Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

668results about How to "Grinding speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

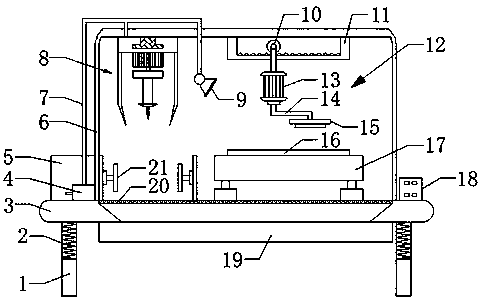

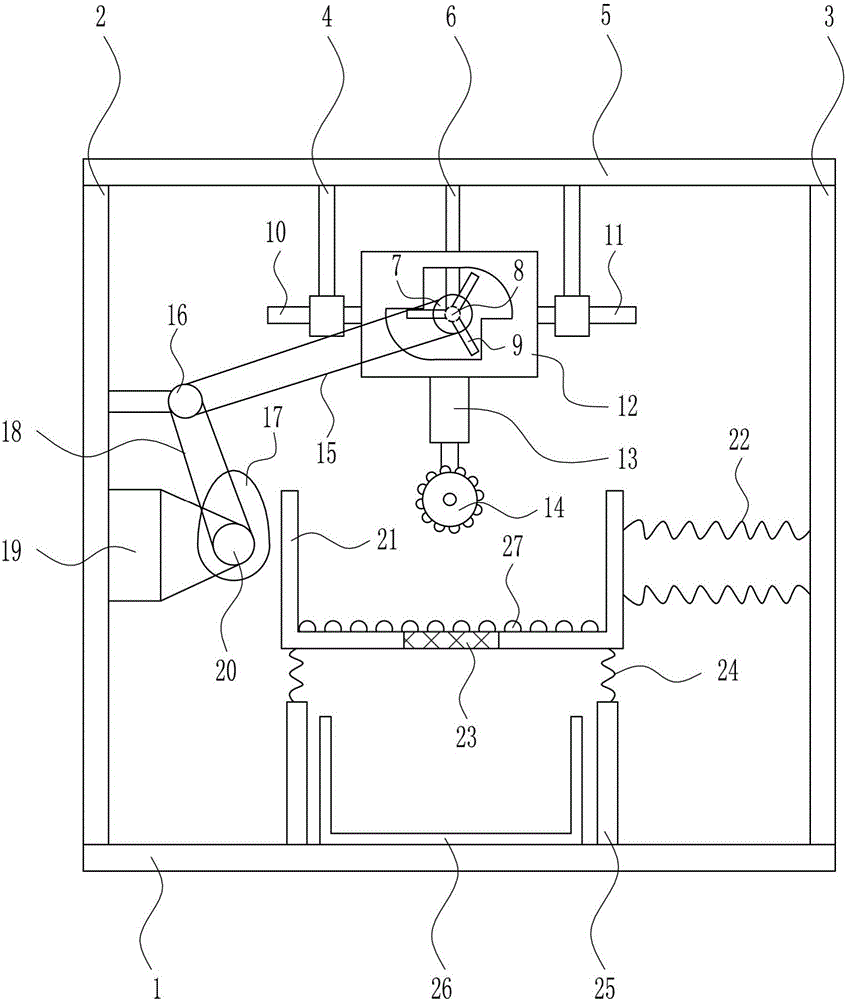

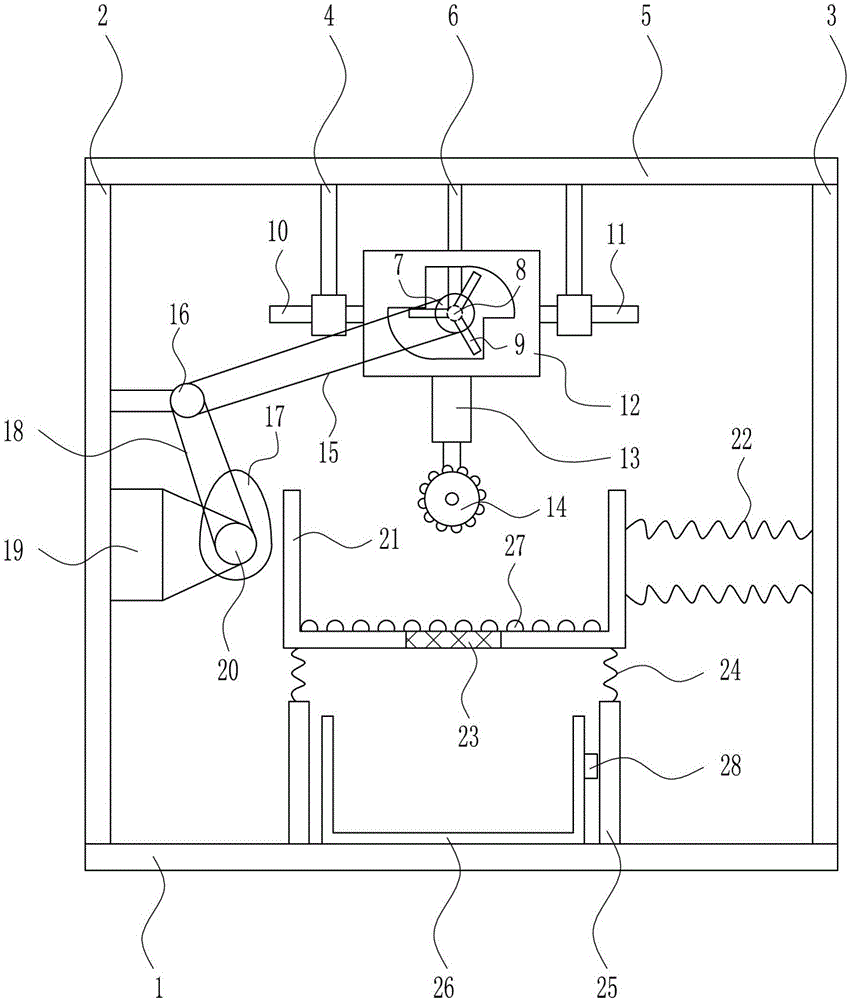

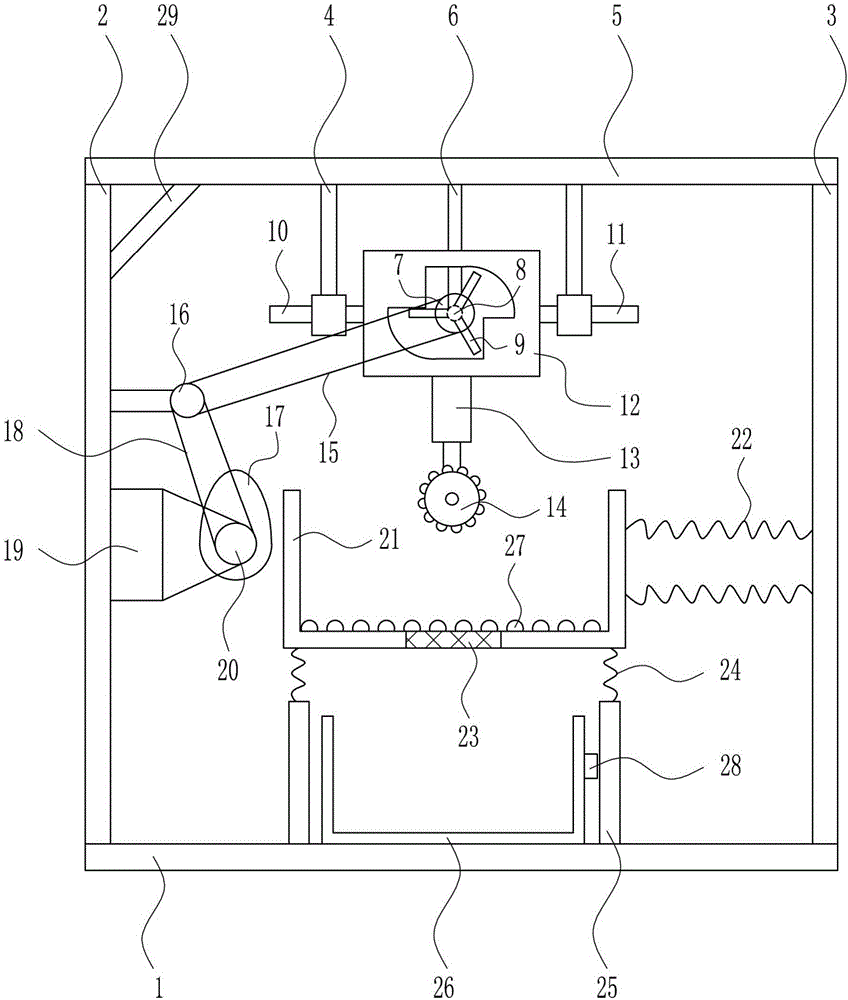

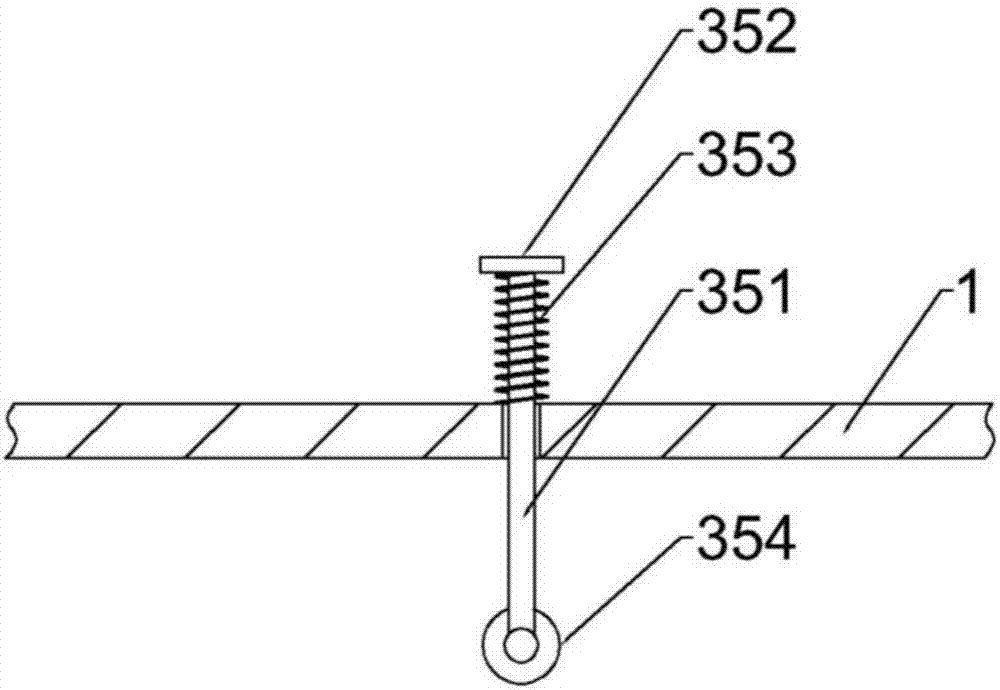

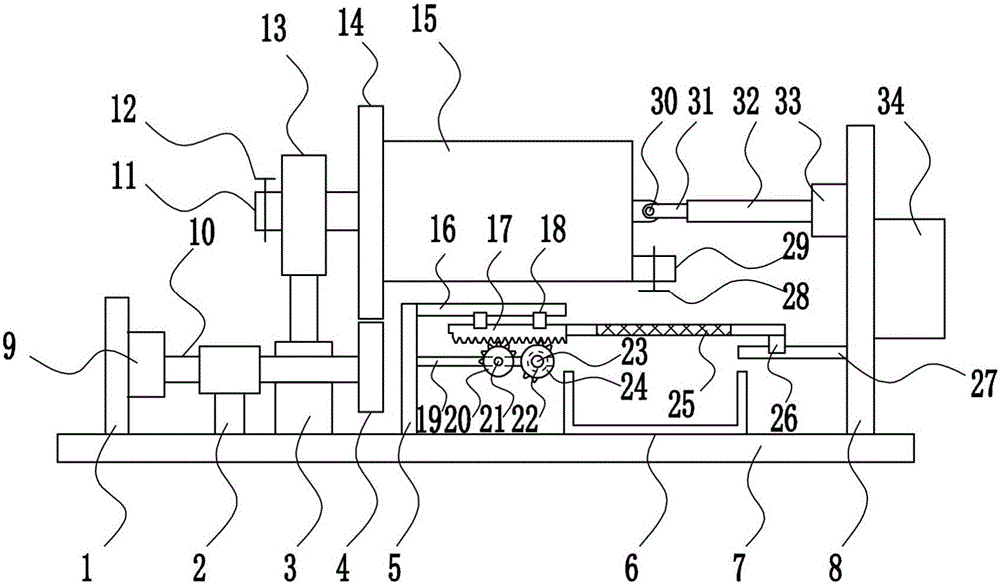

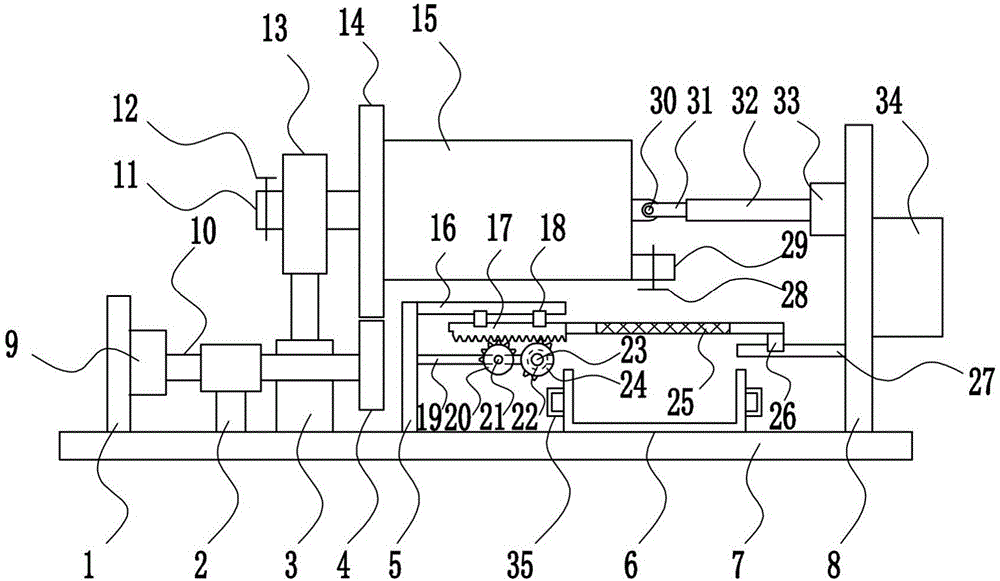

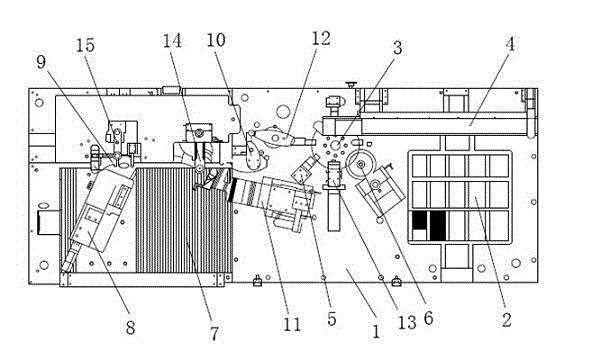

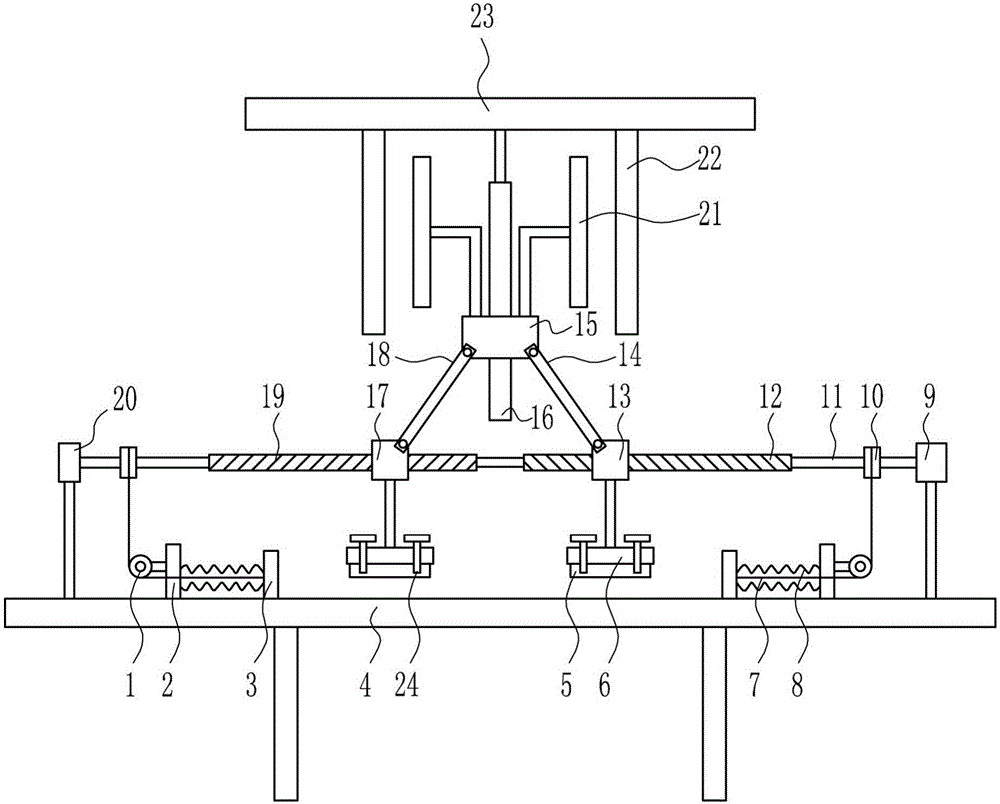

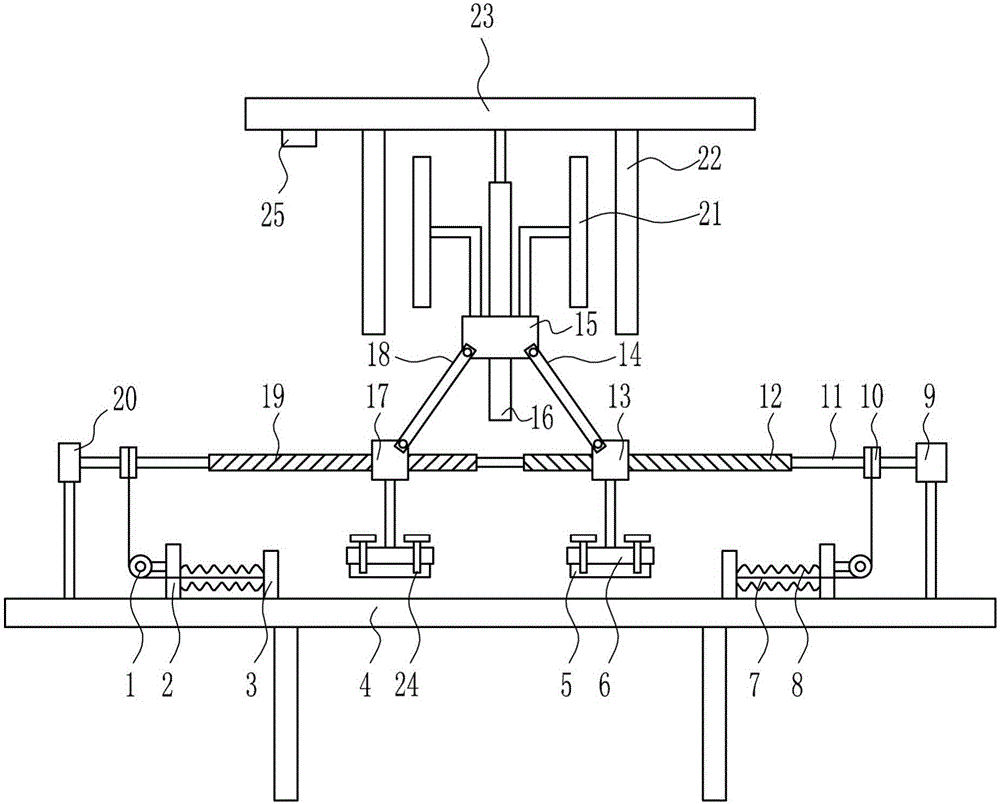

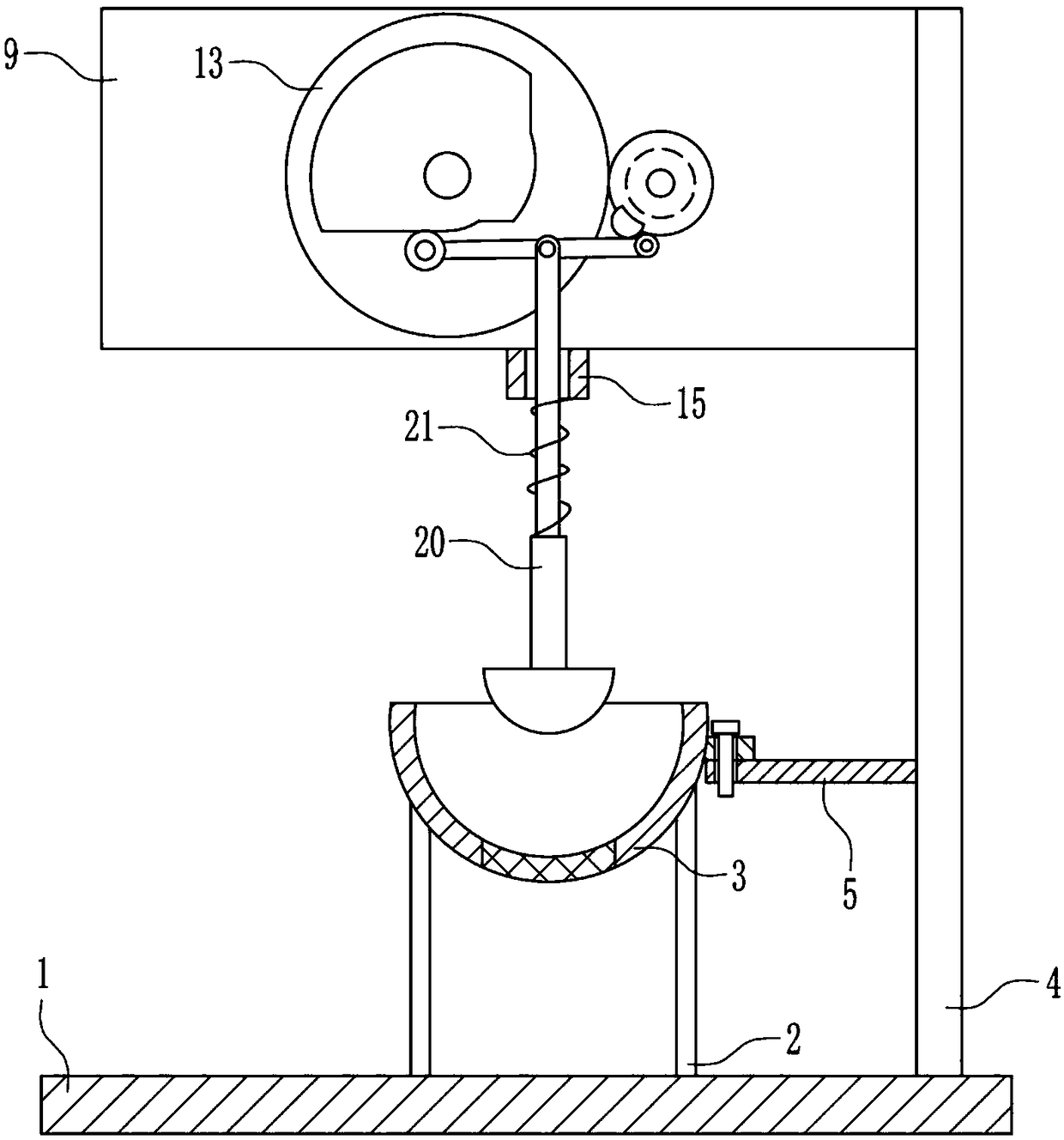

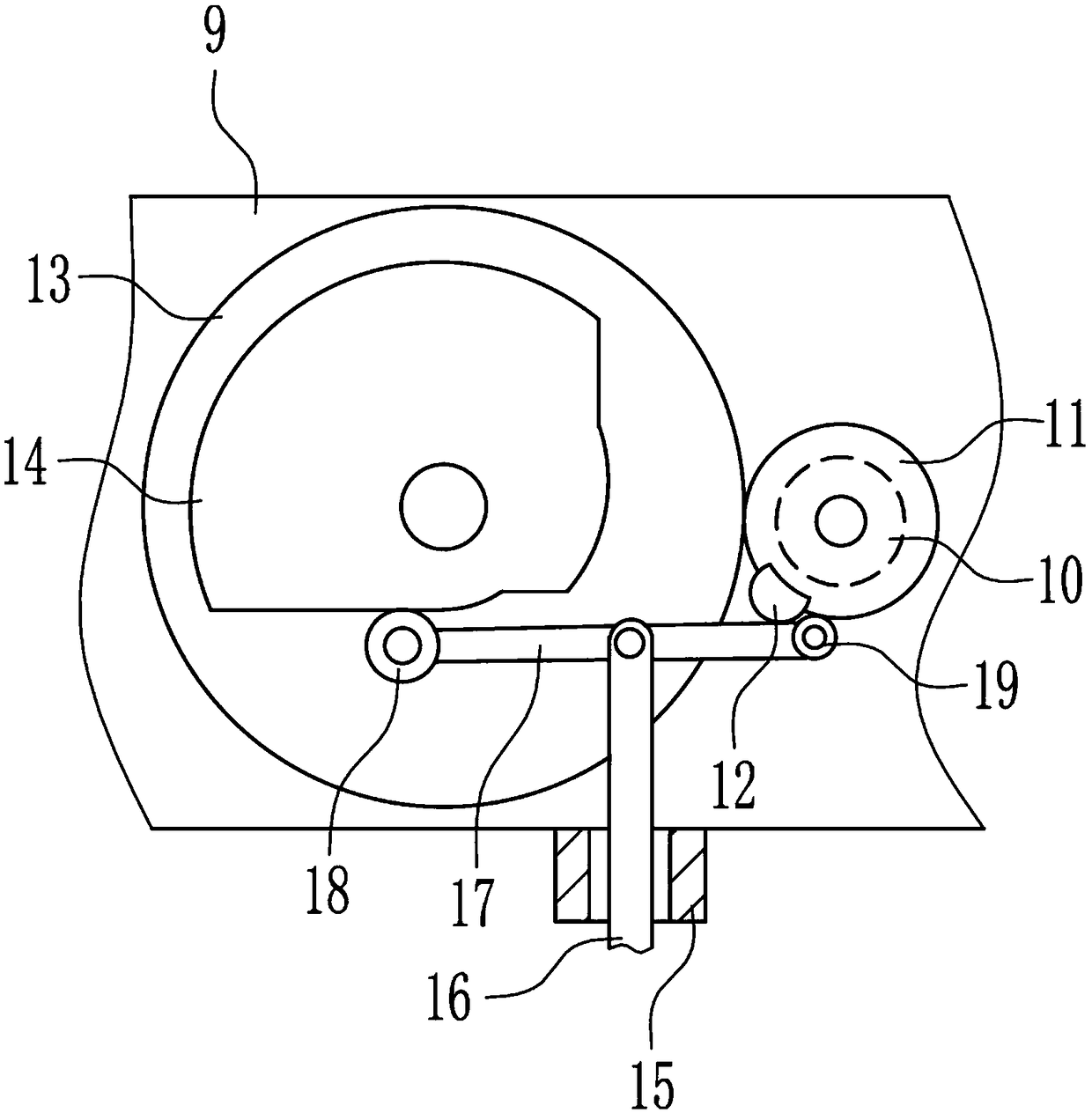

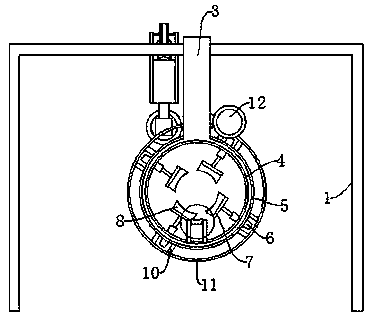

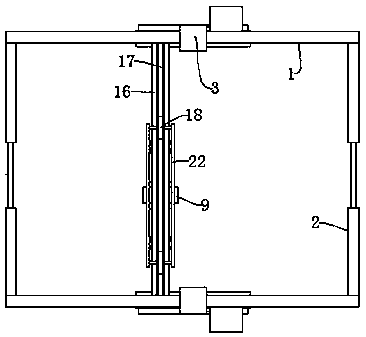

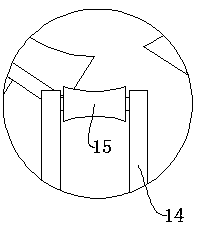

Grinding and rust removing device for chemical pipeline anticorrosion

InactiveCN107962460AGood rust removal effectGrinding speed is fastRevolution surface grinding machinesGrinding drivesReciprocating motionEngineering

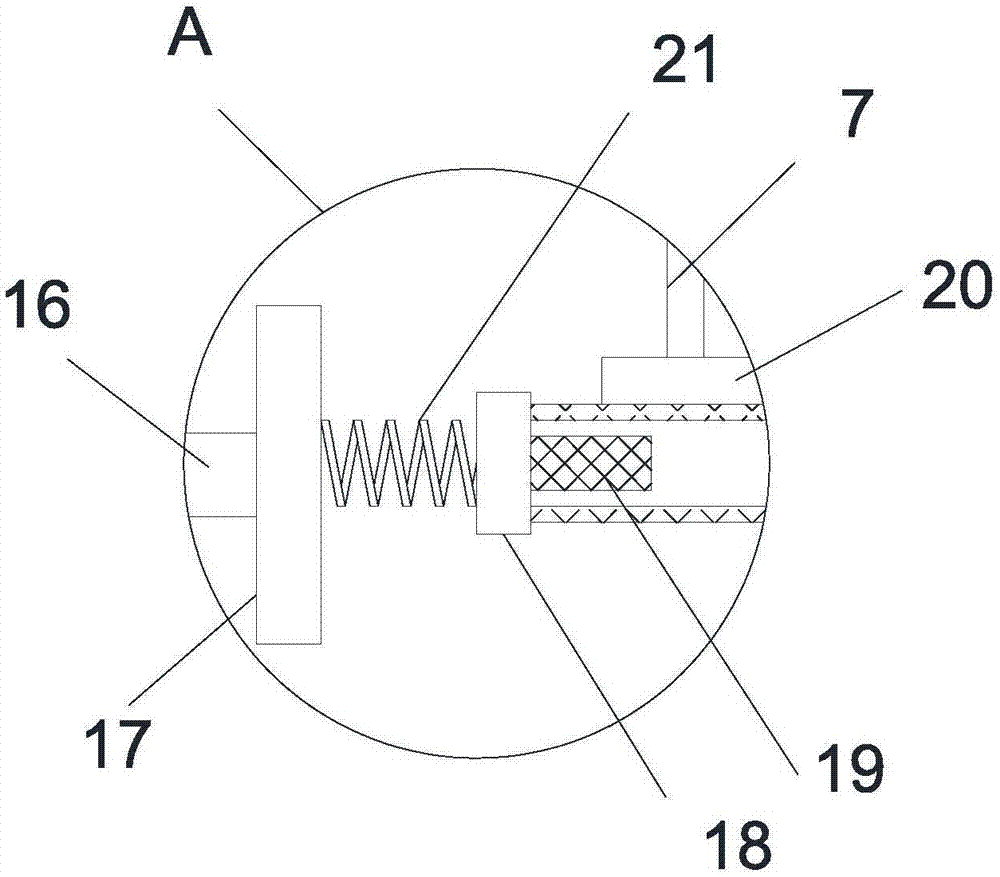

The invention discloses a grinding and rust removing device for chemical pipeline anticorrosion. The grinding and rust removing device for chemical pipeline anticorrosion comprises an operation frame.A first guide rod and a second guide rod are horizontally and fixedly mounted in the operation frame. The first guide rod and the second guide rod are slidably sleeved with an upper sliding sleeve and a second sliding sleeve correspondingly. Grinding heads are fixedly mounted at the ends of telescopic rods correspondingly. A rotary shaft is rotatably arranged on the right sidewall of the operation frame. The rotary shaft is in transmission connection with a second lead screw through a second transmission belt. An output shaft of a forward and reverse rotating motor is coaxially fixed to the second lead screw. According to the grinding and rust removing device, the forward and reverse rotating motor rotates forwards and reversely to drive a first lead screw and the second lead screw to rotate, and then a first threaded sleeve and a second threaded sleeve drive the telescopic rods to do left-right reciprocating motion. Finally, the grinding heads do transverse back and forth motion to grinding the surface of a pipeline. The grinding speed is increased. Meanwhile, the pipeline can rotates along with rotating of the fixed plates so as to be annularly ground. The working efficiency isgreatly improved.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

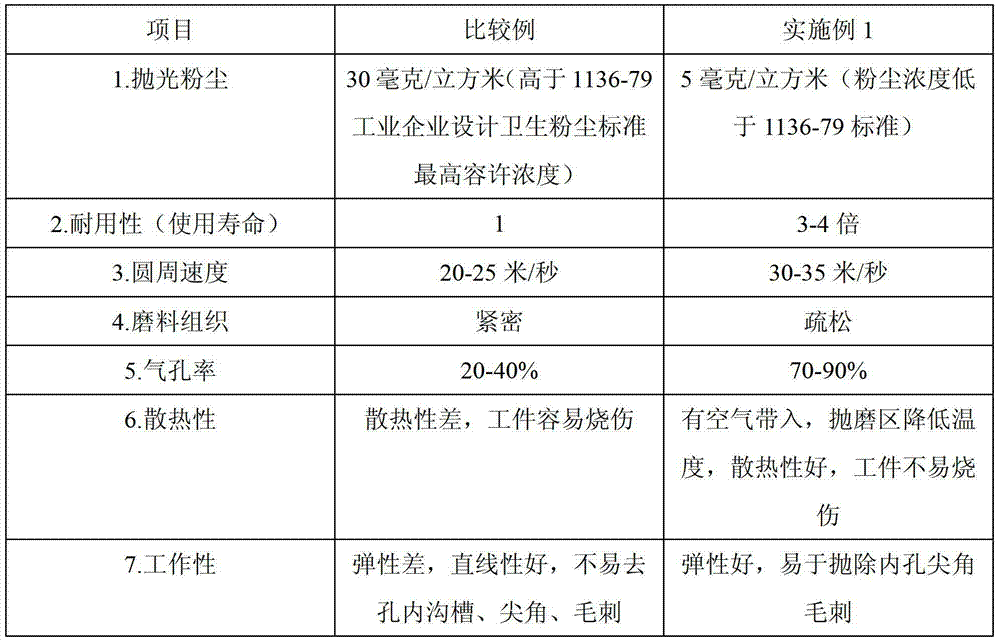

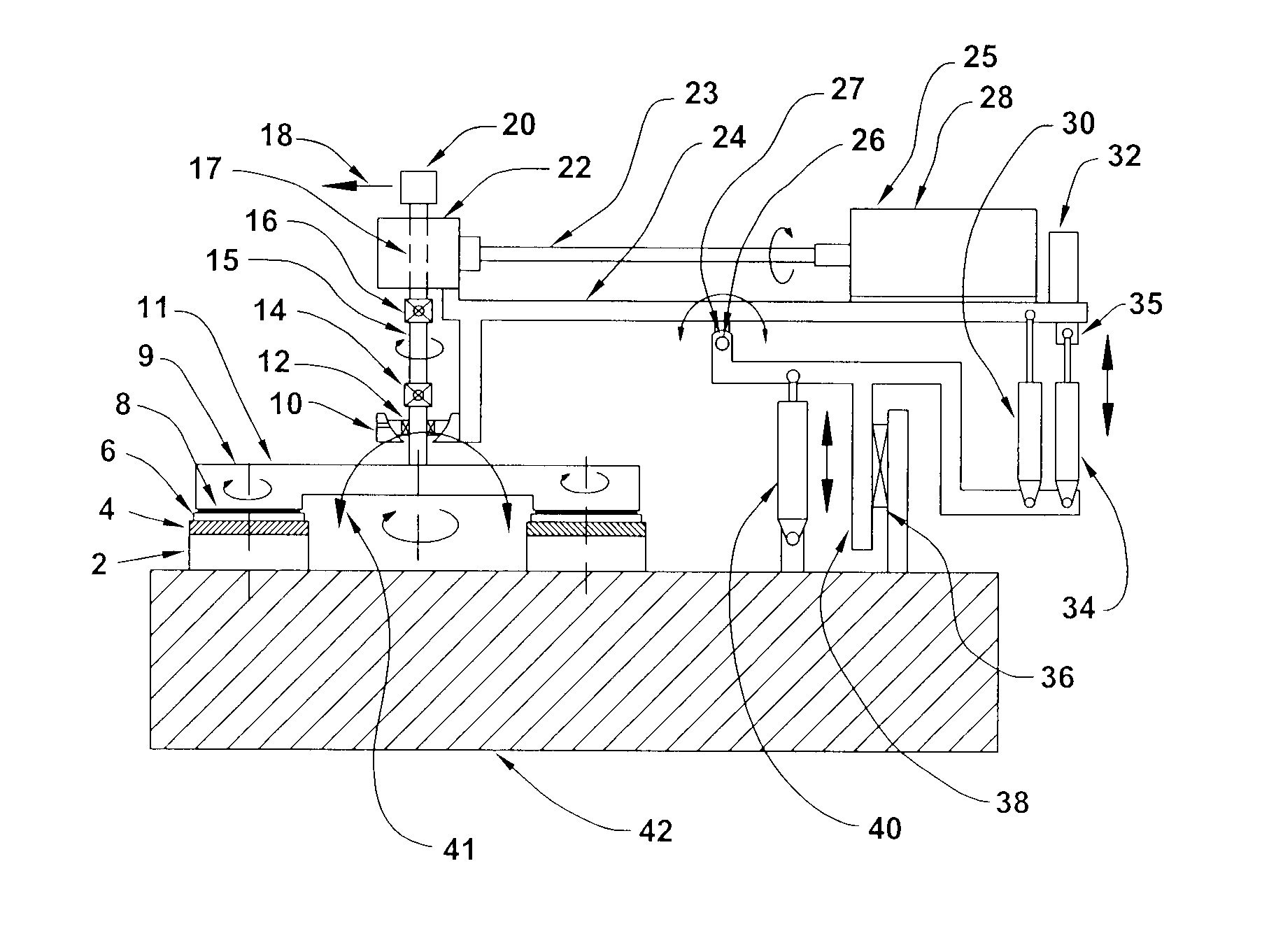

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

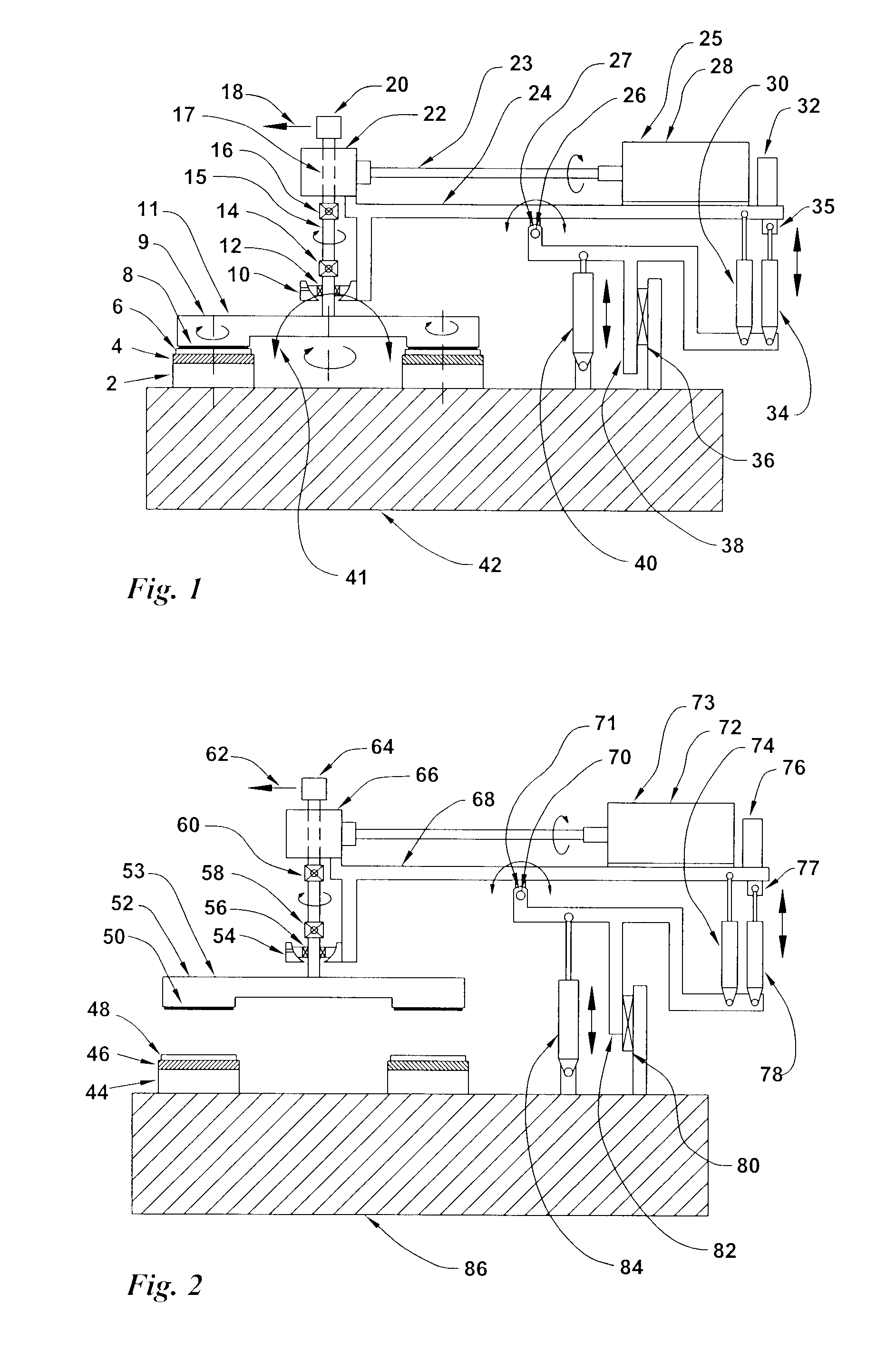

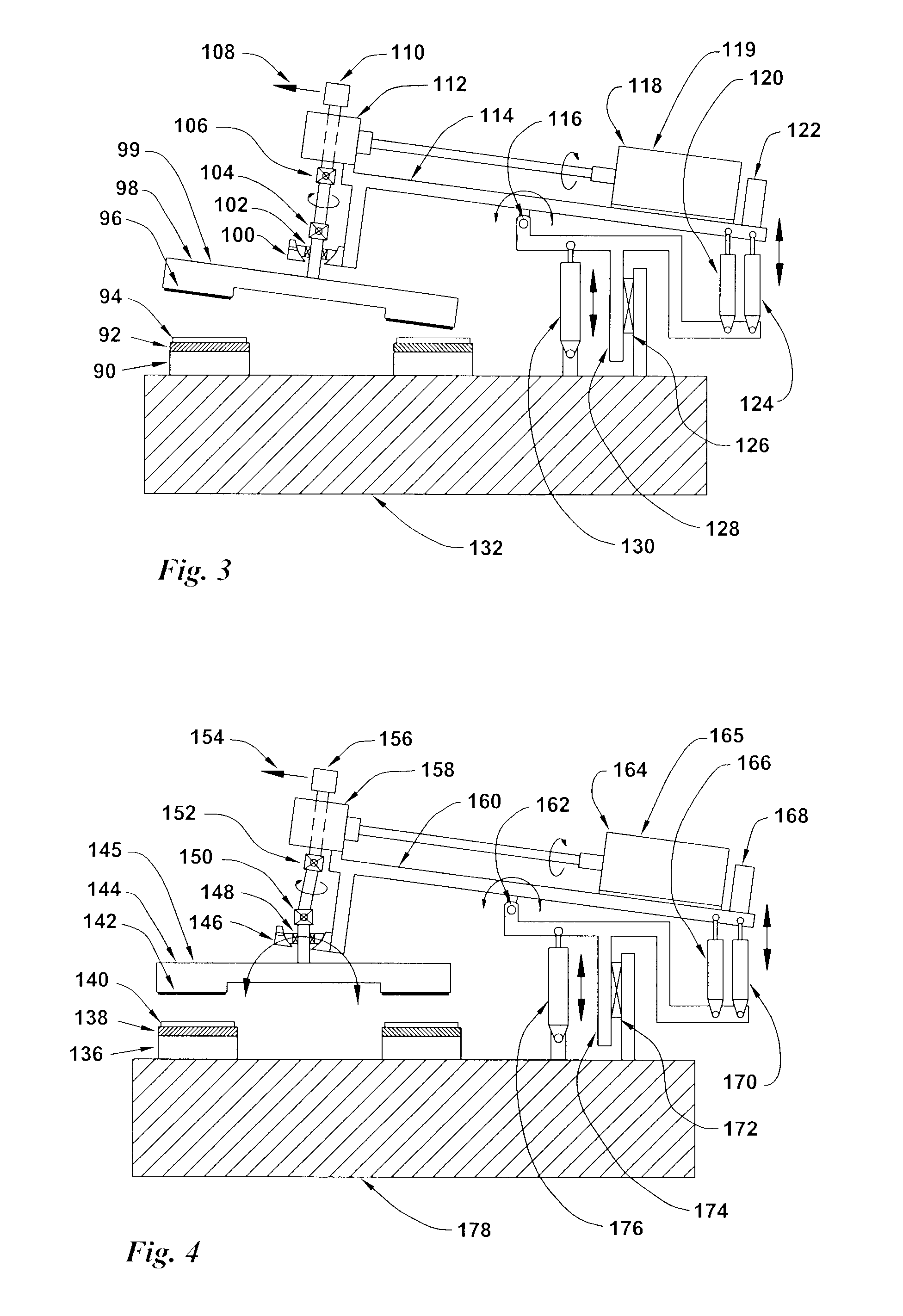

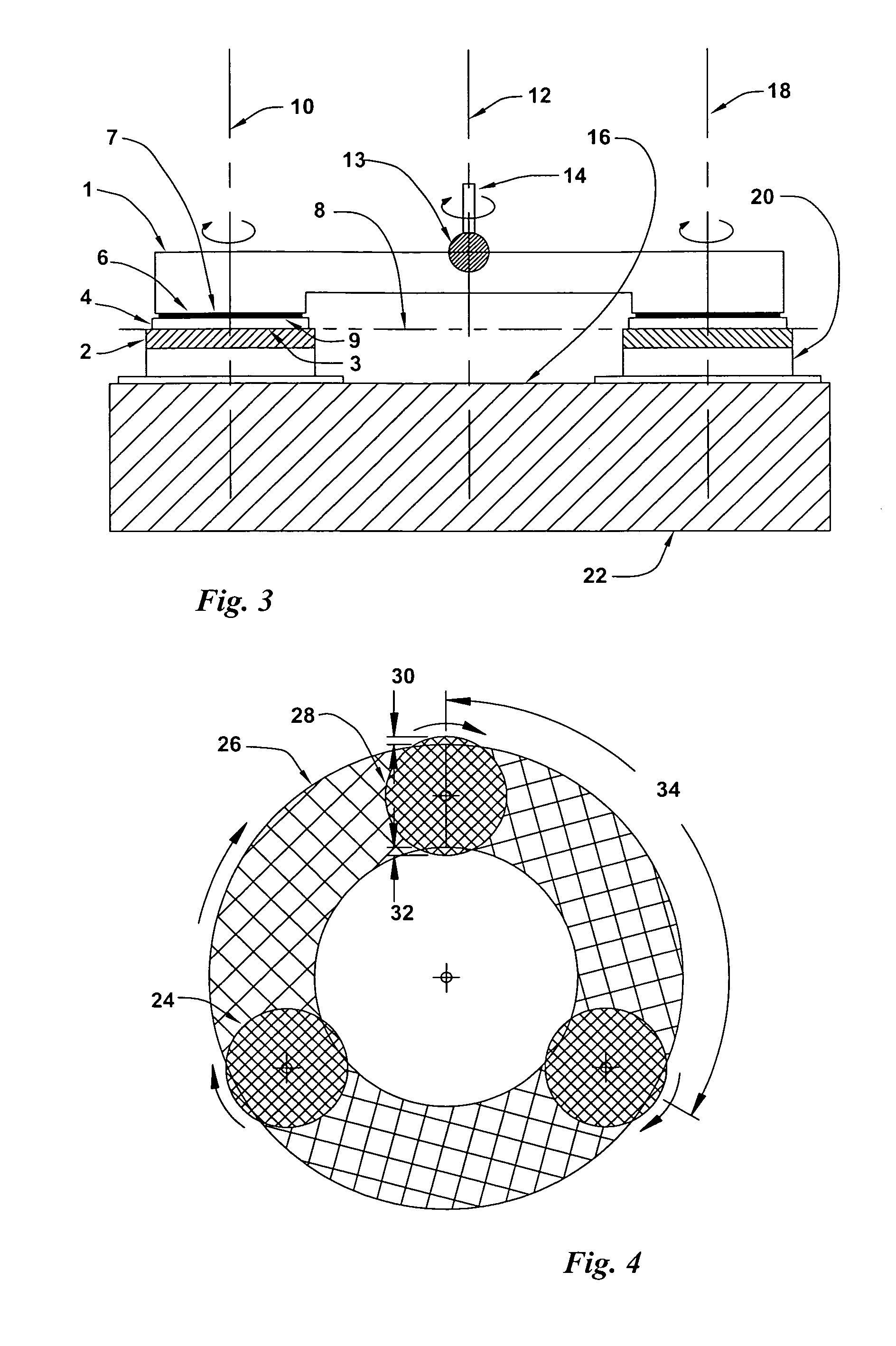

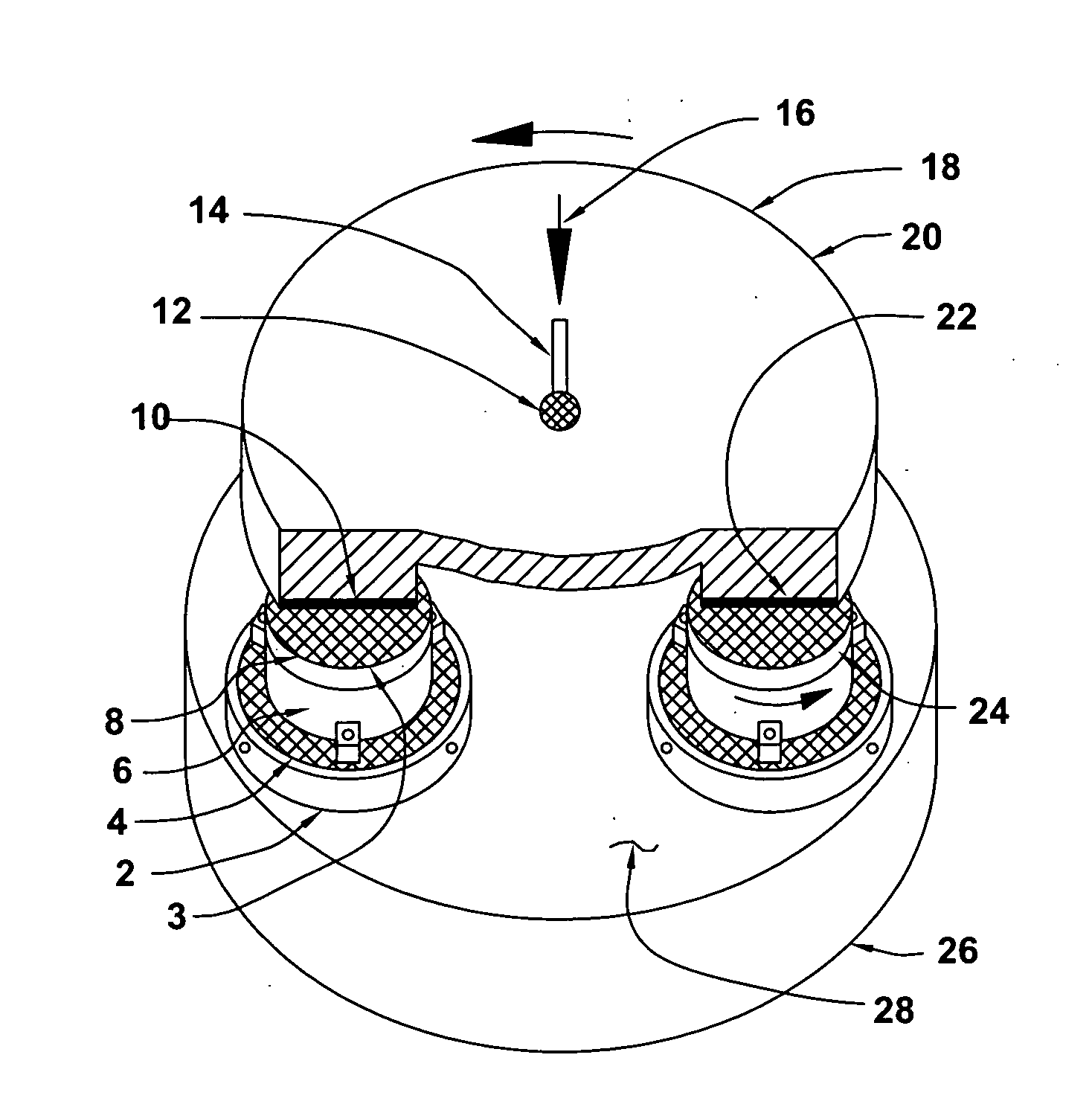

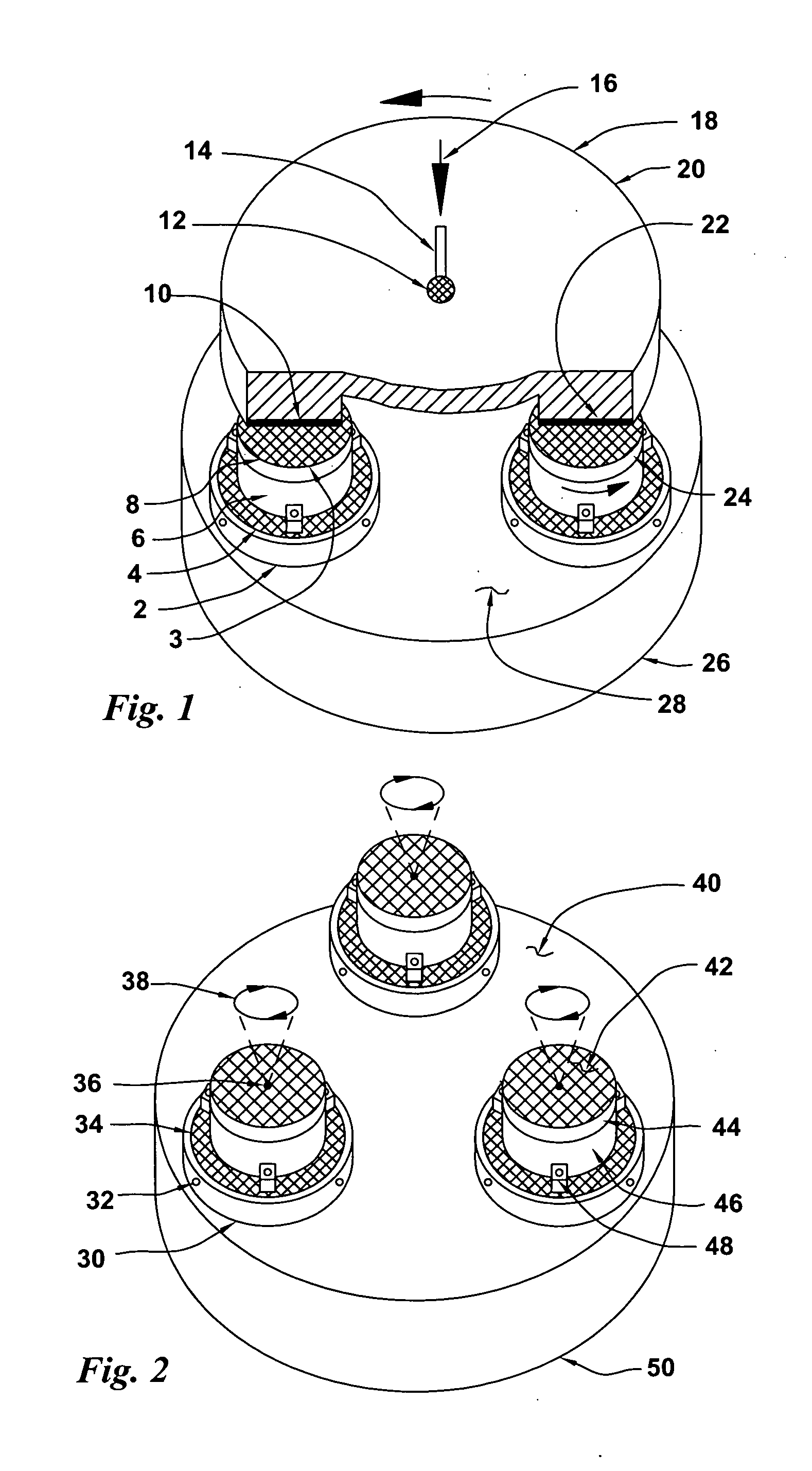

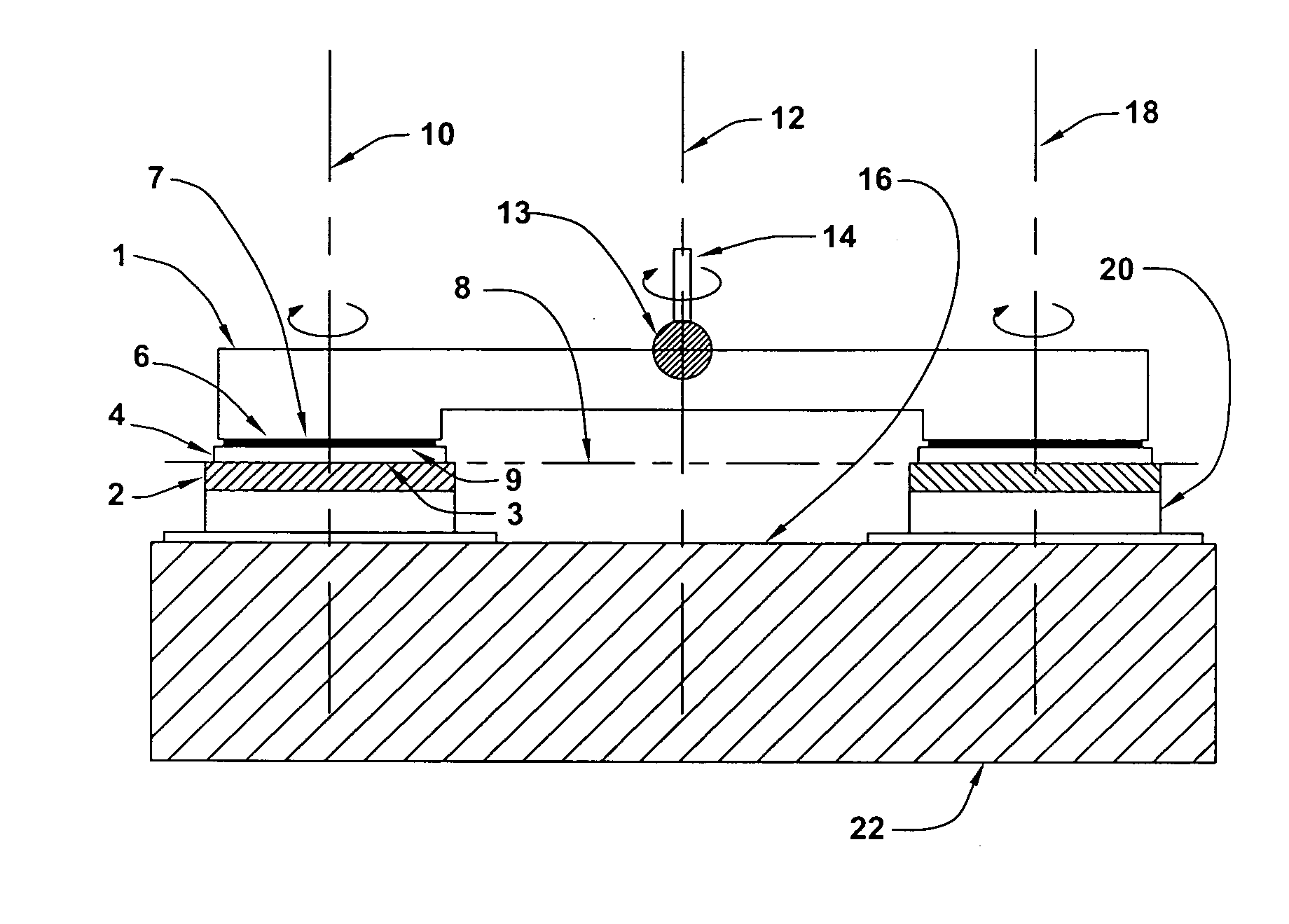

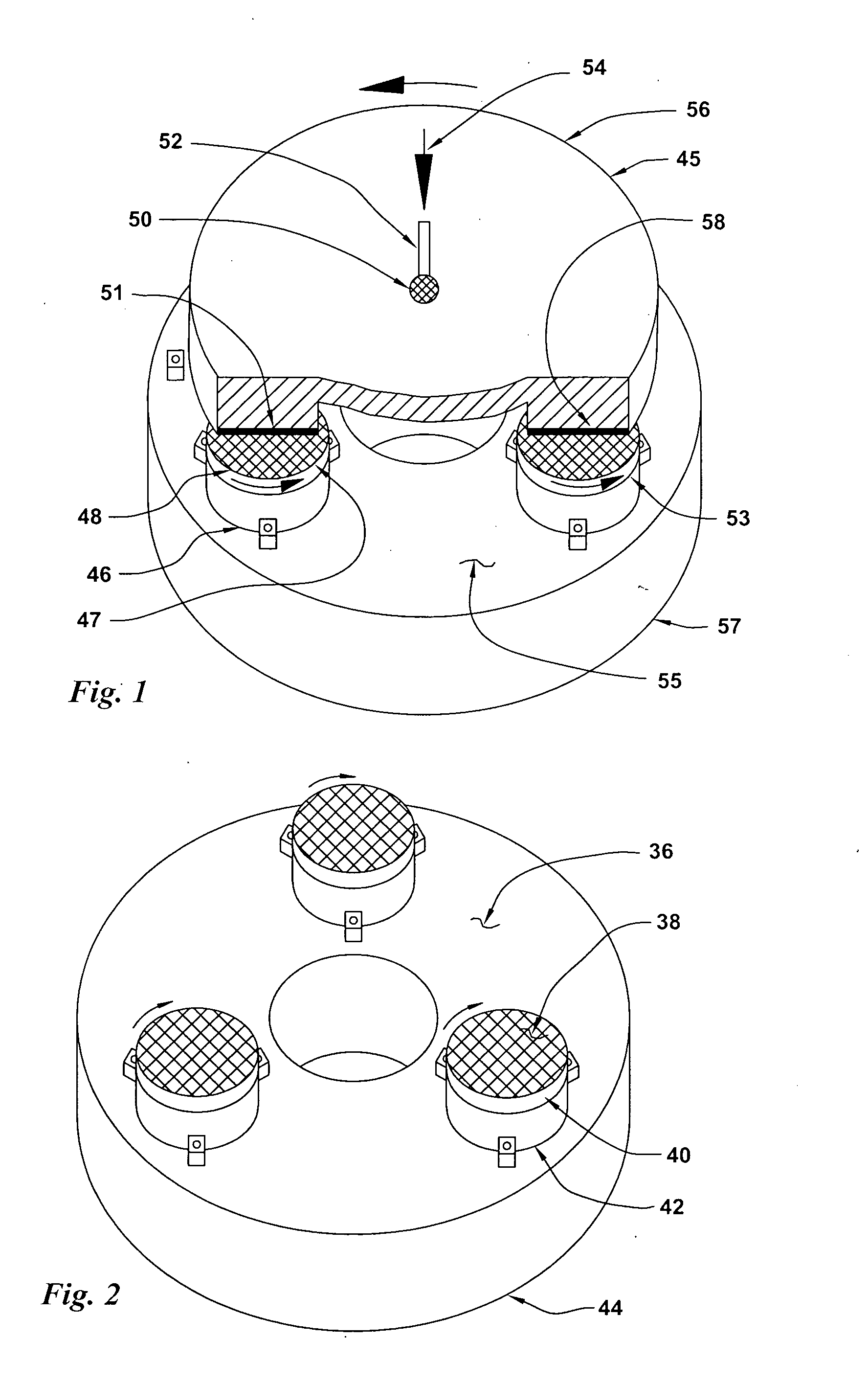

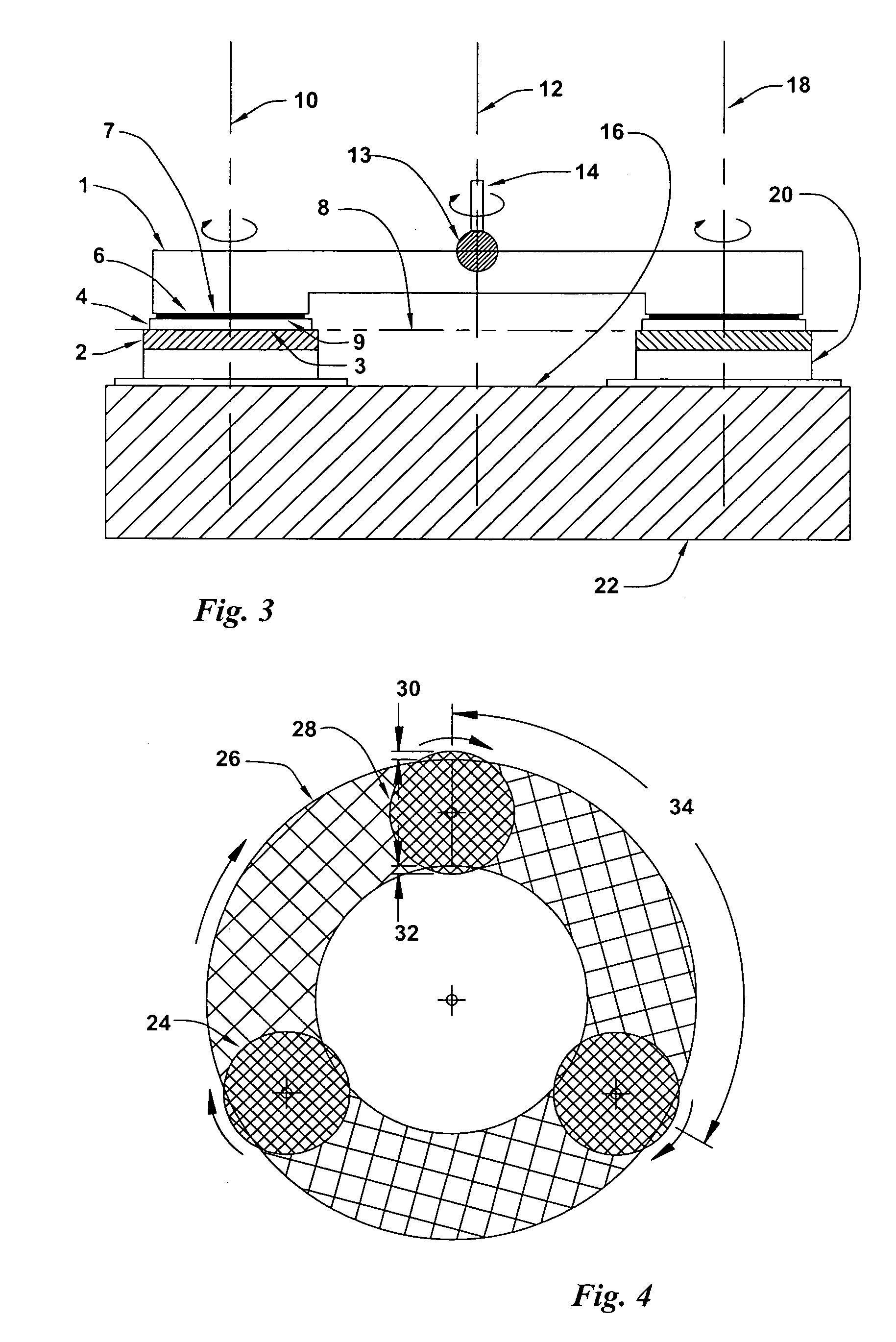

Pivot-balanced floating platen lapping machine

InactiveUS20120028545A1Long life-timeLittle maintenanceEdge grinding machinesLapping machinesDrive motorFixed position

A low friction flat-lapping abrading apparatus and method for releasably attaching flexible abrasive disks to a flat-surfaced platen that floats in three-point abrading contact with flat-surfaced workpieces that are attached to three rotary spindles. The rigid equal-height flat-surfaced rotatable fixed-position workpiece spindles are mounted on a flat abrading machine base. They are positioned to form a triangle to provide stable support of the floating platen. All three spindle-tops are co-planar aligned to provide a precision-flat reference plane for mounting of the workpieces. The lapping operation has very high abrading speeds and very low abrading forces. The lightweight but strong lapping machine employs a pivot-balance structure where the weight of the drive motor is used to balance the weight of the abrading platen. Use of low-friction air bearings provides the capability for precision control of the abrading forces. The lapping machine is robust and well suited for a harsh abrading environment.

Owner:DUESCHER WAYNE O

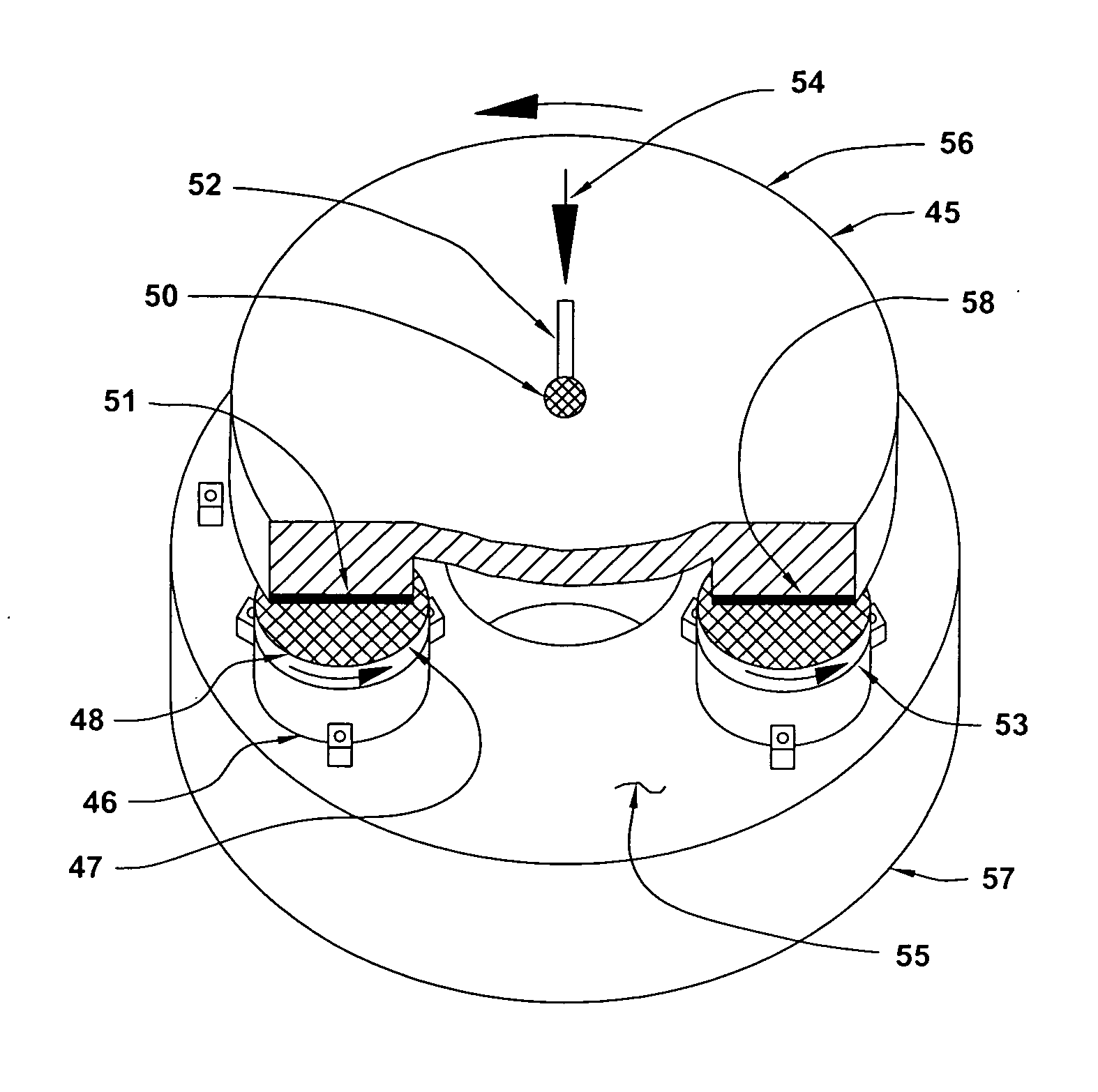

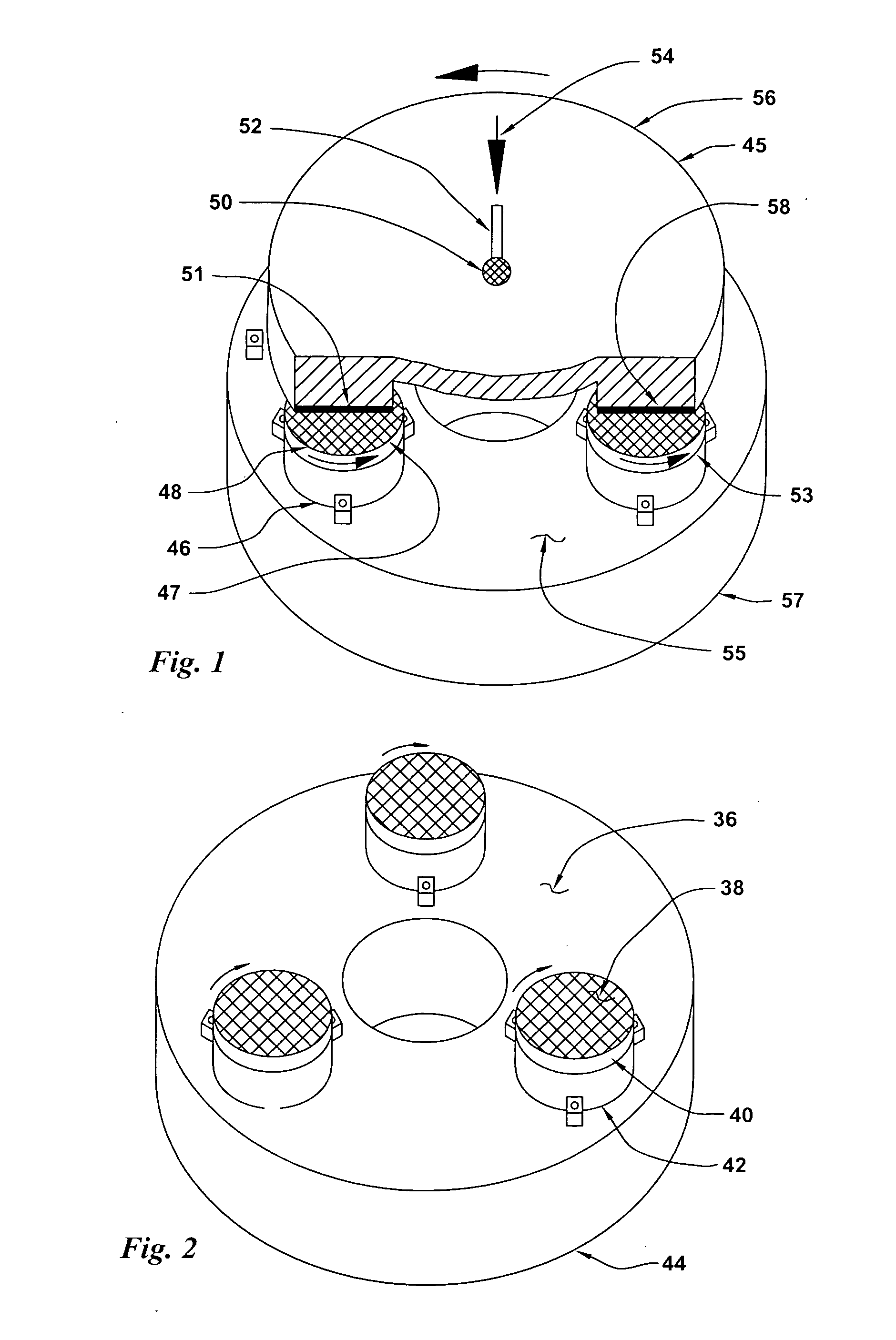

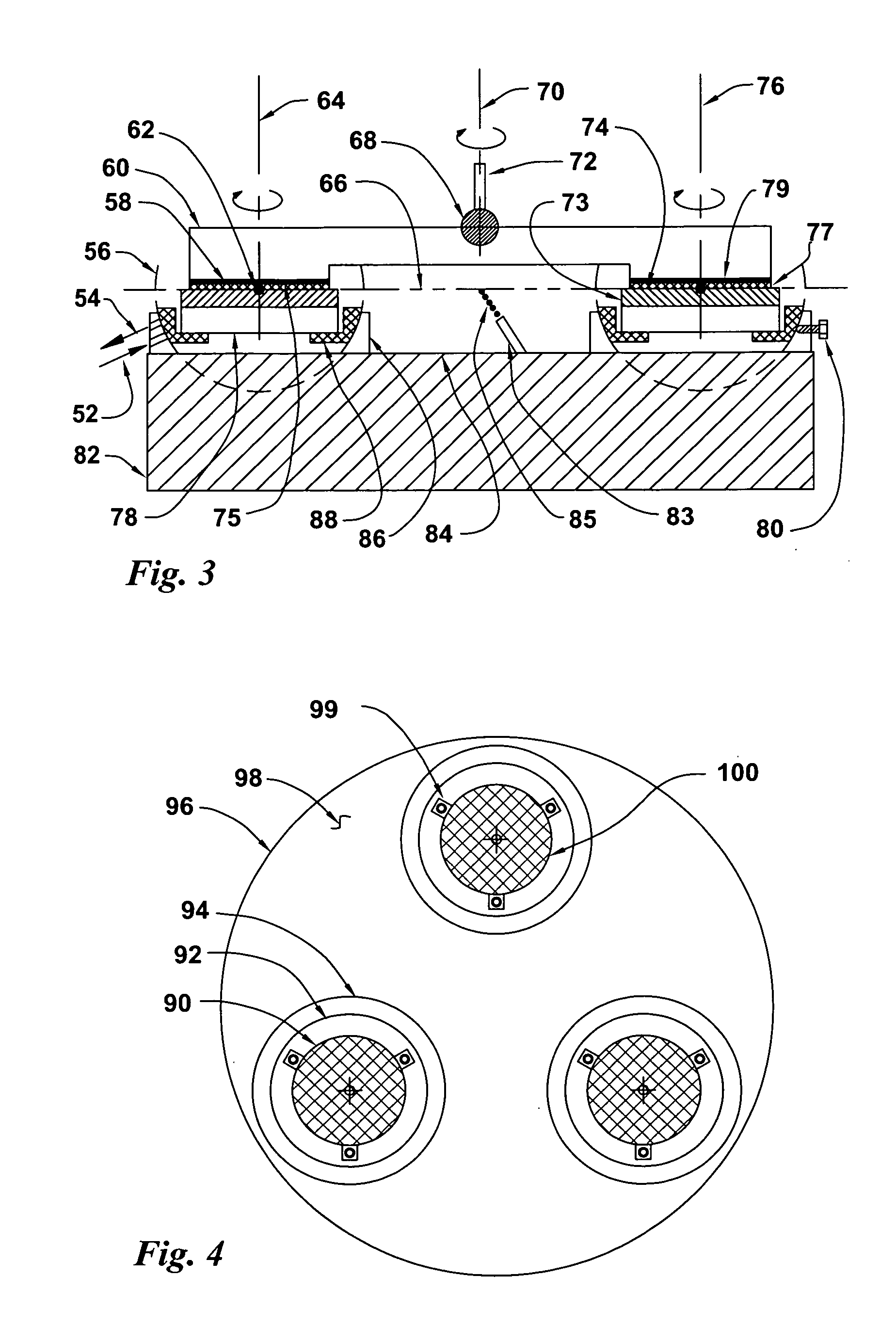

Three-point spindle-supported floating abrasive platen

InactiveUS20110223835A1Grinding speed is fastQuick changePolishing machinesRevolution surface grinding machinesCentre of rotationEngineering

A method and apparatus for releasably attaching flexible abrasive disks to a flat-surfaced platen that floats in three-point abrading contact with three rigid equal-height flat-surfaced rotatable fixed-position workpiece spindles that are mounted on a precision-flat abrading machine base where the spindle surfaces are in a common plane that is co-planar with the base surface. The three spindles are positioned to form a triangle of platen supports where the rotational-centers of each of the spindles are positioned at the center of the annular width of the platen abrading surface. Flat surfaced workpieces are attached to the spindles and the rotating floating-platen abrasive surface contacts all three rotating workpieces to perform single-sided abrading. The platen abrasive surface can be re-flattened by attaching equal-thickness abrasive disks to the three spindles that are rotated while in abrading contact with the rotating platen abrasive. There is no wear of the abrasive-disk protected platen surface.

Owner:DUESCHER WAYNE O

Fixed-spindle and floating-platen abrasive system using spherical mounts

InactiveUS20110223838A1Grinding speed is fastQuick changePolishing machinesRevolution surface grinding machinesSpherical shapedEngineering

A method and apparatus for releasably attaching flexible abrasive disks to a flat-surfaced platen that floats in three-point abrading contact with three flat-surfaced rotatable fixed-position workpiece spindles that are mounted on spherical-rotation two-piece spindle-mount devices that are attached to a nominally-flat abrading machine base. The spindle-top flat surfaces are precisely co-planar with each other. The three spindles are positioned to form a triangle of platen supports where the rotational-centers of each of the spindles are positioned at the center of the annular width of the platen abrading-surface. Flat surfaced workpieces are attached to the spindles and the rotating floating-platen abrasive surface contacts the workpieces to perform single-sided abrading on them. The disk abrasive surfaces can be re-flattened by attaching abrasive disk-type components to the three spindles that are rotated while in abrading contact with the rotating abrasive disk. There is no wear of the abrasive-disk protected platen surface.

Owner:DUESCHER WAYNE O

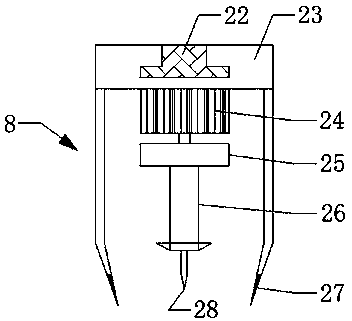

Machine part polishing and drilling integrated equipment

InactiveCN107775356AAvoid pollutionAchieve recyclingOther manufacturing equipments/toolsMaintainance and safety accessoriesControl switchWorkstation

The invention discloses a grinding and drilling integrated equipment for mechanical accessories, which includes a workbench, drilling equipment and grinding equipment. The lower end of the workbench is fixedly connected with a support column, and the upper end of the workbench is welded with a frame. One side of the bottom end of the frame is welded with a water tank, and the other side of the bottom end of the frame is provided with a control switch, and the upper end of the frame is equipped with drilling equipment on the side close to the water tank, and the drilling equipment includes a drill Hole motor and lifting cylinder, the lower end of the drilling equipment is movably connected with a clamping plate, one side of the drilling equipment is equipped with grinding equipment, and the grinding equipment includes a grinding motor and a polishing sheet. The upper end is movably connected with a lifting workbench. The grinding and drilling integrated equipment for mechanical accessories realizes the integration of drilling and grinding through the workbench, drilling equipment and grinding equipment, saving the time for processing mechanical accessories.

Owner:WUJIANG HONGRUI PRECISION MASCH FACTORY

Three-point fixed-spindle floating-platen abrasive system

InactiveUS20110223836A1Grinding speed is fastQuick changePolishing machinesRevolution surface grinding machinesCentre of rotationEngineering

A method and apparatus for releasably attaching flexible abrasive disks to a flat-surfaced platen that floats in three-point abrading contact with three rigid equal-height flat-surfaced rotatable fixed-position workpiece spindles that are mounted on a precision-flat abrading machine base where the spindle surfaces are in a common plane that is co-planar with the base surface. The three spindles are positioned to form a triangle of platen supports where the rotational-centers of each of the spindles are positioned at the center of the annular width of the platen abrading surface. Flat surfaced workpieces are attached to the spindles and the rotating floating-platen abrasive surface contacts all three rotating workpieces to perform single-sided abrading. The platen abrasive surface can be re-flattened by attaching equal-thickness abrasive disks to the three spindles that are rotated while in abrading contact with the rotating platen abrasive. There is no wear of the abrasive-disk protected platen surface.

Owner:DUESCHER WAYNE O

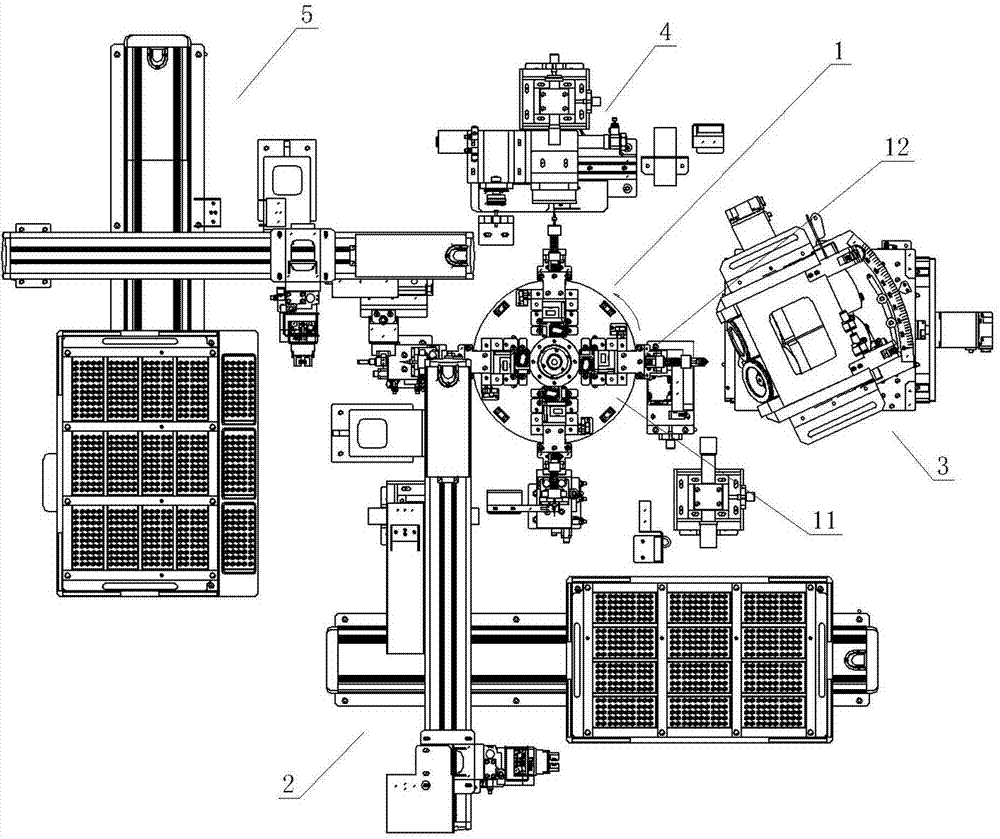

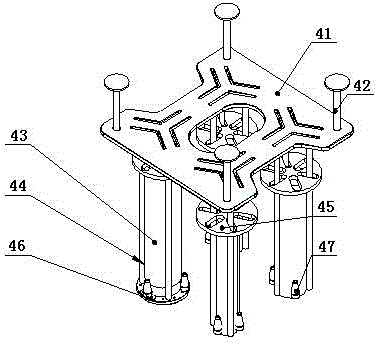

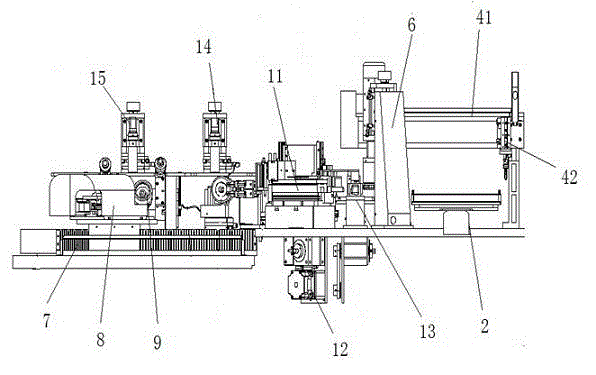

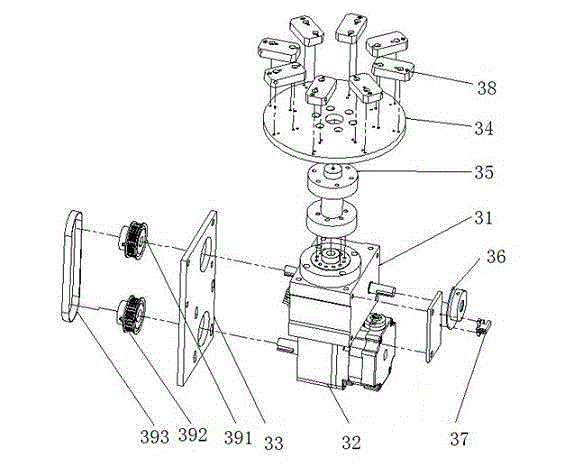

Full-automatic drill grinder

InactiveCN103567821AReduce the number of disassemblyImprove grinding pass rateGrinding feed controlDrilling toolsEngineeringMachining

The invention provides a full-automatic drill grinder. The full-automatic drill grinder comprises a transposition device as well as a feeding device, a grinding device, a detection device and a discharge device which are located around the transposition device, wherein the transposition device comprises a transposition disk and clamping heads arranged on the transposition disk, drills are mounted on the clamping heads through the feeding device, and then the transposition disk is rotated, so that the drills sequentially passes through the grinding device, the detection device and the discharge device for corresponding processing, a whole grinding process can be finished after one-time clamping, both the dismounting time of the drills and errors can be reduced, and the auxiliary time is shortened; servo motors are mounted behind the clamping heads and used for driving the drills on the clamping heads to rotate, so that grinding angles of the drills are adjusted correctly; and the drill grinder is controlled by a program and high in accuracy, the pass percent of the drills is increased, the labor condition is improved, the problems that workers are prone to fatigue and sight losing due to work under microscopes for a long time are solved, and the full-automatic drill grinder is widely applicable to grinding machining of various fine drills.

Owner:刘锦波

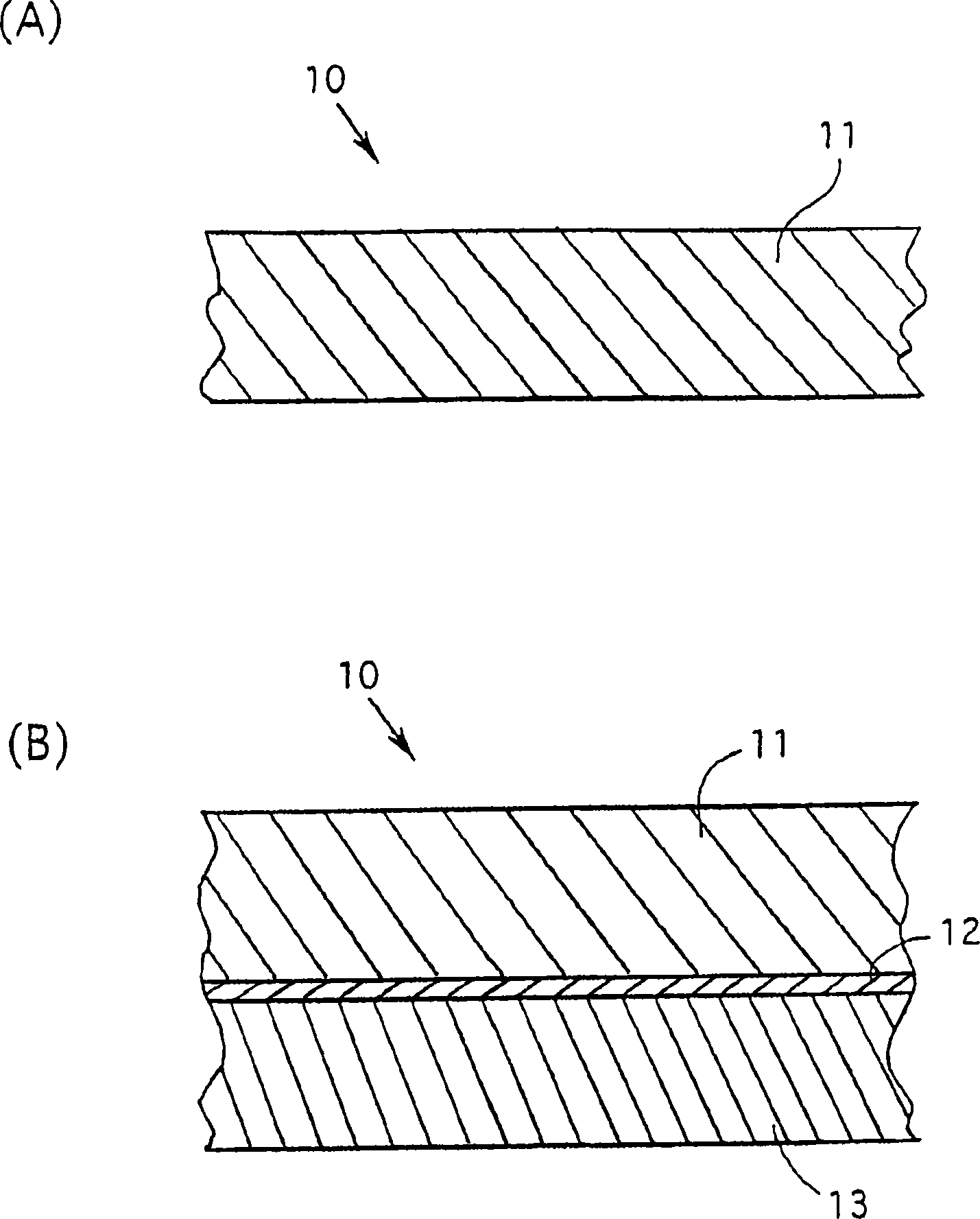

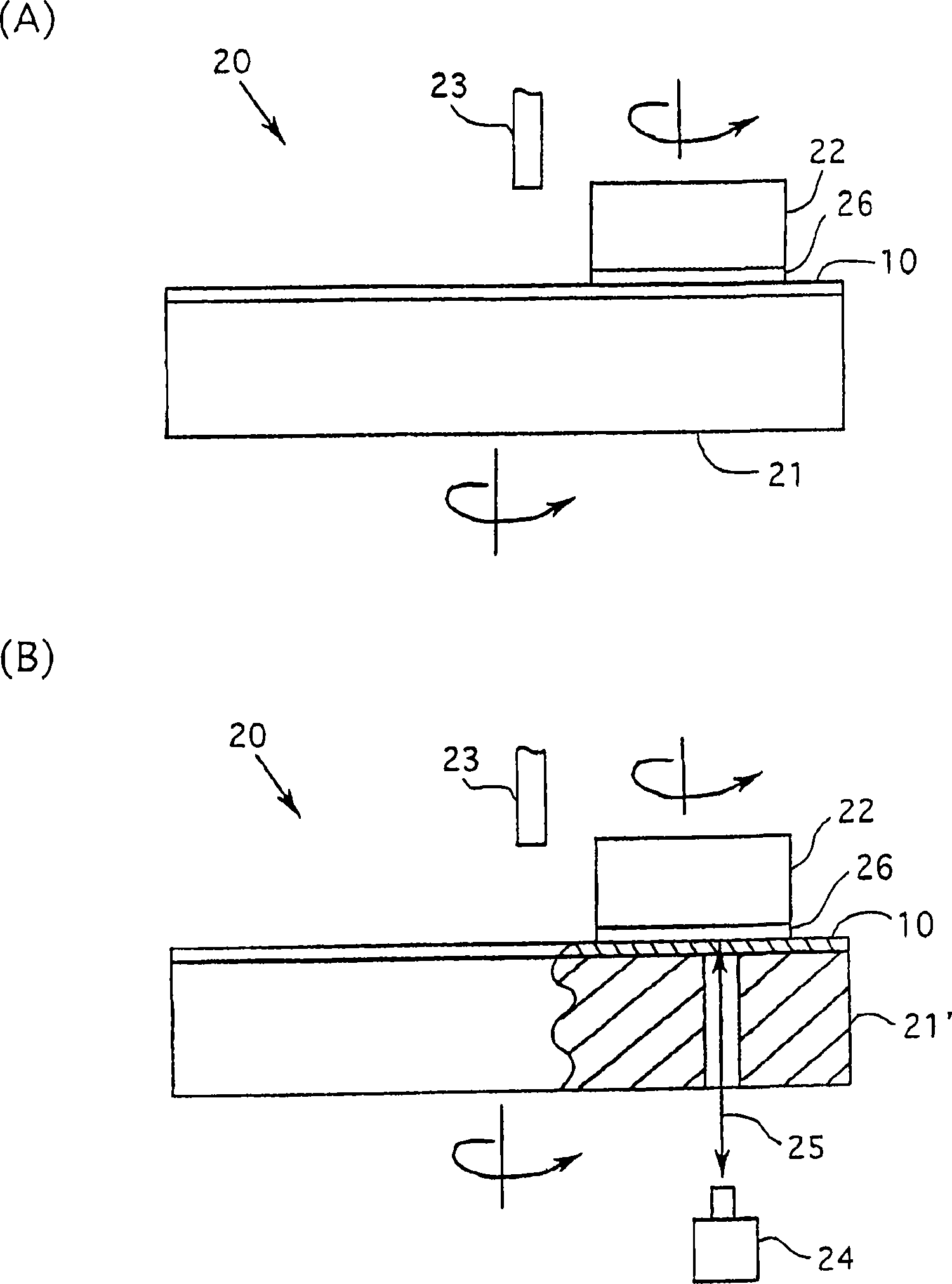

Polishing pad

InactiveCN1905991AGrinding speed is fastReduce residual step height differenceAbrasion apparatusSemiconductor/solid-state device manufacturingHardnessCompressibility

A polishing pad for planarizing the surface of a wafer has a planar main body of a non-foamed synthetic resin, having Shore D hardness of 66.0-78.5, preferably 70.0-78.5, or more preferably 70.0-78.0, compressibility of 4% or less or preferably 2% or less, and compression recovery rate of 50% or greater or preferably 70% or greater.

Owner:NIHON MICRO COATING

Efficient grinding device for graphite for 3D printing

The invention relates to a grinding device for graphite for 3D printing, in particular to an efficient grinding device for the graphite for 3D printing. The efficient grinding device for the graphite for 3D printing is even, thorough and fast in grinding. The efficient grinding device for the graphite for 3D printing comprises a bottom plate, a left rack, a right rack, guiding sleeves, a top plate, a first supporting rod, a first large belt pulley, a motor, rotating rods, a first guiding rod, a second guiding rod and a movable frame. Two second supporting rods are arranged in symmetry with respect to the center of the top of the bottom plate; a collecting frame is arranged on the top, located between the two second supporting rods, of the bottom plate; a second spring is arranged at the top end of each second supporting rod; a grinding frame is arranged at the top ends of the second springs; and a net plate is arranged in the center of the bottom of the grinding frame. According to the efficient grinding device, the effects of even, thorough and fast grinding are achieved due to the action of a first reinforcing rib and a second reinforcing rib.

Owner:浙江泰嘉光电科技有限公司

Board right-angle side polishing device for architectural decoration and finishing

InactiveCN107097119ASimple structureEasy to useEdge grinding machinesGrinding drivesCouplingEngineering

The invention discloses a board right-angle side polishing device for architectural decoration and finishing. The board right-angle side polishing device comprises a first right-angle plate and a second right-angle plate, the first right-angle plate and the second right-angle plate are connected perpendicularly, the second right-angle plate is located on the right upper side of the first right-angle plate, and a motor seat is fixedly connected to the middle of the left side of the first right-angle plate; and a motor is fixedly connected on the motor seat, a coupling is fixedly connected with an output end of the motor, a driving rotary shaft is fixedly connected to the right end of the coupling, and the driving rotary shaft is connected with the first right-angle plate through a bearing in a rotating mode. Compared with the prior art, the board right-angle side polishing device has the beneficial effects that the structure is simple, use is convenient, and the board right-angle side polishing device can conduct polishing on right-angle rough selvedges of a board directly in the using process, so that the condition that the perpendicularity of two right-angle sides is reduced caused by a traditional manual polishing process; and in addition, the polishing speed is high through the mode that reciprocating polishing and rotating polishing are matched with each other, a user can conduct polishing according to polishing needs, and therefore the board right-angle side polishing device is very convenient, and worth being promoted and used.

Owner:河南万创技术服务有限公司

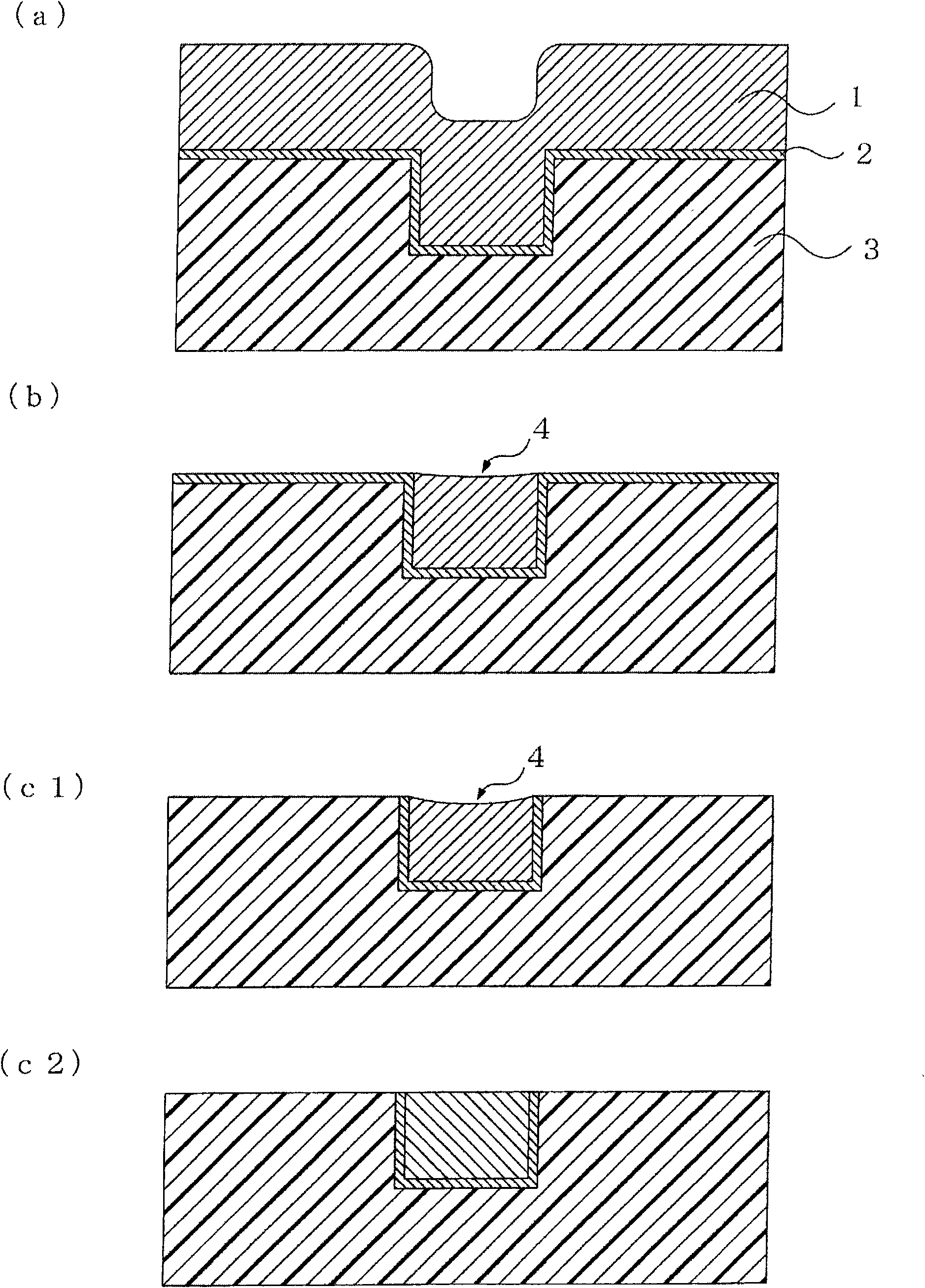

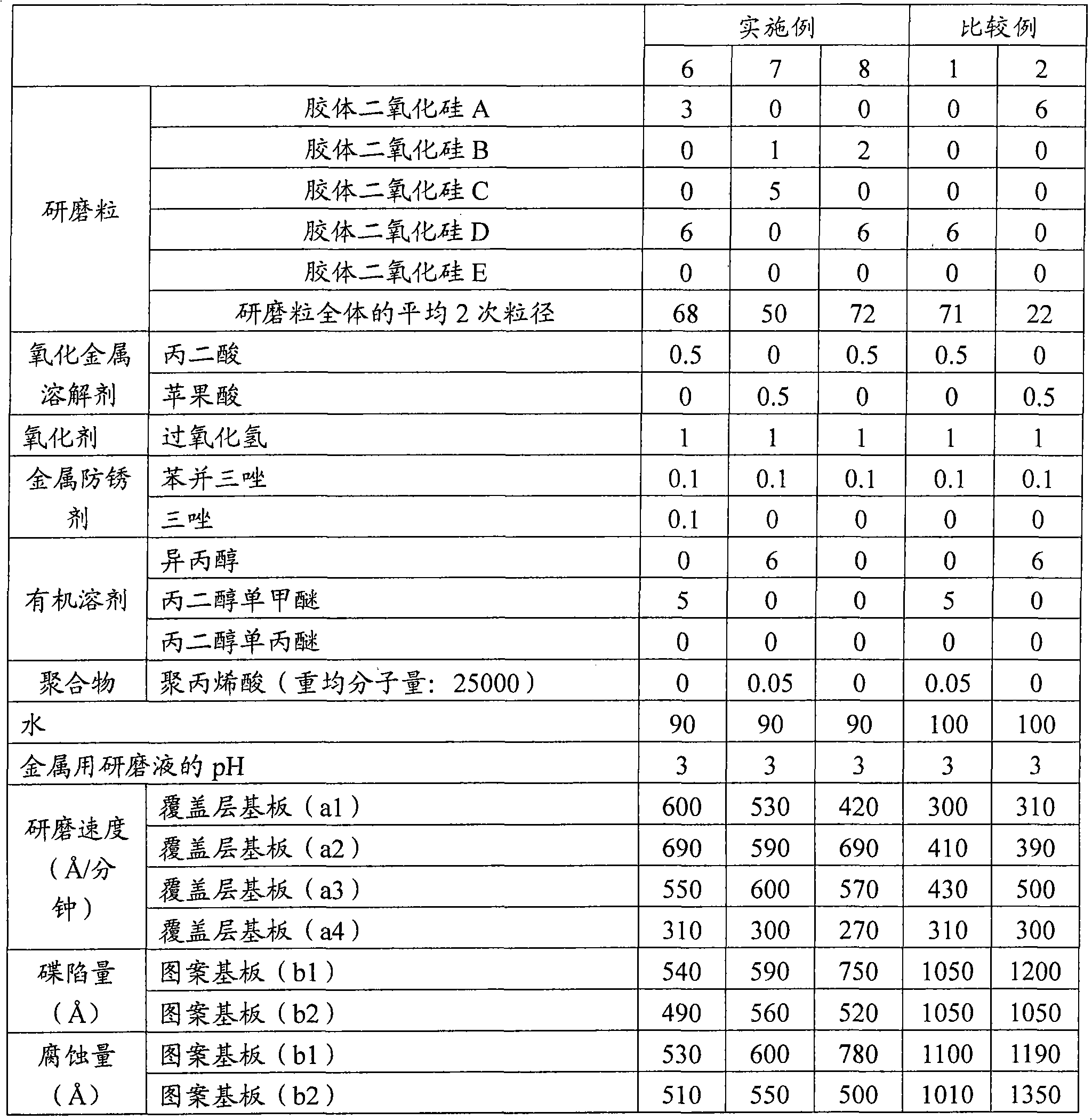

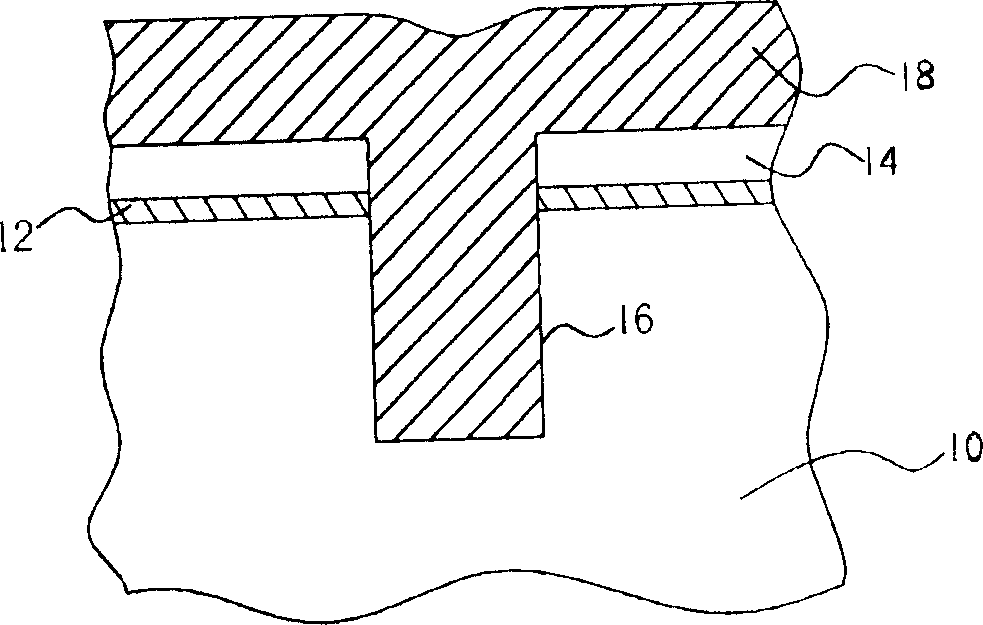

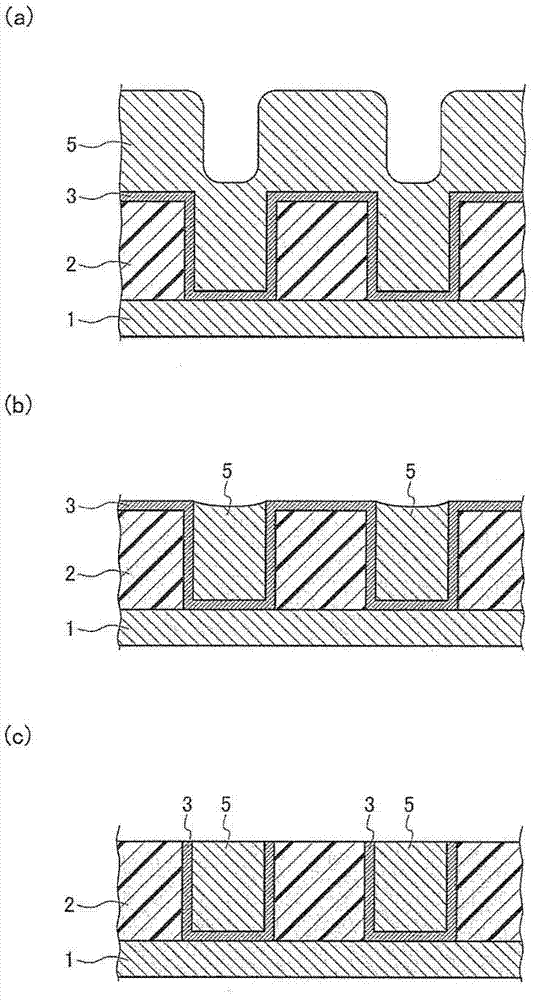

Metal polishing liquid and polishing method

ActiveCN101611476AGrinding speed is fastImprove flatnessOther chemical processesSemiconductor/solid-state device manufacturingMiniaturizationSemiconductor

Disclosed is a metal polishing liquid containing abrasive grains, a metal oxide dissolving agent and water. This metal polishing liquid is characterized by containing two or more kinds of abrasive grains having different average secondary particle diameters. Also disclosed is a polishing method using such a metal polishing liquid, which enables to polish an interlayer insulating film at a high polishing rate while ensuring high flatness in the polished surface. This polishing method is suitable for a highly reliable low-cost semiconductor device which is excellent in miniaturization, reduction of film thickness, dimensional accuracy and electrical characteristics.

Owner:RESONAC CORP

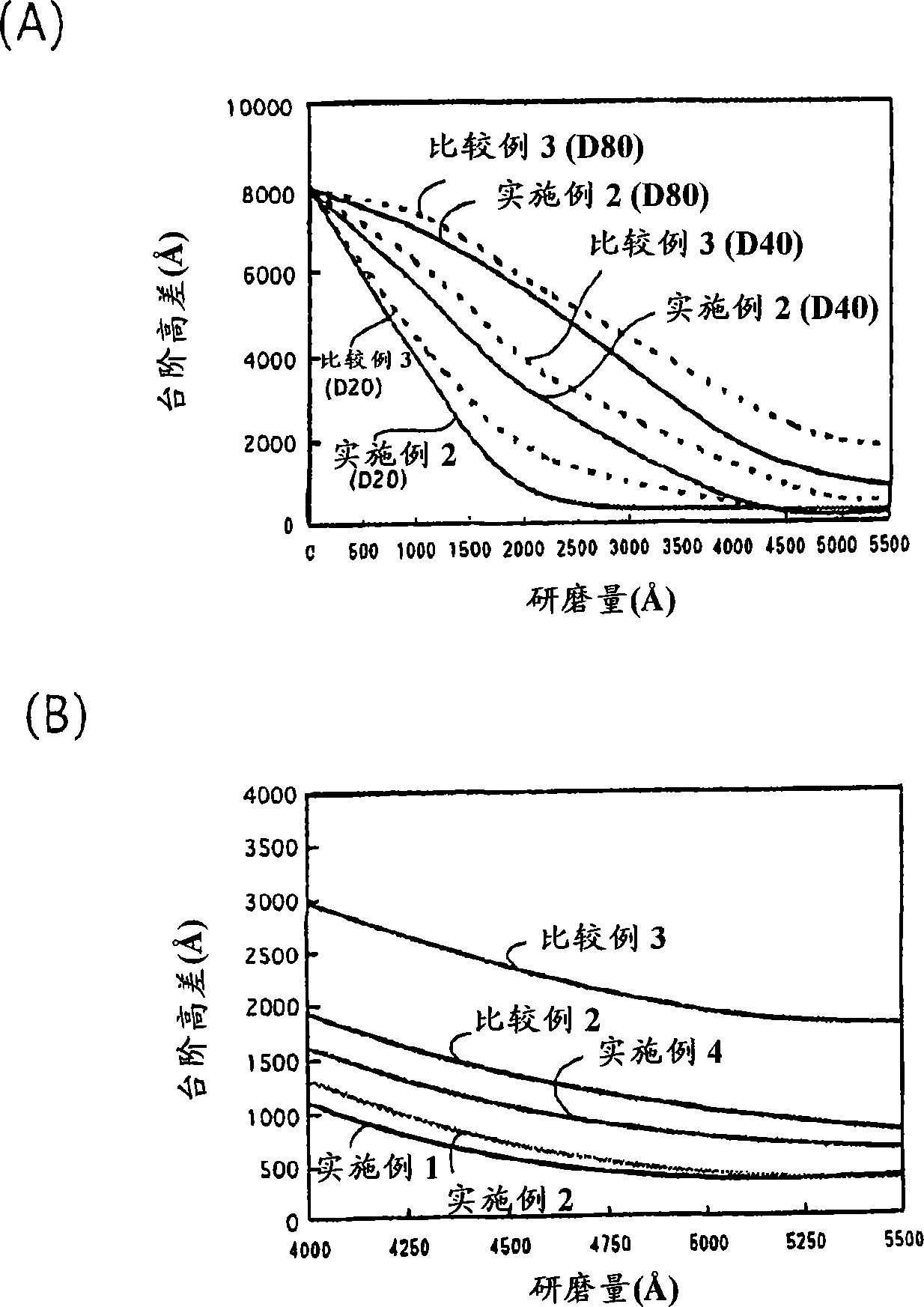

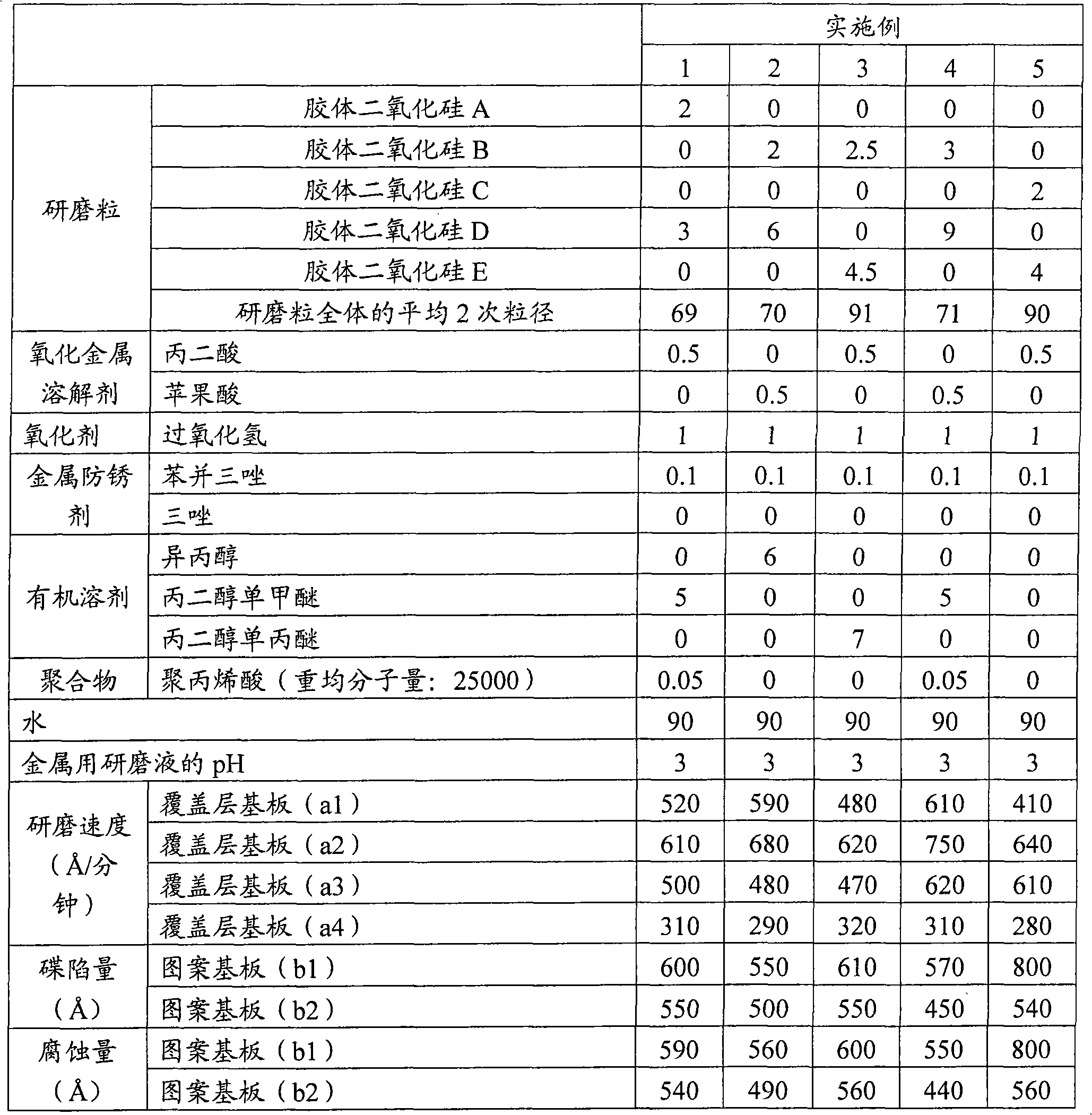

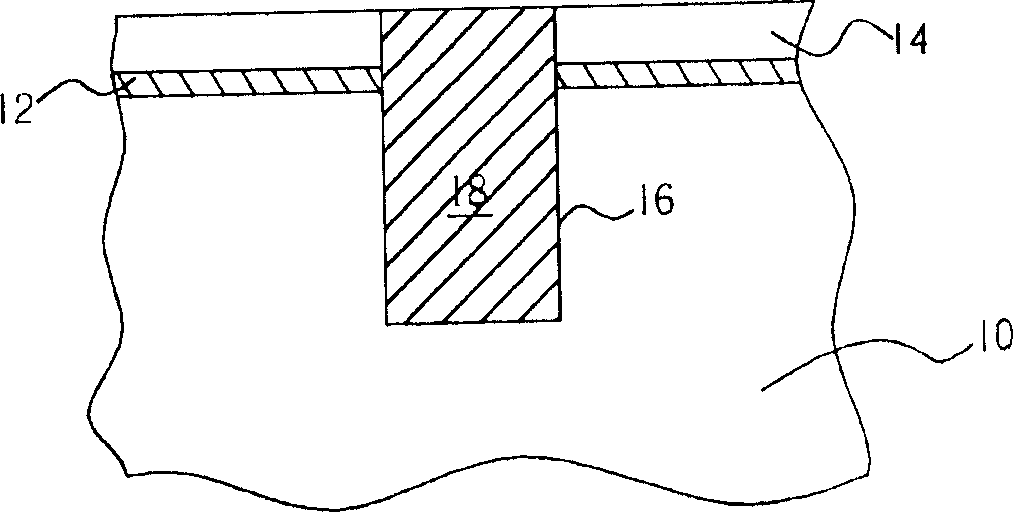

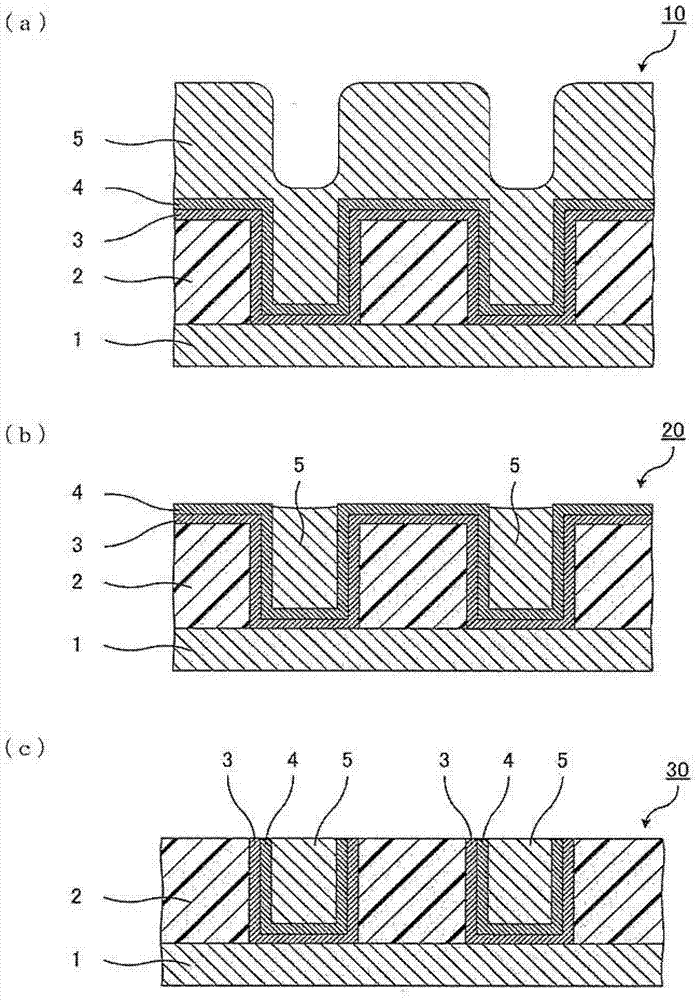

Abrasive composition and method for manufacturing semiconductor integrated circuit device

InactiveCN102210013AGrinding speed is fastInhibit grinding speedOther chemical processesSemiconductor/solid-state device manufacturingColloidal silicaResin acid

An abrasive composition which is used during the pattern formation wherein buried copper wiring and insulating layers are alternately formed by grinding each copper layer which is formed on each insulating layer via a barrier layer, specifically in a process wherein each copper layer is ground until the barrier layer adjacent thereto is exposed. The abrasive composition contains an alicyclic resin acid, a colloidal silica and tetramethylammonium ions. The colloidal silica is contained in an amount of 0.1-1.5% by mass relative to the abrasive composition, and has an average primary particle diameter of 10-40 nm and an average secondary particle diameter of 30-80 nm, with the value obtained by multiplying the average secondary particle diameter by the amount thereof contained in the composition being within the range of 10-40.

Owner:ASAHI GLASS CO LTD

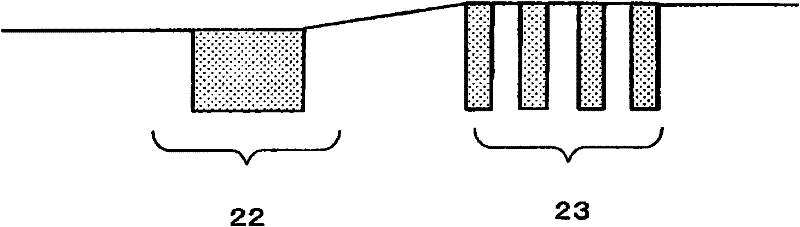

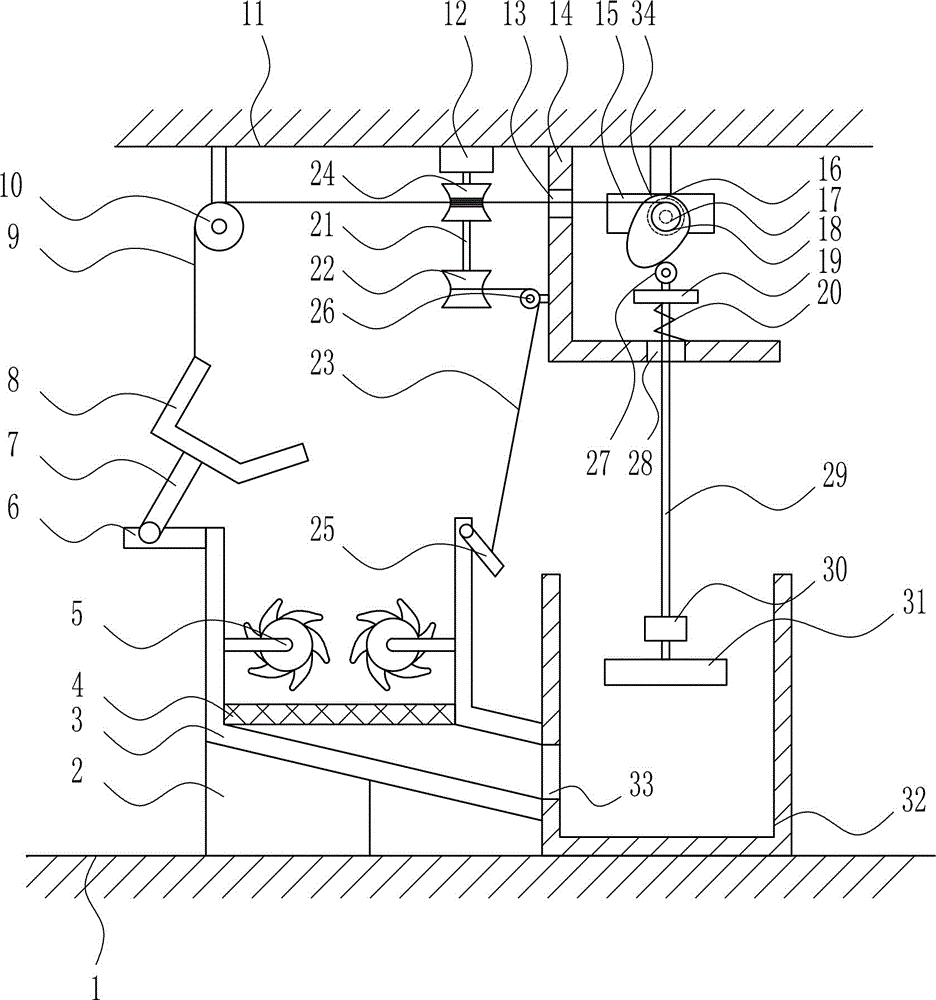

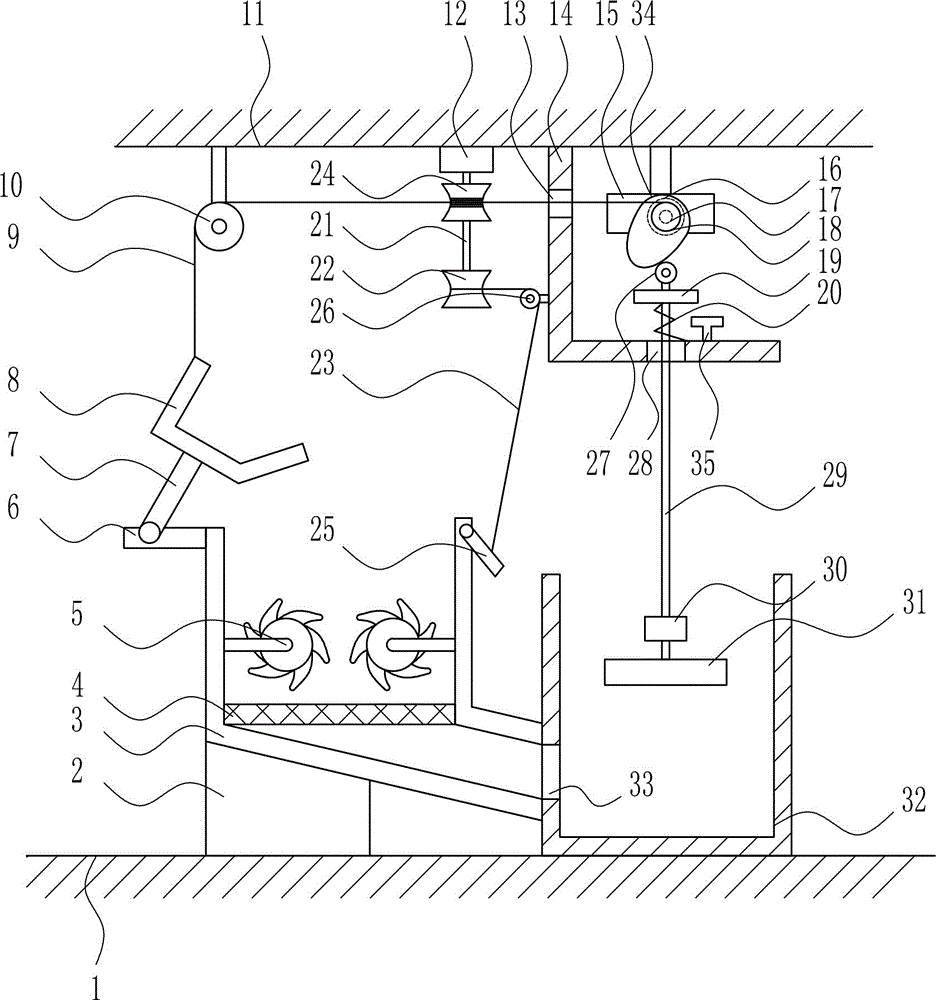

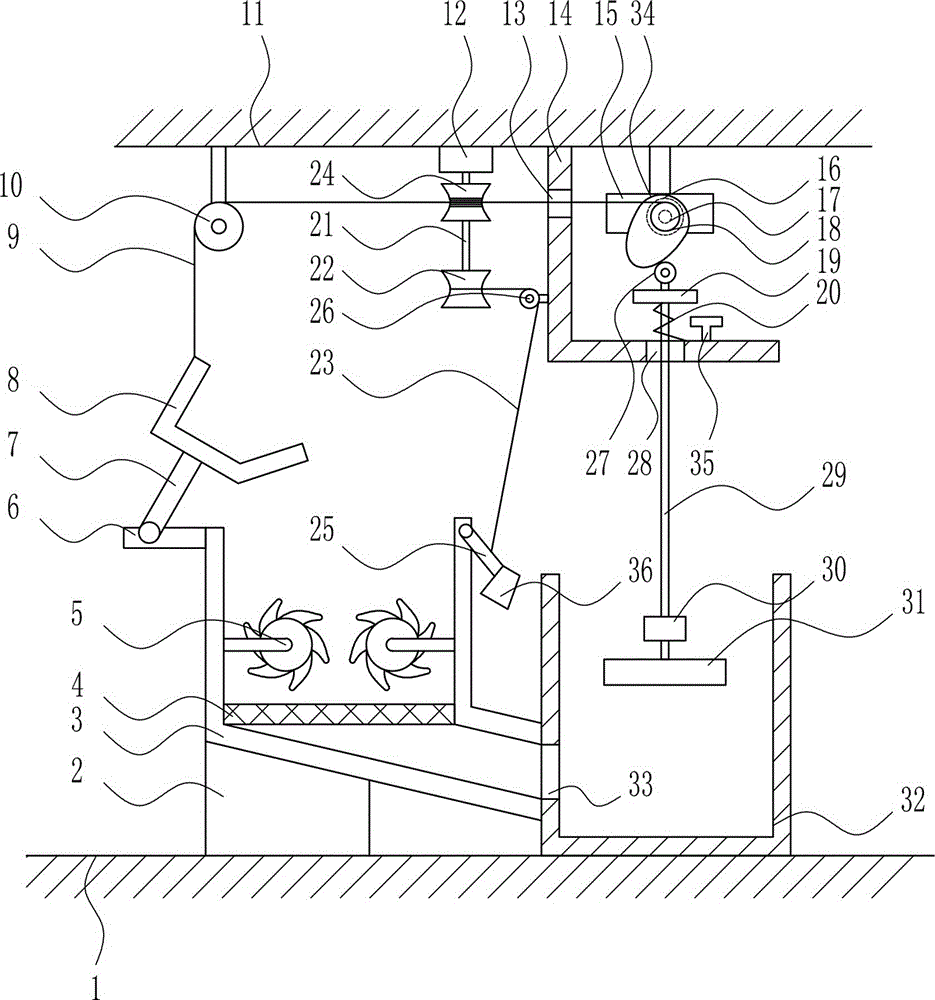

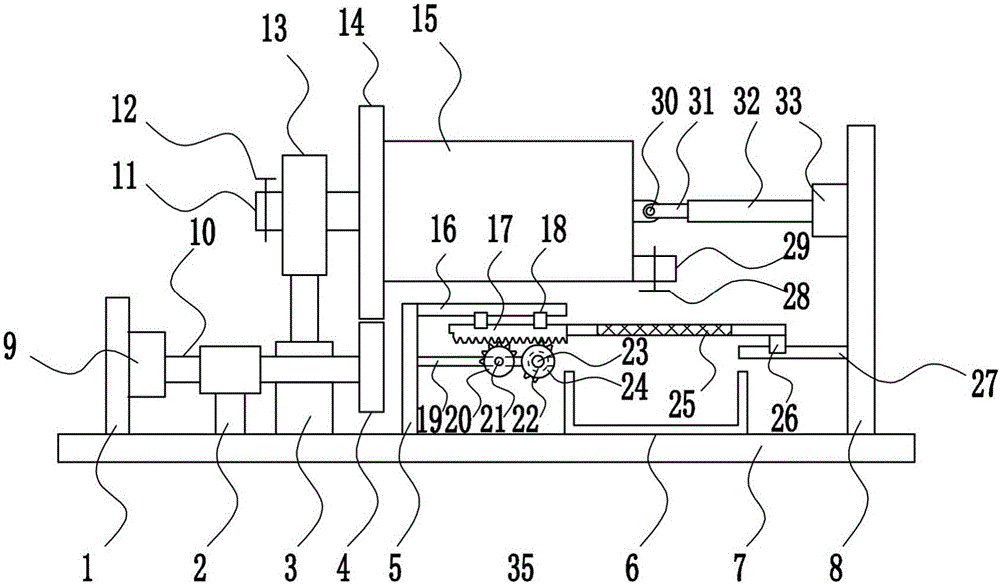

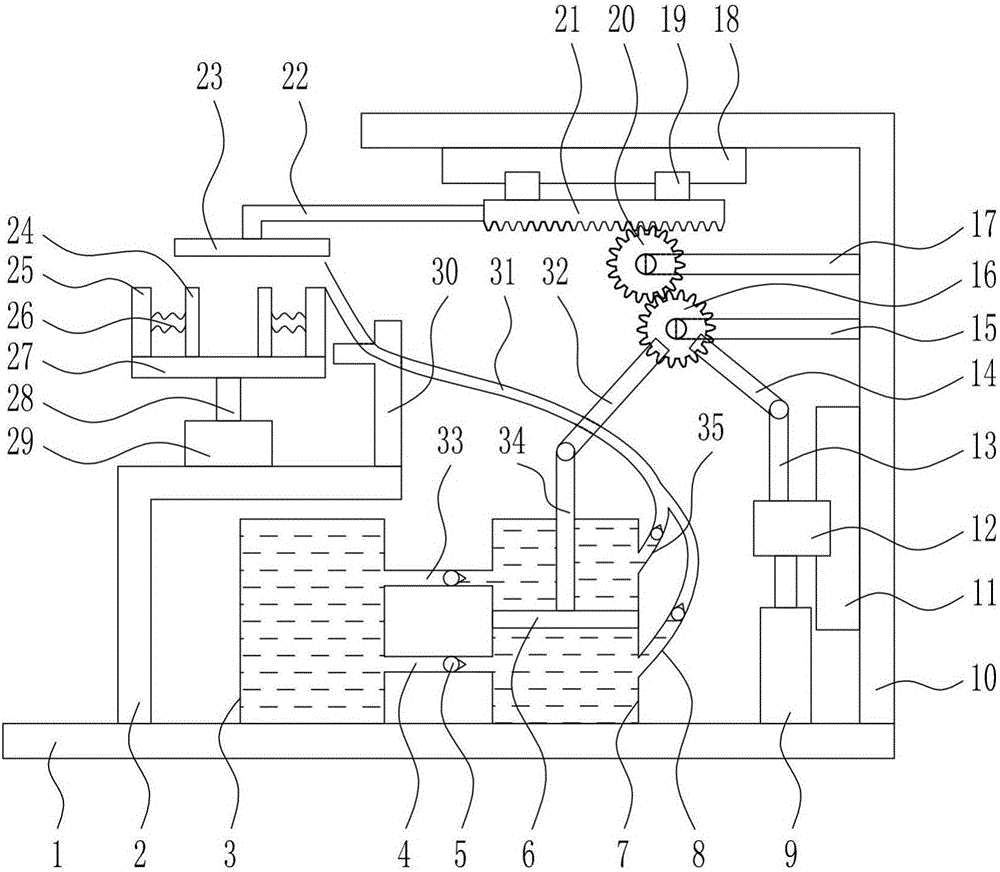

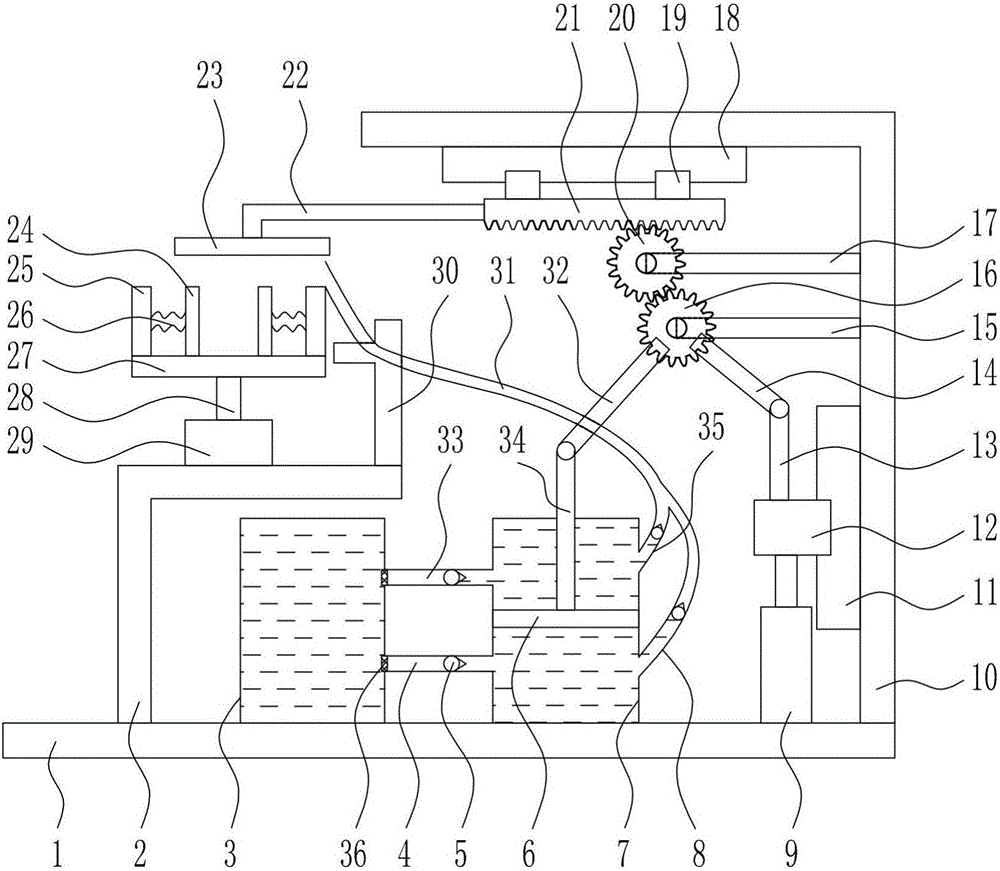

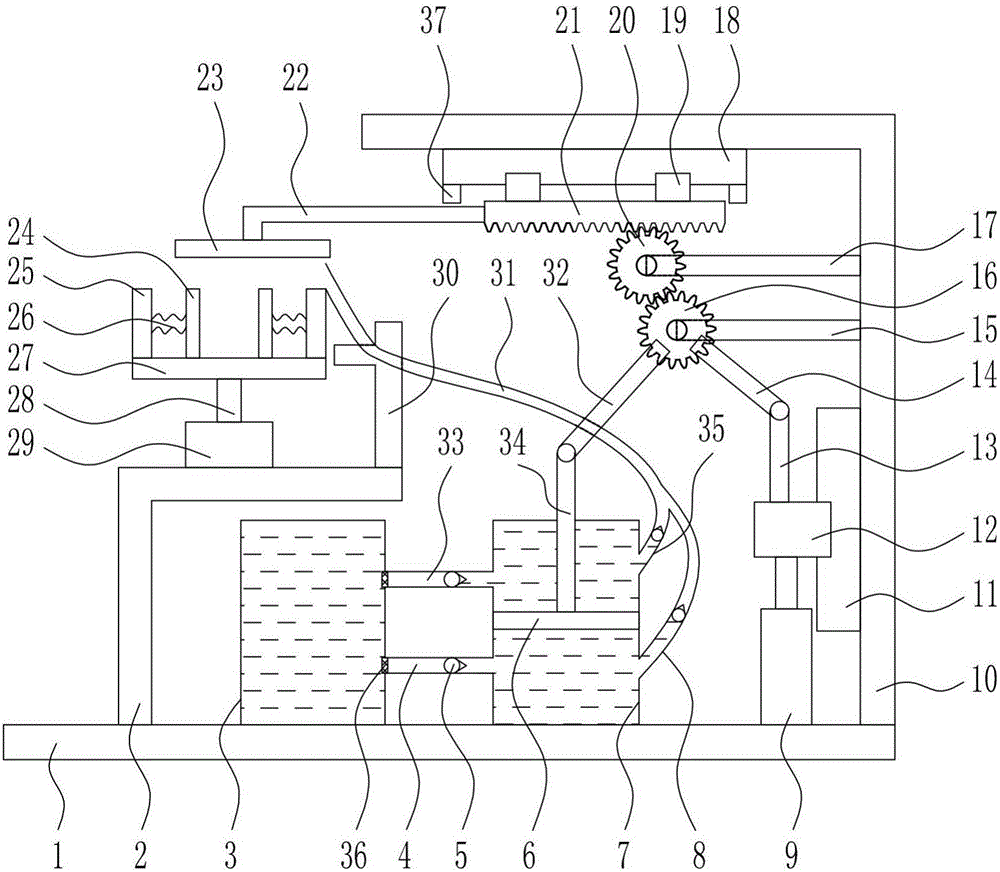

Grinding device for industrial cement manufacturing

InactiveCN106140422AImprove grinding effectGrinding speed is fastGrain treatmentsGrinding wheelConductor Coil

The invention relates to a grinding device, in particular to a grinding device for industrial cement manufacturing. The technical problem to be solved by the invention is to provide the grinding device for industrial cement manufacturing with high grinding efficiency. In order to solve the technical problem, the invention provides the grinding device for industrial cement manufacturing. The grinding device for industrial cement manufacturing comprises a support table, a crushing box, a filter screen, electric crushing wheels, a support rod, a connecting rod, a placing frame, a first pull rope, a first fixed pulley, a first bearing base, a guide plate, a second bearing base, a first rotating motor, a first rotating shaft, a third wire winding wheel, a fixed block, an elastic element, a second rotating shaft, a second wire winding wheel, a second pull rope, a first wire winding wheel, a beating rod and the like; the support table and the grinding box are arranged on the ground; and the grinding box is positioned on the right side of the support table. The grinding device for industrial cement manufacturing achieves the effects of fast grinding speed, high grinding efficiency, long service life, simple structure, low manufacturing cost and simple operation.

Owner:鄂星峄

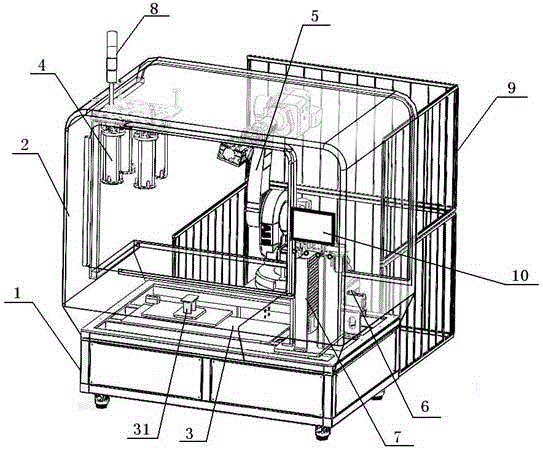

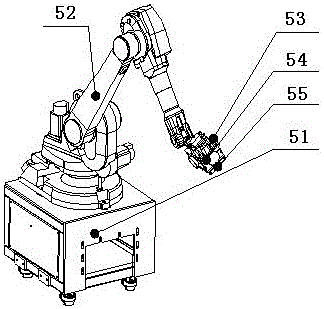

Mechanical arm grinding device

ActiveCN105666283AImprove grinding effectGrinding speed is fastGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a mechanical arm grinding device. The mechanical arm grinding device comprises a rack, a shell, a jig fixing table, an automatic abrasive paper feeding mechanism, a grinding mechanism, an automatic abrasive paper tearing mechanism and an automatic feeding mechanism. The shell is vertically arranged at the upper portion of the rack, and the jig fixing table is horizontally arranged at the upper portion of the rack. The automatic abrasive paper feeding mechanism is arranged on the top of the inner wall of the shell. The automatic abrasive paper tearing mechanism and the automatic feeding mechanism are both arranged on the jig fixing table. The automatic abrasive paper tearing mechanism is arranged on one side edge of the automatic feeding mechanism. The grinding mechanism is movably arranged on one side edge of the rack and extends to be close to the automatic abrasive paper feeding mechanism in the shell. By means of the manner, the whole back face of a mobile phone shell is ground, the side face of the mobile phone shell is subjected to profiling grinding, and the position accuracy and the production efficiency are guaranteed through the grinding mechanism. Meanwhile, the mechanical arm grinding device has the beneficial effects of being simple in appearance, compact in structure, small in occupied space, convenient to move and place, convenient to operate, capable of being controlled in a full-automatic manner, simple, fast and the like.

Owner:江苏华航威泰机器人科技有限公司

Ball-milling equipment for raw materials for producing lithium battery

ActiveCN106311407AImprove plasticityGood welding performanceSievingScreeningBiochemical engineeringEngineering

The invention relates to ball-milling equipment, and particularly relates to ball-milling equipment for raw materials for producing a lithium battery. The invention aims at providing ball-milling equipment for raw materials for producing lithium battery, which has a simple structure and is convenient to operate and fast in milling speed. The ball-milling equipment comprises a left frame, a first bearing seat, an electric push rod, a pinon gear, a baffle plate, a collection frame, a bottom plate, a right frame, a first motor, a first rotating shaft, a feed inlet, a first electrical valve and the like; the left frame is welded on the left end of the top of the bottom plate, the left side of the top of the bottom plate is connected with the first bearing seat and the electric push rod through a bolt connection mode, and the first bearing seat is positioned on the right side of the left frame. The ball-milling equipment achieves the effects of being simple in structure, convenient to operate and fast in milling speed, the ball-milling operation of production raw materials of lithium batteries can be rapidly realized by working staffs through the equipment, not only does the operation be simple, but also the ball-milling equipment is time-saving and effort-saving.

Owner:烟台锂能环保科技有限公司

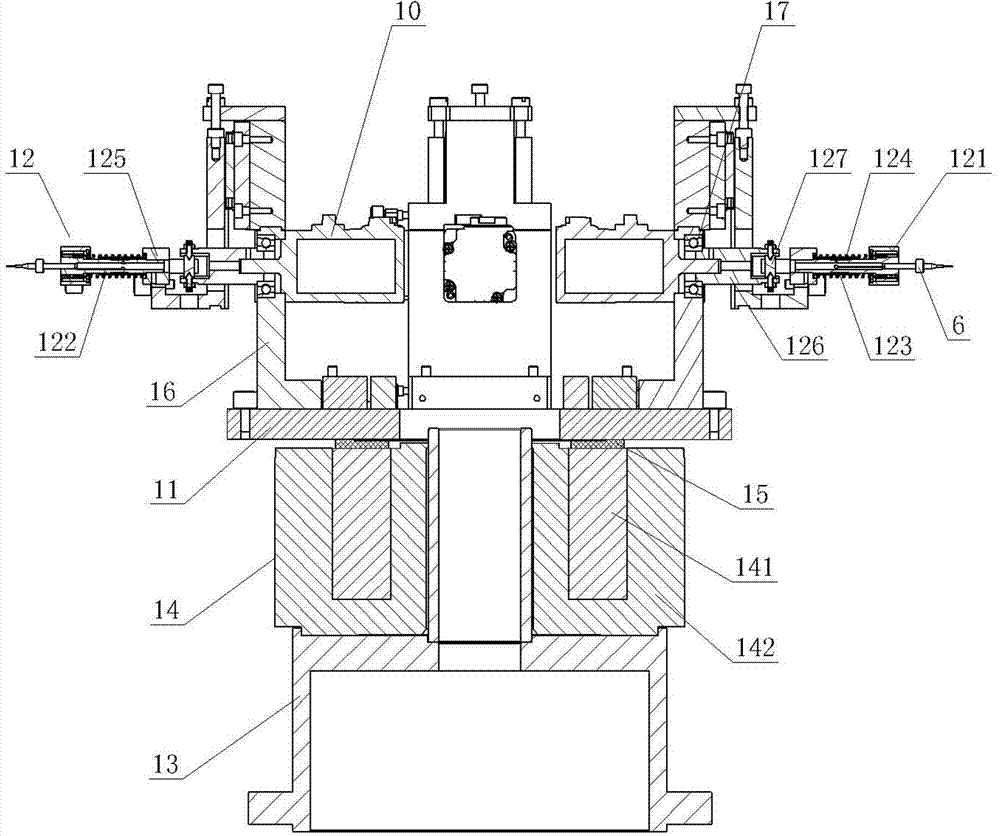

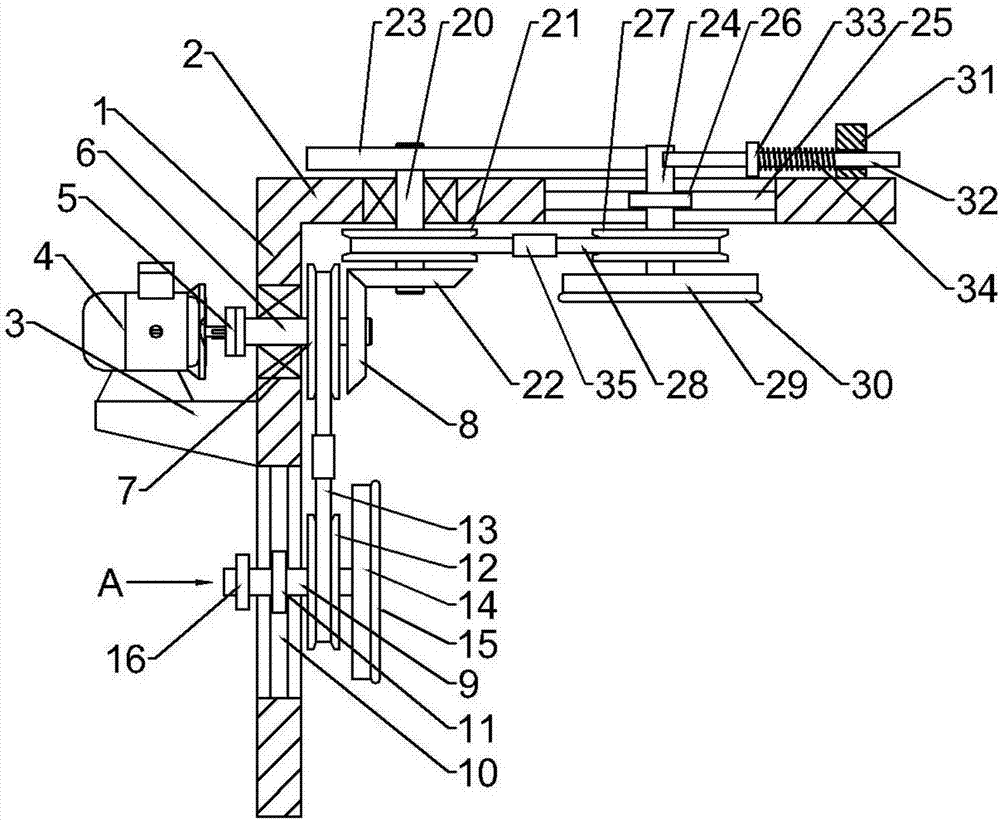

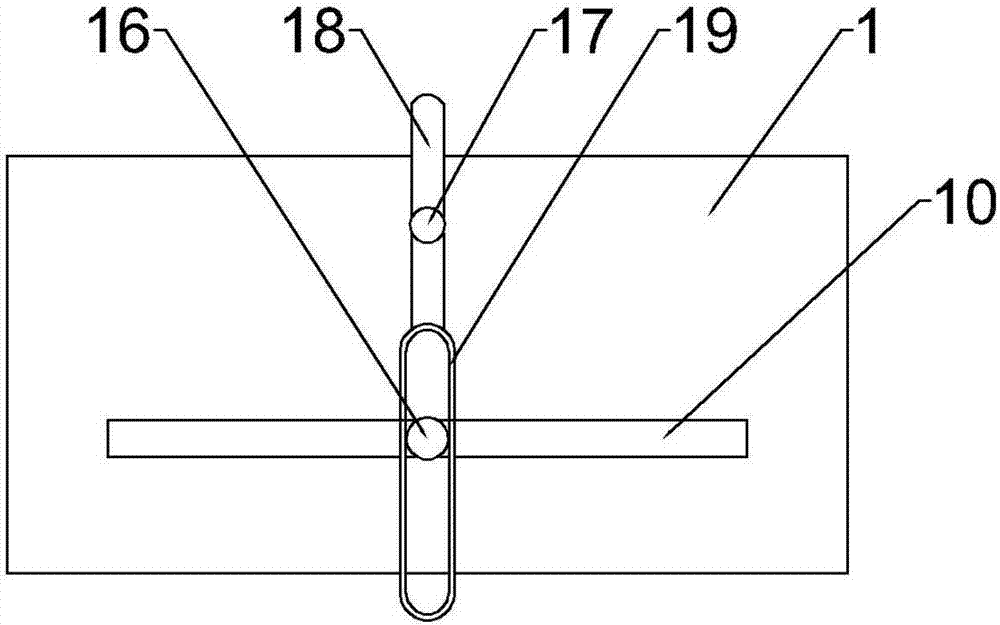

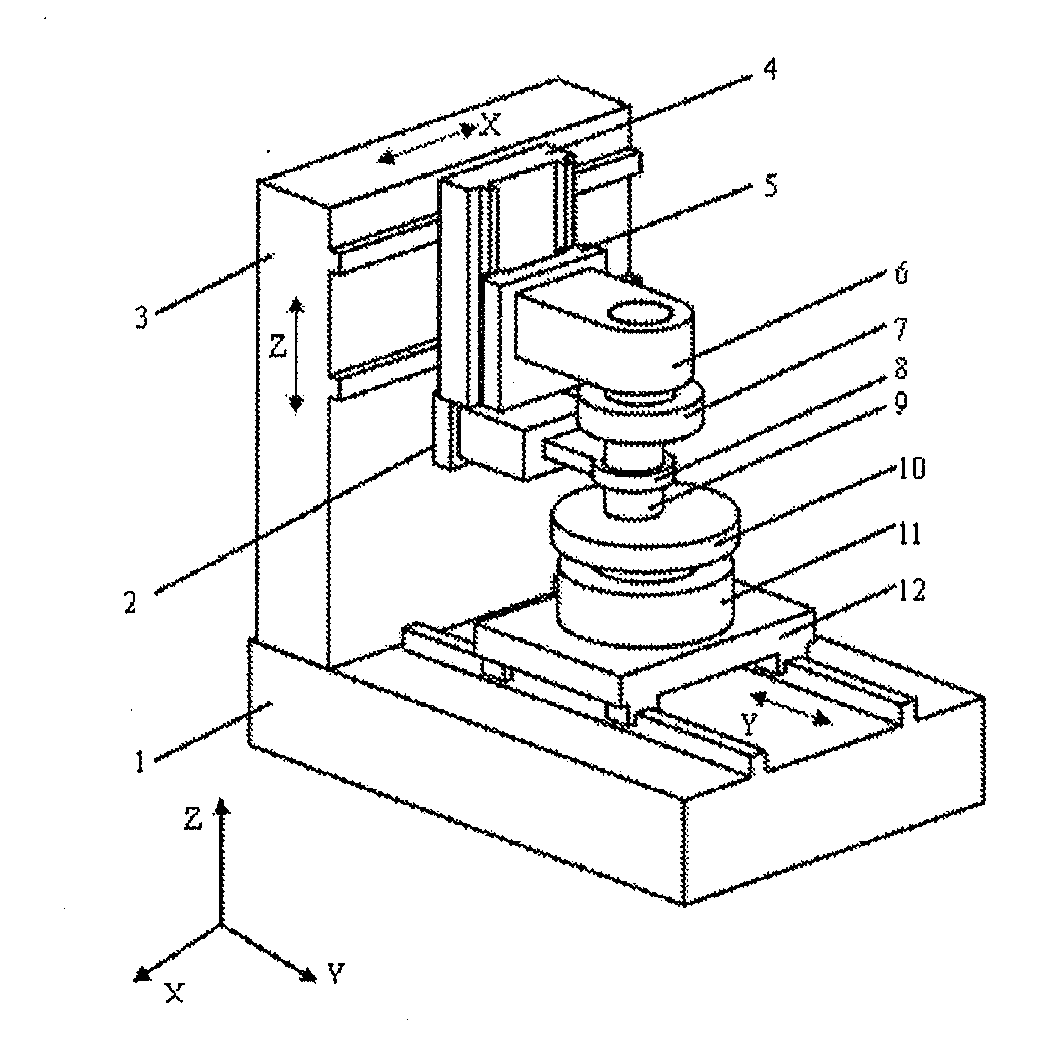

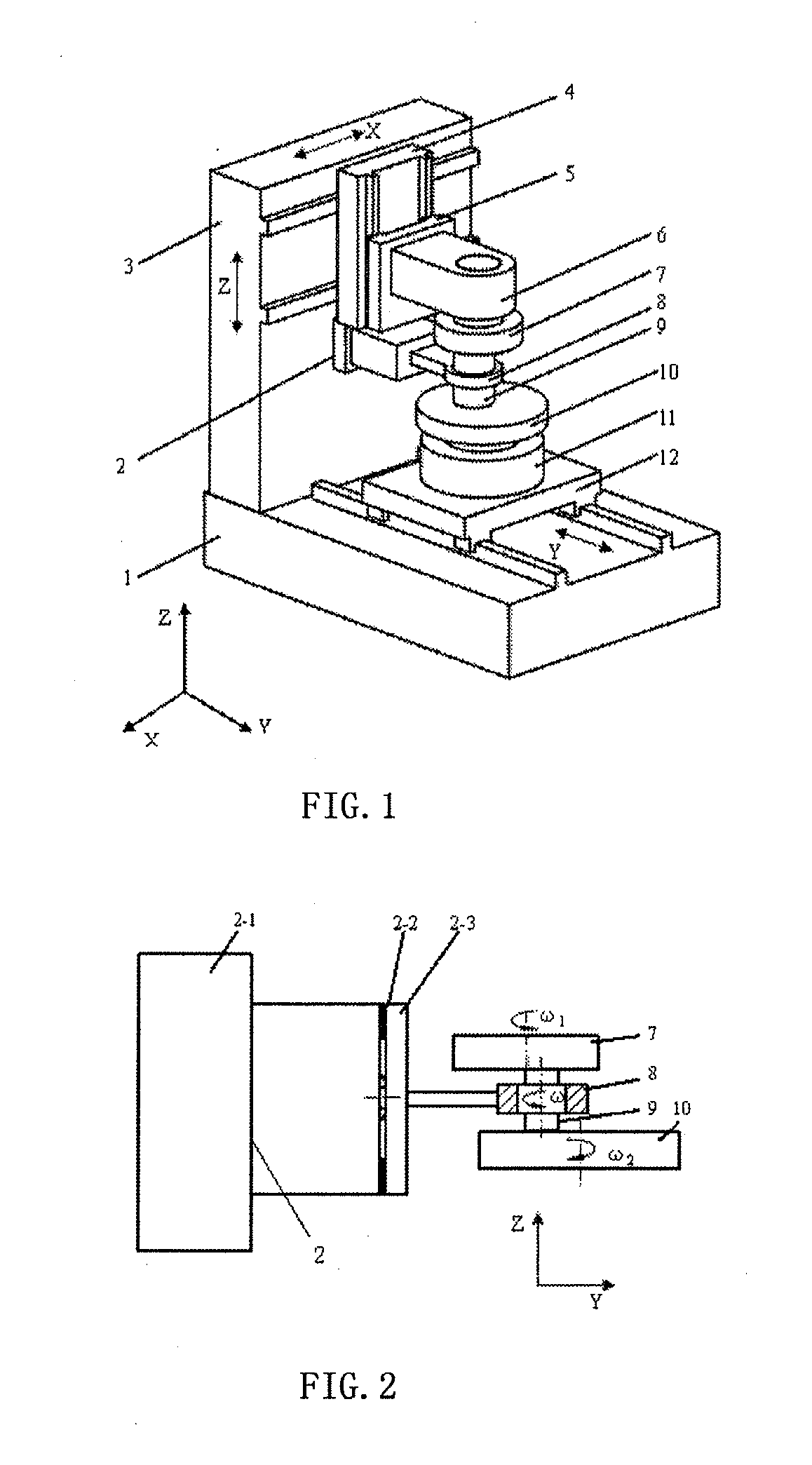

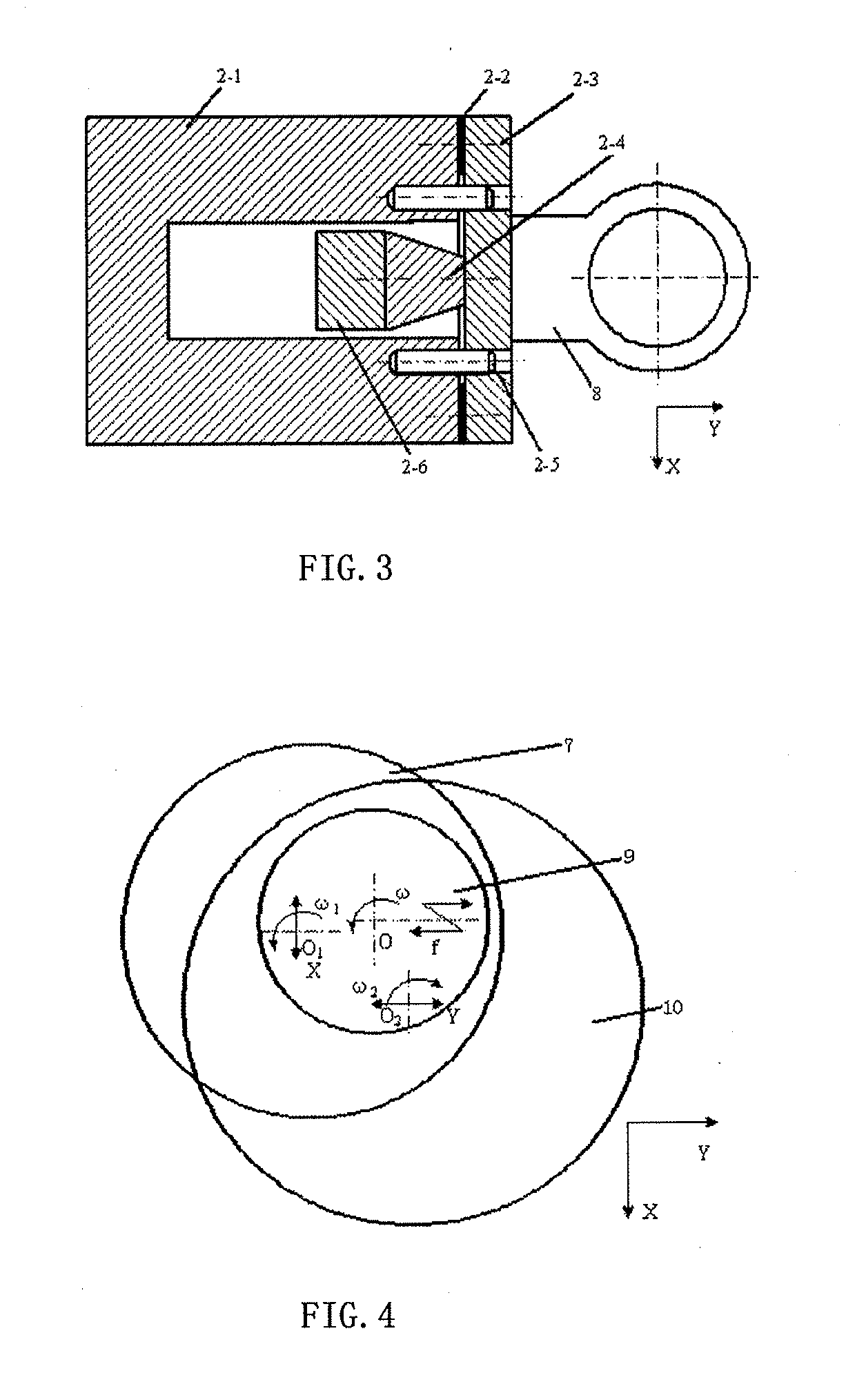

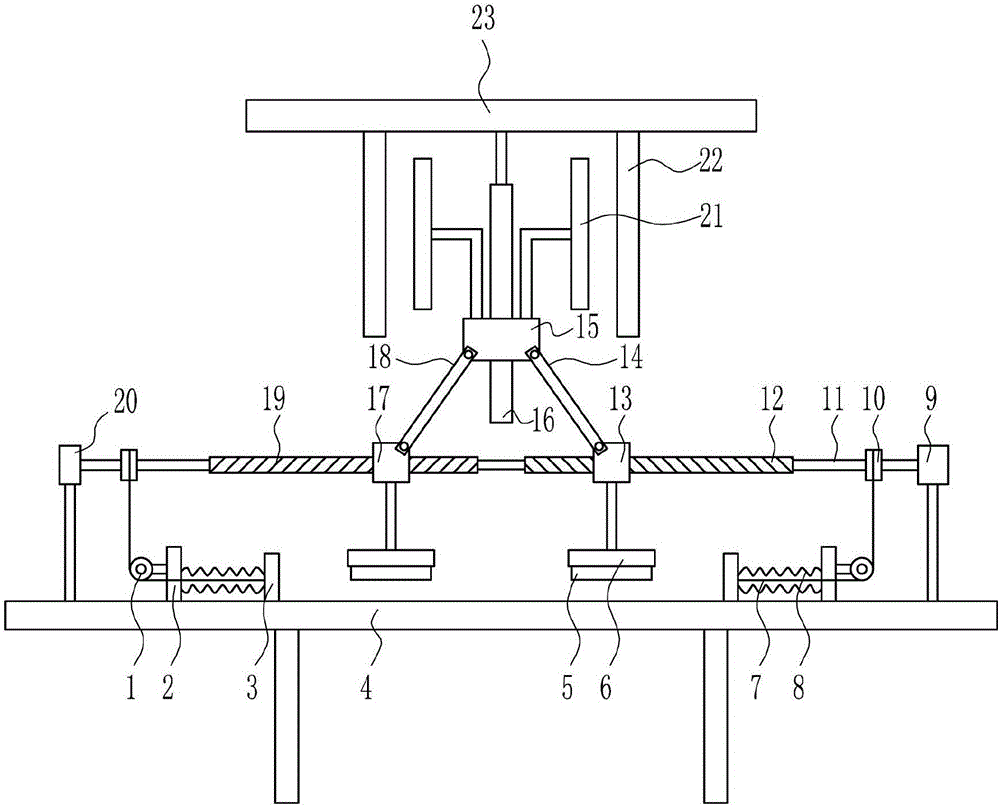

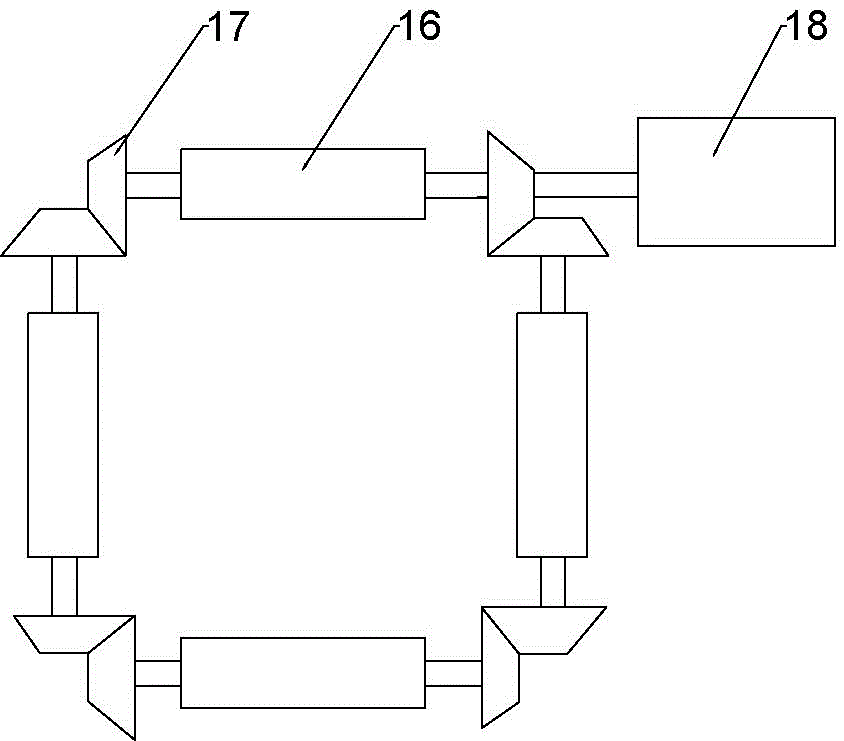

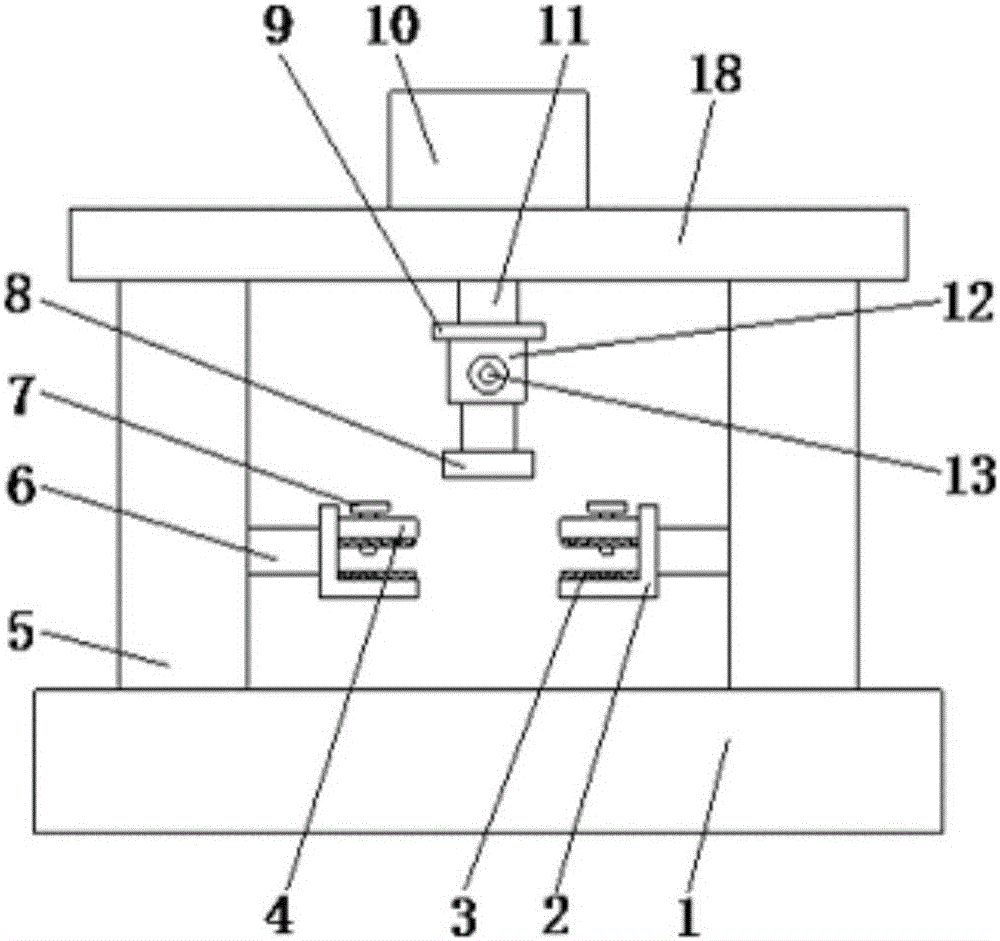

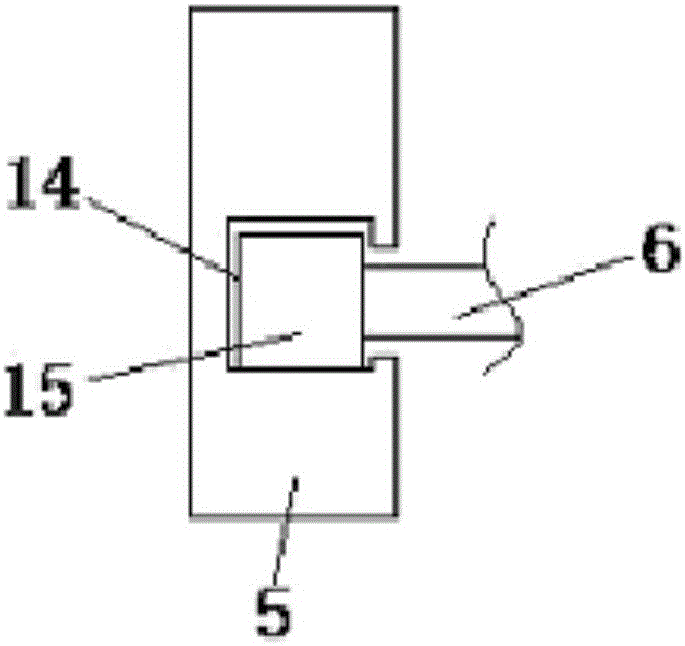

Computer numerical control machine tool for grinding two sides of a plane by shifting self-rotation and ultrasonic vibration

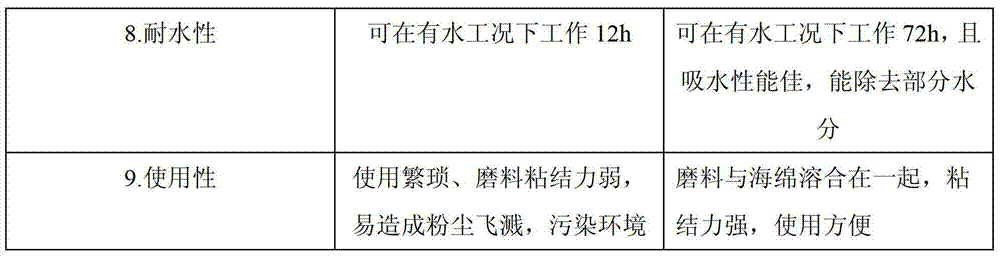

ActiveUS20130165019A1Time variance is goodGrinding speed is fastLapping machinesGrinding feed controlNumerical controlEngineering

A computer numerical control machine tool for grinding two sides of a plane by shifting self-rotation ultrasonic vibration, wherein a pillar (3) is provided on the tool body (1) of the machine tool, a Y axis movement assembly (12) is provided on the platform of the tool body (1), with a lower revolving movement assembly (11), which revolves about a Z coordinate axis, being mounted on the upper surface of the Y axis movement assembly (12), and a lower grinding plate (10) being mounted coaxially above the lower revolving movement assembly (11); an ultrasonic vibration assembly (2) is mounted fixedly on the pillar (3), with a separation plate (8) for clamping a workpiece assembly (9) being provided on the ultrasonic vibration assembly (2); an X axis movement assembly (4) is mounted on the upper part of the pillar (3), a Z axis movement assembly (5) is mounted on the upright face of the X axis movement assembly (4), with an upper revolving movement assembly (6), which revolves about the Z coordinate axis, being provided on the Z axis movement assembly (5), and an upper grinding plate (7) being mounted coaxially on the revolving axis of the upper revolving movement assembly (6). The present invention enhances the time variation of grinding movement tracks, the uniformity of grinding speed distribution, machining efficiency and machining precision.

Owner:XIAN UNIV OF TECH

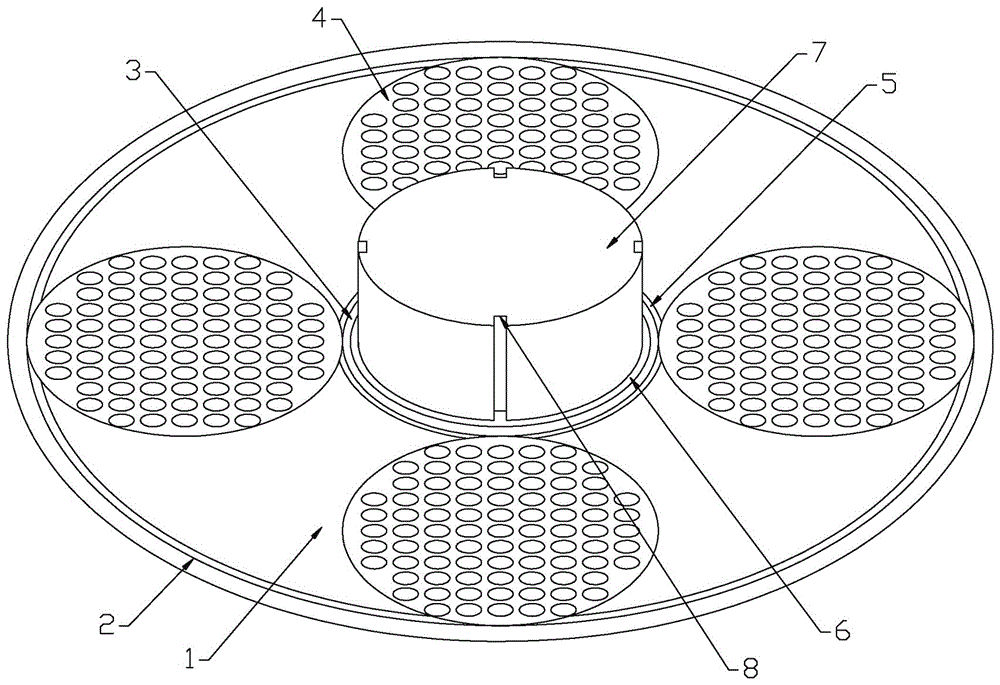

Double-side grinding and polishing machine

InactiveCN106425830ASmall grinding resistanceImprove grinding productivityLapping machinesWork carriersMechanical engineeringSilicon

The invention discloses a double-side grinding and polishing machine. The double-side grinding and polishing machine comprises an upper disc. A lower disc (1) is arranged under the upper disc. The upper disc and the lower disc (1) are driven by different motors and are opposite in rotation direction. An inner gear ring (2) is arranged at the outer edge side of the lower disc (1), and a sun gear (3) is arranged in the middle of the lower disc (1). Planet gears (4) serving as tools and clamps are placed on the lower disc (1). The two sides of each planet gear (4) are engaged with the inner gear ring (2) and the sun gear (3) correspondingly; and the inner gear ring (2) and the sun gear (3) are driven by different motors, and therefore the planet gears (4) can rotate and can also revolve around the sun gear (3) under the action of the inner gear ring (2) and the sun gear (3). By means of the double-side grinding and polishing machine, workpieces can form grinding motion with the speeds coordinated with one another in three or more directions in a carrier; the two sides are ground uniformly; resistance is small; efficiency is high; the workpieces are not damaged; and the double-side grinding and polishing machine is applicable to grinding and polishing of silicon wafers, sapphire substrates and epitaxial wafers.

Owner:YIXING JINGKE OPTICAL INSTR

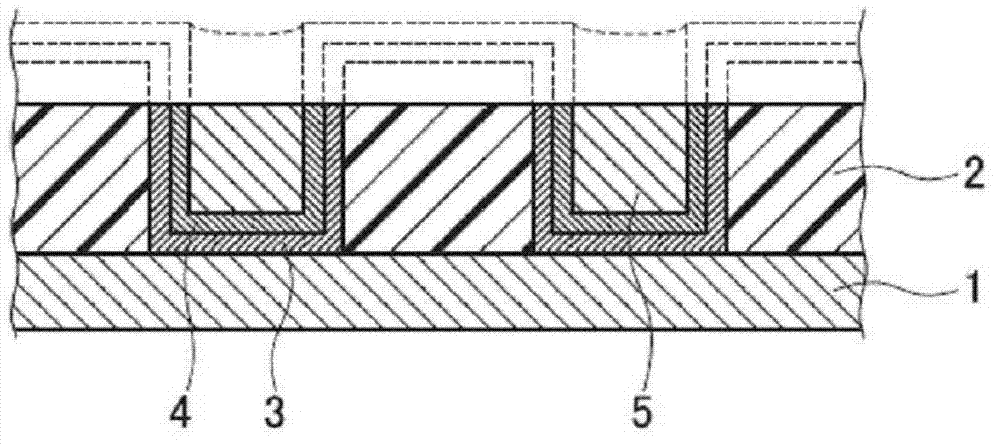

Chemical-mechanical grinding method

ActiveCN1815696AGrinding speed is fastReduces micro-scratch damageSemiconductor/solid-state device manufacturingLapping machinesMetallurgyMaterials science

The invention discloses method for improving grinding effect of chemically machinery grinding technique in use of high selective grinding pulp. After a prearranged time of carrying out a chemically machinery grinding procedure, deionized water is provided on grinding pad to continue chemically machinery grinding procedure in order to raise grinding speed and effect.

Owner:UNITED MICROELECTRONICS CORP

Internal combustion type rail belt grinder

InactiveCN101838956ACompact structureSimple structureRailway track constructionCombustionDrive wheel

The invention discloses an internal combustion type rail belt grinder, comprises a rack, a sanding belt, a driving wheel, a contact wheel, a tension pulley, a front travel contour wheel, a rear travel contour wheel and an explosive motor, wherein the front travel contour wheel and the rear travel contour wheel are arranged on the rack; the explosive motor is arranged on the rack and drives the driving wheel to rotate; the sanding belt is orderly wound on the excircles of the driving wheel, the contact wheel and the tension wheel; and a regulation mechanism for regulating the height of the rack is arranged between the rack and the front travel contour wheel or between the rack and the rear travel contour wheel. In the invention, the sanding belt is adopted to grind; the excircle of the contact wheel pressing the sanding belt on a welding line is provided with annular rubbers; the sanding belt is contacted with the welding line in a flexible mode, and the contact area is large, and the grinding efficiency is high; the variation in sanding belt thickness is small during grinding, thus the regulating operation of the grinding height is less, and the work efficiency is high; the regulation mechanism of the invention is simple, and the regulation is convenient and reliable; the driving wheel, the contact wheel and the tension wheel are all arranged on the support plate and the mounting and the debugging are convenient; and the explosive motor is suitable for field electroless operation.

Owner:李洪彬

Abrasive and substrate polishing method

ActiveCN102888208AGrinding speed is fastImprove corrosion inhibitionOther chemical processesSemiconductor/solid-state device manufacturingCarboxylic acidCobalt

The invention provides an abrasive for polishing cobalt-containing layers. The abrasive comprises a carboxylic acid derivative, a metal corrosion inhibitor and water, the carboxylic acid derivative consisting of at least one selected from a phthalic compound, an isophthalic compound, an alkyl dicarboxylic compound represented by the formula (I), and salts and anhydrides of the phthalic compound, the isophthalic compound and the alkyl dicarboxylic compound. The pH is below 4.0. Formula (I): HOOC-R-COOH.

Owner:RESONAC CORP

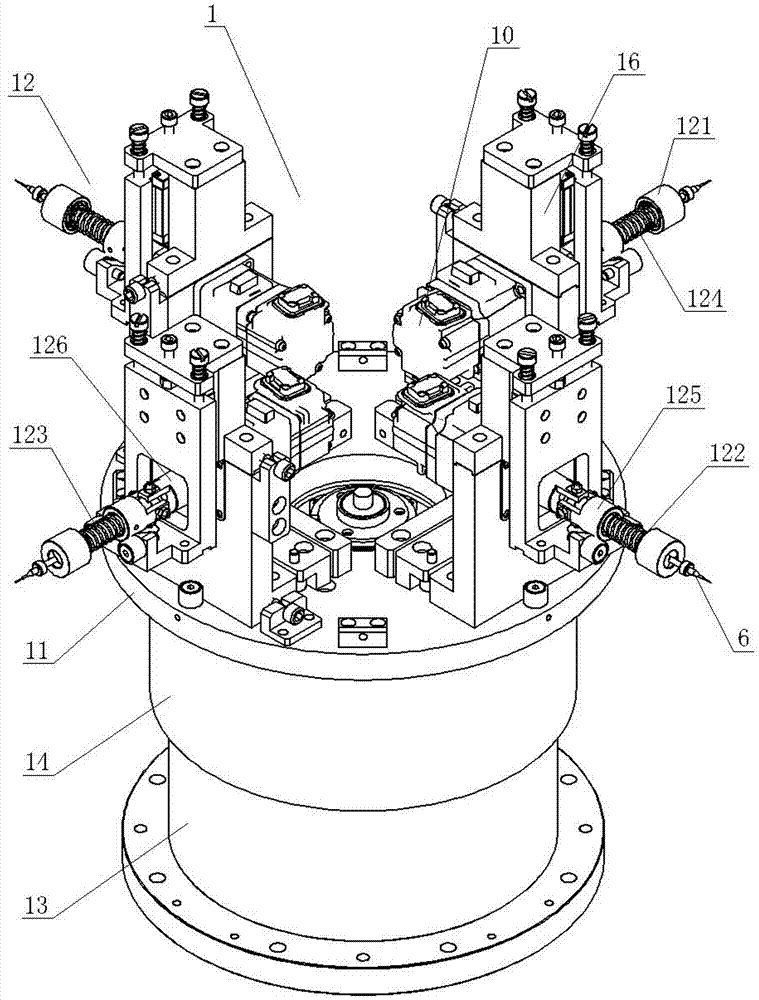

Full-automatic grinding machine and grinding method thereof

InactiveCN103600269AHigh degree of automationImprove efficiencyGrinding feed controlDrilling toolsGrinding wheelColloidal particle

The invention discloses a full-automatic grinding machine and a grinding method thereof. The full-automatic grinding machine comprises a machine platform, a drill point plate, a rotary plate device, a drill point gripping device, a drill point cleaning device, a drill bit appearance detection device, a movable grinding clamping device, a grinding wheel, a switch gripping device, a point transmitting and receiving arm device, a rotary drill point gripping device and a drill point depth compensation device, wherein the rotary plate device has an operation function during double-direct conveying and performs intermittent rotation in the circumferential direction; the drill point gripping device is arranged between the drill point plate and the rotary plate device and used for performing drill point gripping back and forth; the drill bit appearance detection device is used for detecting drill points conveyed to the rotary plate device; the movable grinding clamping device is arranged on a sliding platform; the grinding wheel is used for grinding the drill points clamped on the movable grinding clamping device; the point transmitting and receiving arm device is arranged between the switch gripping device and the movable grinding clamping device and used for performing drill point gripping back and forth; the rotary drill point gripping device is arranged between the rotary plate device and the switch gripping device and used for performing drill point gripping back and forth. By means of the full-automatic grinding machine, grinding, cleaning, colloidal particle depth compensation and drill bit appearance detection can be achieved on the same machine, and then accepted products and defective products of the drill points can be distinguished.

Owner:TEXIN MICROELECTRONICS DONGGUAN

Movable hardware plate surface polishing device

ActiveCN106078384AEasy to useGrinding speed is fastGrinding drivesGrinding work supportsComputer engineering

The invention relates to a hardware plate surface polishing device, in particular to a movable hardware plate surface polishing device. According to the technical problem to be solved, the movable hardware plate surface polishing device saves polishing time, polishes multiple pieces and is easy to use. To solve the technical problem, the movable hardware plate surface polishing device comprises rolling wheels, fixing blocks, pressing blocks, a working table, polishing blocks, installing plates, bracing wires, springs, a servo motor, reels, a rotating rod, a first lead screw, a first nut, a first connecting rod, a sliding block, a sliding rod, a second nut, a second connecting rod, a second lead screw, a bearing pedestal, a first polishing block, a second polishing block and a top plate. The top plate is arranged above the working table. The movable hardware plate surface polishing device has the beneficial effects of saving the polishing time, polishing the multiple pieces and being easy to use, and due to the design, the polishing speed is increased. Moreover, multiple polishing positions are arranged, and similarly the polishing speed can also be increased.

Owner:阜南县德盛隆工艺家具有限公司

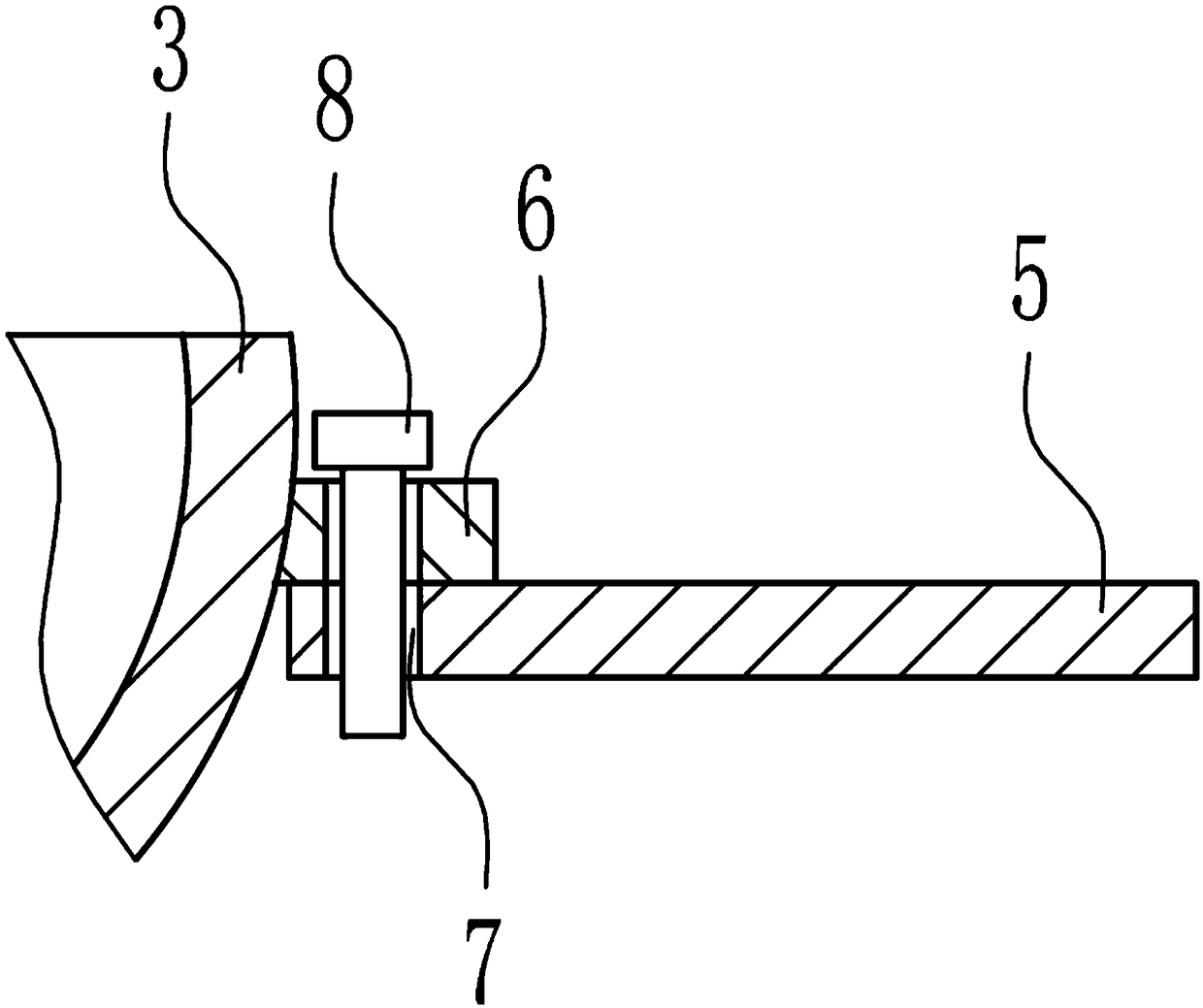

Medical granular tablet crushing device

The invention relates to a crushing device, in particular to a medical granular tablet crushing device. Technically, the invention aims to provide a medical granular tablet crushing device characterized by uniform tablet crushing and faster grinding speed. According to a technical scheme, the medical granular tablet crushing device includes a base plate, support rods, a crushing frame, a support plate, a connecting plate, etc. Two support rods are disposed at the top of the base plate, the crushing frame is connected to the tops of the two support rods, the bottom of the crushing frame is netty, a connecting block is connected to the right side upper part of the crushing frame, the support plate is connected to the right side of the base plate top, and the connecting plate is connected tothe left side lower part of the support plate. According to the invention, reverse rotation of a motor can drive a crushing plate to move up and down so as to crush granular tablets, therefore manualcrushing of granular tablets is unnecessary, and reverse rotation of the motor also enables a knock block to knock the crushing frame continuously, and the crushed granular tablet powder can better fall into a container, thus reaching the effects of uniform crushing of tablets and fast grinding speed.

Owner:沈水秀

Efficient hardware product grinding device

InactiveCN106181720AGrinding speed is fastImprove grinding effectGrinding carriagesGrinding drivesEngineeringAtmospheric pressure

The invention relates to a grinding device, in particular to an efficient hardware product grinding device. The invention aims to provide the efficient hardware product grinding device which is uniform in grinding and high in grinding efficiency and can save labor resources. In order to solve technical problems, the efficient hardware product grinding device comprises a bottom plate, a left rack, a water tank, a first pipe, a one-way valve, a piston, a cylinder body, a third pipe, an electric push rod, a right rack, a first sliding track, a first sliding block, a connecting rod, a first joint lever, a first strut, a first gear, a second strut, a second sliding track, a second sliding block, a second gear, a gear rack and the like; and the left rack, the water tank, the cylinder body, the electric push rod and the right rack are successively arranged on the top of the bottom plate from left to right. The motor and the electric push rod work simultaneously, and respectively drive a hardware product to rotate and a grinding stone to move in the left-right direction, so that the grinding speed is increased, and the acting force of air pressure is utilized.

Owner:周栋

Polishing composition for polishing surface of memory, hard disk and magnetic head and its polihsing method

InactiveCN1384166AReduce surface roughnessReduce defectsOther chemical processesPolishing compositions with abrasivesAlkaneBuffering agent

The present invention belongs to the field of surface polishing treatment technology. The polish composition consists of one or more abrasive(s) selected from nanometer-level diamond, silica, alumina, cerium oxide, zirconium oxide, titania, silicon nitride and manganese dioxide in the amount of 0.01-50 wt%; alkane mineral oil or synthetic oil in 50-99.99 wt%; and buffering agent component in 0-50wt%. The composition has pH value of 6-8. The polish composition is sprayed to grinding plate of polisher to polish the surface of magnetic head in memory and hard disk and to polish other metal and non-metal surface to reach sub-nanometer level roughness.

Owner:NAKE IND SHENZHEN

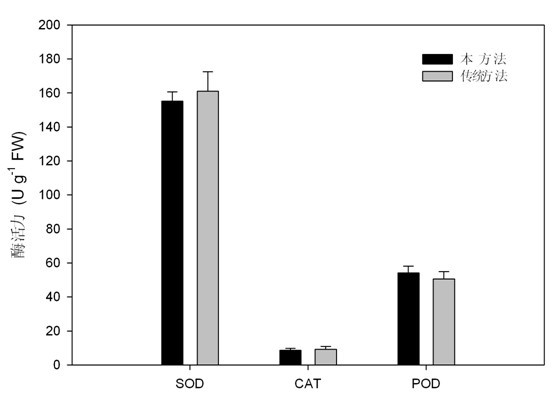

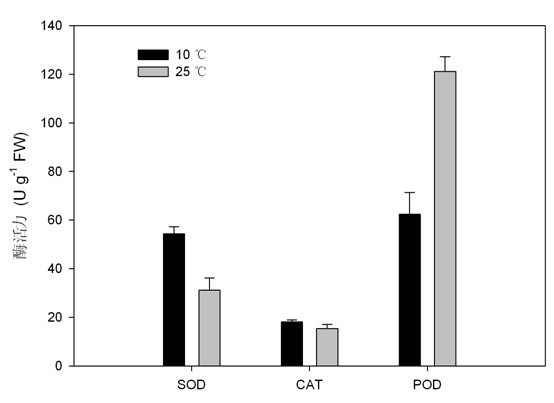

Method for detecting activity of plant superoxide dismutase, catalase and peroxidase

InactiveCN101870998AEasy to detectQuick checkMicrobiological testing/measurementBiotechnologyDismutase

The invention discloses a method detecting activity of plant superoxide dismutase, catalase and peroxidase, which comprises the steps of grinding a sample by using a liquid nitrogen method, extracting three enzymes simultaneously by adopting one buffer solution, detecting enzyme activity and the like. In the method, SOD, CAT and POD in plants can be simultaneously extracted by adopting one buffer solution, so that the method fulfills the aim of simply and quickly detecting the enzyme activity of the SOD, CAT and POD, simplifies operation, saves time and labor, reduces the using amount of samples and reagent and the like, and contributes to the realization of batch operation, and the detection result is similar to that of the conventional method. Furthermore, the sample is ground by adopting a liquid nitrogen grinding method before enzyme solution is extracted, so that the method has the advantages of high grinding speed, good cell crushing effect and high extraction efficiency.

Owner:SICHUAN AGRI UNIV

Square workpiece grinding machine

ActiveCN106826468AWill not affect healthGrinding speed is fastGrinding machine componentsGrinding machinesMechanical engineeringPiston

The invention relates to the field of grinding machines, and discloses a square workpiece grinding machine. The square workpiece grinding machine comprises a rack, a first motor and grinding rollers. The first motor is arranged on the rack, the rack is provided with a conveying mechanism, and a rotary disc is arranged on the part, on one side of the conveying mechanism, of the rack and provided with through holes. First magnets are arranged in the through holes in a sliding manner. A conical hopper is arranged below the part between the conveying belt and the rotary disc. The lower end of the conical hopper is fixedly connected with a guiding barrel. A grinding mechanism is arranged below the grinding barrel. The grinding mechanism comprises the four above grinding rollers. The two ends of each grinding roller are fixedly connected with bevel gears, the bevel gears at the two ends of the grinding rollers are engaged in an end-to-end manner, and the bevel gears are driven by the first motor. A piston barrel is arranged below the grinding mechanism, a second magnet is arranged in the piston barrel in a sliding manner and repels the first magnets, the upper portion of the piston barrel communicates with a suction pipe, and an opening, away from one end of the piston barrel, of the suction pipe faces the grinding mechanism. Compared with the prior art, the periphery of a workpiece can be ground at the same time, and the grinding efficiency is high.

Owner:CHONGQING TENGTONG IND DESIGN

Tubular product grinding device for machining

InactiveCN109648410AGrinding speed is fastImprove efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringMachining

The invention discloses a tubular product grinding device for machining. The tubular product grinding device for machining comprises two front and rear installing frames and a telescopic rod used forfixedly connecting the two installing frames; a hanging rod is hinged to each of beams of the two installing frames; fixed installing rings are fixedly installed at the lower ends of the hanging rods;a movable installing ring is installed on one side of the fixed installing rings in a rolling manner; a plurality of electric-hydraulic pushing rods are fixedly installed on the inner side wall of the movable installing ring; the center axes of the plurality of electric-hydraulic pushing rods all intersect with and are all perpendicular to the center axis of the movable installing ring; an installing plate is fixedly installed on a pushing rod head of each electric-hydraulic pushing rod, and is fixedly provided with an anti-slipping block; and the outer side wall of the movable installing ring is fixedly provided with a plurality of connection columns. The tubular product grinding device for machining has the beneficial effects that the tubular product grinding device for machining can achieve that the outer wall face of a tubular product is automatically ground, the grinding speed is high, efficiency is high, the grinding effect is good, the manpower cost is effectively saved, and practicability is good.

Owner:卢保明

Hardware part polishing device

InactiveCN105965359AAvoid artificial flippingImprove securityGrinding machinesGrinding feedersElectric machineryDrive motor

The invention discloses a hardware part polishing device. The hardware part polishing device comprises a base, symmetrical supporting columns are fixedly connected to the top of the base, notches are formed in the side faces, close to each other, of the two supporting columns, first alternating-current driving motors are arranged inside the two notches, fixing seats are fixedly connected to rotating shafts on the two first alternating-current driving motors, sliding grooves are formed in the inner side walls of the two fixing seats, fixing blocks are arranged over the two fixing seats, protection pads are fixedly connected to the bottom of each fixing block and the inner bottom wall of each fixing seat, a sliding block matched with the corresponding sliding groove is fixedly connected to one side face of each fixing block, the sliding blocks are arranged in the sliding grooves, and a screw is arranged at the top of each fixing block. The hardware part polishing device can drive hardware parts for rotating type polishing, manual overturning of hardware parts is effectively avoided, operation personnel are protected to a certain degree, the safety performance is high, time and labor are saved, the polishing speed is higher, the working efficiency is higher, and the polishing effect is good.

Owner:汪静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com