Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6588 results about "Weld bead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

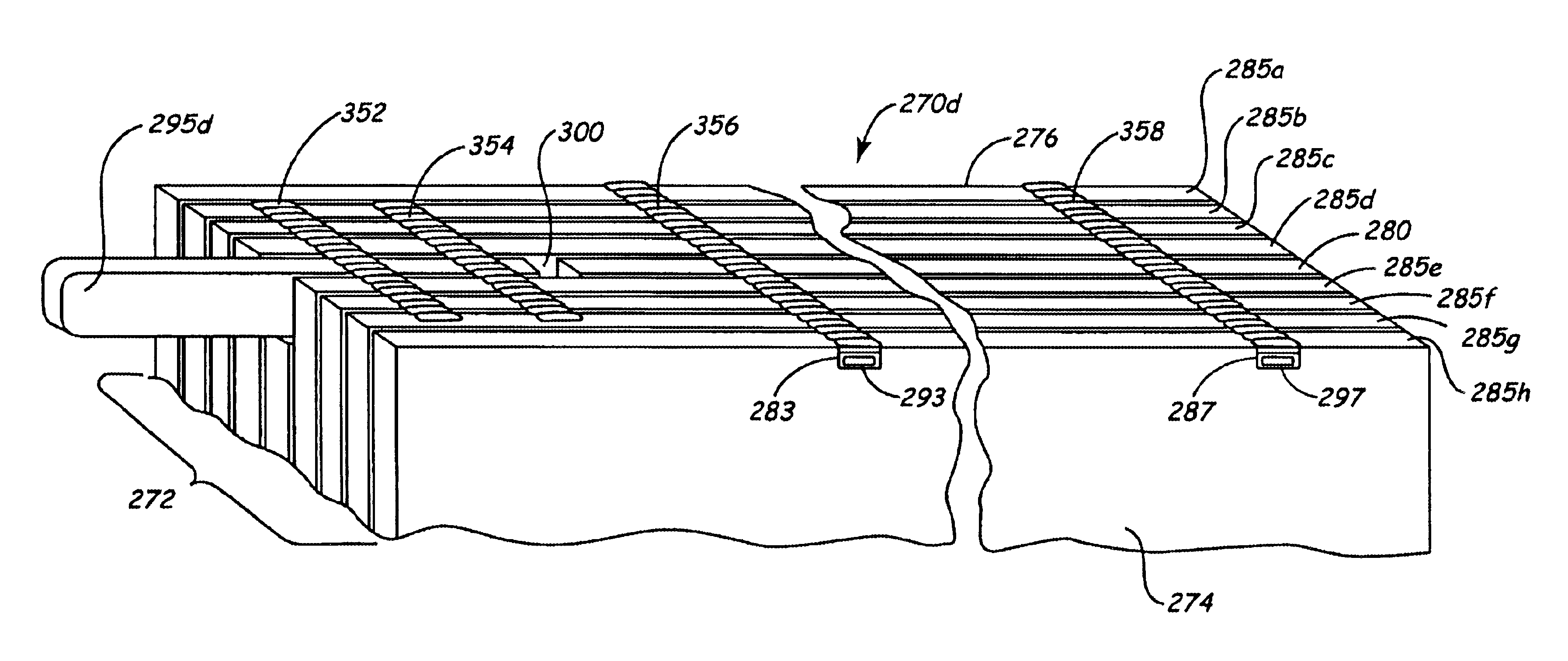

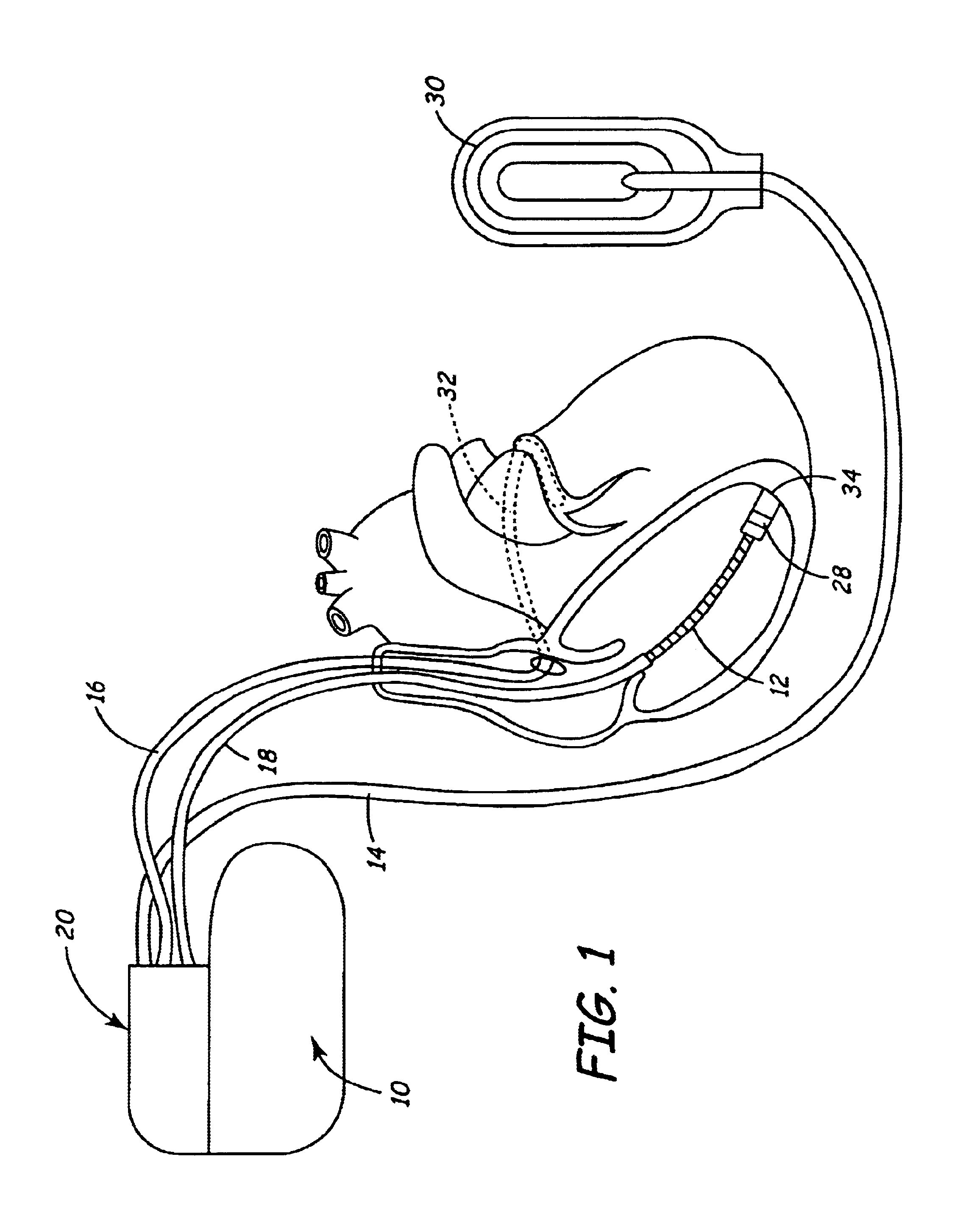

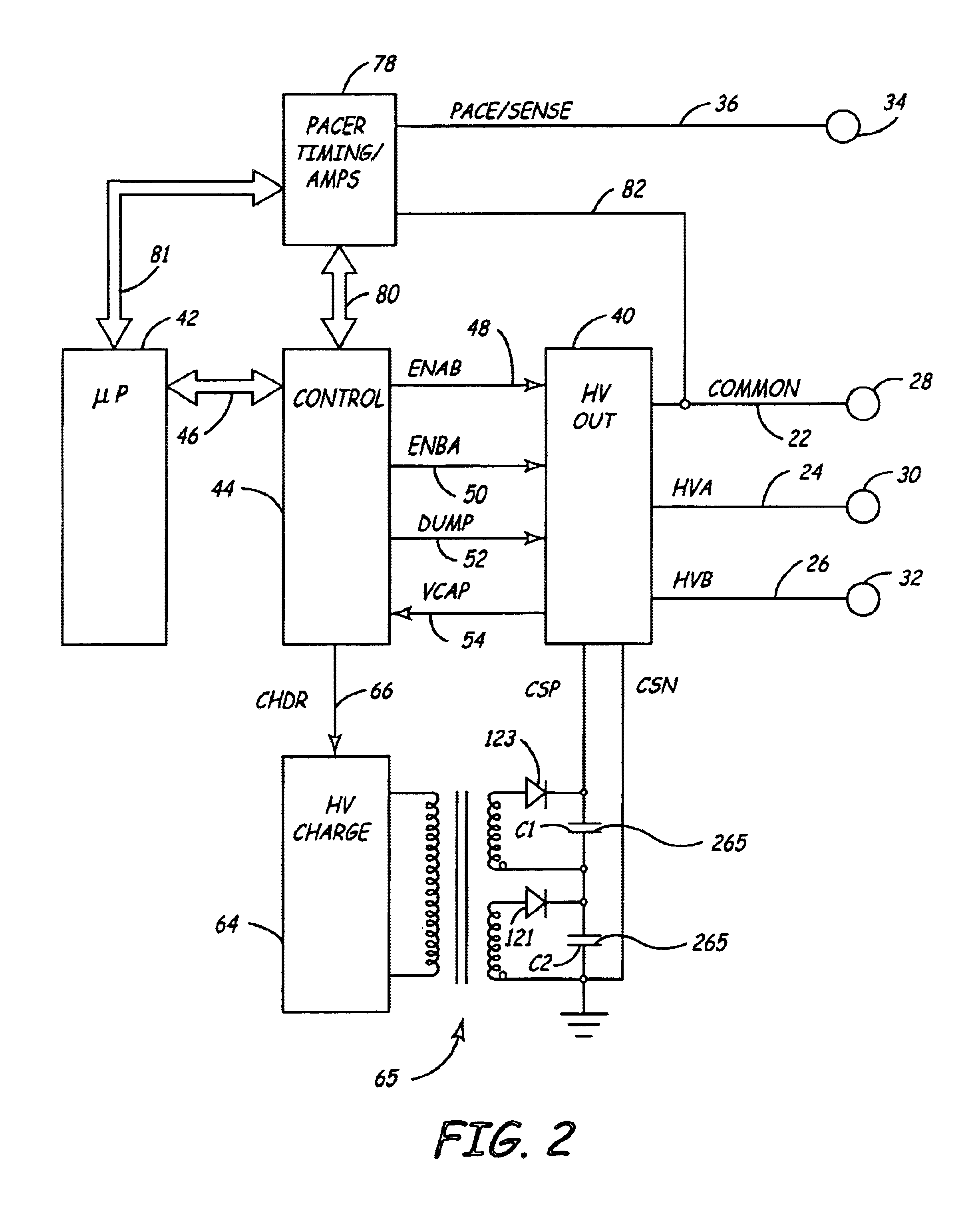

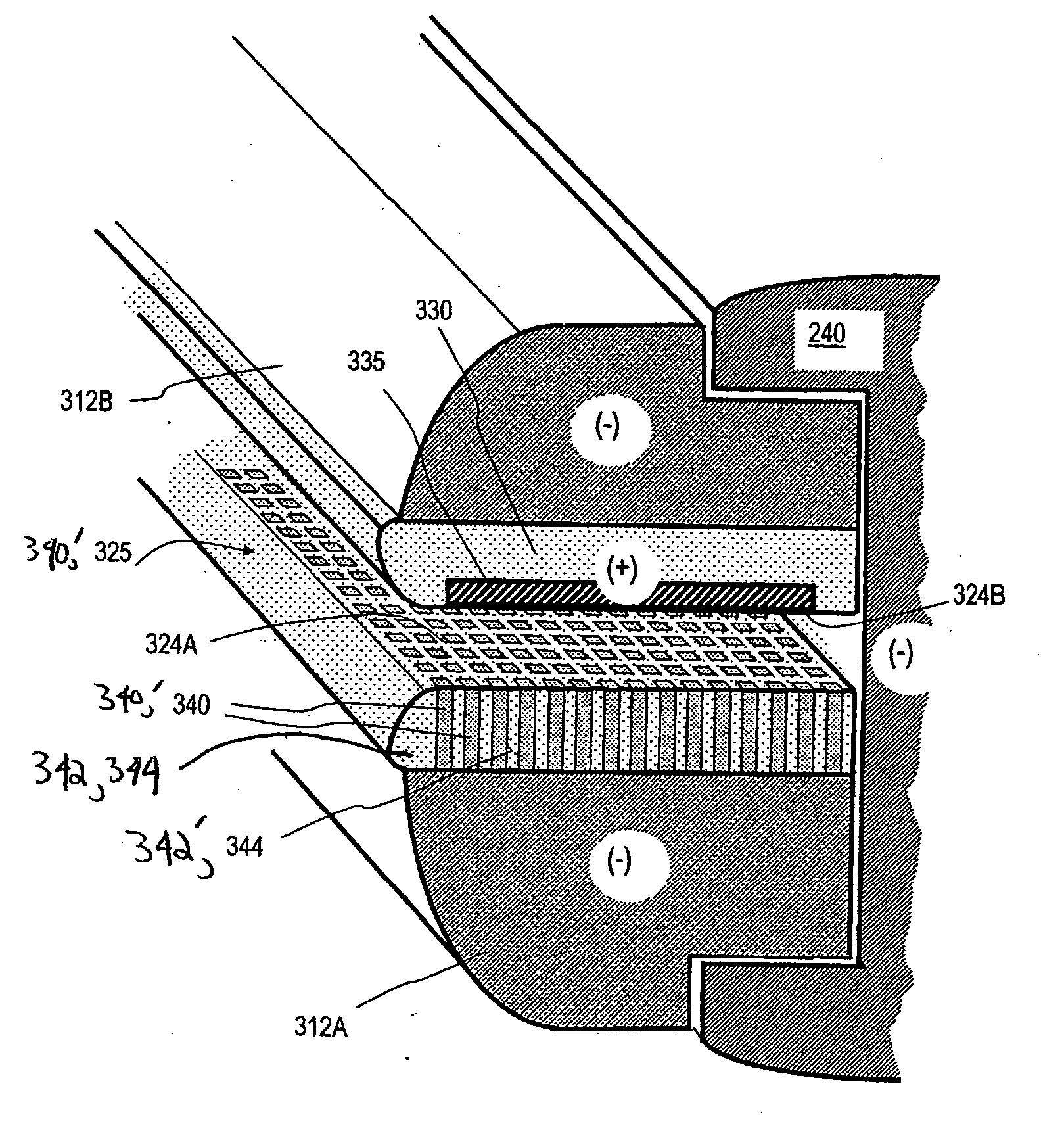

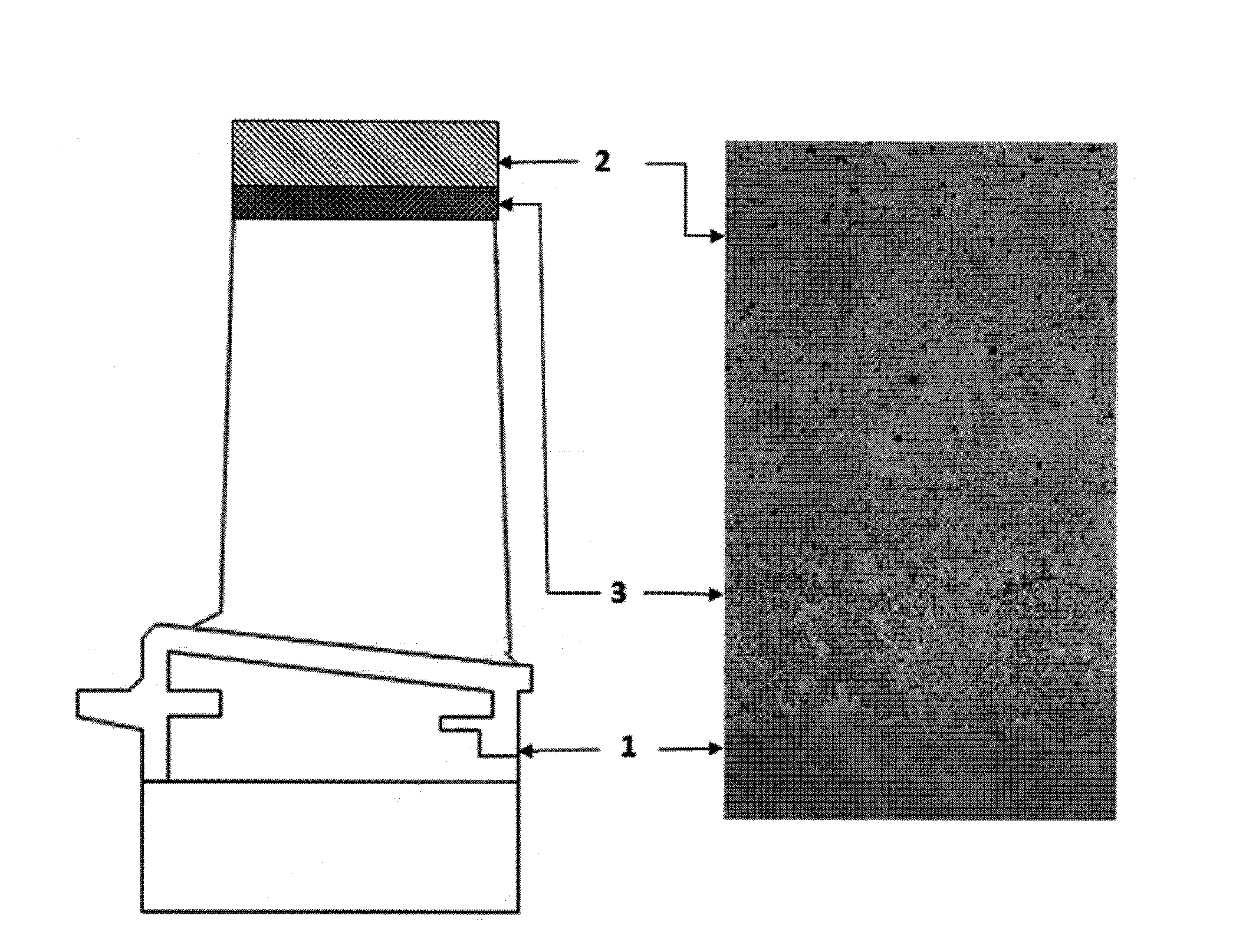

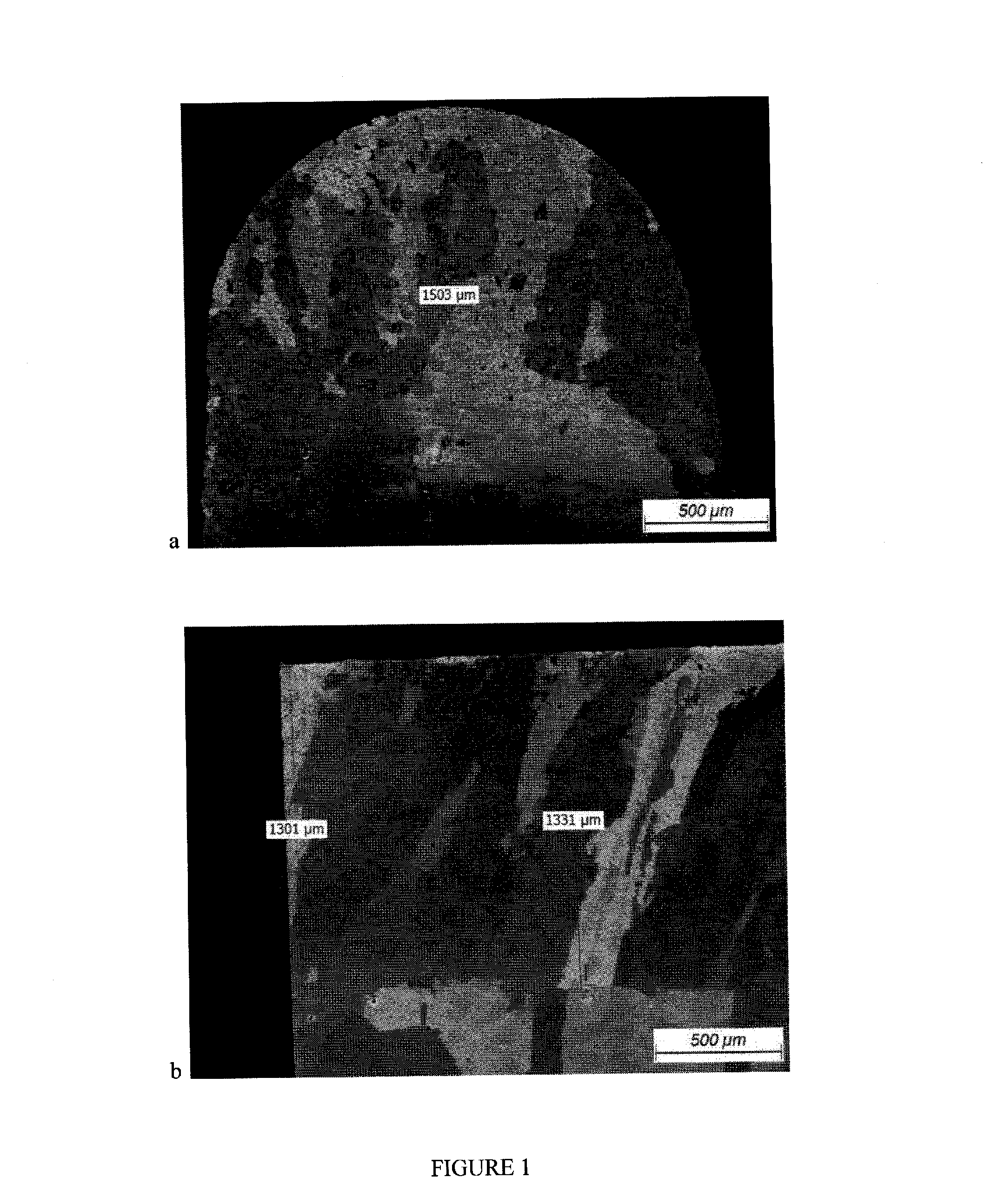

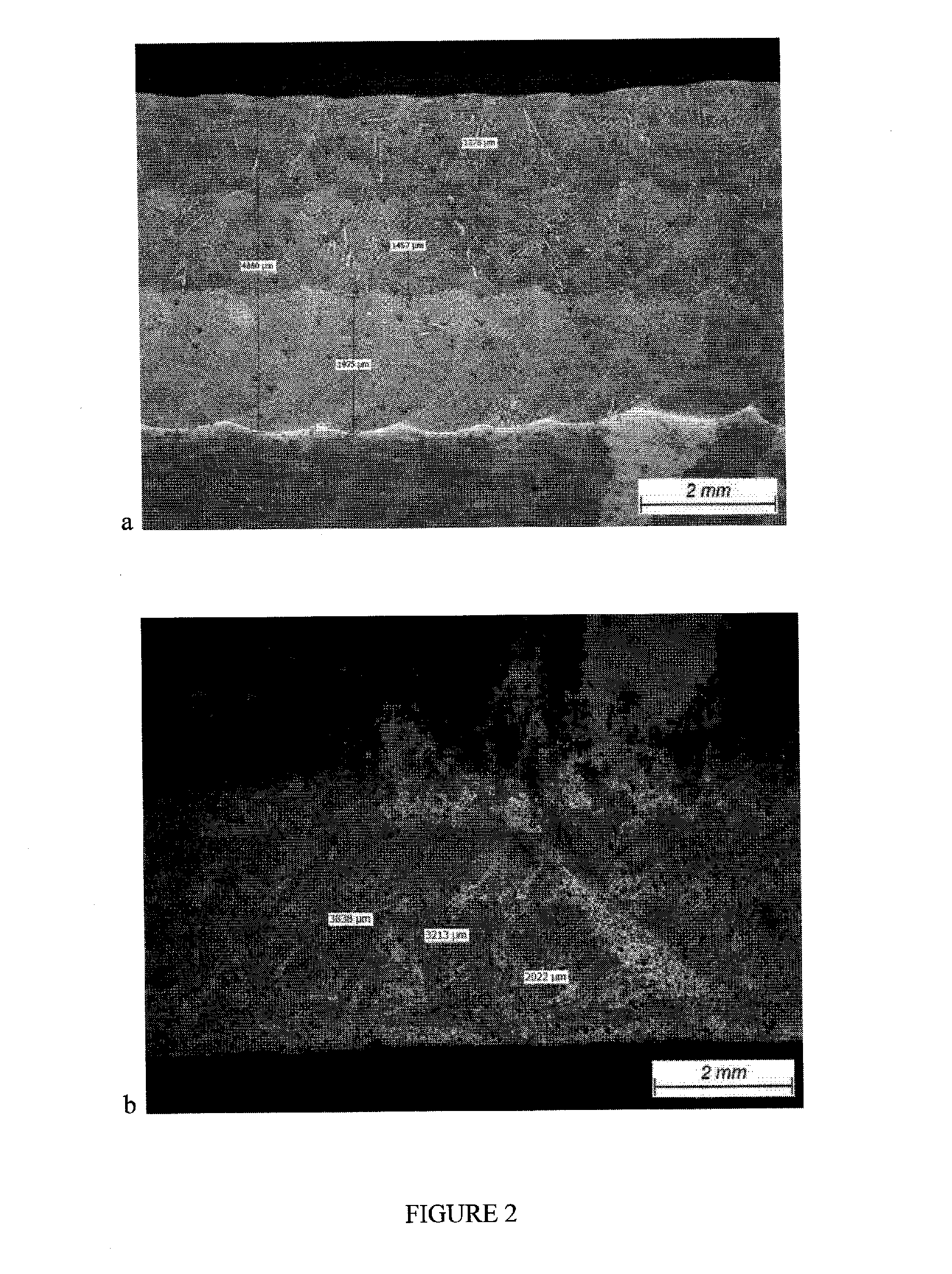

Implantable medical device having flat electrolytic capacitor fabricated with laser welded anode sheets

ActiveUS6922330B2Robust electrical and mechanical connectionMinimize damageLiquid electrolytic capacitorsCapacitor terminalsElectrolysisOptoelectronics

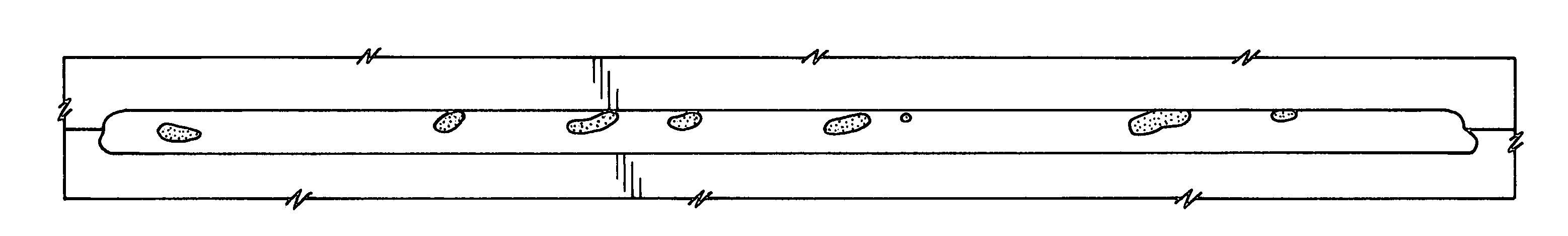

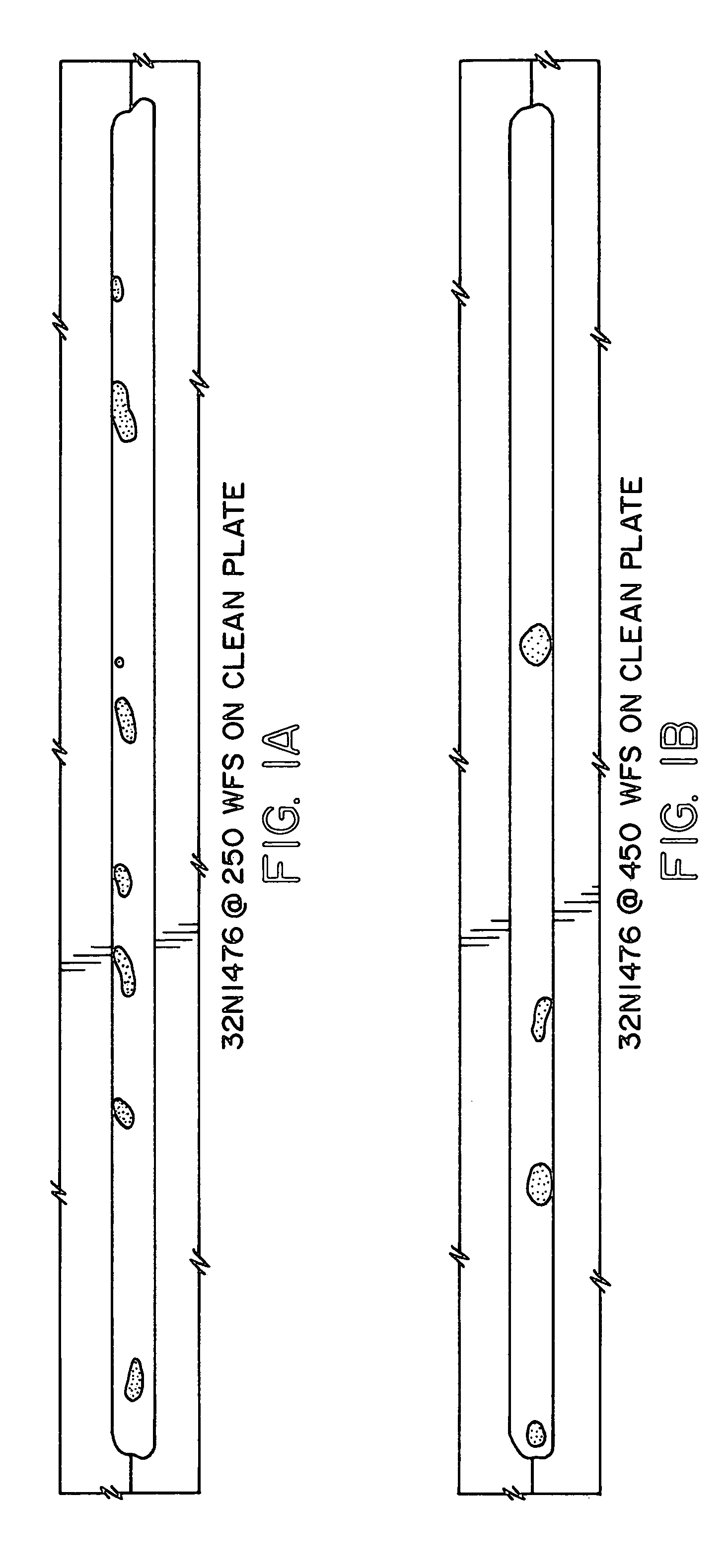

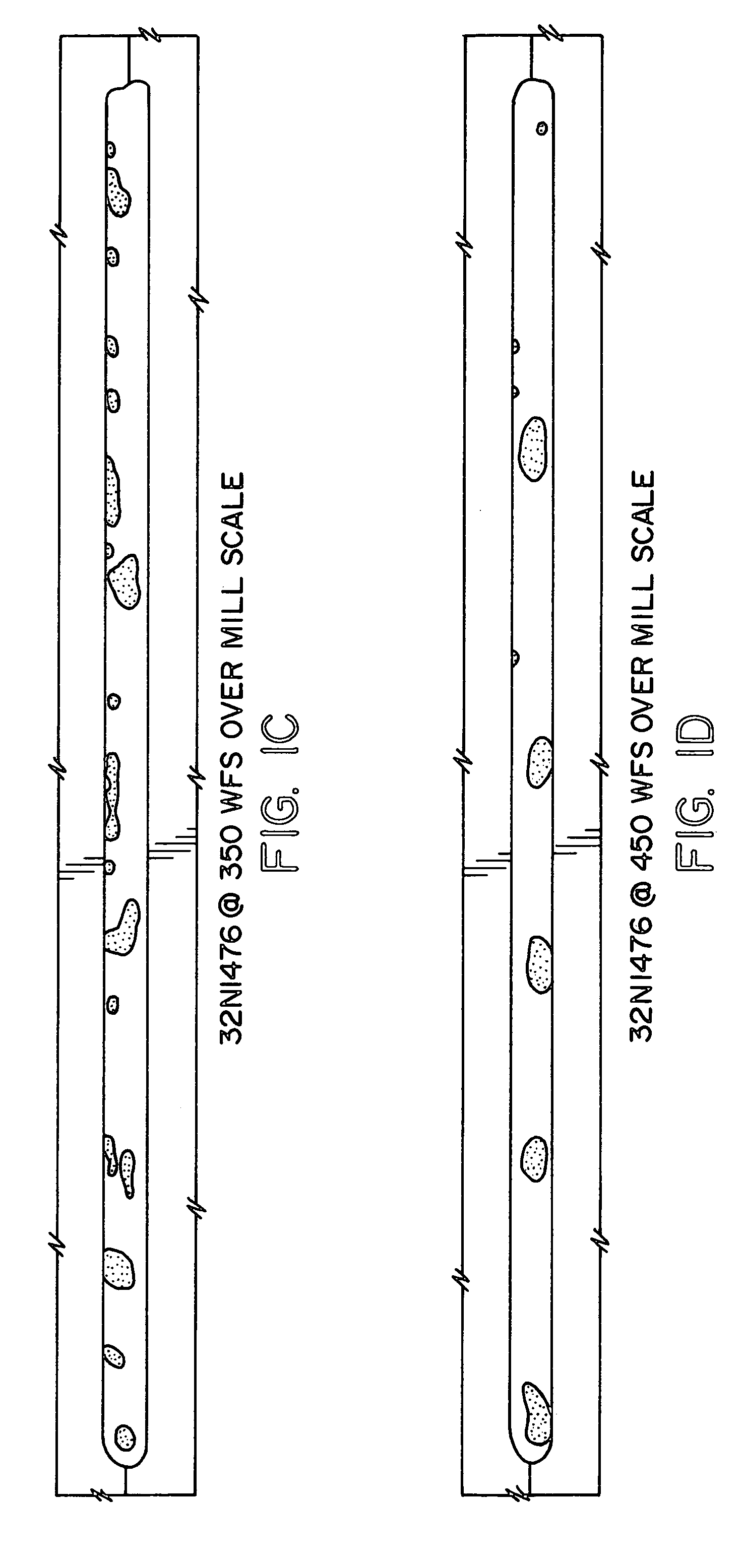

Implantable medical devices (IMDs) and components, including flat electrolytic capacitors and methods of making and using same, particularly an improved electrolytic capacitor fabricated of an electrode stack assembly comprising a plurality of capacitor layers stacked in registration upon one another. Each capacitor layer comprises a valve metal cathode layer having a cathode tab, a valve metal anode layer having an anode tab, and a separator layer located between the cathode layers. The anode layer is assembled from a plurality of valve metal anode sheets that are etched and anodized, stacked side-by-side, and electrically and mechanically joined together by laser weld beads. A valve metal anode tab having a thickness equal to one or more anode sheet is inserted into a tab notch in one or more stacked anode sheet and joined to the anode sheet stack by laser welding the tab and sheet edges together.

Owner:MEDTRONIC INC

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

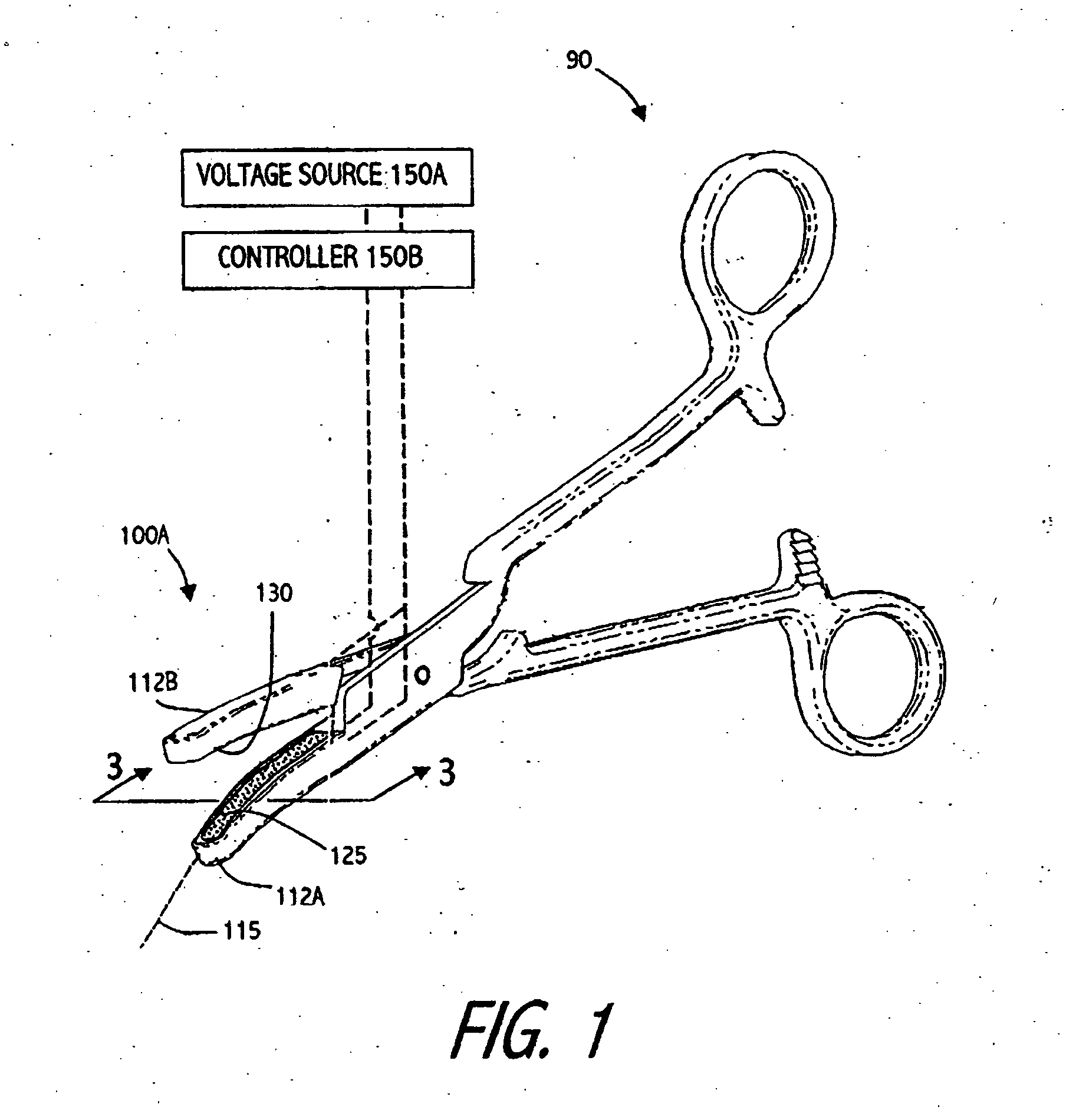

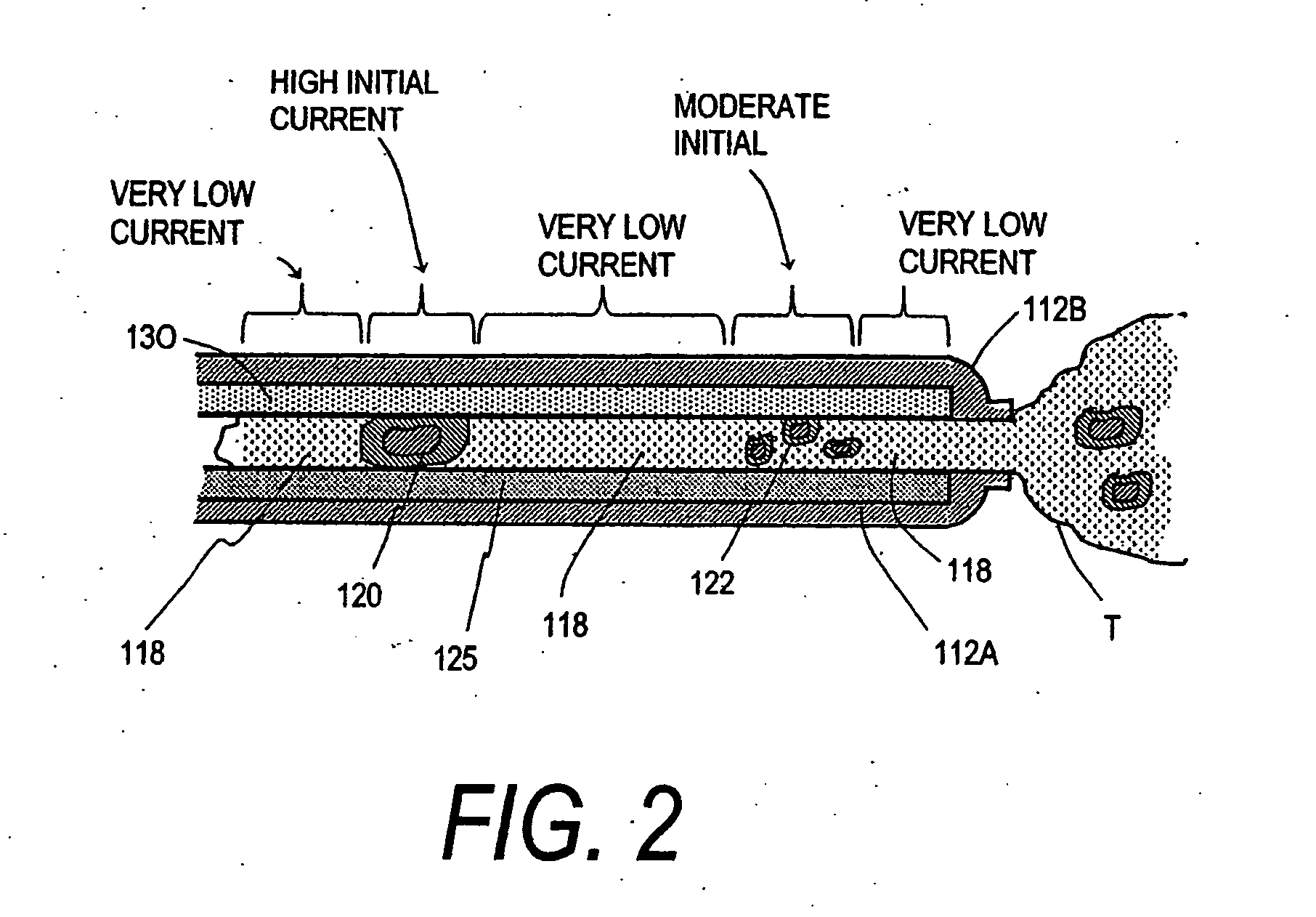

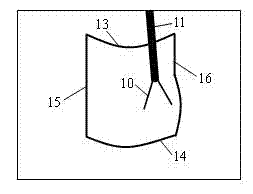

Electrosurgical instrument and method of use

ActiveUS20050203507A1Effective “weld” in tissueAvoid flowSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceHigh intensity

A particular embodiment of the invention provides an electrosurgical working end for performing high strength welding of tissue comprising a body having a tissue contacting energy delivery surface. The body includes pixel portions and non-pixel portions distributed within the tissue contacting surface. The pixel portions comprise a positive temperature coefficient of resistance (PTCR) material with at least one pixel portion configured to switch Rf current on and off in the at least one pixel portion responsive to tissue temperature adjacent the at least one pixel portion. The pixel portions can be configured to be coupled to an Rf current source such as an Rf generator. The pixelated energy delivery surfaces are capable of highly localized modulation of Rf energy application to the engaged tissue to create high strength tissue welds.

Owner:ETHICON ENDO SURGERY INC

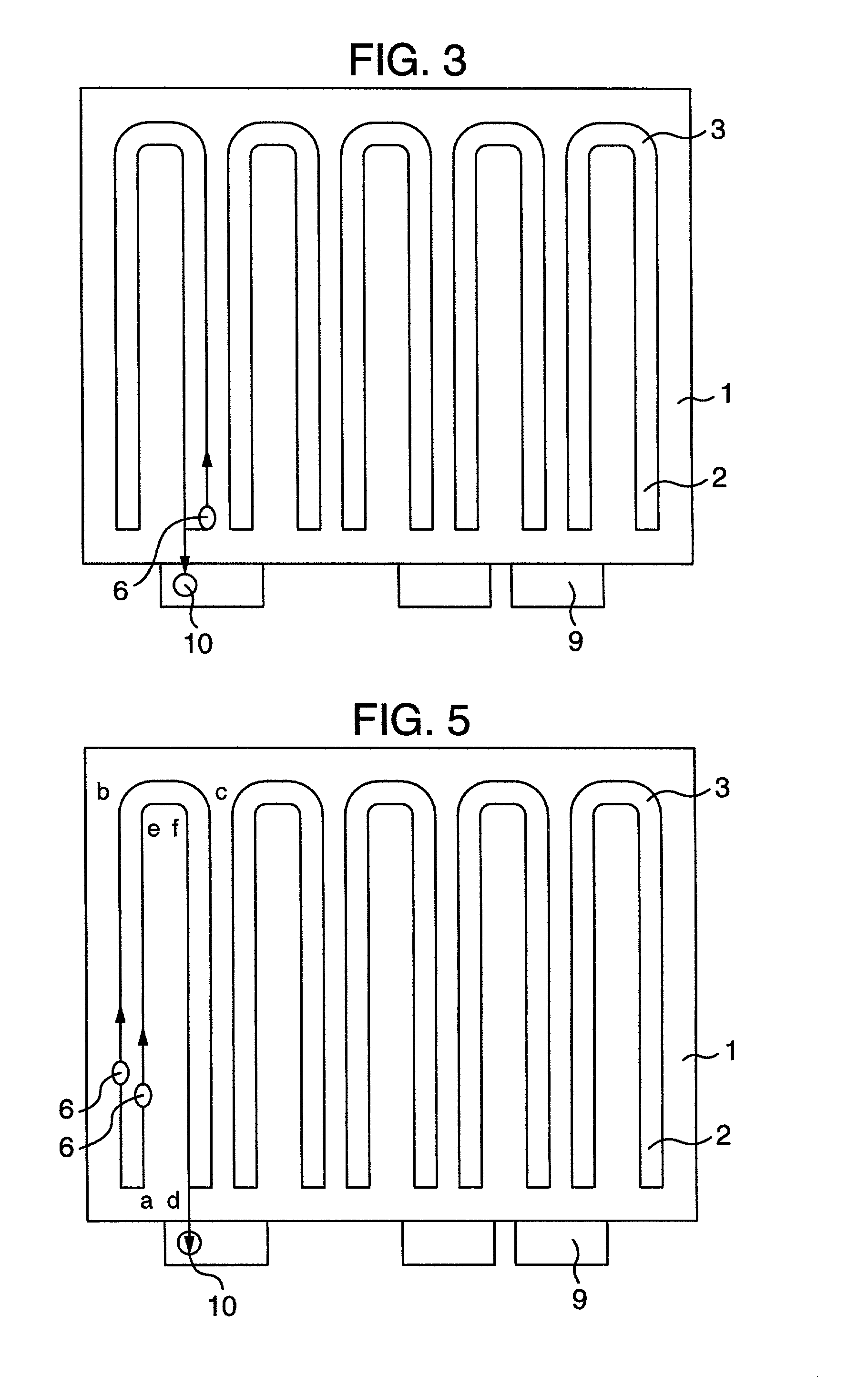

Cooling plate and manufacturing method thereof, and sputtering target and manufacturing method thereof

InactiveUS20020153130A1Improve accuracyAccurate stepElectric discharge tubesVacuum evaporation coatingSputteringEngineering

The present invention is a cooling plate including a groove, which becomes a passage of a coolant, inside a body, wherein one or more fins are provided inside the groove, wherein the groove is covered with a lid having width larger than the groove, wherein the lid is joined to the body by friction stir welding, and wherein a weld bead formed by the joining is outside the passage, and the weld bead formed by the joining is formed within the body and further, is characterized by a manufacturing method of a cooling plate that has a first groove, which becomes a passage of a coolant, and a second groove, which has width larger than the first groove and receives a lid on the first groove, inside a body, receives the lid on the second groove, and is joined to the body, the manufacturing method of a cooling plate wherein, while the lid and the body are joined together by the friction stir welding owing to insertion of a rotation tool having a shoulder and a pin, the joining is performed so that a weld bead formed by the joining may become out of the passage, and furthermore, is characterized in that a target for sputtering is joined to the cooling plate.

Owner:HITACHI CABLE

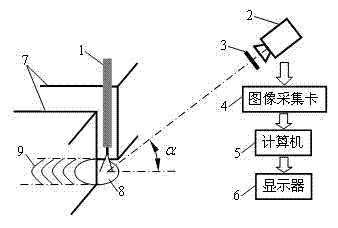

Narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing

ActiveCN102814574AReduce volumeReduce power consumptionArc welding apparatusDisplay deviceEngineering

The invention discloses a narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing and belongs to the technical field of welding. An infrared vision sensing system comprises an infrared complementary metal oxide semiconductor (CMOS) camera, a filtering system, an image collecting card, a computer, a display and the like. Narrow gap welding arc light and molten pool radiation light are used as a light source, an infrared narrow belt filtering system is used for filtering interference signals and adjusting light intensity, and the computer collects and displays a welding image obtained through the infrared CMOS camera. An image capturing window is used for capturing an image away from an arc side, the image is processed, welding line deviation information is obtained by extracting a groove single-side edge, and a real-time property of welding line deviation detecting is improved while arc noise is effectively avoided. The system is simple in formation, clear in monitored image, high in welding line deviation detecting precision, strong in anti-interference capacity and good in engineering practicality and can achieve the purposes of real-time monitoring of narrow gap welding and synchronous detecting of welding line deviation.

Owner:JIANGSU UNIV OF SCI & TECH

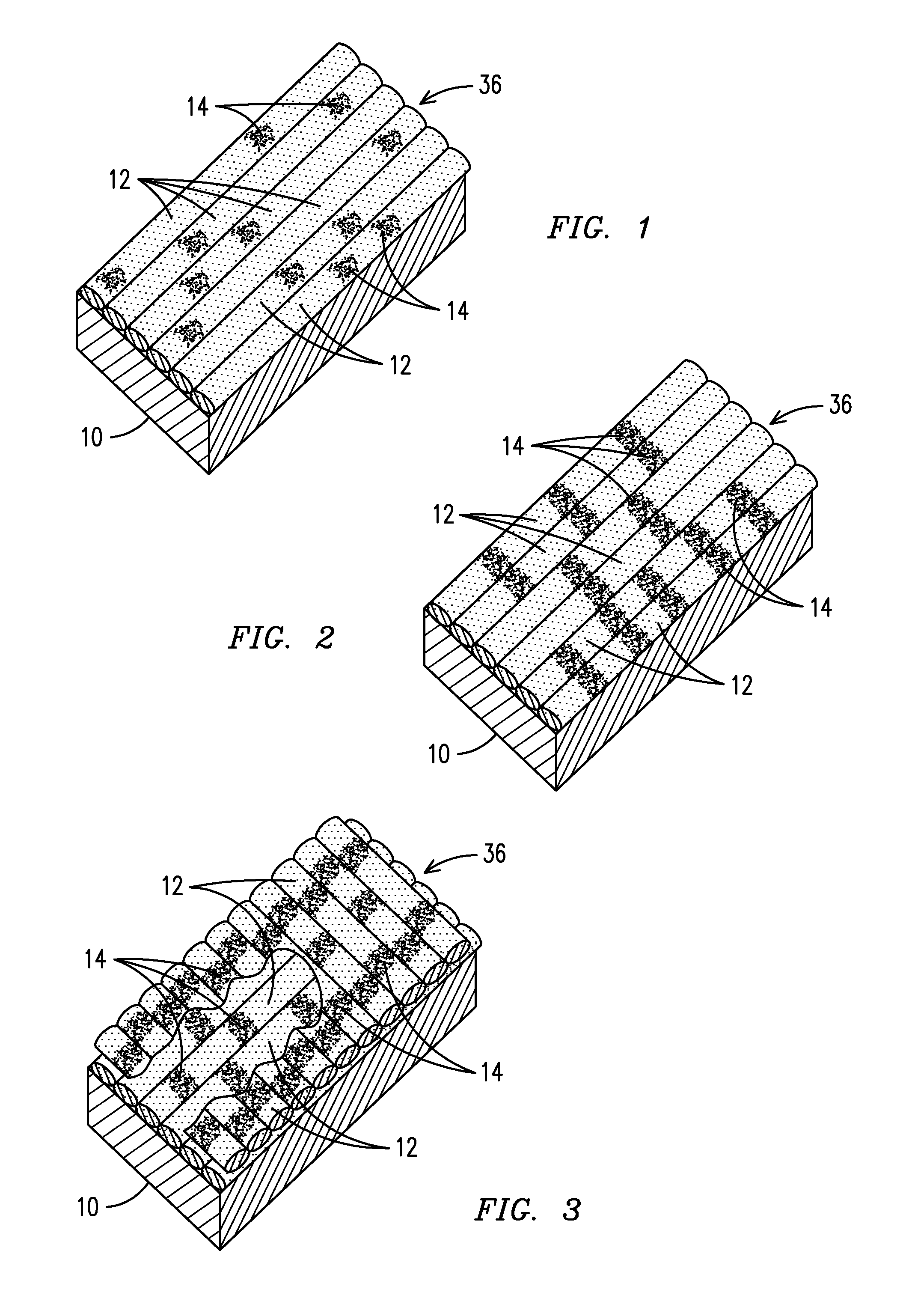

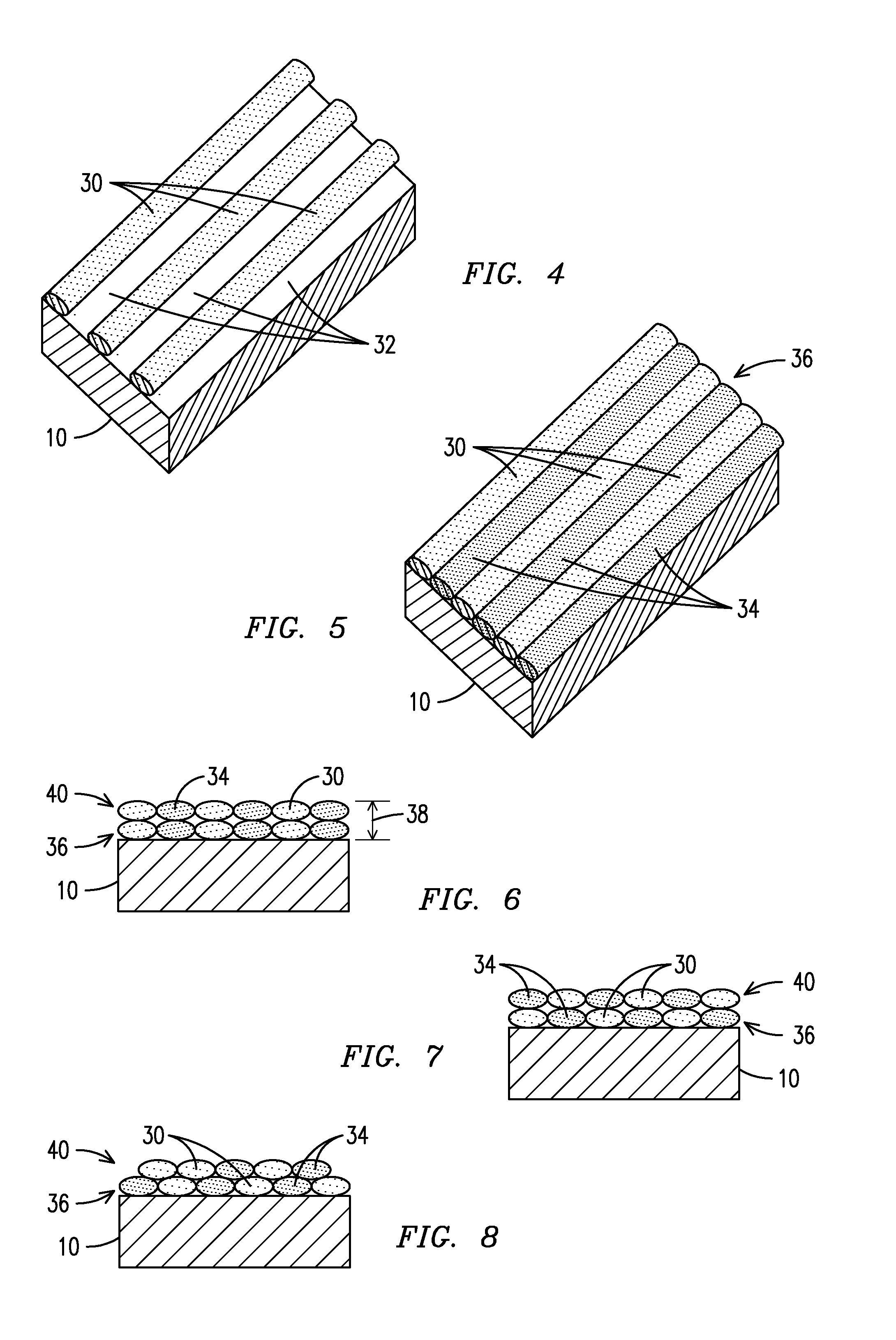

Superalloy Repair Welding Using Multiple Alloy Powders

A method of welding a gas turbine engine substrate composed of a gamma prime precipitation strengthened nickel based superalloy, including the steps of: applying weld beads on the substrate to form a continuous layer the thickness of the weld beads; using a filler material made of a first material exhibiting comparable strength and ductility as the substrate, and a second material exhibiting greater ductility than the substrate; and creating crack propagation mitigating regions within the continuous layer by increasing the percentage of the second material in the crack propagation mitigating regions over the percentage of the second material in the remainder of the continuous layer.

Owner:SIEMENS ENERGY INC

Method for testing undercut on the inner diameter of pipe welds

InactiveUS20070278196A1Reduce and eliminate needArc welding apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

Owner:LINCOLN GLOBAL INC

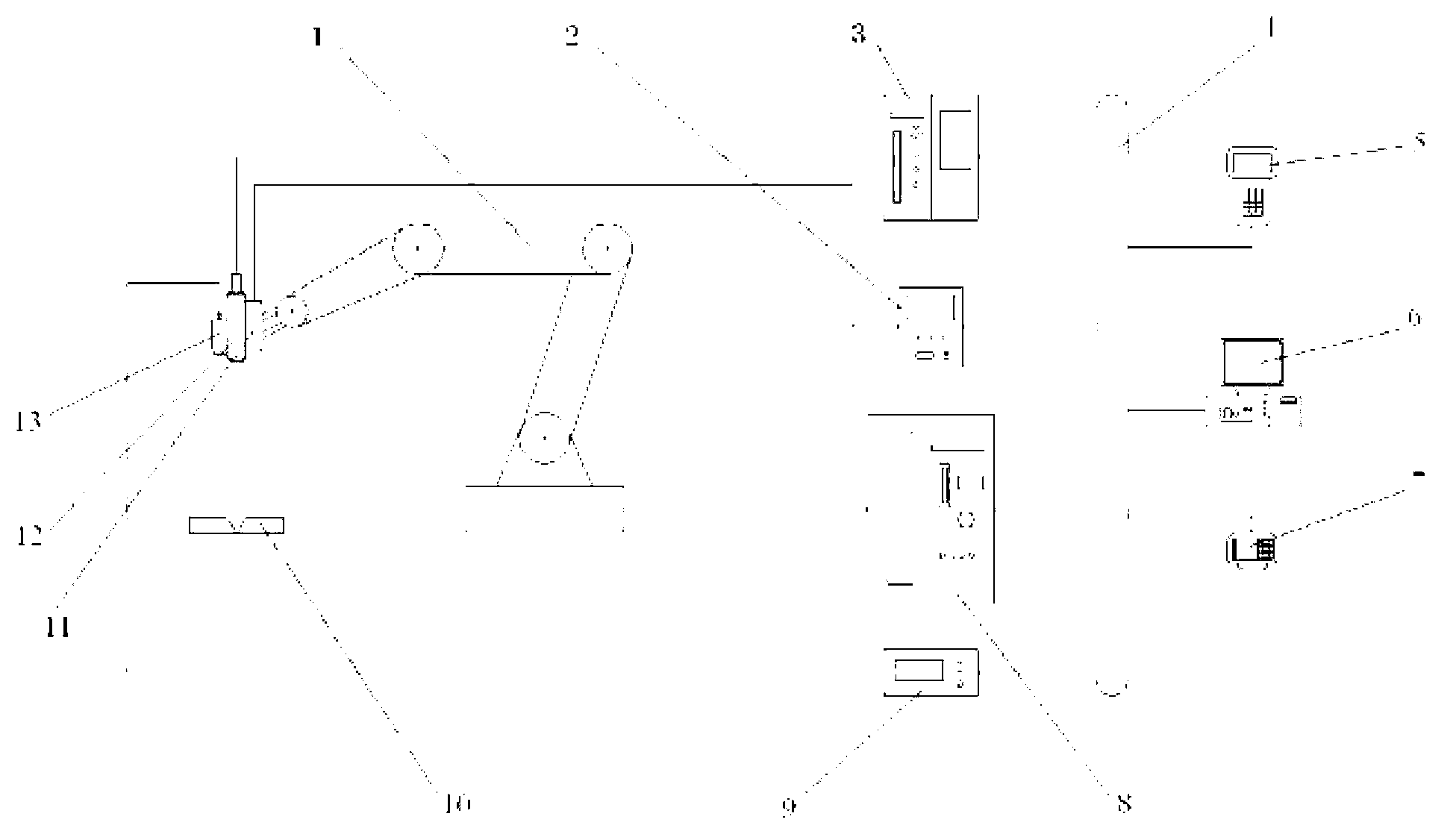

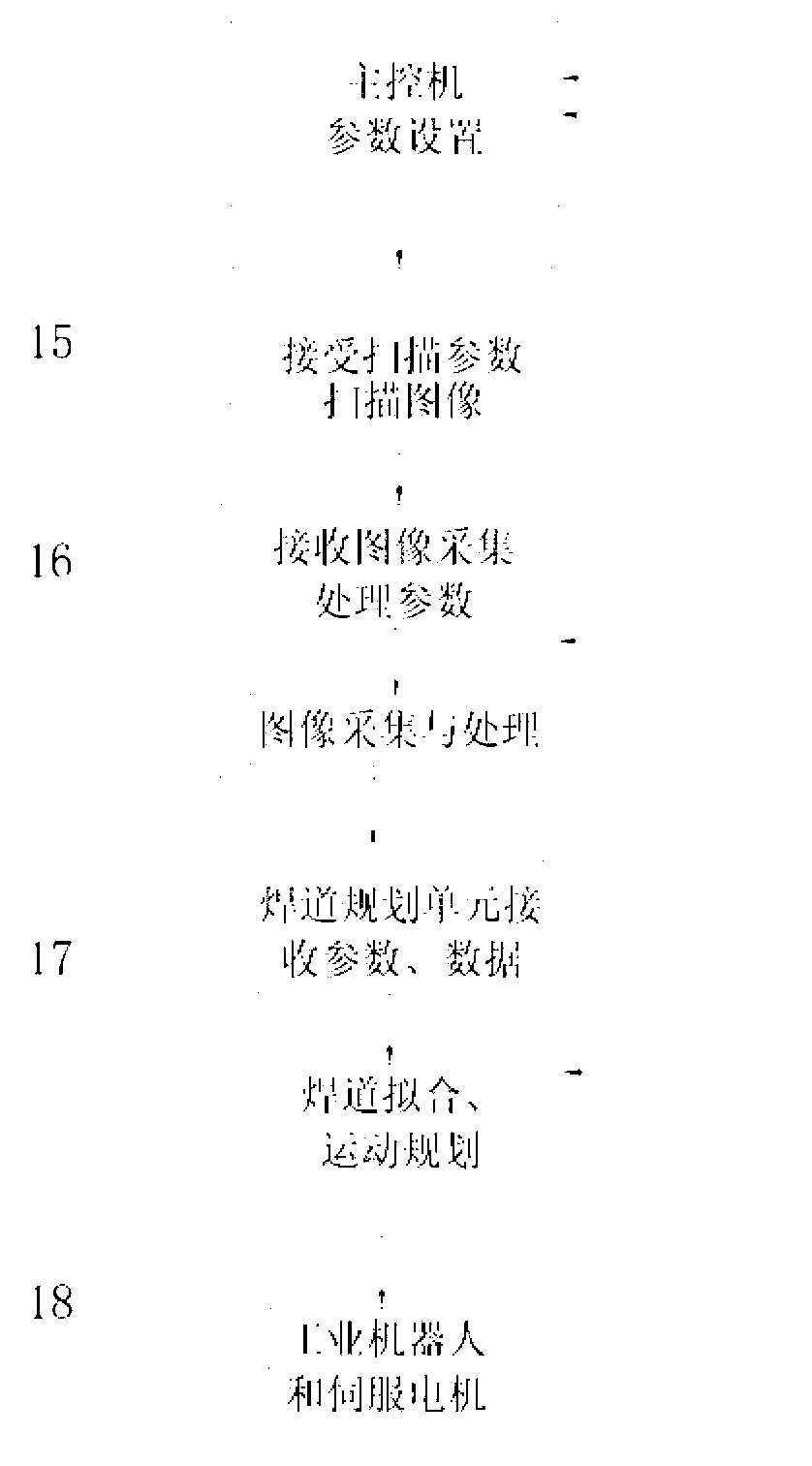

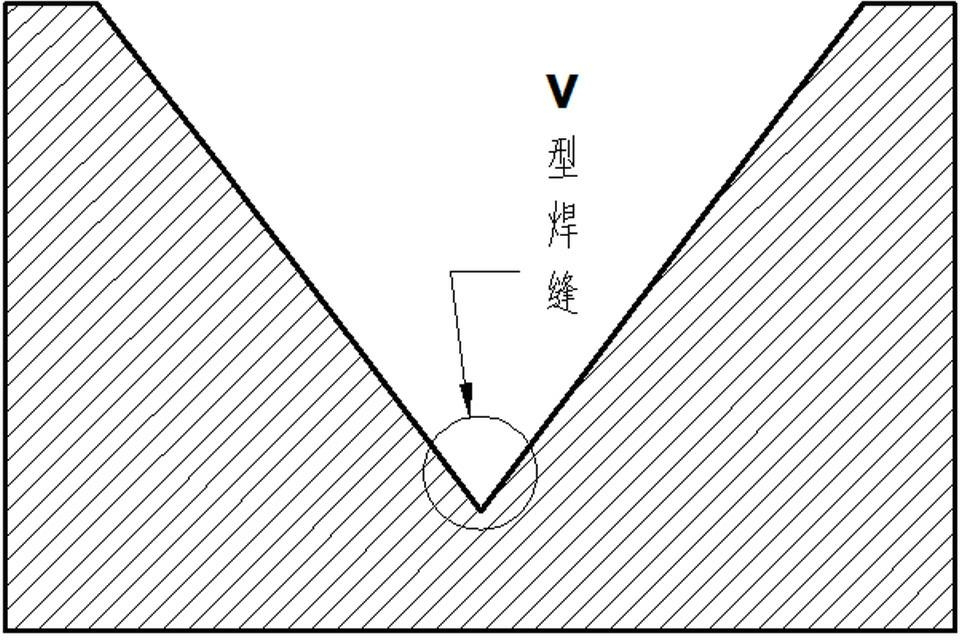

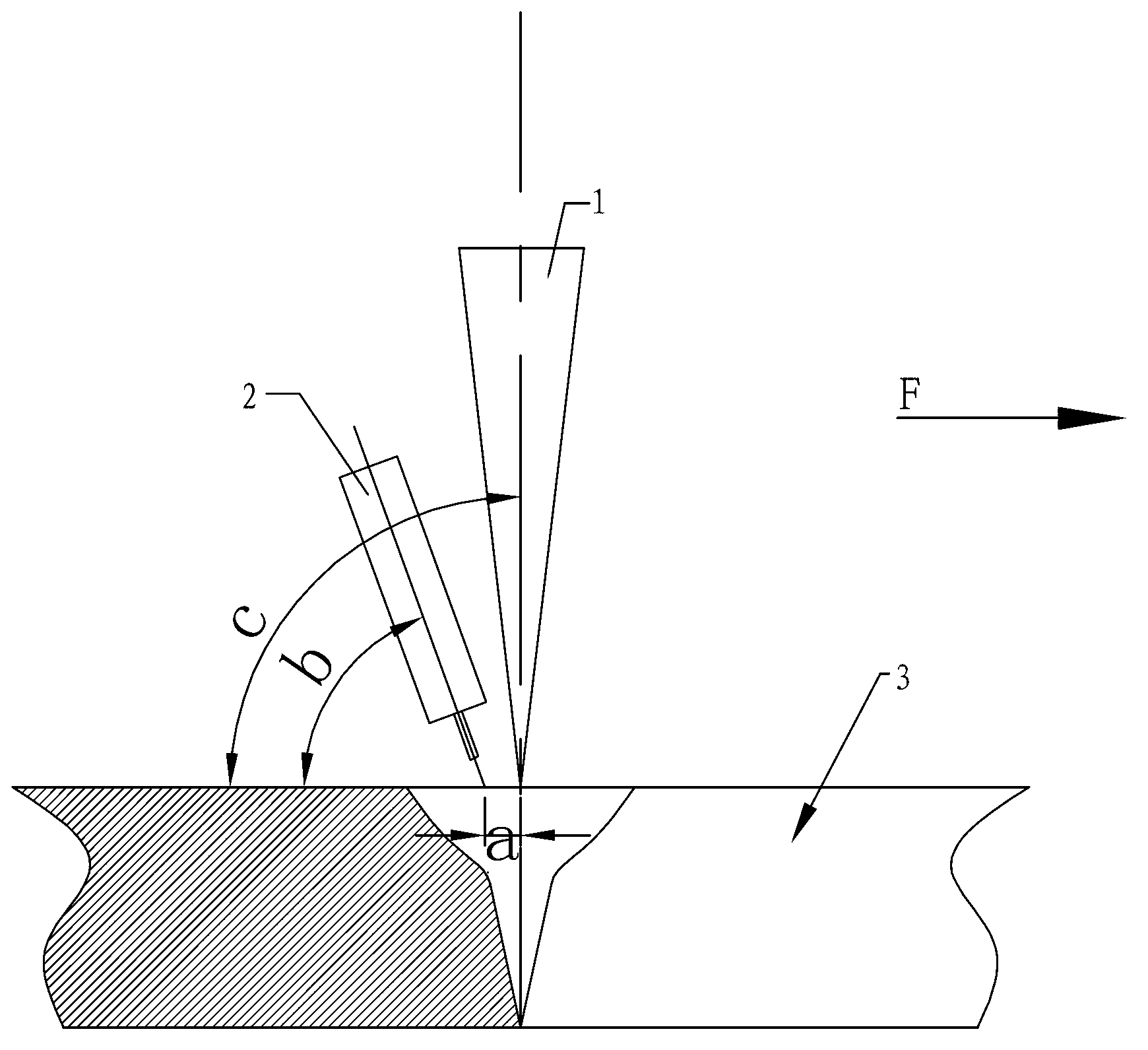

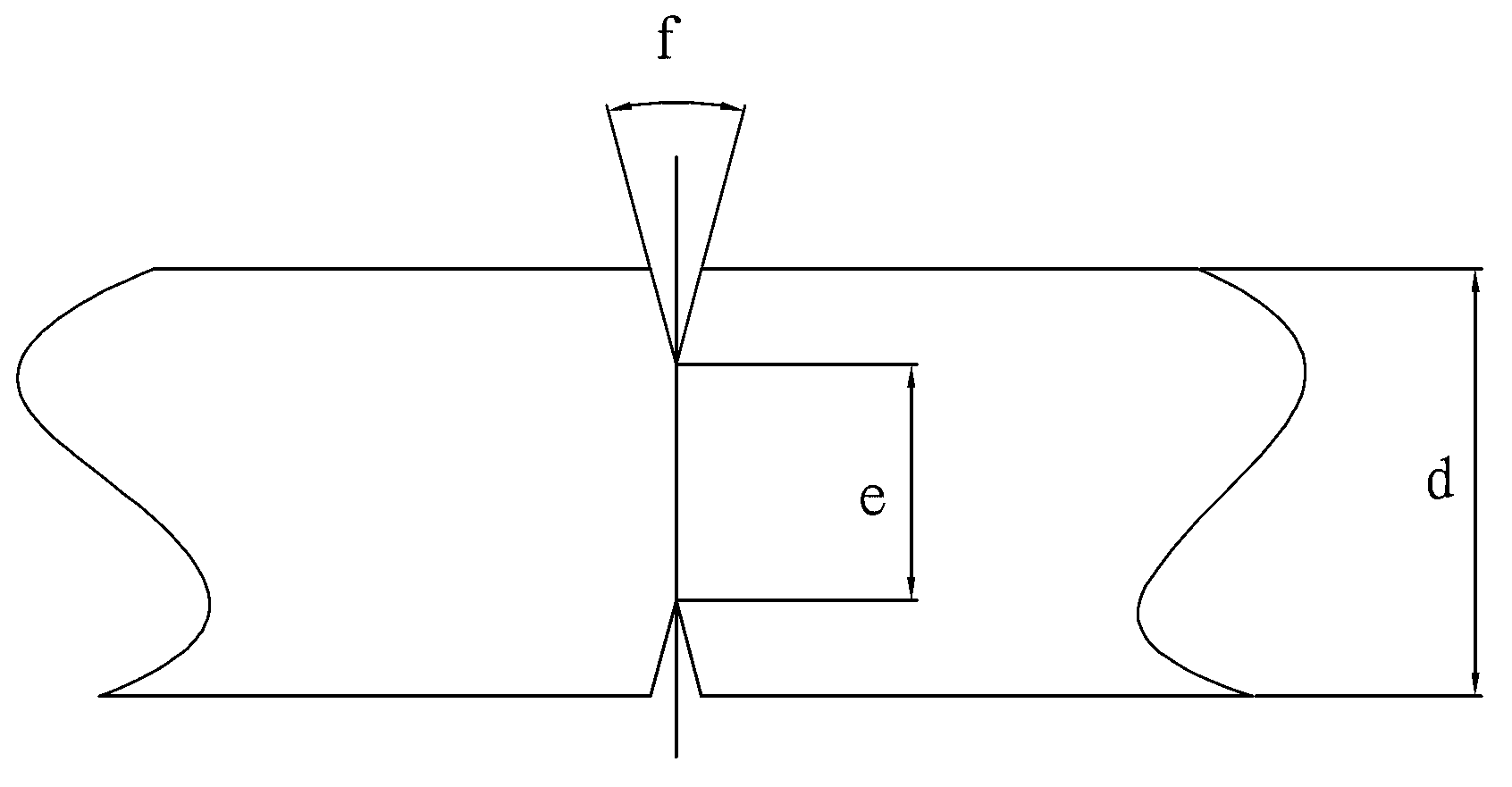

Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

InactiveCN102699534AImprove portabilityIncrease flexibilityLaser beam welding apparatusThick plateImaging algorithm

The invention discloses a scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for a thick plate, relates to a welding method, and aims to solve the problems that the conventional structured light vision sensing-based welding method can only be used for a simple shallow-groove laser weld seam tracking task and that when the conventional structured light vision sensing-based welding method is used for the narrow-gap deep-groove weld seam welding of the thick plate, a covering phenomenon is easily produced, the groove identification accuracy is lower, only real-time weld seam alignment calibration can be realized and narrow-gap deep-groove laser multilayer welding bead planning and welding cannot be realized. The method specifically comprises the following steps of: 1, selecting a groove form; 2, scanning a groove section image of a thick plate workpiece to be welded by using an image scanning unit; 3, processing the acquired groove section image by using an image algorithm to obtain weld seam image data; 4, performing fitting calculation; and 5, finishing the welding of welding beads layer by layer. The method is used for the deep-groove weld seam welding of the thick plate.

Owner:HARBIN INST OF TECH

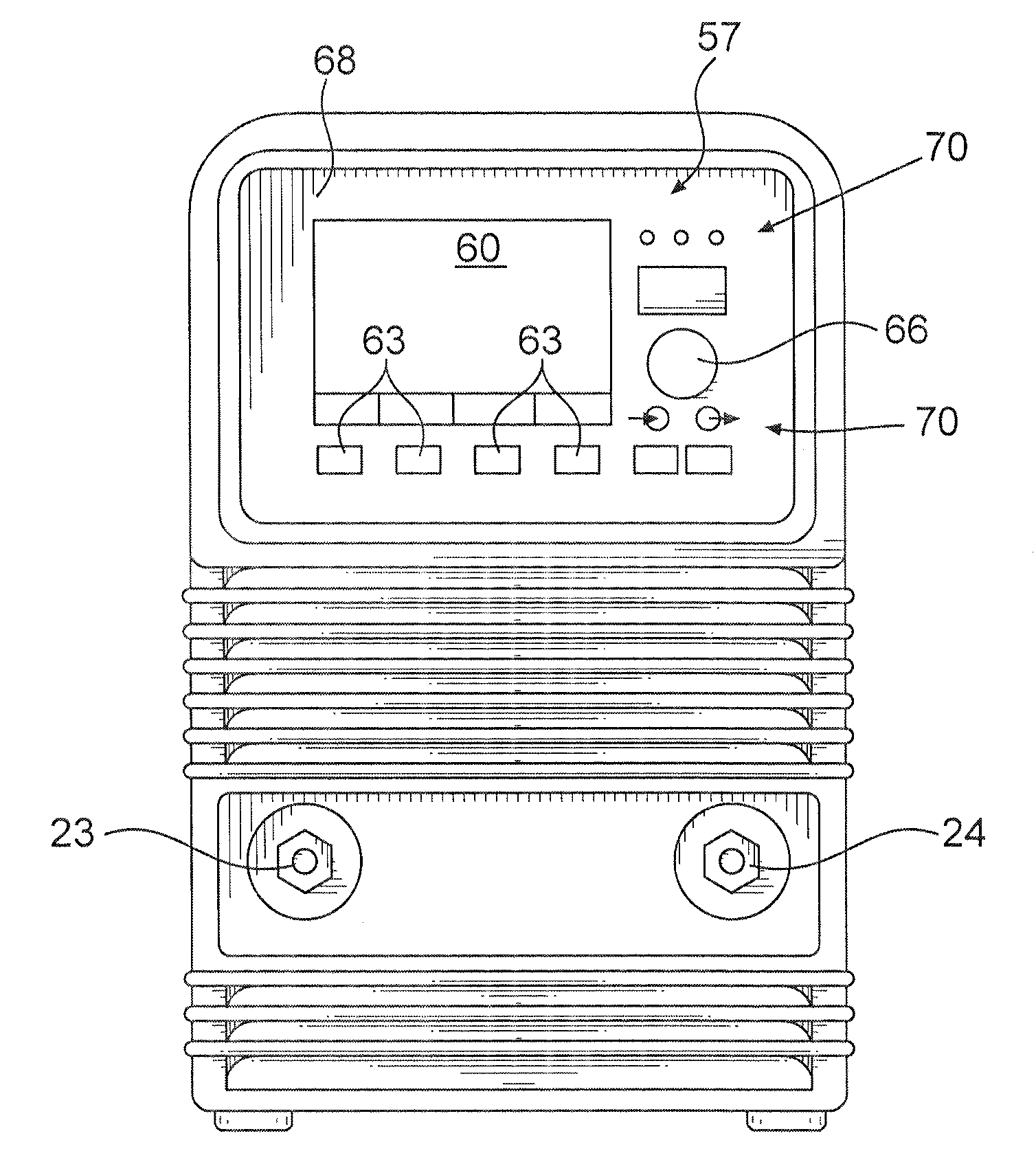

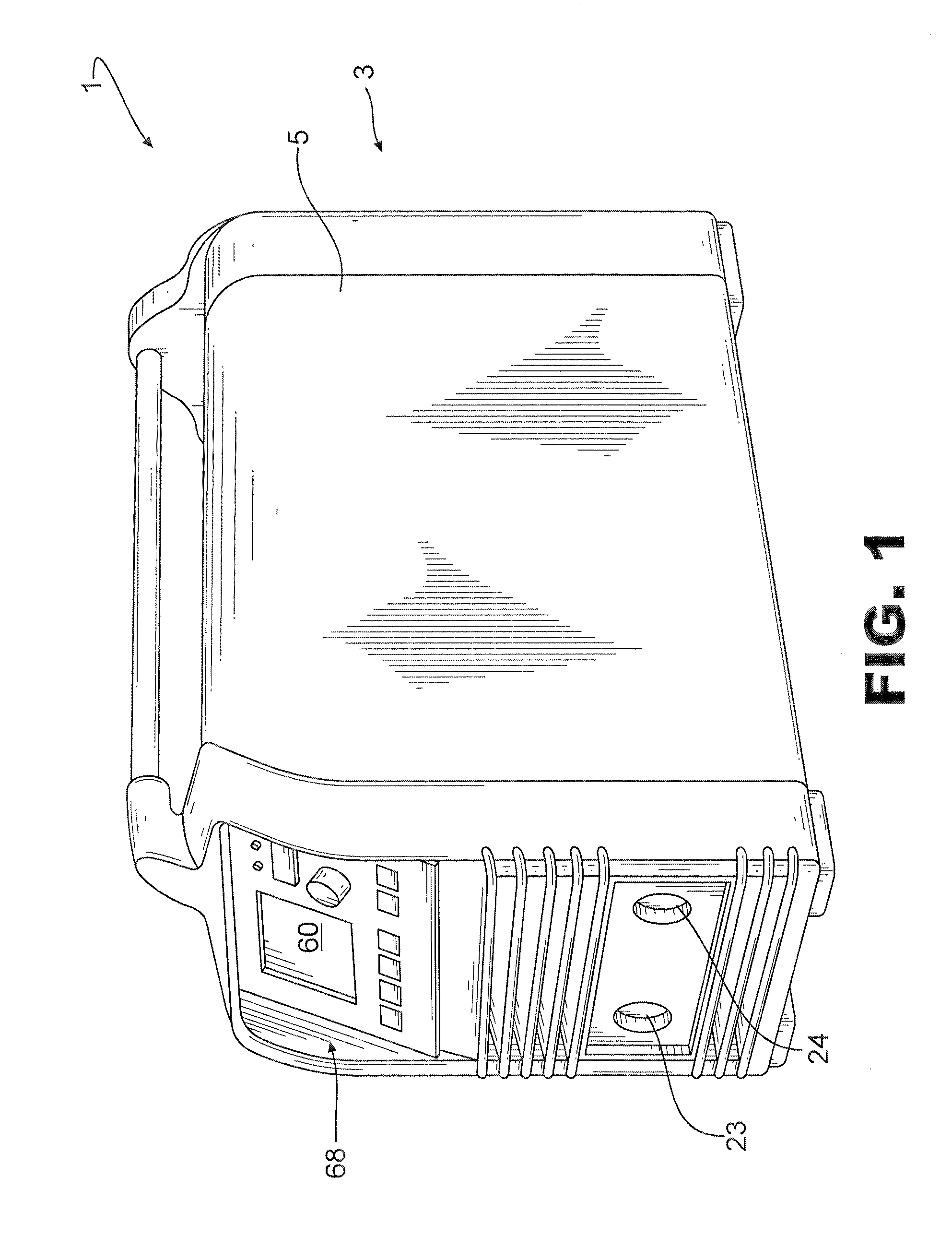

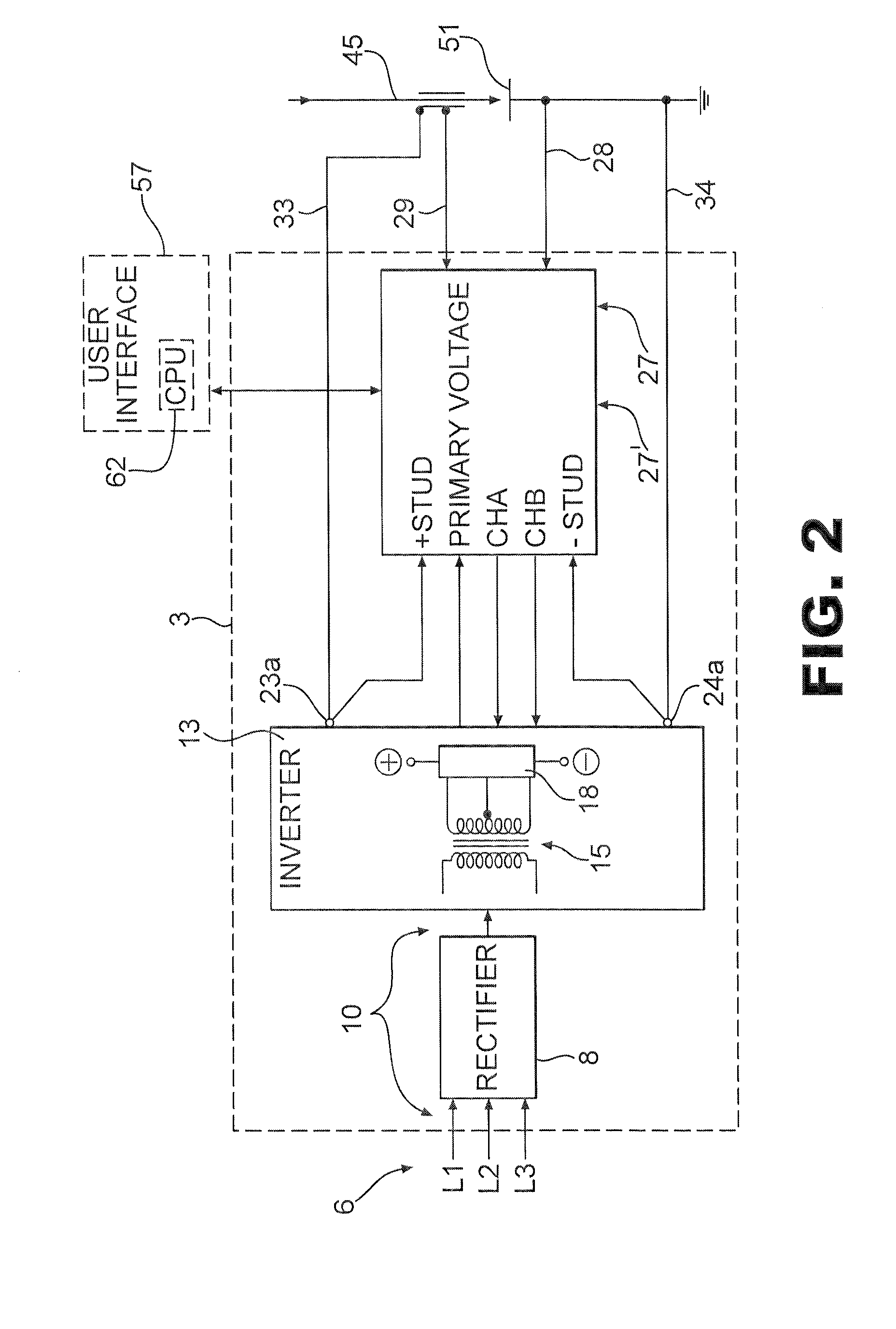

User interface for welding power supply

A welding power supply includes a user interface that allows the operator to adjust one or more welding parameters comprising a welding sequence for a welding process. The user interface may include a display, which may be a graphical display depicting the welding sequence and the one or more welding parameters. The user interface may further dynamically depict a pictograph, icon or other graphical image showing how changes to the one or more welding parameters will affect the welding process, which in an exemplary manner may be the welding bead profile and / or the welding arc profile.

Owner:LINCOLN GLOBAL INC

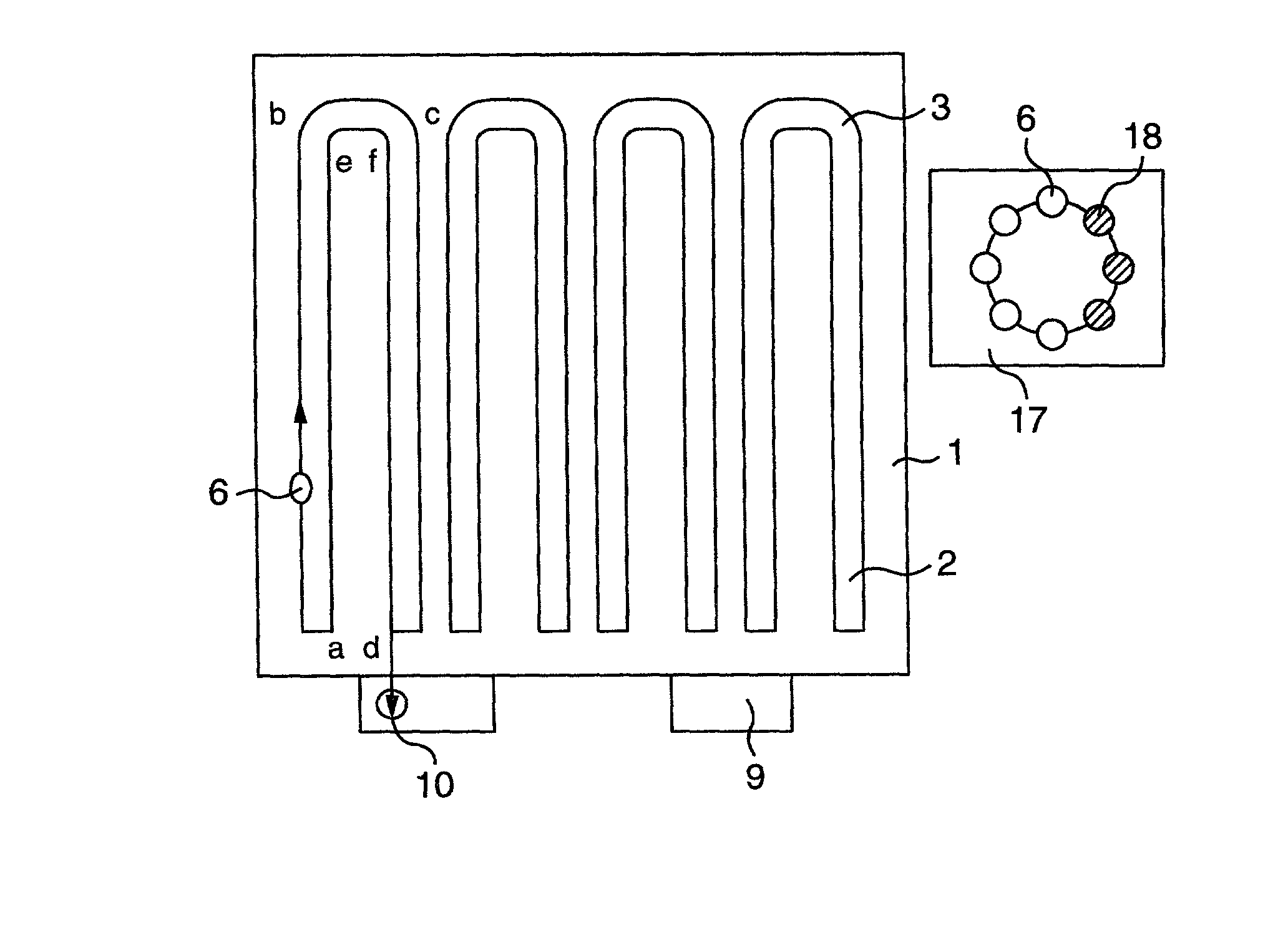

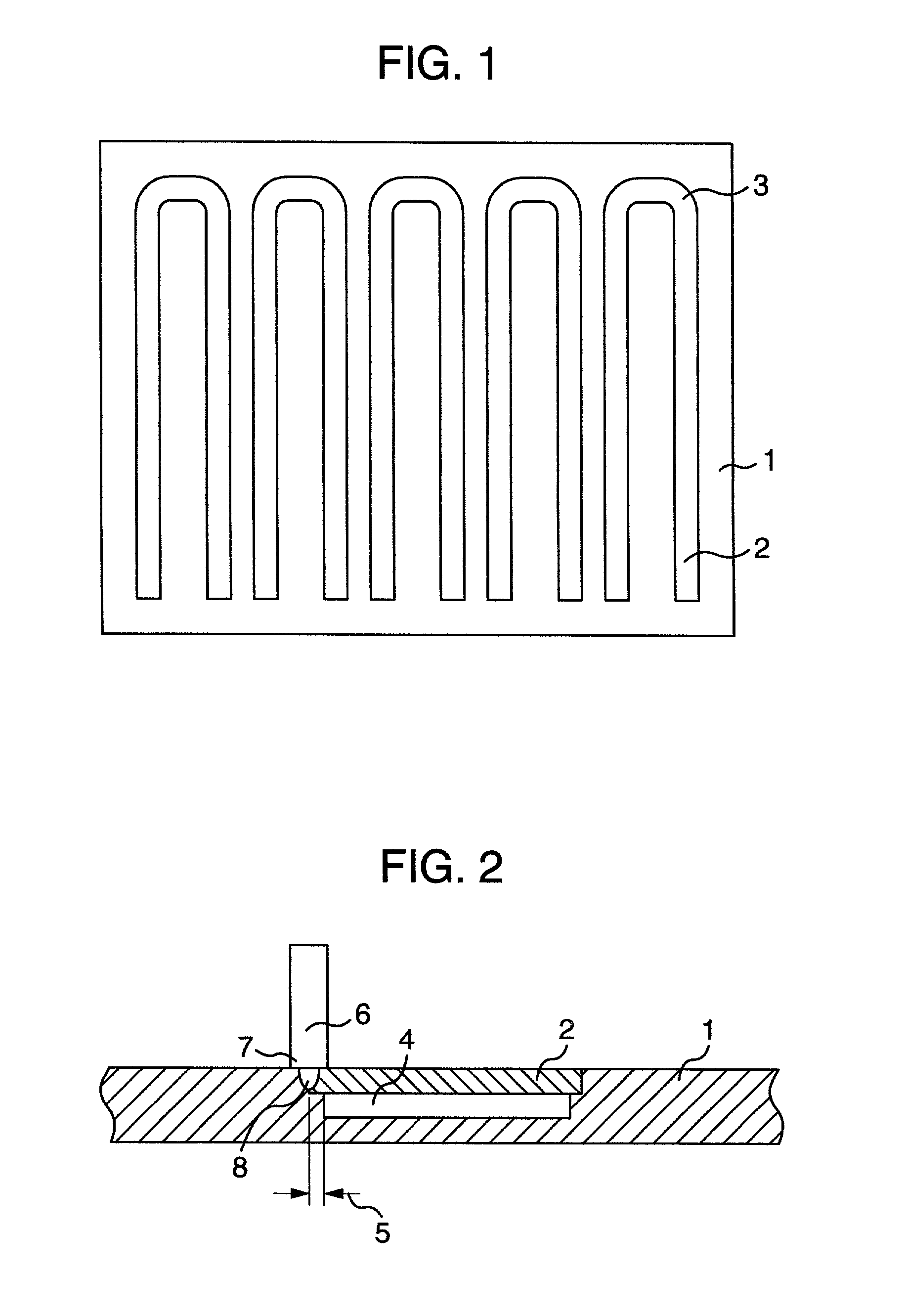

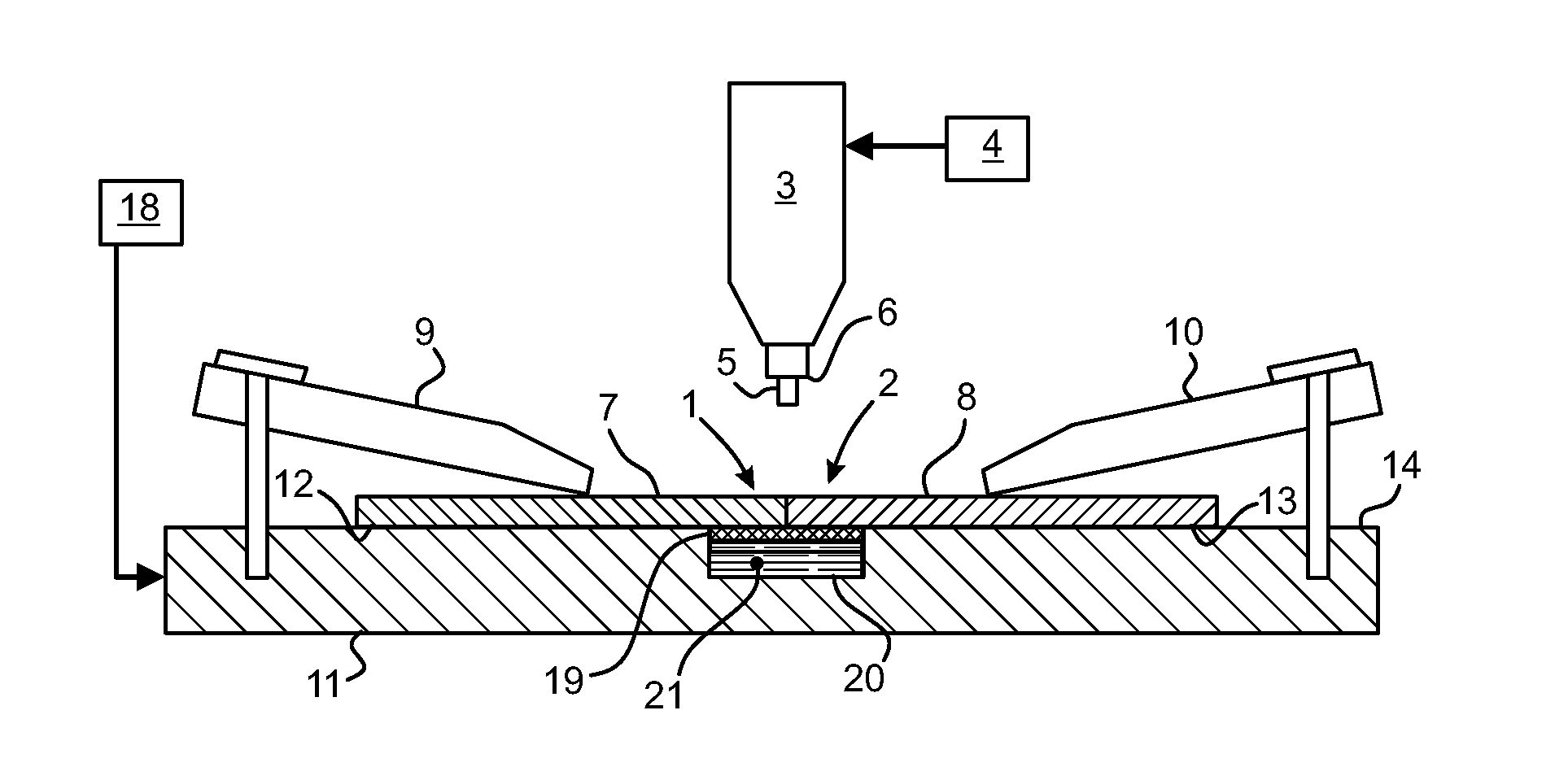

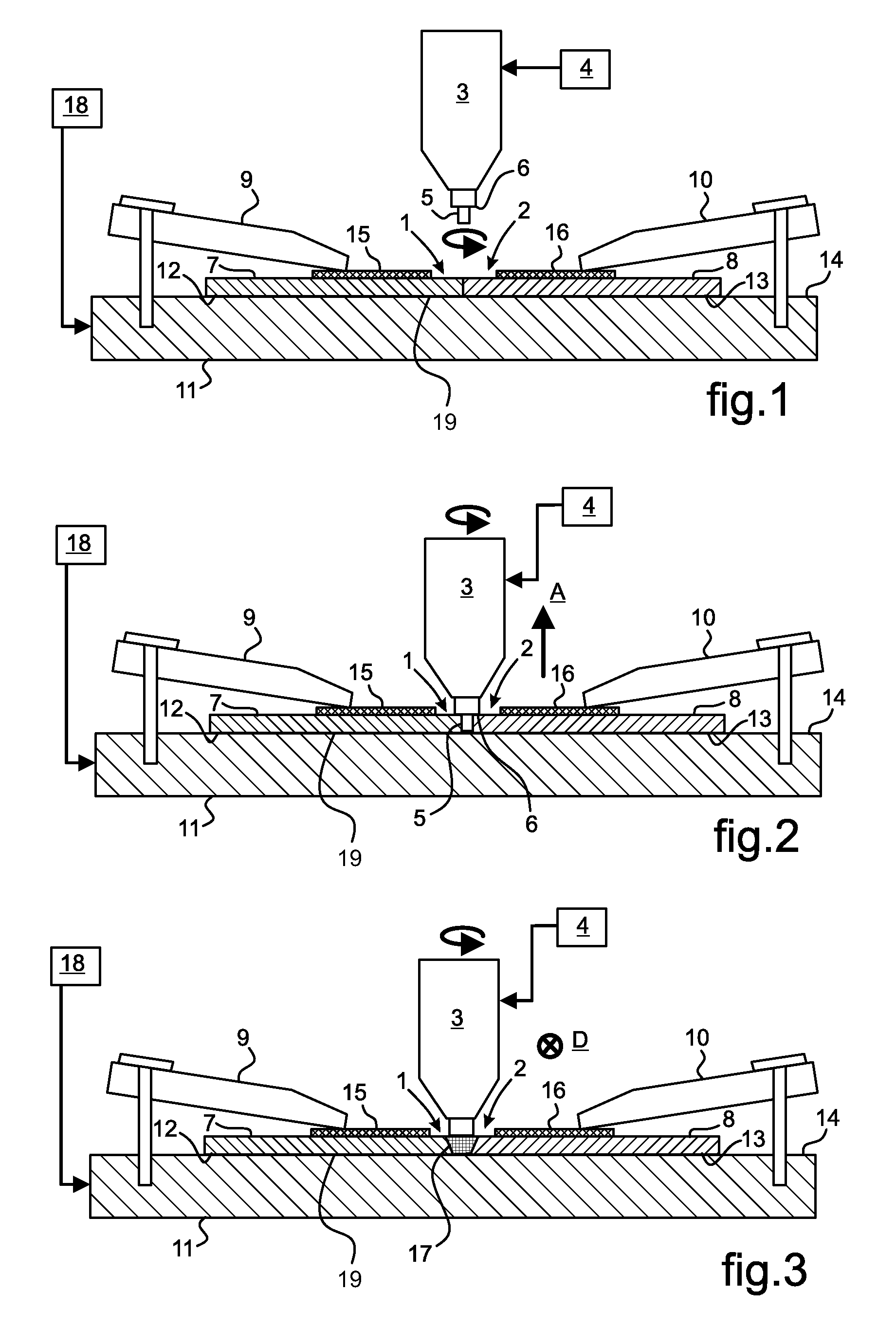

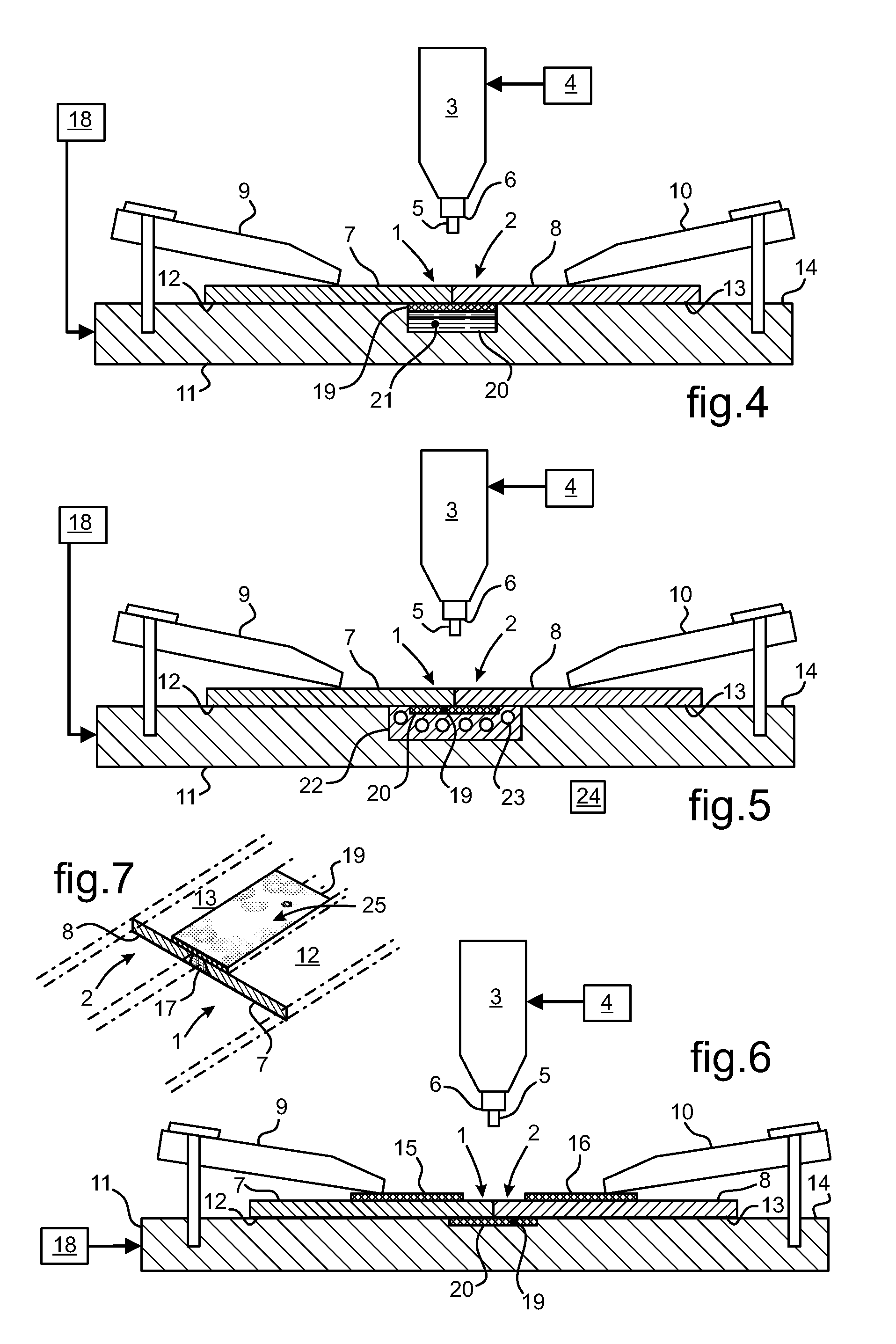

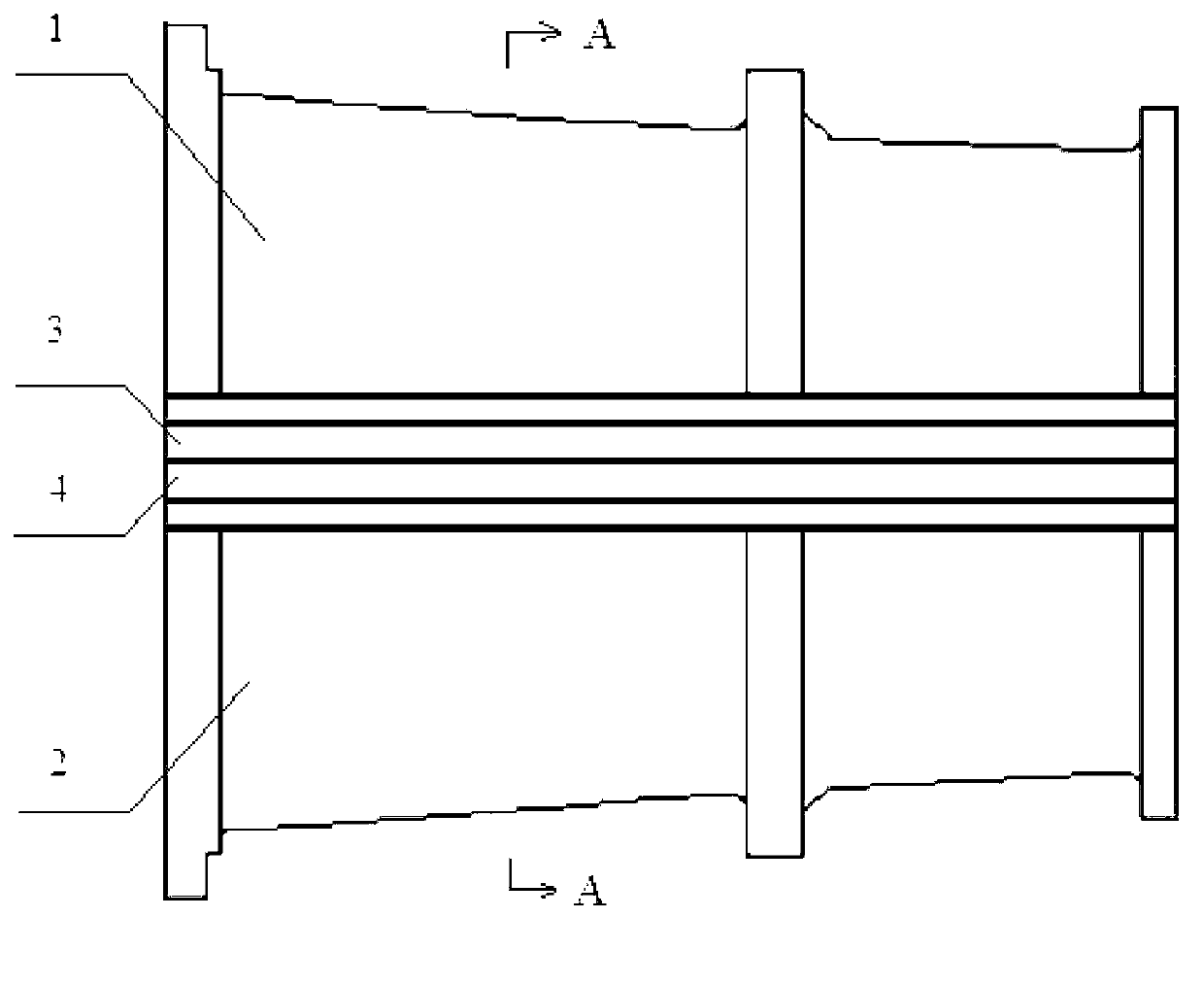

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS8393519B2Optimize rateHigh performance mechanical characteristicWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

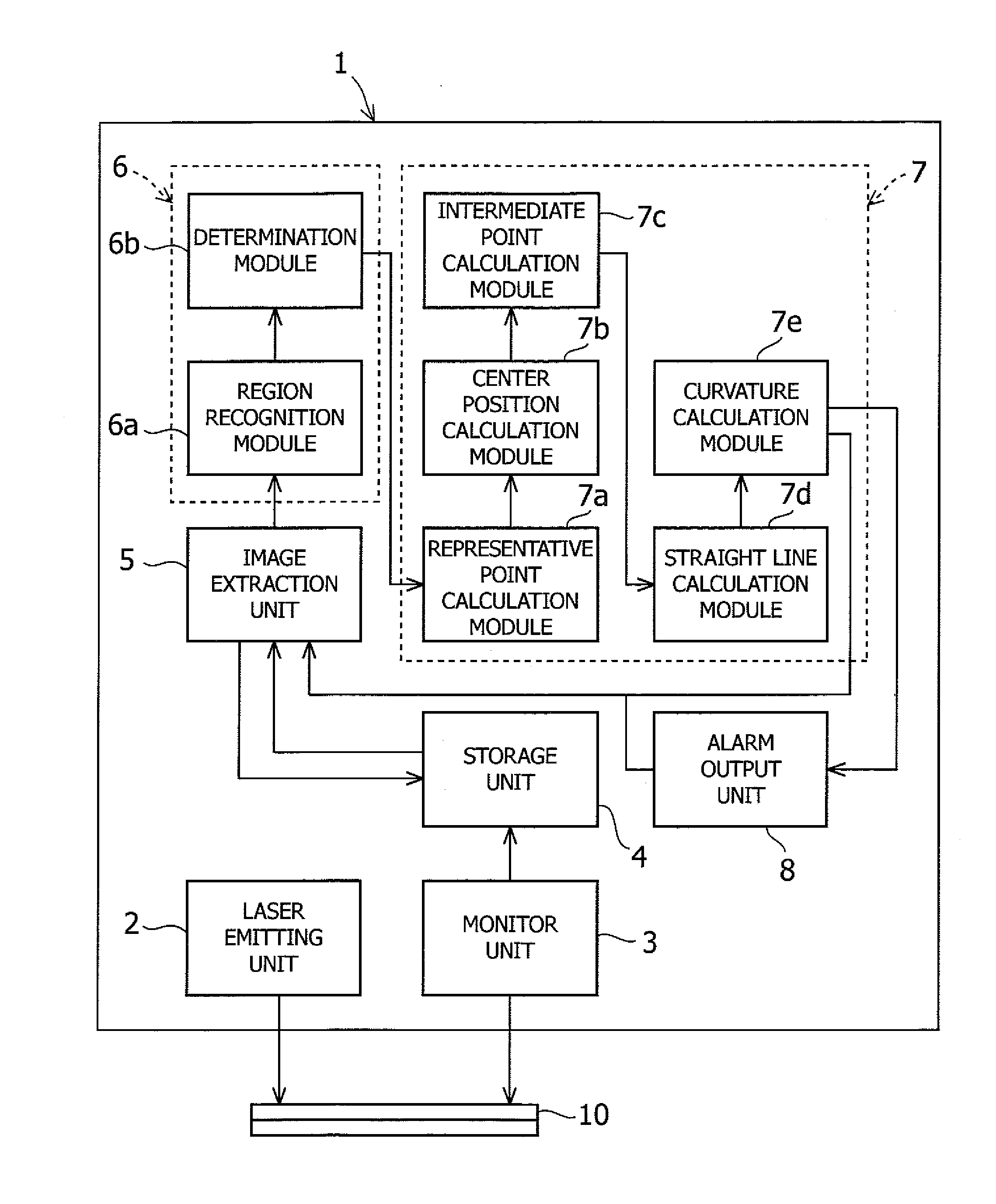

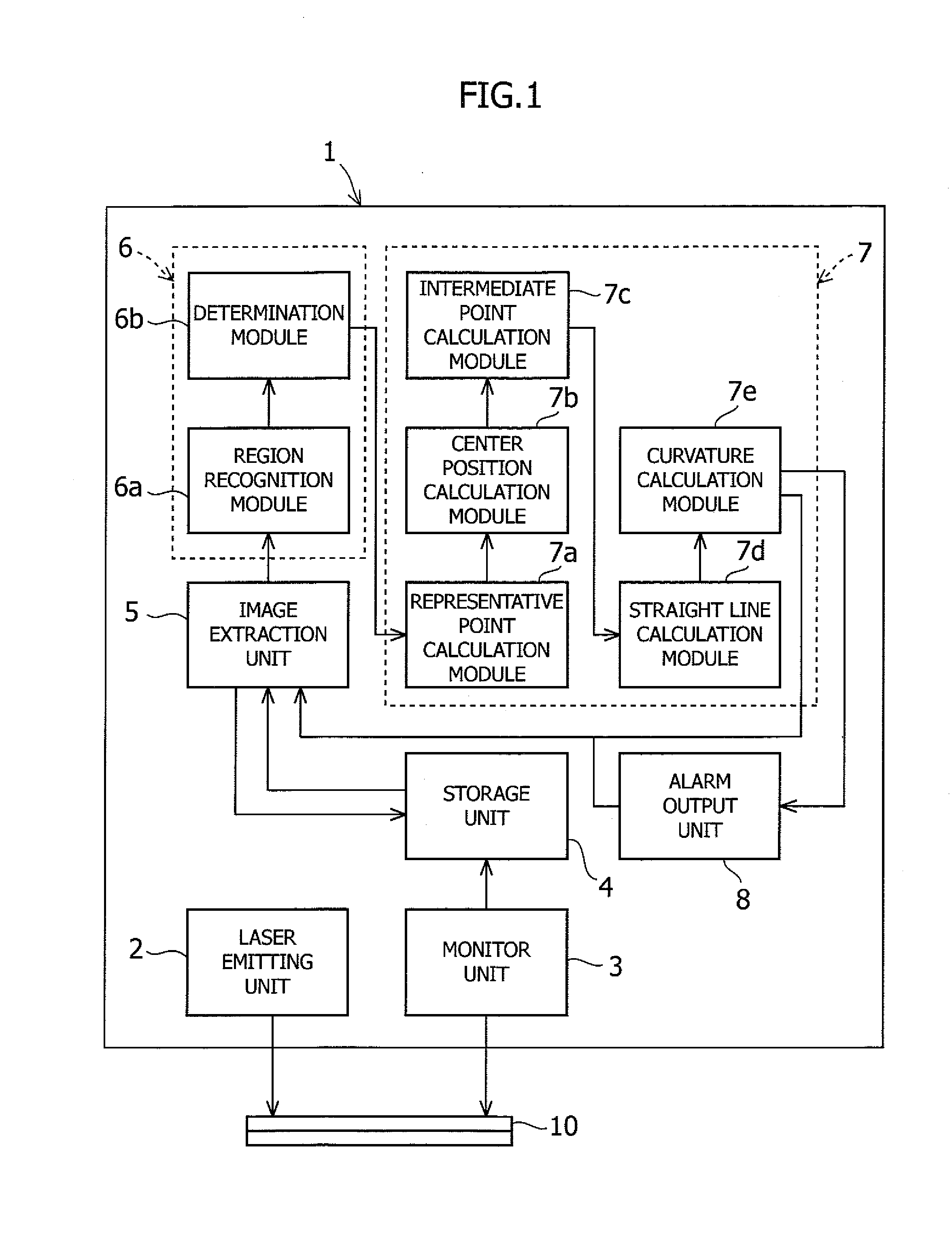

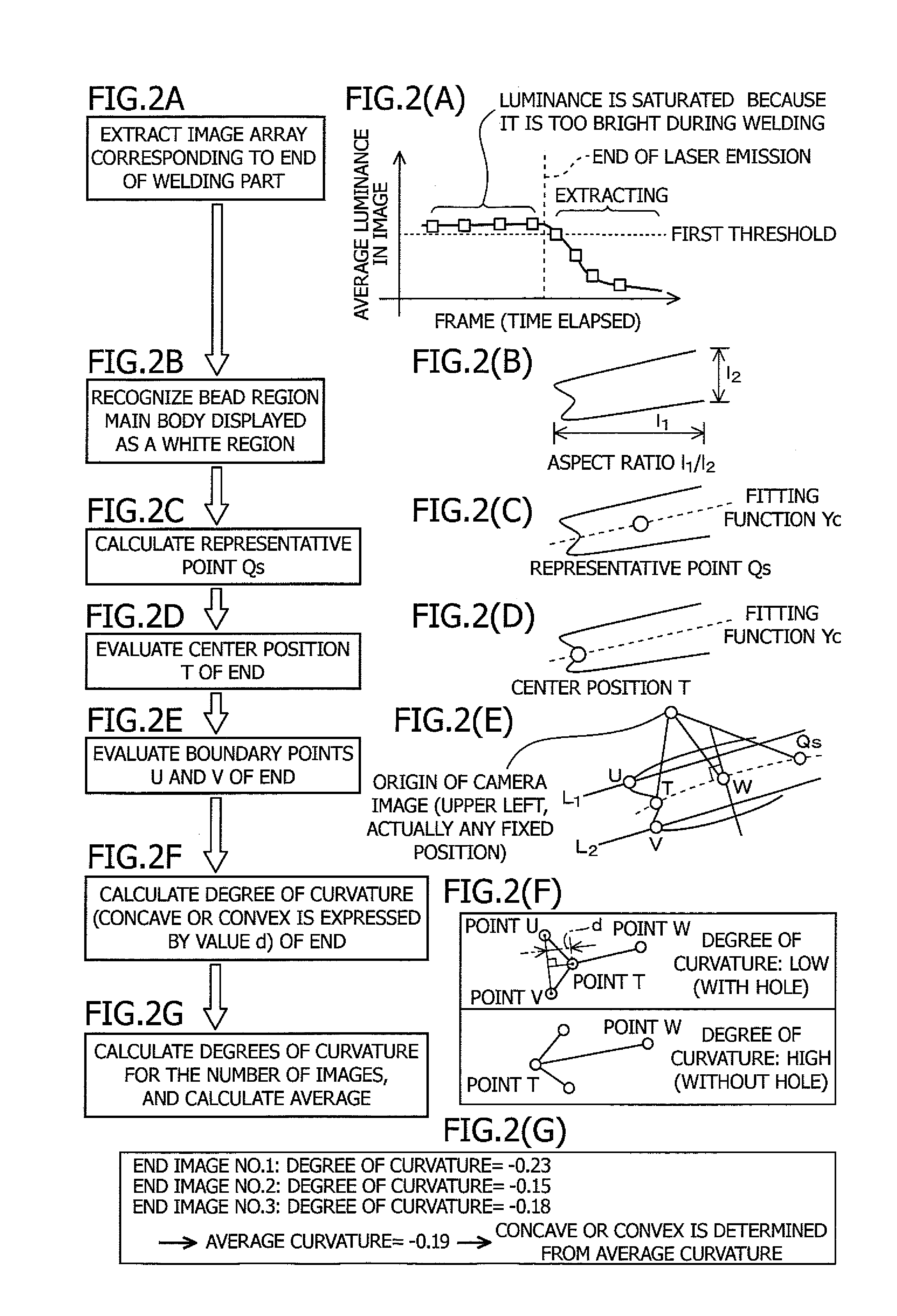

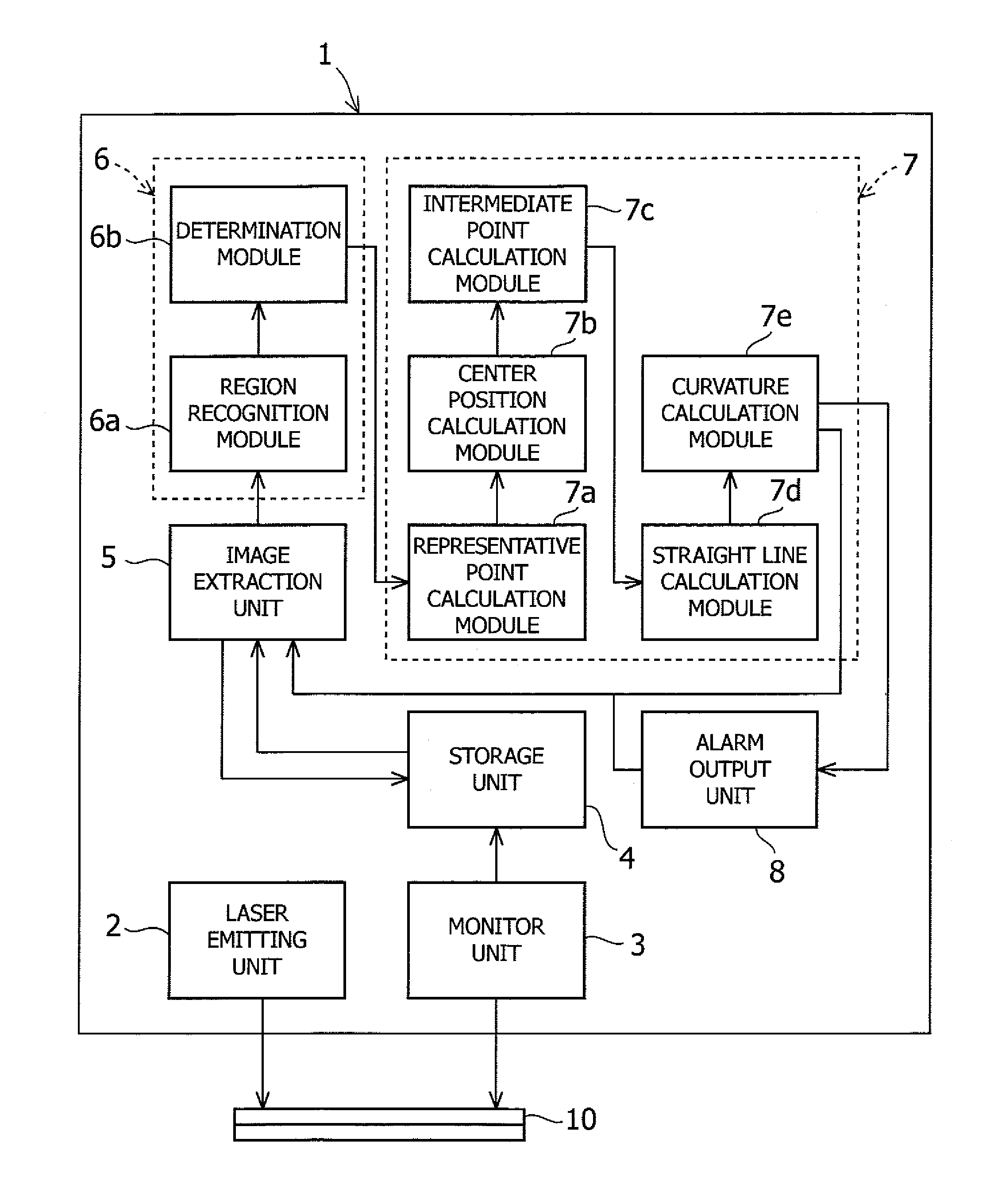

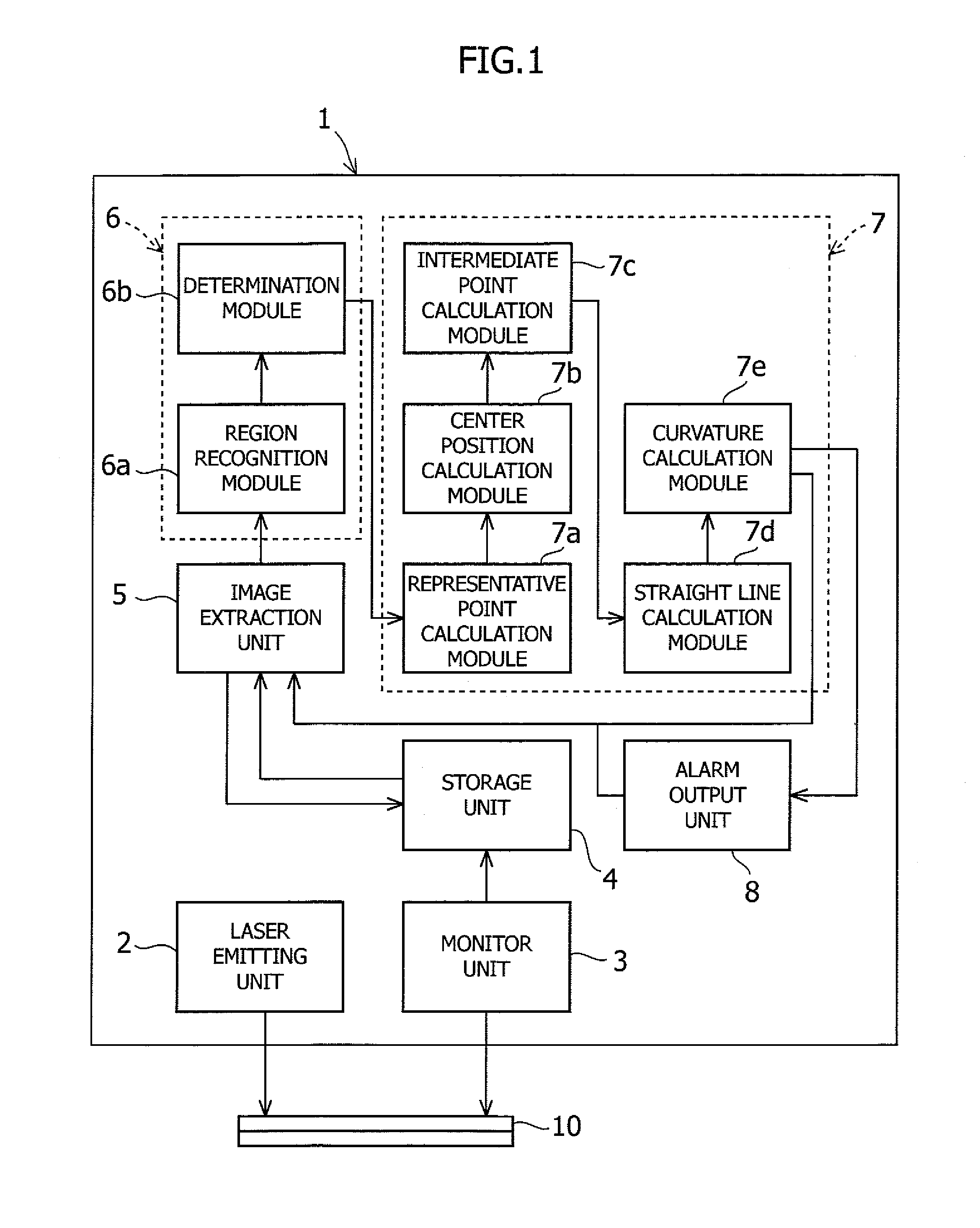

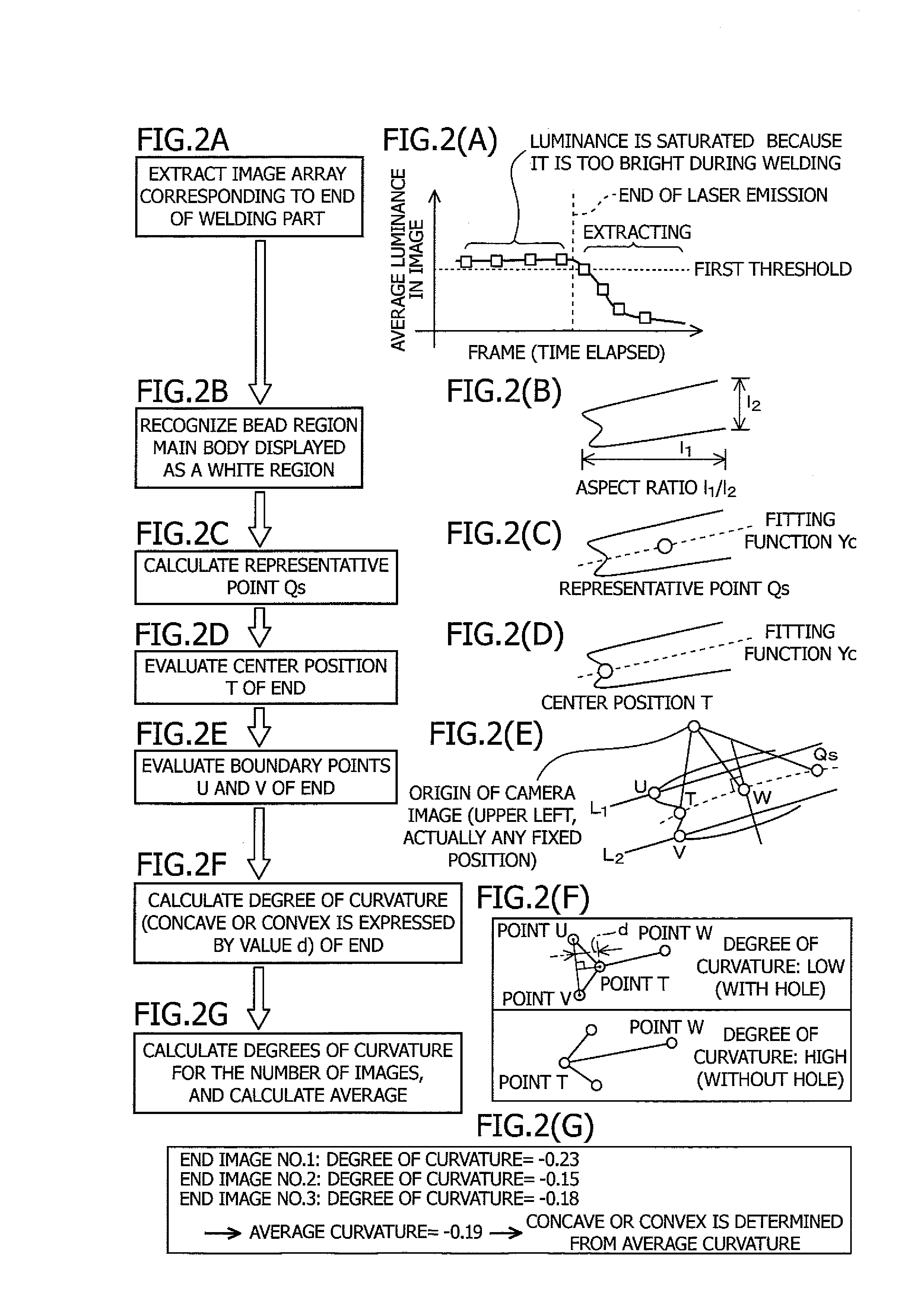

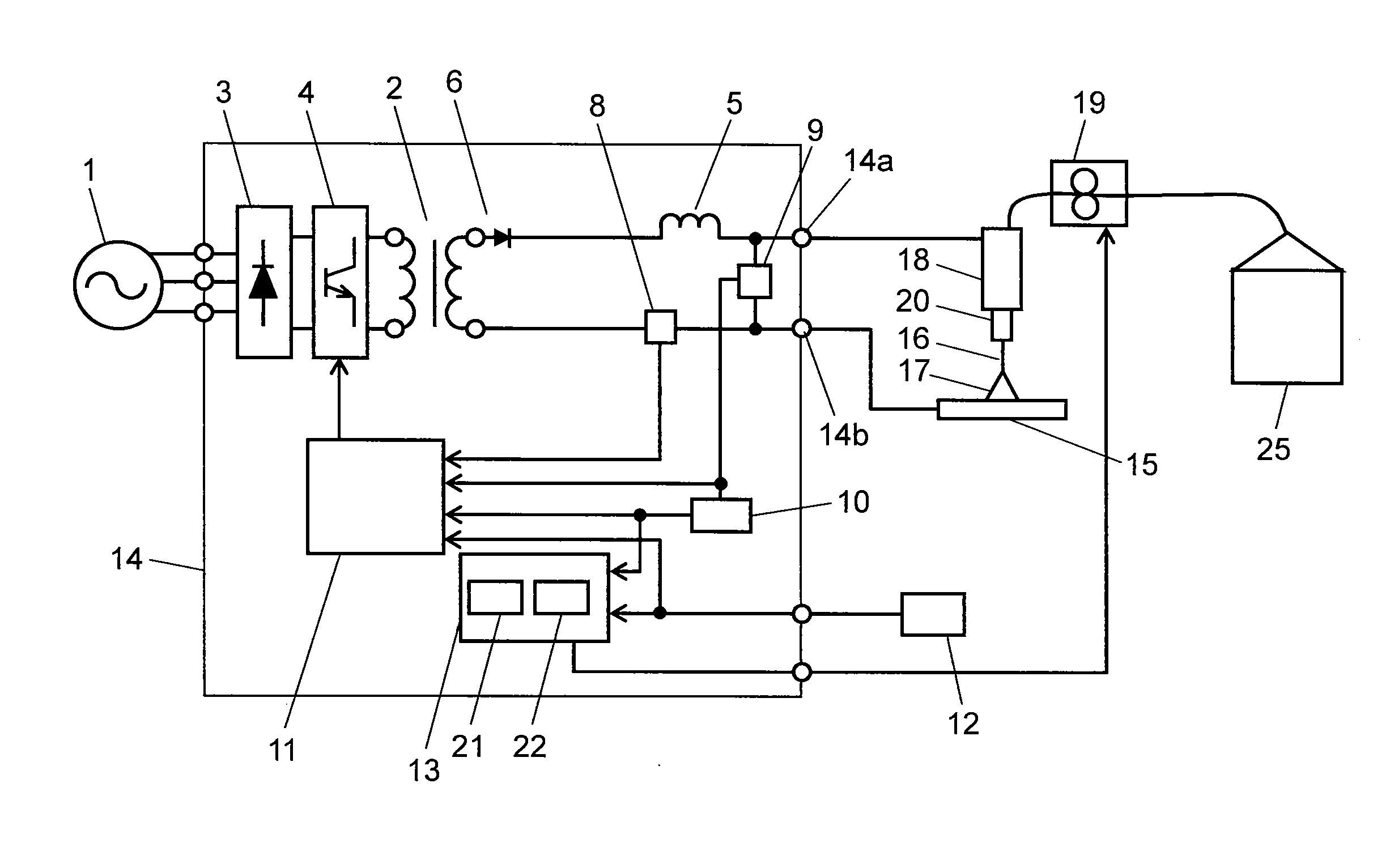

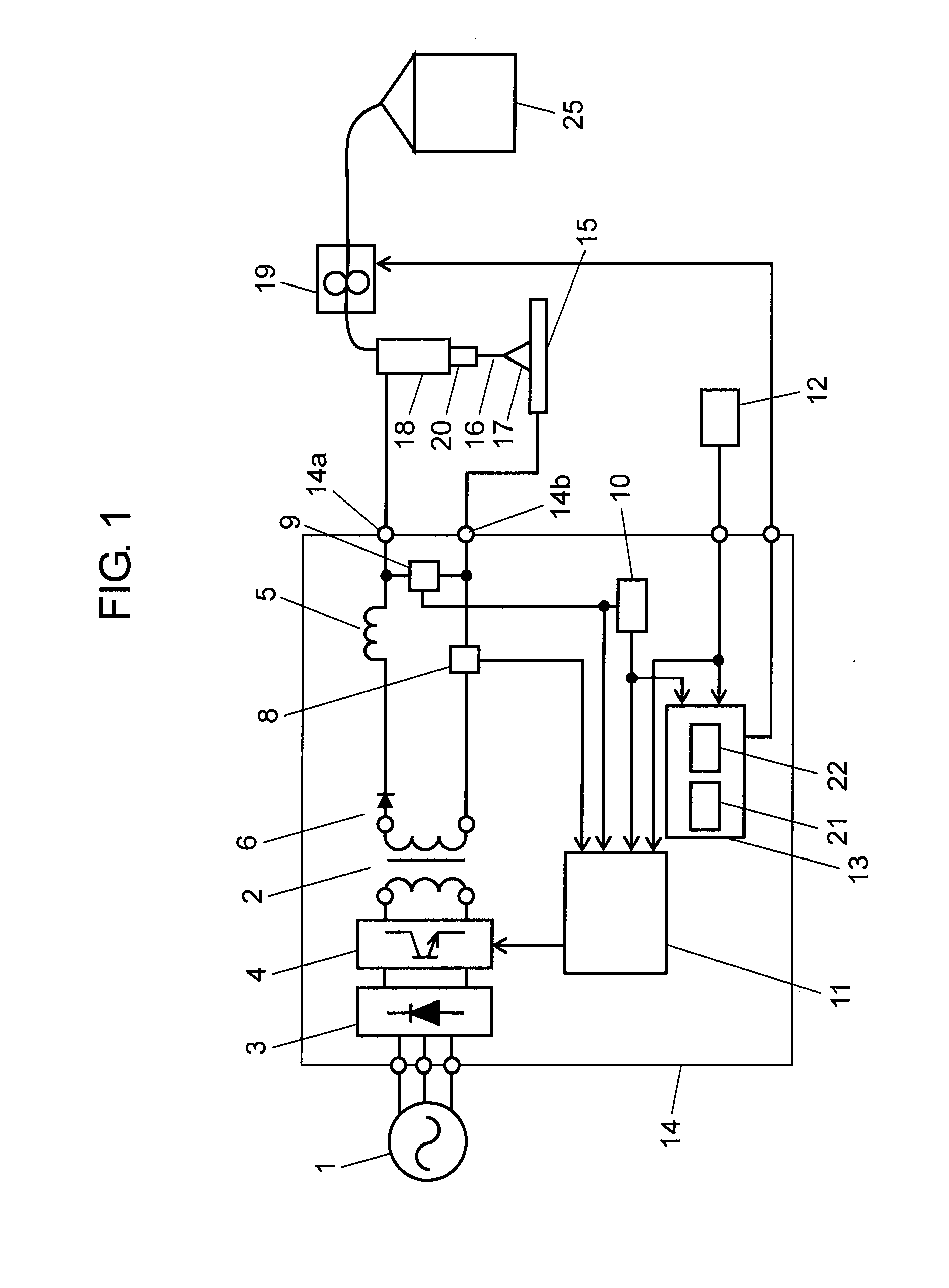

Apparatus and Method for Determining Shape of End of Welding Bead

InactiveUS20120048838A1Improve accuracySimple processUsing optical meansLaser beam welding apparatusImage extractionBead shape

An apparatus 1 of the present invention includes a laser emitting unit 2, a monitor unit 3, a storage unit 4, an image extraction unit 5, a bead recognition unit 6, and a bead shape determination unit 7. The bead shape determination unit 7 is configured to calculate the position of the end of a bead region based on the bead region recognized by the bead recognition unit 6, and to determine whether the shape of the end of the bead region is convex or concave in the extending direction of the bead region.

Owner:SUZUKI MOTOR CORP

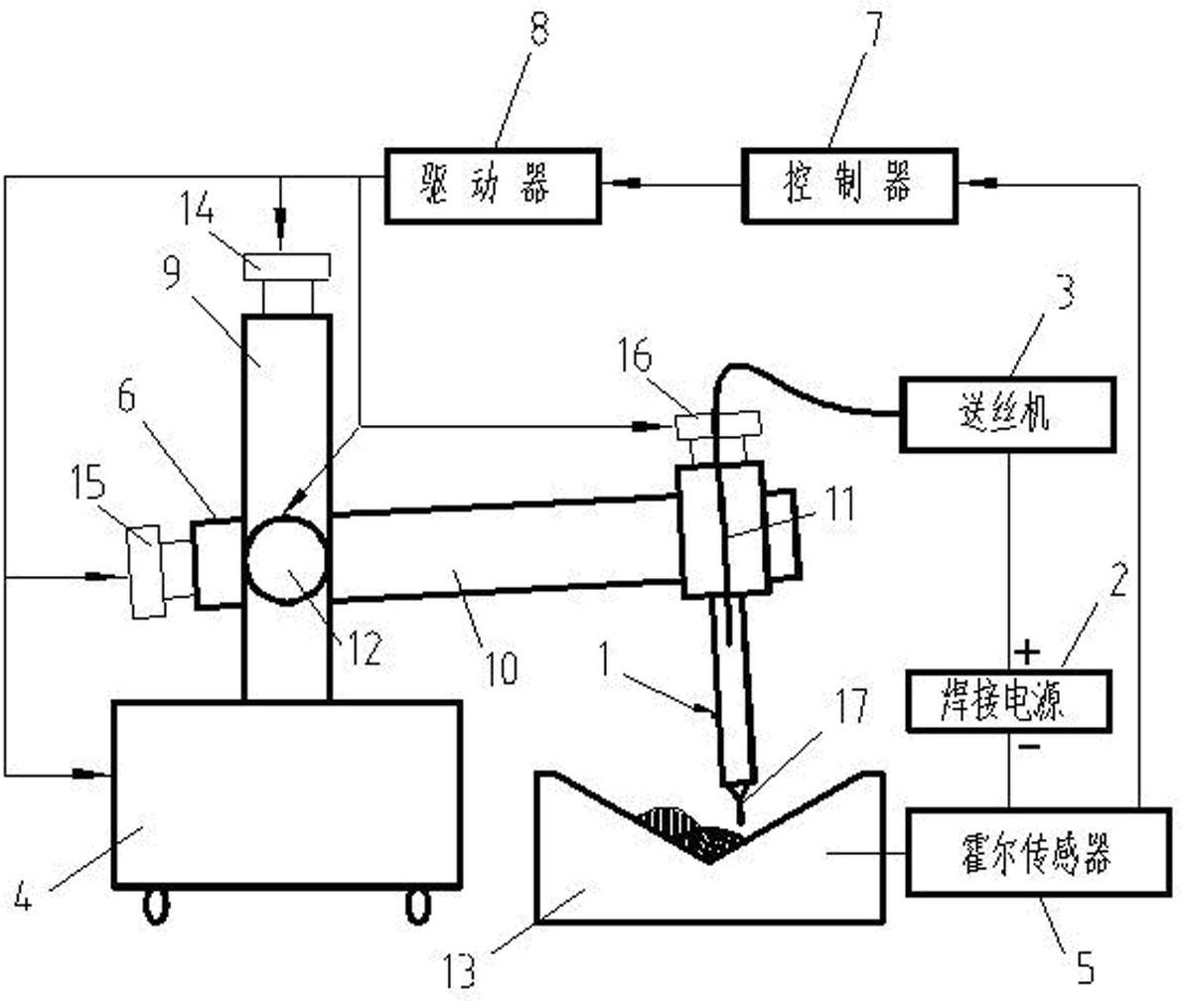

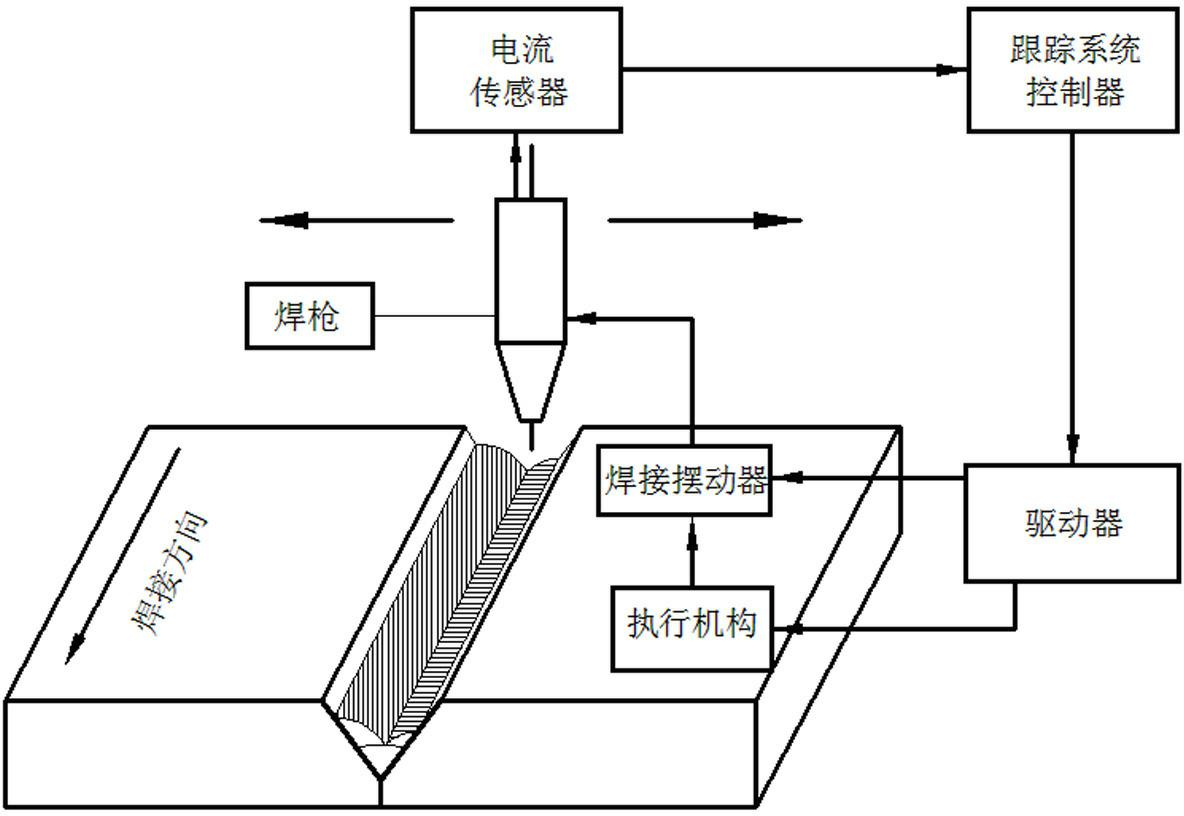

Swing arc-based multi-layer and multi-channel weld tracking system and identification method thereof

InactiveCN102615390AHigh precisionGuaranteed uptimeArc welding apparatusWelding power supplyCurrent sensor

Owner:XIANGTAN UNIV

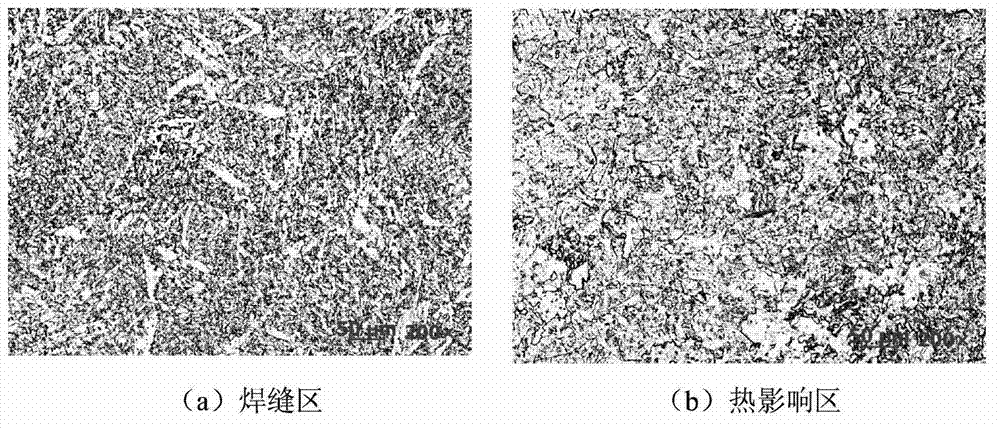

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

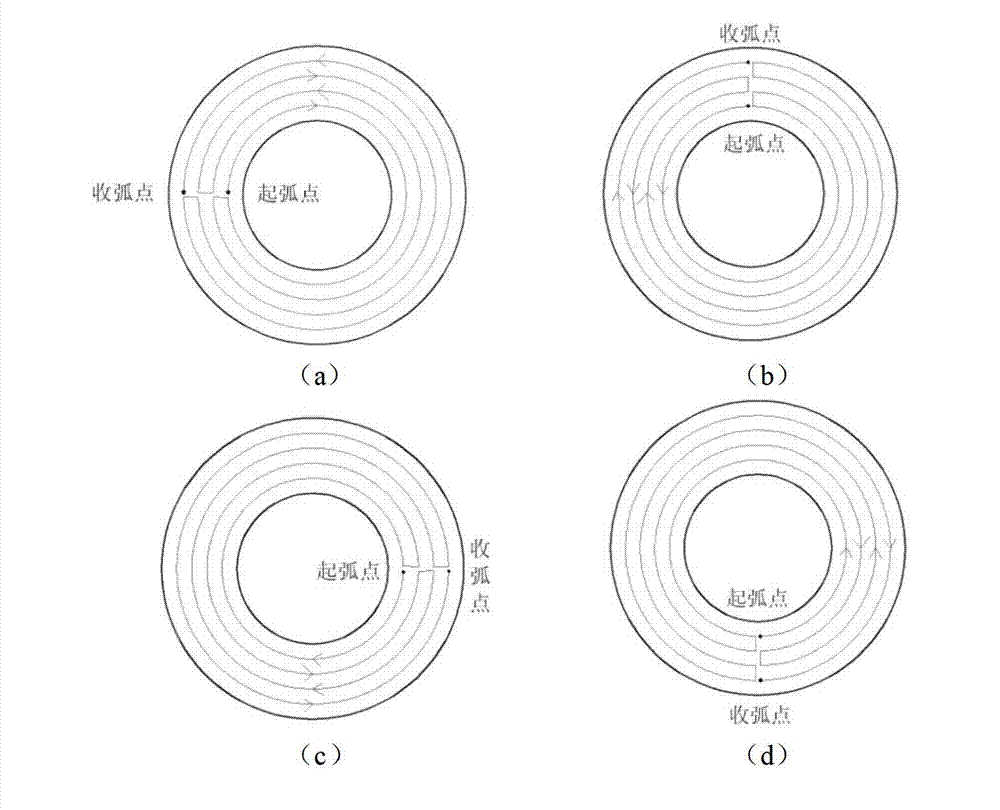

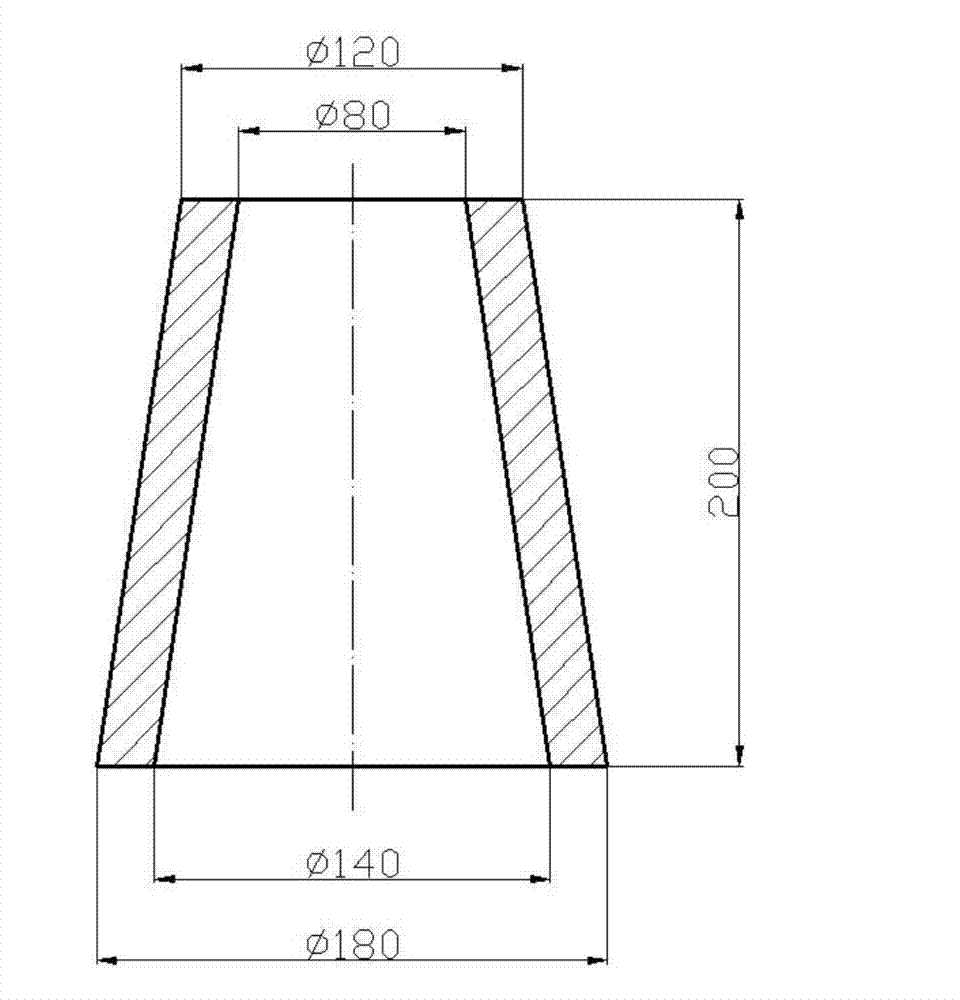

Manufacturing method of arc additive of titanium alloy structural part

ActiveCN102962547AImprove forming qualityUniform chemical compositionArc welding apparatusCrystalliteWeld bead

The invention provides a manufacturing method of an arc additive of a titanium alloy structural part. An arc wire feed additive manufacturing method is used to carry out welding of each layer of ring members, i.e., a wire feeder feeds welding wires, the welding wires are melted by a welding gun to weld, and ring welding beads from the inside to the outside are sequentially lapped to form a layer of ring members; and then one thickness of layer of the welding gun is increased, and the welding method is repeated to form another layer of ring members, and so forth; and finally, a plurality of layers of ring members are overlapped to form a titanium alloy structural part. The welding forming part provided by the invention has a fine and uniform grain size and good mechanical properties, and can meet or exceed the level of congruent castings, and the product has a short development cycle and high processing efficiency.

Owner:CAPITAL AEROSPACE MACHINERY +1

Apparatus and method for determining shape of end of welding bead

InactiveUS8946595B2Improve accuracyReduce transmittanceUsing optical meansLaser beam welding apparatusImage extractionBead shape

Owner:SUZUKI MOTOR CORP

Consumable electrode arc welding method and consumable electrode arc welding device

ActiveUS20120074114A1Uniform beadImproved arc stabilityWelding/cutting media/materialsWelding electrode featuresMechanical engineeringElectric arc

If a short circuit does not occur during deceleration of a wire feed speed in forward feed of a welding wire before the wire feed speed reaches a predetermined wire feed speed, a cyclic change is stopped and the wire feed speed is constantly controlled at the first feed speed. If a short circuit occurs during forward feed at the first feed speed, deceleration from the first feed speed starts, and the cyclic change is resumed for welding. This achieves uniform weld bead without increasing spatters even if any external disturbance such as change of distance between a tip and base material occurs.

Owner:PANASONIC CORP

Method of cladding, additive manufacturing and fusion welding of superalloys and materialf or the same

The present concept is a method of substantially crack-free cladding, fusion welding and additive manufacturing of superalloys. The method involves the application of a high temperature pre-alloyed filler powder that includes melting point depressants, to a superalloy base material. The base material and pre-alloyed filler powder are heated to a temperature that will fully melt the pre-alloyed filler powder and also melt a surface layer of the base material, thereby forming a weld pool. Upon solidification and cooling of the weld pool, there is coalescence between a weld bead and the base material thereby forming the weld bead which is substantially crack-free. The high temperature pre-alloyed filler powder consists in wt % of the following chemical elements: Co 9-15%; Al 3-6.5%; C 0.1-0.2%; Ti, Zr and Hf with a total content from 1 to 8.5%; Ta and Nb with a total content from 0.5 to 8.5%; W and Mo with a total content from 7 to 20%; Cr and Re with a total content from 6.5 to 18.5%; Fe and Mn with a total content from 0.1 to 1%; B 0.1-0.6% with Ni and impurities to balance.

Owner:LIBURDI ENG

Self-shielded flux cored electrode for fracture critical applications

InactiveUS20060096966A1Enhances weld layer(s) layer(s)Enhances layer(s) buffer layer(s)Welding/cutting media/materialsSoldering mediaSlagCerium

A self shielding cored electrode used to form weld beads having high Charpy V-Notch toughness. The cored electrode includes a metal sheath and fill composition. The fill composition includes a slag system having a gas generating compound, magnesium and at least three metals selected from the group consisting of aluminum, cerium, titanium and zirconium.

Owner:LINCOLN GLOBAL INC

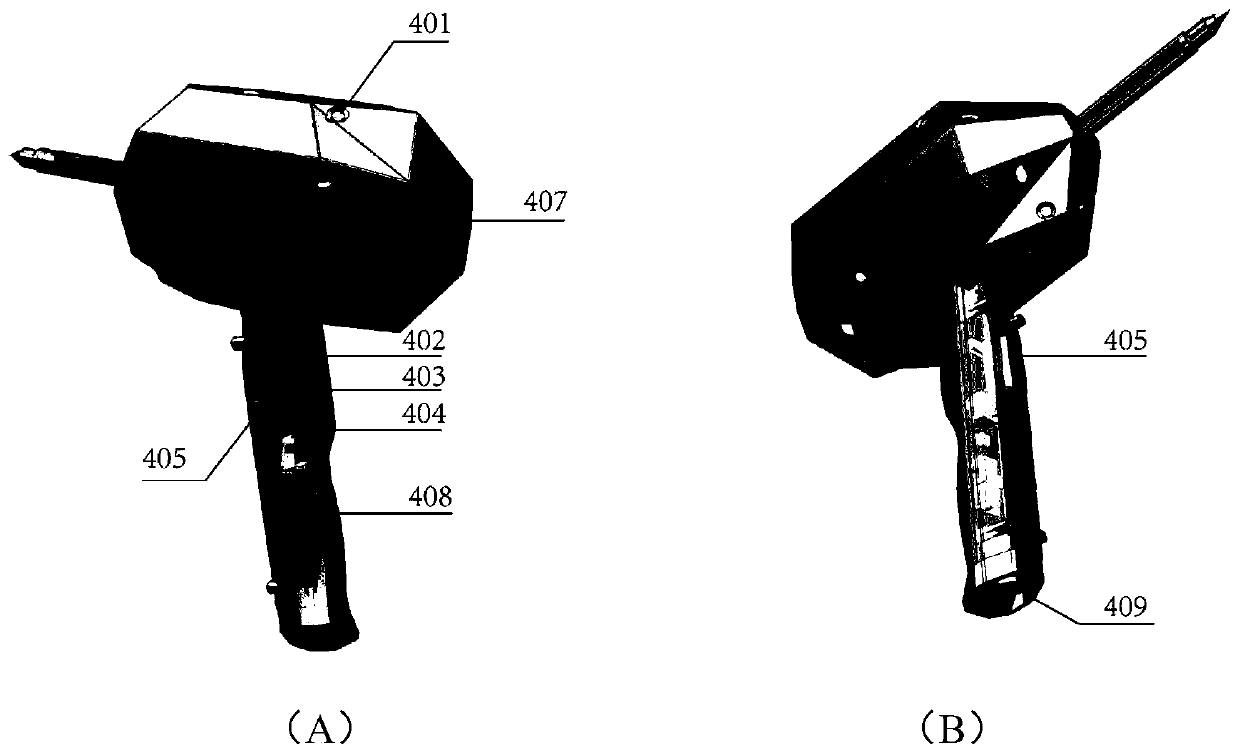

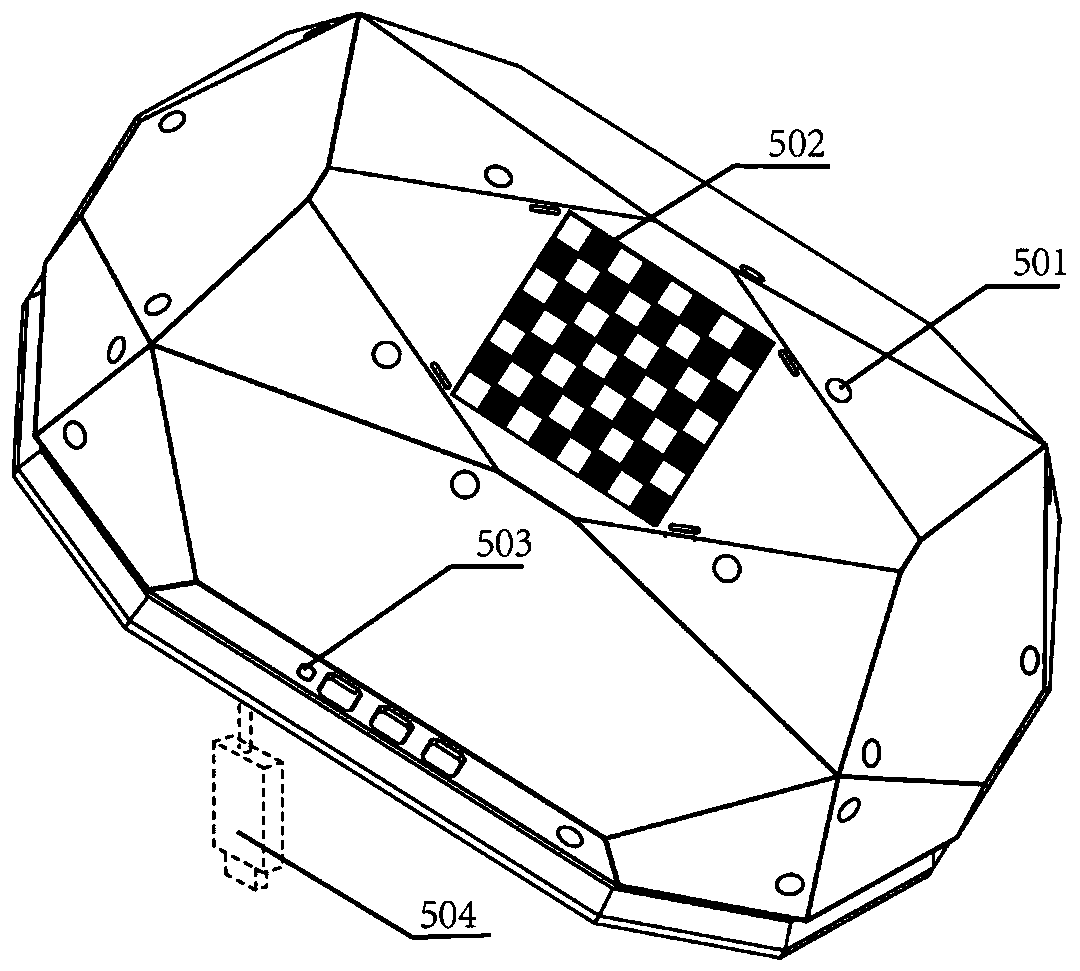

Laser-vision sensing assisted remote teaching method for remote welding

The invention discloses a laser-vision sensing assisted remote teaching method for remote welding, relating to a remote teaching method for remote welding. The purpose of the invention is to solve the problems of difficult-completed remote teaching of complex weld bead in remote welding and long time consumption of position and attitude adjustment of a welding gun in teaching. The method comprises the following steps: 1. initializing a system; 2. setting a weld joint type; 3. automatically obtaining weld bead feature points; 4. calculating to obtain weld bead teaching points Ti = Ps + Rr; 5. recording and forming a teaching point sequence; 6. judging whether the teaching points are enough; 7. downloading a remote teaching program; 8. and finishing teaching. The method is used for remote welding.

Owner:HARBIN INST OF TECH

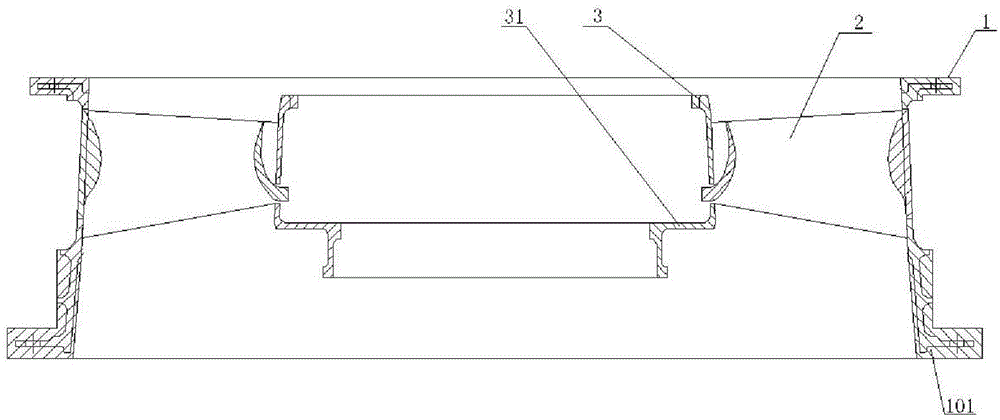

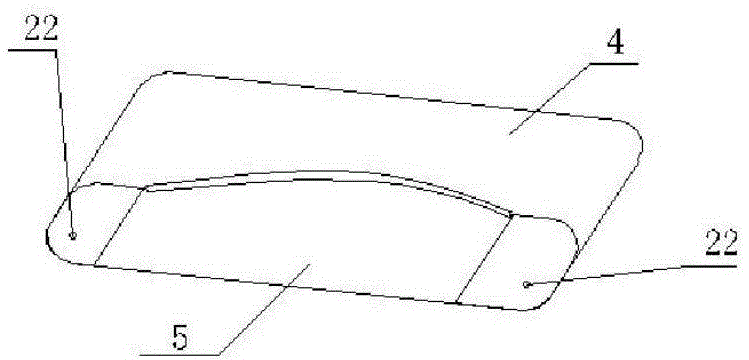

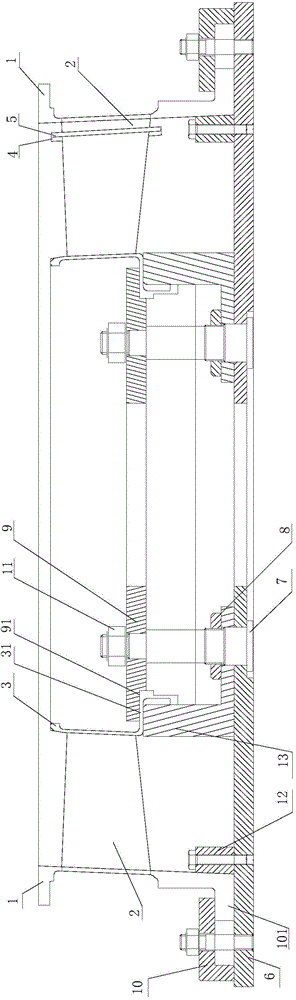

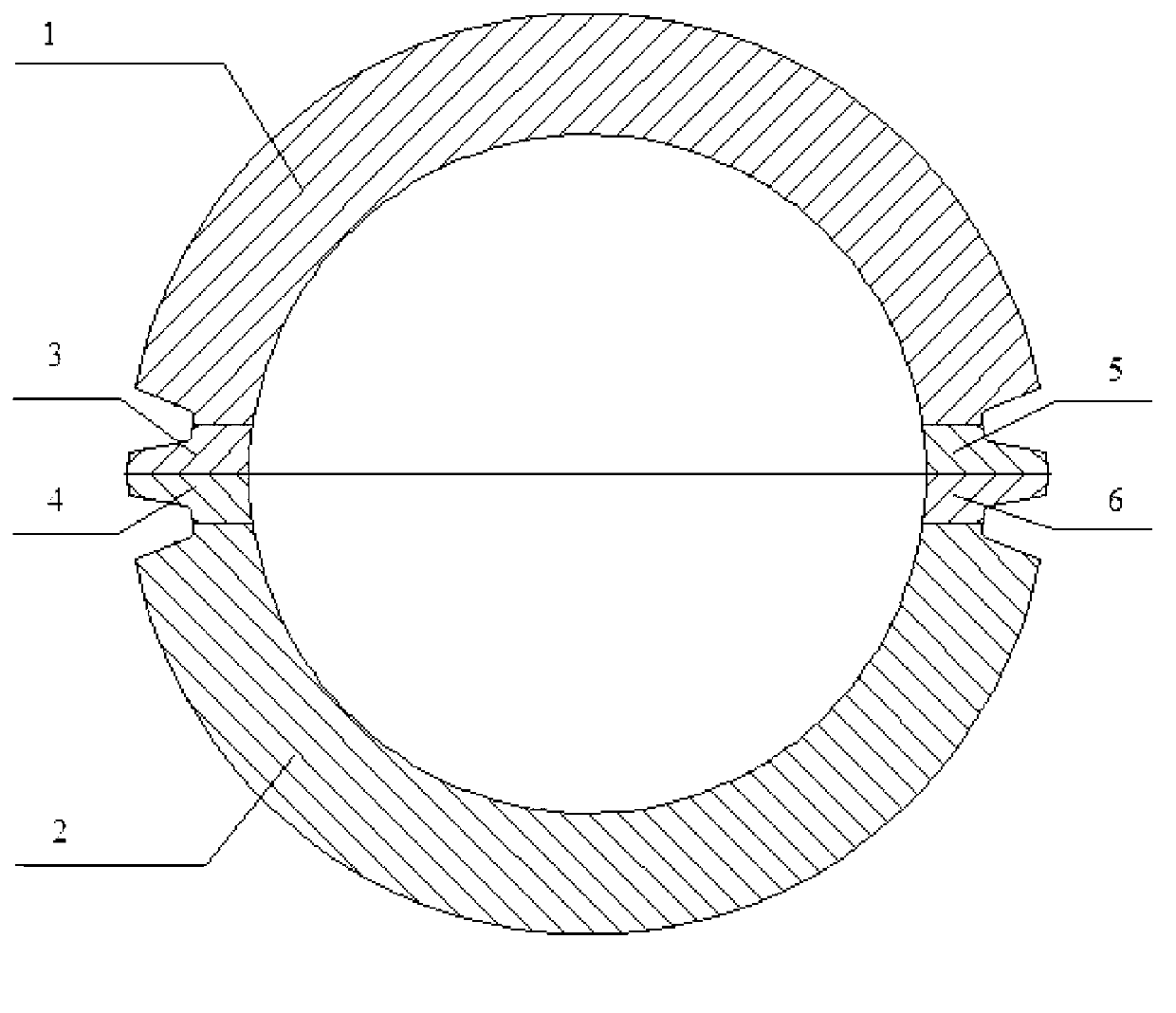

Fan casing assembly welding method and tool for fan casing assembly welding method

ActiveCN104439730AImprove molding qualityControl heightWelding/cutting auxillary devicesWork holdersEngineeringWelding process

The invention discloses a fan casing assembly welding method and a tool for the fan casing assembly welding method and belongs to the technical field of the welding technology. By the adoption of the fan casing assembly welding method and the tool for the fan casing assembly welding method, the problems that in the welding process, the weld joint forming quality is poor, root reinforcement exists on a weld joint, deformation is serious, dimension errors are large and blade protection is difficult are solved. The fan casing assembly welding method comprises the following steps of preparation before welding, positioning, assembly of a baffle, electron beam welding, inspection after welding, assembly of a heat treatment tool and vacuum heat shaping. The baffle is composed of an upper plate and a lower plate. The fixing tool for welding comprises a base plate, a shaft, a gland, a positioning ring, a supporting ring and a plurality of pressing plates. The heat treatment tool comprises a base plate, a cover plate and a plurality of pressing blocks.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

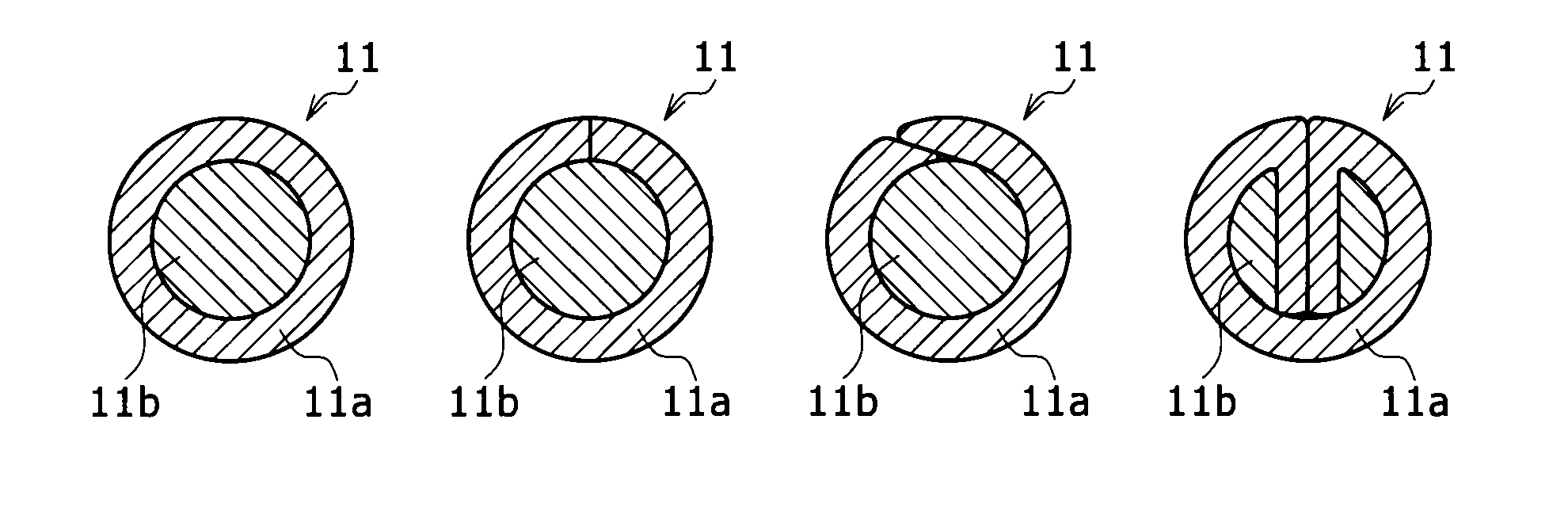

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

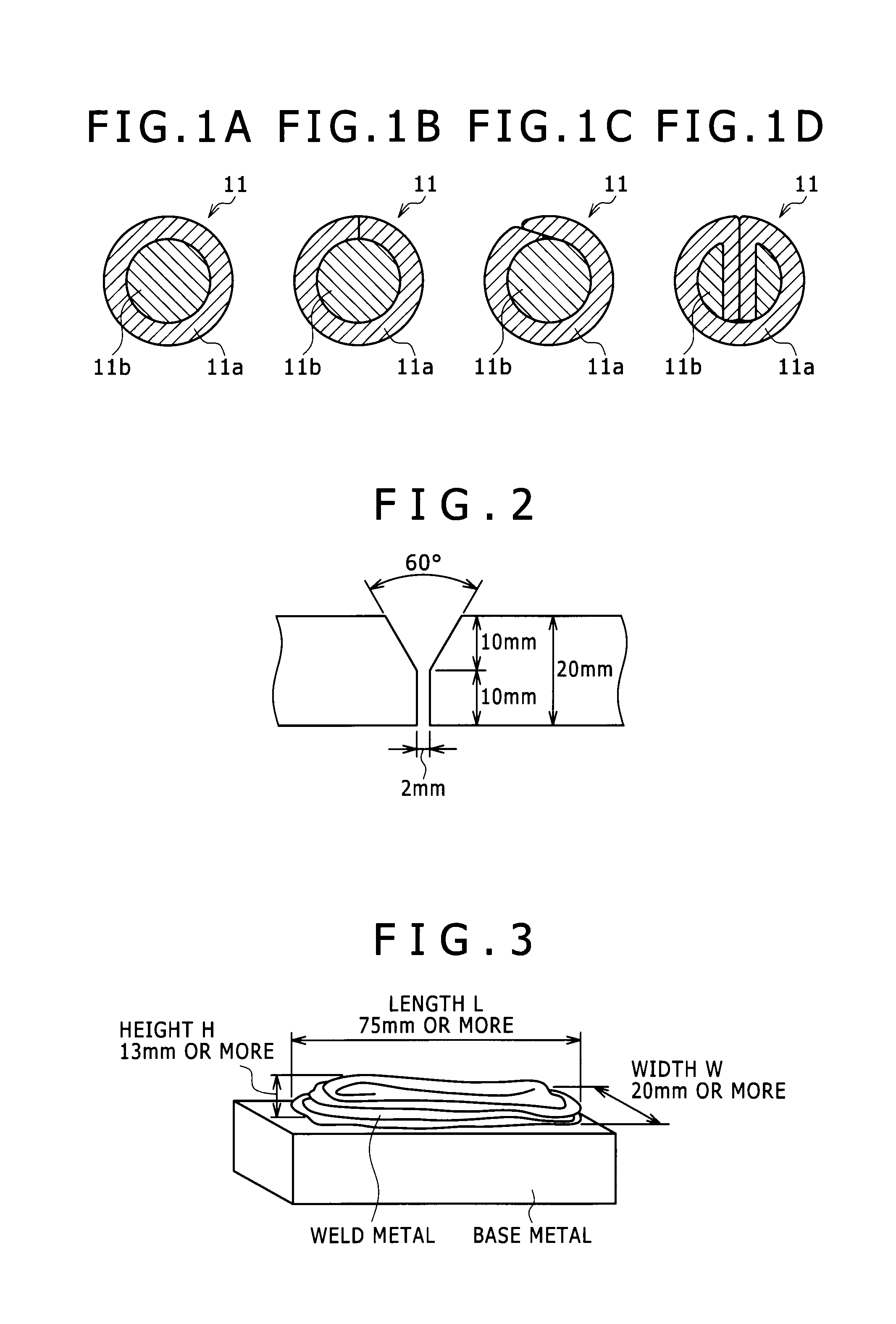

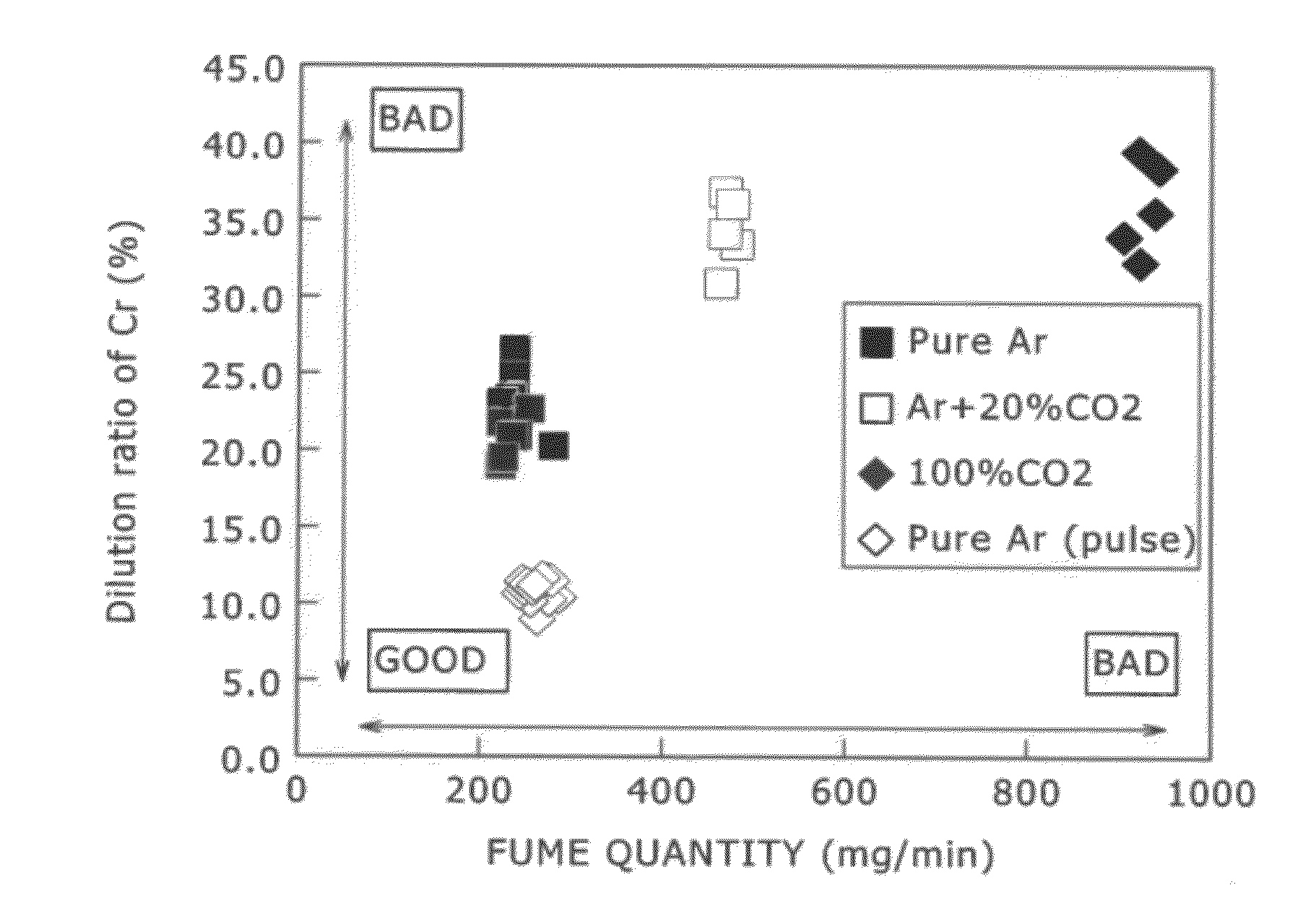

Flux-cored welding wire and method for arc overlay welding using the same

InactiveUS20120055903A1Improve solderabilityLow dilution ratioArc welding apparatusWelding/cutting media/materialsShielding gasCorrosion resistant

To provide a flux-cored welding wire and a method for arc overlay welding attaining excellent weldability and low dilution ratio and obtaining a weld bead excellent in corrosion resistance in overlay welding using the flux-cored welding wire having an advantage of high deposition rate and deposition efficiency. The flux-cored welding wire for gas shielded arc welding including flux filled up in an outer sheath and using pure Ar as a shielding gas contains, as percentage to the total mass of the flux-cored welding wire, C: 0.20 mass % or below, Si: 15.00 mass % or below, Mn: 20.00 mass % or below, P: 0.0500 mass % or below, S: 0.0500 mass % or below, and Cr: 15.0-50.0 mass %, with the remainder being Fe and inevitable impurities.

Owner:KOBE STEEL LTD

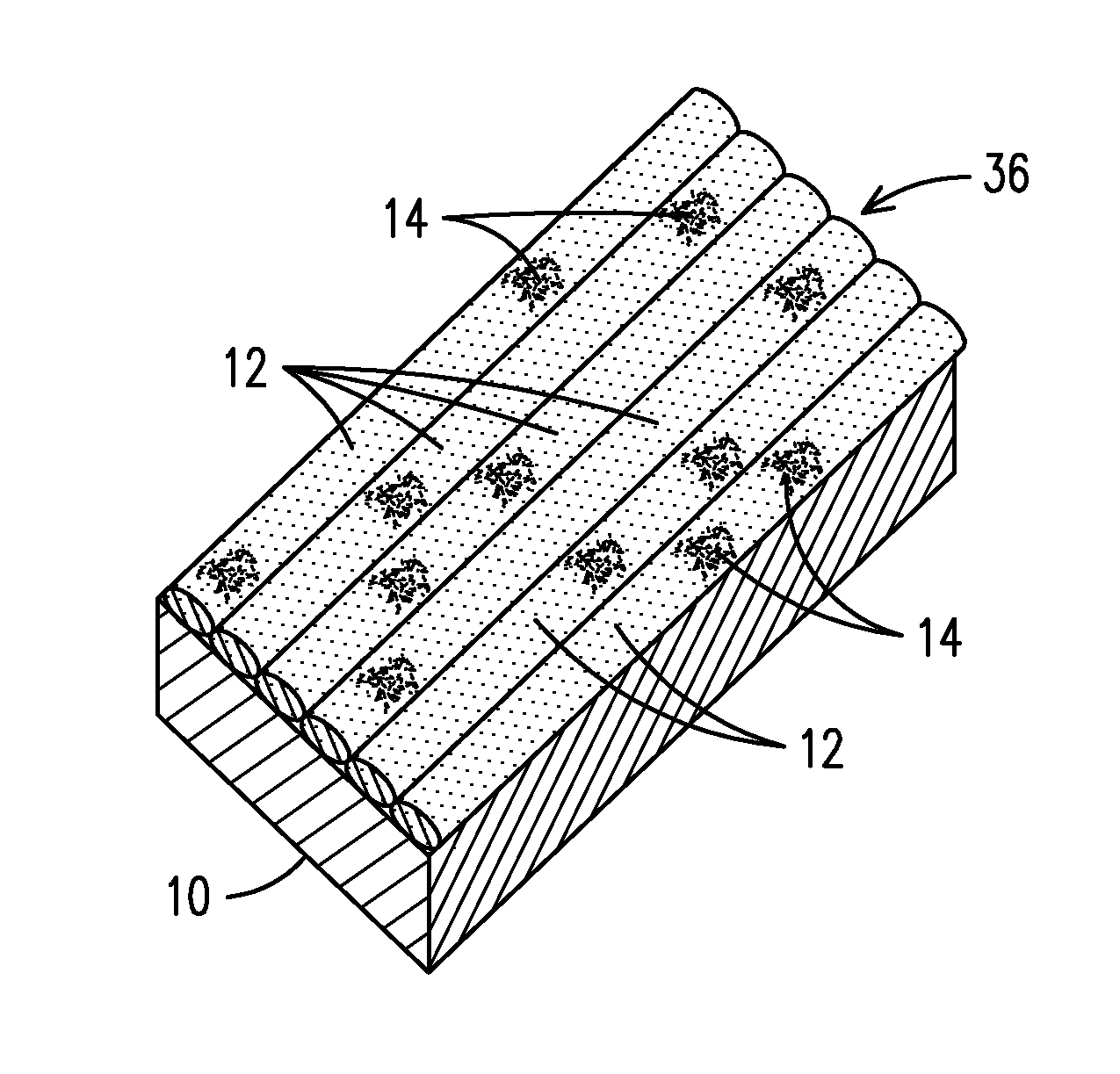

Earth-boring tools having particle-matrix composite bodies, methods for welding particle-matrix composite bodies and methods for repairing particle-matrix composite bodies

Methods for welding a particle-matrix composite body to another body and repairing particle-matrix composite bodies are disclosed. Additionally, earth-boring tools having a joint that includes an overlapping root portion and a weld groove having a face portion with a first bevel portion and a second bevel portion are disclosed. In some embodiments, a particle-matrix bit body of an earth-boring tool may be repaired by removing a damaged portion, heating the particle-matrix composite bit body, and forming a built-up metallic structure thereon. In other embodiments, a particle-matrix composite body may be welded to a metallic body by forming a joint, heating the particle-matrix composite body, melting a metallic filler material forming a weld bead and cooling the welded particle-matrix composite body, metallic filler material and metallic body at a controlled rate.

Owner:BAKER HUGHES INC

Wire electrode with improved slag properties

ActiveUS20060186103A1Easy to shapeIncrease and decrease viscosityWelding/cutting media/materialsSoldering mediaIndiumMolten slag

A metal core electrode used to form weld deposits having improved slag forming properties with respect to reduced accumulation of slag in toes of the weld bead. The metal cored electrode includes a metal rod and a fill composition. The electrode includes a slag-modifying additive that contains metallic indium and / or one or more indium compounds.

Owner:LINCOLN GLOBAL INC

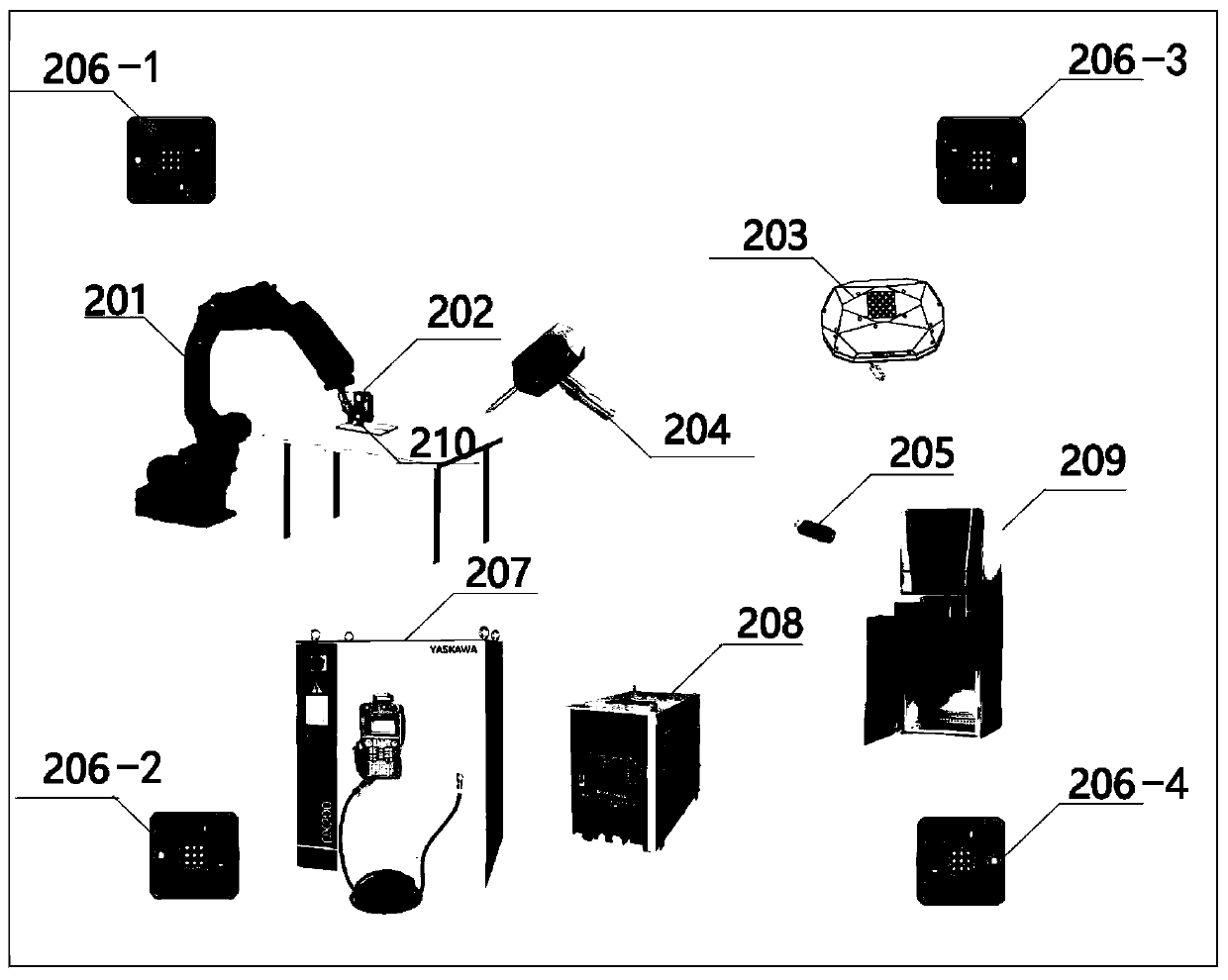

Industrial robot visual servo system and servo method and device

InactiveCN110039523ARealize real-time trackingOptimize workflowProgramme-controlled manipulatorWelding/cutting auxillary devicesRobot controlReal time tracking

The embodiment of the invention discloses an industrial robot visual servo system and a servo method and device. The industrial robot visual servo system comprises a six-axis robot, a weld joint tacker, a calibration object, a wireless handheld demonstrator, a USB wireless receiver, an infrared laser positioning base station, a robot control cabinet, a welding machine power supply control cabinet,an upper computer control cabinet and an automatic wire feeding system. Rapid demonstration without programming is achieved, non-uniform workpiece incoming is avoided, and real-time tracking of welding thermal deformation is achieved; the working process of a traditional welding automatic system is improved, and an operator does not need to use the demonstrator to carry out complex demonstrationprogramming; as the recognition technology based on deep learning is adopted for weld joint tracking, the universality of welding automation is greatly improved; and in addition, welding path planning, demonstration, system calibration and welding real-time tracking are completely integrated in the same upper computer interface, and therefore the process operation and management can be conveniently carried out by the operator.

Owner:北京无远弗届科技有限公司

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Electron beam welding method of gas turbine casing with horizontal flange structure

ActiveCN102990217AImprove manufacturing levelLow costElectron beam welding apparatusStructural engineeringSpot welding

The invention discloses an electron beam welding method of a gas turbine casing with a horizontal flange structure, and relates to the welding method of the casing with horizontal flanges. The invention aims at solving the technical problems of large deformation, complicated tooling design and manufacture, low repetition usage rate of the tooling and low production efficiency after the horizontal flanges are welded by the existing half-ring gas turbine casing welding method. The welding method comprises the following steps of: 1, machining; 2, cleaning the surfaces of parts to be welded; 3, spot welding; 4, scribing; 5, assembling; 6, spot welding at fixed positions; 7, centering; 8, interpolating, and 9, welding the electron beam. Once vacuum electron beam welding of four horizontal flanges is achieved by the welding method disclosed by the invention; the deformation after welding is small; the production efficiency is doubled; X-ray flaw detection non-destructive testing is carried out; a welding line does not generate the defects such as lack of penetration, air holes, cracks and puncture; the quality of the welding line meets the requirements; and the electron beam welding method is simple in tooling design and manufacture, and high in repetition usage rate of the tooling, and can be used for welding the horizontal flanges of the gas turbine casing.

Owner:HARBIN TURBINE

Flux cored electrode with fluorine

InactiveUS20060219685A1Quality improvementReduce the amount requiredPropellersToothed gearingsSlagCompounds of fluorine

Owner:LINCOLN GLOBAL INC

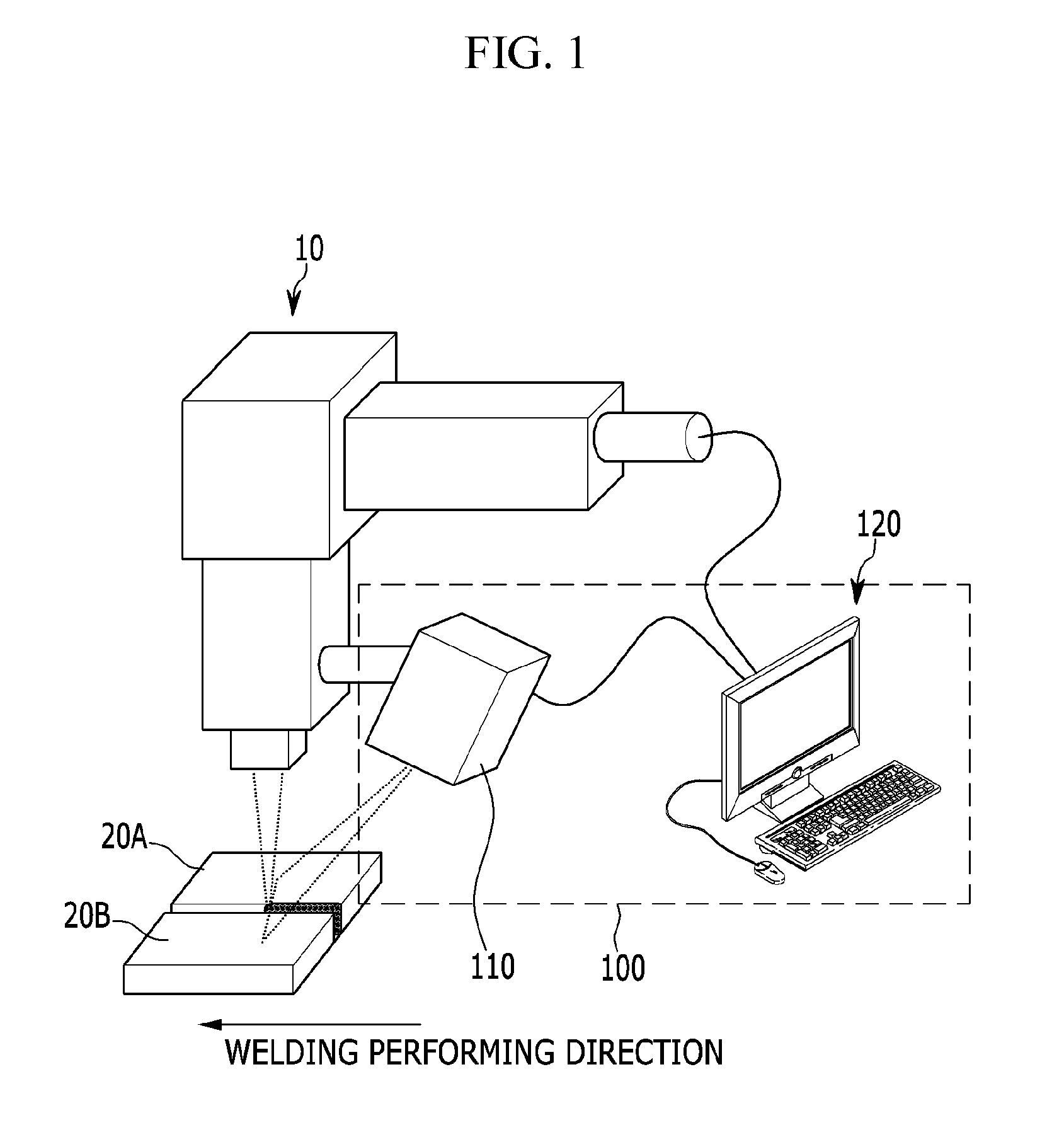

Apparatus and method for monitoring laser welding bead

ActiveUS20150001196A1Easy to manageWelding/soldering/cutting articlesLaser beam welding apparatusBead shapeEngineering

An apparatus for monitoring a laser welding bead irradiates a laser to a surface of a welding bead when welding with a laser welding machine, collects a signal reflected from the surface of the welding bead as an image signal, and then extracts at least one feature variable of a bead shape using the collected image signal. Then, the apparatus for monitoring the laser welding bead determines welding defects using the at least one feature variable, and controls an operation of the laser welding machine according to whether or not the welding defects are generated.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com