Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1182 results about "Balancing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A balancing machine is a measuring tool used for balancing rotating machine parts such as rotors for electric motors, fans, turbines, disc brakes, disc drives, propellers and pumps. The machine usually consists of two rigid pedestals, with suspension and bearings on top supporting a mounting platform. The unit under test is bolted to the platform and is rotated either with a belt-, air-, or end-drive. As the part is rotated, the vibration in the suspension is detected with sensors and that information is used to determine the amount of unbalance in the part. Along with phase information, the machine can determine how much and where to add or remove weights to balance the part.

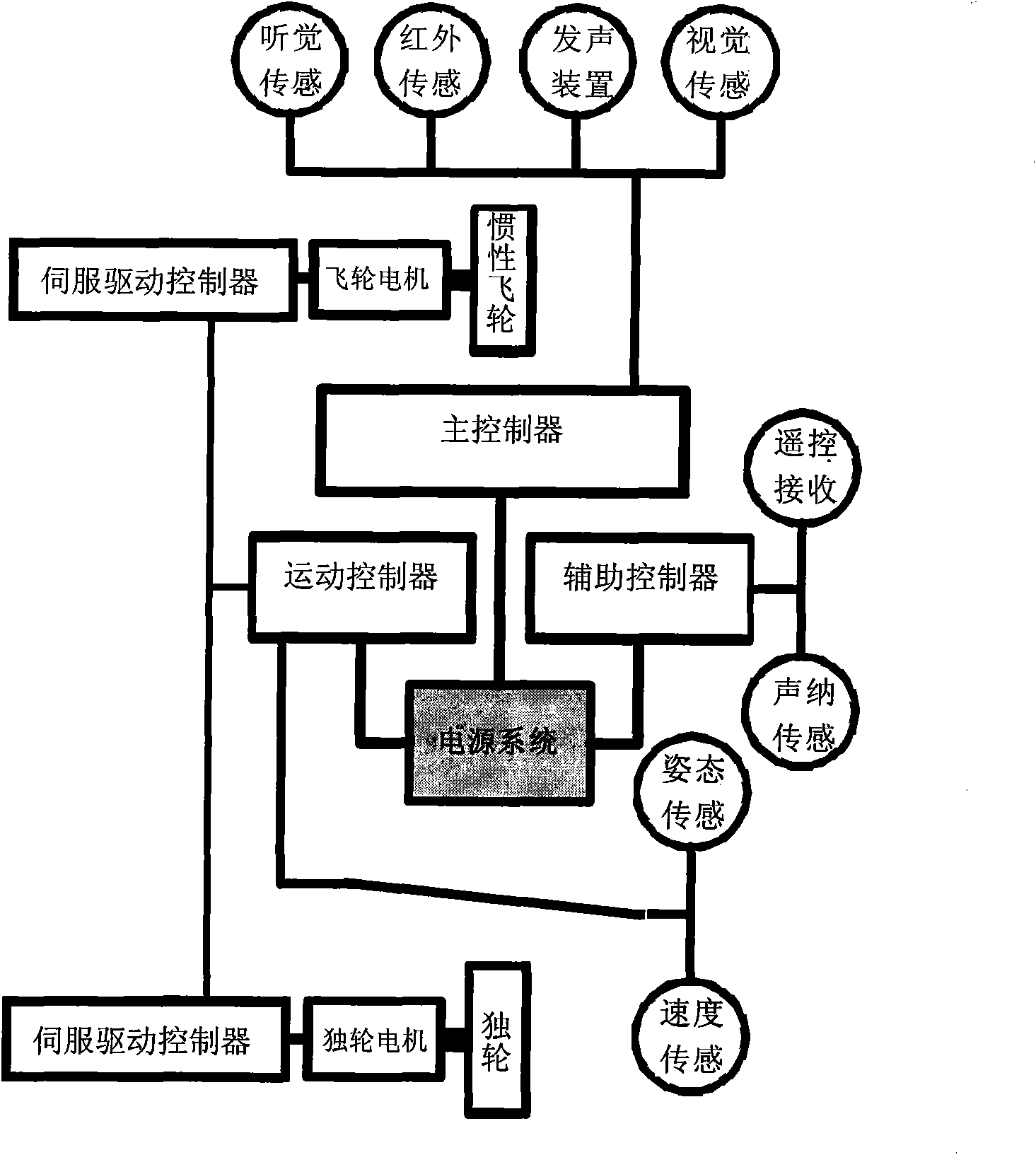

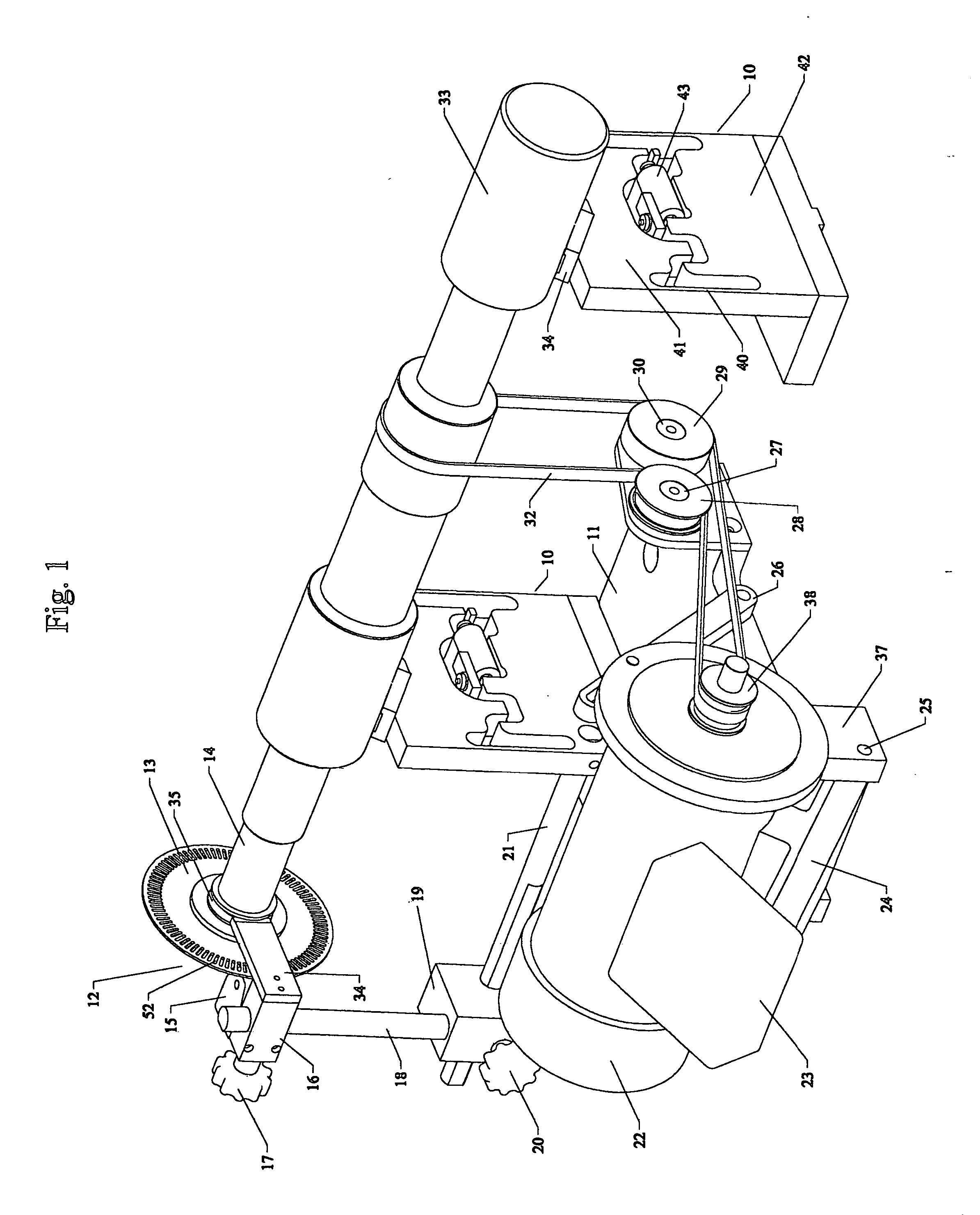

One-wheel robot system and control method thereof

The invention relates to a single-wheel robot system and a control method thereof, belonging to the field of intelligent robot, in particular to a static unbalanced robot which can autonomically control movement balance further to autonomically ride a monocycle and a movement balance control method thereof. The single-wheel robot comprises a robot body and a balance detection and control system and is characterized in that the lower part of the robot body is provided with a single wheel which can rotate front and back, and the middle of the robot is provided with an inertial flywheel which can rotate left and right and is horizontally placed; the balance detection and control system comprises a movement controller, a posture detector and a servo drive controller, wherein the posture detector and the servo drive controller are connected with the movement controller; and the movement controller 10 receives a signal of a posture sensor and processes the received signal according to a control procedure so as to send a control order to control a motor through the servo drive controller to regulate the posture balance of the single-wheel robot. The invention provides a control platform which not only belongs to robotics but also belongs to the field of control science and intelligent control, thereby meeting the needs of multi-subject scientific research and teaching.

Owner:BEIJING UNIV OF TECH

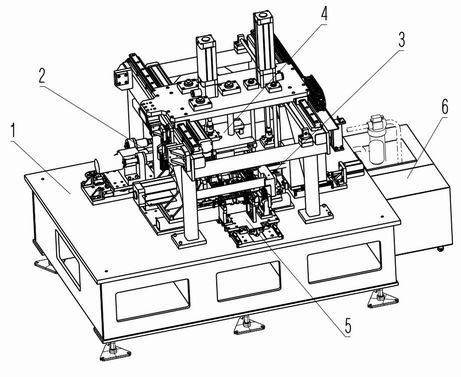

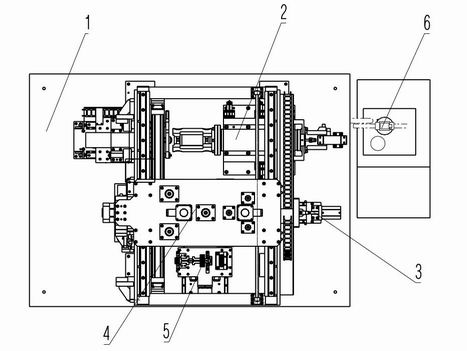

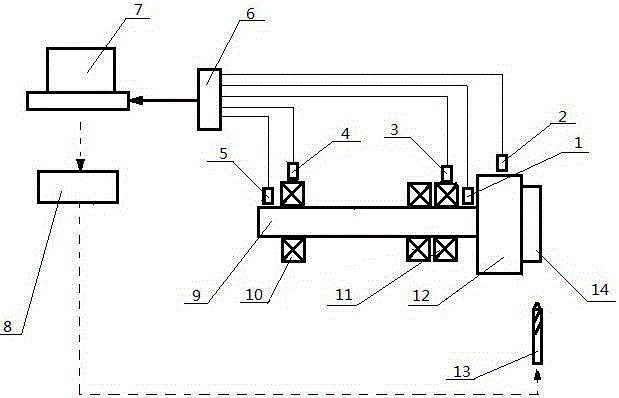

Automatic hot-pressing assembly device of balancing shaft and helical gear

InactiveCN102029501AImprove reliabilityWill not polluteMetal working apparatusBalancing machineGear wheel

The invention discloses an automatic hot-pressing assembly device of a balancing shaft and a helical gear, comprising a dynamic balancing machine (2), a gear hot-pressing machine (3), a manipulator (4) and a feeding and blanking station (5), wherein the manipulator (4) clamps a balancing shaft to be assembled and a helical gear to be assembled on the feeding and blanking station (5) and respectively sends the balancing shaft to be assembled and the helical gear to be assembled to the dynamic balancing machine (2) and the gear hot-pressing machine (3), the dynamic balancing machine (2) measures the dynamic unbalance quantity of the balancing shaft and carries out direction alignment on the balancing shaft, the helical gear is heated in the gear hot-pressing machine (3), and the balancing shaft subjected to dynamic unbalance measurement and direction alignment is sent into the gear hot-pressing machine (3) through the manipulator (4) and is in hot-pressing assembly with the heated helical gear. The device has sufficient static, dynamic and heat stable rigidity and accuracy; the whole system has good dynamic performance; and an execution element which is selected for a detection measurement and display system has the advantages of high accuracy, good reliability, strong anti-interference ability, high response speed and stable continuous processing performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for determining unbalance amounts of rotor

ActiveCN103776587AStatic/dynamic balance measurementManufacturing dynamo-electric machinesBalancing machineMechanical engineering

Owner:BEIJING SYTH TESTING CO LTD

Palletizing robot

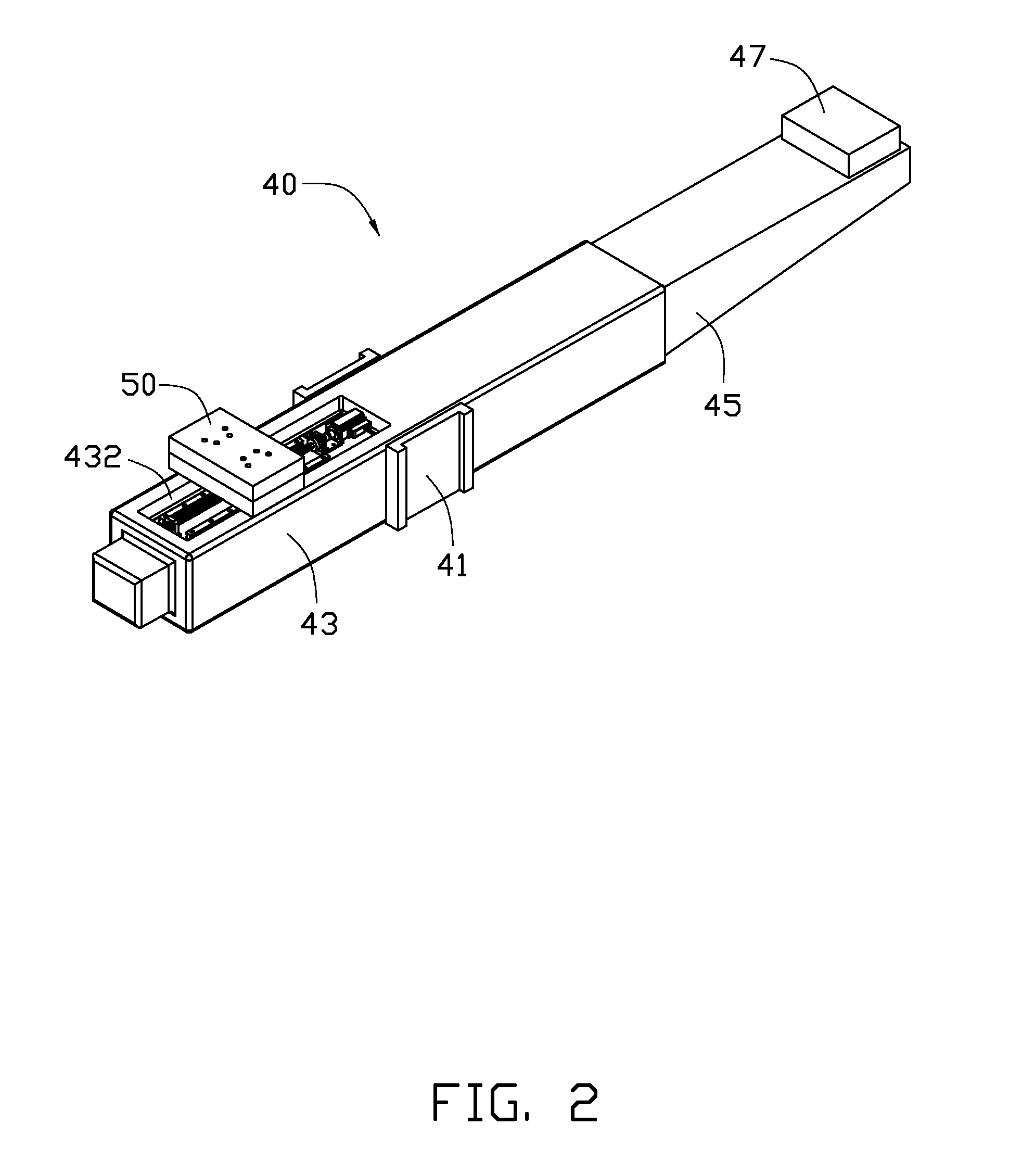

InactiveUS20110268549A1Low balanceProgramme-controlled manipulatorMechanical apparatusEngineeringActuator

A palletizing robot includes a lifting frame, an end-effector, an extensible mechanical arm, and a balancing mechanism. The extensible mechanical arm is rotatably connected to the lifting frame. The balancing mechanism and the end-effector are located on opposite ends of the extensible mechanical arm. The balancing mechanism includes a threaded rod, a sliding member, a driving member, and a counterweight. The threaded rod is located on the extensible mechanical arm. The sliding member receives the threaded rod. The driving member is fixed on an end of the threaded rod. The counterweight is fixed on the sliding member. The driving member rotates the threaded rod such that the sliding member slides relative to the threaded rod.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

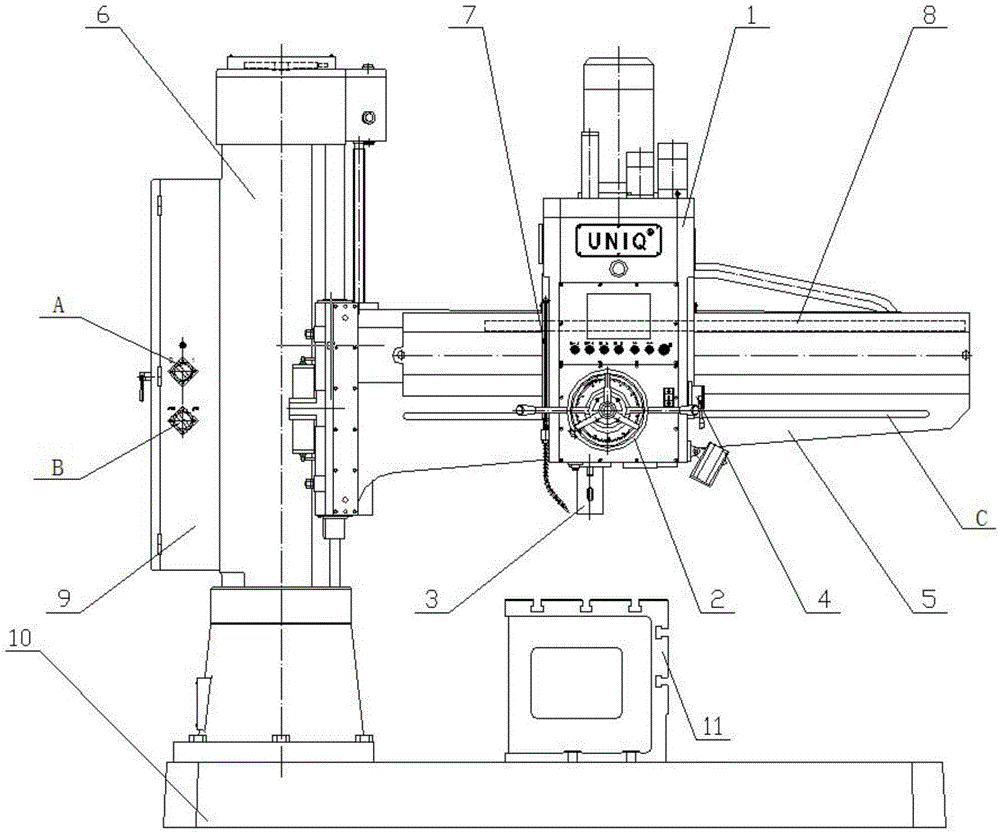

Numerical display type radial drilling machine

ActiveCN105252035AHigh guiding precisionEasy to fixMeasurement/indication equipmentsFeeding apparatusGraphicsBalancing machine

The invention provides a numerical display type radial drilling machine, comprising a spindle speed regulating and spindle feeding speed regulating system, a spindle feeding mechanism, a spindle and balance mechanism, a spindle positive / negative rotation and variable-speed control mechanism, a rocker arm and clamping mechanism, an upright and rocker arm lifting mechanism, a hydraulic and cooling system, a testing system, a numerical display control system and the like; the upright and rocker arm lifting mechanism is mounted on a base; the rocker arm and clamping mechanism is mounted on the upright and rocker arm lifting mechanism; the numerical display control system is mounted on the upright and rocker arm lifting mechanism; the spindle speed regulating and spindle feeding speed regulating system is mounted on the rocker arm and clamping mechanism; the spindle feeding mechanism, the spindle and balance mechanism, the spindle positive / negative rotation and variable-speed control mechanism, and the hydraulic and cooling system are mounted on the spindle speed regulating and spindle feeding speed regulating system. According to the numerical display type radial drilling machine, stepless speed changing of a spindle can be realized without shutdown; graphic and numerical display can be realized at working positions; a die wall clamping device of a guide rail and a spindle limiting structure are sensitive and reliable; in short, the numerical display type radial drilling machine is applicable to machining industries.

Owner:SHENYANG JINGHONG NUMERICAL CONTROL EQUIP CO LTD

Mechanical coupling type magnetic suspension wind turbine generator yaw system

ActiveCN103883469AAchieving Radial OffsetReduce Yaw Power ConsumptionWind motor controlMachines/enginesNacelleYaw system

The invention discloses a mechanical coupling type magnetic suspension wind turbine generator yaw system which is applied to a large and medium wind turbine generator. The mechanical coupling type magnetic suspension wind turbine generator yaw system comprises a planet gear, a conical gear, an electromagnetic clutch, vertical suspension windings, horizontal suspension windings and yaw motors. Wind turbine generator yaw mechanical torque and yaw motor torque are coupled through planet gear torque to drive a wind turbine generator cabin to be yawed. The wind turbine generator yaw mechanical torque is taken from electric generator front side wind turbine generator torque through the electromagnetic clutch and the conical gear with the fixed transformation ratio. The yaw motor torque is controlled by a bidirectional PWM converter during cabin suspension, cabin suspension is jointly controlled by the horizontal suspension windings and the vertical suspension windings, the cabin gravity is balanced through the horizontal suspension windings, the vertical suspension windings restrain off-centering, the yaw motors can work in the two modes including the electric mode and the regenerative braking mode through changes of the wind turbine generator yaw torque, and bidirectional energy flowing is completed through the PWM converter. According to the mechanical coupling type magnetic suspension wind turbine generator yaw system, the yaw power energy conversion link is omitted, the yaw power consumption is greatly reduced, and the wind energy use rate is improved.

Owner:QUFU NORMAL UNIV +1

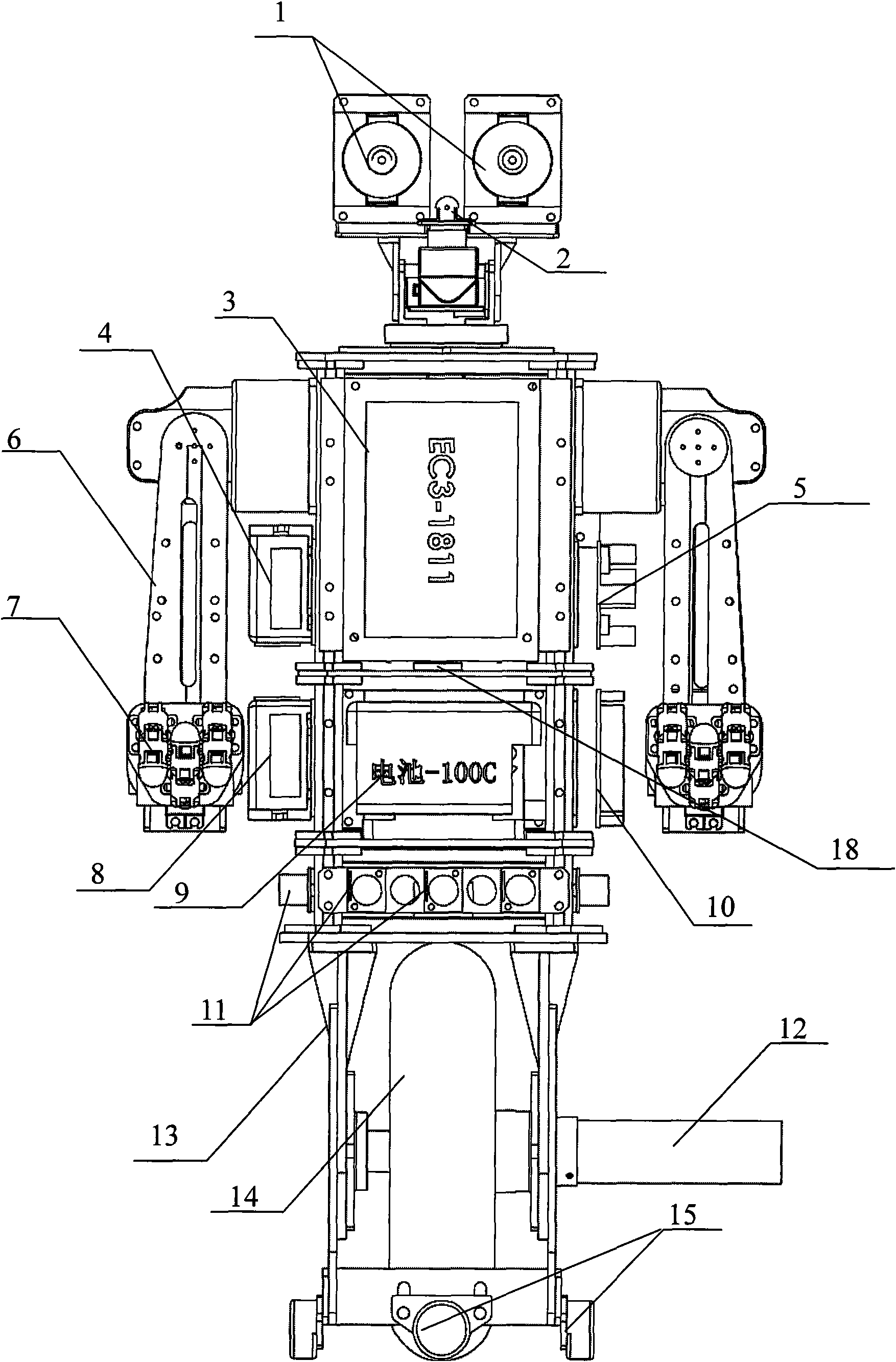

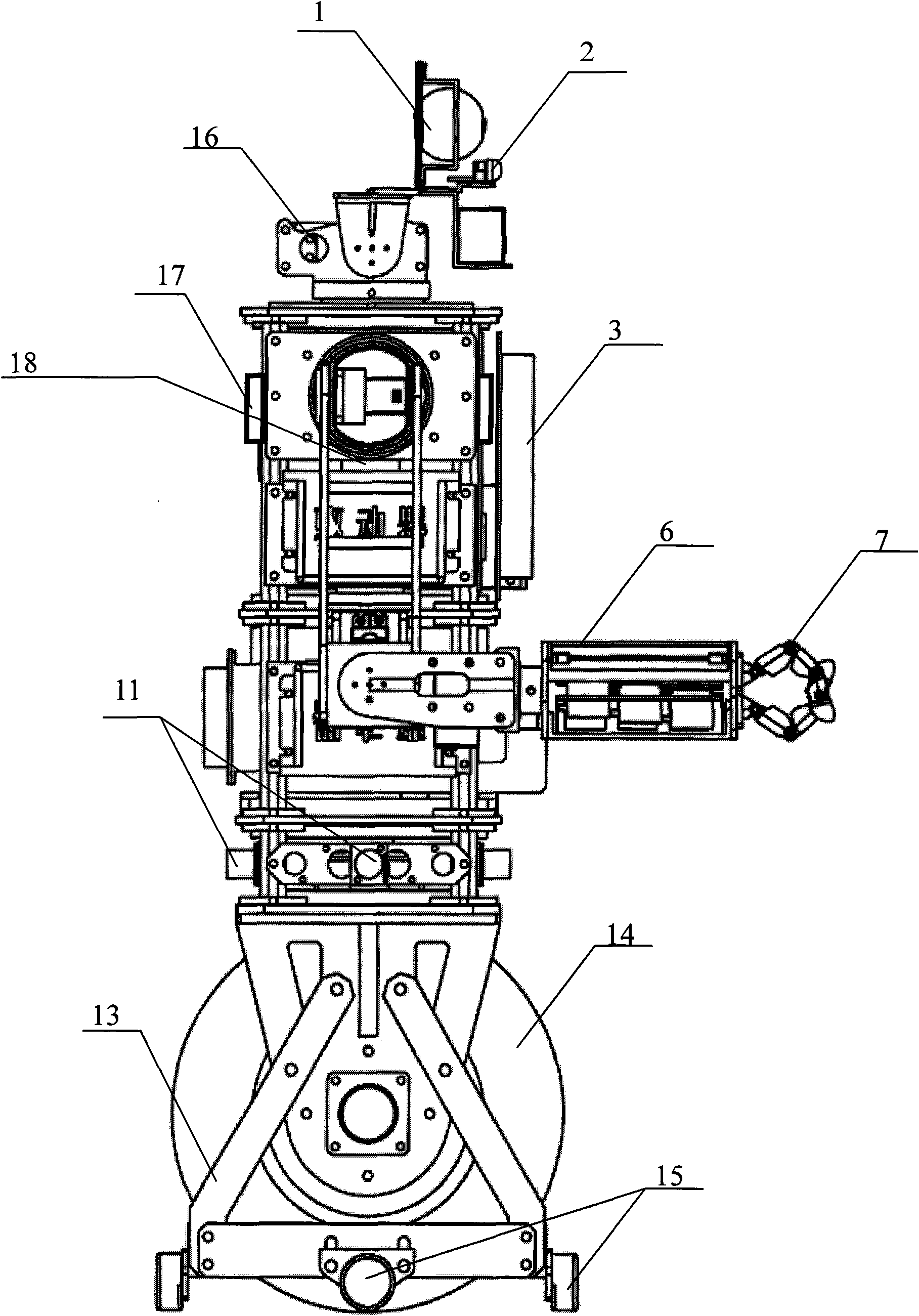

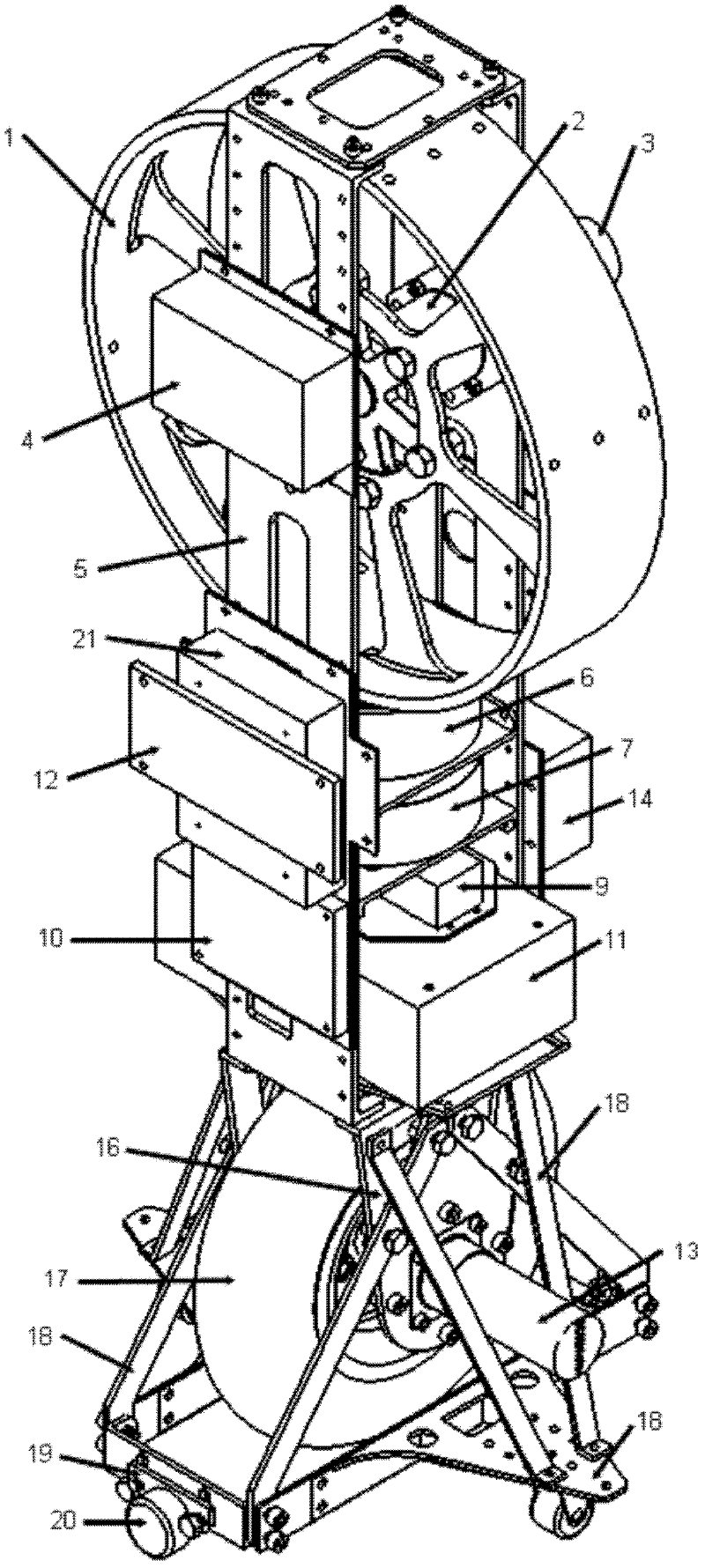

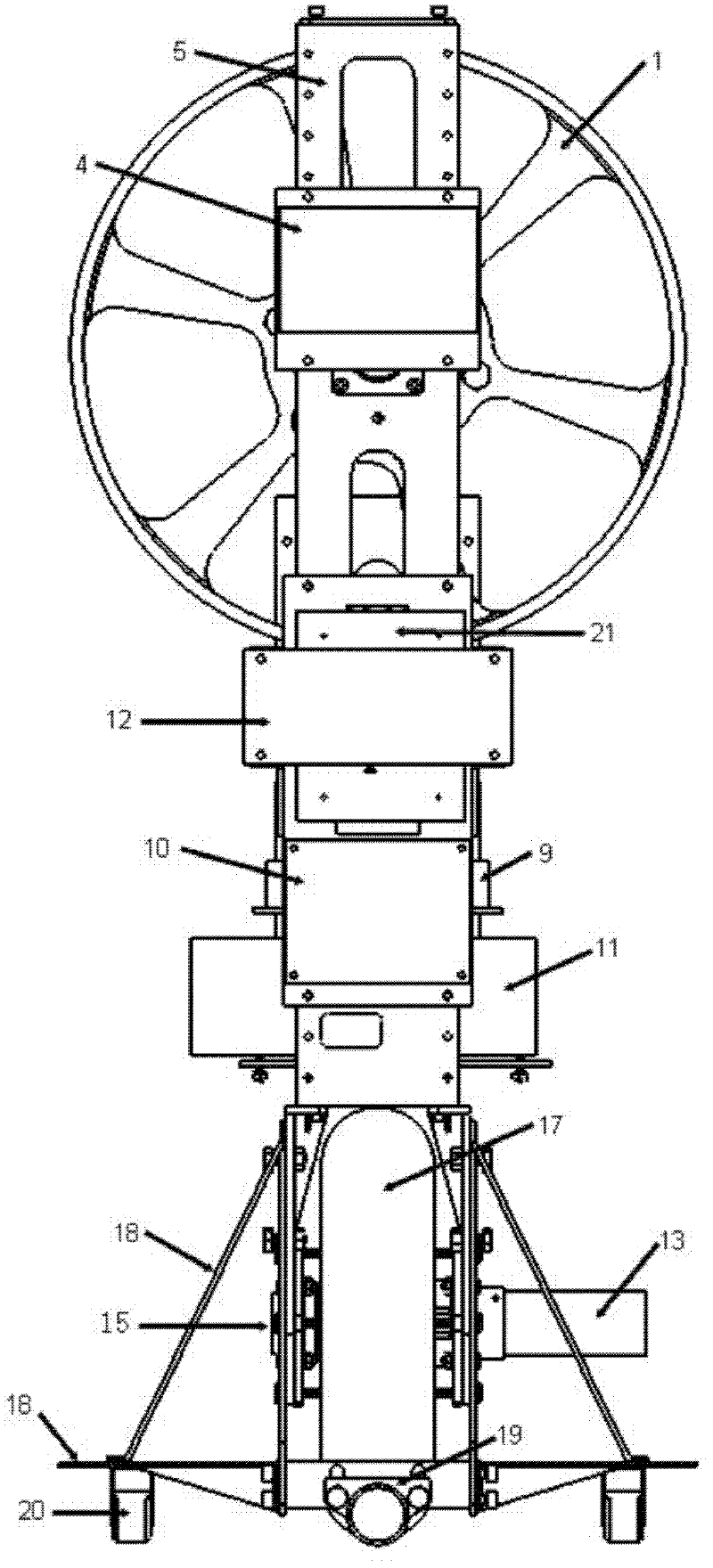

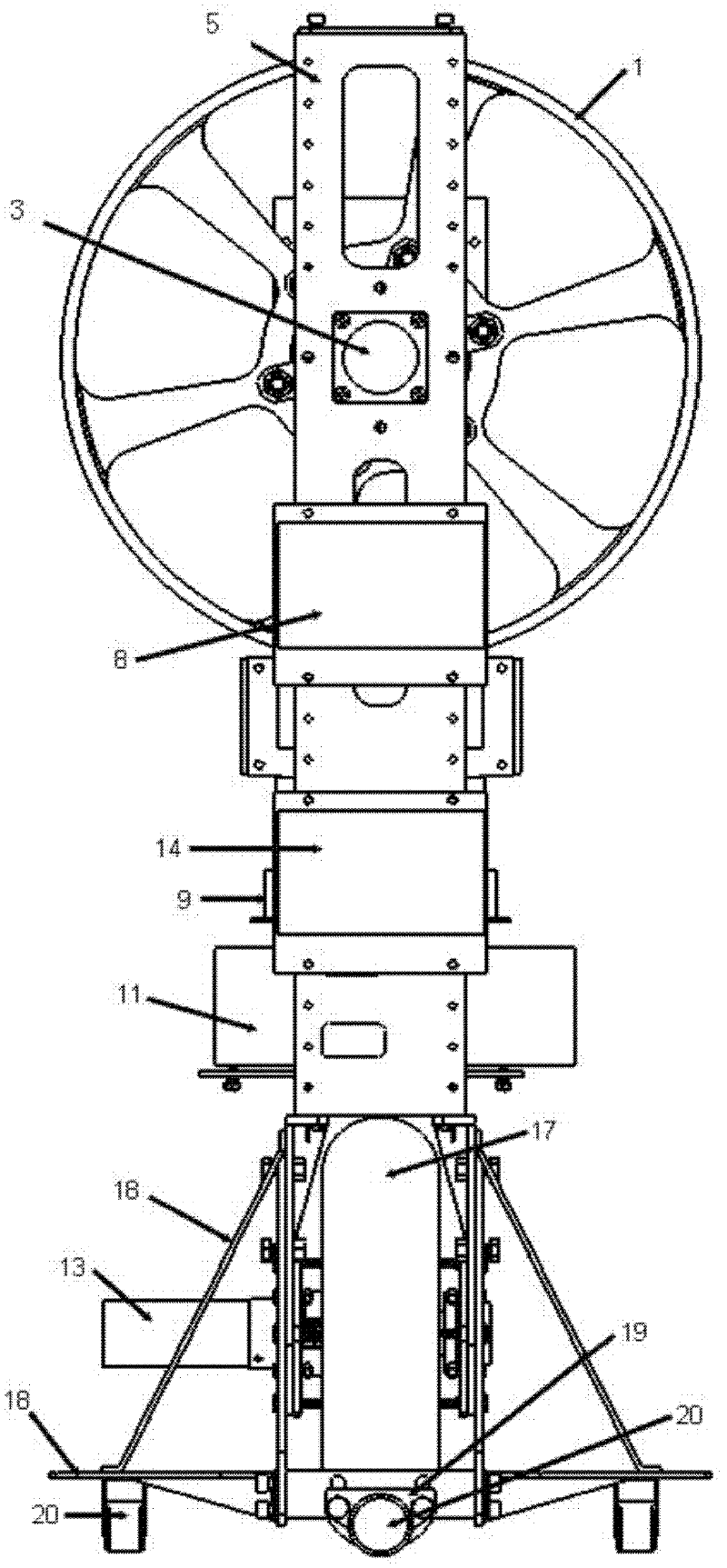

Single-wheel self-balancing robot system

ActiveCN102445944AMeet the needs of multidisciplinary scientific research teachingUnique shapePosition/course control in two dimensionsDrive motorMotion controller

The invention relates to a single-wheel self-balancing robot system belonging to the category of intelligent robots, in particular to a static unbalanced robot which is capable of autonomously controlling motion balance and then autonomously riding a wheelbarrow. The single-wheel self-balancing robot system provided by the invention comprises a mechanical body and an electrical control system and is characterized in that: a vertically-arranged flywheel capable of rotating from side to side is contained in the upper part of the body and used for realizing the horizontal balance controlling of the robot; a rotatable horizontally-arranged flywheel is contained in the middle of the body and used for realizing the turning of the robot; a single wheel capable of rotating forward and backward is contained in the lower part of the body and used for realizing the forward and backward balance walking of the robot; and the electrical control system is composed of a drive motor, a motion controller and an attitude sensor and a servo drive controller which are connected with the electrical control system. The system provided by the invention provides a control platform, relates to the fields of control technology and intelligent control besides robotics and is capable of satisfying the requirements of multidisciplinary research and teaching.

Owner:河北环宇电力通信工程有限公司

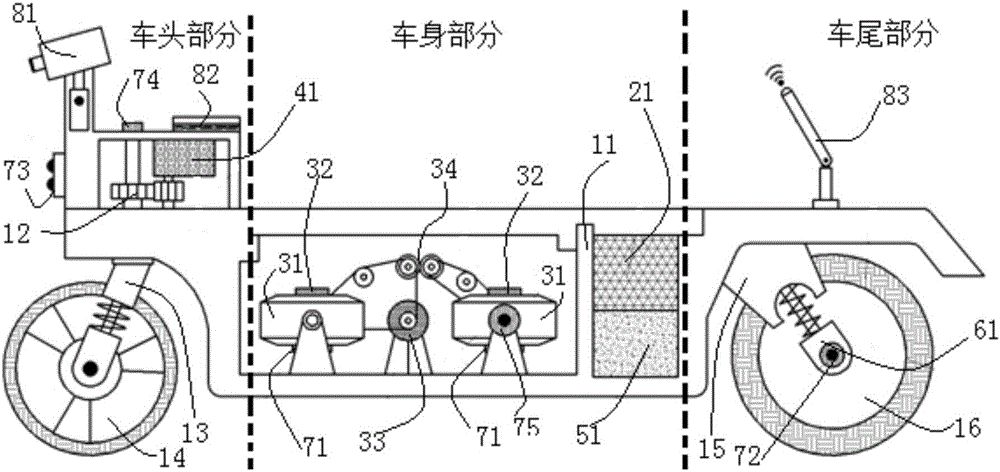

Two-wheeled longitudinal self-balancing robot and control system

InactiveCN106627894AFast functional responseLarge correction torqueCycle sensorsAttitude controlStable stateControl system

The invention discloses a two-wheeled longitudinal self-balancing robot and a control system. The two-wheeled longitudinal self-balancing robot comprises a head part, a body part, a tail part, an electric control box, a front wheel steering mechanism, a front wheel mounting mechanism, a front wheel, a rear wheel mounting mechanism and a rear wheel. The control system for the two-wheeled longitudinal self-balancing robot comprises a master control unit, a dual gyro balancing component, a steering engine drive unit, a rear wheel drive unit, a man-machine interaction unit, an information detection unit and a power supply unit. According to the robot disclosed by the invention, self-balancing is realized based on a dual flywheel gyro effect principle, the control system of the robot adopts an adaptive control algorithm, and the model is gradually close to an actual condition by virtue of on-line identification, so that the two-wheeled longitudinal self-balancing robot can automatically restore to a stable state when stressed by lateral impact force to a certain degree, can be kept in a stable state while bearing an asymmetrical load to a certain degree, can realize automatic obstacle avoidance while meeting an obvious obstacle, and has the advantages of fast response, high corrective moment, low energy consumption and small noise.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

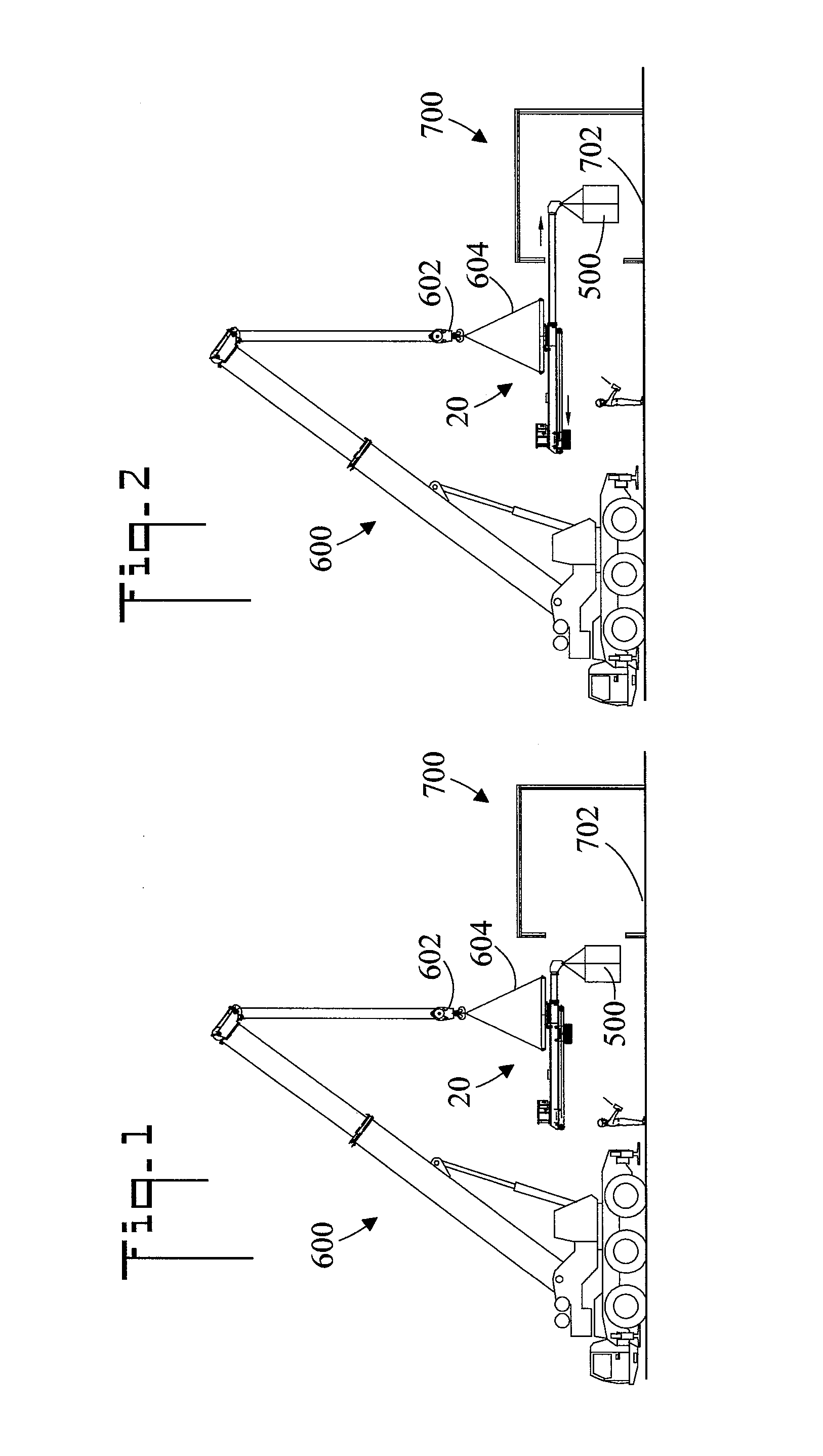

Fly jib for a crane and method of use

A fly jib for a crane having a load block includes a variable length beam to which a load can be connected. A rotation mechanism is connected to the variable length beam, and is connectable to the load block so that said rotational mechanism can selectively rotate the variable length beam with respect to the load block. A balance mechanism is connected to the variable length beam, the balance mechanism automatically keeps the variable length beam in a horizontal position.

Owner:SKYCRANE LLC

Magneto rotor magnetizing and detecting apparatus

InactiveCN1664601AAvoid wastingReduce labor costsManufacturing dynamo-electric machinesDynamo-electric machine testingBalancing machineElectric machine

A magneto rotor magnetizing and detecting apparatus, which contains magnetizing coil located at the position of magneto stator. The coil has the same size with magneto stator periphery and connects with diverter switch. In another pole of diverter switch, one receiving terminal connects with magnetizing device and the other receiving terminal connects with generation capacity detecting device. Magneto rotor is installed on central axis of equilibrator that concerts with computer and is driven by servomotor. Magnetizing coil is squeezed into magneto rotor to be located by compressing apparatus driven by pulling cylinder. On the same rack, on which equilibrator and pulling cylinder are installed, a gravity-alleviated drilling machine is installed. The apparatus also has a device to push out rotor. One computer controls every device.

Owner:CHONGQING UNIV

Balancing machine

InactiveUS20060130576A1Low costIncrease costSampled-variable control systemsComputer controlBalancing machineEngineering

An improved and simplified balancing machine comprising upright supports devices to hold the workpiece to be balanced, a motor and mount to spin the workpiece, and a system to detect and measure imbalance in the workpiece when it is rotated at speed. Said machine configured to be attached to a machine tool or work table without losing functional integrity, thereby eliminating the need for a massive base. Specific preferred structural embodiments are disclosed.

Owner:TURNER LEGAL REPRESENTATIVE JUDITH ANN +2

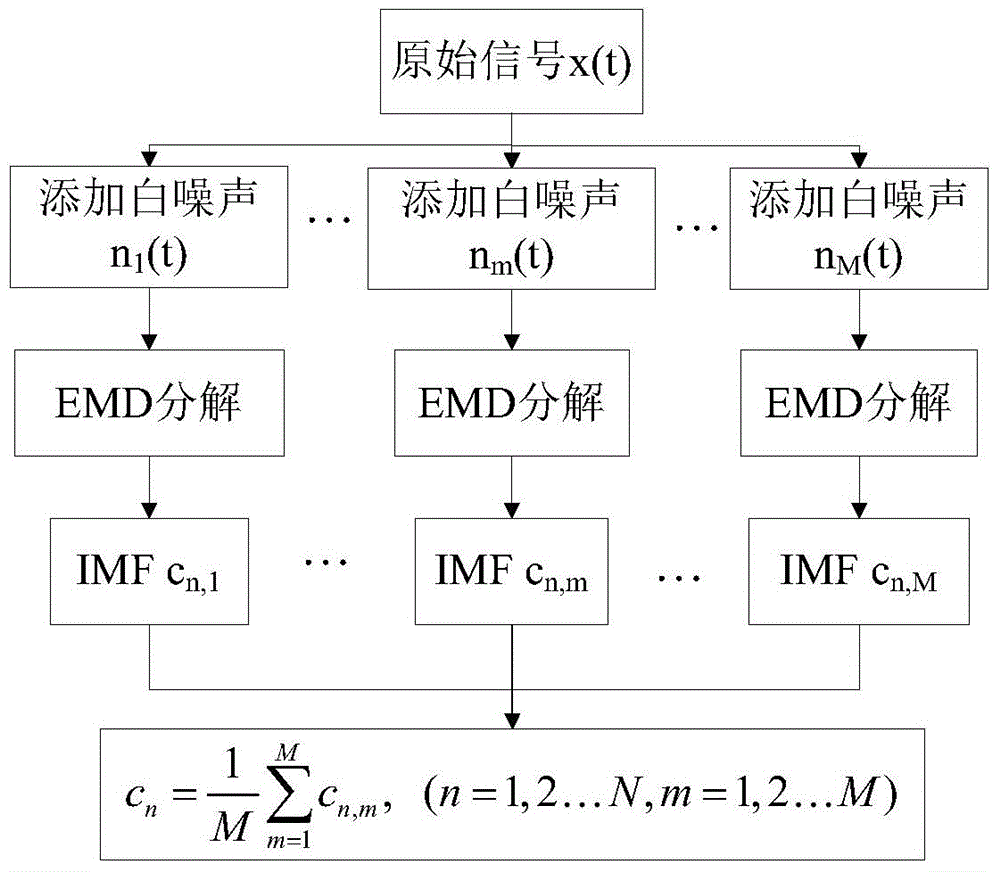

EEMD-based automatic balancing machine vibration signal processing method

InactiveCN104931197AReduce precisionEliminate pulse interferenceStatic/dynamic balance measurementBalancing machineDecomposition

The invention discloses an EEMD-based automatic balancing machine vibration signal processing method. A mathematic morphological filter is adopted to pre-process an extracted vibration signal and eliminate pulse interference in the signal, and for the mode aliasing problem in empirical mode decomposition, an ensemble empirical mode decomposition method is adopted to extract the frequency and phase of unbalance. The method includes the following steps: firstly, a mathematic morphological method is utilized to pre-process a vibration signal measured by a sensor and filter pulse interference; secondly, an ensemble empirical mode decomposition method is utilized to decompose the signal processed by the mathematic morphological method in the first step, and the intrinsic mode function component of the signal is obtained; and thirdly, the amplitude phase of the vibration signal is obtained through Hilbert transform.

Owner:JILIN UNIV

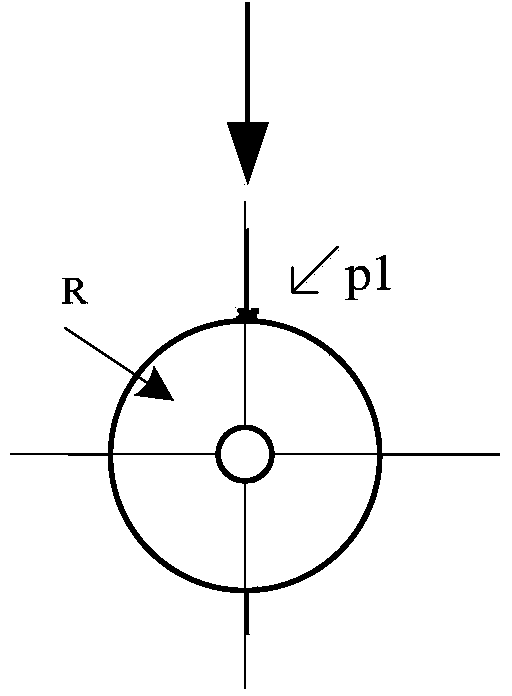

Unbalance magnitude online monitoring and de-weighting method in disc type workpiece processing

ActiveCN105222959APrevent large imbalancesUnbalance reduction or eliminationStatic/dynamic balance measurementMeasurement/indication equipmentsBalancing machineDynamic balance

The invention relates to an unbalance magnitude online monitoring and de-weighting method in disc type workpiece processing, and brings forward a method for indirectly measuring unbalance magnitude of a disc type workpiece in processing through monitoring change of unbalance vibration signals of a main shaft, for overcoming the disadvantages in the prior art that dynamic balancing of a conventional disc type workpiece requires a special-purpose dynamic balancing machine, the balancing efficiency and the precision are low and the like. Based on the method brought forward by the invention, through monitoring of the unbalance state of the disc type workpiece in a processing process, formation and deterioration of too large unbalance magnitude of the disc type workpiece are prevented; and after the disc type workpice is processed, the clamping position of the disc type workpiece on a main shaft of a machine tool maintains unchanged, the unbalance magnitude of the disc type workpiece is measured in an online mode during rotation of the main shaft, and the unbalance magnitude of the disc type workpiece is reduced or eliminated through a method of controlling de-weighing of the machine tool. The method provided by the invention has great significance in improving the balance efficiency and precision of the disc type workpiece and reducing the balance cost.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

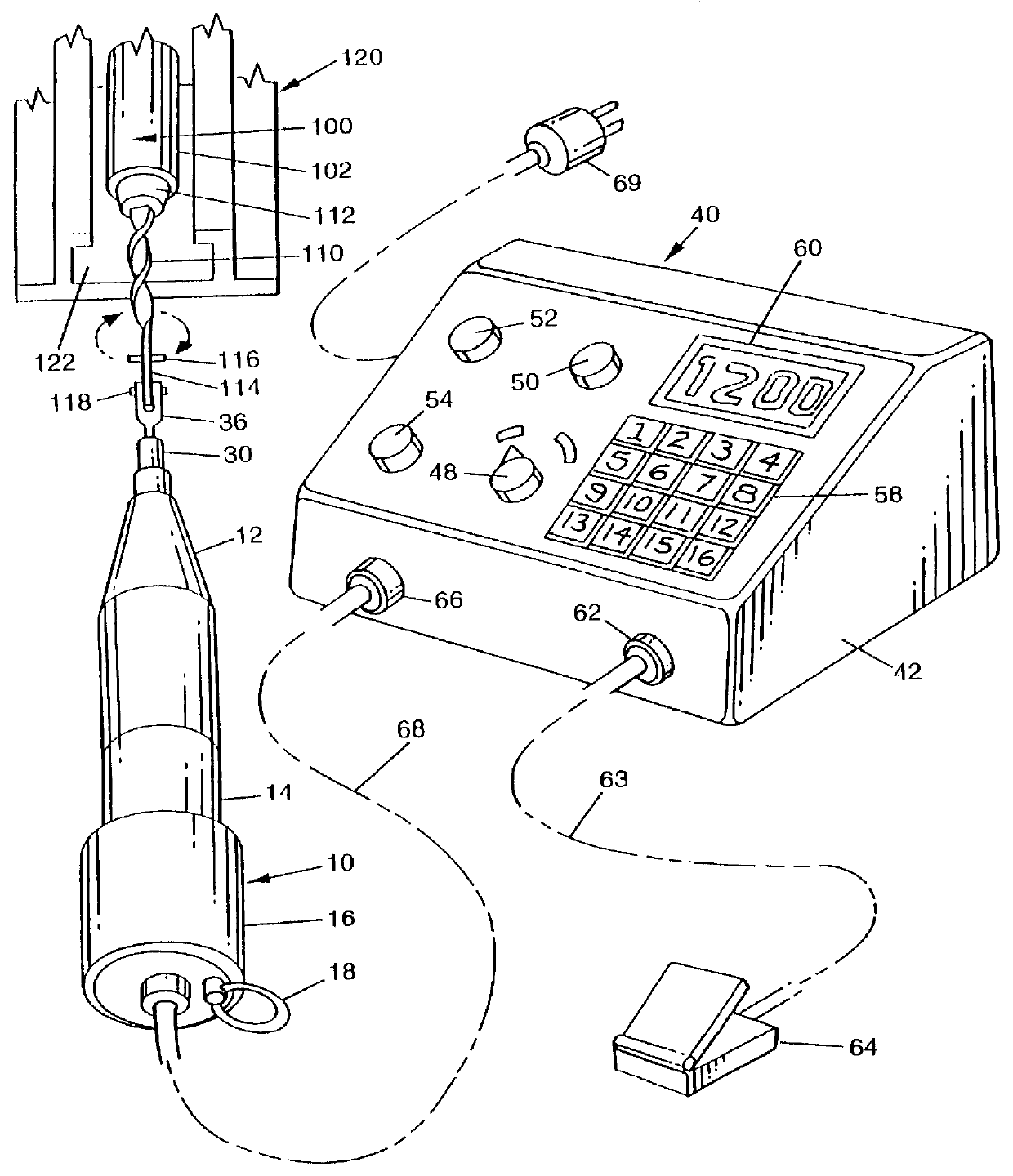

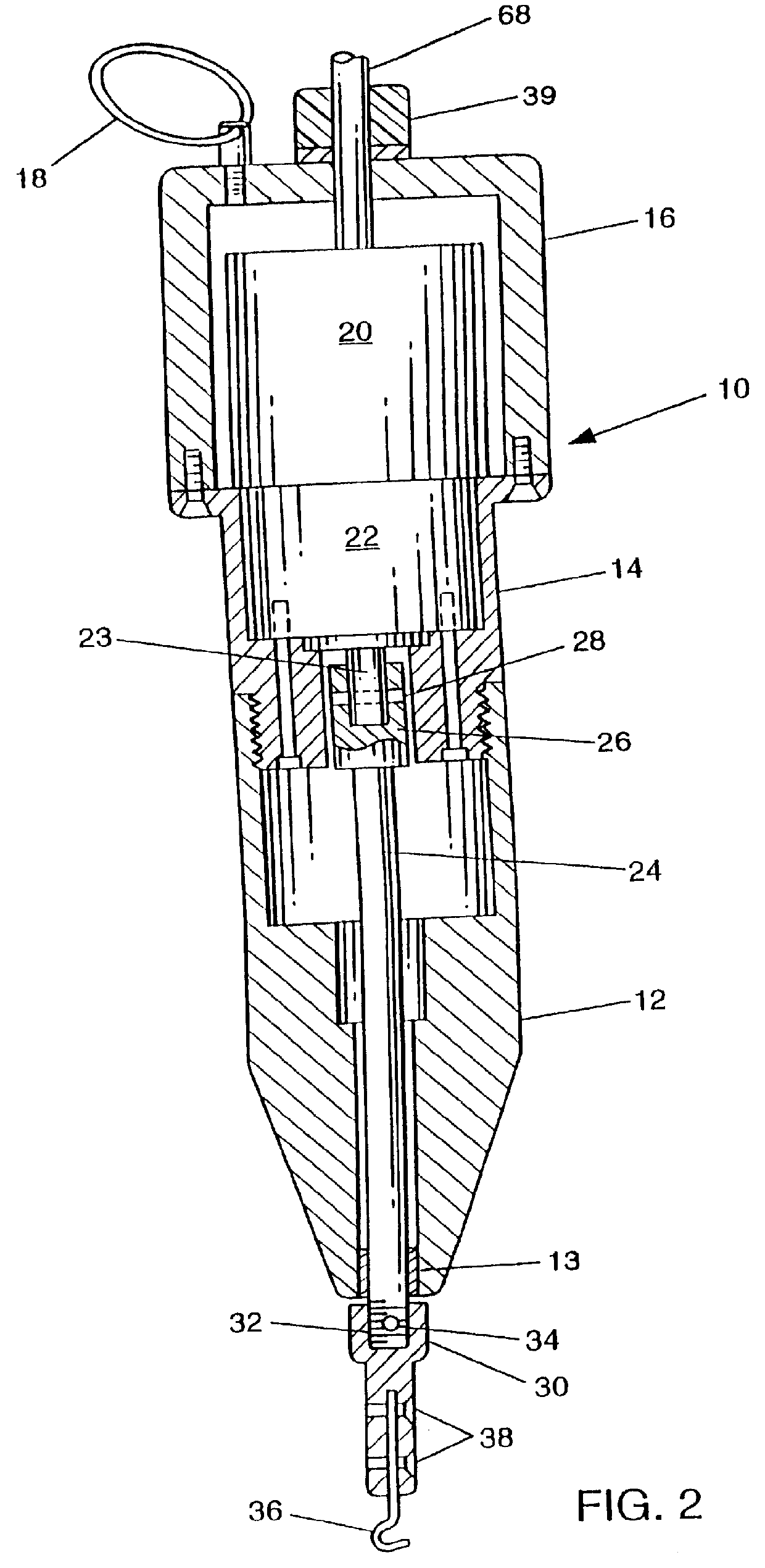

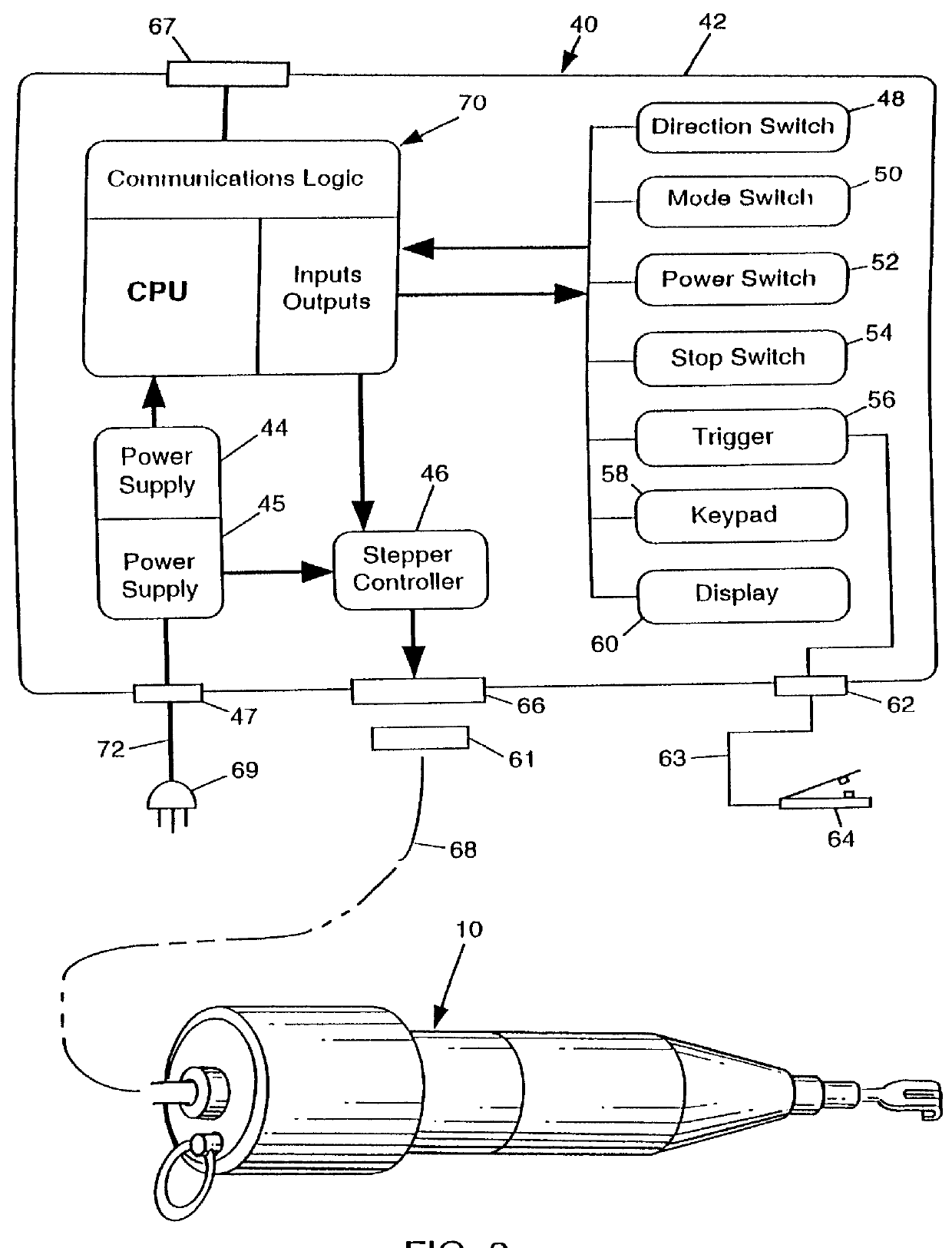

Spring winding device

Window sashes such as double hung sashes often are assembled with a counterbalancing mechanism to facilitate the opening and closing of the window. When the sashes are made from vinyl, the counterbalancing of the window is commonly achieved by the use of a pair of coil springs, one mounted within a channel in the sash on either side of the window. A programmable motorized hand tool is used to apply tension quickly to each of the springs thereby improving production rates and quality control while reducing the risks of repetitive motion injury to the person using the hand tool. A programmable stepper controller drives the motor and controls the functions of the hand tool such as the speed and direction of rotation, the number of revolutions and the start-up and operating torques.

Owner:UPHOLZ MICHAEL R

Balance detection and correction apparatus for magneto rotors

InactiveCN1664602ALow costHigh precisionCentering/balancing rotorsDynamo-electric machine testingBalancing machineDrive motor

A magneto rotor balance check and adjustment device, which comprises equilibrator, installed on the same rack and connects with computer, and unit head equipped with drill to correct equalization. Driving motor of equilibrator is servomotor. Said motor head drill aims at outer wall of magneto rotor, which is installed on equilibrator central axis to be detected and corrected, and is vertical to axis. Swarf removal device is installed at the front of drilling machine, which carries forward with drilling machine. A compressing apparatus compresses magneto rotor to be detected and corrected at axis, in which magnetizing coil of ferrite in magneto rotor is equipped. Lift-out attachment is installed between balance check device and magneto rotor. One computer controls every device.

Owner:CHONGQING UNIV

Quick-clamping device with hub centering ring for securing a vehicle wheel on the shaft of wheel-balancing machines

InactiveUS20060055125A1Avoid disadvantagesEasy to fixSleeve/socket jointsStatic/dynamic balance measurementBalancing machineEngineering

Quick-clamping device with a hub centering ring secures a vehicle wheel rim on the shaft of a wheel-balancing machine. Securely attached to the shaft is a flange to facilitate a friction fit placement on the rim. For centering, a conical assembly is provided, including an inner bore to be slid onto the shaft of the balancing machine, as well as an outer centering surface for engaging the centering hole of the rim. Conical assembly includes a cone, from the apex of which a tubular element extends, and which is mounted with its inner wall axially displaceable on the shaft or an extension of it, and a clamping element for tightening the rim against the flange abuts its outer wall. Advantageously, until reaching the centering and clamping position by using the clamping element, quick-clamping device ensures no forces must be overcome. This provides ease of use of the quick-clamping device.

Owner:WARKOTSCH HORST

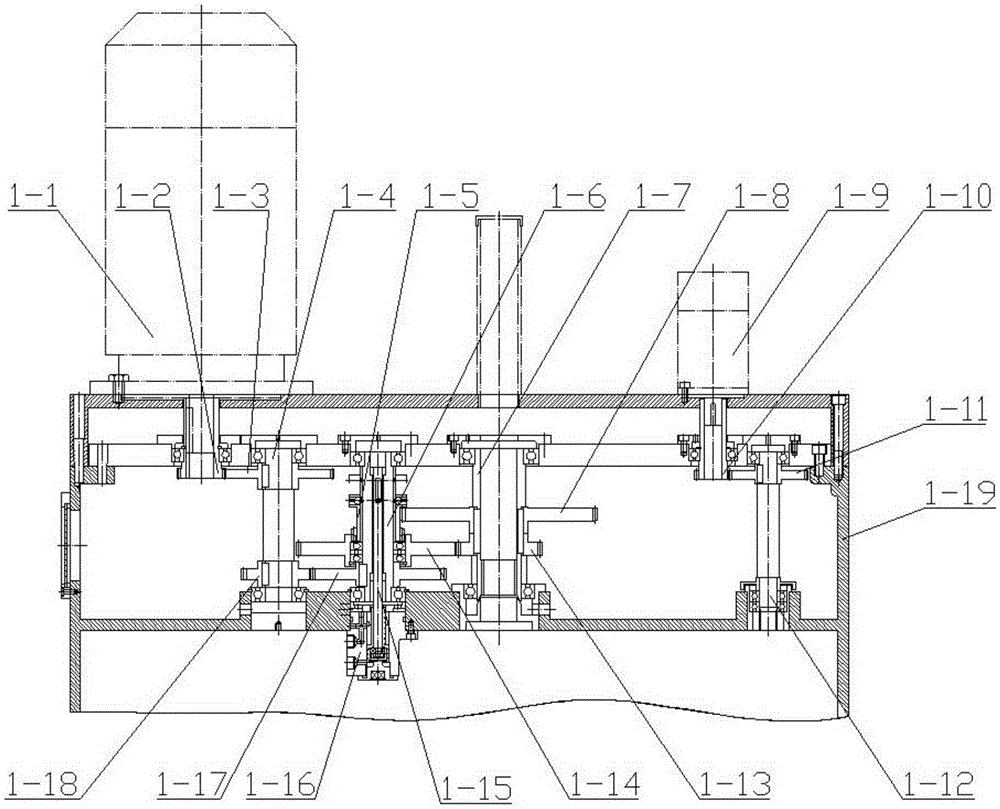

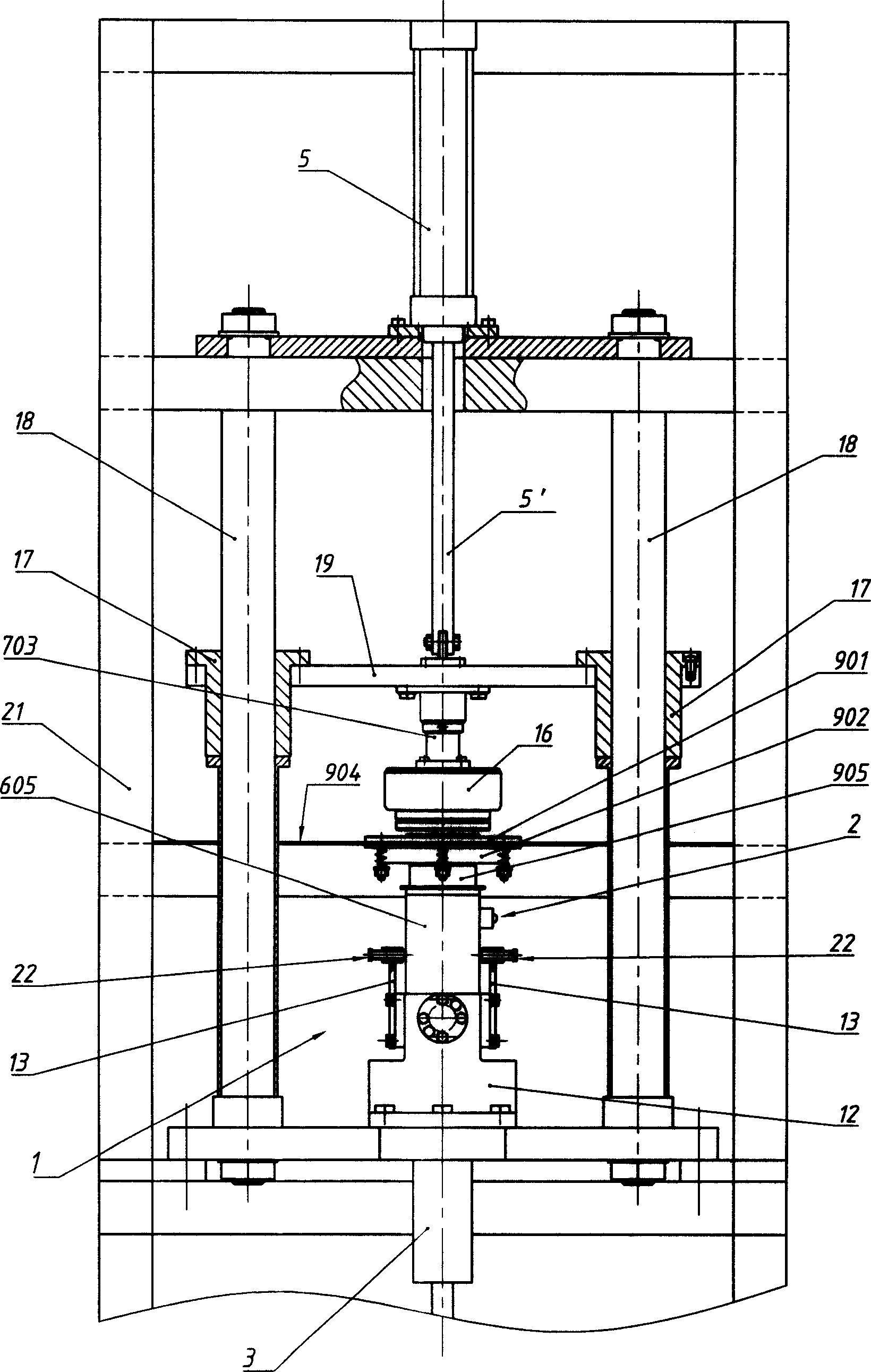

Dynamic balance assembly testing device of engine rotors

ActiveCN102564697AStructural solutionSolve balance problemsStatic/dynamic balance measurementCentering/balancing rotorsBalancing machineDynamic balance

The invention relates to a dynamic balance assembly testing device of engine rotors, which comprises a front balance process casing, a balance mandrel, a rear balance process casing, a balancer, a pulling rod, an ejection rod, a baffle plate, a support block and an upright column, wherein in the balance state, the front balance process casing is connected with the front part of a stator outside an engine rotor, the rear balance process casing is connected with the rear part of a stator outside an engine rotor, the front balance process casing and the rear balance process casing are respectively arranged at the front end and the rear end of the balance mandrel and are arranged on the balancer through the balance mandrel; and in the assembly state, engine rotors of the front balance process casing and the rear balance process casing are arranged on an assembly vehicle, the support block is positioned between an engine stator casing and the assembly vehicle, and the upright column is arranged between the engine rotors and the assembly vehicle. The dynamic balance assembly testing device of the engine rotors, which is provided with the stators, solves the dynamic balance assembly problem of a special structure, realizes multifunctional assembly and transportation and has higher economic and practical values.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

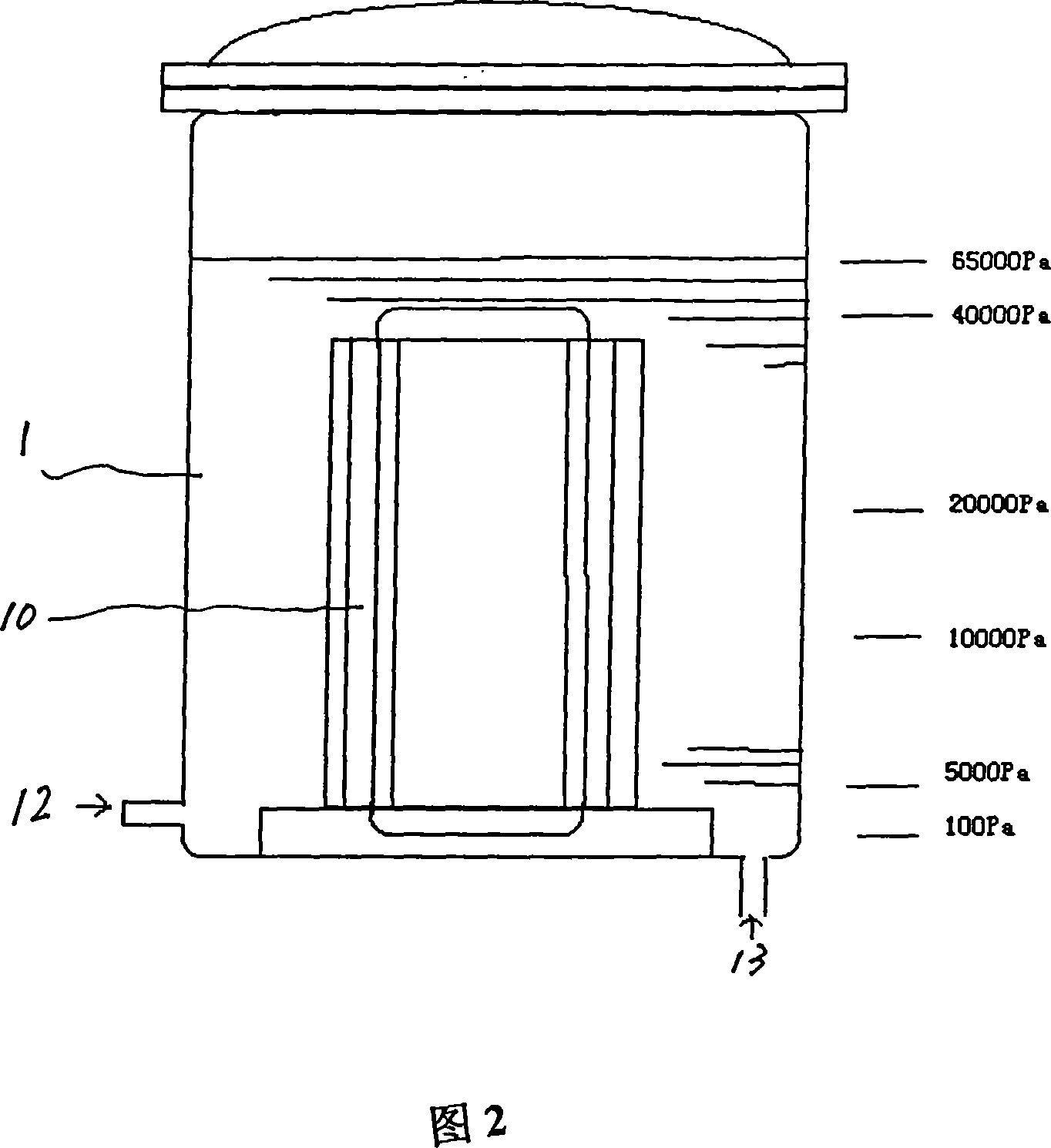

A vacuum balance method of vacuum pressure dipping technology and its device

InactiveCN101086922AAvoid damageUniform dielectric strengthLiquid surface applicatorsCoatingsVacuum pressureEngineering

The invention is a vacuum balancing method of vacuum pressure dipping craftwork and device, it relates to an improved vacuum pressure dipping craftwork, at the same time, it relates to a device of the craftwork. It can be used in preparation of insulating structure of electromotor winding. A kind of vacuum balancing method of vacuum pressure dipping craftwork is adding a storing balancing framework. A kind of vacuum pressure dipping device which aims at said craftwork includes impregnating vessel, storing vessel, vacuum set and air compressor, bottom of said impregnating vessel is connected with bottom of storing vessel via painting tube, the painting tube possesses two-way painting valve, top of the impregnating vessel is connected with vacuum set and air compressor via tube, thereinto, top of the impregnating vessel is connected with a balancing storing framework via connecting tube. With characters of VPI equipment closed pump, system of baking is eliminated; winding iron core is directly loaded into the impregnating vessel for vacuum process.

Owner:上海同立电工材料有限公司

Electric balance swing car

InactiveCN105329386ARealize "foot control"Efficient driveCycle safety equipmentsFoot-restsBalancing machineElectric machinery

The invention discloses an electric balance swing car which comprises a shell, a support arranged in the shell, motor drive mechanisms, a rotary mechanism, an anti-tilting mechanism and a balance mechanism. The motor drive mechanisms are arranged on the two sides of the electric balance swing car and used for providing power support for the electric balance swing car. The balance mechanism is connected with the motor drive mechanisms and used for balance control of the electric balance swing car. The anti-tilting mechanism is used for preventing the electric balance swing car from tilting. The rotary mechanism penetrates through the anti-tilting mechanism and comprises a main shaft, a shaft sleeve and a limiting screw. One end of the main shaft is provided with a boss and used for clamping the main shaft in the support. The other end of the main shaft is provided with the limiting screw and used for limiting the main shaft on the support, and the main shaft is sleeved with the shaft sleeve. According to the electric balance swing, a user can control the moving state of the balance car just through the feet, the size is reduced, and safety is improved.

Owner:胡勇跃

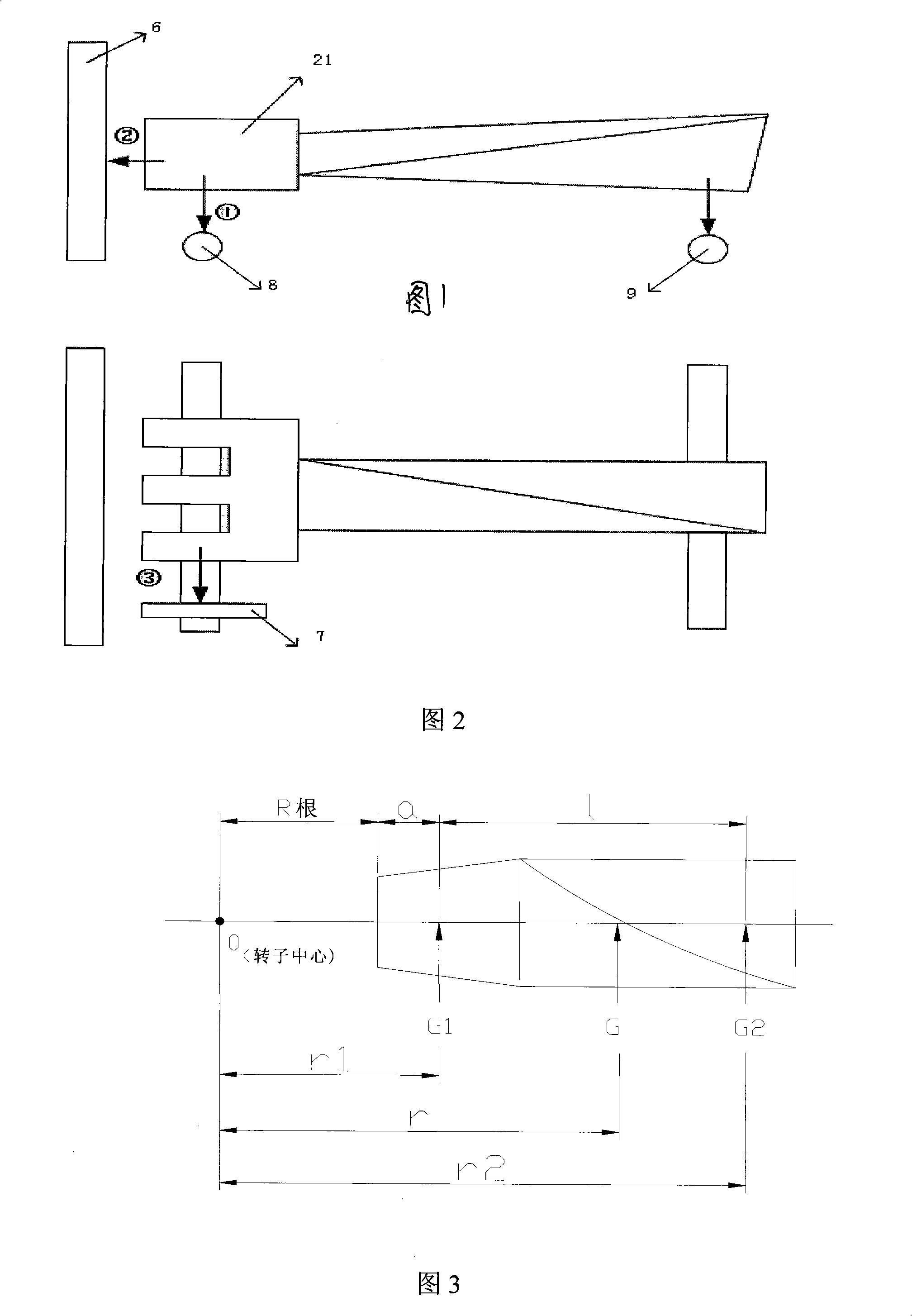

Method for fault detection and diagnosis of a rotary machine

Modem rotary machine production requires built-in fault detection and diagnoses. The occurrence of faults, e.g. increased friction or loose bonds has to be detected as early as possible. Theses faults generate a nonlinear behavior. Therefore, a method for fault detection and diagnosis of a rotary machine is presented. Based on a rotor system model for the faulty and un-faulty case, subspace-based identification methods are used to compute singular values that are used as features for fault detection. The method is tested on an industrial rotor balancing machine.

Owner:SCHENCK ROTEC GMBH

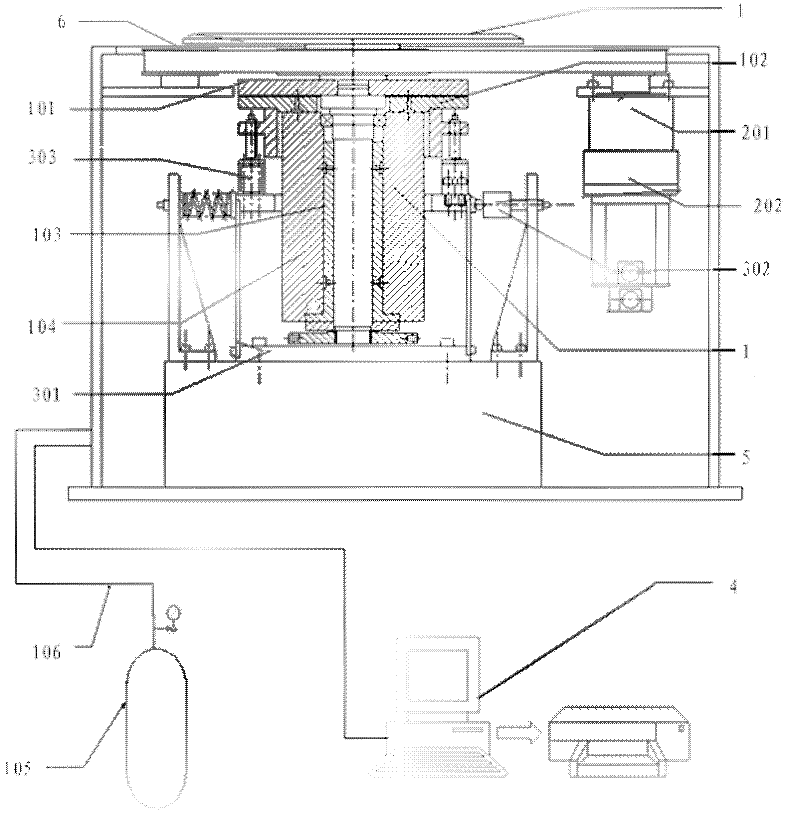

Large-scale rotary load high-precision dynamic balance measuring device for spacecraft

ActiveCN102650560AHigh precisionHigh measurement accuracyStatic/dynamic balance measurementAir bearingLow speed

The invention relates to a large-scale rotary load high-precision dynamic balance measuring device for an spacecraft, which comprises an air main shaft system, a driving system, a measuring system and a data processing and displaying system. The large-scale rotary load high-precision dynamic balance measuring device for the spacecraft is characterized in that the dynamic balance measuring device comprises two measuring modes; in one mode, a tested object is driven by a driving system contained in a dynamic balancing machine; in the other mode, the tested object is driven by a self driving device; and both modes have even and static balance measuring and balancing functions. Furthermore, a support system adopts a high-rigidity and superlow-friction air bearing system; an air main shaft comprises a plurality of air components and adopts a gaseous static pressure mode to separate inner and outer air sleeves as well as upper and lower air plates; the inner and the outer air sleeves provide radial restraint and accurately transmit the radial acting force; and the upper and the lower air plates have sufficient rotation rigidity perpendicular to the rotating shaft and can ensure that the unbalanced quantity of an object can be measured by the air main shaft under a small-friction and low-resistance condition. The large-scale rotary load high-precision dynamic balance measuring device provided by the invention is applicable to the large-scale rotary load high-precision low-velocity dynamic balance measurement of the spacecraft.

Owner:SHANGHAI SATELLITE ENG INST

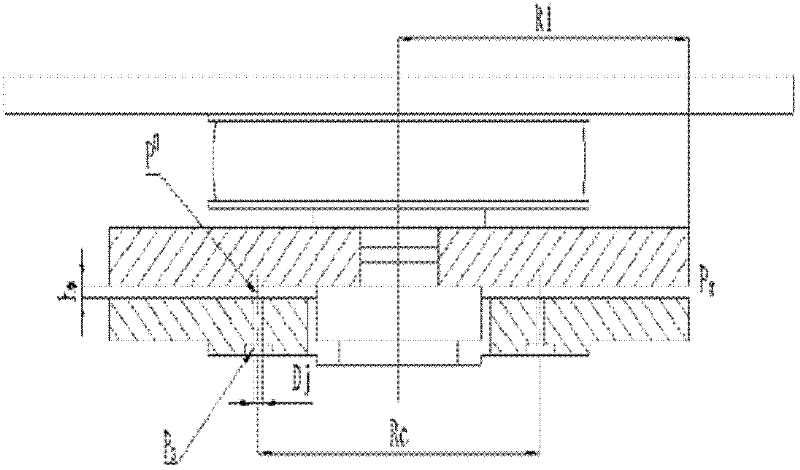

Measuring method and device for locked rotor torque of turbine rotor blade

InactiveCN101271032AShorten test timeCompact designStatic/dynamic balance measurementBalancing machineTurbine blade

The invention discloses a static torque measuring method and a measuring device of a steam turbine rotor blade. The method takes the root and the tip of a twisted blade as two supporting points, weighs the bearing capability of the two supporting points with a high-precision electronic scale, integrates with the distance between the two supporting points, and calculates the torque of the blade with a formula. The measuring device essentially includes a frame, a fixed bracket, a blade root electronic scale, a blade root support post, a blade tip support post, a blade tip electronic scale and a mobile bracket; the blade root electronic scale is arranged on the fixed bracket; the blade root electronic scale is provided with the blade root support post; a front and a rear datum planes are arranged before the blade root support post, and a left and a right datum planes are arranged on the side of the blade root support post. The invention has the advantages of high measuring precision, easiness in operation and low cost; in particular the provided measuring device has the advantages of compact design, small size, convenience in operation, blade arrangement before installation, and shortening the test time of the rotor on a high-speed dynamic balancing machine.

Owner:HANGZHOU STEAM TURBINE

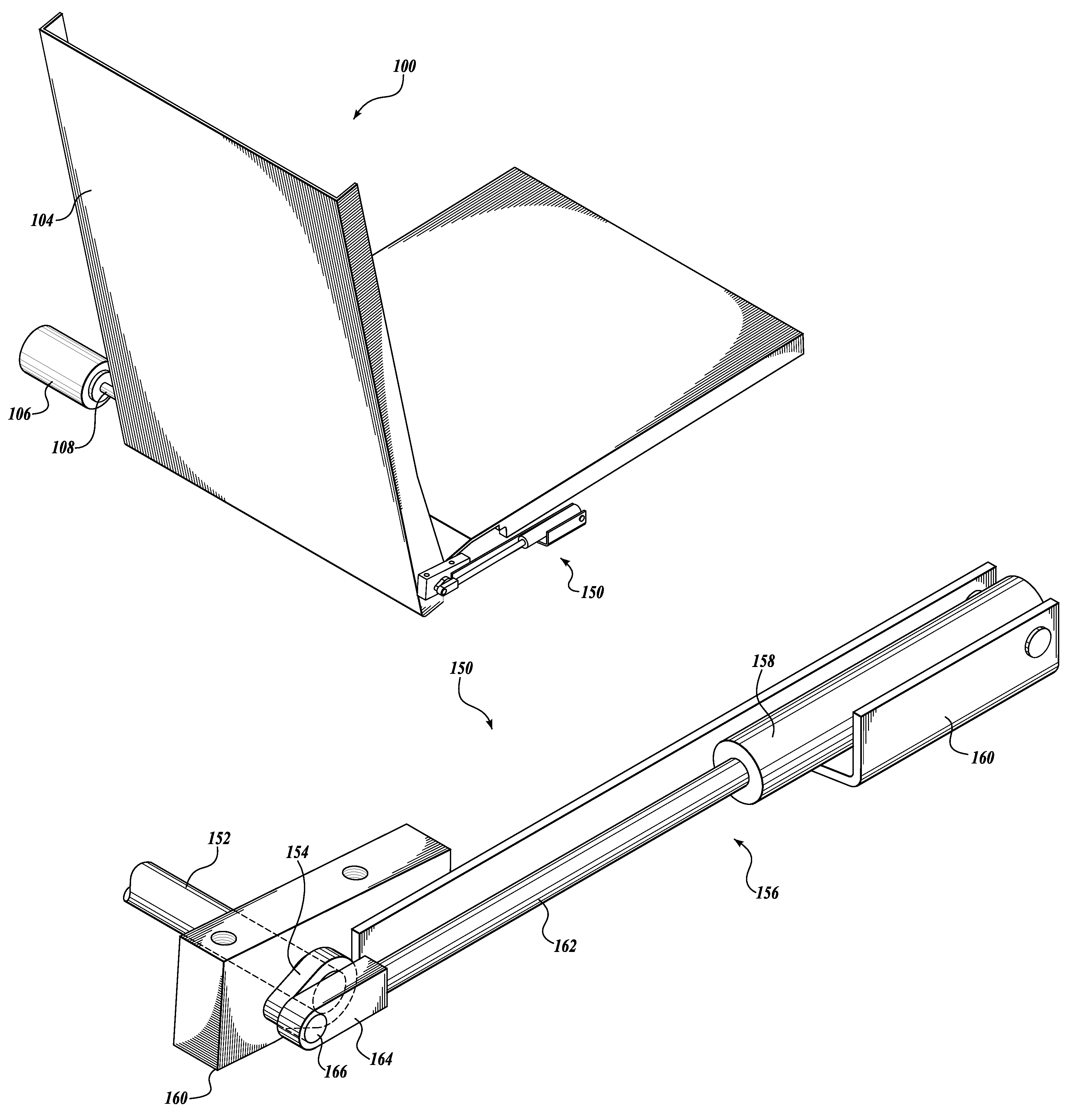

Counterbalance mechanism for fold out ramp

A ramp assembly includes a ramp portion configured for reciprocating motion between a stowed position, a deployed position, and a neutral position. The ramp assembly further includes a counterbalance that provides a force to bias the ramp portion toward the stowed position when the ramp portion is between the deployed position and the neutral position, and toward the deployed position when the ramp portion is between the stowed position and the neutral position. A shaft rotates in a first direction when the ramp portion moves toward the stowed position, and in a second direction opposite the first direction when the ramp portion moves toward the deployed position. A crank is fixedly coupled to the shaft. A rod is rotatably coupled at a first end to the crank about a first axis and at a second end to a cylinder. The cylinder is coupled for rotational movement about a second axis.

Owner:ELEVATOR U DIV OF HOGAN MFG

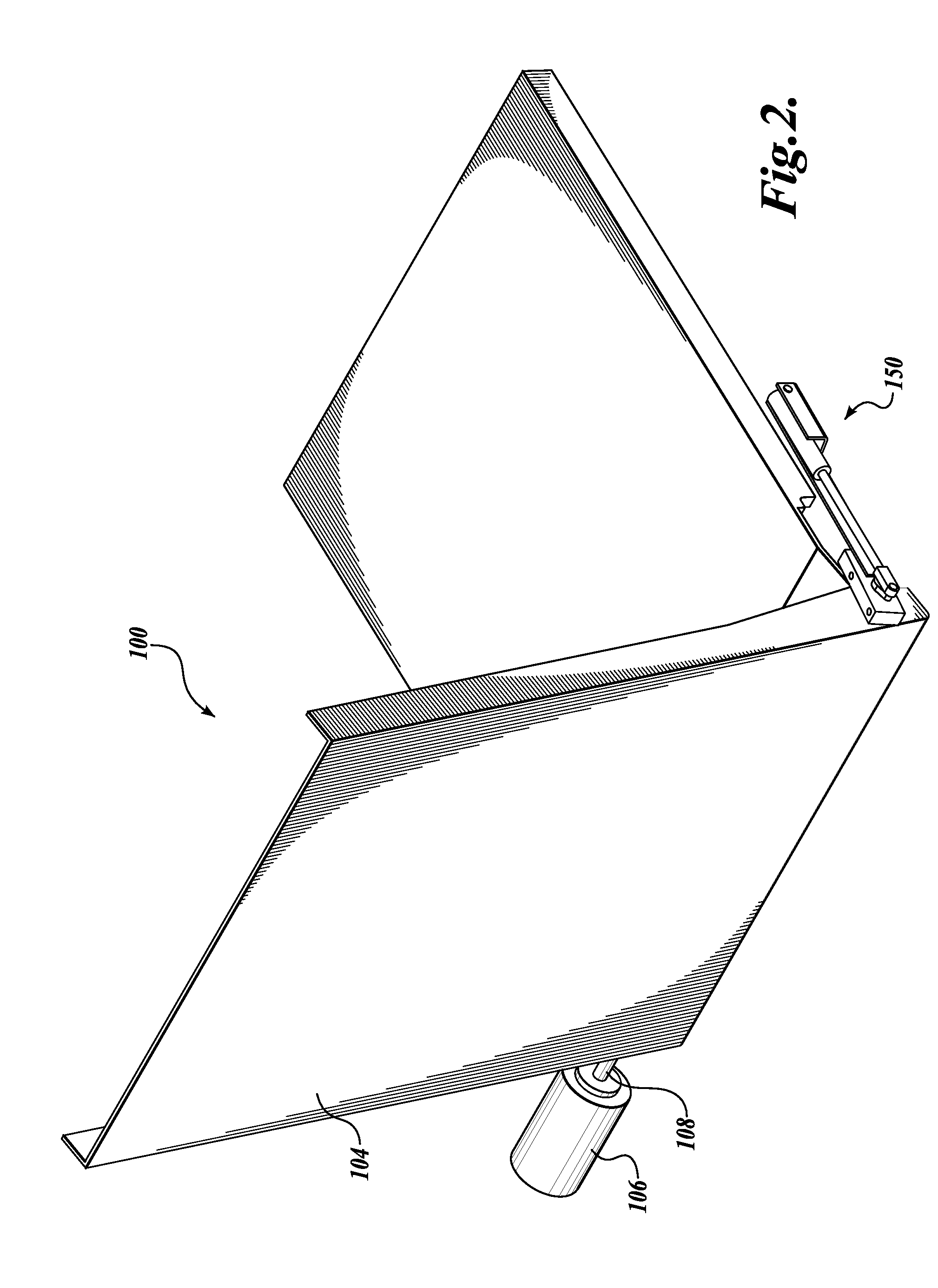

Measurement mechanism and measurement method for crankshaft assembly dynamic poise

InactiveCN101135597AAccurate measurementImprove detection efficiencyStatic/dynamic balance measurementMeasurement deviceDynamic balance

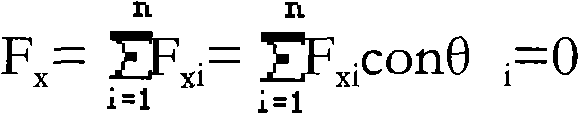

The invention comprises a motor, a right angle support base, a cylinder elastic support whose both ends are flanges, a hollow shaft, a drive shaft, a L-shaped bracket, a dynamic balancing machine, and a train gauge coated on the cylinder elastic support. In the rotation plane of the crank shaft assembly, along with the orthogonal X,Y directions, simultaneously measuring the unbalance vibration or force signal of the crank shaft assembly running in high speed; after processed by computer, synthesizing the unbalance value along with different directions to form a closed curve graph. The invention also reveals a method thereof.

Owner:重庆迪佳科技股份有限公司

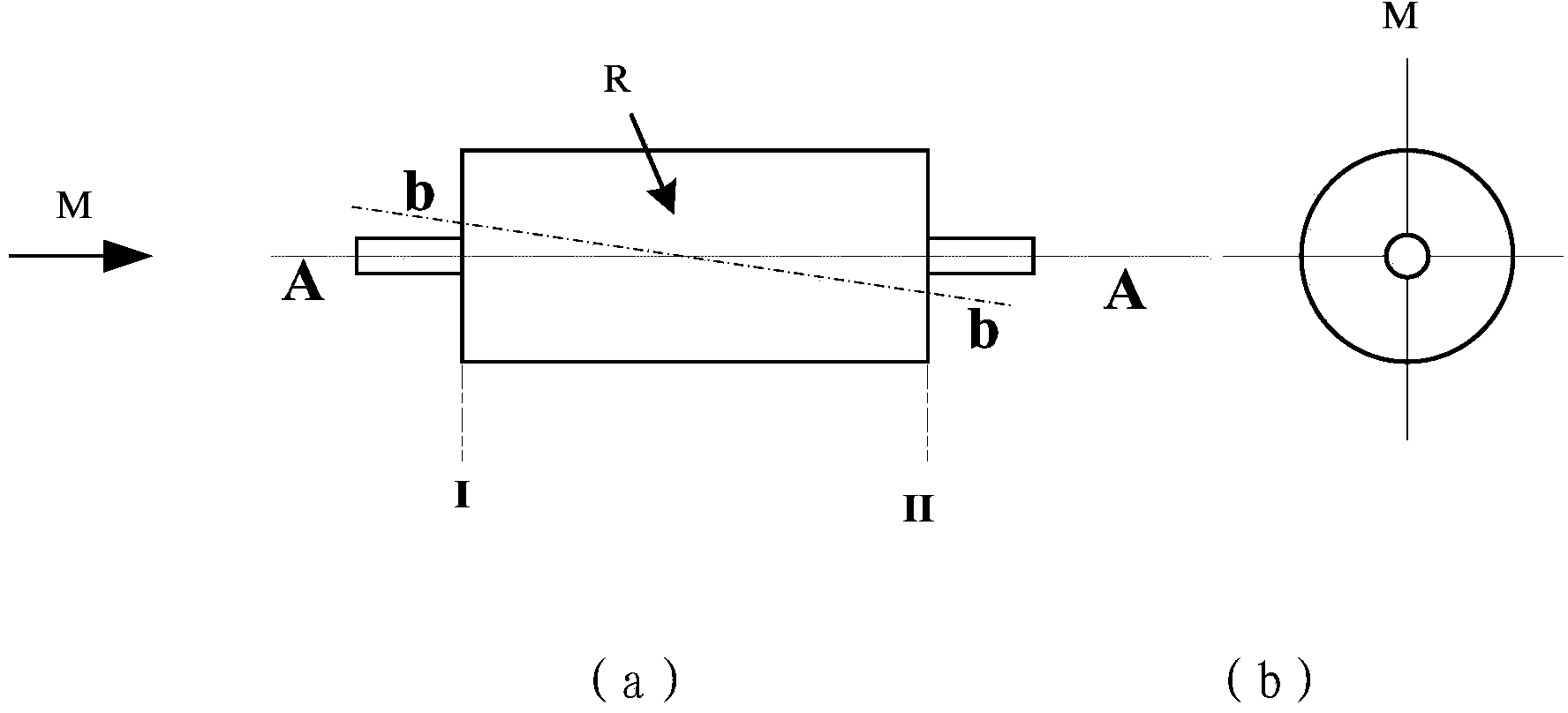

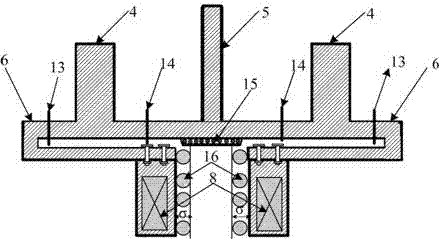

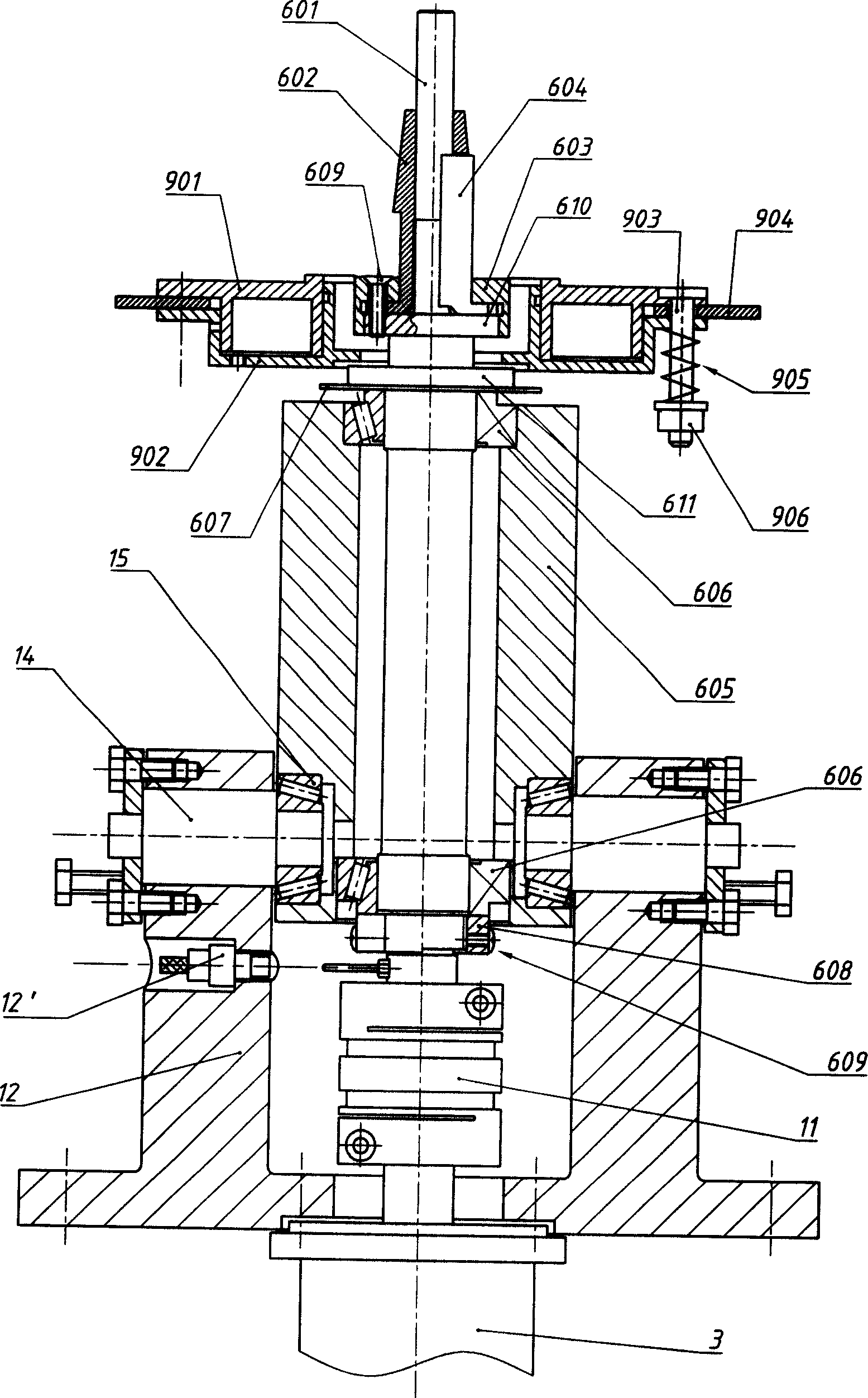

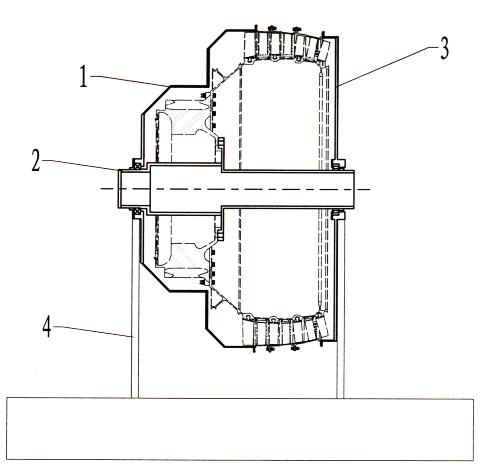

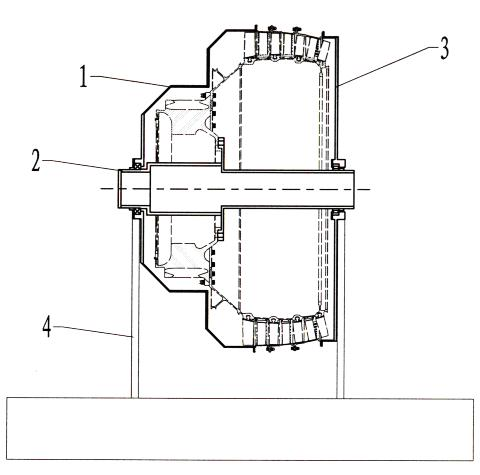

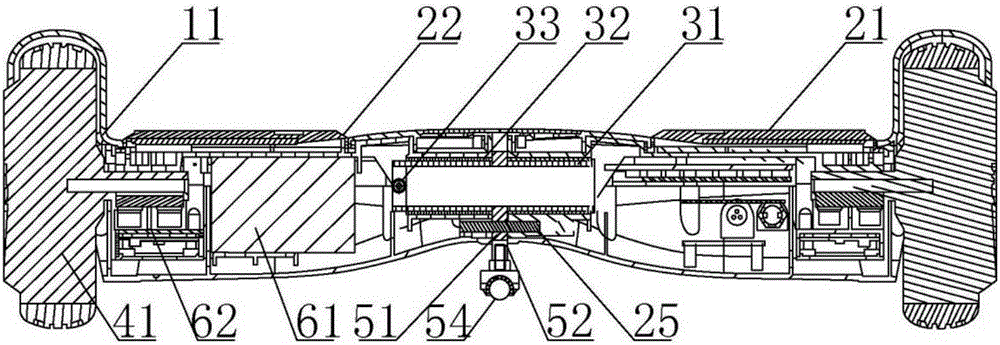

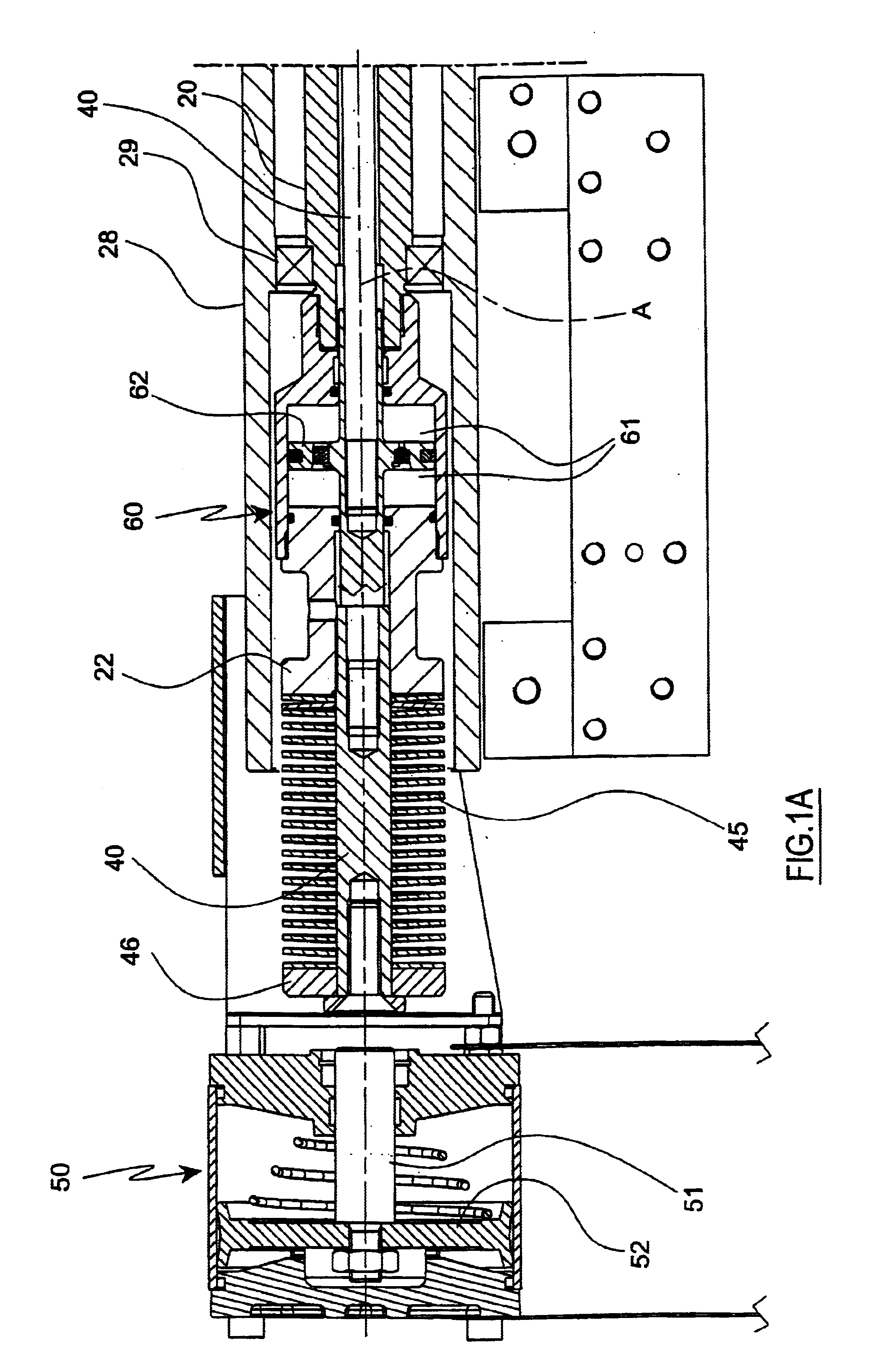

Locking and drive unit for a rotating body, in particular for motor vehicle wheels in a balancing machine

InactiveUS6763715B2Operationally efficientDrawback can be obviatedStatic/dynamic balance measurementVehicle tyre testingBalancing machineEngineering

The locking and drive unit comprises, for supporting the rotating body (10) and rotating it about an axis A, a motorized main shaft (20) carrying flange means which define a counteracting surface (26) for the rotating body; and pressing means (31, 32) coaxial with the shaft (20) to axially press the rotating body (10) against said counteracting surface (26) and to lock it relative thereto; a traction rod (40) is associated with the main shaft (20), is movable axially relative thereto and is connected to the pressing means (31, 32) to pull them against the counteracting surface (26). Elastic thrust means (45) are connected to the traction rod (40) to axially pull, via this latter, the pressing means (31, 32) against the counteracting surface (26) to lock the rotating body relative thereto. The invention comprises an impact damping means (60) acting by mutual movement of two of its elements (61, 62) in the same direction as the axis of the main shaft (20) when the traction rod (40) is moved in the sense of pulling the pressing means (31, 32) towards the counteracting surface (26), one of said elements (61, 62) being rigid with the main shaft (20) and the other element being rigid with the traction rod (40).

Owner:CORGHI

Apparatus for testing and adjusting dynamic and static balance and method thereof

InactiveCN104335714BShorten the timeAccurate adjustment effectStatic/dynamic balance measurementCircular discBalancing machine

The invention discloses a satellite dynamic and static balance test and adjustment device, comprising: a satellite body to be tested is fixed on a satellite connection disc. The satellite connecting disk is connected with the plane of the connecting disk of the dynamic balancing machine, and is fixed with positioning pins to form a transitional tooling. The transition tooling can move horizontally in X and Y directions on the dynamic balancing machine. The connecting disc of the dynamic balancing machine is fixed on the plane of the dynamic balancing machine with connecting bolts, and there is an adjusting gasket in the middle. A fixed support is installed on one side of the planar main table of the dynamic balancing machine, and an adjusting screw is arranged on it. The invention also discloses the test and adjustment method of the dynamic and static balance test and adjustment device, adopts the technical scheme of "torque-couple balance method", and achieves the problem of completing the satellite dynamic and static balance test and adjustment at one time, which not only improves the efficiency of test and adjustment Accuracy, and the adjustment time is reduced from 7 days to 2 days.

Owner:SHANGHAI SATELLITE ENG INST +1

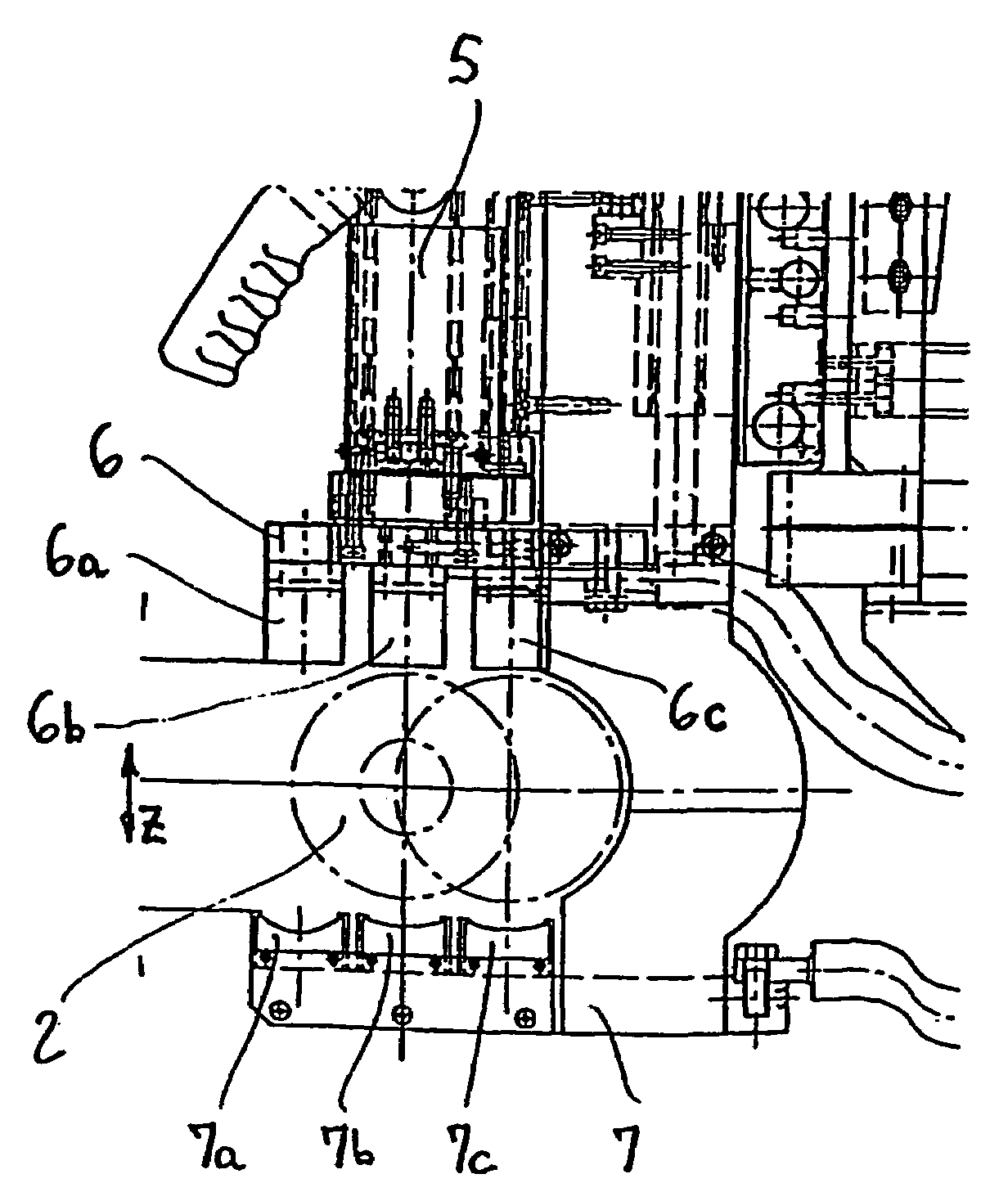

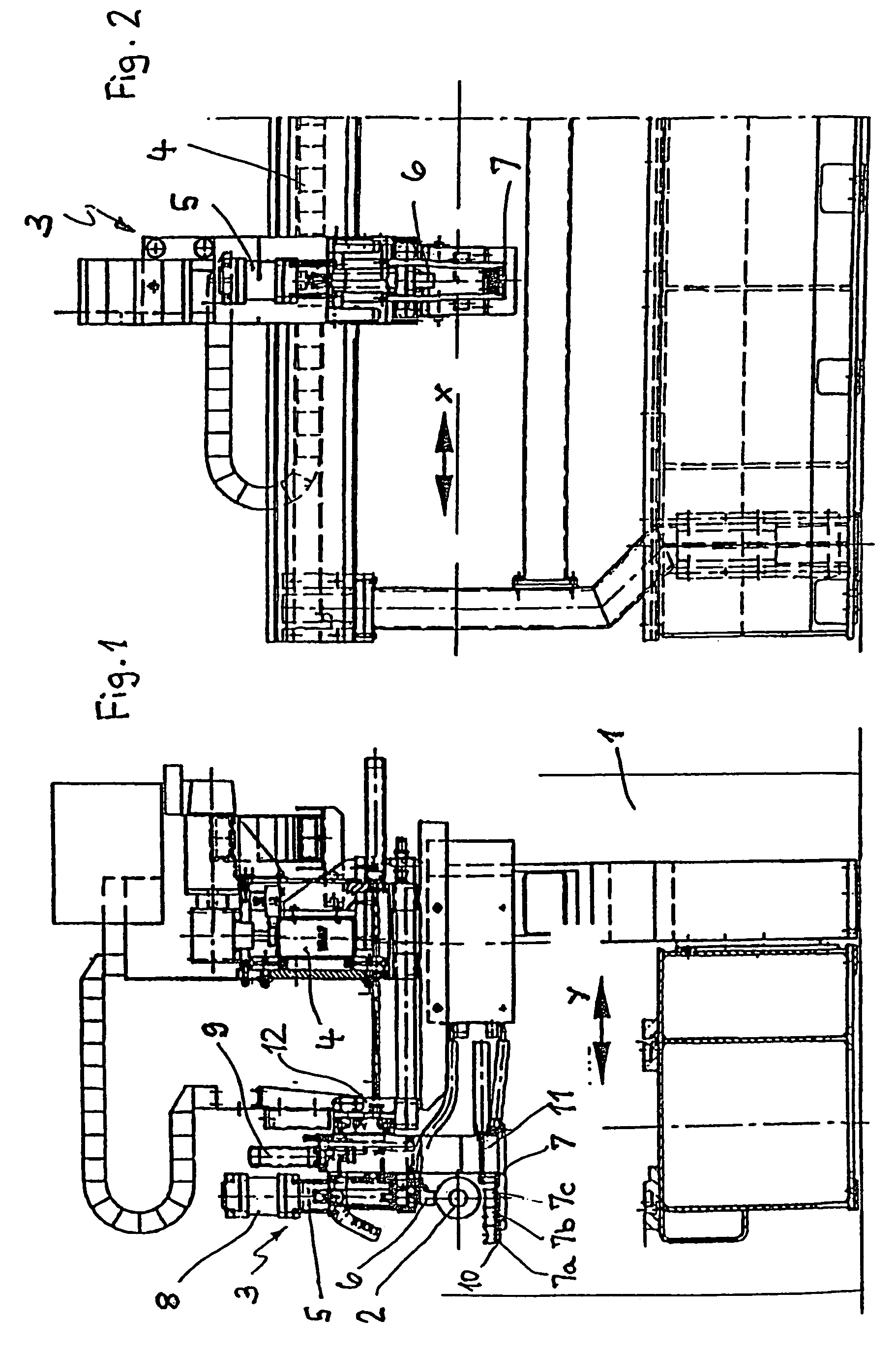

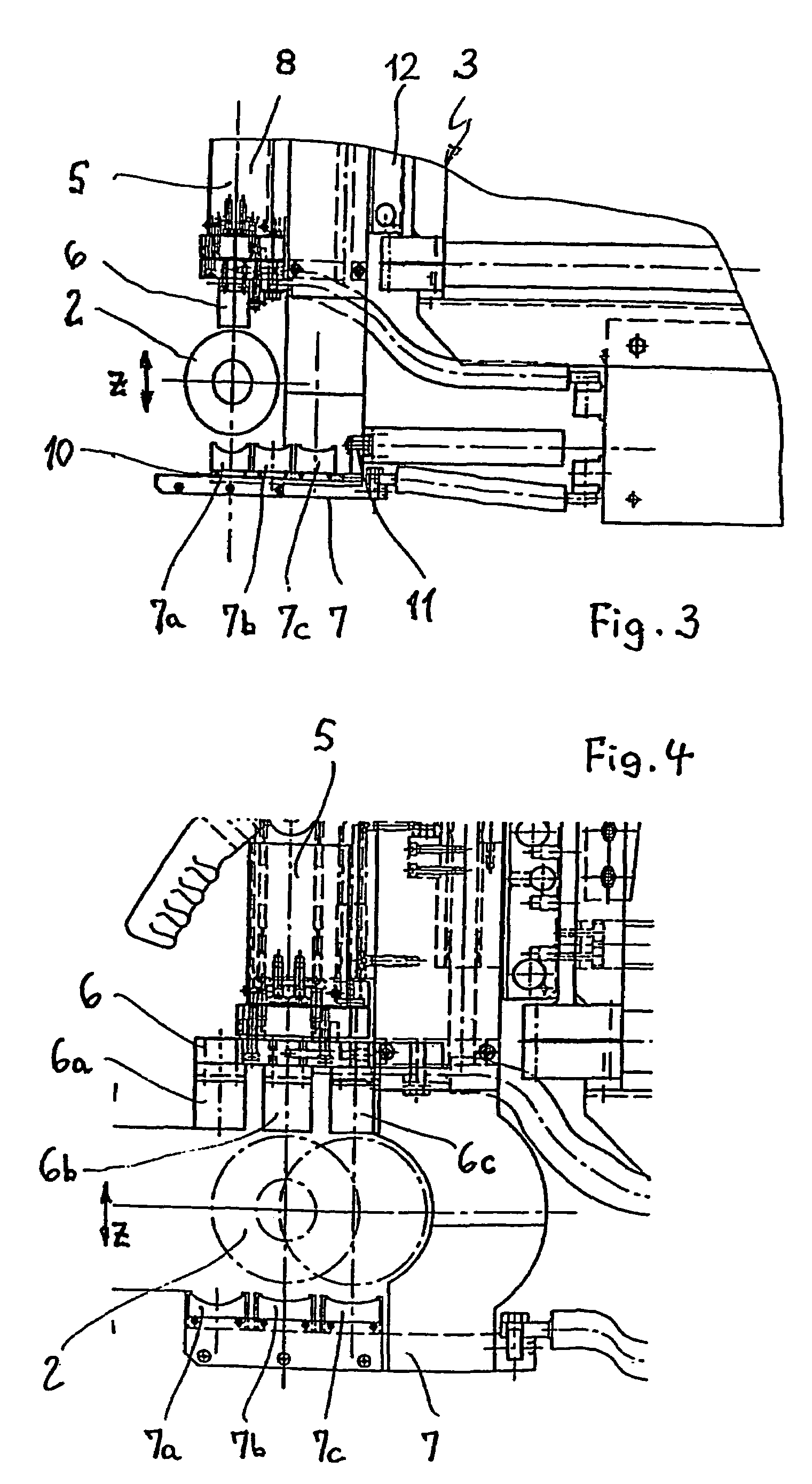

Device and method for fastening balancing weights to rotors, in particular to propeller shafts or cardan shafts

ActiveUS7249508B2Simple and inexpensive applicationShorten the durationPliersStatic/dynamic balance measurementBalancing machinePropeller

In a device (3) for fastening balancing weights to rotors (2) with a plurality of compensation planes, in particular to propeller shafts or Cardan shafts, preferably in a balancing machine (1) that includes at least one gripper-like device which can be positioned along the rotor axis, and with which a balancing weight is placed on the external periphery of the rotor (2) and can be fastened there, the gripper-like device (5) includes plural receivers for receiving a plurality of the balancing weights.

Owner:SCHENCK ROTEC GMBH

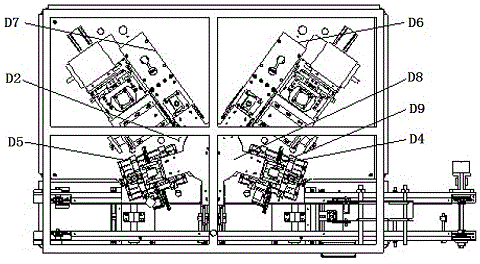

Two-station rotator drilling de-weight full-automatic balance machine

InactiveCN104410231ASimple structureReduce processing costsCentering/balancing rotorsBalancing machineEngineering

The invention disclose a two-station rotator drilling de-weight full-automatic balance machine. The two-station rotator drilling de-weight full-automatic balance machine comprises a machine frame, a balance measuring positioning mechanism, a drilling mechanism, a mechanical rotary ram, a corner mechanism and a compressing and reversing mechanism, wherein the mechanical rotary arm is mounted at the position near the central part of the machine frame; the balance measuring positioning mechanism is arranged below one end part of the mechanical rotary arm; the compressing and reversing mechanism is arranged below the other end of the mechanical rotary arm; the drilling mechanism is mounted on the machine frame; the drilling end of the drilling mechanism corresponds to the compressing position of the compressing and reversing mechanism; the corner mechanism is mounted on the machine frame; the corner mechanism and the drilling mechanism are respectively positioned on the two sides of the compressing and reversing mechanism. The full-automatic balance machine has the advantages that the overall structure is simple; the machining cost is greatly reduced; the size is small; the occupied space is reduced; meanwhile, the machining requirements of a variety of products can be met; the compatibility is high; moreover, due to the mechanical rotary arm and the compressing and reversing mechanism, product machining stations can be switched more quickly, so that the machining efficiency is greatly improved.

Owner:上海剑平动平衡机制造有限公司

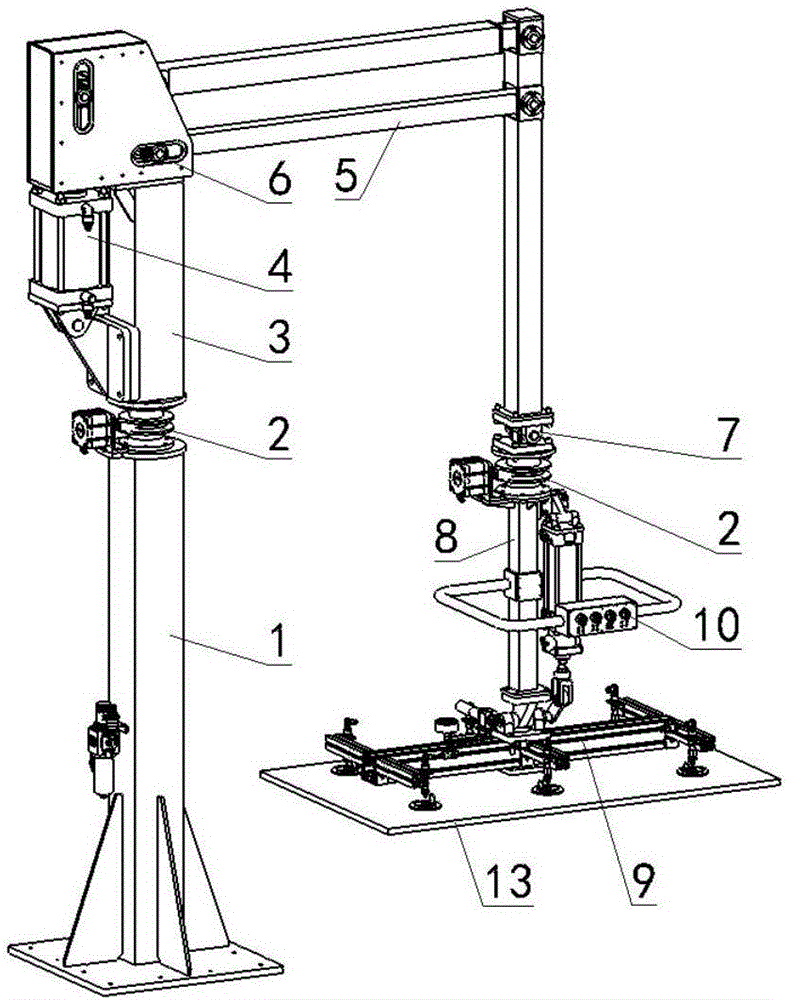

Assistance manipulator and control system thereof

ActiveCN106671055AAchieve "floatingSports balanceProgramme-controlled manipulatorBalancing machineControl system

The invention provides an assistance manipulator and a control system thereof. The assistance manipulator comprises a fixed stand column, a rotating joint, a rotating stand column, a balance cylinder, a parallelogram mechanism, a trajectory self-balance machine 6, a swing joint, a terminal actuation mechanism, a fixture, and a control system. When a force arm at one end of the assistance manipulator is changed, a force arm at the other end is also changed, and a fixed proportional relation is kept, so that a counter force is always balanced with a reaction arm no matter high-low motion, left-right motion and rotating motion of workpieces, the workpieces are always located in a floating state, the gravity is overcome, and the assistance function is realized. The assistance manipulator realizes floating of objects through combined application of the force balance self-adaption and the pneumatic principle, performs zero-gravity carrying and assembly for the objects, realizes hoisting, plane movement and overturning of weights through micro force of human hands, and is smooth and balanced in the motion process.

Owner:XI'AN AIRCRAFT INTERNATIONAL

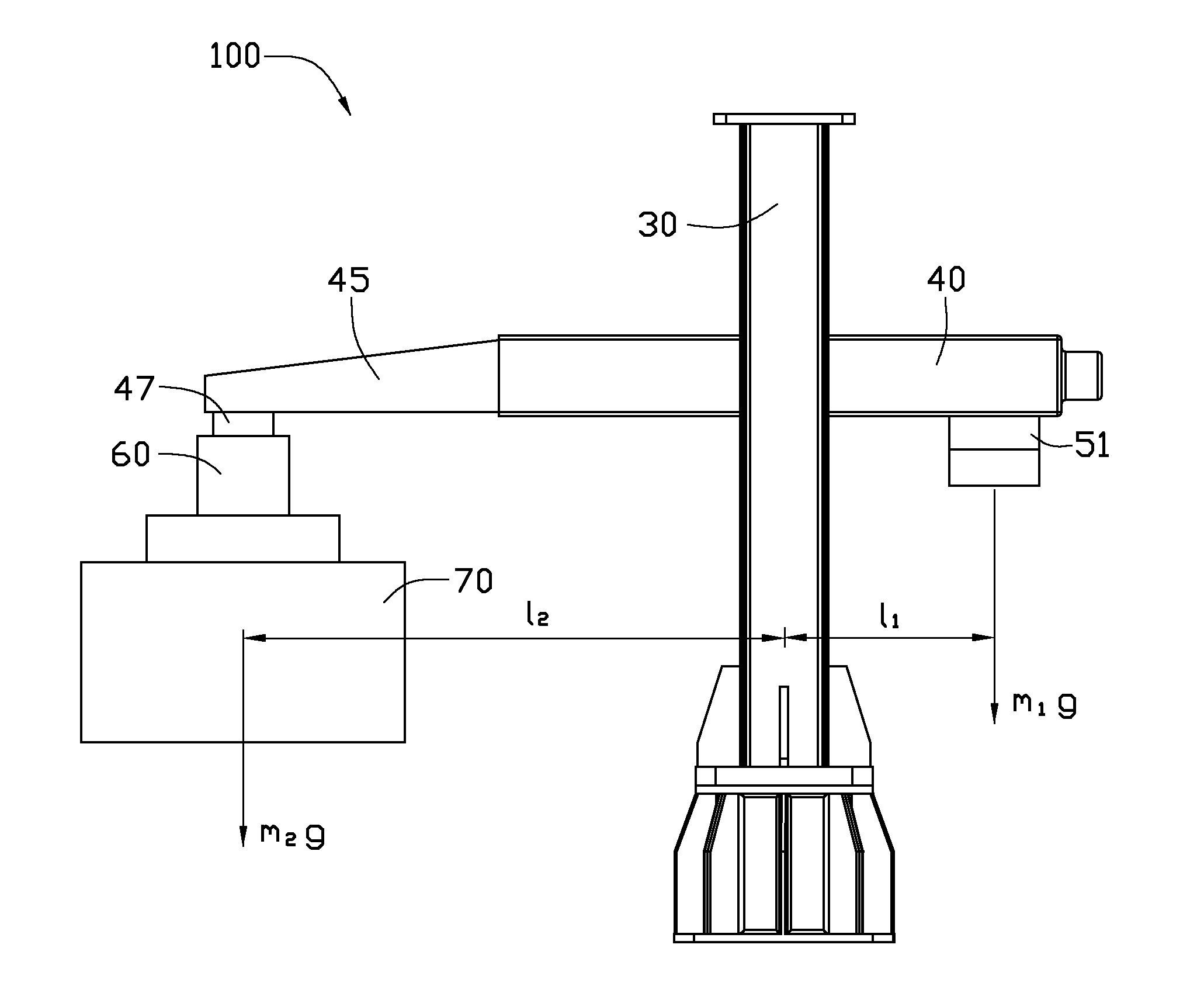

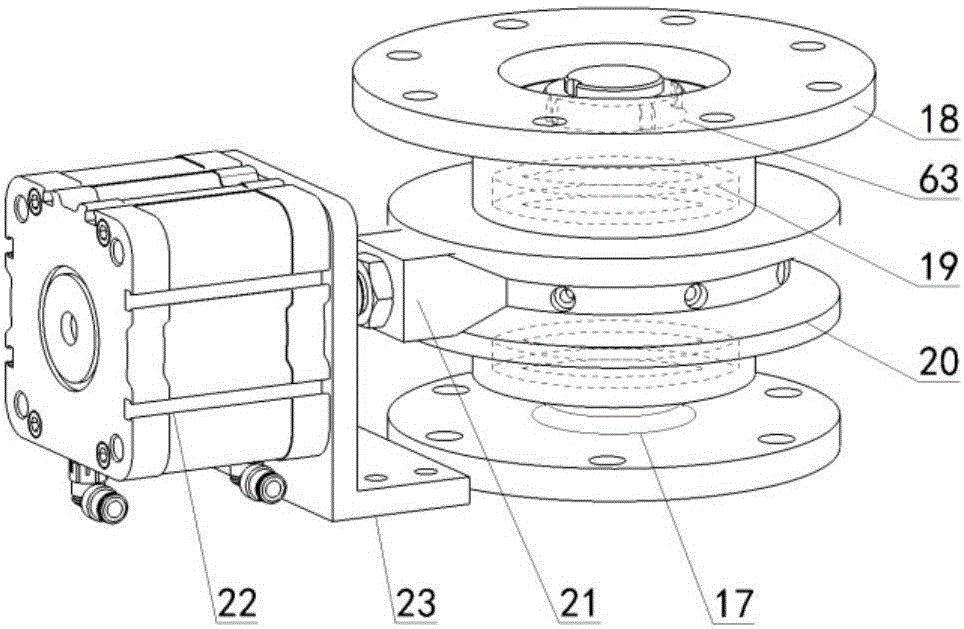

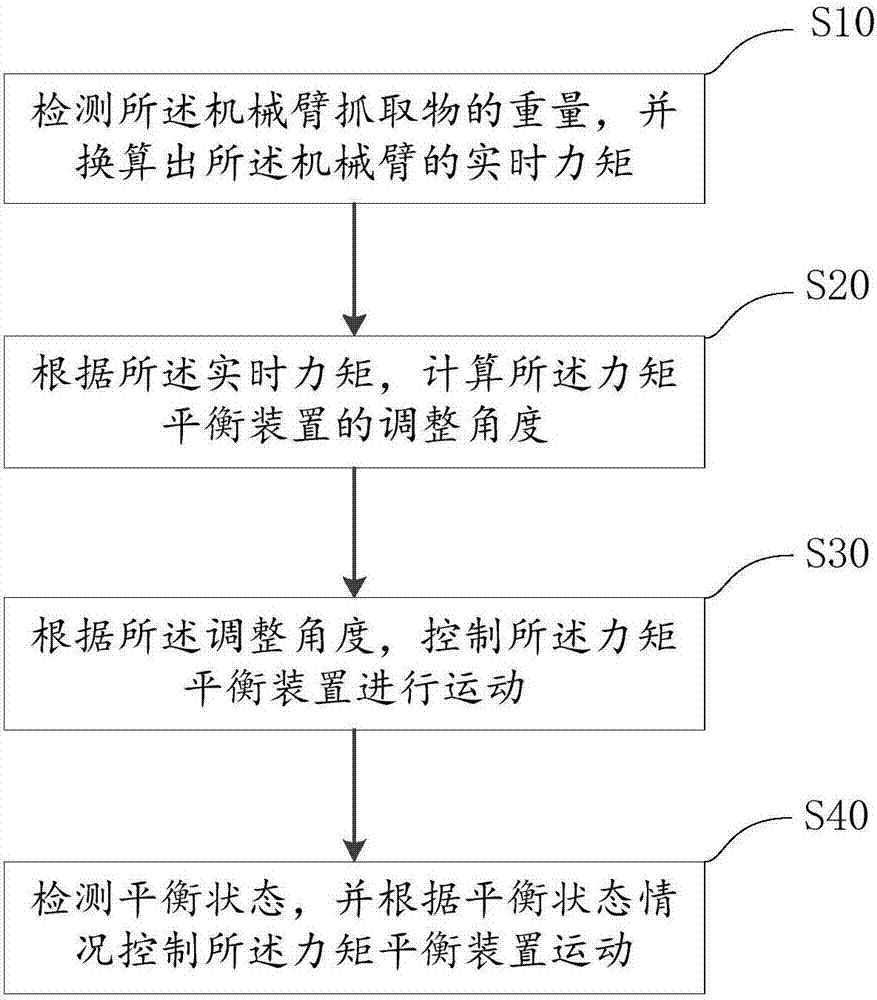

Method and device for adjusting balance according to force moment

PendingCN107414823AStable stateImprove work efficiencyProgramme-controlled manipulatorStable stateEngineering

The invention discloses a method and device for adjusting balance according to force moment. The method comprises a balancing main body, a mechanical arm and a force moment balancing device. The method comprises the steps that the weight of grabbing objects of the mechanical arm is detected, and the real-time force moment of the mechanical arm is converted; and an adjusting angle of the force moment balancing device is calculated according to the real-time force moment; the force moment balancing device is controlled to move according to the adjusting angle. According to the method and device for adjusting the balance according to the force moment, a specific method is utilized to allow a robot provided with the mechanical arm or a manipulator, an unmanned aerial vehicle or other device to keep balance when the mechanical arm is moving, during using, force moment difference generated in the moving process of the mechanism arm is balanced by utilizing a special weight layout structure and being matched with the device for adjusting the balance according to the force moment so that the whole system can have a stable state and a higher working efficiency.

Owner:深圳市拓灵者科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com