Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219results about How to "Improve manufacturing level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

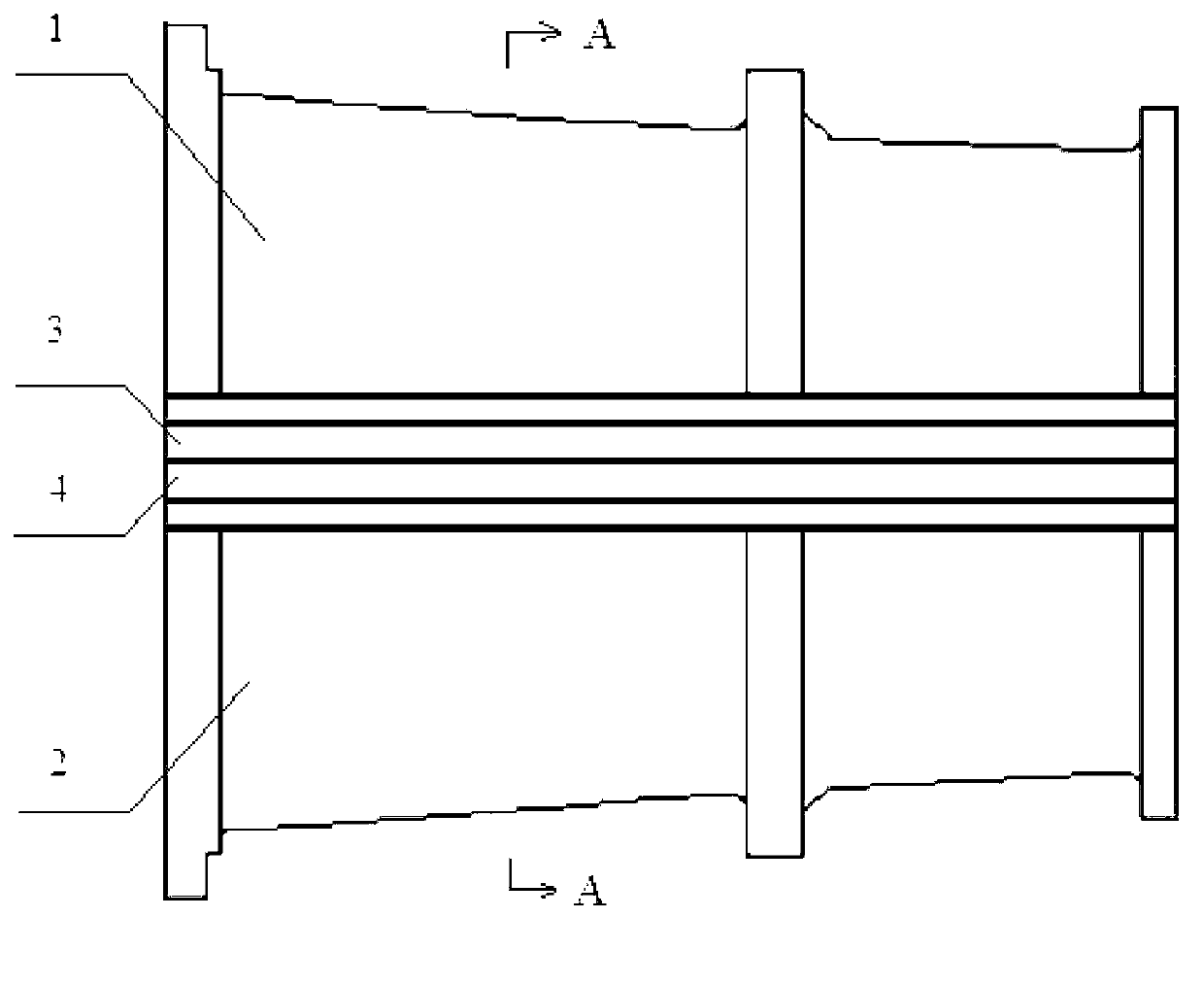

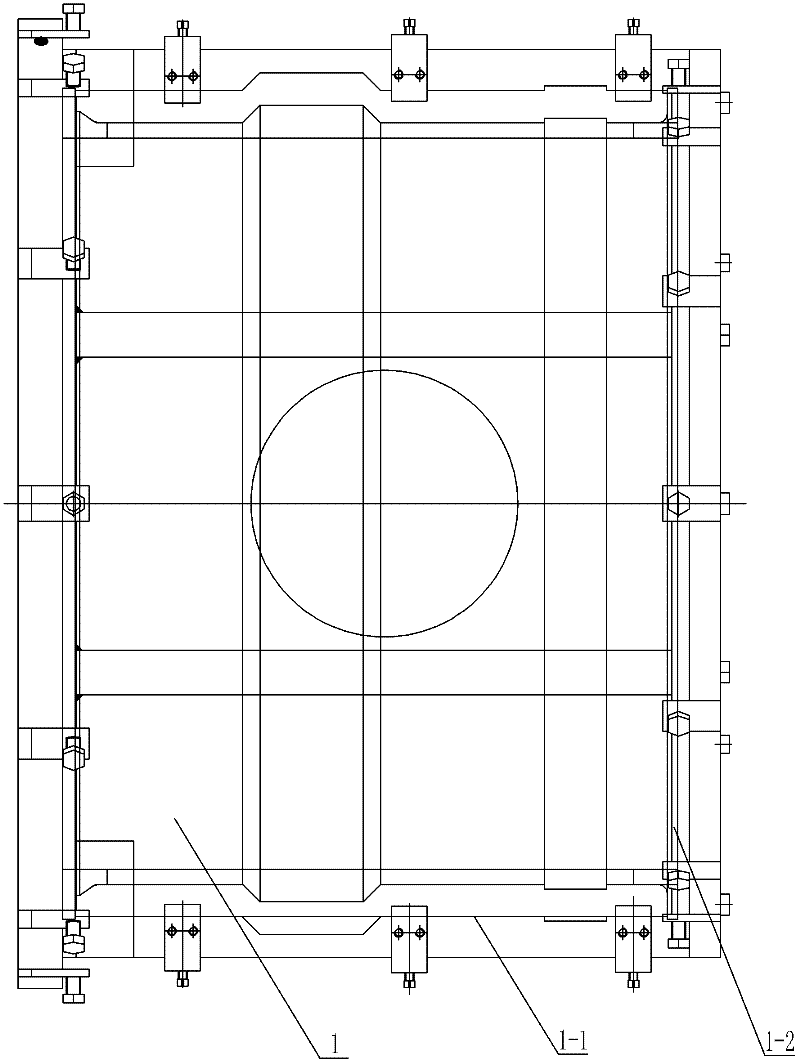

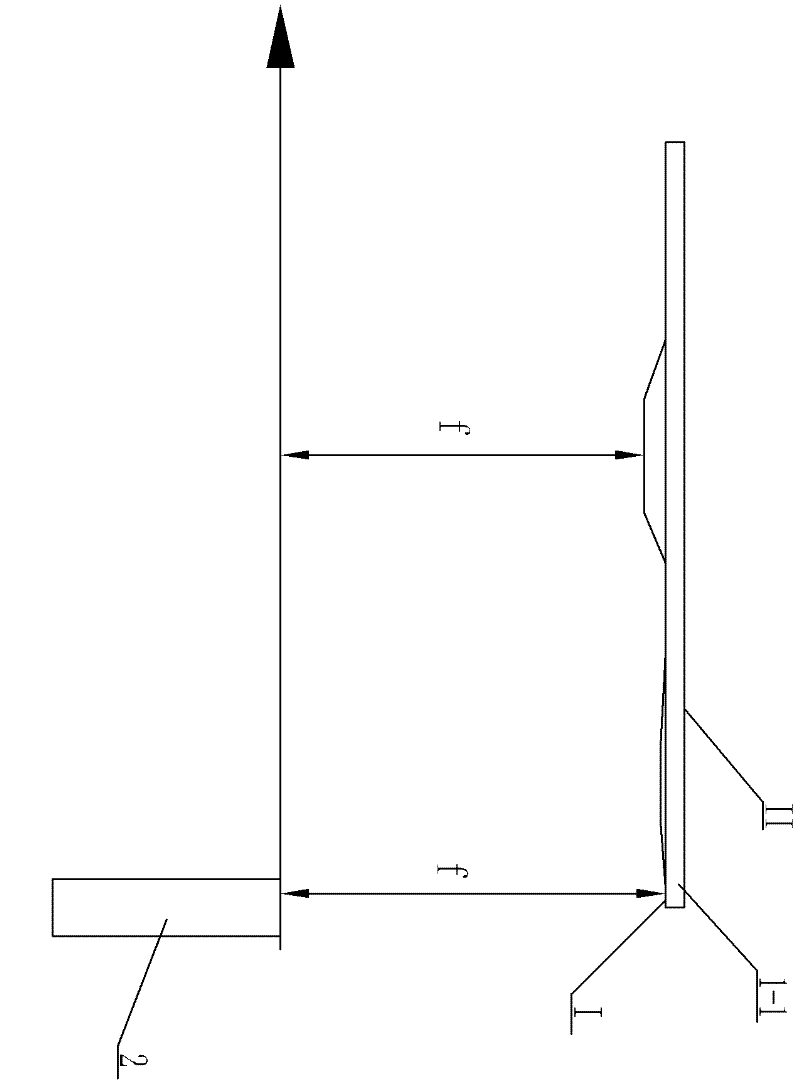

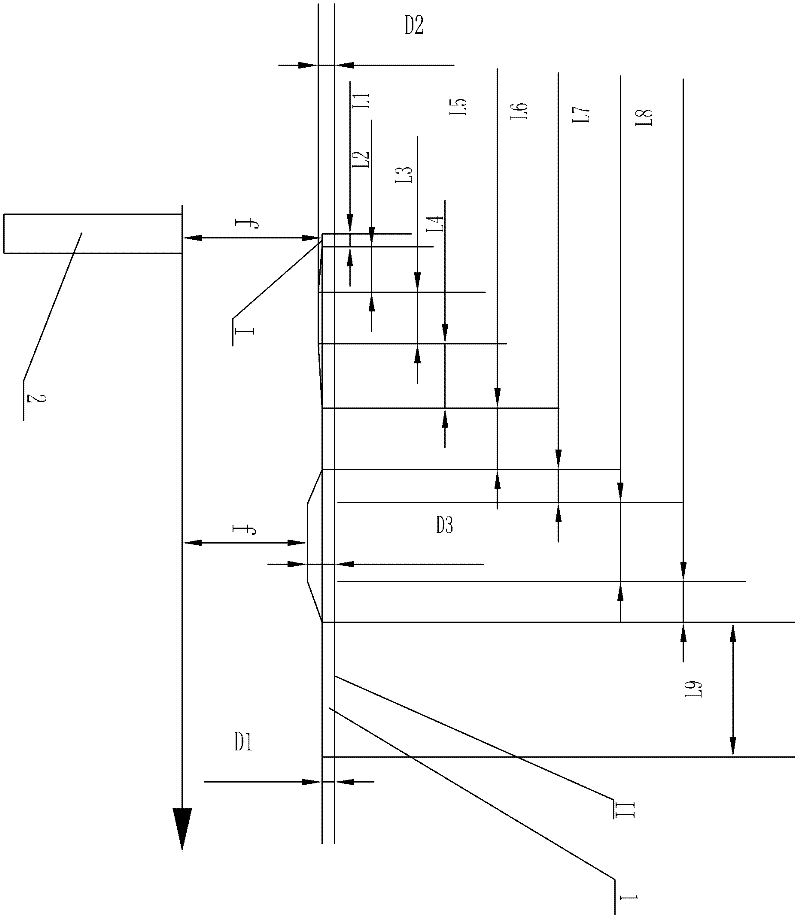

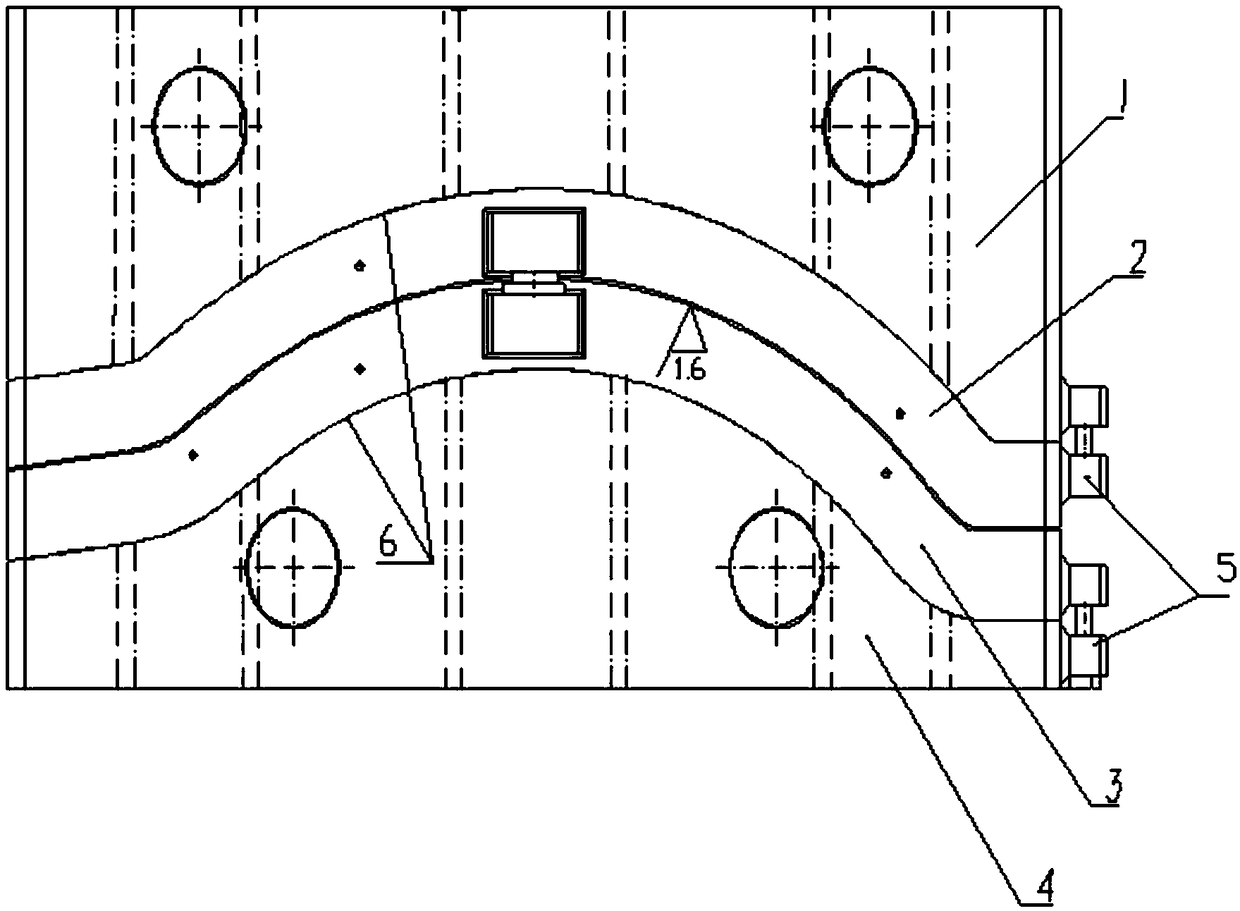

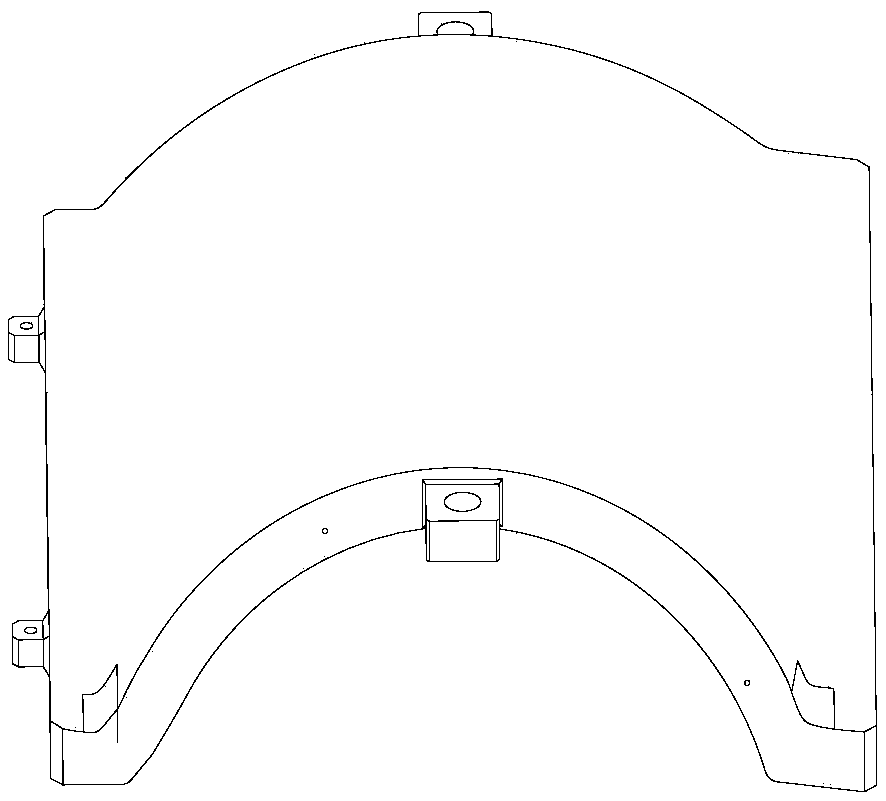

Electron beam welding method of gas turbine casing with horizontal flange structure

ActiveCN102990217AImprove manufacturing levelLow costElectron beam welding apparatusStructural engineeringSpot welding

The invention discloses an electron beam welding method of a gas turbine casing with a horizontal flange structure, and relates to the welding method of the casing with horizontal flanges. The invention aims at solving the technical problems of large deformation, complicated tooling design and manufacture, low repetition usage rate of the tooling and low production efficiency after the horizontal flanges are welded by the existing half-ring gas turbine casing welding method. The welding method comprises the following steps of: 1, machining; 2, cleaning the surfaces of parts to be welded; 3, spot welding; 4, scribing; 5, assembling; 6, spot welding at fixed positions; 7, centering; 8, interpolating, and 9, welding the electron beam. Once vacuum electron beam welding of four horizontal flanges is achieved by the welding method disclosed by the invention; the deformation after welding is small; the production efficiency is doubled; X-ray flaw detection non-destructive testing is carried out; a welding line does not generate the defects such as lack of penetration, air holes, cracks and puncture; the quality of the welding line meets the requirements; and the electron beam welding method is simple in tooling design and manufacture, and high in repetition usage rate of the tooling, and can be used for welding the horizontal flanges of the gas turbine casing.

Owner:HARBIN TURBINE

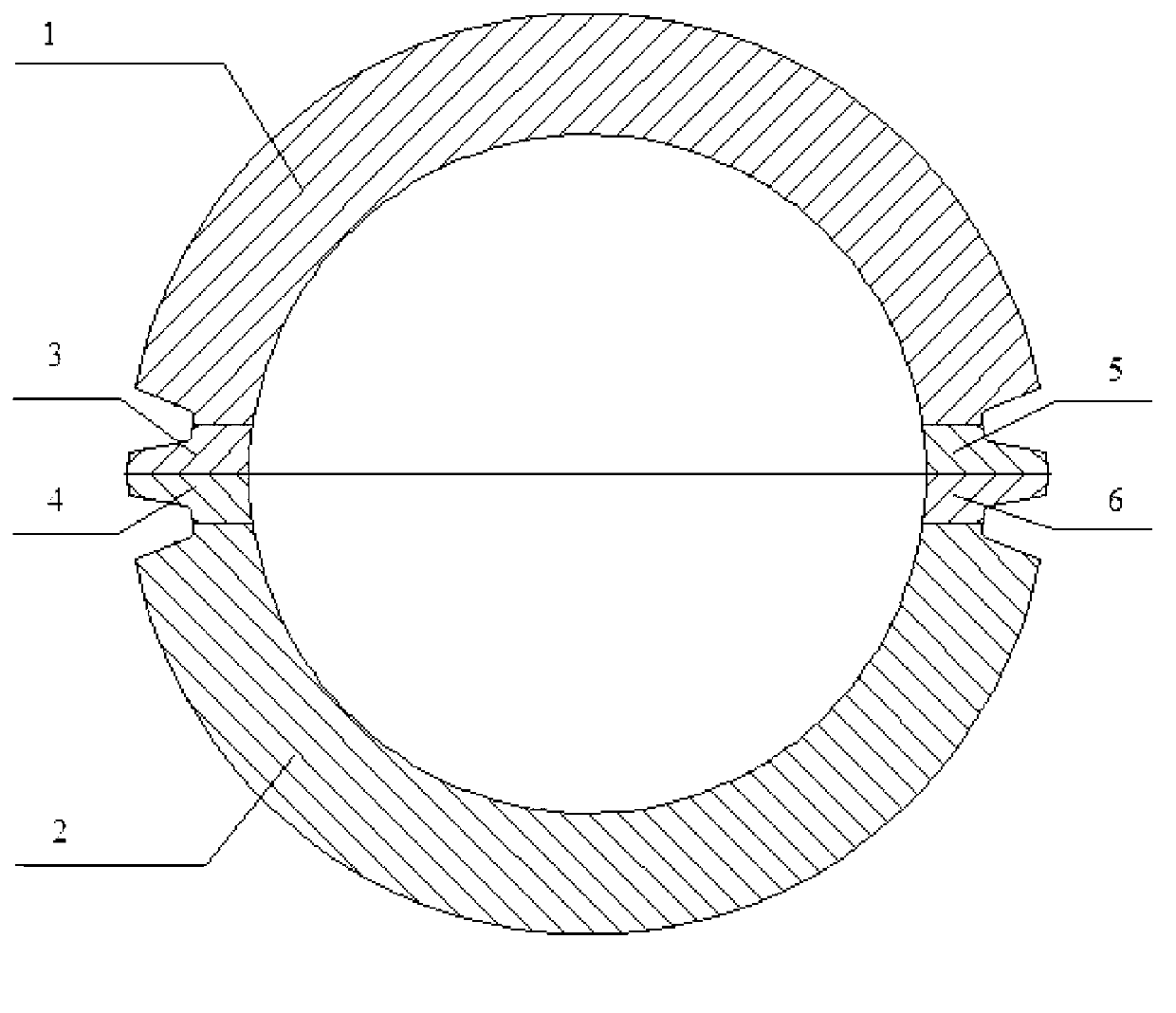

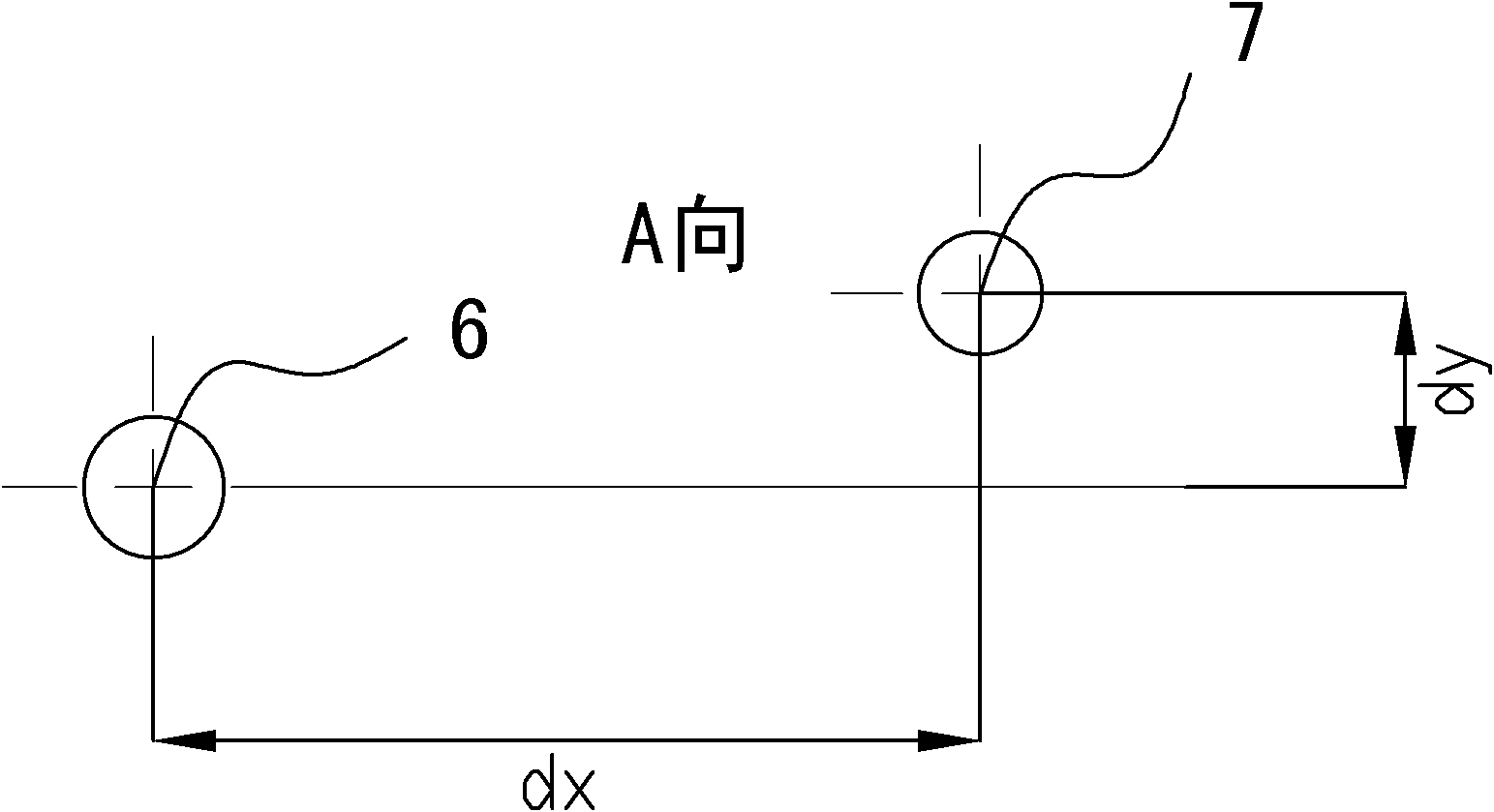

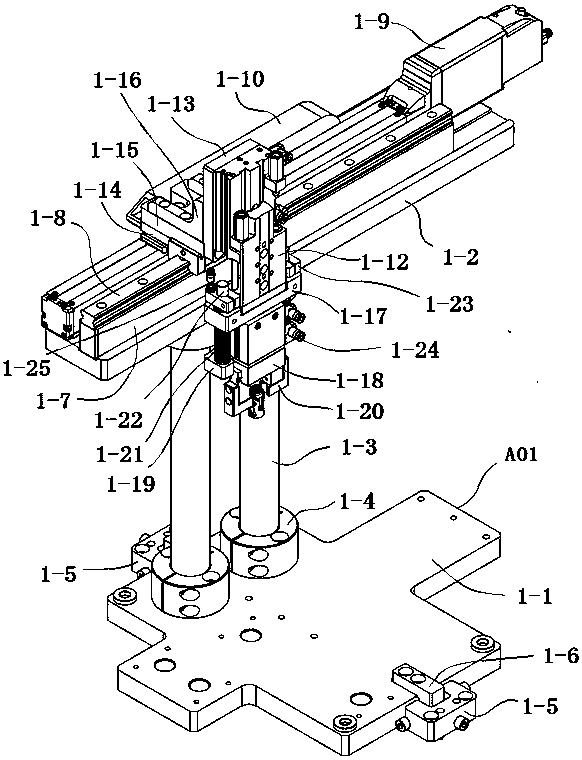

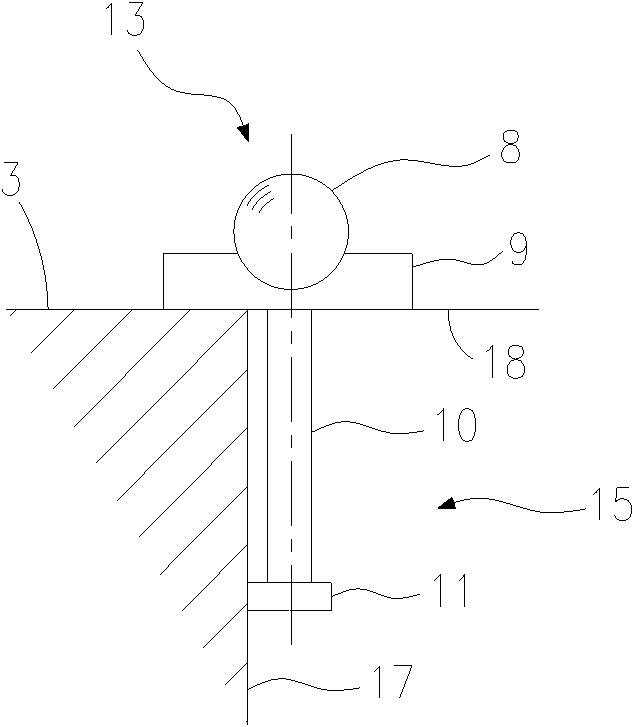

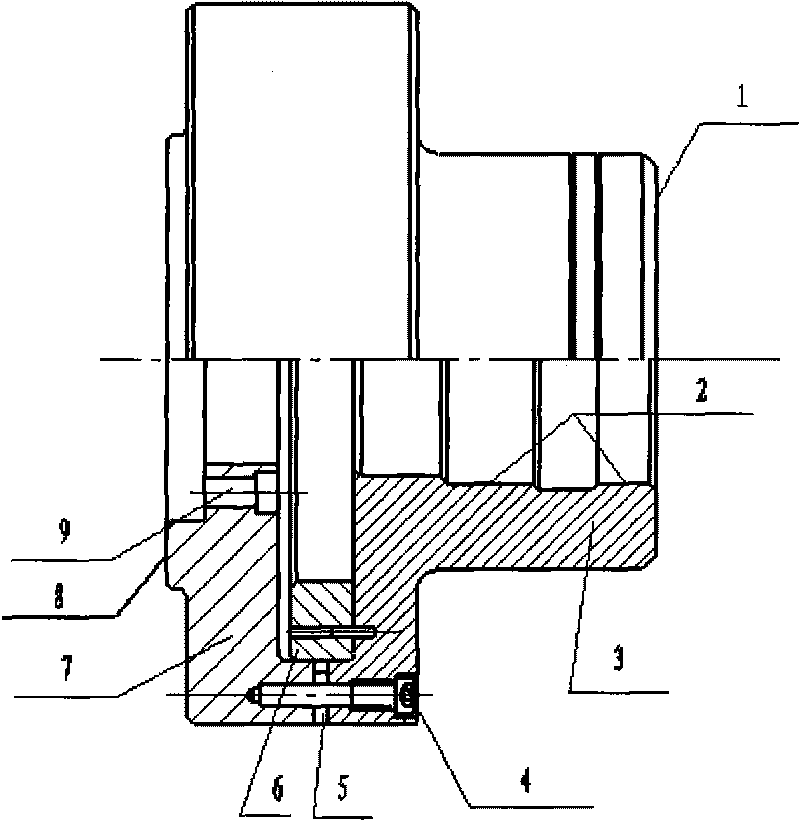

Image centralizing location method for automatic tube plate welding

InactiveCN102152033AReduce consumptionBreak through the positioning problemWelding/cutting auxillary devicesAuxillary welding devicesPosition errorEngineering

An image centralizing location method for automatic tube plate welding is characterized in that a camera is used for picking up the image of the mouth of a tube to be welded; the image is then processed and recognized by a computer system to automatically find the center position of the tube to be welded; and finally, the rotary axial line of a welding torch is translated to the center position of mouth of the tube to be welded by an X-axis moving mechanism and a Y-axis moving mechanism to achieve the location. The method can achieve location of the tube plate by using the image centralizing location method without the need of a core rod and an expansion core, so that the method is a contactless accurate location method, which solves the difficult location problem always puzzling the people for a long time. The method has the following characteristics: (1) the method obviates the position error of the tube mouth caused by machine tooling and welding heat and has high location accuracy; (2) the method can achieve the welding of tube plates with the retracted tubes; and (3) the method can achieve the welding of tube plates with a small diameter (phi3 mm), thereby greatly widening the application range of tube plate welding.

Owner:苏州工业园区华焊科技有限公司 +1

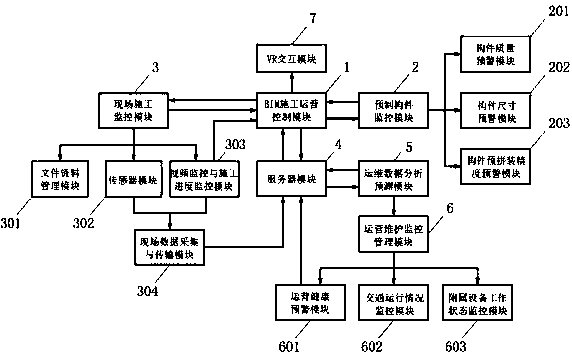

A system and method for monitor that construction and service phases of an assemble building

ActiveCN109472091AClear division of responsibilitiesClarify the crux of the problemGeometric CADForecastingDecision makerComputer module

A system and method for monitor that construction and service phases of an assemble building is disclosed, Taking the BIM construction operation control module as the core, by establishing the three-dimensional BIM model of prefabricated building components, the whole process of prefabricated component fabrication, construction, operation and maintenance can be monitored dynamically, and the decision makers and managers can master the whole process, and the electronization and informationization management of prefabricated building can be realized based on the BIM model. BIM-based three-dimensional model of prefabricated components and related information, to achieve the information management of the quality, size and assembly accuracy of prefabricated components, to improve the manufacturing level of assembled building prefabricated components; Based on BIM technology, it can improve the construction level of assembled building and ensure the safety, rationality and effectiveness of the construction process. It can dynamically monitor the operation period of assembled buildings, timely discover relevant diseases and effectively prevent and treat them, and invoke relevant documentsto find out the crux and attribution, so as to achieve efficient management of the operation period of assembled buildings.

Owner:四川华芯项目管理有限公司

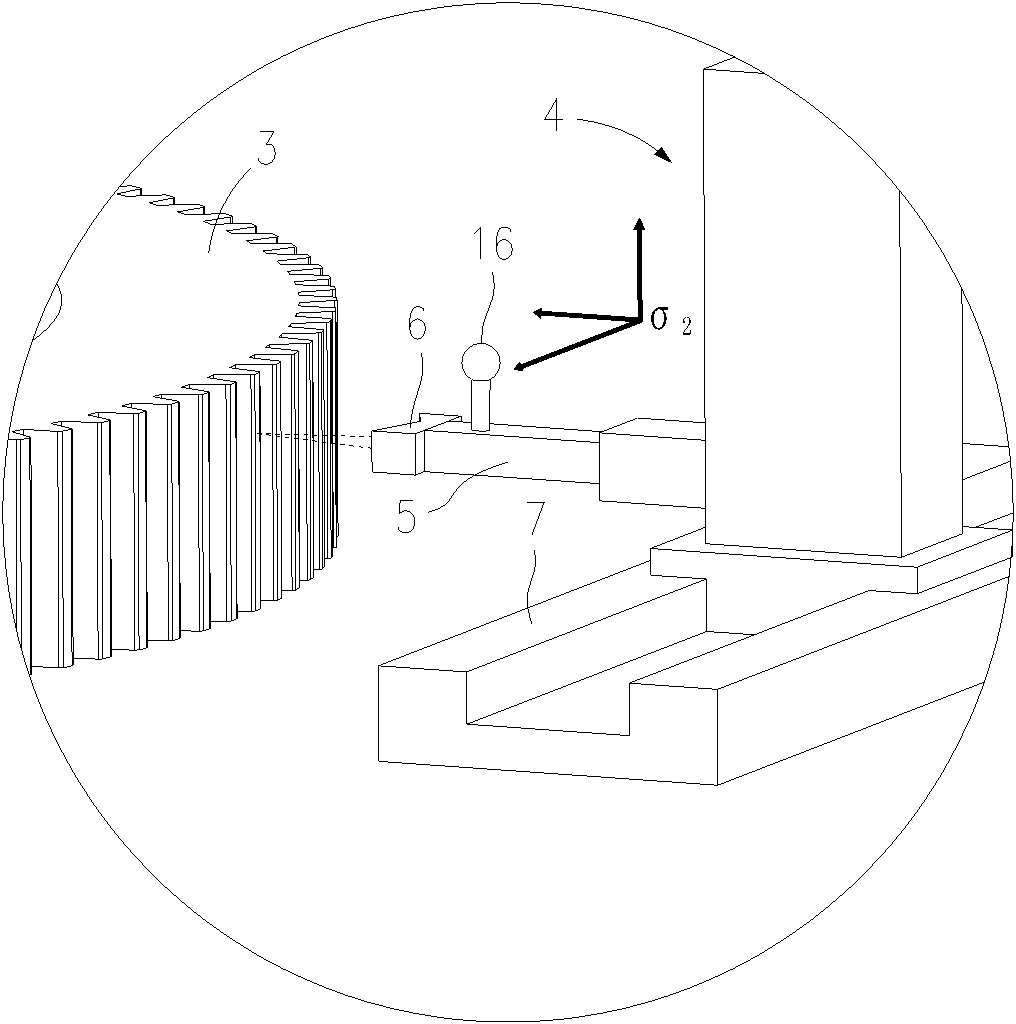

Electron beam welding method for variable-section gas turbine casing

ActiveCN102416525AImprove manufacturing levelConvenient welding methodElectron beam welding apparatusSpot weldingVacuum chamber

The invention relates to an electron beam welding method for a variable-section gas turbine casing, relating to a welding method for a gas turbine casing and solving the problem that the existing welding method for a cylinder and a horizontal flange of the same section in the gas turbine casing cannot meet welding requirements for the cylinder and the horizontal flange of the variable section. The method comprises: 1, selecting an electron beam welding machine; 2, cleaning; 3, arranging the cleaned casing and a tool clamp onto a workbench in a vacuum chamber of the welding machine, assemblingthe casing onto a tool, positioning two variable-section horizontal flanges and a cylinder, and carrying out spot welding; and 4, carrying out electron beam welding. The multi-section welding is adopted for the variable-section horizontal flanges with different thicknesses, the welding of the horizontal flanges of different thicknesses for the variable-section casing can be realized through adjusting and selecting the current, voltage, gun distance and other parameters of the welding machine, and the product quality and the production efficiency can be improved greatly. The method can be applied in welding of the variable-section gas turbine casing.

Owner:HARBIN TURBINE

Method for assessing composite space type face geometric error

The invention relates to a method for evaluating geometrical error of a compound spatial moulding surface, belonging to the field of mechanic parts geometrical error evaluation. The method comprises the following steps: (1) a three-dimensional CAD model of a work piece to be evaluated is read and an ideal work piece model is reconstructed; (2) geometrical data of the work piece to be evaluated is measured to obtain the coordinate information of each measured point; (3) the error value of the measured moulding surface is calculated according to the geometrical error evaluation items of the work piece to be measured including spatial straightness accuracy, cylindricity and punch combination compound position; and (4) the error evaluation result is compared with the read ideal work piece model for analyzing, the processing error information is displayed by adopting colour cloud points, and the error evaluation report is obtained finally. The invention, by the approaching process for constructing minimum zone, realizes fast and accurate evaluation on the geometrical error of the compound spatial moulding surface.

Owner:TIANJIN UNIV

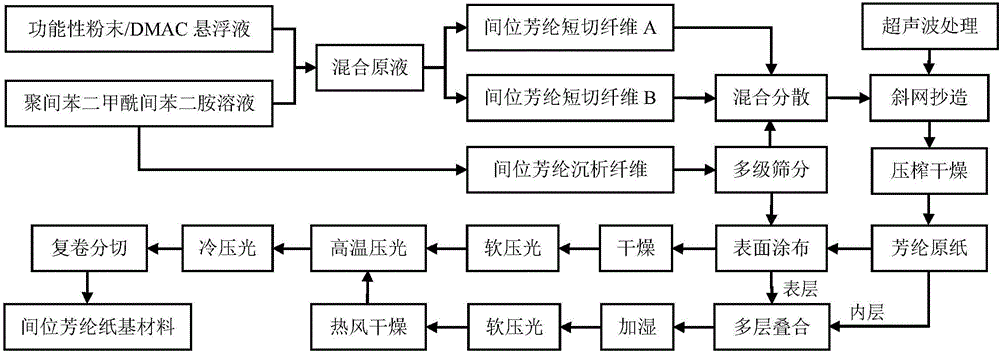

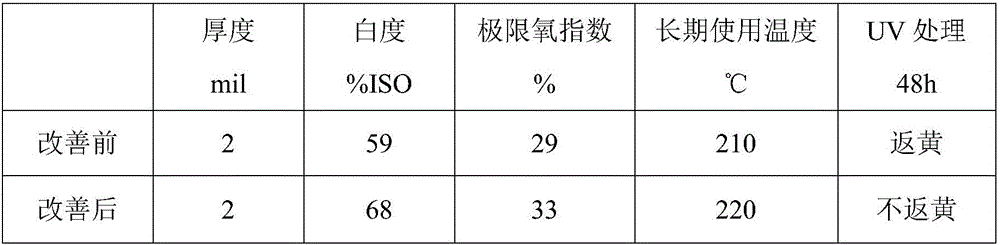

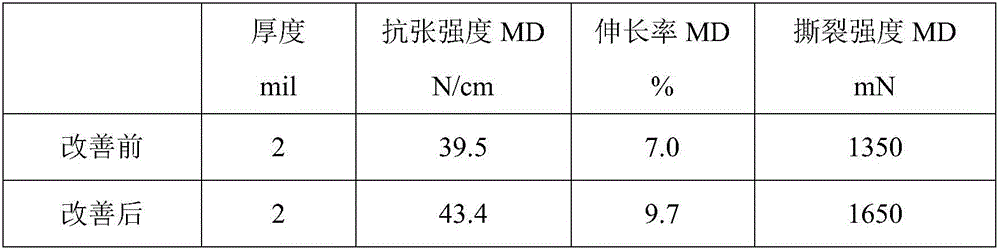

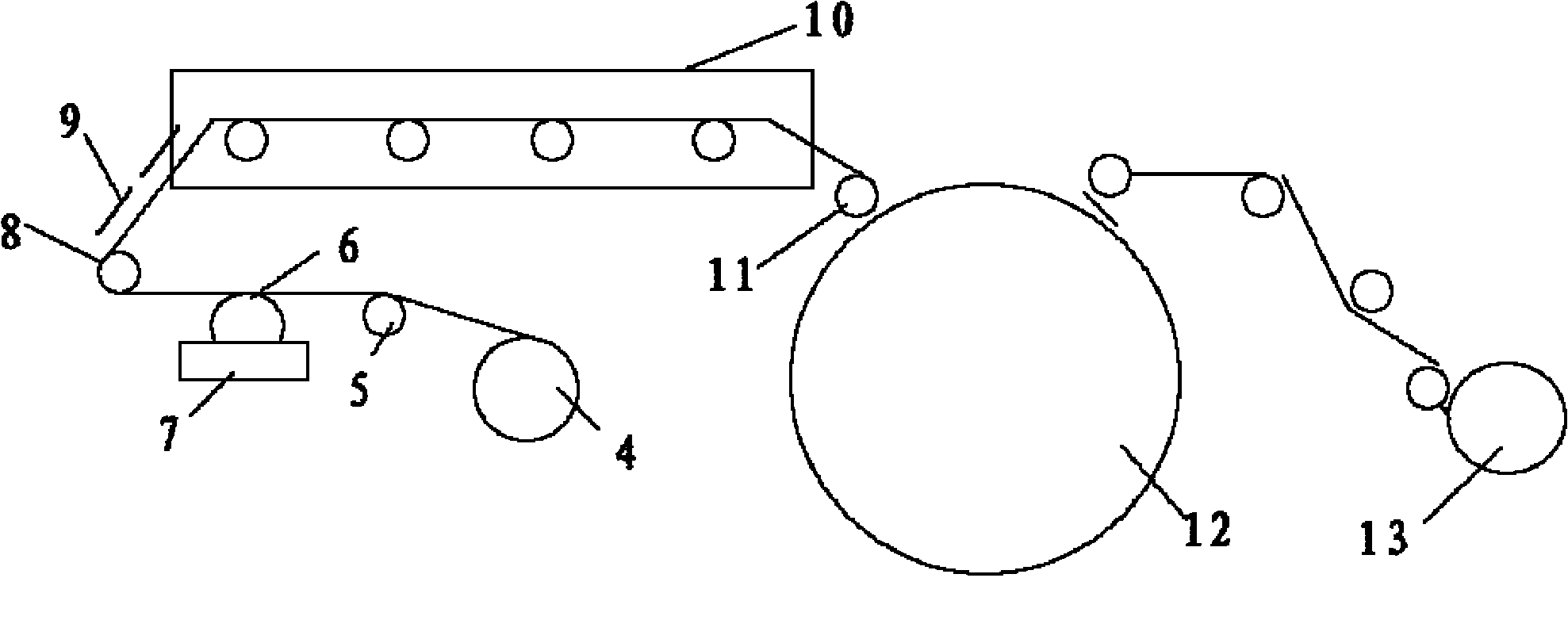

Production method of meta-aramid fiber paper-based material

ActiveCN106245411AHigh whitenessImprove aging resistanceSpecial paperSynthetic cellulose/non-cellulose material pulp/paperAging resistancePapermaking

The invention discloses a production method of a meta-aramid fiber paper-based material. The production method includes the following steps that functional powder is added into a polyisophthaloyl metaphenylene diamine solution to obtain a uniform mixed stock solution, and meta-aramid chopped fiber is prepared through a dry spinning method; meta-aramid fibrid is prepared from the polyisophthaloyl metaphenylene diamine solution; the meta-aramid fibrid is screened in a multi-level mode, and fiber with suitable mesh numbers are selected and combined by the ratio; aramid fiber is mixed and defibered uniformly and is formed by adopting an ultralow-concentration inclined wire forming machine through ultrasonic wave treatment in a wet process papermaking mode, aramid raw paper is obtained through squeezing and drying, and surface coating is carried out on the raw paper; multi-section calendaring and rewinding cutting are carried out to prepare the high-performance aramid paper-based material. The meta-aramid paper-based material with the thickness of 1.5-30 mil can be prepared and is high in whiteness, excellent in mechanical strength, dielectric property, ageing resistance and flame retardance and high in performance stability, and the surface is smooth and even.

Owner:YANTAI METASTAR SPECIAL PAPER

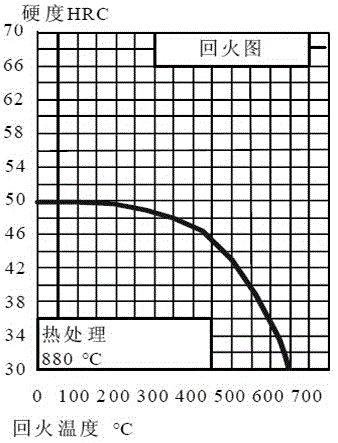

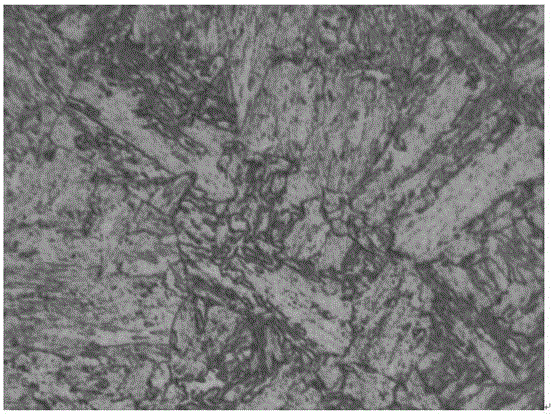

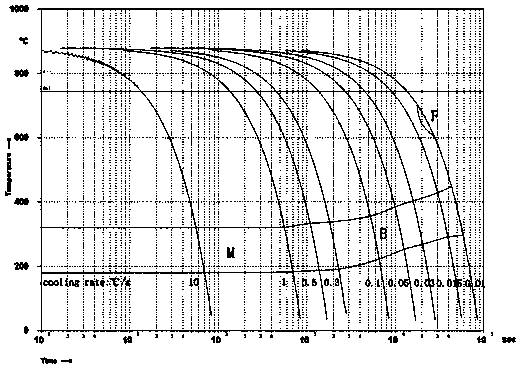

Boron microalloyed die steel and preparation process thereof

The invention relates to boron microalloyed die steel and a preparation process thereof and belongs to the technical field of alloy steel preparation processes. The main alloy elements in alloy chemical components of the die steel comprise, by mass, 0-0.20% of C, 0-0.20% of Si, 1.20-1.60 of Mn, 1.10-1.50% of Cr, 0-0.30% of Ni, 0.20-0.35% of Mo, 0-0.10% of V, less than 0.015% of P, less than 0.005% of S, 0.005-0.01% of B, and the balance Fe. The preparation process of the steel includes the following steps of conducting burdening, smelting, casting and hot delivery; conducting high temperature diffusion heat treatment, multi-directional forging hot working and post-forging hydrogen diffusion tempering treatment; and finally conducting quenching-and-tempering heat treatment so as to obtain a tempered martensite structure with the hardness being 32-38 HRC. The boron microalloyed die steel and the preparation process thereof have the advantages that the prepared die steel has low cost, high hardenability, high hardness, high polishing performance and high skin grain etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

Underwater robot device for shallow water observation

InactiveCN103419915AHigh strengthImprove pressure resistanceUnderwater equipmentPropellerEngineering

The invention discloses an underwater robot device for shallow water observation. An electronic cabin is a body of the underwater robot device, transparent fairings are connected with the electronic cabin and mounted at two ends of the same, battery cabins are arranged on the electronic cabin, battery cabin sealing heads are connected with each battery cabin and mounted at two ends of the same, propeller and illuminating lamp cabins are arranged on the electronic cabin and mounted above the battery cabins bilaterally symmetrically, illuminating lampshades are connected with the illuminating lamp cabins, propellers are hermetically sleeved at the tail ends of the propeller and illuminating lamp cabins through O-rings, a handle is fixed on the electronic cabin, and an umbilical cable connecting port is formed in an electronic cabin body. The electronic cabin is made of PVC selectively, so that strength and pressure resistance of the electronic cabin are improved; through stability analysis of the electronic cabin, the illuminating lampshades, the handle, the umbilical cable connecting port, the propellers, the propeller and illuminating lamp cabins, the battery cabins, the battery cabin sealing heads and the transparent fairings, stability of a underwater robot is determined, and domestic production level is increased.

Owner:QINGDAO YUANCHUANG ROBOT AUTOMATION

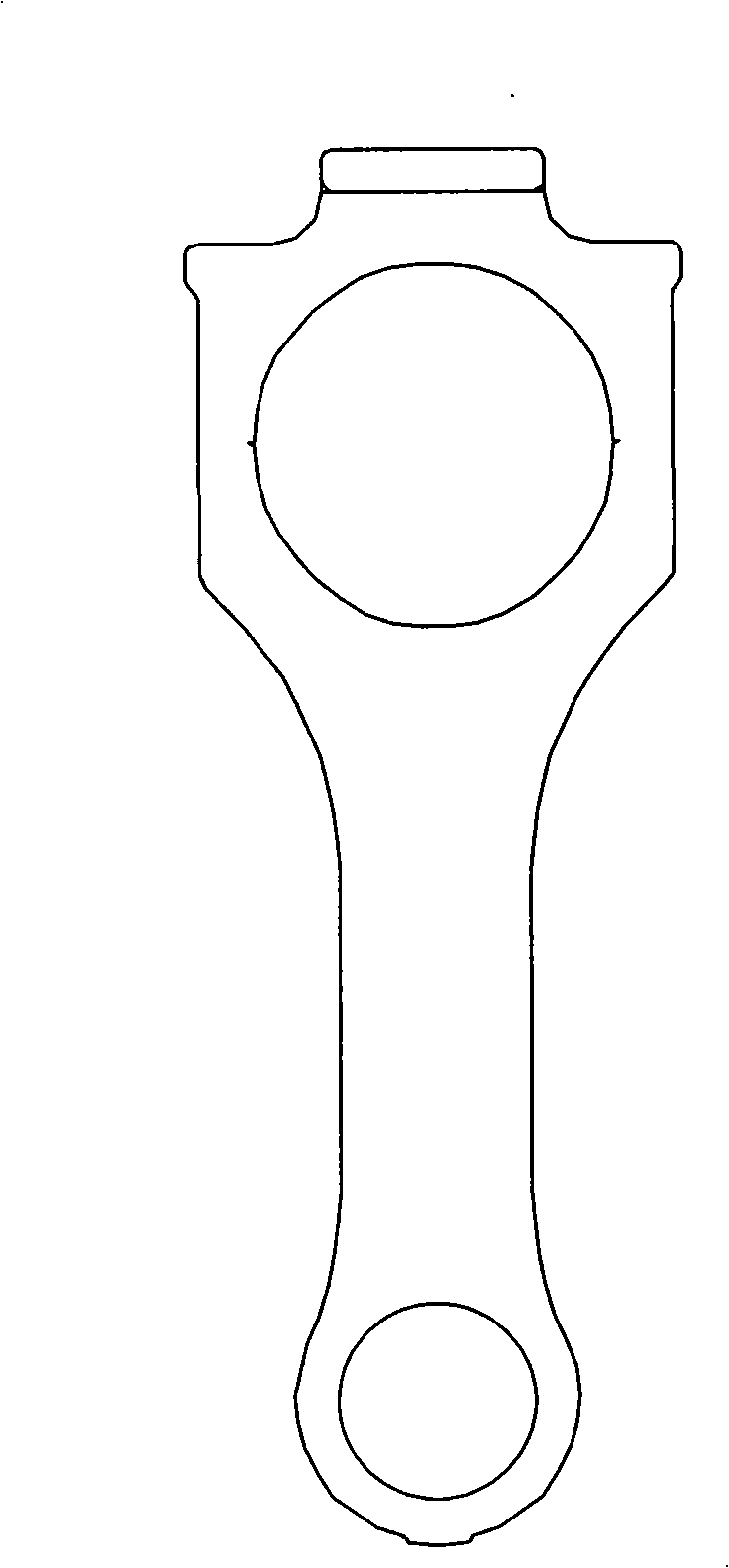

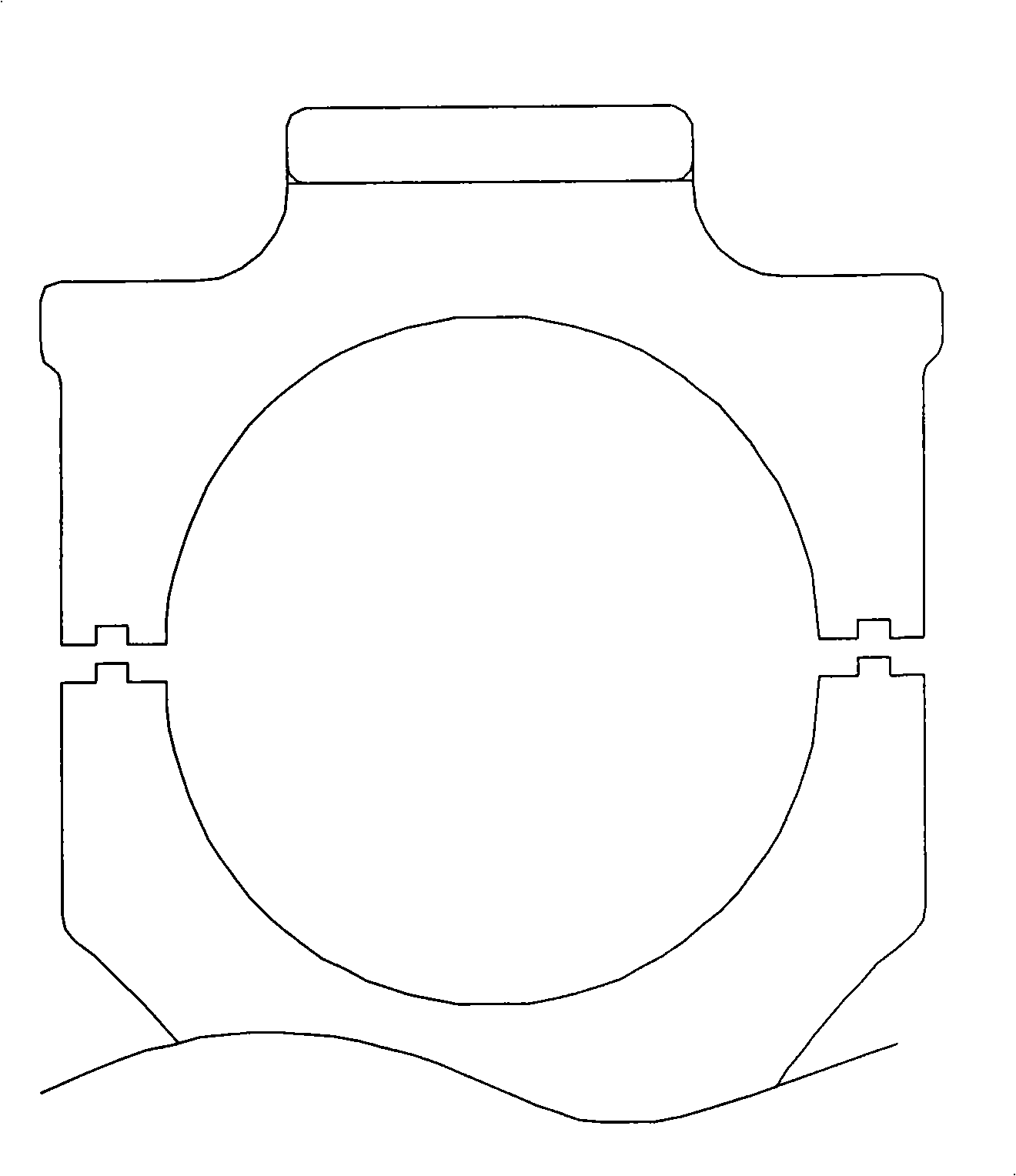

High intensity alloyed steel linkage rod deep cooling embrittlement bulge-breaking process

InactiveCN101307796AChange ductilityAchieve brittle fractureConnecting rodsHigh intensityLiquid nitrogen

The invention provides a process for deep-cooling, embrittling and broken-expanding of a connecting rod of high-rigid alloy steel, relating to an improvement of the process for processing engine components. The process comprises the following steps of: a. putting the connecting rod in liquid nitrogen for deep cooling for more than 5 minutes; basically deep cooling of the connecting rod to a test piece core part after ending of heat exchange; and measuring temperature at a fracture of the cracked test piece same as surface temperature of the test piece; b. keeping the deep cooling temperature to be lower than 156 DEG C below zero; c. placing an expanding sleeve in a macropore of the connecting rod and fixing the connecting rod on an operating board of a pressure machine, and punching the expanding sleeve by an expanding head to expand the connecting rod to be broken. The process has the advantages of changing tractility of the connecting rod of a high-power engine, and ensuring radically no conversion of mechanical performance before deep cooling and after deep cooling through utilizing the deep cooling technology. The technology is popularized and used in the high-power engine manufacture field of our country, which can combine seven or ten steps of key steps of the process for producing the connecting rod into one or two steps, thereby reducing much precision equipment for carrying out precise broaching and form grinding and so on.

Owner:CHANGCHUN EQUIP TECH RES INST

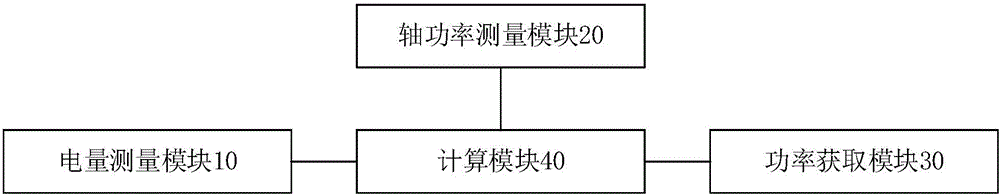

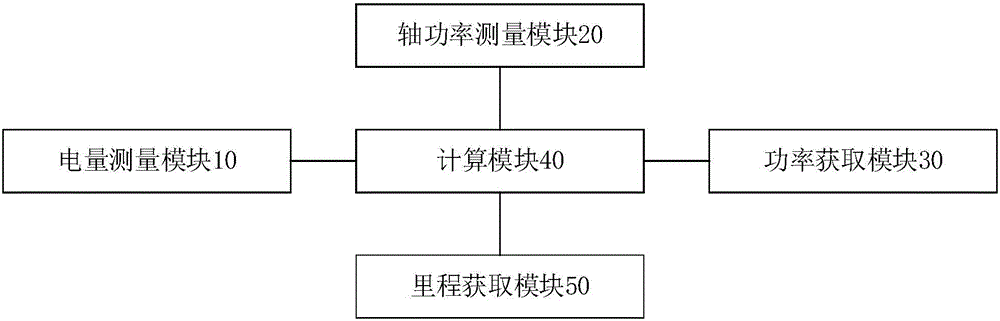

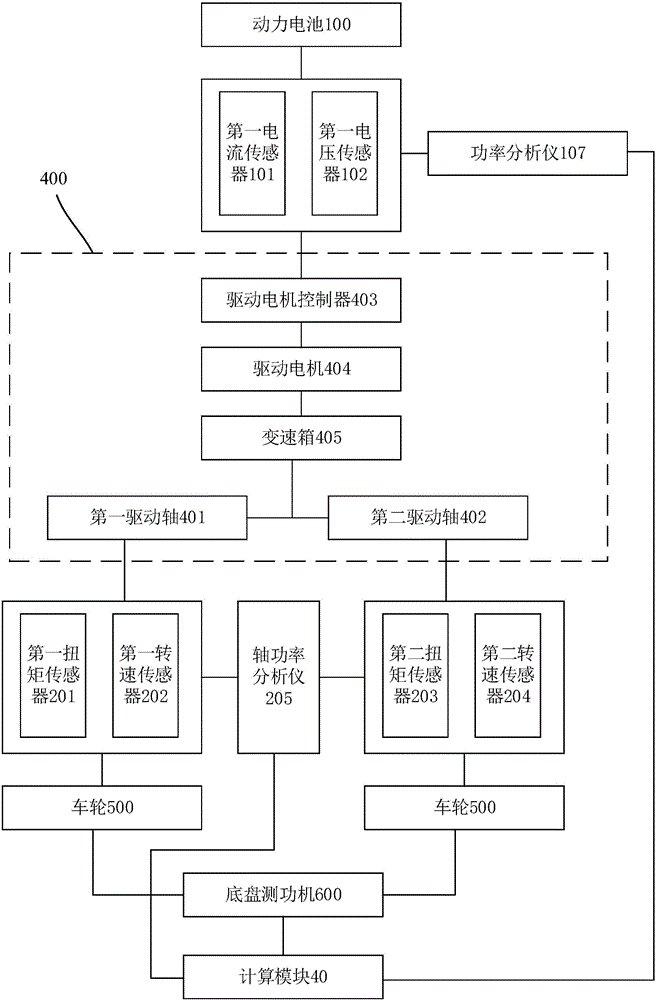

System and method of analyzing energy consumption of electric vehicle

The invention discloses a system and a method of analyzing energy consumption of an electric vehicle. The system comprises an electric quantity measuring module, a shaft power measurement module, a power acquisition module and a calculation module, wherein the electric quantity measuring module is used for measuring total output electric quantity of a power battery when a test vehicle drives at a preset vehicle speed at a preset ambient temperature; the shaft power measurement module is used for measuring total power absorbed by a driving shaft of a transmission system assembly when the test vehicle drives at the preset vehicle speed at the preset ambient temperature; the power acquisition module is used for acquiring total power absorbed by a chassis dynamometer when the test vehicle drives at the preset vehicle speed at the preset ambient temperature; and the calculation module is respectively connected with the electric quantity measuring module, the shaft power measurement module and the power acquisition module for respectively calculating the transmission system assembly efficiency and the wheel efficiency according to the total output electric quantity of the power battery, the total power absorbed by the driving shaft of the transmission system assembly and the total power absorbed by the chassis dynamometer. Thus, the overall energy consumption and the efficiency of the electric vehicle at the preset ambient temperature and the preset vehicle speed can be effectively analyzed.

Owner:BEIJING ELECTRIC VEHICLE

Preparation method of high-strength and high-conductivity beryllium copper alloy

ActiveCN102383078AConductivity has little effectLittle tensile strengthNiobium alloyComposite structure

The invention relates to a preparation method of a high-strength and high-conductivity beryllium copper alloy. In the method, the high-strength and high-conductivity beryllium copper alloy is obtained through hot working, high-working rate cold working, solution treatment, finish rolling or product drawing and aging treatment after smelting the low-beryllium alloy and copper-niobium composite materials together and casting into an ingot. The dispersively distributed copper-niobium composite materials are added into the high-conductivity low-beryllium alloy, the dispersively distributed niobium particles form an ordered composite structure in the low-beryllium alloy after one-time hot working and multiple high-working rate cold working, so that the strength and hardness of the low-beryllium alloy are greatly improved, the conductivity of the low-beryllium alloy is not influenced, and the beryllium copper alloy with the tensile strength sigma b equal to 1200-1400Mpa, hardness HB equal to 334-374 and conductivity g equal to 45-60% IAC is finally obtained. The beryllium niobium alloy prepared by the invention has high strength, high hardness, high elasticity and high wear resistance of the high-beryllium alloy and high conductivity and thermal conductivity of the low-beryllium alloy at the same time, and the comprehensive property of the beryllium copper alloy is greatly improved.

Owner:CNMC NINGXIA ORIENT GRP

Oversized-section bainite pre-hardening plastic die steel and manufacturing method

The invention relates to a low-cost oversized-section bainite pre-hardening plastic die steel and its manufacturing method and belongs to the technical field of an alloy steel manufacturing technology. The steel is characterized in that main alloy elements in alloy chemical components comprise, by weight, 0.15-0.30% of C, 0.10-0.30% of Si, 2.00-3.00% of Mn, 1.00-2.00% of Cr, 0.10-0.30% of Mo, 0.10-0.30% of V, P being less than 0.03%, S being less than 0.03%, 0.10-0.30% of Ni, Nb being less than or equal to 0.15%, and the balance Fe. The manufacturing process of the steel comprises steps as follows: burdening, smelting, casting and hot charging; heat treatment by high-temperature heat diffusion, hot working by multi-directional forging, and controlled cooling after forging; and heat treatment by tempering. The steel provided by the invention has advantages of short period, low cost, high hardenability, high uniformity of hardness and dermatoglyph etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

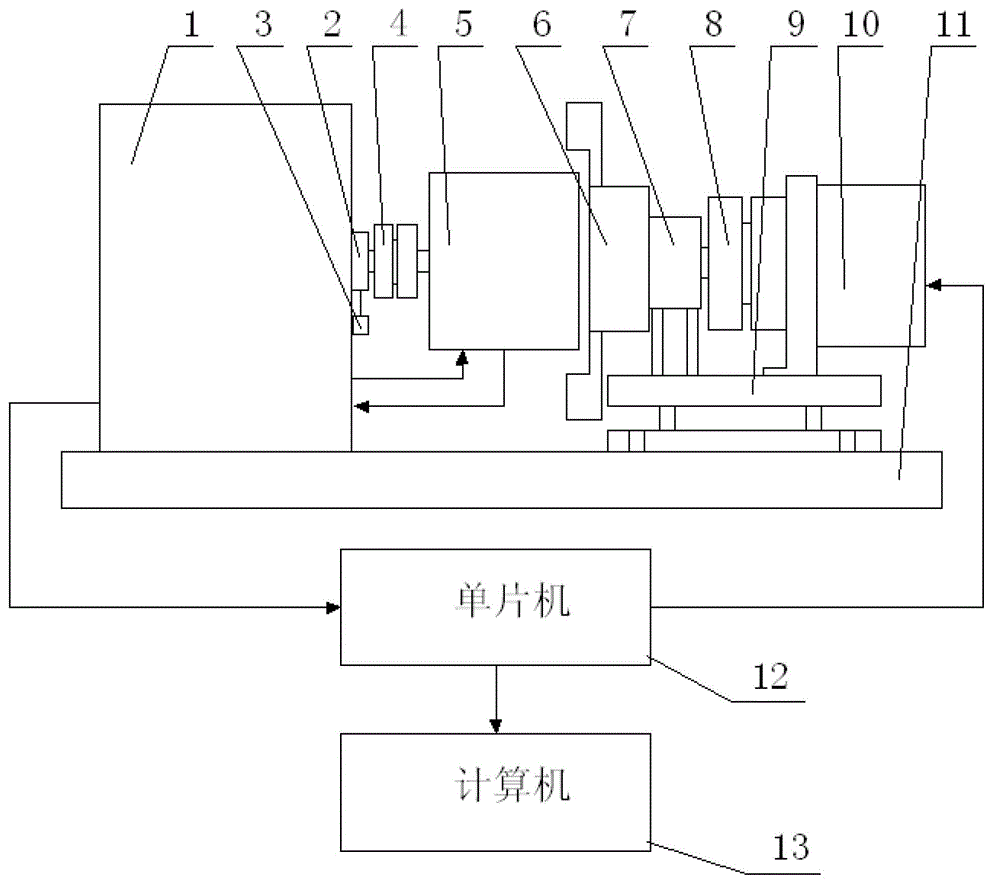

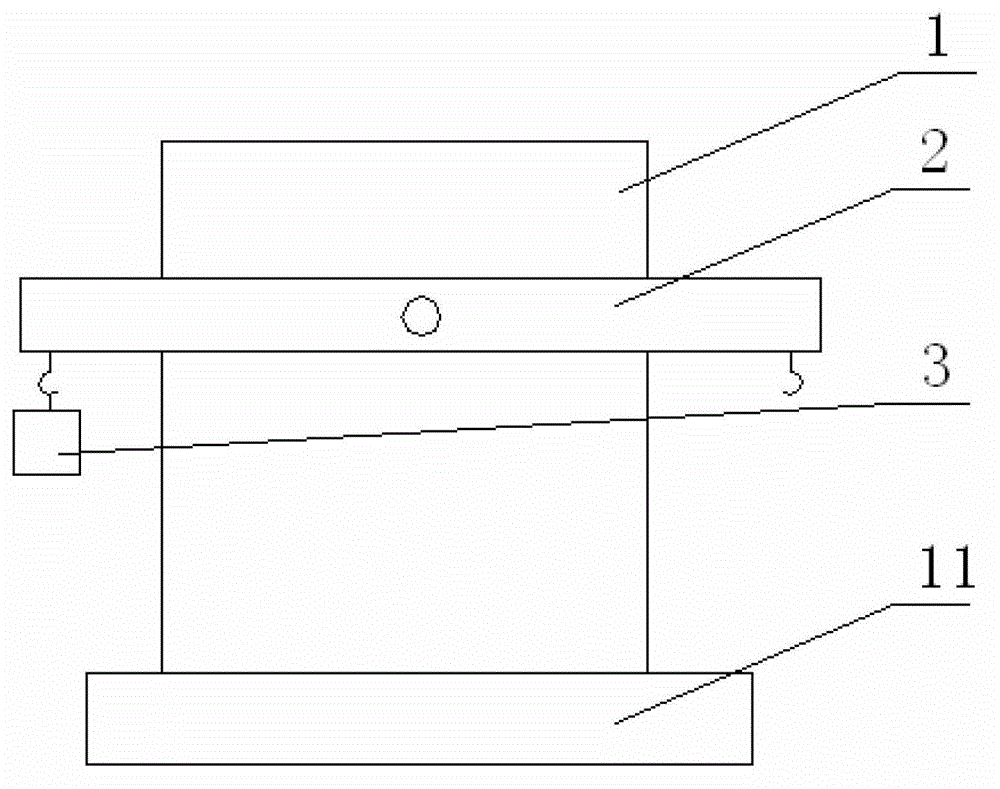

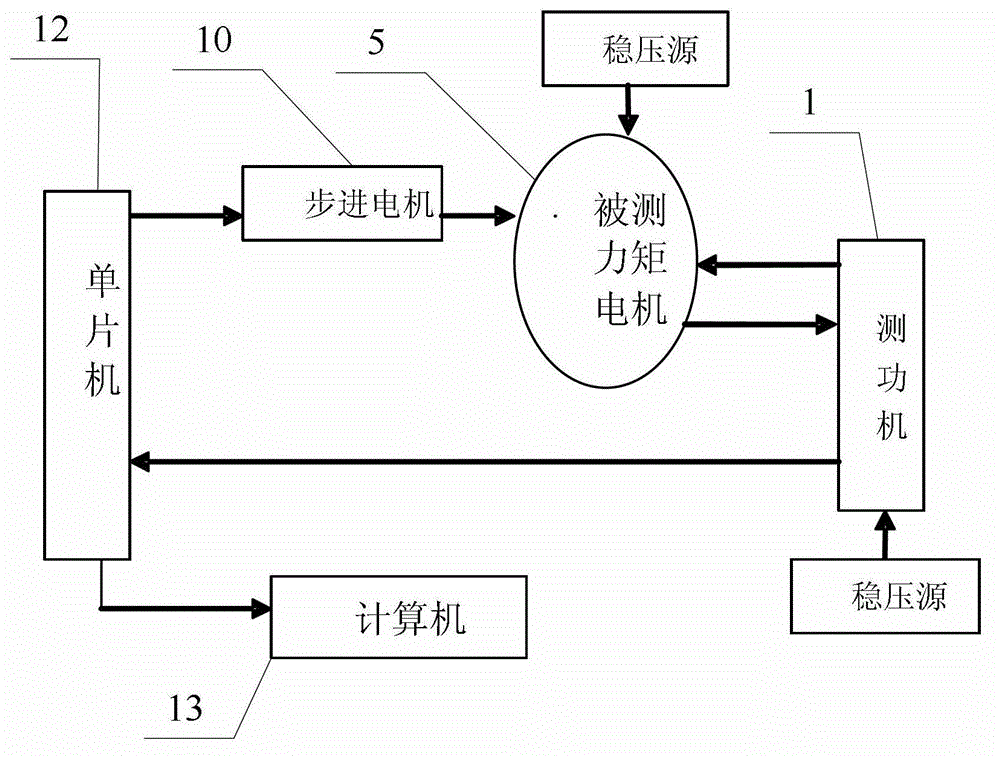

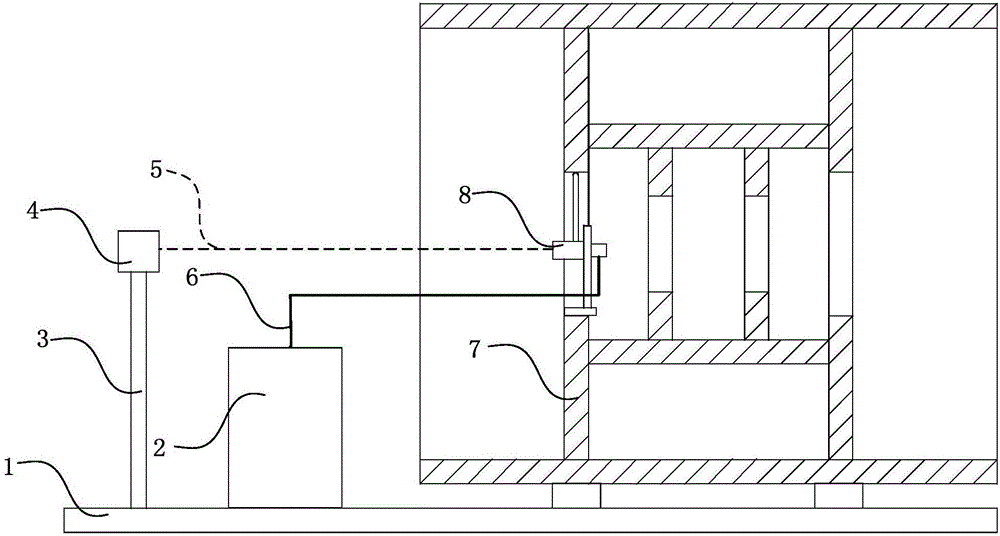

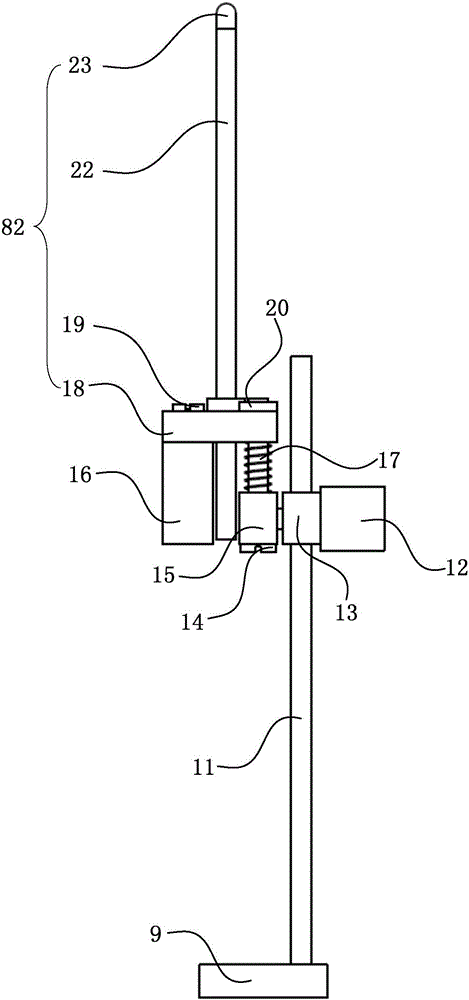

Torque motor torque fluctuation coefficient detector and detecting method

InactiveCN102944344AScientific and reasonable structureEasy to operateWork measurementTorque measurementMicrocontrollerElectric machine

The invention relates to a torque motor torque fluctuation coefficient detector and a detecting method and belongs to the technical field of torque motor torque fluctuation measurement. The torque motor torque fluctuation coefficient detector and the detecting method solve the problems that during the process of measuring force from a stator to a sensor, existing torque motor torque fluctuation coefficient detectors are unreliable in detected results due to gravity interference of the stator. The detector comprises a dynamometer, a calibration assembly, a first coupler, a torque motor to be measured, a chuck mechanical arm, a load bearing, a second coupler, a position adjusting base, a stepping motor, a stabilizing base, a singlechip and a computer. The detecting method comprises the steps of firstly performing initial calibration; then adjusting the chuck mechanical arm to firmly clamp a stator of the torque motor to be measured; powering up the torque motor to be measured to enable the torque motor to be measured to generate torque, then enabling the torque motor to be measured to be under a lock rotor state; and finally driving the stator of the torque motor to be measured by the stepping motor to rotate a circle, synchronously collecting torque signals, and outputting the torque signals to the computer. The torque motor torque fluctuation coefficient detector and the detecting method are suitable for detection of torque motor torque fluctuation coefficients.

Owner:HARBIN INST OF TECH

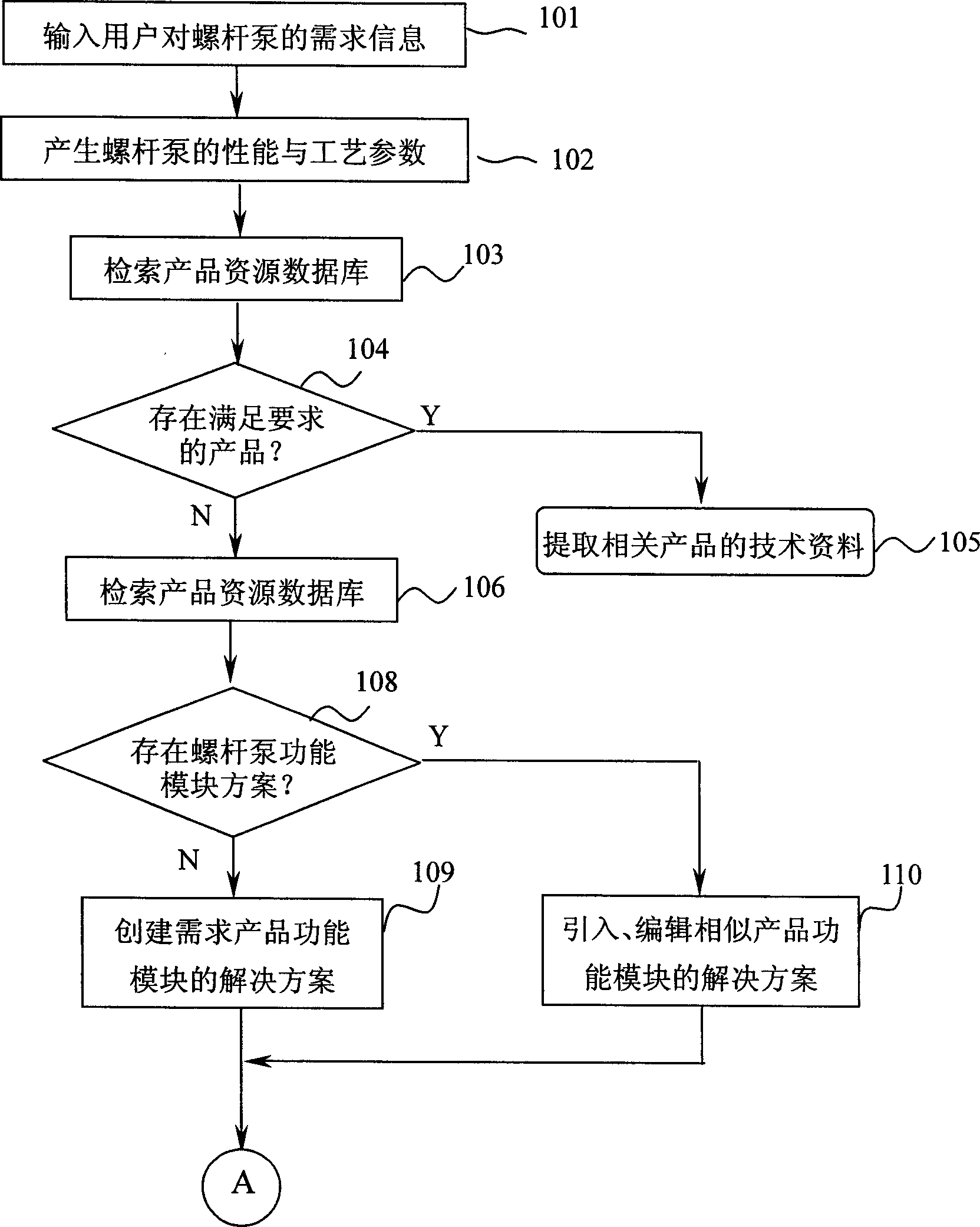

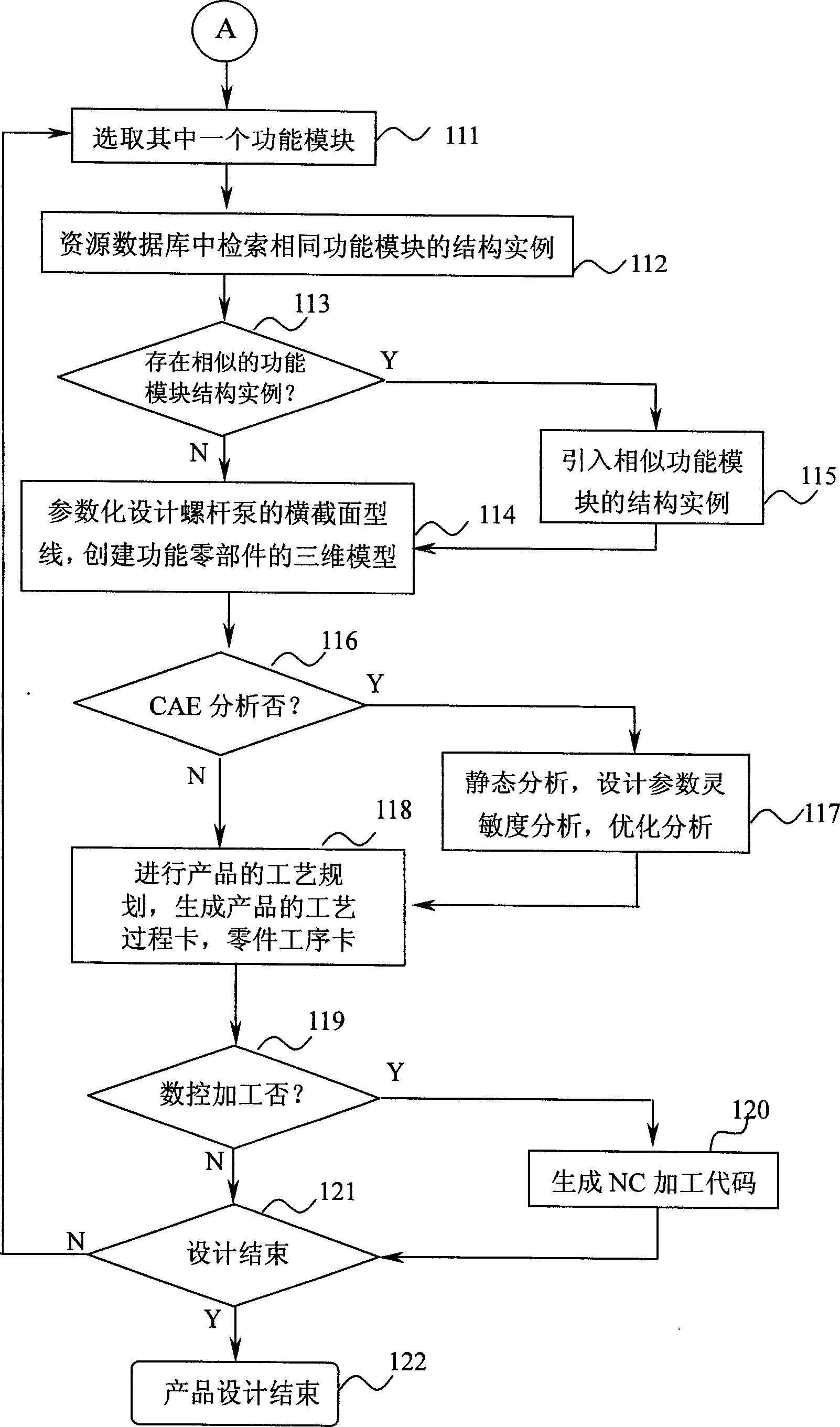

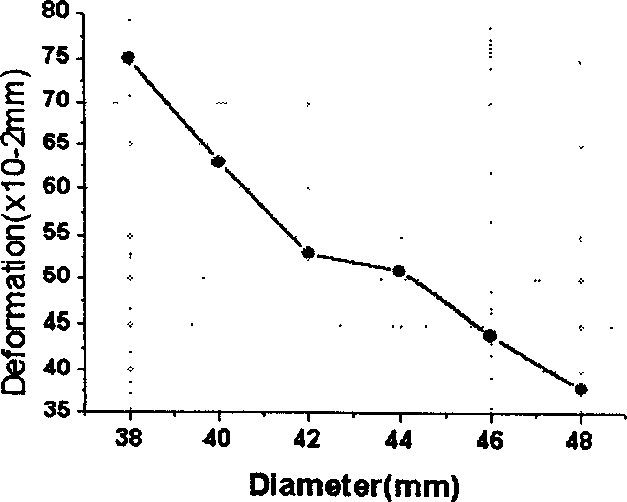

Method for integrated designing screw pump

InactiveCN1760876AImprove manufacturing levelRealize unified managementProgramme controlComputer controlNumerical controlElement analysis

Applying KBE, CBR etc. knowledge design, modularized and variable techniques, the method is built based on 3D CAD platform. The method includes following steps: (1) based on userí»s need, creating main parameters for preliminary design; (2) based on the said parameters, searching database to see whether there are products to meet userí»s need; (3) based on design scheme of functional module in the said products, searching structure instance of functional module in the said products to determine whether there is similar structure instance of functional module in the said products; (4) whether ANSYS finite element analysis is carried out for the said functional module; (5) based on structure of functional module, carrying out process planning, generating technological process sheet and operation sheet; using CAM subsystem generates NC machining codes for making module structure needed of using digital control machine-tool.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

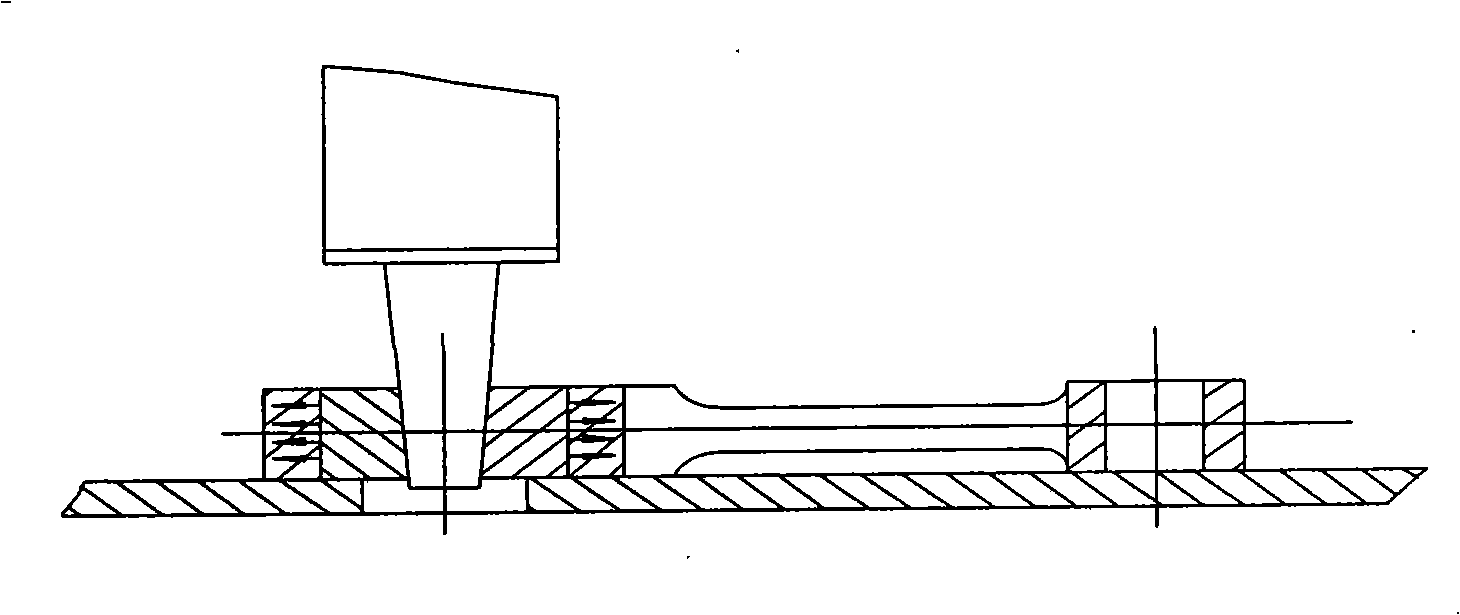

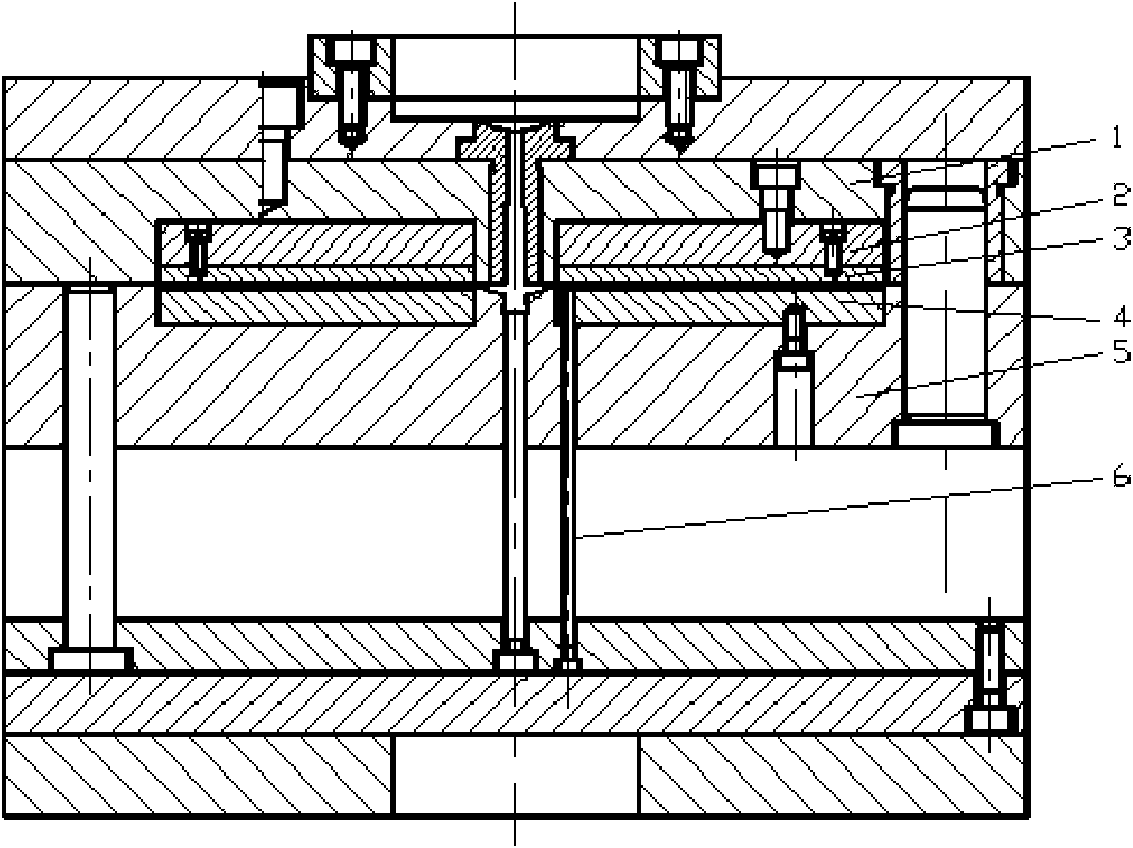

Injection molding process of plastic microfluidic chip

InactiveCN101863104AImprove manufacturing levelSolve technical problems such as incomplete replicationLaboratory glasswaresChemical/physical/physico-chemical processesEngineeringInjection moulding

The invention discloses a microfluidic chip injection molding process capable forming a micro-channel structure on the surface, which belongs to the technical field of injection molding. The appearance of the formed microfluidic chip is in a plate structure, and the thickness thereof is generally 1.2 to 1.5mm; the chip is provided with the crisscross micro-channel, and the cross section thereof is a rectangle with the depth of about 50mu m and the width between 30 to 100mu m. PMMA raw material is selected, the mold temperature is 85 to 90DEG C, and the melt temperature is 230 to 250DEG C. The injection speed is in a control method of slow-quick-slow, wherein the speed of a high-speed section of about 140mm / s. The injection pressure is 100 to 130MPa, the holding pressure is 50 to 70MPa, the holding time is 2 to 5s, and the cooling time is 30 to 40s. After cooling, the mold is opened, a product is taken out to complete the whole forming process. The invention has the beneficial effects that the injection forming process can form plastic microfluidic chips with high efficiency in a large scale, effectively solves the technical difficult problems of incomplete replication of the micro-channel and the like during the forming process, and promotes the application of an injection molding technology in the micro-mechanical system field.

Owner:DALIAN UNIV OF TECH

Hot-pressed mounting paper capable of being lifted off and re-mounted with water and manufacturing method thereof

InactiveCN102134821AGuaranteed water demountableConvenient mounting operationSpecial paperPaper/cardboardPulp and paper industryHot melt

The invention relates to hot-pressed mounting paper capable of being lifted off and re-mounted with water and a manufacturing method thereof, belonging to the technical field of manufacturing of paper. The hot-pressed mounting paper capable of being lifted off and re-mounted with the water is formed by uniformly coating a coating capable of being lifted off and re-mounted with the water on the surface of rice paper, parchment and other types of paper through a coating machine, forming a coating layer capable of being lifted off and re-mounted with the water, drying, pressing, cutting and packaging into rolled or flat sheet hot mounting paper capable of being lifted off and re-mounted with the water, a layer of hot melt adhesive film needs to be added between the mounting paper and a calligraphy or a painting during the use for realizing hot-pressing mounting of the calligraphy or the painting, and the mounting paper can be lifted off and re-mounted with the water; or a hot melt adhesive film coating layer is formed on the surface of the coating layer capable of being lifted off and re-mounted with the water through one way or combination of plural ways of powdering, coating, hot melting, extrusion or compounding, then the pressing and the cutting are performed, the rolled or the flat sheet hot mounting paper capable of being lifted off and re-mounted is further prepared by packaging, and the mounting paper can be directly used for hot-pressing and mounting the calligraphy or the painting during the use and can be lifted off and re-mounted with the water. The two types of the hot-pressed mounting paper capable of being lifted off and re-mounted with the water can greatly facilitate the mounting operation and ensure that the calligraphy or the painting can be lifted off and re-mounted with the water so as to achieve the finishing purpose.

Owner:刘景阳

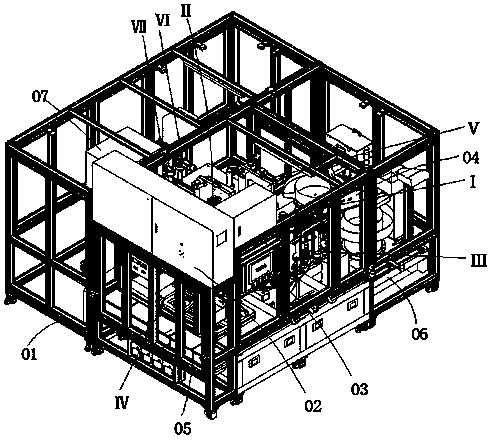

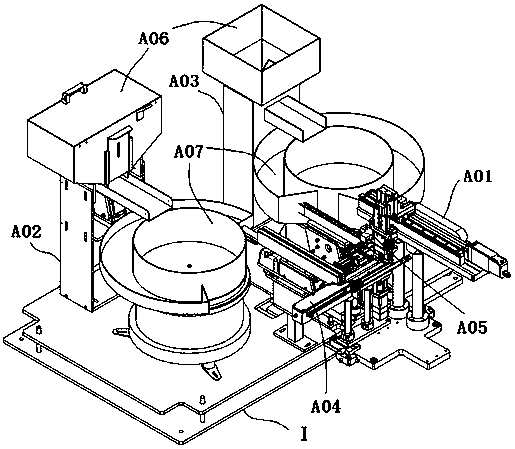

Check valve assembly detection line

ActiveCN108127399AImprove manufacturing levelReasonable structureAssembly machinesMetal working apparatusEngineeringSteel ball

The invention relates to a check valve assembly detection line and belongs to the field of automobile part assembly detection. The check valve assembly detection line comprises a shell feeding mechanism, a rotary table tool assembly, a spring taking mechanism, a spring feeding mechanism, a steel ball strainer assembly mechanism, an overturning testing mechanism, a frame main body, a base and a spring machine. The shell feeding mechanism, the spring taking mechanism, the spring feeding mechanism, the steel ball strainer assembly mechanism and the overturning testing mechanism are all installedon the base and are all arranged in the frame main body. The shelf feeding mechanism is arranged on one side of the rotary table tool assembly. The overturning testing mechanism is arranged on the other side of the rotary table tool assembly. The steel ball strainer assembly mechanism is matched with the rotary table tool assembly. The spring taking mechanism is connected with the spring machine and the spring feeding mechanism. According to the check valve assembly detection line, labor intensity can be lowered, cost is reduced, assembly quality and detection efficiency are high, and safety and reliability are achieved.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

Highly-polished prehardened die steel, and preparation method thereof

The invention relates to a highly-polished prehardened die steel, and a preparation method thereof. The highly-polished prehardened die steel is composed of, by mass, 0.21 to 0.25% of C, Si<=0.30%, 1.40 to 2.00% of Mn, 1.30 to 1.70% of Cr, 0.60 to 1.00% of Ni, 0.40 to 0.60% of Mo, V<=0.10%, P<0.015%, S<0.005%, 0.02 to 0.04% of Nb, and the balance Fe. The preparation method comprises following steps: material blending, smelting, casting, and hot charging; high temperature diffusion heat treatment, multi-directional forging heat processing, after-forging heat treatment, and sawing; and hardeningand tempering heat treatment. The hardness of the obtained tempered martensite structure ranges from 38 to 42HRC. The advantages of the highly-polished prehardened die steel are that: cost is low, hardenability and hardness are high, and polishing properties and cleavage line etching performance are excellent.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

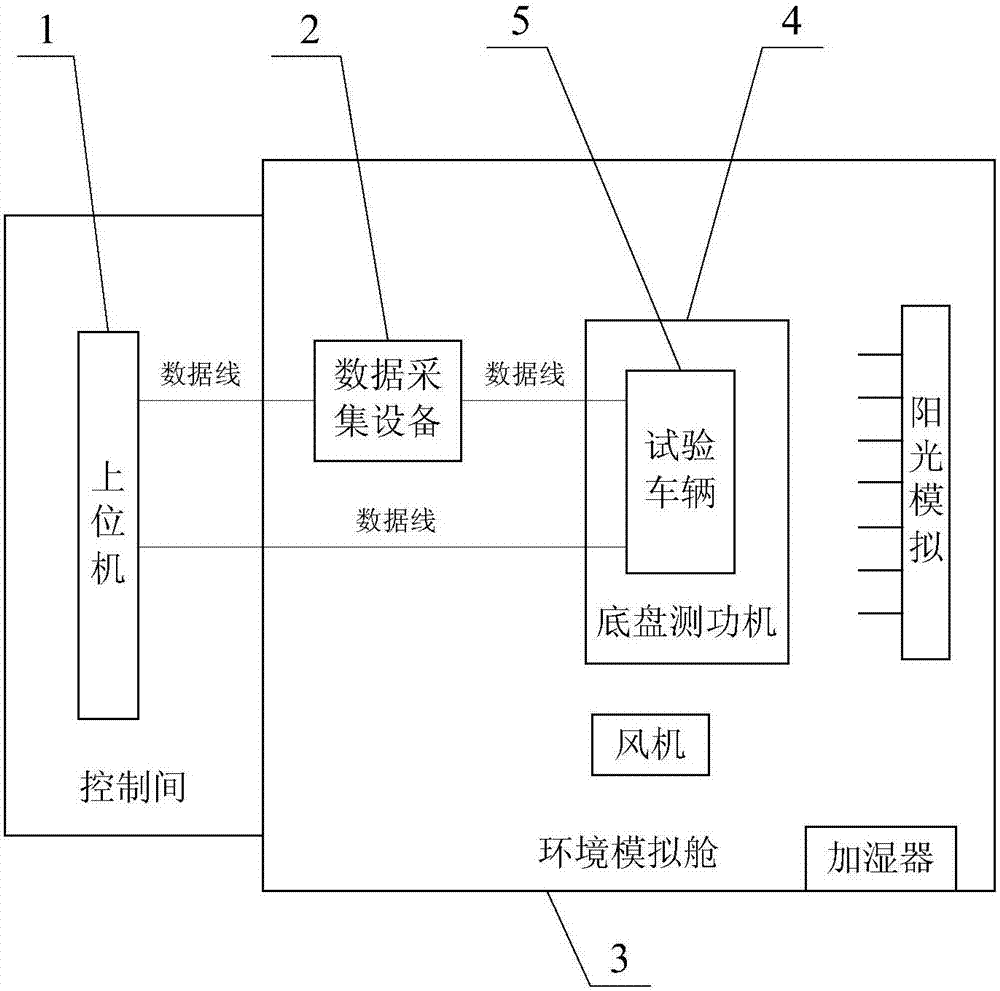

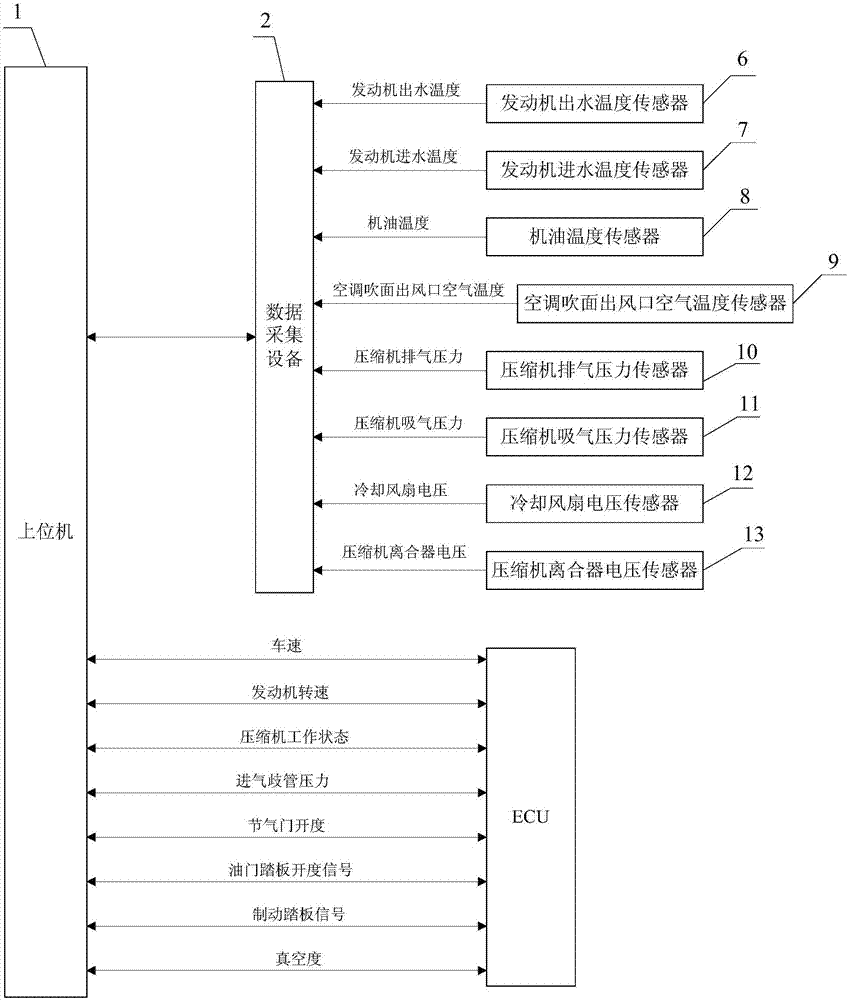

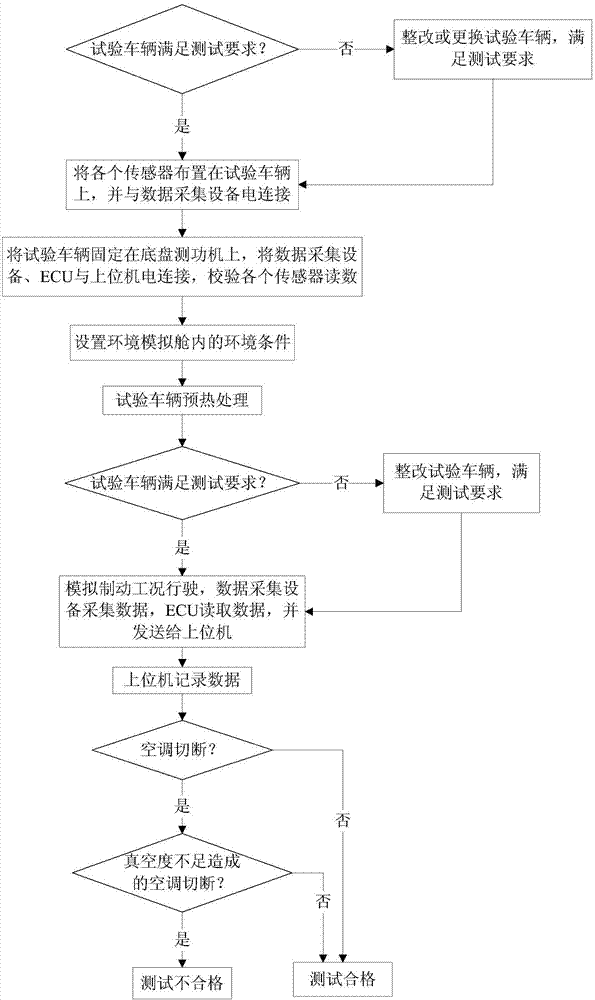

Bench test system and test method for air conditioner cutting condition and whole vehicle braking condition

ActiveCN107490491AImprove comparabilityHigh precisionVehicle testingWork measurementData acquisitionBench test

The invention discloses a bench test system and test method for an air conditioner cutting condition and a whole vehicle braking condition. The bench test system comprises a host computer, a data acquisition device, an environment simulation cabin, a chassis dynamometer, a test vehicle and also comprises an engine outlet water temperature sensor, an engine inlet water temperature sensor, an engine oil temperature sensor, an air conditioner blowing surface air outlet air temperature sensor, a compressor air discharge pressure sensor, a compressor air suction pressure sensor, a cooling fan voltage sensor and a compressor clutch voltage sensor which are electrically connected to the data acquisition device. The host computer is electrically connected to the data acquisition device and an ECU of the test vehicle. The test method comprises the steps of carrying out test vehicle access inspection, laying each sensor and connecting wires, fixing the test vehicle and connecting wires, setting a simulation environment, preheating the test vehicle, simulating the breaking condition to drive and collecting data, and recording and analyzing the data. According to the system and the method, the test universality and the comparability of a test result can be improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for producing medium chromium tungsten-containing composite anti-wear roll ring

InactiveCN1943860AReduce contentImprove liquidityFurnace typesHeat treatment process controlBrickRare earth

The present invention relates to production process of medium chromium tungsten-containing composite antiwear roller ring, and belongs to the field of high performance cast iron alloy material and casting producing technology. The production process includes centrifugal composite casting and heat treatment. The composite roller ring has one outer layer of medium chromium tungsten-containing cast iron alloy comprising Cr 12-20 wt%, W 1.0-3.0 wt%, C 2.2-3.4 wt%, Cu 0.6-1.5 wt%, Mn 0.4-1.4 wt%, Ce 0.1 wt%, Si not more than 0.7 wt%, P not more than 0.1 wt%, S not more than 0.06 wt% and Fe for the rest; and one inner layer of high strength nodular cast iron. The composite roller ring has the advantages of high wear resistance, less internal stress, high toughness, long service life and low production cost, and is suitable for use in crushing coal gangue and other hard material in brick making industry.

Owner:SHANDONG JINGTAI WEAR RESISTANT MATERIAL

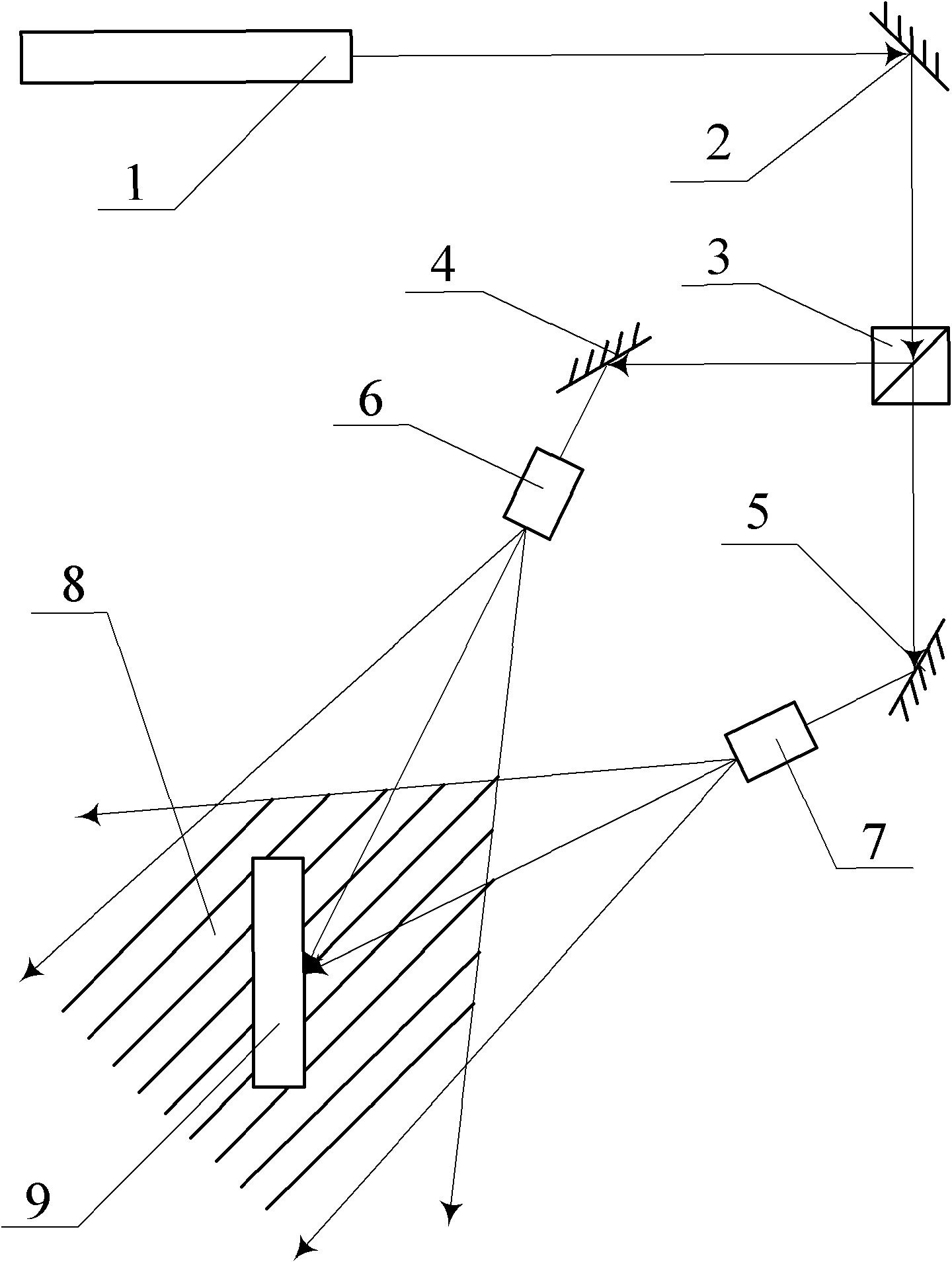

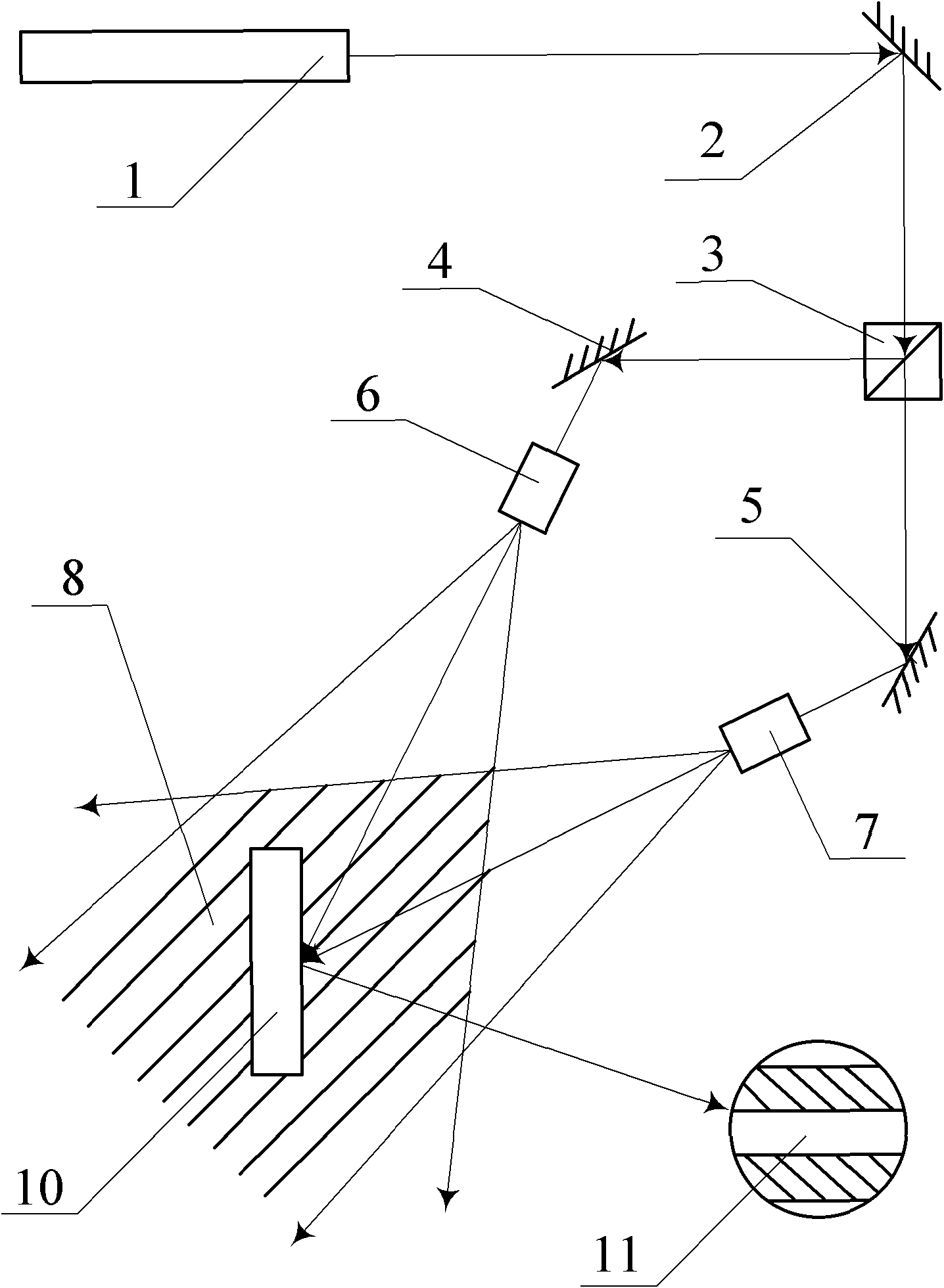

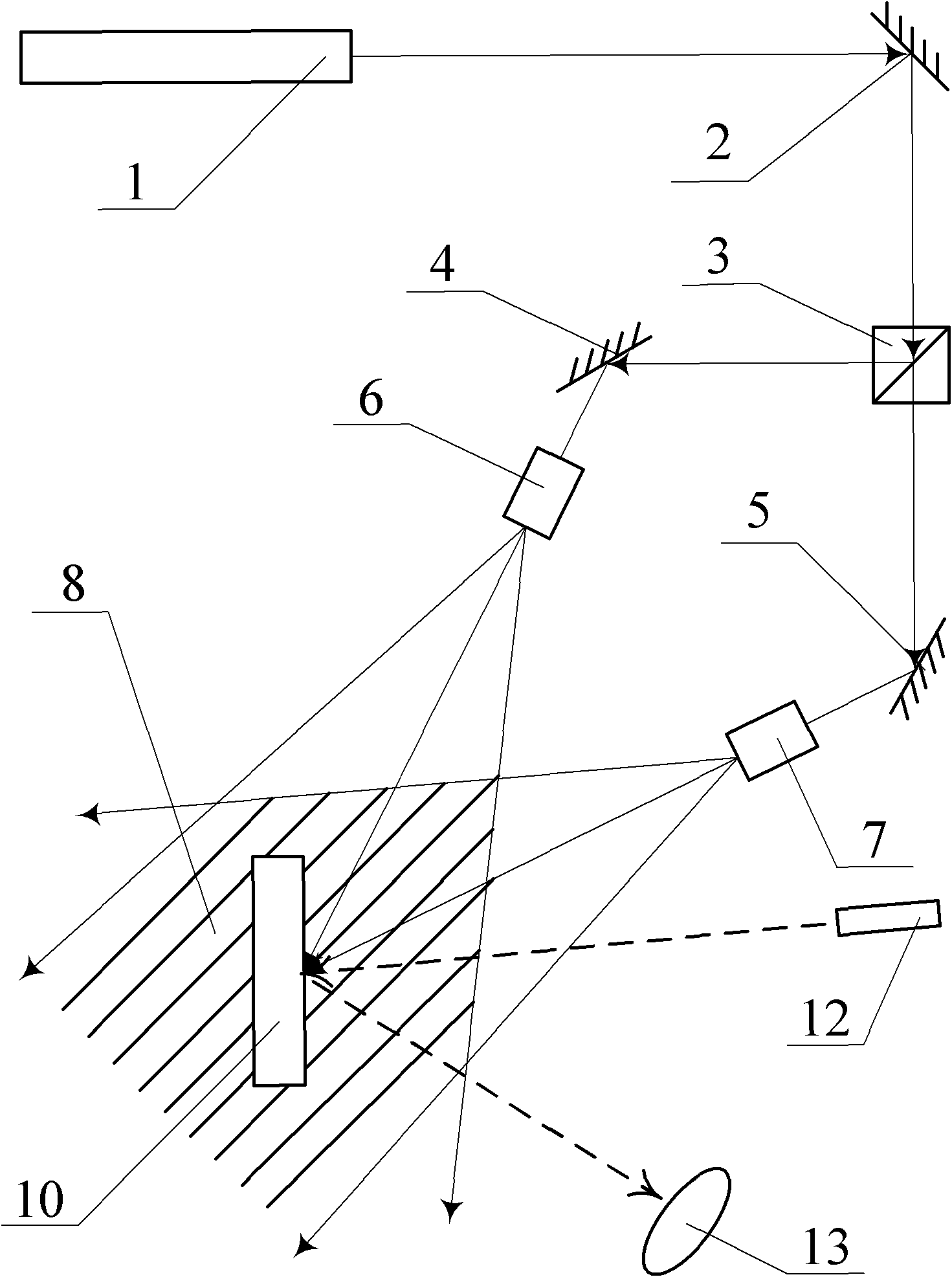

Method for adjusting real-time monitor device in exposure path of concave holographic grating

InactiveCN102087481ASolve the misalignment of monitoring lightImprove production levelDiffraction gratingsPhotomechanical exposure apparatusOptical pathPhotovoltaic detectors

The invention belongs to the field of spectrum technology, and relates to a method for adjusting a real-time monitor device in the exposure path of a concave holographic grating. According to the technical scheme, the method comprises the following steps: (1) establishing a set of concave holographic grating exposure device; (2) resetting the holographic grating in the concave holographic grating exposure device to a position on which the original grating substrate is placed, and adjusting the position of the holographic grating to a position of the grating substrate by an optical interference method; and (3) irradiating the holographic grating with a monitoring beam emitted by a He-Ne laser, and placing a photoelectrical detector on the emergent light axis direction of the diffracted beam of the He-Ne laser. The method can accurately adjust the real-time monitor device in the exposure path of the concave holographic grating, and has the important value for improving the concave holographic grating fabrication technique.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

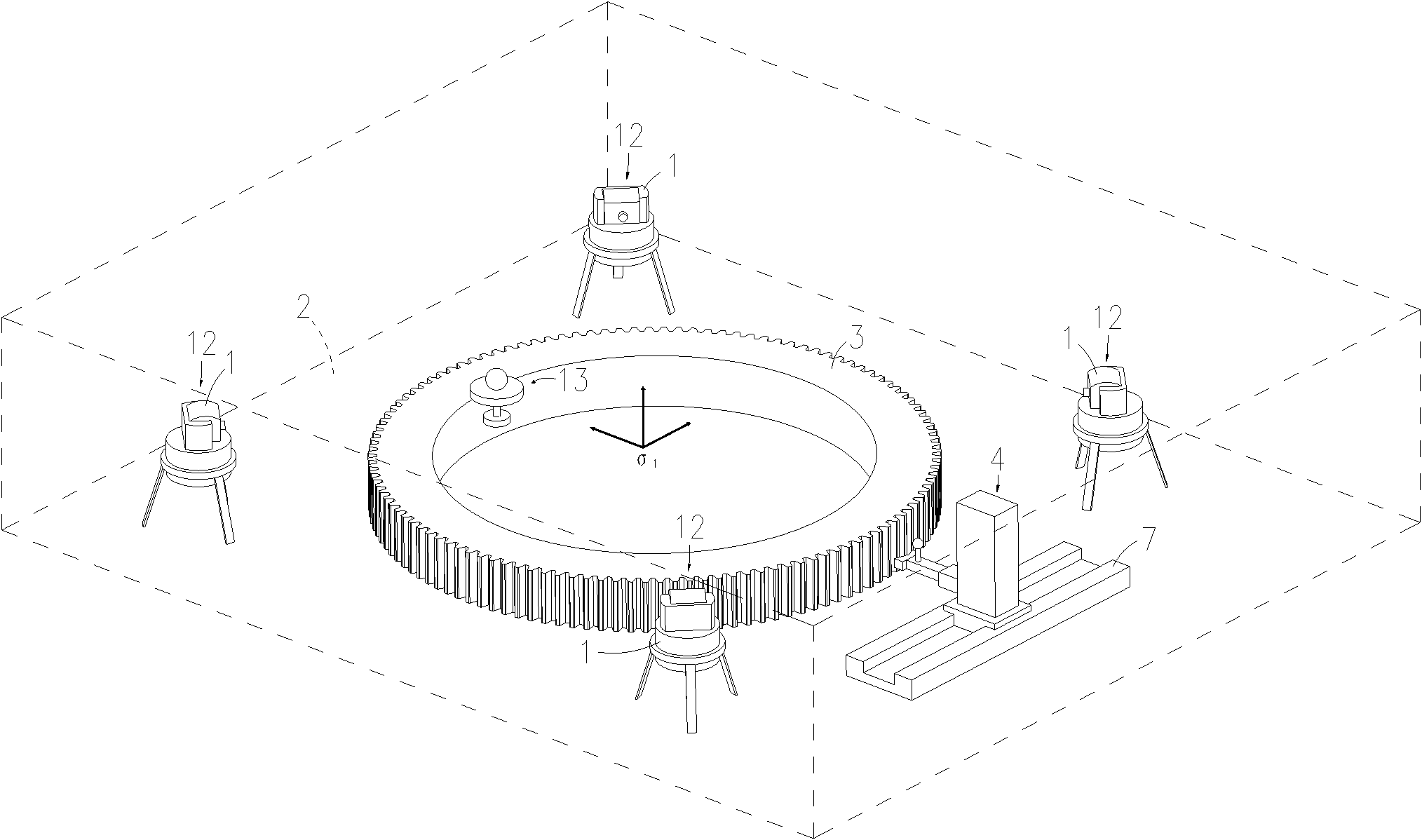

Gear measuring system, gear measuring method and special handheld movable optical reverse reflector

ActiveCN102059588AImprove manufacturing levelMeasurement/indication equipmentsUsing optical meansOptoelectronicsLaser interference

The invention discloses a gear measuring system with high measurement accuracy, a gear measuring method and a special handheld movable optical reverse reflector. The global measuring equipment of the system adopts a multi-path laser interference tracking system which comprises at least three laser interference tracking instruments, a handheld movable optical reverse reflector and a fixed optical reverse reflector, wherein the handheld movable optical reverse reflector is used in match with at least three laser interference tracking instruments so as to carry out the space positioning on a gear to be measured, the fixed optical reverse reflector is used for rigid connection with the movable part of front-end measuring equipment, and the handheld movable optical reverse reflector comprises a reflector and a positioning structure which is connected with the reflector and used for driving the handheld movable optical reverse reflector to move on the datum of the gear to be measured along a special direction. The measuring system and the measuring method can be used for accurately measuring an oversize high-accuracy gear with the diameter of 3000-10000 mm, the minimum modulus of 6 mm and the accuracy at 6 level or above and improve the manufacture level of the oversize high-accuracy gear.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +3

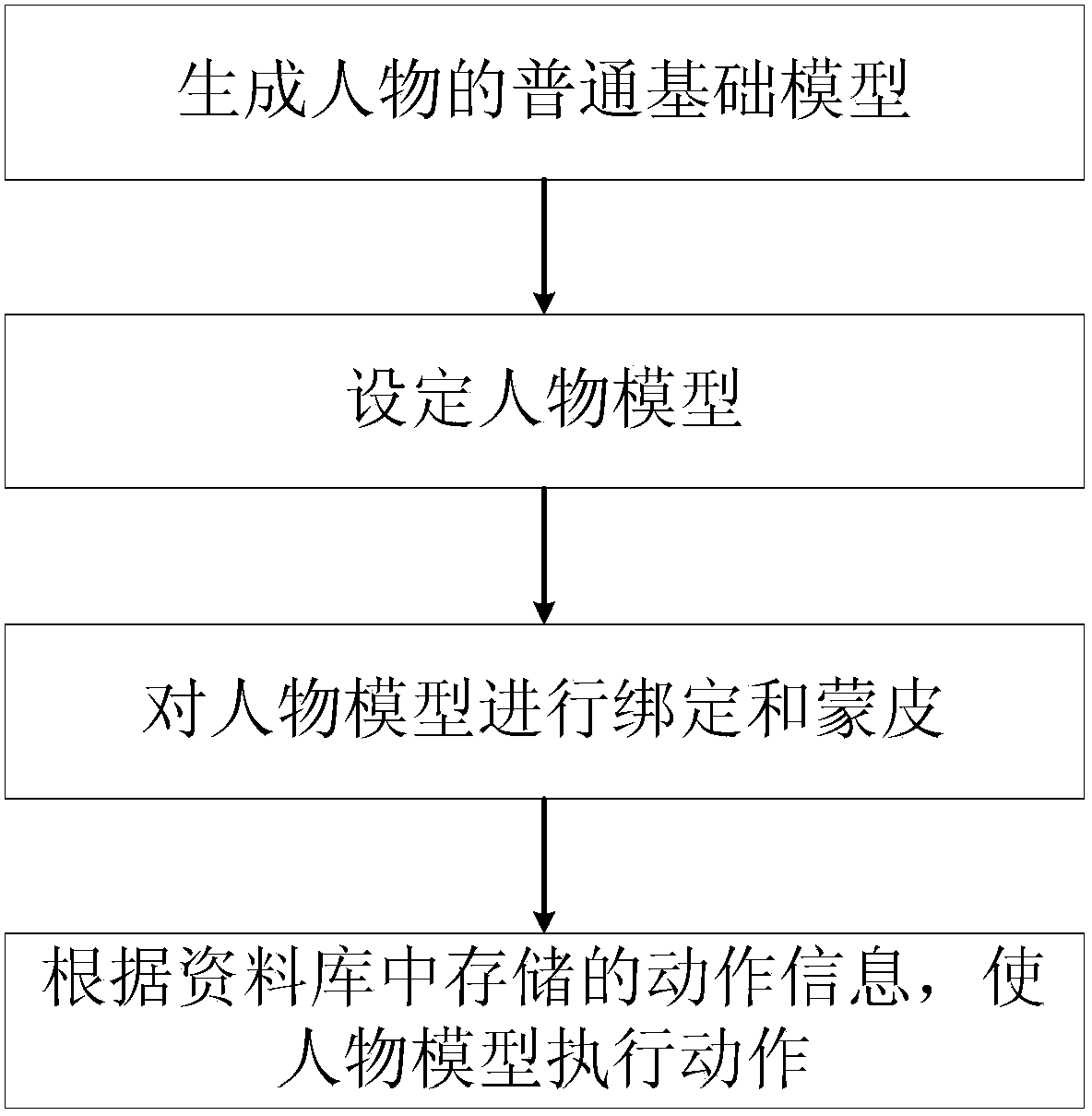

Cloud animation production method

InactiveCN103729871AShorten production timeImprove manufacturing levelAnimationAnimationModel system

The invention provides a cloud animation production method which is used for producing person models in a Maya scene. The cloud animation production method comprises the steps that (1) an ordinary basic model of a person is generated, (2) a person model is set, (3) binding and skinning are conducted on the person model, and (4) the person model is made to execute actions according to action information stored in a database. According to the cloud animation production method, a person modeling system with Maya as an implementation platform is adopted, and the method can help animation personnel accomplish animation production.

Owner:林世仁

Multi-hole parameter detection system and detection method

ActiveCN106403863AJudgment of coaxialityImprove manufacturing levelMeasurement devicesLaser transmitterPhysics

The embodiment of the invention discloses a multi-hole parameter detection system and a detection method, which relate to the technical field of hole detection for simply and conveniently realizing detection on hole diameters, the roundness and the coaxiality. The multi-hole parameter detection system comprises a laser transmitter, a mounting assembly, a laser receiving device and an angle measuring device, wherein the laser receiving device is retractably arranged in a to-be-detected hole of a detected workpiece through the mounting assembly; the laser receiving device can receive laser transmitted by the laser transmitter; and the angle measuring device can measure the rotating angle of the laser receiving device. By adopting the above multi-hole parameter detection system, multiple parameters such as the hole diameters, the roundness and the coaxiality can be detected, and detection on multiple hole parameters by one system can be realized.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Method for producing high chromium tungsten-containing composite anti-wear roll ring

InactiveCN1943861AOptimize quantityImprove liquidityFurnace typesHeat treatment process controlBrickRare earth

The present invention relates to production process of high chromium tungsten-containing composite antiwear roller ring, and belongs to the field of high performance cast iron alloy material and casting producing technology. The production process includes centrifugal composite casting and heat treatment. The composite roller ring has one outer layer of medium chromium tungsten-containing cast iron alloy comprising Cr 12-20 wt%, W 1.0-3.0 wt%, C 2.2-3.4 wt%, Cu 0.6-1.5 wt%, Mn 0.4-1.4 wt%, Ce 0.1 wt%, Si not more than 0.7 wt%, P not more than 0.1 wt%, S not more than 0.06 wt% and Fe for the rest; and one inner layer of high strength nodular cast iron. The composite roller ring has the advantages of high wear resistance, less internal stress, high toughness, long service life and low production cost, and is suitable for use in crushing coal gangue and other hard material in brick making industry.

Owner:SHANDONG JINGTAI WEAR RESISTANT MATERIAL

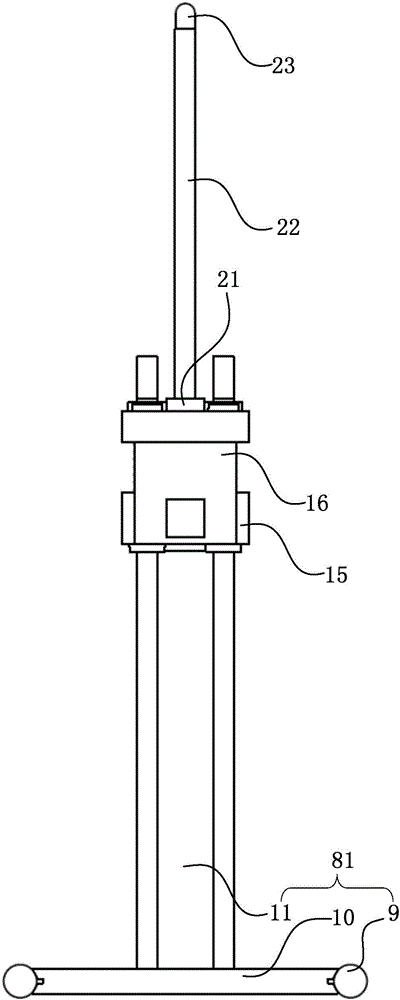

Microfluidic control chip injection molding die

InactiveCN101659105AImprove manufacturing levelPrevent leakageInjection mouldingInjection molding machine

A microfluidic control chip injection molding die belongs to the technical field of the injection molding die. The injection molding die comprises an injection die die-set part and a cavity insert. The injection die die-set uses a two-plate type injection die die-set; the cavity insert comprises a fixed die insert, a moving die insert and a micro machining insert. The fixed die insert is arrangedin a fixed die plate in a matching way and connected by a bolt; the micro machining insert of a microchannle of a molding chip is arranged in the fixed die insert in the matching way and connected with the fixed die insert; the moving die insert is arranged in a moving die plate in the matching way and connected by the bolt; after compound die, a cavity is formed between the micro machining insertand the moving die insert. The side structure of the cavity of the moving die insert is designed to be a rectangular through groove and has the same size with the chip products. The moving die plateadopts lengthening cross gate and stream-line fan gate design. The injection molding die can mold plastic microfluidic control chip with high efficiency on a large scale, further increases the manufacture level of the microfluidic control chip and promotes the application of the injection molding technology in the micro machinery system field.

Owner:DALIAN UNIV OF TECH

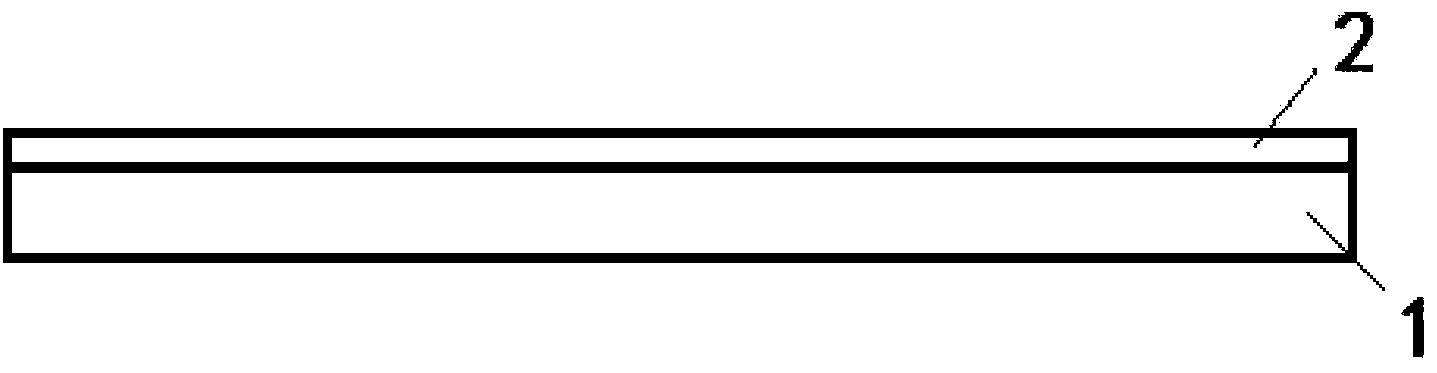

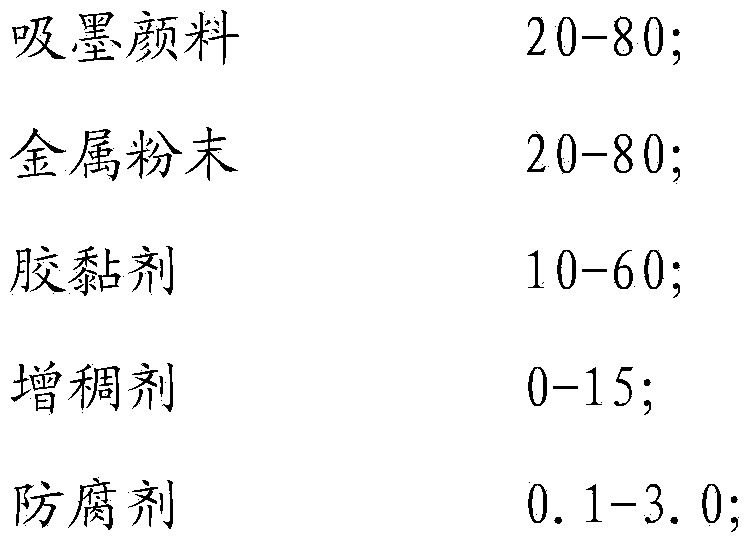

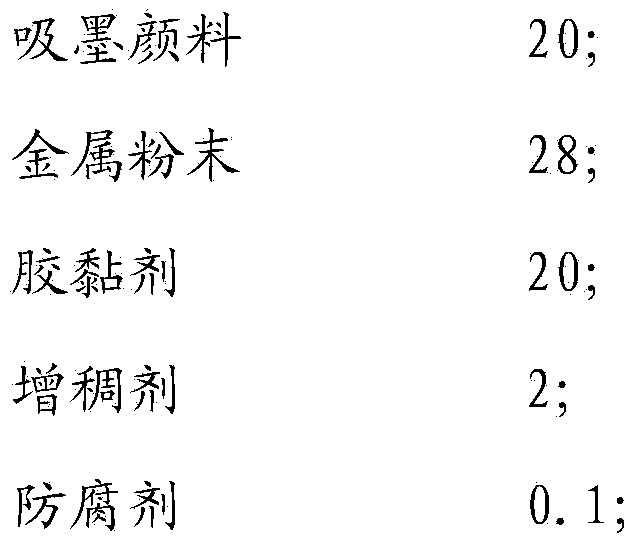

Surface ink blotting type gold and silver cardboard and manufacturing method thereof

The invention discloses surface ink blotting type gold and silver cardboard and a manufacturing method thereof and belongs to the technical field of paper making. The surface of a common cardboard or paperboard base material is coated with a metallic ink blotting coating. The ink blotting coating comprises the following components in parts by weight: 20-80 parts of ink blotting pigment, 20-80 parts of metal powder, 10-60 parts of adhesives, 0-15 parts of a thickening agent and 0.1-3.0 parts of a preservative. The ink blotting gold and silver cardboard has the advantages that because the coating processing is finished once by adopting a coating technology, and the processes of repeatedly coating, evaporating, transferring and stripping in a polyester (PET) film vacuum evaporation technology are simplified in the production process, the production cost is greatly reduced, and the environmental pollution brought by waste of polyester (PET) films is reduced. Because ink can be absorbed on the surface of the ink blotting gold and silver cardboard, the ink blotting gold and silver cardboard is relatively easily used in various high-quality packages due to the applicability to various printing equipment and ink. Therefore, the ink blotting gold and silver cardboard has high economic and social benefits.

Owner:刘景阳

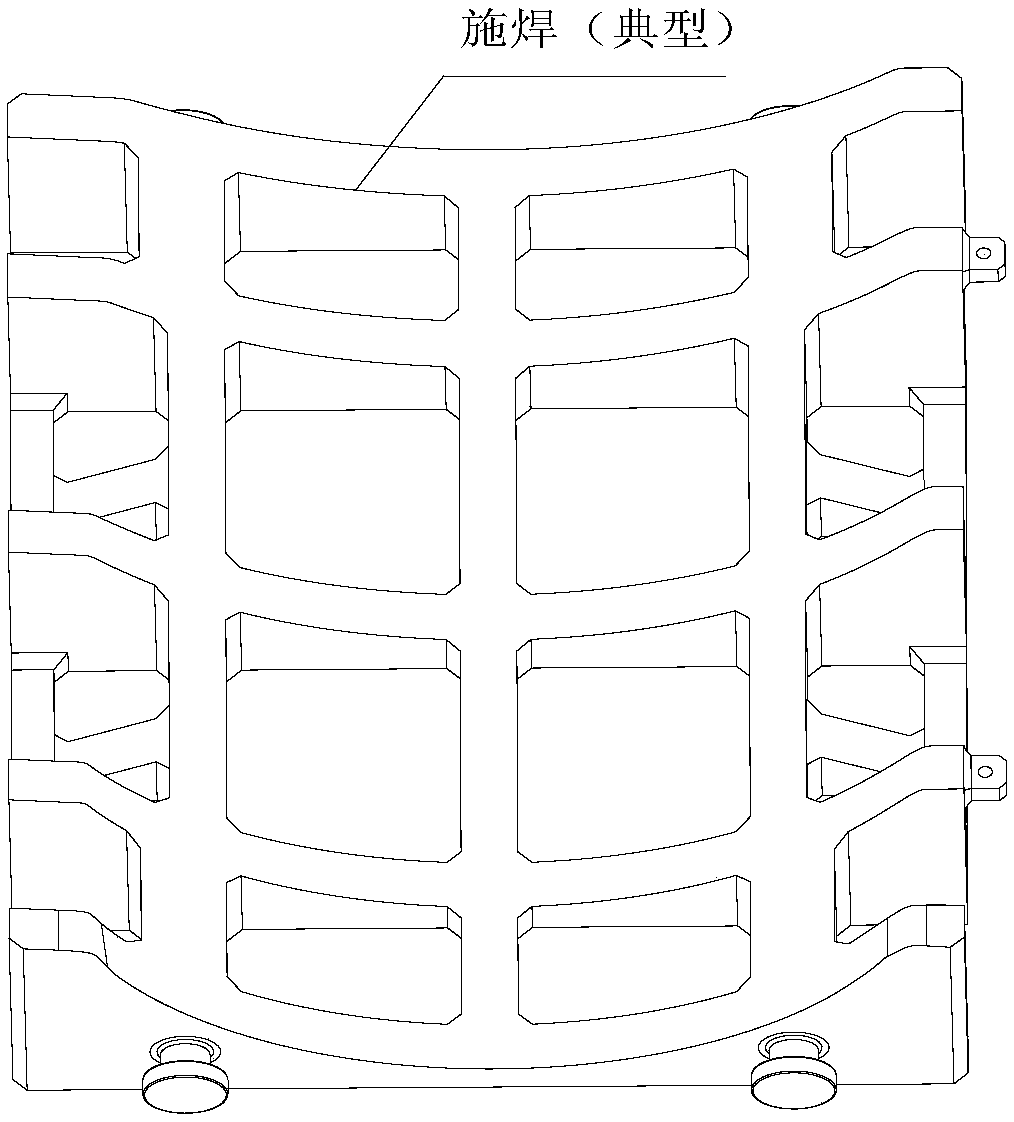

Method for designing and manufacturing ultra-plastic forming and diffusion bonding mould suitable for complex titanium alloy parts

InactiveCN108637568AImprove stabilityReduce casting defectsWelding/cutting auxillary devicesArc welding apparatusNumerical controlCasting defect

The invention provides a method for designing and manufacturing an ultra-plastic forming and diffusion bonding mould suitable for complex titanium alloy parts, belonging to the field of mould design.The ultra-plastic forming and diffusion bonding mould comprises an upper mould component and a lower mould component, wherein each mould component comprises a mould base reinforcing rib and a mould profile web, and the mould base reinforcing rib and the mould profile web are both separately casted and formed; the mould base reinforcing rib and the mould profile web are positioned by welding a positioning lug device, and the binding faces of the mould base reinforcing rib and the mould profile web are connected in a welding mode to form the mould component; and the upper mould component and thelower mould component form the mould in the welding mode. The profile web and the reinforcing rib are separated, are subjected to numerical control milling and cutting and are connected in a weldingmethod to form a whole, so that the method can realize high stability and less casting defects of the mould, is convenient in manufacturing, and provides a reliable means for forming complex large titanium alloy ultra-plastic forming / diffusion bonding parts.

Owner:SHENYANG AIRCRAFT CORP

Preparing method for embedded expanding piece of car

Am embedded expandable plate for car is prepared through prepairng the foaming mother particles from resin, foaming agent, foaming assistant and disperser, proportionally mixing then with polyolefin resin and cross-linking agent, and injection moulding.

Owner:HENKEL CORP

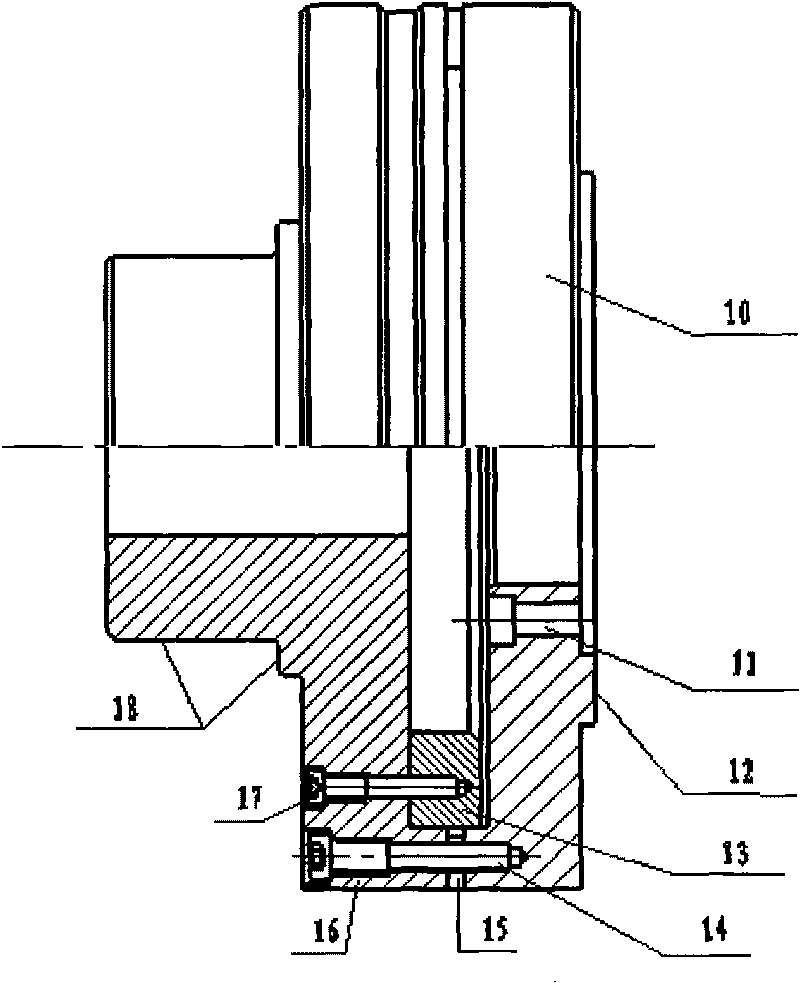

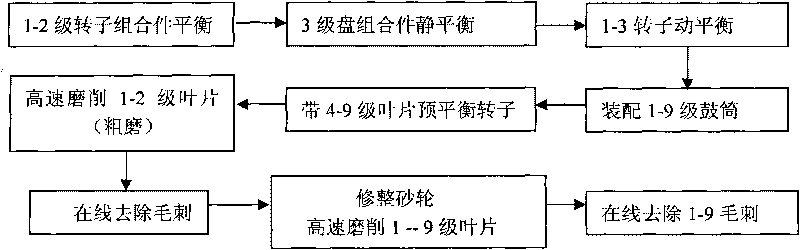

Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

ActiveCN101722459AGuaranteed GrindingMeet the design requirementsGrinding machinesAviationEngineering

The invention relates to a composite processing method for grinding the vane apex of a rotor vane of an aeroengine at a high speed, which comprises the following steps of: firstly, balancing a rotor in advance, controlling unbalance quantity which is permitted to be used for balancing the rotor in advance to be within 254g.mm, then installing the rotor on a fixture, enabling the rotor to be in a stretching state and grinding at a high speed. In the grinding process, the rotational speed of a processing part is 1600-2000r / min, the linear speed of a grinding wheel is 33-36m / s, the rotational speed of a scrubbing brush is 1500-1900r / min, and the control temperature during grinding is 20+ / -5 DEG C.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com