Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

An aero-engine and rotor blade technology, applied in the field of grinding processing, can solve the problems of unstable quality, burns, low efficiency, etc., and achieve the effect of improving processing efficiency and improving manufacturing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

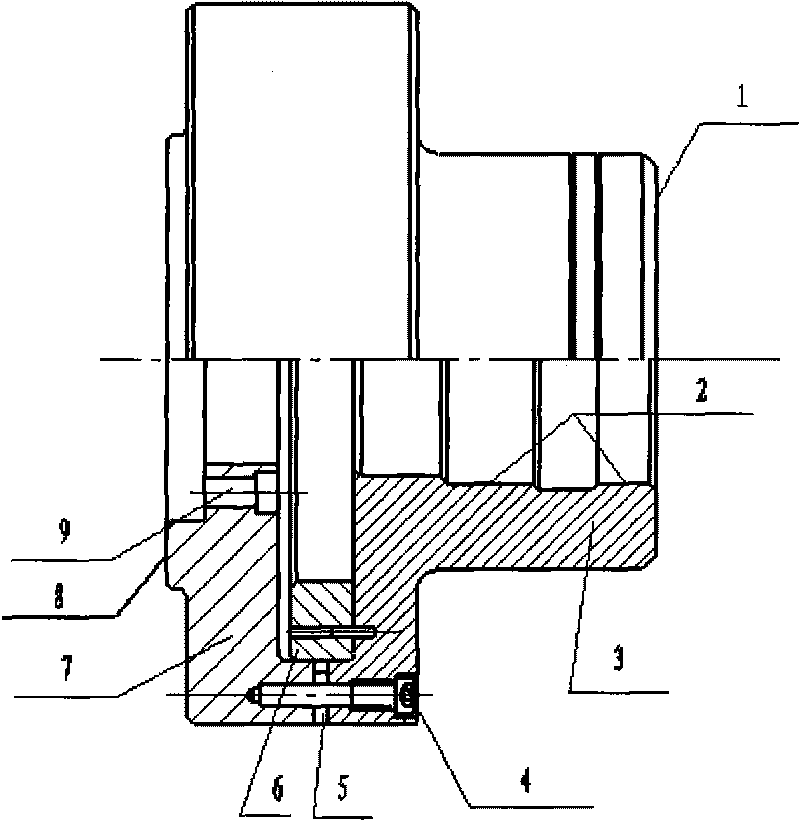

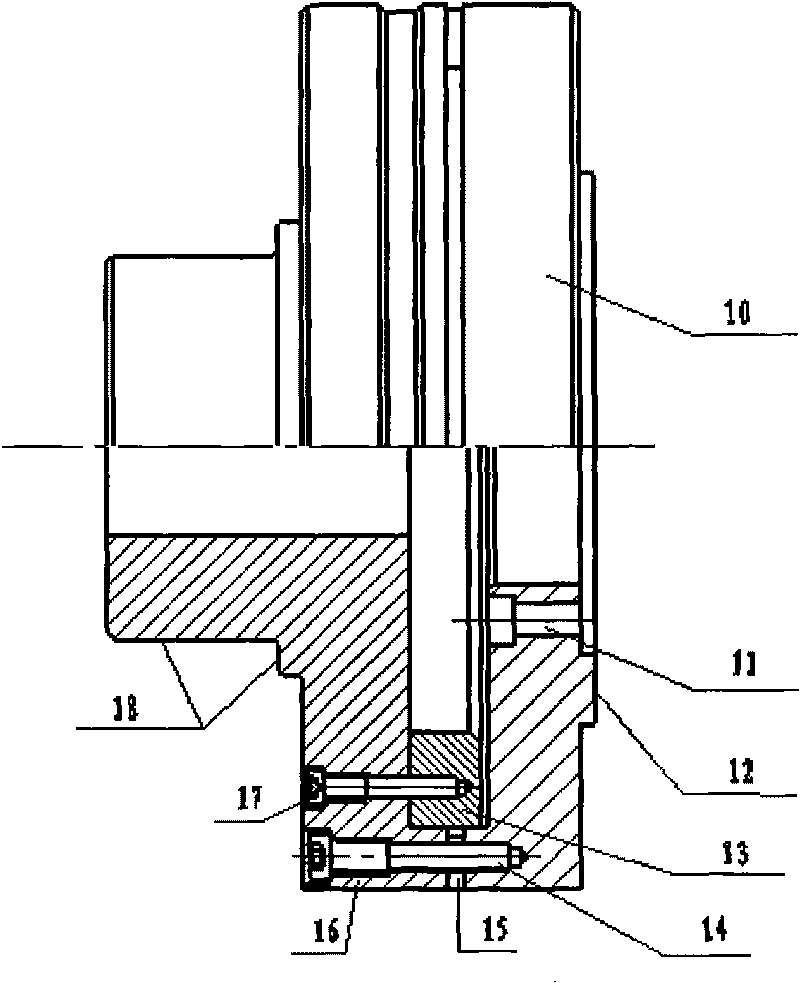

Method used

Image

Examples

Embodiment 1

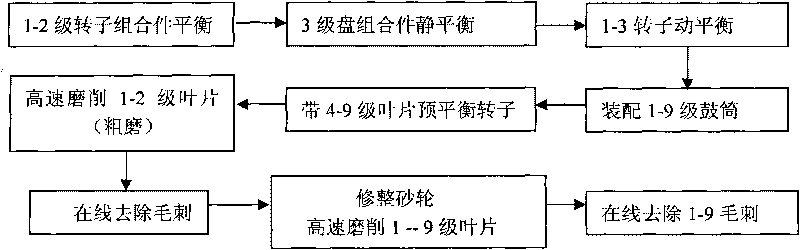

[0041] Step 1: Pre-Balance the Rotor

[0042] Install the rotor on the balancing machine, adopt single-stage balancing of turntables at all levels, group and combine balancing, and repeat balancing. The specific steps are as follows:

[0043] 1) The final dynamic balance of the primary and secondary rotors: the initial unbalance of each correction plane of the initial primary and secondary rotors is 513.8g.mm and 357.5g.mm respectively. By adjusting the position of the primary and secondary rotor blades, each The unbalance amounts of the two correction planes are 186.7g.mm and 150.4g.mm respectively.

[0044] 2) Balance the third-stage disc assembly: statically balance the third-stage disc assembly, and adjust the position of the third-stage blades so that the unbalance of the correction plane is 184.3g.mm.

[0045] 3) Rotor initial leveling: The high-pressure compressor rotor installed with 1-3 blades is dynamically balanced, and the initial unbalance of each correction plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com