Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

593results about How to "Reduce assembly errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

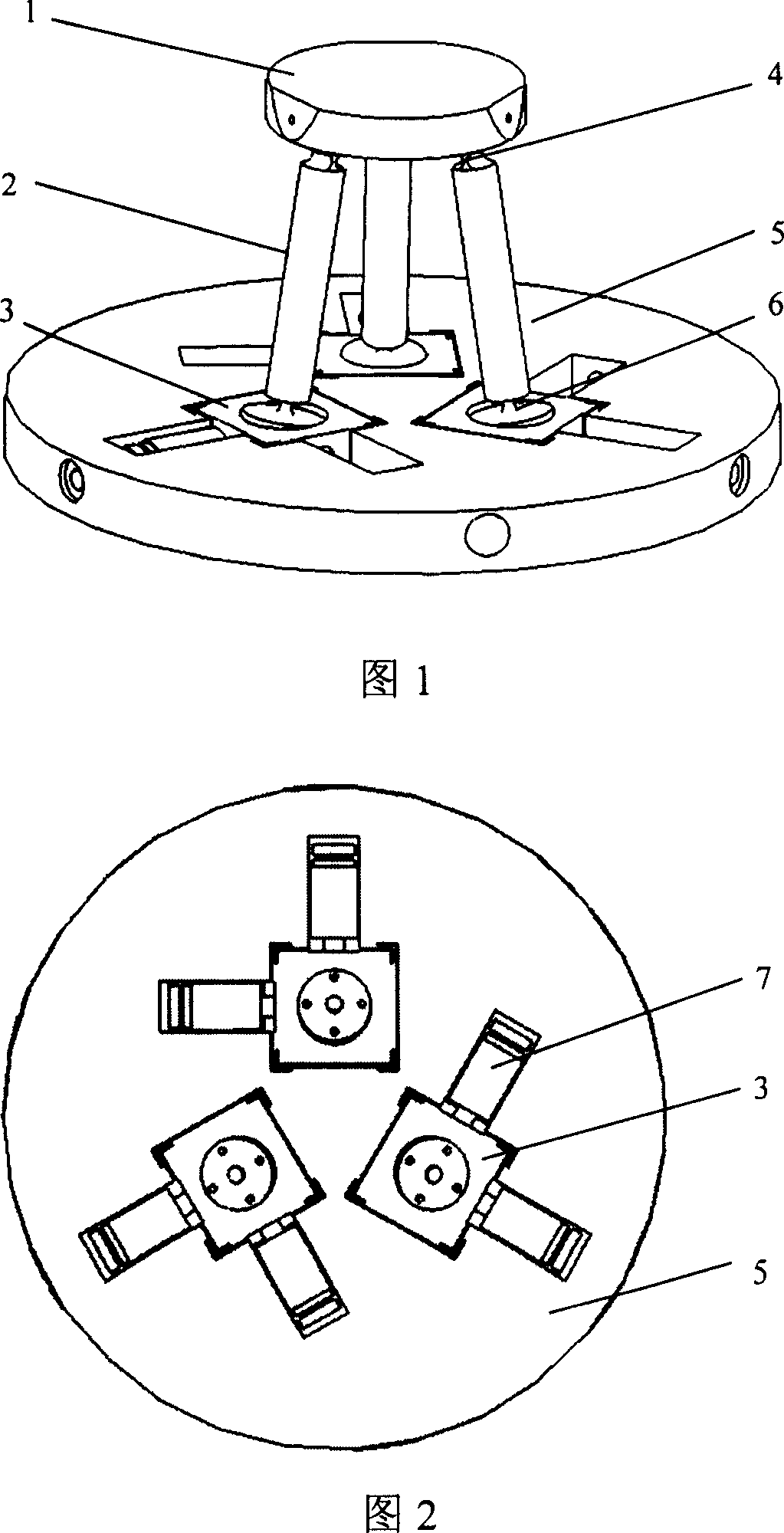

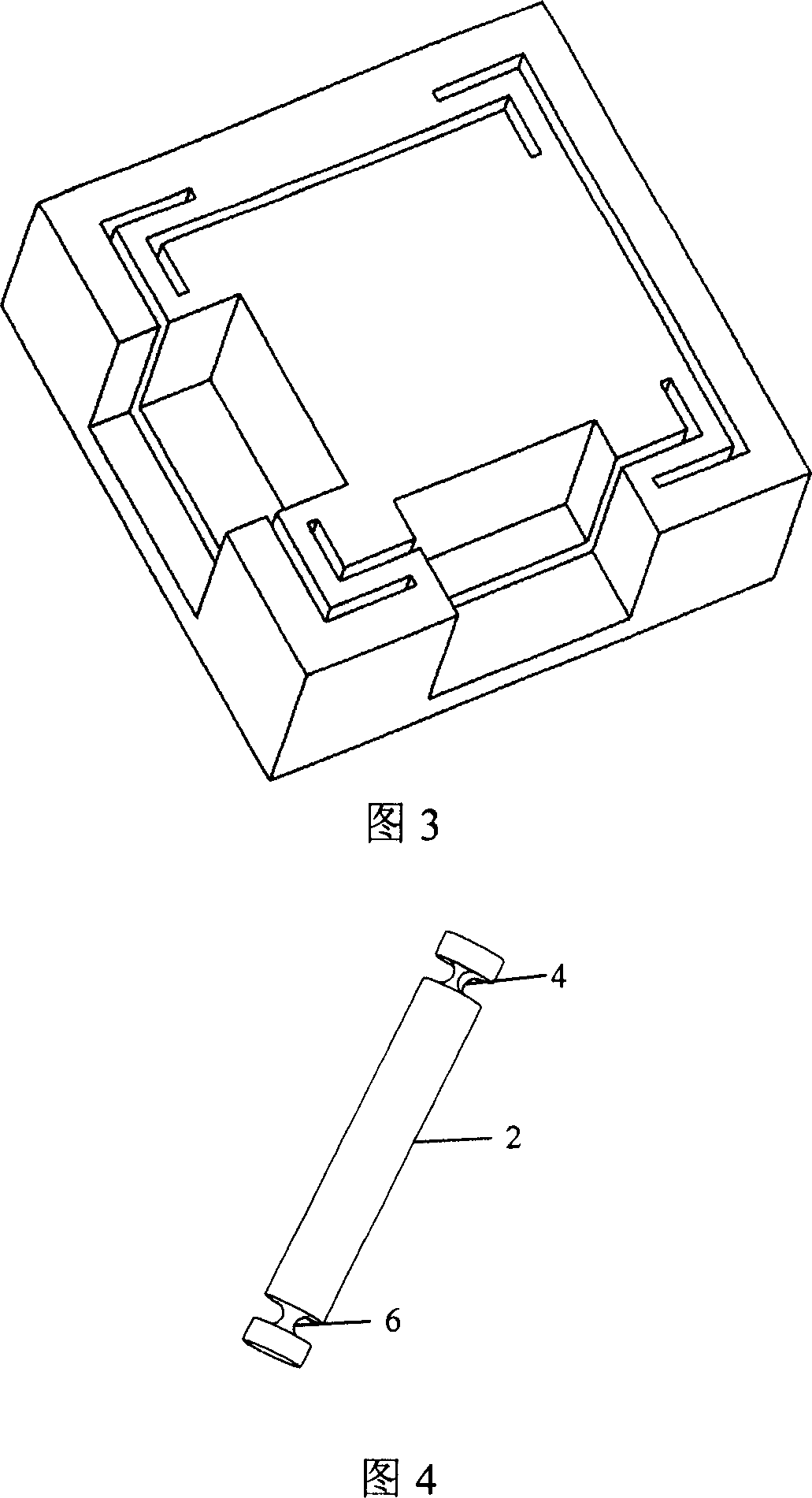

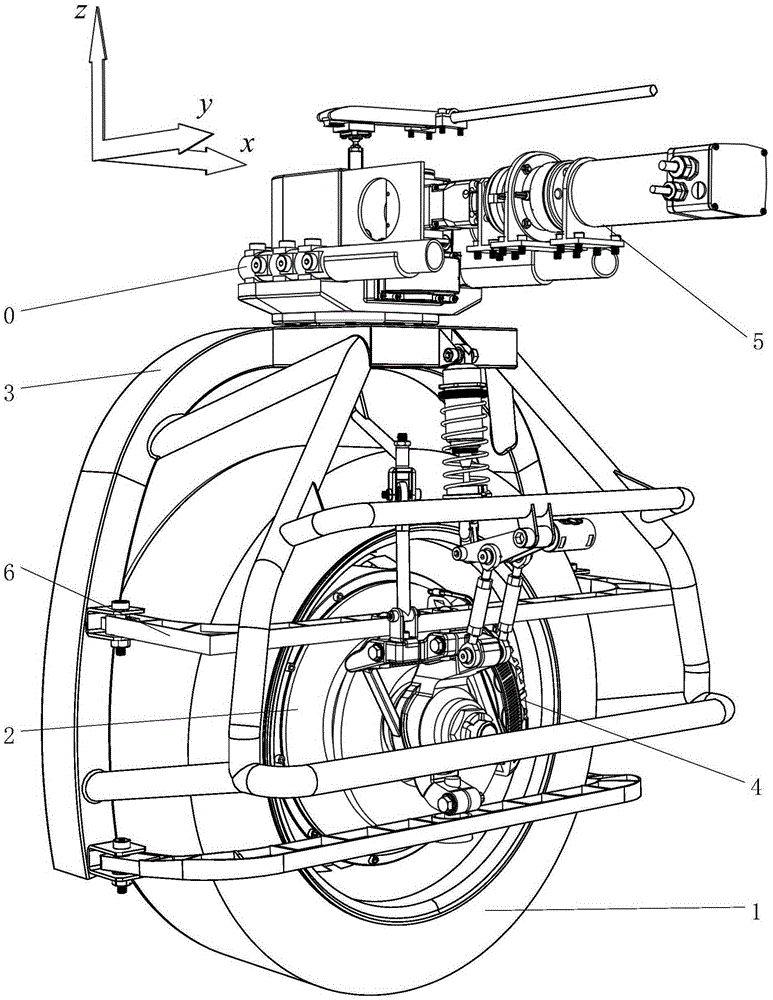

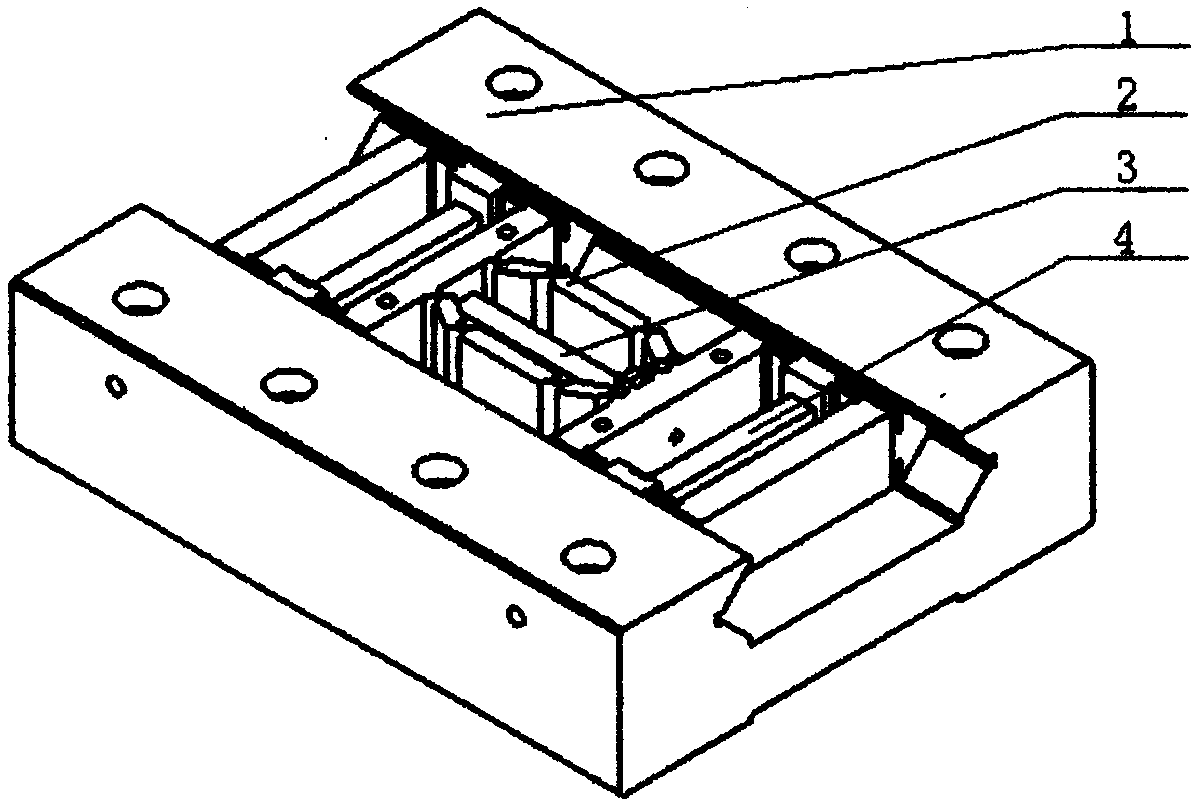

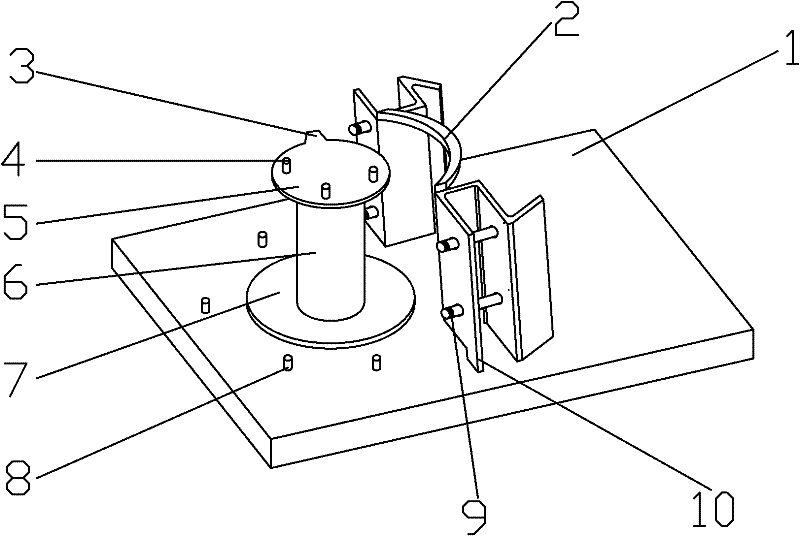

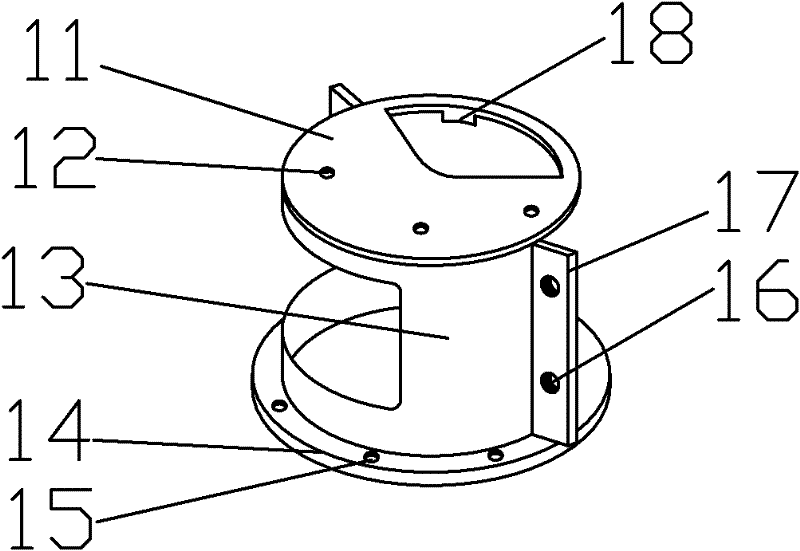

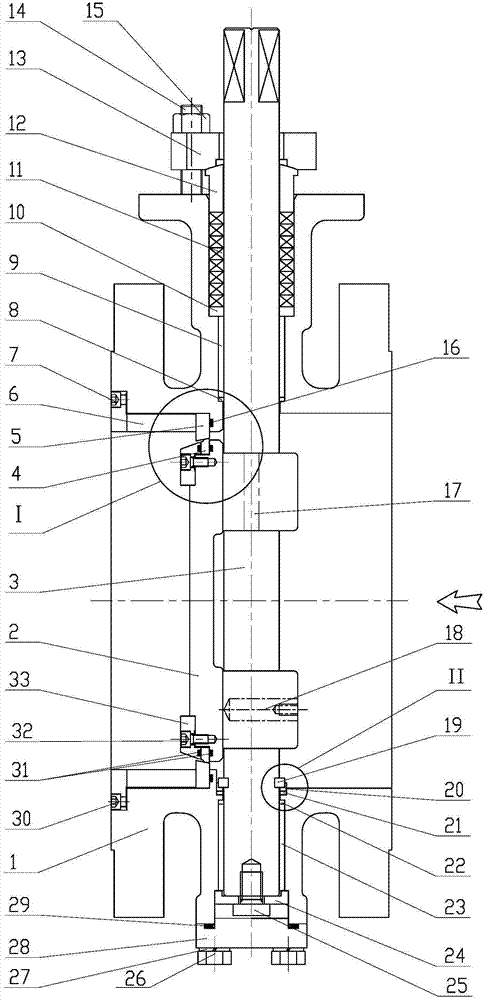

Three-branch chain six-freedom degree parallel flexible hinge micromotion mechanism

InactiveCN1962209AAvoid errorsCompact structureProgramme-controlled manipulatorElectricityEngineering

The invention relates to a three-chain six-freedom parallel flexible hinge micro motion device, wherein it comprises base platform, movable platform, driver on the base platform, and three support rods via flexible joints connected to the driver and movable platform. Said driver comprises three flexible plates on the base platform and piezoelectric ceramic driver connected to the flexible plates; three flexible plates are integrated processed, while each plate is connected to two piezoelectric ceramic drivers in right angle. The invention has compact structure and low installment error.

Owner:HARBIN INST OF TECH

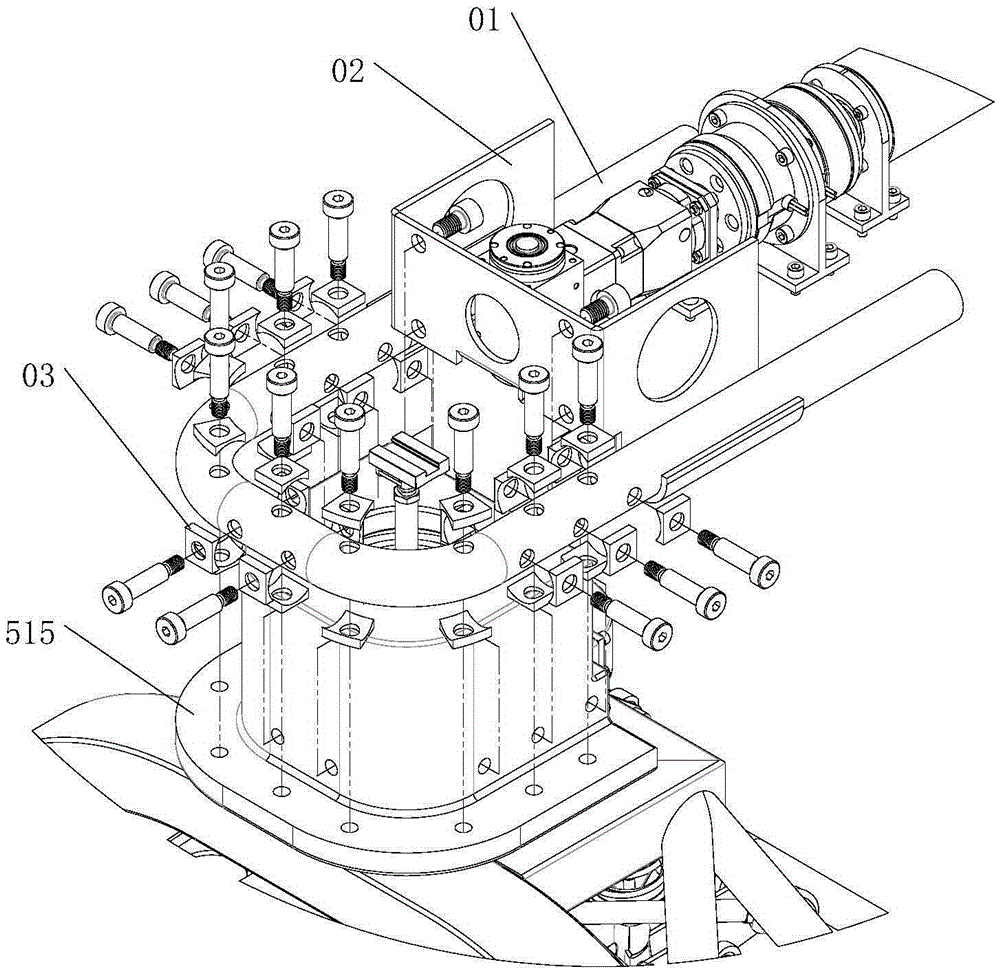

Terahertz subharmonic frequency doubling and mixing device based on monolithic integrated circuit

ActiveCN104467681AReduce the numberSmall sizeModulation transference by semiconductor devices with minimum 2 electrodesHarmonicLow-pass filter

The invention discloses a terahertz subharmonic frequency doubling and mixing device based on a monolithic integrated circuit. The device comprises a fundamental wave input waveguide micro-strip transition, a CMRC structure local oscillator low-pass filter, a frequency doubling matching circuit, a four-die frequency doubling diode, a local oscillator matching circuit, a frequency mixing diode, a radio frequency matching circuit, a radio frequency input waveguide micro-strip transition, and a CMRC structure intermediate frequency low-pass filter. According to the terahertz subharmonic frequency doubling and mixing device based on the monolithic integrated circuit, on the one hand, the number of dielectric substrates is decreased, and circuits are integrated on one substrate, so that the number of cavities to be processed is decreased, and processing and assembling are easy; on the other hand, waveguide transitions to be designed and processed are reduced, and the cavity size is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

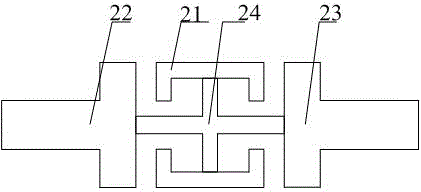

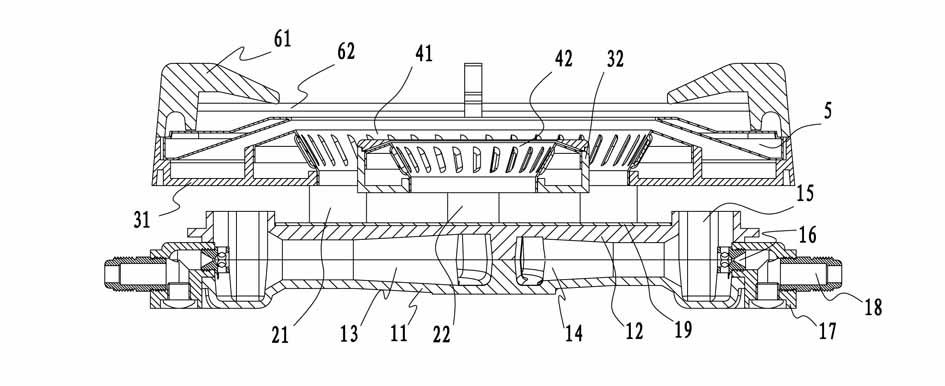

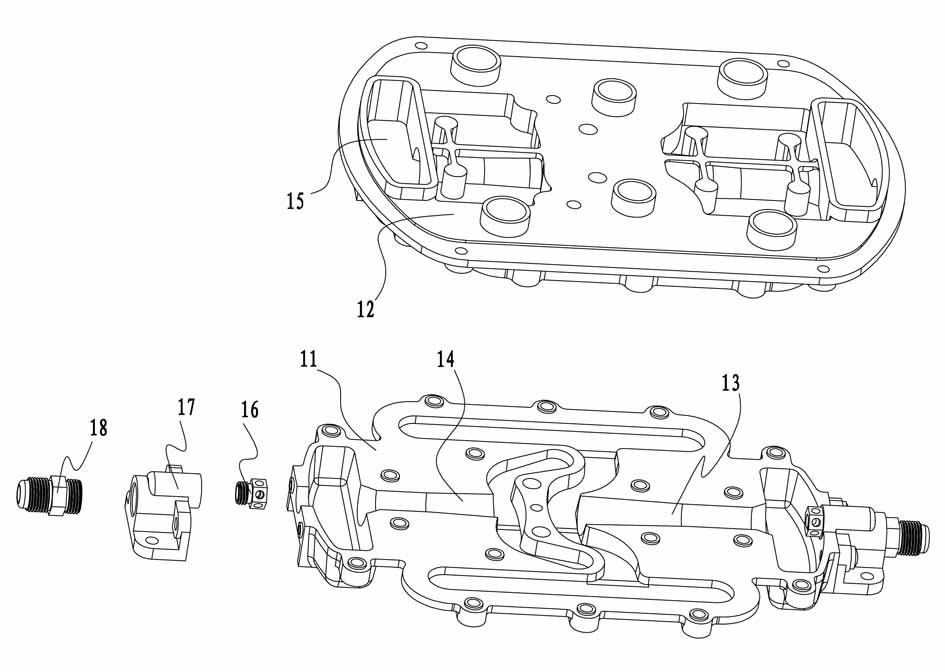

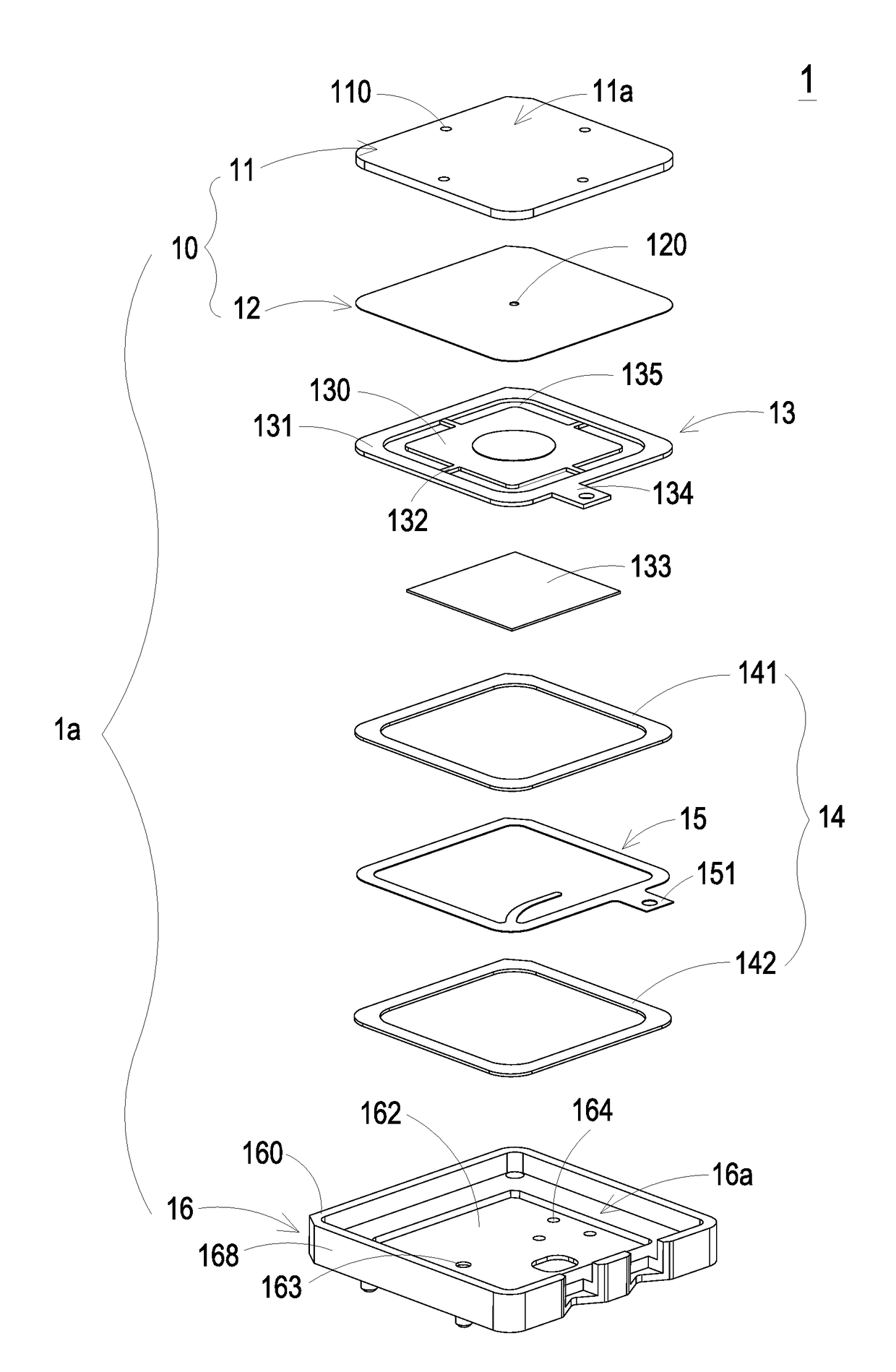

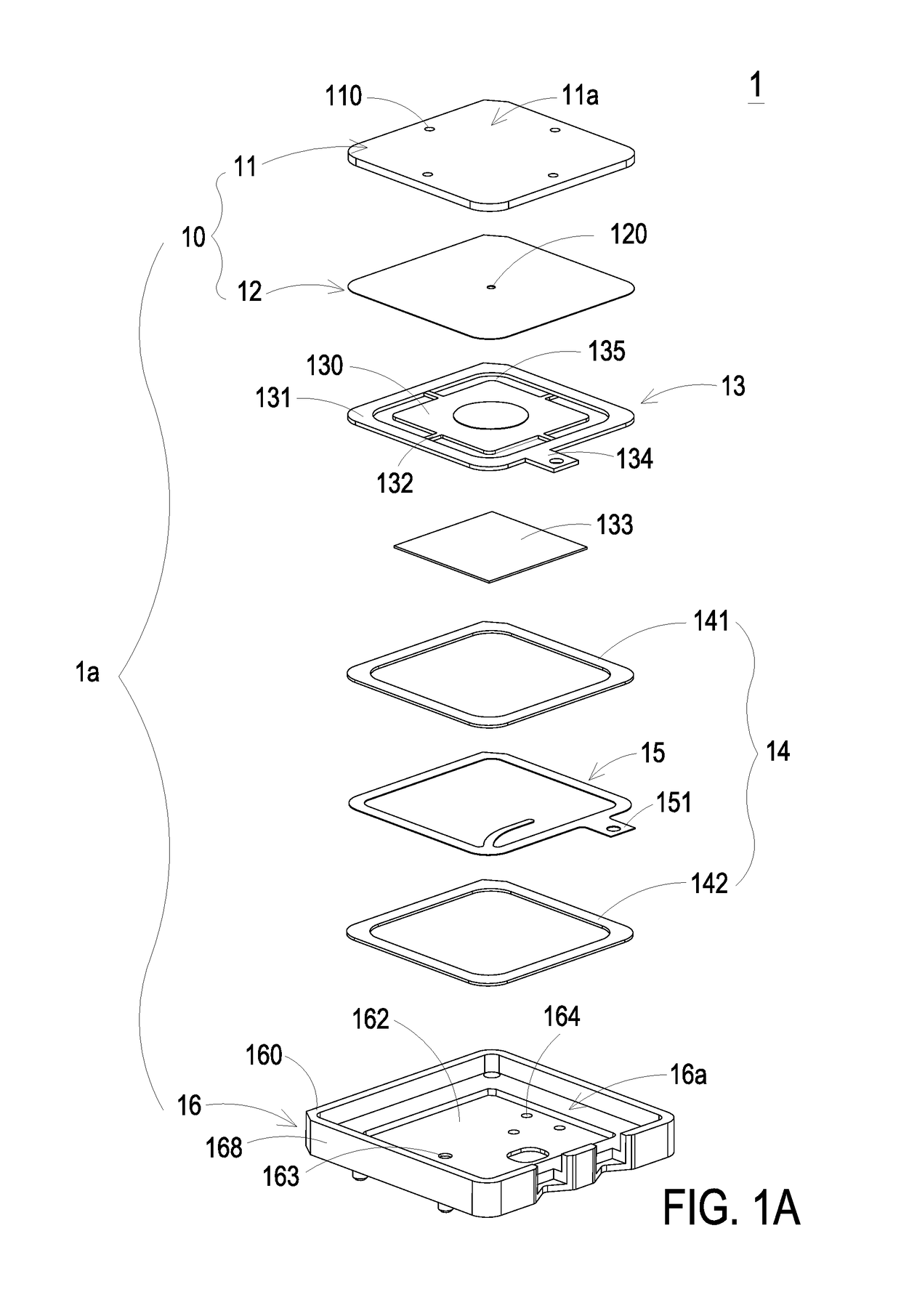

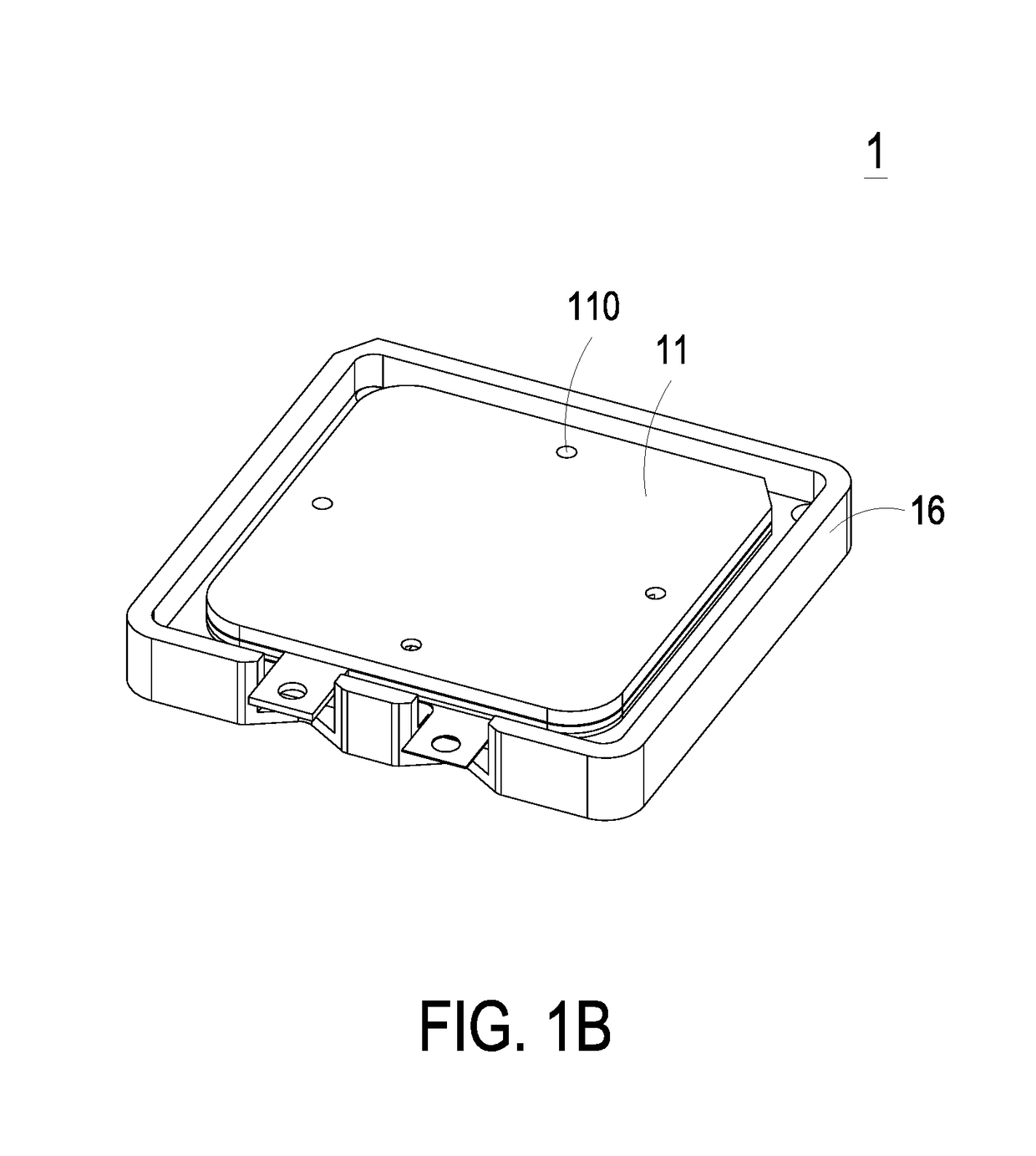

Miniature fluid control device and piezoelectric actuator thereof

ActiveUS20180066768A1Steadiness and performance be intensifyDecrease motionValve arrangementsPiezoelectric/electrostriction/magnetostriction machinesEngineeringPiezoelectric actuators

A piezoelectric actuator includes a square suspension plate, an outer frame, plural brackets and a square piezoelectric ceramic plate. The outer frame is arranged around the suspension plate. A second surface of the outer frame and a second surface of the suspension plate are coplanar with each other. The plural brackets are perpendicularly connected between the suspension plate and the outer frame for elastically supporting the suspension plate. Each bracket has a length in a range between 1.11 mm and 1.21 mm and a width in a range between 0.2 mm and 0.6 mm. A length of the piezoelectric ceramic plate is not larger than a length of the suspension plate. The piezoelectric ceramic plate is attached on a first surface of the suspension plate.

Owner:MICROJET TECH

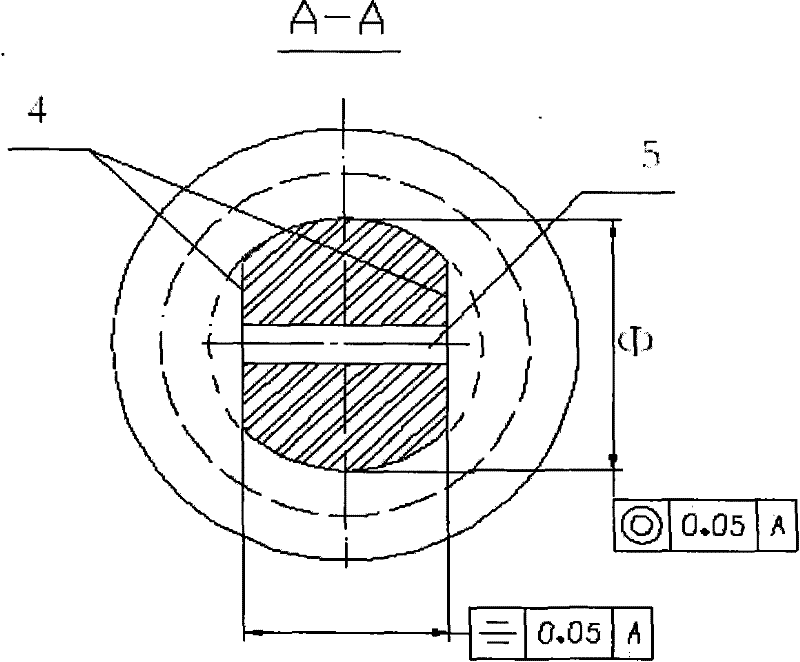

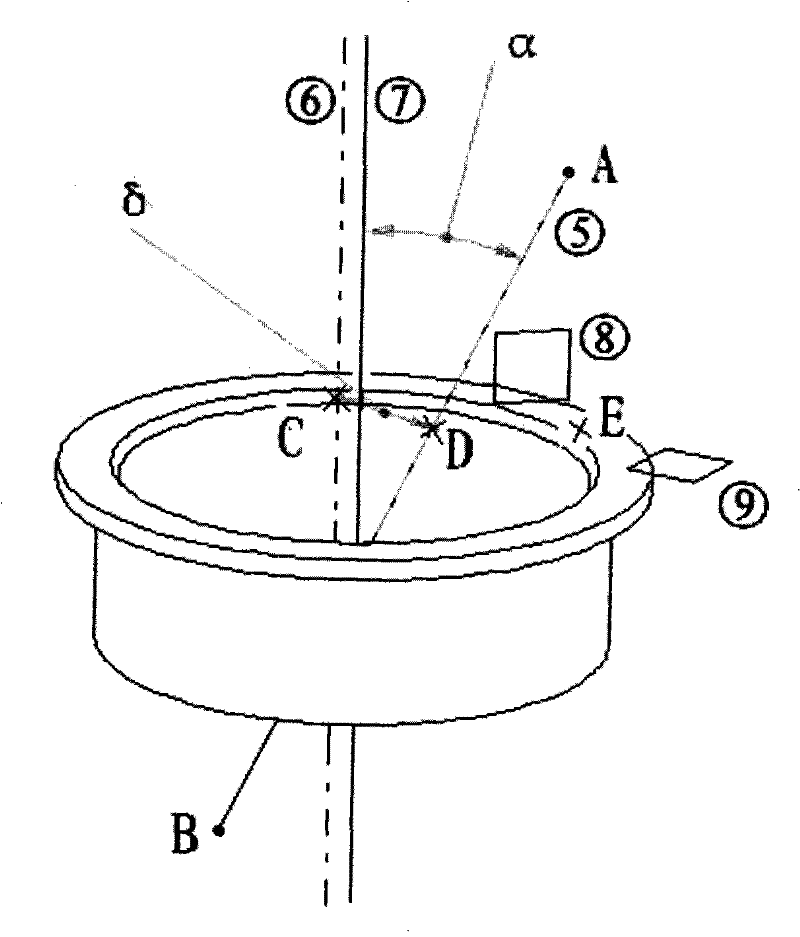

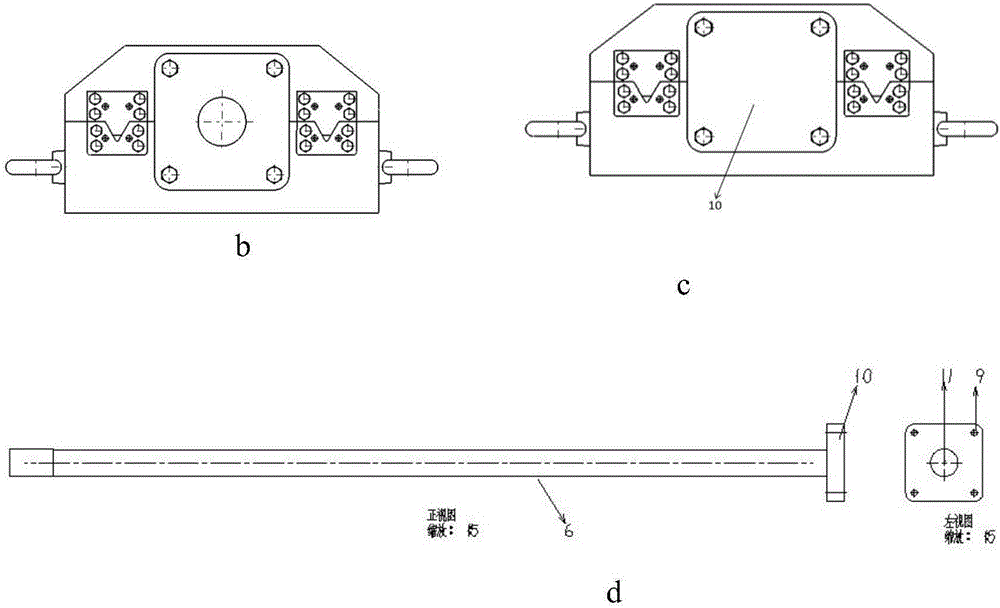

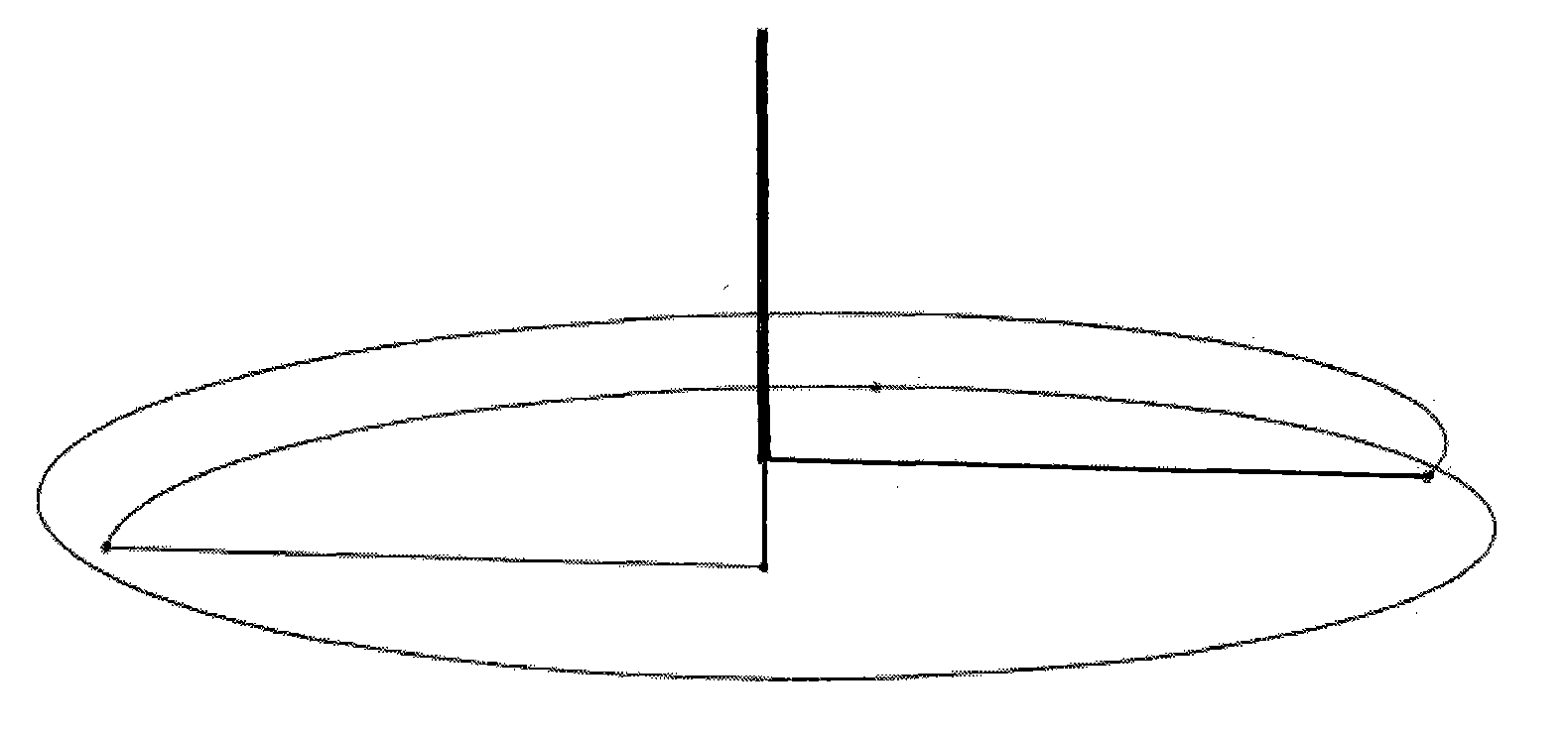

Hole axis detection tool and detection method thereof

InactiveCN102494641AImprove installation accuracyReduce assembly errorsUsing optical meansEngineeringAirplane

The invention belongs to the airplane assembly technology, relates to a tool and a method for detecting assembly error of center points of end faces of joint holes and assembly error of joint hole axes during airplane assembly, and particularly relates to a hole axis detection tool and a detection method thereof. The hole axis detection tool is a shaft, the lower end of the shaft is matched with an assembling join hole, the upper portion of the shaft is provided with two planes machined by utilizing the plane of the axis as a symmetry plane, two through holes are manufactured on the two planes vertically, and center lines of the through holes are intersected with the axis of the shaft. The method includes steps of mounting the shaft in a joint bushing hole of an assembled product during use; measuring coordinates of points 1, 2, 3 and 4 respectively; computing coordinates of center points A and B according to the coordinates of points 1,2,3 and 4; drawing the actual axis, running through the center points A and B, of the joint hole; comparing and analyzing the actual axis of the joint hole and the theoretical axis; accurately analyzing assembly error of the center point of the end face of the joint hole and the hole axis after assembling; and finally taking measures to guarantee assembly accuracy of joints so that quality of products is guaranteed.

Owner:HARBIN

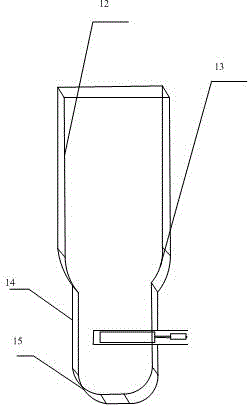

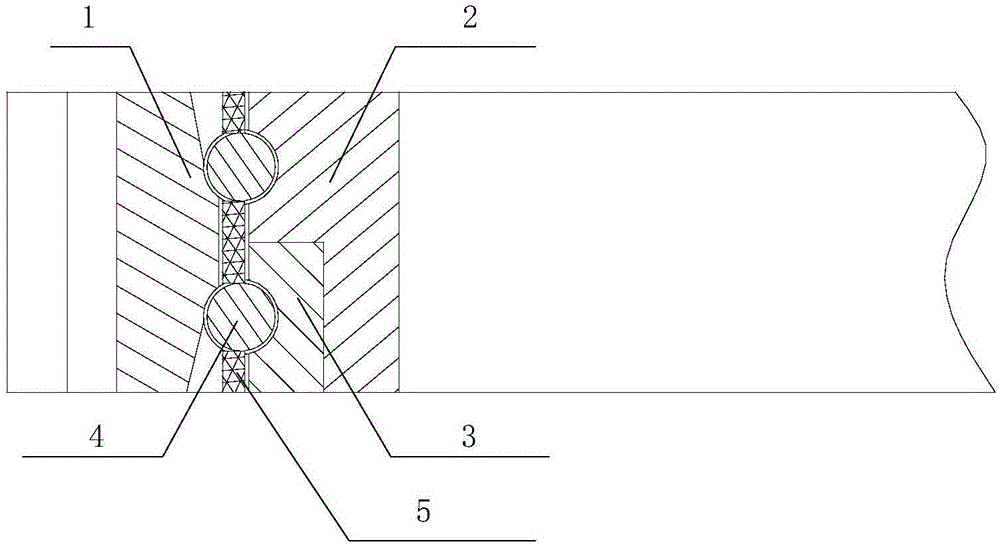

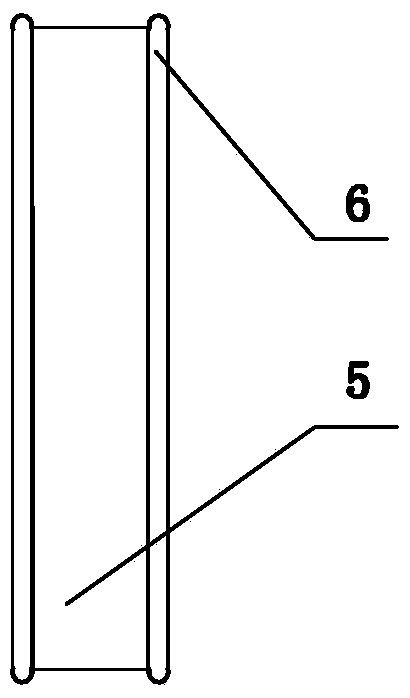

Double-reed large-turning angle flexible joint

InactiveCN104791377AImprove axial stiffnessImprove radial stiffnessPivotal connectionsKinematic pairEngineering

The invention discloses a double-reed large-turning angle flexible joint, relates to the technical field of mechanical kinematic pairs, and solves the problem that the conventional flexible hinge is small in motion range. The double-reed large-turning angle flexible joint is characterized in that a first shell is integrally formed by a 210-degree arc plate and a 90-degree arc plate; the side wall of the 210-degree arc plate and the side wall of the 90-degree arc plate are integrally connected, and the thickness of the 90-degree arc plate is smaller than that of the 210-degree arc plate; the 210-degree arc plate of the first shell is arranged outside a 90-degree arc plate of a second shell, the 90-degree arc plate of the first shell is arranged inside a 210-degree arc plate of the second shell, and a gap is formed between the first shell and the second shell; a first flexible plate is inserted into the first shell and the second shell through a first through groove and a second through groove; a second flexible plate is inserted into the first shell and the second shell through the remaining parts of the first through groove and the second through groove. The double-reed large-turning angle flexible joint is applied to the field of large-stroke precision transmission mechanisms and flexible transmission.

Owner:HARBIN INST OF TECH

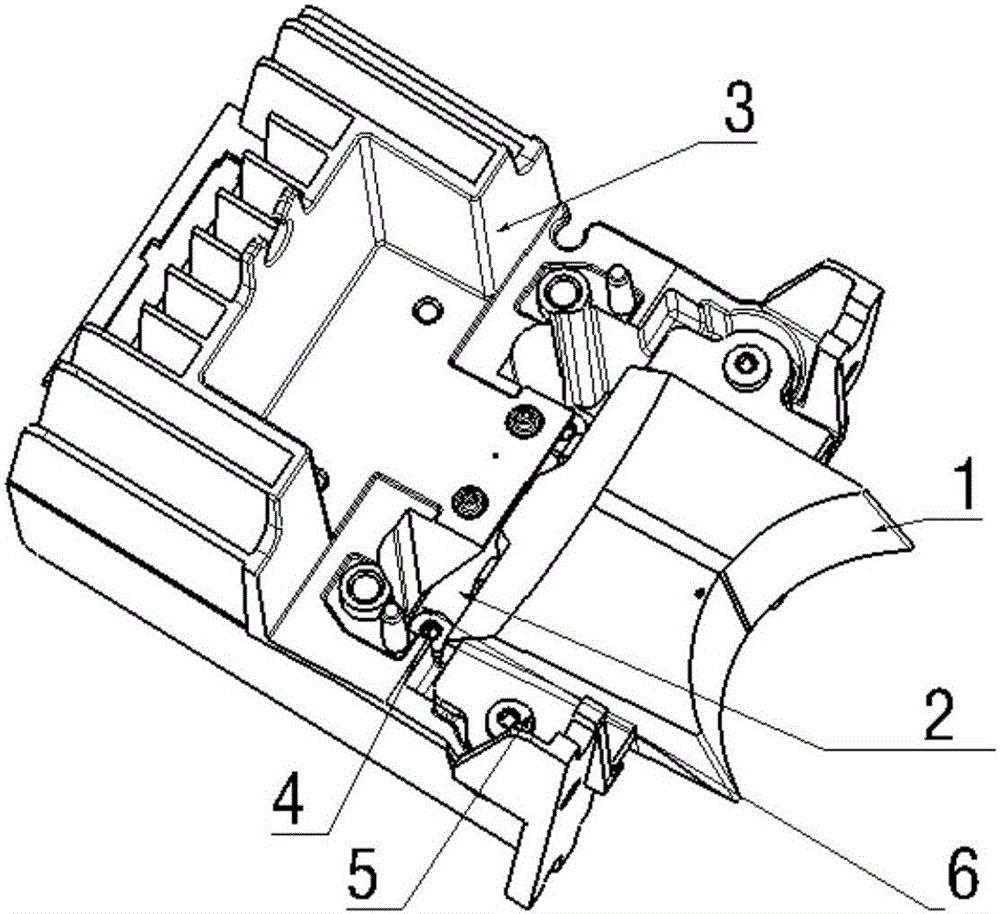

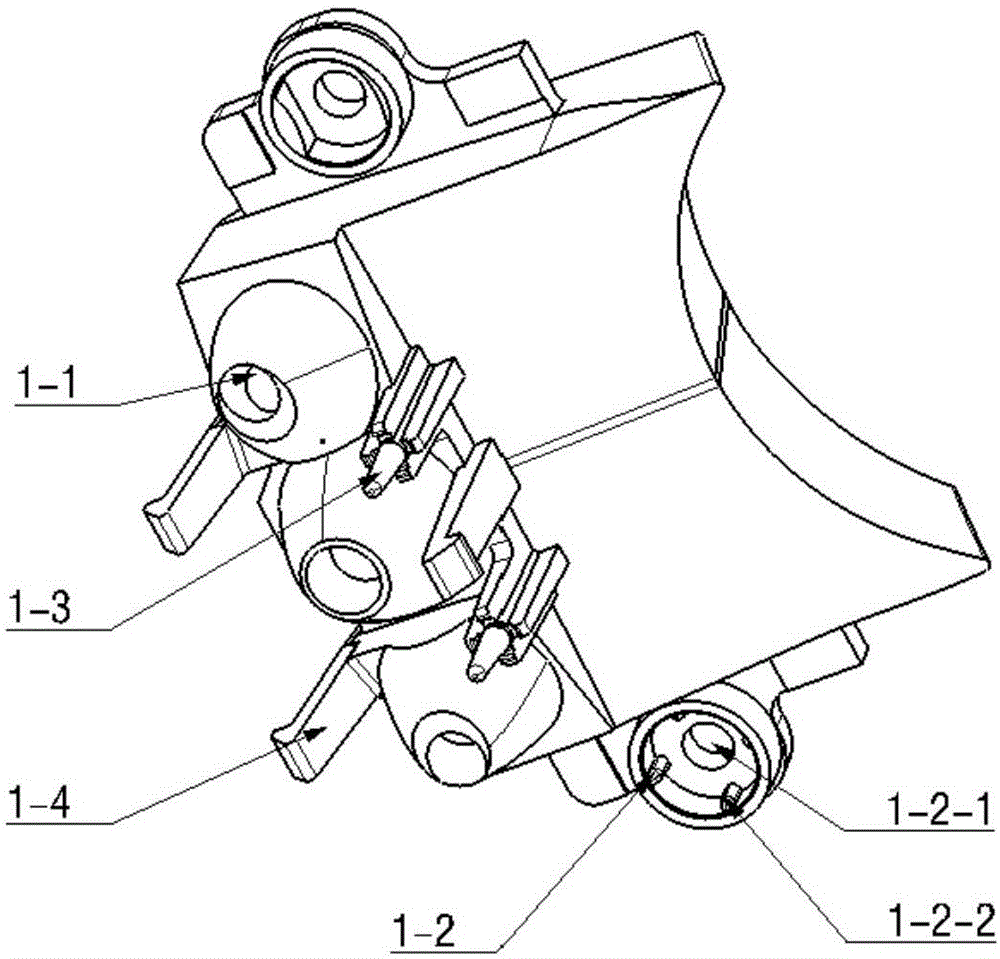

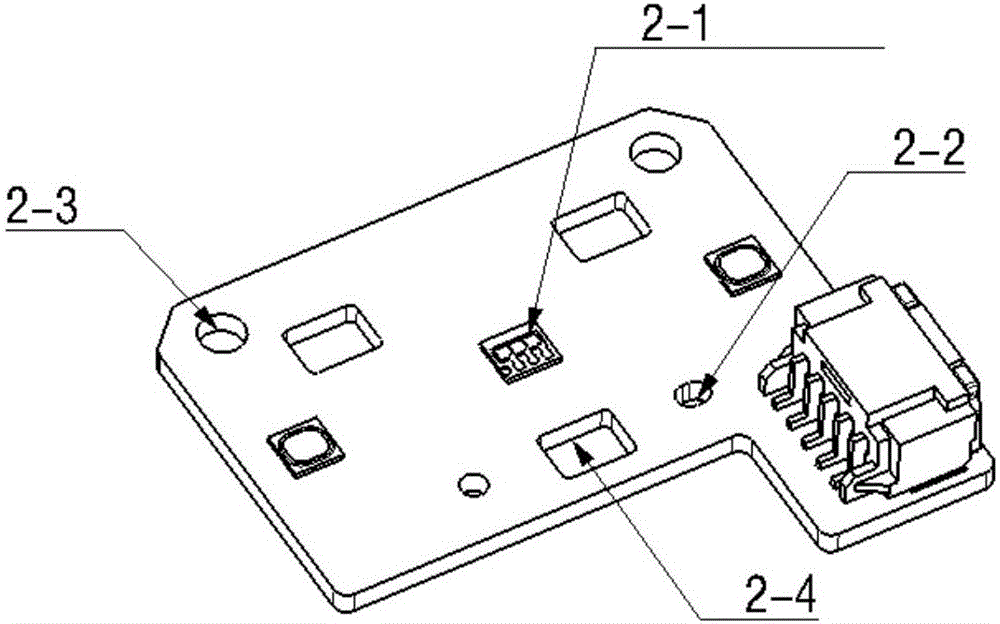

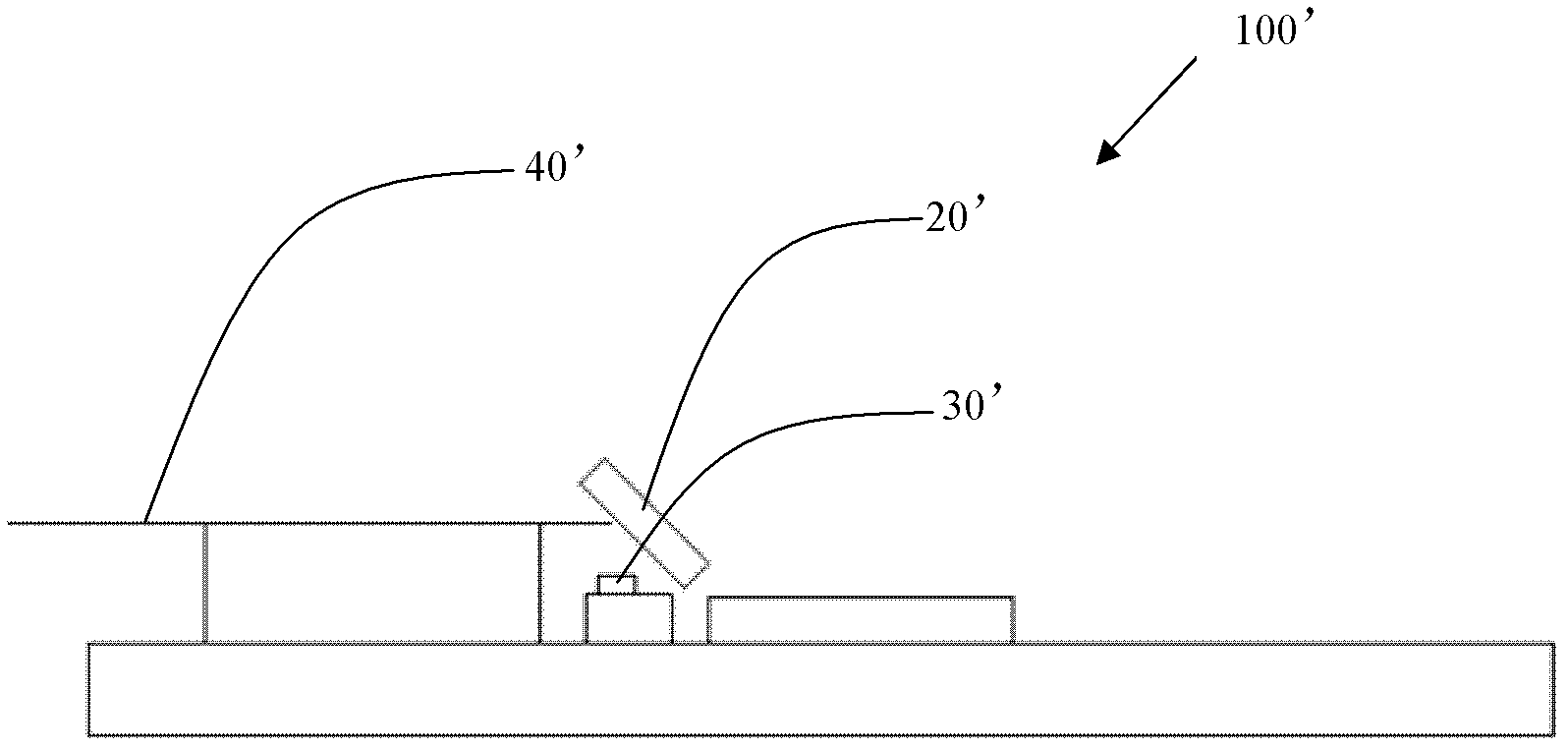

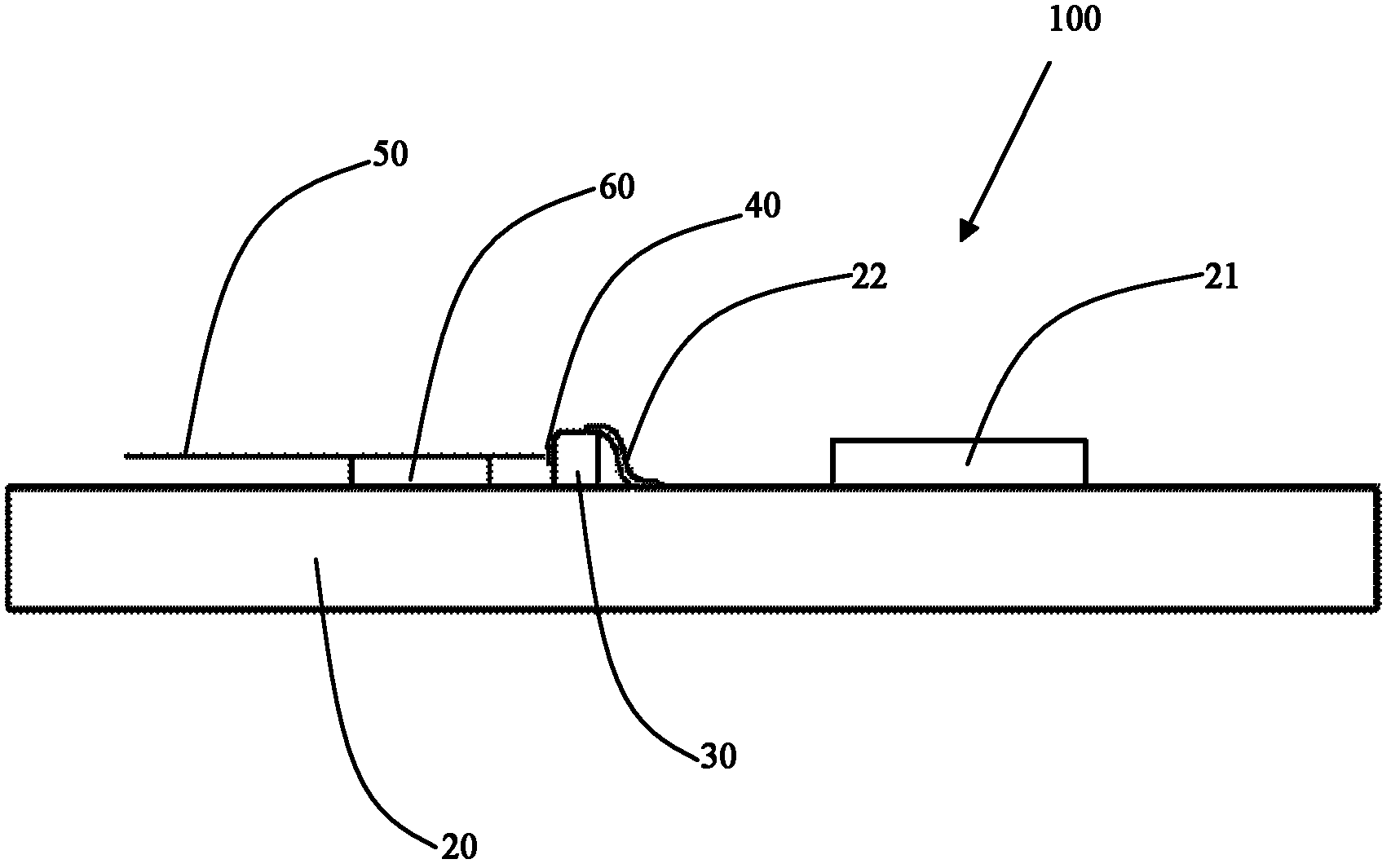

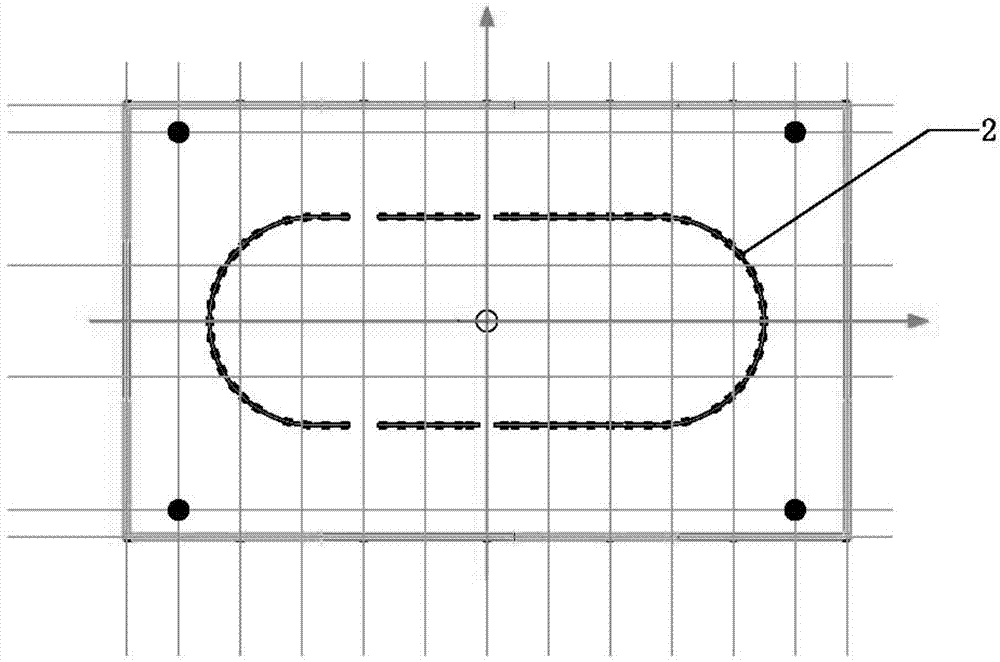

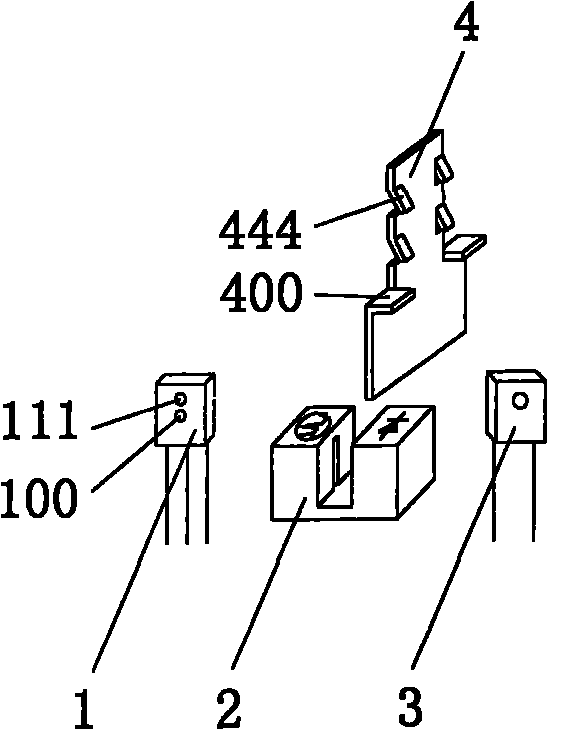

Positioning system and positioning method for optical module for automobile lamp

PendingCN107525005AHigh positioning accuracyReduce assembly errorsVehicle headlampsLight fasteningsOptical ModuleEngineering

The invention discloses a positioning system for an optical module for an automobile lamp. The positioning system comprises the optical module (1), an LED panel (2) and an installing bracket (3). The positioning system is characterized in that the LED panel (2) is arranged below the optical module (1), the optical module (1) and the LED panel (2) form a small detachable installing assembly (7), and the small detachable installing assembly (7) is directly positioned and installed on the installing bracket (3) through positioning sleeves. According to the positioning system, the LED panel (2) and the optical module (1) are directly positioned through positioning pins and pre-fixed through hooks, the optical module (1) and the LED panel (2) are directly positioned, therefore, the position precision of the optical module (1) and the LED panel (2) is relatively high, the assembling error is reduced, and the positioning precision of an optical system is improved.

Owner:HASCO VISION TECHNOLOGY CO LTD

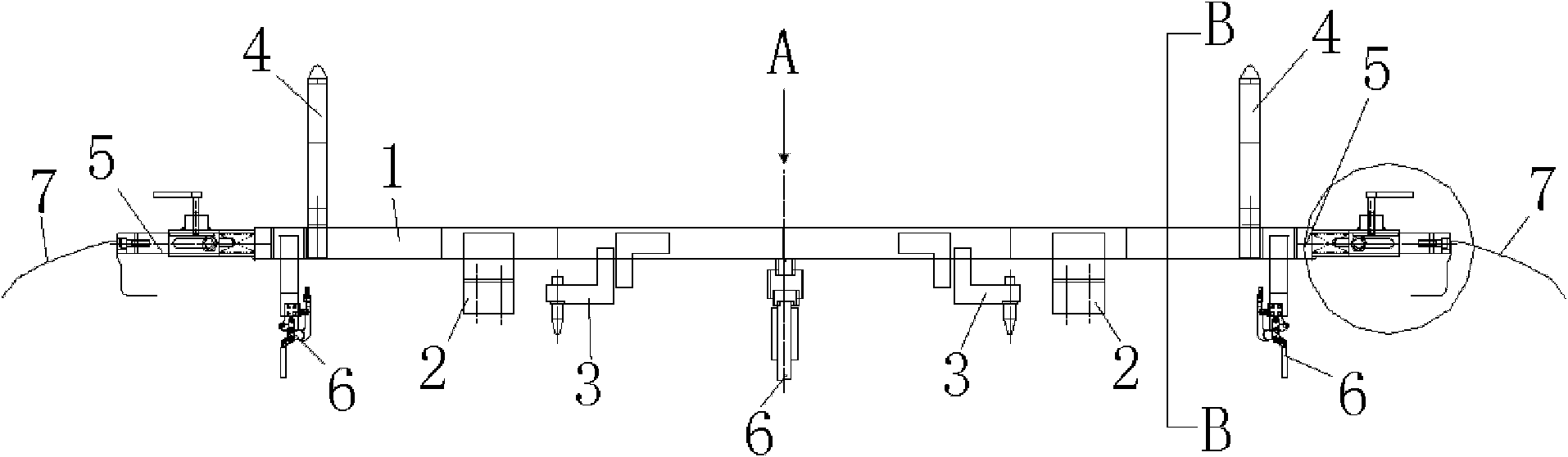

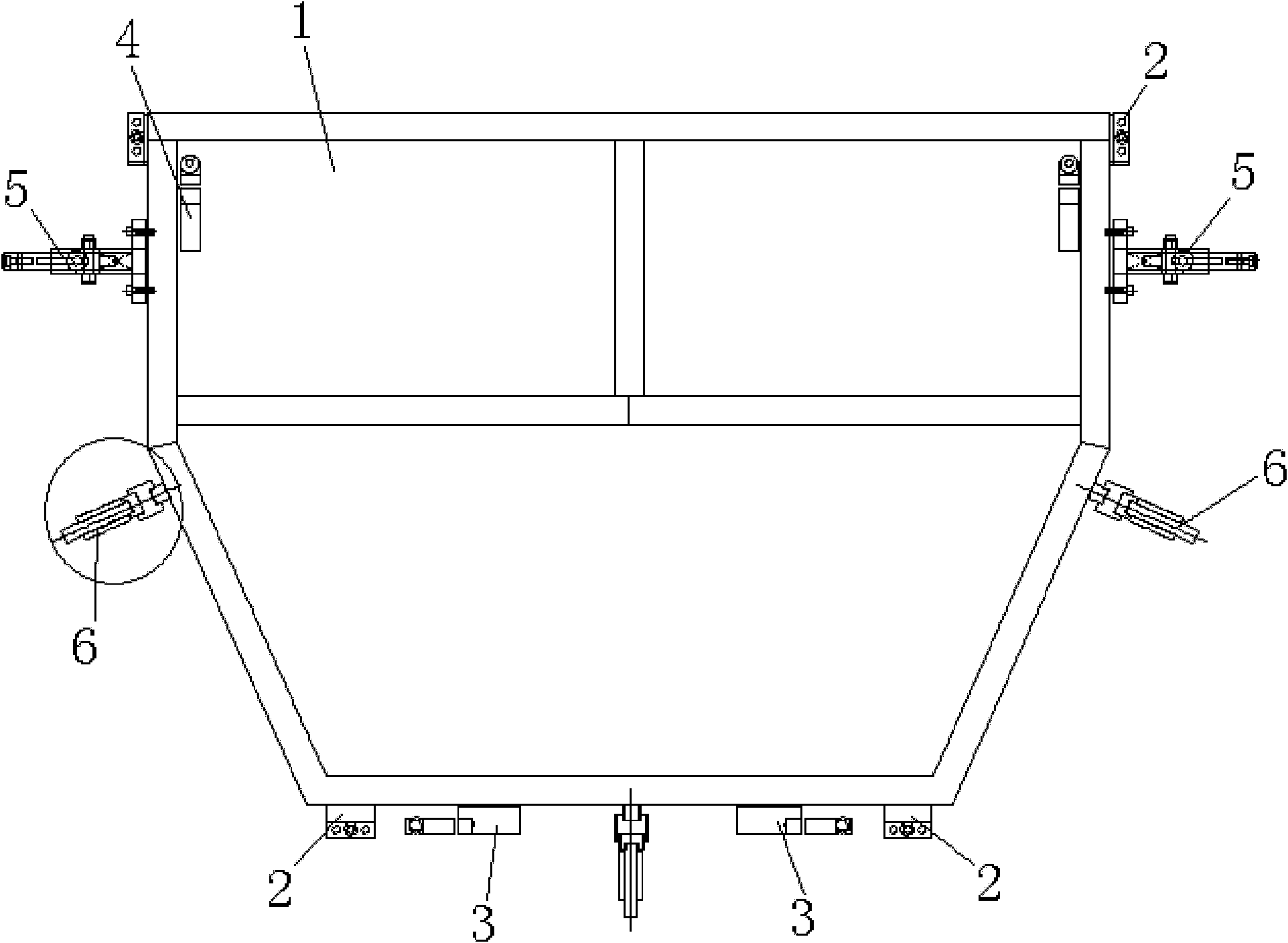

Centering and positioning fixture for automobile assembly

ActiveCN102490137AReduce assembly errorsReduce labor intensityWork holdersMetal-working hand toolsEngineeringUltimate tensile strength

The invention discloses a centering and positioning fixture for automobile assembly, which comprises a positioning support provided with a workpiece positioning pin. A Z-directional support block is arranged at the bottom end of the positioning support; X-directional positioning pins are arranged on two sides of the positioning support positioned in the X direction of an automobile respectively; centering and positioning mechanisms are arranged on two sides of the positioning support positioned in the Y direction of the automobile respectively; and central lines of the centering and positioning mechanisms are overlapped. The centering and positioning fixture is used for centering and positioning workpieces when the workpieces are assembled, assembly adjusting time is shortened, assembly adjusting operation is decreased, the labor intensity of staff is reduced, errors of workpiece assembly are decreased, and production assembly efficiency, product quality and production efficiency are simultaneously improved.

Owner:CHERY AUTOMOBILE CO LTD

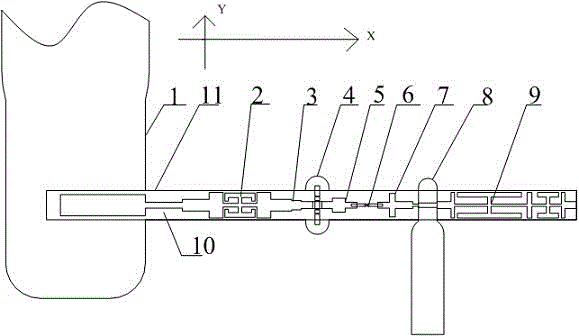

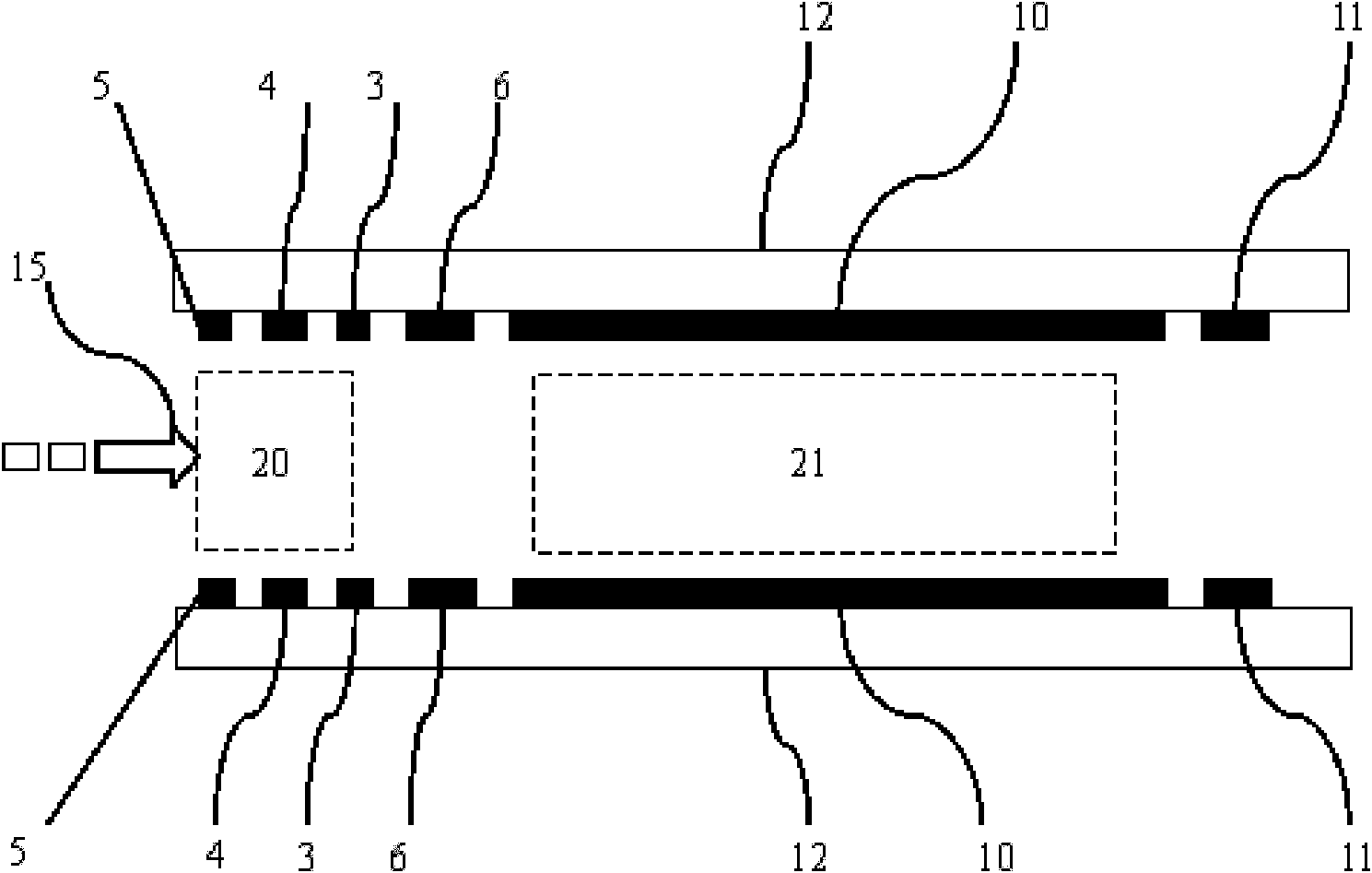

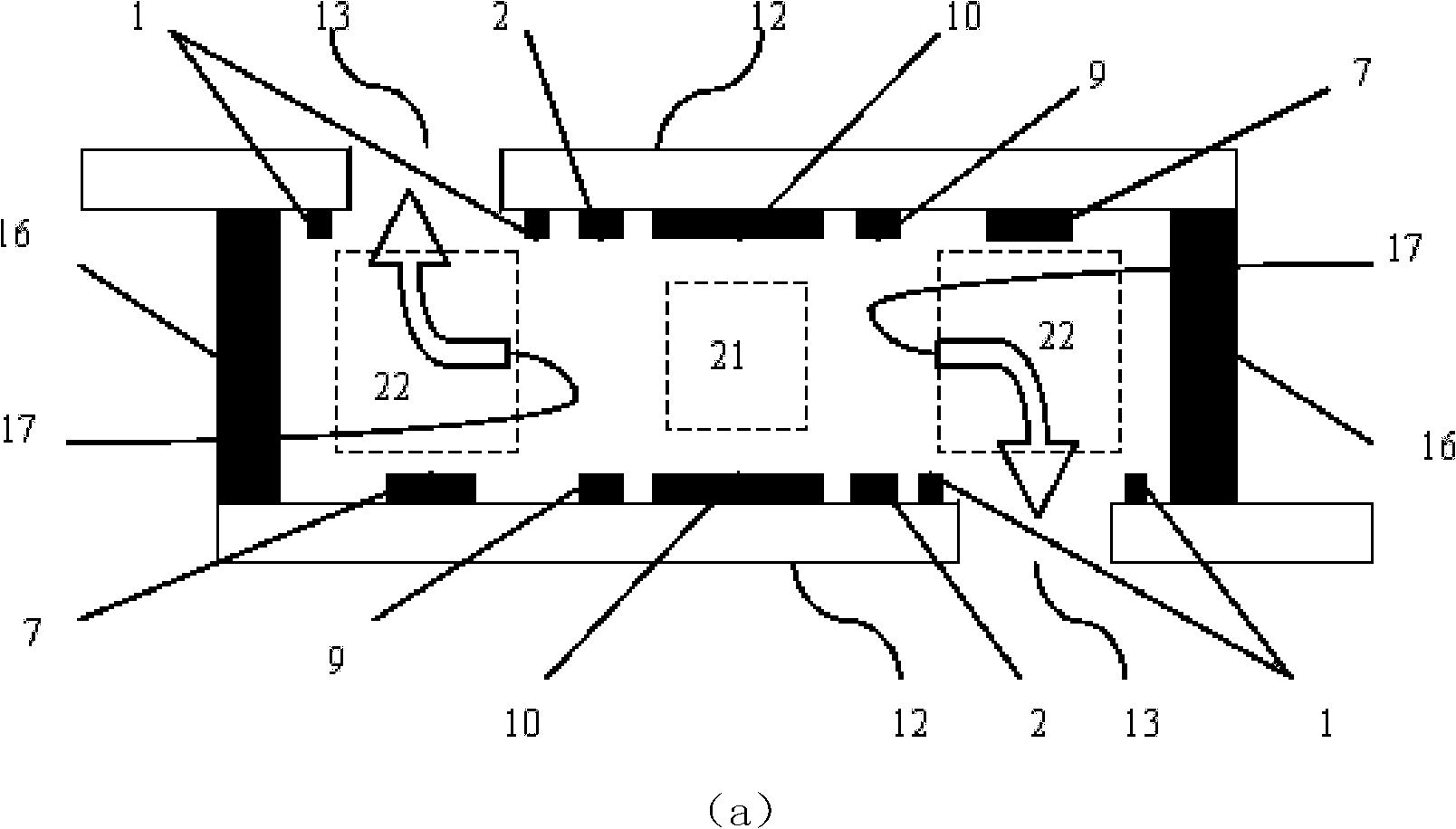

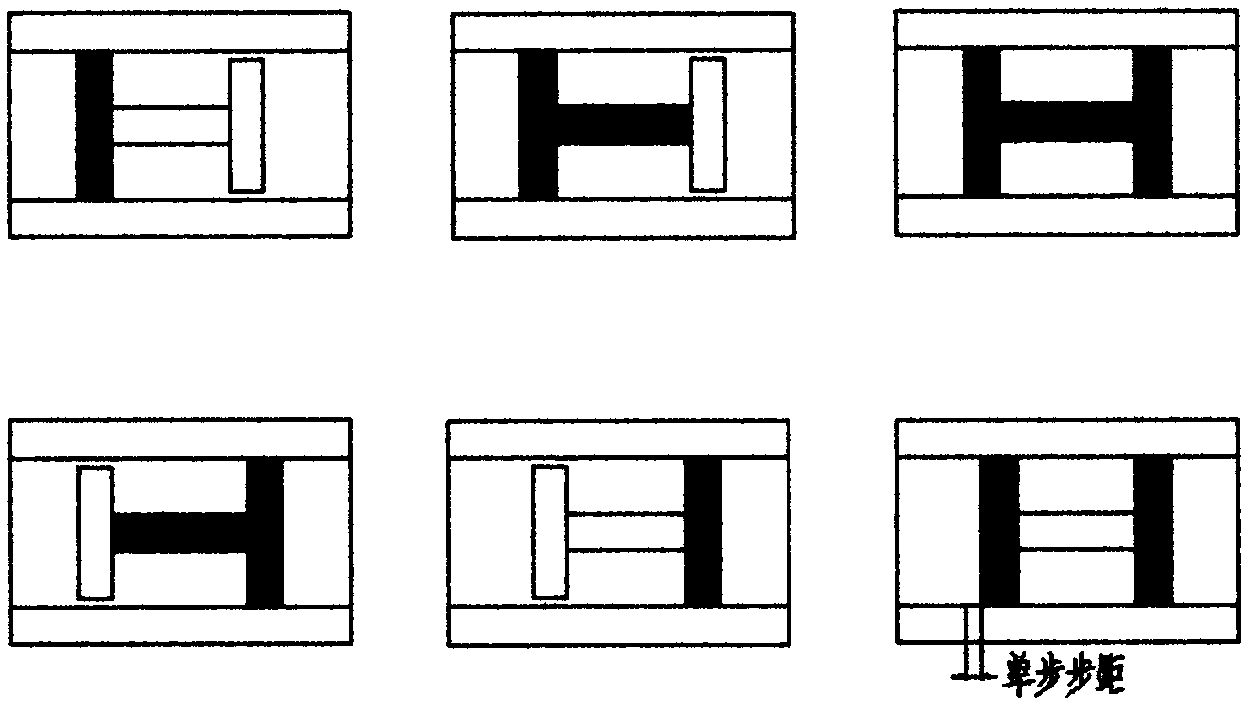

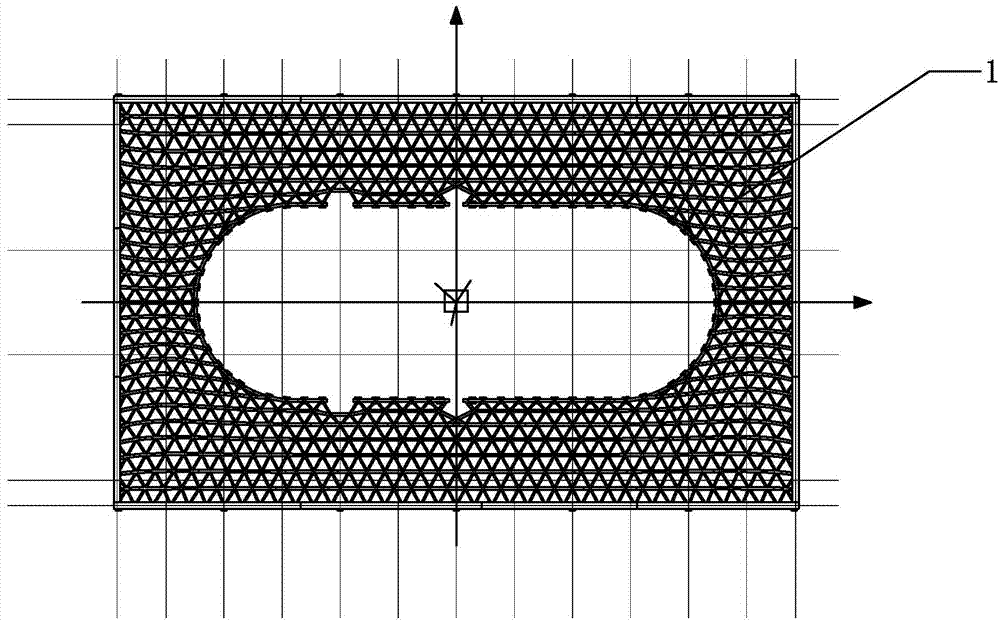

Flat line type ion trap mass analyzer based on MEMS (micro electro mechanical system) process and manufacturing method thereof

InactiveCN102163531AReduce assembly errorsReduce ion lossStability-of-path spectrometersDecorative surface effectsRadio frequencyPhysics

The invention discloses a flat line type ion trap mass analyzer based on an MEMS (micro electro mechanical system) process and a manufacturing method thereof. The flat line type ion trap mass analyzer based on the MEMS (micro electro mechanical system) process comprises a substrate, a support beam, an ion focusing electrode, a front gate electrode, a main radio frequency electrode, an auxiliary radio frequency electrode, a rear gate electrode, an ion exit repulsion electrode and an ion exit, wherein the integrated ion focusing electrode reduces ion loss, and the ion capture rate is improved; compared with an external ion focusing lens, an error caused by assembling accuracy is reduced; and the manufacturing method adopts the MEMS process, and the processing accuracy and the yield are improved, thus batch production is easy to realize.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

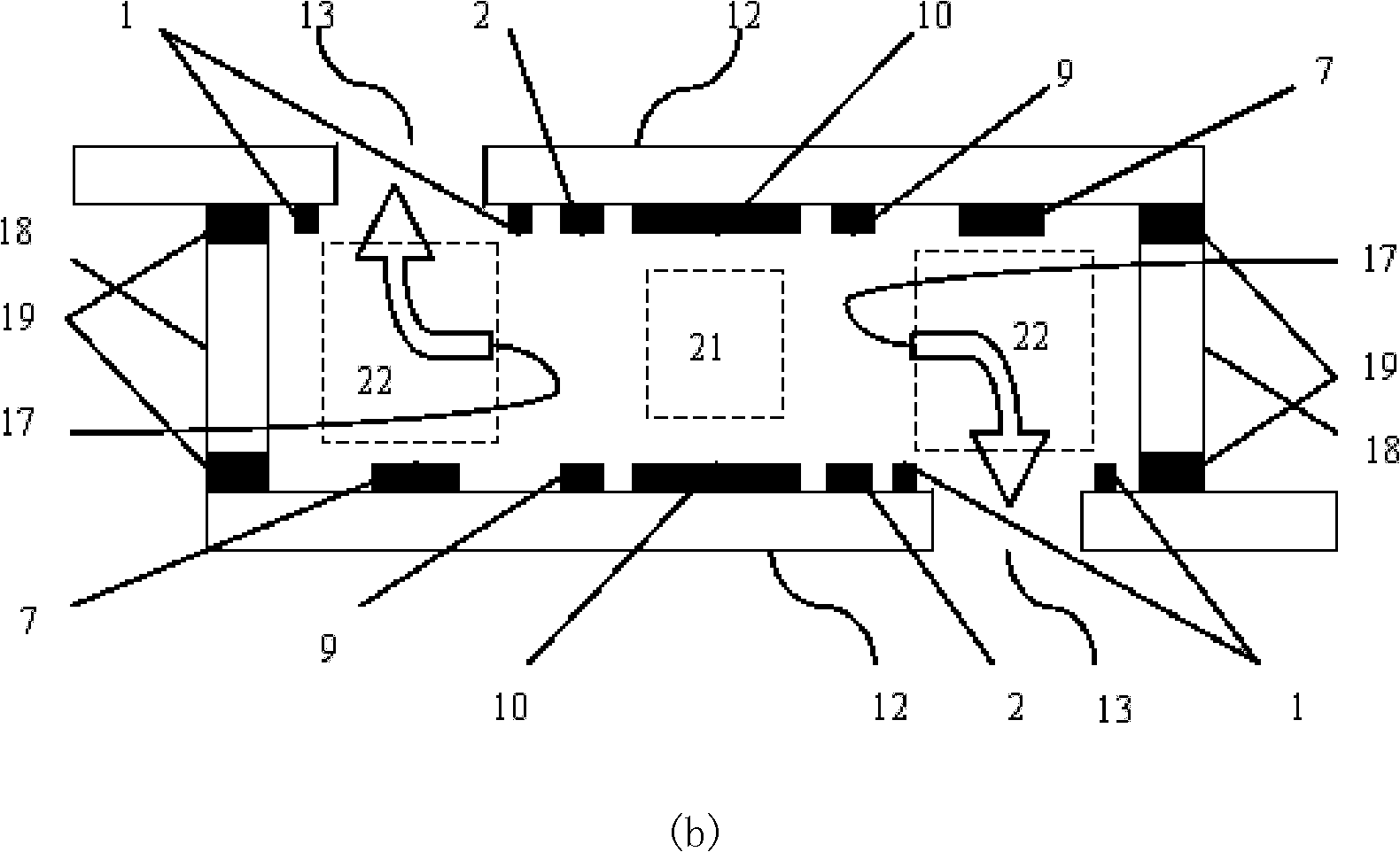

Suspension system and steering system for distributed driving and independent steering electric automobile

ActiveCN105415996AImprove groundingReduce wearElectrical steeringPivoted suspension armsDouble wishbone suspensionGround state

The invention discloses a suspension system and steering system for a distributed driving and independent steering electric automobile. The suspension system and steering system is fixed to an automobile body through an installation support and comprises wheels, a hub motor, a wheel support, a brake, a steering system body and a double-cross-arm suspension system. The steering system body is installed on the installation support of the automobile body, the wheel support is connected with the output end of the steering system, the double-cross-arm suspension system is installed on the wheel support, and the movement of the double-cross-arm suspension system does not interfere with the movement of the steering system body. By means of the suspension system and steering system, the double-cross-arm suspension system with a lateral stabilizer is integrated while each wheel can have large steering angular capability, so that the grounding state of tires is improved, the attachment limit is increased, friction of the tires is reduced, and the side lurch rigidity of the automobile is increased; thus, the control stability is improved, and the whole system is easy to calibrate.

Owner:JILIN UNIV

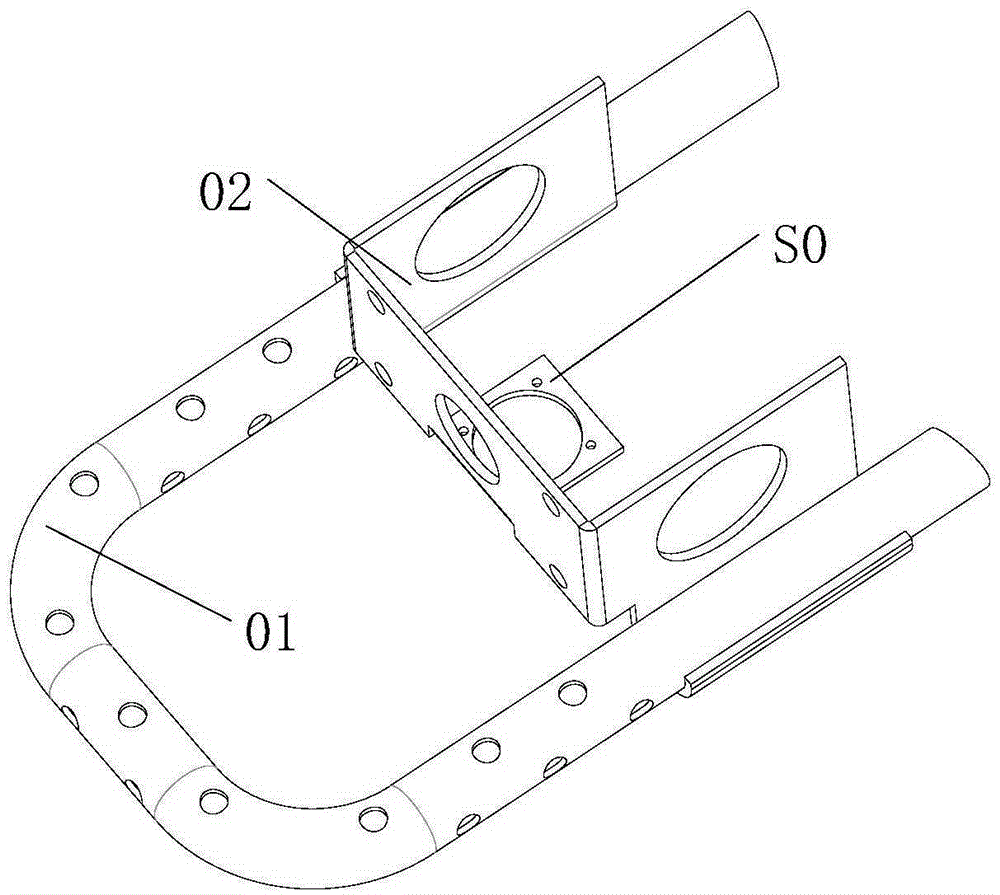

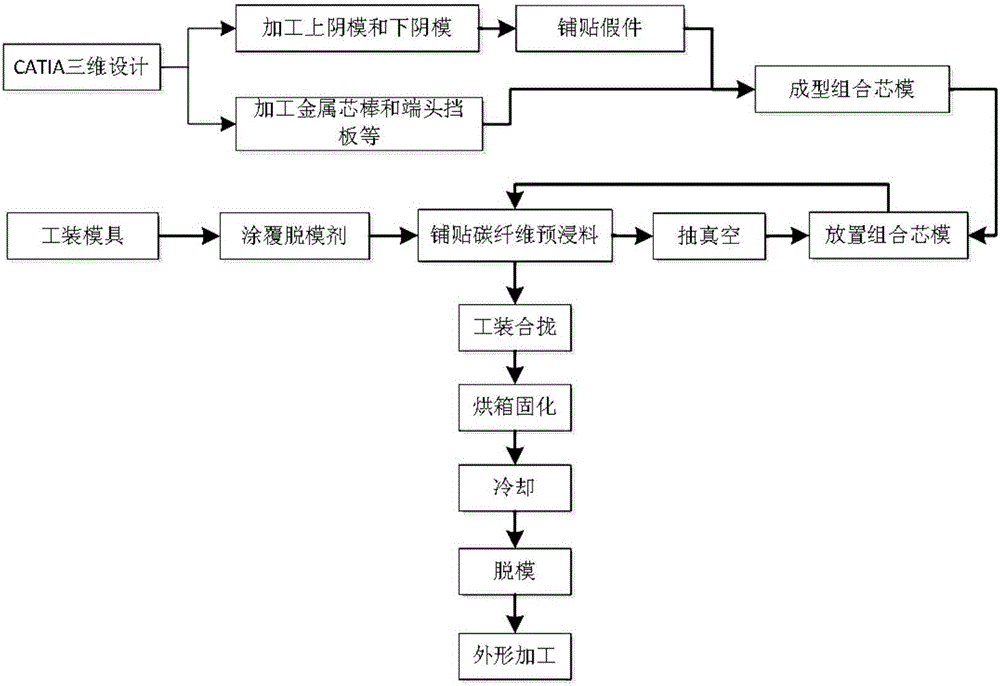

Manufacturing technology of carbon fiber composite equal-diameter tubular structure

ActiveCN106182805AImprove performanceGuaranteed flatnessTubular articlesManufacturing technologyMetal

The invention relates to a manufacturing technology of a carbon fiber composite equal-diameter tubular structure. A combined female die is adopted to control the outer diameter size of a product, a combined core bar of a metal bar and silicone rubber is prepared as a core die, prepreg is continuously laid on the core die, after die assembly, and through expansion and pressure application of silicone rubber, a product with the stable performance is obtained. Compared with CN 103802329 A and the traditional technology, the problems that the size precision of a product exterior face is inaccurate, and mold releasing is difficult are solved, meanwhile, flatness of the inner surface and the outer surface can be ensured, the assembling error can be reduced, curing in a hot pressure tank is not needed, the manufacturing cost is reduced, and the developing requirement of an unmanned aerial vehicle tail supporting pipe of a certain type can be met.

Owner:XIAN AISHENG TECH GRP +1

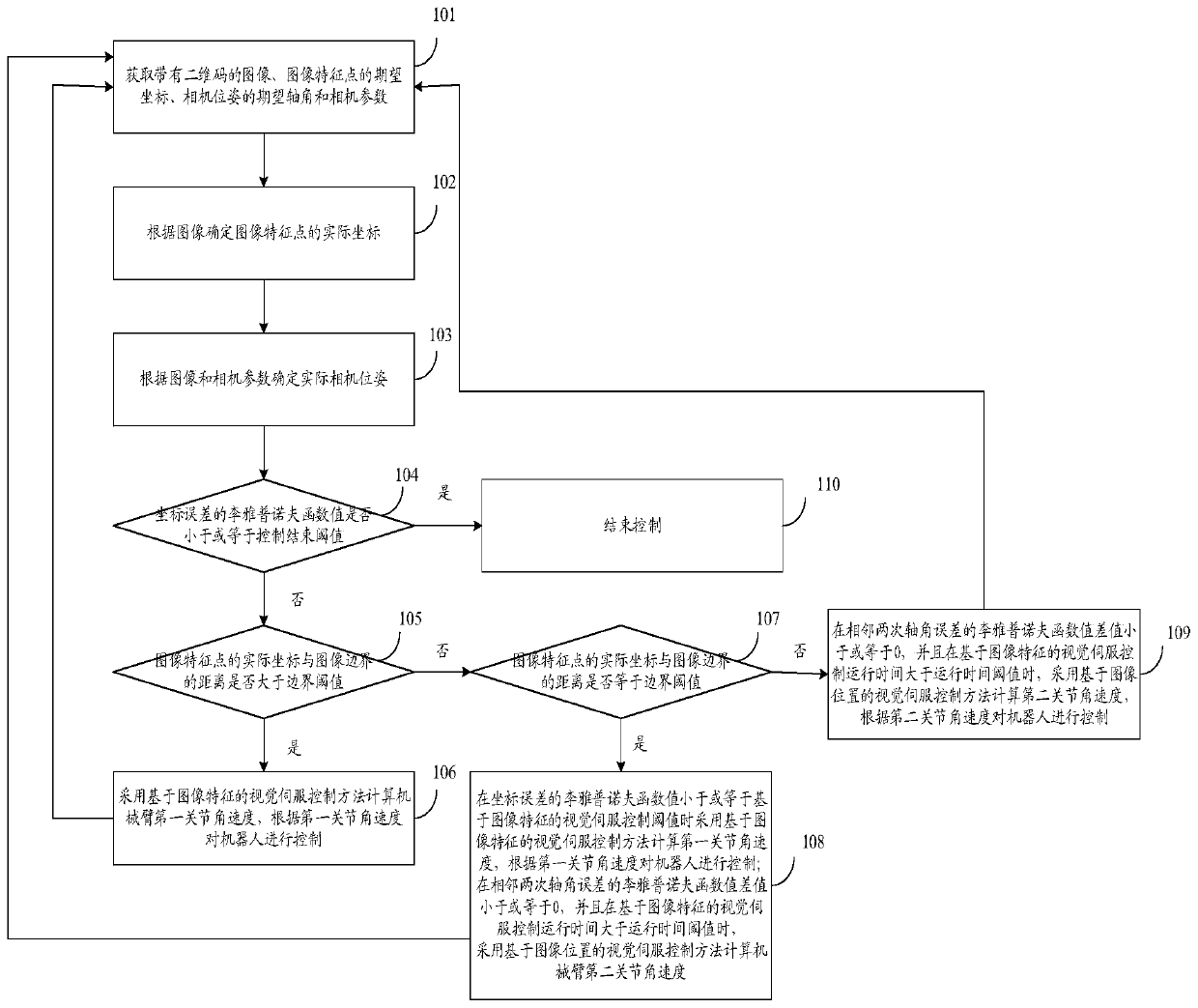

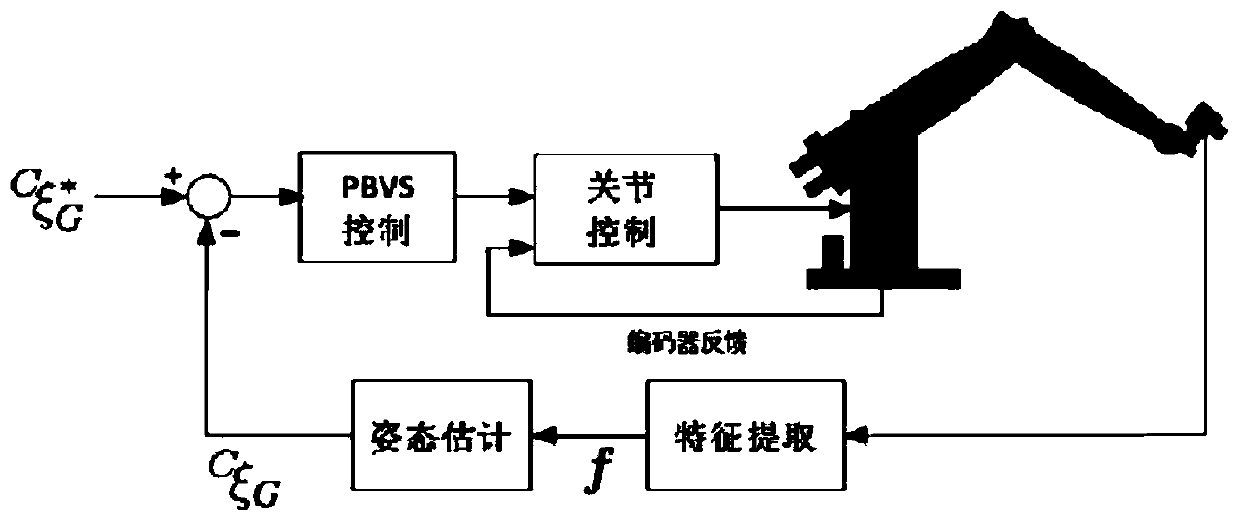

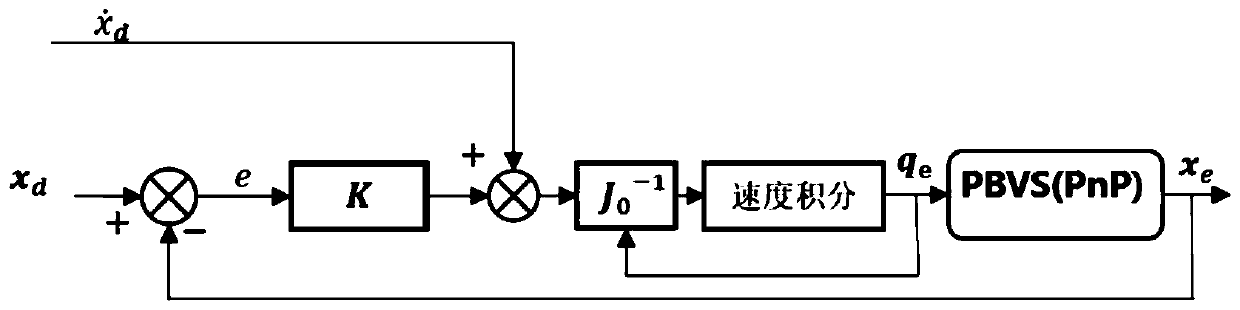

Visual servo switching control method and system

ActiveCN111360827AHigh precisionImprove stabilityProgramme-controlled manipulatorVisual servoingControl system

The invention discloses a visual servo switching control method and system. The method comprises the following steps: determining actual coordinates and actual camera poses of image feature points with two-dimensional codes; if a distance between the actual coordinates of the image feature points and an image boundary is greater than a boundary threshold value, adopting the visual servo control method based on image features to calculate first joint angular velocity of a mechanical arm, and controlling a robot according to the first joint angular velocity; judging whether the distance betweenthe actual coordinates of the image feature points and the image boundary is equal to the boundary threshold value or not, distinguishing and calculating the joint angular velocity; and adopting the visual servo control method based on the image positions to calculate second joint angular velocity if a difference value of Lyapunov function values of adjacent twice axle angle errors is smaller thanor equal to 0, and operation time of the visual servo control based on the image features is greater than an operation time threshold value. The method and the system disclosed by the invention havethe advantages of being capable of strengthening stability of a robot control system, and improving the visual servo effect.

Owner:HARBIN INST OF TECH

Calibration method suitable for visual servo plug-pull operation

ActiveCN109318234AIncreased durabilityGood Visual Servo EffectProgramme-controlled manipulatorVisual servoingImaging Feature

The invention relates to a calibration method suitable for a visual servo plug-pull operation, and belongs to the field of image identification. The problems that servo alignment control precision based on the visual servo is low, and the effect of the plug-pull operation controlled by an open loop is poor in a plug-pull stage are solved; the calibration method suitable for the visual servo plug-pull operation is provided, an image containing pins, a socket and a plug clamping device is collected by using a camera; a depth learning algorithm is utilized to obtain a center point of each pin inthe socket and the center point of each calibration board on the plug clamping device; then a socket middle point coordinate, a socket deflection angle, a plug clamping device middle point and a plugclamping device deflection angle are calculated; the point coordinate is transferred into a joint coordinate system at the tail end of a mechanical arm of a robot; the socket middle point coordinatesin a tail end coordinate system of the robot is obtained; a visual servo image feature error is calculated in the tail end coordinate system; and a visual servo feature is sent to a robot visual servoalgorithm, and the robot is controlled to move. According to the method, the operation precision in visual servo plug-pull operation is improved.

Owner:HARBIN INST OF TECH

Signboard punch forming die and punching machine

ActiveCN106734582AImprove Assembly ConsistencyImprove efficiencyShaping toolsPerforating toolsPunch pressEngineering

The invention discloses a signboard punch forming die and a punching machine and relates to the technical field of die machining. The signboard punch forming die and the punching machine are designed for solving the problems that a signboard product is low in machining efficiency and poor in assembling consistency. The signboard punch forming die comprises an upper die seat, a lower die plate, a collecting device and a lower cushion plate, all of which are sequentially arranged from top to bottom. A forming punch is fixedly installed below the upper die seat, and the punching stroke of the forming punch is larger than the thickness of the lower die plate. A groove is formed in the upper surface, fixedly connected with the lower die plate, of the lower cushion plate. The collecting device comprises a colleting material belt arranged in the groove, an unrolling device arranged in the feeding direction of the collecting material belt, and a rolling device arranged in the discharging direction, wherein the sticky surface of the collecting material belt is arranged upwards. The signboard punch forming die is suitable for manufacturing signboard products and collecting the signboard products.

Owner:烯友金电子科技(苏州)有限公司

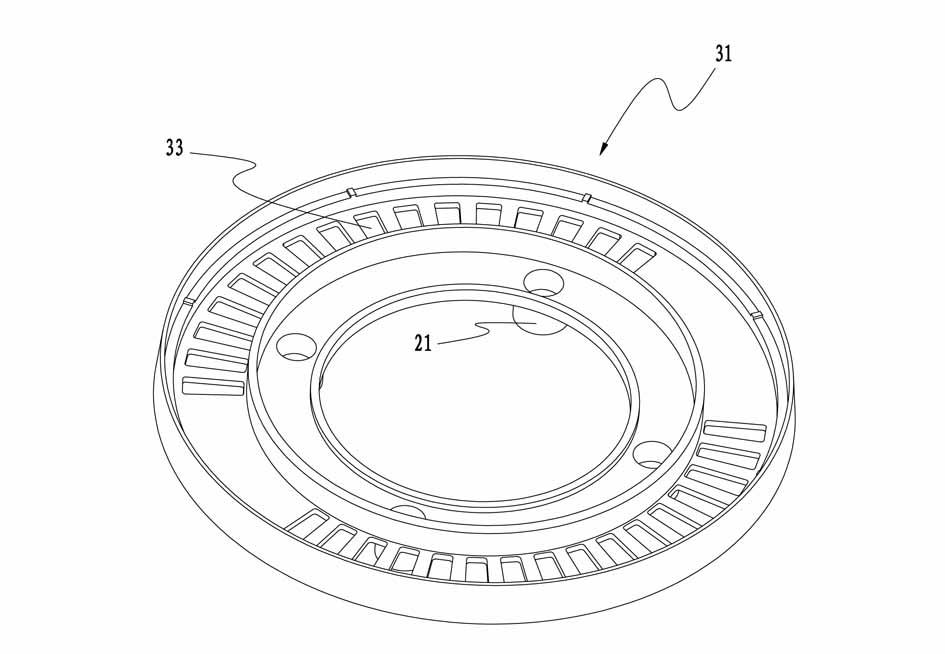

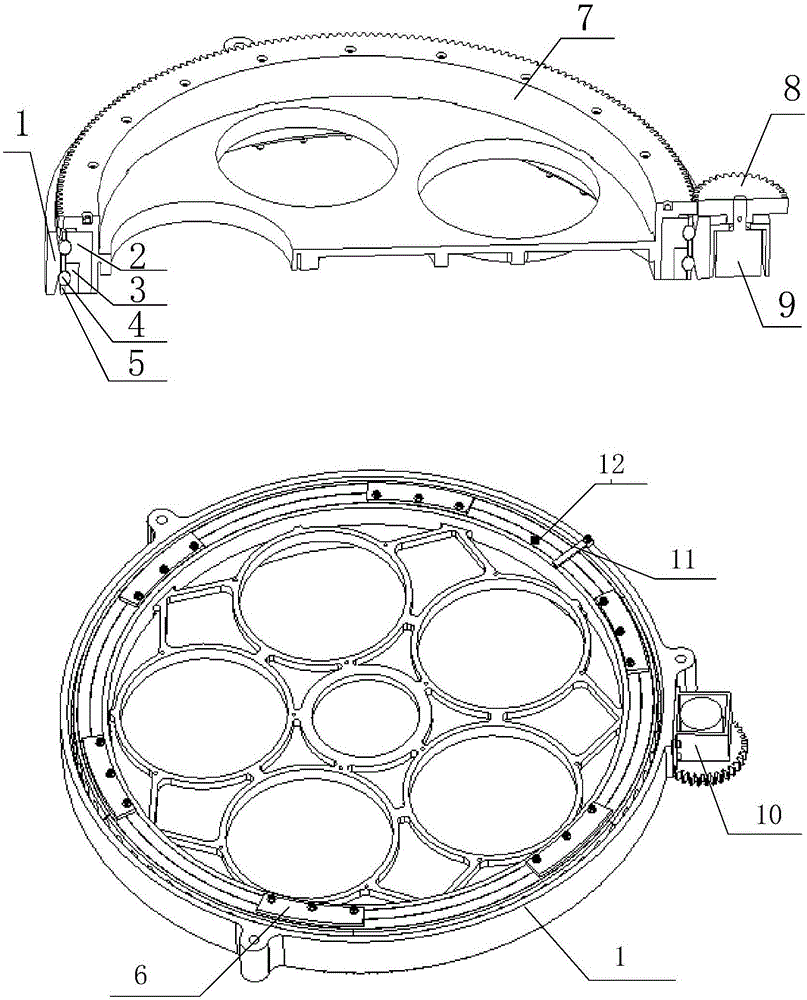

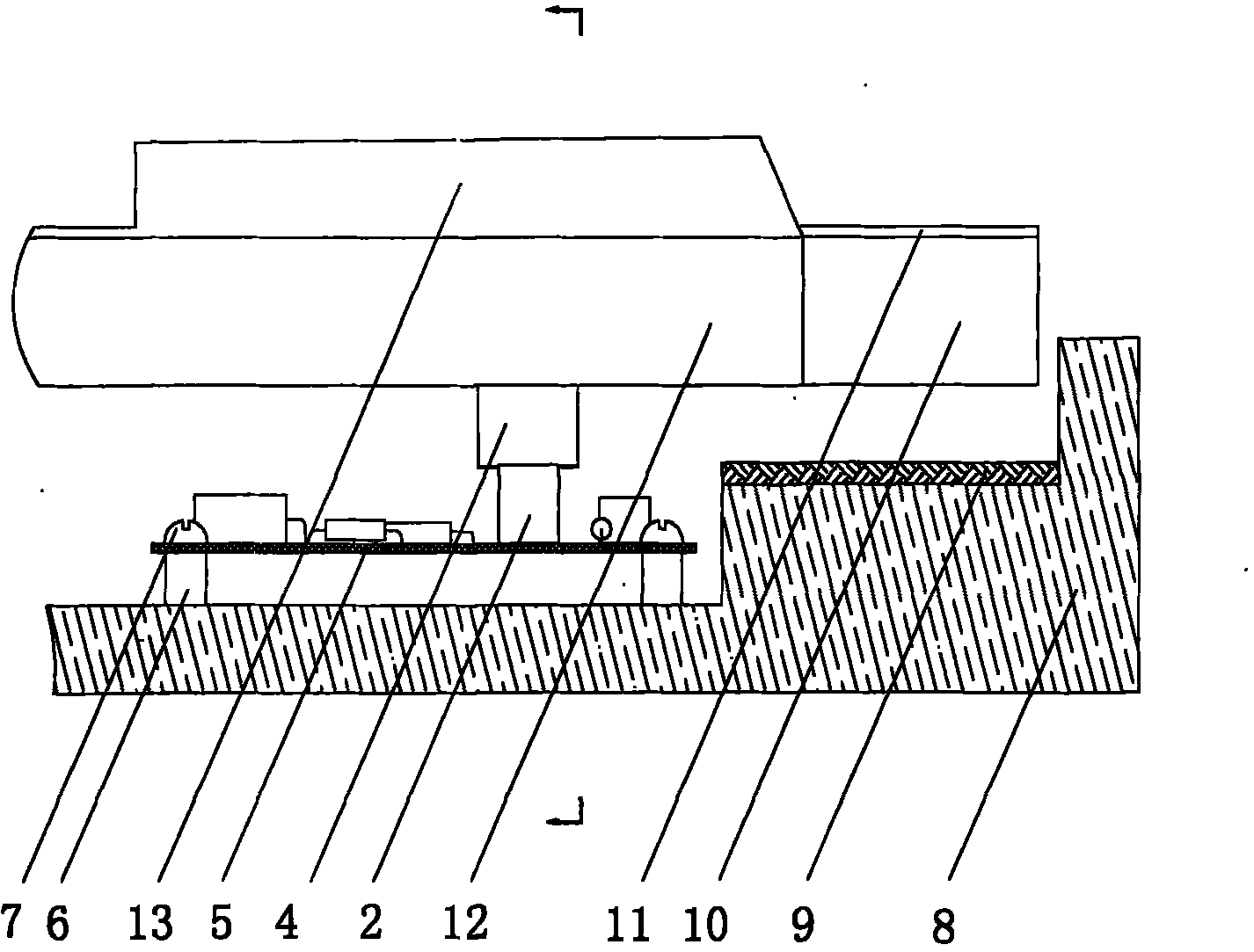

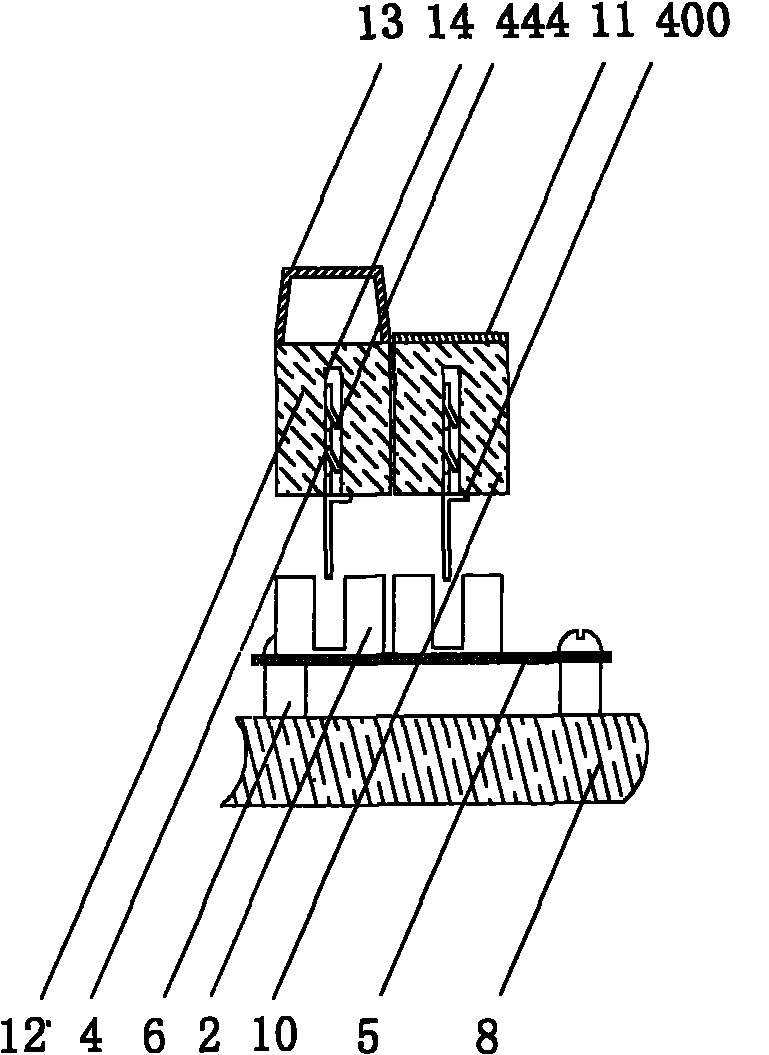

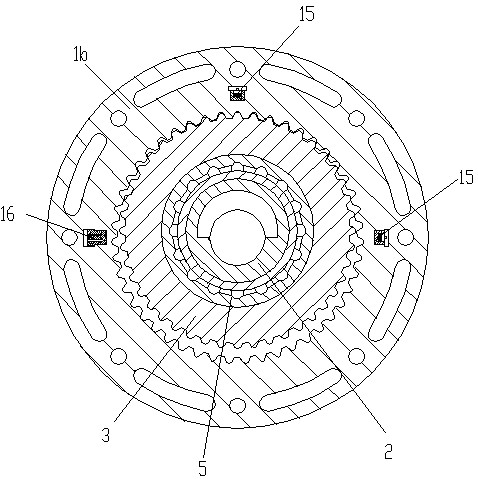

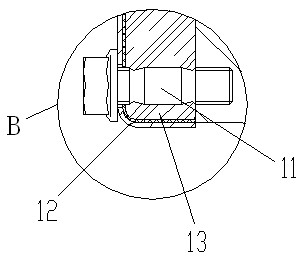

High-precision high-rigidity space camera filter switching mechanism

ActiveCN105068362AAvoid configurationIncrease stiffnessMountingsCamera body detailsMotor driveThermal deformation

The invention relates to a high-precision high-rigidity space camera filter switching mechanism, and the mechanism is used for enabling space camera filters to enter into an optical path sequentially. The mechanism consists of an integrated bearing part, a gear pair, and a drive control assembly. The integrated bearing part comprises an integrated bearing outer ring, an inner shaft ring, an embedded ring, a ball, a ball holder, and a pressure block. The gear pair consists of a filter installation disc and a small gear, and is connected with the inner shaft ring of an integrated bearing part. A driving part comprises a motor, a motor installation frame, a magnetic steel, and a Hall sensor. The motor drives the small gear to drive the filter installation disc to rotate under a control instruction. According to the invention, the mechanism employs a mode that the bearing is disposed outside and the filter installation disc is disposed inside, and increases the rigidity. The mechanism employs the integrated design of the bearing, is high in rotation precision, is excellent in axial bearing performance, and is low in assembly difficulty. The mechanism employs a stress relief design of the filter installation disc, reduces the installation stress and thermal deformation under a low-temperature working condition.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

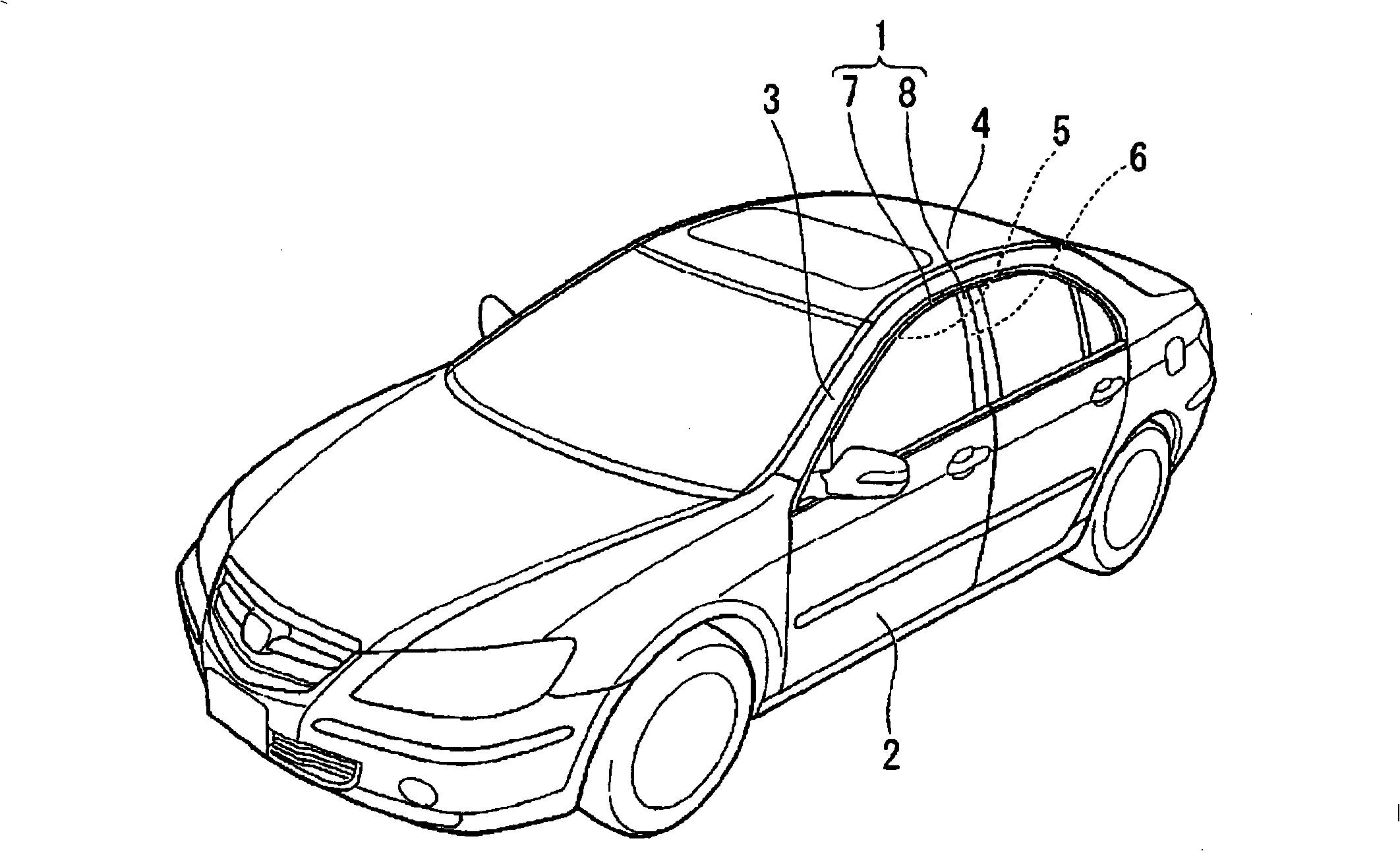

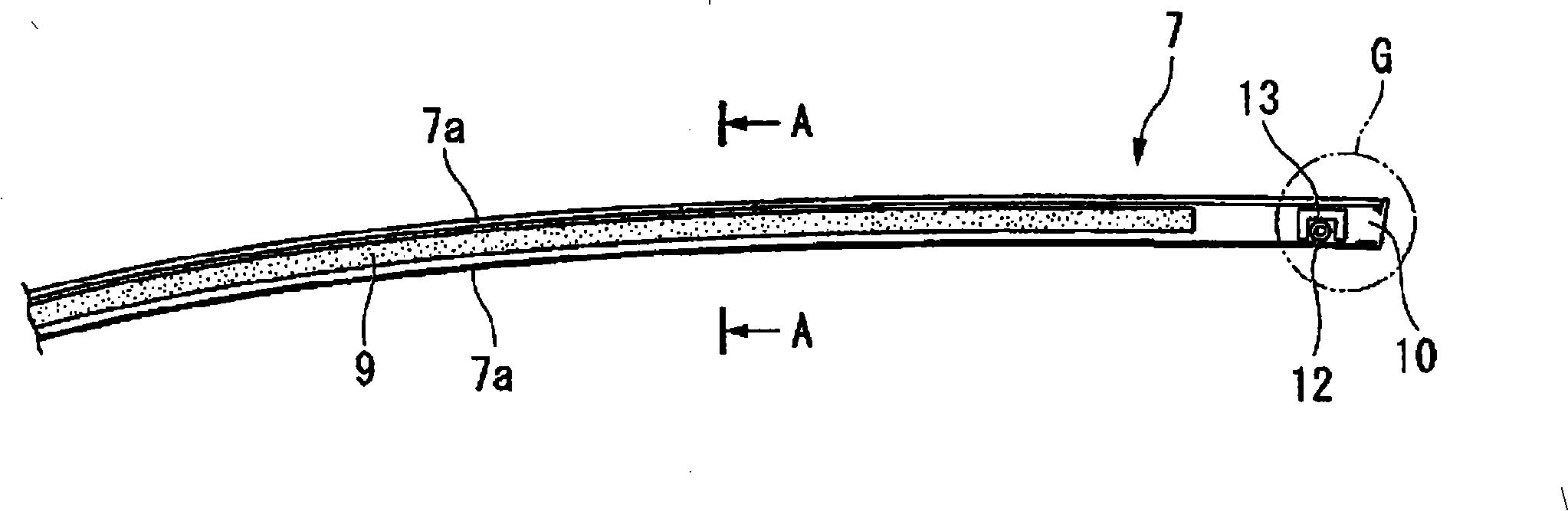

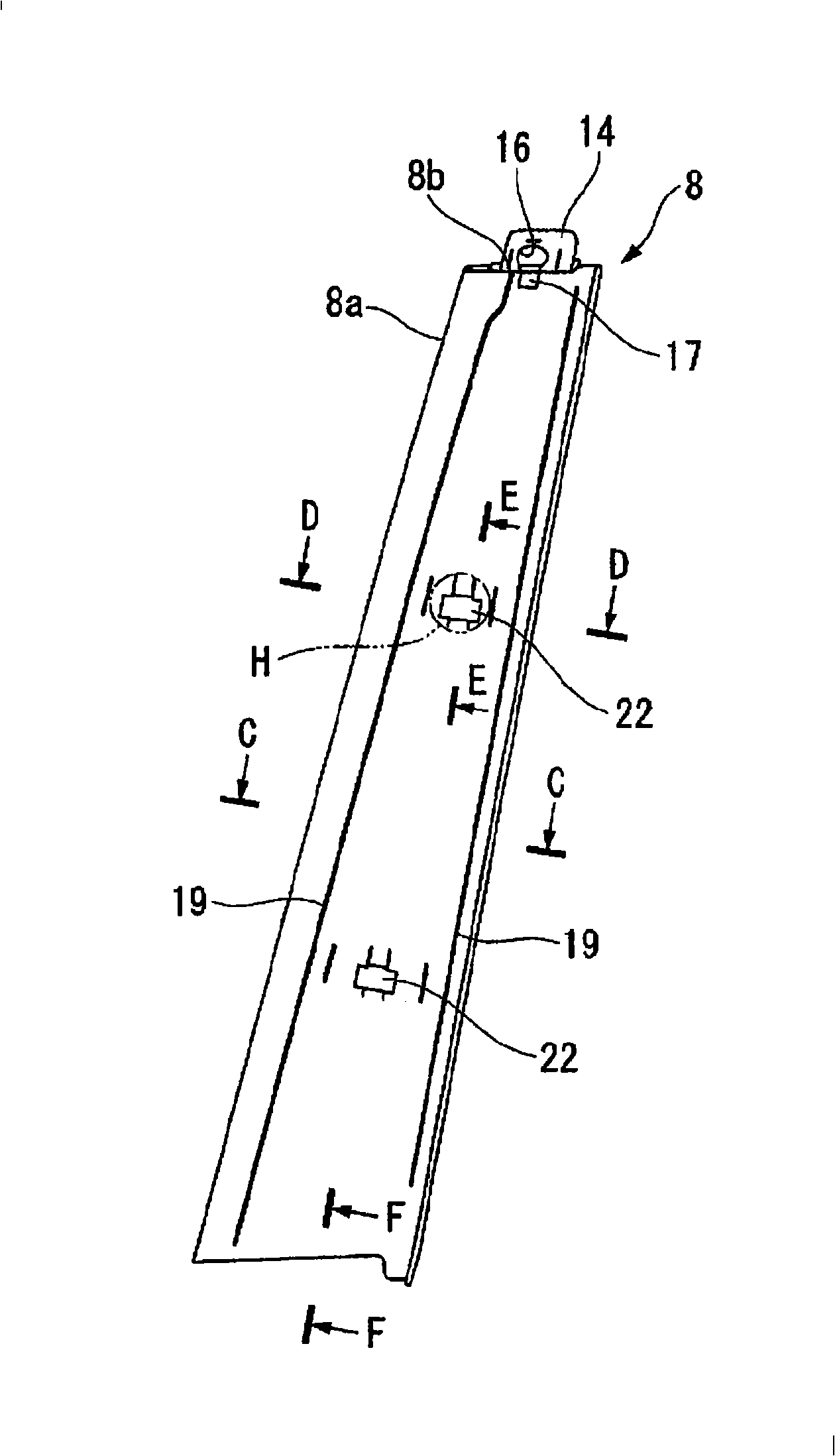

Assembling portion structure and assembling method of door or window decorative piece

InactiveCN101353009AImprove appearance qualityReduce assembly errorsEngine sealsVehicle sealing arrangementsEngineeringCar door

The invention provides an assembly portion structure of vehicle internal gadgets and an assembly method thereof. The assembly portion structure and the assembly method thereof can not only eliminate unfolding of a gap between mutually abutting portions of a top-side window frame trim strip rear end and a post-side gadget that are caused by assembly error in the process of assembly, but also improve appearance quality. As far as the assembly portion structure is concerned, an upper end of the post-side gadget (8) is formed with a tabling aperture (16). The rear end of the top-side window frame trim strip (7) is provided with a mounting portion (12) that can be tabled into the tabling aperture (16). A lock hook (17) engaged with a lock aperture (15) of a post-side window frame portion (6) is formed on the post-side gadget (8). The lock hook (17) is maintained in a state of moving upwards for the purpose of being engaged with the lock aperture (15), the post-side gadget and the post-side window frame portion are secured temporarily. The mounting portion is tabled into the tabling hole while maintaining the state, and the post-side window frame portion and the top-side window frame trim strip are positioned. Afterwards, the mounting portion is secured over the post-side window frame portion.

Owner:HONDA MOTOR CO LTD

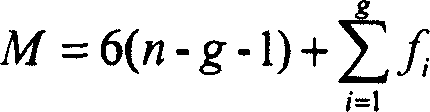

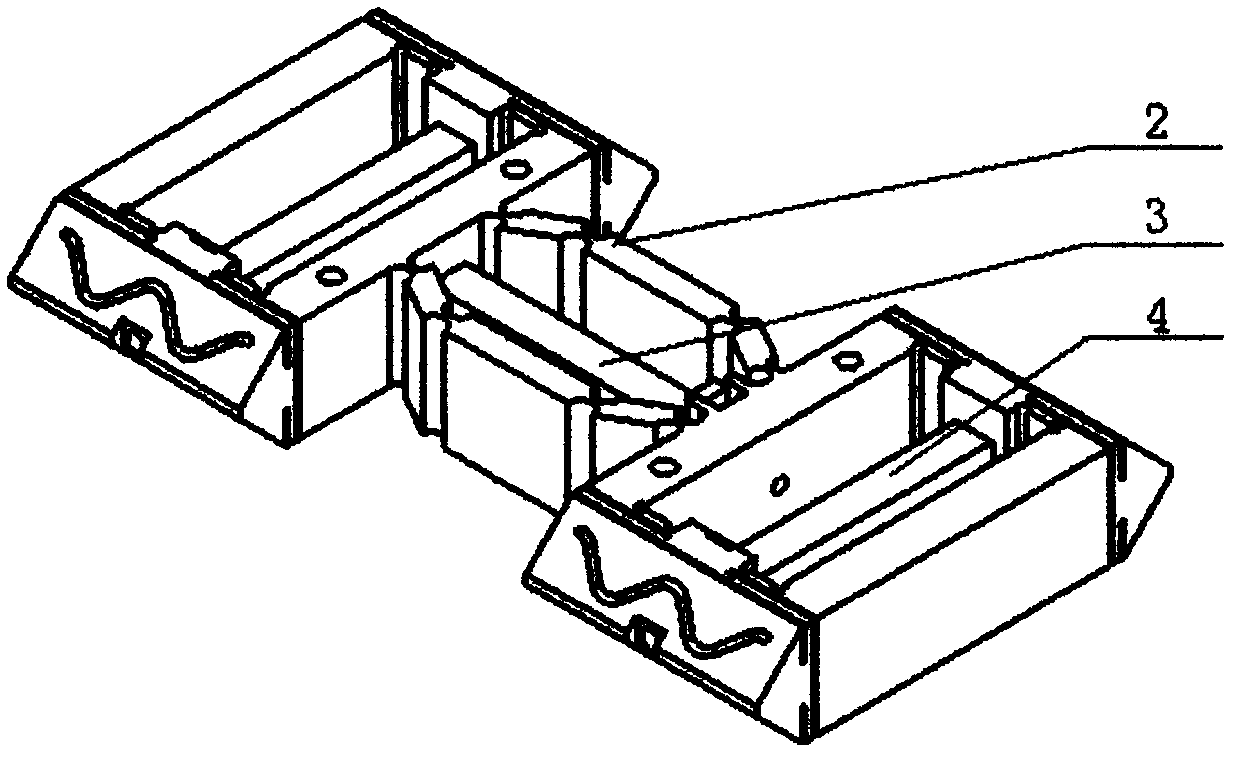

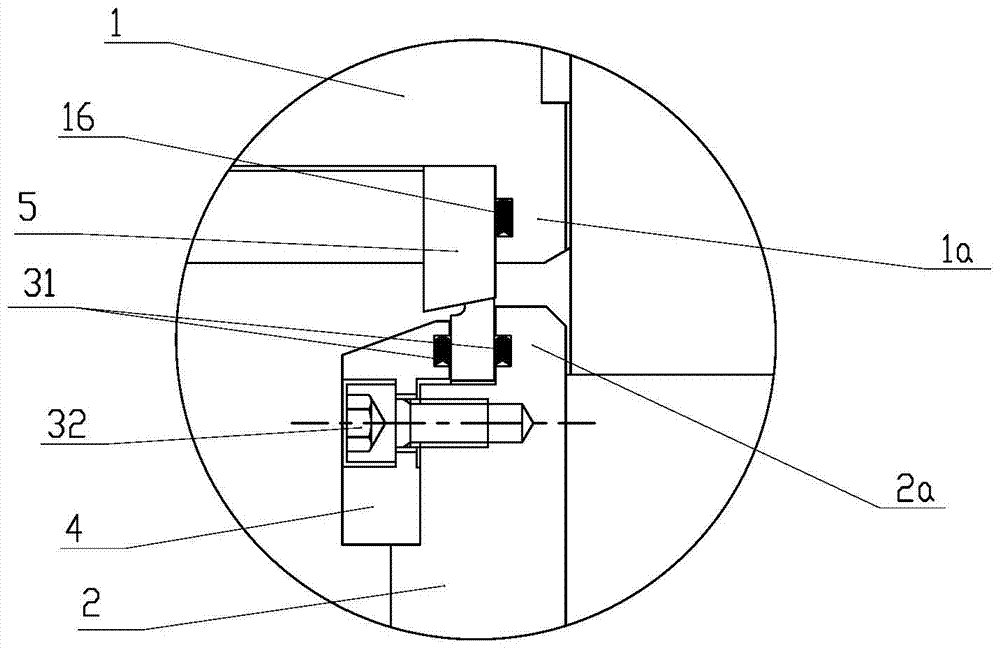

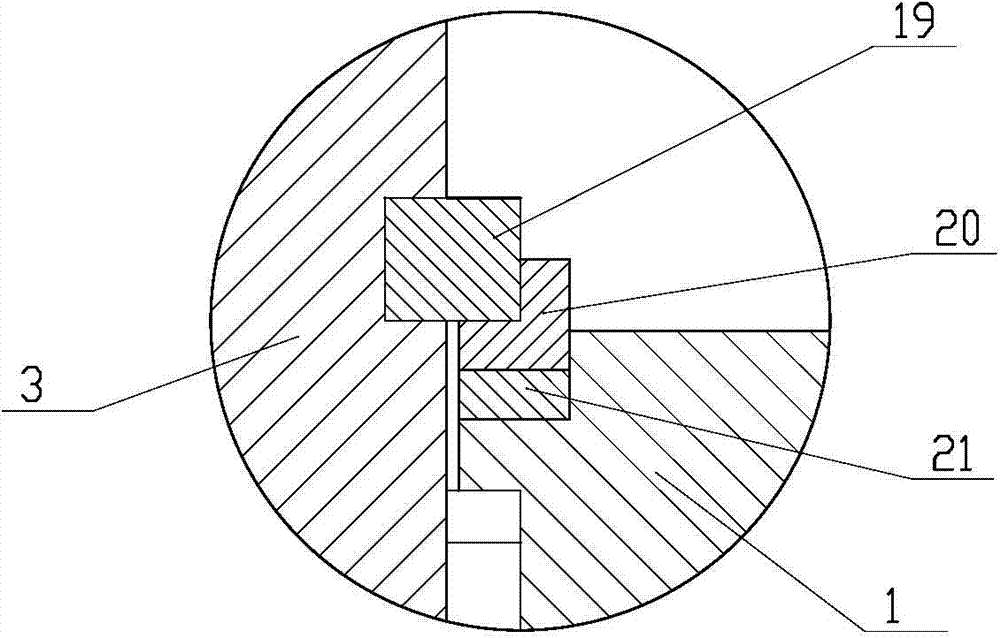

Piezoelectric linear driver

InactiveCN102361411AReduce assembly errorsReduce usagePiezoelectric/electrostriction/magnetostriction machinesFlexible MechanismsEngineering

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

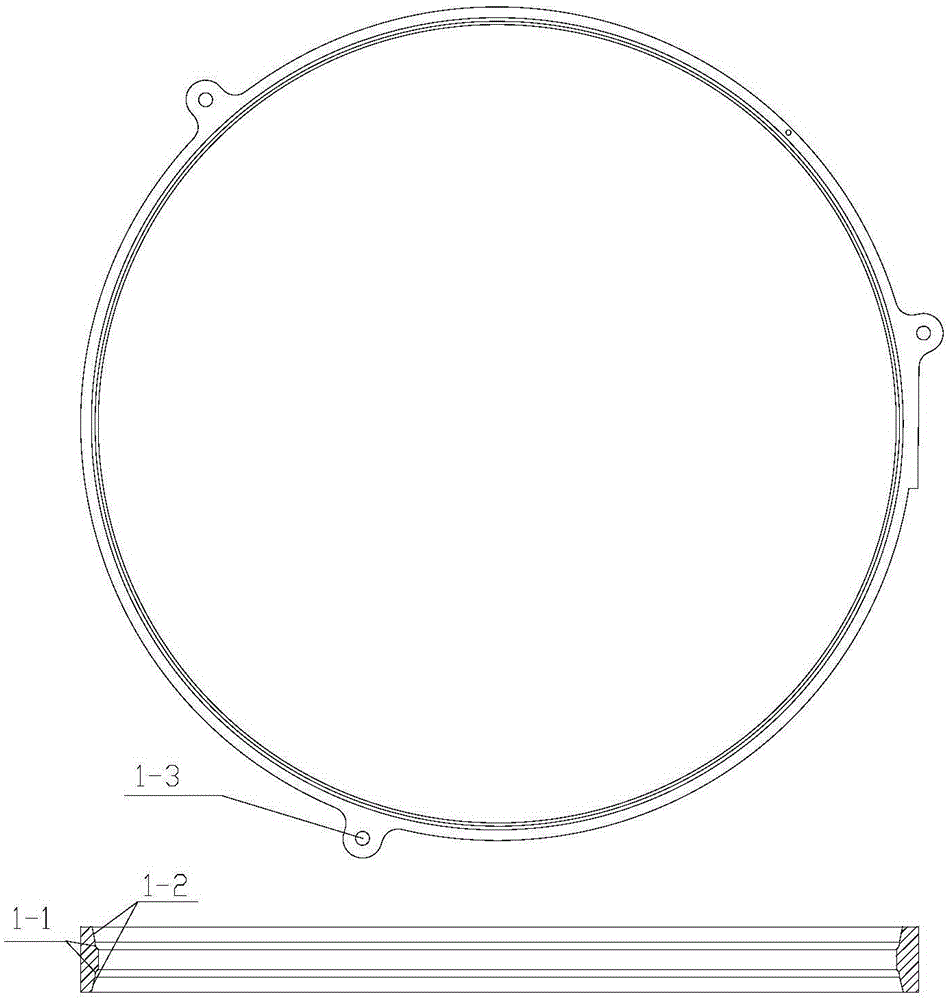

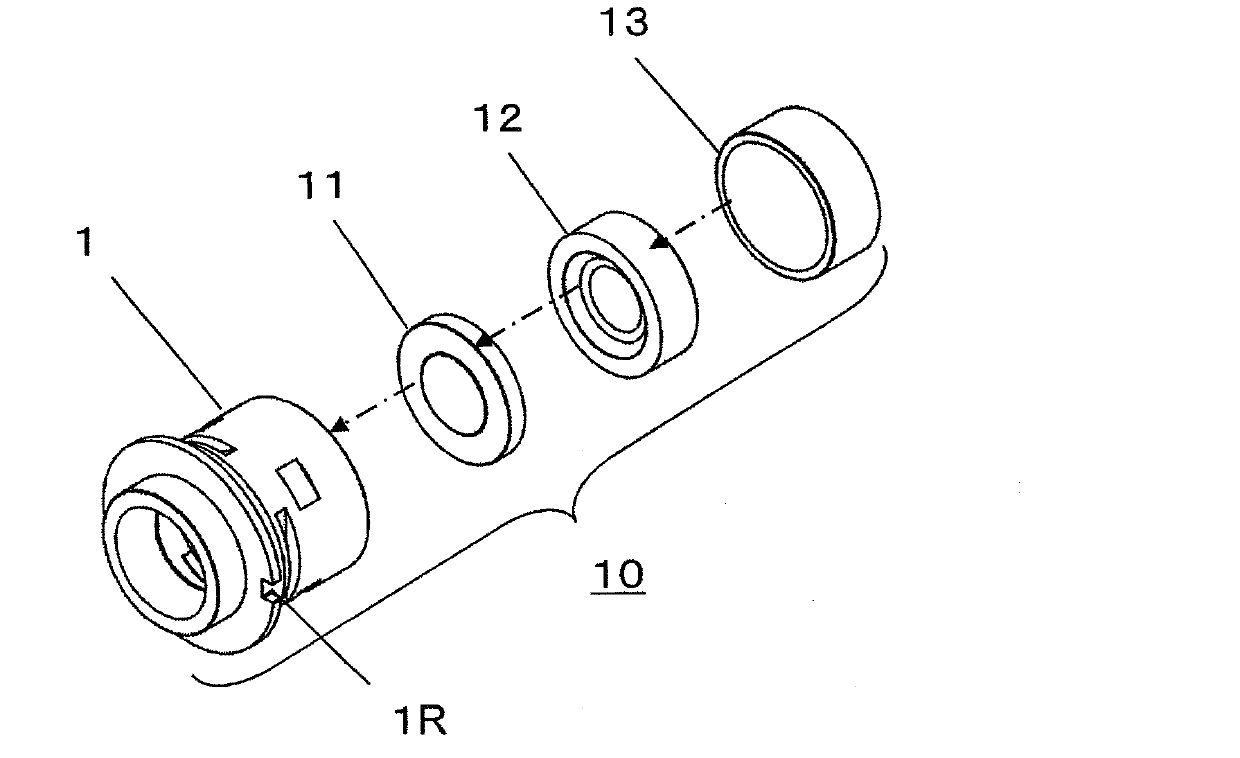

Lens unit

Disclosed is a lens unit which comprises: first and second lens groups, each of which comprises at least one lens, and which have a focusing function by being arranged in series on the same optical axis; a first lens barrel (1) that holds the first lens group; a second lens barrel (2) that holds the second lens group and contains at least a part of the first lens barrel; and an adjustment mechanism for adjusting the first lens barrel and the second lens barrel with respect to the relative positions of the optical axis directions, the relative inclinations of the optical axes, and the relative eccentricities.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Multi-channel small form-factor transceiver and assembly method

InactiveCN102385125AExactly verticalReduce assembly errorsCoupling light guidesElectromagnetic transmissionTransceiverCoupling

The invention discloses a multi-channel small form-factor transceiver which comprises a circuit board, a heat sink substrate, semiconductor laser array chips or semiconductor diode receiving chips and coupling optical fiber, wherein the heat sink substrate is arranged on the circuit board, and the semiconductor laser array chips or semiconductor diode receiving chips are arranged on the heat sink substrate, are perpendicular to the optical fiber and can be used for directly aligning with the optical fiber for coupling, so that the distance from the optical fiber to the semiconductor laser chips is shortened, more light can be input into the optical fiber for transmission, and the problem of mutual interference among the semiconductor laser array chips due to distance is solved.

Owner:JIANGSU ALLRAY

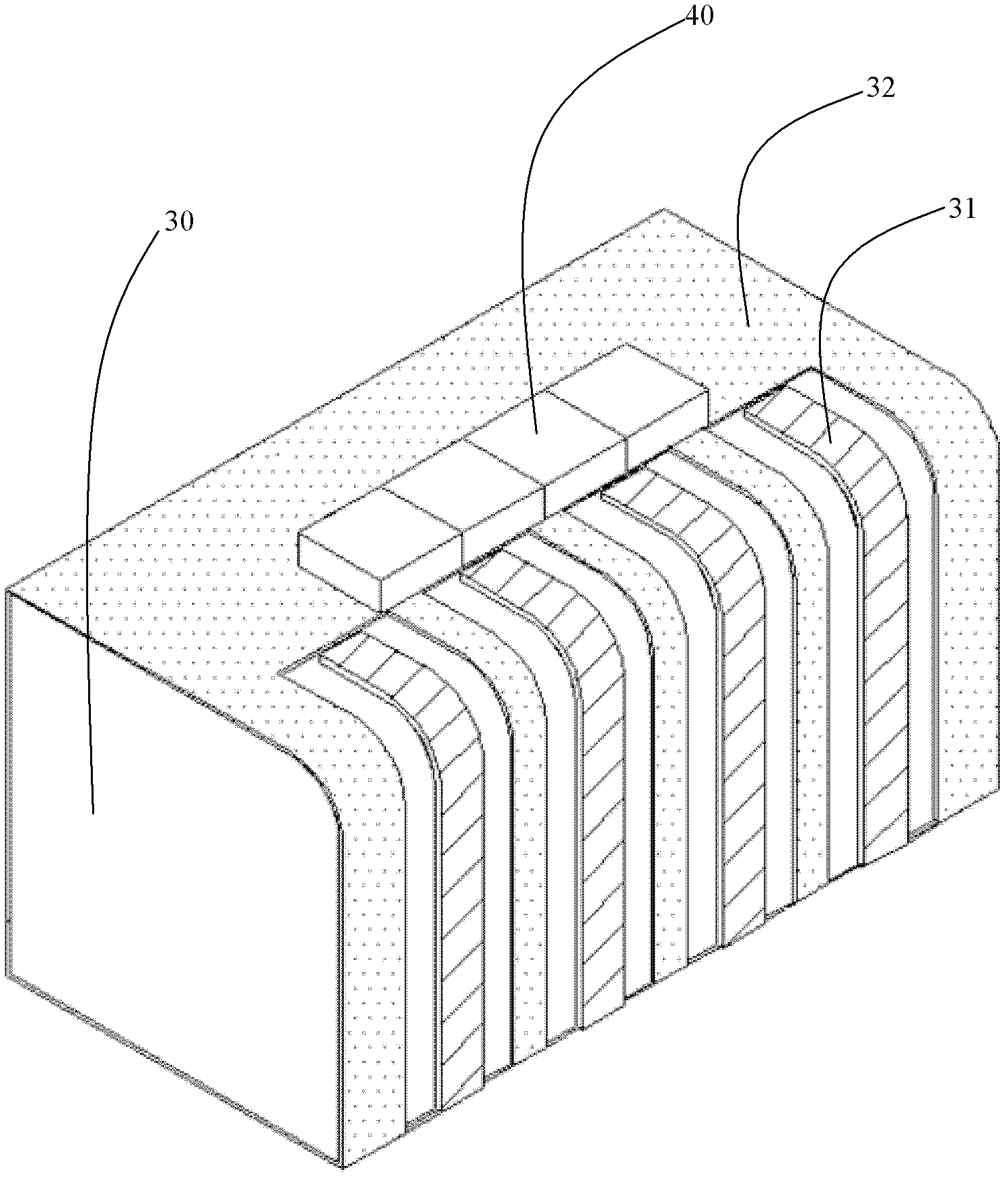

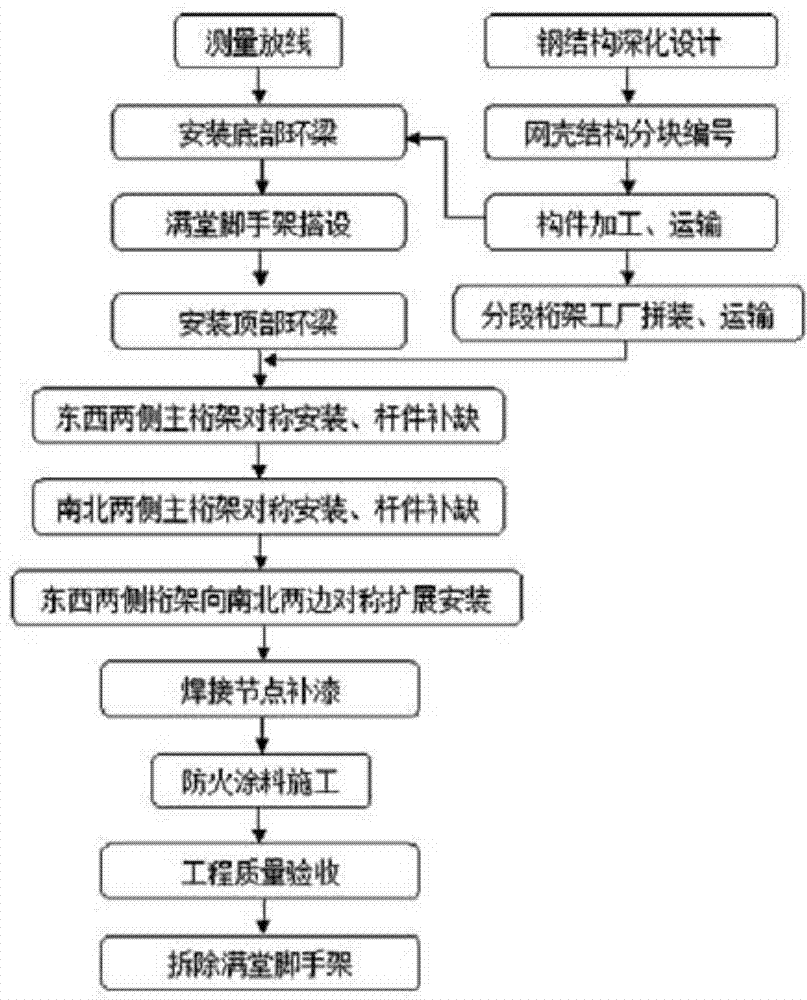

Method for installation construction of roof free-form surface single-layer latticed shell structure of super high-rise building

InactiveCN104727564AReduce direct liftingReduce storage spaceBuilding material handlingSocial benefitsFree form

The invention discloses a method for installation construction of a roof free-form surface single-layer latticed shell structure of a super high-rise building. The roof free-form surface single-layer latticed shell structure comprises a building frame and a latticed shell structure arranged at the top of the building frame. The latticed shell structure comprises a bottom ring beam arranged at the top of the building frame, a top ring beam arranged at the top end of the latticed shell structure and a net-shaped truss arranged between the bottom ring beam and the top ring beam. The method is characterized in that a latticed shell structure installing process comprises the steps of performing measurement and setting out, partitioning the latticed shell structure, installing the latticed shell structure, performing painting make-up on welded nodes, performing fireproof coating construction, performing acceptance of engineering quality and dismantling an all-round scaffold. The method is good in construction quality and quick in speed and has safety in construction and good economic benefits and remarkable social benefits.

Owner:ZHONGYIFENG CONSTR GRP

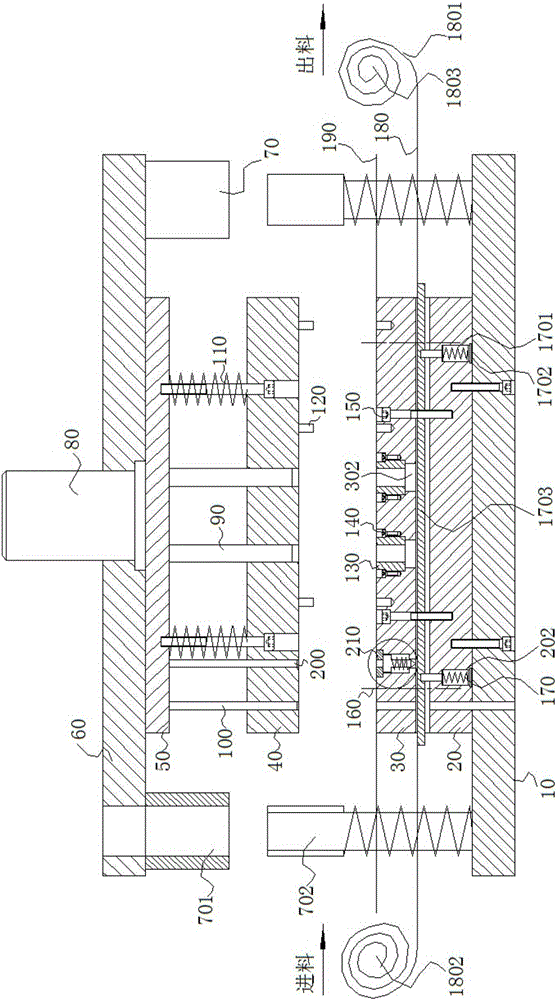

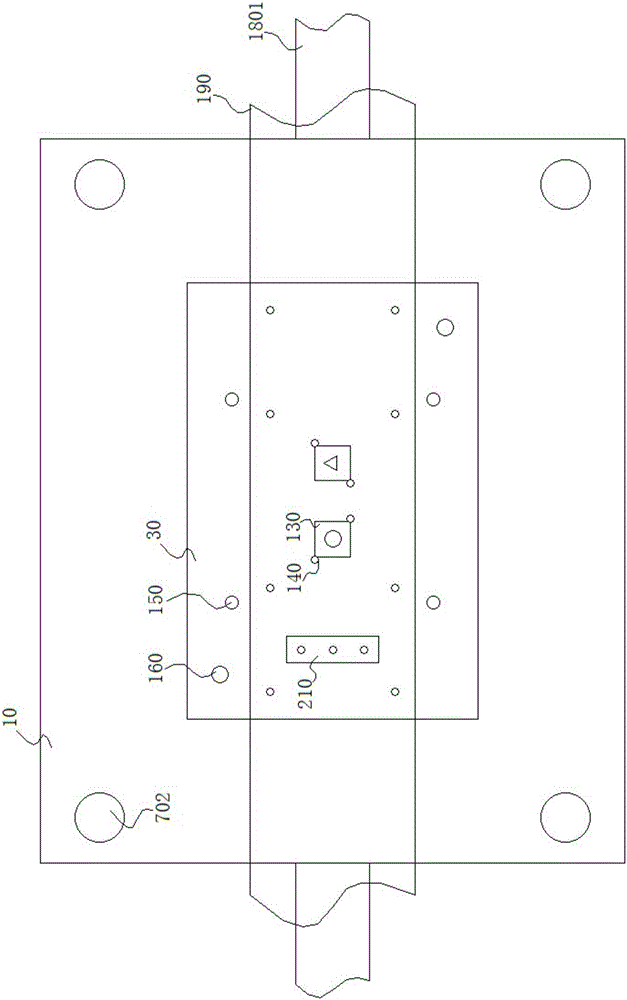

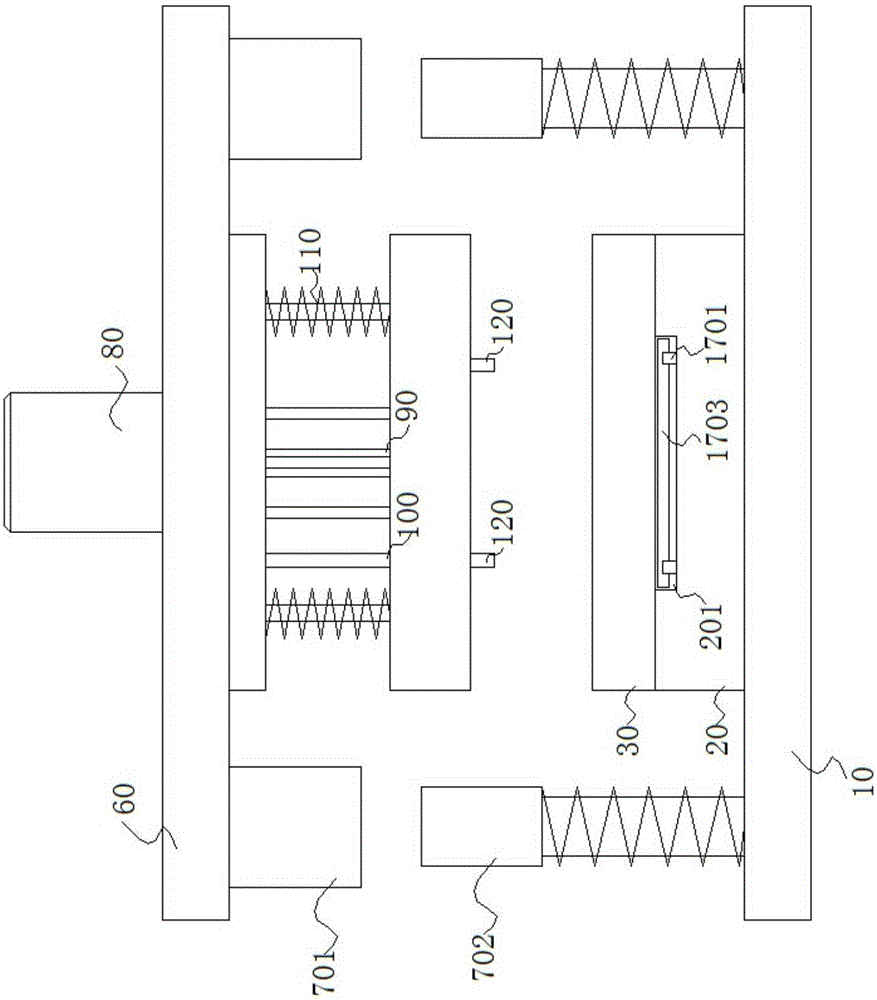

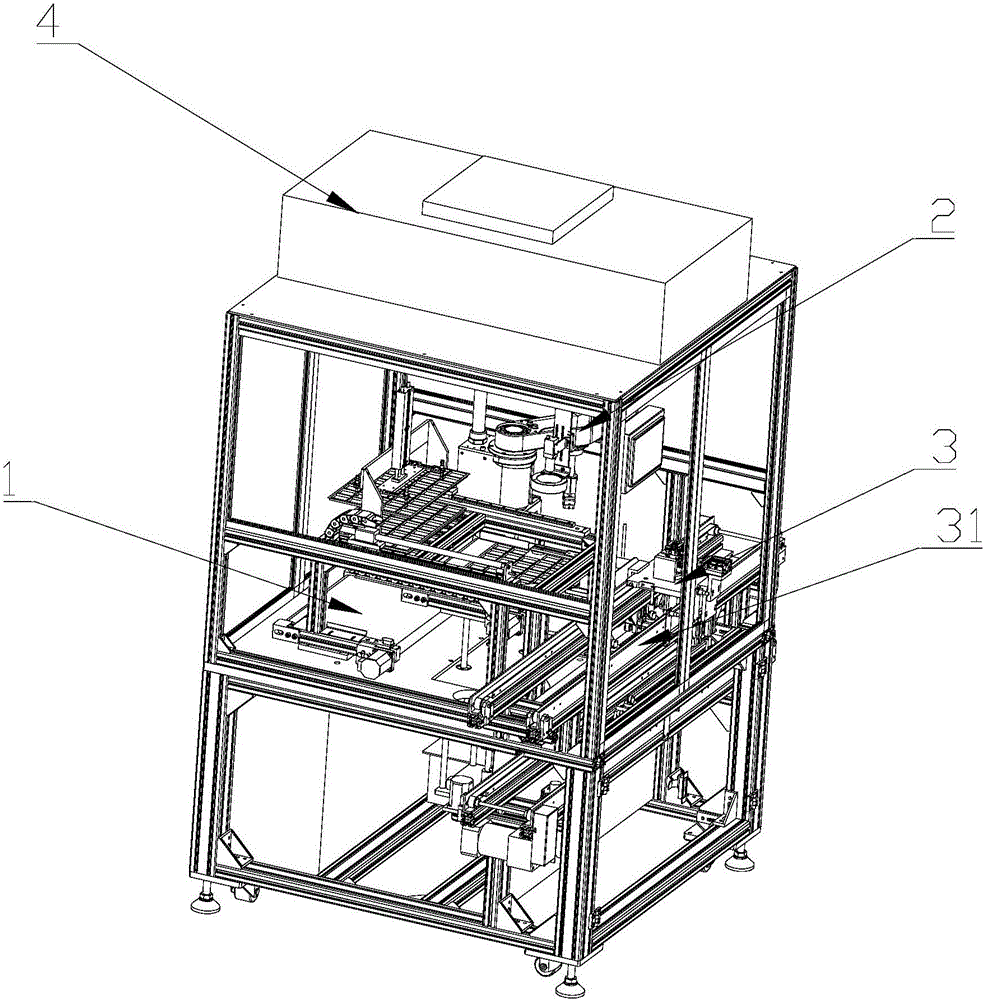

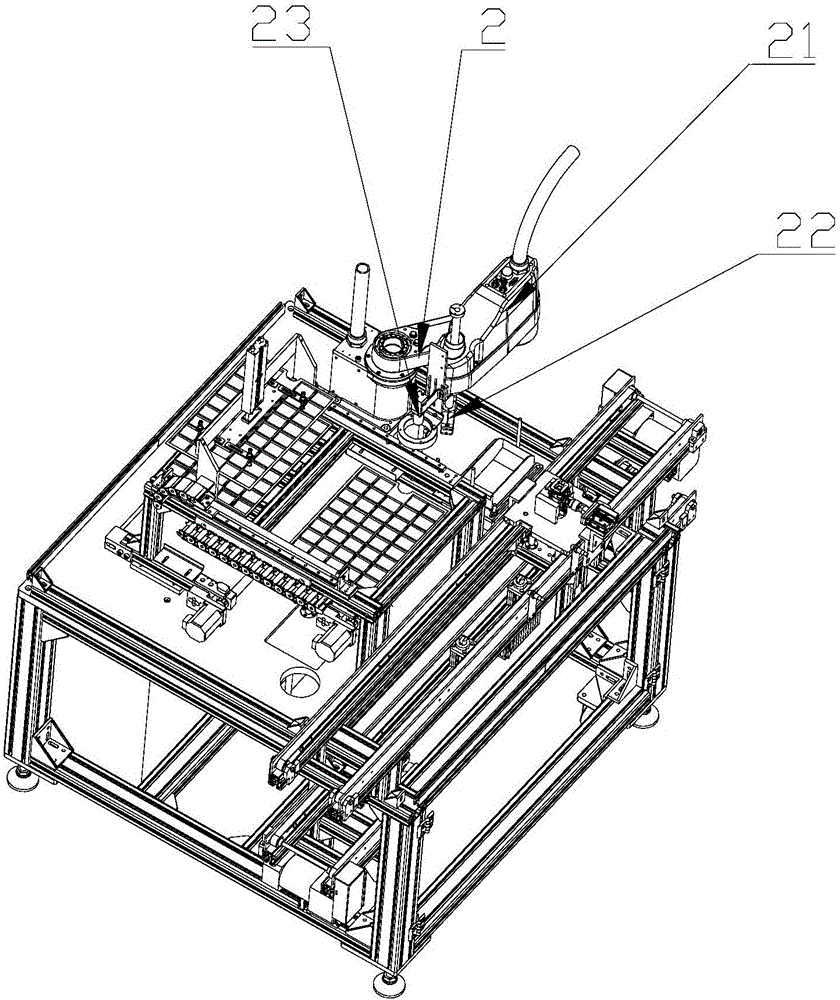

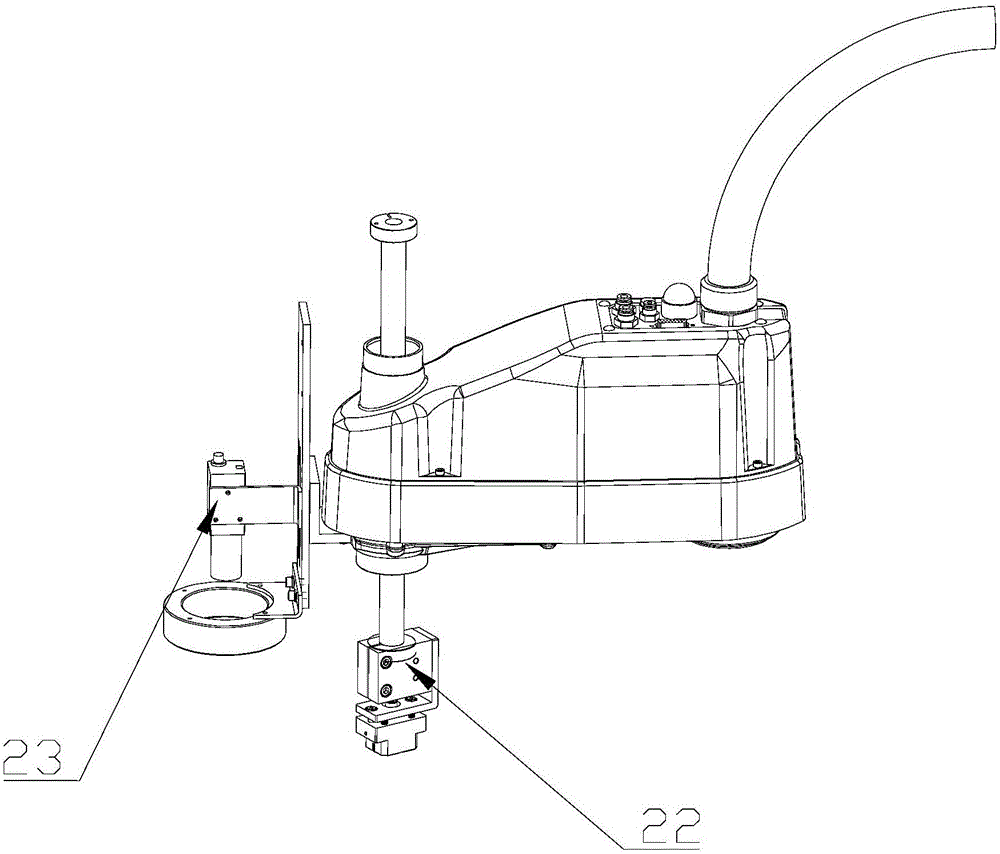

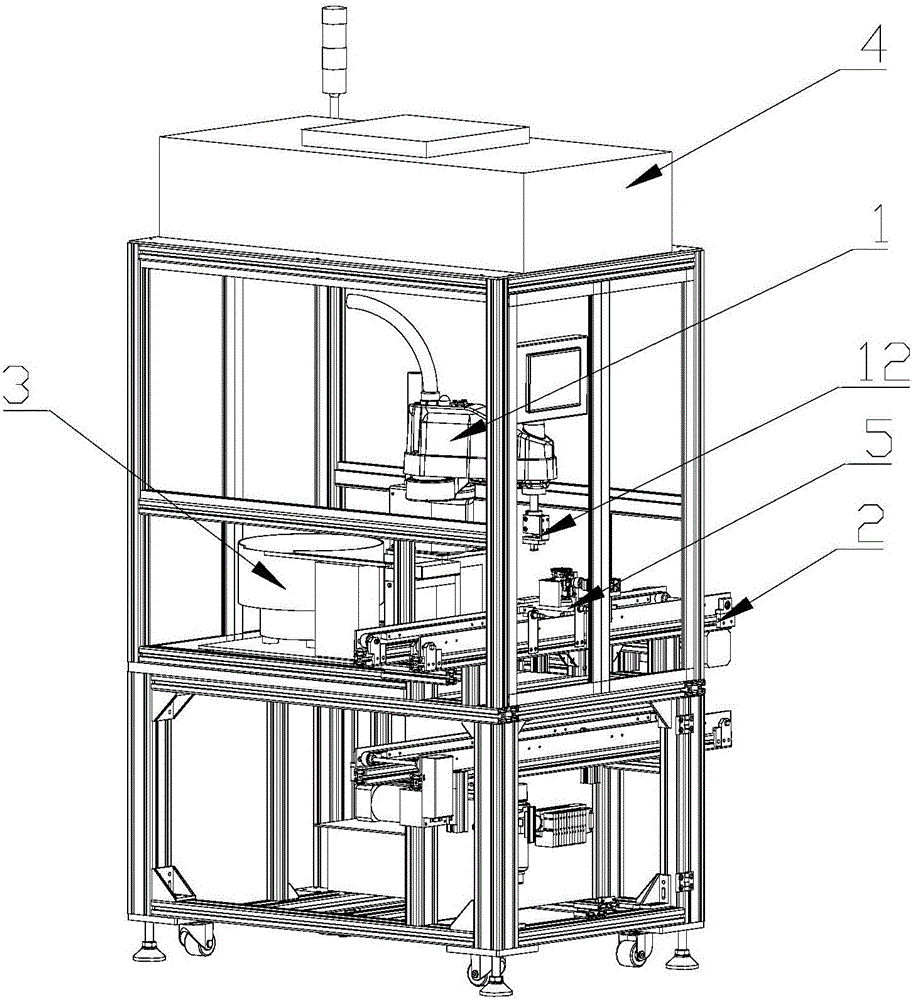

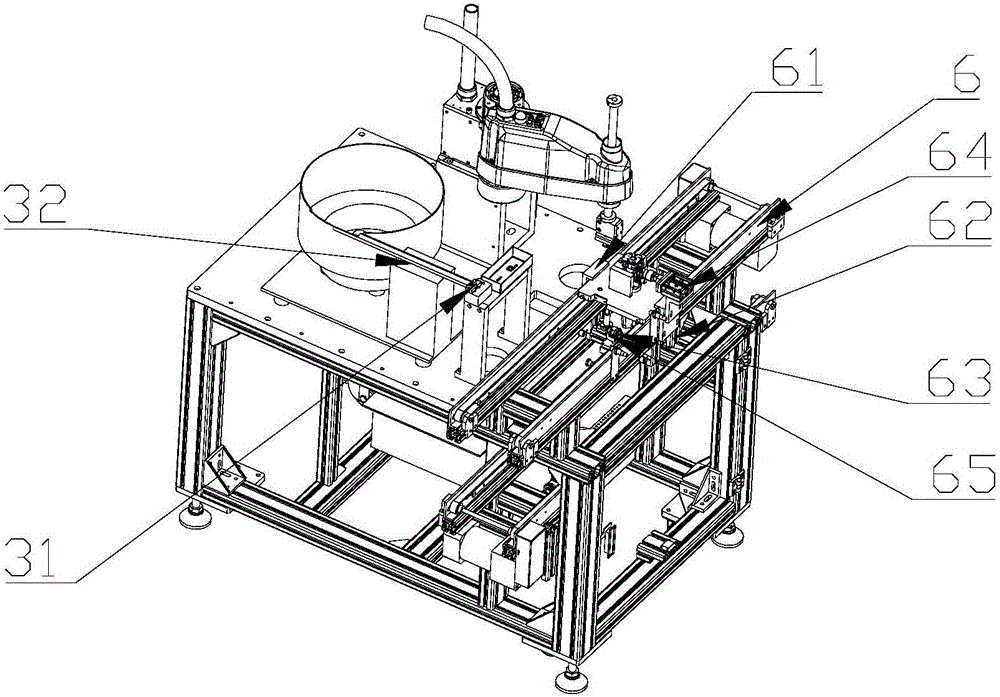

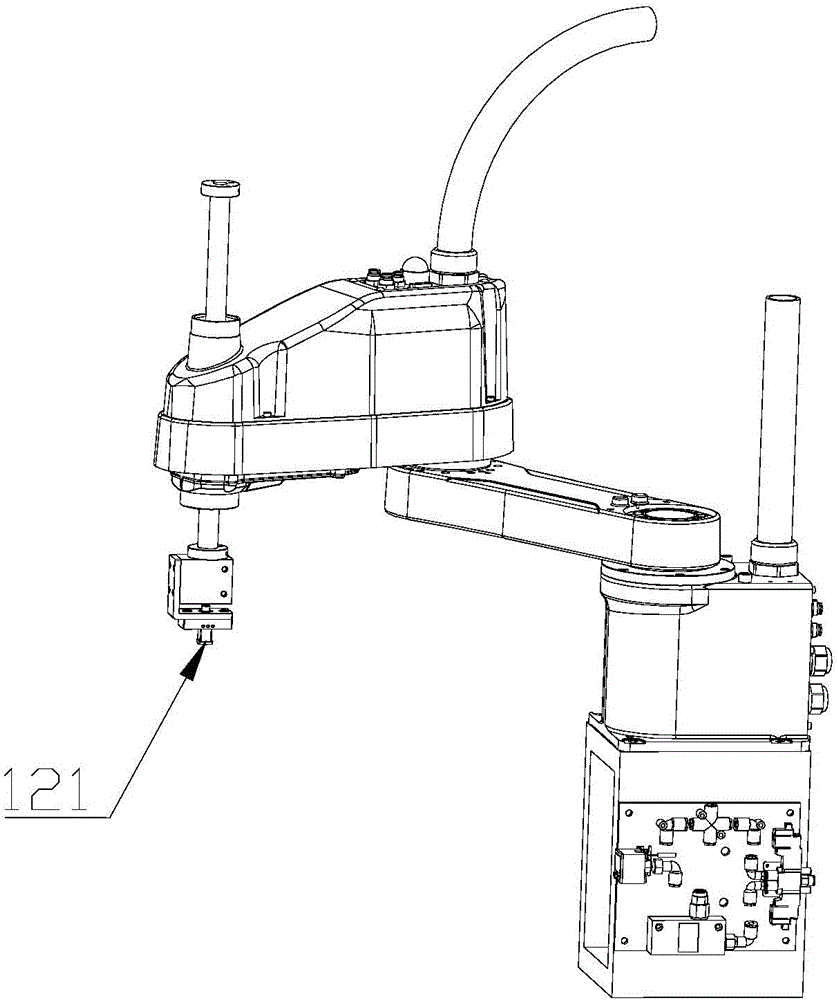

Automatic feeding and assembling machine for aluminum pad of all-in-one machine core

The invention discloses an automatic feeding and assembling machine for an aluminum pad of an all-in-one machine core. According to the automatic feeding and assembling machine for the aluminum pad of the all-in-one machine core, an automatic feeding mechanism is used for feeding the aluminum pad in place, an industrial four-axis robot moves to the position above a material disc, a visual detection mechanism on the head carries out shooting and then absorbs the aluminum pad, the position of the aluminum pad is judged accurately, meanwhile, a wire body carries a workpiece on a working panel to an assembling position, an absorbing head structure is discharged and installed, and full automation of the assembling process is achieved. The industrial four-axis robot is started stably, and is high in acceleration, precise and low in complementary vibration, the beneficial effects of small assembling errors and high precision are achieved, the problem of great demands on labor is solved greatly, and the assembling efficiency and the assembling precision are improved. The automatic feeding and assembling machine is applicable to the field of optical lens assembling.

Owner:GUANGDONG JINHONGDA AUTOMATION TECH CO LTD

Continuous feeding assembly machine for rubber mat of all-in-one machine movement

ActiveCN105836458AFully automatedSmooth startJigging conveyorsConveyor partsEngineeringAssembly machine

The invention discloses a continuous feeding assembly machine for a rubber mat of an all-in-one machine movement. The continuous feeding assembly machine comprises a worktable, wherein a sucker mechanism used for sucking and placing the rubber mat is arranged on the worktable and arranged on an industrial four-axis robot and sucks the rubber mat from a positioning groove, and the positioning groove is connected with a feeding mechanism used for conveying the rubber mat. According to the continuous feeding assembly machine for the rubber mat of the all-in-one machine movement, the feeding mechanism feeds the rubber mat into the positioning groove, meanwhile, the industrial four-axis robot moves above the positioning groove, and the sucker mechanism sucks the rubber mat from the positioning groove to an assembly site of the worktable so as to complete assembly and realize full automation of the assembly process; and the continuous feeding assembly machine is steady in starting, quick and accurate in acceleration, low in residual oscillation, small in assembly error and high in precision, not only reduces the labor force but also further improves the assembly efficiency, and is suitable for the field of assembly of optical lenses.

Owner:GUANGDONG JINHONGDA AUTOMATION TECH CO LTD

Photoelectronic device for touch response of musical instrument

InactiveCN101794569AEasy to assembleDoes not affect the playing feelElectrophonic musical instrumentsStringed musical instrumentsElectronic instrumentElectrical connection

The invention relates to an improved circuit device of an infrared photoelectronic switch, which is used for detecting the key action and playing force of a keyboard musical instrument. The circuit device is characterized in that: two identical phototriode chips manufactured on the same electrode support are packaged into an integrity to be an infrared double-control photo diode by plastic resin, the infrared double-control photo diode and an infrared emitting diode form an infrared double-control photoelectronic switch; each key corresponds to a group of infrared double-control photoelectronic switches and an auxiliary circuit, the keys, the infrared double-control photoelectronic switches and the auxiliary circuit are mutually in electrical connection according to line and row relation to form the matrix scanning circuit of the whole keyboard; and the underside of each key is provided with an infrared photoresist plate, the two phototriodes arranged in the infrared double-control photo diode are cut off or conducted in sequence when the photoresist plate moves up and down along with the key, and a corresponding signal is output to the master control board of an electronic musical instrument after being detected by the matrix scanning circuit. The time interval of the signals output when the two phototriodes are cut off in sequence is detected to calculate the force of playing the keys. Compared with the prior art, the invention has reliability and accuracy, sensitive response, small volume, relatively low cost and strong practicability, and particularly does not influence the playing handfeel of the keys.

Owner:SHANGHAI JIUGE MUSIC INSTR

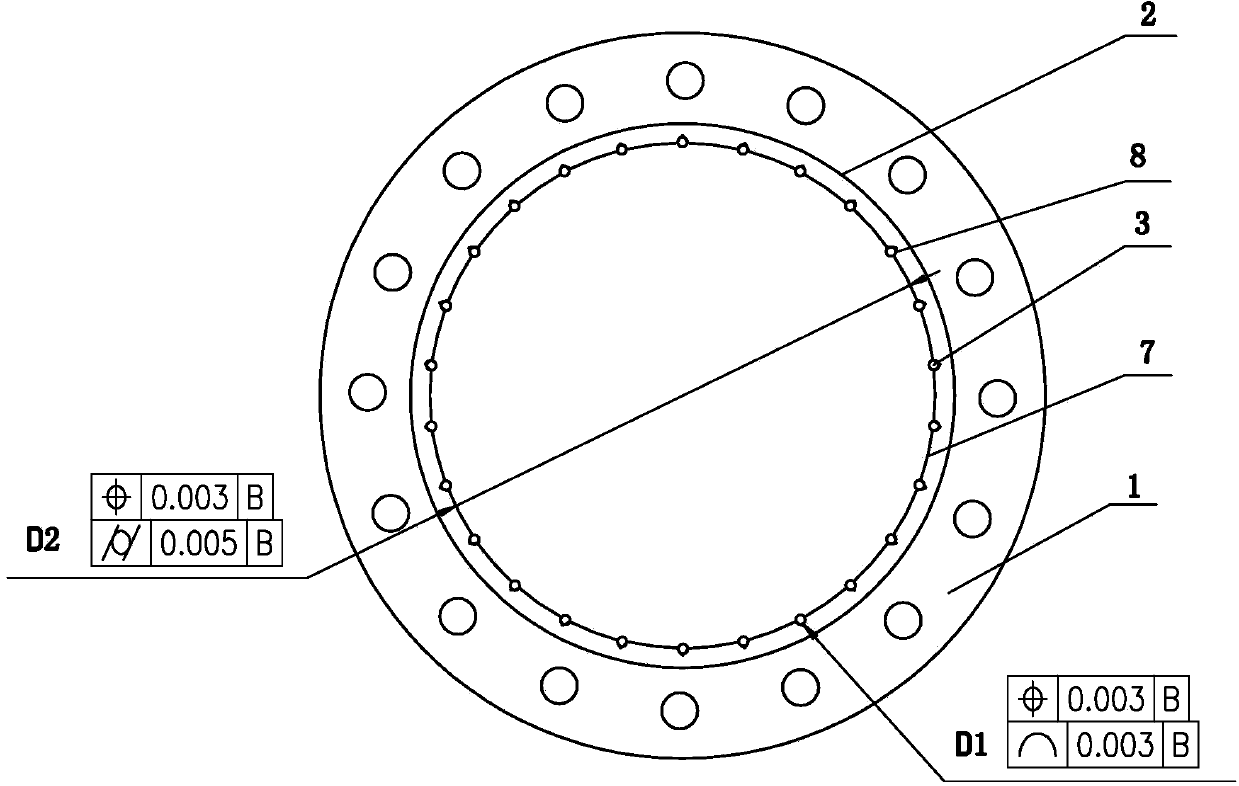

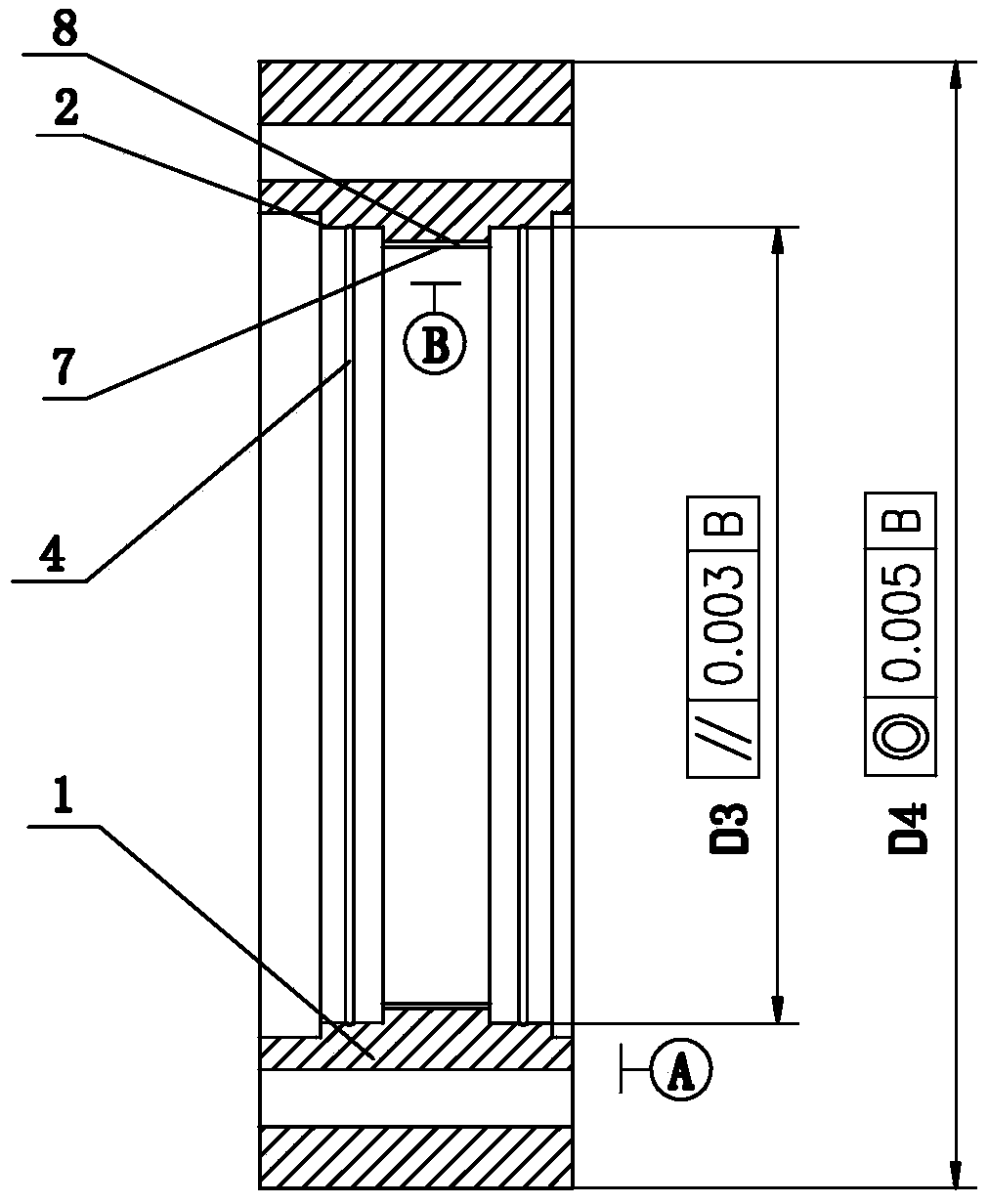

Processing technology of robot RV speed reducer needle gear shell

The invention discloses a processing technology of a robot RV speed reducer needle gear shell, and belongs to the technical field of robot RV speed reducer processing. The processing technology includes the steps that precise casting or forging is carried out on a needle gear shell blank; the needle gear shell blank is clamped after the surface of the needle gear shell blank is machined, and the rotation center of the needle gear shell blank is taken as a positioning reference; the end face of the needle gear shell blank, a bearing position of a roller pin bearing and bearing positions of two main bearings are machined; finish machining is carried out on the inner surface of the roller pin bearing according to the positioning reference; finish machining is carried out on a roller pin groove in line contact with a roller pin of the roller pin bearing according to the positioning reference; inner grooves are simultaneously machined in the bearing positions of the two main bearings in a finish machining mode according to the positioning reference; finish machining is carried out on the outer surface of the needle gear blank. The needle gear shell machined according to the steps improves machining precision and the parallelism degree of the bearing positions of the main bearings, guarantees coaxiality, the position degree and cylindricity of the main bearings after installation, achieves one-time clamping, can meet requirements of multiple process parameters, improves machining precision and installation precision of the needle gear shell, reduces accumulated errors, meets the high-precision requirements, and prolongs service life.

Owner:SHANDONG SHKE MACHINERY MFG

Method for milling large diameter thread of titanium alloy or high-temperature alloy material pieces

InactiveCN101767227AReduce labor intensityReduce assembly errorsThread cutting machinesMilling cutterSuperalloy

The invention provides a method for milling a large diameter thread of titanium alloy or high-temperature alloy material pieces, which particularly aims at machining threads, with a large bore diameter over M30, of a difficult-to-machine material such as high-temperature alloy or titanium alloy. Due to the adoption of the digital control technology and the analysis of parameters of the large diameter thread, a thread milling cutter is determined; spiraling is mainly realized by the motions of a machine tool during machining, so the important thing of thread milling is how to control the motions of the machine tool, and particularly the thread milling has higher requirements on the machining parameters; and the method improves the machining efficiency and simultaneously ensures the thread verticality and the thread surface finishment, so the quality of thread machining is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

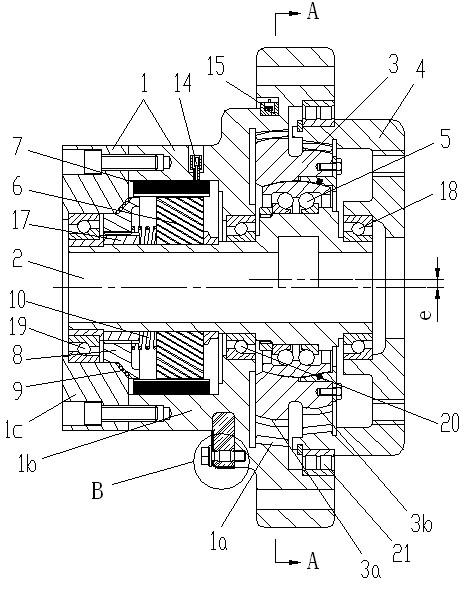

Robot driving joint

The invention discloses a robot driving joint. The joint comprises a driving joint shell, a power input shaft, twin coupling outer arc shaped crowned teeth and a power output gear, wherein a first rolling bearing is sleeved outside the power input shaft, and the first rolling bearing and the power input shaft are in eccentric arrangement; the twin coupling outer arc shaped crowned teeth are sleeved outside the first rolling bearing, the first coupling crowned tooth is engaged with an inner crowned gear on the driving joint shell in a small teeth difference mode, and the second coupling crowned tooth is engaged with the power output gear in a small teeth difference mode; a drive motor, a brake, a vibration attenuation unit and a sensor are integrated on the driving joint. By adopting transmission of the twin coupling outer arc shaped crowned teeth, the non-linear fluctuation of a transmission can be attenuated, the strength and rigidity of a carrying gear can be ensured, the system reliability and stability under the actions of overloading and long-term circular alternating stress can be guaranteed; and the functions of driving, torque increasing, vibration attenuating, braking, monitoring and the like are integrated into a whole; in addition, the robot driving joint is multifunctional and has the advantages of concise structure, short transmission chain, high transmission efficiency, small system vibration and noise.

Owner:重庆奔腾科技发展有限公司

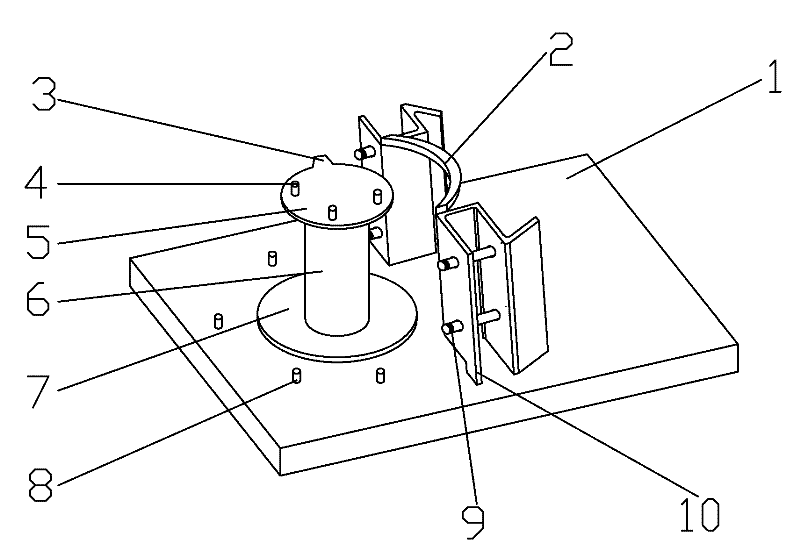

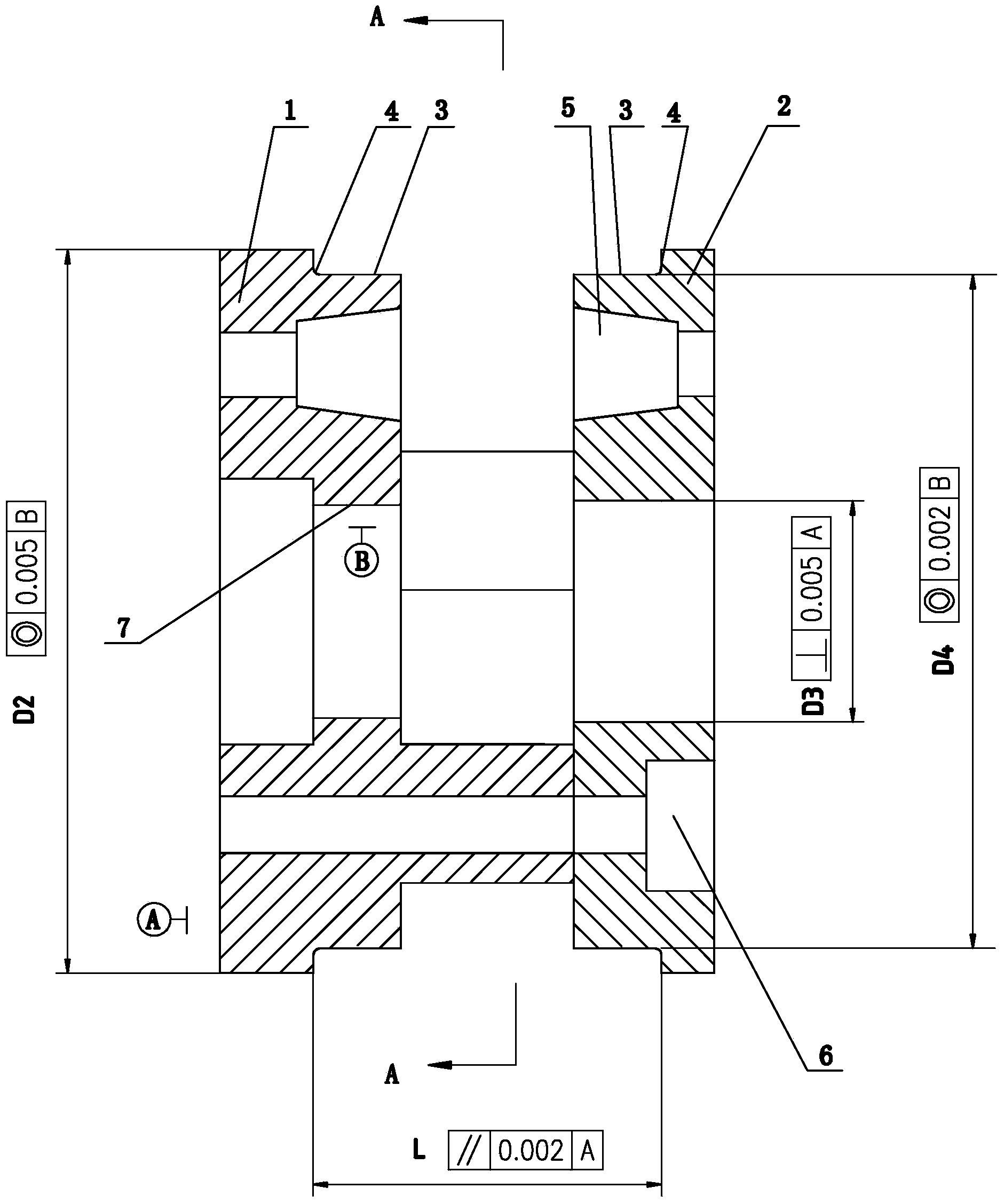

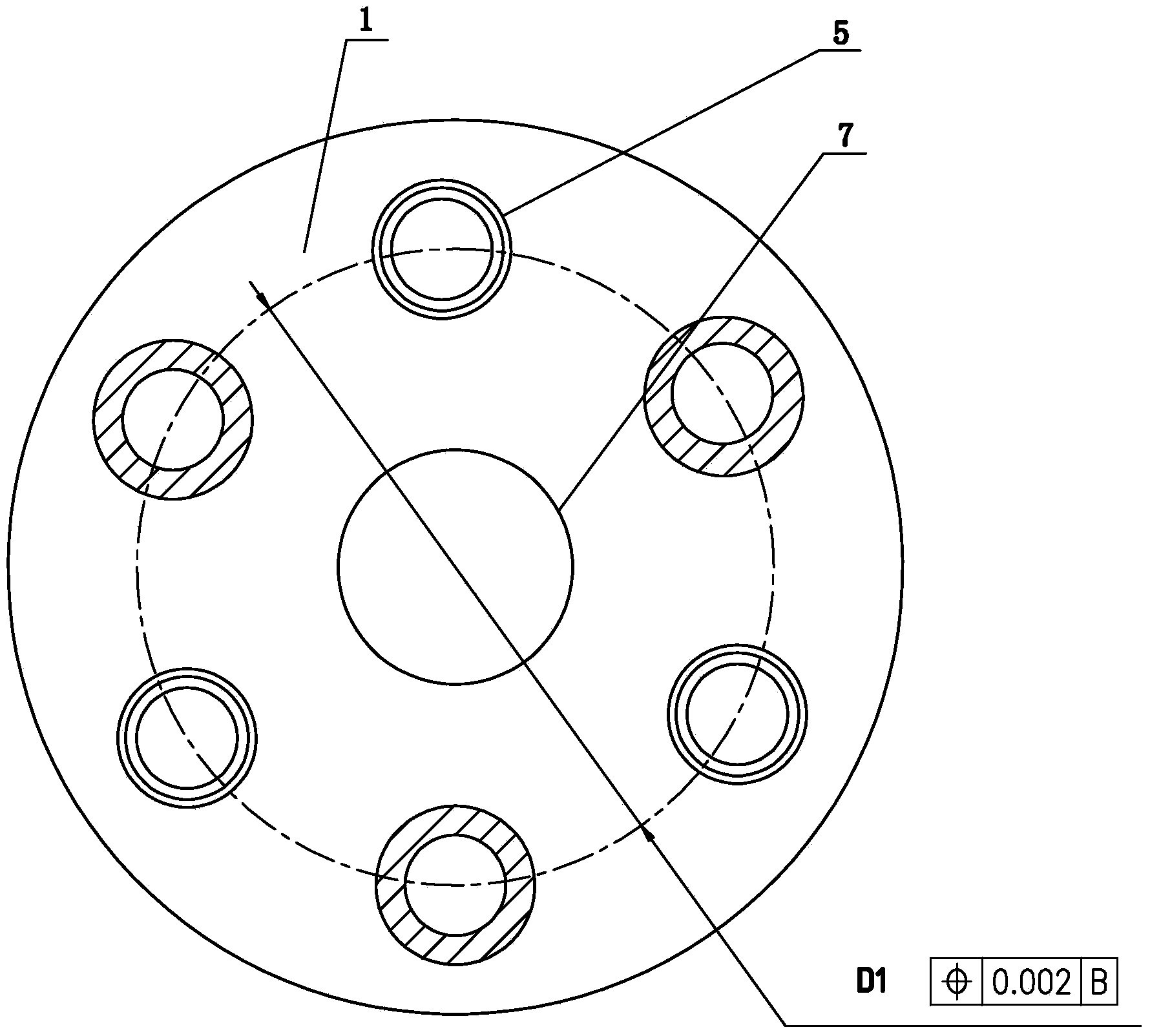

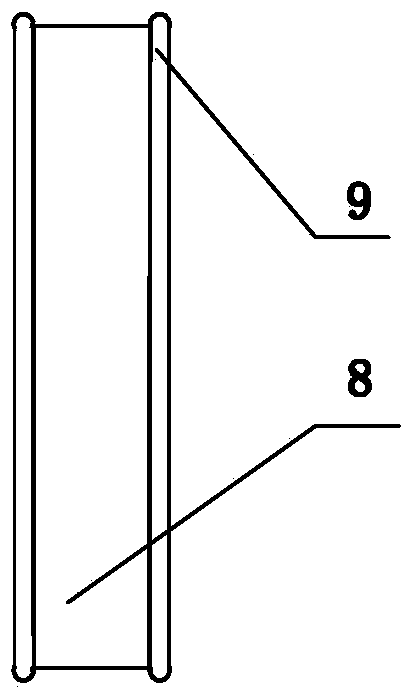

Assembly tool for rethresher shell of harvester

ActiveCN102198578AHigh dimensional accuracyAchieve precise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh dimensional

The invention discloses an assembly tool for a rethresher shell of a harvester. The assembly tool is used for integrally assembling a spiral case, an end cover and a flange of the rethresher shell, and comprises a pedestal, a spiral case positioning part, an end cover positioning part and a flange positioning part, wherein the spiral case positioning part is in positioning connection with the spiral case; the end cover positioning part is in positioning connection with the end cover; the flange positioning part is in positioning connection with the flange; and the spiral case positioning part, the end cover positioning part and the flange positioning part are arranged on the pedestal. By adopting the technical scheme, the accurate positioning of each part is realized when the rethresher shell is assembled; assembly efficiency is increased; the assembly tool is easy to operate and is time-saving and labor-saving; each part can be prevented from being deformed during assembly; assembly errors are reduced; and the rethresher shell has higher dimensional accuracy after being assembled.

Owner:ZOOMLION HEAVY MASCH CO LTD

Integrated machining method of planet carrier of robot RV reducer

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

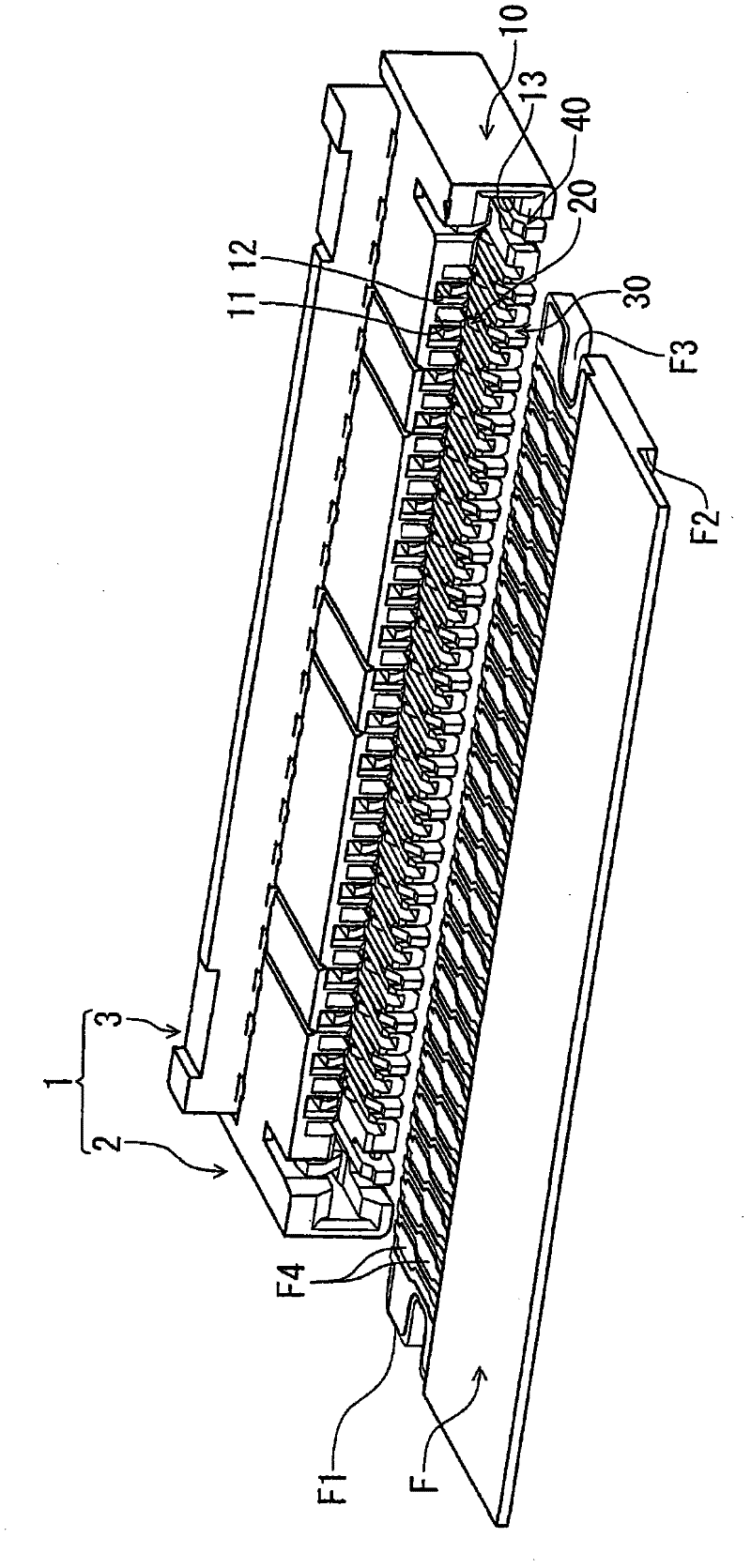

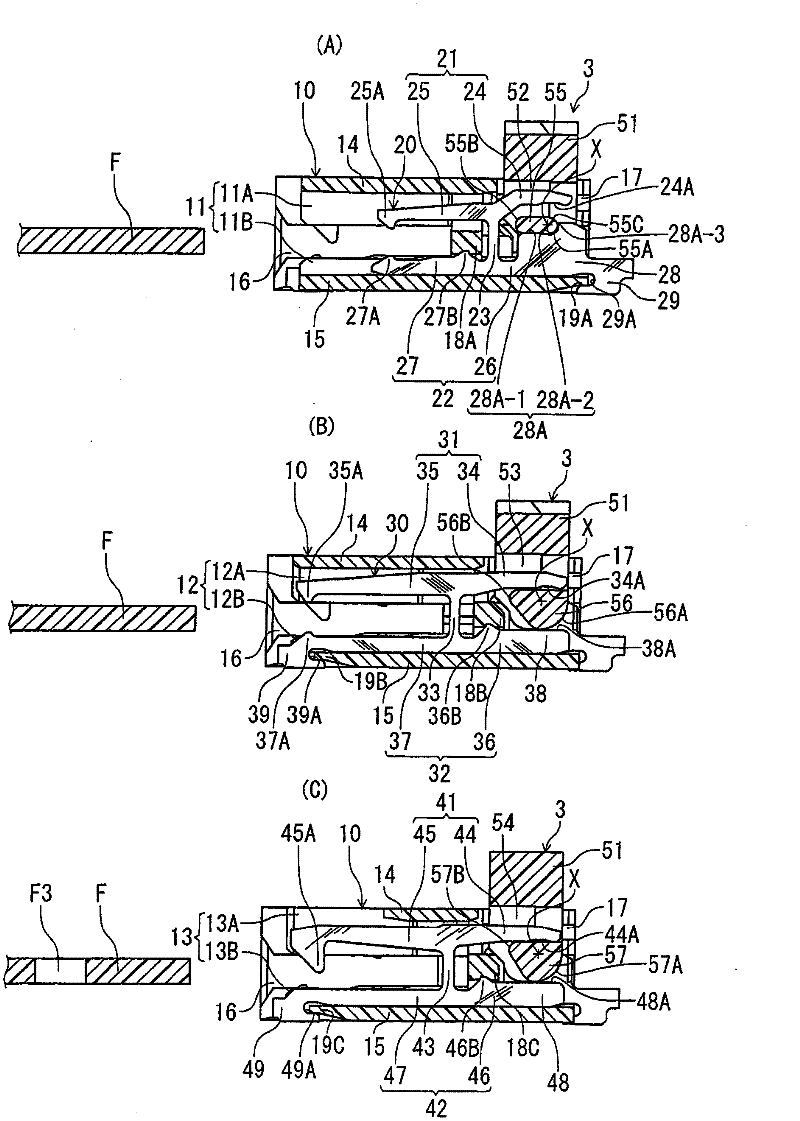

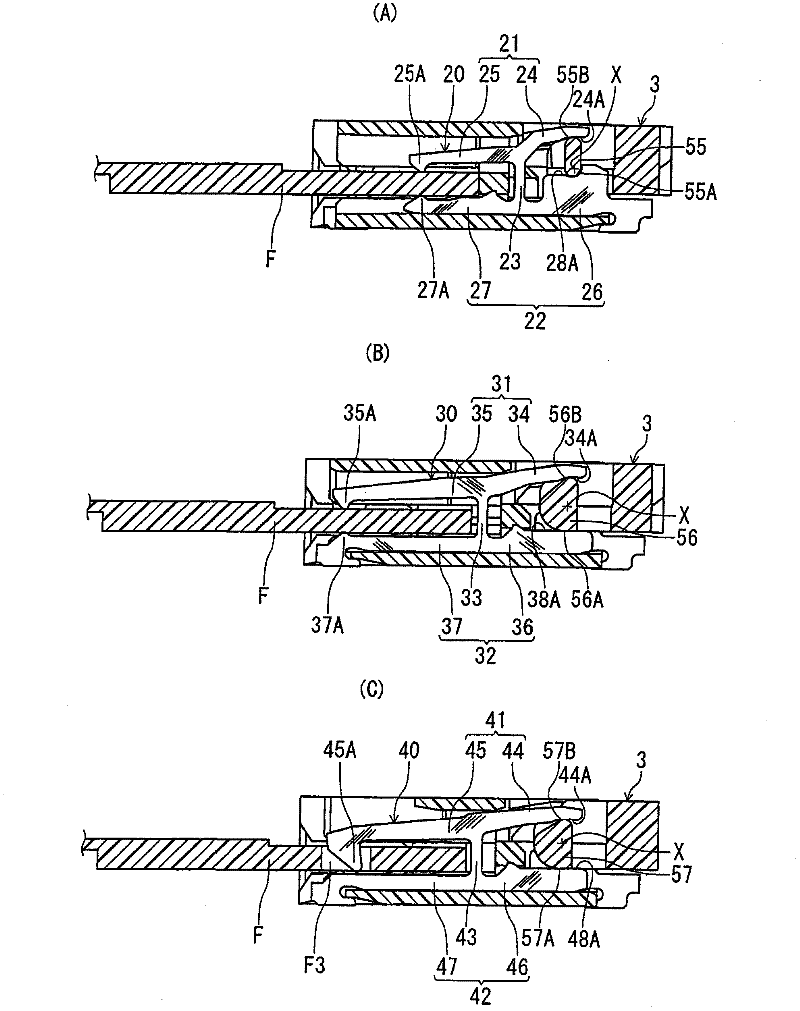

Electric connector for flat conductor

InactiveCN102332648AReduce manufacturing errorsReduce assembly errorsEngagement/disengagement of coupling partsCoupling contact membersElectrical conductorCam

An electric connector for a flat conductor comprises two kinds of terminals with different assembling directions towards a shell and can greatly reduce position error of cam parts. In the flat type electric connector for the conductor, an attaching part (38A) of a second terminal (30) attached with the cam is arranged at a position which is the same with a lower edge of a position limiting part (18B) or therebelow, an attaching part (28A) of a first terminal (20) is arranged above the attaching part (38A) of the second terminal (30), a first cam part (55) and a second cam part (56) of a movable construction member (3) can rotate around a common axes, the movable construction member (3) is provided with upper cam edges (55B), (56B) and lower cam edges (55A), (56A) which are abutted against upper arm parts and lower arm parts of the first terminal and the second terminal, the lower cam edges (55A), (56A) of the first cam part (55) and the second cam part (56) can form that when the movable construction member (3) turns towards a closed position, the difference of radius lengths of the cams which are movably contacted with the lower arm part within a movable contacting range and in the optional same angle positions is a fixed value.

Owner:HIROSE ELECTRIC GROUP

Three-eccentric and bidirectional metal sealing butterfly valve

ActiveCN104329475APrevent plastic deformation or even close the phenomenonAchieve sealingValve members for absorbing fluid energyLift valveEngineeringButterfly valve

The invention relates to a three-eccentric and bidirectional metal sealing butterfly valve. A flow passage is arranged in a valve body, a valve seat is sealed and fixedly arranged on the inner wall of the flow passage, a valve rod is vertically arranged and penetrates through the flow passage, the upper end of the valve rod and the valve body are sealed and connected by a first rotary type sealing and connecting structure, the lower end of the valve rod and the valve body are sealed and connected by a second rotary type sealing and connecting structure, a valve plate is arranged in the flow passage and is fixedly arranged on the valve rod, a mounting step is arranged at the periphery of the valve plate, a sealing ring is arranged on the mounting step and is pressed and fixed by a sealing ring press ring, the sealing ring press ring is fixedly connected with the valve plate by a first screw, and the sealing ring is in fit with the valve seat, so as to control the opening or closing of the valve. The three-eccentric and bidirectional metal sealing butterfly valve is characterized in that virtual gaps are respectively arranged between the inside surface of the sealing ring and the mounting step surface as well as between the outside surface of the sealing ring and the pressing surface of the sealing ring press ring, and sealing ring sealing gaskets are arranged in the virtual gaps. The three-eccentric and bidirectional metal sealing butterfly valve has the advantages that the structure design is novel, the requirement of stricter working condition is well met, the whole cost is reduced, and the service life of the valve is prolonged.

Owner:WUXI YADI FLUID CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com