Preparation method of cubic ultra-fine calcium carbonate particles

An ultra-fine calcium carbonate, cubic technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of not improving product performance, difficult to obtain cubic calcium carbonate, etc., to achieve high performance and additional Value, regular crystal shape, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

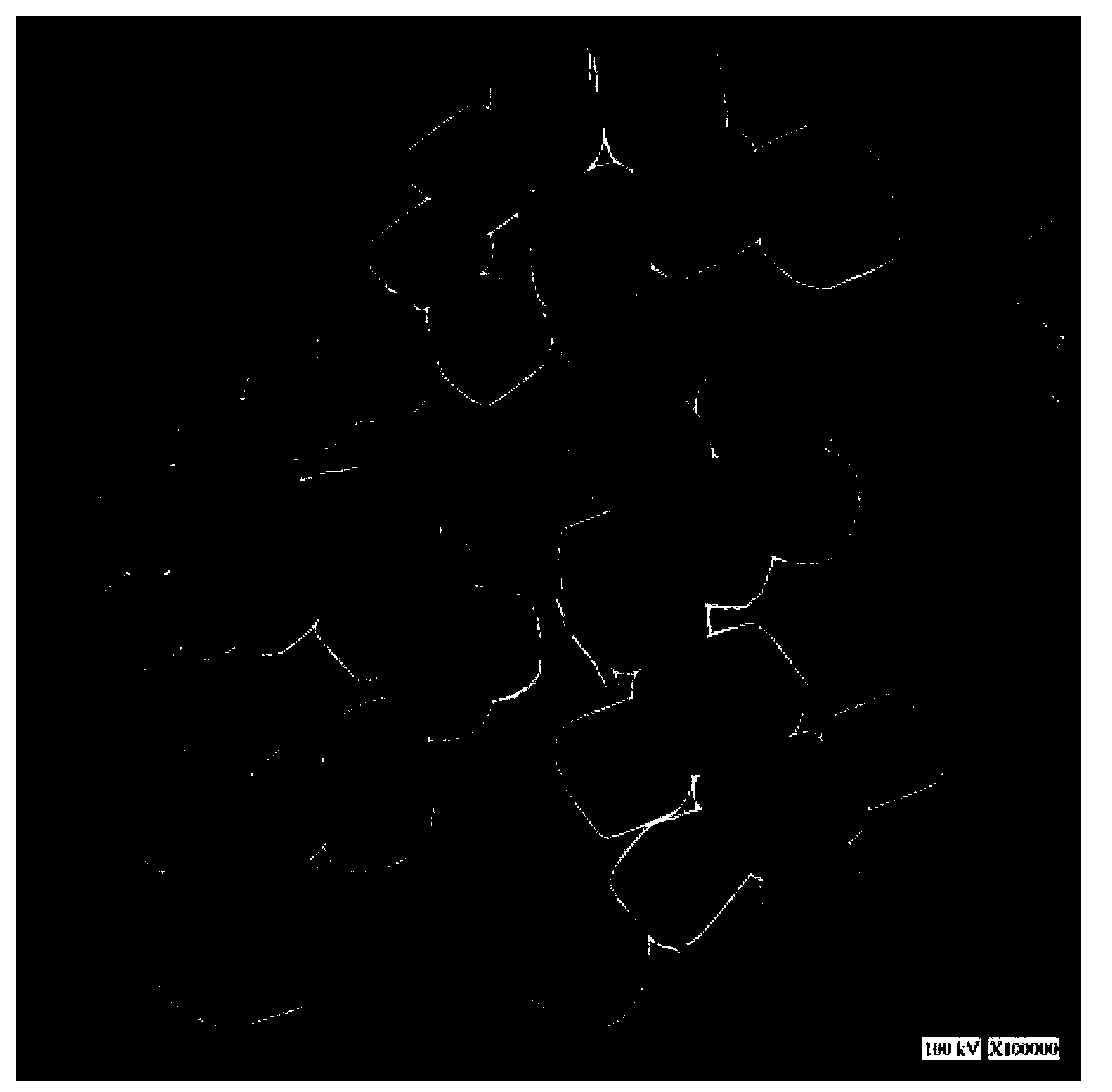

[0033] In a 10L reactor, add 8L of milk of lime with a mass percentage of calcium hydroxide of 12wt%, the temperature is 36°C, and 14.4g of sucrose is added, and a gas with a carbon dioxide concentration of 50% (volume fraction) is introduced under mechanical stirring. , carry out the carbonization reaction, the gas flow rate is 230L / h, when the carbonization reaches a pH of 10, the temperature of the system is 53°C, stop the aeration and add 7.2g of sodium bicarbonate, raise the temperature to 55°C and age for 4h, then re-introduce the above Concentration of carbon dioxide gas, stop ventilation when the pH is 6.5, add sodium stearate emulsion containing 28.8g of sodium stearate, concentration of 20wt%, and temperature of 70°C, perform coating activation treatment for 1h, and then filter while hot, The filter cake is dried at 100°C to obtain cubic nanometer calcium carbonate. The product is regular cubic, the particle size distribution is 80-100nm, and the specific surface is ...

Embodiment 2

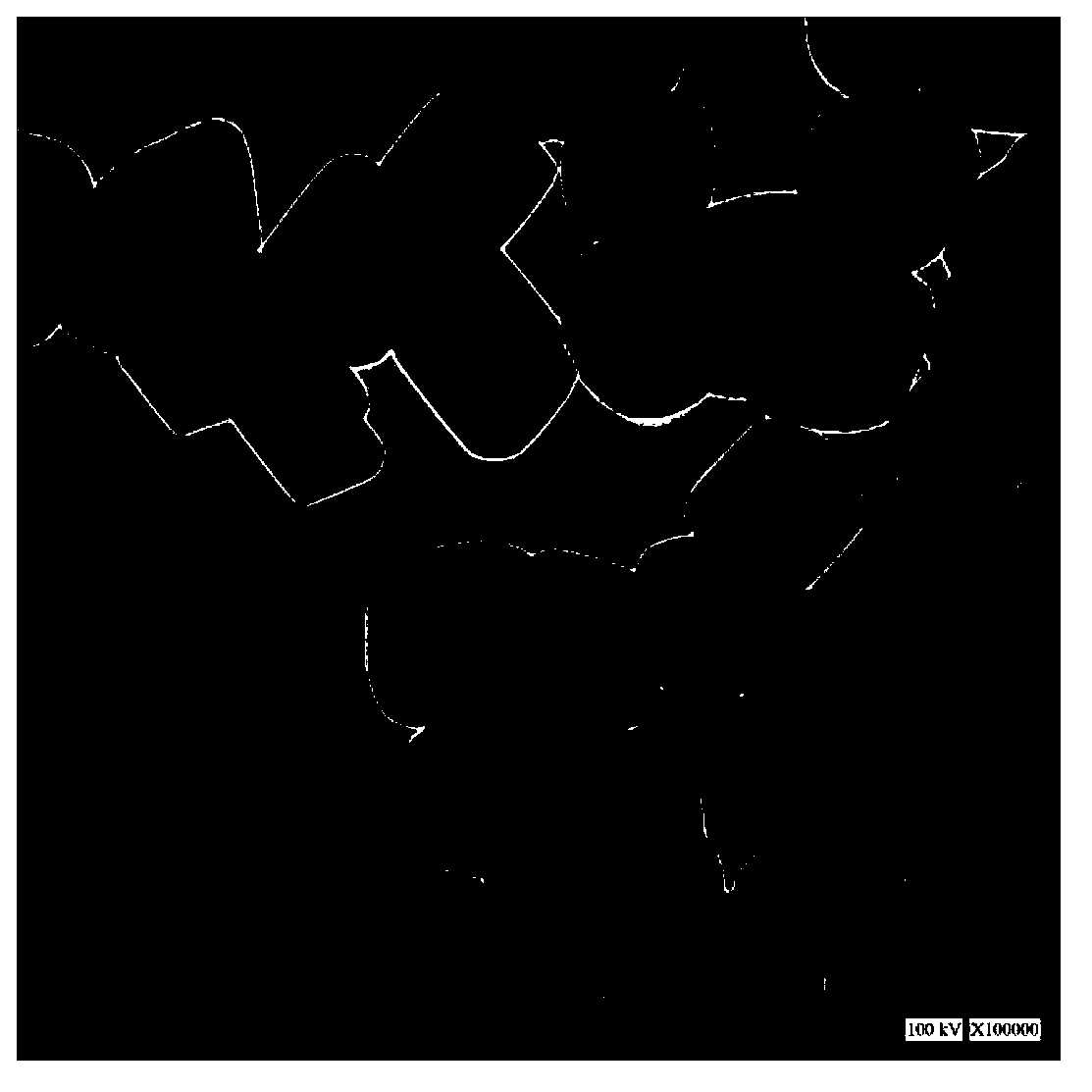

[0035] Add 8L of refined milk of lime with a calcium hydroxide mass percentage concentration of 16wt% in a 10L reactor at a temperature of 40°C, add 3.8g of sucrose, and pass in gas with a carbon dioxide concentration of 36% (volume fraction) under mechanical stirring. Carry out the carbonization reaction, the gas flow rate is 300L / h, when the carbonization reaches the pH of 12, the system temperature is 75°C, stop the aeration, keep warm and add 19.2g of sodium chloride, after aging for 8 hours, re-introduce carbon dioxide gas, and wait until the pH is At 6.8, stop ventilation. Add potassium stearate emulsion containing 38.4g of potassium stearate, concentration of 15% (weight concentration) and temperature of 80°C to the calcium carbonate suspension, carry out coating activation treatment for 2 hours, filter while hot, and filter cake in Dry at 100°C to obtain cubic nanometer calcium carbonate. The particle size distribution of this product is 100-130nm, the crystal form is...

Embodiment 3

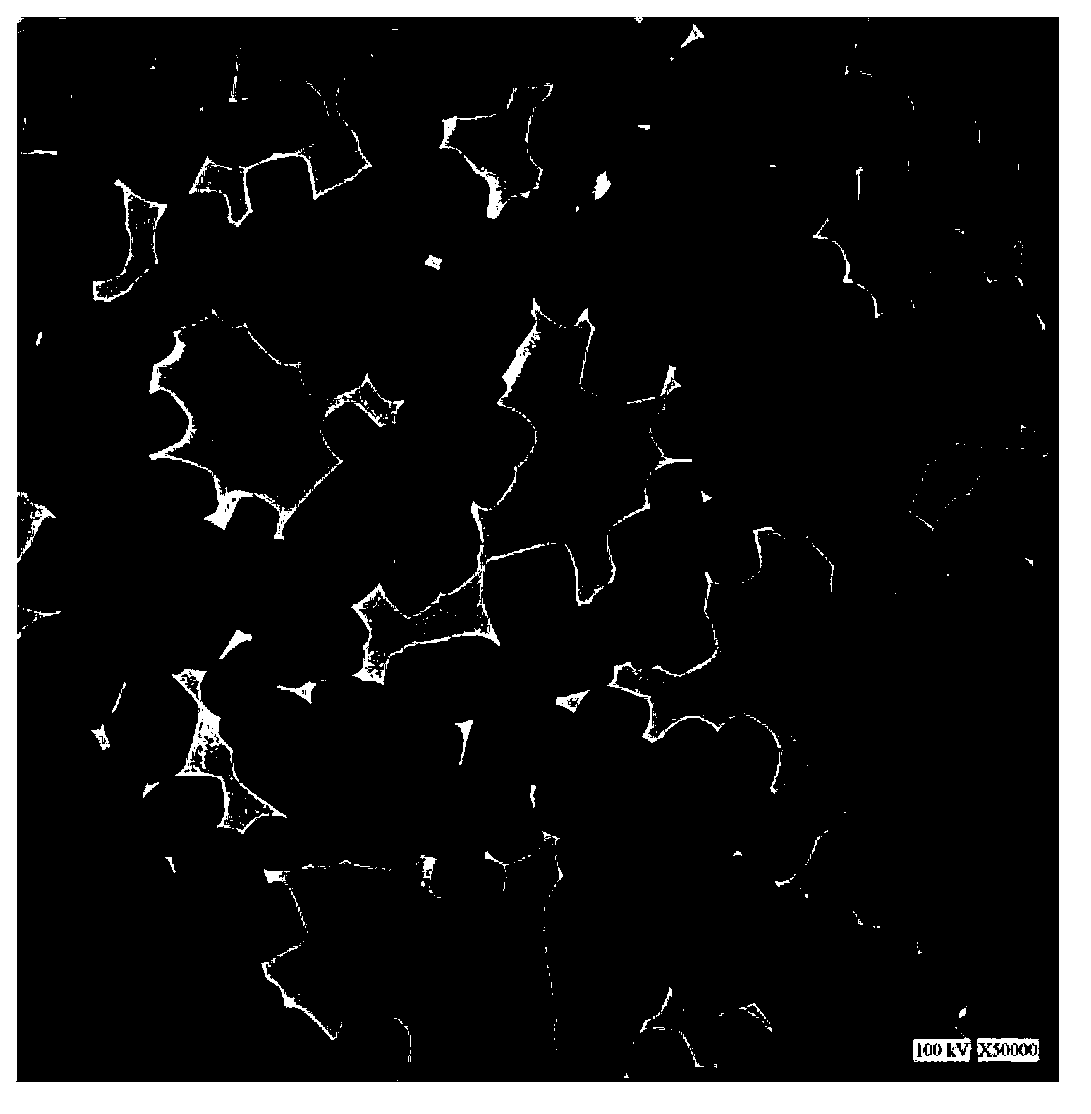

[0037]Add 8L of refined milk of lime with a mass percentage of calcium hydroxide of 8wt% in a 10L reactor, the initial temperature is 35°C, and 5g of sucrose and 2.2% of glucose are added, stirred and introduced with a carbon dioxide concentration of 67% (volume fraction) Gas, carry out carbonization reaction, the gas flow rate is 160L / h, when the carbonization reaches pH 9, the temperature of the system is 50°C, stop aeration and raise the temperature to 65°C, add 19.2g NaOH, after aging for 2 hours, re-introduce carbon dioxide gas , when the pH is 6.5, stop the ventilation and add sodium abietate emulsion containing 15.4g sodium abietate, the concentration is 10% (weight concentration), and the temperature is 85°C, carry out coating activation treatment for 1.5h, filter while hot, and wash , The filter cake is dried at 100°C to obtain cubic nanometer calcium carbonate. The particle size distribution of this product is 130-150nm, the crystal form is regular cubic, and the spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com