Welding method of low-alloy ultra-high-strength steel with yield strength of 1100mpa

A technology of yield strength and ultra-high-strength steel, which is applied in the field of ultra-high-strength steel welding, can solve problems such as restricting production efficiency and being unsuitable for ultra-high-strength steel welding, so as to reduce steel consumption and energy consumption, excellent welding process performance, and applicable convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

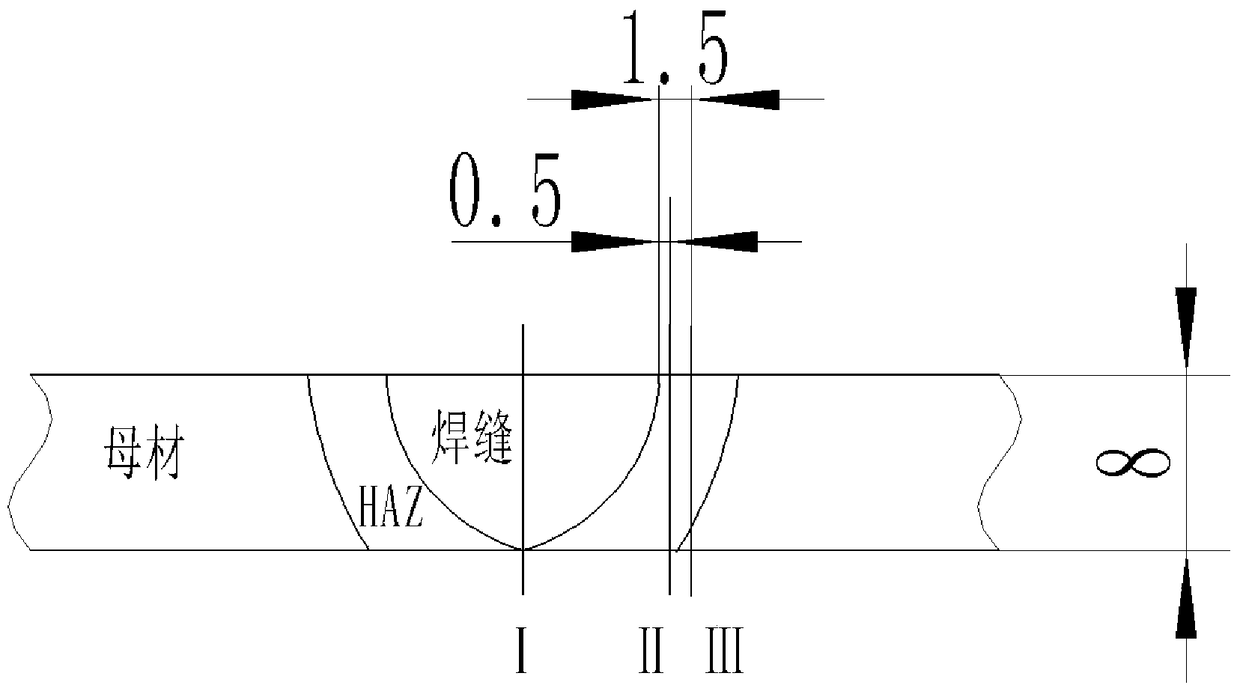

[0031] The welding method of low-alloy ultra-high-strength steel with a yield strength of 1100MPa is as follows:

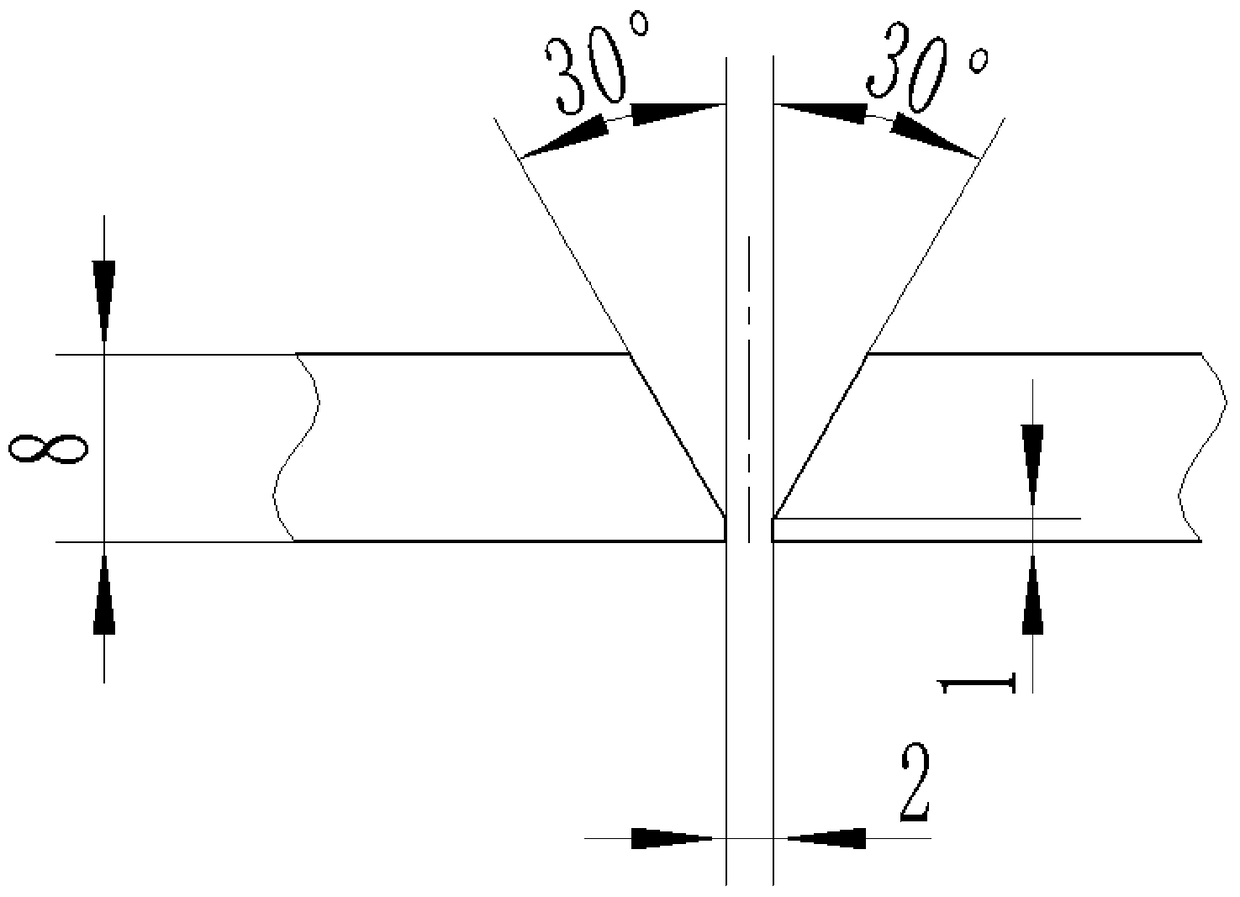

[0032] The steel plate to be welded is ultra-high-strength low-alloy steel with a yield strength of 1100MPa, and the combination of plate thickness is 8mm+8mm;

[0033] 1) The chemical composition weight percentage of base metal is: C 0.15-0.22%, Si 0.20-0.60%, Mn 0.60-1.50%, Cr 0.30-0.80%, Ni 0.400-1.60%, Mo 0.10-0.7%, Nb 0.01- 0.05%, V 0.01-0.05%, Al 0.02-0.08%, the production process of the base metal is smelting-continuous casting-controlled rolling and controlled cooling (TMCP)-quenching+tempering, the mechanical properties of the base metal: R p0.2 =1138MPa, R m =1300MPa, A 50 =9%, -40 longitudinal impact average value 27J;

[0034] 2) Matching welding material: EDFK1000 welding wire, diameter 1mm, yield strength of welding wire (R p0.2 )≥900MPa, tensile strength (R m )≥1000MPa, elongation (A)≥11%, -40℃ impact energy (Akv)≥27J;

[0035] 3) Protective g...

Embodiment 2

[0045] The welding method of low-alloy ultra-high-strength steel with a yield strength of 1100MPa is as follows:

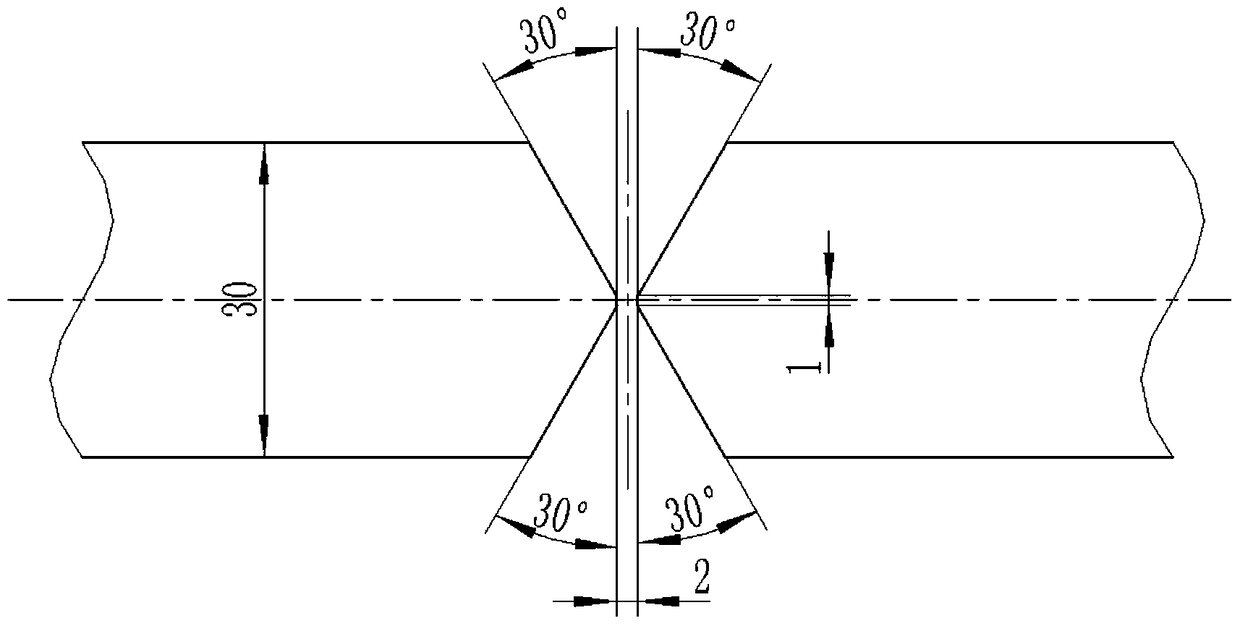

[0046] The steel plate to be welded is ultra-high-strength low-alloy steel with a yield strength of 1100MPa, and the combination of plate thickness is 30mm+30mm;

[0047] 1) The chemical composition weight percentage of base metal is: C 0.15-0.22%, Si 0.20-0.60%, Mn 0.60-1.50%, Cr 0.30-0.80%, Ni 0.400-1.60%, Mo 0.10-0.7%, Nb 0.01- 0.05%, V 0.01-0.05%, Al 0.02-0.08%, the production process of the base metal is smelting-continuous casting-controlled rolling and controlled cooling (TMCP)-quenching+tempering, the mechanical properties of the base metal: R p0.2 =1138MPa, R m =1380MPa,A 50 =11.8%, -40 longitudinal impact average value 44J;

[0048] 2) Matching welding material: EDFK1000 welding wire, diameter 1.2mm, the chemical composition weight percentage of welding wire is: C0.1-0.15%, Si 0.5-1.0%, Mn 1.5-2.0%, Cr 0.25-0.5%, Ni 2.0- 2.4%, Mo 0.4-0.8%, P≤0.015%, S≤...

Embodiment 3

[0057] Other operating steps are basically the same as in Embodiment 2 of the present invention, except that the plate thickness combination is 4mm+4mm, and the parameter of welding heat energy is controlled between 10-12KJ / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com