Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

390 results about "Resin acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

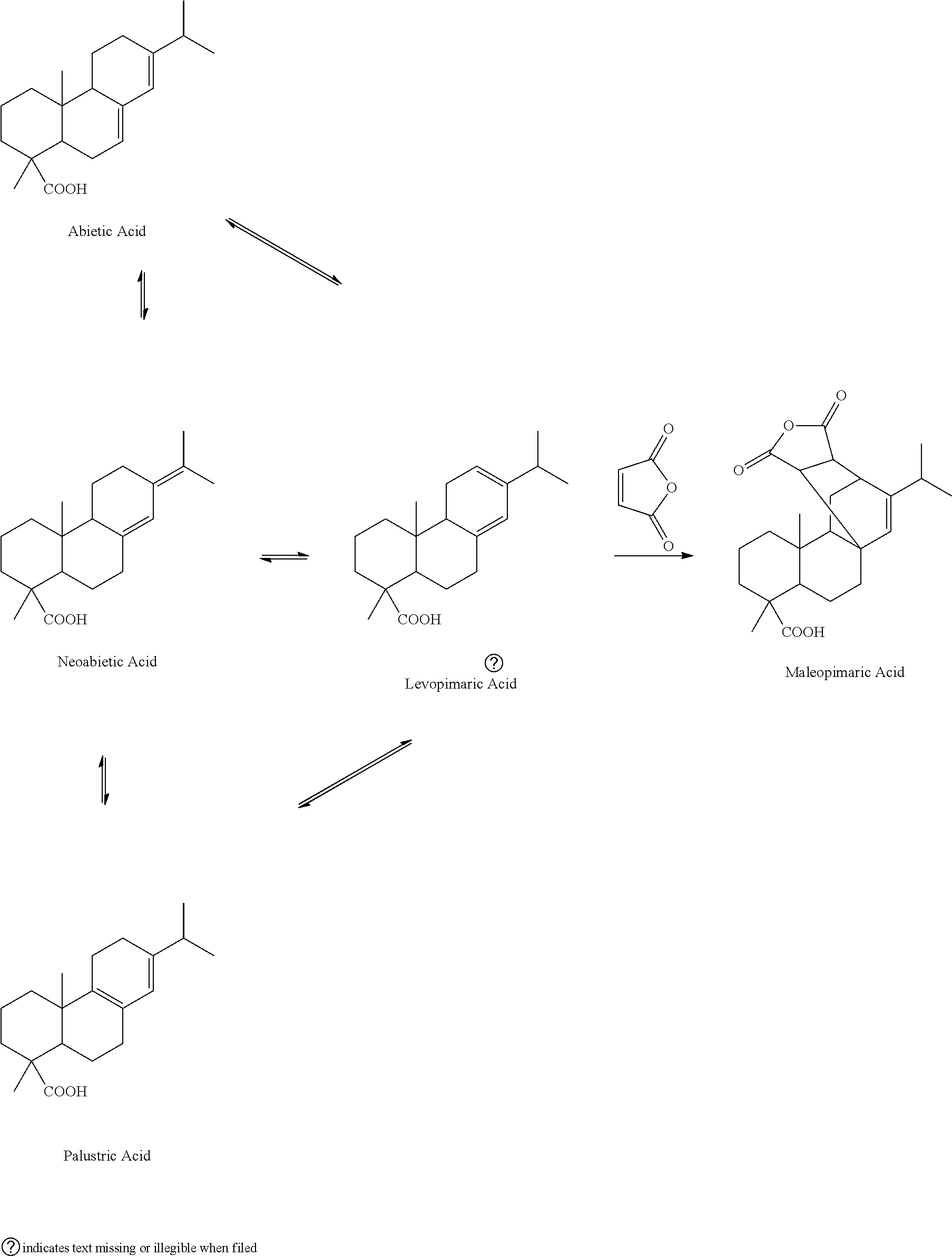

Resin acid refers to mixtures of several related carboxylic acids, primarily abietic acid, found in tree resins. Nearly all resin acids have the same basic skeleton: three fused rings having the empirical formula C₁₉H₂₉COOH. Resin acids are tacky, yellowish gums that are water-insoluble. They are used to produce soaps for diverse applications, but their use is being displaced increasingly by synthetic acids such as 2-ethylhexanoic acid or petroleum-derived naphthenic acids.

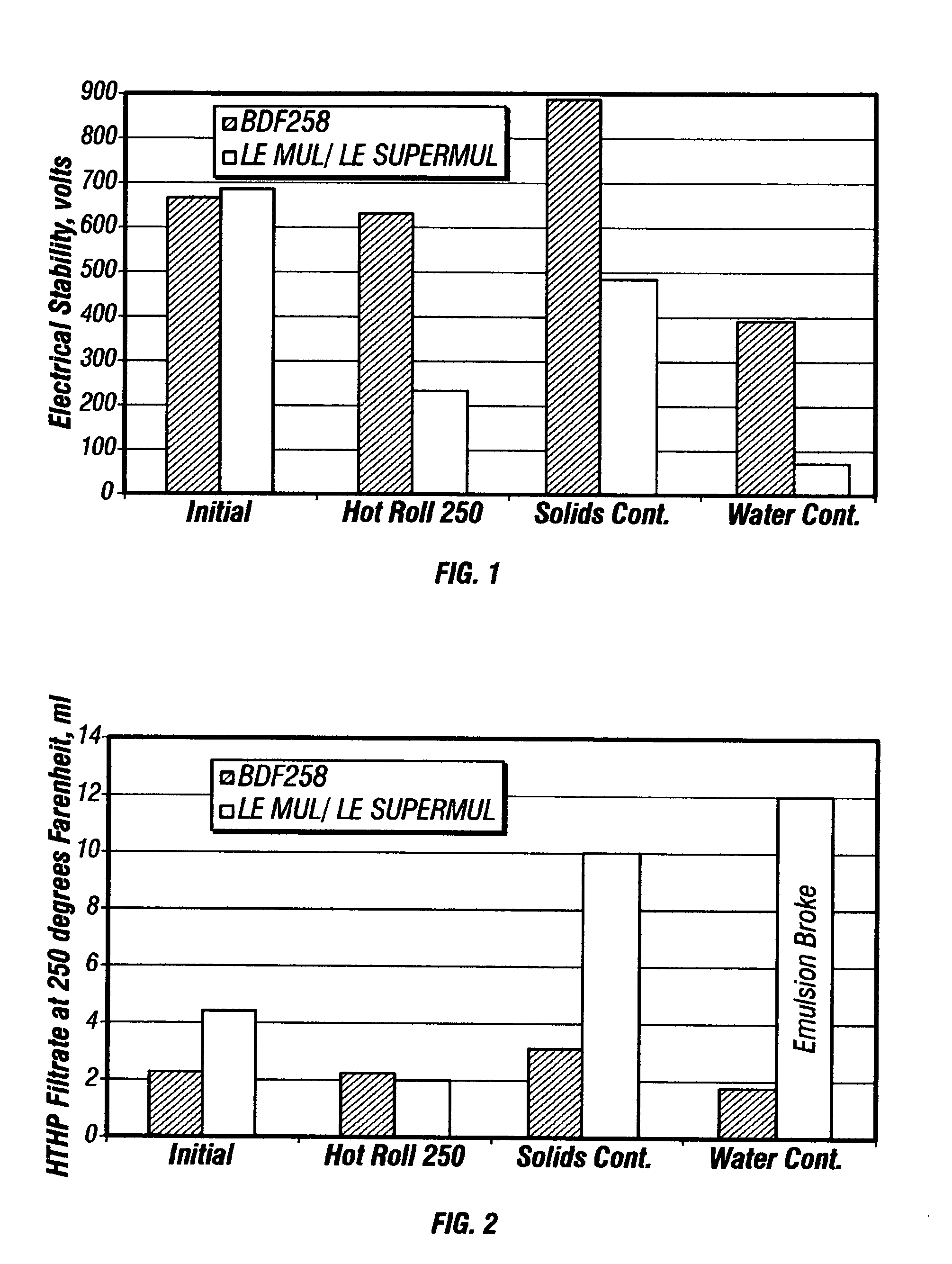

Additive for oil-based drilling fluids

InactiveUS7008907B2High level of filtration controlReduces and eliminates needTransportation and packagingFluid removalFiltrationPolyamide

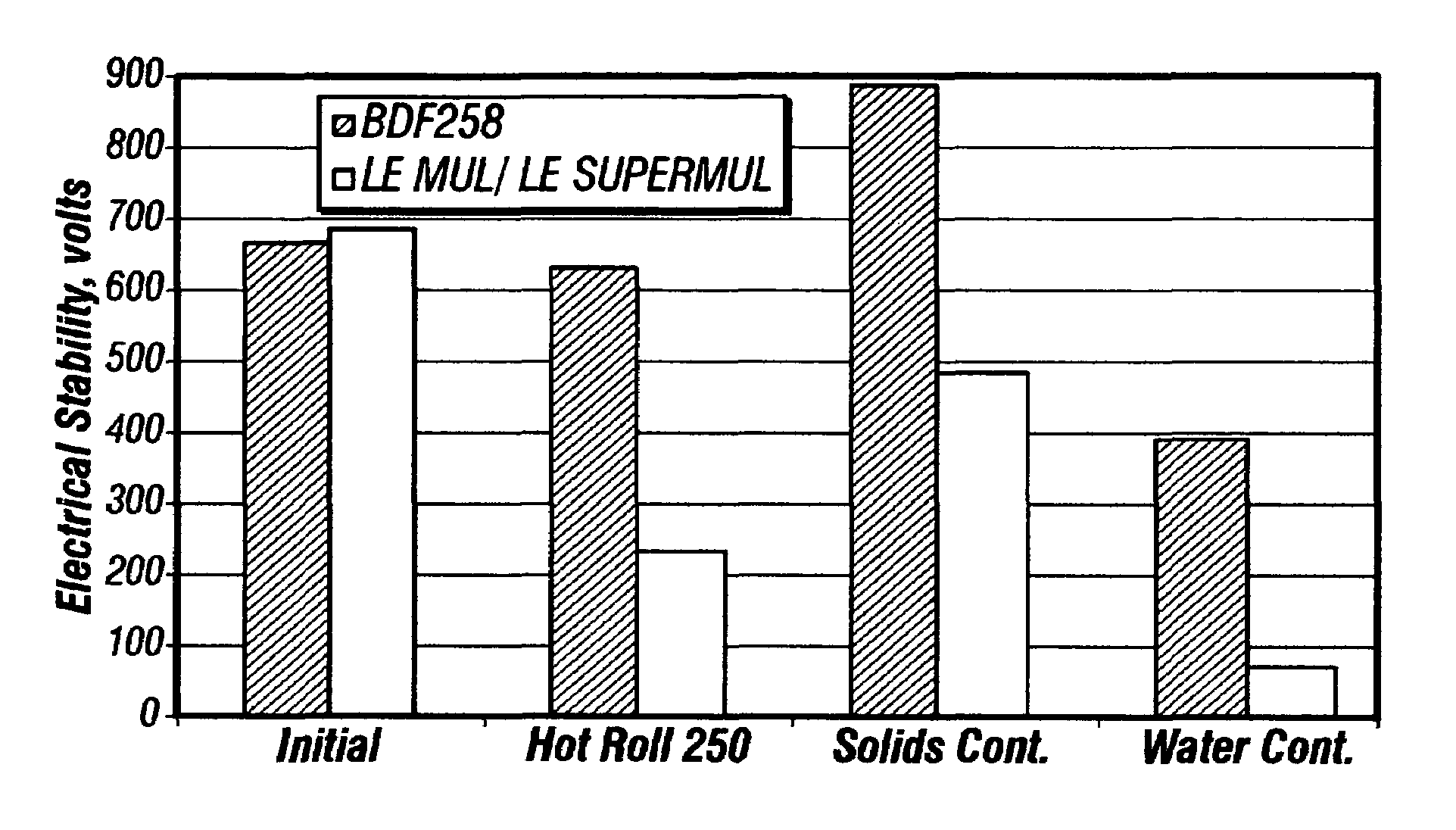

A method and product is disclosed which provides emulsion stability and filtration control to invert emulsion drilling fluids. The product comprises a blend of a carboxylic acid terminated polyamide and / or a wetting agent with a reaction product or mixture produced by the Diels-Alder reaction of dienophiles, preferably carboxylic acids, polycarboxylic acids, acid anhydrides, or combinations or mixes thereof, with a mixture of fatty acids and resin acids. The product of the invention is extremely effective, decreasing by about two-thirds the amount of emulsifier generally required to formulate an effective drilling fluid. The product of the invention also greatly reduces and in many cases eliminates the need for conventional fluid loss additives, and additionally provides electrical stability. Moreover, the product of the invention has a pour point as low as about 20 degrees Fahrenheit with minimal solvents, thereby eliminating the need to ship large amounts of inert material for use, and may be transported in a highly active state.

Owner:HALLIBURTON ENERGY SERVICES INC

Preparation method of cubic ultra-fine calcium carbonate particles

ActiveCN103663527AParticle size controllableNarrow rangeCalcium/strontium/barium carbonatesNanotechnologySodium bicarbonateSucrose

The invention provides a preparation method of cubic ultra-fine calcium carbonate particles. The method comprises the following steps: (1) adding a nucleation promoter to calcium hydroxide suspension liquid, wherein the nucleation promoter is selected from more than one of glucose, sucrose or sodium citrate; (2) carbonizing by introducing carbon dioxide until the pH value is 8-12, adding a crystal modifier and ageing for 0.5-10 hours, wherein the crystal modifier is selected from one of sodium chloride, sodium carbonate, sodium bicarbonate or sodium hydroxide; (3) further introducing carbon dioxide and carbonizing until the pH value is 6.5-7.0; (4) coating by adding a coating agent, filtering and drying to obtain a product, wherein the coating agent is selected from a resin acid, a resin acid alkali metal salt, a fatty acid or a fatty acid alkali metal salt. According to the calcium carbonate particles, the particle sizes are 90-180nm, the calcium carbonate particles are in a cubic shape, and the specific surface area is 10-18m<2> / g. Thus, the cubic ultra-fine calcium carbonate particles can be used as functional fillers in coating, rubber, plastic and sealant industries.

Owner:建德华明科技有限公司

Carbon fiber-reinforced resin composition

A carbon fiber-reinforced resin composition including (A) a polyolefin resin, (B) an acid-modified polyolefin resin and (C) modified carbon fibers of which the adhesion amount of an amino group-containing modified polylolefin resin is 0.2 to 5.0 mass %, wherein the mass ratio of (A):(B) is 0 to 99.5:100 to 0.5 and the mass ratio [(A)+(B)]:(C) is 40 to 97:60 to 3.

Owner:PRIME POLYMER CO LTD

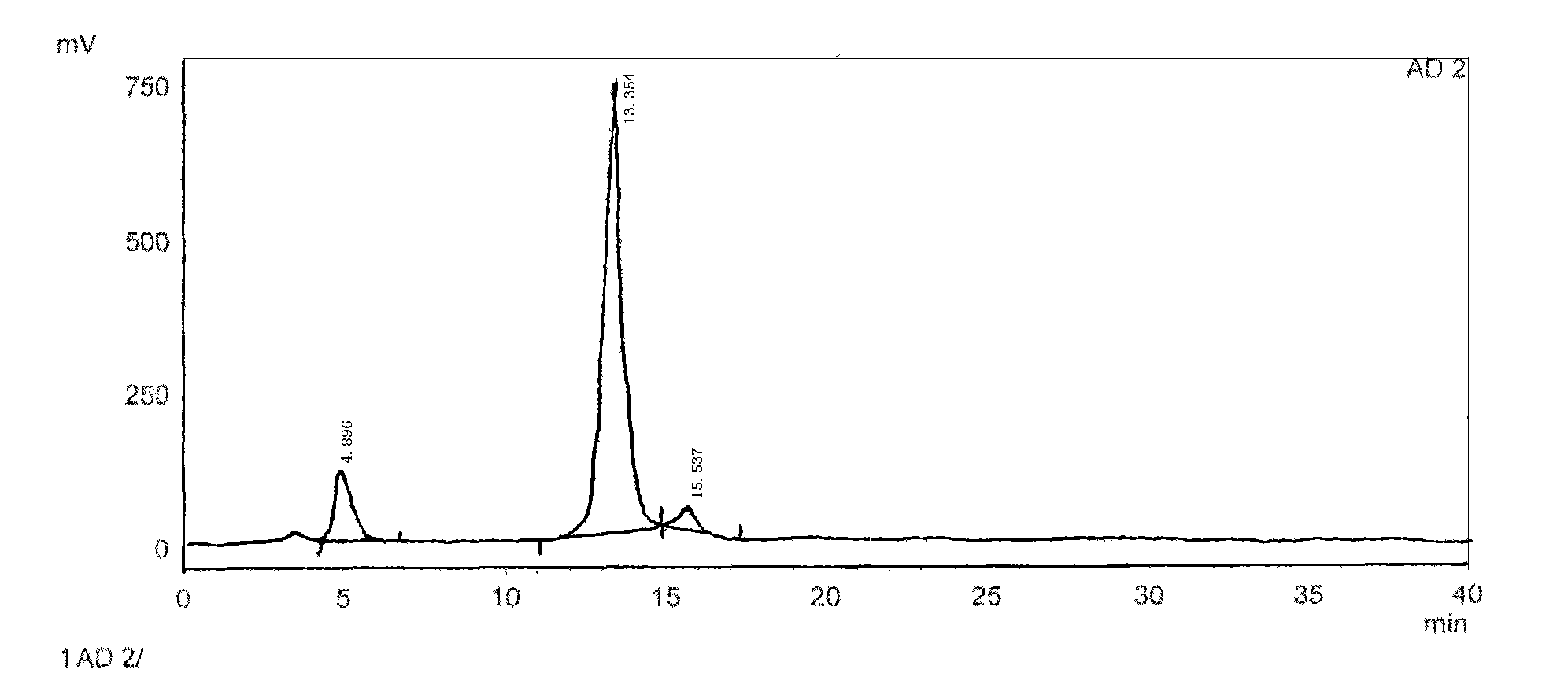

Pimaric type resin acid product, and method of preparing the same

InactiveUS20140148572A1Increase medium temperatureLengthening reaction durationNatural resin processFunctional group formation/introductionBottleSolvent

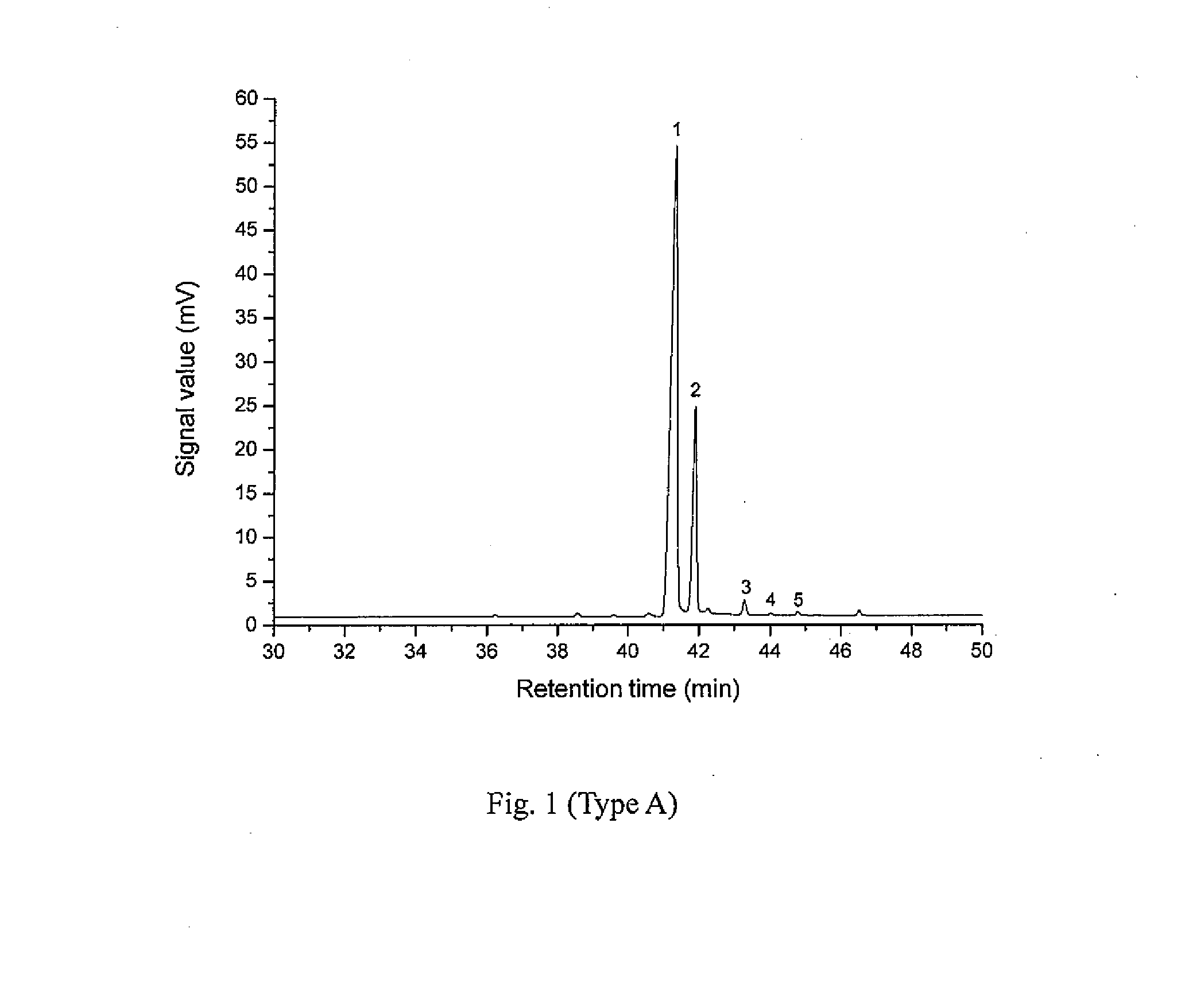

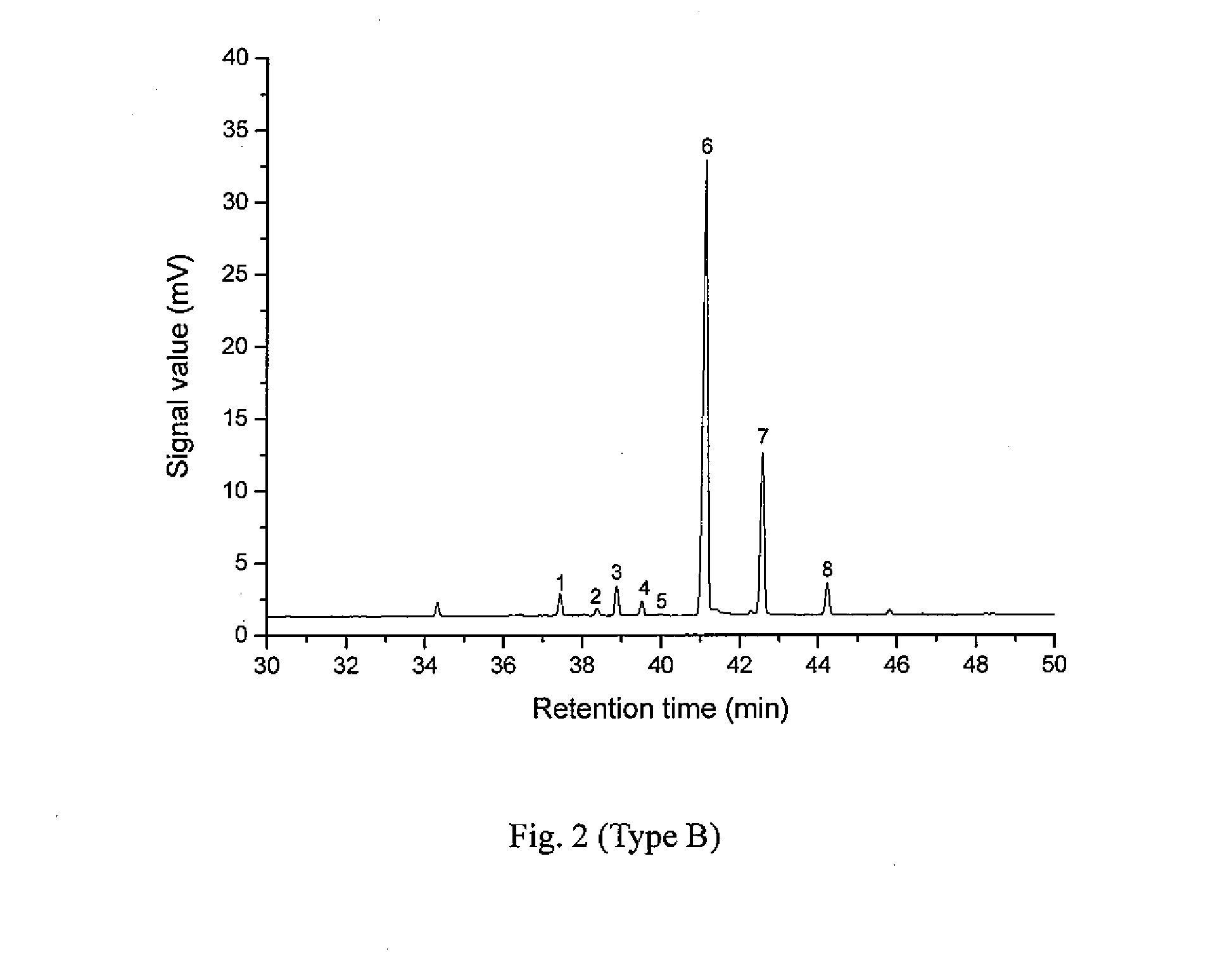

A method for preparing pimaric acid type resin acids includes: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH to 6-14 with a mineral acid or an organic acid, and either directly purifying or acidifying followed by purifying to obtain the final product.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing ultra-thick polyimide film with high heat conductivity and low thermal expansion coefficient

InactiveCN101168598AImprove thermal conductivitySmall coefficient of thermal expansionFlat articlesCoatingsPolyamideConductive materials

The invention relates to a method for preparing an ultra-thick polyimide film with high thermal conductivity and low thermal expansion coefficient. The process steps are: dissolving monomeric diamine in an aprotic polar solvent, adding The dianhydride and the surface-treated nano heat-conducting material are reacted for 4-10 hours to synthesize the polyamic acid resin containing the nano-heat conducting material. Wherein, the addition amount of the nano-thermal conductive material accounts for 1%-10% by mass of the synthetic polyamic acid resin; the preferred addition amount is 3%-8% by mass; Take it on the belt, dry it at 100-200°C, and dehydrate and imidize the obtained salivating film at a high temperature of 300-480°C to obtain an ultra-thick polyimide film with good thermal conductivity and low thermal expansion coefficient. The ultra-thick polyimide film prepared by the method of the invention has high thermal conductivity and low thermal expansion coefficient.

Owner:JIANGYIN YUNDA ELECTRONICS NEW MATERIAL

Fire retardant compositions with reduced aluminum corrosivity

InactiveUS6905639B2Reduced-tendency to corrode various metalBroaden applicationFireproof paintsAntifouling/underwater paintsBiopolymerFerrous Gluconate

Corrosion-inhibited fire retardant compositions and methods of making and using the same are provided. The corrosion-inhibited fire retardant compositions are comprised of at least one fire retardant component, at least one biopolymer having a particle size diameter of less than about 100 microns, and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group of compounds including azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, soluble ferric orthophosphate, insoluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxide, ferric lactate, ferric resinate and any combination thereof. In a specific embodiment, the corrosion-inhibited fire retardant composition includes a xanthan biopolymer.

Owner:PERIMETER SOLUTIONS LP

Method for enhancing the solderability of a surface

InactiveUS6905587B2Improve solderabilityResistant to electromigrationPretreated surfacesLiquid/solution decomposition chemical coatingSilver plateSolderability

A method for enhancing the solderability of a metallic surface is disclosed where the metallic surface is plated with an immersion silver plate prior to soldering, which immersion silver plate is treated with an additive selected from the group consisting of fatty amines, fatty amides, quaternary salts, amphateric salts, resinous amines, resinous amides, fatty acids, resinous acids, ethoxylated derivatives of any of the foregoing, and mixtures of any of the foregoing. The immersion silver deposits created are resistant to electromigration.

Owner:MACDERMID INC

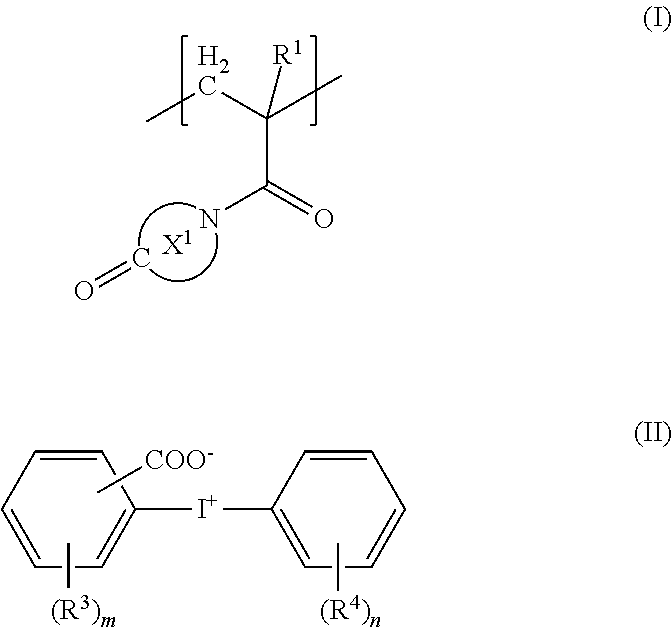

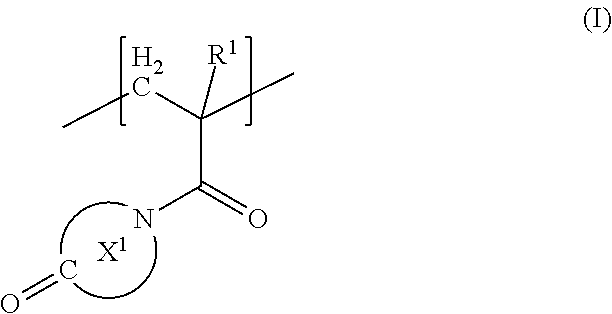

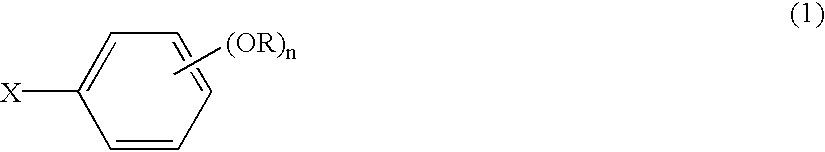

Resist composition and method for producing resist pattern

ActiveUS20120219907A1Good line edge roughnessIncrease roughnessPhotosensitive materialsPhotomechanical exposure apparatusResistStructural unit

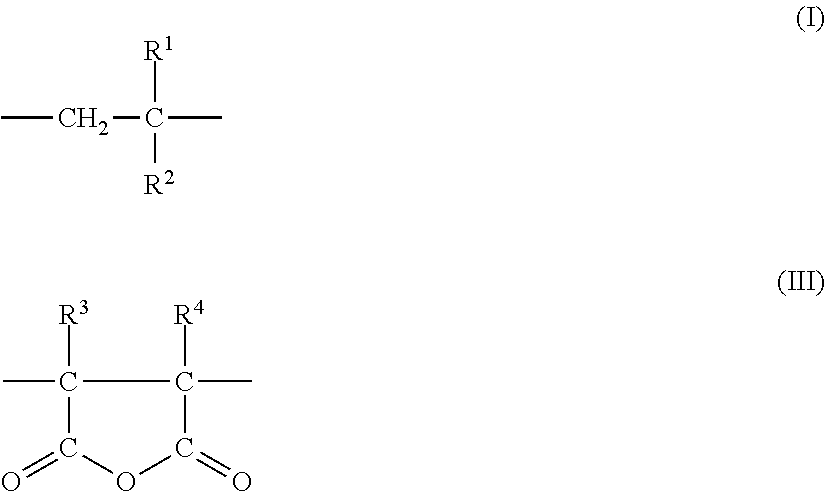

A resist composition contains (A) a resin having a structural unit represented by the formula (I), (B) an acid generator and (D) a compound represented by the formula (II),wherein R1, ring X1, R3, R4, m, and n are defined in the specification.

Owner:SUMITOMO CHEM CO LTD

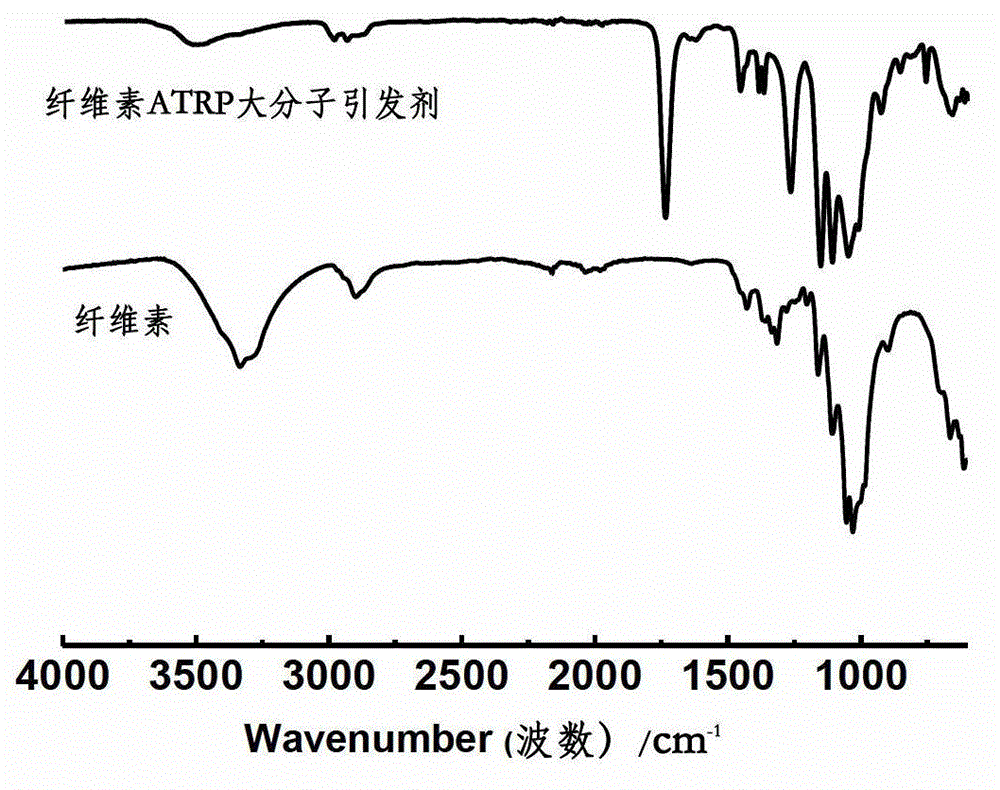

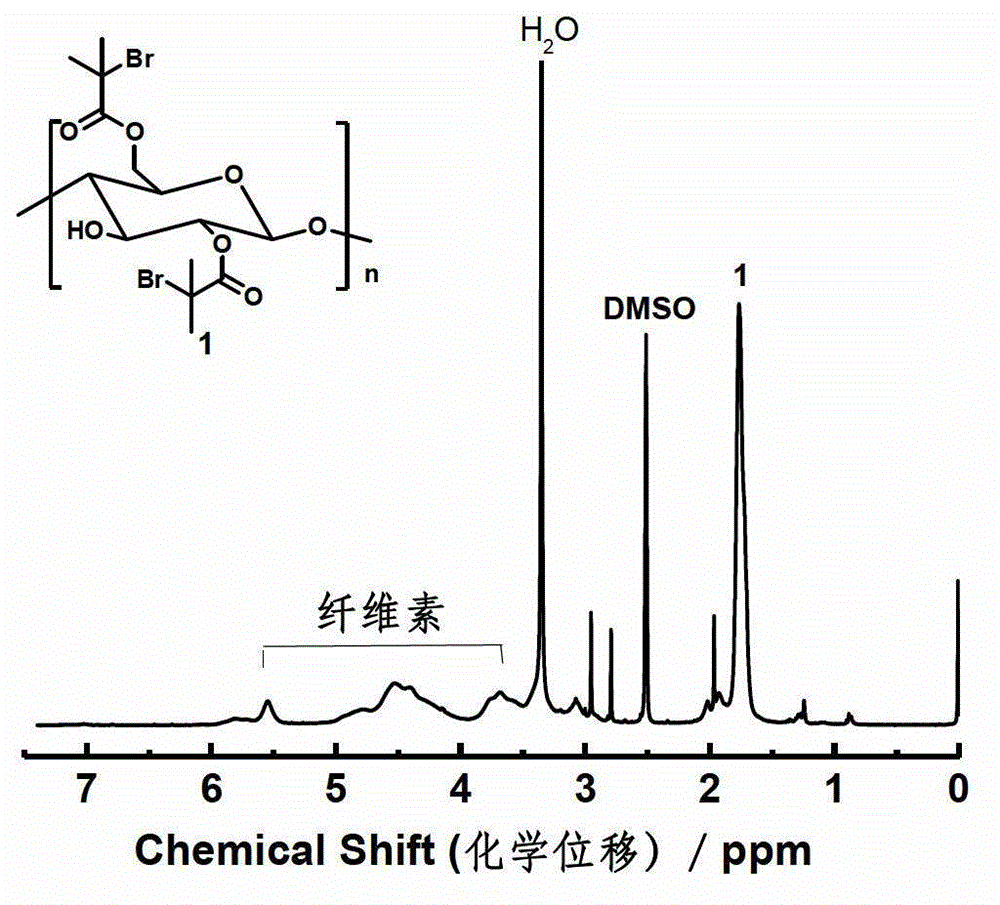

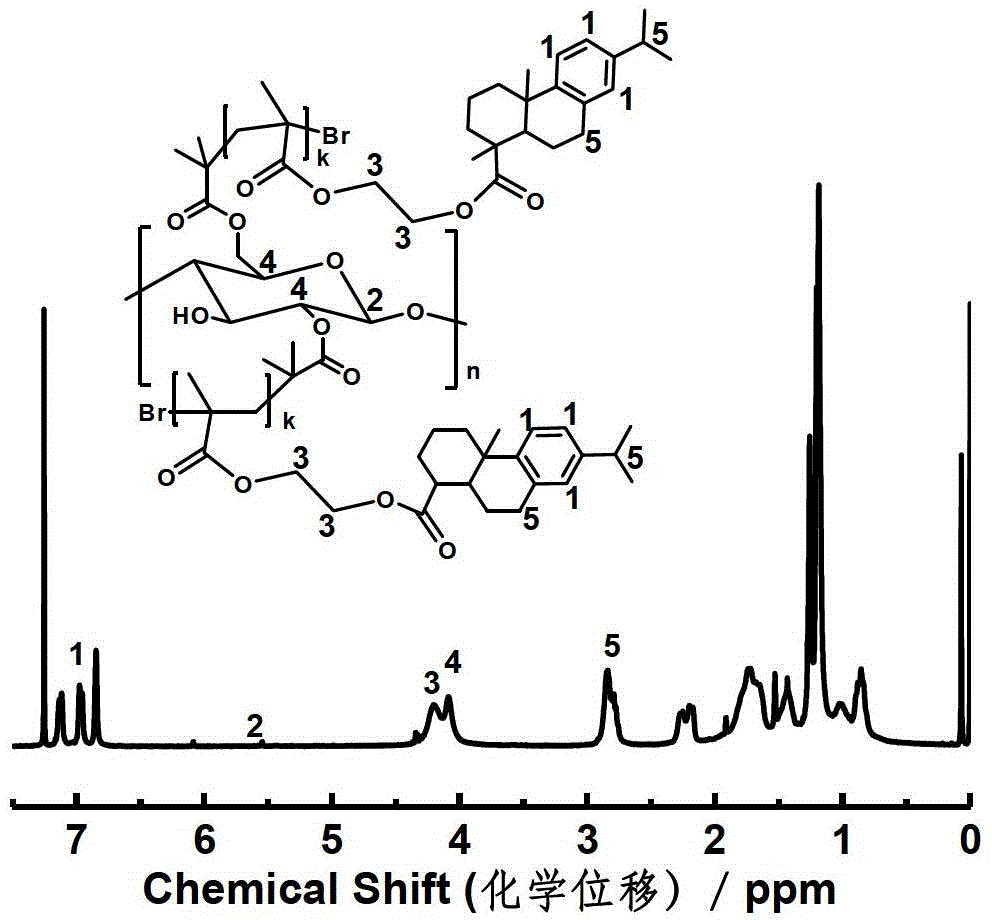

Preparation method of cellulose-g-resin acid grafted copolymer

The invention relates to a preparation method of cellulose-g-resin acid grafted copolymer. The preparation method of the cellulose-g-resin acid grafted copolymer comprises the steps that cellulose atom transfer radical polymerization (ATRP) macroinitiator is synthesized by reaction of cellulose and 2-Bromoisobutyryl bromide in a homogeneous solution system; resin acid monomer, cellulose ATRA macroinitiator, catalytic agents, ligand and rosinyl monomer good solvent are added to a reaction bulb, fully stirred, and dissolved, freezing is carried out for three times, oxygen in the mixed solution is removed in a circulation process of vacuum pumping and nitrogen filling, after the reaction is carried out for 1-24 hours at the temperature of 50-120 DEG C, the polymer is enabled to be deposited in methanol, filtered, and dried, and finally the cellulose-g-resin acid grafted copolymer is obtained. According to the preparation method of the cellulose-g-resin acid grafted copolymer, cellulose-g-resin acid grafted copolymer with different molecular weights and different molecular weight distributions can be obtained. The cellulose-g-resin acid grafted copolymer can be used for improving tenacity of materials by serving as functional additive agents.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

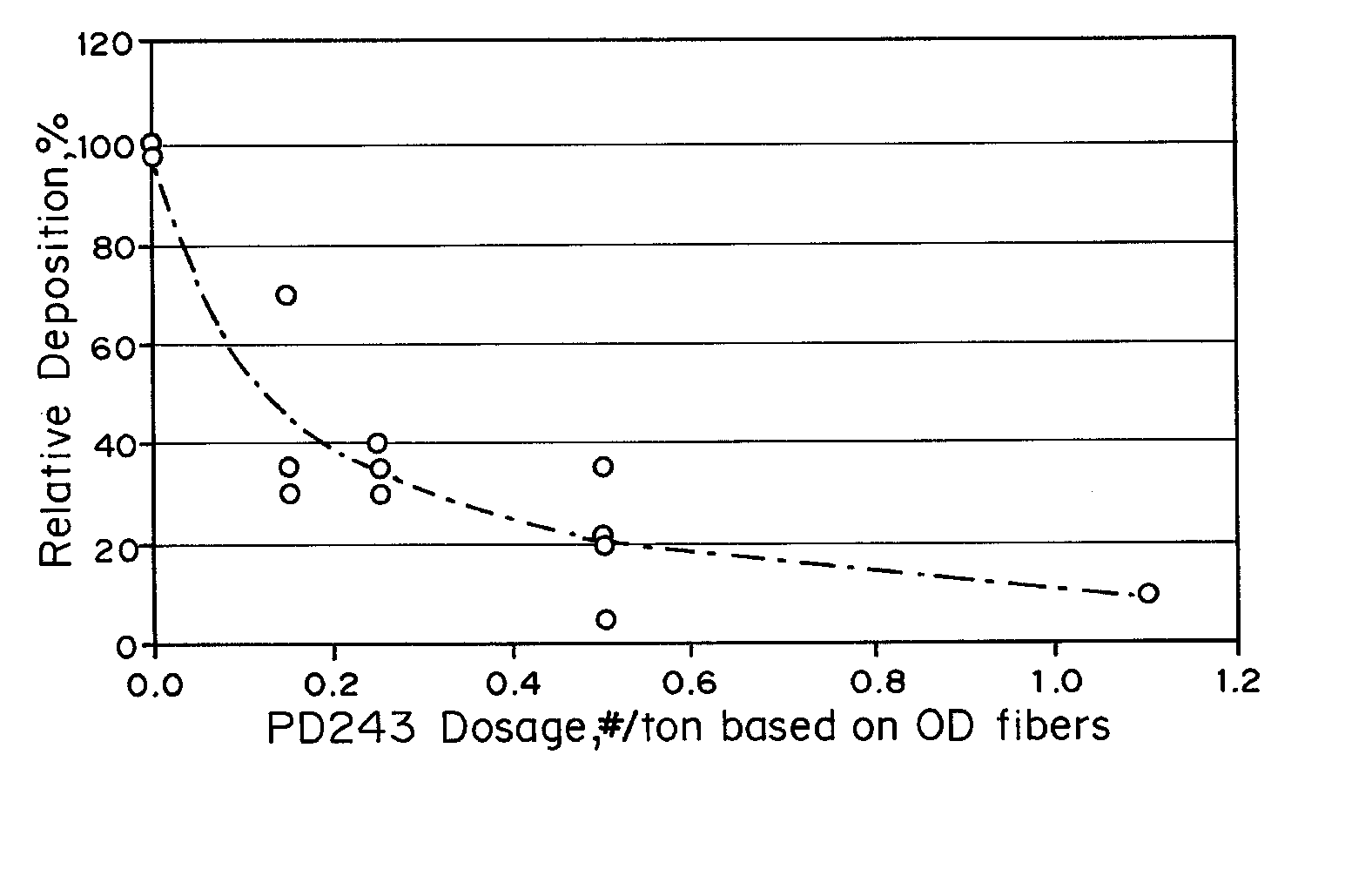

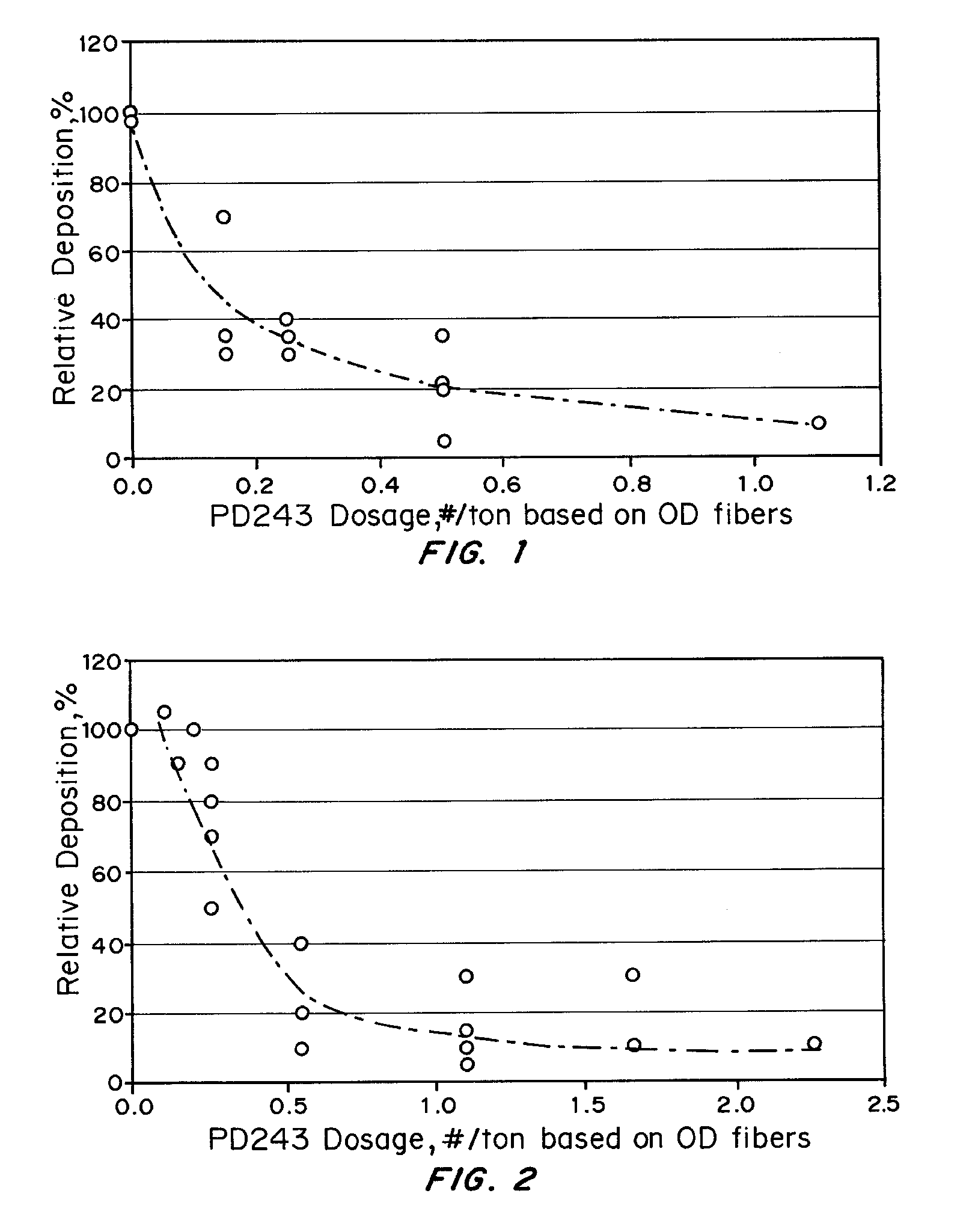

Treatment of Pulp Stocks Using Oxidative Enzymes to Reduce Pitch Deposition

InactiveUS20070261806A1Lower energy requirementsImprove paper strengthPulp liquors combustionFats/resins/pitch/waxes removal in pulpTime rangeResin acid

Methods of treating pulp stocks with an enzyme formulation containing one or more oxidative enzymes, to reduce pitch deposition, control pitch related problems, modify the physical and / or chemical properties of tri, di-, and mono-glycerides, fatty acids, resin acids, esters of fatty acids and resin acids, and metal soaps of fatty acids and resin acids, or change the concentration of triglycerides, fatty acids, resin acids, and esters of fatty acids and resin acids, have been developed. The pulp stock is treated with an enzyme formulation containing laccases, peroxidases, esterases, and / or combinations thereof. The enzyme formulations may also contain a laccase mediator and / or a dispersant. The enzyme formulation can be applied at any of several locations during the pulping and / or papermaking process. The enzyme formulation is typically applied as a solution to the pulp stock. The enzyme treatment is effective at a temperature of between about 30° C. to about 95° C., more preferably from about 50° C. to about 80° C. The pH of the pulp stock is from about 4.0 to about 7.0, more preferably from about 4.5 to 5.5. The stock can be treated for a period of time ranging from about 5 minutes to about 10 hours.

Owner:ENZYMATIC DEINKING TECH LLC

Method to upgrade bio-oils to fuel and bio-crude

This invention relates to a method and device to produce esterified, olefinated / esterified, or thermochemolytic reacted bio-oils as fuels. The olefinated / esterified product may be utilized as a biocrude for input to a refinery, either alone or in combination with petroleum crude oils. The bio-oil esterification reaction is catalyzed by addition of alcohol and acid catalyst. The olefination / esterification reaction is catalyzed by addition of resin acid or other heterogeneous catalyst to catalyze olefins added to previously etherified bio-oil; the olefins and alcohol may also be simultaneously combined and catalyzed by addition of resin acid or other heterogeneous catalyst to produce the olefinated / esterified product.

Owner:MISSISSIPPI STATE UNIVERSITY

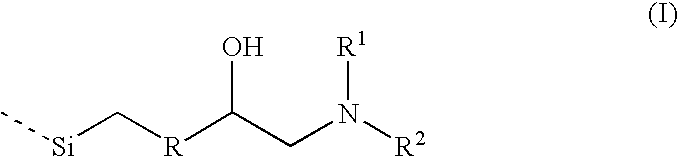

Aqueous, two-component polyurethane compositions containing OH-functional polydimethylsiloxanes

The present invention relates to aqueous, two-component compositions containing A) hydroxyl-containing polydimethylsiloxanes having number average molecular weights of 400 to 3000 and an average OH functionality of ≧1.8, and containing at least one structural unit of formula I) wherein R is an aliphatic, linear or branched C1 to C20 radical, R1 is a linear or branched hydroxyalkyl radical having 2 to 10 carbon atoms and R2 is either hydrogen or a linear or branched hydroxyalkyl radical having 2 to 10 carbon atoms, B) addition polymers containing hydroxyl groups and having a number average molecular weight Mn of 500 to 50,000, a hydroxyl number of 16.5 to 264 mg KOH / g solid resin, an acid number of 0 to 150 mg KOH / g solid resin and a chemically bound carboxylate and / or sulphonate group content of 5 to 417 milliequivalents per 100 g of polymer solids, and C) polyisocyanates. The present invention also relates to coatings, adhesives or sealants obtained from these compositions.

Owner:BAYER MATERIALSCIENCE AG

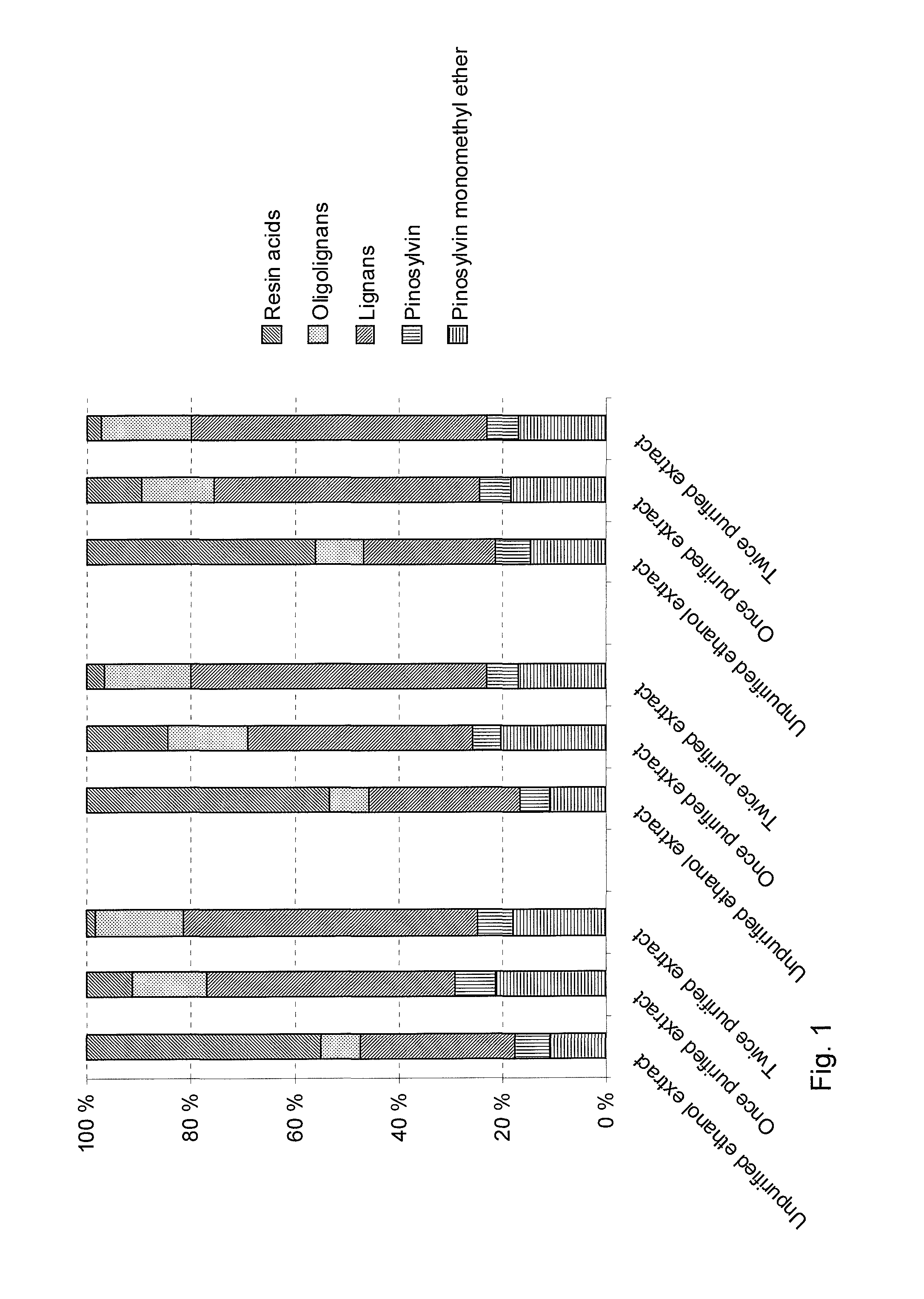

Method for the fractionation of knotwood extract and use of a liquid-liquid extraction for purification of knotwood extract

The invention relates to a method for the fractionation of knotwood extract, which has been obtained by extraction of knotwood with a hydrophilic solvent. The hydrophilic extract is extracted with a lipophilic solvent to remove lipophilic impurities. The invention also relates to the use of a liquid-liquid extraction for the purification of hydrophilic knotwood extract. The present process provides a purified knotwood extract, which contains more than 90% lignans, flavonoids and stilbenes and less than 10% impurities selected from resin acids, fatty acids, sterols, juvabiones, triglycerides and combinations thereof.

Owner:UPM-KYMMENE OYJ

Additive for oil-based drilling fluids

InactiveUS20050037929A1High level of filtration controlReduces and eliminates needTransportation and packagingFluid removalFiltrationPolyamide

A method and product is disclosed which provides emulsion stability and filtration control to invert emulsion drilling fluids. The product comprises a blend of a carboxylic acid terminated polyamide and / or a wetting agent with a reaction product or mixture produced by the Diels-Alder reaction of dienophiles, preferably carboxylic acids, polycarboxylic acids, acid anhydrides, or combinations or mixes thereof, with a mixture of fatty acids and resin acids. The product of the invention is extremely effective, decreasing by about two-thirds the amount of emulsifier generally required to formulate an effective drilling fluid. The product of the invention also greatly reduces and in many cases eliminates the need for conventional fluid loss additives, and additionally provides electrical stability. Moreover, the product of the invention has a pour point as low as about 20 degrees Fahrenheit with minimal solvents, thereby eliminating the need to ship large amounts of inert material for use, and may be transported in a highly active state.

Owner:HALLIBURTON ENERGY SERVICES INC

Abrasive composition and method for manufacturing semiconductor integrated circuit device

InactiveCN102210013AGrinding speed is fastInhibit grinding speedOther chemical processesSemiconductor/solid-state device manufacturingColloidal silicaResin acid

An abrasive composition which is used during the pattern formation wherein buried copper wiring and insulating layers are alternately formed by grinding each copper layer which is formed on each insulating layer via a barrier layer, specifically in a process wherein each copper layer is ground until the barrier layer adjacent thereto is exposed. The abrasive composition contains an alicyclic resin acid, a colloidal silica and tetramethylammonium ions. The colloidal silica is contained in an amount of 0.1-1.5% by mass relative to the abrasive composition, and has an average primary particle diameter of 10-40 nm and an average secondary particle diameter of 30-80 nm, with the value obtained by multiplying the average secondary particle diameter by the amount thereof contained in the composition being within the range of 10-40.

Owner:ASAHI GLASS CO LTD

Fluoroelastomer heat-shrinkable tube and manufacturing method thereof

ActiveCN101956876AImprove high temperature resistanceGood low temperatureFlexible pipesPlasticizerEngineering

The invention relates to a fluoroelastomer heat-shrinkable tube and a manufacturing method thereof. In order to overcome the defects that a traditional heat-shrinkable tube has poorer performance on resisting temperature, oil and solvents and cannot adapt to high performance requirements on resisting the oil and the solvents in industries of automobiles, high-speed trains, war industry, aerospaceand the like, the invention provides the fluoroelastomer heat-shrinkable tube which mainly comprises the materials of a fluoroelastomer, a fluorine resin acid acceptor, a reinforcing agent and a plasticizer. Meanwhile, the invention also provides a method for manufacturing the heat-shrinkable tube by using the materials. The fluoroelastomer heat-shrinkable tube provided by the invention can be applied to the industries of automobiles, high-speed trains, war industry, aerospace and the like which have higher requirements for resisting high and low temperature and the solvents.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Magnetic foamed plastic

The invention relates to the foaming plastic technical field, in particular to magnetic foaming plastic, which comprises 25-65% plastic rubber composition, 20-60% magnetic powder, 5-15% foamable agent, 5-30% talcum powder filling agent and 2-10% resin acids lubricating agent according to parts by weight, wherein plastic rubber composition is one of EVA, PVC, PE, POE and TPE, magnetic powder is rare earth magnet neodymium iron boron magnetic powder, foamable agent is azobisformamide, adhesive agent is dicumyl peroxide, resin acids lubricating agent is one of monoglyceryl stearate and calcium stearate. Plastic after shaped can be randomly bended according to demanded shapes, and has elasticity, and can joint with other materials, the surface can be randomly polished, and the magnetism is much stronger after polished, recovery and usage space is large, the plastic can be shaped secondly, which is reshaped into shapes which is required through coining heating, and is easy to process since hardness is small.

Owner:林彬

Modified calcium carbonate, polymer composition containing the same and process for producing them

InactiveCN1668710AImprove mechanical propertiesImprove wear resistanceCalcium/strontium/barium carbonatesPigmenting treatmentOrganic acidResin acid

A modified calcium carbonate comprising calcium carbonate as a raw material and, superimposed on the surface thereof, (i) a silica layer, (ii) an organic acid layer constituted of at least one member selected from the group consisting of fatty acids, fatty acid salts, fatty acid esters, resin acids, resin acid salts and resin acid esters and (iii) a layer of silane coupling agent; and a polymer composition comprising the modified calcium carbonate.

Owner:SHIRAISHI KOGYO KAISHA LTD +1

Lead-free solder flux and solder paste

ActiveCN101090797AReduce productionPrinted circuit assemblingWelding/cutting media/materialsResin acidSolder paste

A flux for a lead-free solder that is able to reduce "void(s) appear within solder joint", "void(s) appear within solder joint", and "solder-balling" without impairing general solderabilities. The flux for a lead-free solder comprising 6-55 wt% of a polyvalent alcohol ester of a resin acid (a1) as a base resin (A). Further, a solder paste comprising the said flux for a lead-free solder and a lead-free solder powder provides a very small number of void(s) or a very small amount thereof.

Owner:ARAKAWA CHEM IND LTD

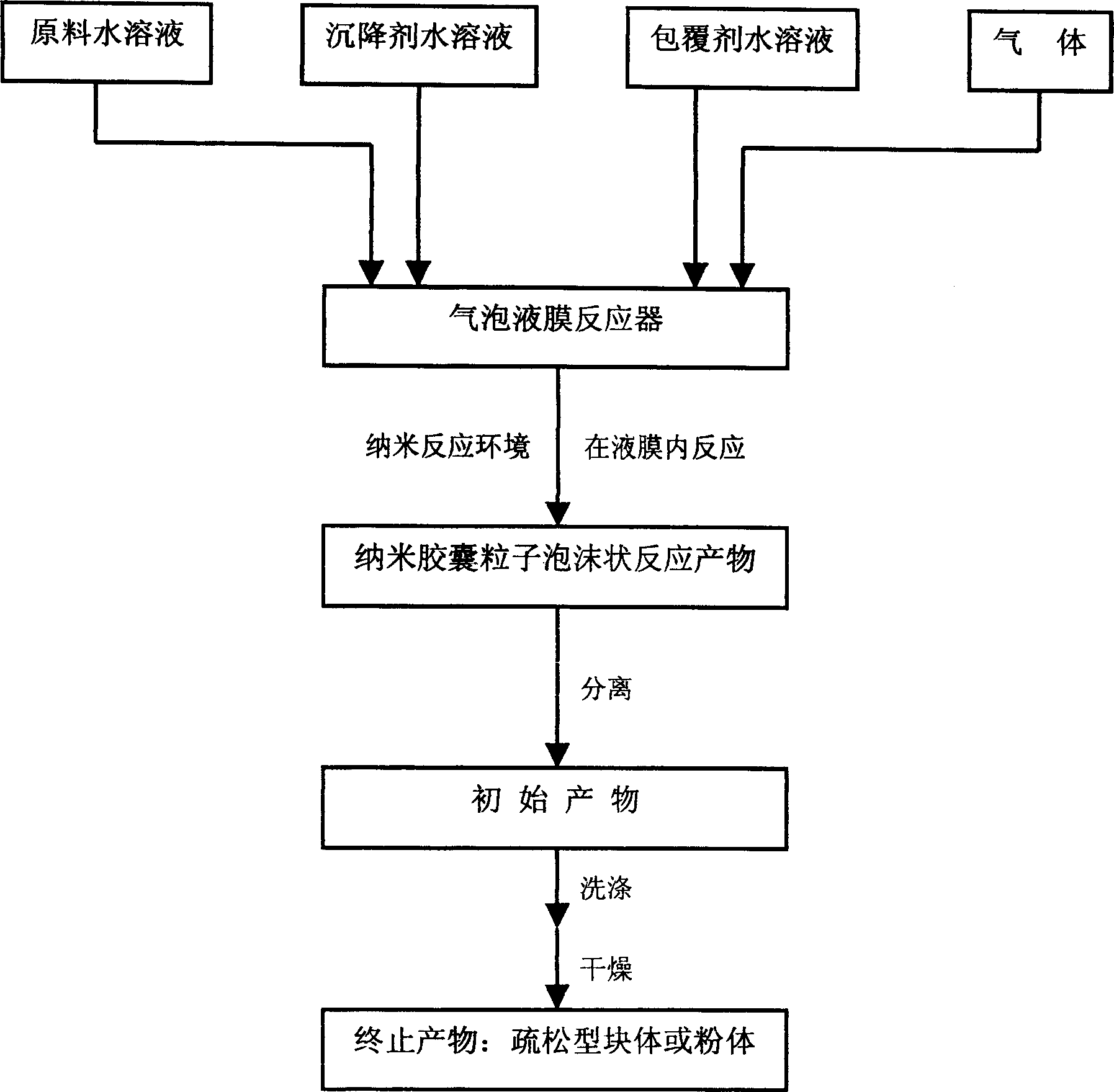

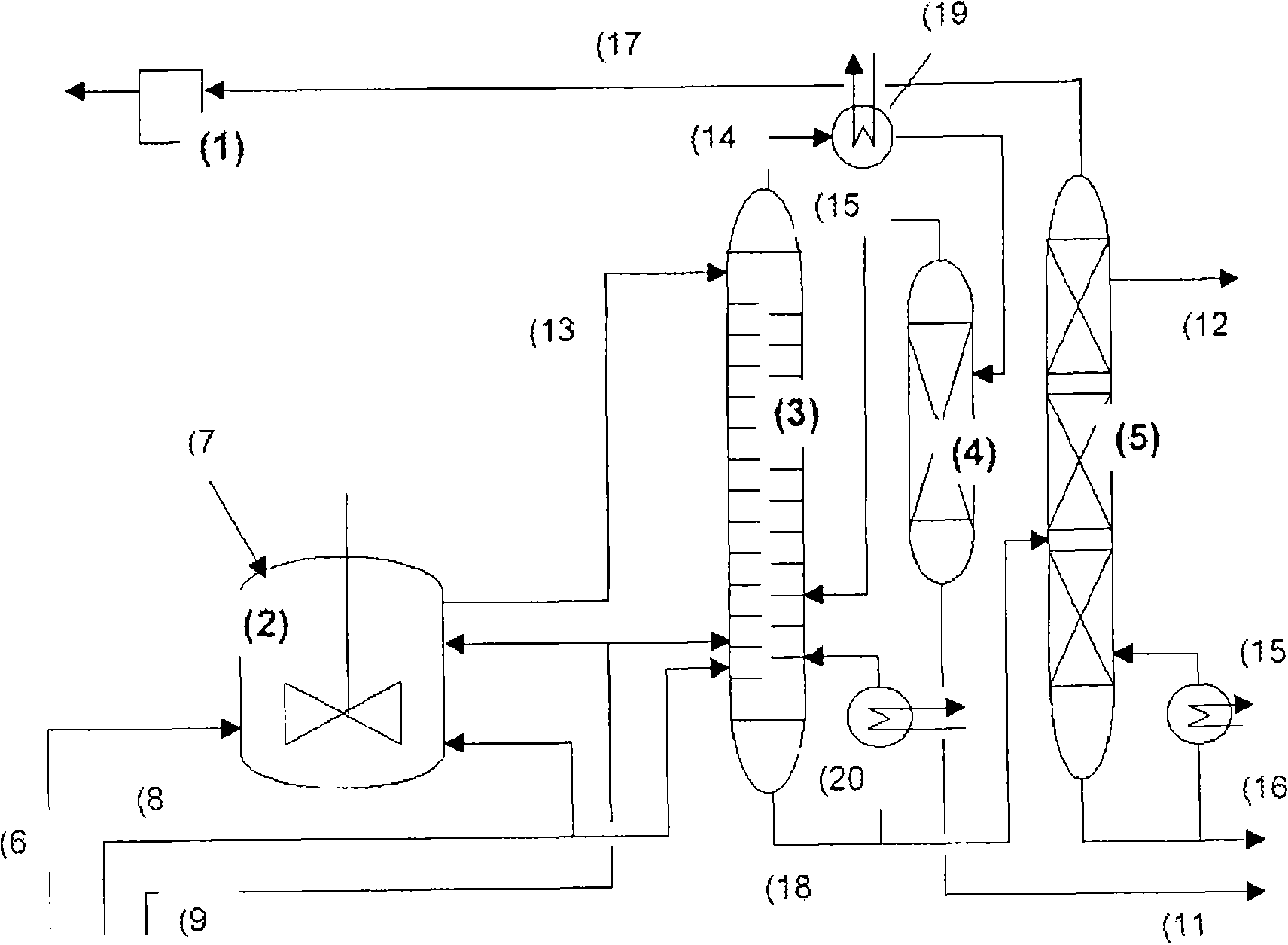

Air bubble liquid membrane method for producing nanometer granule material

ActiveCN1803272AReduce pollutionEasy to separateChemical/physical/physico-chemical processesLiquid-liquid reaction processesForming gasGas phase

Owner:LANZHOU LANSHI ZHONGKE NANOTECHNOLOGY CO LTD

Automotive fuels and fine chemicals from crude tall oil

InactiveCN101297024AHigh yieldImprove oxidation stabilityFatty oils/acids recovery from wasteFatty acid esterificationResin acidAlcohol

Owner:桑佩有限责任公司

Aqueous resin composition, aqueous coating material containing the composition, coating provided by the material, and metal plate coated with the material

There is provided an aqueous resin composition excellent in settability, flexibility, retort resistance, hygienicity, sprayability and dispersibility in water, and used to coat an internal surface of a can. The aqueous resin composition contains: polyester resin having a specific structure in a molecular chain thereof and / or at a terminal of the molecular chain, the polyester resin having added thereto an opened ring of a compound having a molecule with a carboxylic anhydride group therein, at least no less than 10% by mole of the compound being a compound having a molecule with no less than two carboxylic anhydride groups, the polyester resin having a resin acid value of 150 to 800 eq / 106 g and a number-average molecular weight of 5,000 to 100,000; resol-type phenol resin corresponding to a copolymer of a formaldehyde and a phenol compound containing no less than 50% by weight of a phenol compound having no less than three reactive point with formaldehyde, the resol-type phenol resin having no less than one alkoxy methyl group on average per aromatic nucleus; a basic compound; and water, or water and an organic solvent.

Owner:TOYO TOYOBO CO LTD

Pigment-dispersed composition, curable composition, color filter and production method thereof

The present invention provides a pigment-dispersed composition including at least a polymer compound (A-1) having at least one selected from the structural units represented by the following formulae (1) to (3), a pigment (B) and a solvent (C), and a pigment-dispersed composition including at least a resin (D) having an acid number of 100 mg KOH / g or more, a dispersion resin (A-2) having an acid number of less than 100 mg KOH / g and an unsaturation equivalent of less than 600, a pigment (B), and a solvent (C) [R1 to R20: a hydrogen atom, a monovalent organic group; A1 to A3: an oxygen atom, a sulfur atom, —N(R21)—; G1 to G3: a divalent organic group; X, Z: an oxygen atom, a sulfur atom, —N(R22)—; Y: an oxygen atom, a sulfur atom, a phenylene group, —N(R23)—; and R21 to R23: an alkyl group].

Owner:FUJIFILM CORP

Room-temperature-curable polyorganosiloxane composition

InactiveUS20100249308A1Without deteriorating physical propertySuppress surface glossPigment pastesResin acidCentistokes

The present invention provides a room-temperature-curable polyorganosiloxane composition which can become a silicone rubber with matte surface and is free from deterioration in physical properties. Specifically, the room-temperature-curable polyorganosiloxane composition comprises:(A) 100 parts by weight of a substantially straight-chain polyorganosiloxane having a viscosity of 20 to 1,000,000 centistokes at 25° C., and having a molecular chain terminal being sealed with a silanol group or a silicon atom-bonded hydrolyzable group;(B) 0.1 to 15 parts by weight of an organic silicon compound having 3 or more silicon atom-bonded hydrolyzable groups in a single molecule;(C) 0 to 15 parts by weight of a condensation reaction catalyst;(D) 100 to 400 parts by weight of a non-treated ground calcium carbonate or a ground calcium carbonate surface-treated with resin acid; and(E) 1 to 200 parts by weight of a non-treated precipitated calcium carbonate or a precipitated calcium carbonate surface-treated with resin acid,wherein at least one of (D) component and (E) component is required to be treated with resin acid, andwherein the amount of (D) component relative to the sum of (D) component and (E) component is within the range of 50 to 99.9% by weight.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Flux for Lead-Free Solder and Solder Paste

InactiveUS20080115861A1Small amountImprove thermal stabilityPrinted circuit assemblingWelding/cutting media/materialsResin acidSolder paste

A flux for a lead-free solder that is able to reduce “void(s) appear within solder joint”, “void(s) appear within solder joint”, and “solder-balling” without impairing general solderabilities. The flux for a lead-free solder comprising 6-55 wt % of a polyvalent alcohol ester of a resin acid (a1) as a base resin (A). Further, a solder paste comprising the said flux for a lead-free solder and a lead-free solder powder provides a very small number of void(s) or a very small amount thereof.

Owner:ARAKAWA CHEM IND LTD

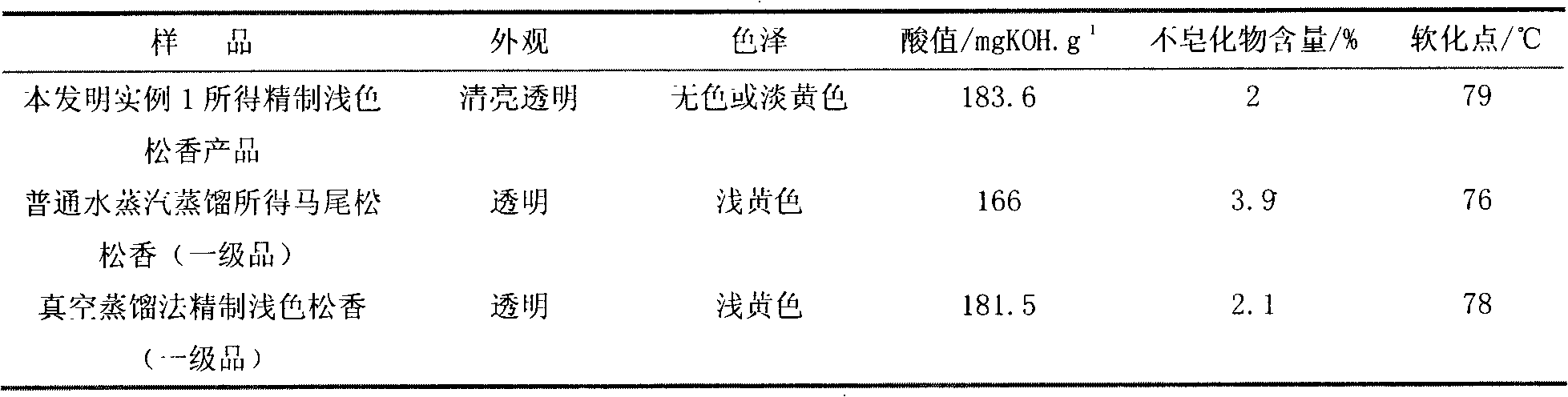

Method for producing refined light-color rosin by using turpentine as raw material

InactiveCN101649160AReduce consumptionThe process steps are simpleNatural resin chemical modificationResin acidAcid value

The invention discloses a method for producing refined light-color rosin by using turpentine as a raw material, which comprises the following steps: dissolving turpentine, purifying turpentine liquid,depositing and separating the rosin (resin acid), fusing the resin acid deposit, distilling and recycling the solvent and the terebinth, and the like. The rosin has the characteristics of light color, high acid value and low content of unsaponifiable matters, and achieves or exceeds the performance indexes of the refined light-color rosin prepared by the vacuum distillation technique. The methodhas the advantages of low equipment investment, simple operation and low operation cost, has favorable social and economic benefits, and is suitable for medium and small rosin fabrication plants.

Owner:GUANGXI UNIV FOR NATITIES

Void reducing asphalt membrane composition, method and apparatus for asphalt paving applications

ActiveUS20160265169A1Reduce void volumeReduce viscosityIn situ pavingsSuspension bridgeBrickRoad surface

A void reducing asphalt membrane composition for asphalt pavements that includes: an asphalt binder; an elastomeric polymer; a wax modifier; and at least one of: i) fumed silica or fumed alumina; and ii) a saponified fatty acid and a resin acid gelling compound. The composition is resistant to flow when applied and migrates into hot mix asphalt in the area of the longitudinal joint to reduce air voids to 7% or less and reduce water permeability. The composition becomes tack-free quickly after application. The composition bonds to asphalt, concrete, brick, stone and metal.

Owner:HERITAGE RES GROUP LLC

Mediator-Enzyme System for Controlling Pitch Deposits in Pulp and Paper Production

InactiveUS20080210393A1Reduce decreaseQuality improvementFats/resins/pitch/waxes removal in pulpMicroorganism/enzyme additionEnzyme systemFatty alcohol

The invention relates to the use of mediator-enzyme system, which is characterised in that the enzyme comprises a laccase-type enzyme and the mediator comprises a chemical compound which acts as a redox intermediate in the enzymatic oxidation, for the elimination of lipophilic compounds (including, among others, sterols that are free and conjugated in the form of esters and glycosides, triglycerides, fatty alcohols and resin acids) which cause deposits in the product, the machinery and the circuits during the production of pulp and paper (both from hardwood and softwood and non-woody plants). The treatment eliminates up to 100% of the aforementioned lipophilic compounds, depending on the material treated, and, in this way, improves the quality of the pulp obtained, the operation of the industrial installations and the characteristics of the end product.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

Chlorinated polyvinyl chloride resin acid-phase method production process

The invention discloses a chlorinated polyvinyl chloride resin acid-phase method production process. The working procedures of the production process comprises chlorination, deacidification by filtering, washing by water, neutralizing and drying, reactants of the chlorination procedure comprise the following components in parts by weight: 100 parts of polyvinyl chloride, 500 to 600 parts of hydrochloric acid solution with the mass concentration being 0.1 to 22 percent, 0.2 to 0.4 part of dispersing agent, 0.1 to 0.2 part of emulsifier and 0.1 to 0.3 part of initiator; the operating steps of the chlorination procedure are as follows: (1) adding the dispersing agent, the emulsifier and the polyvinyl chloride into the hydrochloric acid solution, and then stirring for emulsification and dispersion; (2) heating up to 70 to 80 DEG C, adding the initiator, then pumping a chlorine gas into reaction liquid for a chlorination reaction, wherein the reaction temperature is not over 110 DEG C, the pressure is controlled to be not higher than 0.45 MPa, and when the chlorine content reaches needing, the reaction is finished. According to the production process, the chlorination reaction is performed by replacing an aqueous medium with a hydrochloric acid medium with a certain concentration, so that the uniformity of the chlorination reaction is improved, and the chlorine content is stable; meanwhile, after the concentration of acid is increased, acid liquor is recycled, and an assistant in mother liquor is recycled, so that the discharge of waste acid is reduced, the discharge of organic matters is also reduced, the efficiency is improved, the cost is lowered and environment protection is strengthened.

Owner:山东旭业新材料有限公司

Preparation method of dibasic acid of higher fatty acid and rosin resin acid

InactiveCN101597544ABiodegradableComply with green environmental protectionFatty acid chemical modificationNatural resin chemical modificationFlexural strengthFirming agent

The invention discloses a preparation method of dibasic acid of higher fatty acid and rosin resin acid, comprising the following steps: step 1, appropriate grease is heated up to 150-190 DEG C, which is then catalyzed and hydrolyzed with high pressure to obtain fatty acid used for polymerization reaction; and step 2, the above higher fatty acid and appropriate rosin are premixed and added with a catalyst and a promoter, so that the mixed system is maintained at the pressure of 0.4-1.0MPa, then polymerization addition is carried out at 200-280 DEG C to obtain the required novel dibasic acid. Compared with versamid prepared by ordinary dimer acid, the versamid firming agent synthesized by the novel dibasic acid of the invention has better miscibility with epoxy resin due to the addition of the alicyclic structure of rosin, and the epoxy resin solidifying material has higher mechanical properties of compression strength, modulus of compressibility, bending strength, bending modulus and the like. The invention takes biomass resource grease and rosin as materials, having the biological degradability with which the petrified materials are not provided.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com