Unbalance magnitude online monitoring and de-weighting method in disc type workpiece processing

A technology of balancing quantity and workpiece, applied in the testing of metal processing equipment, metal processing mechanical parts, machine/structural components, etc., can solve the problem of low balancing accuracy, reduce dynamic balancing costs, reduce assembly errors, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

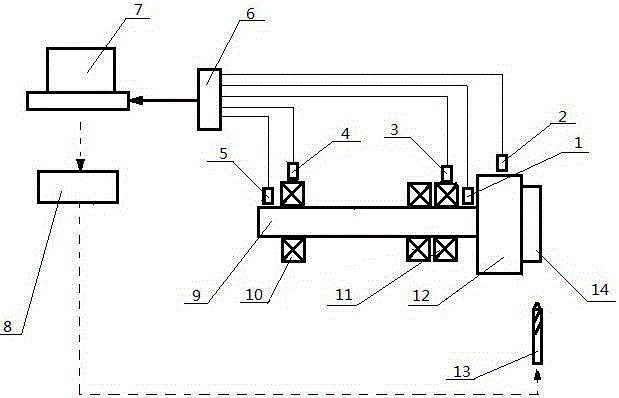

[0048] combined with figure 1 , 2, 3, 4 describe in detail the specific implementation of the present invention.

[0049] 1. The unbalance online monitoring and weight removal system in the processing of disk workpieces of the present invention includes a turn-milling compound numerical control machine tool and a set of information monitoring system.

[0050] The information monitoring system is used to monitor the vibration signal of the main shaft, the temperature signal of the bearing and the reference signal, and analyze the monitoring signal. figure 1 The information monitoring system includes two eddy current sensors (1) (5), two thermocouples (3) (4), one photoelectric sensor (2), signal acquisition card (6), PC (7), CNC control center (8) and the corresponding signal lines. The eddy current sensor (1) is connected to the signal acquisition card (6) through the data line, and the end part is not in contact with the main shaft (9), and is used to measure the vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com