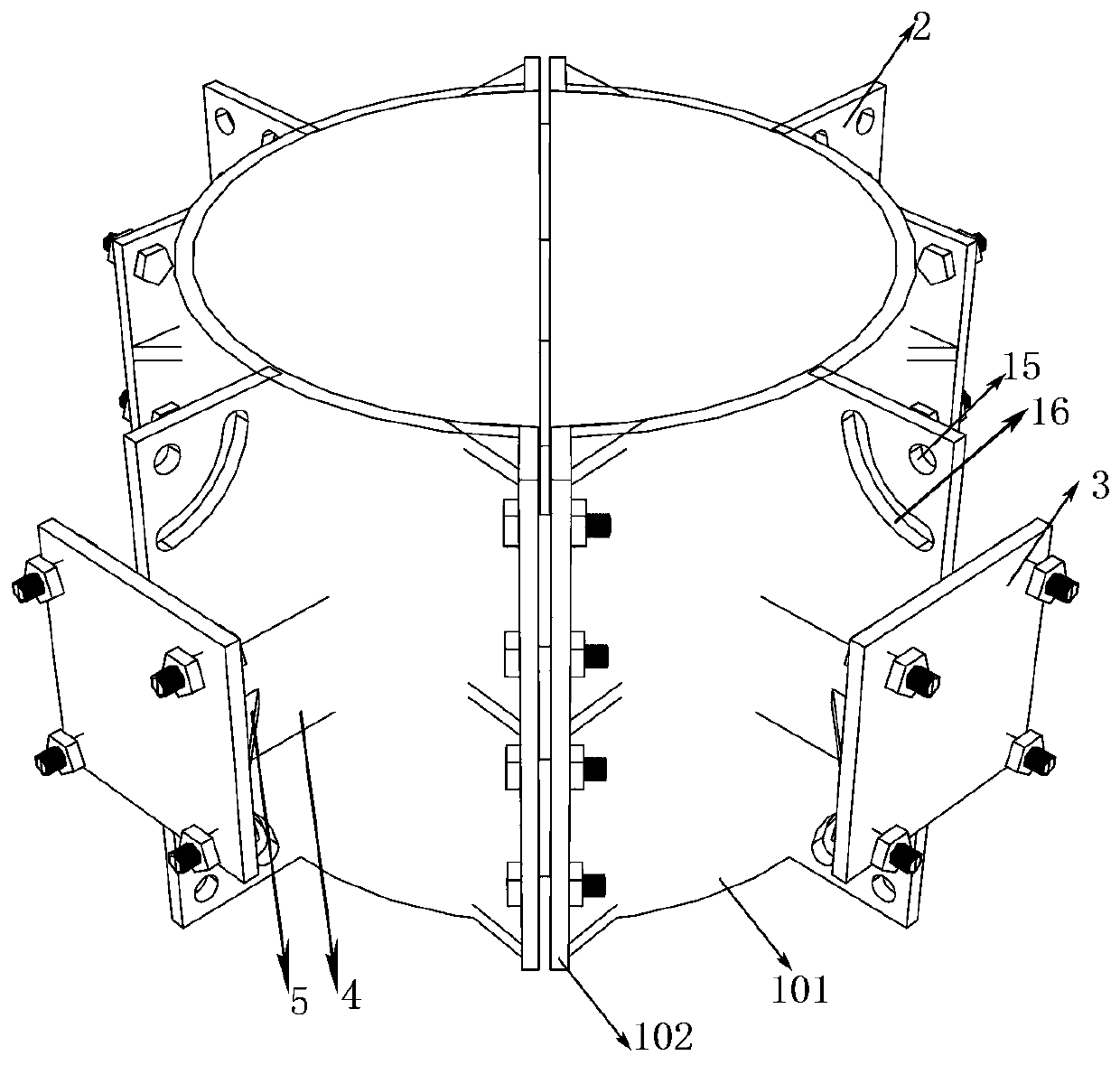

Fabricated spacing adjustable steel stand column connecting hoop structure

PendingCN110158977AEasy to operateReduce manual laborBuilding material handlingSteel tubeSteel columns

The invention relates to the field of buildings, in particular to a fabricated spacing adjustable steel stand column connecting hoop structure. The fabricated spacing adjustable steel stand column connecting hoop structure comprises a plurality of hoop hoops sleeving each steel stand column separately, every two hoops on every two adjacent steel stand columns which are positioned at the same height are connected through horizontal telescopic sleeves, the every two hoop hoops on the every two adjacent steel stand columns which are positioned at diagonal lines of the upper and lower rows are connected through oblique telescopic connecting rods, and the horizontal telescopic sleeves comprise outer sleeve square pipes and inner sleeve square pipes, part of the pipe sections of the outer sleevesquare pipes and part of the pipe sections of the inner sleeve square pipes are overlapped and connected with one another in a sleeving mode, each oblique telescopic connecting rod comprises two angle adjusting arms, and the suspended ends of each two angle adjusting arms are connected through an intermediate connecting rod arm. The structure is horizontally and obliquely connected between steelpipes, high overall rigidity is achieved, the spacing between the steel columns can be adjusted meanwhile, and the fabricated spacing adjustable steel stand column connecting hoop structure is suitable for building steel column support systems with different spacing.

Owner:ZHENGZHOU NO 1 CONSTR ENG GRP

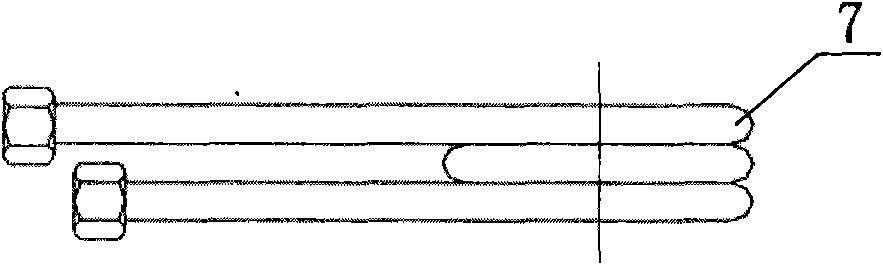

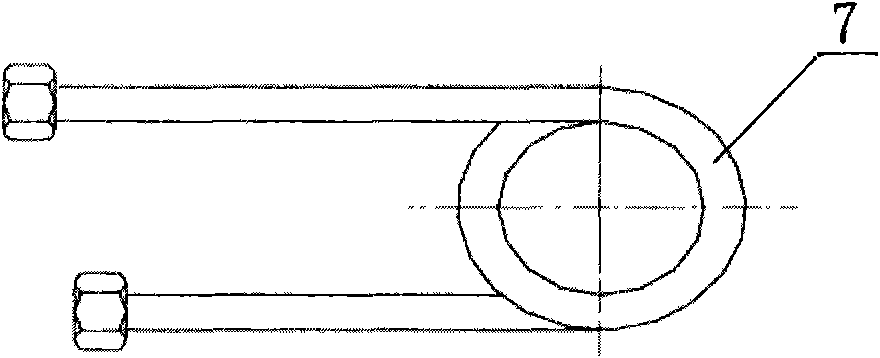

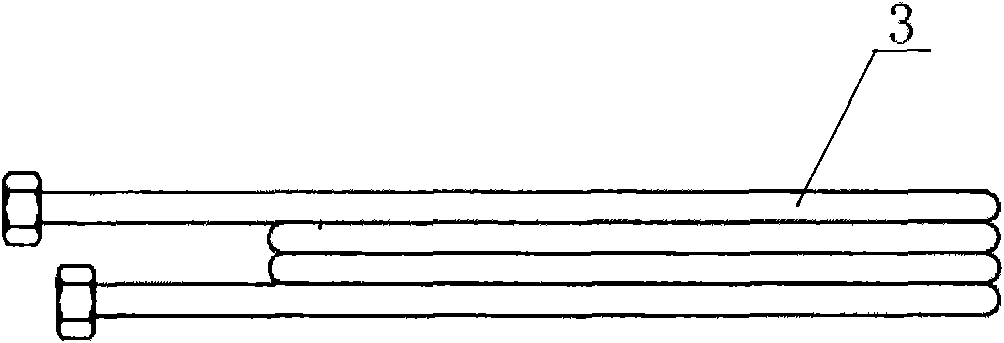

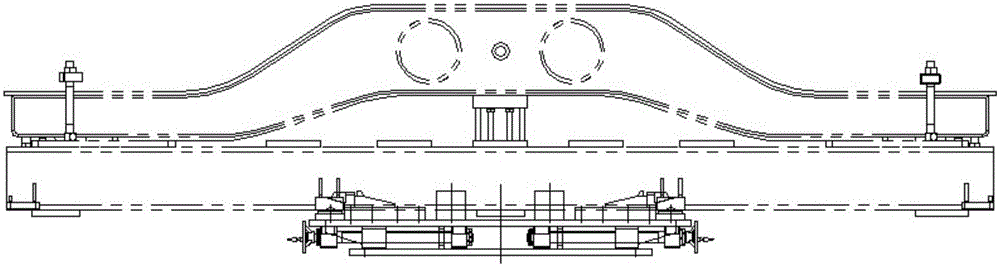

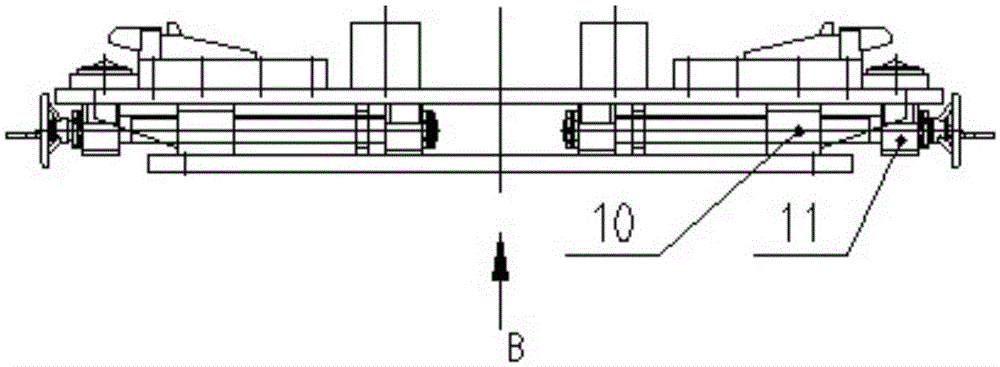

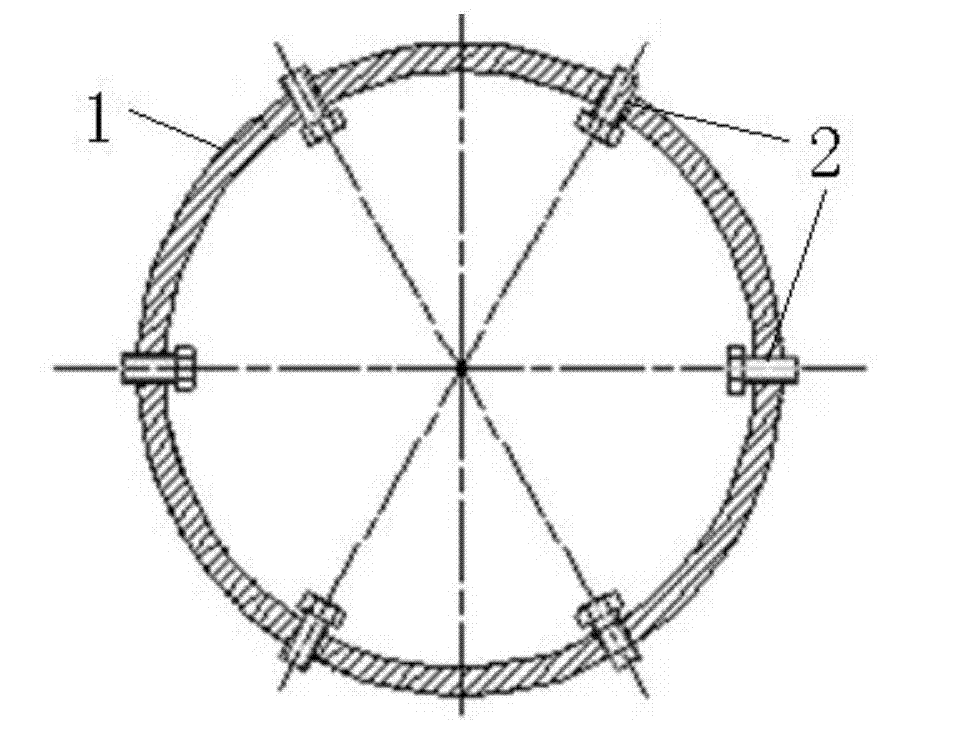

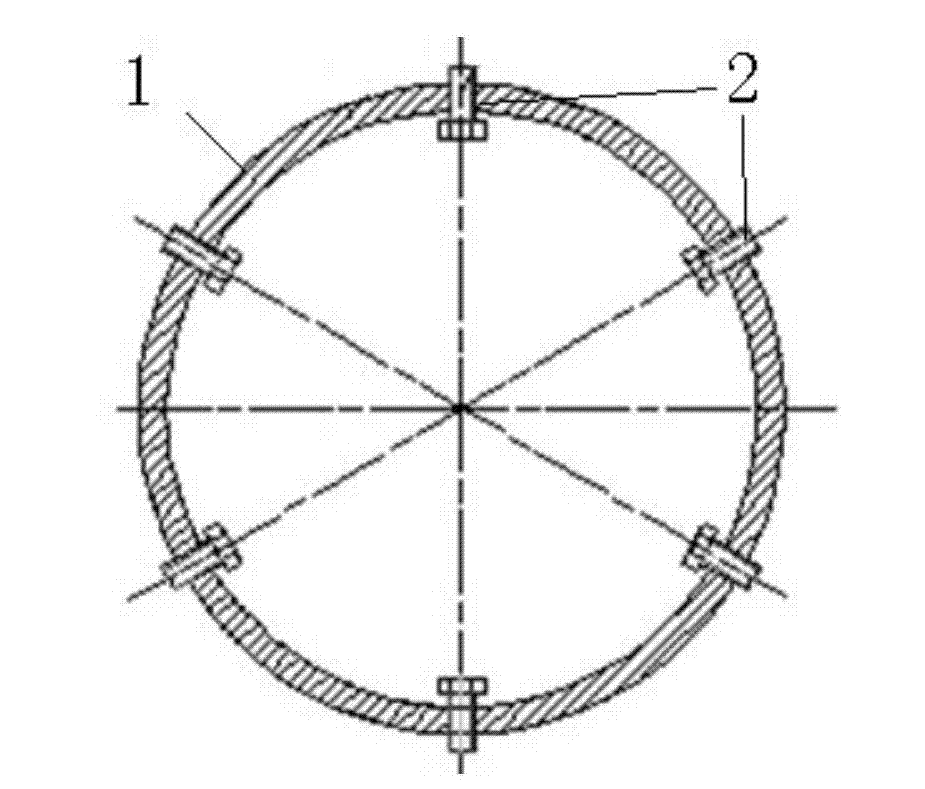

Large-aperture pipe circular seam line-up clamp and large-aperture pipe circular seam line-up clamping method

ActiveCN102922194AFirmly connectedGuaranteed Position ToleranceWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringLarge aperture

The invention discloses a large-aperture pipe circular seam line-up clamp, which comprises a sleeve body, wherein the sleeve body is a steel piece; two tightening and adjusting mechanisms are arranged on the sleeve body along the circumferential direction; each tightening and adjusting mechanism is positioned in a circumferential section which is spaced from an end of the sleeve body by a certain distance and comprises a plurality of groups of adjusting bolts uniformly arranged along the circumference of the tightening and adjusting mechanism; ends of bolted caps of all the adjusting bolts face the axial lead direction of the sleeve body; a circle of groove is formed in the outer wall of an axial center section of the sleeve body; and a plurality of observation holes are uniformly formed along the circumferential direction of the groove. The invention also discloses a large-aperture pipe circular seam line-up clamping method, which is implemented by using the line-up clamp. By the line-up clamp and the line-up clamping method, large-aperture pipe circular seams can be assembled and welded, workpieces are connected with one another firmly and reliably, and the line-up clamp is easy to operate.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Preparation method for aluminum foil welding solder organic flux

InactiveCN105414801ADevice deformation is smallThe welding process is stable and reliableWelding/cutting media/materialsWelding/soldering/cutting articlesTriethanolamineBrass

The invention provides a preparation method for an aluminum brazing organic flux. An alumina film can be damaged at the temperature of 180 DEG C-275 DEG C, deformation is small after the alumina film is welded, stabilizing and shaping is achieved, corrosion is avoided, corrosion to aluminum and aluminum alloy is very small, the welding temperature is far from the melting point of an aluminum material, the welding process is reliable, and the brazing qualified rate is greater than 98%. According to the technical scheme, 70 wt%-90 wt% of triethanolamine, 1 wt%-5 wt% of zinc tetrafluoroborate hydrate, 5 wt%-10 wt% of cadmium fluoroborate, and 5 wt%-10 wt% of ammonium fluoroborate are added; the zinc tetrafluoroborate hydrate, the cadmium fluoroborate and the ammonium fluoroborate are weighed at the room temperature and put into a mortar to be ground into fine powder, and grinding and mixing are uniform; the uniformly ground and mixed drug is poured into the weighed triethanolamine, and after being stirred uniformly, the drug is placed for a certain period of time. The welding problems of the aluminum, the aluminum alloy, aluminum bronze and aluminum brass at the temperature of 180 DEG C-275 DEG C are solved through the preparation method.

Owner:四川泛华航空仪表电器有限公司

Welding method of low-alloy ultra-high-strength steel with yield strength of 1100mpa

ActiveCN105522262BAvoid welding cold cracksImprove toughnessArc welding apparatusWelding/soldering/cutting articlesShielding gasEngineering

The invention provides a welding method of low-alloy ultra-high-strength steel with a yield strength of 1100MPa, which includes the following steps: preheating the welding base metal with a yield strength of more than 1100MPa to 150-170°C; After docking, use a mixed gas of argon and carbon dioxide as the protective gas, use a welding wire with a yield strength of more than 900MPa and a diameter of 1-1.2mm for continuous welding, and control the interlayer temperature of the weld bead between 150-250°C. The energy is controlled at 9-15KJ / cm; hydrogen elimination treatment is performed after welding, the heat preservation temperature is 200-220°C, and the heat preservation time is more than 1 hour. The welding method of the embodiment of the present invention adopts small linear energy argon-rich mixed gas shielded welding to ensure the strength of the welded joint while improving the toughness and plasticity of the welded joint.

Owner:NORTHEASTERN UNIV LIAONING +1

Laser welding process for dissimilar metal connecting material at tab part of lithium battery

PendingCN112439994AEasy to shapeLaser power is stableWelding/soldering/cutting articlesLaser beam welding apparatusSingle mode laserSurface cleaning

The invention relates to a laser welding process, and particular relates to a laser welding process for a dissimilar metal connecting material at a tab part of a lithium battery. The laser welding process comprises the following steps: adopted dissimilar metals are aluminum alloy and nickel-plated copper, the aluminum alloy is 6061 aluminum alloy, the mark of the nickel-plated copper is Ni6T2, a stitch welding mode is adopted for welding, and the welding process is carried out in a dust-free working chamber; before welding, the surface of an experimental material is cleaned firstly, and it isguaranteed that the surface of a plate is clean and free of pollution; then the plate is stacked on a workbench and fixed through a clamp, and the laser position is adjusted to be located at the center of a to-be-welded part; and laser welding parameters and the welding process are adjusted through a laser control system. According to the process, the welding problem of the series-parallel connection end of the tab in the production process of the 6061 aluminum alloy and the Ni6T2 is solved, stable laser power can be output by adopting the single-mode laser welding process, various welding process parameters are adjusted in the welding process, the process environment is improved, it is guaranteed that welding spots are well formed, macroscopic defects are avoided, and all performances meet the production and application standards.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com