Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about How to "Low cooling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal combustion engine

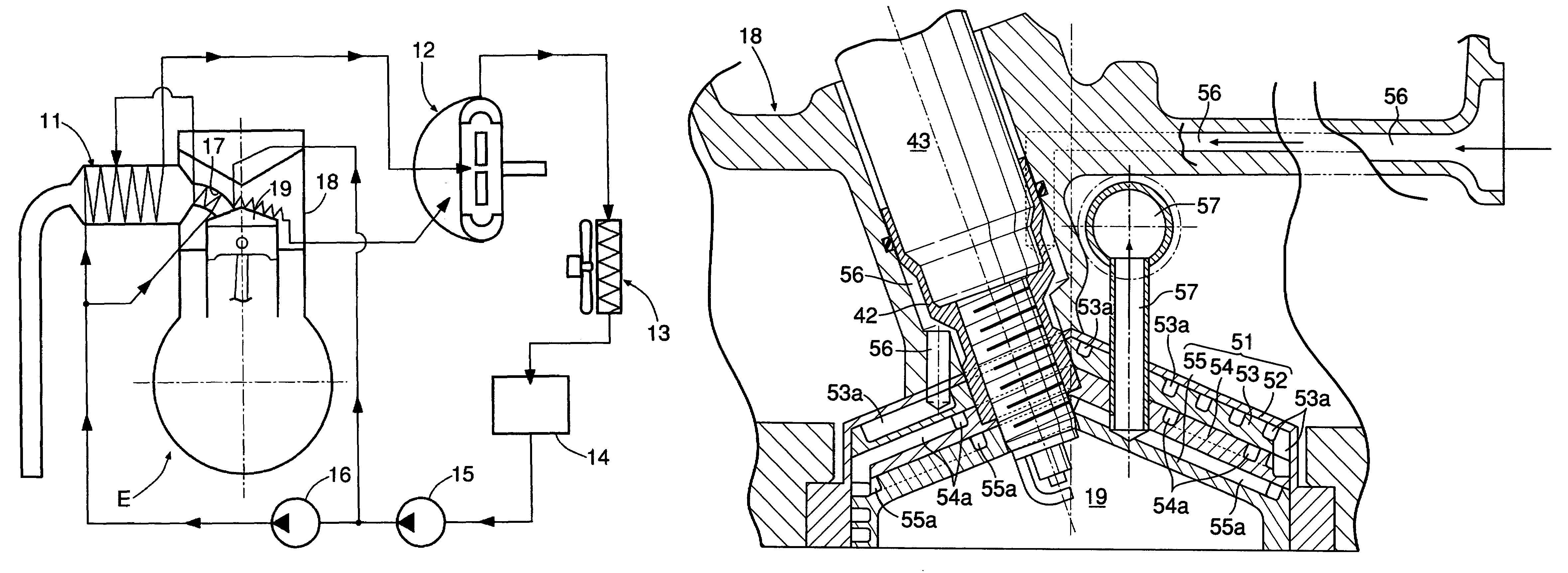

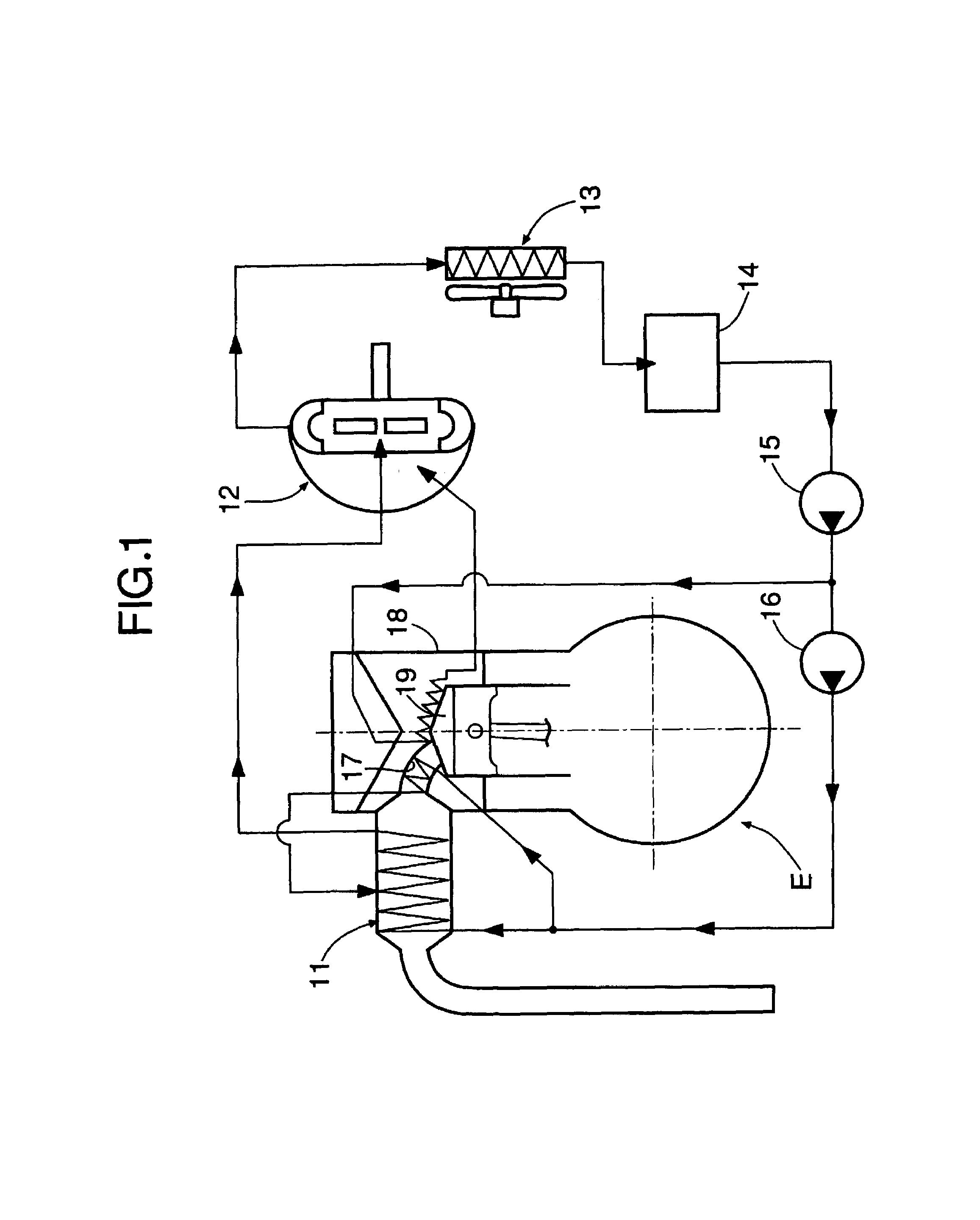

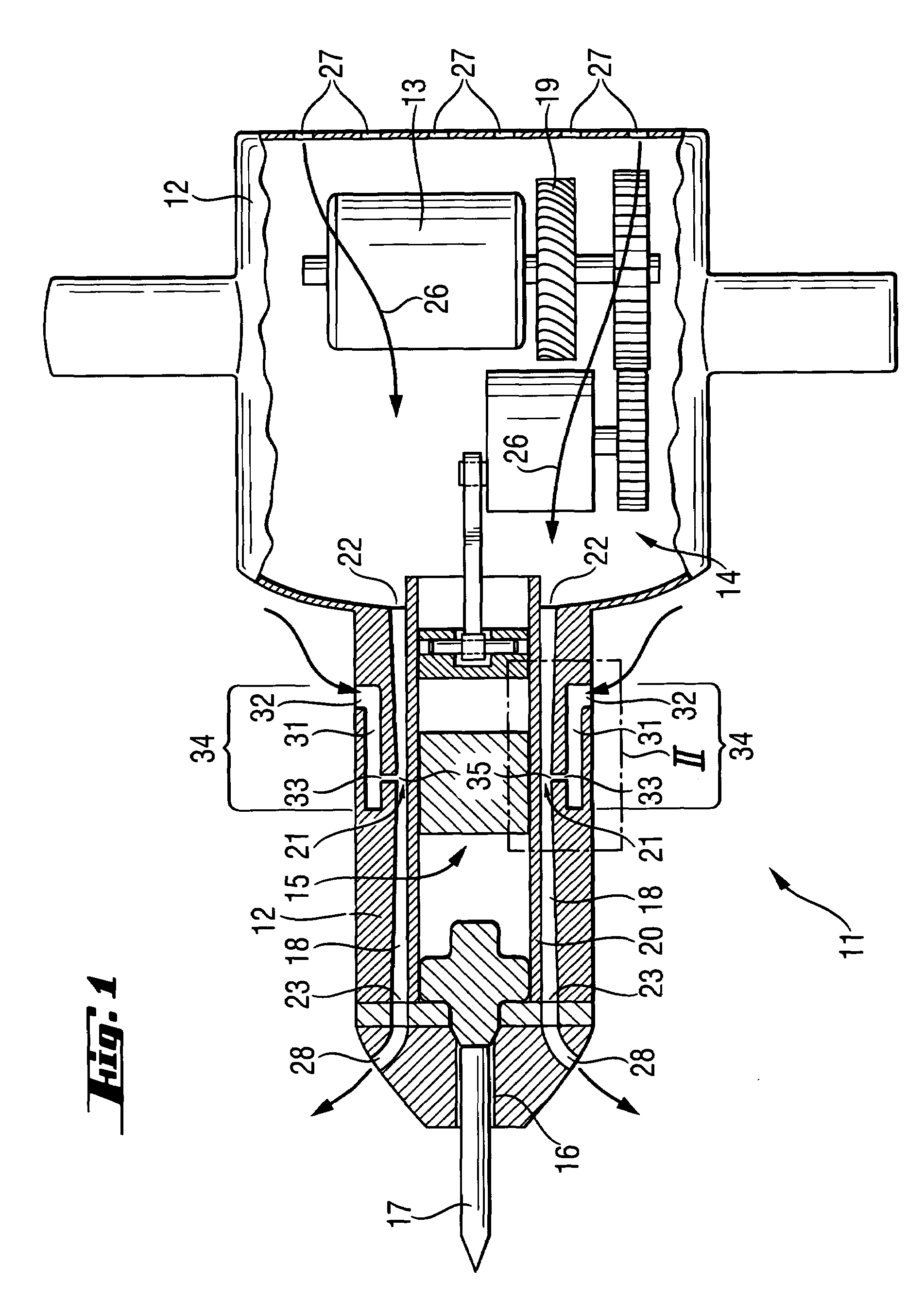

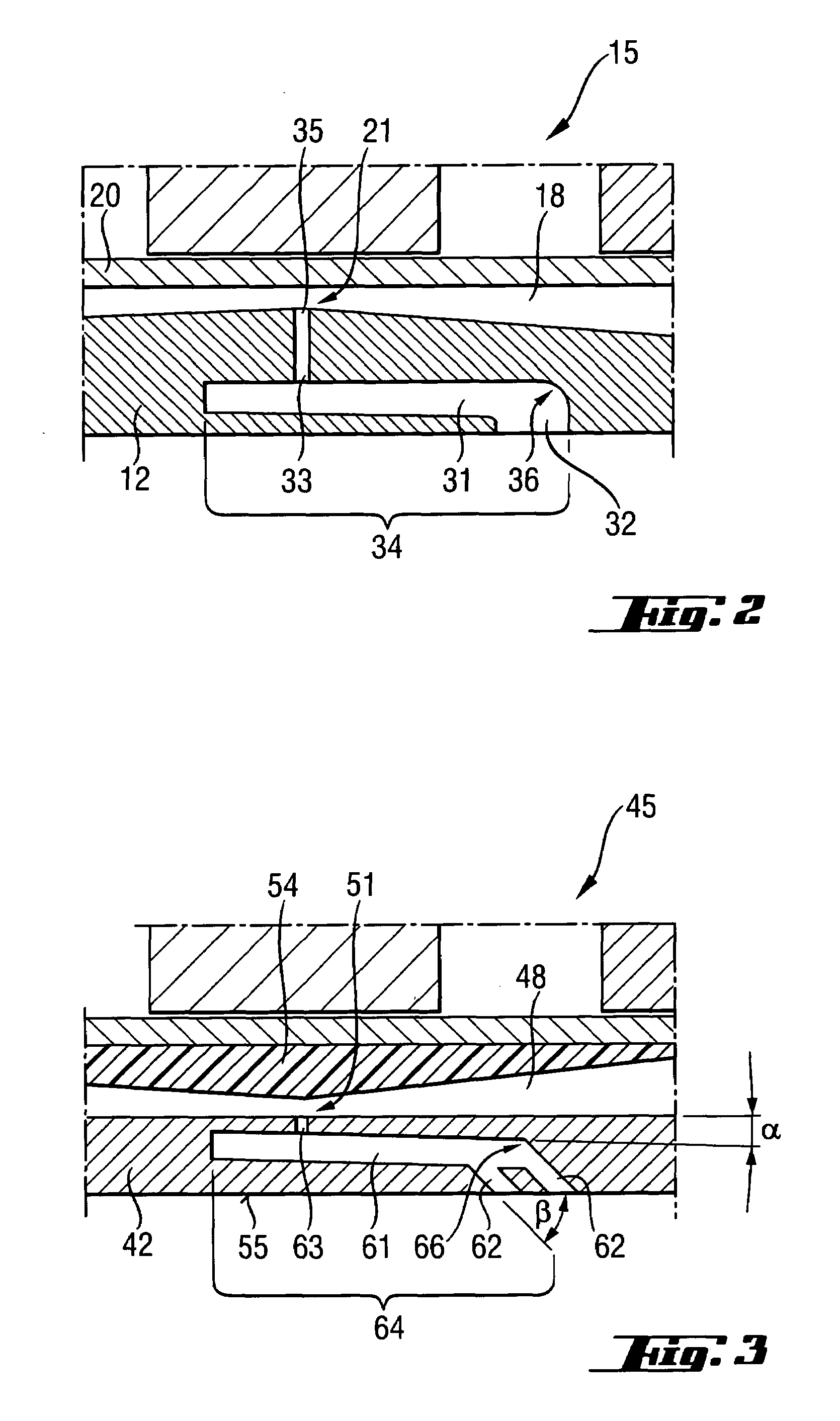

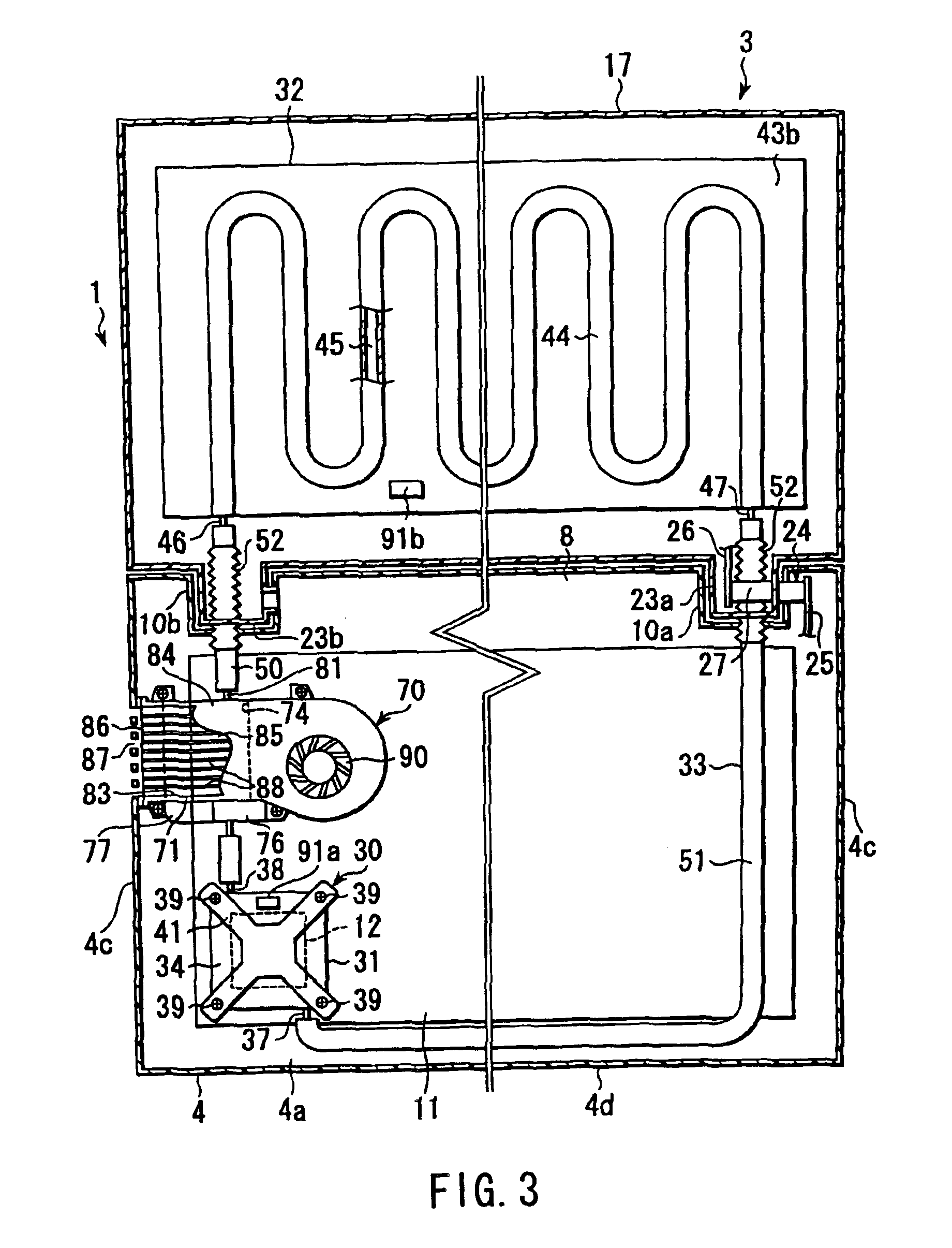

InactiveUS7191740B2Good effectIncrease temperatureLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

A cooling block forming a top wall of a combustion chamber of an internal combustion engine is formed by layering, from the outside to the inside, a casing, an upper layer block, a middle layer block, and a lower layer block. Labyrinth-shaped cooling water passages are formed on upper side faces of the three layers of blocks, and cooling water supplied from a cooling water supply passage flows from the cooling water passage on the side far from the combustion chamber to the cooling water passage on the side close to the combustion chamber, and is discharged from a cooling water discharge passage. Since the cooling water flows in a direction opposite to the direction of emission of heat of combustion from the combustion chamber, it is possible to ensure that there is sufficient difference in temperature between a cylinder head and the cooling water throughout the cooling water passages.

Owner:HONDA MOTOR CO LTD

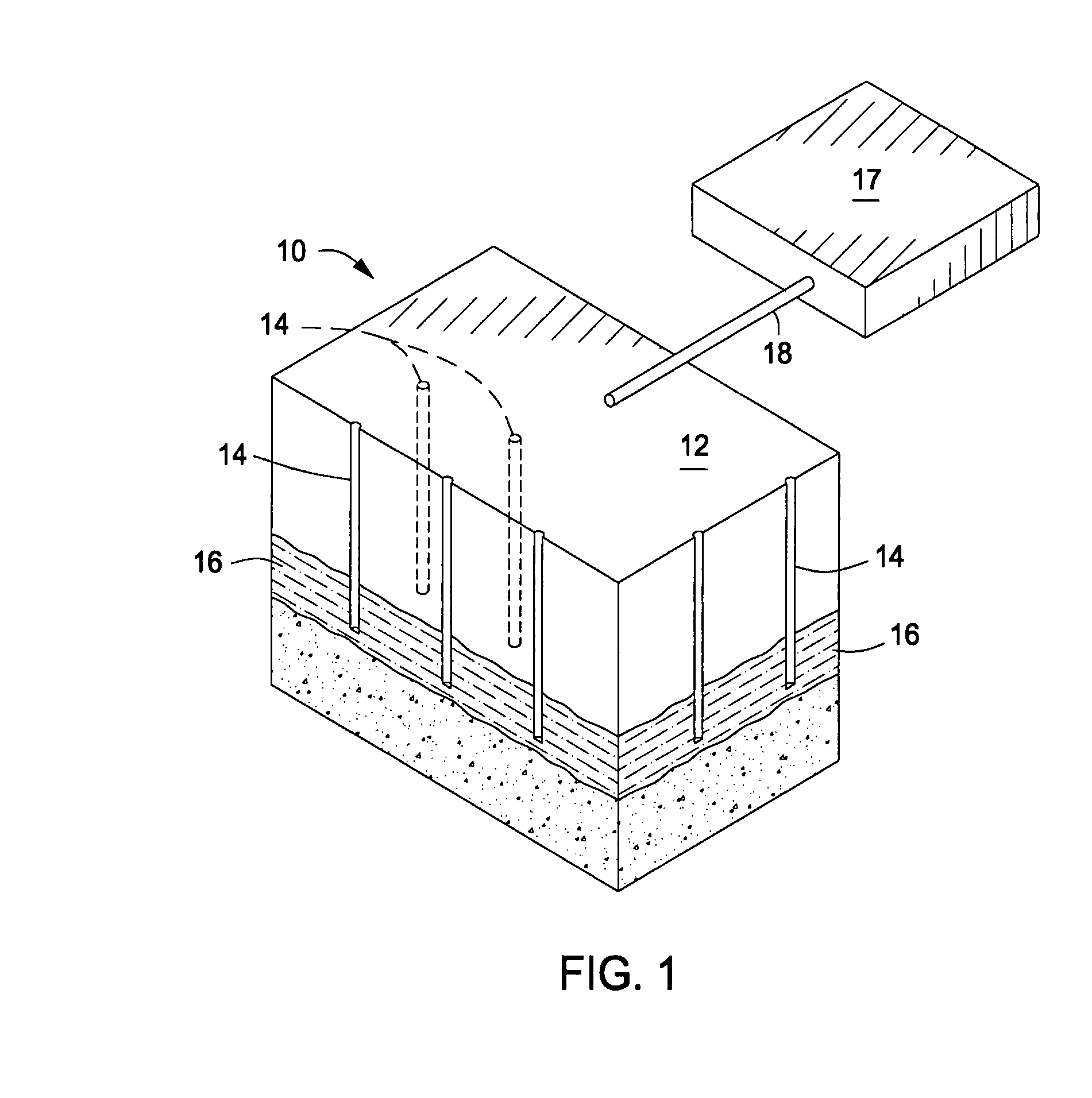

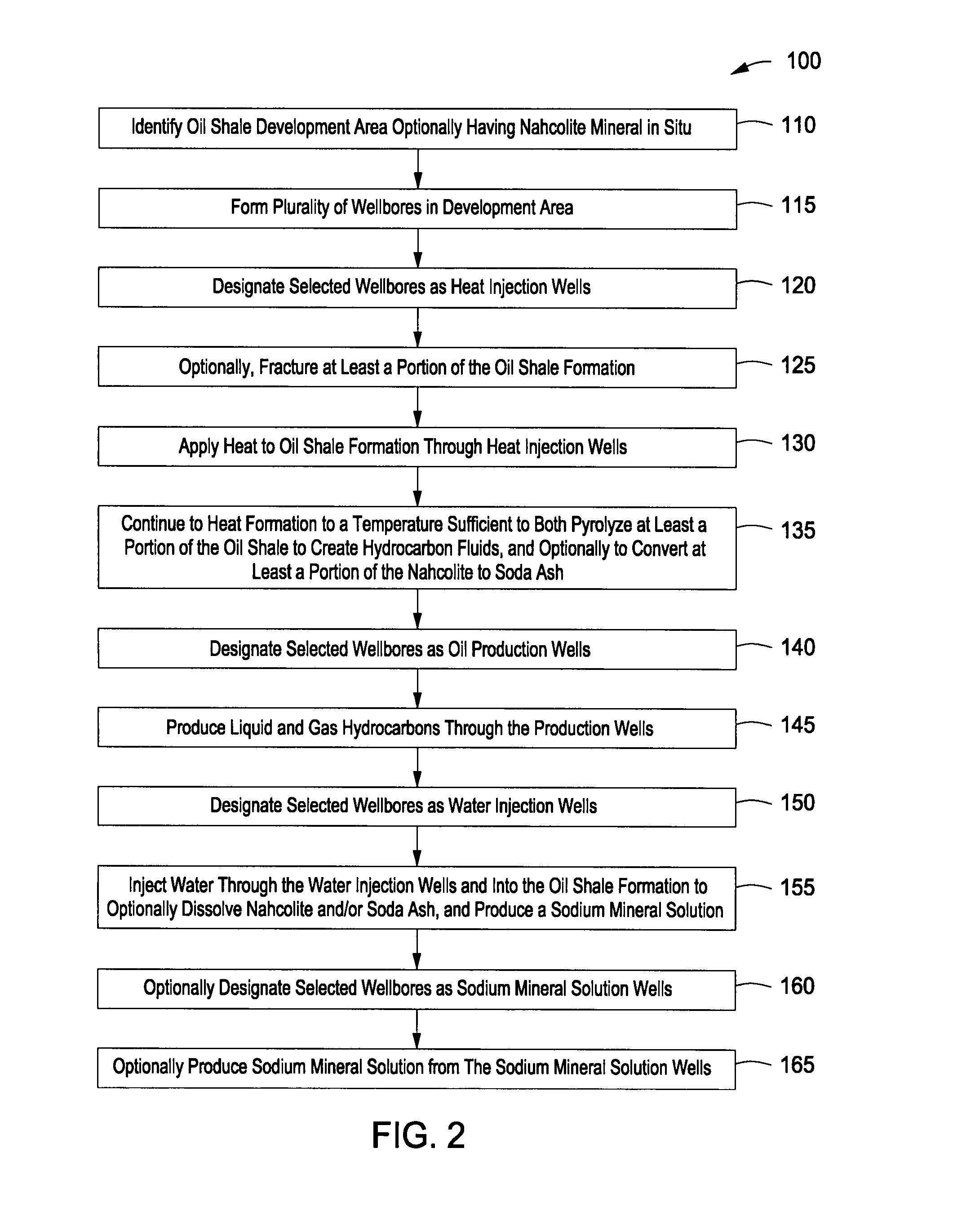

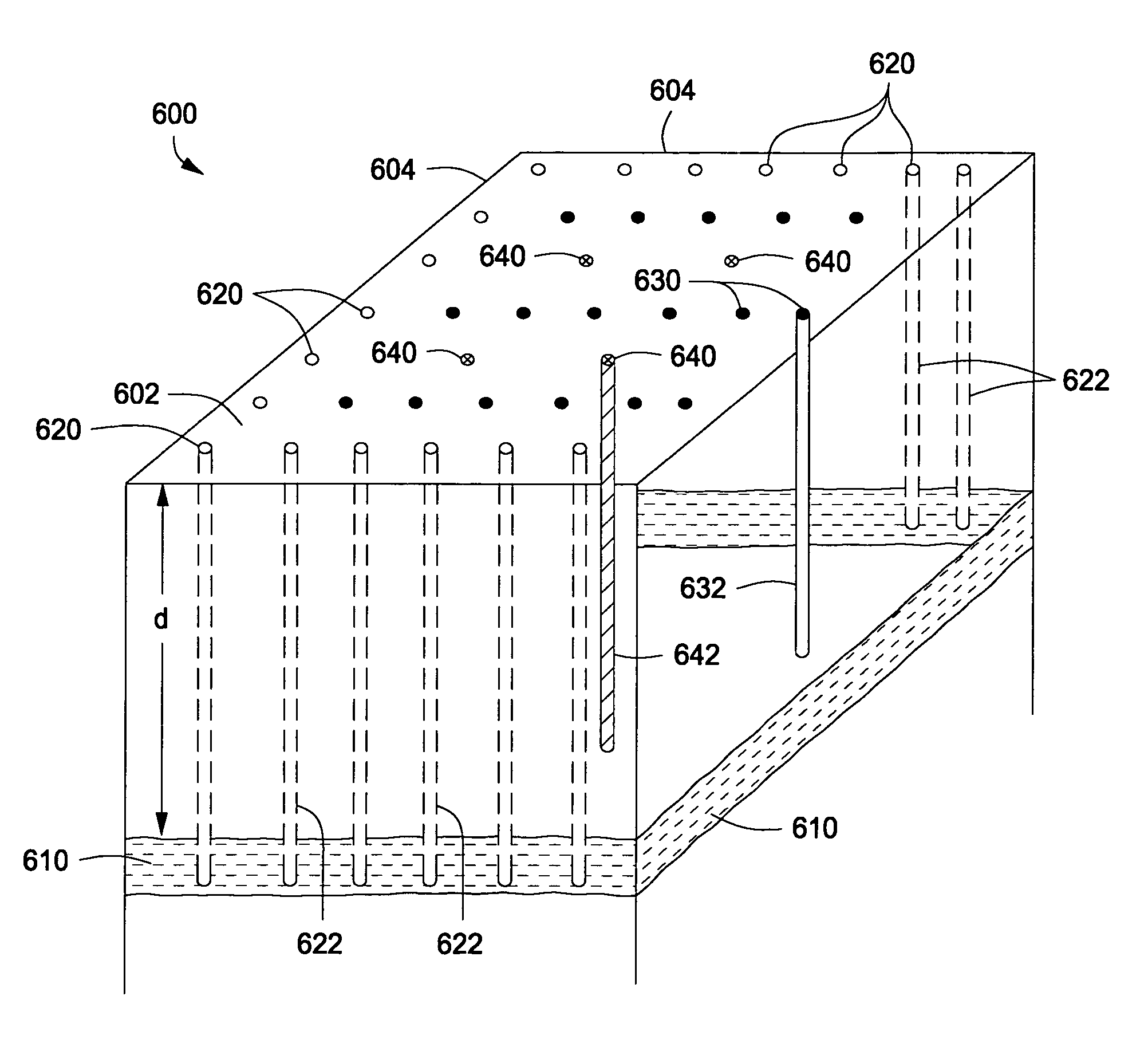

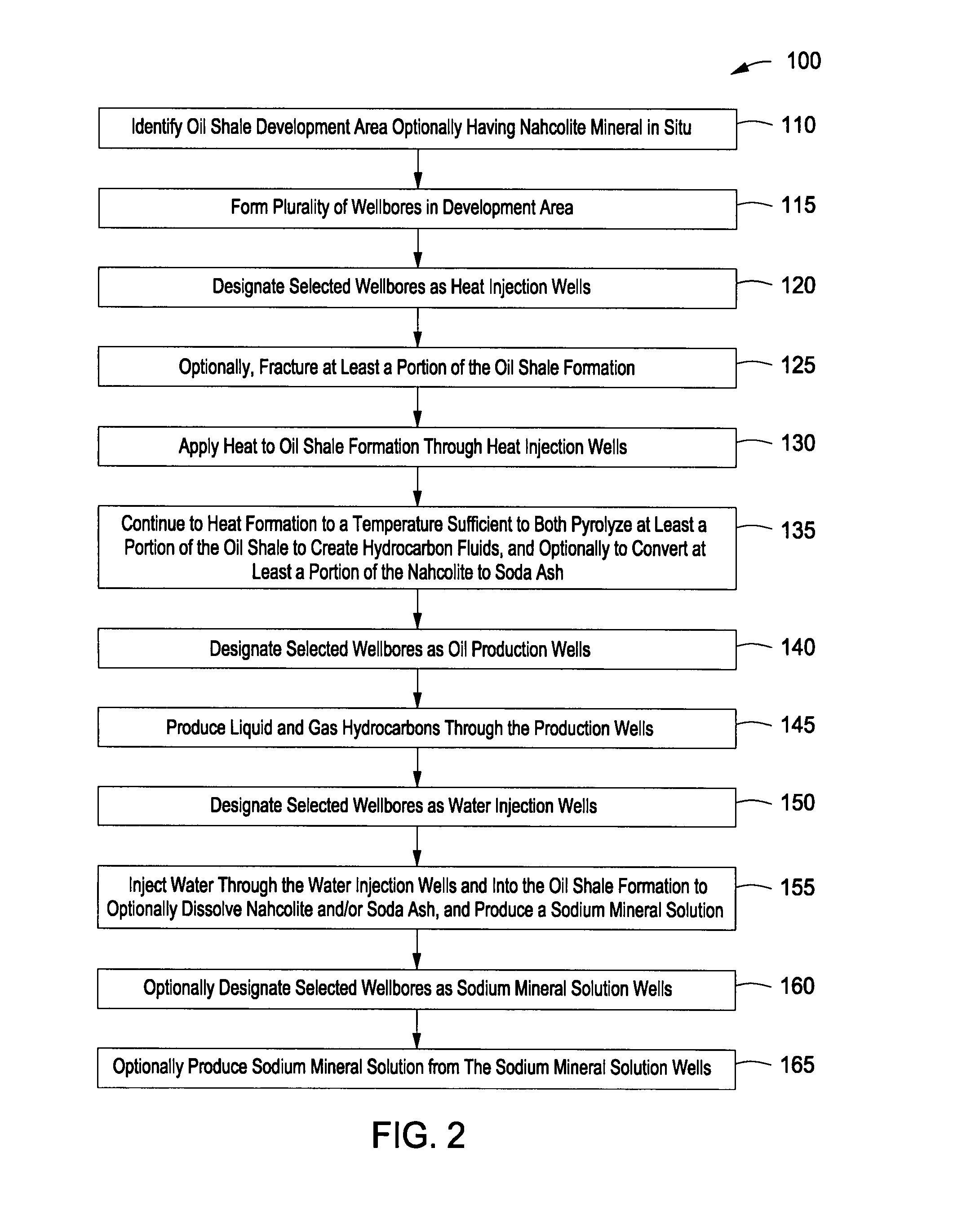

Method of developing subsurface freeze zone

InactiveUS20080087421A1Reduce natural salinityRaise freezing temperatureSurveyDrilling rodsSlurryCooling fluid

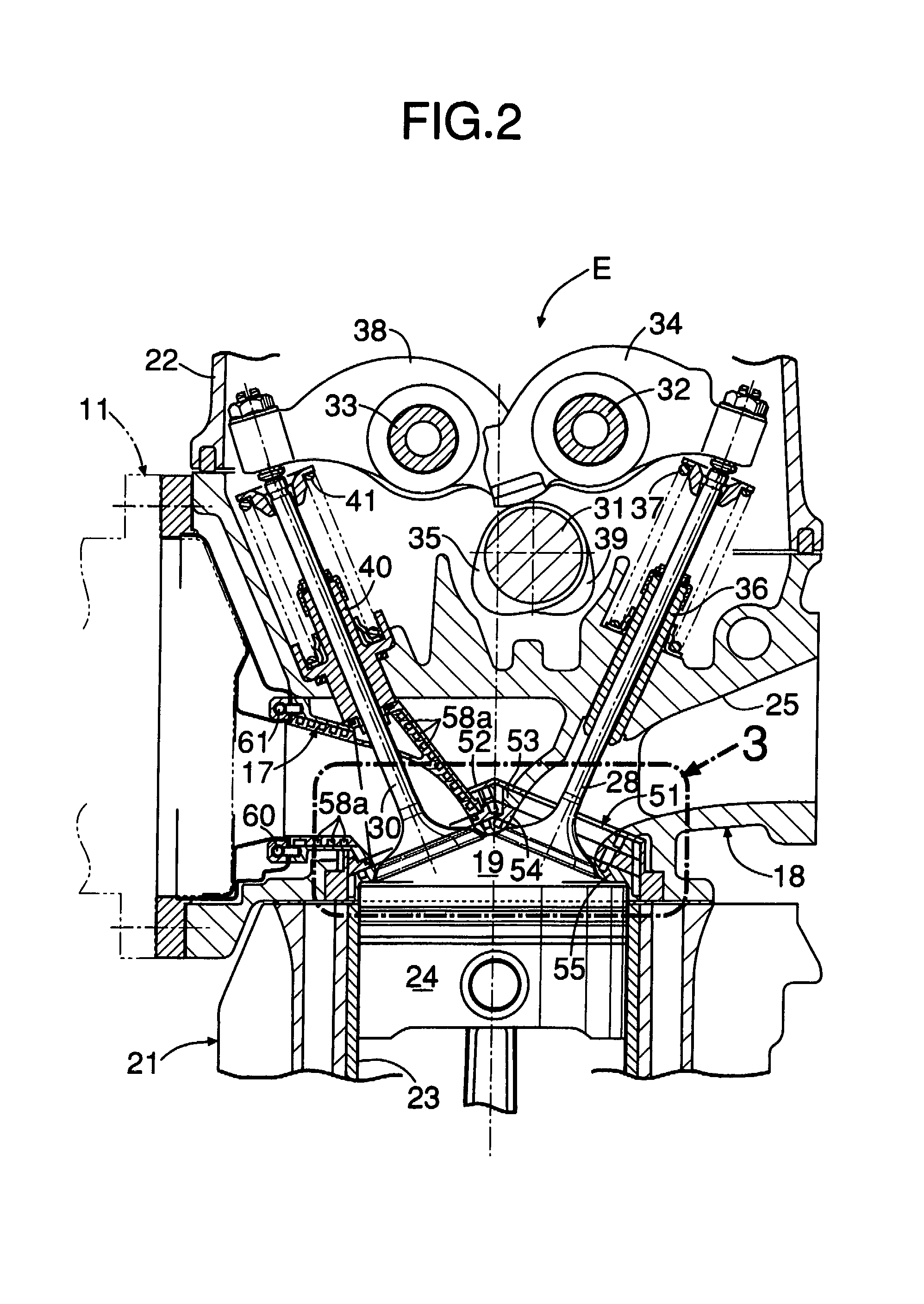

A method for lowering the temperature of a portion of a subsurface formation is provided. Preferably, the formation is an oil shale formation. The method includes the step of injecting a cooling fluid under pressure into a wellbore, with the wellbore having been completed at or below a depth of the subsurface formation. In one embodiment the wellbore has an elongated tubular member for receiving the cooling fluid and for conveying it downhole to the subsurface formation. The wellbore also has an expansion valve in fluid communication with the tubular member through which the cooling fluid flows. The method then includes the steps of injecting a cooling fluid under pressure into the wellbore, and expanding the cooling fluid across the first expansion valve. In this way, the temperature of the cooling fluid is reduced. The temperature of the surrounding formation is likewise reduced through thermal conduction and convection. In another embodiment, a partially frozen slurry is used as the cooling fluid.

Owner:EXXONMOBIL UPSTREAM RES CO

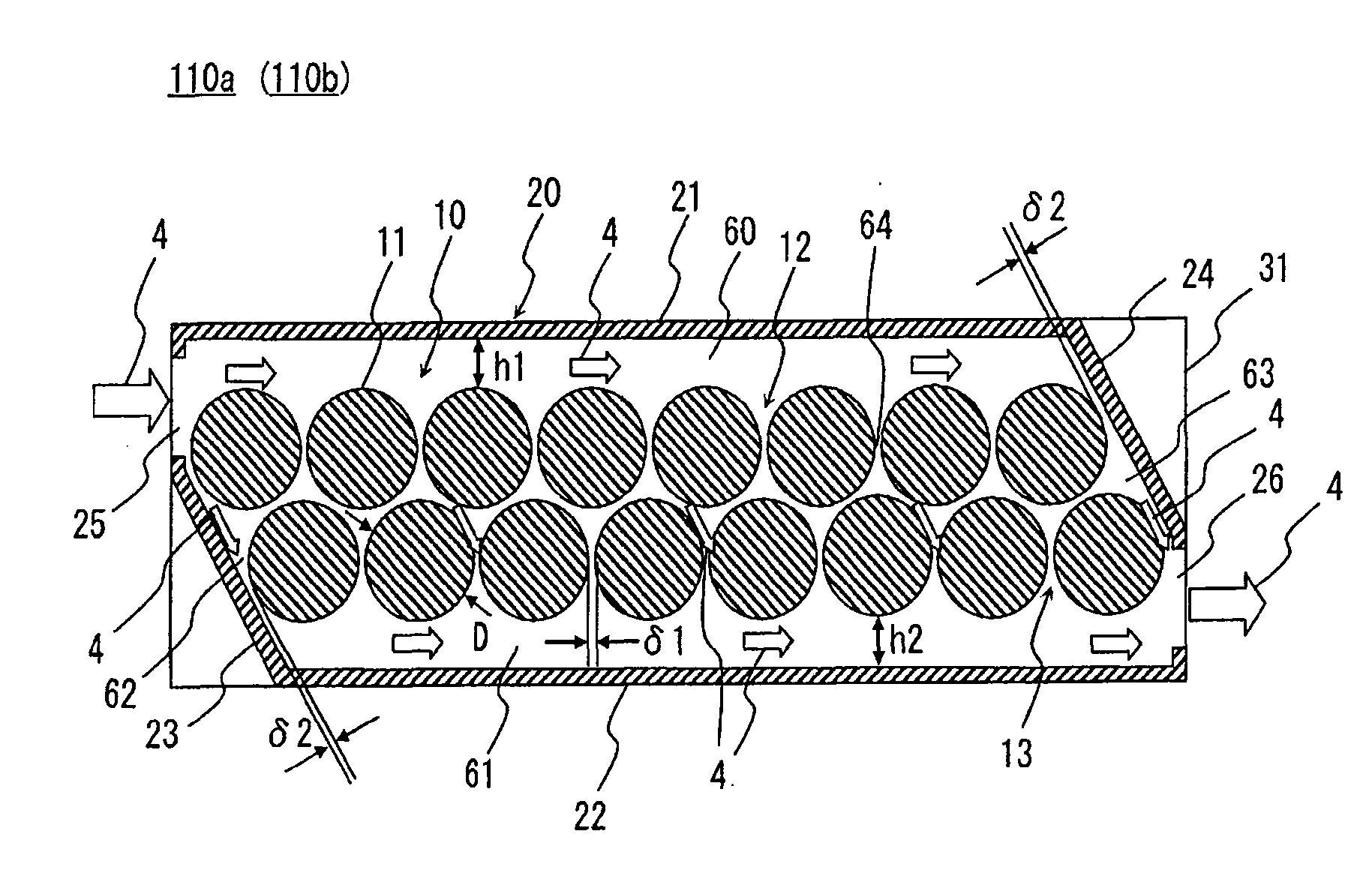

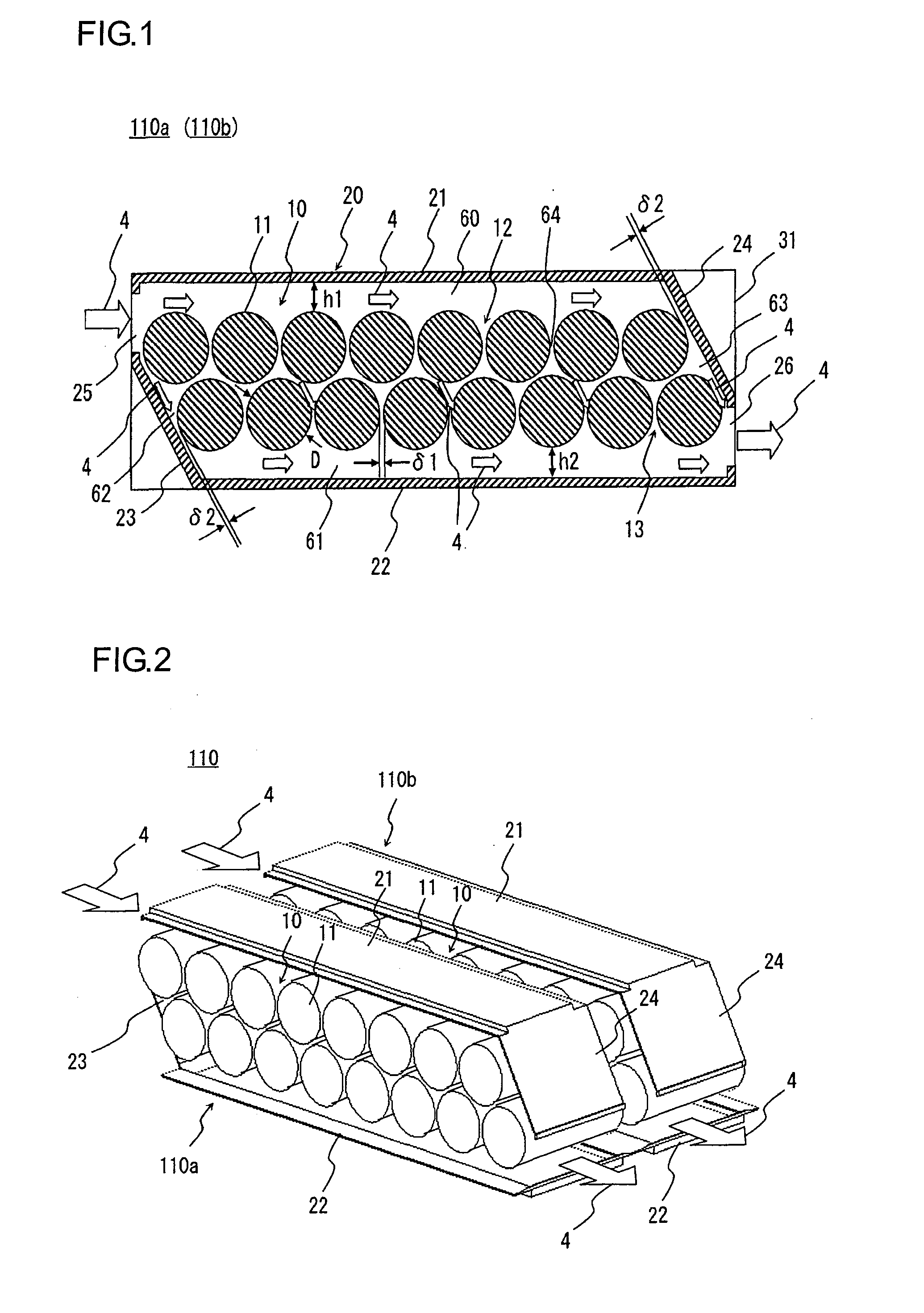

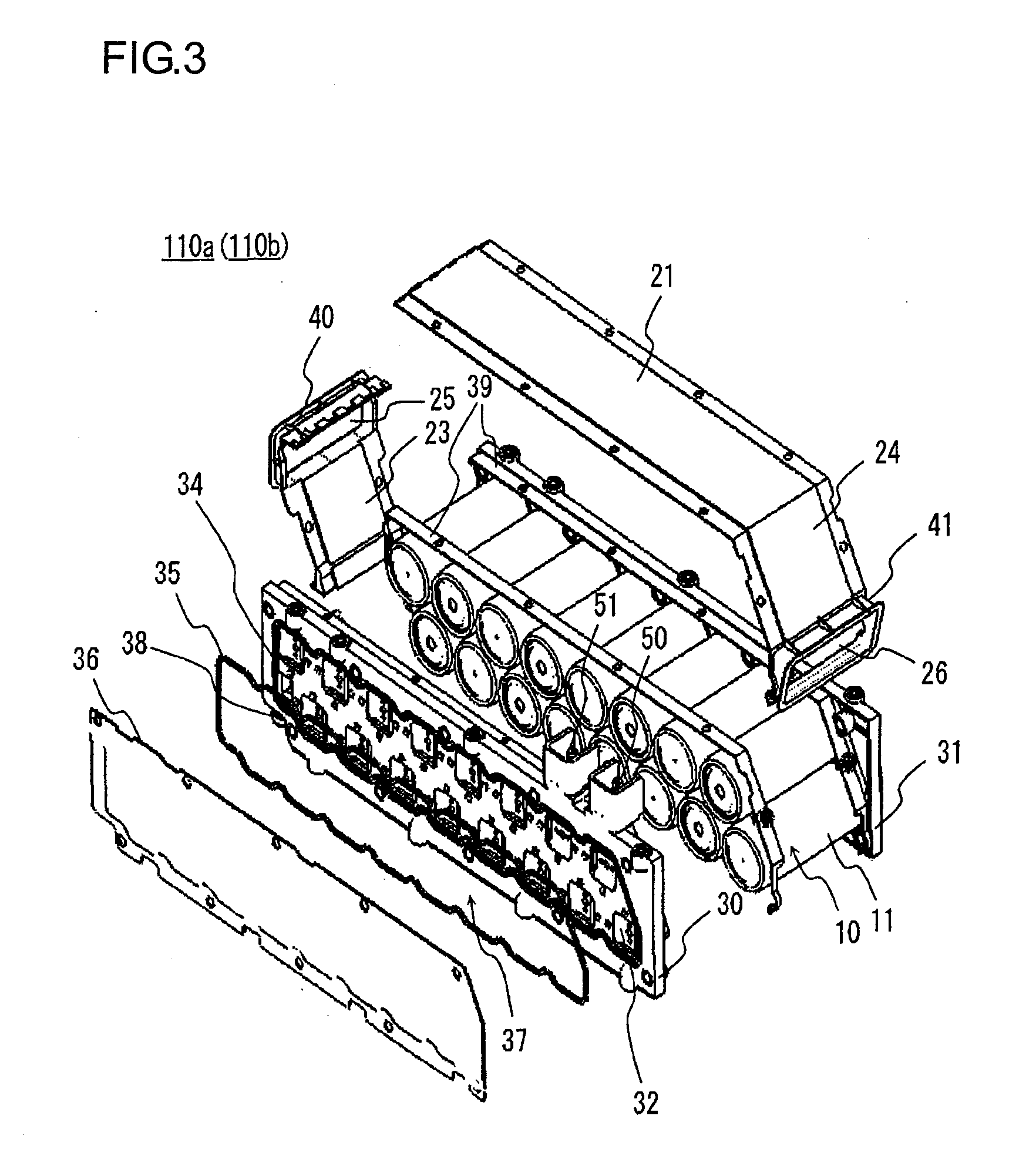

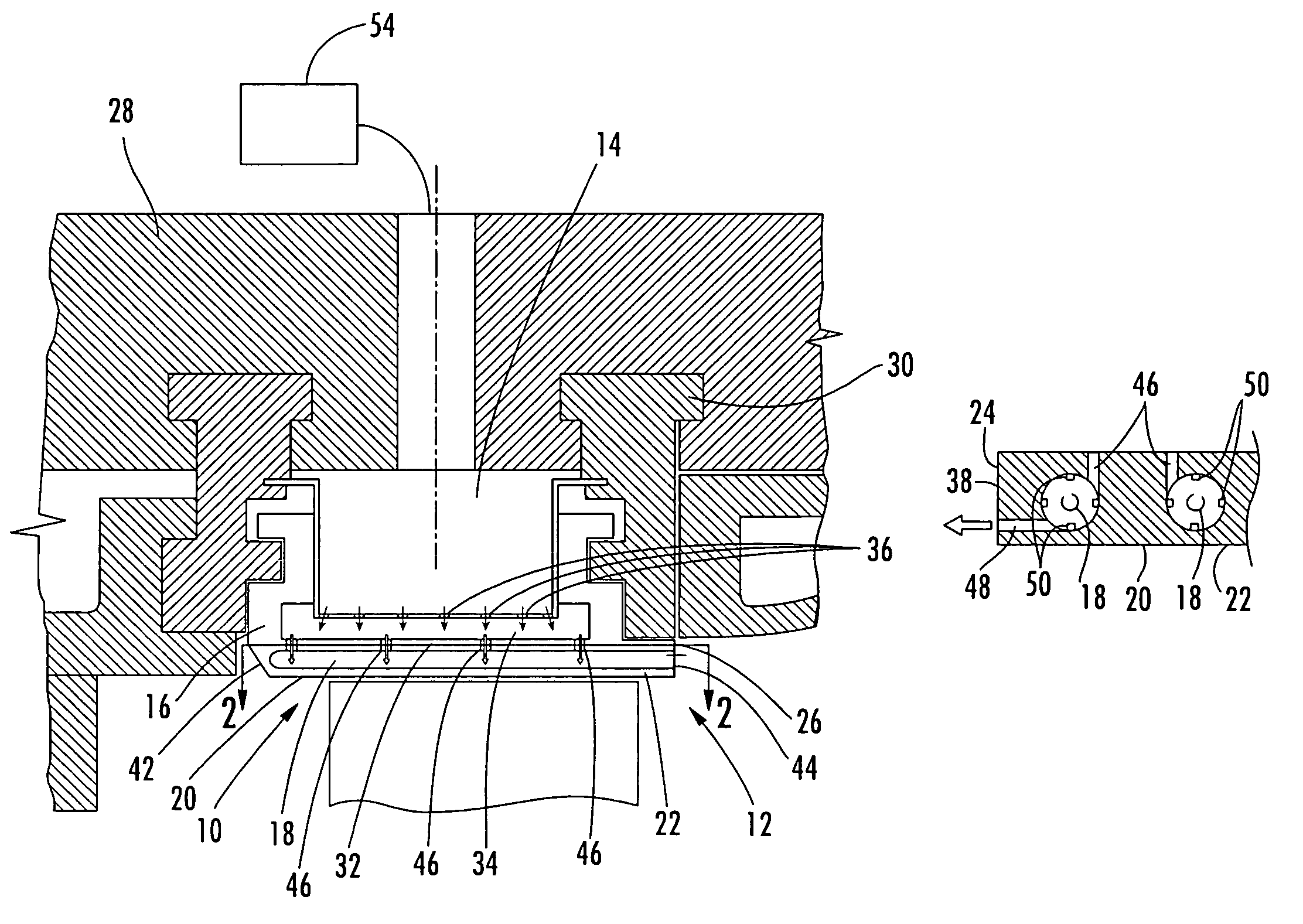

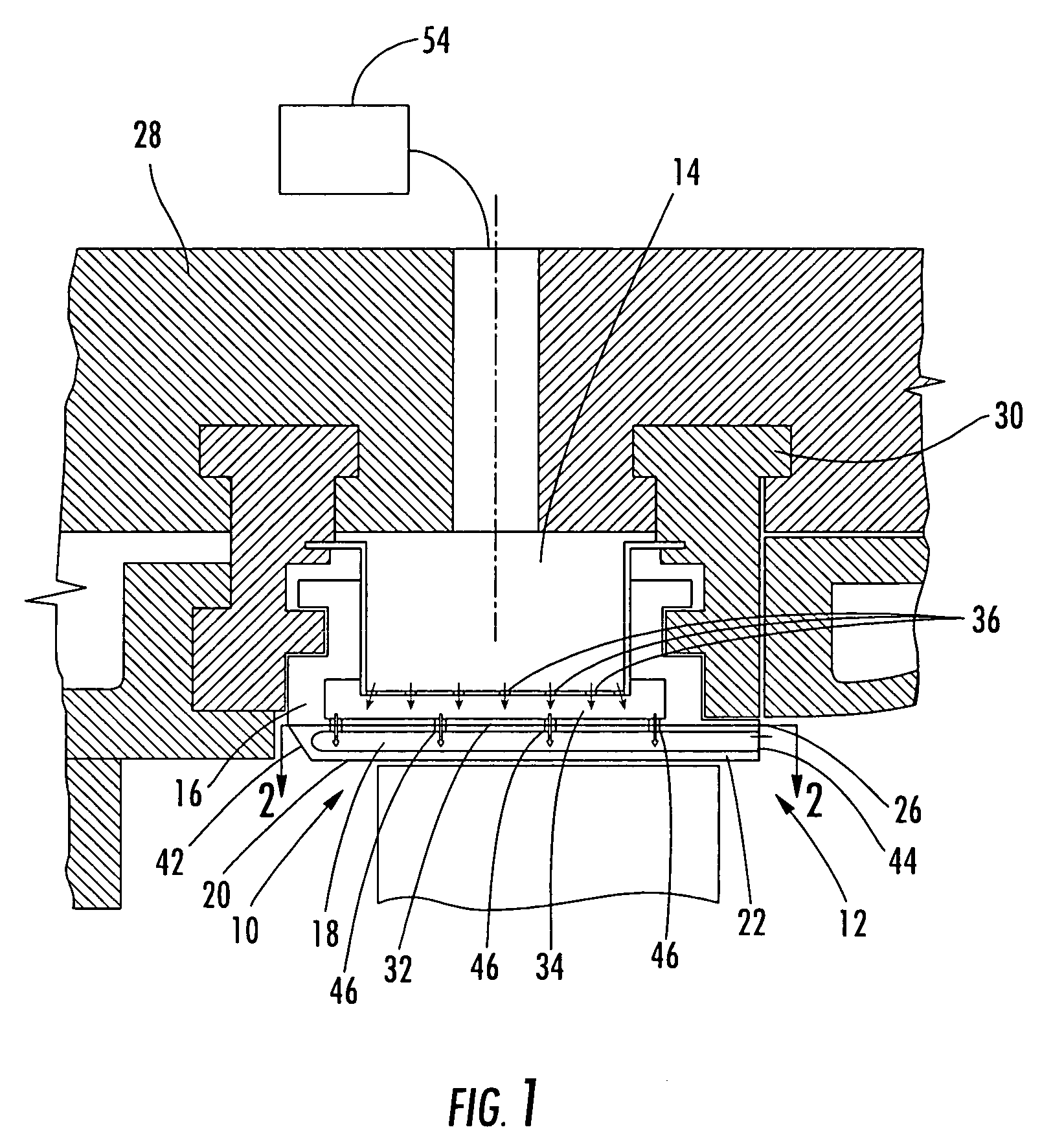

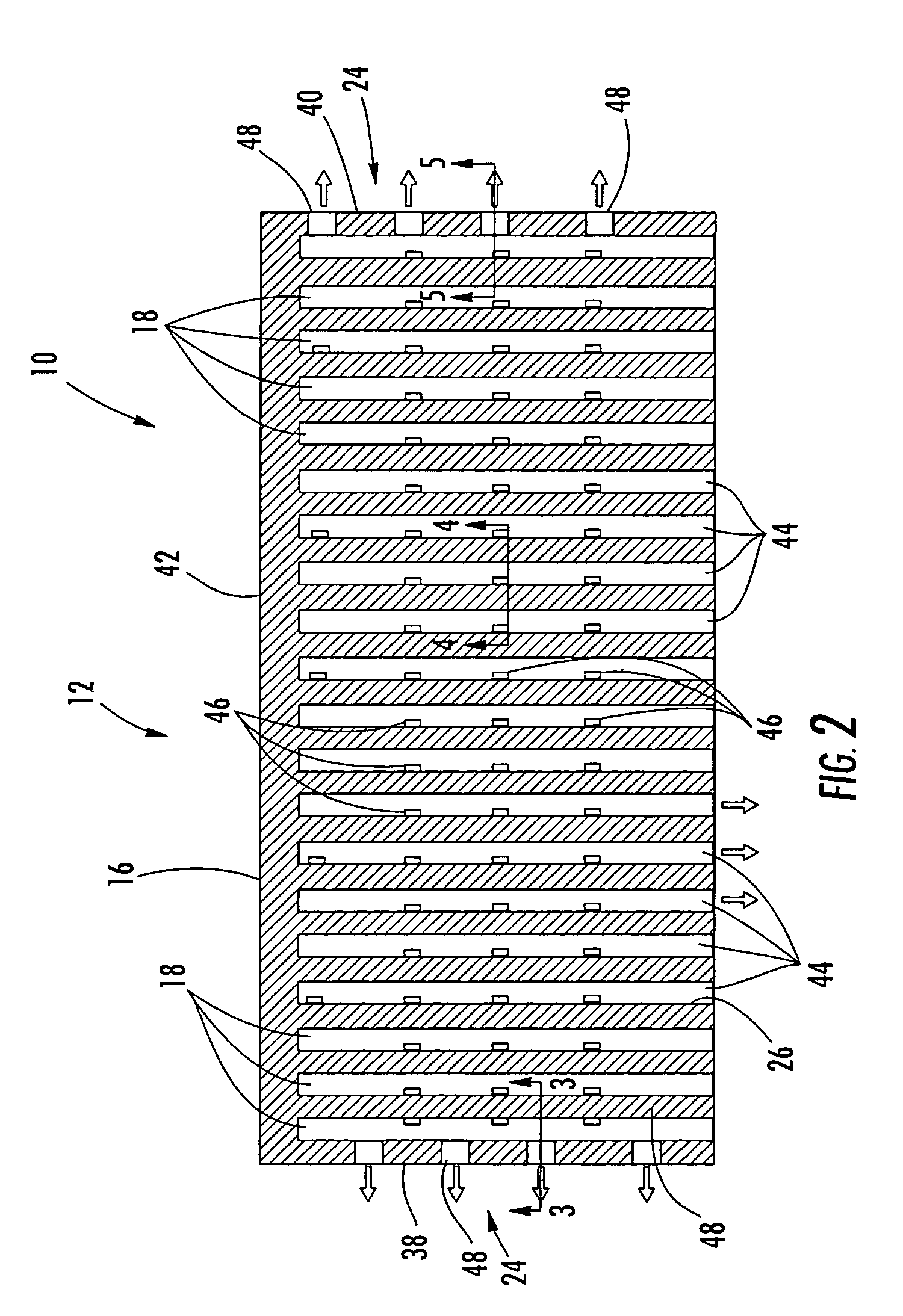

Battery Module, Electric Storage Device and Electric System

ActiveUS20090258282A1Large thicknessImprove cooling effectCell temperature controlCell component detailsEngineeringElectrical battery

A battery module is configured so that the first cell string and the second cell string are arranged between the first plate member and the second plate member and the second cell string is arranged closer to the second plate member side than the first cell string is and is arranged closer to the outlet side than the first cell string is. At the inlet side of the housing, the inlet is arranged closer to the first plate member than to the second cell string, at least a part between the inlet side of the second cell string and the second plate member is covered by the inlet-side guide plate, and the cooling air is introduced into the housing through the inlet so as to form a flow of the cooling air along the first plate member and a flow of the cooling air along the inlet-side guide plate.

Owner:HITACHI VEHICLE ENERGY

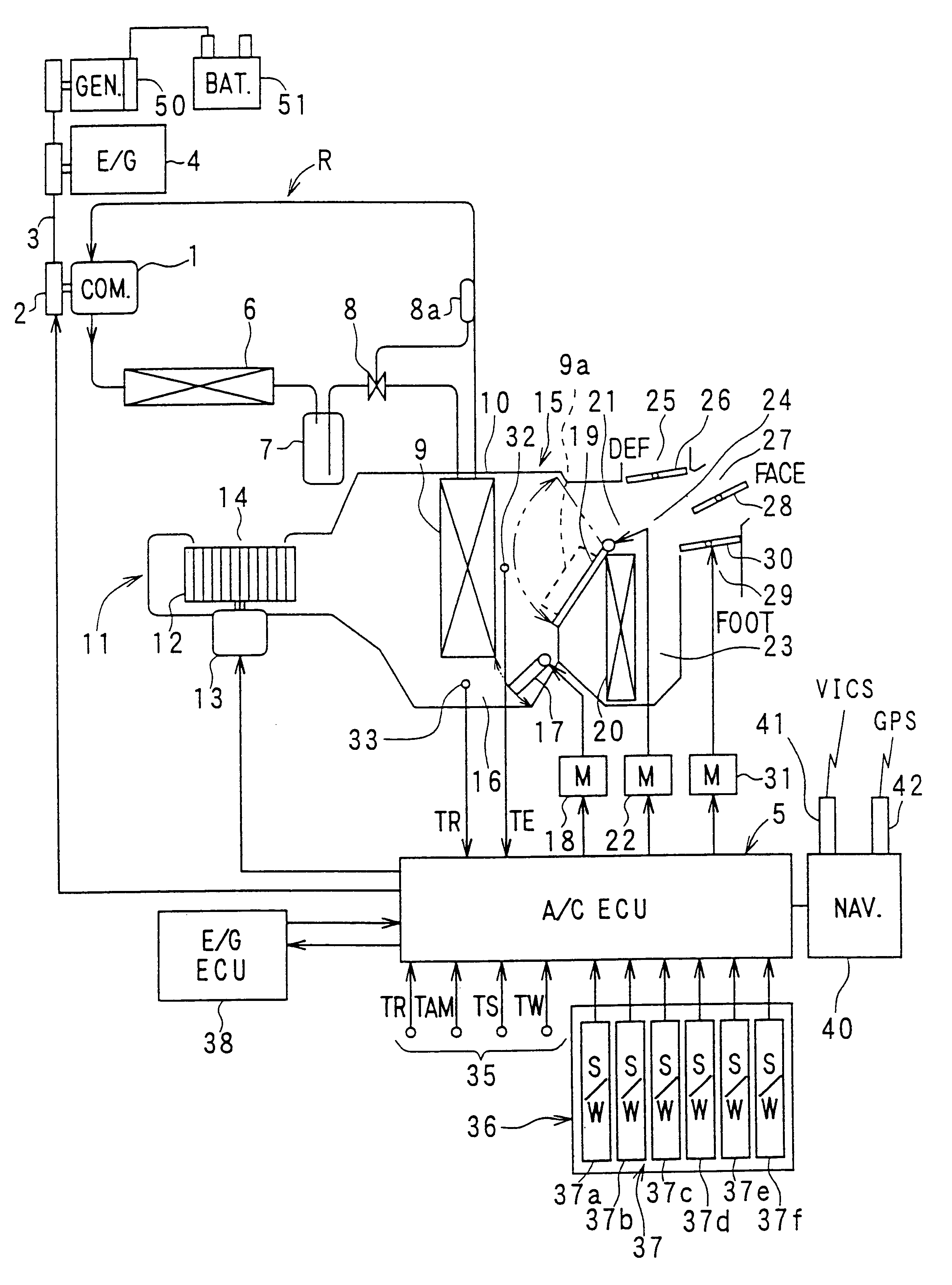

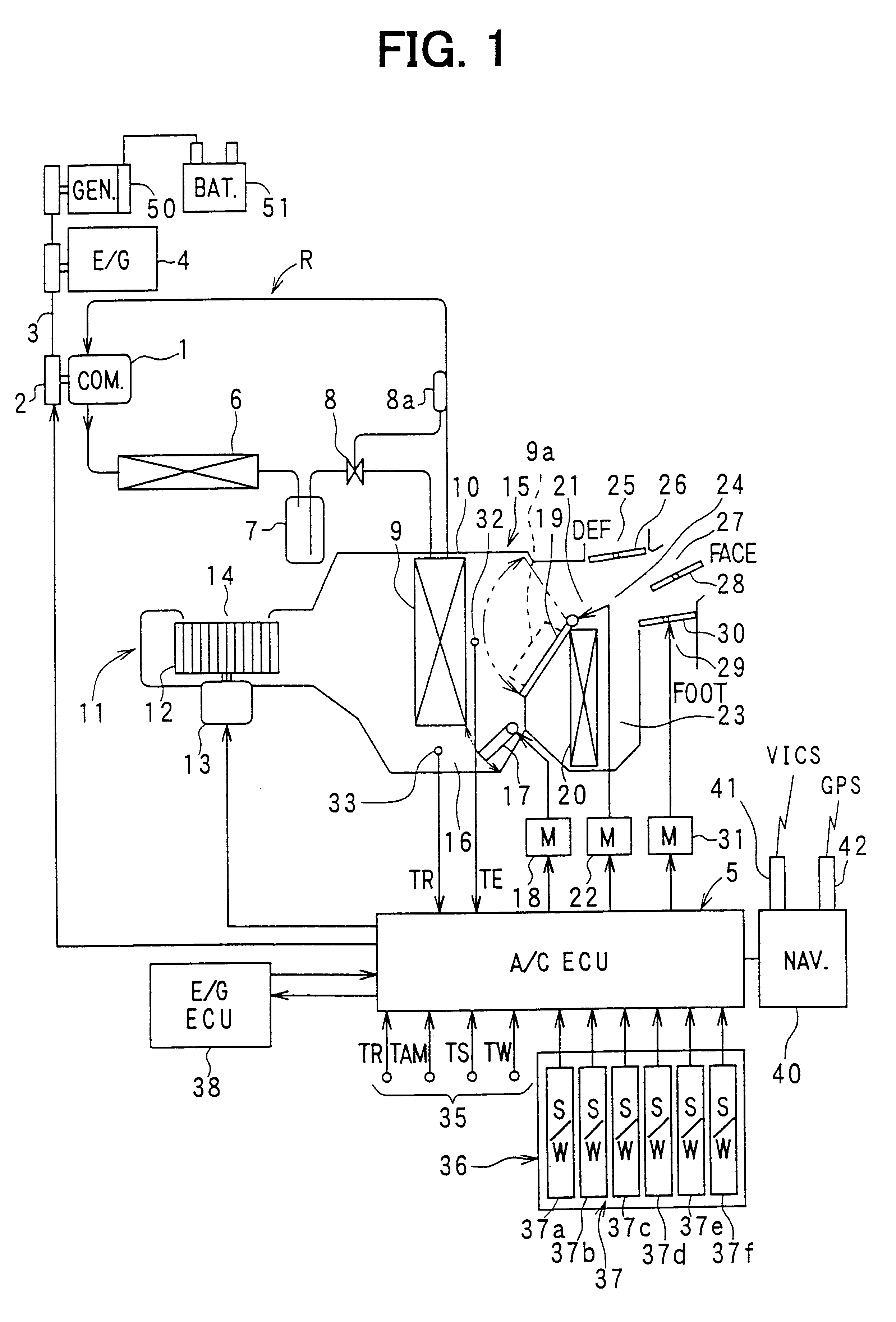

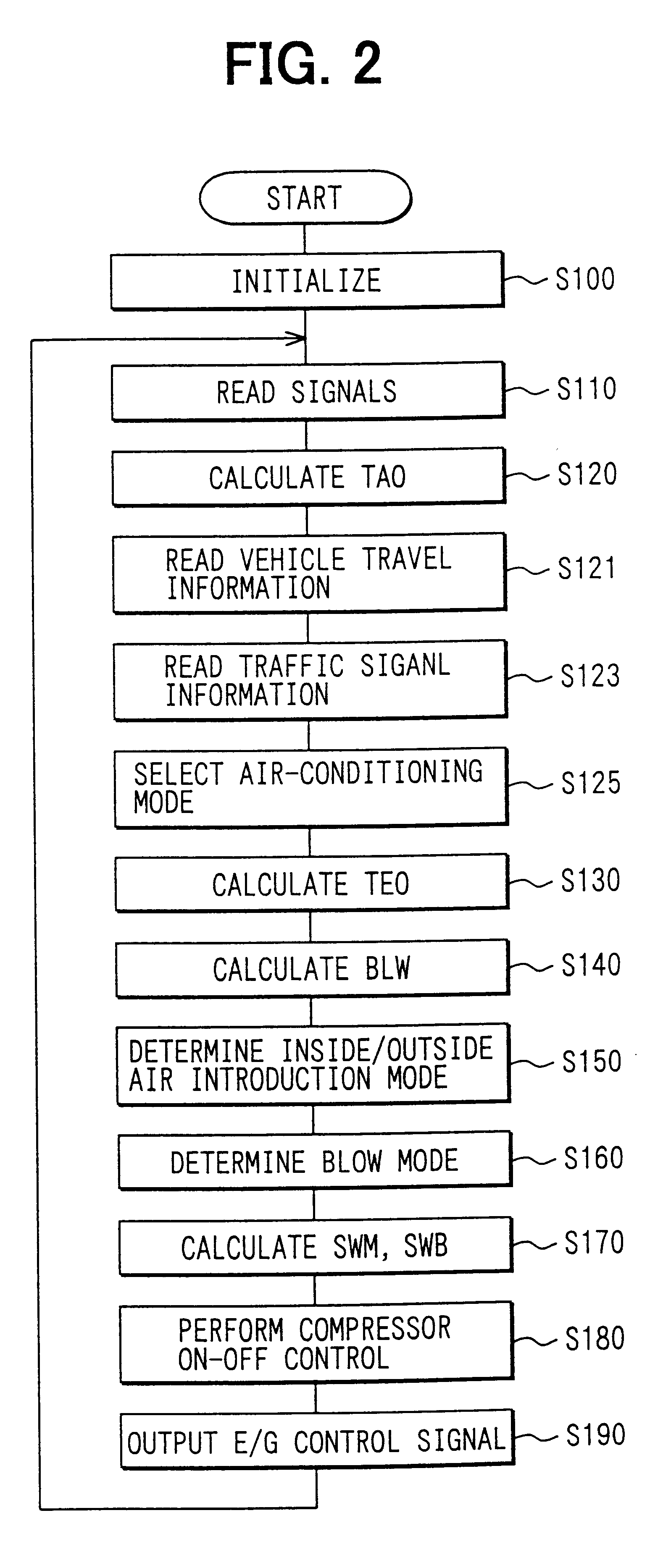

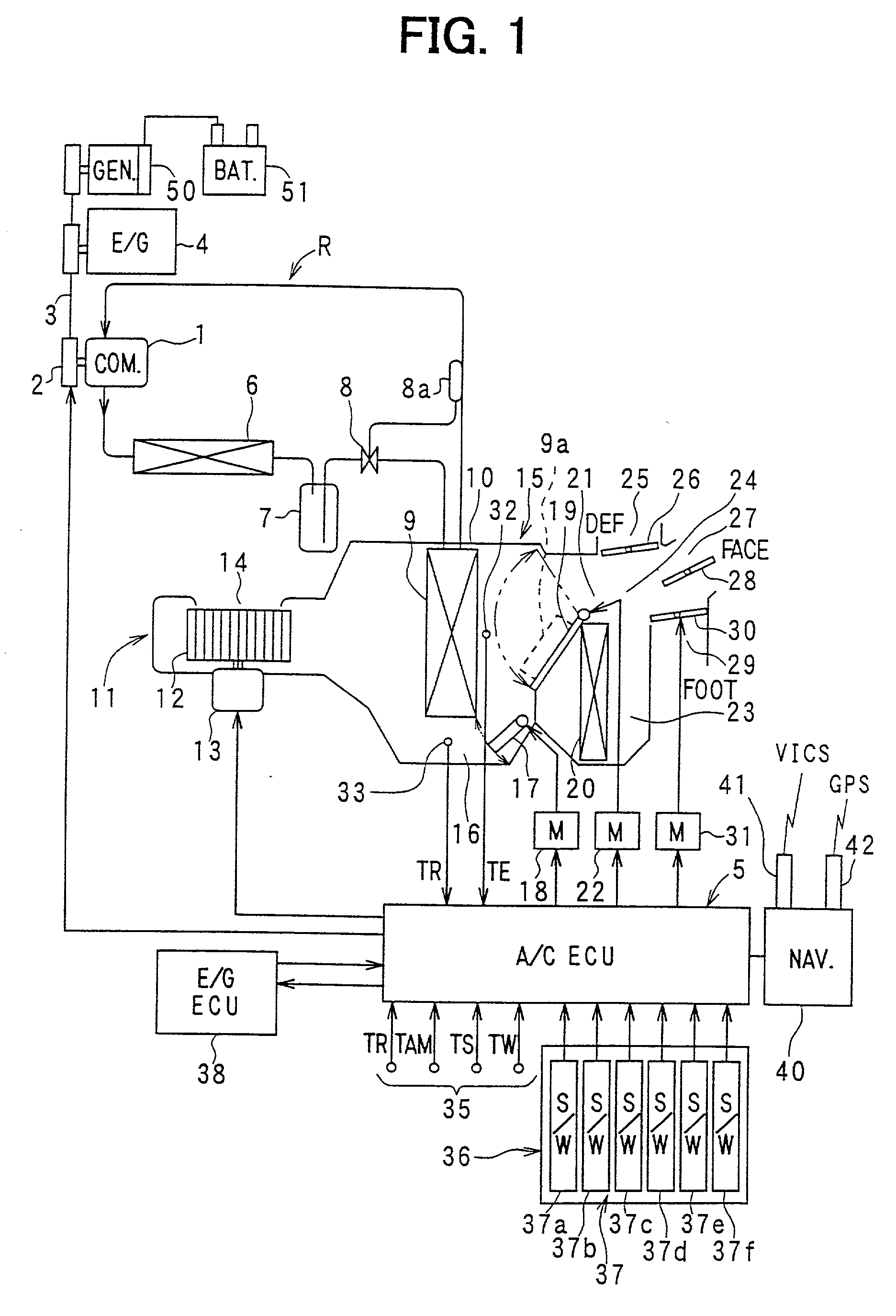

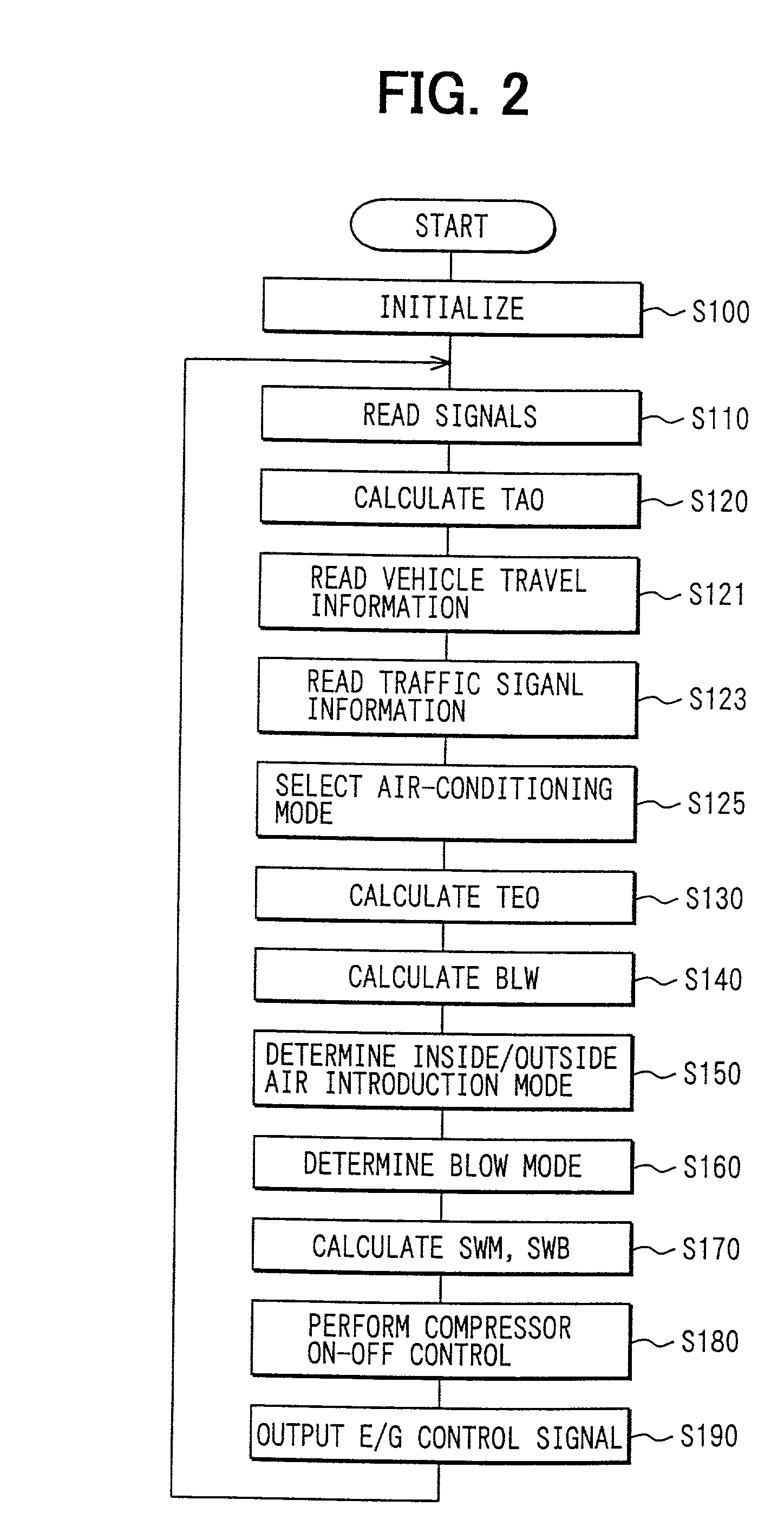

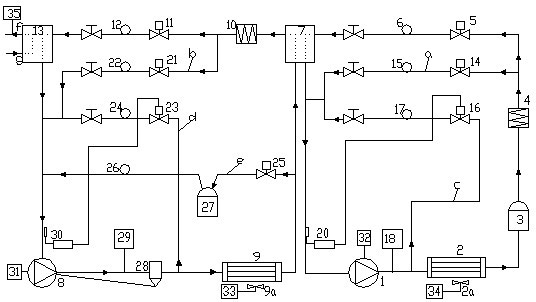

Vehicle air conditioner with cold storage and cold release

InactiveUS6688120B2Feel goodReduce power consumptionAir-treating devicesVehicle heating/cooling devicesMobile vehicleTraffic signal

In a control unit of a vehicle air conditioner, a necessary time period T1, between the present time and a time at which the vehicle is stopped next, and a vehicle stopping time period T2, between the time at which the vehicle is stopped next and a time at which the vehicle is re-started, are estimated based on vehicle-travel state information and traffic signal information in a vehicle traveling. Further, a necessary cold release amount Q required for cooling in the vehicle stopping time period T2 is calculated based on the vehicle stopping time period T2, and a cold storage operation is controlled so that the necessary cold release amount Q is stored for the necessary time period T1.

Owner:DENSO CORP

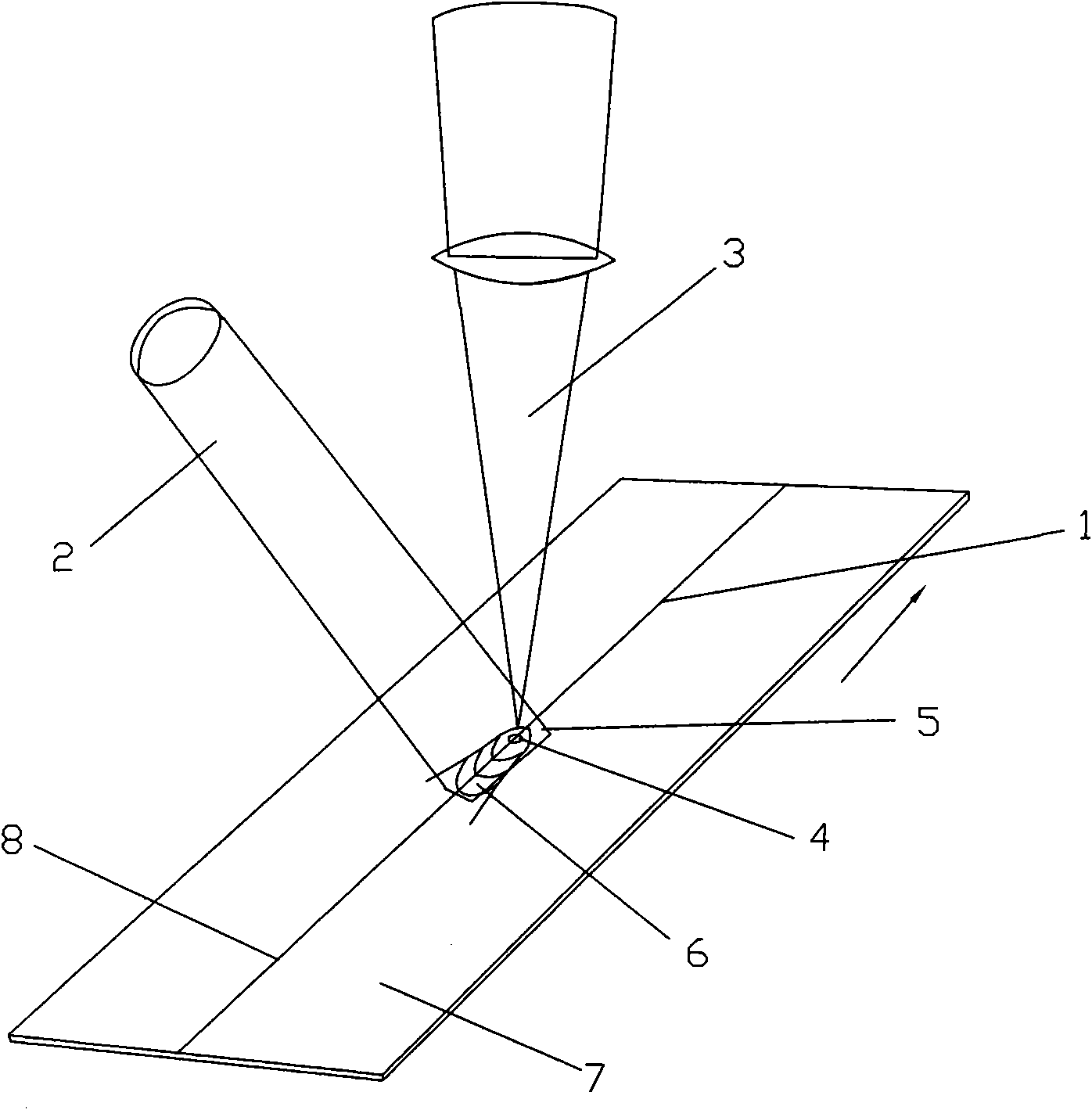

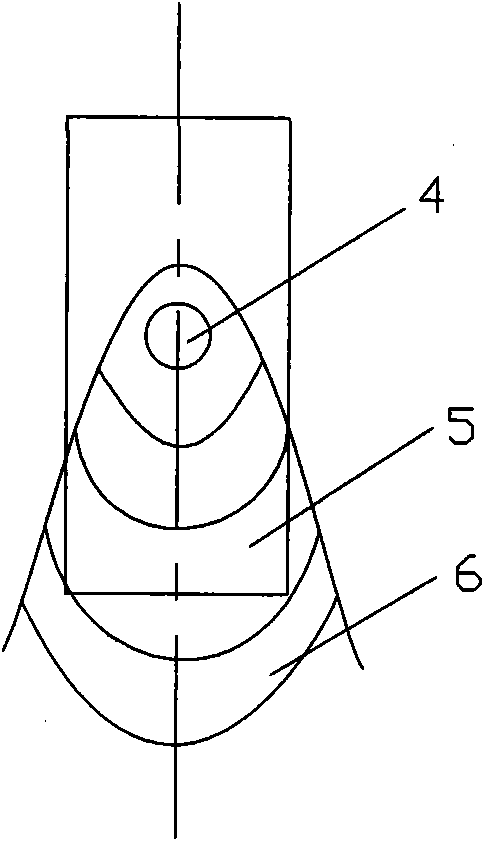

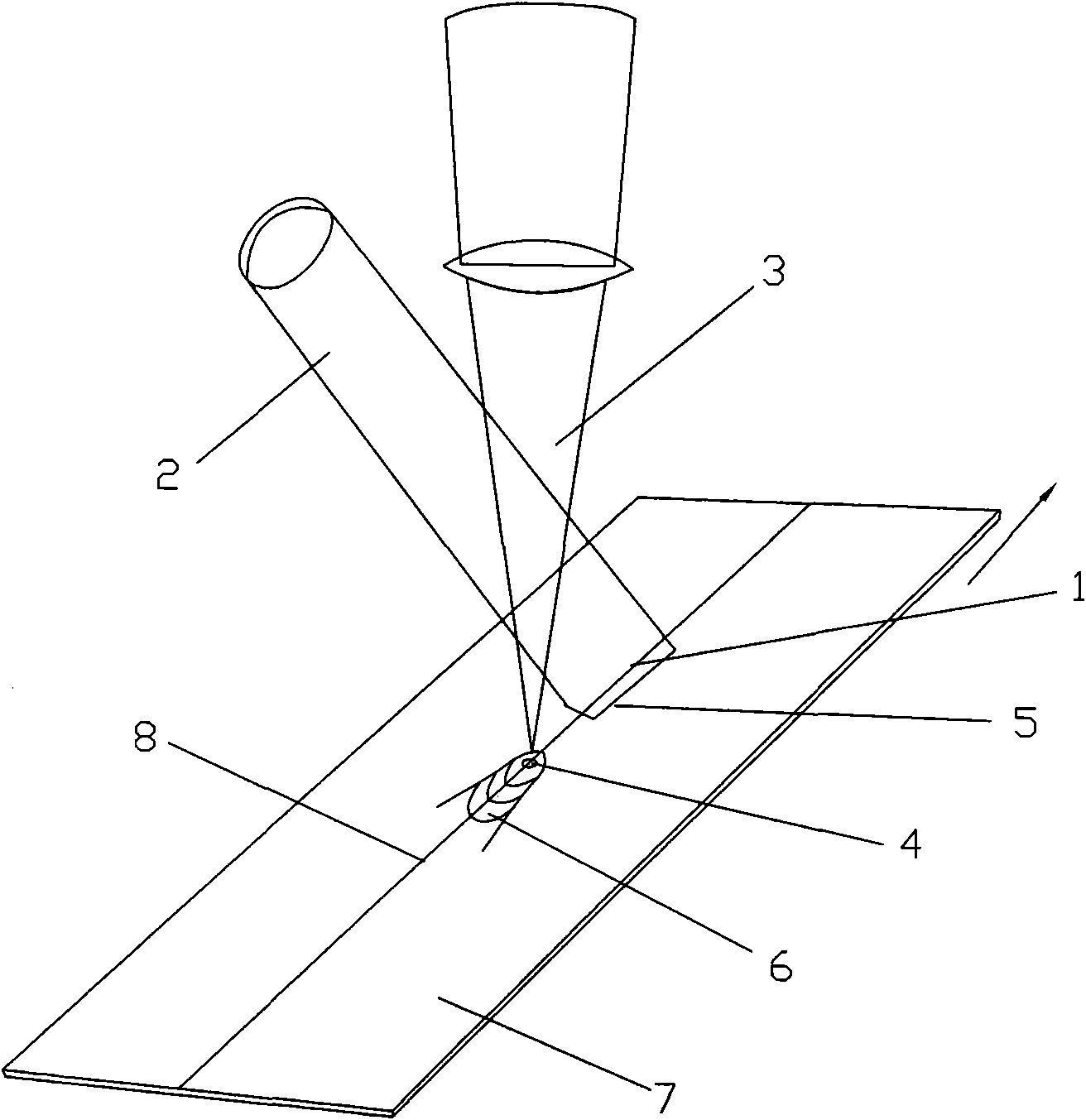

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of developing subsurface freeze zone

InactiveUS7516785B2Improve cooling efficiencyReduce the amount requiredSurveyDrilling rodsSlurryCooling fluid

A method for lowering the temperature of a portion of a subsurface formation is provided. Preferably, the formation is an oil shale formation. The method includes the step of injecting a cooling fluid under pressure into a wellbore, with the wellbore having been completed at or below a depth of the subsurface formation. In one embodiment the wellbore has an elongated tubular member for receiving the cooling fluid and for conveying it downhole to the subsurface formation. The wellbore also has an expansion valve in fluid communication with the tubular member through which the cooling fluid flows. The method then includes the steps of injecting a cooling fluid under pressure into the wellbore, and expanding the cooling fluid across the first expansion valve. In this way, the temperature of the cooling fluid is reduced. The temperature of the surrounding formation is likewise reduced through thermal conduction and convection. In another embodiment, a partially frozen slurry is used as the cooling fluid.

Owner:EXXONMOBIL UPSTREAM RES CO

Vehicle air conditioner with cold storage and cold release

InactiveUS20020134093A1Feel goodReduce power consumptionAir-treating devicesVehicle heating/cooling devicesMobile vehicleTraffic signal

In a control unit of a vehicle air conditioner, a necessary time period T1, between the present time and a time at which the vehicle is stopped next, and a vehicle stopping time period T2, between the time at which the vehicle is stopped next and a time at which the vehicle is re-started, are estimated based on vehicle-travel state information and traffic signal information in a vehicle traveling. Further, a necessary cold release amount Q required for cooling in the vehicle stopping time period T2 is calculated based on the vehicle stopping time period T2, and a cold storage operation is controlled so that the necessary cold release amount Q is stored for the necessary time period T1.

Owner:DENSO CORP

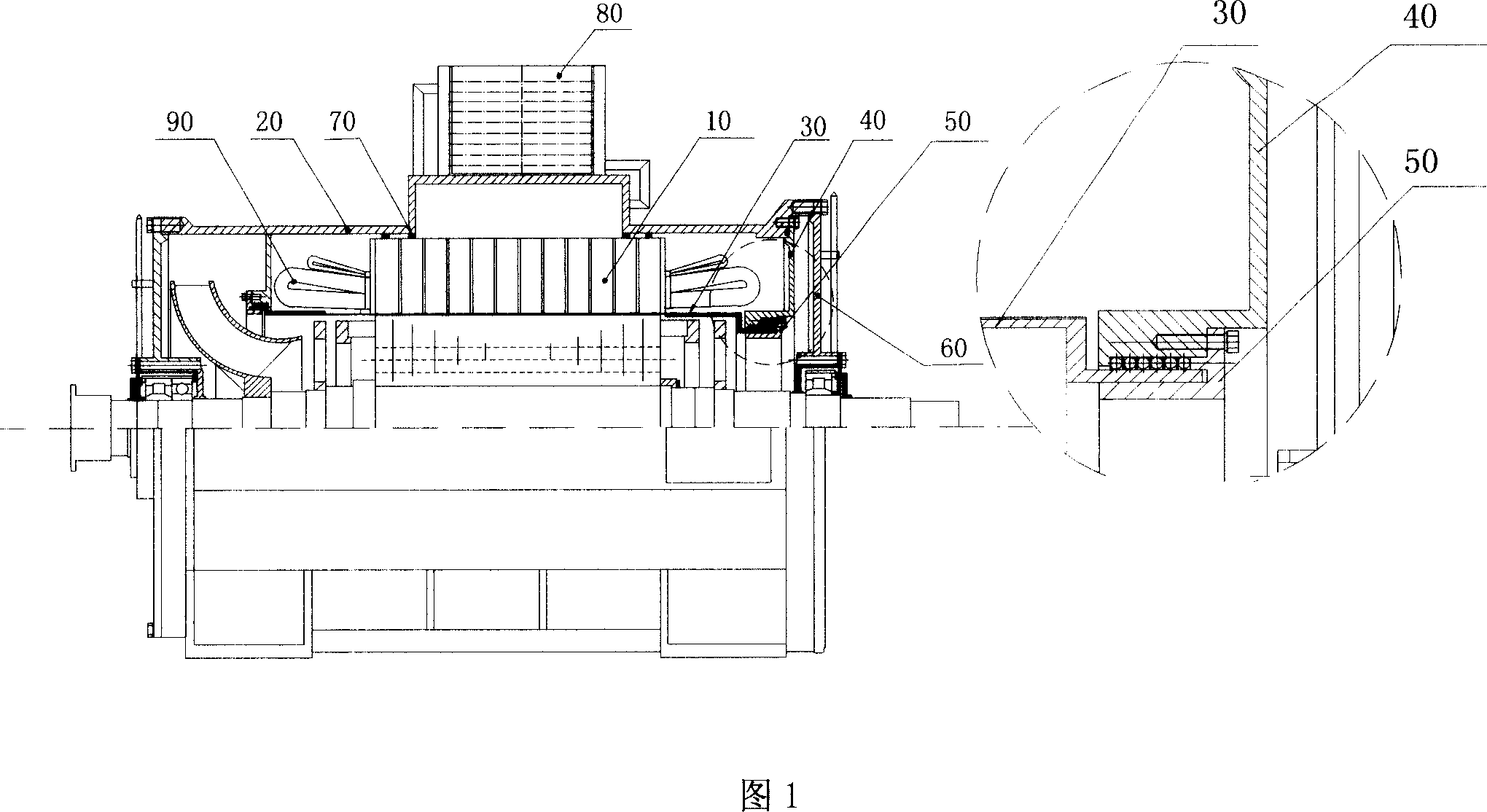

Transpirationcooled wind driven generator stator

ActiveCN1960126AReduce lossNo maintenanceMagnetic circuit stationary partsWind drivenCore temperature

The tightly closed space of the stator consists of the stator chassis, the non-magnetic stainless steel isolated sleeve, the tightly closed end cap and the pressuring ring. The cooling loop consists of the liquid-lead groove between the stator core sections, the stator winding / stator end winding, the stator vaporizing space and the air condenser (AC). Via the gas entering tube and the liquid returning tube, AC connects to the stator chassis to form a main cooling circle loop. The heat produced due to the consumption of the stator components transfers to the vaporization cooling media (VCM) to raise its temperature. When the temperature reaches the saturation value based on inner pressure, VCM in the capacitor vaporize and occur phase-changing decalescence, then cool down by AC and finally liquidize. The invention causes stator core temperature distributing evenly. Features are: safe and reliable, simple structure, small volume, and large power density.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

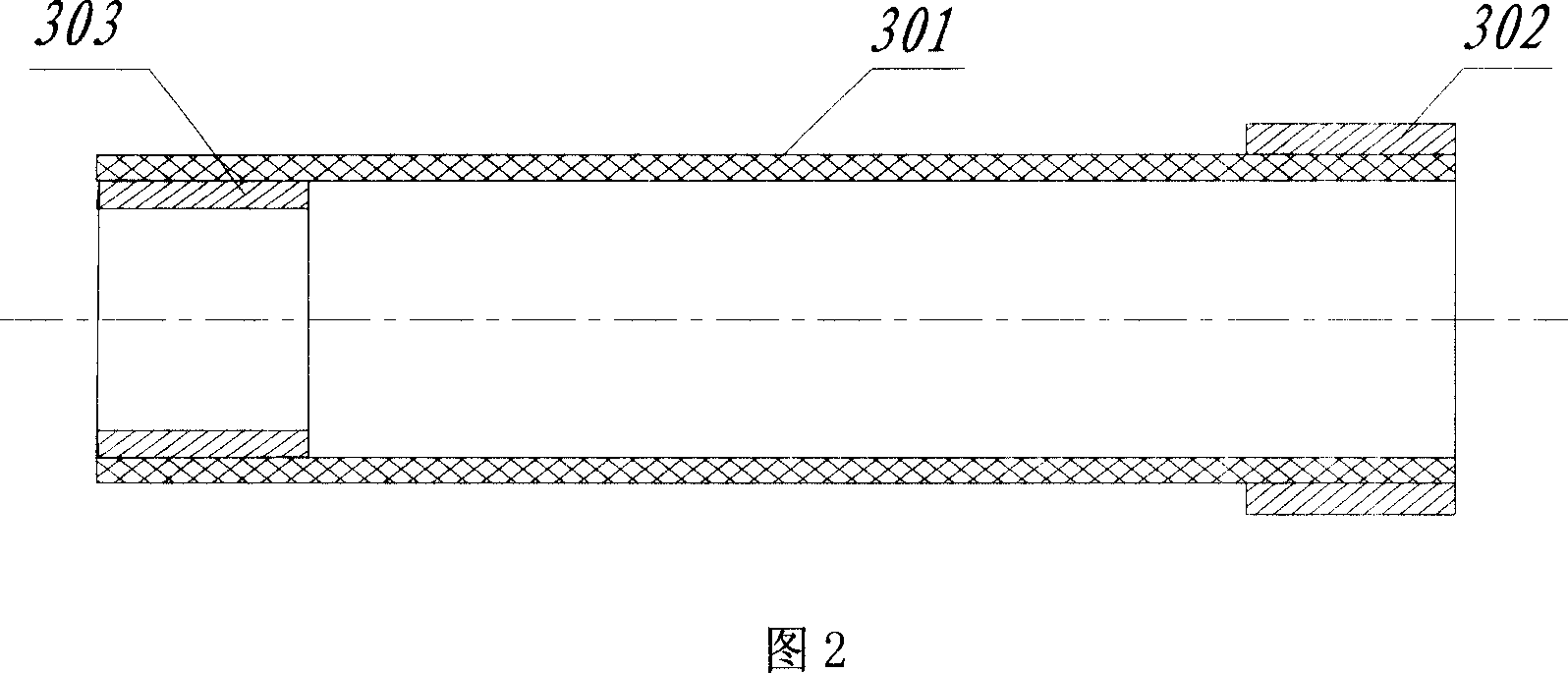

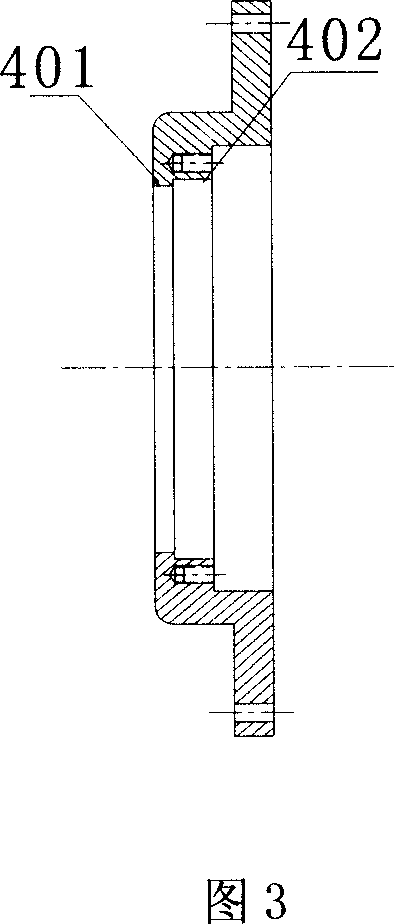

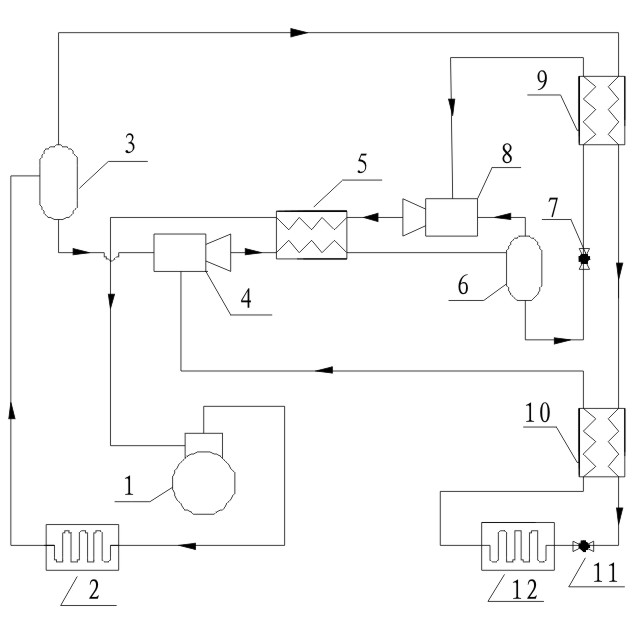

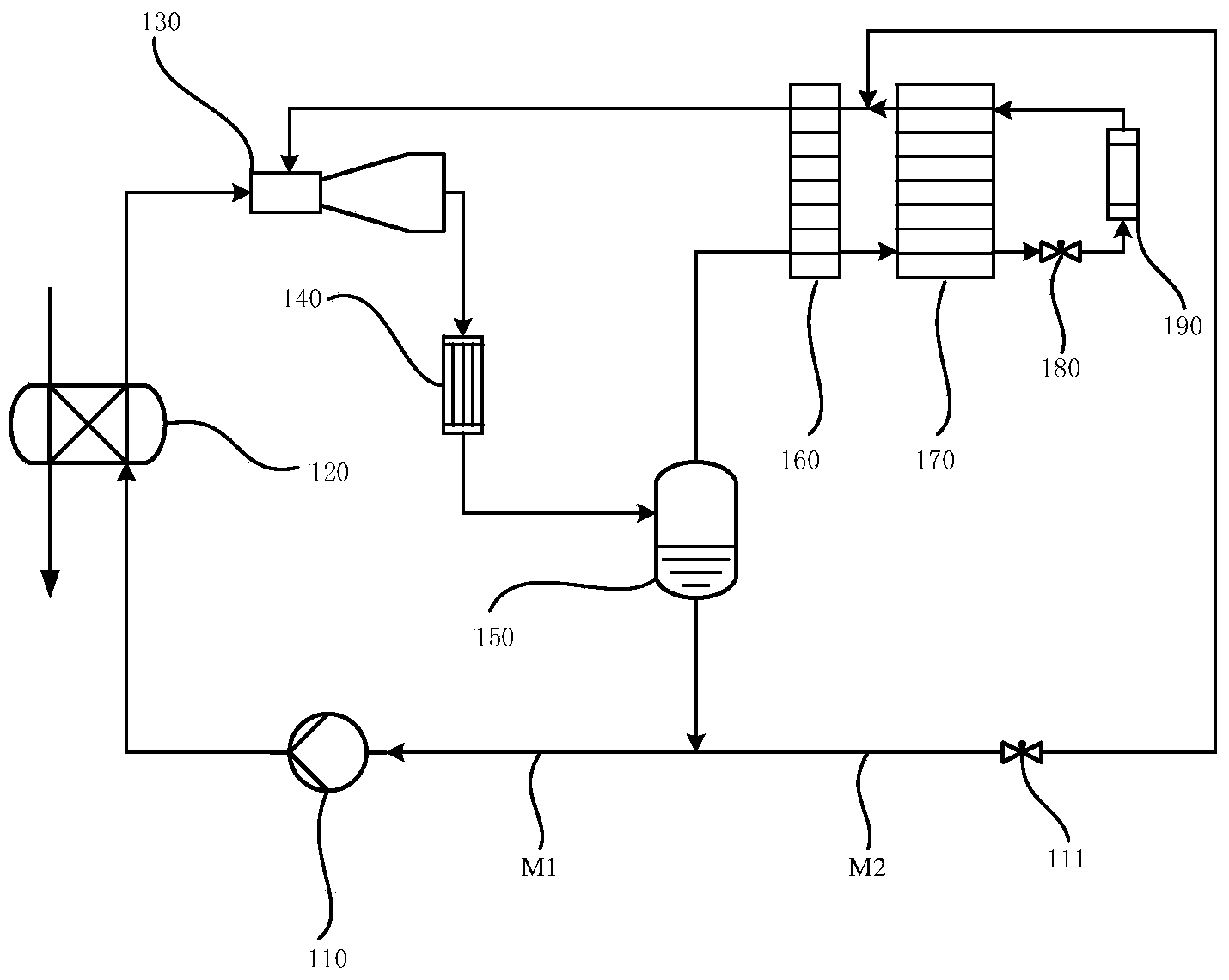

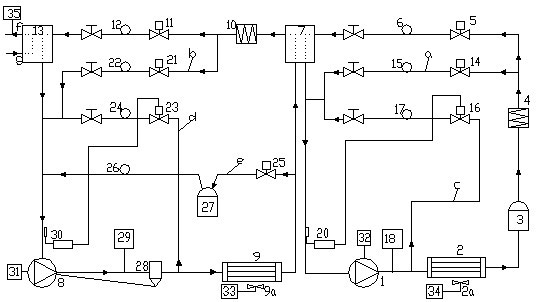

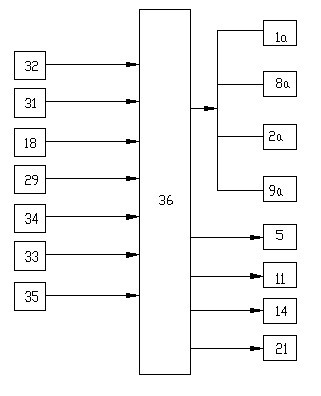

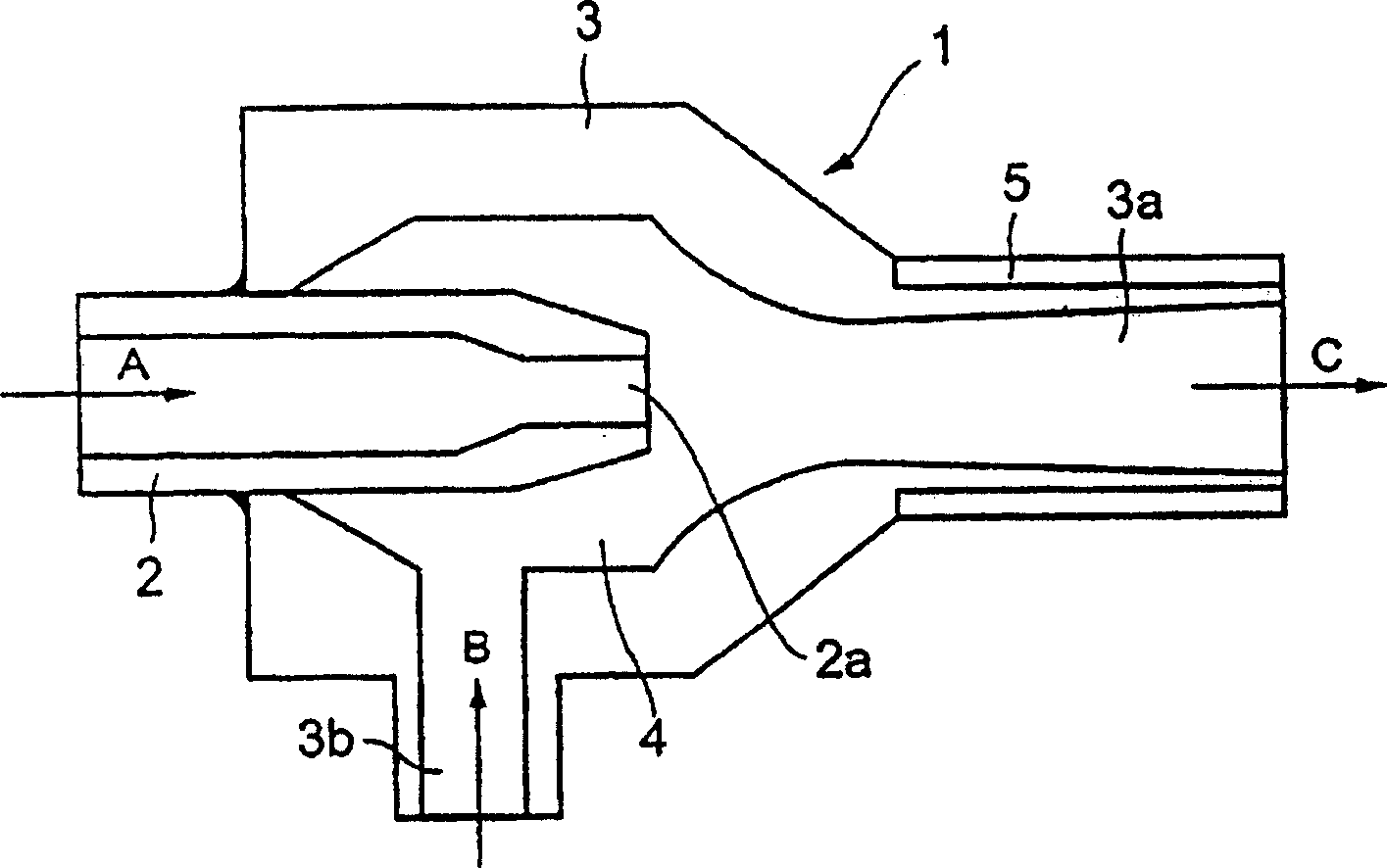

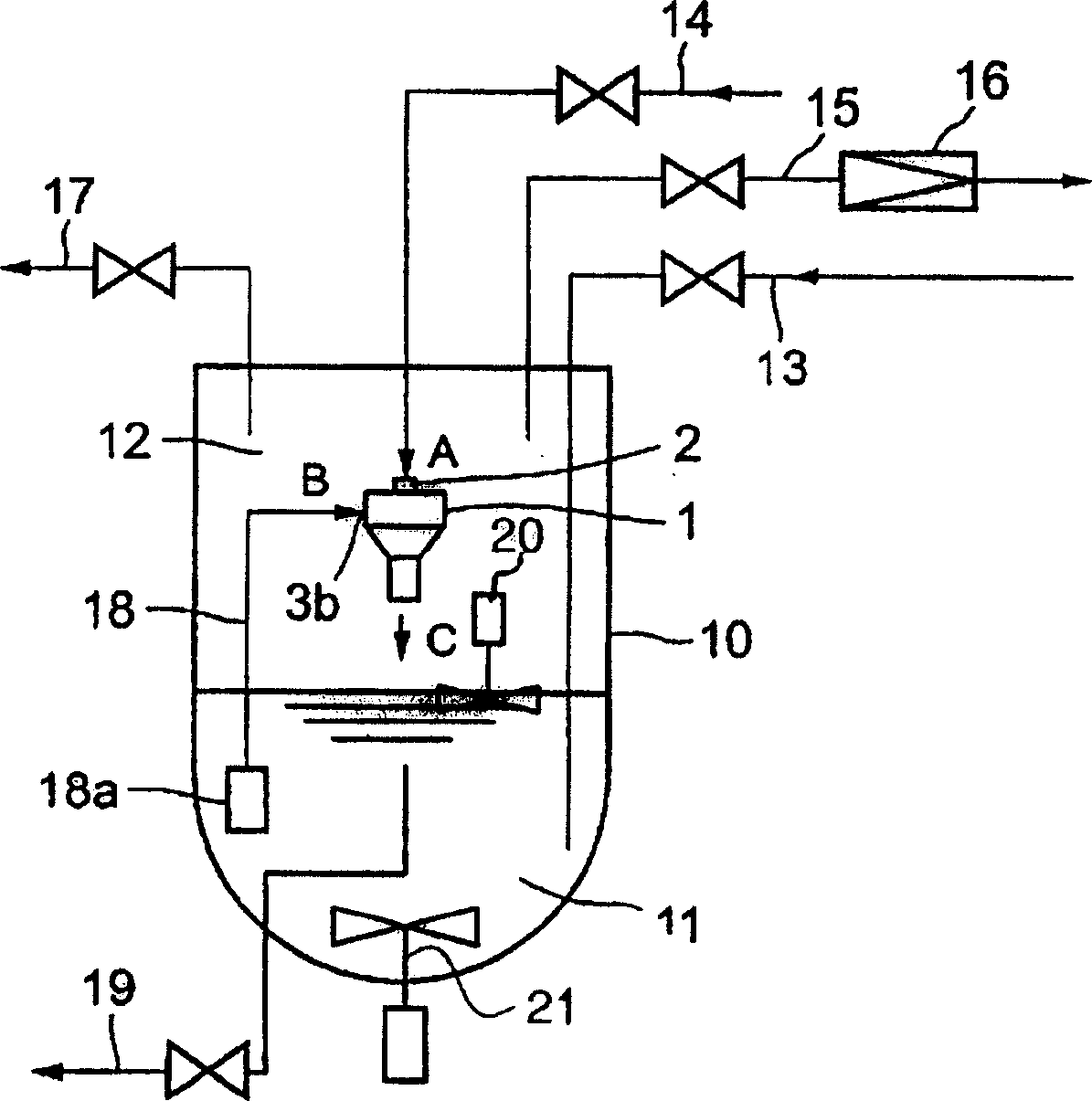

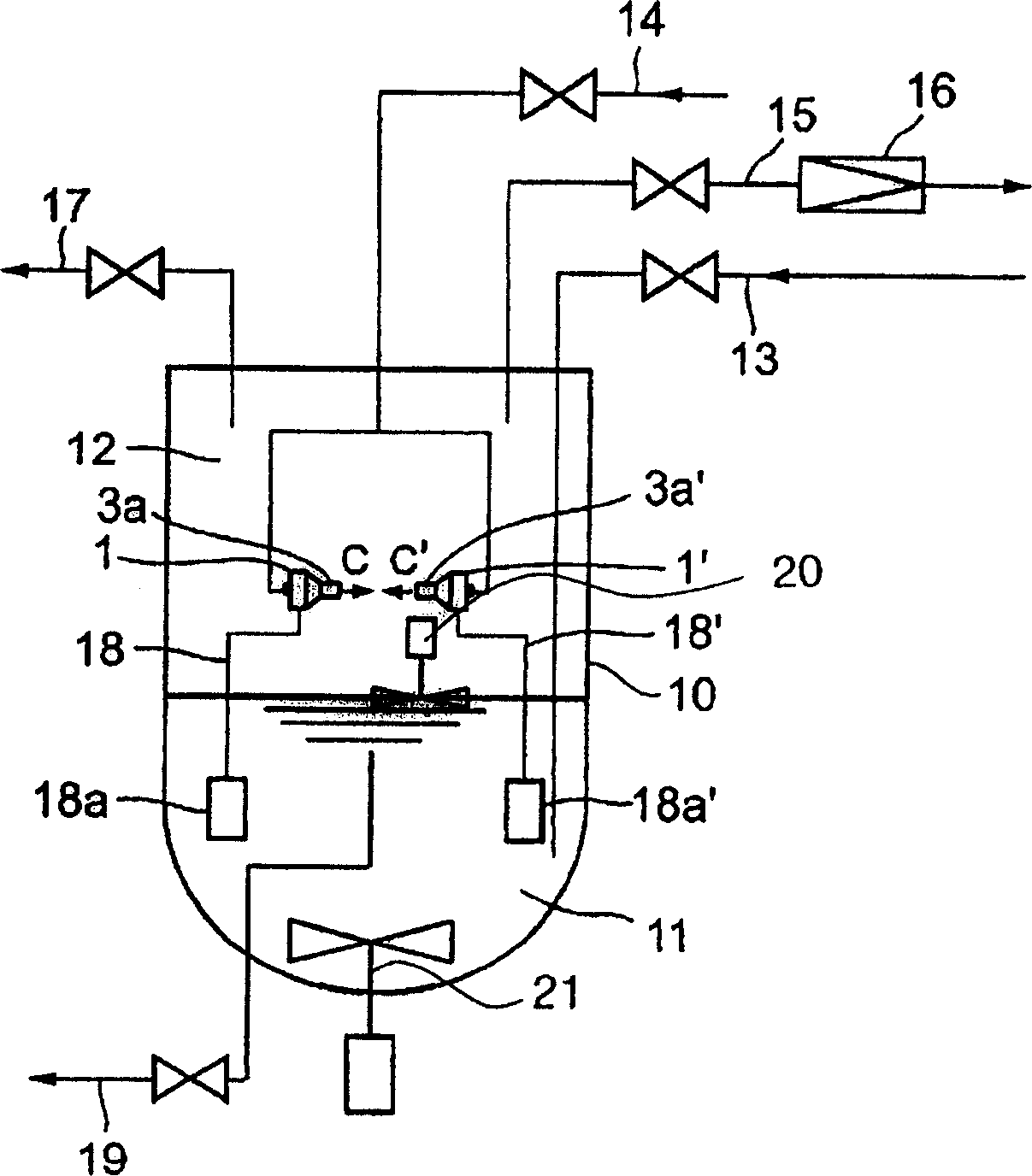

Ultra-low temperature circulation refrigeration method employing injectors

InactiveCN102003826AImprove cycle performanceIncrease inspiratory pressureCompression machinesFluid circulation arrangementVapor–liquid separatorWorking fluid

The invention relates to an ultra-low temperature circulation refrigeration method employing injectors. In the method, high-pressure mixed refrigerants compressed by a compressor (1) enter a condenser (2) and then enter a first gas-liquid separator (3) to realize gas and liquid phase separation, liquid refrigerants flowing out of the first gas-liquid separator (3) enter a first injector (4), gas and liquid two-phase mixed work media from an outlet of the first injector (4) are cooled by a first heat regenerator (5) and then enter a second gas-liquid separator (6) to be separated, work fluid of a second injector (8) is processed into low-pressure steam through a first throttling member (7) and a condensing evaporator (9), and the low-pressure steam is pressurized by the second injector (8), flows into the first heat regenerator (5) to be subjected to overheating and then flows back to the compressor (1); and gaseous refrigerants flowing out of the top of the first gas-liquid separator (3) flow into the condensing evaporator (9), are recooled through a second heat regenerator (10) and enter an evaporator (12) through a second throttling member (11) for refrigeration at low temperature, the ultra-low temperature can reach minus 40 DEG C to minus 170 DEG C, and the energy saving effect is good.

Owner:HENAN UNIV OF SCI & TECH

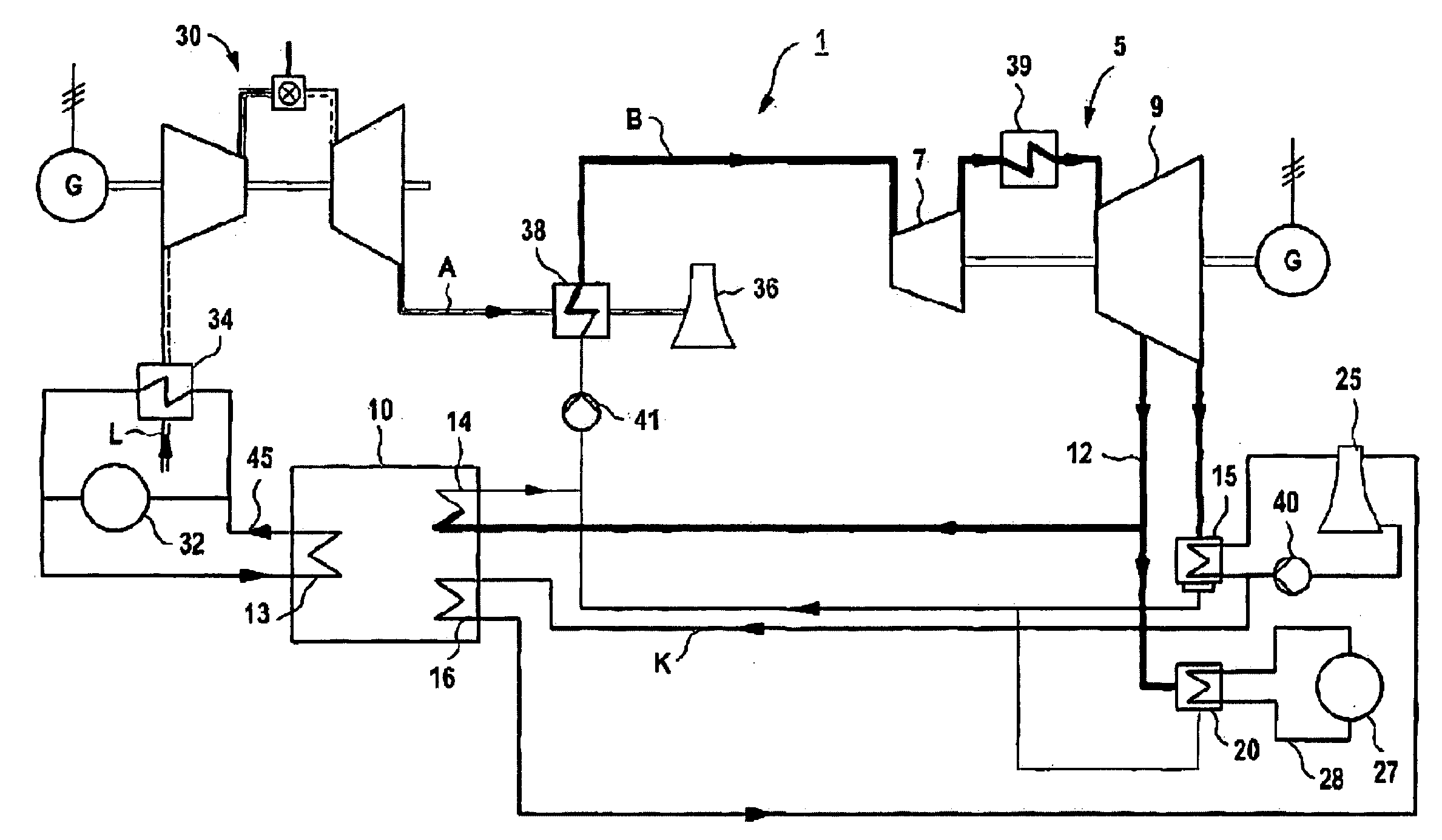

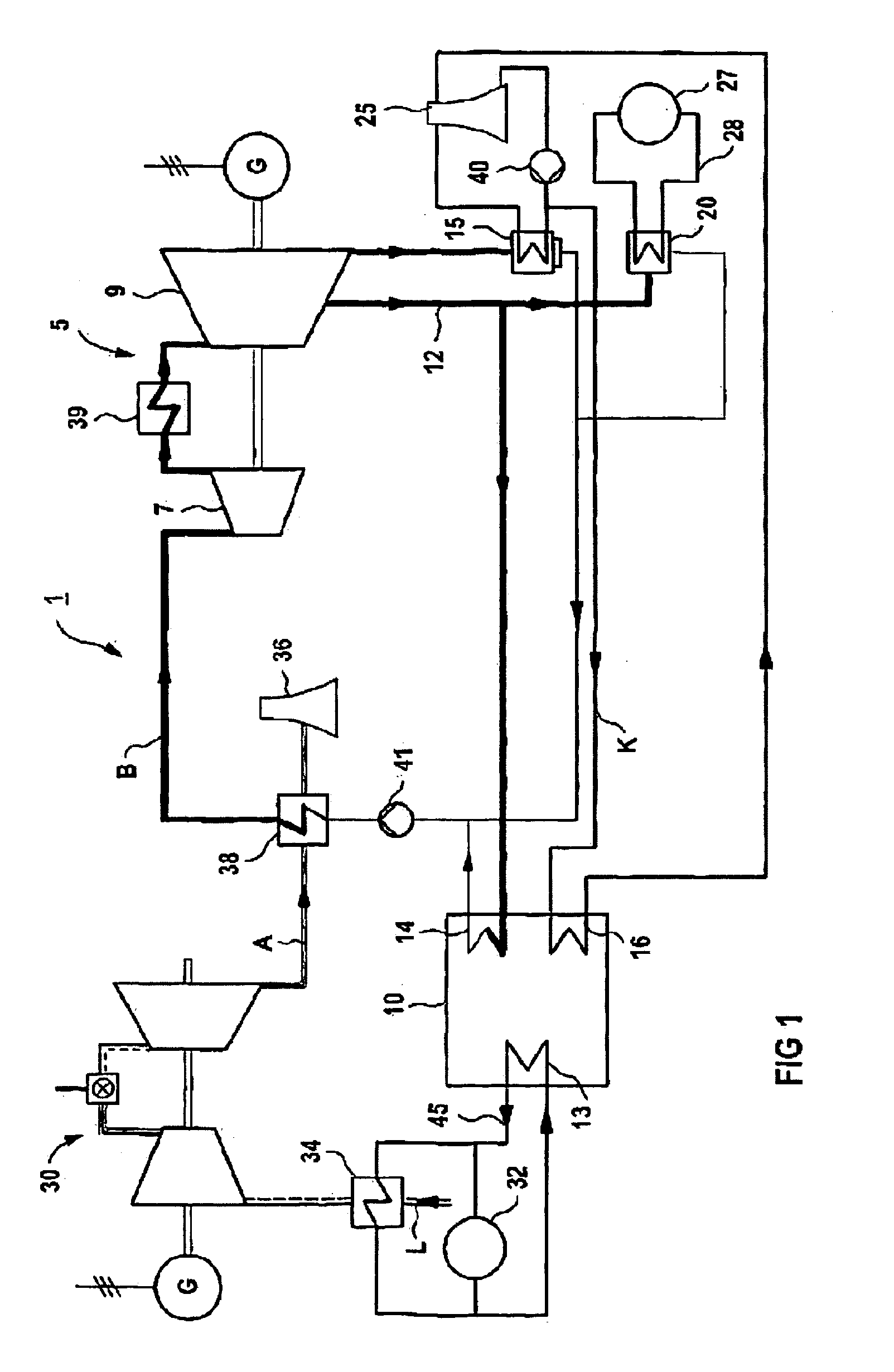

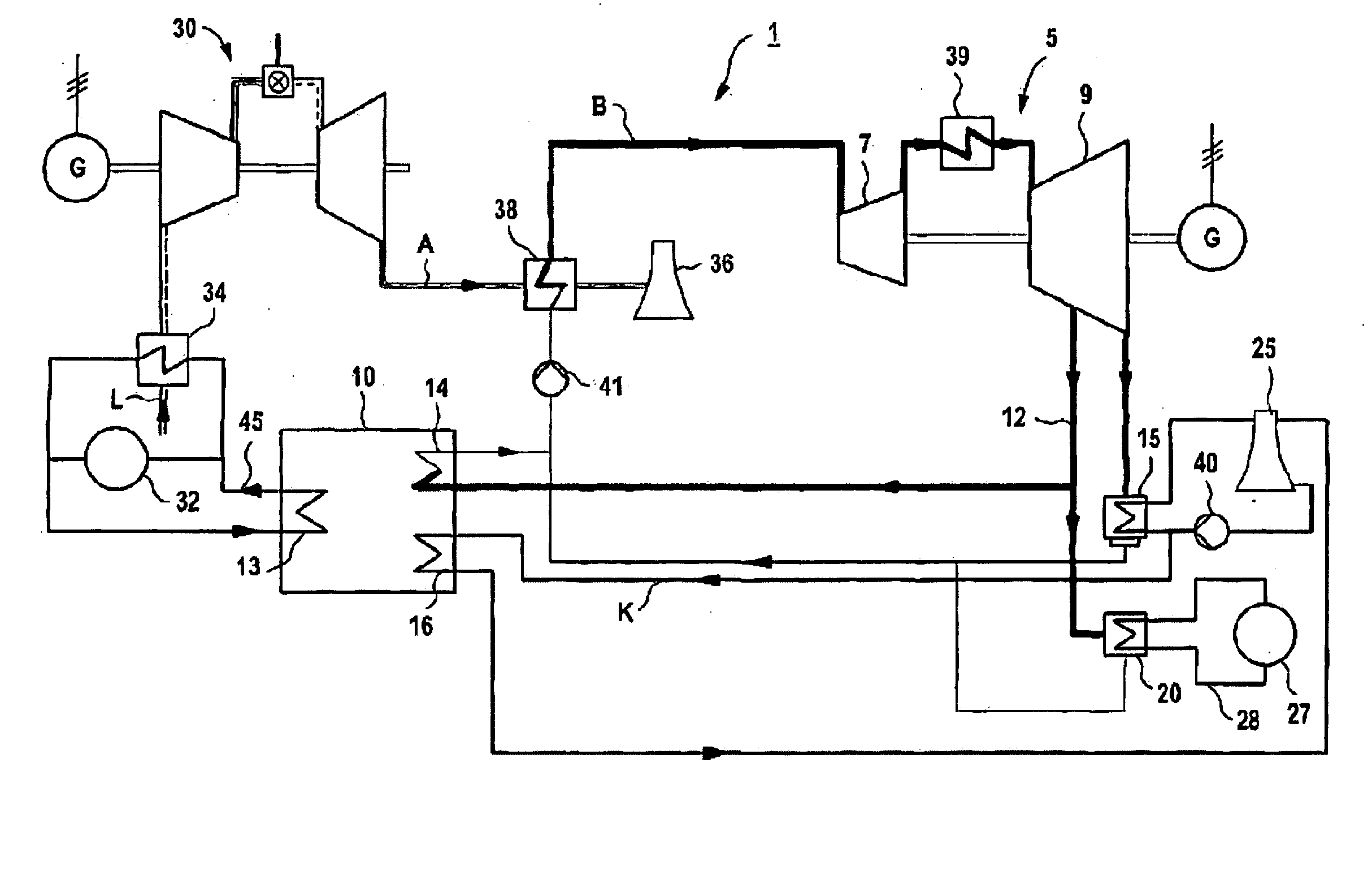

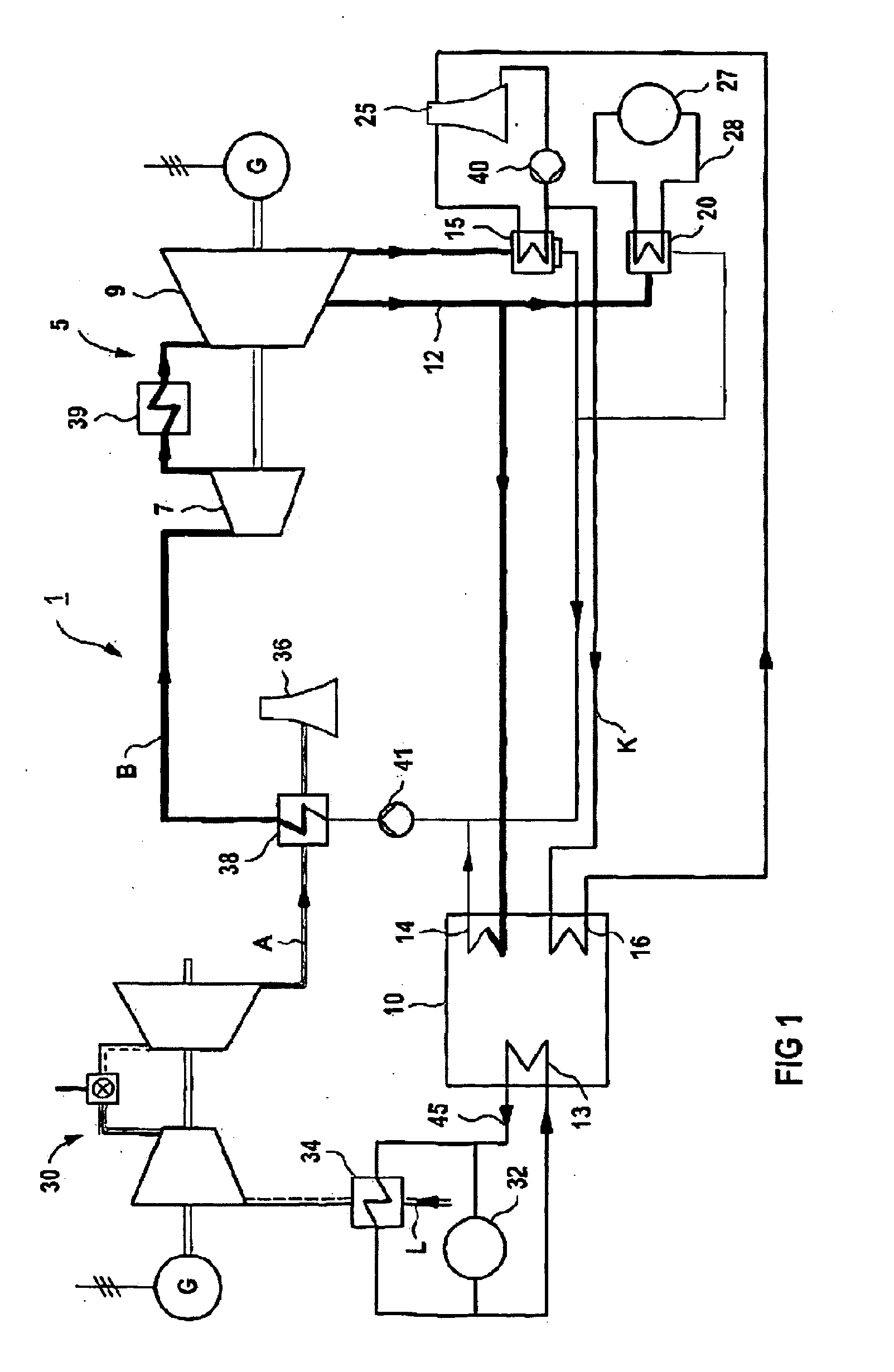

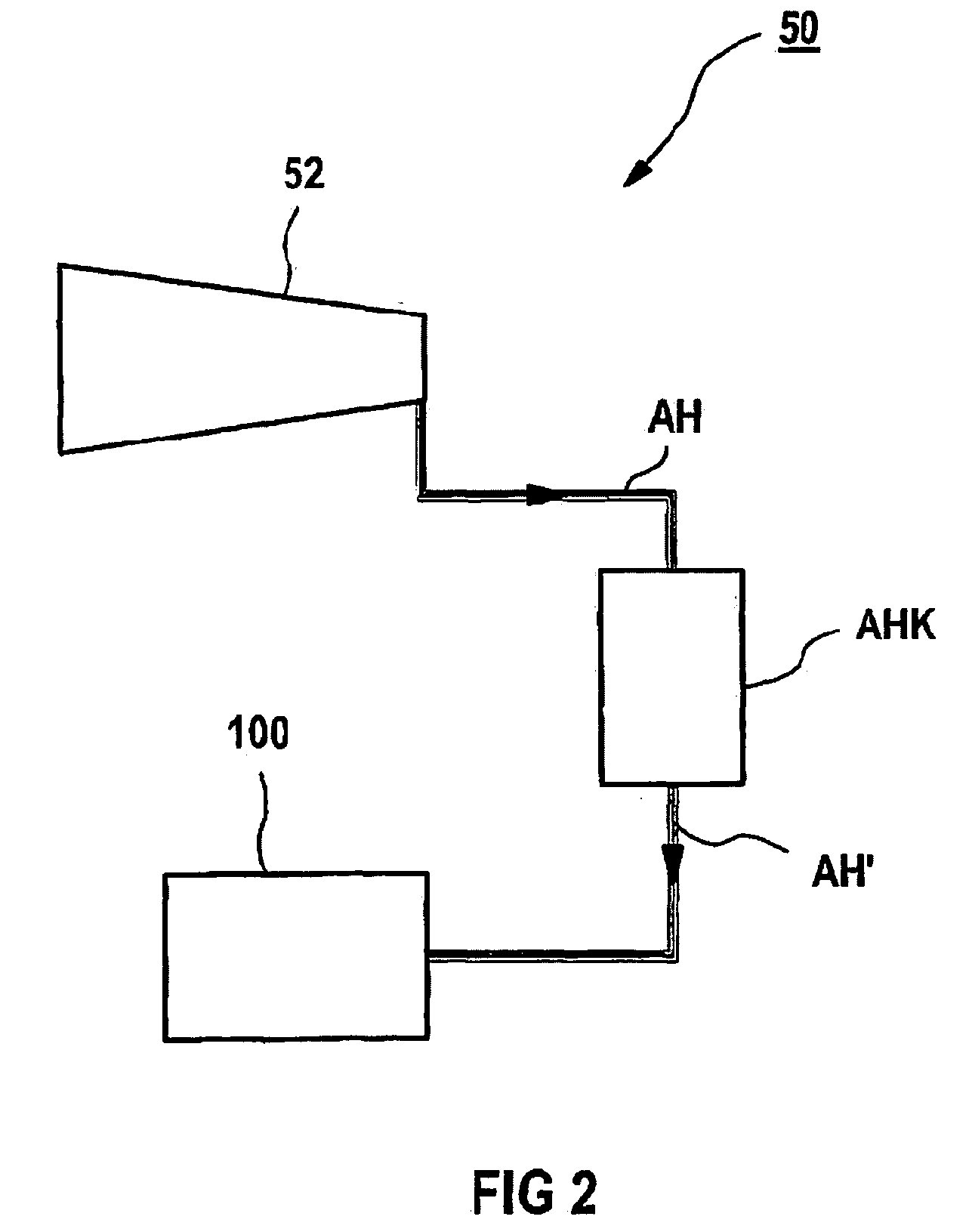

Refrigeration power plant

InactiveUS7178348B2Low cooling temperatureRobust and durableBoilers/analysersCompression machines with non-reversible cyclePower stationEngineering

The invention relates to a power station comprising at least one steam turbine and / or gas turbine which is connected to at least one absorption type refrigeration machine in order to produce refrigeration, whereby the absorption type refrigeration machine is operated by means of steam which is taken from the steam turbine, or by means of waste heat produced by the gas turbine.

Owner:SIEMENS AG

Refrigerator power plant

InactiveUS20050223728A1Low cooling temperatureSufficient energyBoilers/analysersClimate change adaptationPower stationEngineering

The invention relates to a power station comprising at least one steam turbine and / or gas turbine which is connected to at least one absorption type refrigeration machine in order to produce refrigeration, whereby the absorption type refrigeration machine is operated by means of steam which is taken from the steam turbine, or by means of waste heat produced by the gas turbine.

Owner:SIEMENS AG

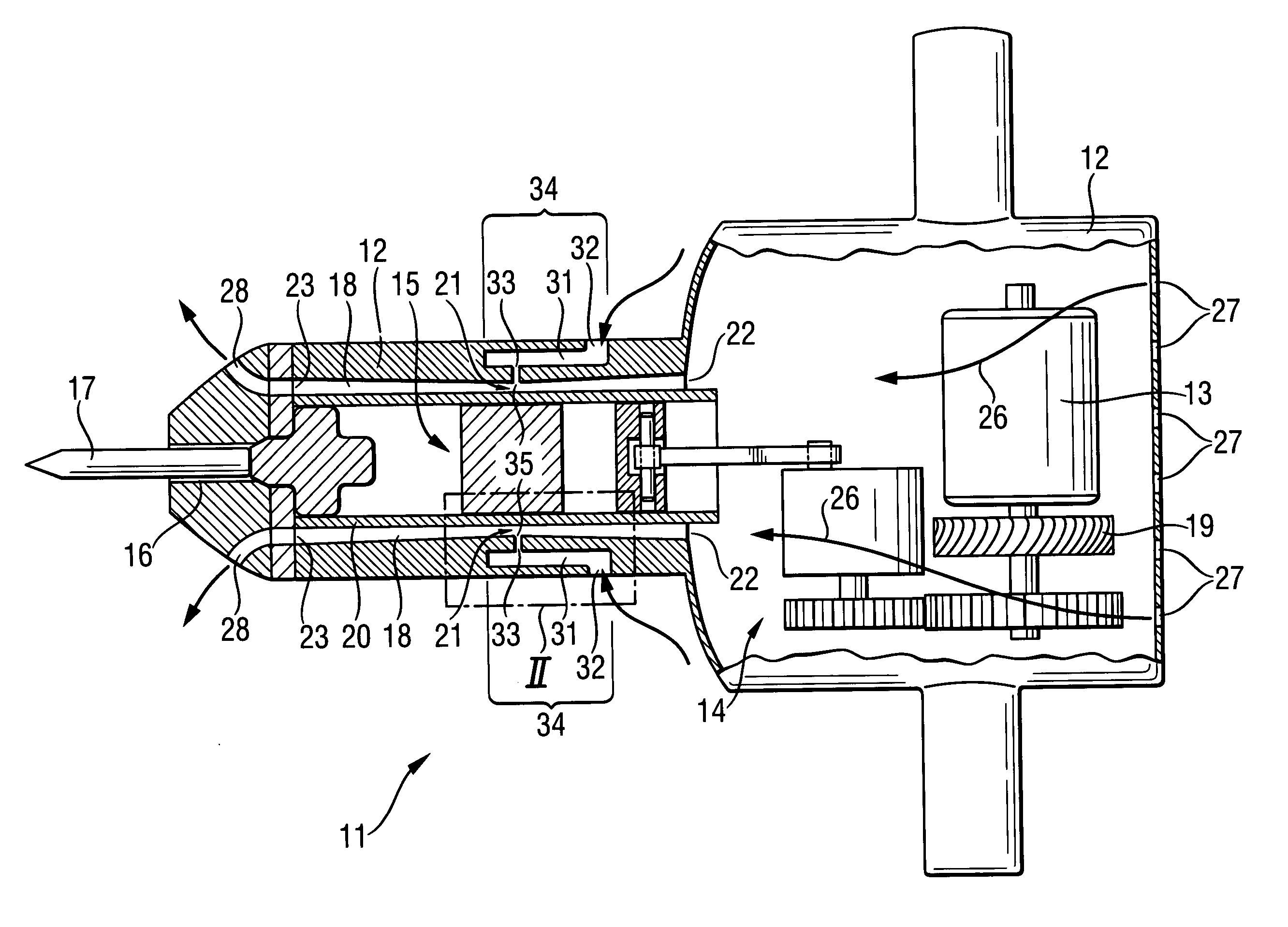

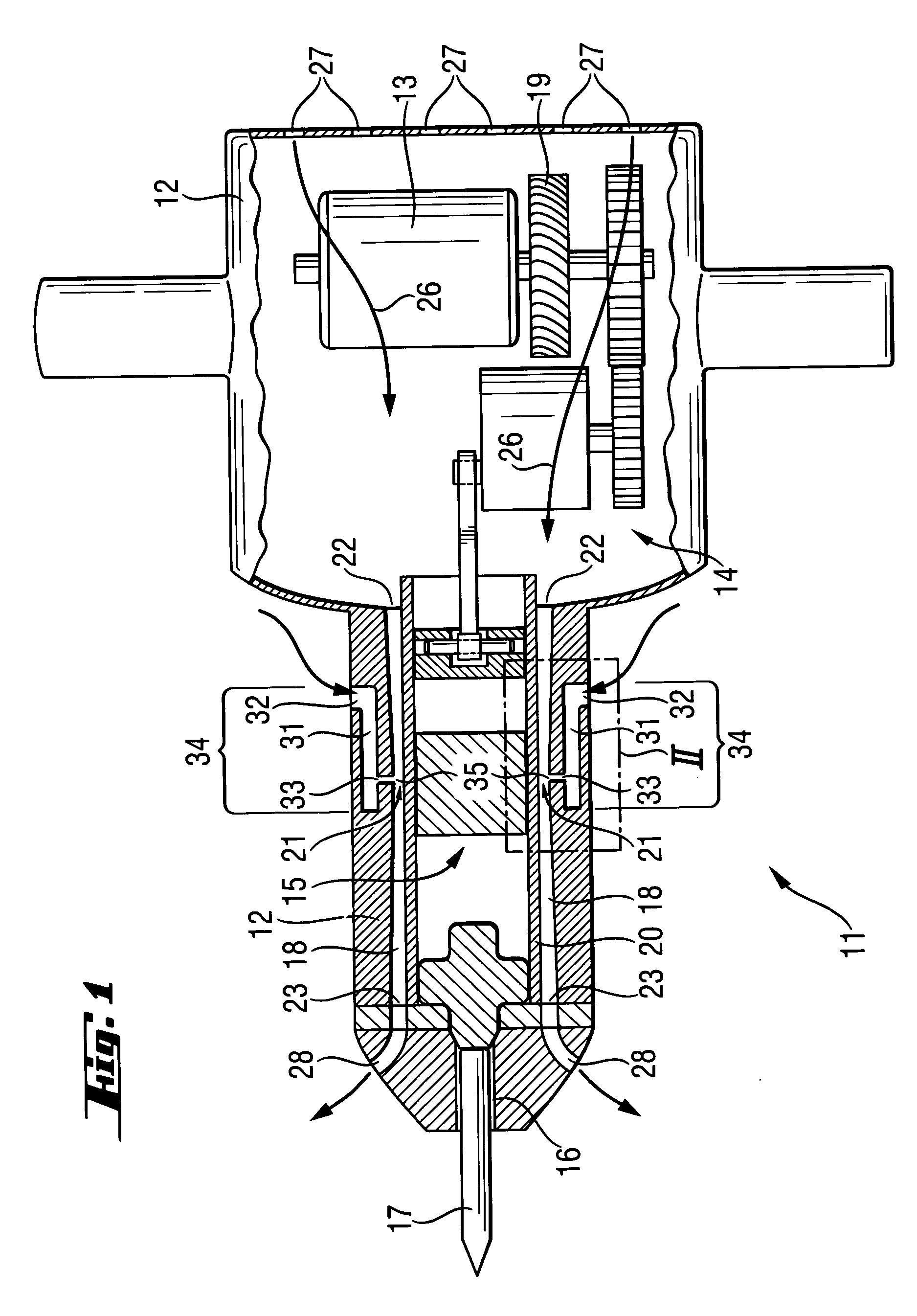

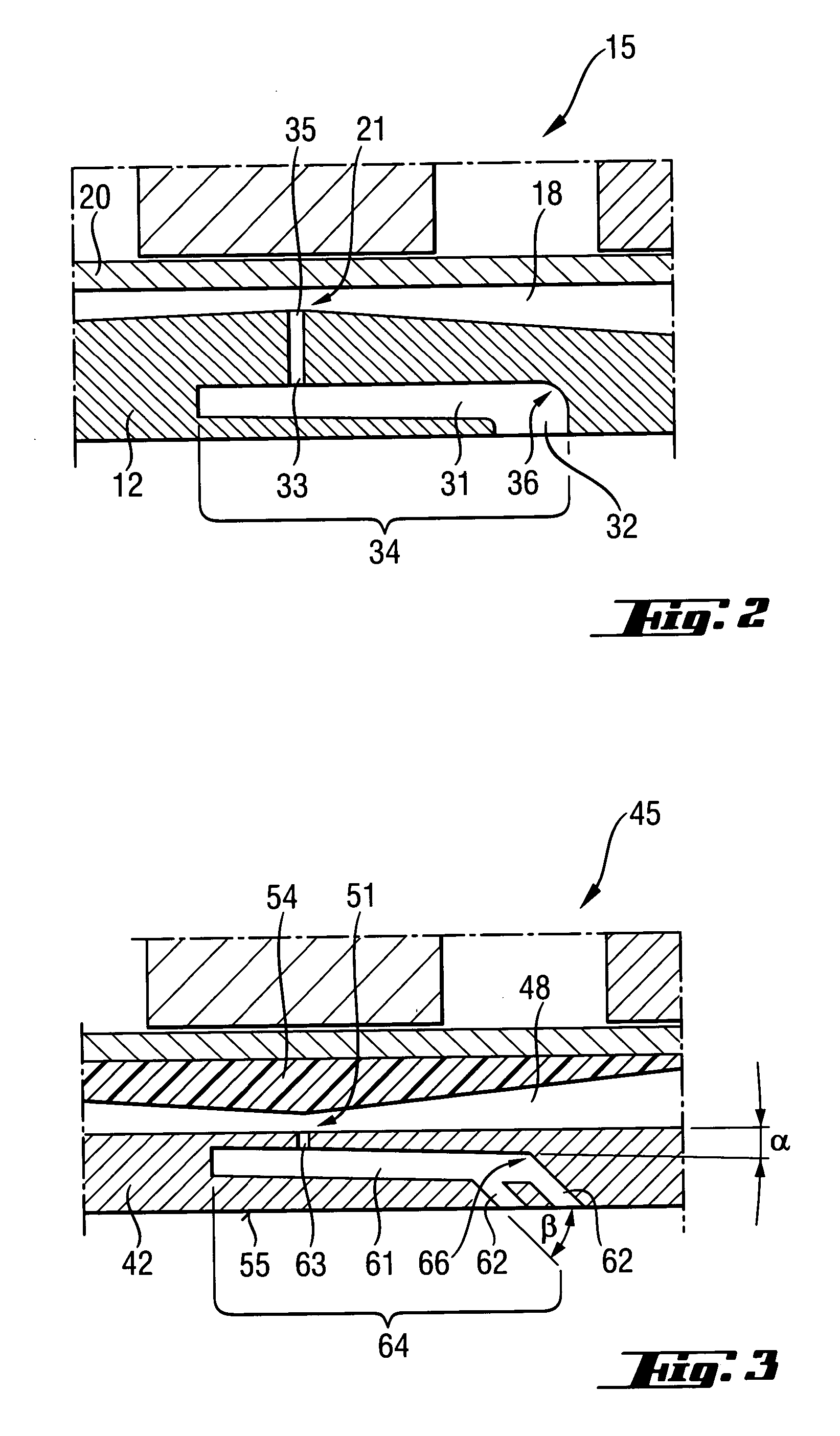

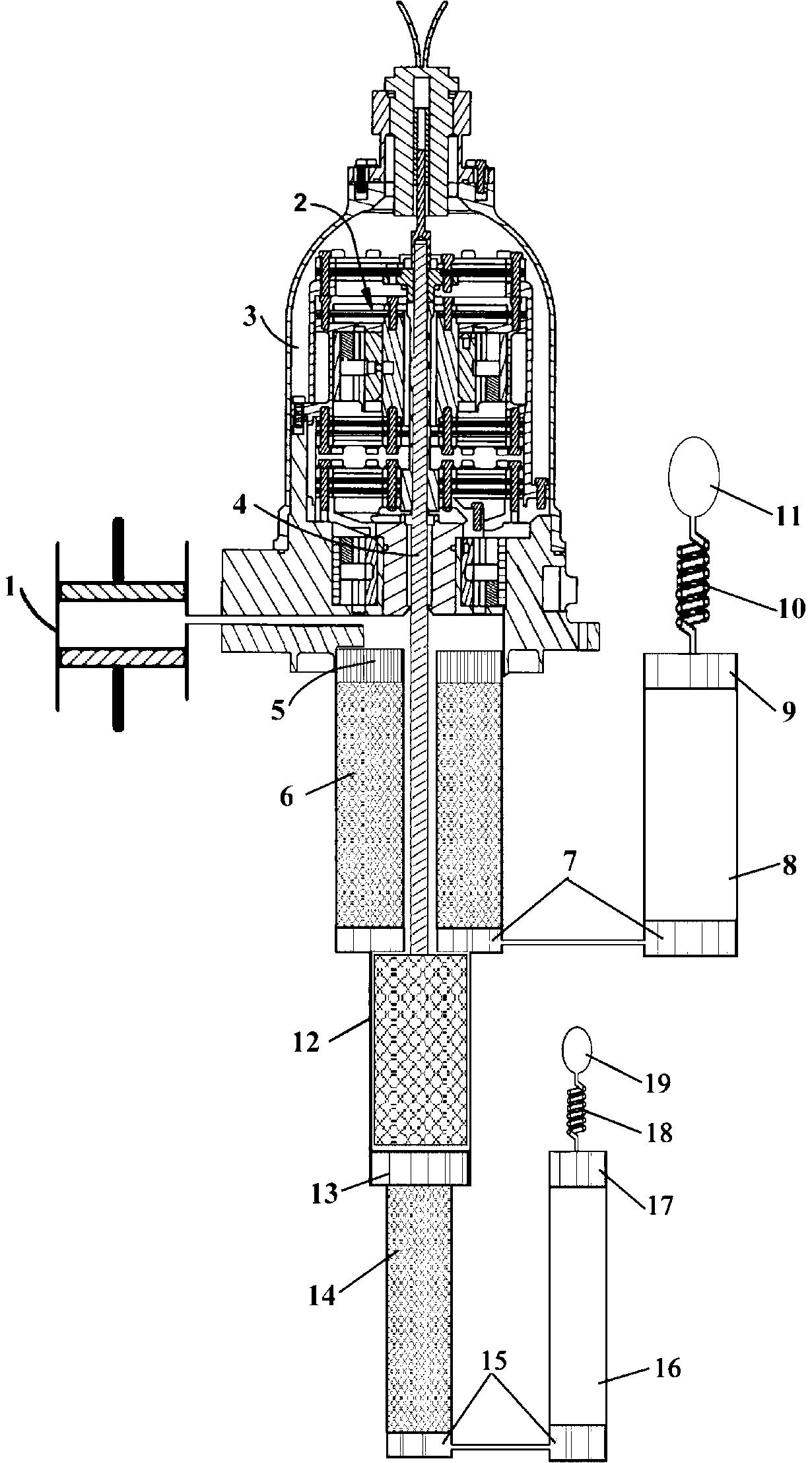

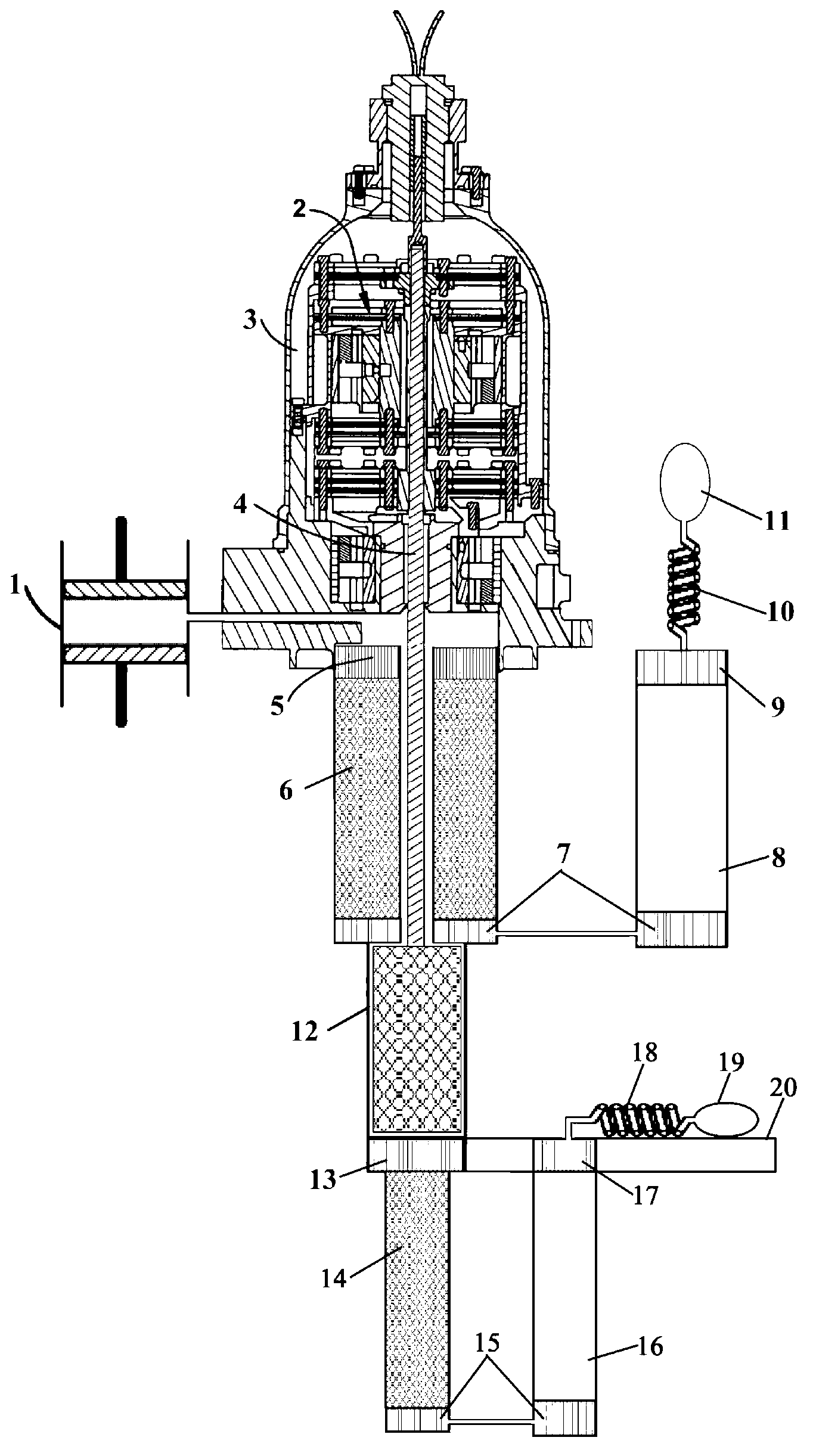

Electric power tool

ActiveUS20060131042A1Simple to manufactureLow energy consumptionDrilling rodsConstructionsPower toolElectric machinery

Owner:HILTI AG

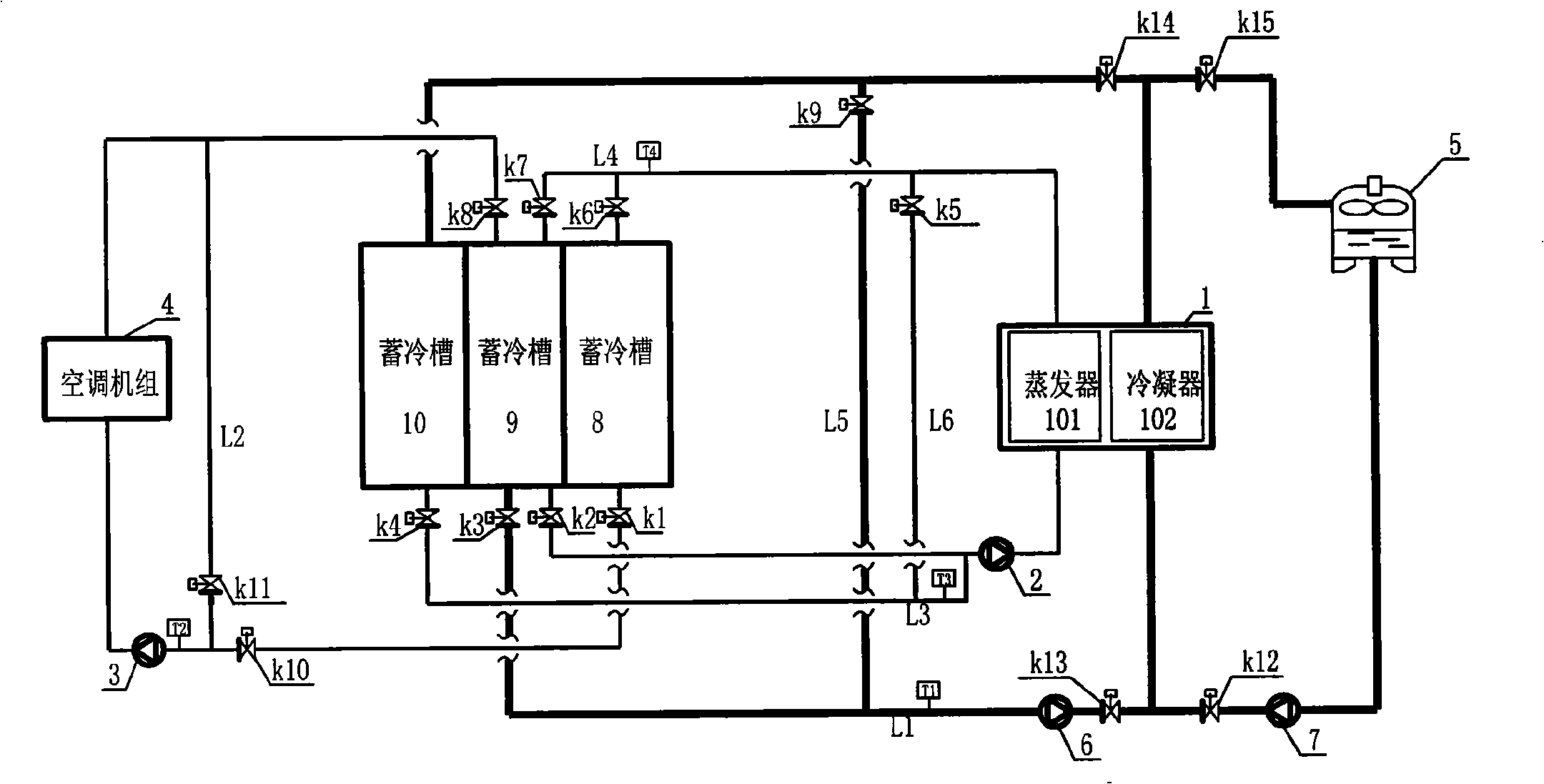

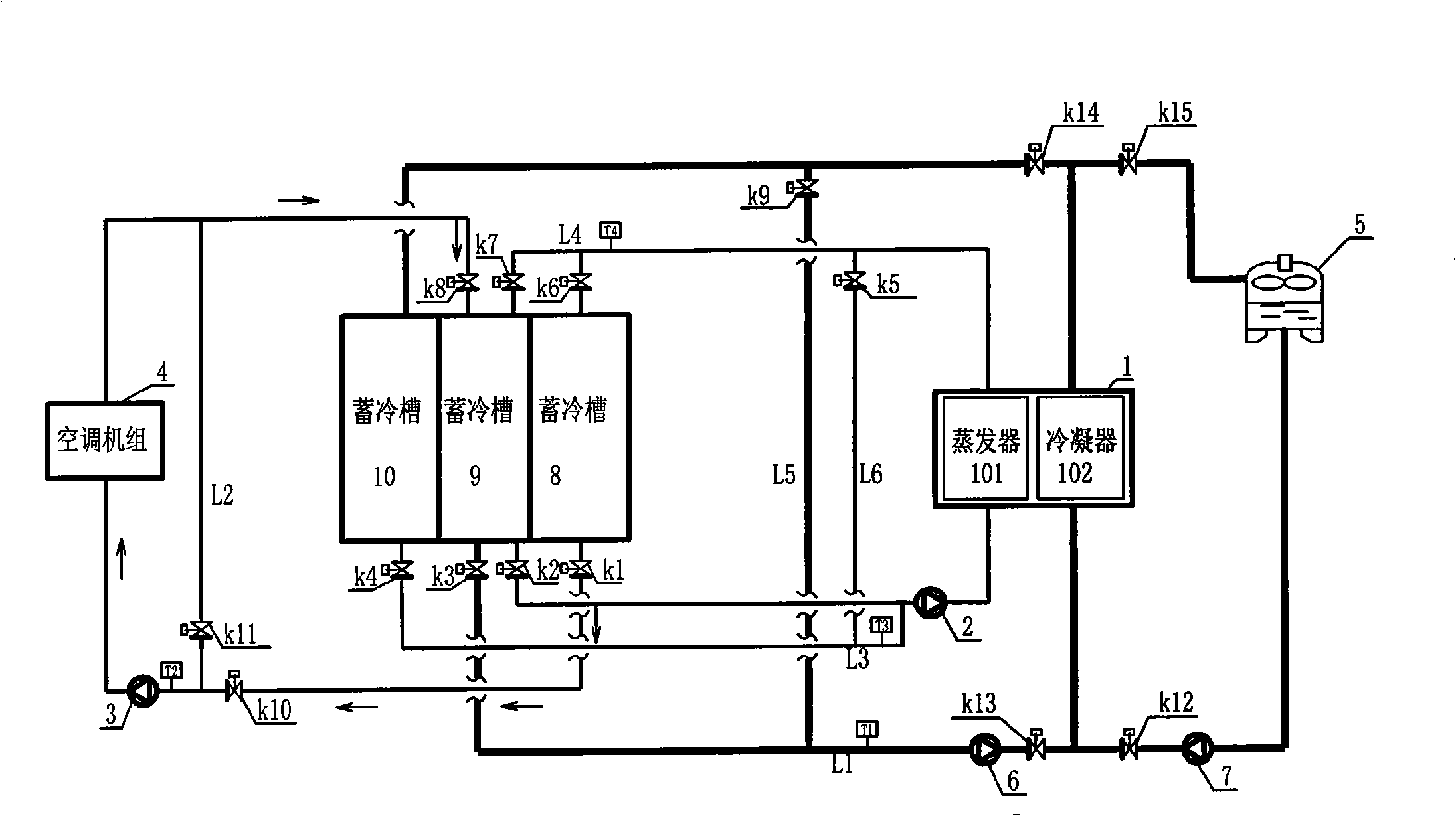

Method for enhancing cold-storage density of cold storage air conditioner system and cold storage air conditioner system

InactiveCN101334203AImprove efficiencySave running electricityLighting and heating apparatusAir conditioning systemsPower gridChilled water

The invention relates to a cold storage density improving method for the cold storage air conditioning system and a cold storage air conditioning system. The method of the invention adopts the technical proposal that during the cold discharging stage, under the state that the refrigerating unit is started, a part of high-temperature cooling water is taken as low-temperature cooling water to replace the water cooling system to be supplied to the condenser of the refrigerating unit; when the cold storage is required, the high-temperature cooling water is refrigerated and is changed into the low-temperature refrigerated water by the condenser of the refrigerating unit. The cold storage air conditioning system of the invention comprises a refrigerating unit, a cold storage equipment, a chilled water pump, an air conditioning unit, a cooling water system, one to a plurality of low-temperature cooling water circulating pipelines and two to a plurality of high-temperature refrigerated water refrigeration pipelines. The cold storage density improving method for the cold storage air conditioning system and the cold storage air conditioning system have the advantages that electric power consumption in the power consumption peak time can be more reduced, the operation cost can be reduced, and the cold storage density can be increased, thereby a positive effect can be taken on the peak load shifting of the electric network.

Owner:龙涛

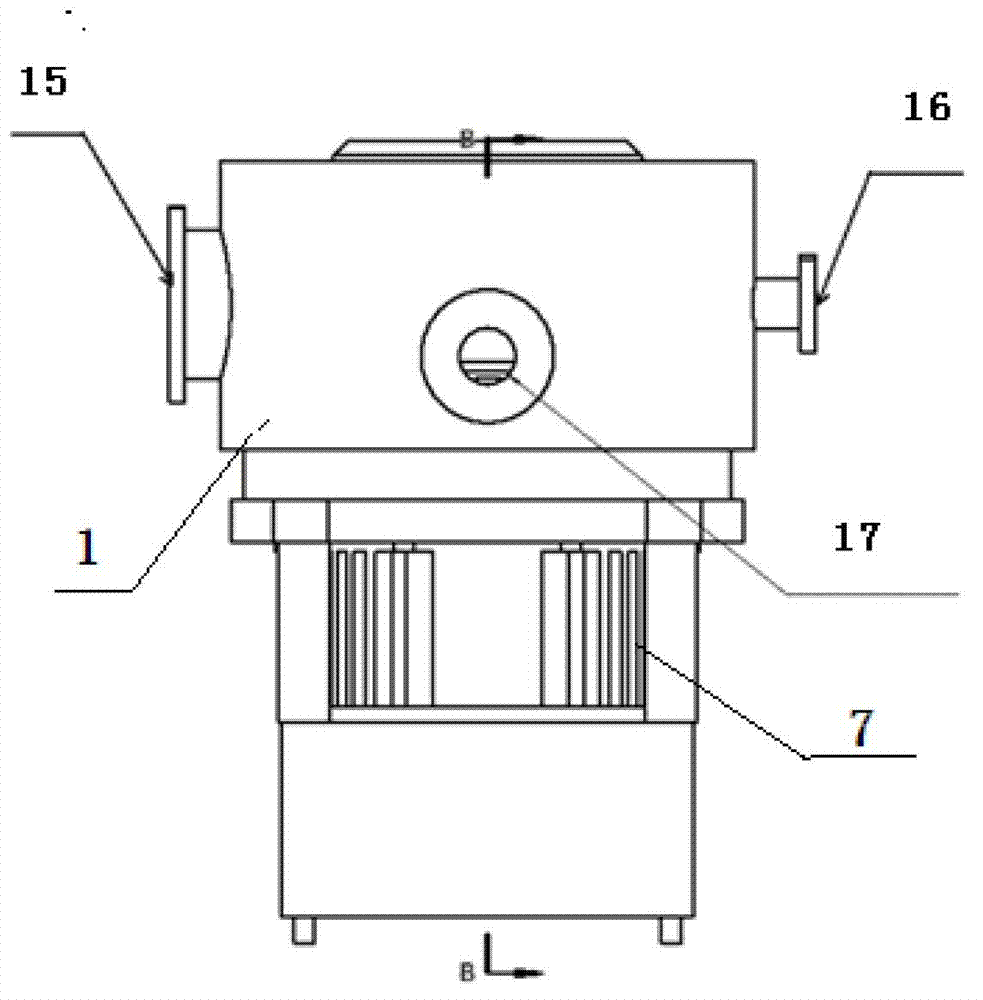

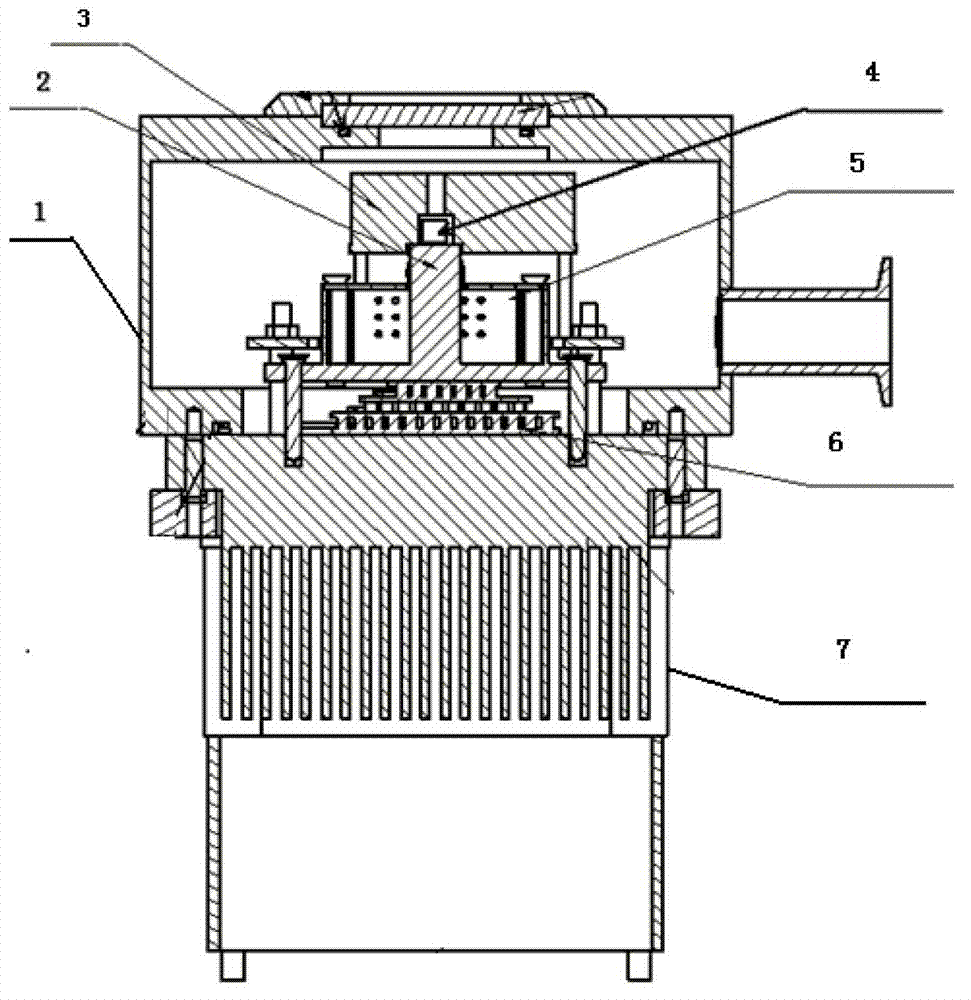

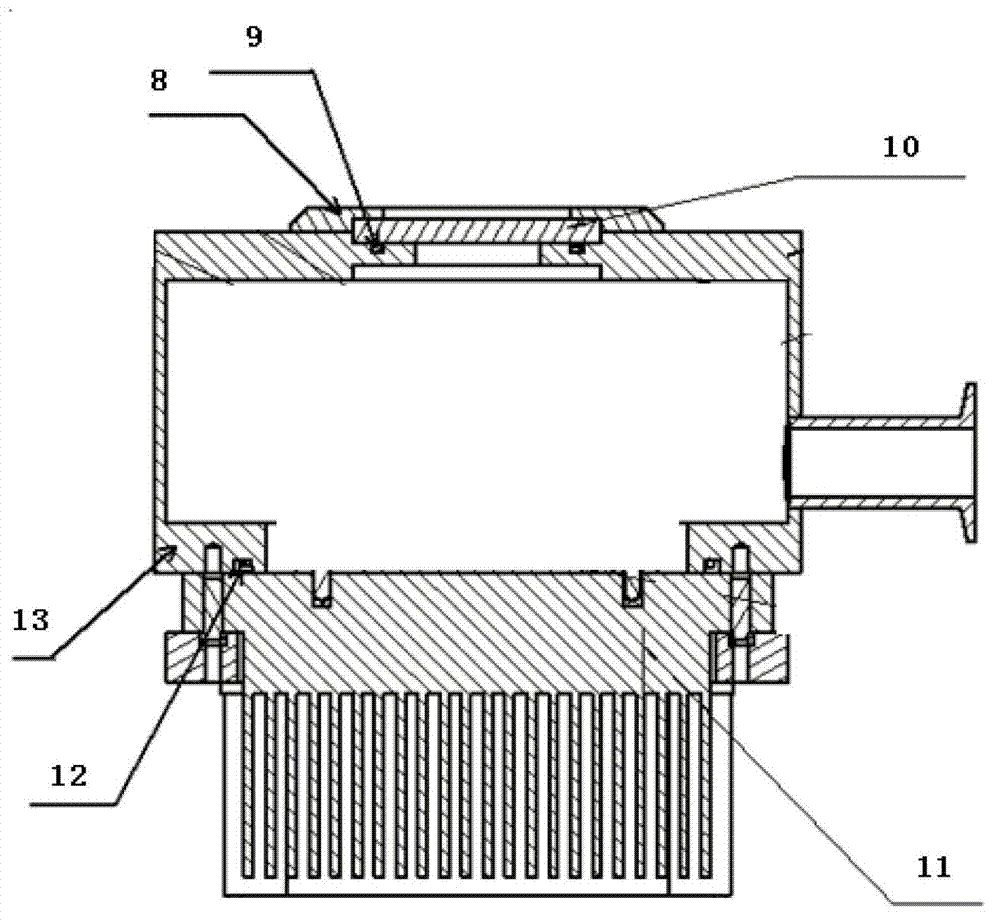

Air cooling heat dissipation thermoelectric cooler (TEC) electric refrigeration charge coupled device (CCD) Dewar

InactiveCN103090586AEfficient heat dissipationLow cooling temperatureMachines using electric/magnetic effectsMolecular sieveRefrigeration temperature

The invention provides an air cooling heat dissipation thermoelectric cooler (TEC) electric refrigeration charge coupled device (CCD) Dewar which comprises a vacuum Dewar (1), a CCD detector (3), a TEC, an air cooling heat dissipation system (7) and a molecular sieve (5), wherein the CCD detector (3), the TEC and the molecular sieve (5) are arranged inside the vacuum Dewar (1), a cold end of the TEC is in heat conductance with the CCD detector (3), a hot end of the TEC is in heat conductance with the air cooling heat dissipation system (7), and the air cooling heat dissipation system (7) is connected with a vacuum Dewar cavity body (1) in a sealed mode. Due to the fact that the TEC and the molecular sieve are used for maintaining the technologies such as vacuum and air cooling heat dissipation in a long term to ensure low temperature requirements of a CCD in operation of the system, the air cooling heat dissipation TEC electric refrigeration CCD Dewar has the advantages of being large in a heat sink heat dissipation surface area, fast in temperature cooling speed, low in absolute refrigeration temperature, long in vacuum maintaining time, small in size, less in quality, convenient to install and control, capable of observing at any angle, simple in operation and maintenance and capable of being directly used for imaging and photometry of a astronomical telescope CCD lens.

Owner:贾磊

Electric power tool

ActiveUS7258173B2Easy to manufactureReduce energy consumptionDrilling rodsConstructionsElectric power systemElectric machine

Owner:HILTI AG

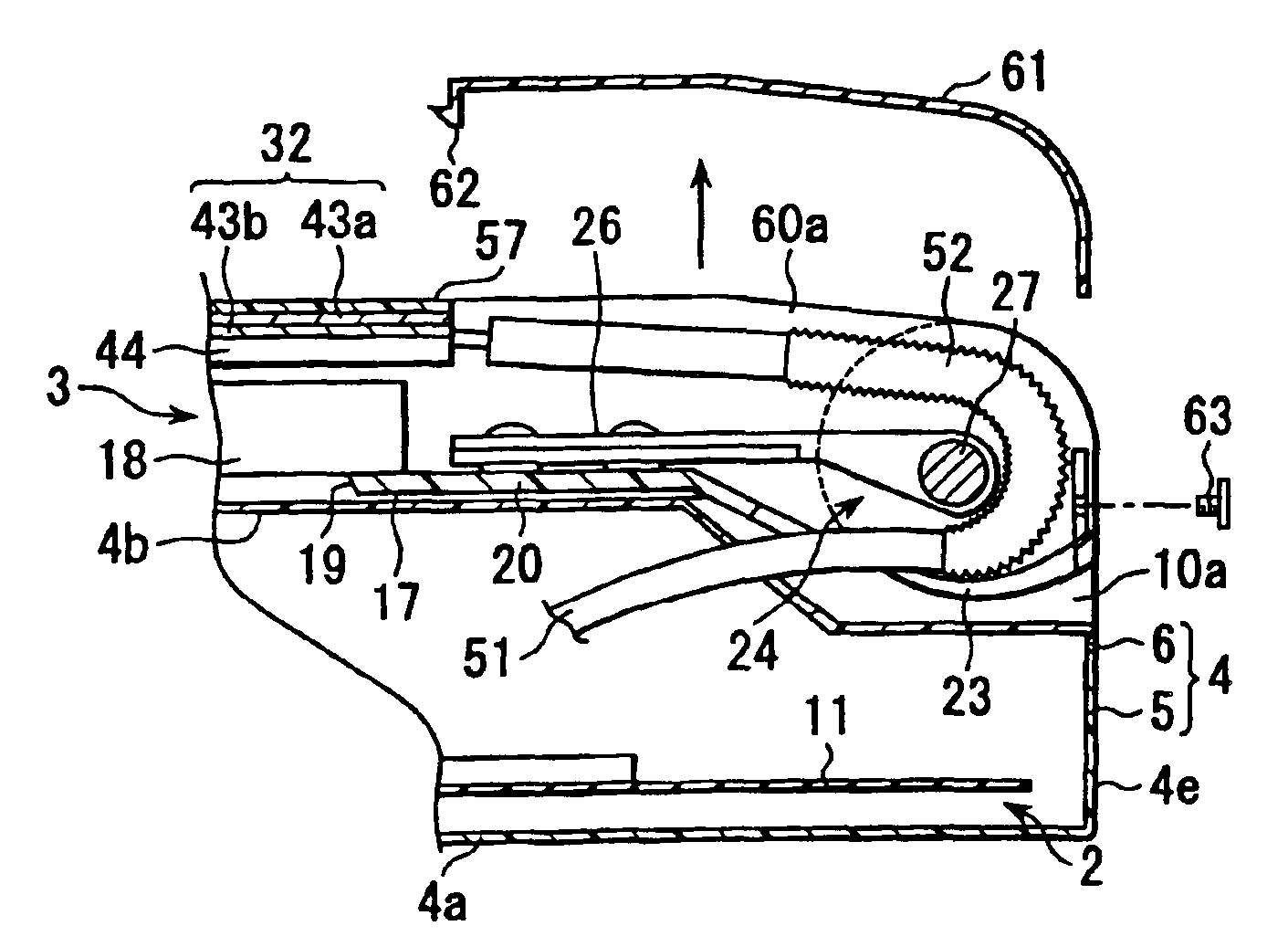

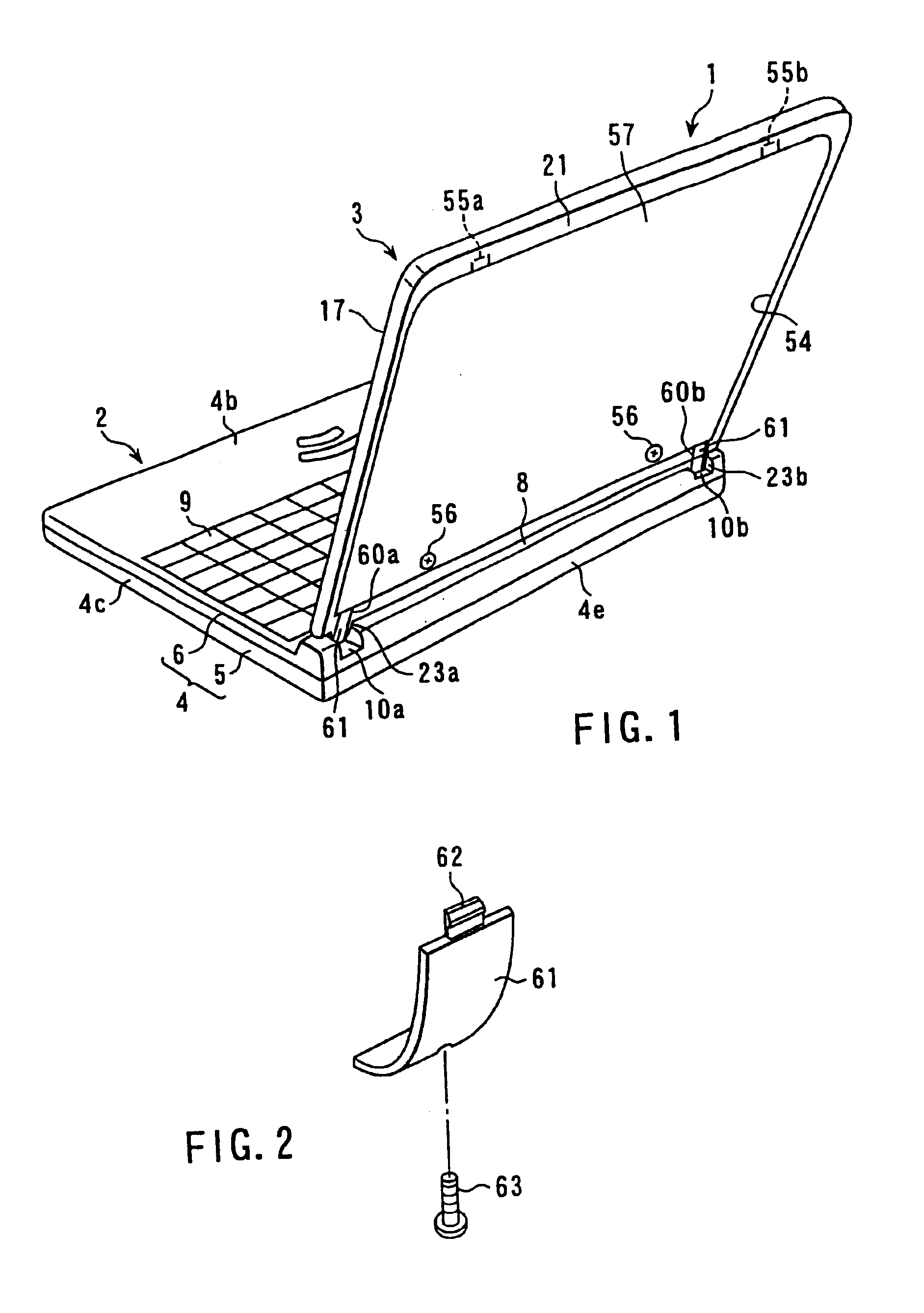

Electronic apparatus including a circulation path for circulating cooling medium

InactiveUS6920043B1Avoid temperature riseDisassembled/reassembled easilyDigital data processing detailsSemiconductor/solid-state device detailsCooling mediumElectrical and Electronics engineering

An electronic apparatus includes a first housing including a convex portion and housing a heat generating component, a second housing including a leg portion rotatably supported by the convex portion, a heat receiving portion provided in the first housing and thermally connected to the heat generating component, a heat radiating portion provided in the second housing, and a circulation path for circulating a cooling medium between the heat receiving portion and the heat radiating portion. The circulation path extends between the first housing and the second housing through the interior of the convex portion and the interior of the leg portion. The leg portion includes an opening at the part corresponding to the circulation path for exposing the circulation path. The opening is covered with a removable lid.

Owner:KK TOSHIBA

Vortex cooled turbine blade outer air seal for a turbine engine

InactiveUS7665955B2Enhanced convectionReduce traffic requirementsPump componentsEngine fuctionsTurbine bladeCooling fluid

A cooling system for a turbine blade outer air seal that is positioned in close proximity to a tip of a rotatable turbine airfoil to seal the gap between the tip of the turbine blade and the blade ring carrier. The turbine blade outer air seal may be formed from a housing including a cooling fluid collection chamber and one or more vortex cooling channels in fluid communication with the cooling fluid collection chamber via one or more vortex channel feed holes. In one embodiment, a plurality of vortex cooling channels may extend from proximate to an upstream edge of an outer sealing plate of the outer air seal to a downstream edge of the outer sealing plate. During use, cooling fluids pass through the vortex channel feed holes and into the vortex cooling channels, in which vortices may be created.

Owner:SIEMENS ENERGY INC

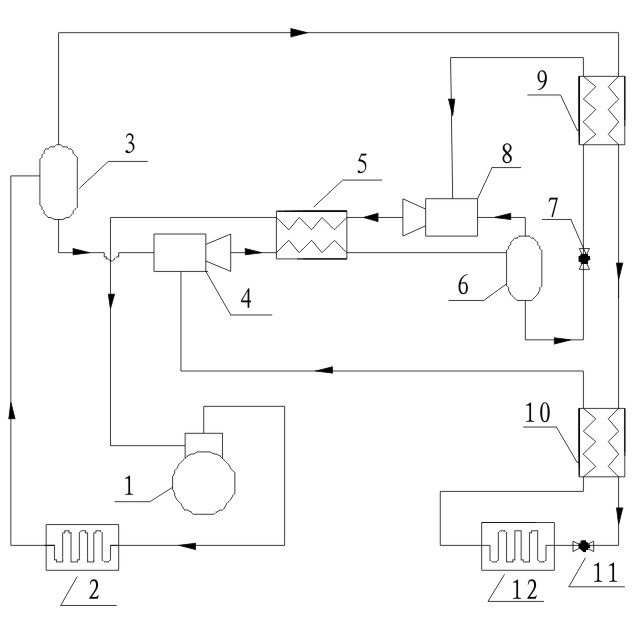

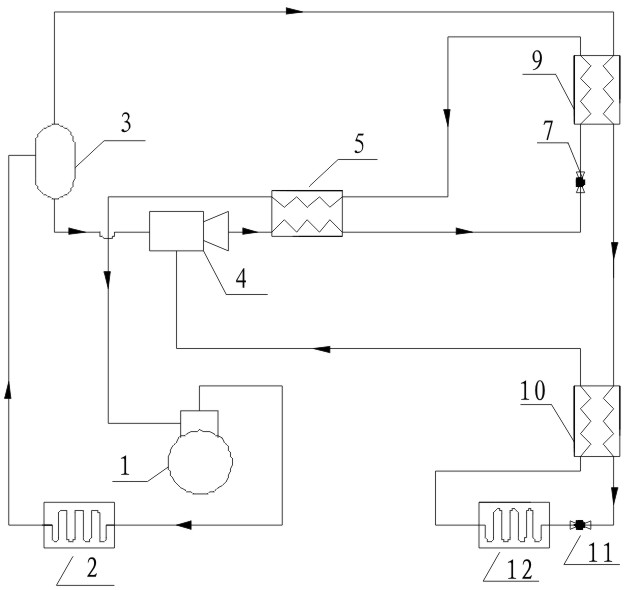

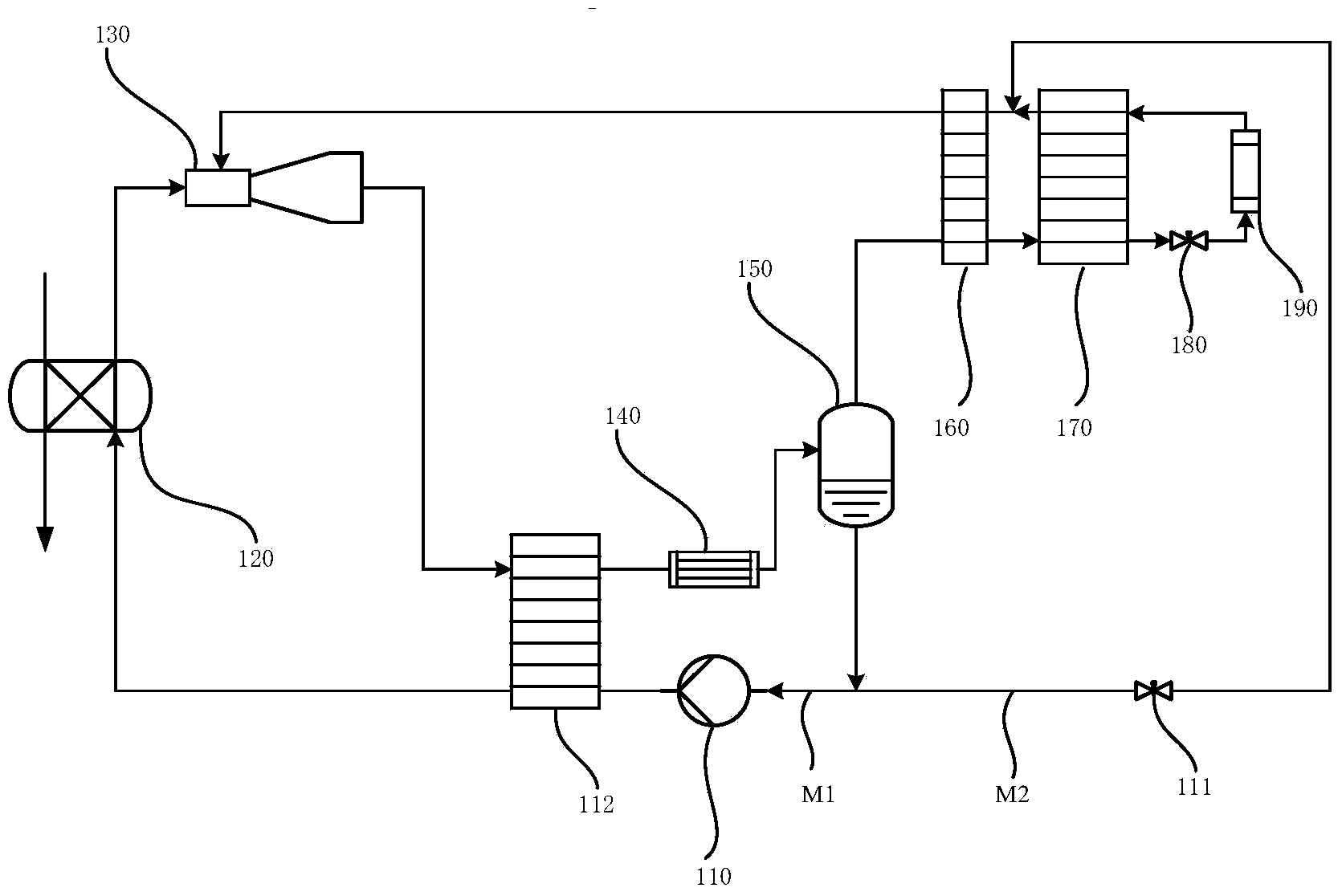

Mixed working medium low-temperature refrigerating cycle system driving ejector through waste heat

ActiveCN104019579ASignificant energy-saving effect of the systemReduce calorie consumptionClimate change adaptationFluid circulation arrangementProcess engineeringThrottle

A mixed working medium low-temperature refrigerating cycle system driving an ejector through waste heat comprises a drive pump, a steam generator, the ejector, a condenser, a gas-liquid separator, a first returning heat exchanger, a second returning heat exchanger, a first throttling valve and an evaporator. A mixing working medium liquid-phase component is pressurized through the pump and then enters the steam generator to become high-temperature and high-pressure gas, and the high-temperature and high-pressure gas enters the ejector to eject the mixing working medium throttling refrigerating fluid; the gas enters the condenser to be cooled into gas-liquid fluid, the gas-liquid fluid is separated, a gas-phase component enters the returning heat exchanger throttling valve, the low temperature is generated, the heat of the gas-phase component is absorbed by the evaporator , the gas-phase component enters the returning heat exchangers, the temperature is reset, and then the gas-phase component is ejected by the ejector. The liquid-phase working medium is divided into two parts, one part is throttled and enters the returning heat exchangers to provide precooling, the working medium and the gas-phase working medium are mixed to be ejected by the ejector, and the other part enters the pump to be pressurized to serve as ejecting fluid to finish circulation. According to the mixed working medium low-temperature refrigerating cycle system, the high-temperature and high-pressure steam generated by waste heat is completely utilized for driving the ejector to eject the throttled working medium, and therefore efficient, energy-saving and low-temperature refrigerating can be achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

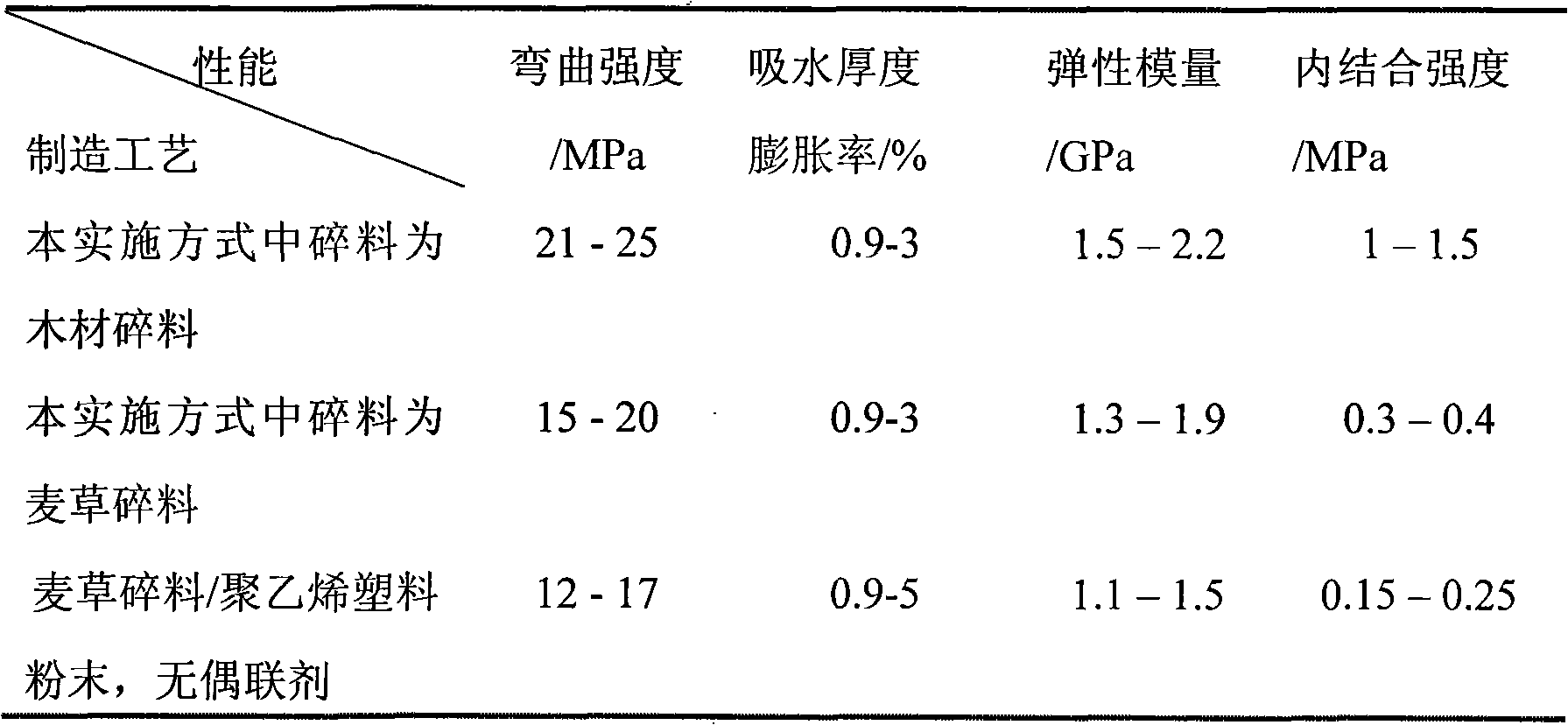

Heat pressing production method of polyethylene fiber-plant fibre compound material

InactiveCN101323130AShorten heating timeEasy to melt and transfer heatFlat articlesDomestic articlesFlexural strengthPlastic compounding

A heat pressing method for polyethylene plant fiber composite material relates to a method for manufacturing plant fiber material. The invention solves the problems that only fibril can be applied, plant format is narrower, straw is liable to thermolysis and charring and the mechanical properties of plant manufactured by pre-heat pressing are poor in the production of WPC in the manner of extraction. The method of the invention has the steps that: PE plastic fiber is mixed with crushed plant aggregates to obtain mixture that is paved into a plate base; the plate base is pre heated under a pressure of 1 to 3 MPa and at a temperature of 170 to 190 CEG D; the plate base is kept under a pressure of 4 to 6 MPa for 8 to 15mins; and at last, the plate base is cooled to 70 to 80 CEG D under a pressure of 3 to 6 MPa; and after pressure relief, the plank is obtained. The flexural strength of the plank manufactured in the method of the invention is 20 MPa. The invention adopts the polyethylene in fiber configuration and the crushed aggregates of the plant and the fiber is evenly mixed and has high productivity. In addition, the crushed aggregates of the plant and the fiber can be prevented from being deteriorated and darkened due to high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

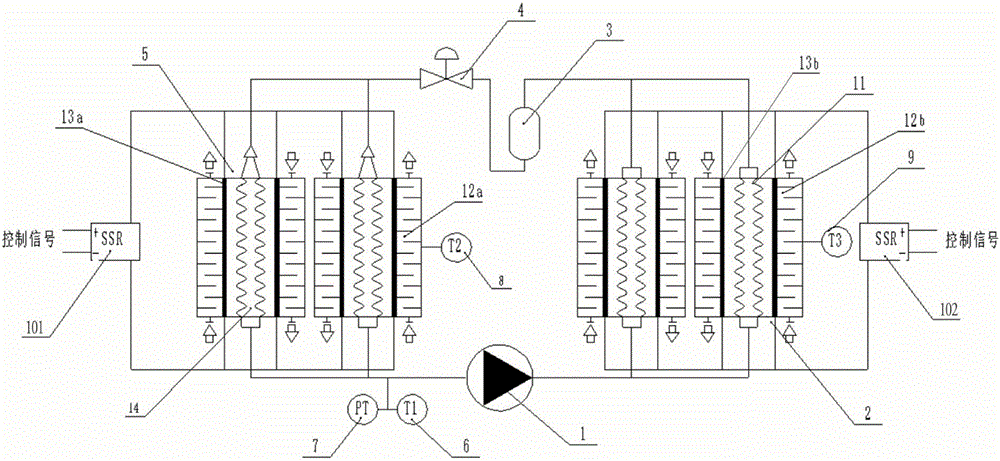

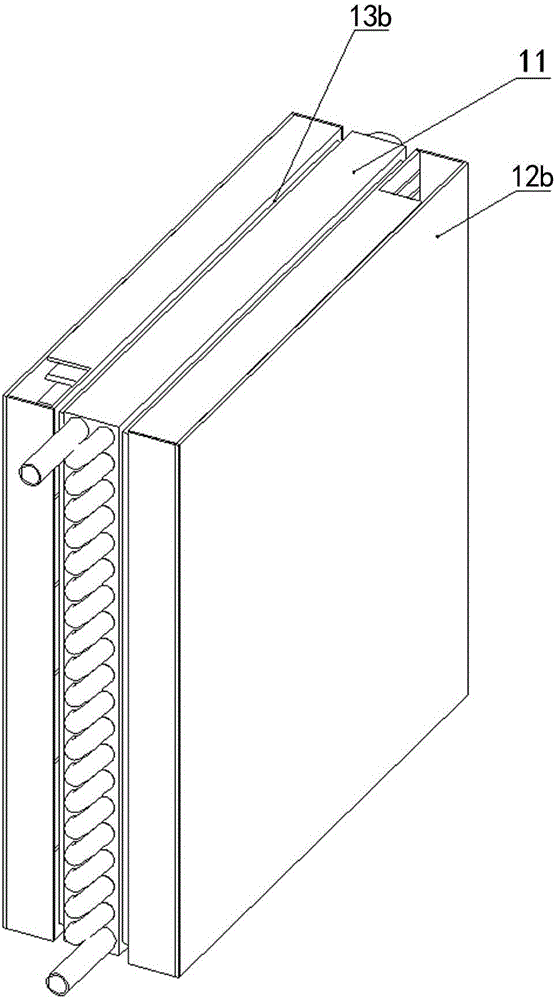

Semiconductor overlaying low-temperature energy storage refrigeration device and working method thereof

ActiveCN106196706AImprove heat transfer efficiencyLarge specific heat capacityMachines using electric/magnetic effectsRefrigerantEvaporator

The invention discloses a semiconductor overlaying low-temperature energy storage refrigeration device and a working method thereof. The semiconductor overlaying low-temperature energy storage refrigeration device comprises a compressor, a hot end energy storage heat exchanger, a liquid storage device, a throttle valve and a cold end energy storage heat exchanger, all of which communicate in sequence according to the refrigerating medium flow path. The cold end energy storage heat exchanger comprises at least one set of box type or shell-coiled pipe type cold end evaporator, and the hot end energy storage heat exchanger comprises at least one set of box type or shell-coiled pipe type hot end condenser. A semiconductor chilling plate is attached to at least one heat radiation plane of each of the cold end evaporators and the hot end condensers. Cold and hot end medium cavities for containing energy storage media are formed in the outer portions of the other faces of the semiconductor chilling plates. Cold and hot end medium temperature probes are arranged in the medium cavities correspondingly. Temperature probes and pressure probes are arranged between an outlet of the cold end energy storage heat exchanger and the compressor. According to the semiconductor overlaying low-temperature energy storage refrigeration device and the working method, the system internal stability and heat exchange efficiency are improved, and the energy consumption ratio is correspondingly reduced. By means of the energy storage media, the refrigerating fluid operation condition can be relatively stable, the energy storage device is flexible in configuration, and combination can be carried out according to the system size.

Owner:SHANGHAI JANZY BIOTECHNOLOGY CO LTD

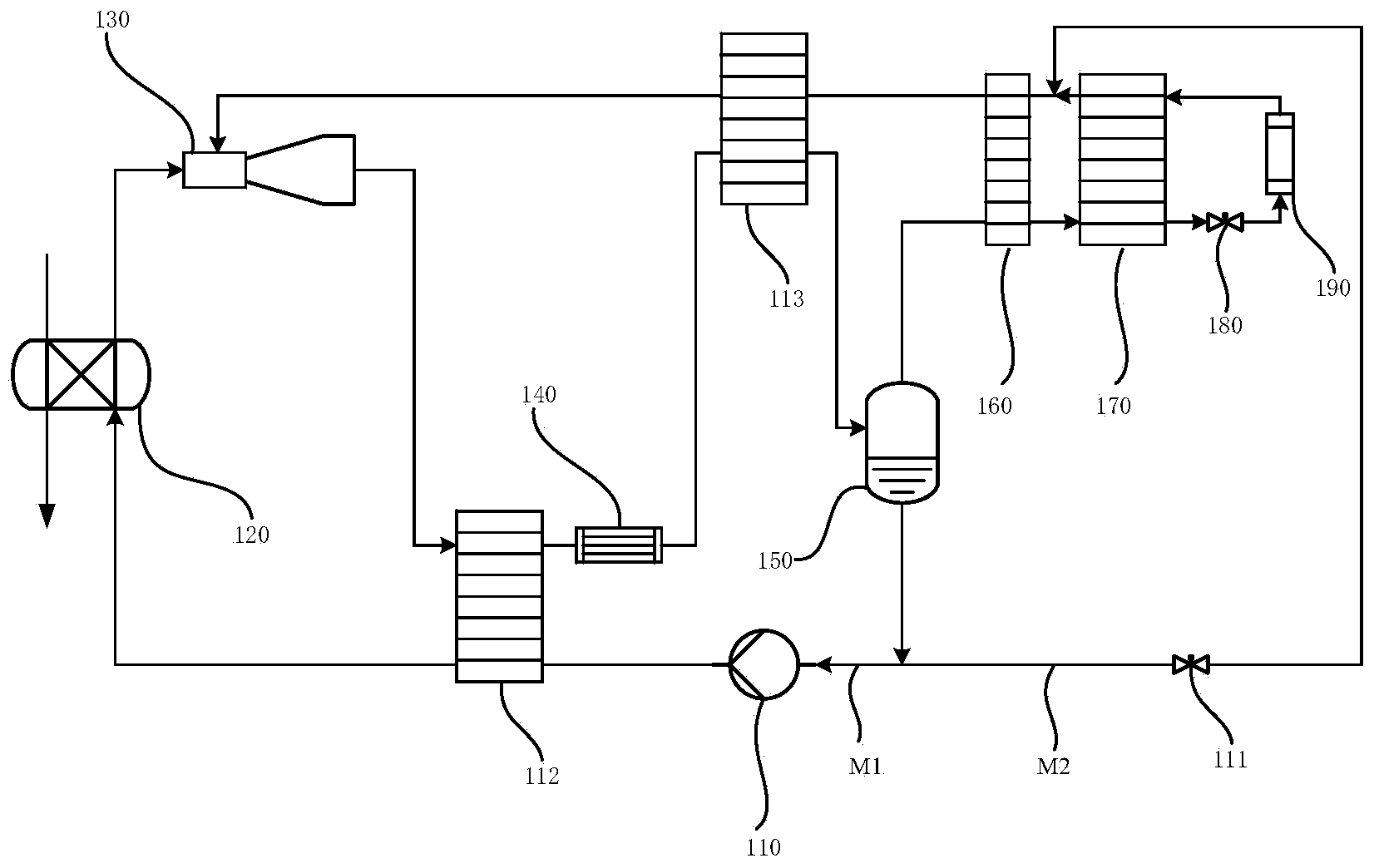

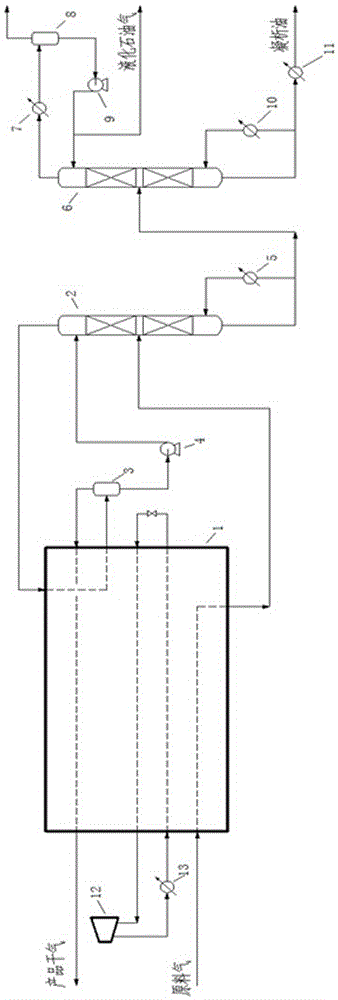

Method and device for recycling mixed refrigerant refrigeration natural gas light hydrocarbon

ActiveCN105716371AFlexible load adjustment functionAdaptableSolidificationLiquefactionProcess engineeringProduct gas

The invention discloses a method and device for recycling mixed refrigerant refrigeration natural gas light hydrocarbon, and belongs to the field of natural gas light hydrocarbon recycling. The method and device aim at solving the problems that according to an existing natural gas light hydrocarbon recycling method, the C3 recycling rate is low, the technological process is complex, the load adjusting capacity is poor, and energy consumption is high. According to the method and device, feed gas enters a main heat exchanger, is subject to partial condensation and then enters a deethanization tower; a gas phase produced from the tower top of the deethanization tower is subject to reheating through the main heat exchanger and then is transported outwards as product gas, and a liquid phase guided out from the tower bottom of the deethanization tower enters a debutanization tower; and a liquefied petroleum gas product is obtained from the tower top of the debutanization tower, and a condensate oil product is obtained from the tower bottom of the debutanization tower. The cold amount needed in the light hydrocarbon recycling process is provided by a mixed refrigerant refrigeration system. The method and device have the beneficial effects of being high in C3 recycling rate, flexible in operation, high in raw material adaptability, low in energy consumption, simple in flow, small in investment and the like, has the good application prospects, and is worth of large-scale application and popularization.

Owner:CHENGDU SEPMEM SCI & TECH

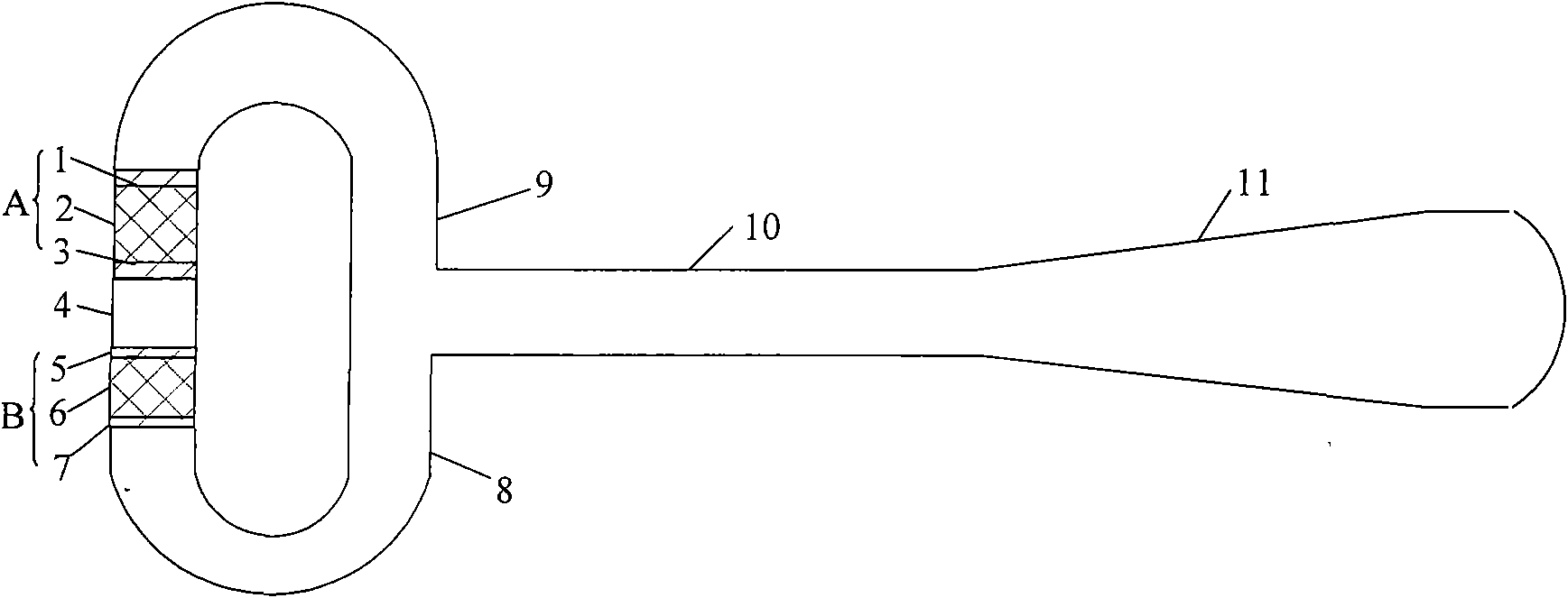

Pulse tube/Stirling gas coupling composite multi-stage refrigerator

InactiveCN103062952AImprove reliabilitySolution to short lifeCompression machinesCouplingLinear compressor

The invention discloses a pulse tube / Stirling gas coupling composite multi-stage refrigerator which comprises a Stirling refrigeration unit and a pulse tube refrigeration unit, wherein the Stirling refrigeration unit and the pulse tube refrigeration unit are connected in a gas coupling mode and are driven by one same linear compressor; an opening part of an air cylinder of the Stirling refrigeration unit is fixed with a cold end heat exchanger of the pulse tube refrigeration unit in a sealing manner; an end part (filled with return heat fillers) of a discharger inside the Stirling refrigeration unit penetrates through a hot end heat exchanger, a first-stage pulse tube refrigerator return heater and a first-stage cold end heat exchanger of the pulse tube refrigeration unit in sequence, and is arranged inside the air cylinder; and the discharger is coaxially arranged with the first-stage pulse tube refrigerator return heater and is matched in a sliding manner. According to the pulse tube / Stirling gas coupling composite multi-stage refrigerator, multi-stage performances are all considered, so that optimal performances and the high reliability can be obtained; and compared with the conventional multi-stage pulse tube refrigerator, the pulse tube / Stirling gas coupling composite multi-stage refrigerator can obtain a large pressure ratio from the cold end through the control of the discharger, so that the lower refrigeration temperature and the large refrigeration amount can be obtained.

Owner:ZHEJIANG UNIV

Low temperature cold air two-stage refrigeration system and cold air jet machine thereof

ActiveCN102003823AReduce jet velocityLower gas temperatureCompression machines with cascade operationFluid circulation arrangementEngineeringCold blast

The invention discloses a low temperature cold air two-stage refrigeration system and a cold air jet machine thereof. A two-stage refrigeration structure is used, and the gas temperature at a cold air jet outlet can be effectively decreased to -60 DEG C minimum; an air cooler is used, thereby having high jet speed, being beneficial to breaking and removing chips, and having low cooling temperature suitable for high speed and high accuracy machining; and simultaneously, the two-stage refrigeration structures is respectively with a refrigeration bypass used for cooling a medium at the inlet of a compressor; therefore, along with the prolonged life cycle, the temperature of the compressor can not rise without limit, thereby keeping a long-time proper operating state. Through the regulation of the flow rate of the medium of the refrigeration bypass, the temperature of the cold air is capable of being regulated indirectly; the structure is simple, the operation is convenient, and the use cost is decreased.

Owner:重庆高洁绿色机械设备智能制造研究院有限公司

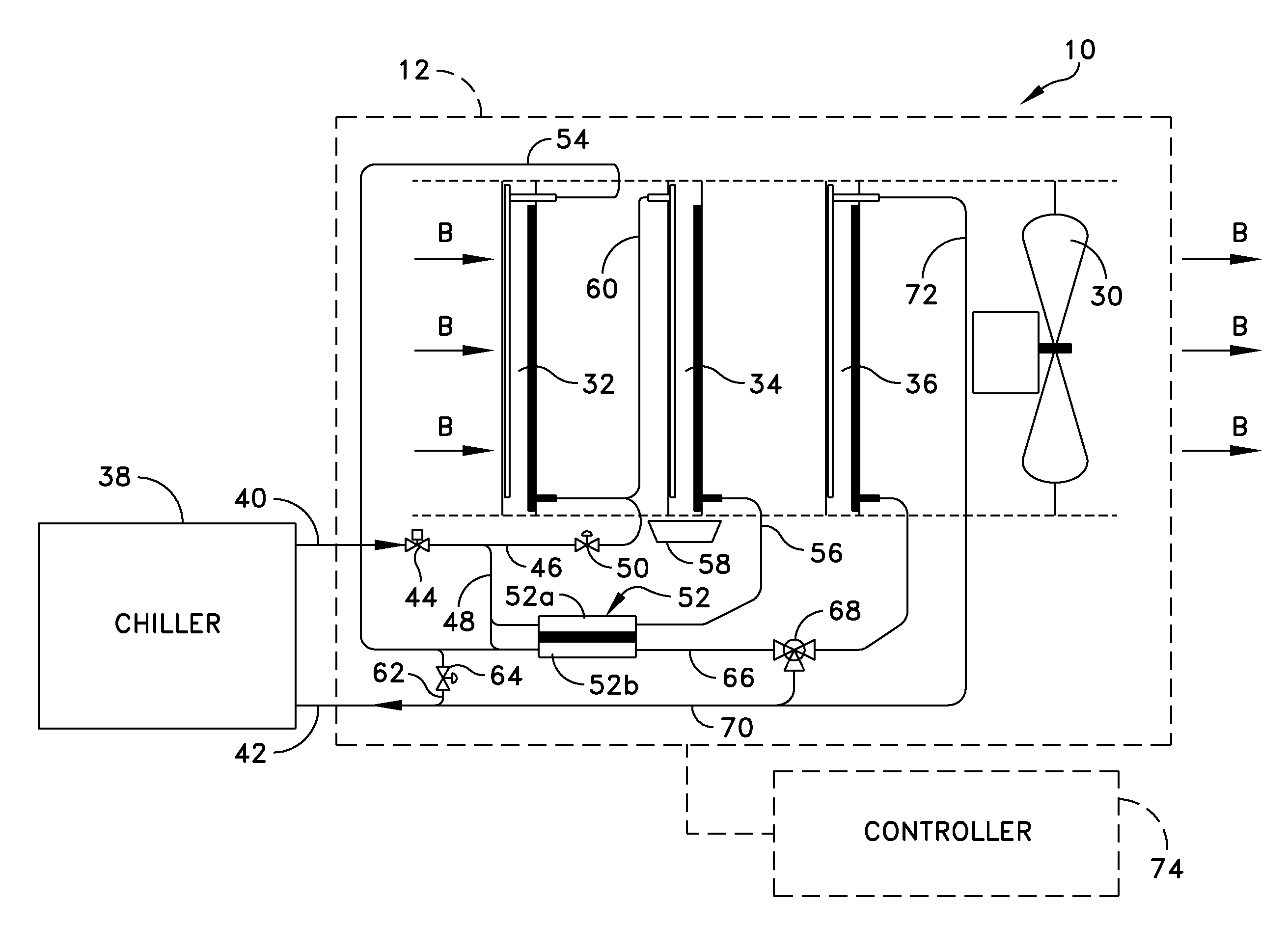

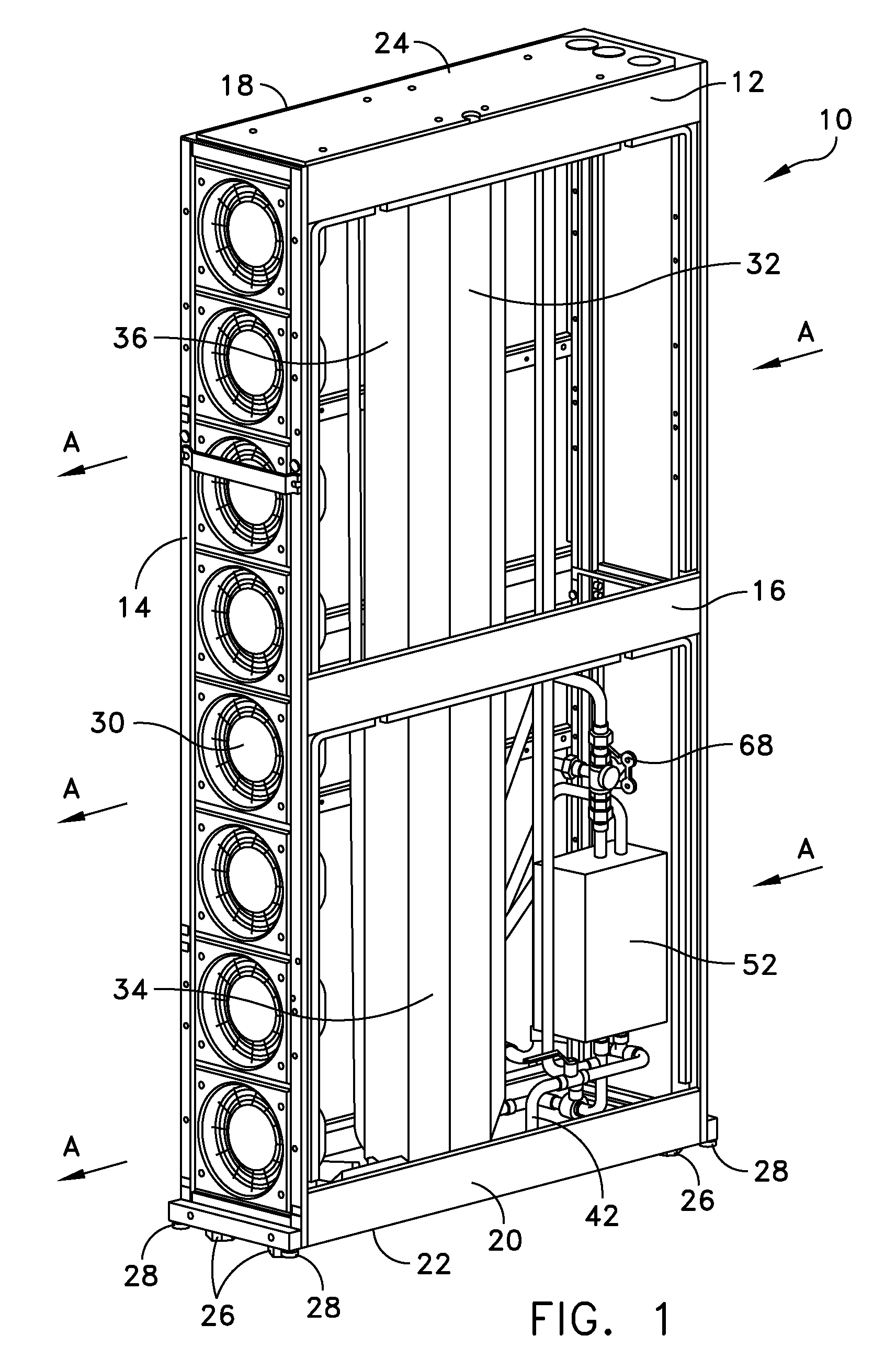

Dehumidifier apparatus and method

ActiveUS8033122B2Low cooling temperatureIncrease temperatureLighting and heating apparatusElectrical apparatus contructional detailsEngineeringCooling fluid

A dehumidifier unit includes a first coil in fluid communication with a source of cooling fluid, a second coil in fluid communication with the source of cooling fluid, a third coil in fluid communication with the source of cooling fluid, and a thermal unit disposed between the source of cooling fluid and the second and third coils. The thermal unit may be adapted to remove heat from cooling fluid flowing to the second coil and adapted to heat cooling fluid flowing to the third coil. A fan may be configured to move air across the first, second and third coils. The first coil may be configured to pre-cool air moving over the first coil, the second coil may be configured to dehumidify the air moving over the second coil, and the third coil may be configured to warm the air moving over the third coil. Other embodiments and methods of cooling are further disclosed.

Owner:AMERICA POWER CONVERSION CORP

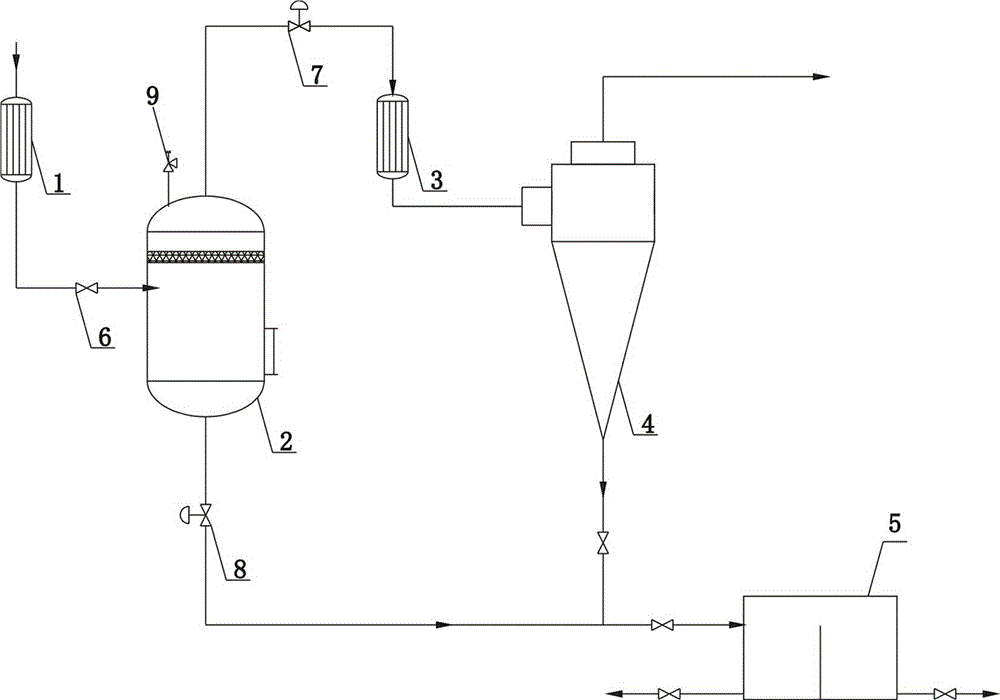

Device for increasing recovery rate of aromatic hydrocarbons of oxidized tail gas of hydrogen peroxide

InactiveCN106139789AReduce moisture contentLow cooling temperatureCombination devicesVapor condensationFluid phasePhysical chemistry

A device for increasing the recovery rate of aromatic hydrocarbons of oxidized tail gas of hydrogen peroxide comprises a primary condenser, an intermediate separation tank, a secondary condenser, a cyclone separator and an oil-water separator, wherein the primary condenser is connected with the intermediate separation tank through a pipeline; a gas phase outlet at the top of the intermediate separation tank is connected with the top of the secondary condenser through a pipeline; a liquid phase outlet at the bottom of the intermediate separation tank is connected with the oil-water separator through a pipeline; an outlet of the secondary condenser is connected with an inlet of the cyclone separator; a liquid phase outlet at the bottom of the cyclone separator is connected to the oil-water separator through a pipeline. With the adoption of the device for increasing the recovery rate of the aromatic hydrocarbons of the oxidized tail gas of hydrogen peroxide, entrainment of the tail gas can be effectively reduced, the water content of the tail gas can be reduced, the recovery effect of the aromatic hydrocarbons can be enhanced, and the recovery rate can be increased.

Owner:HUBEI SANNING CHEM

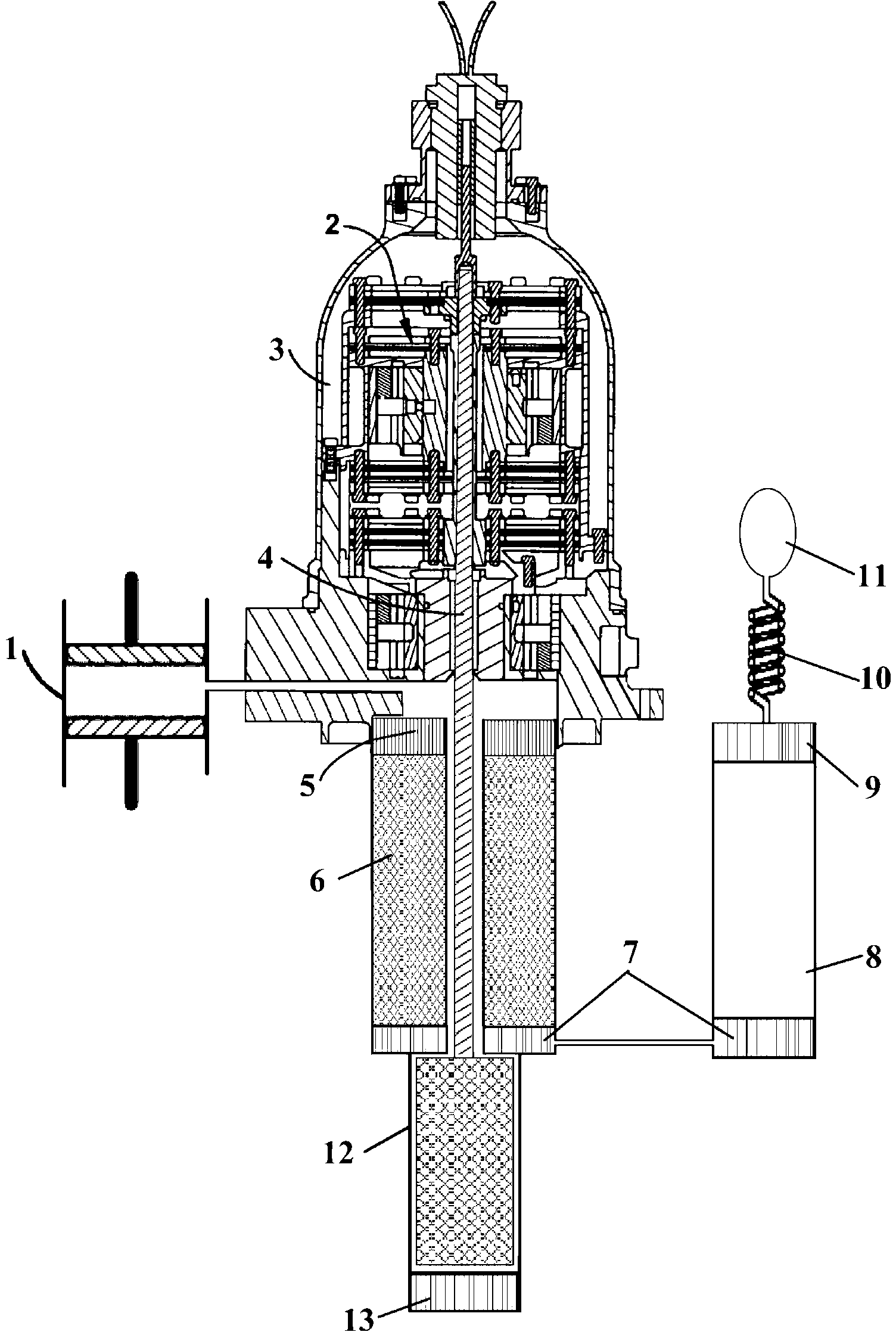

Small skid-mounted evaporation gas reliquefaction and recovery device for liquefied natural gas

InactiveCN103759496ALow cooling temperatureLarge cooling capacitySolidificationLiquefactionRefrigerated temperatureControl system

The invention provides a small skid-mounted evaporation gas reliquefaction and recovery device for liquefied natural gas. The small skid-mounted evaporation gas reliquefaction and recovery device comprises a cryogenic storage tank (1), a regenerative cryo refrigerator (3), an externally-finned condensing heat exchanger (4), a pressure testing device (5), a temperature testing device (6), a heating device (7) and a control system (8). Real-time monitoring and stepless regulation can be performed on cryogenic temperature and output cold of the cryo refrigerator according to requirements on actual pressure and heat loads inside the cryogenic storage tank, and zero consumption of an LNG (liquefied natural gas) storage tank system can be realized; pumpless circulation of gas liquid flow inside the device can be realized by relying on self differential pressure and gravity; the small skid-mounted evaporation gas reliquefaction and recovery device is low in system energy consumption, compact in structure, simple in technology process, high in reliquefaction efficiency and low in operation and maintenance costs, and skid mounting of the device can be realized.

Owner:SHANGHAI JIAO TONG UNIV +1

Process for producing slush nitrogen and apparatus therefor

InactiveCN1741963AControl granularitySmall granularityNitrogen purification/separationSuperconductors/hyperconductorsSolid nitrogenAtmospheric pressure

A process for producing slush nitrogen, comprising charging a low-temperature container with liquid nitrogen and arranging an ejector capable of drawing out liquid nitrogen by suction by spewing a refrigerant liquid or gas, such as low-temperature helium gas or liquid helium of pressure higher than in the space within the container, into the container so that the liquid nitrogen drawn out by suction by the refrigerant and spewed together with the refrigerant is refrigerated by the refrigerant, becomes particulate solid nitrogen and falls, while discharging the gas lying in the space within the container outside the container so as to constantly maintain the space at atmospheric pressure or higher. Further, there is provided a method of refrigerating a superconductive object including a substance exhibiting a superconductive state at temperatures close to the temperature of liquid nitrogen or close to the temperature at which the liquid nitrogen and the solid nitrogen coexist, characterized in that the object is immersed in slush nitrogen held in an adiabatic container so as to effect contact of the object with slush nitrogen and refrigeration thereof.

Owner:MAYEKAWA MFG CO LTD

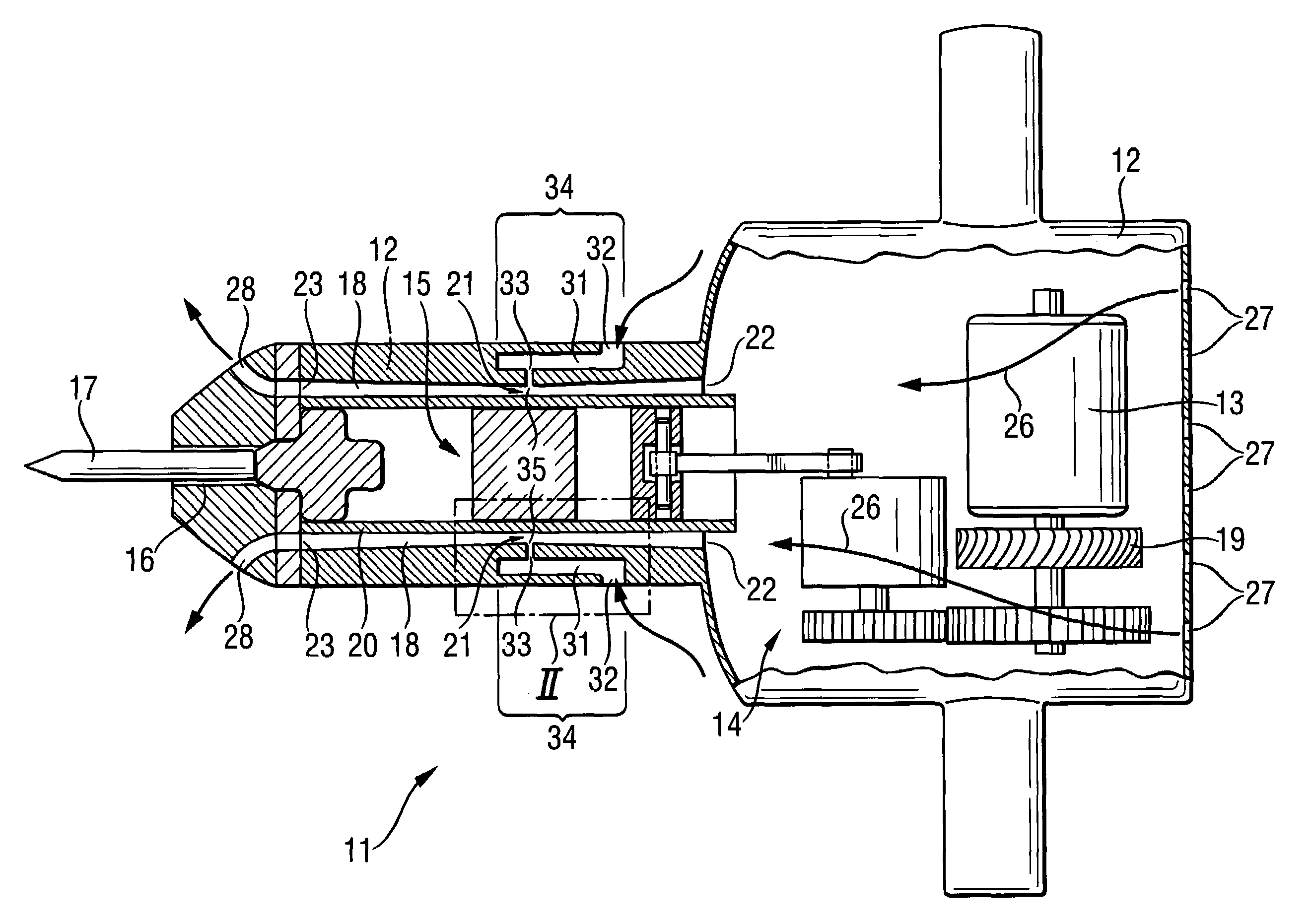

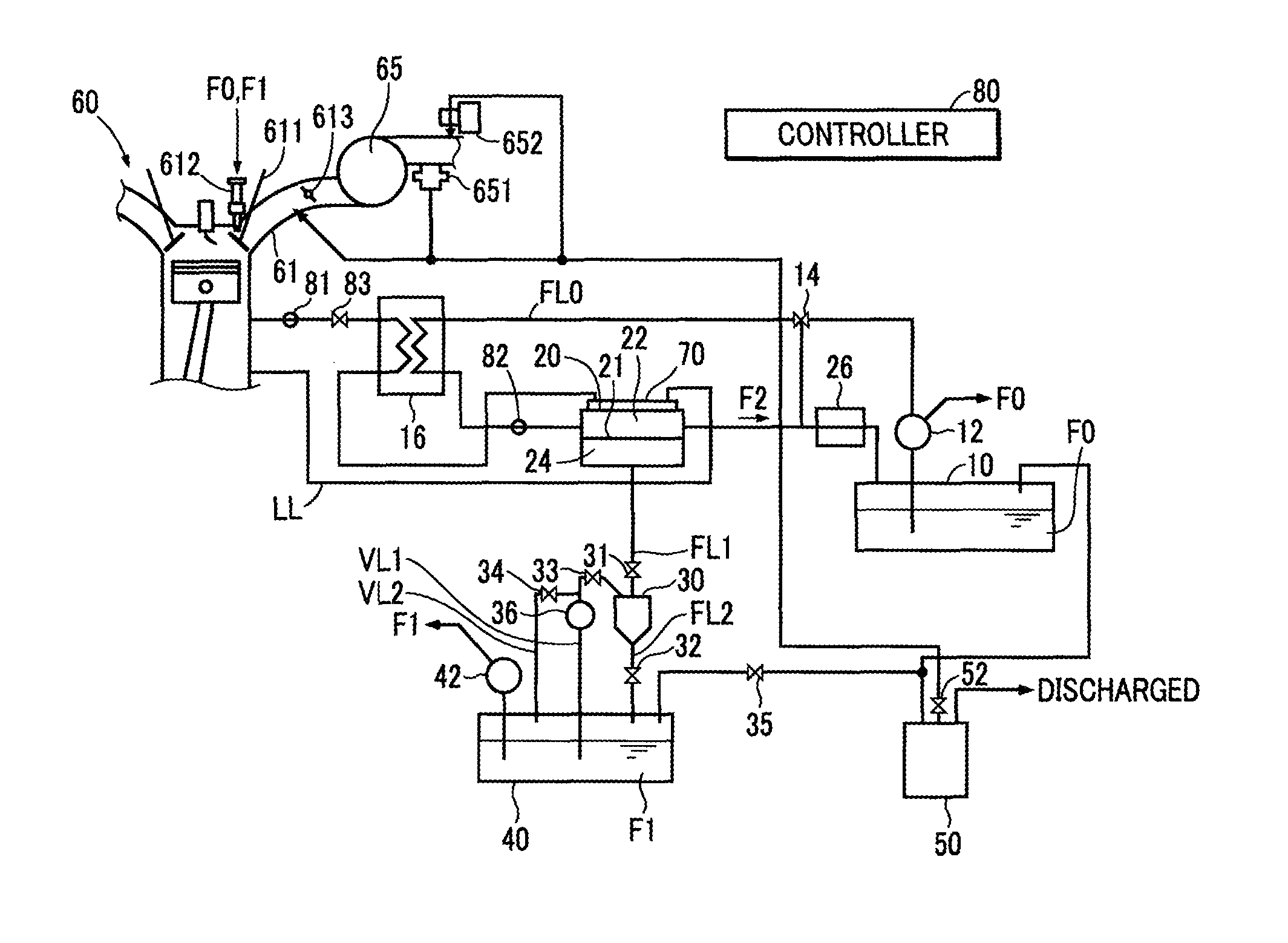

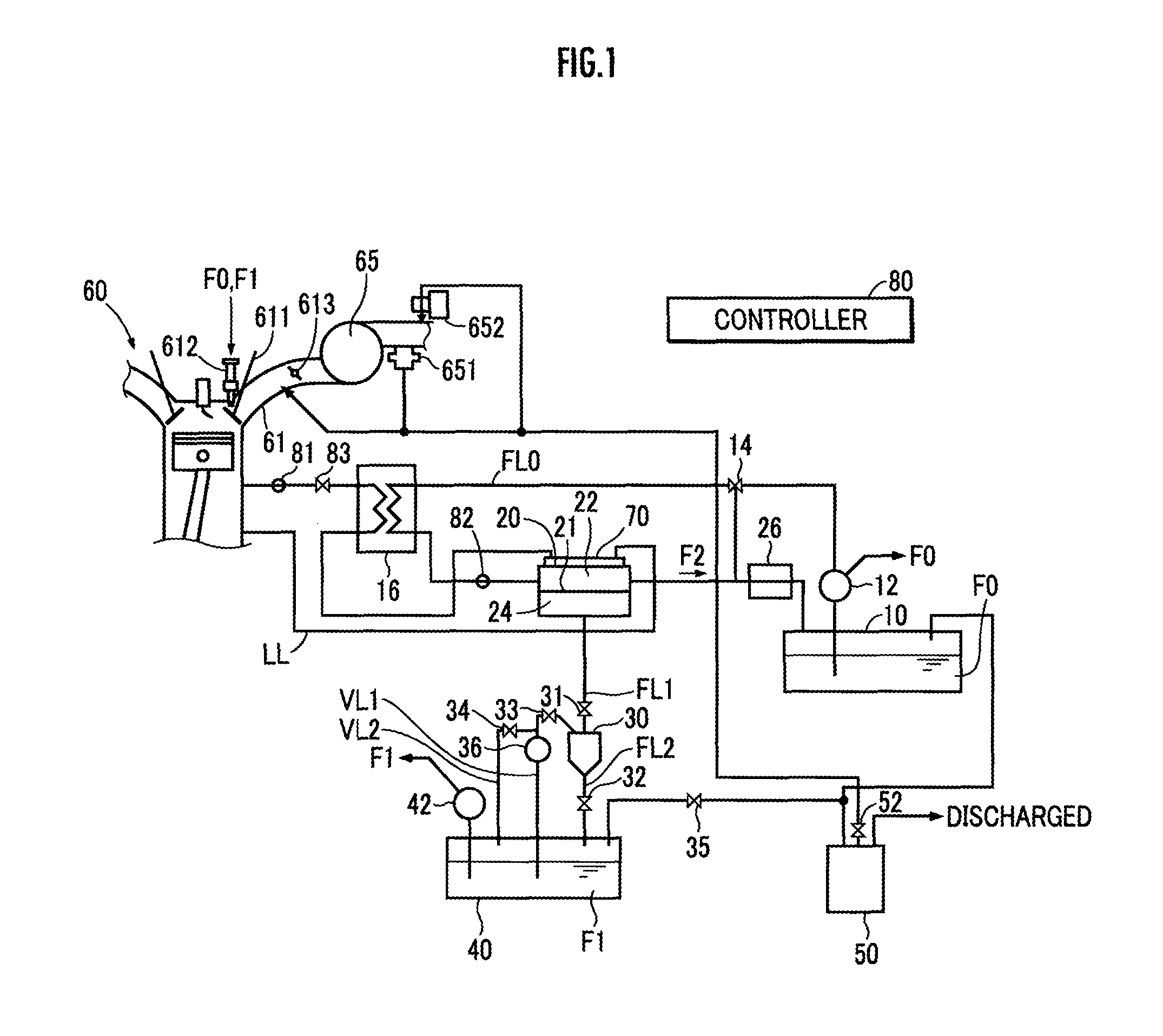

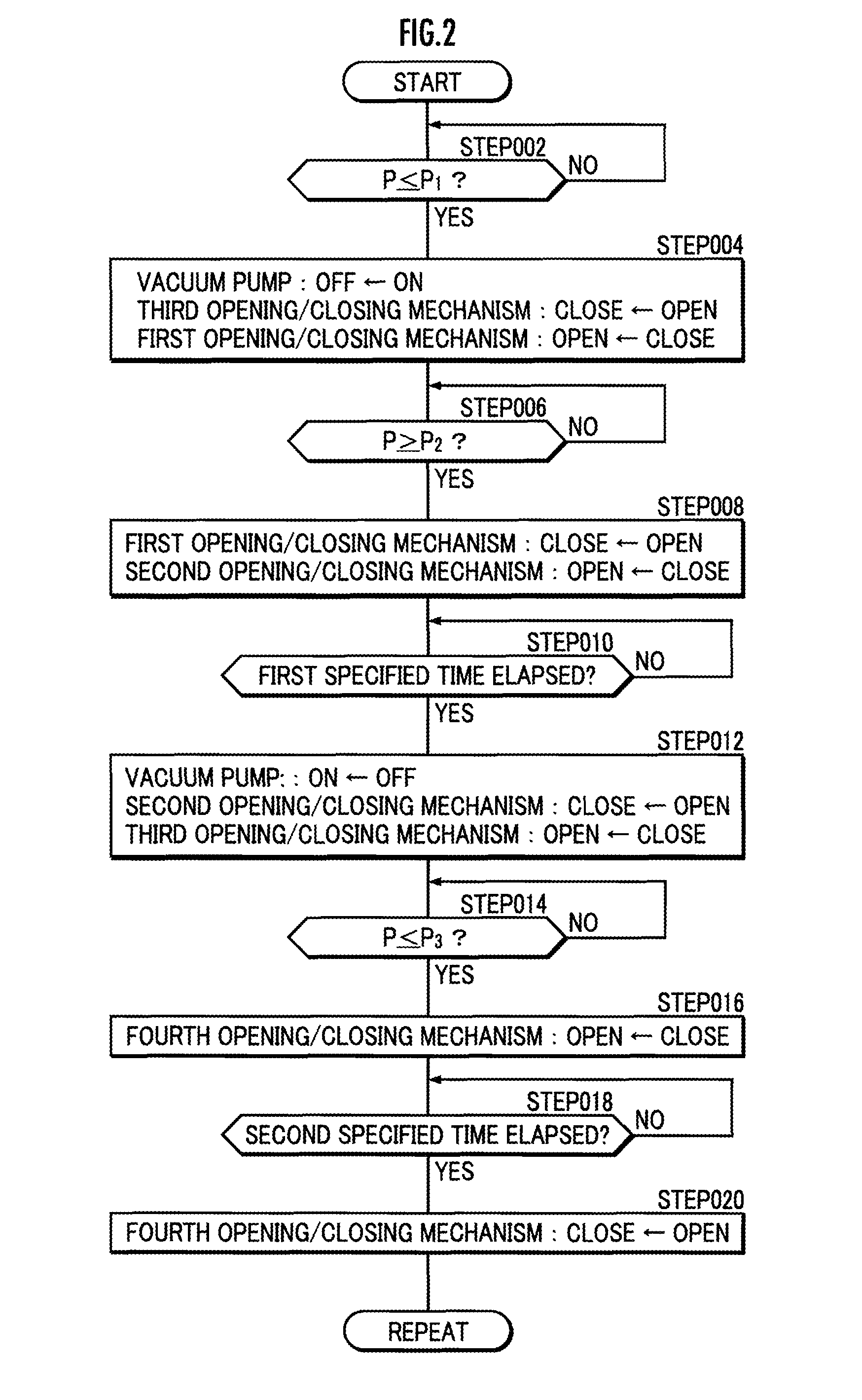

Fuel supply device

ActiveUS20130333644A1Separation performanceMounting spaceCoolant flow controlInternal combustion piston enginesFuel supplyNuclear engineering

A device capable of supplying an internal combustion engine 60 with a first fuel F1 of a high octane number fuel, and a second fuel F2 of a low octane number fuel or a raw fuel F0. The device is equipped with a cooling medium circulating path LL configured to perform heat exchange between a cooling medium for cooling the internal combustion engine 60 and a separator 20. The device adjusts a flow rate of the cooling medium in the cooling medium circulating path LL, so that a separator temperature T1 is contained in a predetermined temperature range, according to T1, a raw fuel temperature T2 and a cooling medium temperature T3.

Owner:HONDA MOTOR CO LTD

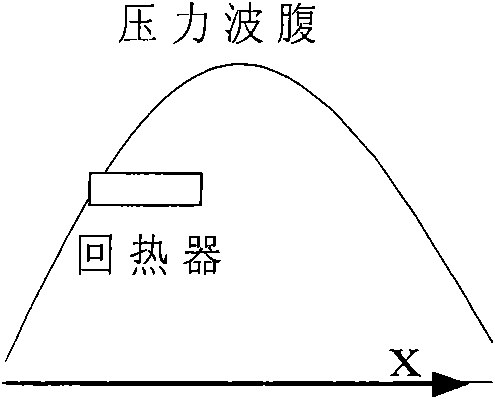

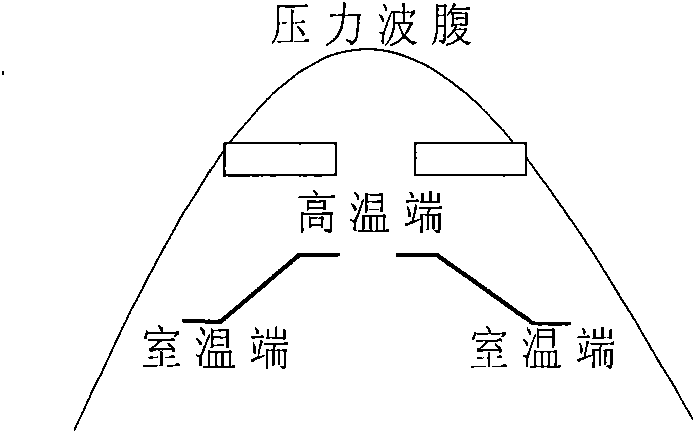

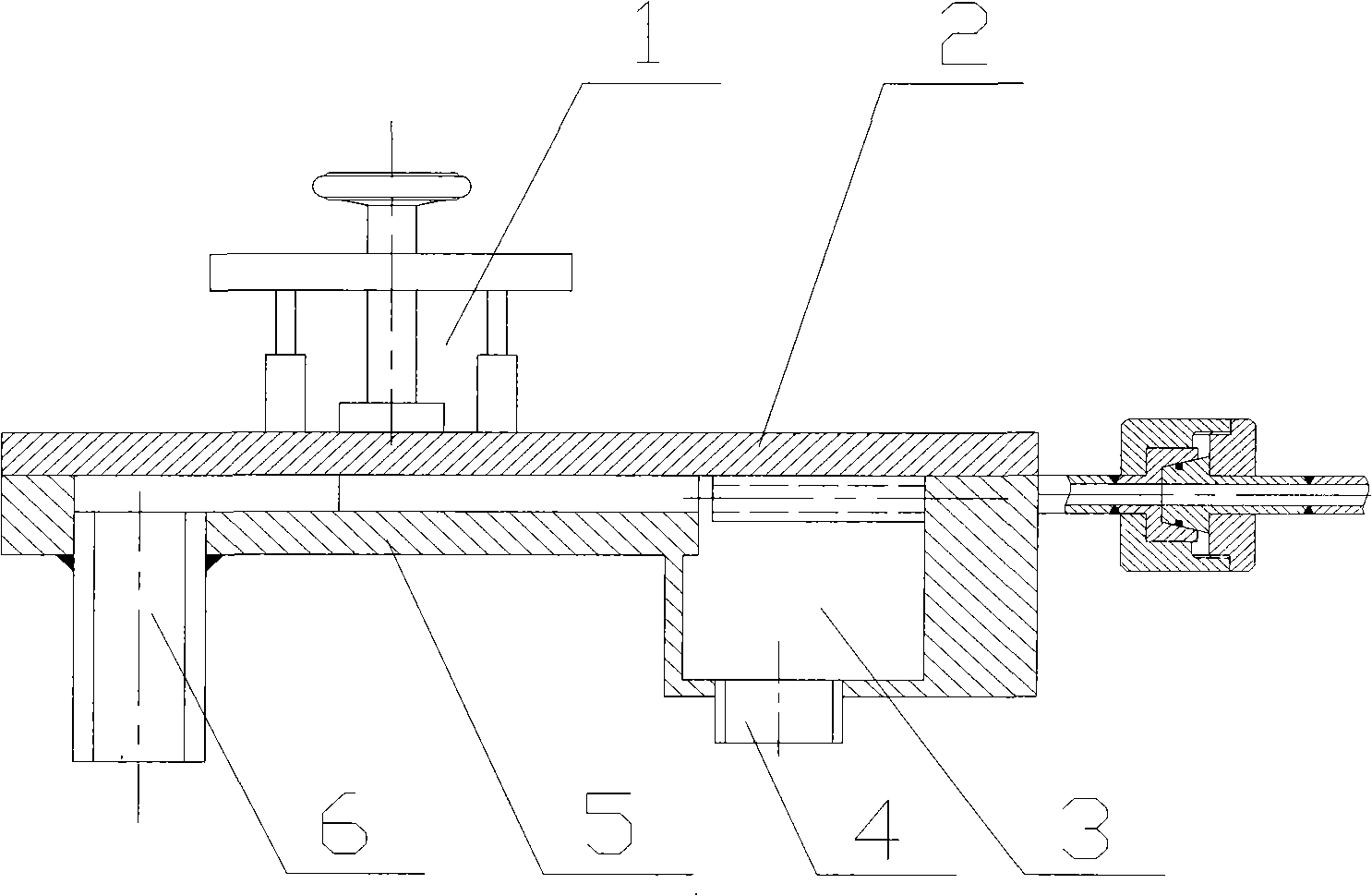

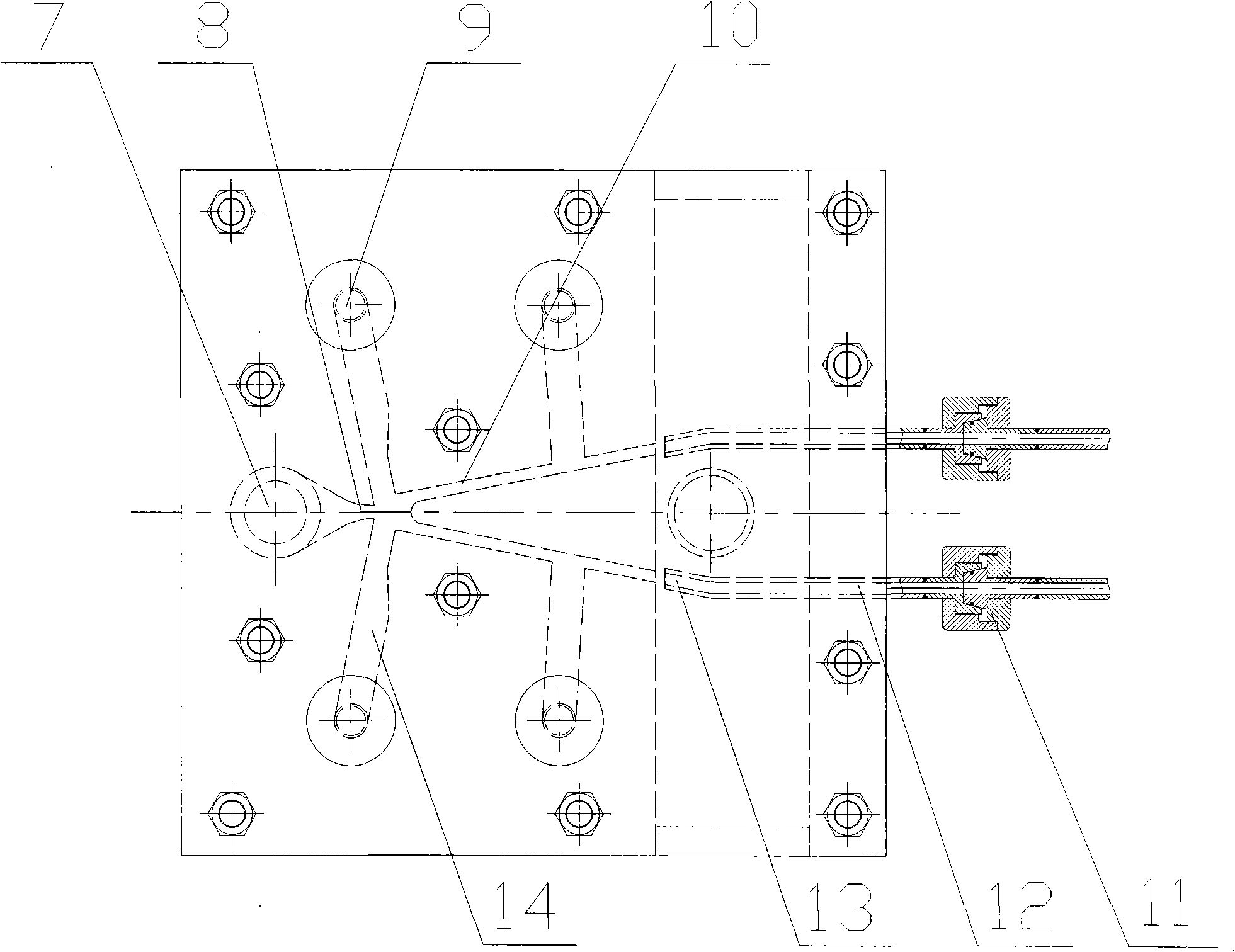

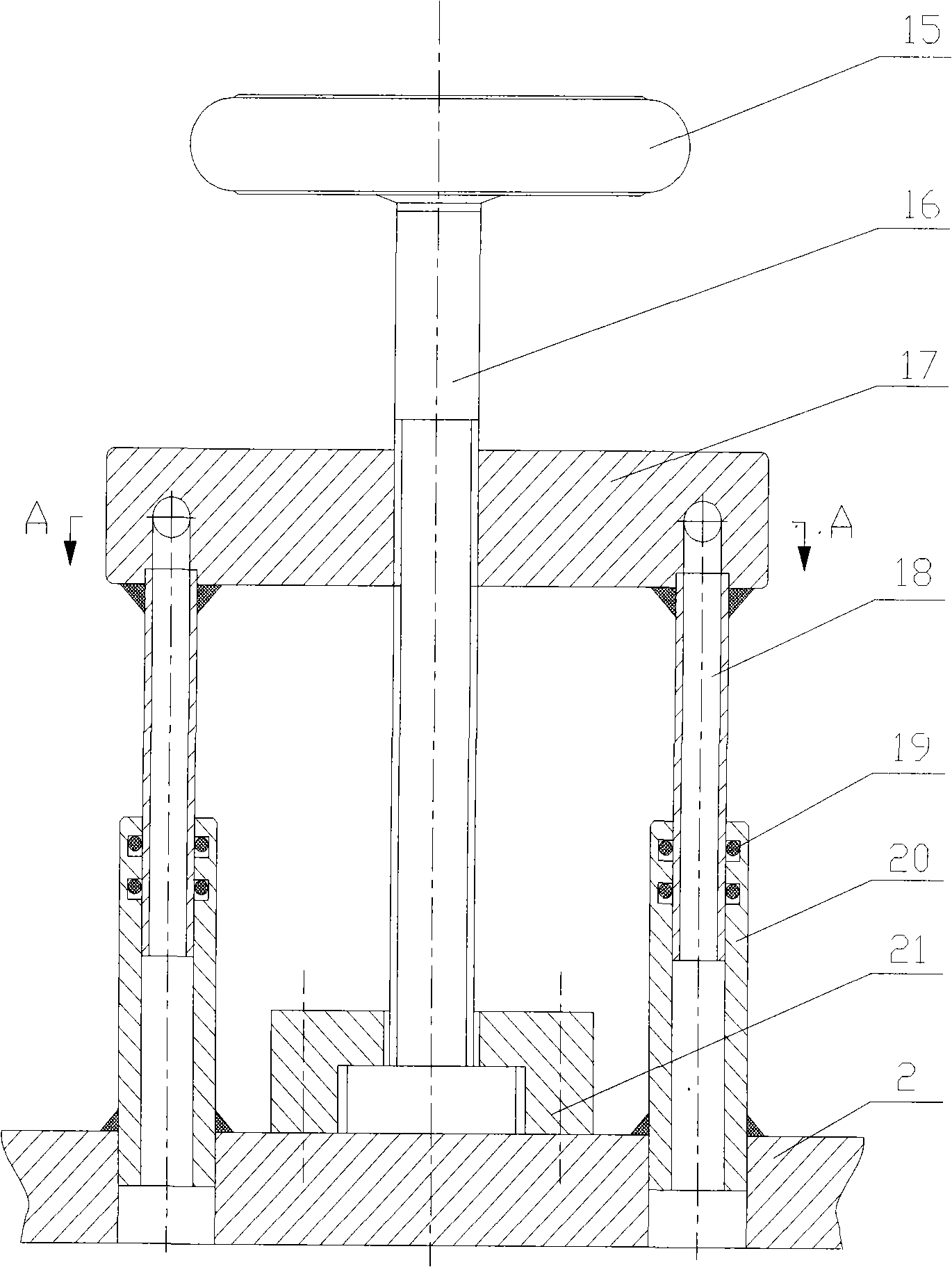

Thermally-driven thermoacoustic refrigerator device in traveling and stationary wave type acoustic field

InactiveCN101566405AImprove efficiencyCompact structureRefrigeration machinesEngineeringRefrigerated temperature

The invention relates to a thermally-driven thermoacoustic refrigerator device in a traveling and stationary wave type acoustic field, which comprises an acoustic wave circuit consisting of an acoustic power feedback tube, a motor room temperature end cooler, a motor thermoacoustic regenerator, a motor heater, a heat buffer tube, a refrigerator room temperature end cooler, a refrigerator thermoacoustic regenerator, a refrigerator cold end exchanger and an acoustic power recovery tube, and a resonant straight tube communicated with both the acoustic power feedback tube and the acoustic power recovery tube, wherein the acoustic wave circuit and the resonant straight tube are connected sequentially; the other end of the resonant straight tube is communicated with a resonant cavity to form a resonant branch circuit; a thermoacoustic motor and a thermoacoustic refrigerator are positioned in the acoustic wave circuit; and the motor heater of the thermoacoustic motor and the refrigerator room temperature end cooler of the thermoacoustic refrigerator are communicated through the heat buffer tube. In the device, two systems of thermoacoustic conversion are comprehensively used to allow traveling and stationary wave components of acoustic waves to generate a thermoacoustic effect in the motor thermoacoustic regenerator and a pump heating effect in the refrigerator thermoacoustic regenerator; and the acoustic power flow generated by the motor can directly enter the refrigerator for refrigeration, and the structure is simple and compact.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Feedback type oscillating jet stream refrigerating machine

InactiveCN101294750AAvoid or minimize lossesAdjustable lengthCompression machinesSelf-oscillationEngineering

The invention provides a reaction-type oscillation jet flow refrigerating machine and belongs to the gas pressure energy expansion refrigeration field. The whole machine of the invention is totally static, and adopts the combined structure of a reaction-type oscillation fluidic generator and an adopter, the actuation to the jet flow is realized by the compression wave reaction in order to generate the oscillatory wall-attachment jet, unsteady gas expansion refrigeration is realized by the cooperating work of a flow channel component, a regulating mechanism is coupled in a compression wave reaction channel, the switching frequency of the jet wall-attachment oscillation is changed via regulating gas capacity to adapt to different operating conditions, thereby obtaining the highest operating efficiency. The invention has no moving member or dynamic sealing, thereby being particularly suitable for high pressure situations, such as high pressure natural gas deep freezing dehydration, recovering heavy component from high pressure gas mixture and so on. The variable gas capacity frequency modulation self-oscillation jet flow refrigerating machine with higher refrigerating efficiency and lower refrigerating temperature than that of throttling decompression can run with liquid, thereby providing an efficient method and a device for efficient utilization of pressure energy in the combination gas stratum.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com