Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269 results about "Degree Fahrenheit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Fahrenheit temperature scale is named after the German physicist Gabriel Fahrenheit (1686-1736), who proposed it in 1724. In this scale, the freezing point of water is 32 degrees Fahrenheit and the boiling point is 212 degrees, placing the boiling and melting points of water 180 degrees apart. In this scale a degree Fahrenheit is 5/9ths of a Kelvin (or of a degree Celsius), and minus 40 degrees Fahrenheit is equal to minus 40 degrees Celsius. (NCI)

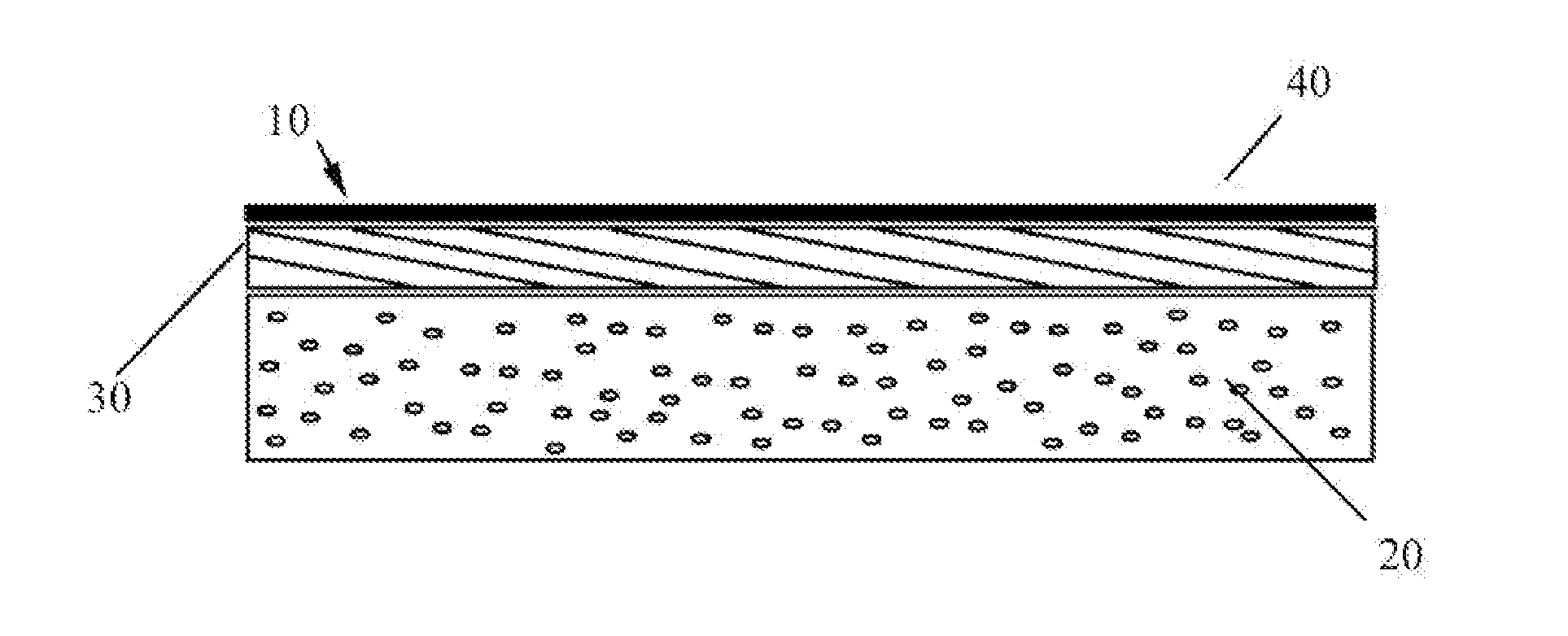

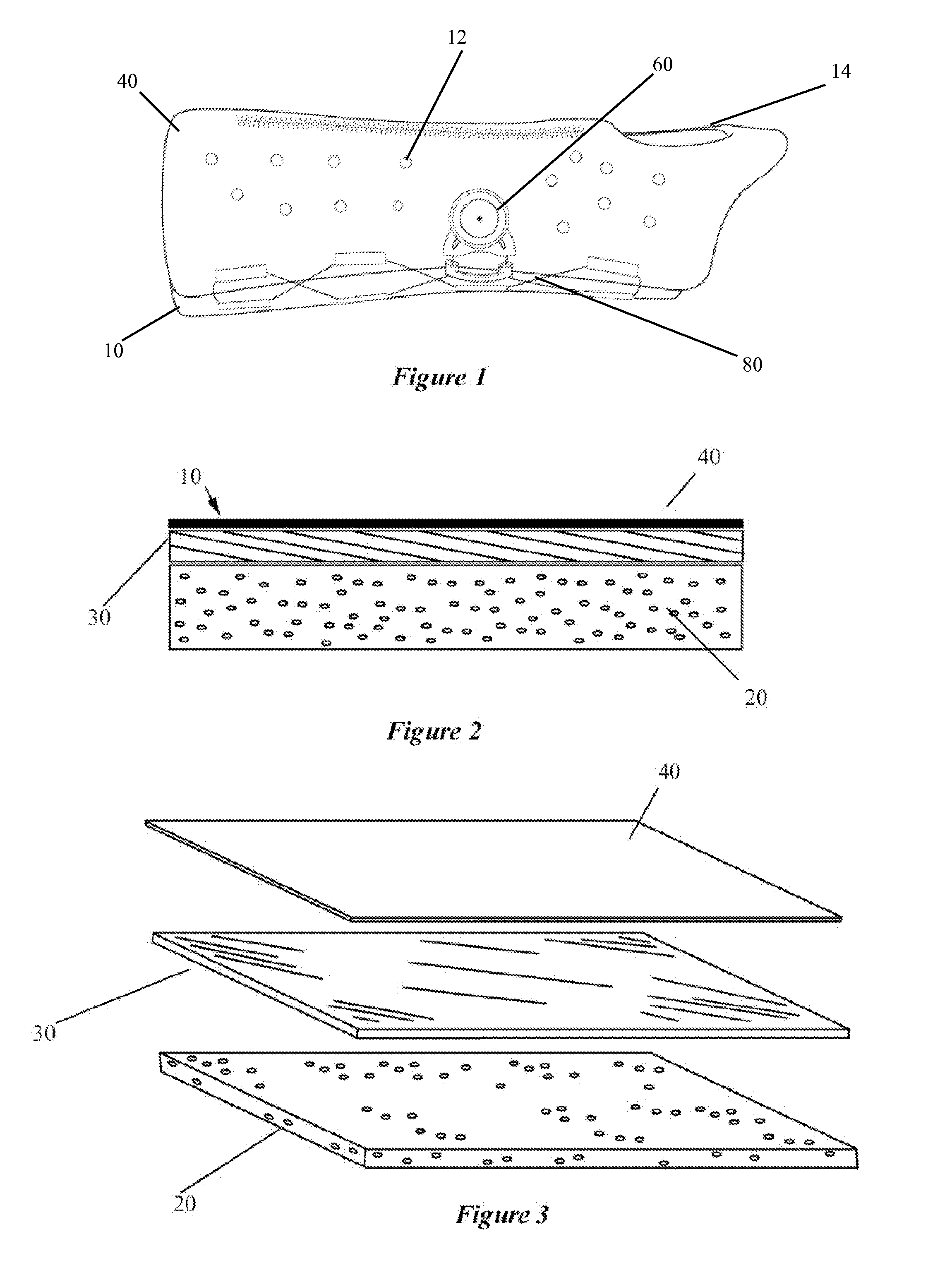

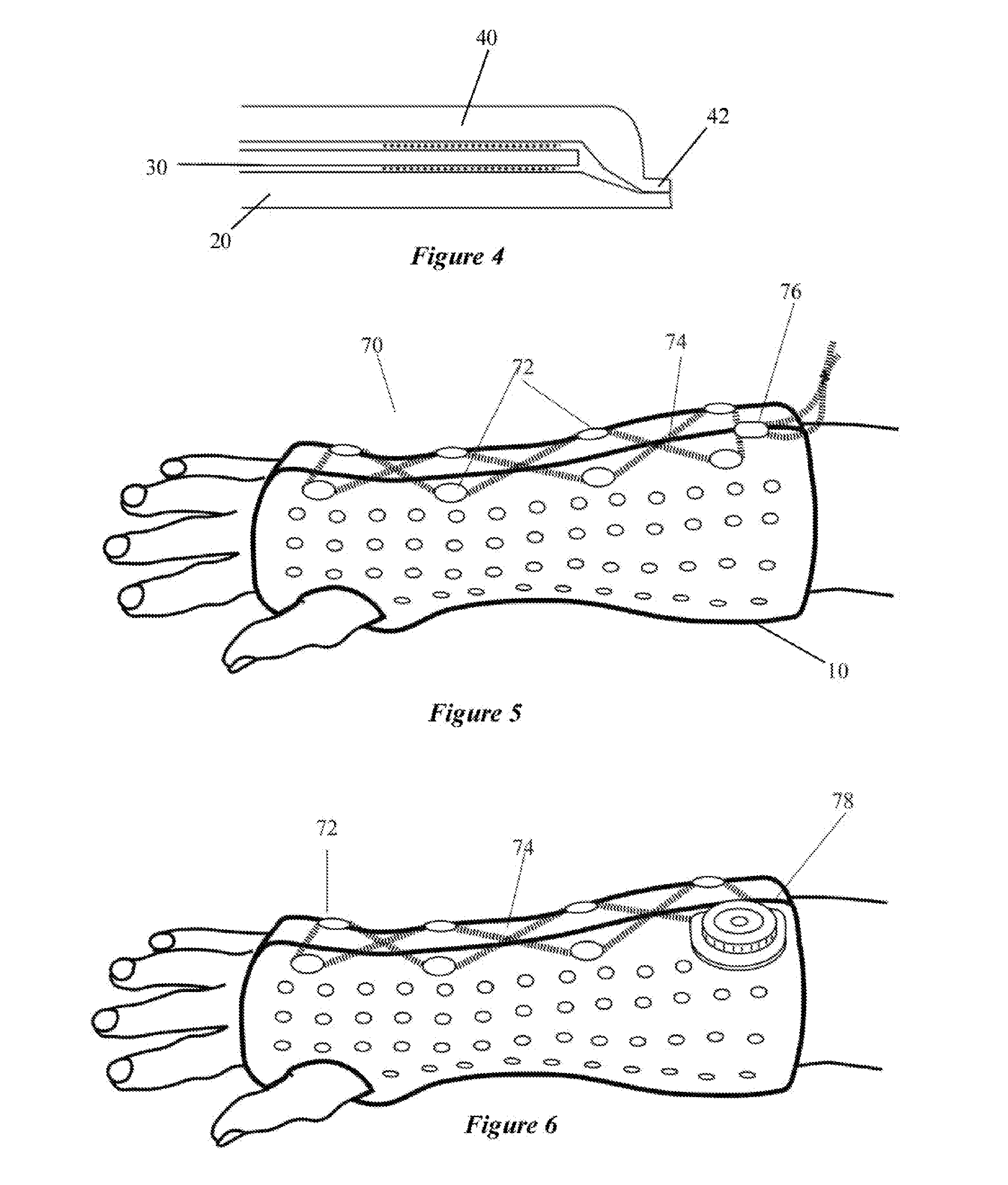

Composite material for custom fitted products

ActiveUS20120101417A1Easily custom fittedHighly rigidLayered productsDomestic articlesDegree FahrenheitCustom-fit

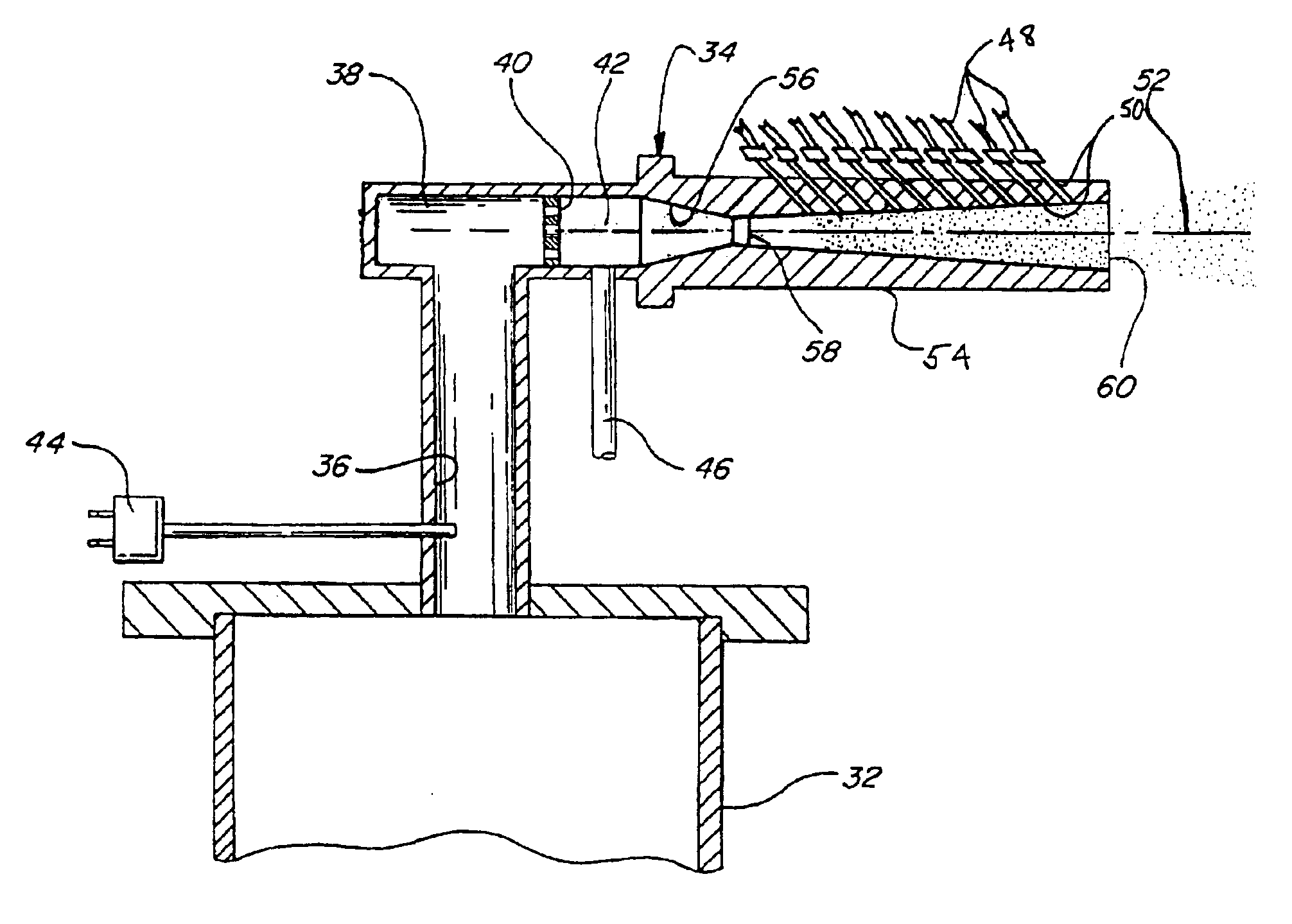

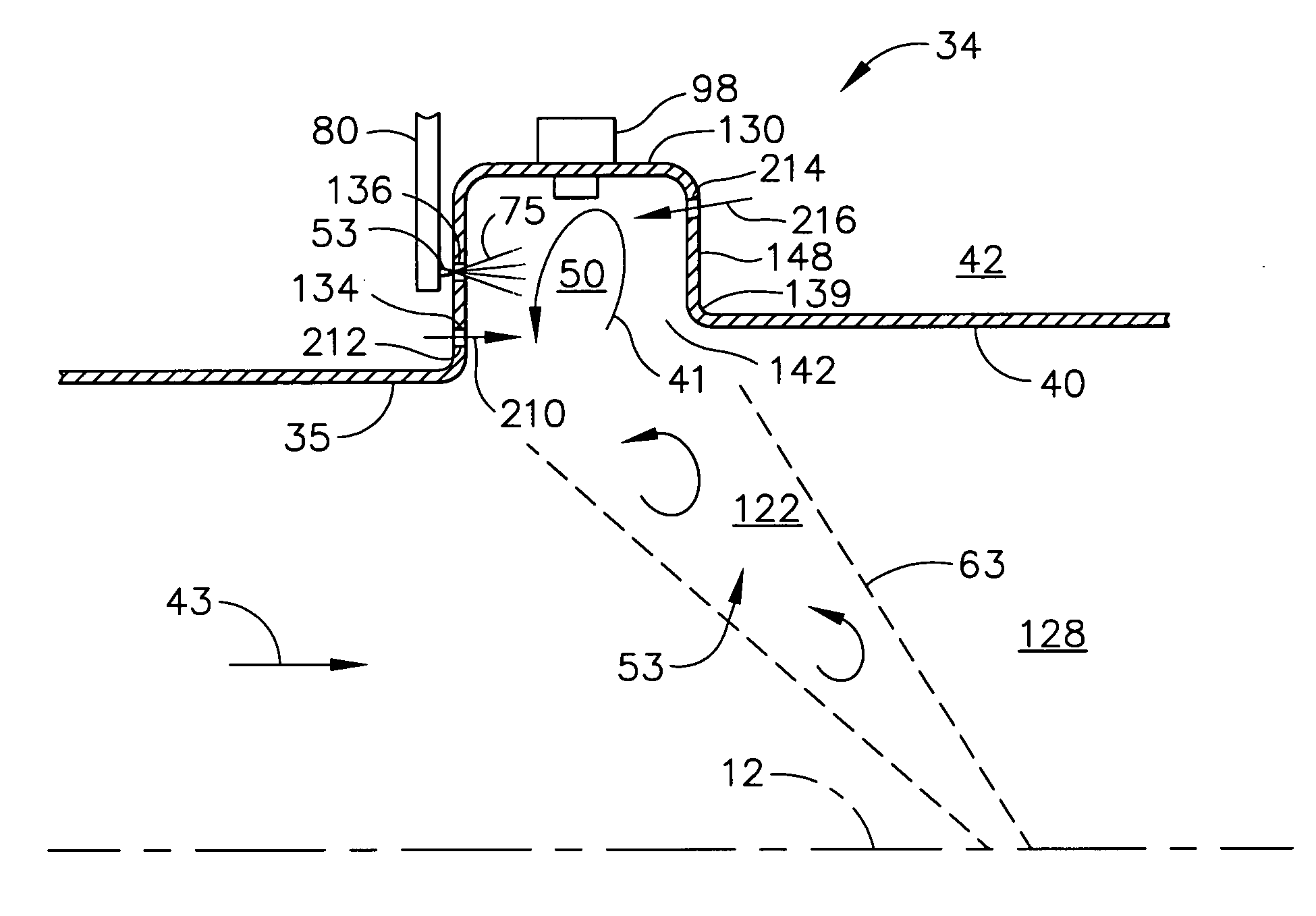

A composite material 10 for forming custom fitted orthopedic and other products. The composite material is easily formable when heated to temperatures of about two hundred degrees Fahrenheit for a time of at least six to eight minutes and then is rigid at temperatures of about one hundred thirty degrees. The composite material can be sewn and formed in complex shapes when initially heated to about two hundred degrees. Closure attachments 60 can be secured to the composite material as needed on site rather than at the manufacturing facility. The composite material can be custom fitted to a patient in situ.

Owner:DJO

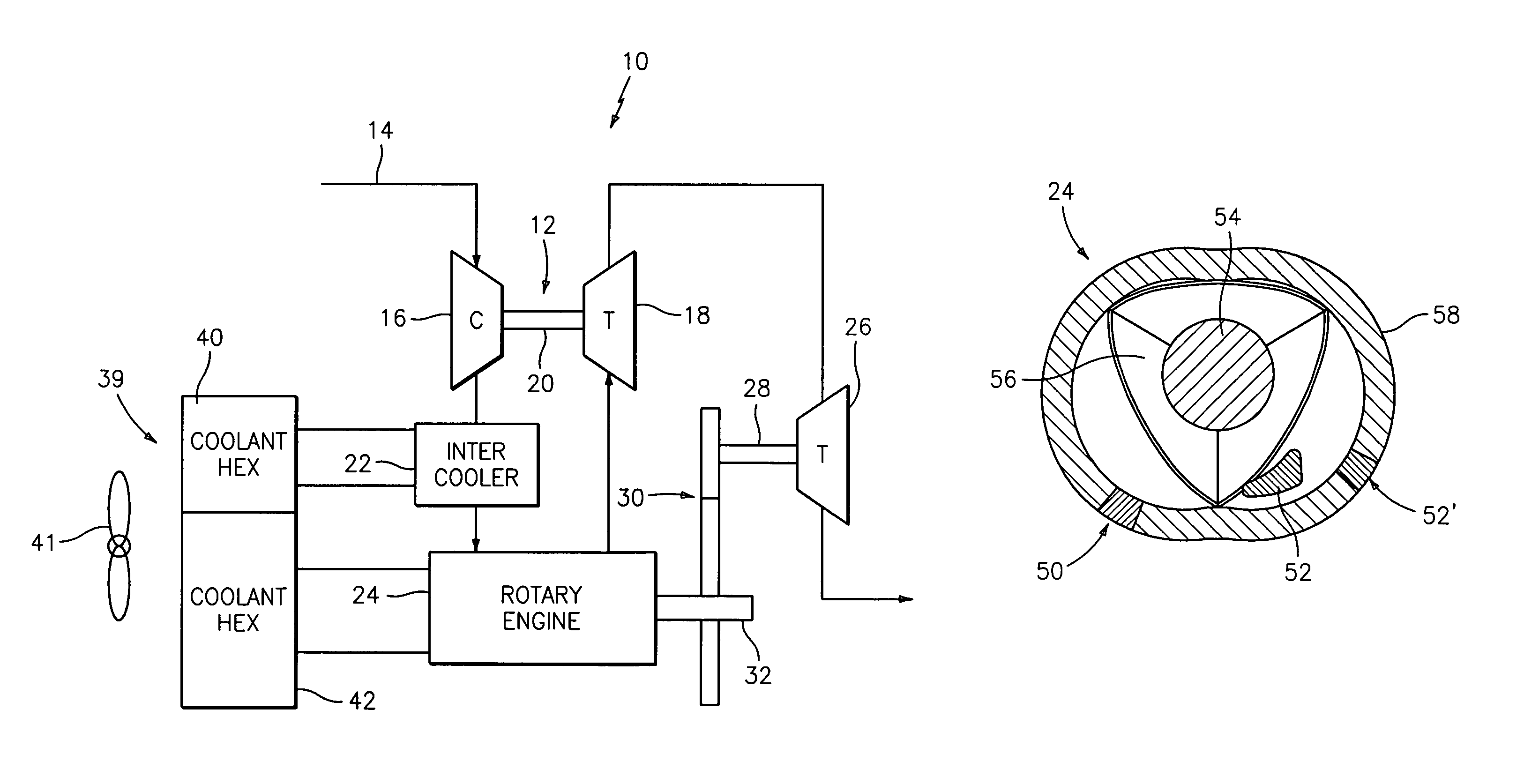

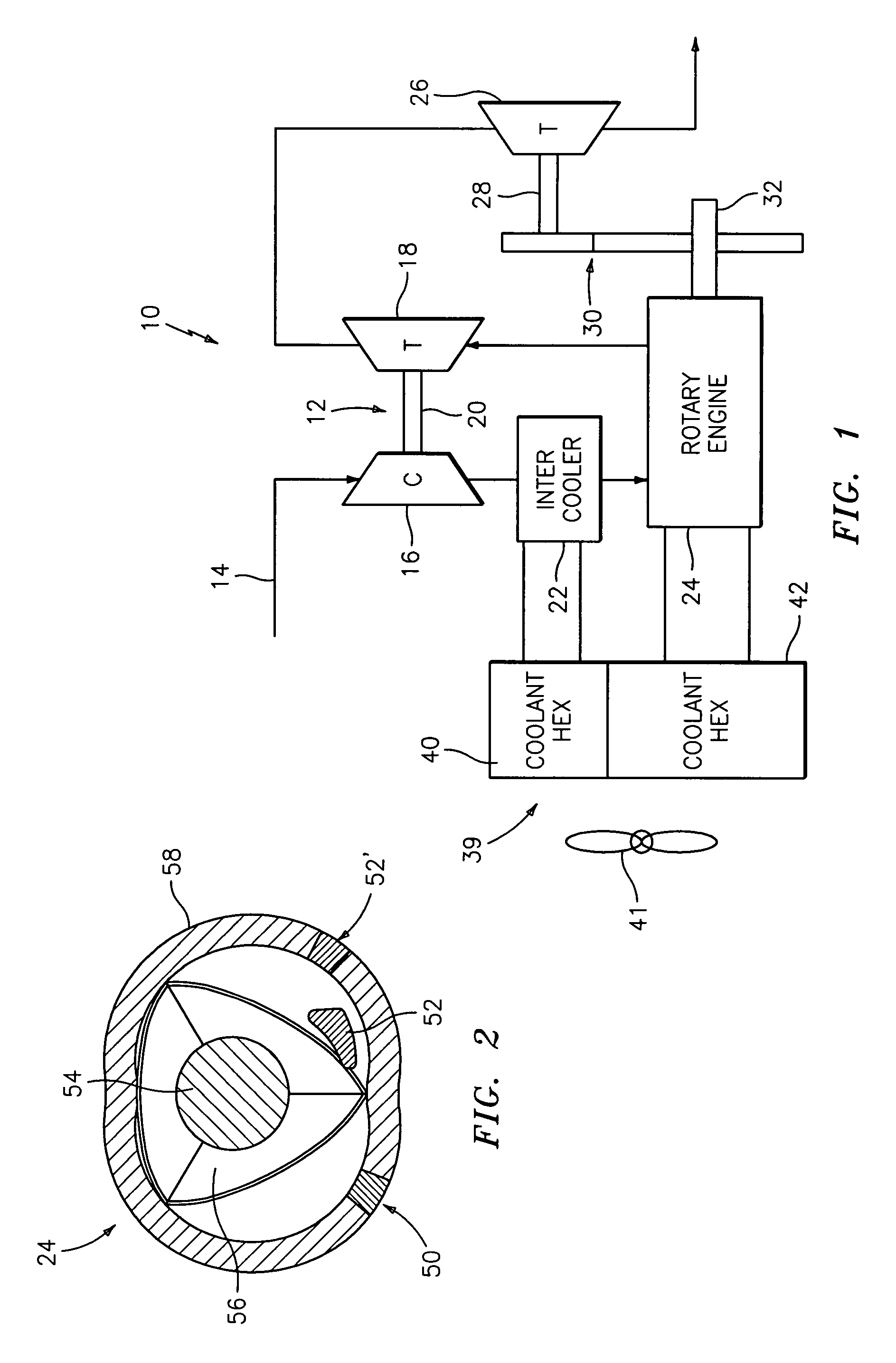

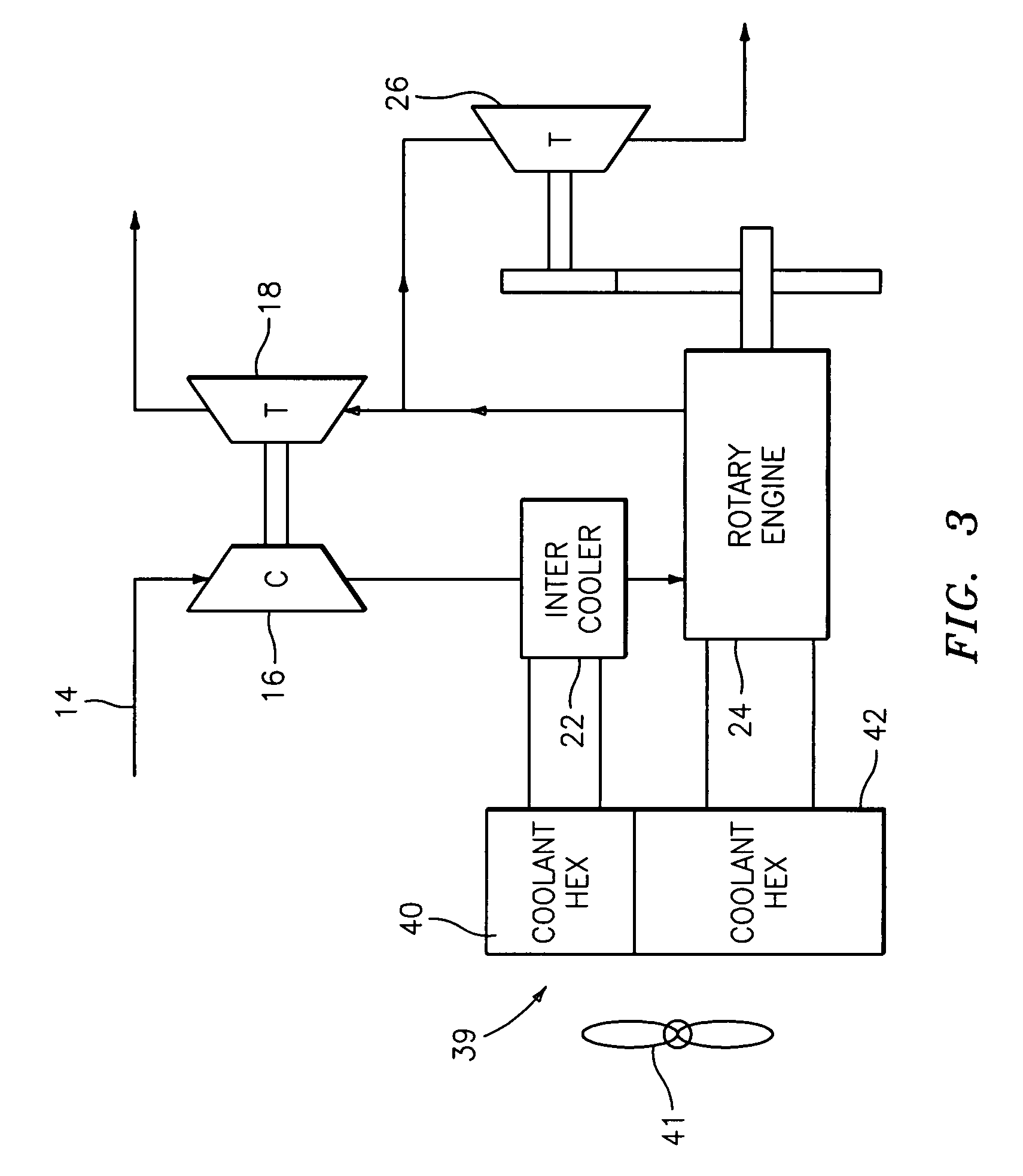

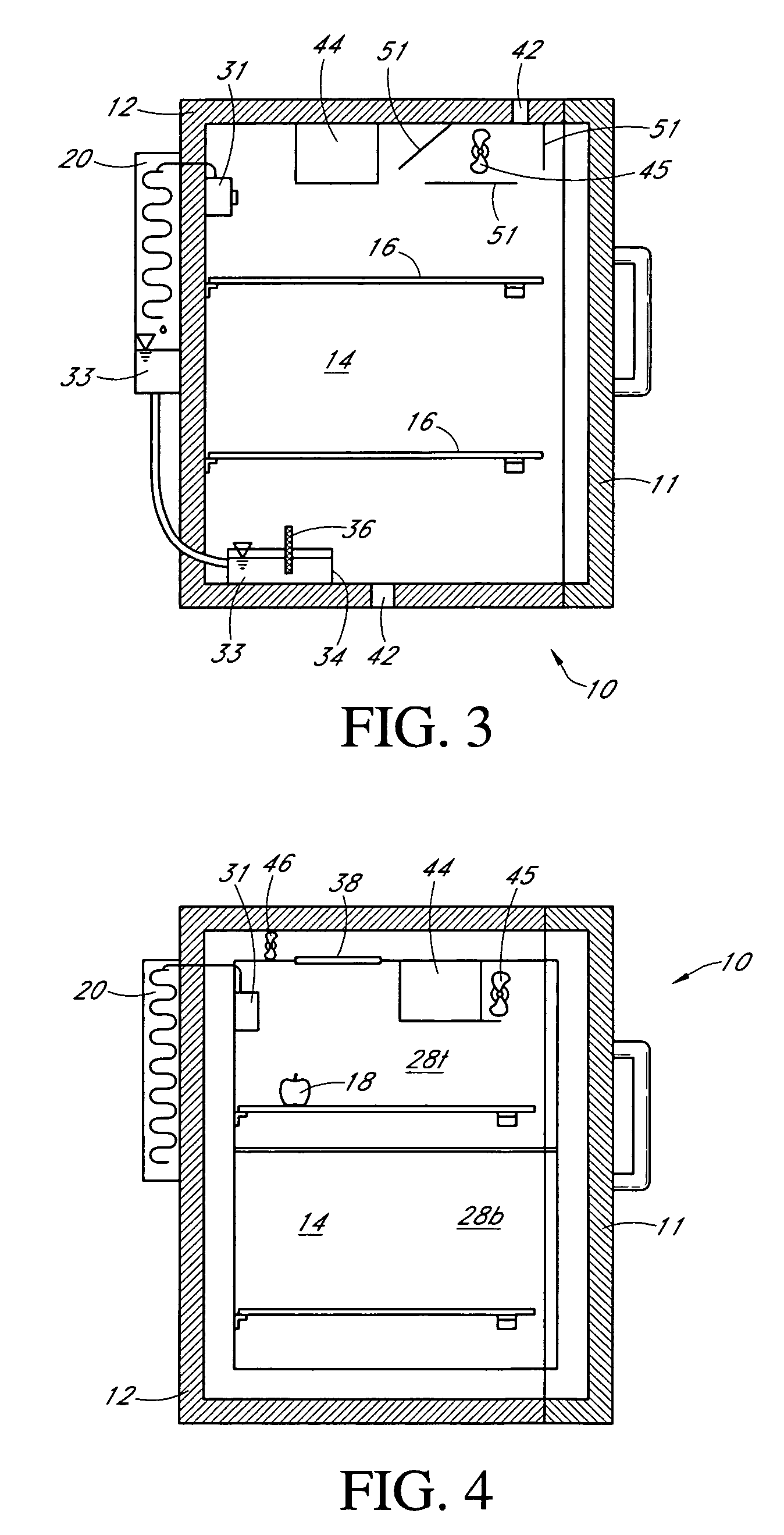

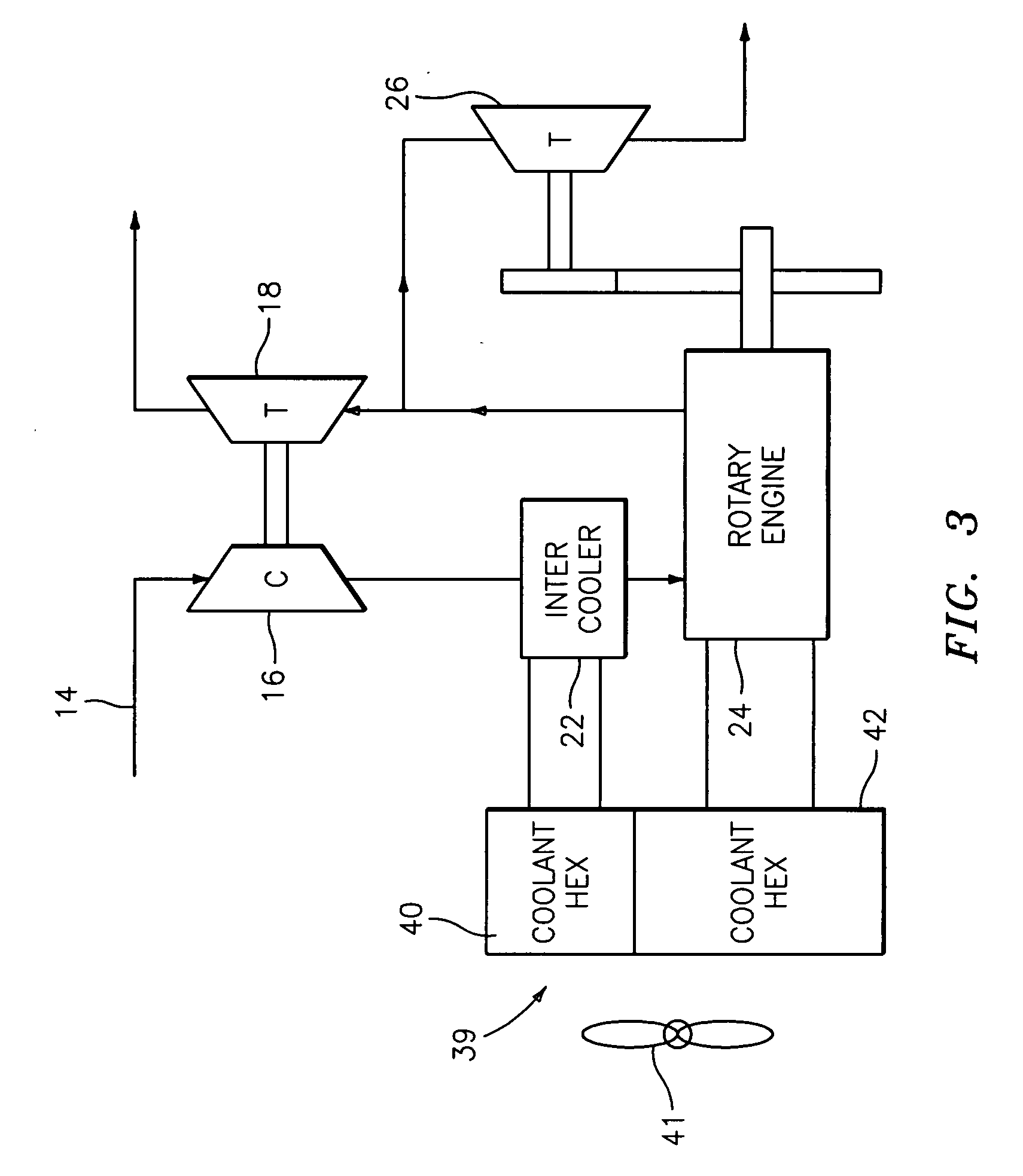

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

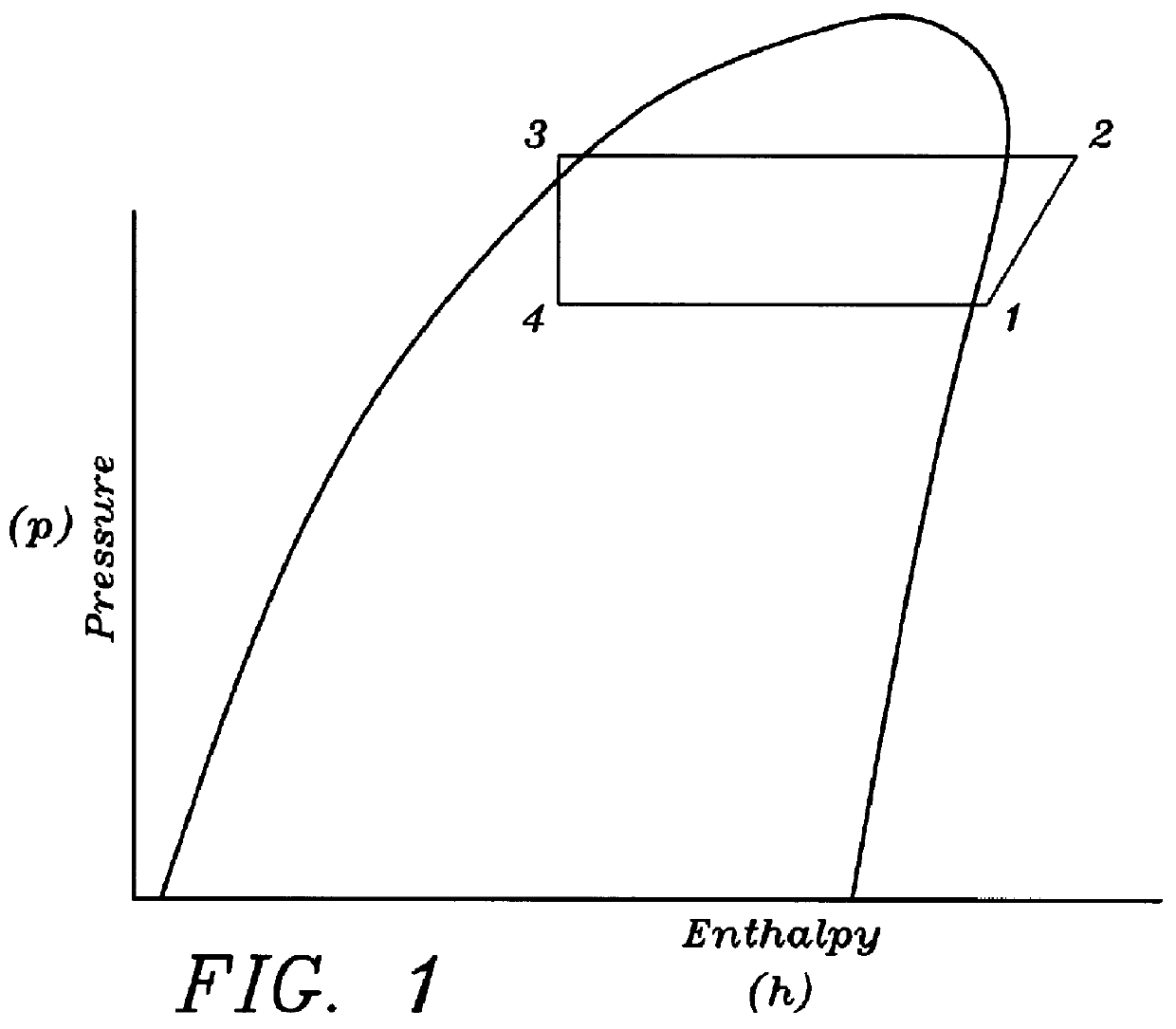

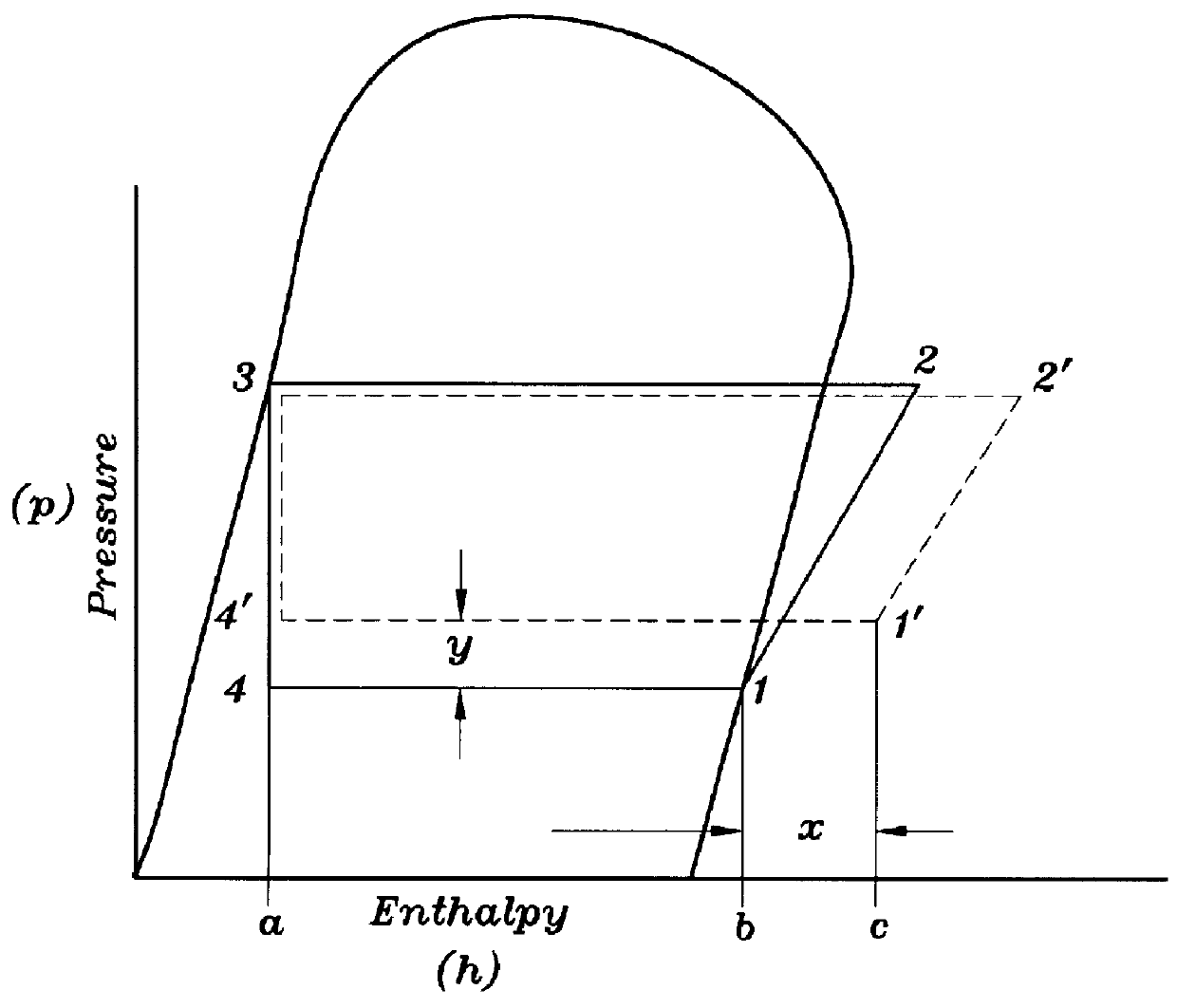

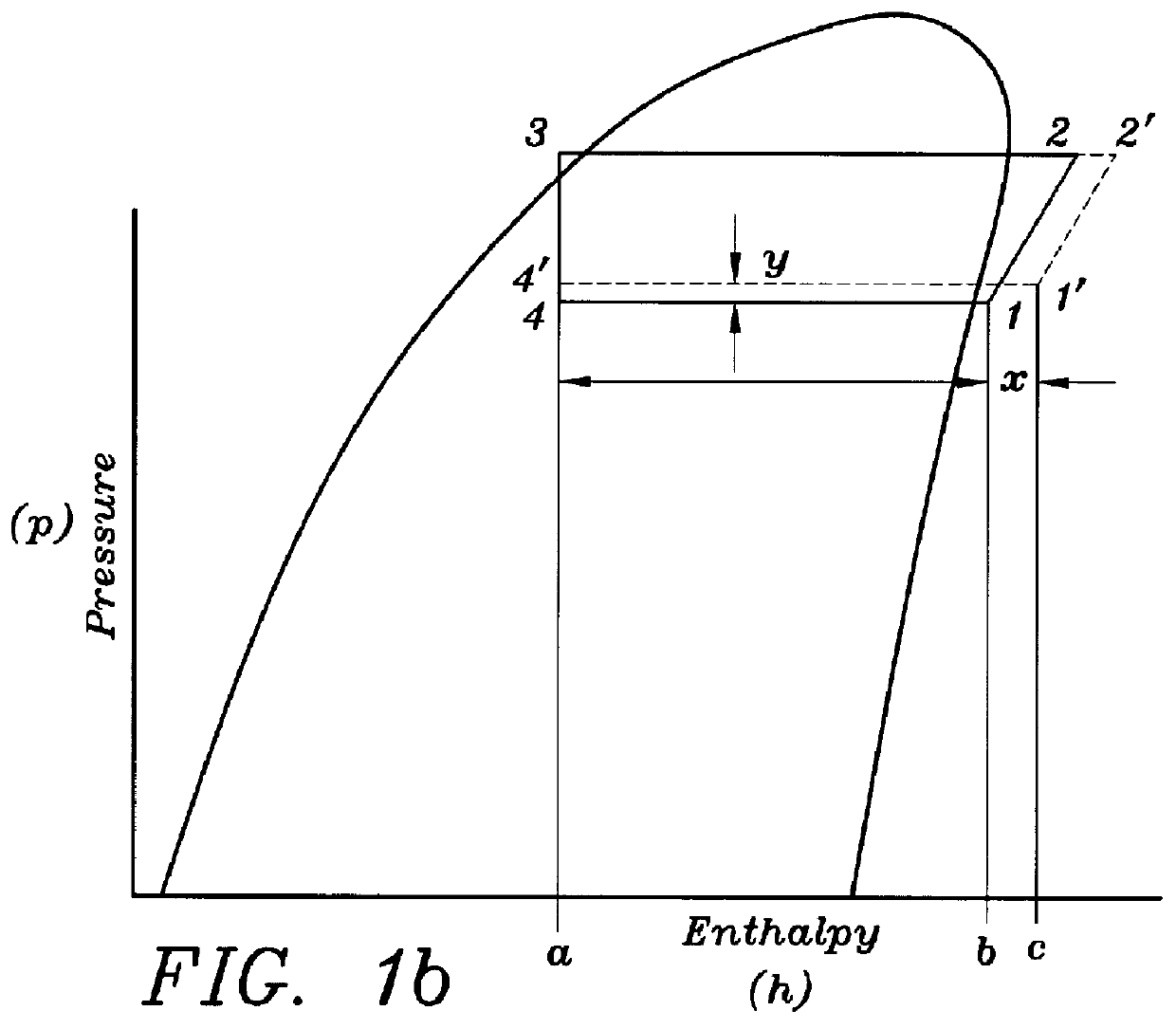

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

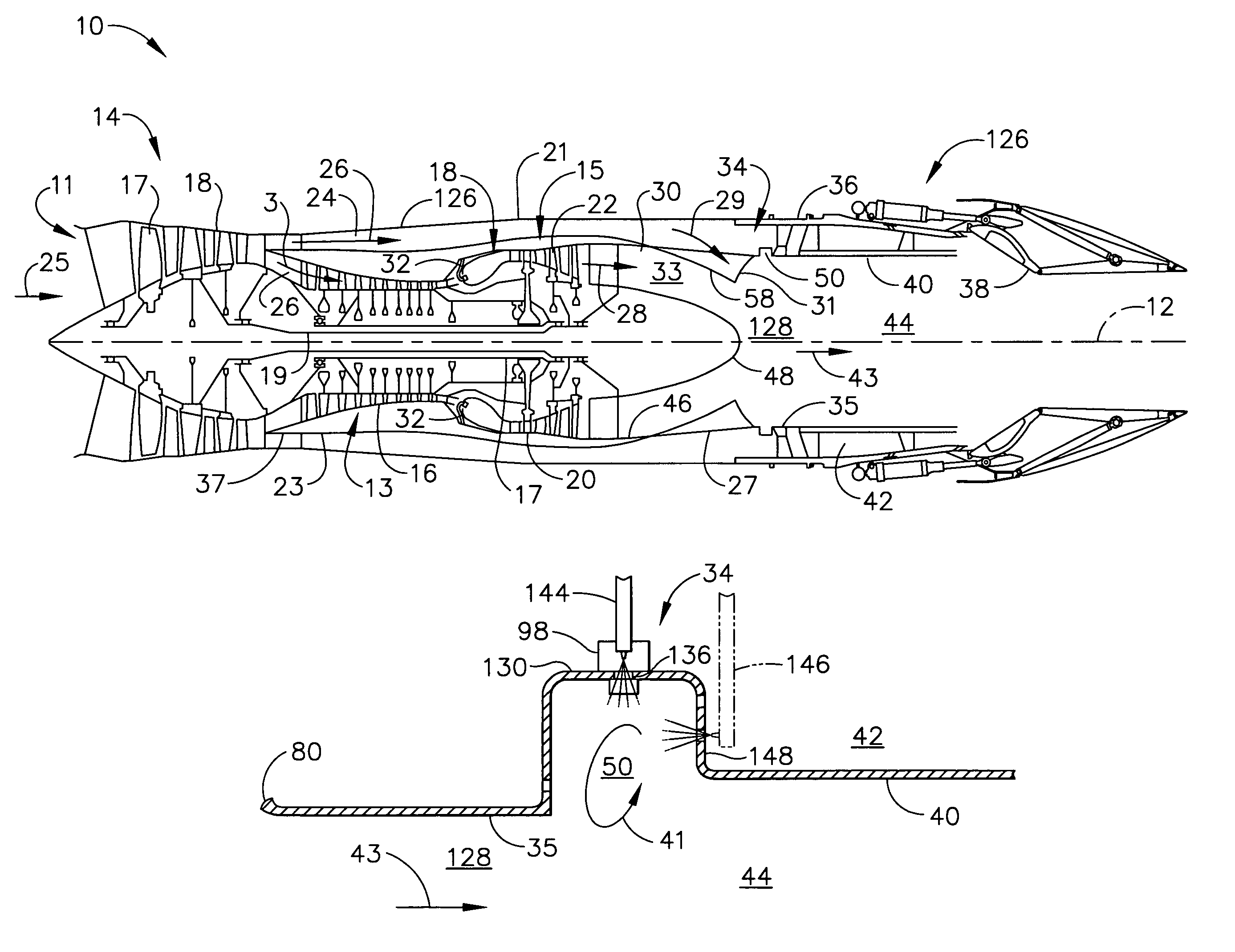

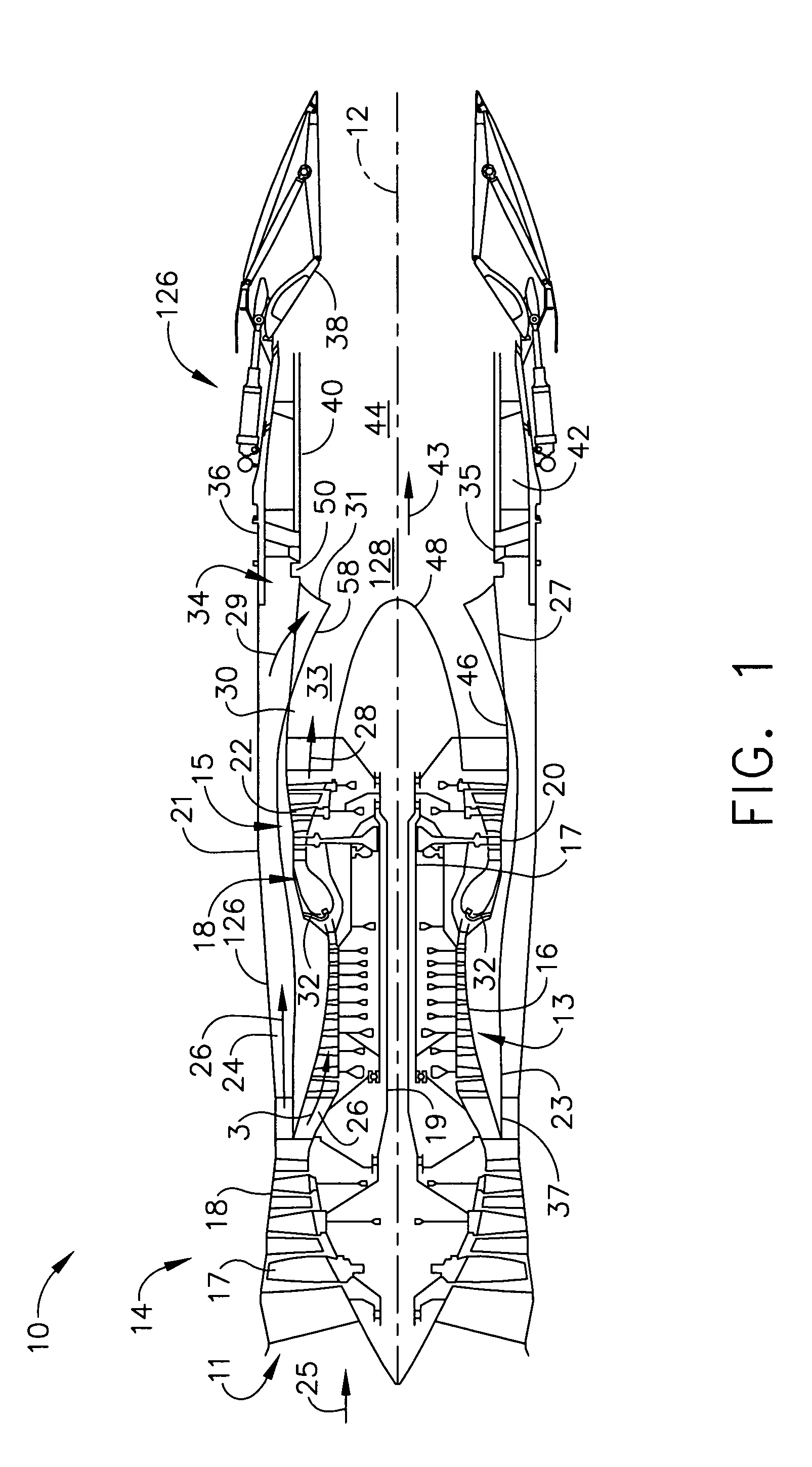

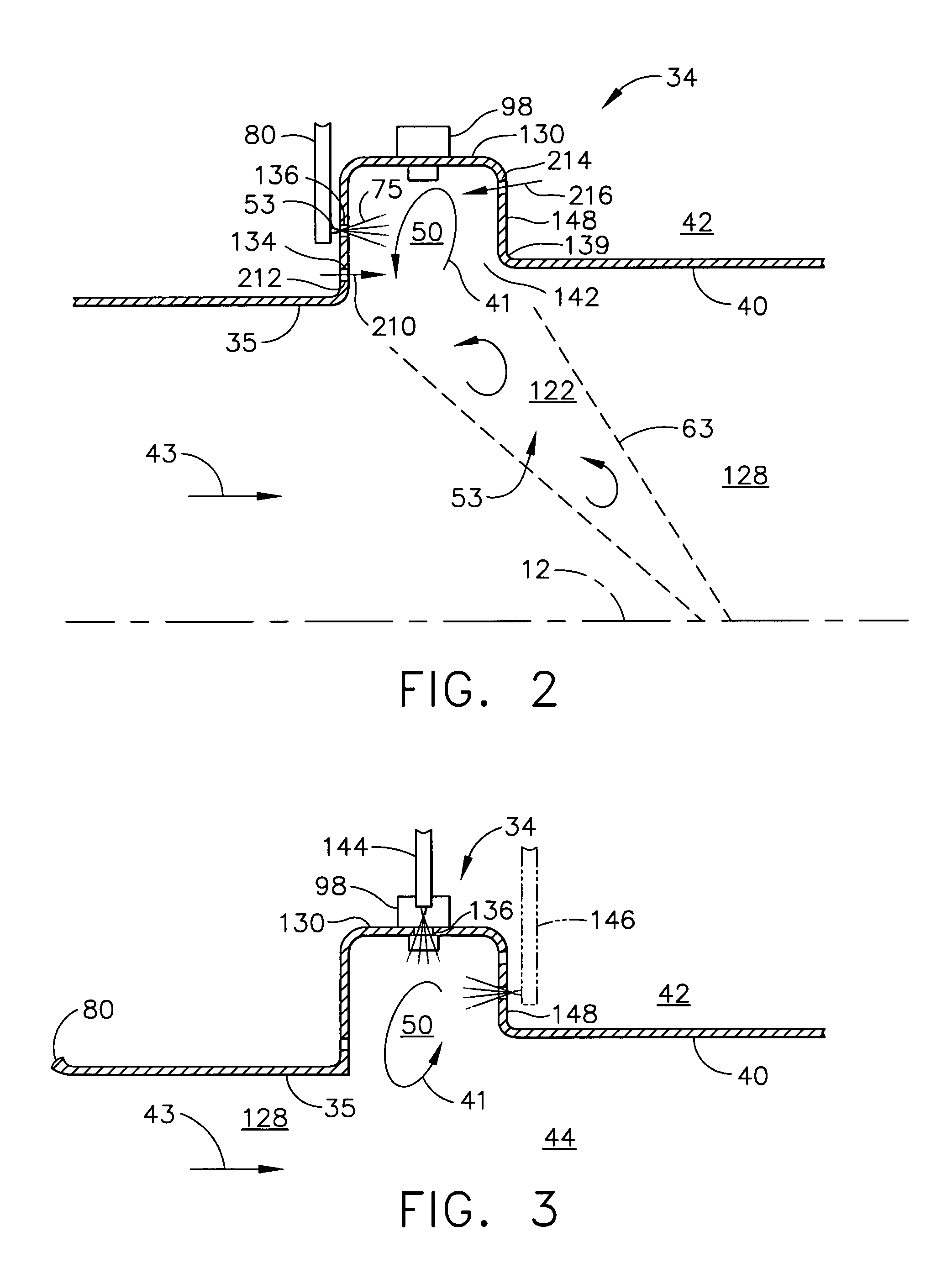

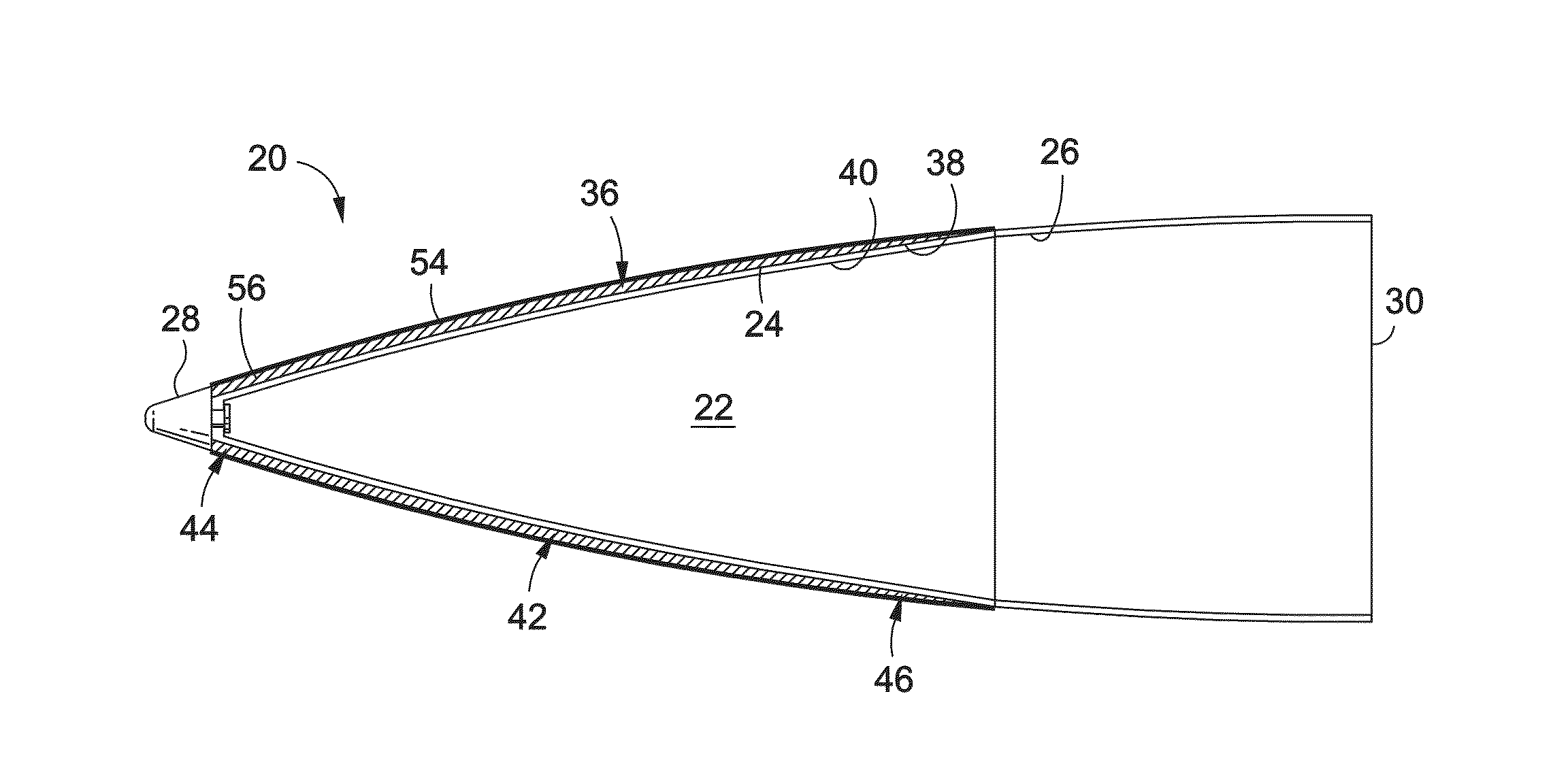

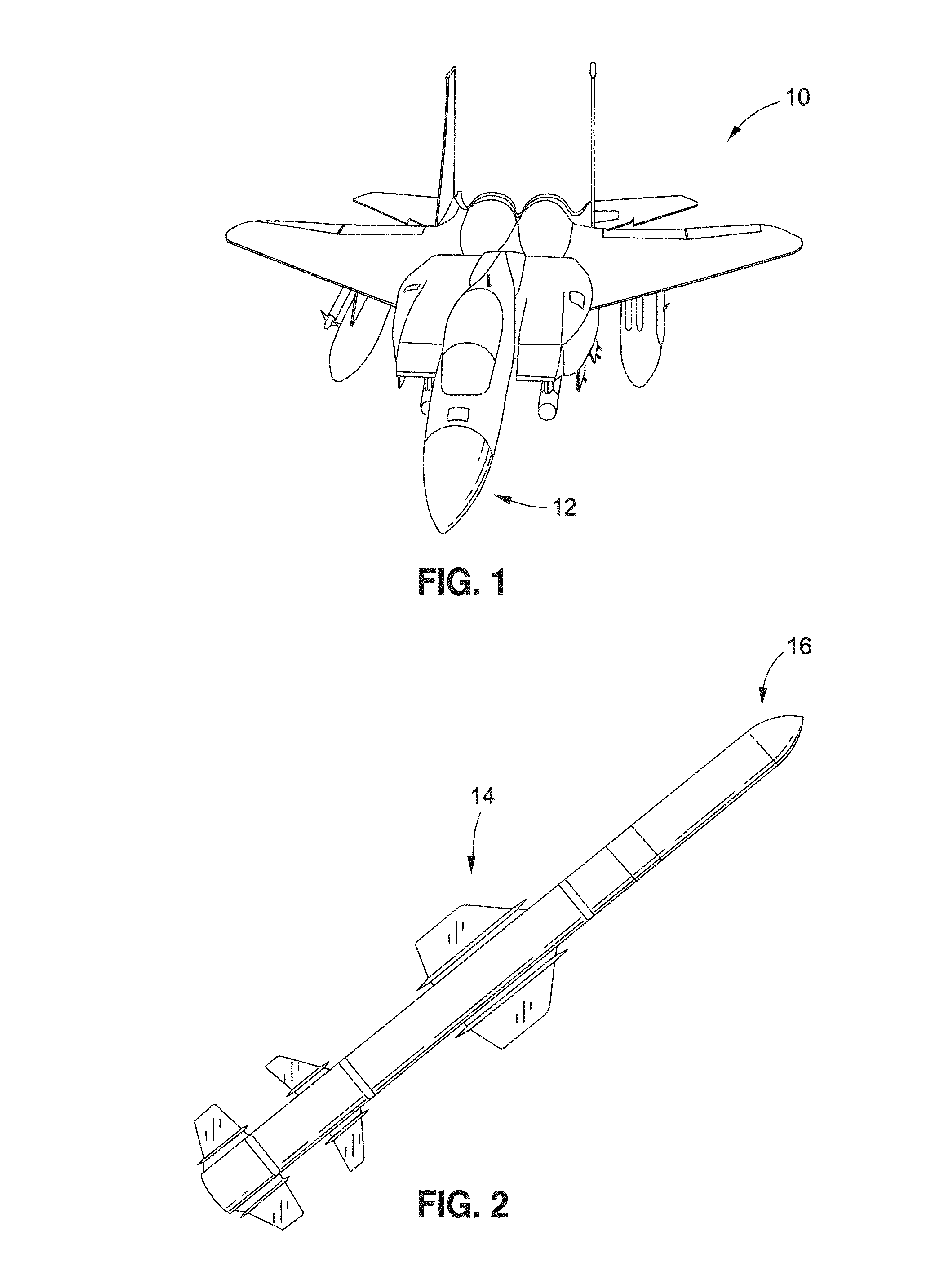

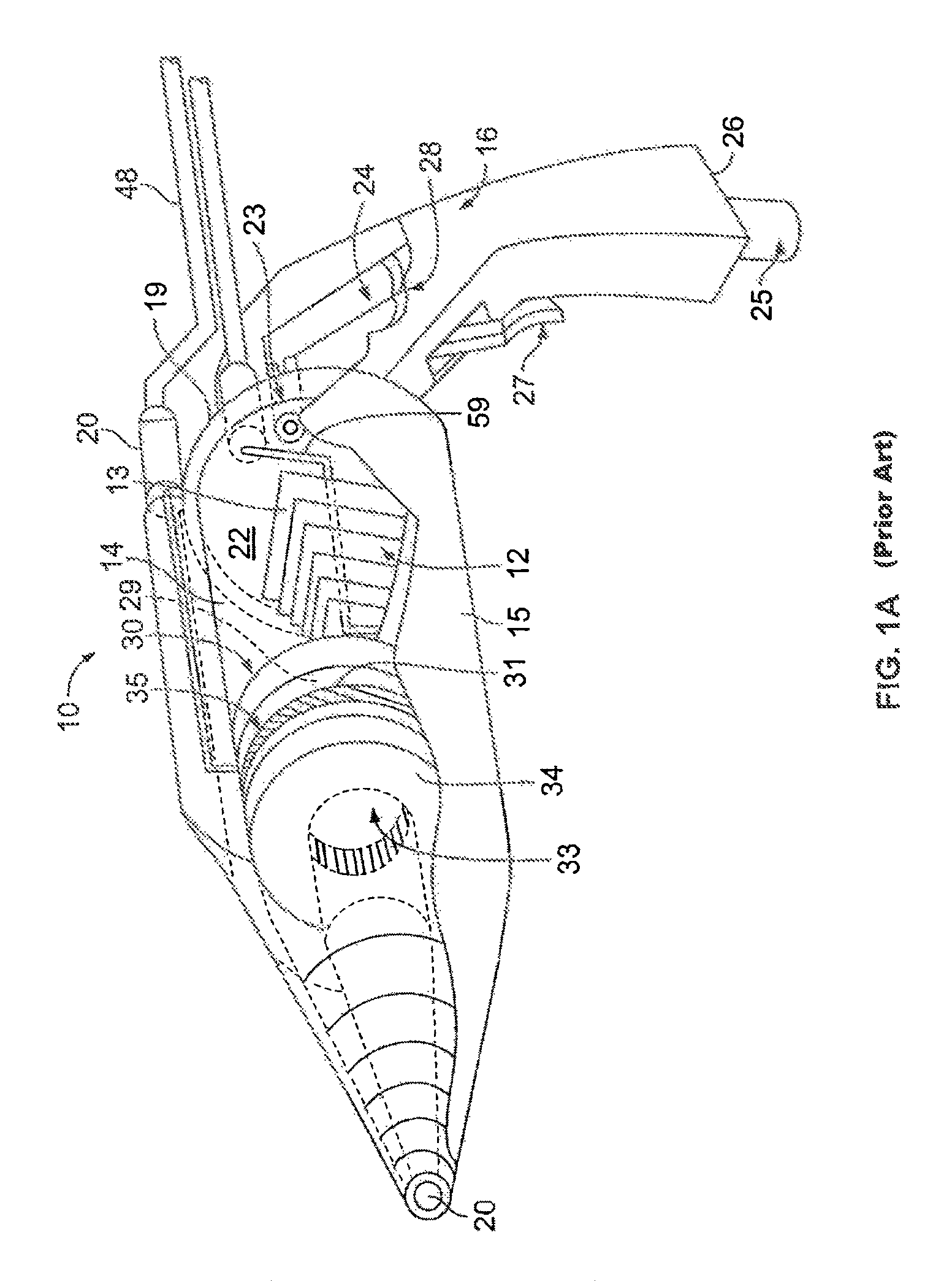

Trapped vortex cavity afterburner

ActiveUS7225623B2Continuous combustion chamberTurbine/propulsion fuel supply systemsTrailing edgeDegree Fahrenheit

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

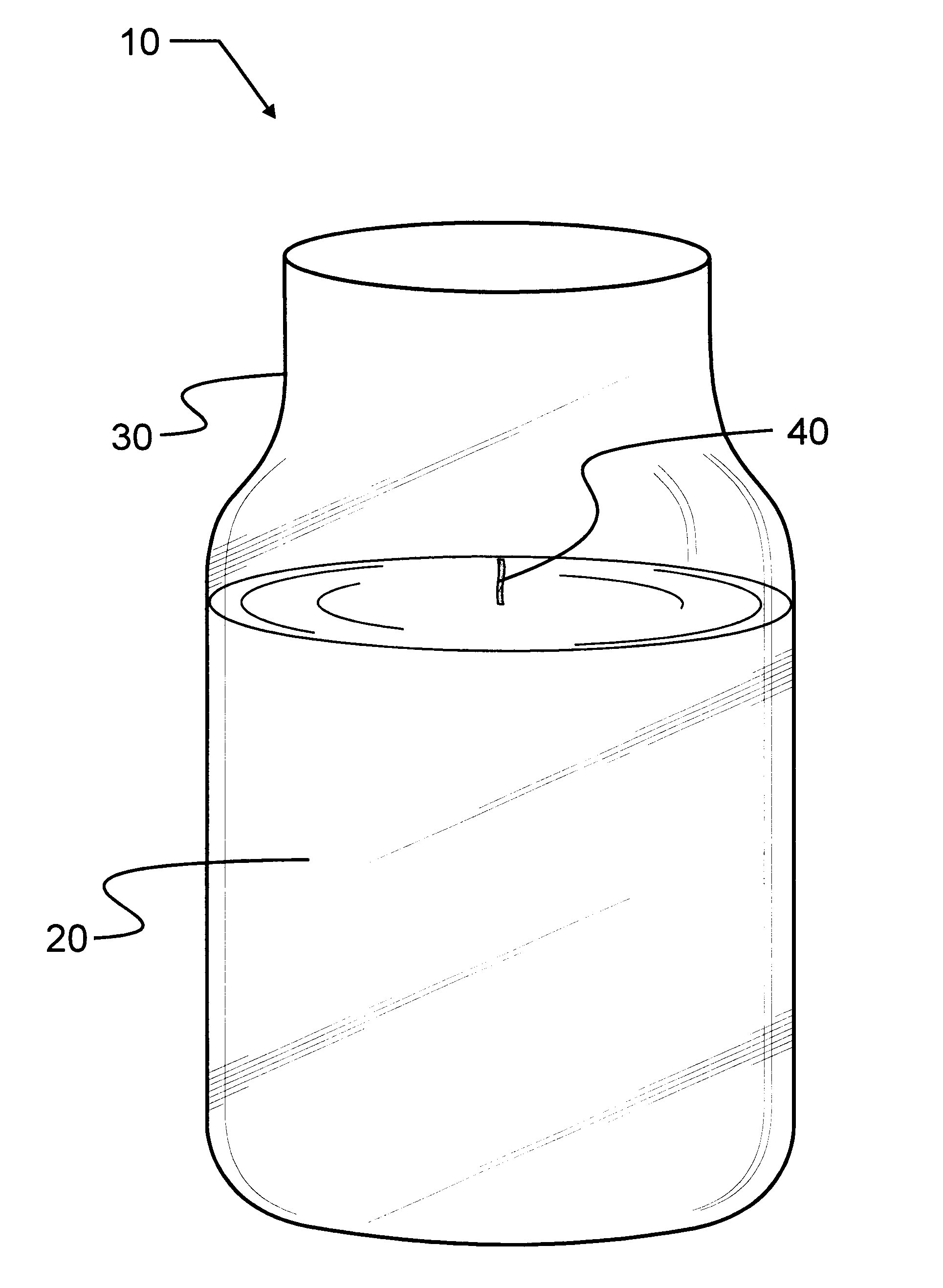

Soybean wax candles

InactiveUS6599334B1Increase profitWithout and crackingSolid fuelsCapillary burnersVegetable oilAlpha-olefin

A solid fuel candle which is highly adapted for use both in a container and also as a free-standing candle includes at least 85 percent hydrogenated soybean oil, approximately 0 to 4 percent synthetic wax composition, approximately 0 to 4 percent of a second hydrogenated vegetable or petroleum oil, approximately 0 to 10 percent fragrance or scent, and approximately 0 to 3 percent dye. The hydrogenated vegetable oil most preferably has an iodine value of approximately 50 and a melting point of approximately 125 degrees Fahrenheit, with a free fatty acid content of less than one-tenth of one percent. The synthetic wax composition is most preferably formed from alpha olefin monomers and oligomers under free radical conditions at relatively low pressures to yield a highly branched polymer wax having congealing and melting points lower than the starting alpha olefin material and a higher molecular weight.

Owner:ANDERSON JILL M

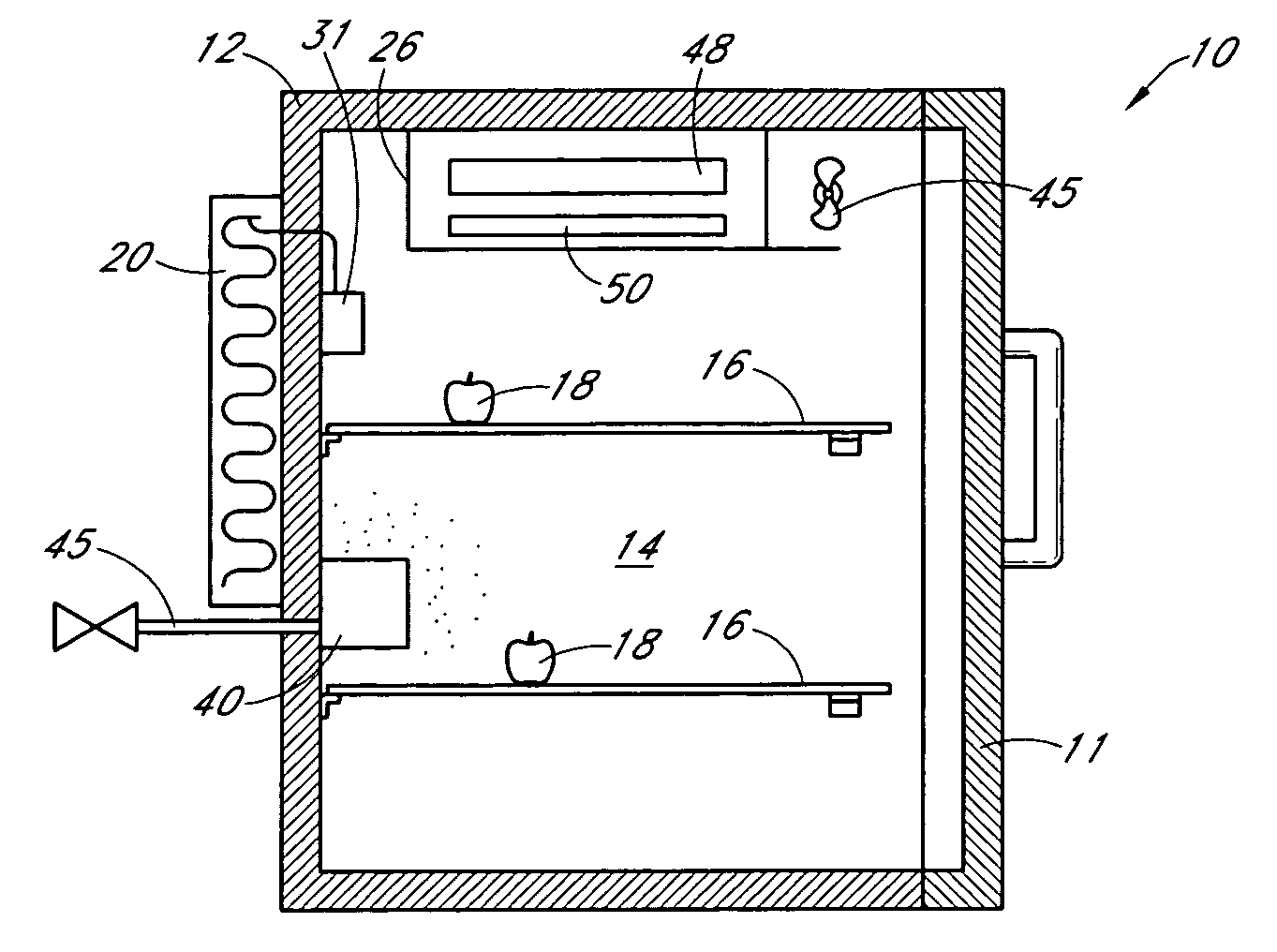

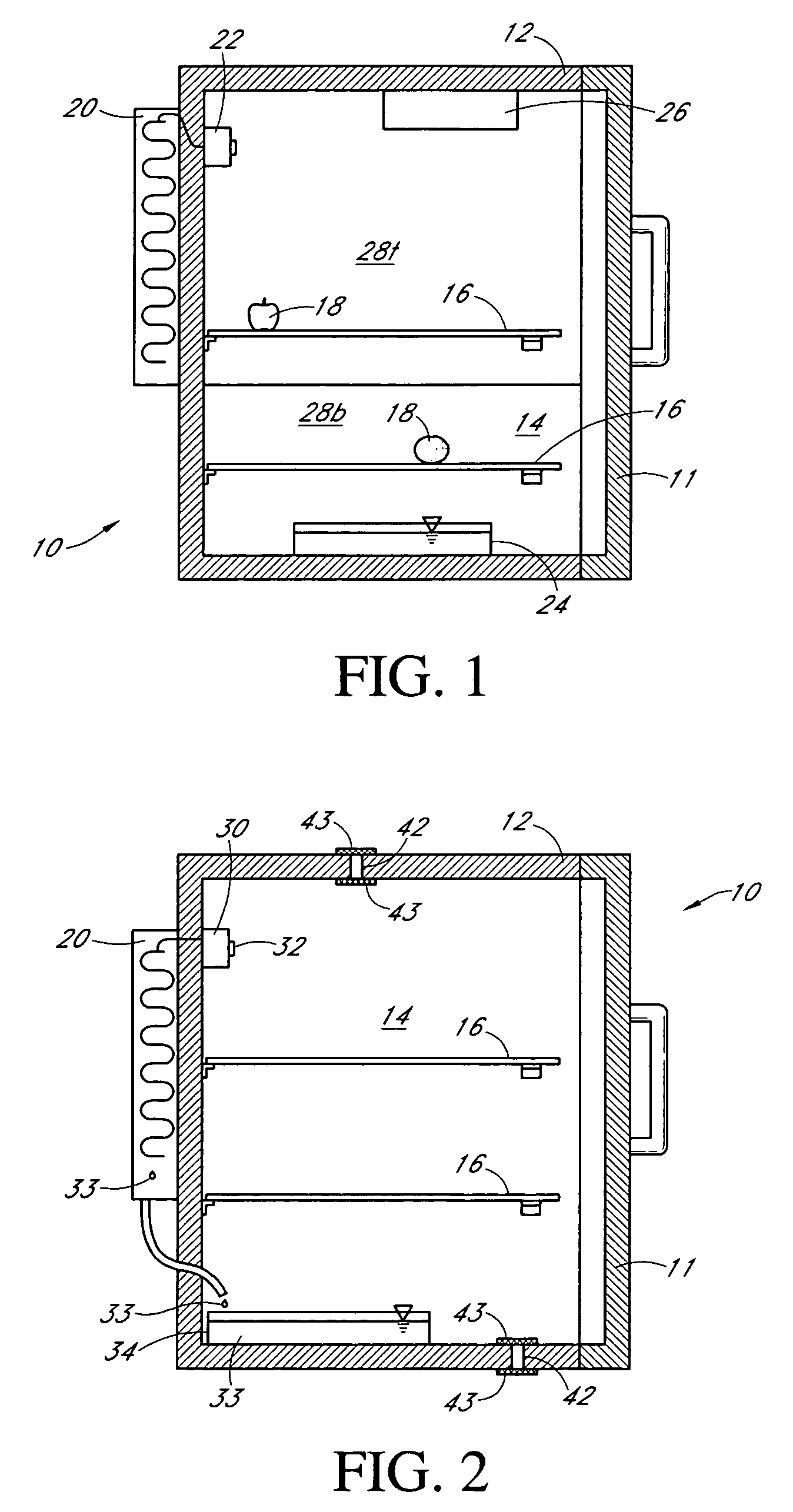

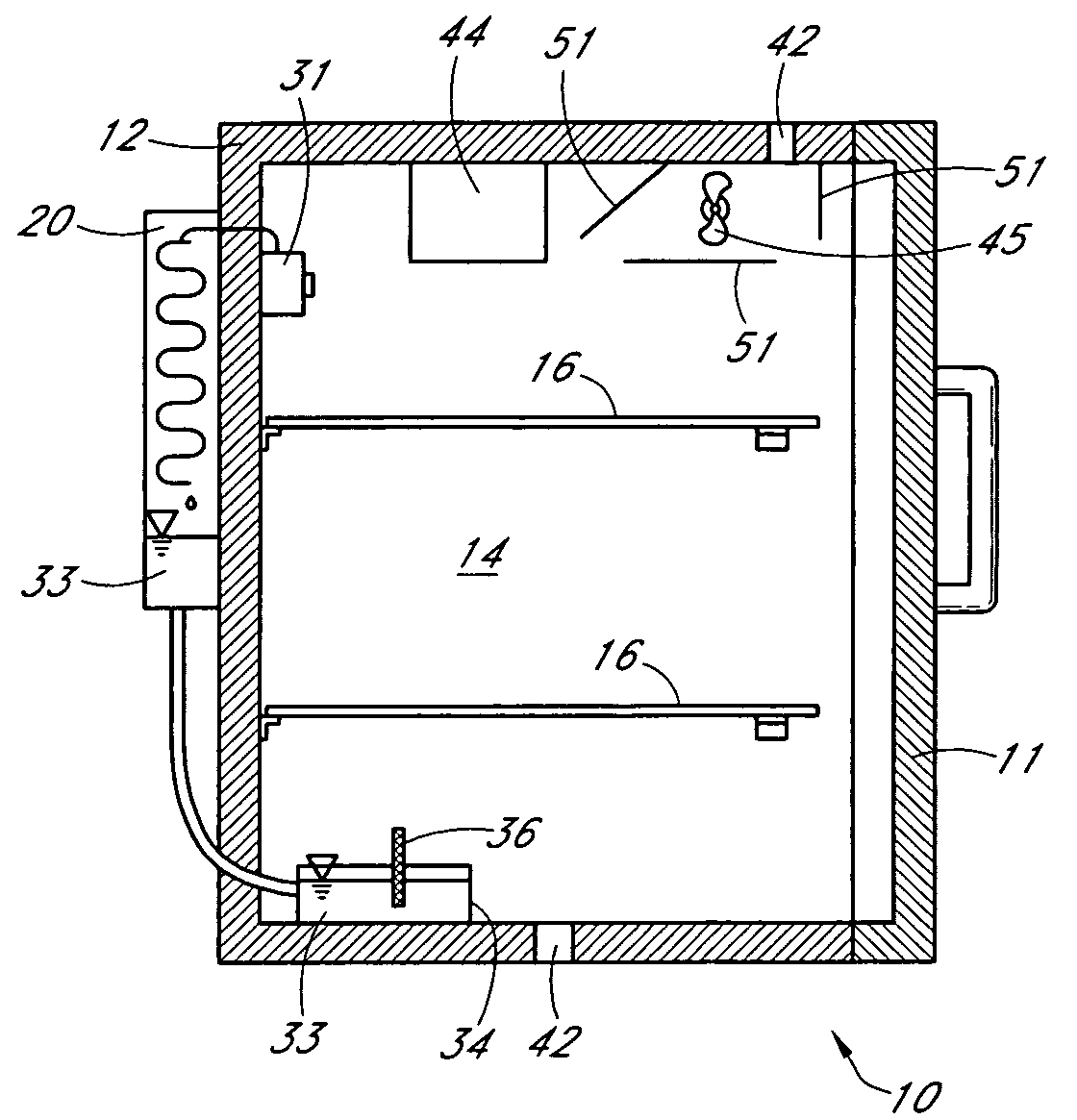

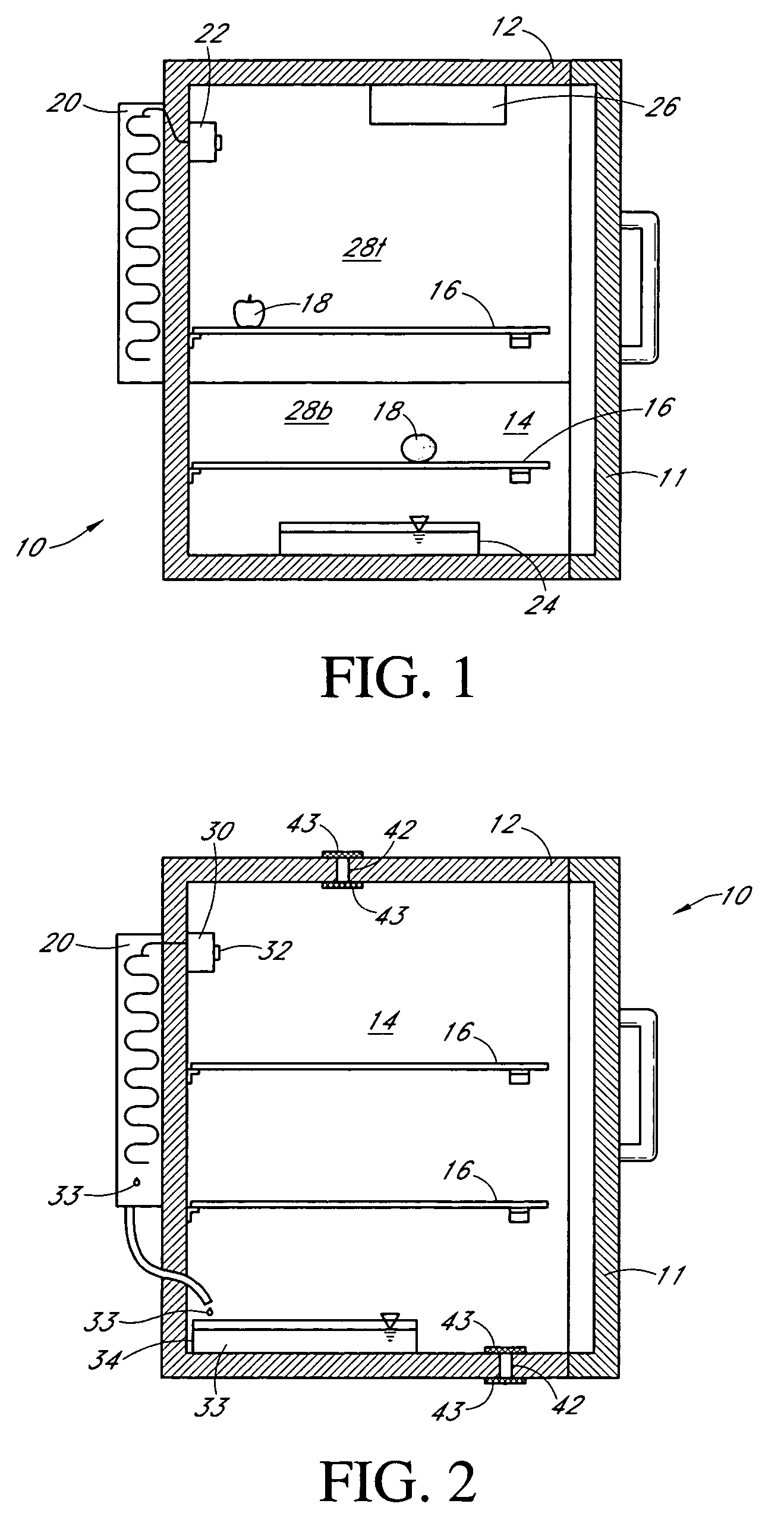

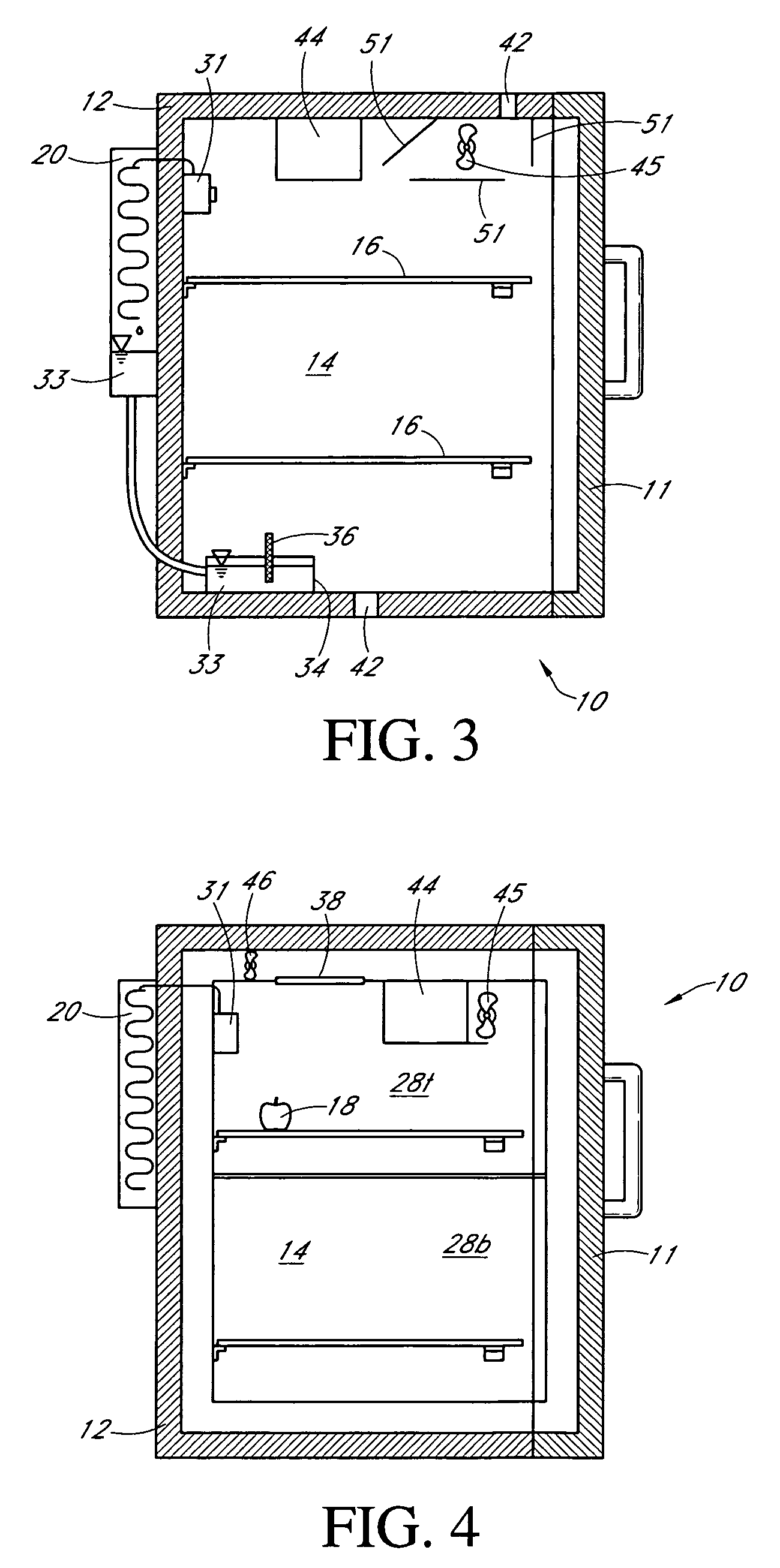

Produce preservation system

ActiveUS20050217282A1Prevent excessive dryingAccelerated ripeningFruit and vegetables preservationDomestic refrigeratorsRipeningEngineering

A refrigerated unit is well suited for storing fruits and vegetables. A household-sized refrigerated unit includes a storage space for retaining fruits and vegetables. The temperature within the storage space is controllable within a range of approximately 40-65 degrees Fahrenheit. The humidity level within the storage space is regulated to prevent unnecessary desiccation of the fruit and vegetables, and to prevent excessive condensation. The unit is provided with a mechanism for regulating the level of ethylene gas within the storage space to either retard or accelerate ripening, as desired.

Owner:MAYTAG

Compound cycle rotary engine

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

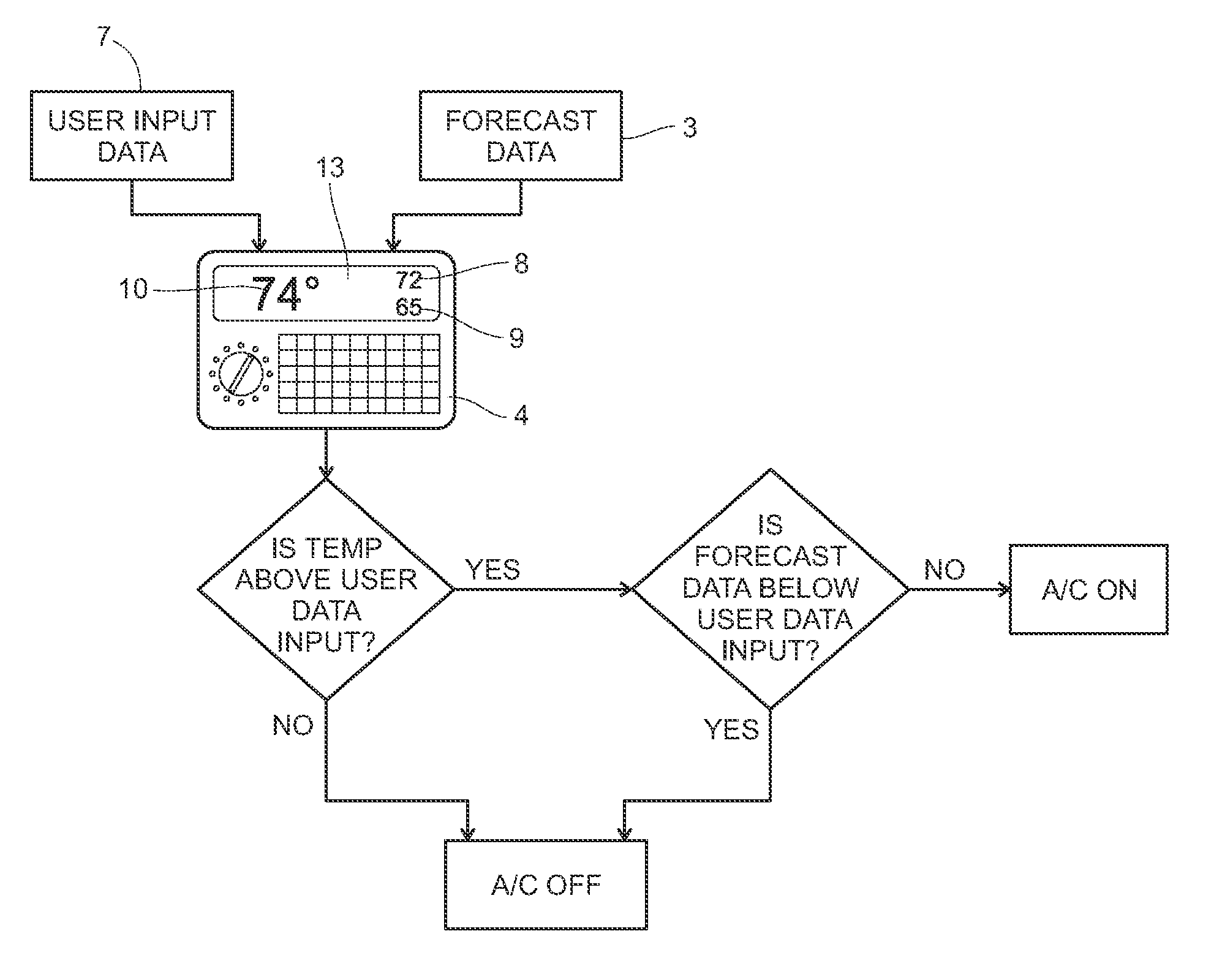

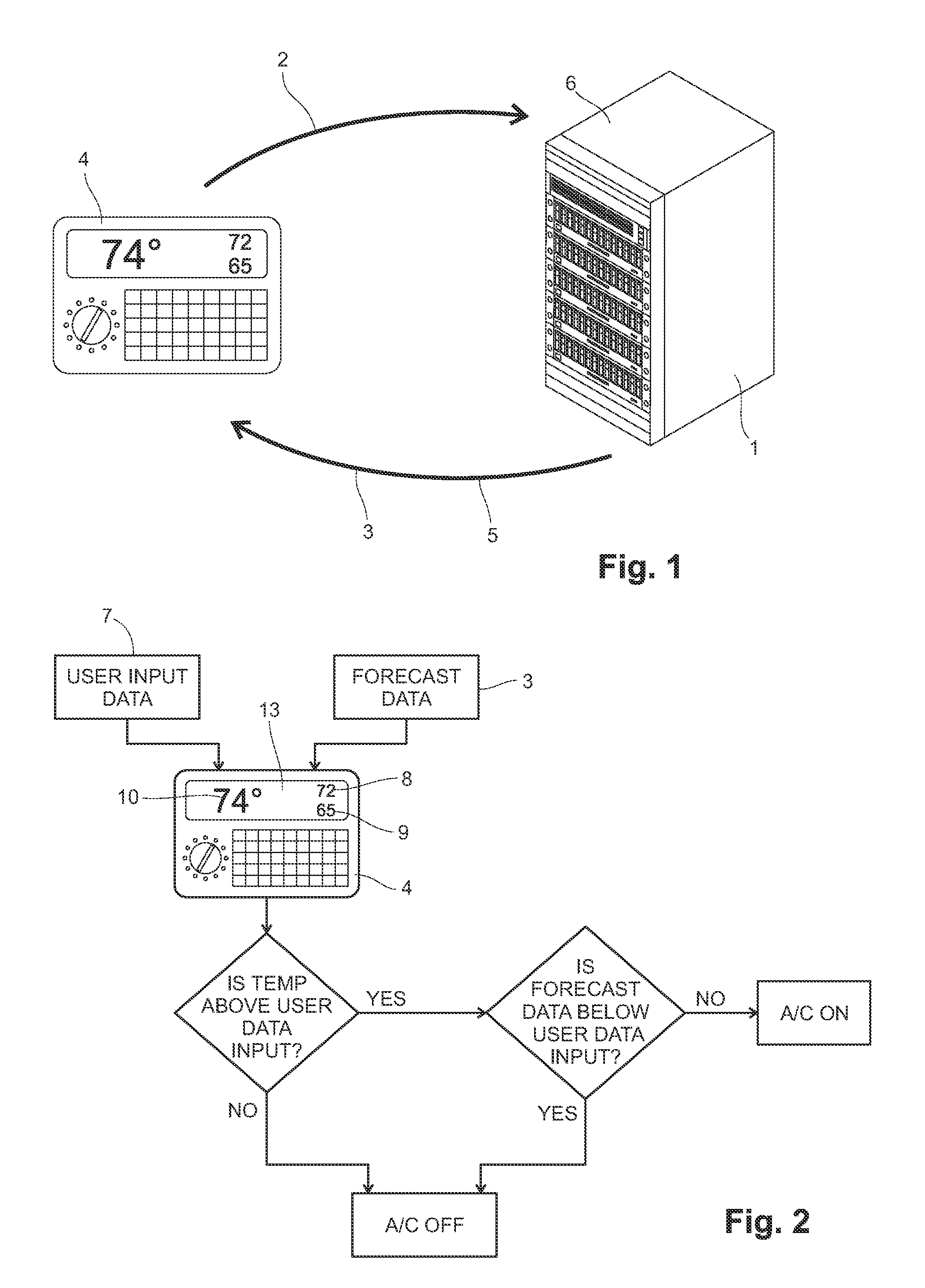

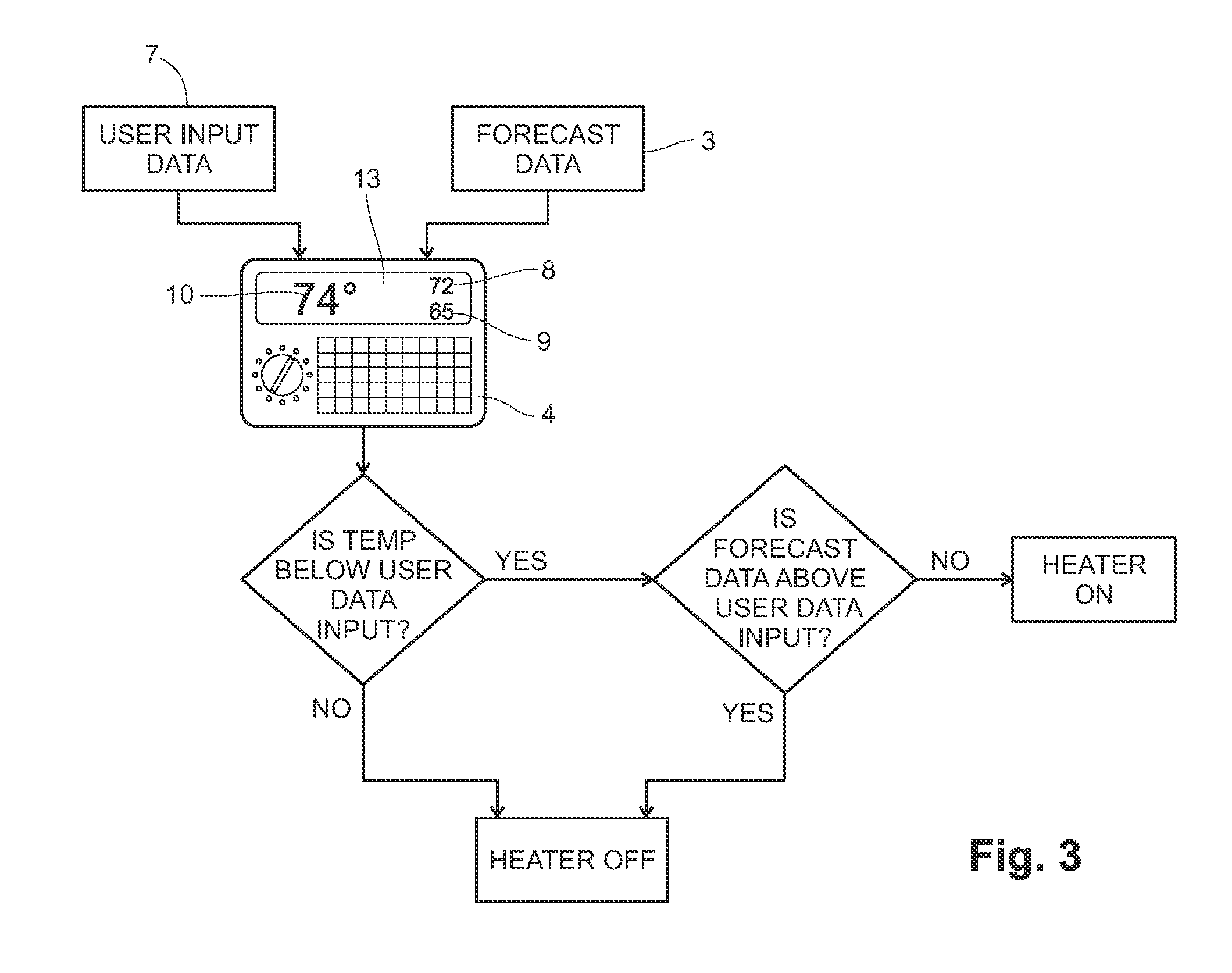

Building temperature control appliance recieving real time weather forecast data and method

InactiveUS20120259470A1Sampled-variable control systemsSpace heating and ventilation safety systemsResponse processTemperature control

The invention is a web enabled building temperature control appliance that receives data from the national weather service or from any other suitable source. This data consists of current temperature and pressure as well as forecasted temperature fluctuations. The building temperature control appliance would have a constant request / response process by using a Simple Object Access Protocol (SOAP) to gain access to the National Digital Forecast Database or other such weather forecast database. The building temperature control appliance would not turn on if the forecasted weather was within a zone of comfort chosen by the users. The zone of comfort is the band of temperature within which a person feels comfortable. This band of temperature is usually between 66 and 74 degrees Fahrenheit. Rather than having the heat turn on in the morning to heat the home to a set temperature the building temperature control appliance would allow the sun and the ambient outside air heat the home. In areas where the nights are cold and days are hot the building temperature control appliance would not heat the home in the morning when the forecast was for temperature hotter than the zone of comfort. There are many similar scenarios where the building temperature control appliance would act differently than a commonly known thermostat based upon information about the forecasted weather.

Owner:NIJHAWAN NEIL +1

Dual evaporator for indoor units and method therefor

InactiveUS6116048AImprove cooling effectIncrease temperatureEvaporators/condensersAir conditioning systemsEngineeringRefrigerant

A dual (or multi) sectional evaporator system comprising first and second (or more) evaporator sections capable of cooling the air supply through the evaporator. The first evaporator section is positioned upstream of the second evaporator section (second upstream of the third and so on). However, the warmest refrigerant passes through the first evaporator section and the coldest refrigerant passes through the second evaporator section (or last evaporator section if more than two sections), such that the air supply is precooled prior to reaching the second (or last) evaporator. Providing a two (or more) passes of refrigerant through the dual (or multi) sectional evaporator system increases the superheat temperature out of the first evaporator up to about 25 degrees Fahrenheit, and / or increases the mass flow of refrigerant because of the increased heat exchange efficiency provided by counterflow heat exchange. Moreover, in the preferred embodiment for an A-coil or slant coil, the second evaporator section is positioned over the top of the first evaporator section such that the second evaporator overlays the first evaporator section in order to maximize the use of available space. Also, A-coil or slant coil forms of the present invention are configured such that they include contoured cut-out shaped corner portions wherein the squared corners of the evaporators are substantially eliminated thereby eliminating the dead air flow spaces typically associated with other known evaporators. The elimination of the dead air space allows the system to operate at a lower fan speed as well as allows the system to be constructed and operate within smaller confines.

Owner:OLIVE TREE PATENTS 1 +1

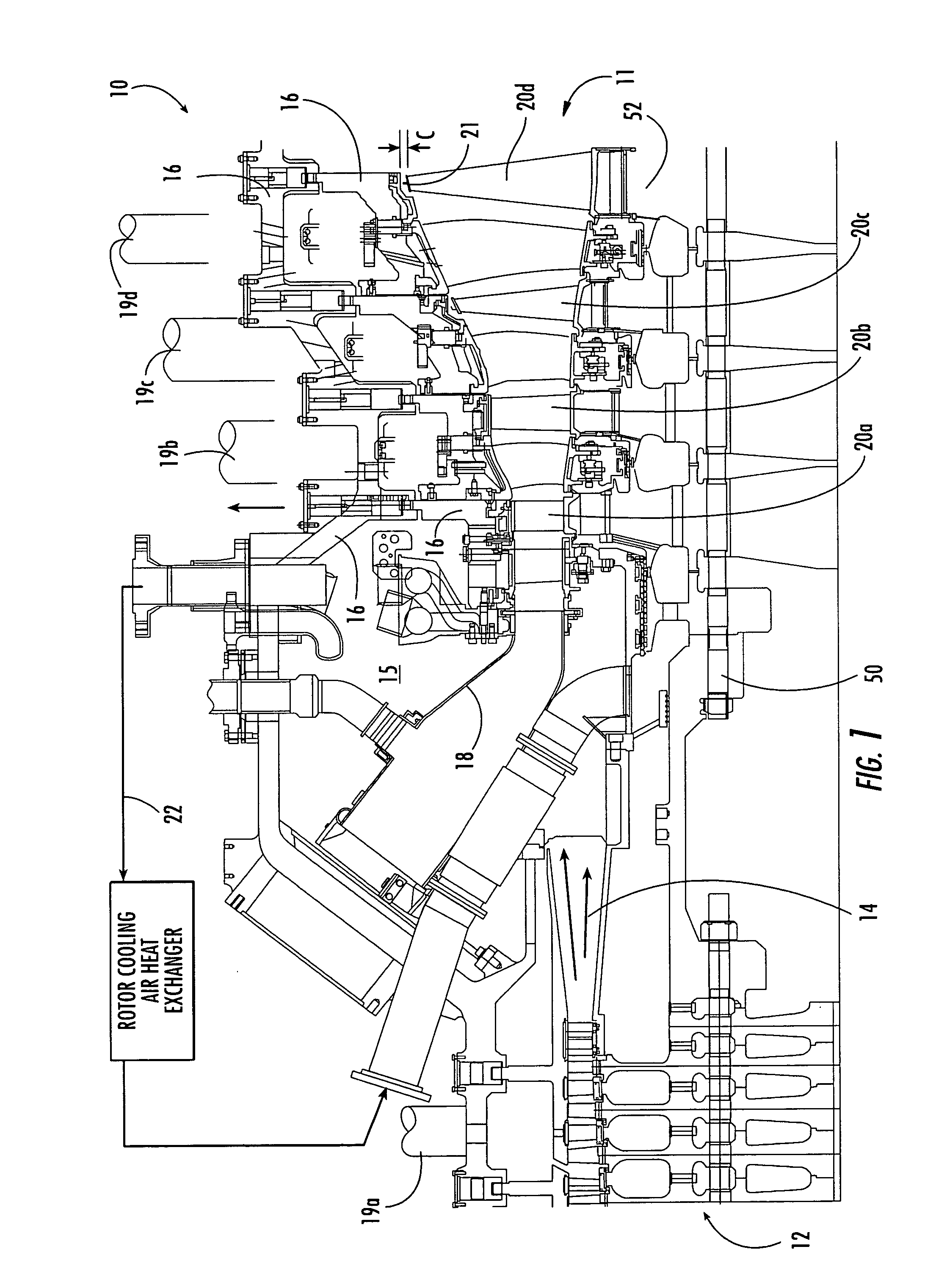

Part load blade tip clearance control

InactiveUS20050050901A1Reduce the temperatureLow cooling temperatureTurbine/propulsion engine coolingBlade accessoriesCircular discTurbine blade

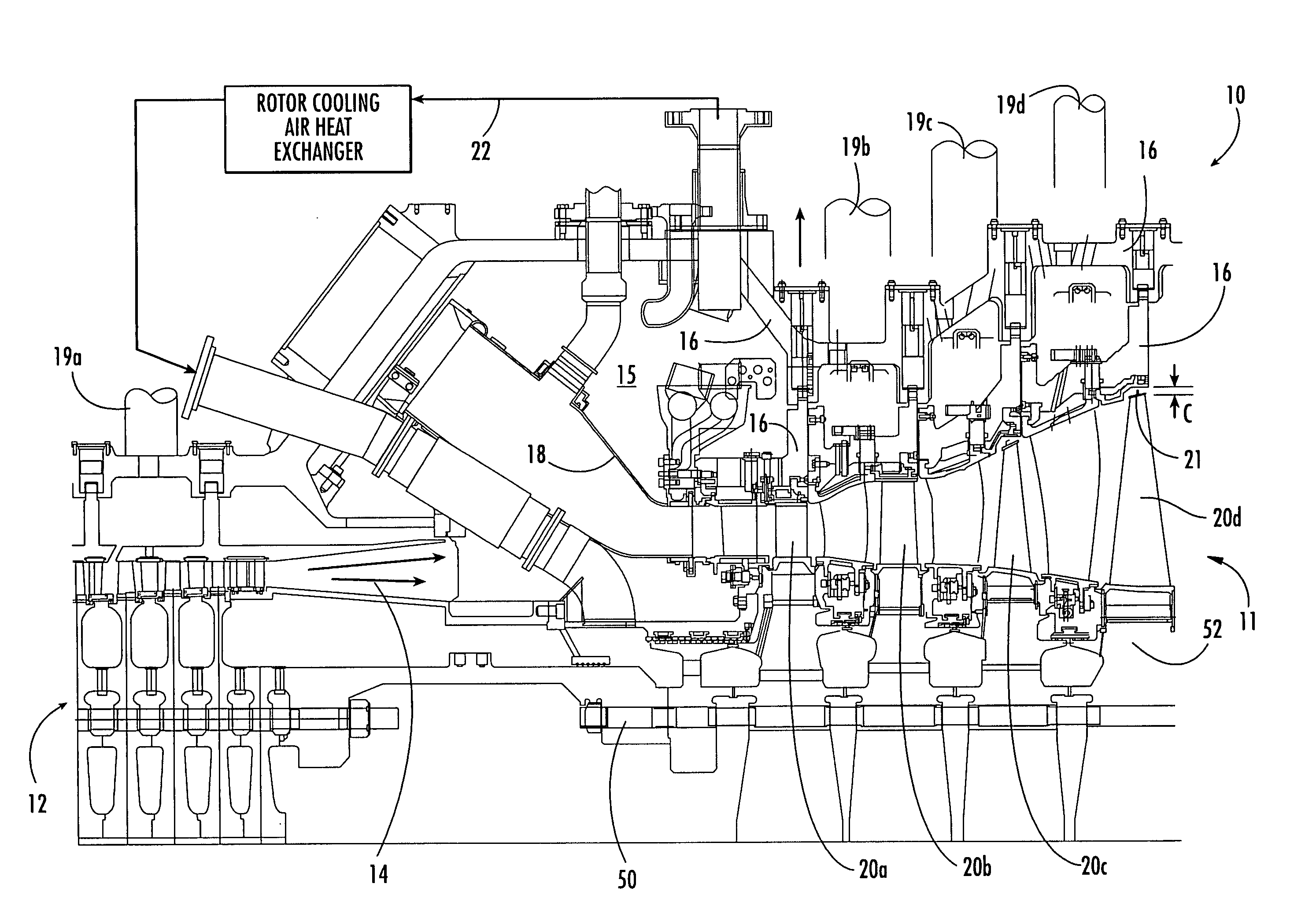

Aspects of the invention relate to a turbine engine configuration and method for overcoming a turbine blade tip clearance problem that can arise when the turbine inlet temperature is maintained at a high level during part load operation of the turbine. Aspects of the invention relate to reducing rotor cooling air to a temperature below the design temperature level by using, for example, additional heat extraction devices or by reconfiguring or resizing existing heat exchanger devices. Upon exposure to the cooled air, the discs and blades of the turbine will shrink so as to provide a clearance between the blade tips and surrounding stationary support structure. The design rotor cooling air temperature can be from about 350 degrees Fahrenheit to about 480 degrees Fahrenheit. Aspects of the present invention can be used to decrease the rotor cooling air to about 150 degrees Fahrenheit at about 70 percent load.

Owner:SIEMENS ENERGY INC

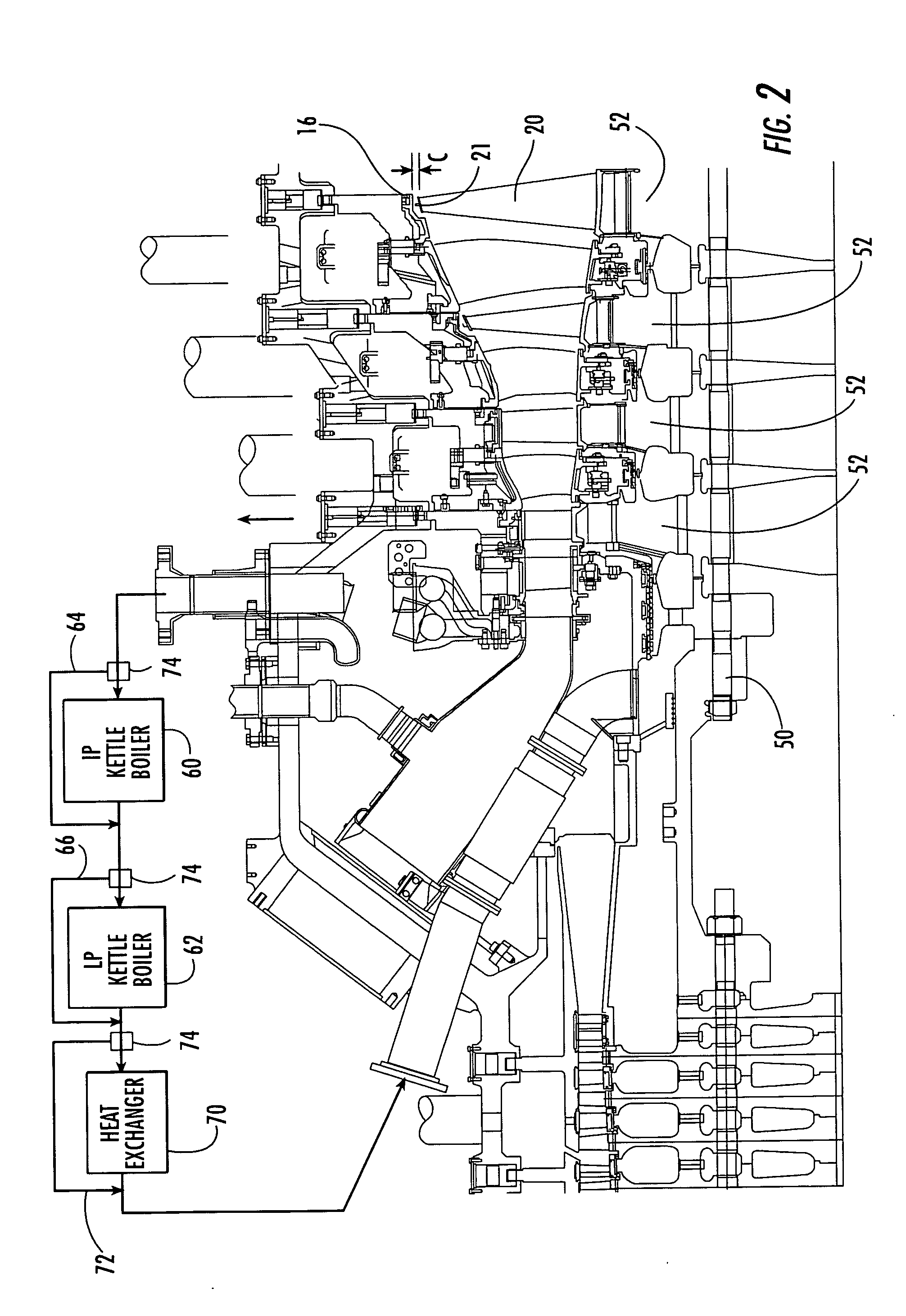

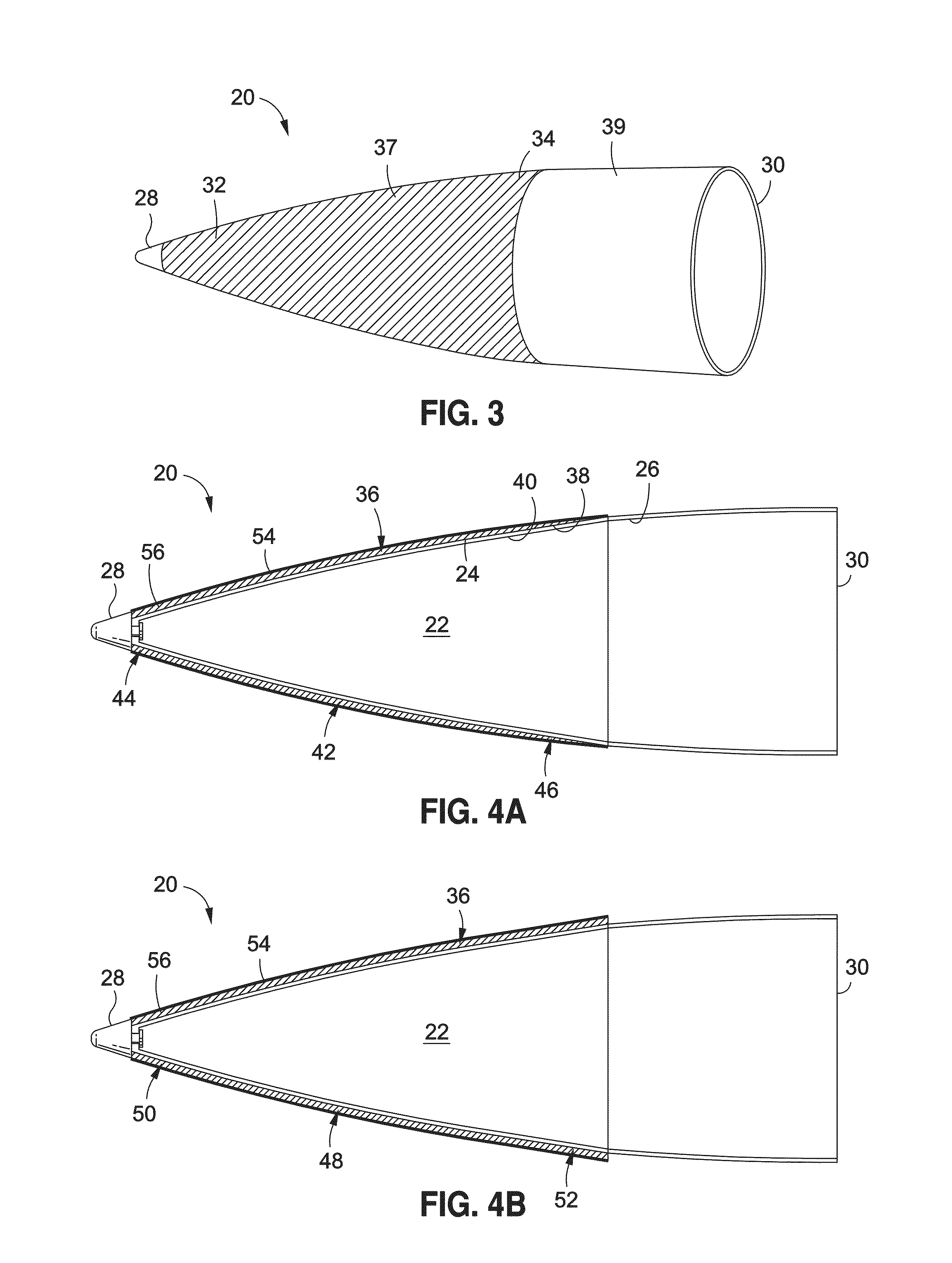

Thermal barrier coated RF radomes and method

ActiveUS8765230B1Improve performanceLow costLiquid surface applicatorsAntenna adaptation in movable bodiesRadio frequencyThermal barrier coating

Thermal barrier coated RF radomes and a method for making the same are provided. In an embodiment of the disclosure, there is provided a method for making a thermal barrier coated radio frequency (RF) radome. The method comprises providing a radio frequency (RF) radome. The method further comprises applying a thermal barrier coating having a dielectric constant less than about 2.0 onto a surface of the radome to form a thermal barrier coated RF radome. The thermal barrier coating reduces a structure temperature of the radome by greater than 300 degrees Fahrenheit to enhance thermo-mechanical properties and performance of the RF radome.

Owner:THE BOEING CO

Produce preservation system

ActiveUS7296422B2Prevent excessive dryingPrevent water condensationFruit and vegetables preservationDomestic refrigeratorsRipeningEngineering

A refrigerated unit is well suited for storing fruits and vegetables. A household-sized refrigerated unit includes a storage space for retaining fruits and vegetables. The temperature within the storage space is controllable within a range of approximately 40-65 degrees Fahrenheit. The humidity level within the storage space is regulated to prevent unnecessary desiccation of the fruit and vegetables, and to prevent excessive condensation. The unit is provided with a mechanism for regulating the level of ethylene gas within the storage space to either retard or accelerate ripening, as desired.

Owner:MAYTAG

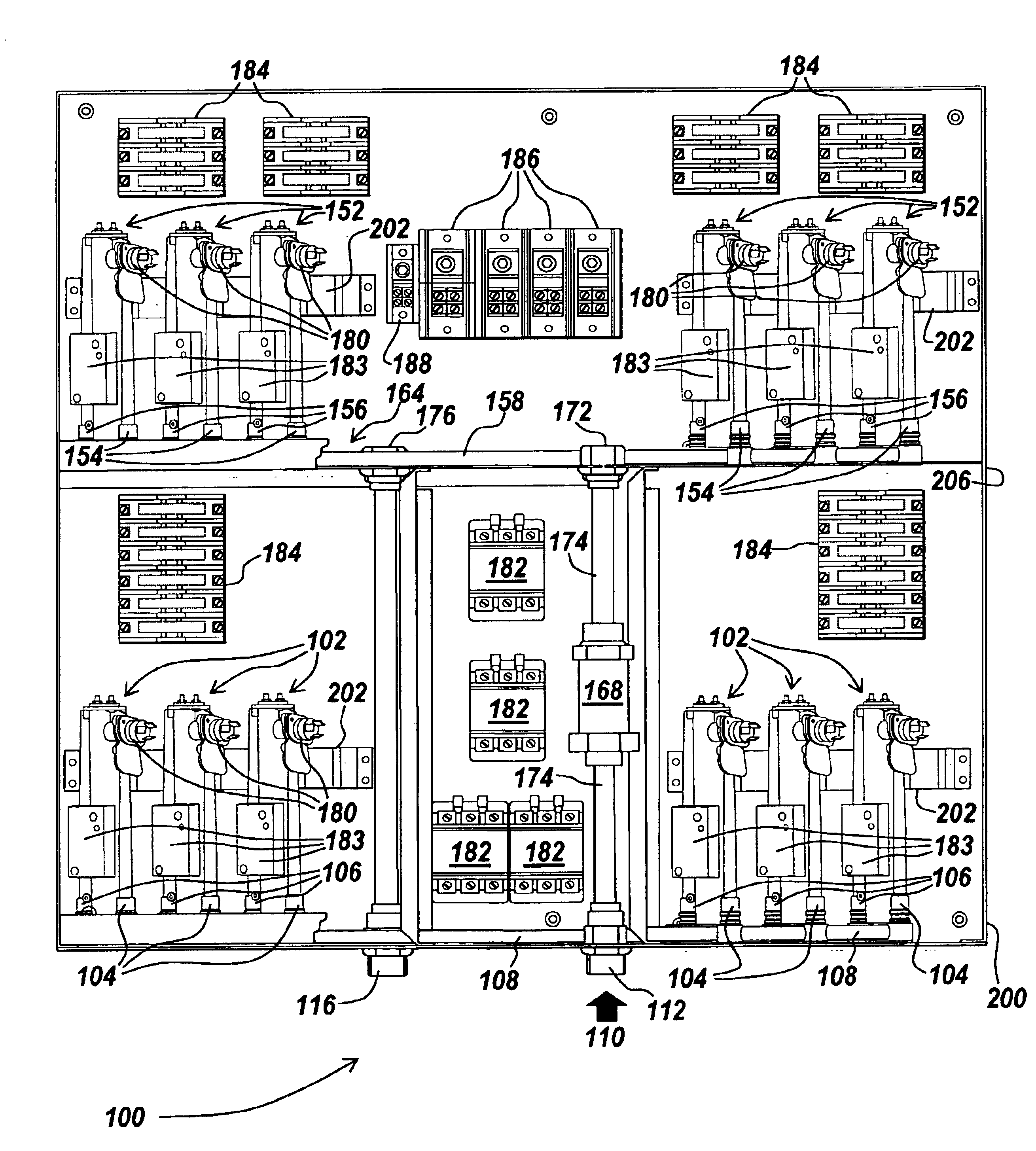

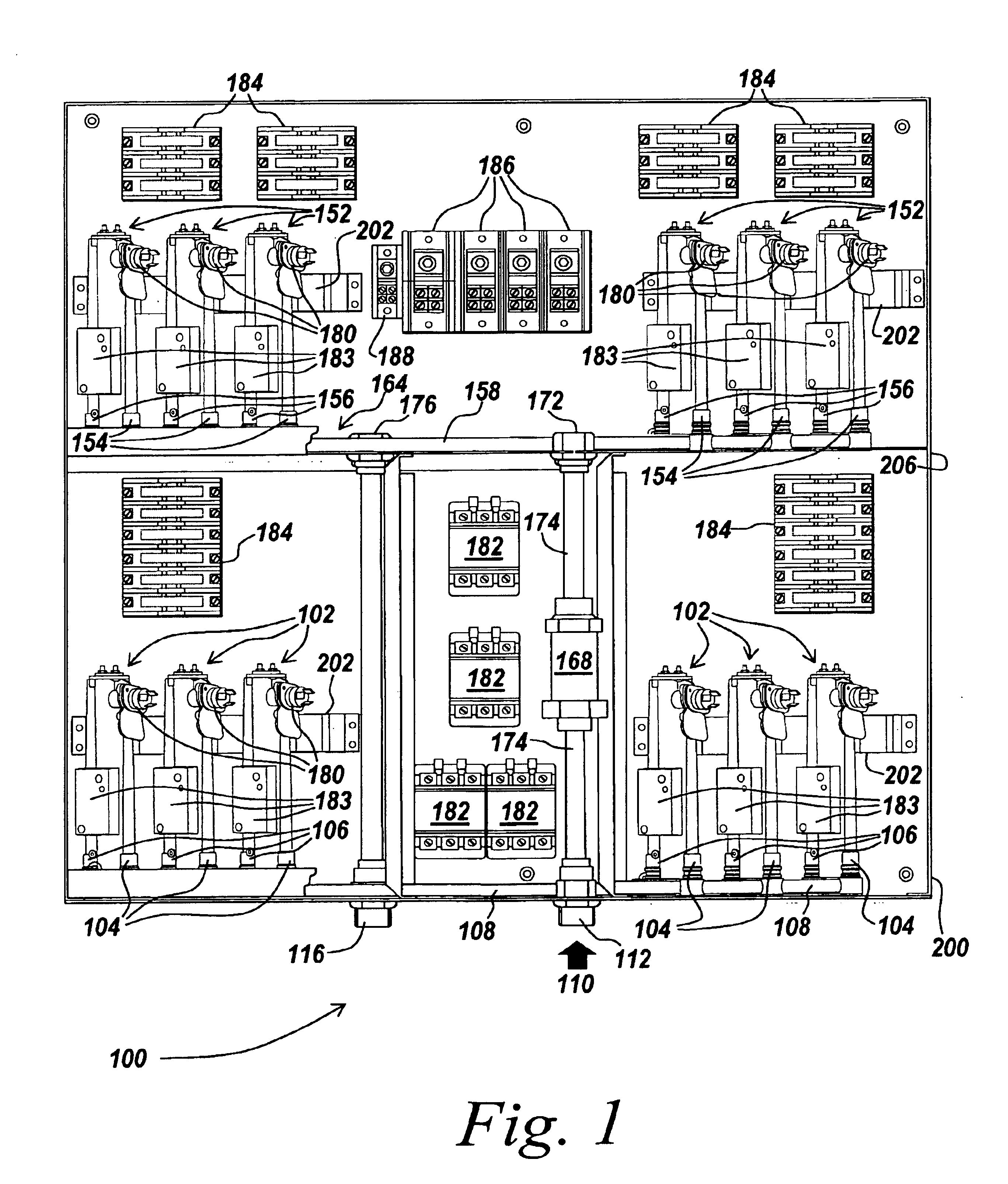

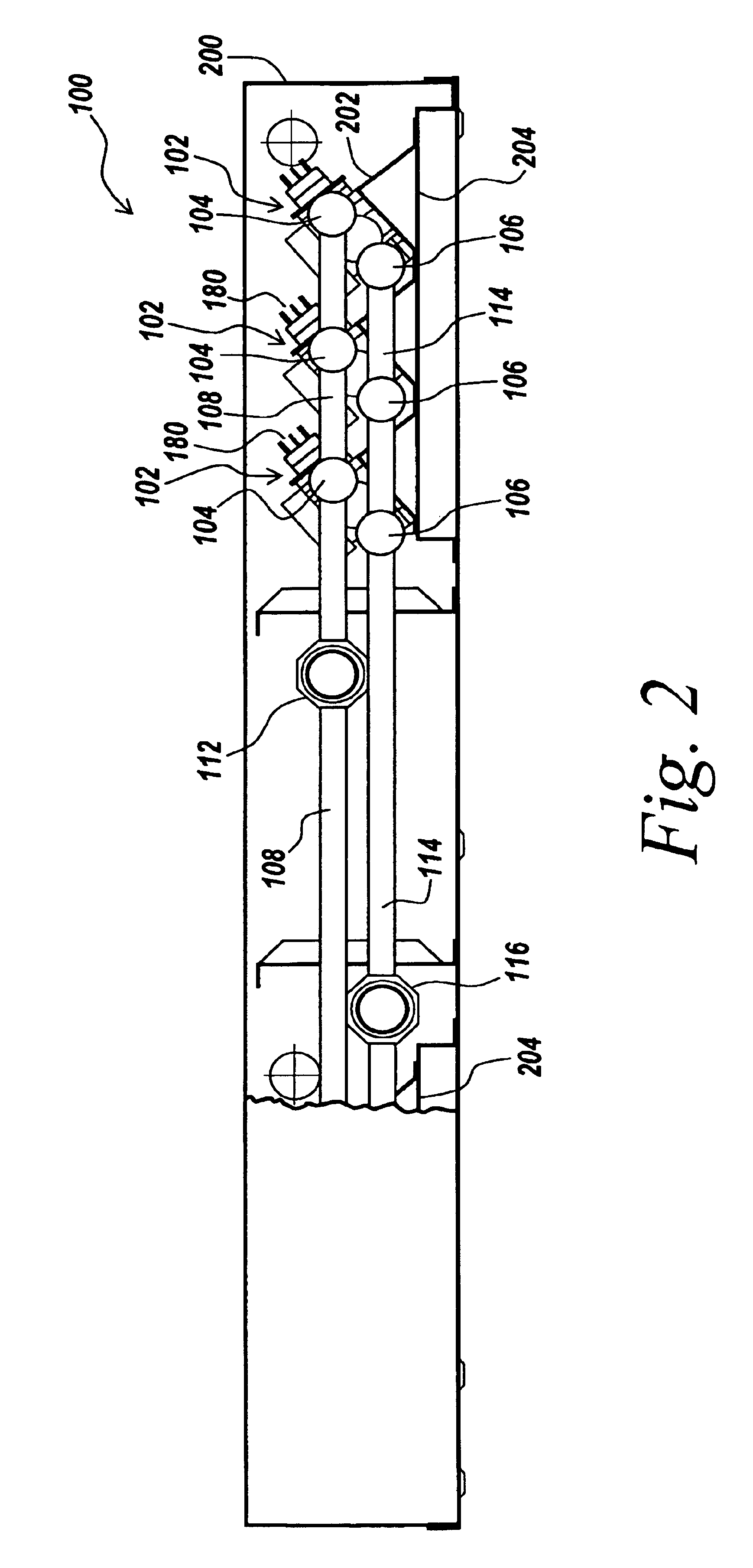

Electric tankless water heater

In various embodiments, the invention provides a system for heating a liquid, such as, for example, water, comprising a plurality of liquid heaters, the inlets and outlets of which are respectively connected in a parallel flow relationship by respective manifolds, and configured to provide liquid having a temperature of greater than about 90 degrees Fahrenheit at a flow rate of greater than about 10 gallons per minute. In various embodiments, the present invention provides an electric tankless liquid heater system capable of delivering hot liquids, and in particular water, at even higher flow rates and or temperatures, including, but not limited to, flow rates greater than about: (1) 12 gpm; (2) 18 gpm; (3) 20 gpm; and (5) 20 gpm; and / or temperatures of greater than about: (1) 100° F.; (2) 120° F.; (3) 140° F.; and (4) 180° F.

Owner:RHEEM MFG CO

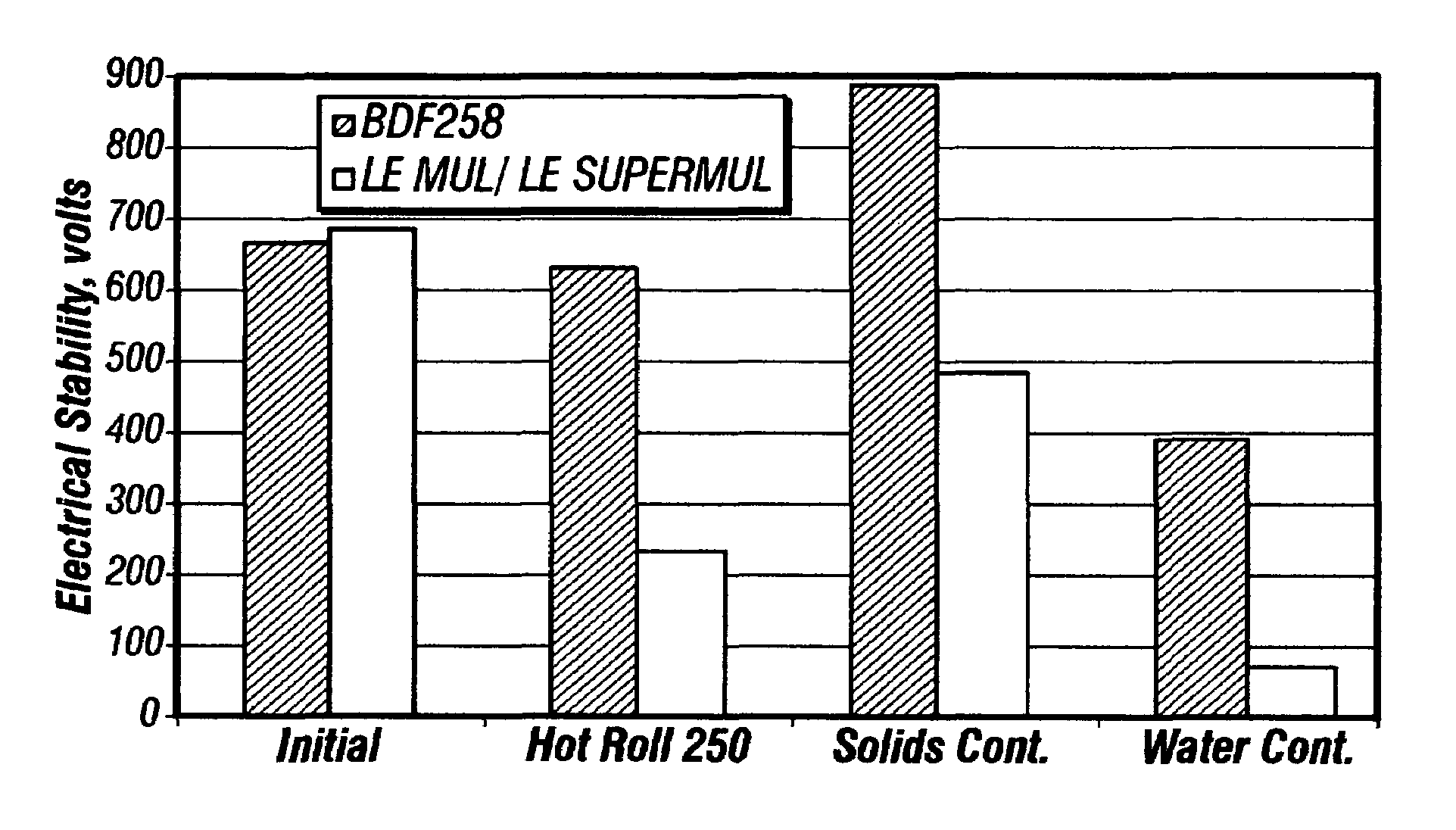

Additive for oil-based drilling fluids

InactiveUS7008907B2High level of filtration controlReduces and eliminates needTransportation and packagingFluid removalFiltrationPolyamide

A method and product is disclosed which provides emulsion stability and filtration control to invert emulsion drilling fluids. The product comprises a blend of a carboxylic acid terminated polyamide and / or a wetting agent with a reaction product or mixture produced by the Diels-Alder reaction of dienophiles, preferably carboxylic acids, polycarboxylic acids, acid anhydrides, or combinations or mixes thereof, with a mixture of fatty acids and resin acids. The product of the invention is extremely effective, decreasing by about two-thirds the amount of emulsifier generally required to formulate an effective drilling fluid. The product of the invention also greatly reduces and in many cases eliminates the need for conventional fluid loss additives, and additionally provides electrical stability. Moreover, the product of the invention has a pour point as low as about 20 degrees Fahrenheit with minimal solvents, thereby eliminating the need to ship large amounts of inert material for use, and may be transported in a highly active state.

Owner:HALLIBURTON ENERGY SERVICES INC

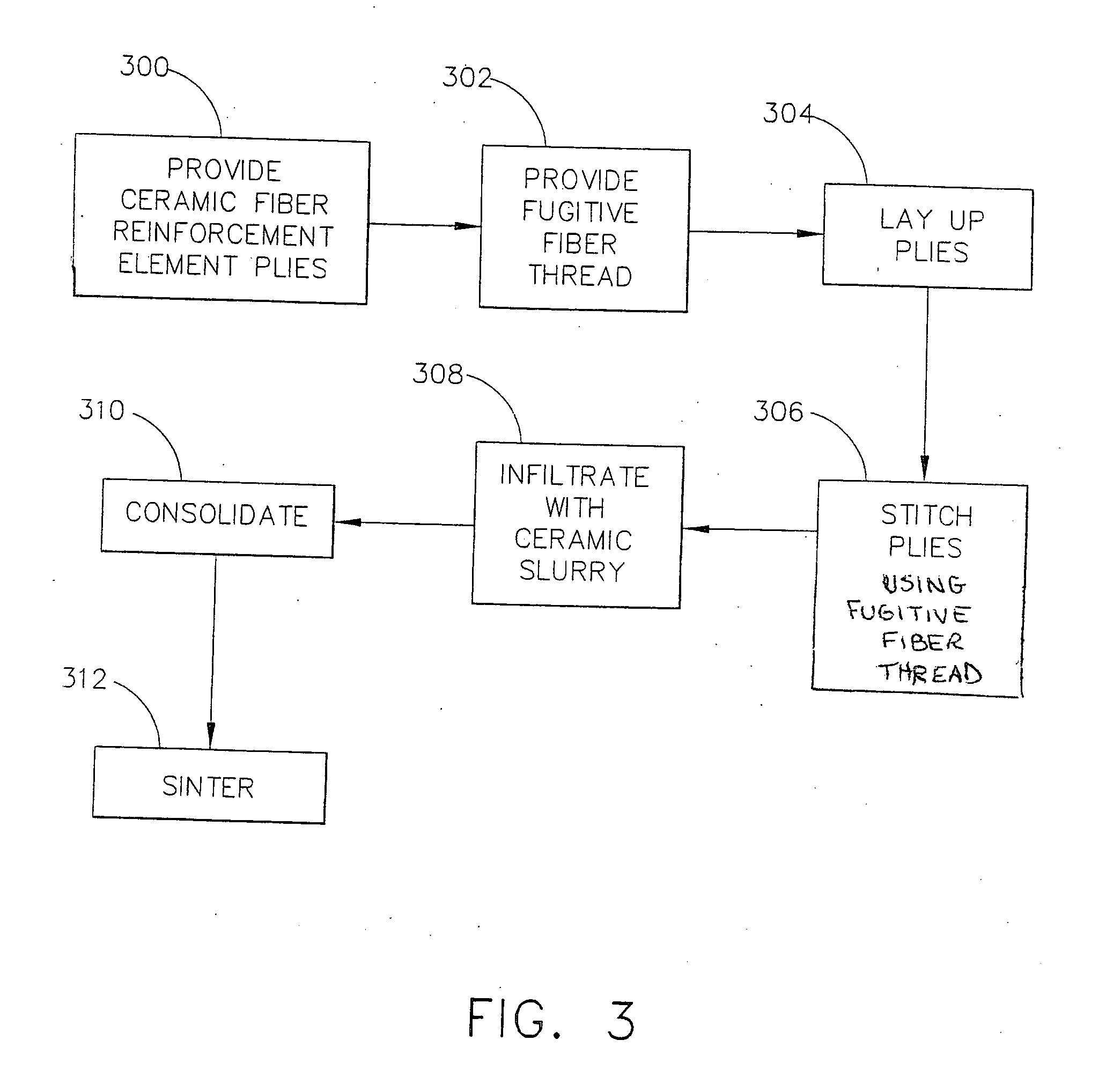

Method of cooling for ceramic matrix composites

ActiveUS20050118392A1Increased cooling flow capabilityLayered productsWood working apparatusSlurryDegree Fahrenheit

A ceramic matrix composite (CMC) structure, and method of forming same, the structure having internal air flow channels and cooling holes created by the process of sewing or stitching a fugitive fiber or thread into plies of ceramic cloth, preferably prior to consolidation of the ceramic cloth with a CMC slurry, followed by heating to convert the slurry material to a hardened ceramic component part of a predetermined shape. Upon heating the infiltrated and consolidated ceramic cloth to about between 1100 and 2100 degrees Fahrenheit, such as by hot pressing the structure containing the fugitive fibers therein, the fugitive fibers disintegrate, leaving channels and cooling holes wherever the stitched fugitive fiber or thread was previously located. Thus, the channels and cooling holes flow between plies as well as across the surface of the top and bottom plies.

Owner:GENERAL ELECTRIC CO

Method of making porous ceramic matrix composites

ActiveUS7153464B2Increased cooling flow capabilityLayered productsWood working apparatusSlurryDegree Fahrenheit

A ceramic matrix composite (CMC) structure, and method of forming same, the structure having internal air flow channels and cooling holes created by the process of sewing or stitching a fugitive fiber or thread into plies of ceramic cloth, preferably prior to consolidation of the ceramic cloth with a CMC slurry, followed by heating to convert the slurry material to a hardened ceramic component part of a predetermined shape. Upon heating the infiltrated and consolidated ceramic cloth to about between 1100 and 2100 degrees Fahrenheit, such as by hot pressing the structure containing the fugitive fibers therein, the fugitive fibers disintegrate, leaving channels and cooling holes wherever the stitched fugitive fiber or thread was previously located. Thus, the channels and cooling holes flow between plies as well as across the surface of the top and bottom plies.

Owner:GENERAL ELECTRIC CO

Cold plasma treatment devices and associated methods

A compact cold plasma device for generating cold plasma having temperatures in the range 65 to 120 degrees Fahrenheit. The compact cold plasma device has a magnet-free configuration and an induction-grid-free configuration. An additional configuration uses an induction grid in place of the input electrode to generate the cold plasma. A high voltage power supply is provided that includes a controllable switch to release energy from a capacitor bank to a dual resonance RF transformer. A controller adjusts the energy input to the capacitor bank, as well as the trigger to the controllable switch.

Owner:COLD PLASMA MEDICAL TECH

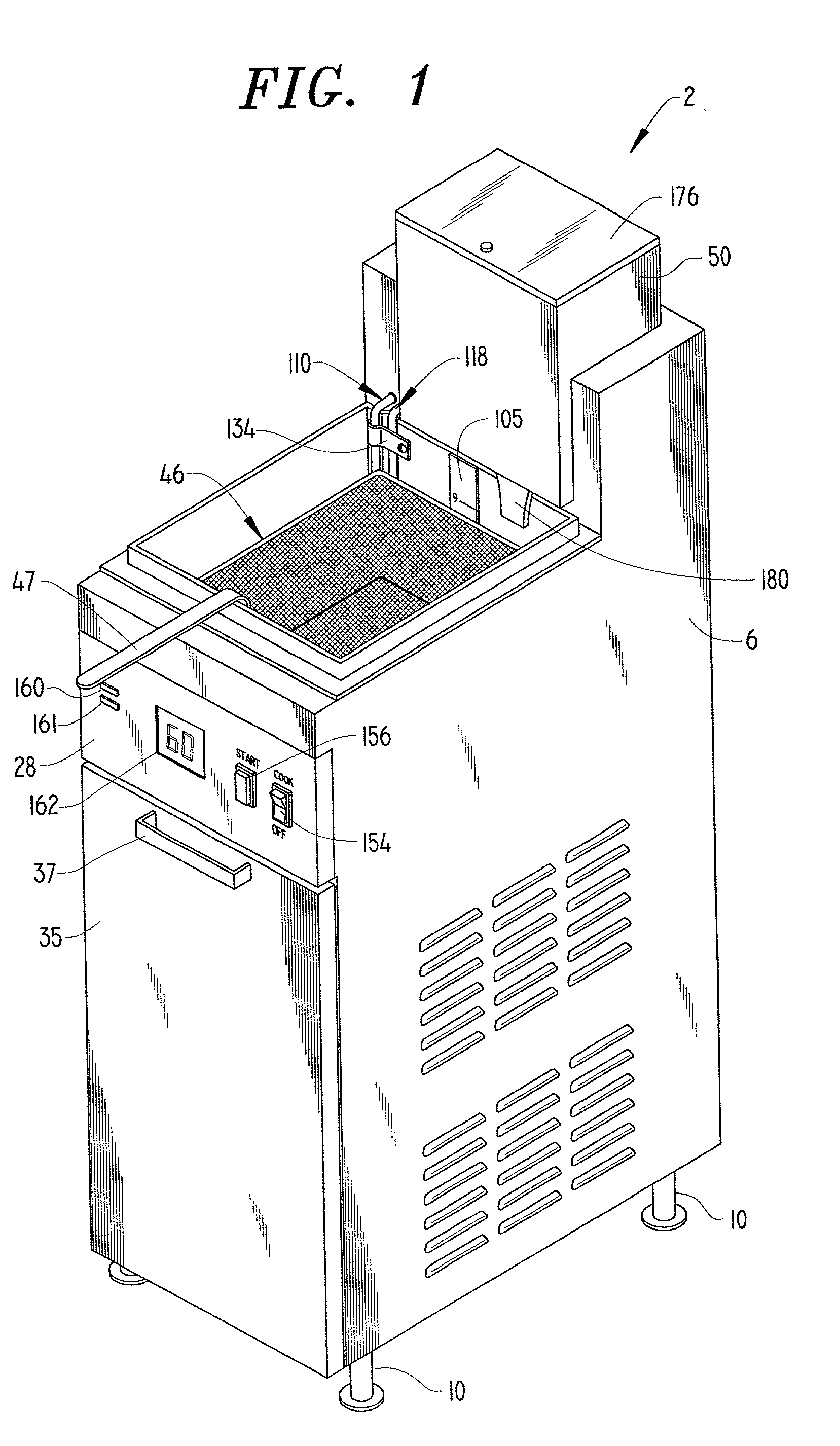

High temperature, oil saving, rapid cook fryer system

A deep fat fryer able to quickly cook food items, in about one-third to one-half of a typical cook time in the art for corresponding food items, includes a high powered, preferably high efficiency heating unit utilized to establish a cooking oil temperature in the order of about forty or more degrees Fahrenheit above a typical cook time, while preferably remaining lower than or equal to 410° F. A controller regulates the heat input from the heating unit so as to keep the temperature of the oil from dropping drastically after a product to be fried is placed in the oil for cooking. The amount of cooking oil employed is minimized. A sensing arrangement is utilized to input sensed operating conditions to the controller in order to maintain a desired operating temperature and oil level.

Owner:PITCO FRIALATOR LLC

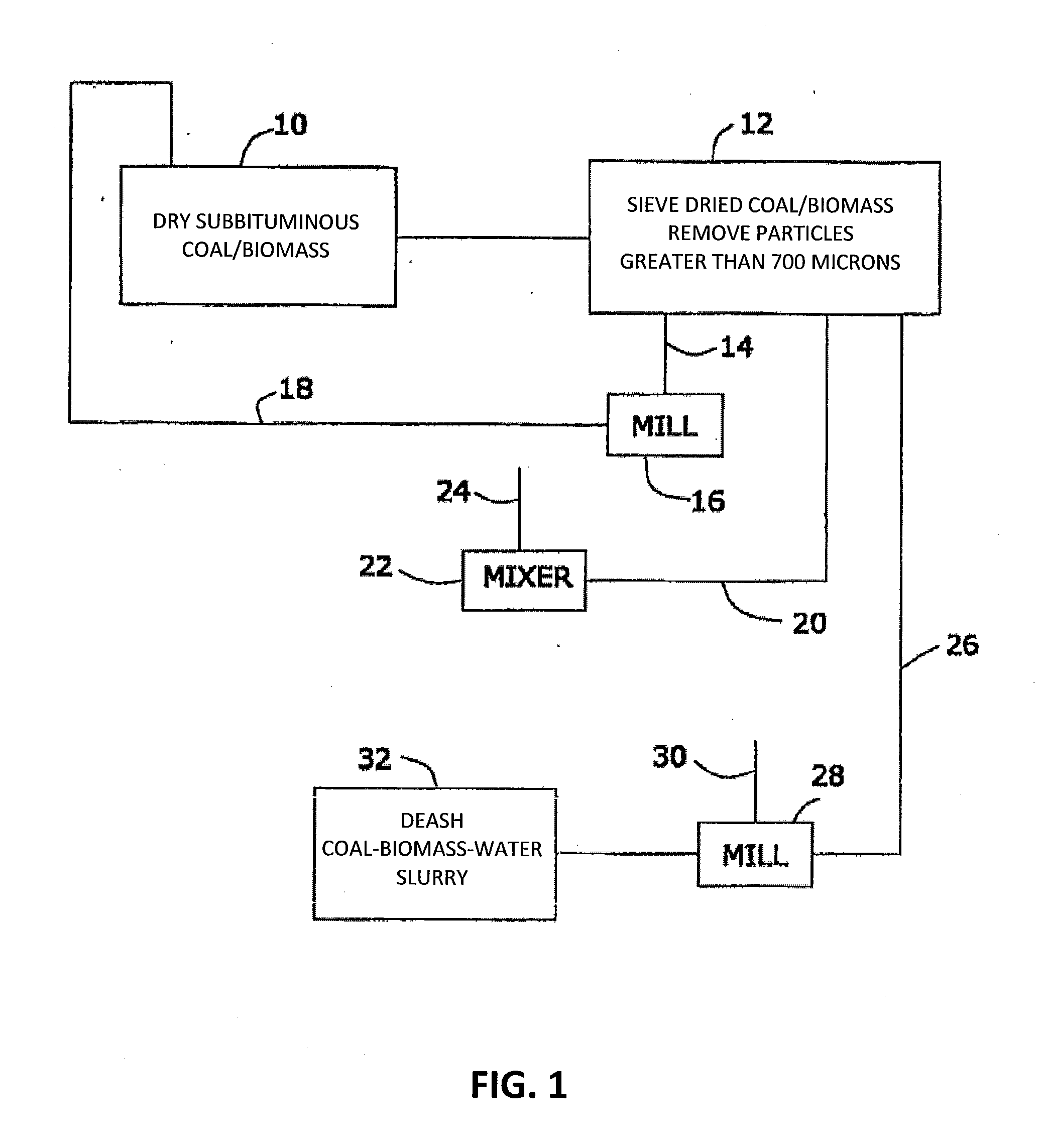

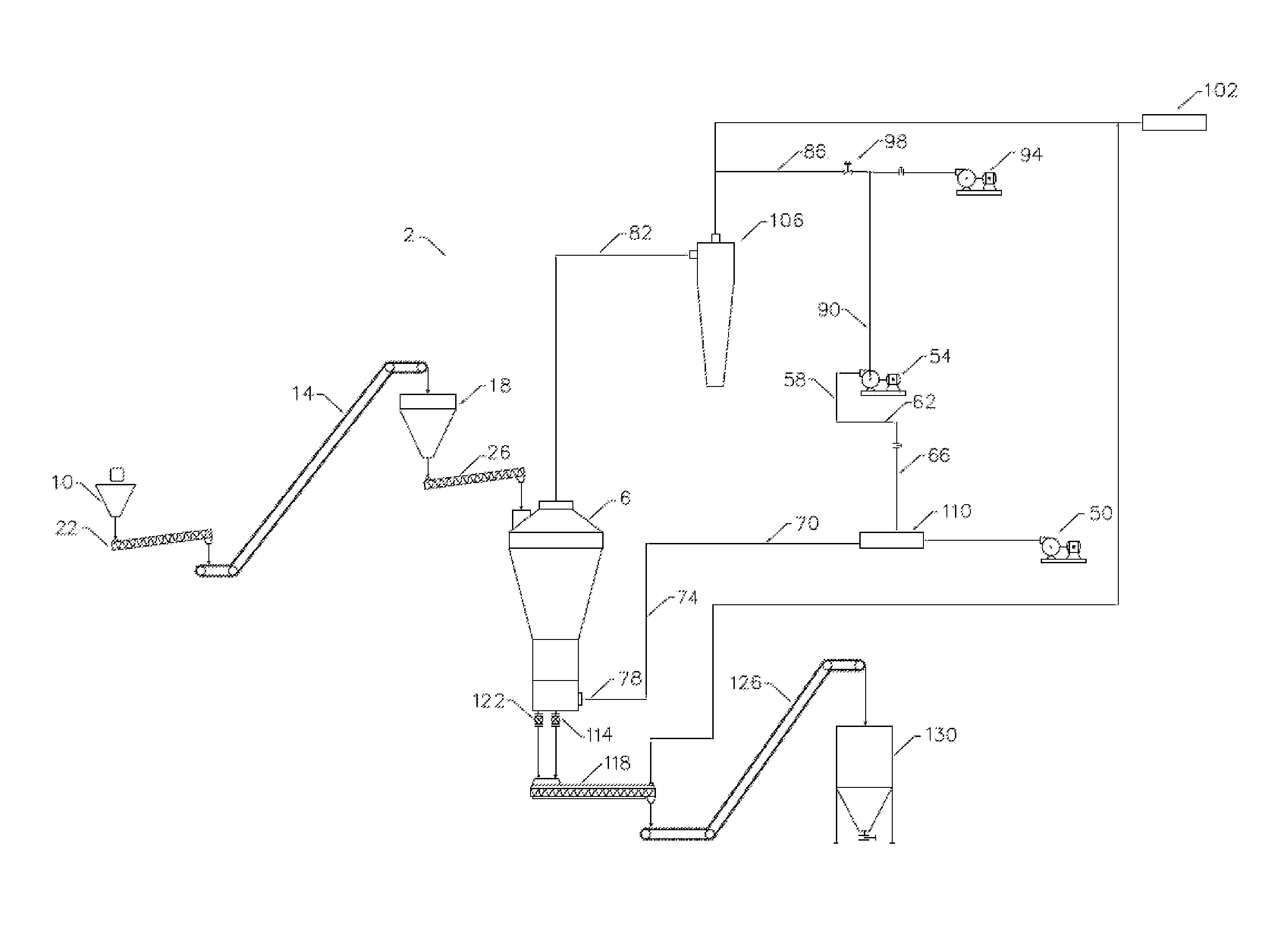

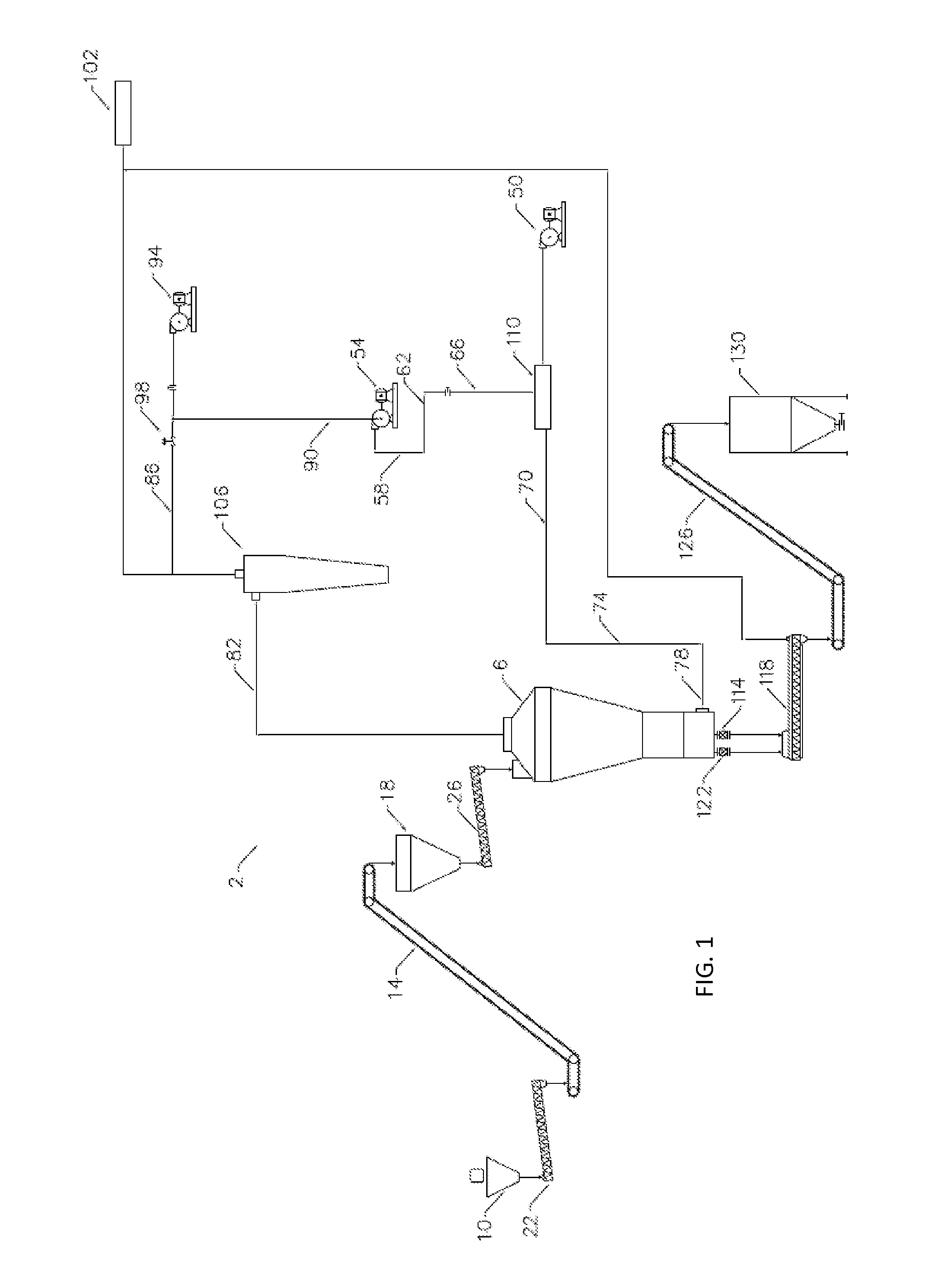

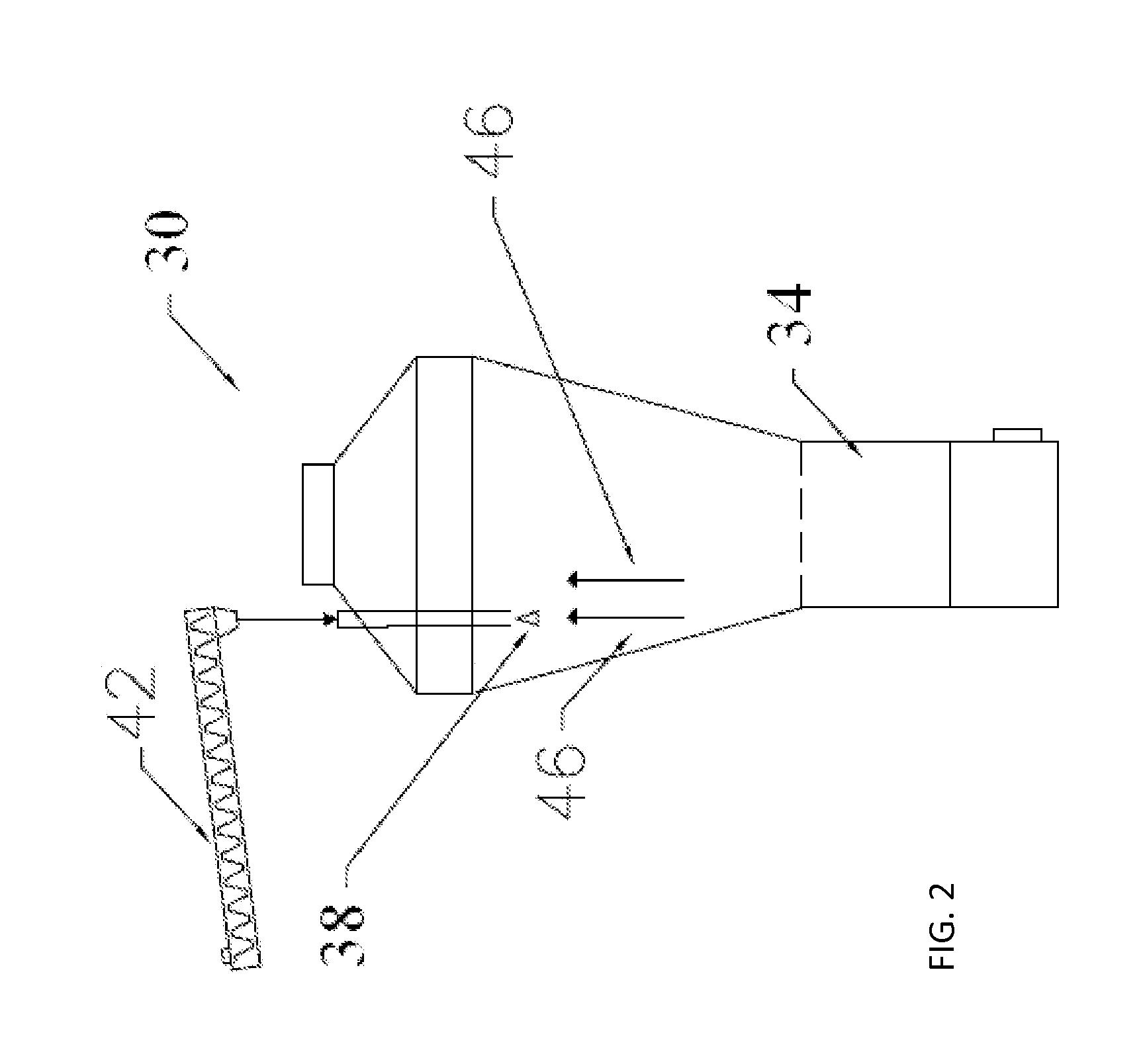

Method of Simultaneously Drying Coal and Torrefying Biomass

InactiveUS20110314728A1Improve water distributionReduce probabilityBiofuelsSolid fuelsFluidized bedEngineering

A process for simultaneously drying coal and / or torrefying biomass is provided in which coal and / or biomass are passed into a fluidized bed reactor and heated to a predetermined temperature. The dried coal and / or biomass is then fed to a cooler where the temperature of the product is reduced to approximately 200 degrees Fahrenheit and water is added to further passivate the coal.

Owner:BIOMASS SECURE POWER INC

Method of Drying Biomass

A process for torrefaction of biomass is provided in which biomass are passed into a fluidized bed reactor and heated to a predetermined temperature in an oxidizing environment. The dried biomass is then fed to a cooler where the temperature of the product is reduced to approximately 100 degrees Fahrenheit.

Owner:RIVER BASIN ENERGY

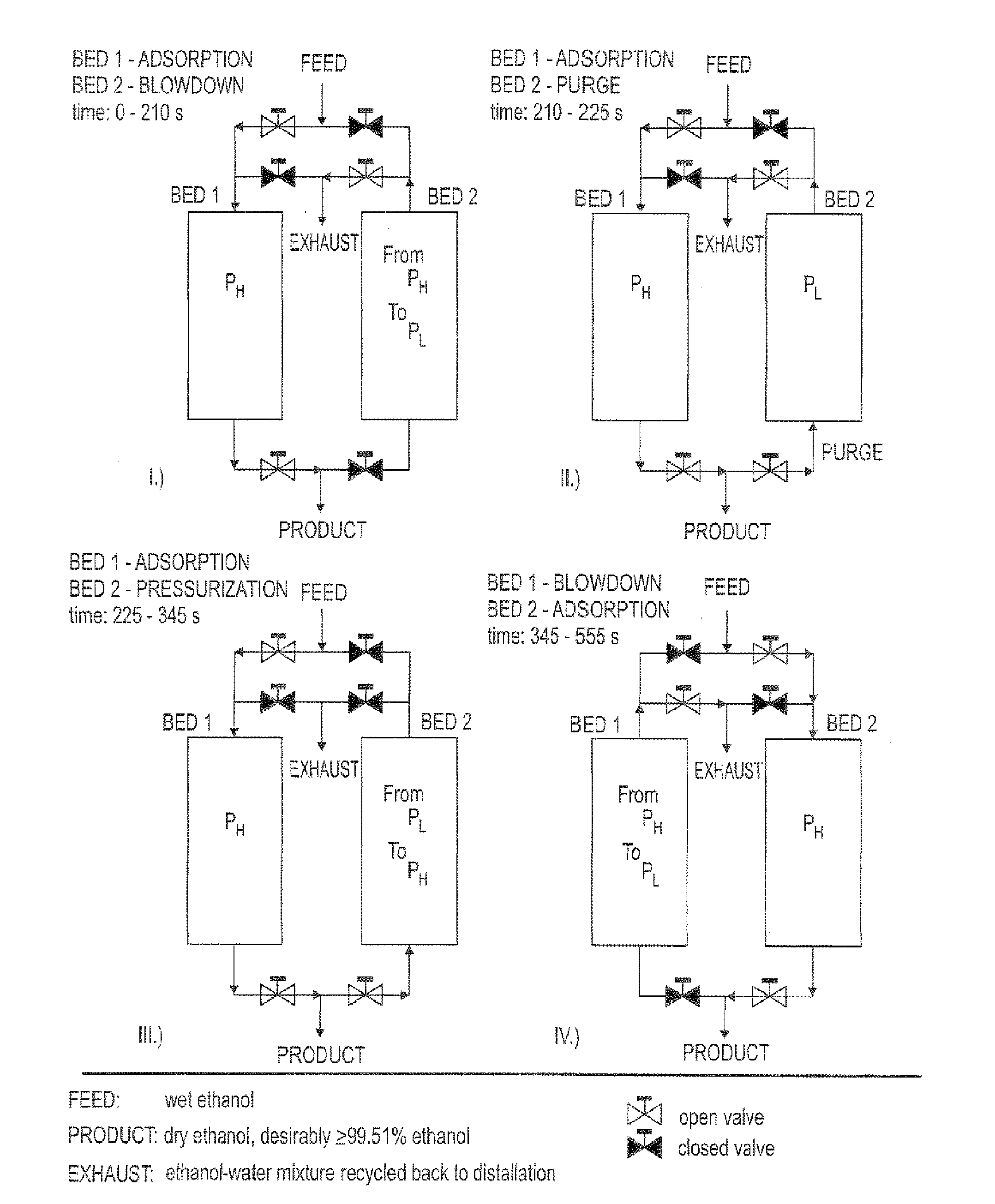

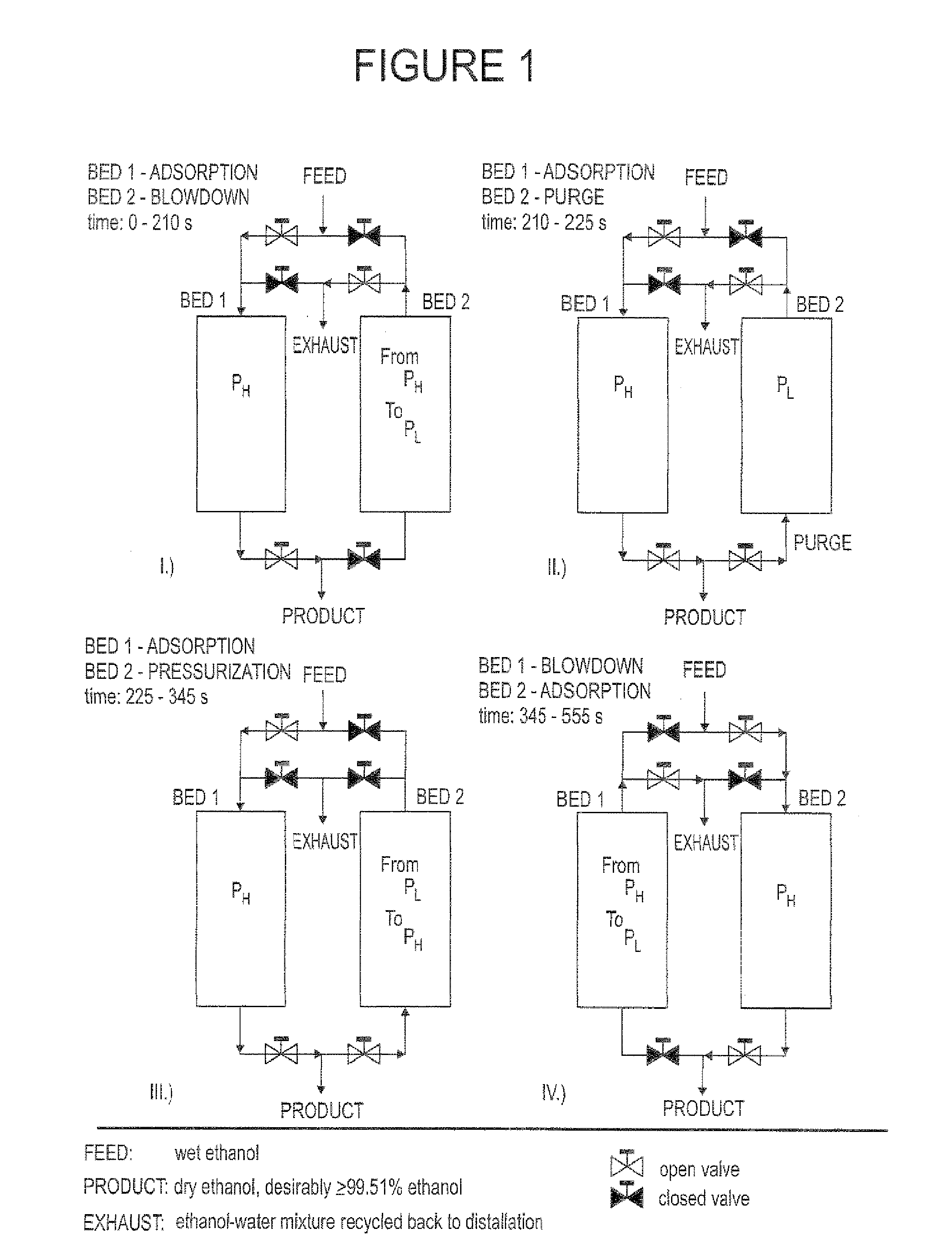

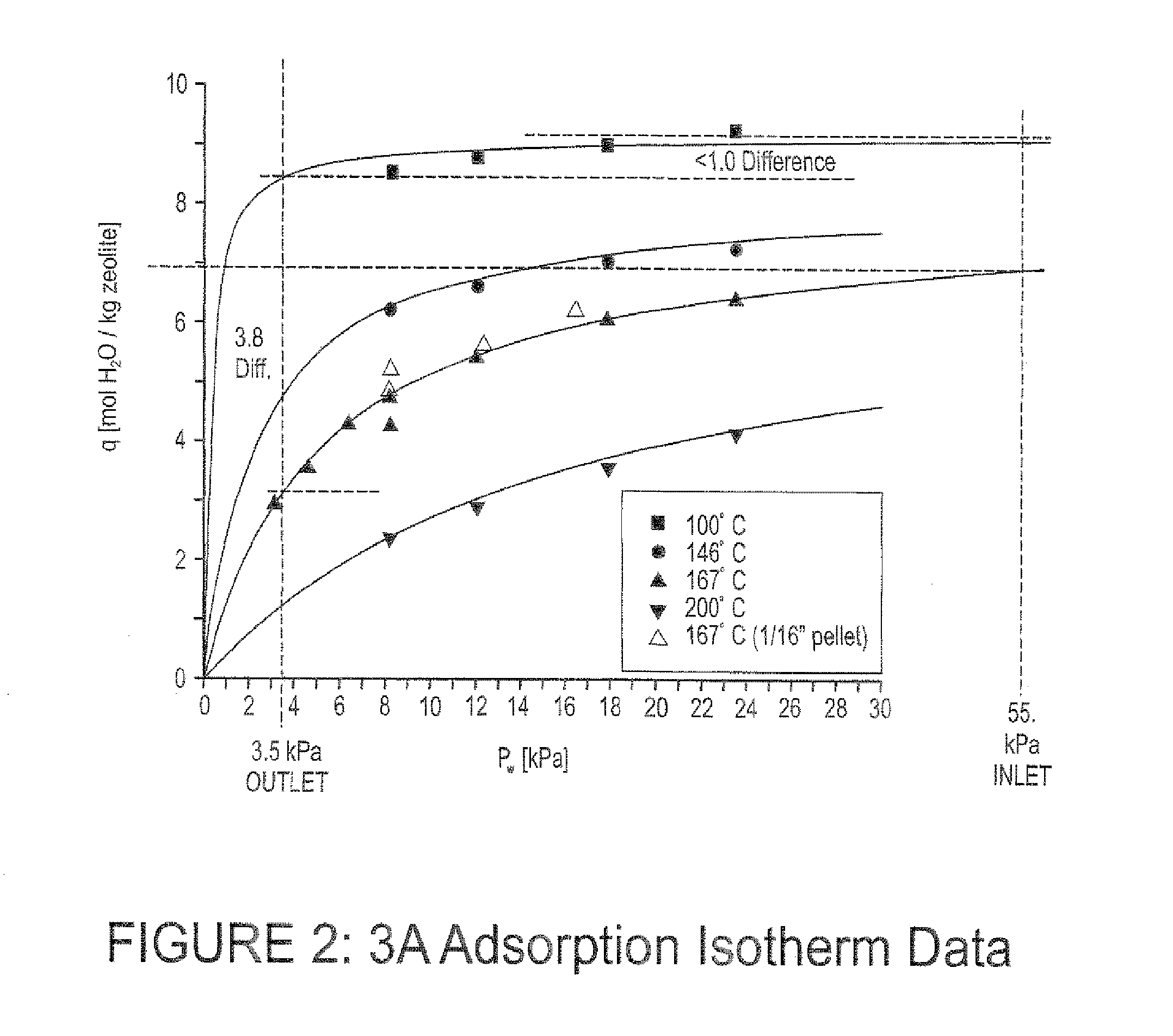

Adsorption process for the dehydration of alcohol

ActiveUS20130225880A1Increase productivityImprove performanceGas treatmentOrganic compound preparationAqueous alcoholHigh pressure

The present invention includes a process for the dehydration of ethanol by adsorption of water at elevated pressure and for the regeneration (purging) of adsorbent at a lower pressure than the pressure used for the adsorption of water where the ratio of the duration of the regeneration (purge) step to the duration of the water adsorption step is higher than 0.1 and the temperature of adsorption is greater than 260 degree Fahrenheit.

Owner:RCM TECH USA INC

Fire fighting system

InactiveUS20070256842A1Highly effectiveOvercome difficultiesFire rescueBoring toolsJet engineWater source

A fire fighting system for fighting forest and brush fires under dry, hot and windy conditions which includes a jet engine for generating a high speed air stream, a water source for supplying water to a cooling system which lowers the water temperature to between forty and fifty degrees fahrenheit, a nozzle for injecting cold water into the air steam and a filter which provides very fine particles of cold water within the stream. The stream of cold water is directed to a forest or brush fire dropping the temperature of the fire which eventually extinguishes the fire.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Method for producing electrical contacts using selective melting and a low pressure kinetic spray process

A new kinetic spray process is disclosed that enables the coating to withstand severe bending and stress without delamination. The method includes use of a low pressure kinetic spray supersonic nozzle having a throat located between a converging region and a diverging region. A main gas temperature is raised to from 1000 to 1300 degrees Fahrenheit and the coating particles are directly injected into the diverging region of the nozzle at a point after the throat. The particles are entrained in the flow of the gas and accelerated to a velocity sufficient to result in partial melting of the particles upon impact on a substrate positioned opposite the nozzle and adherence of the particles to the substrate. The coating also has a desirable shinny surface. The method finds special application in coating substrates for use in formation of electrical connections.

Owner:DELPHI TECH INC

Trapped vortex cavity afterburner

ActiveUS20070044476A1Increase temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberTrailing edge

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

Part load blade tip clearance control

InactiveUS6968696B2Reduce the temperatureConstant cooling temperatureTurbine/propulsion engine coolingBlade accessoriesTurbine bladeDegree Fahrenheit

Aspects of the invention relate to a turbine engine configuration and method for overcoming a turbine blade tip clearance problem that can arise when the turbine inlet temperature is maintained at a high level during part load operation of the turbine. Aspects of the invention relate to reducing rotor cooling air to a temperature below the design temperature level by using, for example, additional heat extraction devices or by reconfiguring or resizing existing heat exchanger devices. Upon exposure to the cooled air, the discs and blades of the turbine will shrink so as to provide a clearance between the blade tips and surrounding stationary support structure. The design rotor cooling air temperature can be from about 350 degrees Fahrenheit to about 480 degrees Fahrenheit. Aspects of the present invention can be used to decrease the rotor cooling air to about 150 degrees Fahrenheit at about 70 percent load.

Owner:SIEMENS ENERGY INC

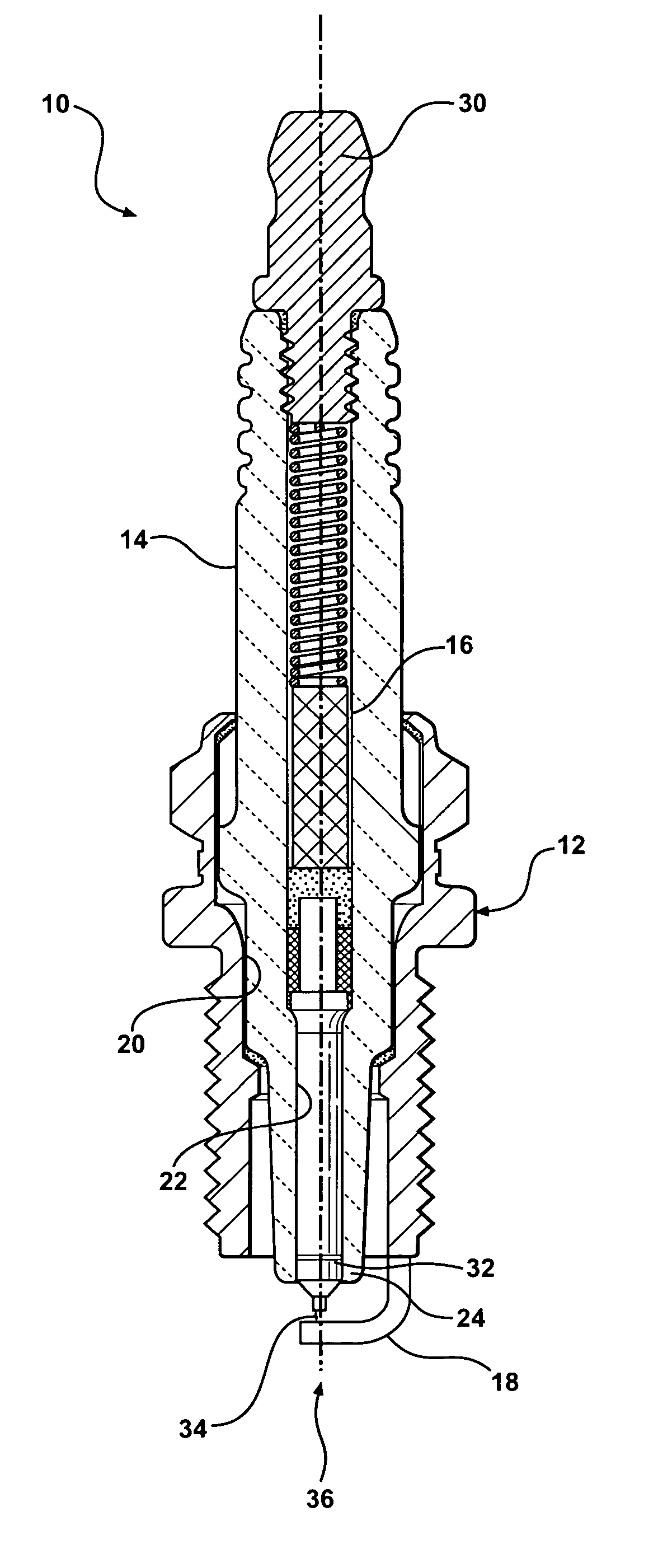

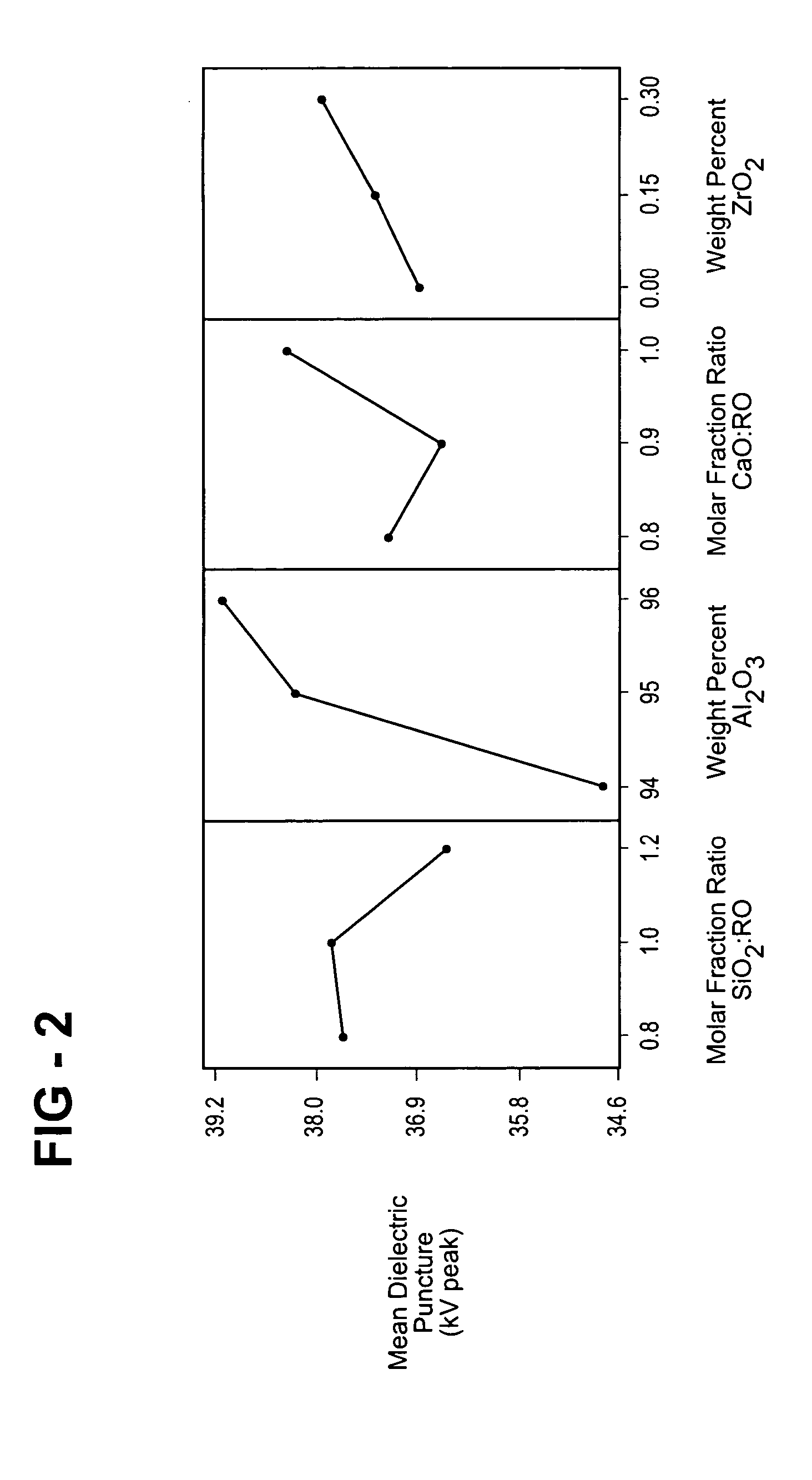

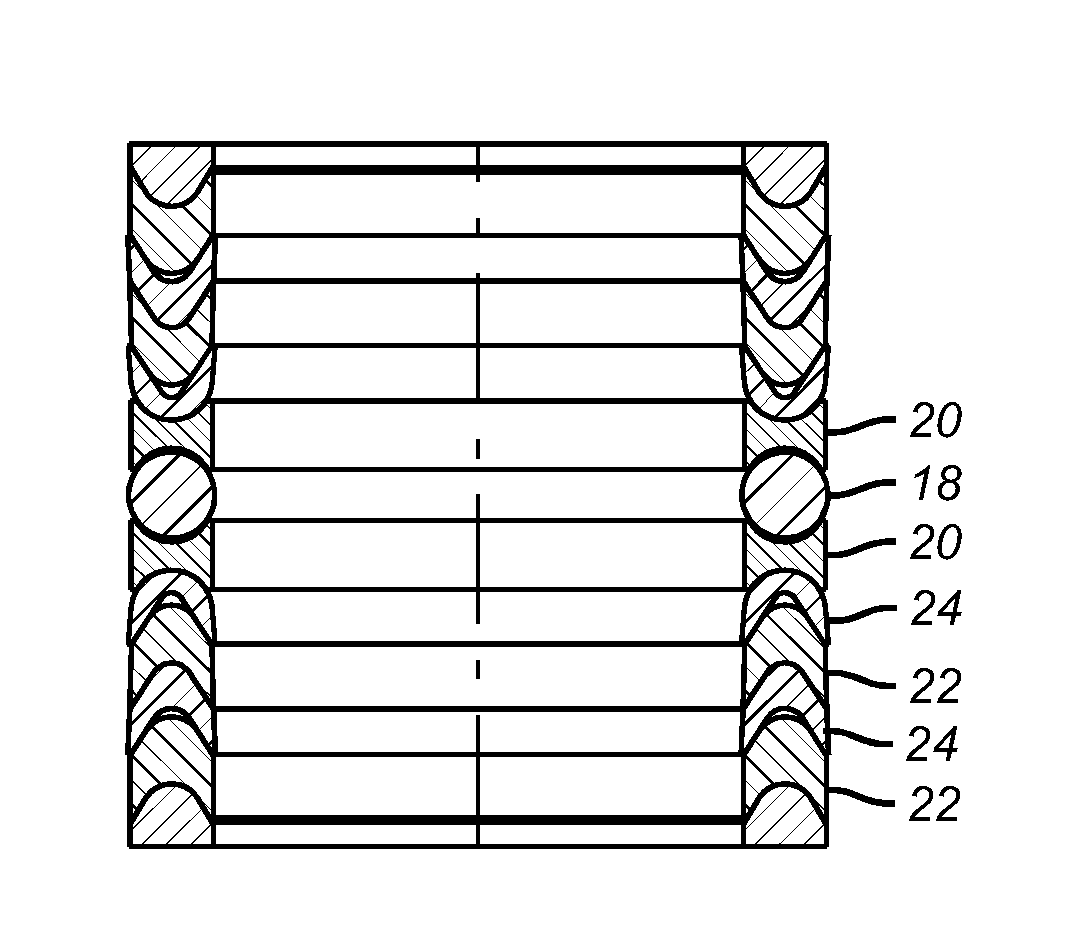

Ceramic with improved high temperature electrical properties for use as a spark plug insulator

ActiveUS20050110382A1Improved dielectric breakdown propertyImproved shunt resistanceSparking plugsElectrical resistance and conductanceElectricity

A ceramic includes alumina in an amount between about 90 and about 99% by weight, a zirconium containing compound in an amount between about 0 and about 1% by weight, and an oxide mixture in an amount between about 1 and about 10% by weight. The oxide mixture includes a glass former and a network modifier, wherein the molar ratio of the glass former to the network modifier ranges between about 0.8:1 and 1.2:1. The ceramic insulator is particularly adapted for use as an insulator in a spark plug to provide improved dielectric strength and shunt resistance of greater than one 1000 megaohms at 1000 degrees Fahrenheit, so as to reduce the shunting of the spark plug and thereby improve the quality of the spark generated by the spark plug.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Fire fighting system

A fire fighting system for fighting forest and brush fires under dry, hot and windy conditions which includes a jet engine for generating a high speed air stream, a water source for supplying water to a cooling system which lowers the water temperature to between forty and fifty degrees fahrenheit, a nozzle for injecting cold water into the air steam and a filter which provides very fine particles of cold water within the stream. The stream of cold water is directed to a forest or brush fire dropping the temperature of the fire which eventually extinguishes the fire.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

System and method for online inspection of turbines using an optical tube with broadspectrum mirrors

ActiveUS20140063227A1Improve transmission efficiencyImprove image qualityMirrorsColor television detailsCelsius DegreeReflectance spectroscopy

An optical inspection system for nondestructive internal visual inspection and non-contact infra-red (IR) temperature monitoring of an online, operating power generation turbine. The optical inspection system includes an optical tube having a viewing port, at least one reflective mirror or a mirror array having a reflectivity spectral range from 550 nm to 20 μm, and capable of continuous operation at temperatures greater than 932 degrees Fahrenheit (500 degrees Celsius), and a transparent window with high transmission within the same spectral range mounted distal the viewing port. The same optical mirror array may be used to measure selectively surface temperature of metal turbine blades in the near IR range (approximately 1 μm wavelength) and of thermal barrier coated turbine blades in the long IR range (approximately 10 μm wavelength).

Owner:SIEMENS ENERGY INC

Fire fighting system

A fire fighting system for fighting forest and brush fires under dry, hot and windy conditions which includes a jet engine for generating a high speed air stream, a water source for supplying water to a cooling system which lowers the water temperature to between forty and fifty degrees Fahrenheit, a nozzle for injecting cold water into the air steam and a filter which provides very fine particles of cold water within the stream. The stream of cold water is directed to a forest or brush fire dropping the temperature of the fire which eventually extinguishes the fire.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

High pressure and temperature seal for downhole use

Owner:BAKER HUGHES HLDG LLC

Repair process

In accordance with the present invention, a process for repairing metal workpieces, such as turbine engine components, is provided. The process comprises the steps of forming a braze paste containing a first nickel base alloy material containing boron and chromium and a second nickel base alloy material containing chromium and cobalt, applying the brazing paste to an area of the metal workpiece containing at least one crack, and subjecting the workpiece and the brazing paste to a brazing cycle by heating the brazing paste and the workpiece, preferably to a temperature in the range of from 2000 to 2200 degrees Fahrenheit. During the brazing cycle, the brazing paste flows into and fills the at least one crack and thus repairs the metal workpiece.

Owner:RAYTHEON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com