A livestock feed screening device

A feed sieving and sieving technology, which is applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of automatic sieving of feed, inability to reuse, low work efficiency, etc., and achieve novel and practical design Strong, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

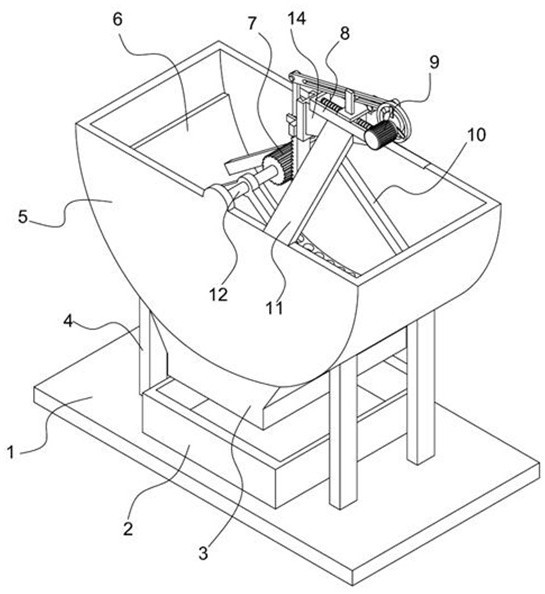

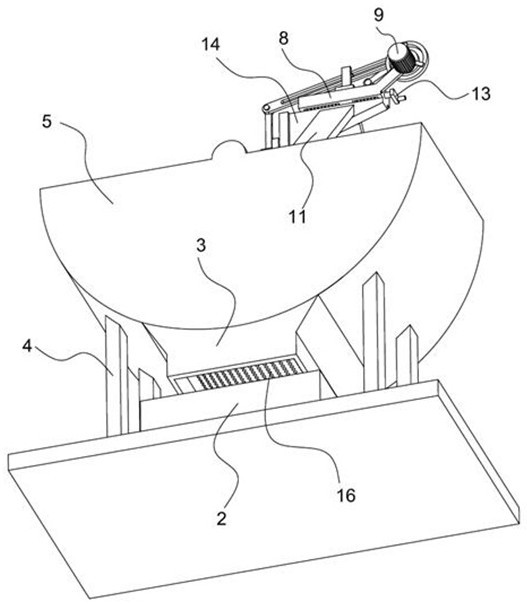

[0032] see Figures 1 to 9 , In the embodiment of the present invention, a livestock feed screening device includes a fixed base 1, and a screening box 5 is installed on the upper side of the fixed base 1 through a support column 4, thereby ensuring the stable support and installation of the screening box 5, and the screen The screening shaft 12 is rotated and installed on the upper side of the sub-box 5. The screening gear 7 is installed in the middle of the screening shaft 12. The screening shaft 12 and the screening gear 7 are fixedly connected by keys. The connecting frame 10 is fixedly installed at the side position, and the bottom of the connecting frame 10 is installed with the screening plate 6 close to the inner bottom side of the screening box 5. For effective grinding and screening, a limit plate 14 is installed on the upper side of the screening box 5 through the limit frame 11, and a power mechanism for driving the screening shaft 12 to reciprocate is installed on...

Embodiment 2

[0039] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment lies in that, one end of the lead screw 28 is installed with the handle 13 through the limit frame 8, which facilitates the staff to adjust the lead screw 28 Rotation is performed to further improve the reliability of the device.

[0040] The working principle of the present invention is: when working, the feed that needs to be screened is placed on the screening plate 6 inside the screening box 5, the larger particles will stay on the upper side of the screening plate 6, and the smaller particles of feed It will be introduced into the position between the bottom of the screening plate 6 and the bottom of the screening box 5 through the screening hole 17, and then start the power motor 9, so that the screening plate 6 swings back and forth inside the screening box 5, and then the feed is carried out. Grinding and squeezing, and finally discharge the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com