Thermally-driven thermoacoustic refrigerator device in traveling and stationary wave type acoustic field

A thermoacoustic refrigerator and heat-driven technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of reduced sound power, high consumption, poor thermoacoustic conversion effect, etc., and achieve the goal of optimal design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

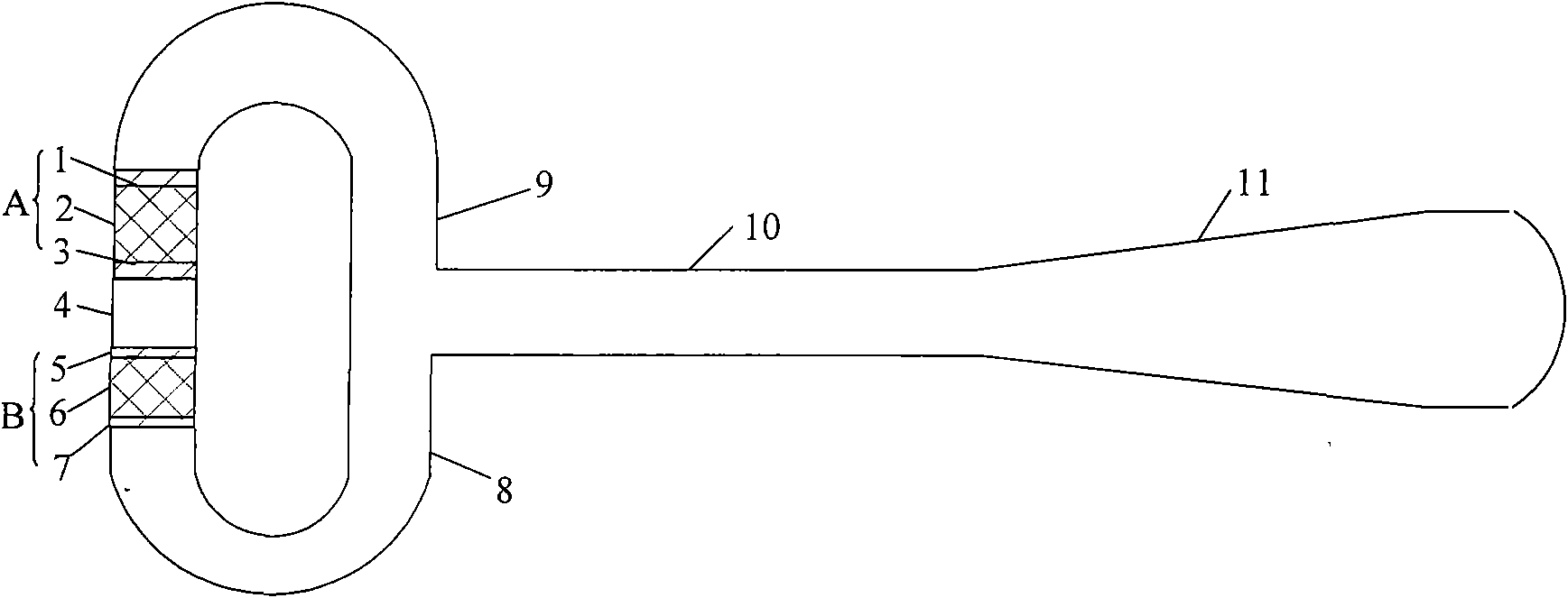

[0048] The structure of this embodiment is as Image 6 As shown, it includes an acoustic power feedback tube 9, a cavity 12, an elastic membrane 13, an engine room temperature cooler 1, an engine thermoacoustic regenerator 2, an engine heater 3, a thermal buffer tube 4, and a refrigerator room temperature. end cooler 5, refrigerating machine thermoacoustic regenerator 6, refrigerating machine cold end heat exchanger 7 and acoustic power recovery pipe 8 form the acoustic wave loop, and the acoustic power feedback pipe 9 and acoustic power feedback pipe 9 in the acoustic wave loop The power recovery pipe 8 is connected to the resonant straight pipe 10 connected at the same time, and the other end of the resonant straight pipe 10 is connected to the resonant cavity 11 to form a resonant branch; wherein the engine room temperature side cooler 1, the engine thermoacoustic regenerator 2 and the engine Thermoacoustic engine A composed of heater 3; thermoacoustic refrigerator B compos...

Embodiment 2

[0052] The structure of this embodiment is as Figure 7 As shown, it includes an acoustic power feedback tube 9, a cavity 12, an elastic membrane 13, an engine room temperature cooler 1, an engine thermoacoustic regenerator 2, an engine heater 3, a thermal buffer tube 4, and a refrigerator room temperature. end cooler 5, refrigerating machine thermoacoustic regenerator 6, refrigerating machine cold end heat exchanger 7 and acoustic power recovery pipe 8 form the acoustic wave loop, and the acoustic power feedback pipe 9 and acoustic power feedback pipe 9 in the acoustic wave loop The power recovery pipe 8 is connected to the resonant straight pipe 10 connected at the same time, and the other end of the resonant straight pipe 10 is connected to the resonant cavity 11 to form a resonant branch; the engine room temperature end cooler 1, the engine thermoacoustic regenerator 2 and the The thermoacoustic engine part A composed of the heater 3; the thermoacoustic refrigerator B comp...

Embodiment 3

[0057] The structure of this embodiment is as Figure 8As shown, it includes an acoustic power feedback tube 9, a capacitive tube 15, an engine room temperature end cooler 1, an engine thermoacoustic regenerator 2, an engine heater 3, a thermal buffer tube 4, a jet pump 16, and a refrigerator connected in sequence. The acoustic wave loop formed by the room temperature end cooler 5, the thermoacoustic regenerator 6 of the refrigerator, the cold end heat exchanger 7 of the refrigerator, and the acoustic power recovery pipe 8, and the acoustic power feedback pipe 9 and the acoustic power feedback pipe 9 in the acoustic wave loop The sound power recovery pipe 8 is connected to the resonant straight pipe 10 connected at the same time, and the other end of the resonant straight pipe 10 is connected to the resonant cavity 11 to form a resonant branch; The thermoacoustic engine A composed of the engine heater 3; the thermoacoustic refrigerator B composed of the room temperature end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com